Stero Dishwasher SG-40 Installation Manual

STERO

INSTRUCTION

MANUAL

Undercounter

Dishwasher

MODELS: MODELS:

SU-L ML-130274 SG-42 ML-130259

SU-H ML-130273 SG-40 ML-130289

Undercounter

Glasswasher

ST50406 (01/16)

STERO, a division of Illinois Tool Works, Inc. 1758 Corporate Circle Petaluma, CA 94954

Phone: 800-762-7600 Fax: 707-762-5036 Website: Stero.com

2 | STERO UNDERCOUNTER DISHWASHER & GLASSWASHER

TABLE OF CONTENTS

GENERAL

SU Dishwashers ........................................................................3

SG Glasswashers .......................................................................4

START-UP CHECKLIST ................................................................5

INSTALLATION ........................................................................6

Unpacking ............................................................................6

Location ..............................................................................6

Leveling ..............................................................................6

Water Requirements .................................................................. 6-7

Plumbing Connections ..................................................................7

Electrical Connection ...................................................................8

Electrical Data .........................................................................8

Connection Method ..................................................................8-9

Detergent and Rinse Aid .................................................................9

Chemical Sanitizer (SU-L & SG Models) ....................................................10

Checking Sanitizer Concentration ........................................................11

Priming Chemical Pumps ................................................................ 11

Installation Diagrams

SU Dishwashers ....................................................................12

SG Glasswashers .................................................................13-14

PARAMETERS MENU TABLE ........................................................15

OPERATION ..........................................................................16

Before First Use .......................................................................16

Controls .............................................................................16

Operating the Stero Dishwasher & Glasswasher .............................................17

Diagnostic/Error Messages ..............................................................18

Wash/Rinse Cycle Times .................................................................19

Preparation ..........................................................................19

CLEANING ............................................................................20

Do's and Don'ts for Your New Stero Dishwasher ............................................20

MAINTENANCE ......................................................................21

Deliming ............................................................................21

Lubrication ..........................................................................21

TROUBLESHOOTING .............................................................. 22-23

© STERO 2014

STERO UNDERCOUNTER DISHWASHER & GLASSWASHER | 3

Installation,

Operation

and Care of

SU SERIES

DISHWASHERS

SAVE THESE INSTRUCTIONS

GENERAL

The Stero SU dishwashers are fully automatic, front-loading dishwashing machines. The machines are capable

of doing 31-33 racks per hour.

All SU Series dishwashers shut down automatically 4 hours after last use to conserve energy.

All SU-H Series dishwashers include rinse assurance tehnology to insure proper hot water temperature during

rinse.

Standard equipment includes electronic controls, drain pump, rinse pump, chemical pumps, fill hose, and drain

hose.

MODEL DESCRIPTION

SU-L Fresh water rinse; low-temperature, chemical-sanitizing models for use with 6% sodium hypochlo-

rite solution (bleach) as the sanitizing agent*. Note: If 8.40% bleach is to be used, contact your local

service provider or your chemical supplier to change the sanitizer pump settings. (Charges may apply)

-H Fresh water rinse with a built-in 70°F rise booster heater. This allows an incoming water temperature

SU

of 110°F.

* Sanitizing agent must be used in accordance with the EPA-registered label use instructions.

4 | STERO UNDERCOUNTER DISHWASHER & GLASSWASHER

Installation,

Operation

and Care of

SG

GLASSWASHER

SAVE THESE INSTRUCTIONS

GENERAL

The Stero SG glasswasher is fully automatic and front-loading. The machine is capable of doing 34 racks per

hour.

All SG glasswashers shut down automatically 4 hours after last use to conserve energy.

Standard equipment includes electronic controls, drain pump, rinse pump, chemical pumps, fill hose, and drain

hose.

MODEL DESCRIPTION

SG Fresh water rinse; low-temperature, chemical-sanitizing models for use with 6% sodium hypochlo-

rite solution (bleach) as the sanitizing agent*. Note: If 8.40% bleach is to be used, contact your

ocal service provider or your chemical supplier to change the sanitizer pump settings. (Charges may

l

apply)

* Sanitizing agent must be used in accordance with the EPA-registered label use instructions.

STERO UNDERCOUNTER DISHWASHER & GLASSWASHER | 5

START-UP CHECKLIST

BEFORE POWER IS APPLIED

____ 1. Check all utility service connections for tightness.

____ 2. Check for any loose hardware, level machine, check for proper form fit of side panels and top

control lid.

____

3. Check door closing operation.

____ 4. Check free rotation of wash/rinse arms, remove any inside packing material.

____ 5. Check all wash strainers in place (dishracks slide in freely).

____ 6. Check proper routing of all chemical tubing out rear of machine to bottle (red – detergent, blue – rinse

aid, white – sanitizer)

AFTER POWER IS APPLIED AND WATER TURNED ON

____ 1. Verify correct supply voltage and phase to machine. Confirm with data plate.

____ 2. Turn machine on, start warming up/fill cycle.

____ 3. Wait for “Ready” status for both holding/booster tank and sump.

____ 4. Check for leaks.

____ 5. Verify proper water levels.

RUN CYCLE(S) AND CHECK THE FOLLOWING

____ 1. Check for proper operation of keypad and display illumination.

____ 2. Check operation of door interlock switch, and good seal of door gasket.

____ 3. Check for proper pump motor operation and check for leaks.

____ 4. Verify proper water flow out drain, during drain portion of cycle.

____ 5. Verify proper operation of rinse pump (proper flow of water out final rinse arms).

____ 6. Verify final rinse temperature.

____ 7. Test bleach concentration, while running bleach rinse cycle (gold only) (50-100 ppm).

REINSTALL ANY PANELS REMOVED

6 | STERO UNDERCOUNTER DISHWASHER & GLASSWASHER

INSTALLATION

UNPACKING

Immediately after unpacking the dishwasher, check for possible shipping damage. If this machine is found to

be damaged, save packaging material and contact the carrier within 15 days of delivery.

LOCATION

Prior to installation, verify that the electrical supply agrees with the specifications on the machine data plate,

which is located on the top of the door.

Steam generated from normal operation may escape from the door. Wood, laminates, veneers, etc. are

unsuitable materials for use in areas exposed to dishwasher steam and detergents. Stainless steel or other

moisture-resistant shields are recommended for surfaces adjacent to dishmachine sides and top.

LEVELING

The machine must be level to operate properly. Place the dishwasher in its operating location. Level the machine

before any connections are made. Using a carpenter's level placed diagonally on the rack tracks, level the

machine front to back and side to side by threading the adjustable feet in or out. After leveling the machine,

cover the exposed threads of the adjustable feet with black rubber tubing supplied. (See separate instructions

furnished with machine.)

WATER REQUIREMENTS

Proper water quality can improve ware washing performance by reducing spotting, enhancing effectiveness of

labor and extending equipment life. Water conditions vary from one location to another. The recommended

proper water treatment for effective and efficient use of this equipment will also vary depending on the local

water conditions. Ask your municipal water supplier for details about your local water conditions prior to

installation.

Recommended water hardness is 3 grains of hardness per gallon or less. Higher hardness may cause excessive

formation of lime scale. Water hardness above 3 grains per gallon requires water treatment. Water treatment

has been shown to reduce costs associated with machine cleaning, reduce deliming of the dishwasher, and

reduce detergent usage in the dishwasher.

High iron levels in the water supply can cause staining and may require an iron filter. High chloride

levels in the water supply can cause pitting and may require a chloride removal system. Contact your local

water treatment professional for proper water treatment.

Sediment may require a particulate filter. Dissolved solids may require water treatment such as a water soft

ener, reverse osmosis system, etc. Contact your local water treatment professional for proper water treatment.

f an inspection of the dishwasher or booster heater reveals lime buildup after the equipment has been in

I

service, water treatment is recommended. If a water softener is already in place, ensure there is a sufficient

level of salt.

-

A water hammer arrestor (meeting ASSE-1010 Standard or equivalent) should be installed (supplied by others)

in the common water supply line at the service connection.

STERO UNDERCOUNTER DISHWASHER & GLASSWASHER | 7

INSTALLATION (continued)

The plumber connecting this machine is responsible for making certain that water lines are THOROUGHLY

FLUSHED OUT BEFORE connecting to the dishwasher. This “flush-out” is necessary to remove all foreign matter, such as chips (resulting from cutting or threading of pipes) pipe joint compound from the lines; or, if

soldered fittings are used, bits of solder or cuttings from the tubing. Debris, if not removed, may lodge in the

dishwasher’s plumbing components and render them inoperative. Manual valves or solenoid valves fouled by

foreign matter and any expenses resulting from this fouling are NOT the responsibility of the manufacturer

and associated repair costs are not covered under warranty.

Water supply requirements are as follows:

Model Description

SU-L 120°F Minimum

SU-H 110°F Minimum

SG 120°F Minimum

Required flowing water pressure to the dishmachine is 15-65 PSIG. If pressures higher than 65 PSIG are present,

a pressure regulating valve must be installed in the water line to the dishmachine (by others). If flowing pres

sure is less than 15 psi, improper machine operation may result. The dishmachines are equipped with a pumped

inse system; therefore, a water pressure gauge is not required and is not supplied with the machine.

r

-

The water pressure regulator must have a relief bypass. Failure to use the proper type of pressure

regulator may result in damage to the unit.

A manual shutoff valve (not supplied) should be installed upstream of the fill hose to accommodate servicing

the machine.

It is recommended that a line strainer (not supplied) be installed in the supply line between the manual shutoff

valve (not supplied) and the connection point on the machine. Make plumbing connections with

copper piping OD (

diagram,s, pages 12-14.

3

⁄4" recommended), with a 3⁄4" male garden hose fitting (not supplied). See installation

1

⁄2" minimum

PLUMBING CONNECTIONS

Plumbing connections must comply with applicable sanitary, safety, and plumbing

codes.

Drain

A drain hose, 5⁄8" inside diameter and 6' long, is provided. This should be securely plumbed into a drain. Use

care not to kink hose. See installation diagrams, pages 12-14. Drain must have a minimum flow capacity of

5 gallons per minute.

8 | STERO UNDERCOUNTER DISHWASHER & GLASSWASHER

INSTALLATION (continued)

ELECTRICAL CONNECTION

Electrical and grounding connections must comply with the applicable portions of

the National Electrical Code and/or other local electrical codes.

Disconnect the electrical power to the machine and follow lockout/tagout proce-

dures.

ELECTRICAL DATA

Complied in accordance with the National Electrical Code NFPA-70, latest addition.

For supply connections, use copper wire only rated at 90°C minimum.

Minimum Supply

Model Volts/Hertz/Phase

SU-L 120/60/1 20 20

SU-H

SG 120/60/1 20 20

* The (3W) systems require three power wires that include a current carrying neutral. An additional fourth

wire must be provided for machine ground.

Refer to the data plate on the door handle of the machine and the electrical label on the back side of the

lower front panel for proper selection.

120/208-240

(3W )/60/1*

Circuit Conductor

Ampacity

40 40

Maximum

Protective Device

Ampacity

CONNECTION METHOD

1. Remove the lower front panel by removing the two screws at the bottom of the panel (Figure 1).

2. Open door of dishwasher and remove the two left screws and the top right screw (Figure 2). Pull top of

unit forward approximately 1" and remove the left side panel.

REMOVE TWO SCREWS

Figure 1

REMOVE THREE SCREWS

Figure 2

STERO UNDERCOUNTER DISHWASHER & GLASSWASHER | 9

INSTALLATION (continued)

3. A hole for 1" trade size conduit is supplied at the lower right in the back of the machine (Figure 3). If

necessary due to space requirements, remove the knockout and use a 45° fitting.

KNOCKOUT

Figure 3

4. Install 1" trade size conduit and fitting. Leave at least four feet of electrical line between wall connection

and machine. This allows machine to be pulled away from the wall for cleaning and/or servicing.

5. Feed wires thru base of unit to front of unit. At least 24" and not more than 28" of the required wire

size must extend from the end of the conduit fitting.

6. Make electrical connections according to wiring diagram supplied with the machine and secure wires

to the machine service connection. Keep excess wire in the base of the unit to a minimum.

7. Replace the left side panel, top of unit, and lower front panel. Re-install the three screws located behind

the door and the two screws at the bottom of the front panel.

10 | STERO UNDERCOUNTER DISHWASHER & GLASSWASHER

INSTALLATION (continued)

DETERGENT AND RINSE AID

Use only commercial-grade detergents recommended by your chemical professional. Do not use detergents

formulated for residential dishwashers.

SU UNDERCOUNTER ONLY:

The detergent and rinse aid pump “ON” times are factory-set. If adjustments are required, contact your local

service provider or your chemical supplier.

Place the detergent and rinse aid containers (which are obtained from an independent supplier) in a location

where the delivery tubes will reach them.

Remove the detergent bottle cap and put the red delivery tube in the detergent container.

Remove the rinse aid bottle cap and place the blue delivery tube in the rinse aid container.

Be sure to push the delivery tube standpipes completely to the bottom of each container. Check to make sure

there are no obstructions or kinks in the delivery tubes.

SG GLASSWASHER ONLY:

Place the detergent and rinse aid containers (which are obtained from an independent supplier) under the

glasswasher (or nearby for shorter version).

Remove the detergent bottle cap and put the red delivery tube in the detergent container by snapping the

bottle connector onto the container.

Remove the rinse aid bottle cap and place the blue delivery tube in the rinse aid container by snapping the

bottle connector onto the container.

Be sure to push the delivery tubes completely to the bottom of each container. Check to make sure there are

no obstructions or kinks in the delivery tubes.

CHEMICAL SANITIZER

Items such as pewter, aluminum and silver will be attacked by sodium hypochlorite (bleach).

Therefore, chemical-sanitizing dishwashers should not be used to wash such items.

The chemical sanitizer pump is factory-set for use with 6% sodium hypochlorite solution.

On SU-L & SG models, place a 1-gallon bottle of 6% or 8.40% sodium hypochlorite solution (bleach) in a suitable location no higher than 10 inches off the floor. Do not pre-mix sanitizing solution with water or any other

iquid.

l

Never premix a wetting agent with the sanitizing solution. Mixing may cause

hazardous gas to form.

Remove the sanitizer bottle cap and place the white delivery tube in the sanitizer container. Be sure to push

the delivery tube standpipe completely to the bottom of the container. Check to make sure there are no

bstructions or kinks in the delivery tube.

o

Frequently check your sanitizer bottle to make sure there is a sufficient chemical supply.

STERO UNDERCOUNTER DISHWASHER & GLASSWASHER | 11

INSTALLATION (continued)

CHECKING SANITIZER CONCENTRATION

Verify there is sufficient chemical supply in the sanitizer bottle and that the delivery tube standpipe is inserted

completely to the bottom of the chemical container. Place a glass rack, with glasses, in the machine.

Press the WASH key to run a cycle. At the end of the cycle, open the door.

Follow the directions precisely that are on the litmus paper vial and test the water on the surface of the bottom

of the glasses. Concentration should be 50 p.p.m. minimum to 100 p.p.m. maximum.

If reading is incorrect, contact your chemical provider for adjustments.

PRIMING CHEMICAL PUMPS

When a chemical becomes empty, the priming operation starts automatically the next time the machine is

turned on or a wash cycle is started. Note that the initial prime time for all pumps (Detergent, Rinse Agent,

and Sanitizer) is 60 seconds. If the chemical is not sensed within 60 seconds, the add chemical indicator will

flash. After the chemical is sensed, the indicator in the display turns off; and the pump continues to prime for

10 seconds to allow the chemicals to reach the machine. If all chemicals are empty, the sanitizer will prime first

followed by detergent. Only one chemical pump will run at a time.

If chemicals are not sensed after three consecutive priming operations, the add chemical indicator will flash

and priming is cancelled. The next time a wash cycle is started, the add chemical indicator will continue to flash.

Verify that the chemical bottles are not empty and that the delivery tube standpipes are inserted completely

to the bottom of the containers.

The priming operation can be reset by turning the dishwasher off, then back on.

If the chemical bottles are not empty and the delivery tube standpipes are inserted correctly, then the chemical

sensor or pumps may have malfunctioned; contact your local chemical provider.

12 | STERO UNDERCOUNTER DISHWASHER & GLASSWASHER

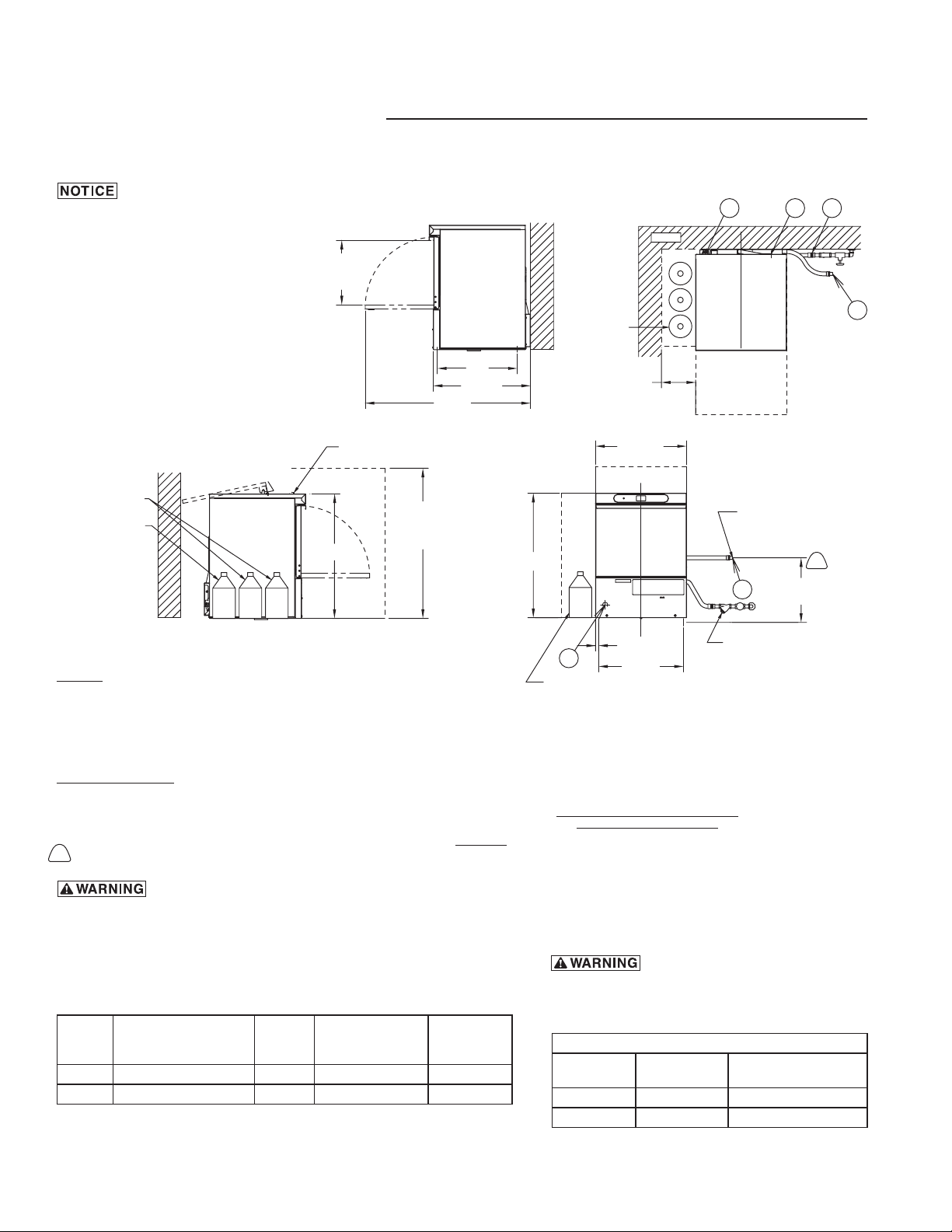

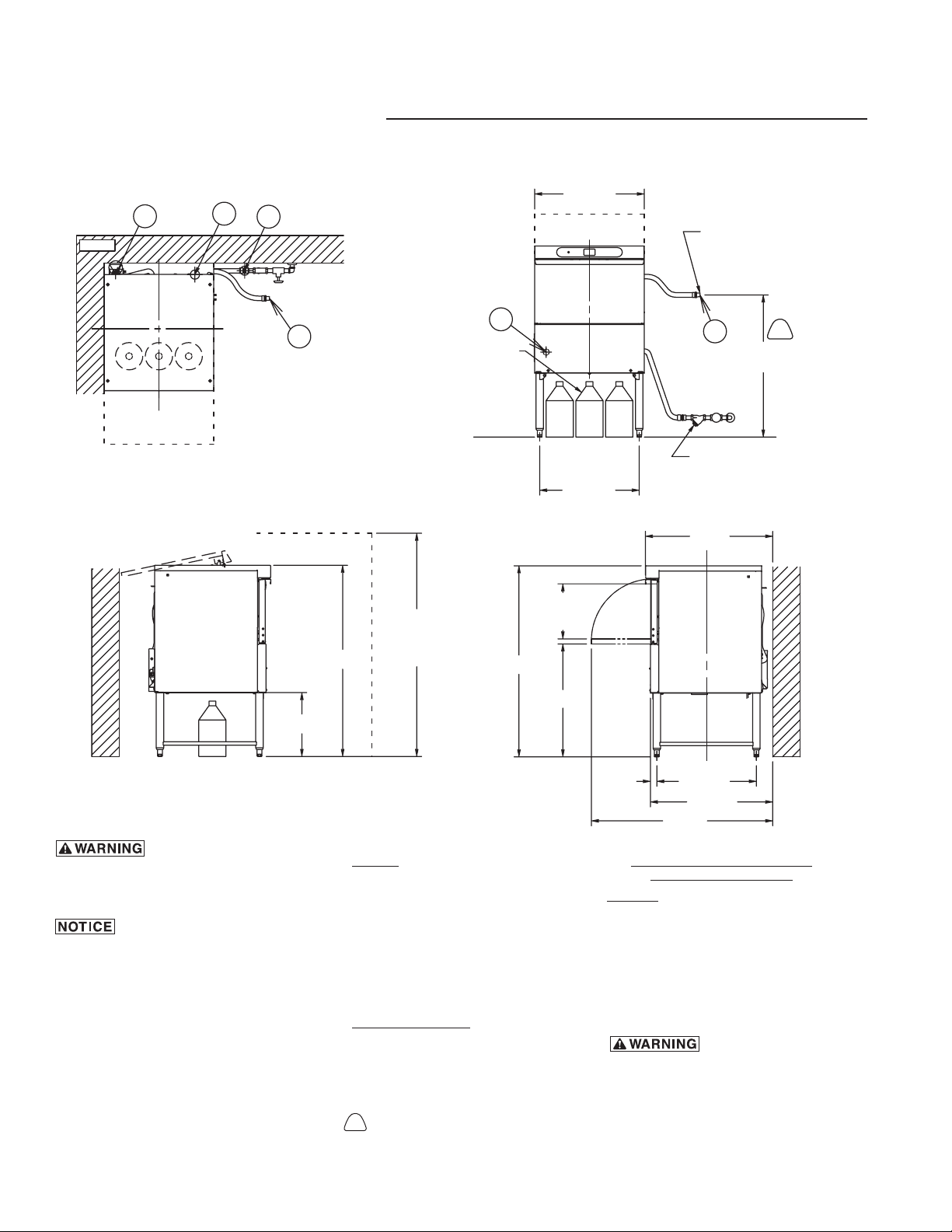

EITHER SIDE OF MACHINE

32 3/4"

23 15/16"

CUSTOMER).

RECOMMENDED

SLIDE UNIT FORWARD FOR SERVICE ONLY

TRIM STRIP

DETERGENT

RINSE-AID

CLEARANCE

43-1/2"

17" MAX.

CHLORINE

SANITIZER

(SU-L ONL

INSTALLATION (continued)

SU UNDERCOUNTER DISHWASHER INSTALLATION DIAGRAM

Required flowing water pressure to the

dishmachine is 15-65 PSIG. If pressures higher

than 65 PSIG are present, a pressure regulating

valve must be installed in the water line to the

dishmachine (by others).

Pressure gauge not required on pumped rinse

machines.

LOADING

HEIGHT

Important: Chemical containers should be placed

no higher than 10" above floor.

If chemical containers are to be placed in cabinet

adjacent to machine, a 1/2" dia. hole is required

in the cabinet to run chemical supply line.

Use only 6% or 8.4% sodium hypochlorite (liquid

bleach) as sanitizing chemical to insure proper

21"

25-9/16"

operation of dishmachine (SU-L only).

(OPTIONAL)

&

CHLORINE

SANITIZER

(SU-L ONLY)

32-3/4"

ADDITIONAL CLEARANCE REQUIRED TO

40"

SERVICE

MIN

NOTES:

1. All vertical machine dimensions taken from floor may be increased by 1".

2. Moist air escapes from the door. Use only moisture resistant materials

adjacent to dishmachine sides and top.

3. A vent hood is not recommended above the undercounter dishmachine

since it does not produce excessive vapors.

PLUMBING NOTES:

1. Water hammer arrestor (meeting ASSE-1010 Standard or equivalent)

to be supplied (by others) in common water supply line at service

connection.

2. Recommended water hardness to be 3 grains or less for best results.

3. If drain hose is looped above a sink, the loop must not exceed 38" AFF.

Electrical and grounding connections must comply with the

applicable portions of the National Electrical Code and/or other

local electrical codes.

Plumbing connections must comply with applicable sanitary,

safety and plumbing codes. Drain and fill line configurations

vary, some methods are shown on this drawing.

MODEL VOLTS/HERTZ/PHASE

RATED

AMPS

SU-H 120/208-240(3W)/60/1* 30.5 40 40

SU-L 120/60/1 15.4 20 20

NOTE: FOR SUPPLY CONNECTIONS, USE COPPER WIRE ONLY RATED AT 90°C MINIMUM

ACCESSORY CORD KIT AVAILABLE FOR ALL MODELS.

* THIS SYSTEM REQUIRES THREE POWER WIRES WHICH INCLUDES A CURRENT CARRYING NEUTRAL, AN

ADDITIONAL FOURTH WIRE MUST BE PROVIDED FOR A MACHINE GROUND.

MIN SUPPLY

CKT CONDUCTOR

AMPACITY

CAUTION: CERTAIN MATERIALS, INCLUDING SILVER, ALUMINUM AND

PEWTER ARE ATTACKED BY SODIUM HYPOCHLORITE (LIQUID BLEACH) IN

THE CHEMICAL SANITIZING DISHWASHER MODE OF OPERATION. WATER

HARDNESS MUST BE CONTROLLED TO 4-6 GRAINS FOR BEST RESULTS.

LEGEND

E1 ELECTRICAL CONNECTION: 1-3/8" DIA. HOLE FOR 1" TRADE SIZE CONDUIT;

4-5/8" AFF

P1 SINGLE FILL AND RINSE CONNECTION: 3/4" FEMALE GARDEN HOSE FITTING

ON 6' LONG HOSE SUPPLIED WITH MACHINE;

P2 DRAIN CONNECTION: 5/8" BARB FITTING WITH 6' LONG HOSE SUPPLIED WITH

MACHINE.

MAX

PROTECTIVE

DEVICE

WALL

Y)

9"

MIN.

E1

CHEMICAL BOTTLES

MAY BE LOCATED ON

CONNECTION INFORMATION

13/16"

22 5/16"

(AFF = ABOVE FINISHED FLOOR)

E1

1-1/2" TRADE SIZE

PIPE MIN. REDUCED

DOWN TO 3/4" FPT

CONNECTION (BY

CUSTOMER)

P2

FLOOR LINE

RECOMMENDED WATER

SERVICE ROUGH-IN

1/2" TRADE SIZE

PIPE MIN. W/SHUTOFF

VALVE, LINE STRAINER

& 3/4" MALE GARDEN

HOSE FITTING (BY

P2 P1

P2

3

17" OR LESS

Do not premix other chemicals and sodium hypochlorite

(liquid bleach).

Mixing may cause hazardous gas to form (SU-L only).

SHIPPING WEIGHTS

MODEL

NET

WEIGHT

DOMESTIC

SHIPPING WEIGHT

SU-H 150 lbs. 170 lbs.

SU-L 150 lbs. 170 lbs.

OVERALL DIMENSIONS: 32-3/4"H x 23-15/16"W x 25-9/16"D

STERO UNDERCOUNTER DISHWASHER & GLASSWASHER | 13

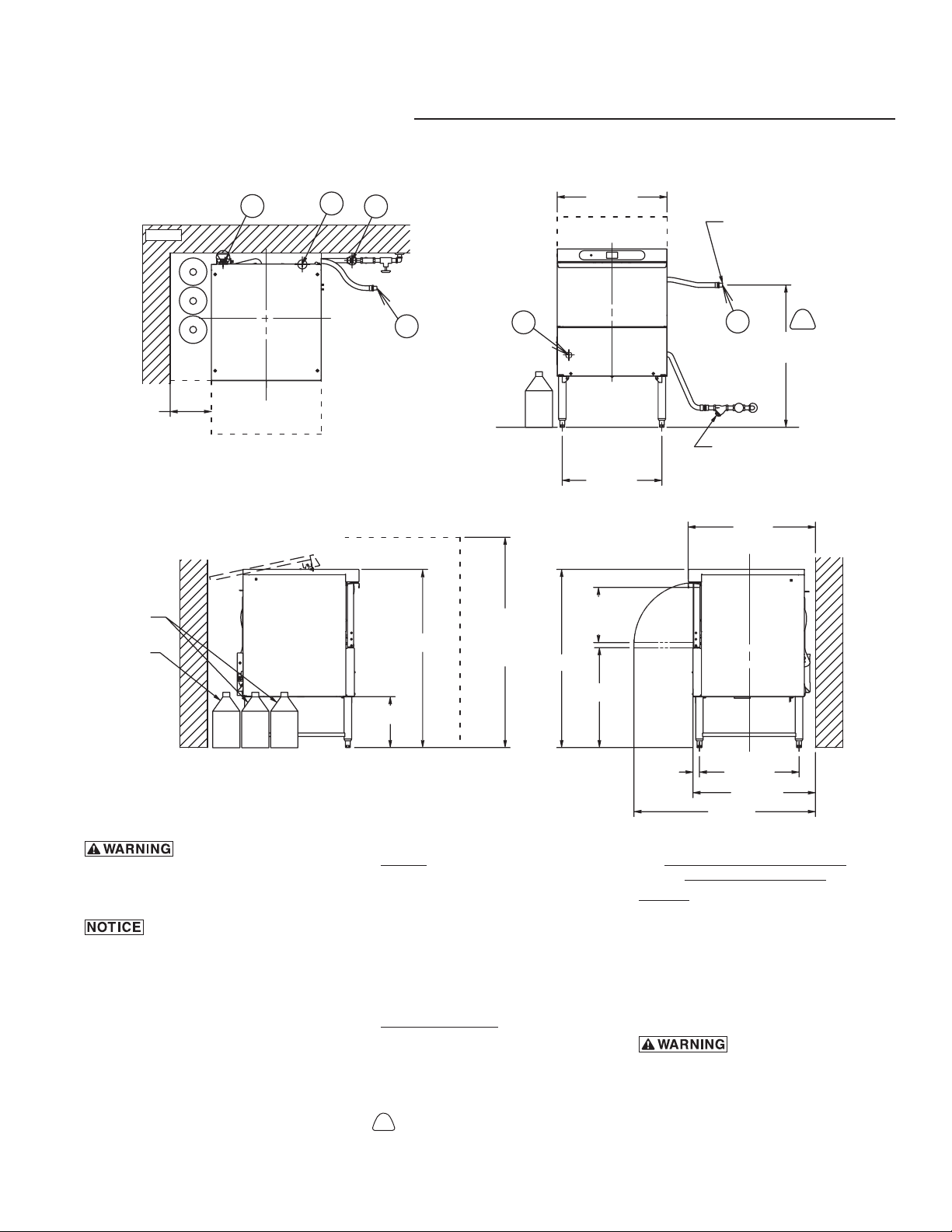

23 15/16"

HOSE FITTING (BY CUSTOMER).

27 3/4"

39 9/16"

38 7/8"

MI

SLIDE UNIT FORWARD FOR SERVICE ONLY

DETERGENT

RINSE-AI

E

INSTALLATION (continued)

SG40 UNDERCOUNTER GLASSWASHER INSTALLATION DIAGRAM

&

D

CHLORINE

SANITIZER

WALL

9"

N

E1

E1

P2

P1

DH

P2

38 7/8"

E1

45 7/8"

SERVICE

CLEARANC

MIN

21 11/16"

12" MAX

LOADING

HEIGHT

1-1/2" TRADE SIZE

PIPE MIN. REDUCED

DOWN TO 3/4" FPT

CONNECTION (BY

CUSTOMER)

P2

RECOMMENDED

FLOOR LINE

RECOMMENDED WATER SERVICE

ROUGH-IN 1/2" TRADE SIZE PIPE

MIN. W/SHUTOFF VALVE, LINE

STRAINER & 3/4" MALE GARDEN

3

31" OR LESS

11 1/8"

ADDITIONAL CLEARANCE REQUIRED TO

Do not premix other chemicals and sodium

hypochlorite (liquid bleach).

Mixing may cause hazardous gas to form.

Required flowing water pressure to the dishmachine is

15-65 PSIG. If pressures higher than 65 PSIG are present,

a pressure regulating valve must be installed in the

water line to the dishmachine (by others).

Pressure gauge not required on pumped rinse machines.

Important: The chemical containers should be placed no

higher than 24" above floor.

If chemical containers are to be placed in cabinet

adjacent to machine, a 1/2" dia. hole is required in the

cabinet to run chemical supply line.

Use only 6% or 8.4% sodium hypochlorite (liquid bleach)

as sanitizing chemical to insure proper operation of

dishmachine.

Certain materials, including silver plate, aluminum and

pewter are attacked by sodium hypochlorite (liquid

bleach). See instructional manual.

NOTES:

1. All vertical machine dimensions taken from

2. Moist air escapes from the door.

Use only moisture resistant materials

3. A vent hood is not recommended above the

PLUMBING NOTES:

1. Water hammer arrestor (meeting ASSE-1010

2. Recommended water hardness to be 3 grains

3. If drain hose is looped above a sink, the loop

21 13/16"

floor may be increased by .875" or decreased

by .375".

adjacent to dishmachine sides and top.

undercounter dishmachine since it does not

produce excessive vapors.

Standard or equivalent) to be supplied (by

others) in common water supply line at

service connection.

or less for best results.

must not exceed 51" AFF.

1 3/8"

21 11/16"

26 11/16"

MODELS:

SG 40"

00-950420

REV C

CONNECTION INFORMATION

(AFF = ABOVE FINISHED FLOOR)

LEGEND

E1 ELECTRICAL CONNECTION: 1-3/8" DIA. HOLE FOR

1" TRADE SIZE CONDUIT; 15-5/16" AFF

P1 SINGLE FILL AND RINSE CONNECTION: 3/4"

FEMALE GARDEN HOSE FITTING ON 6' LONG HOSE

SUPPLIED WITH MACHINE; 120°F WATER MIN.

FOR SG, 140°F RECOMMENDED.

P2 DRAIN CONNECTION: 5/8" BARB FITTING WITH

6' LONG HOSE SUPPLIED WITH MACHINE.

Electrical and grounding connections must

comply with the applicable portions of the

National Electrical Code and/or other local

electrical codes.

Plumbing connections must comply with

applicable sanitary, safety and plumbing codes.

Drain and fill line configurations vary, some

methods are shown on this drawing.

14 | STERO UNDERCOUNTER DISHWASHER & GLASSWASHER

HOSE FITTING (BY CUSTOMER).

DETERGENT

RINSE-AID,

CHLORINE

SANITIZE

BOTTLES MA

BE LOCA

UNDER THE

MACHINE

23 15/16"

E

SLIDE UNIT FORWARD FOR SERVICE ONLY

39 9/16"

41 11/16"

27 3/4"

INSTALLATION (continued)

SG42 UNDERCOUNTER GLASSWASHER INSTALLATION DIAGRAM

WALL

E1

P2

P1

P2

42 1/8"

48 11/16"

SERVICE

CLEARANC

MIN

E1

R

TED

1-1/2" TRADE SIZE

PIPE MIN. REDUCED

DOWN TO 3/4" FPT

CONNECTION (BY

CUSTOMER)

,

Y

21 11/16"

12" MAX

LOADING

HEIGHT

P2

RECOMMENDED

FLOOR LINE

RECOMMENDED WATER SERVICE

ROUGH-IN 1/2" TRADE SIZE PIPE

MIN. W/SHUTOFF VALVE, LINE

STRAINER & 3/4" MALE GARDEN

3

31" OR LESS

Do not premix other chemicals and sodium

hypochlorite (liquid bleach).

Mixing may cause hazardous gas to form.

Required flowing water pressure to the dishmachine is

15-65 PSIG. If pressures higher than 65 PSIG are present,

a pressure regulating valve must be installed in the

water line to the dishmachine (by others).

Pressure gauge not required on pumped rinse machines.

Important: The chemical containers should be placed no

higher than 24" above floor.

If chemical containers are to be placed in cabinet

adjacent to machine, a 1/2" dia. hole is required in the

cabinet to run chemical supply line.

Use only 6% or 8.4% sodium hypochlorite (liquid bleach)

as sanitizing chemical to insure proper operation of

dishmachine.

Certain materials, including silver plate, aluminum and

pewter are attacked by sodium hypochlorite (liquid

bleach). See instructional manual.

13 15/16"

ADDITIONAL CLEARANCE REQUIRED TO

24 1/2"

NOTES:

1. All vertical machine dimensions taken from

floor may be increased by .875" or decreased

by .375".

2. Moist air escapes from the door.

Use only moisture resistant materials

adjacent to dishmachine sides and top.

3. A vent hood is not recommended above the

undercounter dishmachine since it does not

produce excessive vapors.

PLUMBING NOTES:

1. Water hammer arrestor (meeting

ASSE-1010 Standard or equivalent) to be

supplied (by others) in common water supply

line at service connection.

2. Recommended water hardness to be 3 grains

or less for best results.

3. If drain hose is looped above a sink, the loop

must not exceed 51" AFF.

1 3/8"

21 11/16"

26 11/16"

MODELS:

SG 42"

00-950420

REV C

CONNECTION INFORMATION

(AFF = ABOVE FINISHED FLOOR)

LEGEND

E1 ELECTRICAL CONNECTION: 1-3/8" DIA. HOLE FOR

1" TRADE SIZE CONDUIT; 18-1/8" AFF

P1 SINGLE FILL AND RINSE CONNECTION: 3/4"

FEMALE GARDEN HOSE FITTING ON 6' LONG HOSE

SUPPLIED WITH MACHINE; 120°F WATER MIN.

FOR SG, 140°F RECOMMENDED.

P2 DRAIN CONNECTION: 5/8" BARB FITTING WITH

6' LONG HOSE SUPPLIED WITH MACHINE.

Electrical and grounding connections must

comply with the applicable portions of the

National Electrical Code and/or other local

electrical codes.

Plumbing connections must comply with

applicable sanitary, safety and plumbing codes.

Drain and fill line configurations vary, some

methods are shown on this drawing.

STERO UNDERCOUNTER DISHWASHER & GLASSWASHER | 15

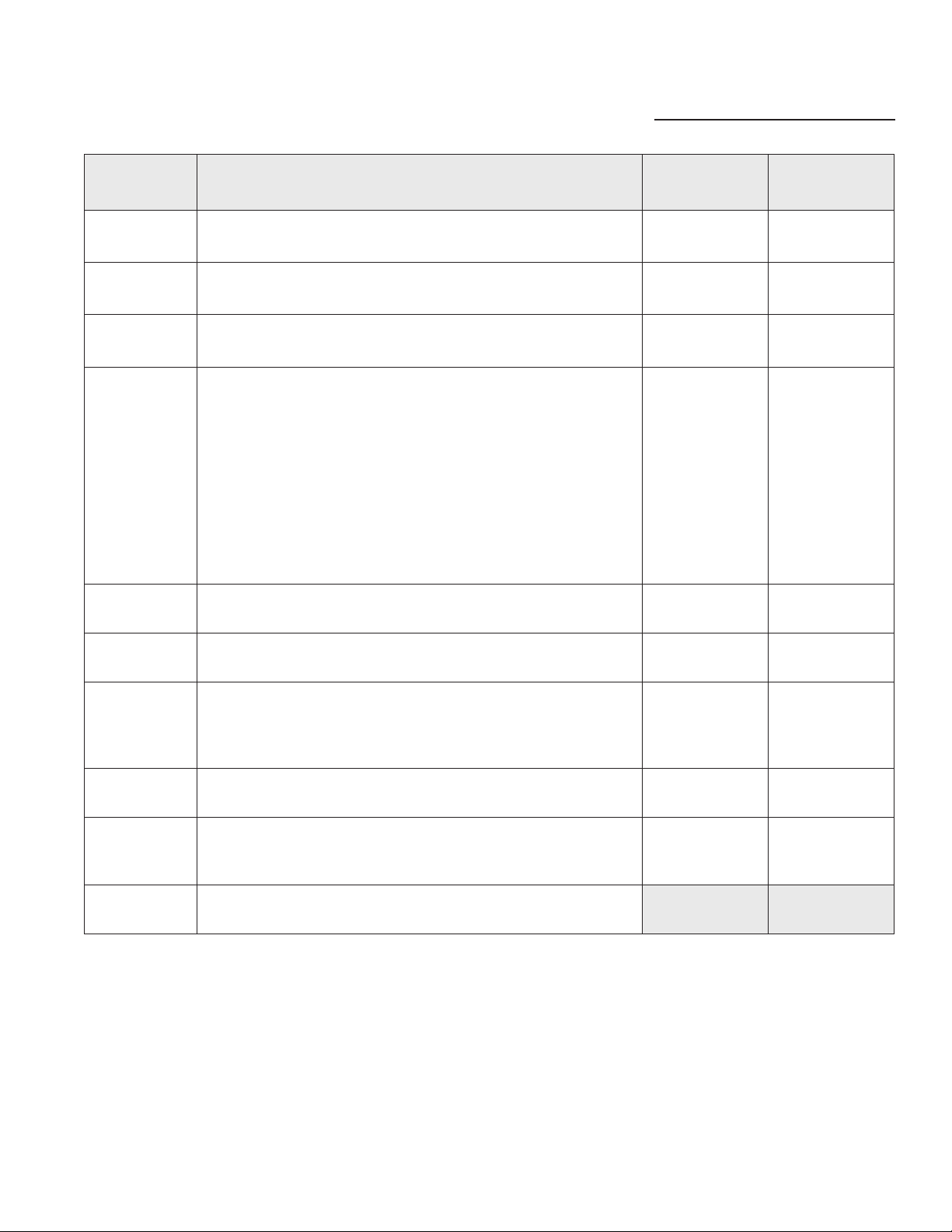

PARAMETERS MENU TABLE

Parameter

Name

Detergent

Pump

Rinse Aid

Pump

Wash Cycle Sets the cycle duration.

Low Temp

Alarms

(SU-H

Model Only)

Delime Enables or disables the alert to delime option.

Enables or disables the detergent pump.

Enables or disables the rinse aid pump.

Enables or disables a visual alert on the display that indicates that the Final Rinse water temperature is below the

required minimum of 180°F (82°C). When enabled, a message will display notifying the user of this condition after

three consecutive cycles do not reach the required final rinse

temperature. However, machine operation will not change

and ware will continue to wash as expected. After the temperature increases past the minimum, the message stops.

When disabled, there will be no extra message indicating a

low temperature event; however, the temperature display

will still show the current Final Rinse water temperature.

Description

Possible

Values

Disabled or

Enabled

Disabled or

Enabled

Light, Normal,

or Heavy

Disabled or

Enabled

Disabled or

Enabled

Default

Value

Enabled

Enabled

Normal

Disabled

Enabled

Temperature

Units

Add

Chemical

Alert

End Cycle

Audio Alert

Language Sets the language on the display to either English or French.

Exit Menu

Sets the display units to either Fahrenheit or Celcius.

Enables or disables an audible alert if chemical is not being

detected.

Enables or disables an audible alert at the end of a cycle.

Press ENT to exit the Parameters Menu and return to the

Manager Menu. Any settings that were changed are saved.

Fahrenheit or

Celsius

Disabled,

Visual, or

Audio and

Visual

Disabled or

Enabled

English (US) or

French

(Canada)

Fahrenheit

Audio and

Visual

Disabled

English (US)

Loading...

Loading...