Stero Dishwasher SD3 Installation Manual

SERVICE and PARTS

MANUAL

SD3 Series

SD3 ML-130232

F45576 (1015)

SD3 Series

TABLE OF CONTENTS

GENERAL .................................................................................................. 3

INTRODUCTION ....................................................................................... 3

MODELS COVERED ................................................................................... 3

SPECIFICATIONS ...................................................................................... 3

REFERENCE MATERIAL ............................................................................... 4

POWER-UP ............................................................................................ 4

FILL CYCLE ............................................................................................ 4

BOOSTER TEMPERATURE CONTROL ................................................................ 4

BOOSTER TEMPERATURE CONTROL ............................................................ 4

READY MODE ......................................................................................... 5

RUNNING A CYCLE .................................................................................... 5

CHANGING CYCLE TIME .............................................................................. 5

CHANGING CYCLE TIME .......................................................................... 5

LUBRICATION ......................................................................................... 5

TOOLS ................................................................................................. 5

SERVICE PROCEDURES AND ADJUSTMENTS ............................................................ 6

CONTROL BOARD PROGRAMMING ................................................................... 6

SERVICE PROGRAMMING ............................................................................. 7

TANK HEATER - TEST ................................................................................ 10

BOOSTER HEATER - TEST

PUMP MOTOR - TEST ................................................................................ 12

THERMISTOR - TEST 1QTM, 2QTM & 3QTM .......................................................... 12

QUICK CHECK USING SERVICE DIAGNOSTICS .................................................. 12

MEASURING THERMISTOR RESISTANCE ....................................................... 12

TRANSFORMER 1T - TEST ........................................................................... 13

TRANSFORMER 2T - TEST ........................................................................... 14

DELIMIMG PROCEDURE ............................................................................. 15

DOOR TENSION ADJUSTMENT ...................................................................... 15

........................................................................... 11

ELECTRICAL OPERATION ................................................................................ 16

COMPONENT FUNCTION ............................................................................ 16

COMPONENT LOCATION ............................................................................. 17

CONTROL BOARD / RELAY BOARD LAYOUT ........................................................ 18

SEQUENCE OF OPERATION ......................................................................... 19

CONTROL AND RELAY BOARD LEDS ................................................................ 21

WIRING DIAGRAM - 1 PHASE ........................................................................ 23

WIRING DIAGRAM - 3 PHASE ........................................................................ 24

TROUBLESHOOTING ..................................................................................... 25

QUICK REFERENCE CHART - ELECTRIC HEAT ...................................................... 25

CONTROL BOARD AND RELAY BOARD LEDS ................................................... 27

CONTROL BOARD AND RELAY BOARD .............................................................. 27

OPERATING CONDITIONS ....................................................................... 27

NO DISPLAY AFTER ON KEY IS PRESSED ....................................................... 28

NO FILL OR RINSE ............................................................................... 29

LONG FILL TIME (6 MINUTES) .................................................................... 30

NO WASH CYCLE ................................................................................ 30

NO TANK HEAT ................................................................................... 31

SERVICE DIAGNOSTICS ............................................................................. 32

SERVICE DIAGNOSTICS CHART ..................................................................... 33

OUTPUT TESTS ...................................................................................... 34

VERIFY CONTROL BOARD IS CONFIGURED AS AN SD3 ............................................ 35

ERROR CODE CHART ................................................................................ 35

TROUBLESHOOTING TABLE ......................................................................... 35

PARTS CATALOG ............................................................................................................................................. 36

F45576 (1015)

© COMPETITIVE 2015

Page 2 of 37

SD3 Series - GENERAL

GENERAL

INTRODUCTION

This manual is applicable to the models and ML

numbers listed on the cover page. Procedures apply

to all models unless specified otherwise.

MODELS COVERED

SD3-H: Single water inlet. Incoming water of 110°F

minimum is

machine. The machine is configured for a 70°F rise

depending on incoming water temperature. The

booster maintains water temperature to be used for

180°F final rinse.

SD3-P: Single water inlet. Water temperature to

machine must be a minimum of 180°F for the final

rinse. This water is provided by the customer external

of the machine. The SD3-P has the option to be

reprogramed to change from plain to chemical.

heated by a booster tank mounted on the

SPECIFICATIONS

• Low water protection.

• One incoming plumbing connection to

dishwasher through an electrically operated

valve.

The fill/rinse valve is installed prior to the 3.6

•

gallon booster tank.

• Supply flowing water pressure 20 ±5 psi.

• Provides a minimum 70°F rise with incoming

water temperature of 110°F for a final rinse

temperature of 180°F at 20 psi (flowing).

• The dishwasher, with the booster, can operate at

full capacity with back-to-back cycles (SD3).

• SD3 machines are available in several operating

voltages for single or three phase operation.

• Operates as an atmospheric booster (SD3 with

built-in booster).

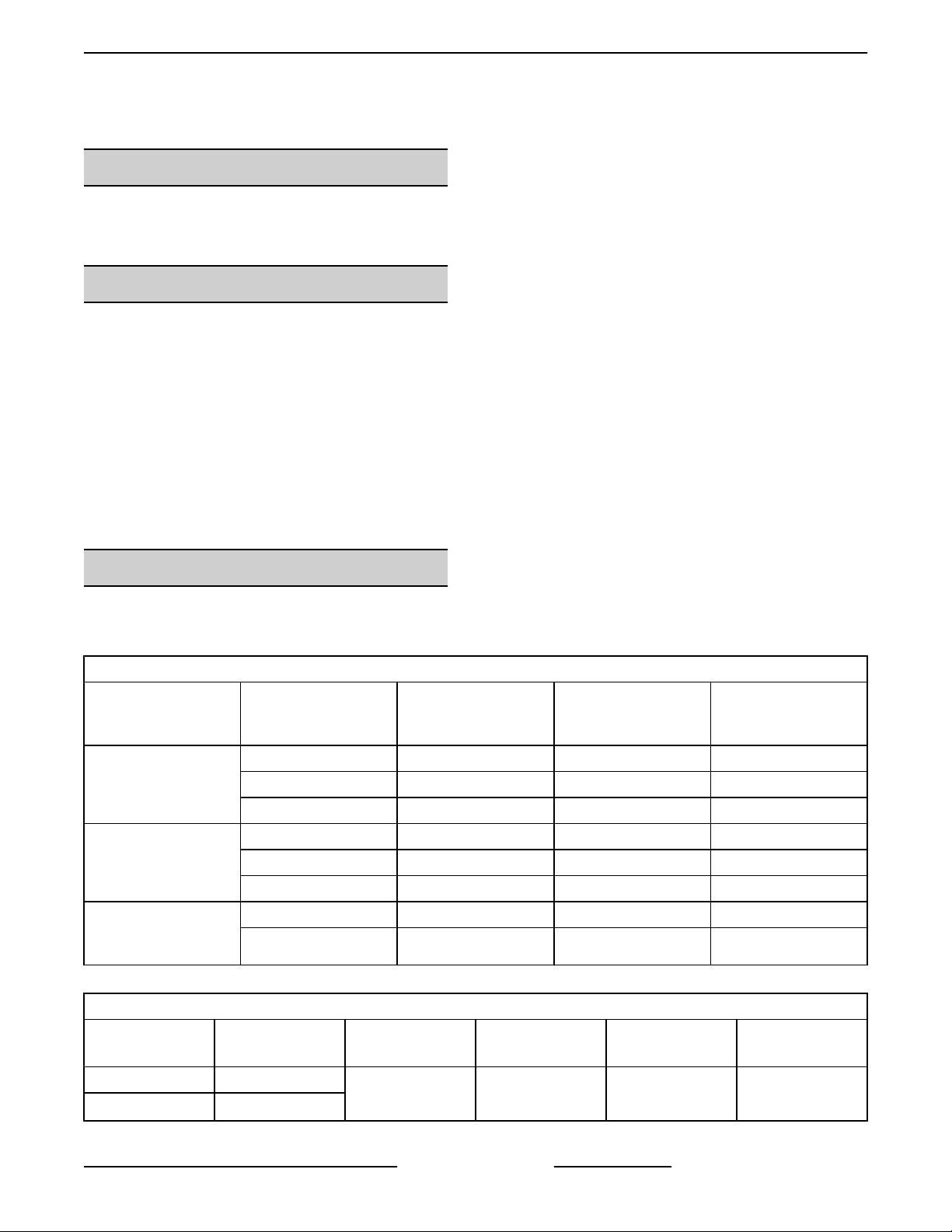

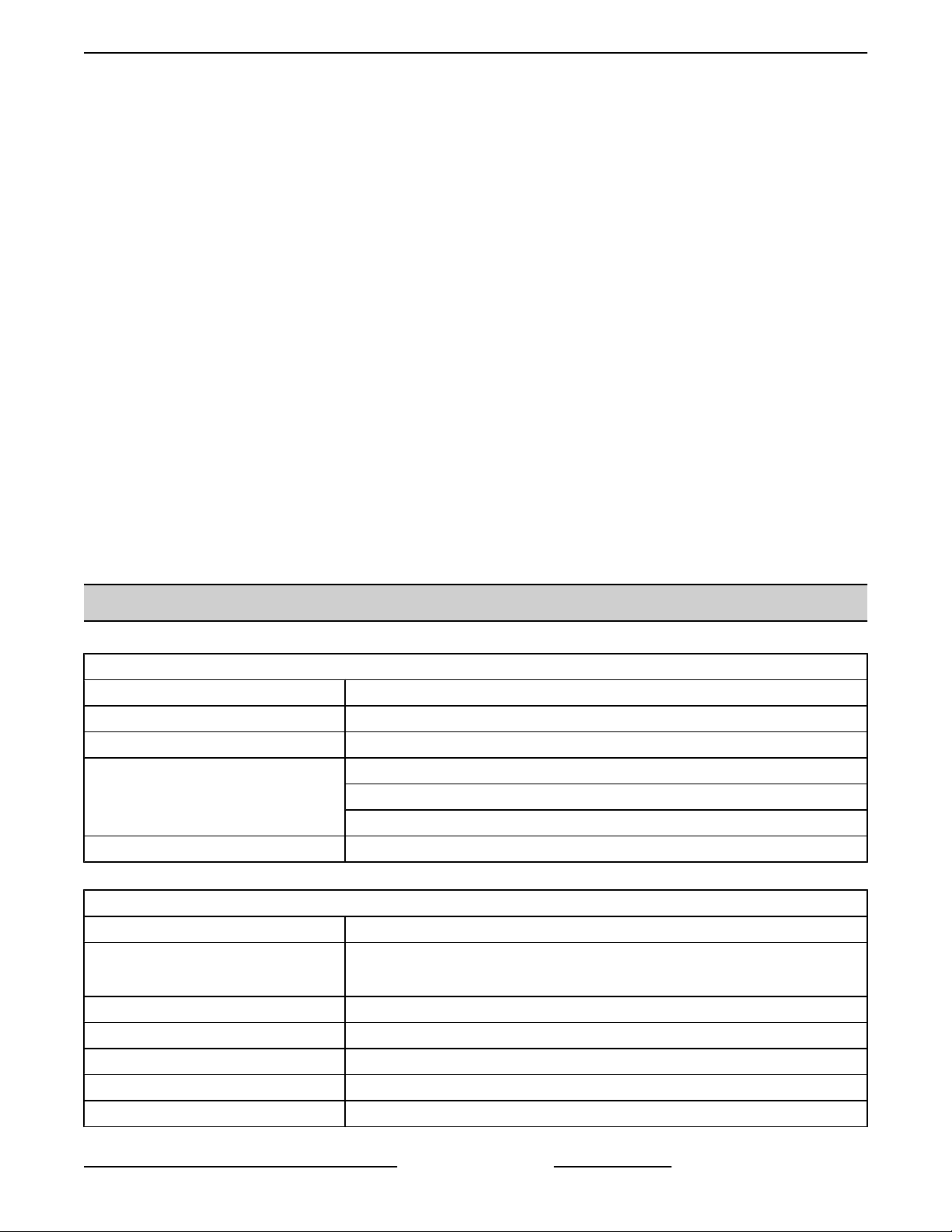

ELECTRICAL SPECIFICATIONS

Model Electrical Specs Rated Amps

208-240/60/1 43.0 50 50

SD3 with Electric

Heat

Booster Ampacity

Ratings 8.5KW

Optional SD3 Single

Point Electrical

Service Connection

Model

SD3 -P (Plain) 140°F

SD3-H (Hot) 110°F

208-240/60/3 24.9 30 30

480/60/3 13.4 15 15

208-240/60/1 35.4 50 50

208-240/60/3 20.4 30 30

480/60/3 10.2 15 15

208-240/60/3 45.4 60 60

480/60/3 23.7 30 30

WATER SUPPLY REQUIREMENTS

Temperature

(minimum)

Flowing

Pressure

20±5 psi

Hardness

grains/gal.

Under 3

1 to 3

Minimum Supply

Circuit Conductor

Ampacity

Chlorides ppm Water Usage

1

≤ 50 0.74 gal/rack

Maximum

Overcurrent

Protective Device

Page 3 of 37 F45576 (1015)

SD3 Series - GENERAL

WATER SUPPLY REQUIREMENTS

Model

1

Water hardness below 4 grains/gal requires water treatment to reduce potential corrosion. Hardness

above 6 grains/gal should be treated by water conditioner, water softener or in-line treatment.

Model

All

1

Machine cycles 1, 2, and 4 are selected via the keypad. Cycle 1 wash duration is adjustable through the

SERVICE PROGRAMMING mode, where the wash time can be adjusted to values above NSF minimums.

2

Dwell,

rinse and sani-dwell times are adjustable to values above NSF minimums. Times chosen for each

Temperature

(minimum)

MACHINE CYCLE TIMES AND CAPACITY (RACKS / HOUR)

Cycle

Settings

1

4 360

1st 1/2 Fill 2nd 1/2 Fill

Variable up

to 150

parameter will apply to all cycle selections.

Flowing

Pressure

Time in Seconds (maximun time settings)

Variable

75-120

REFERENCE MATERIAL

For replacement parts, refer to SD3 Catalog of

Replacement Parts.

to Lubrications Manual F-20067 for current

Refer

values.

For operation and care instructions, refer to

Operator's Manual.

POWER-UP

On power-up, the control board will perform a

self-test. Once the control successfully

completes and exits the selftest routine, the

machine is ready for operation.

FILL CYCLE

Hardness

grains/gal.

Wash

Duration

38 (38-99)

chamber door is opened any time after the float switch

is closed, the fill cycle will be terminated, even if

second

door is closed after the float switch is closed, a wash

cycle will begin.

If the float switch does not close after the maximum

allowed time for the first half of fill (150 seconds), an

[ E2 ] error code will be displayed. To clear an error

from the display, cycle power by turning the machine

off then back on. When the float switch closes, the

controls will begin regulating tank heat. When the fill

cycle is complete, the FILL icon turns off while the tank

temperature continues to be displayed. The machine

will continue heating the tank as required to reach and

maintain the tank heat set point.

1

part of fill did not complete. When the chamber

Chlorides ppm Water Usage

1

Dwell

2 (2-15) 10 (10-35) 7 (7-15)2 120

2

Rinse

2

Sani-Dwell

BOOSTER TEMPERATURE

CONTROL

2

The fill consists of two parts. The first part of the fill is

defined as the time required to fill the tank until the

switch 1FS closes (150 seconds maximum). The

float

time duration for the second part of the fill is equal to

the time elapsed for the first part of fill multiplied by

1.25 (75 seconds minimum, 120 seconds maximum).

The chamber door must be closed for the fill/rinse

solenoid (1SOL) to be energized and begin filling the

tank. Opening the chamber door before the float

switch is closed will de-energize the fill/rinse solenoid

1SOL suspending the fill cycle. When the chamber

door is closed, the fill cycle will continue. If the

F45576 (1015) Page 4 of 37

Booster Temperature Control

NOTE: The Rinse Assurance is on by default for an

SD3. Adjustments to this selection can be made by

the service technician through CONTROL BOARD

PROGRAMMING.

Once

booster has eight minutes to reach its set point. If the

booster does not reach temperature within the eight

minute timeout, an error code [ EE ] will be displayed.

To clear an error from the display, cycle power by

turning the machine off then back on.

the initial fill is complete, if no cycles are run, the

SD3 Series - GENERAL

The control board is programed to cause the booster

heater

and turn off at the end of the cycle. This occurs even

if the booster water temperature meets or is above the

booster temperature set point. Should the booster

temperature be below the set-point, the booster

heater will remain energized until set-point is

achieved.

If the booster water temperature is below the booster

temperature set point at the end of a wash cycle, and

Rinse Assurance is enabled, the wash cycle will be

extended (maximum total wash time is one minute).

The extended wash time allows the booster water

temperature to reach set point before the rinse cycle

begins.

The tank float also controls the heat for the booster. If

the float is down (float switch open), the booster heater

circuit will be disabled. If the float is up (float switch

closed), the control board will regulate the booster

heat as needed.

to turn on at the beginning of every rinse cycle

READY MODE

When a cycle is not in progress, the machine will be

maintained in a ready state. In the ready state, tank

and booster temperatures are maintained. If water

level drops below the tank float in ready mode, tank

booster heating elements are de-energized and a

and

fill cycle will be initiated the next time the chamber

door is opened and then closed. An error code [ Ed ]

will be displayed indicating the machine has a slow

leak. To clear an error from the display, cycle power

by turning the machine off then back on.

the default settings. Refer to SERVICE

PROGRAMMING for procedures on altering the preprogrammed times of cycle one.

NOTE: Cycle 1's times cannot be adjusted below the

NSF minimums.

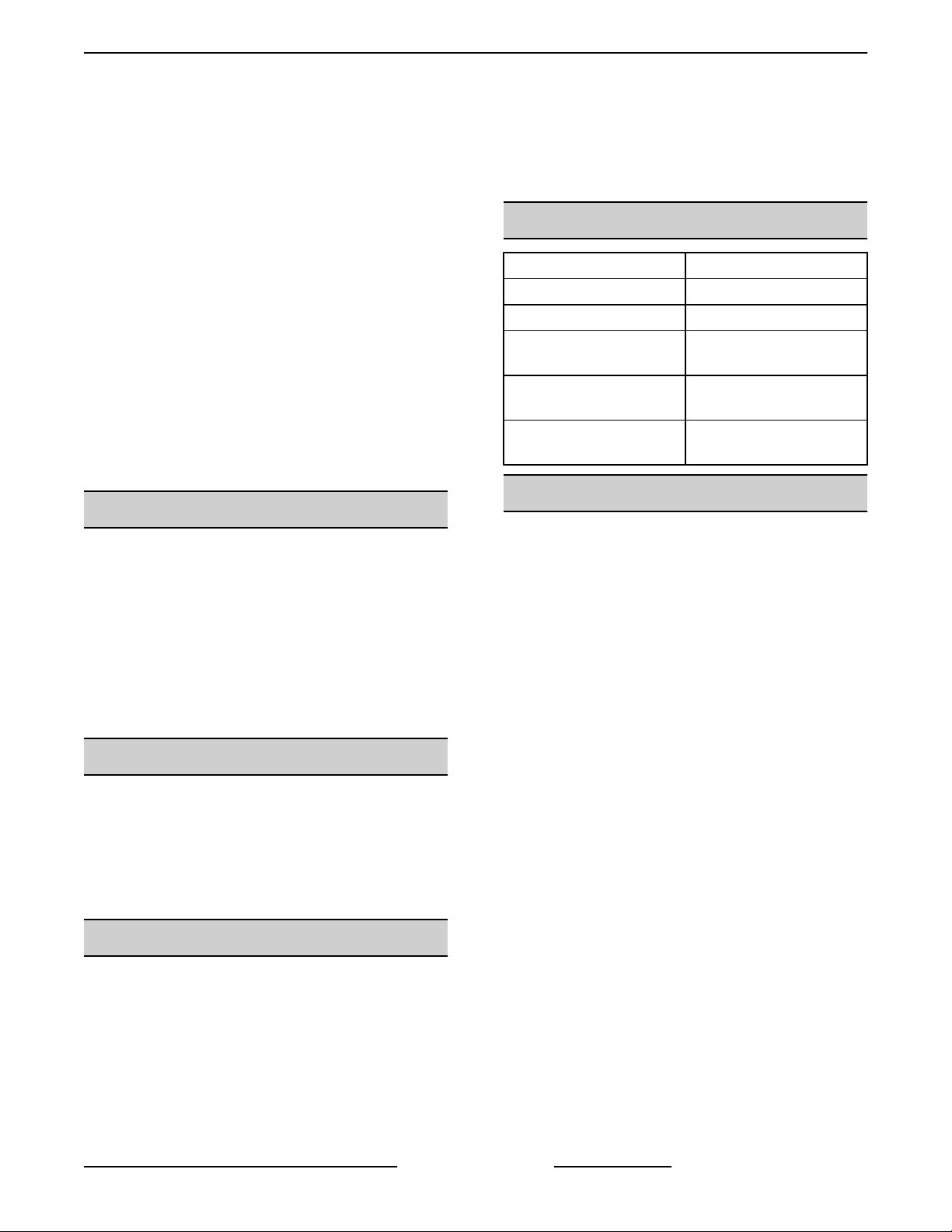

LUBRICATION

Component Lubrication Type

Impeller O - Ring P 80® Rubber Lube

Booster Heater Screws Never Seez

All NPT Fittings

High-Limit Thermostat

1TAS

High-Limit Thermostat

3TAS (Booster Option.)

Pipe Thread Sealant,

Locktite 565

Thermal-Joint Compound

Thermal-Joint Compound

TOOLS

• Standard set of hand tools.

VOM with A/C current tester (any quality VOM

•

with a sensitivity of at least 20K ohms per volt can

be used).

• Anti Static Kit

• Temperature Tester.

• Clamp on type amp meter for meausring heating

element current draw.

RUNNING A CYCLE

After the fill cycle is complete, a cycle is initiated by

raising and lowering the chamber door.

NOTE: If

a cycle, the wash pump and rinse solenoid will

deenergize. The control will start a new cycle once the

chamber door is closed.

the chamber door is raised any time during

CHANGING CYCLE TIME

Changing Cycle Time

Wash cycle duration can be selected at any time

whether the machine is at rest or in a cycle. Pressing

the CYCLE button will step through the preprogrammed timed cycle selections 1, 2, or 4. The

selected

when power is removed and turned back on.

Cycle selection 1 is programmable allowing the wash,

dwell, rinse, and sani-dwell times to be changed from

cycle time will be retained by the control even

Page 5 of 37 F45576 (1015)

SD3 Series - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

CONTROL BOARD

PROGRAMMING

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times and follow Arc Flash

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

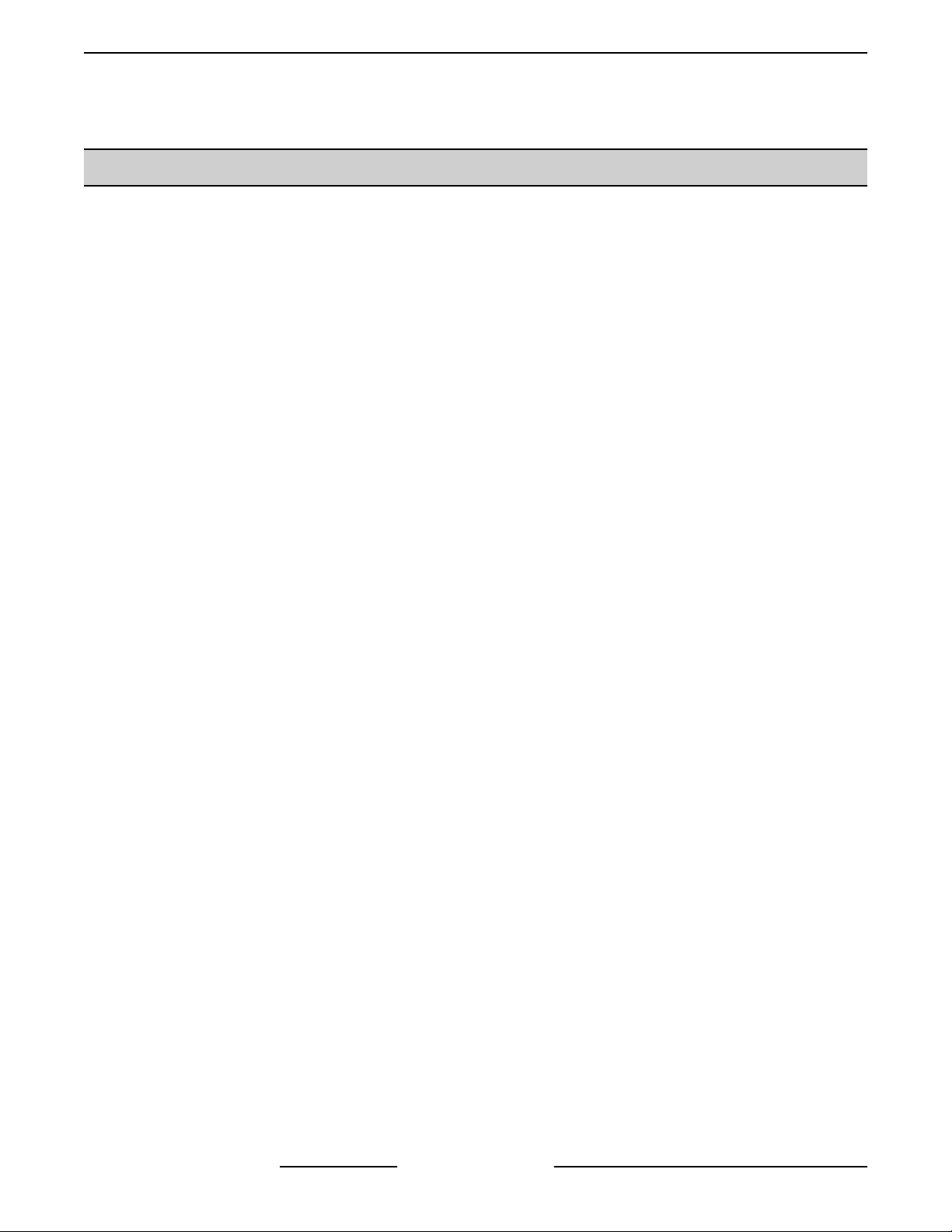

NOTE: The control board is mounted in the machine

in such a way that the printing is upside down. The

control board will be depicted in the manual as it is

found on the machine for consistency purposes.

NOTE: Prior to removing board from machine, check

and note the settings of the programmable variables

as outlined under SERVICE PROGRAMMING when

possible. When unable to access Service

Programming, check with establishment manager to

determine customer control settings.

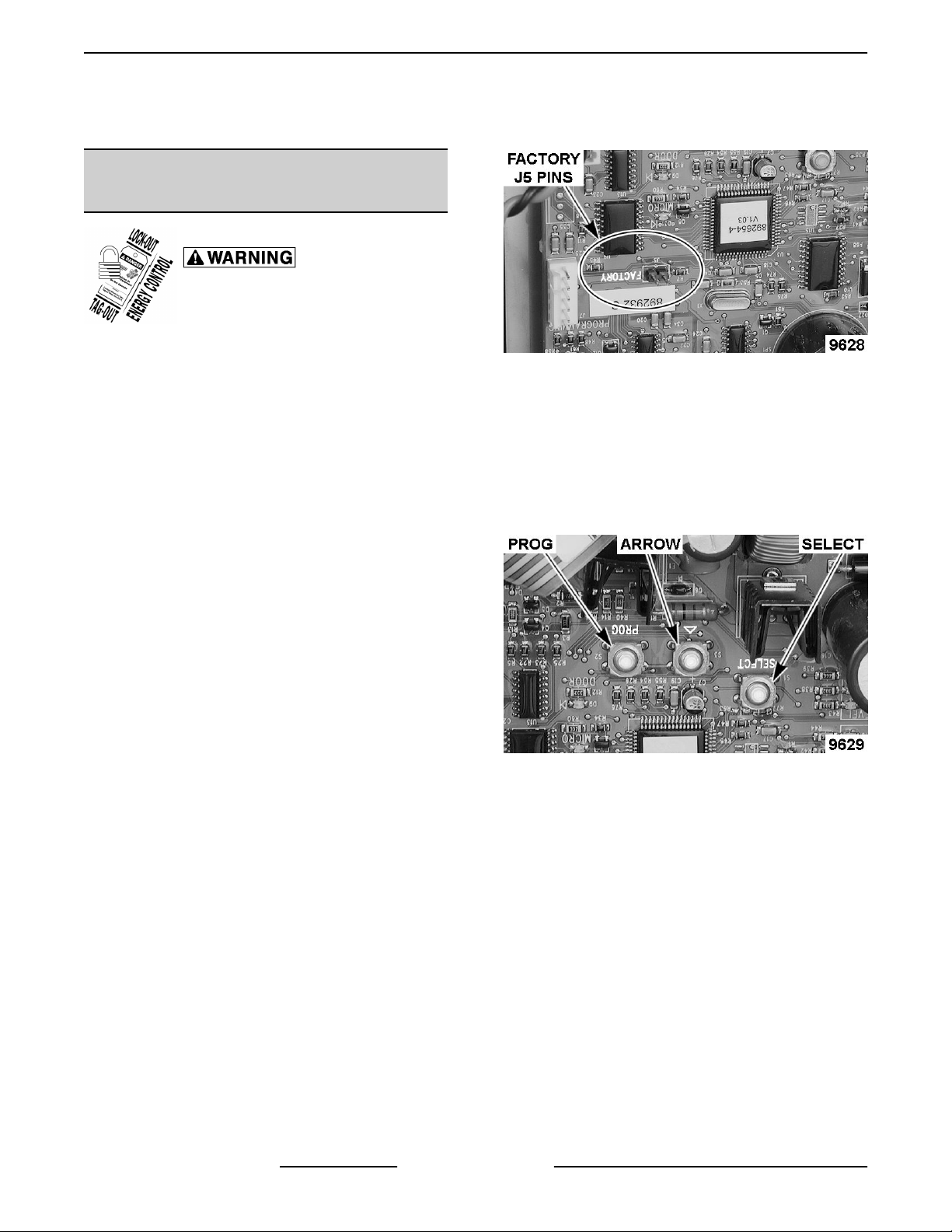

Fig. 1

4. Program the control board using the information

retrieved from the board being replaced and the

information found in CONTROL BOARD

PROGRAMMING table.

5. Use the SELECT switch on control board to

select the feature and the (up arrow) switch to

change the feature settings.

NOTE: The replacement control board will come

programmed as a different model. Step through this

procedure to set up the control board to function as an

SD3.

1. Remove FRONT COVER.

2. Open control door.

3. Carefully short the two FACTORY pins of J5

together and press the ON key on switch

membrane keypad (user controls on front of

machine). Keep short across pins of J5 until

display indicates [ 88 ], then remove the short.

A. Display will cycle between [ SET ty ] and

[ Sd, fd, GL, AS, HL, or St ].

NOTE: SD3 machine type designation is [ St ].

Fig. 2

NOTE:

and setting.

6. Press OFF key on switch membrane keypad

7. Program the variables. Refer to SERVICE

8. Close control door.

9. Check machine for proper operation by running

The display will alternate between the feature

(user controls on front of machine) to store

selections.

PROGRAMMING.

one fill cycle and two normal cycles.

F45576 (1015) Page 6 of 37

SD3 Series - SERVICE PROCEDURES AND ADJUSTMENTS

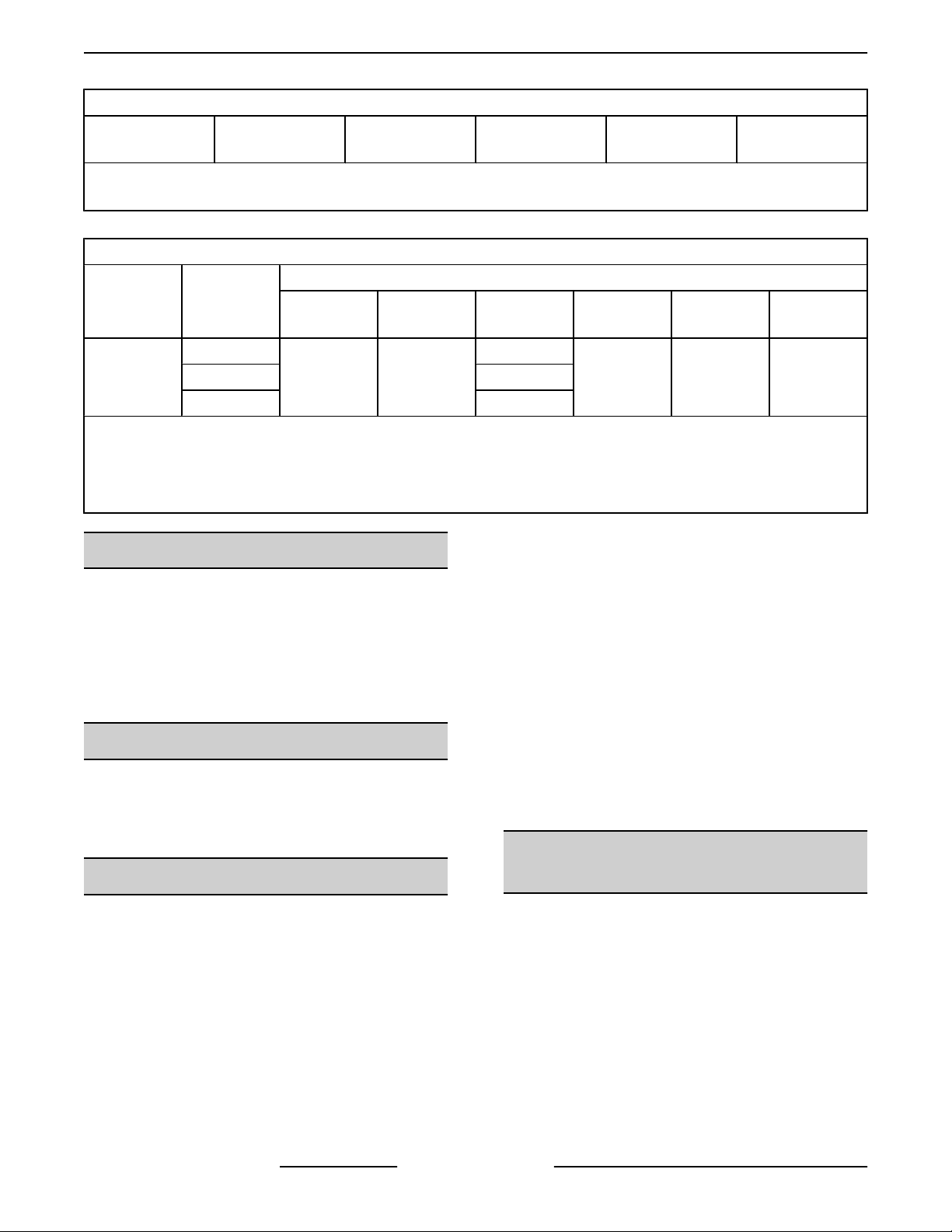

CONTROL BOARD PROGRAMMING

Feature Description Display Setting Display

Standard

1

Not Applicable in SD3

Not Applicable in SD3 fd

Machine Type ty

Not Applicable in SD3 GL

Not Applicable in SD3 AS

Not Applicable in SD3 HL

SD3 St

Hot SD3 with Booster H

ID Id

Chemical C

Plain SD3 No Booster P

2

Rinse Assurance tc

Yes

No no

Manual Temperature Control tr

Flow Options FL

Diagnostics override dG

These parameters are not available for SD3. If either one of

are displayed, return to MachineType and select [ St ].

these

Show Error Codes

2

Disable Error Codes 2

Shorted water thermistor

detections

2

This feature is not available on SD3 - Plain or Chemical models.

SP

These parameters are not available for SD3. If either one of

are displayed, return to MachineType and select [ St ].

these

1

Default setting.

Sd

yE

1

SERVICE PROGRAMMING

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

at all times and follow Arc Flash

Page 7 of 37 F45576 (1015)

SD3 Series - SERVICE PROCEDURES AND ADJUSTMENTS

NOTE: Service programming mode can be accessed by two methods.

Entering Programming Mode When Machine is OFF

Remove front cover.

1.

2. Open control door.

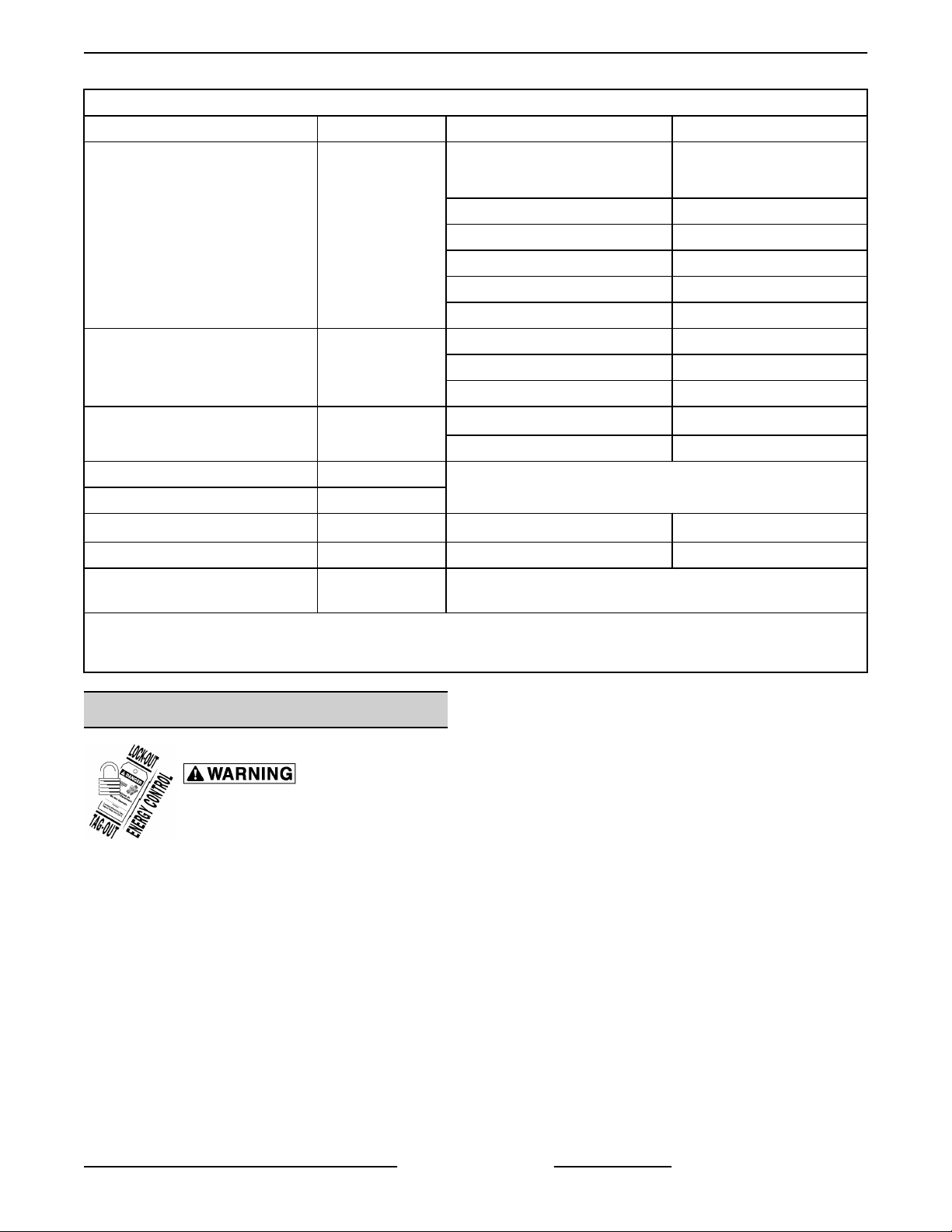

3. Press and hold the PROG switch on the control board, then press the ON key on the switch membrane keypad

(user controls on front of machine) to enter programming mode.

A. Release PROG switch when display shows [ 88 ].

Entering Programming Mode When Machine is ON (Tank Temperature Displayed and Fill Cycle is Complete)

1. Remove FRONT COVER.

Open control door.

2.

3. Press and hold the PROG switch on the control board, then press the CYCLE key on the switch membrane

keypad (user controls on front of machine) to enter programming mode.

A. Release PROG switch when display shows [ 88 ].

Programming Mode

NOTE: Refer to SERVICE PROGRAMMING CHART.

Change each function setting by pressing the (up arrow) switch on board until correct value is entered.

1.

2. Press the SELECT switch on the board to enter next function.

NOTE: Pressing the OFF key on display keypad at any time during programming will store your selections.

Fig. 3

3. To exit service programming and store your selections do one of the following:

A. Press OFF key (machine will shut down).

B. Press PROG switch (machine will stay on with tank temperature being displayed).

C. Close control door.

D. Check for proper operation by running one fill cycle and two normal cycles.

F45576 (1015) Page 8 of 37

SD3 Series - SERVICE PROCEDURES AND ADJUSTMENTS

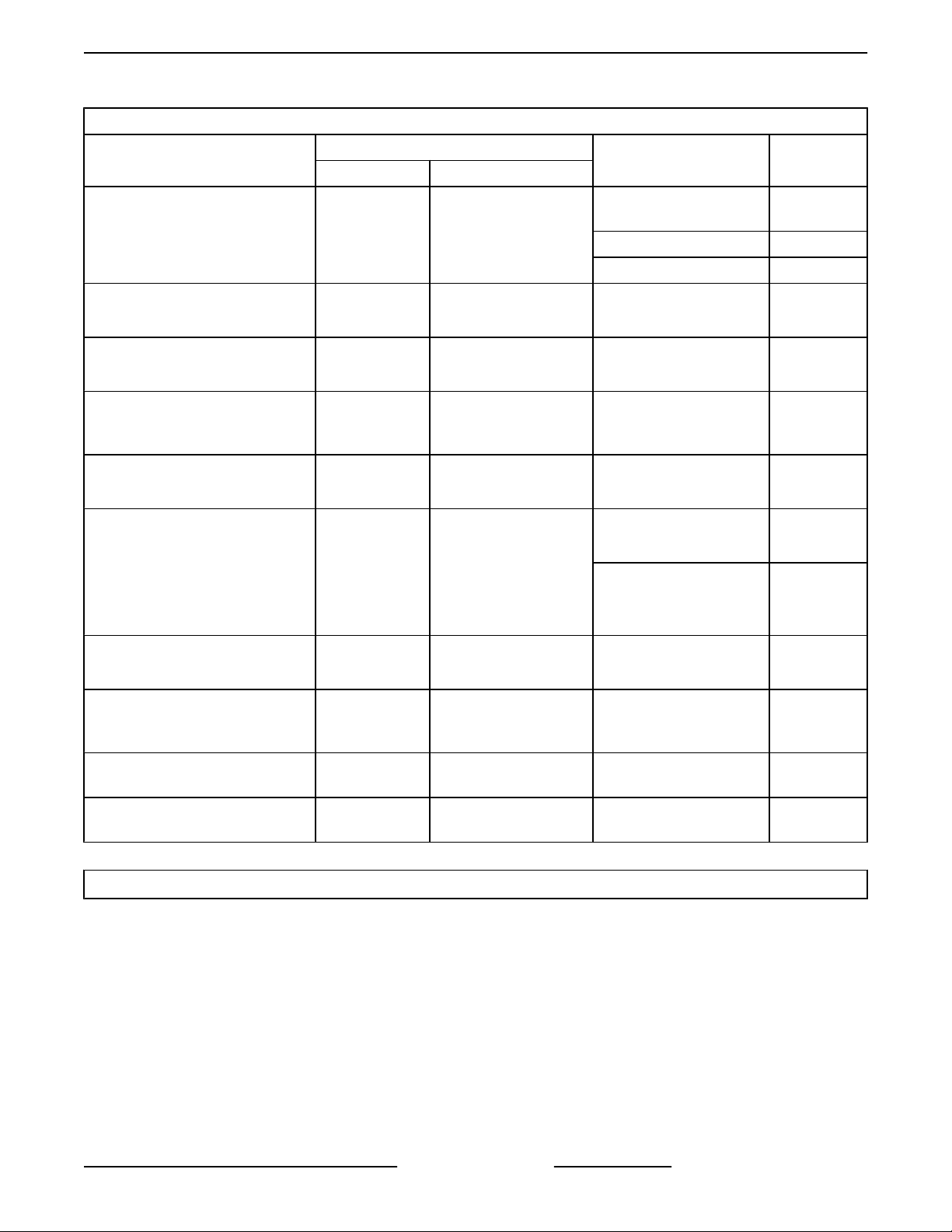

PARAMETER

Tank Temperature

Booster Temperature (Hot

Machines Only

Cycle 1 Wash Time

Dwell Time (all cycles) SET

Rinse Time (all cycles)

Sani-dwell Time (all cycles) SET

°F or °C

Display

Idle Shut Down Time

Empty Water Level Detection

Clean Float Setting

1

1

SERVICE PROGRAMMING CHART

DISPLAY

ICONS NUMERIC VALUE

SET

WASH

SET

RINSE

SET

WASH

Programmed

Temperature

Programmed

Temperature

Programmed Wash

Time

[1dt] Alternating with

Programmed Dwell

Time

SET

RINSE

Programmed Rinse

Time

[dt] Alternating with

Programmed Sani-

Dwell Time

SET

No Numeric Display °F,° C °F

°F or °C

SET

[IdL] Alternating with

Programmed Shut

IdL

SET

SET

Down Time in Hours

Present Sensitivity

Setting

Present Sensitivity

Setting or [dE]

PROGRAMMING

VARIABLES

Chemical Models:

120-150°F

DEFAULT

130°F

Hot Models: 150-170°F 158°F

Plain Models: 150-170°F 158°F

180 - 195°F (Hot Models

Only)

186°F

38 - 99 seconds 38 sec.

2 - 15 seconds 2 sec.

10 - 15 seconds 10 sec.

SD3 -H and -P

7 sec.

7 - 15 seconds

SD3 - C

dE = disabled; 1 - 15

dE

seconds

dE = 0 = disabled; 0 - 12

(hours)

6

20 - 80 60

0 - 18 15

1

Although parameter is adjustable, this setting has no affect on the float switch circuit of SD3 machines.

Page 9 of 37 F45576 (1015)

SD3 Series - SERVICE PROCEDURES AND ADJUSTMENTS

TANK HEATER - TEST

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times and follow Arc Flash

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

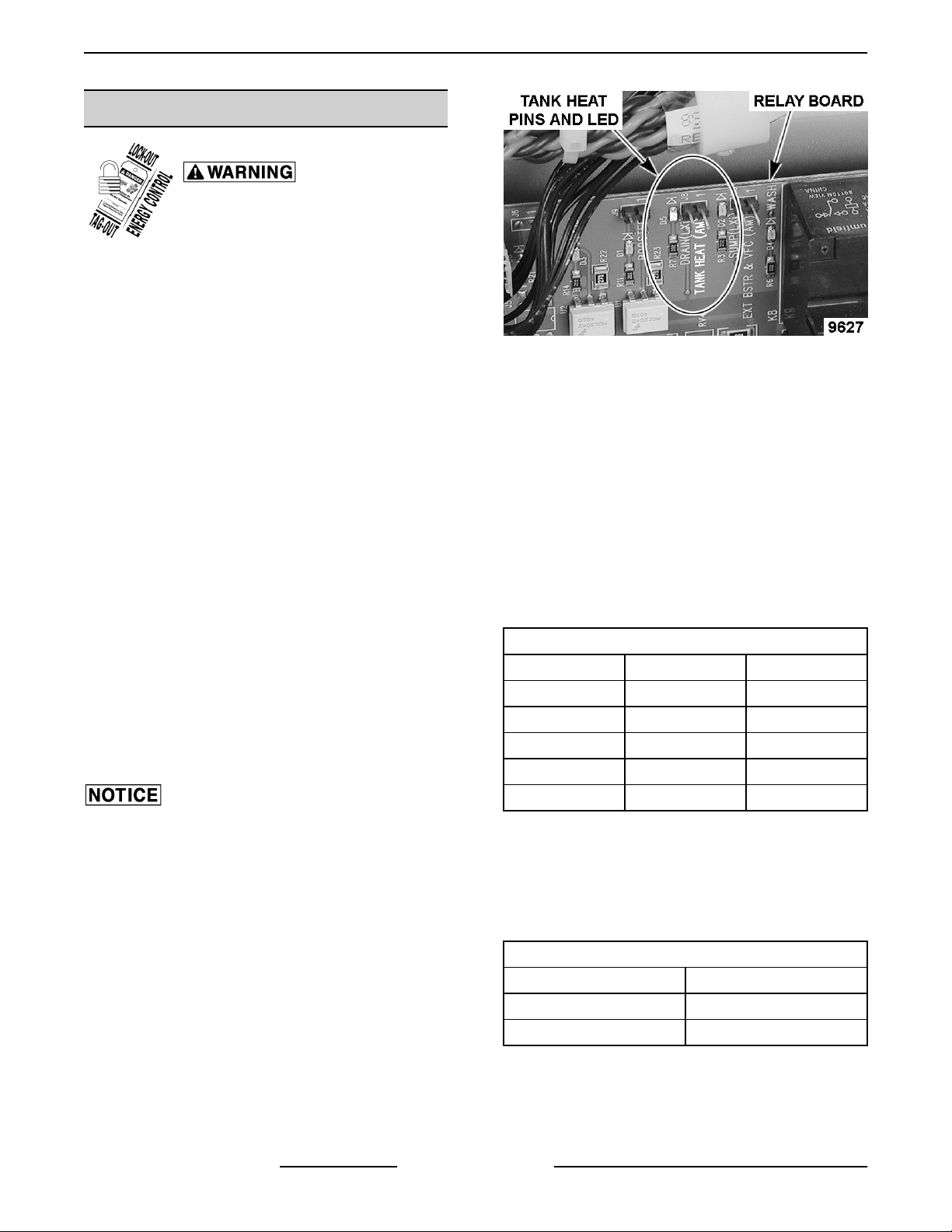

NOTE: Tank must be filled with water (float switch

closed) in order to test tank heat circuit.

1. Remove FRONT COVER.

2. Open control door.

3. Apply power to machine.

A. Measure incoming voltage across line side

of the tank contactor 2CON and verify it

matches machine specifications on data

plate.

4. Verify the following conditions are met.

A. Tank is full of water.

Fig. 4

6. While the TANK HEAT (AM) LED is on, verify that

the tank heat contactor 2CON is energized.

A. If contactor is not energized, check for

120VAC across coil.

1) If 120VAC is not present, check high

limit thermostat 1TAS.

B. If contactor is energized, check:

1) Voltage across all legs on load side of

contactor.

2) Current flow through all elements of

heater.

B. Float switch 1FS is closed.

C. Wash tank thermistor 1QTM is good, not

open or shorted.

D. There is a demand for heat (tank water

temperature is below set point).

5. Turn machine on.

Shorting J8 terminals together without

having water in the tank may result in damaging the

tank heater.

A. If temperature control circuit is not calling for

heat (relay board TANK HEAT LED not lit),

run machine through a cycle to activate tank

heater. Alternately, short the relay board

TANK HEAT (AM) -J8 pins together to

energize the tank heater.

RATED TANK HEATER ELEMENT CURRENTS

Voltage/Phase Amperes Power (Watts)

208/60/1 26A 5.4kW

240/60/1 30A 7.2kW

208/60/3 15A 5.4kW

240/60/3 17.3A 7.2kW

480/60/3 6A 5kW

7. If the current reading on any of the elements is

not correct:

A. Check the contacts of contactor 2CON.

B. Check the wash tank heater element

resistance.

INDIVIDUAL TANK ELEMENT RESISTANCE

Voltage Cold Resistance

208 - 240V 21.7 - 25.1Ω

480V 105 - 121.7Ω

F45576 (1015) Page 10 of 37

SD3 Series - SERVICE PROCEDURES AND ADJUSTMENTS

BOOSTER HEATER - TEST

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times and follow Arc Flash

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

NOTE: Tank must be filled with water (float switch

closed) in order to test booster heat circuit.

1. Measure incoming voltage and verify it matches

machine specifications.

2. Remove FRONT COVER.

3. Open control door.

4. Apply power to machine and booster.

A. Measure incoming voltage across line side

of the tank contactor 2CON and booster

contactor 3CON. Verify voltages match

machine specifications on data plate.

5. Verify the following conditions are met.

A. Tank is full of water.

B. Float switch 1FS is closed.

C. Booster thermistor 3QTM is good, not open

or shorted.

D. There is a demand for heat (booster water

temperature is below set point).

6. Turn machine on.

Shorting J9 terminals together without

having water in the tank may result in damaging the

tank heater.

A. If temperature control circuit is not calling for

heat (relay board BOOSTER LED not lit),

run machine through a cycle to activate

booster heater. Alternately, short the relay

board pins BOOSTER - J9 together to

energize the booster heater.

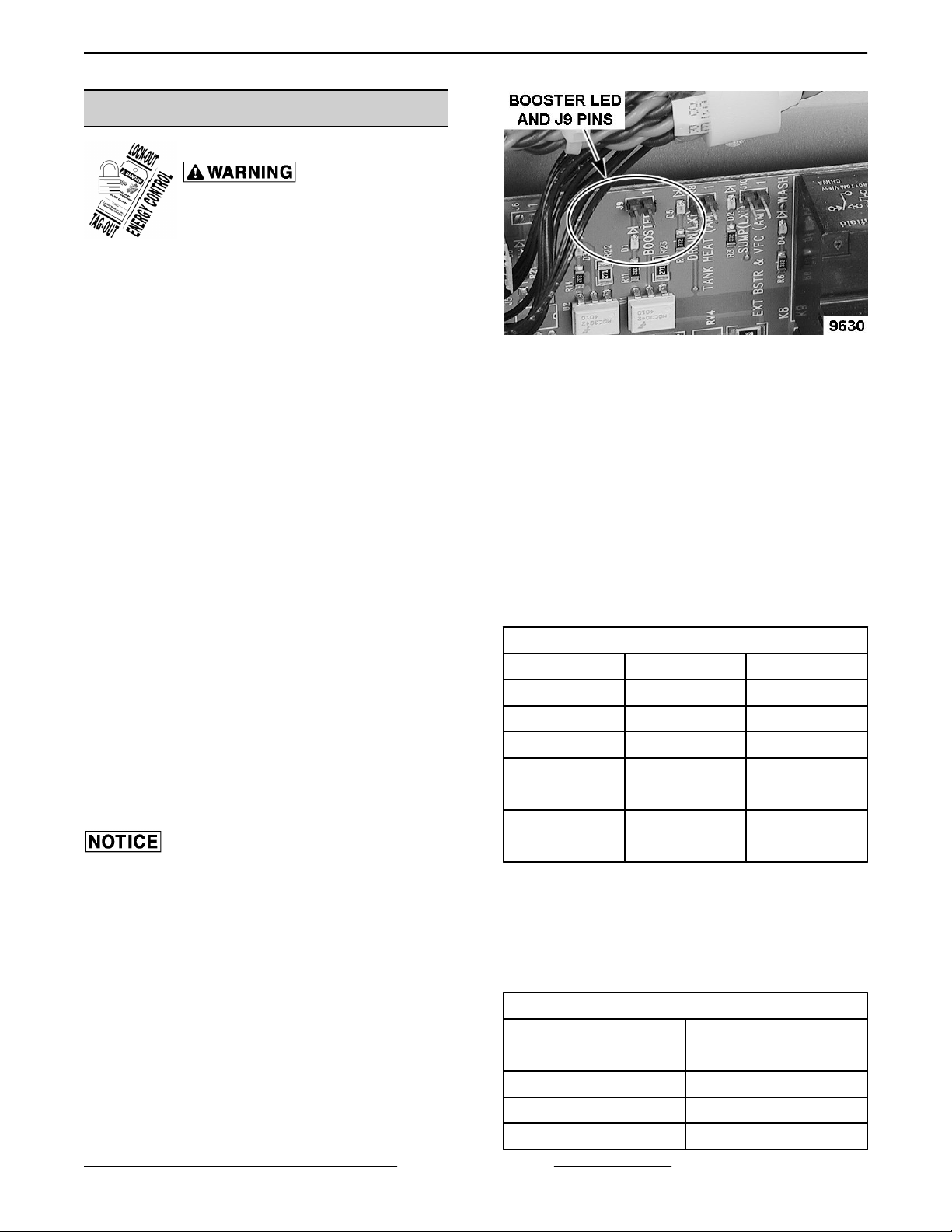

Fig. 5

7. While the BOOSTER LED is on, verify that the

booster contactor 3CON is energized.

A. If contactor is not energized, check for

120VAC across coil.

1) If 120VAC is not present, check high

limit thermostats 2TAS and 3TAS.

B. If contactor is energized, check:

1) Voltage across all legs on load side of

contactor.

2) Current flow through all elements of

heater.

BOOSTER HEATER ELEMENT CURRENTS

Voltage/Phase Amperes Power (Watts)

200/60/1 45.1A 9kW

208/60/1 40.7A 9.8kW

240/60/1 54.2A 13kW

200/60/3 26A 9kW

208/60/3 27.2A 9.8kW

240/60/3 31.3A 13kW

480/60/3 13.6A 13kW

8. If the current reading on any of the elements is

not correct:

A. Check the contacts of contactor 3CON.

B. Check the booster heater element

resistance.

INDIVIDUAL ELEMENT RESISTANCE

Voltage Cold Resistance

200 - 208V 9.0 - 10.5Ω

220 - 240V 12 - 13.9Ω

380 - 415 30.2 - 34.9Ω

440 - 480V 48.2 - 55.7Ω

Page 11 of 37 F45576 (1015)

SD3 Series - SERVICE PROCEDURES AND ADJUSTMENTS

INDIVIDUAL ELEMENT RESISTANCE

Voltage Cold Resistance

575 - 600V 75.3 - 87.0Ω

PUMP MOTOR - TEST

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times and follow Arc Flash

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

NOTE: The pump motor for all machines is rated at 2

H.P. and has thermal overload protection.

1. Remove FRONT COVER.

2. Open control door.

3. Apply power and measure incoming voltage

verifying it meets machine requirements.

4. Turn machine on and take an amperage reading

of one of the tank heater leads connected to

contactor (2CON).

SD3 MOTOR CURRENTS (Maximum)

Voltage/phase Amps

208/60/1 11.0A

240/60/1 10.6A

208/60/3 5.6A

240/60/3 5.4A

480/60/3 2.7A

THERMISTOR - TEST 1QTM, 2QTM

& 3QTM

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times and follow Arc Flash

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

NOTE: The temperature/resistance characteristics

are the same for all the thermistors used in SD3.

NOTE: The resistance of each thermistor can be

measured by removing the plug connected to J2 on

the control board.

1. Remove FRONT COVER.

2. Open control door.

Quick Check Using Service Diagnostics

1. Enter Service Diagnostics mode.

A. Apply power. With machine off, press and

hold the PROG and SELECT switches on

control board and press and release the ON

key on the switch membrane keypad.

B. Continue to hold in on the PROG and

SELECT switches until display shows [ 88 ]

then release both switches.

NOTE: XXX represents the actual water temperature.

C. Press the SELECT switch repeatedly until

[ WASH XXX°F (°C) ] which is tank water

temperature.

NOTE:

pump and motor assembly will be less than the

amperage values listed.

5. If motor current exceeds those values listed in the

6. If current in one phase of a three phase motor is

F45576 (1015) Page 12 of 37

Current consumption for a normally operating

table, inspect pump for blockage causing a

locked-rotor condition.

A. If blockage is not present, replace motor.

low or missing, also inspect incoming line

service, contactor 1CON and other related

circuitry to missing phase.

Measuring Thermistor Resistance

1. Disconnect the plug from J2 on the control board.

D. Press the SELECT switch once to display

[ XXX°F (°C) RINSE ] which is rinse water

temperature.

E. Press the SELECT switch once to display

[ WASH XXX°F (°C) RINSE ] which is

booster water temperature.

SD3 Series - SERVICE PROCEDURES AND ADJUSTMENTS

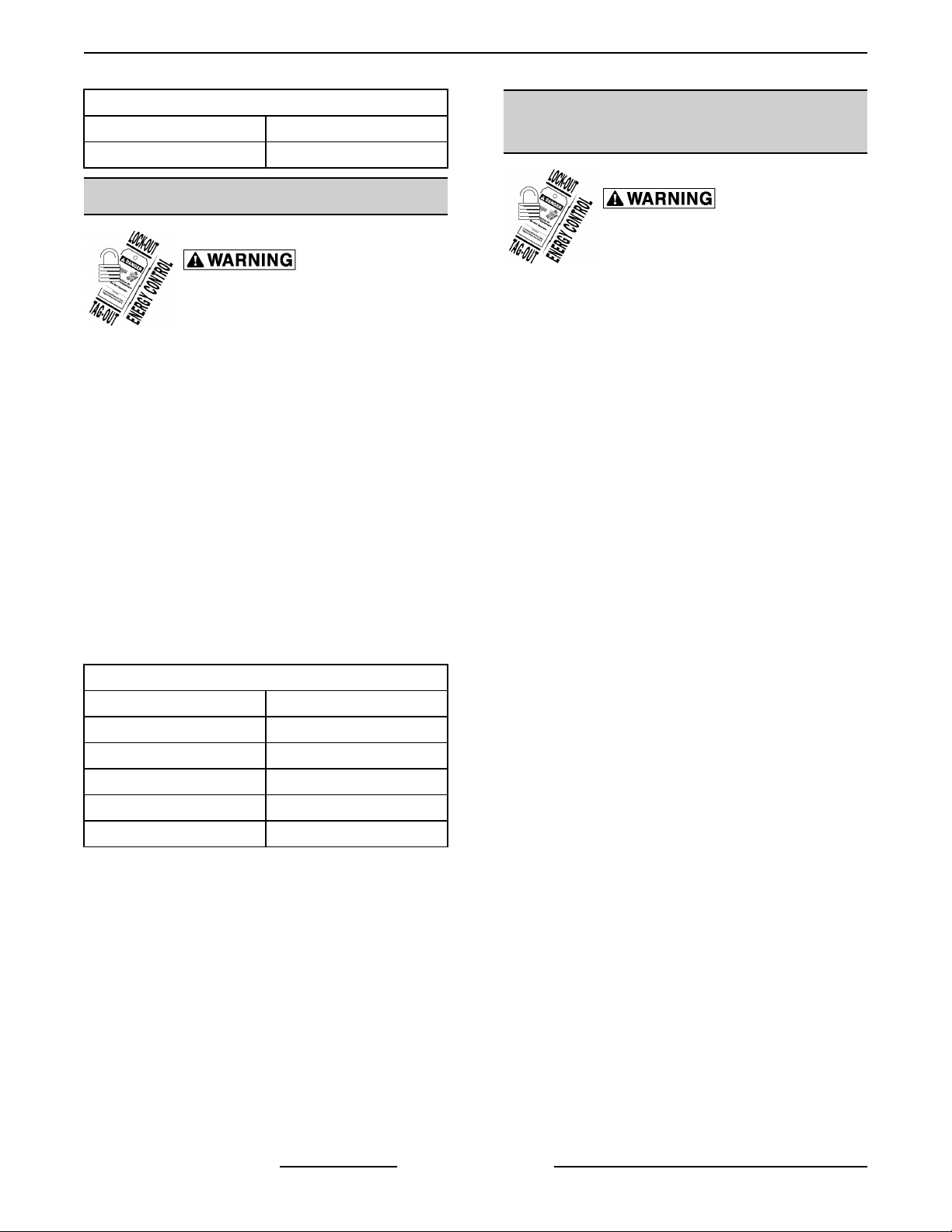

Fig. 6

2. Refer to the following photograph to locate the

thermistor leads of interest.

TEMPERATURE VS. RESISTANCE FOR 1QTM,

2QTM AND 3QTM THERMISTORS

DEGREE (°F) RESISTANCE (Ω)

190°F 8.2 kΩ

200°F 6.9 kΩ

210°F 5.8 kΩ

250°F 2.9 kΩ

257°F 2.626 kΩ

284°F 1.734 kΩ

290°F 1.6 kΩ

TRANSFORMER 1T - TEST

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times and follow Arc Flash

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

Fig. 7

PINS FOR THERMISTORS AND FLOAT

SWITCH

3.

Refer to the table that follows for thermistor

resistance values.

TEMPERATURE VS. RESISTANCE FOR 1QTM,

2QTM AND 3QTM THERMISTORS

DEGREE (°F) RESISTANCE (Ω)

70°F 120 kΩ

80°F 91 kΩ

90°F 72 kΩ

100°F 55 kΩ

110°F 44 kΩ

120°F 34.5 kΩ

130°F 28 kΩ

140°F 22.5 kΩ

150°F 18 kΩ

160°F 14.5 kΩ

170°F 12 kΩ

180°F 10 kΩ

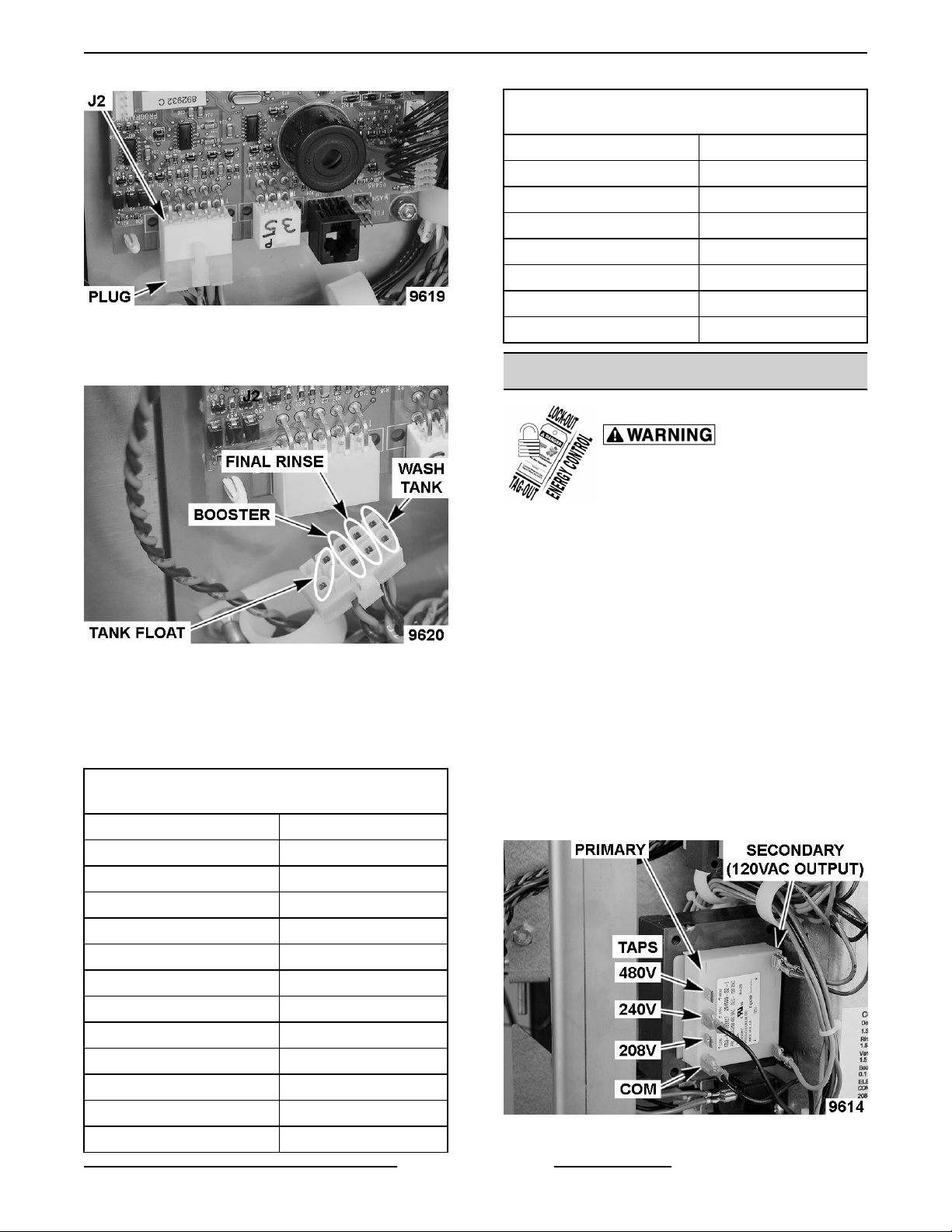

NOTE: Transformer 1T steps down incoming line

voltage to 120VAC for use by the machine's control

components.

1. Remove FRONT COVER.

2. Open control door.

3. Remove right side cover.

4. Verify transformer is strapped correctly by

comparing connection wiring points on

transformer with machine data plate.

Fig. 8

Page 13 of 37 F45576 (1015)

SD3 Series - SERVICE PROCEDURES AND ADJUSTMENTS

5. Connect power to machine.

6. Verify

7. Verify incoming voltage is present to primary side

8. Measure output AC voltage across secondary

incoming AC line voltage at the line service

connection point.

of transformer 1T.

windings of transformer. Voltage should be

approximately 120VAC.

A. If voltage is present, transformer is

functioning.

B. If output voltage is not present, verify

transformer wiring connections.

1) If connections are correct, replace

transformer.

C. If output voltage is low, disconnect power

from machine.

1) Disconnect one side of the secondary.

2) Apply power to machine.

3) Check output voltage across

secondary windings.

a. If voltage is still low, replace

transformer.

Fig. 9

A. If 120VAC is not present, check fuse F2 on

relay board.

1) If fuse is good, perform

TRANSFORMER 1T - TEST.

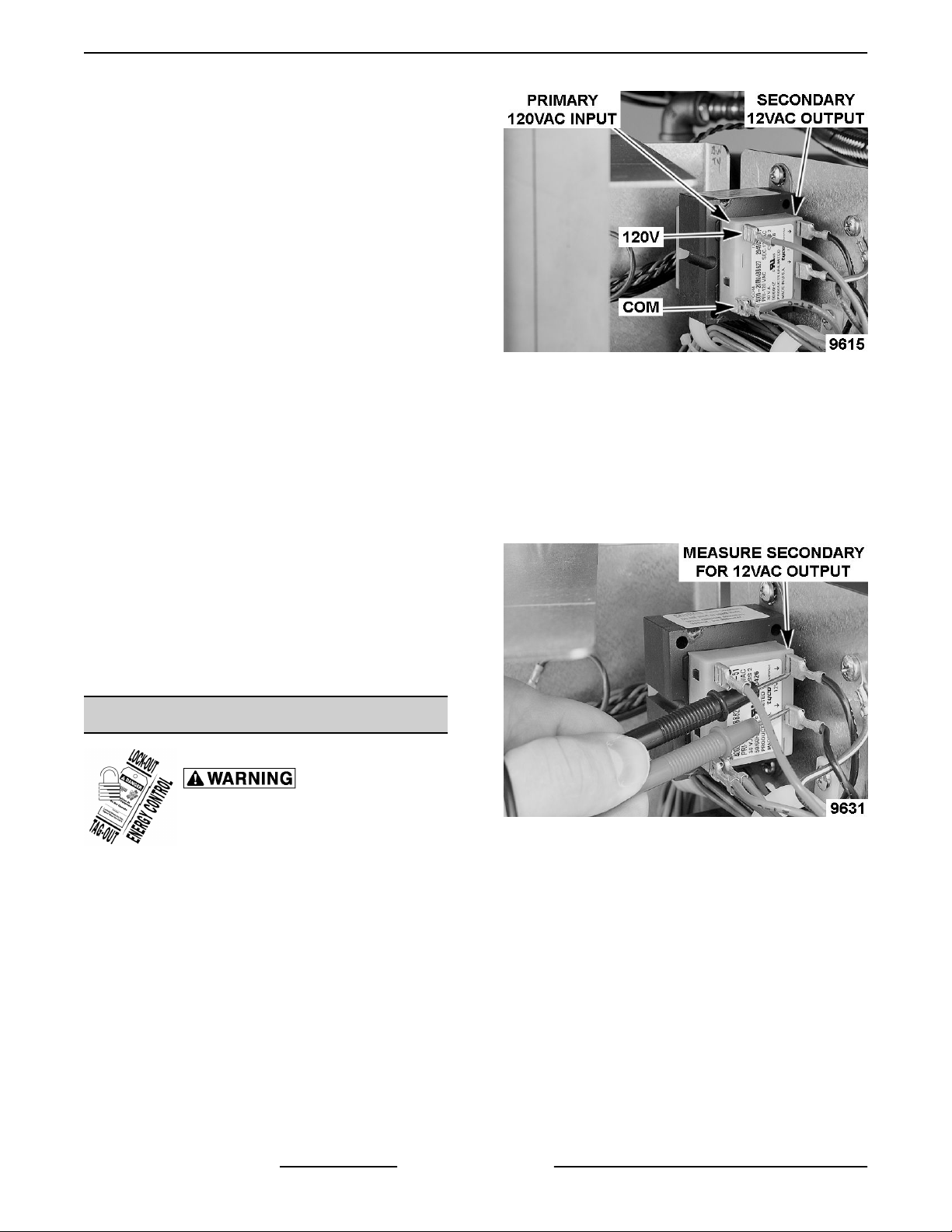

6. Measure output AC voltage across secondary

windings of transformer. Voltage should range

between (11.5 - 16VAC).

b. If voltage is approximately

120VAC, check components and

related wiring connected to the

secondary.

TRANSFORMER 2T - TEST

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times and follow Arc Flash

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

1. Remove FRONT COVER.

2. Open control door.

3. Remove right side cover.

4. Connect power to machine.

5. Verify incoming 120VAC voltage is present to

primary side of transformer 2T.

Fig. 10

A. If

voltage is present at output, transformer is

functioning.

B. If voltage is not present at output, verify

transformer wiring connections.

1) If connections are correct, replace

transformer.

C. If voltage is low, disconnect power from

machine.

1) Disconnect one side of the secondary.

2) Apply power to machine.

3) Check voltage across secondary

windings.

F45576 (1015) Page 14 of 37

SD3 Series - SERVICE PROCEDURES AND ADJUSTMENTS

a. If voltage at output is still low,

replace transformer.

b. If voltage at output is between

11.5 - 16VAC, check the control

board assembly.

DELIMIMG PROCEDURE

DELIMING SOLUTION, RINSE

AGENTS, OR ANY OTHER KIND OF ACID MUST

NOT COME IN CONTACT WITH BLEACH OR RINSE

SOLUTION CONTAINING BLEACH USED IN

CHEMICAL SANITIZING MACHINES. MIXING MAY

CAUSE HAZARDOUS GAS TO FORM. THIS

ENTIRE PROCEDURE MUST BE FOLLOWED

STEP-BY-STEP FOR SAFE AND SATISFACTORY

RESULTS.

1. Remove rack, drain tank, press "OFF".

2. Press and hold "Cycle & "ON for three seconds.

3. Open door & add delime agent per supplier

instructions for 14 gallon tank.

4. Close door, pump starts & display flashes

“DELIME”. After 12 minutes display scrolls

“DRAIN ”.

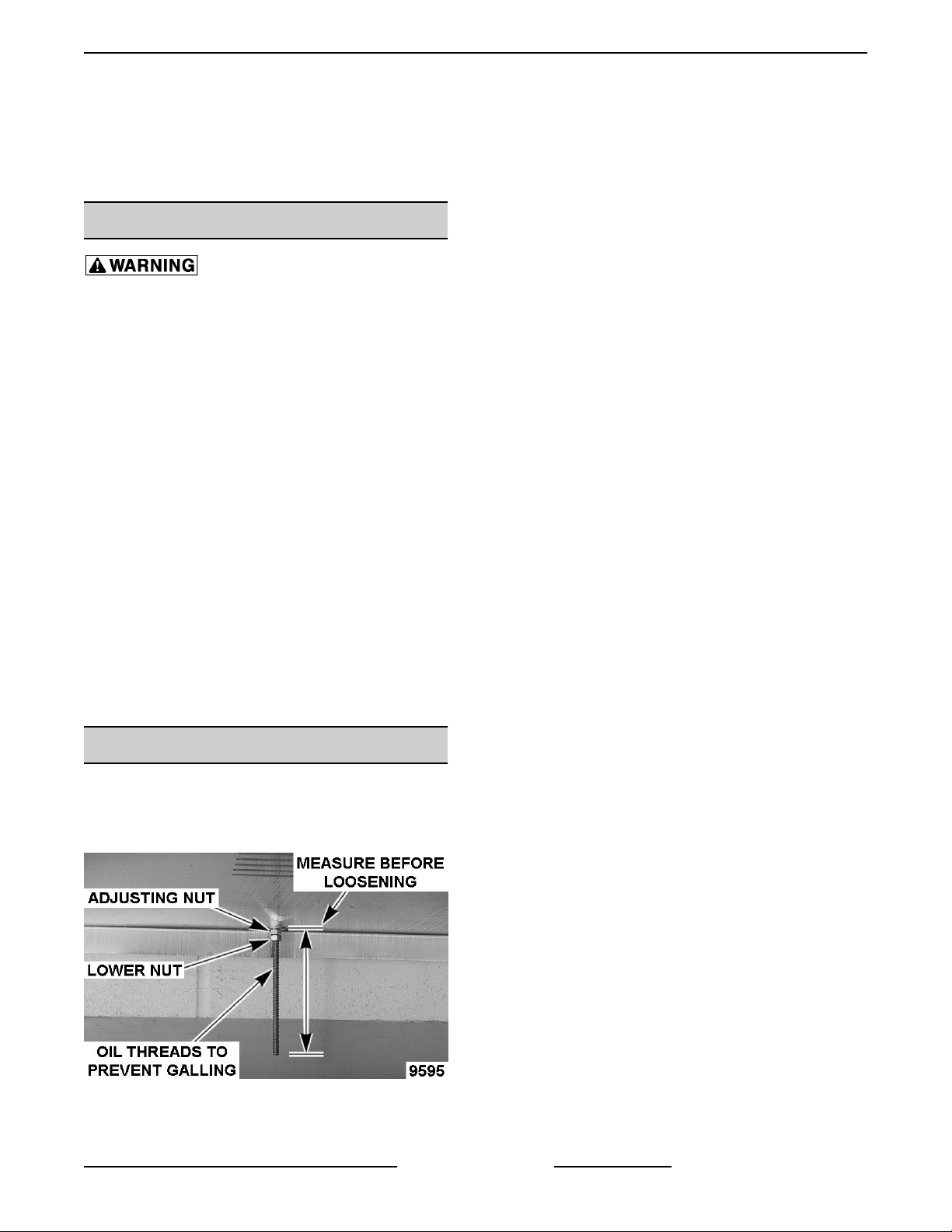

3. Lock adjusting nut in position with lower nut.

5. Check interior, close door to run additional cycles

if necessary.

6. Drain tank, turn unit off.

NOTE: The delime counter feature is disabled from

the factory.

DOOR TENSION ADJUSTMENT

NOTE: Door is

in place at any position.

1. Loosen lock nut.

adjusted correctly if the door remains

Fig. 11

2. Holding the spring rod in position to prevent

rotation, adjust the nut to provide proper tension.

Page 15 of 37 F45576 (1015)

SD3 Series - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

Control Board

Assembly .............

Relay Board .......... Controlled by control board assembly, the on board relays and fuses deliver energy to

Fuse, Relay Board

(F1) ...................

Fuse, Relay Board

(F2) ...................

Switch Membrane

Keypad ...............

Display Module ....... Provides machine information to user through the use of LEDs, lighted icons, and

Contactor (1CON) ..... Controls electrical power to wash pump (120VAC coil).

Contactor (2CON) ..... Controls electrical power to wash tank heater (120VAC coil).

Contactor (3CON) ..... Controls electrical power to booster heater (120VAC coil).

Relay (1CR) ........... Controlled by the control board assembly through the relay board, provides a means of

Float Switch (1FS) .... Detects water level in tank. On SD3, control board only uses Low Water Level LED with

Controls dishwasher electrical operation.

machine control components.

1/10A fuse. Protects rinse feeder 1CR coil circuit.

fuse. Protects primary of transformer 2T, 1CON, 2CON, 3CON, 1SOL and external

1.0A

booster control from over-currents.

User interface to machine. Used to select wash mode and program control board

assembly.

illuminated text and numbers.

controlling energy to RPS1 and RPS2 on terminal block 3TB.

the float switch.

Heater, Booster (BSTR

HTR) ..................

Heater, Tank (Tank

HTR) ..................

High Limit Thermostat

(1TAS) ................

High Limit Thermostat

(2TAS) ................

High Limit Thermostat

(3TAS) ................

Interlock Switch

(1LS) ..................

Solenoid (1SOL) ...... Fill/rinse solenoid.

Thermistor, Wash

(1QTM) ................

Thermistor, Rinse

(2QTM) ................

Thermistor, Booster

(3QTM) ................

Terminal Block

(1TB) ..................

Heating element for booster (8.5kW).

Heating element for wash tank (5kW to 7.2kW).

Protects tank heater circuit.

Protects booster circuit. Frame mounted, capillary design

Protects booster circuit. Mounted on the booster.

Feed back to control board on state of door (open or closed).

Senses tank water temperature.

Senses rinse water temperature

Senses booster water temperature

Line service to tank contactor 2CON (1 phase only).

F45576 (1015) Page 16 of 37

SD3 Series - ELECTRICAL OPERATION

Terminal Block

(2TB) ..................

Terminal Block

(3TB) ..................

Transformer (1T) ..... Provides 120VAC to control circuit and 2T.

Transformer (2T) ..... Provides 12VAC to control board.

Line service to booster contactor 3CON (1 phase only).

Connection point for detergent and rinse aid control devices.

COMPONENT LOCATION

Control Door Mounted Components

NOTE: The components present are determined by

the voltage, hertz, phase, and options on the

dishwasher.

Control Panel Mounted Components

Page 17 of 37 F45576 (1015)

SD3 Series - ELECTRICAL OPERATION

CONTROL BOARD / RELAY BOARD LAYOUT

Control Board

F45576 (1015) Page 18 of 37

SD3 Series - ELECTRICAL OPERATION

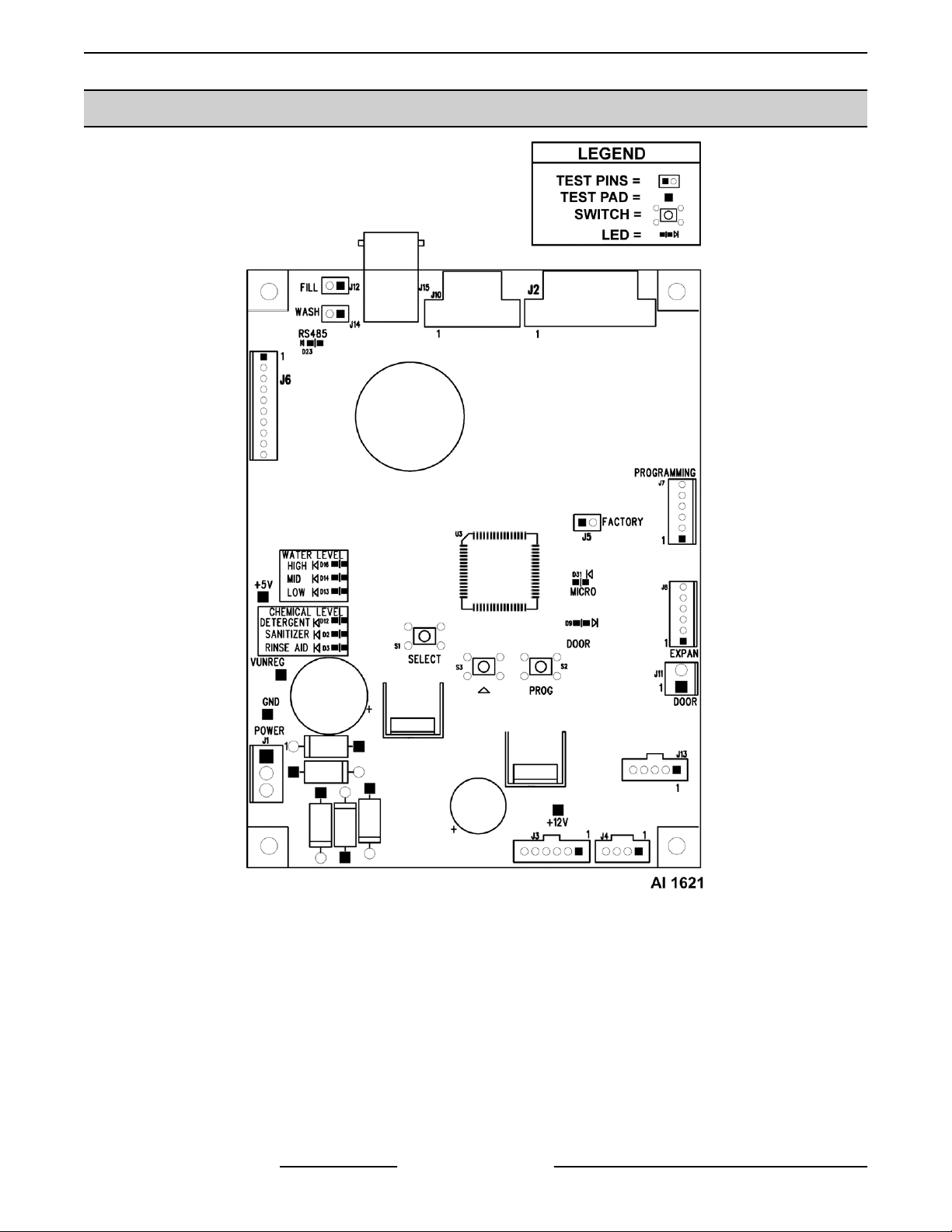

Relay Board

NOTE: DETERGENT AND RINSE AID CIRCUITS

NOT USED ON SD3.

SEQUENCE OF OPERATION

Refer to the correct wiring diagram for model being

serviced when reviewing sequence of operation.

WIRING DIAGRAM - 3 PHASE

WIRING DIAGRAM - 1 PHASE

Initial Conditions

• Door up (Door Interlock 1LS open).

• Dishwasher tank empty (Float 1FS open).

• Water supply requirements (110°F @ 20 ± 5 psi)

to machine are satisfied.

• Voltage supplied to machine is correct.

• High limits are closed.

Page 19 of 37 F45576 (1015)

1. Machine is off. Display is not lit.

A. Line voltage present at the following

components.

1) Primary windings of transformer 1T.

2) Line sides of 1CON (pump motor) and

2CON (tank heater).

3) Booster heater line side of 3CON.

4) Relay terminals 1CR 4 and 8.

B. 120VAC from transformer 1T present at the

following components.

1) Triac Q2 (1CR coil) thru fuse F1.

2) Primary windings of transformer 2T

thru fuse F2.

3) Triac Q3 (3CON coil) thru fuse F2.

4) Triac Q4 (1SOL) thru fuse F2.

SD3 Series - ELECTRICAL OPERATION

5) Relay

NOTE: It is normal for the secondary voltage (output)

from transformer 2T to range between 11.5 to 16VAC.

C. 12VAC present to control board J1-1/3 from

secondary windings of transformer 2T.

Acceptable voltage is 11.5 - 16VAC.

1) Power supply on control board

2. ON key on membrane switch is pressed.

A. Control board enters self-test, also tests

display LEDs.

B. K5 coil on relay board energize.

1) EXT BSTR & VFC (AM) LED on relay

3. Self-test completes.

A. Machine type (AP, AH or AC) is displayed

followed by tank temperature.

board relays K5-C, K8-C and K9-

C thru fuse F2.

converts AC voltage to 12VDC and

5VDC to power control board, display

and membrane switch.

board turns on.

a. BOOSTER LED on relay board

turns on.

3) Control board signals relay board

(relay K9) to energize 2CON coil.

2CON contacts close energizing tank

heater.

a. TANK HEAT (AM) LED on relay

board turns on.

5. Depending on the fill time required to close float

switch 1FS, the control board will fill an additional

amount of time (75 - 120 seconds) after which

time the control board de-energizes the fill/rinse

solenoid 1SOL through the relay board.

A. FILL LED on relay board turns off.

NOTE: Tank Heat and Booster circuits remain

energized until set point has been reached; however,

a wash cycle may be started at any point.

6. Booster temperature reaches set-point.

A. Control board de-energizes 3CON coil

through the relay board. 3CON contacts

open de-energizing booster heater.

B. MICRO LED on control board blinks at a 1

second on - 1 second off rate.

C. 5VDC present across 1QTM, 2QTM, 3QTM

and open contacts of 1FS.

D. Tank temperature is displayed.

E. Membrane switch - last selected cycle LED

is on. Cycle selection is enabled.

4. Door is shut.

A. Door interlock switch 1LS closes.

B. Control board senses float switch is open

and energizes fill/rinse solenoid 1SOL

through relay board. Tank begins to fill.

1) FILL LED on relay board turns on.

C. FILL icon and tank temperature are

displayed on display board.

NOTE: Once tank float switch is closed, a wash cycle

can be started by opening and closing the door even

though fill is not complete.

D. Tank float 1FS closes.

1) LOW LEVEL WATER LED on control

board turns on.

2) Control board energizes 3CON coil

through the relay board. 3CON

contacts close energizing booster

heater.

1) BOOSTER LED on relay board turns

off.

7. Tank temperature reaches set-point.

A. Control board de-energizes 2CON coil

through the relay board. 2CON contacts

open de-energizing tank heater.

1) TANK HEAT (AM) LED on relay board

turns off.

8. Door is opened and closed.

A. Control board senses that float switch 1FS

was closed before the door was closed and

energizes relay K8 on relay board. 1CON

contacts close energizing the pump motor

MTR. A wash cycle begins.

1) WASH LED on relay board turns on.

2) Machine line voltage present at

terminals DPS1 and DPS2.

9. Wash cycle.

A. The WASH icon and water temperature are

displayed.

B. Wash cycle continues for time selected.

C. Wash cycle completed.

1) Relay board K8 de-energizes. Wash

coil (1CON) de-energizes and pump

N.O. contacts open. Pump stops.

F45576 (1015) Page 20 of 37

SD3 Series - ELECTRICAL OPERATION

a. WASH LED on relay board turns

off.

Dishwasher enters a dwell cycle.

2)

Default is two seconds.

3) Machine line voltage removed from

terminals DPS1 and DPS2.

D. Rinse cycle begins.

1) Control board energizes the fill/rinse

solenoid (1SOL) through the relay

board.

a. FILL LED on relay board turns on.

2) Control board energizes the rinse

feeder relay coil (1CR) through the

relay board. Relay 1CR N.O. contacts

4/2 and 8/6 operate (close).

3) The RINSE icon and final rinse

temperature are displayed.

4) Machine line voltage present at

terminals RPS1 and RPS2.

5) Rinse cycle continues for the

programmed time. Default is 10

seconds.

E. Rinse cycle completed.

1) Control board enters seven second

sani-dwell. RINSE icon is displayed

until sani-dwell cycle is complete.

2) Control board de-energizes the rinse

feeder 1CR through the relay board.

Relay 1CR de-energizes and 1CR

N.O. contacts 4/2 and 8/6 open.

3) Control board de-energizes the fill/

rinse solenoid 1SOL through the relay

board. Rinsing stops.

a. FILL LED on relay board turns off.

4) Machine line voltage removed from

terminals RPS1 and RPS2.

5) Tank temperature is displayed.

10. Tank Heat and Booster temperatures continue to

be monitored and maintained by the control

board through the relay board.

CONTROL and RELAY BOARD LEDs

CONTROL BOARD LEDs

CONTROL BOARD DESCRIPTION

DOOR On when door interlock 1LS is closed.

MICRO Flashes at a rate of 1sec on, 1 sec off when machine is on.

LOW - On when float switch 1FS is closed.

WATER LEVEL

RS485 Used with NAFEM Gateway.

RELAY BOARD LEDs

RELAY BOARD DESCRIPTION

On when triac Q3 (booster circuit) is gated on.

BOOSTER

FILL On when triac Q4 (fill circuit) is gated on. 1SOL on.

TANK HEAT AM On when K9 is energized. Tank heat on.

EXT BSTR & VFC On when machine is on.

WASH On when K8 is energized. Pump motor on.

RINSE AID On when triac Q2 (rinse feeder) is gated on. 1CR is energized.

MID - Not used with SD3.

HIGH - Not used with SD3

Booster heat on.

Page 21 of 37 F45576 (1015)

SD3 Series - ELECTRICAL OPERATION

RELAY BOARD LEDs

RELAY BOARD DESCRIPTION

DETERGENT

SANITIZER

LEDs present on service replacement relay boards, but not used on SD3

machines.

F45576 (1015) Page 22 of 37

Loading...

Loading...