Stero Dishwasher SD-1 Installation Manual

STERO SD1

Low Temp Dishwasher

MODEL:

SD1 ML-130225

INSTRUCTION

MANUAL

ST50409 (11/14)

STERO, a division of Illinois Tool Works, Inc. 1758 Corporate Circle Petaluma, CA 94954

Phone: 80 0 -762-7600 Fax: 707-762-5036 Website: Stero.com

2 | STERO SD1 LOW TEMP DISHWASHER

TABLE OF CONTENTS

GENERAL ................................................................................... 3

START-UP CHECKLIST ....................................................................... 4

INSTALLATION .............................................................................. 5

Unpacking ................................................................................ 5

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Leveling .................................................................................. 5

Converting from Straight-Through to Corner Operation ........................................... 5

Installation Drawing ........................................................................ 6

Dish Tables ............................................................................... 7

Plumbing Connections ...................................................................... 7

Drain Connection ....................................................................... 7

Water Supply Connection ................................................................ 7

Electrical Connection ....................................................................... 8

Chemical Supplies .......................................................................... 8

Pump Priming ............................................................................. 8

Cycle Timer Adjustment ..................................................................... 9

OPERATION ................................................................................ 10

Controls ................................................................................. 10

Machine Preparation ...................................................................... 11

Dishwashing ............................................................................. 12

Draining the Dishwasher ................................................................... 12

CLEANING ................................................................................. 13

Cleaning the Dishwasher ................................................................... 13

Cleaning the Wash Arms ................................................................ 14

Do's and Don'ts for Your Stero Dishwasher .................................................... 14

MAINTENANCE ............................................................................ 14

Delime Instructions ........................................................................ 14

Lubrication .............................................................................. 14

TROUBLESHOOTING ....................................................................... 15

SERVICE ................................................................................... 15

© STERO 2014

STERO SD1 LOW TEMP DISHWASHER | 3

Installation,

Operation

and Care of

SD1

DISHWASHER

SAVE THESE INSTRUCTIONS

GENERAL

The Model SD1 Dishwasher is a low temperature (140°F recommended, 120°F minimum), chemical sanitizing,

rack-type dishwasher for use with accessory 20" x 20" racks. It is equipped with a 1 HP thermally protected

(internal) pump motor. The motor must cool to restart the pump.

The revolving stainless steel ball bearing wash / rinse arms above and below provide thorough distribution of

water jets to all dishware surfaces. Arms are easily removable for cleaning and are interchangeable. Stainless

steel tubing connects upper and lower systems.

All three doors open together when the spring counter-balanced handle is raised. Durable door glides provide

easy opening and closing.

The SD1 can wash up to 37 racks per hour. Water usage is 1.7 gallons per rack.

After initial manual fill, the machine automatically washes a rack of dishes, drains the wash water, and then

refills with fresh water for the rinse cycle. The rinse water remains in the machine for the next wash cycle.

At the proper time during each cycle, an appropriate amount of detergent, rinse aid, and sanitizer chemicals

are pumped into the wash tank.

Cycle timing is as follows:

Wash 40 seconds

Drain 10 seconds

Flush 3 seconds

Fill 9 seconds

Rinse 20 seconds

4 | STERO SD1 LOW TEMP DISHWASHER

START-UP CHECKLIST

BEFORE POWER IS APPLIED

____ 1. Check all utility service connections for tightness (electric, hot water and drain(s)).

____ 2. Verify drain is connected with air gap (per your local code) and properly draining.

____ 3. Check for any loose hardware.

____ 4. Check door wrap to table for interference.

____ 5. Check free rotation of wash/rinse arms.

____ 6. Check to see that all strainer pans and screens are in place.

AFTER POWER IS APPLIED AND WATER TURNED ON

____ 1. Verify water supply is connected properly and not leaking.

____ 2. Verify correct supply voltage and phase to machine and confirm with data plate ratings.

____ 3. Close door and allow machine to fill completely.

____ 4. Check wash tank to ensure 140° operating temperature after fill.

RUN A 1 MINUTE CYCLE

____ 1. Check operation of door interlock switch.

____ 2. Check for proper pump motor operation and check for leaks.

____ 3. Check wash tank for proper water level during start up and operation.

REINSTALL ANY PANELS REMOVED

STERO SD1 LOW TEMP DISHWASHER | 5

INSTALLATION

UNPACKING

Immediately after unpacking the dishwasher, check it for possible shipping damage. If this machine is found to

be damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, verify that the electrical service agrees with the specifications on the machine data plate

which is located to the right of the control box.

LOCATION

Before finalizing machine location, make sure that consideration has been given for water supply, drain connection, electrical conduit, tabling, chemical containers and supply lines, as well as adequate clearance for

opening the doors. A hood or vent may be required in order to meet local codes.

LEVELING

The dishwasher must be level before any connections are made. With the dishwasher in its operating location,

turn the threaded feet as required to level the machine front-to-back and side-to-side.

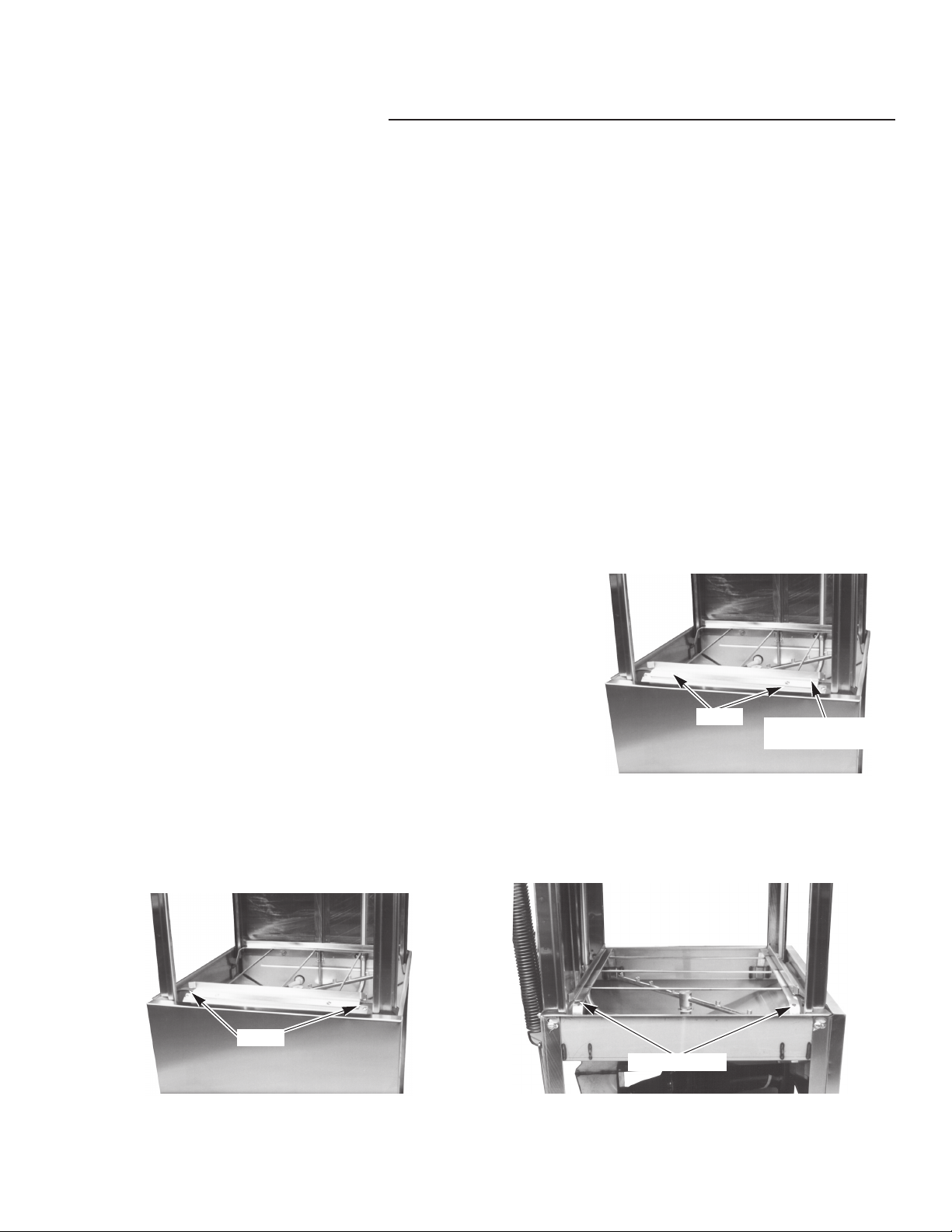

CONVERTING FROM STRAIGHT-THROUGH TO CORNER OPERATION

The SD1 is shipped from the factory for straight-through operation. To convert to corner operation, move the rack track and

splash guard as follows:

1. Remove the two screws and nuts that secure the front rack

track and splash guard (Figure 1) and remove the front rack

track and splash guard. Reassemble the front rack track and

splash guard by replacing the two screws and nuts in the

same mounting holes from which they were removed.

2. Remove the two screws and nuts at the outer edges of the

splash guard (Figure 2).

3. With the two screws and nuts removed in step 2, reattach the front rack track and splash guard to the

left side of the rack track assembly, using the mounting holes (Figure 3) provided.

SCREWS

Figure 1

FRONT RACK TRACK

AND SPLASH GUARD

SCREWS

Figure 2

MOUNTING HOLES

Figure 3

Loading...

Loading...