Stern Pinball WHOA NELLIE! BIG JUICY MELONS Service And Operation Manual

PINBALL MACHINE

SERVICE AND OPERATION MANUAL

WARNING

IMPORTANT HEALTH WARNING: PHOTOSENSITIVE SEIZURES - A very small percentage of people may experience a seizure when exposed to

certain visual images, including ashing lights or patterns. Even people with no history of seizures of epilepsy may have an undiagnosed condition that

can cause “photosensitive epileptic seizures” due to certain visual images, ashing lights or patterns. Symptoms can include light-headedness, altered

vision, eye or face twitching, jerking or shaking of arms or legs, disorientation, confusion, momentary loss of awareness, and loss of consciousness or

convulsions that can lead to injury from falling down or striking nearby objects.

IMMEDIATELY STOP PLAYING AND CONSULT A DOCTOR IF YOU EXPERIENCE ANY OF THESE SYMPTOMS.

Stern Pinball machines are assembled in Melrose Park, Illinois, USA; each pinball machine has unique characteristics that make it a one-of-a-kind

American-made product. Each machine will have variations in appearance resulting from dierences in the machine’s particular wood parts, individual

silk screened art and mechanical assemblies. Stern Pinball has inspected each game element to insure it meets our quality standards.

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC. ™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

Games congured for North America operate on 60 cycle electricity only. These games will not operate in countries with 50 cycle electricity (Europe

UK, Australia).

1-800-KICKERS - PARTS.SERVICE@STERNPINBALL.COM

WWW.STERNPINBALL.COM - FACEBOOK.COM/STERNPINBALL

WHOA NELLIE!

™

BIG JUICY MELONS

WNBJM #500-55D7-00

MANUAL #780-50D7-00

TABLE OF CONTENTS

1. GAME Setup ............................................ 3

1.1 First-time Setup Instructions................................ 3

1.2 USA Cable Connections ...................................... 8

1.3 International Cable Connections.......................... 9

1.4 Maintenance ...................................................... 11

1.5 Maintenance Kits ............................................... 11

1.6 Common Maintenance Parts ............................. 11

2. SPIKE System and Node Guide .......... 12

2.1 SPIKE System Overview .................................... 12

2.2 Node Bus Cabling .............................................. 12

2.3 System Power .................................................... 12

2.4 SPIKE Node addresses ...................................... 12

2.5 SPIKE Node Programming................................. 12

2.6 SPIKE System Terminology ............................... 13

2.7 Common SPIKE Node Boards ........................... 13

3. Light, Switch, and Driver Reference ... 14

3.1 Driver Reference ................................................ 15

3.2 Lighting Reference ............................................. 16

3.3 Switch Reference ............................................... 20

4. Electronic Pinouts and Schematics.... 22

4.1 SPIKE CPU Node 0 ............................................ 22

4.2 Cabinet Node 1 ................................................. 24

4.3 Lower Playeld 48V 8-Driver Pinout Node 8 ..... 25

4.4 Mid1 Playeld 4-Driver 48V Node 9 Pinout ....... 26

4.5 Node 10 Mid Playeld Pinout ............................ 27

4.6 Node 11 Backbox 4-Driver 48V Pinout ............. 28

4.7 9-lamp Bottom Extension 11a Pinout ................ 29

4.8 10-lamp Top Extension 11b Pinout .................... 29

4.9 Stepper Motor Opto ........................................... 29

4.11 Star Rollover RGB .............................................. 30

4.10 Main Power Supply ............................................ 30

4.13 Stepper Motor Controller ................................... 31

4.12 Mini Diagnostics Display .................................... 31

4.14 Power Distribution Board ................................... 32

4.15 Power Plug Wiring.............................................. 32

5. Parts Reference .................................... 33

5.1 Playeld Rubber Parts ....................................... 33

5.2 Rubber Size Chart .............................................. 33

5.3 Playeld assemblies, Top ................................... 34

5.4 Playeld assemblies, Bottom ............................. 35

5.5 Backbox Electronics .......................................... 36

5.6 Backbox LED Bottom Assy................................ 36

5.7 Backbox LED Top Assy ...................................... 36

5.8 Score Reel Assy ................................................. 37

5.10 Credit Reel Assy ................................................. 37

5.9 Score Reel Assy ................................................. 37

5.11 Long Range Opto Assy ...................................... 37

5.12 Pop Bumper Assembly ...................................... 38

5.14 Flipper Assy, Left CLASSIC ............................... 39

5.13 Flipper Assy, Right CLASSIC ............................. 39

5.15 Beehive Ball Shooter Assy ................................. 40

5.17 Bullseye Target ................................................... 40

5.16 Trough Coil Assy ............................................... 40

SPIKE PINBALL SOFTWARE UPDATE INSTRUCTIONS

1. Obtain game software update le (lename ends

in “.spk”) from www.sternpinball.com or from

authorized Stern distributor.

2. Place game software update le ( “.spk”) in root

directory of a blank FAT32-formatted USB ash

drive

3. Use backbox power switch to turn o game

4. Plug in USB ash drive to CPU board USB connector (CN20 or CN21). Refer to www.sternpinball.com

5. Turn on game

6. The game will automatically begin software

update

7. Select the correct .spk update le from list.

8. Press Enter on the service switches to start

update

9. When the display indicates “Update Complete”,

turn o game

10. Remove USB ash drive from CPU board

11. Turn game on to complete the update and play

pinball!

12. Detailed instructions and troubleshooting tips

are available in the game manual, www.sternpinball.com and authorized Stern distributors.

5.18 Knocker Assy .................................................... 40

5.19 Sling shot Assemblies ........................................ 41

5.20 Star Rollover ...................................................... 41

5.21 Star Rollover Switch........................................... 41

5.22 Bumper Assembly .............................................. 42

5.23 30-Degree Eject ................................................. 42

5.24 Crate End Panel ................................................. 43

5.26 Crate Top Panel.................................................. 43

5.25 Crate Side Panel ................................................ 43

5.27 Crate Leg Plate .................................................. 43

6. Specications ....................................... 44

7. Warranty ................................................ 45

7.1 Warnings, Compliance, and Legal Notices ........ 45

2

WHOA NELLIE! MANUAL #780-50D7-00

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

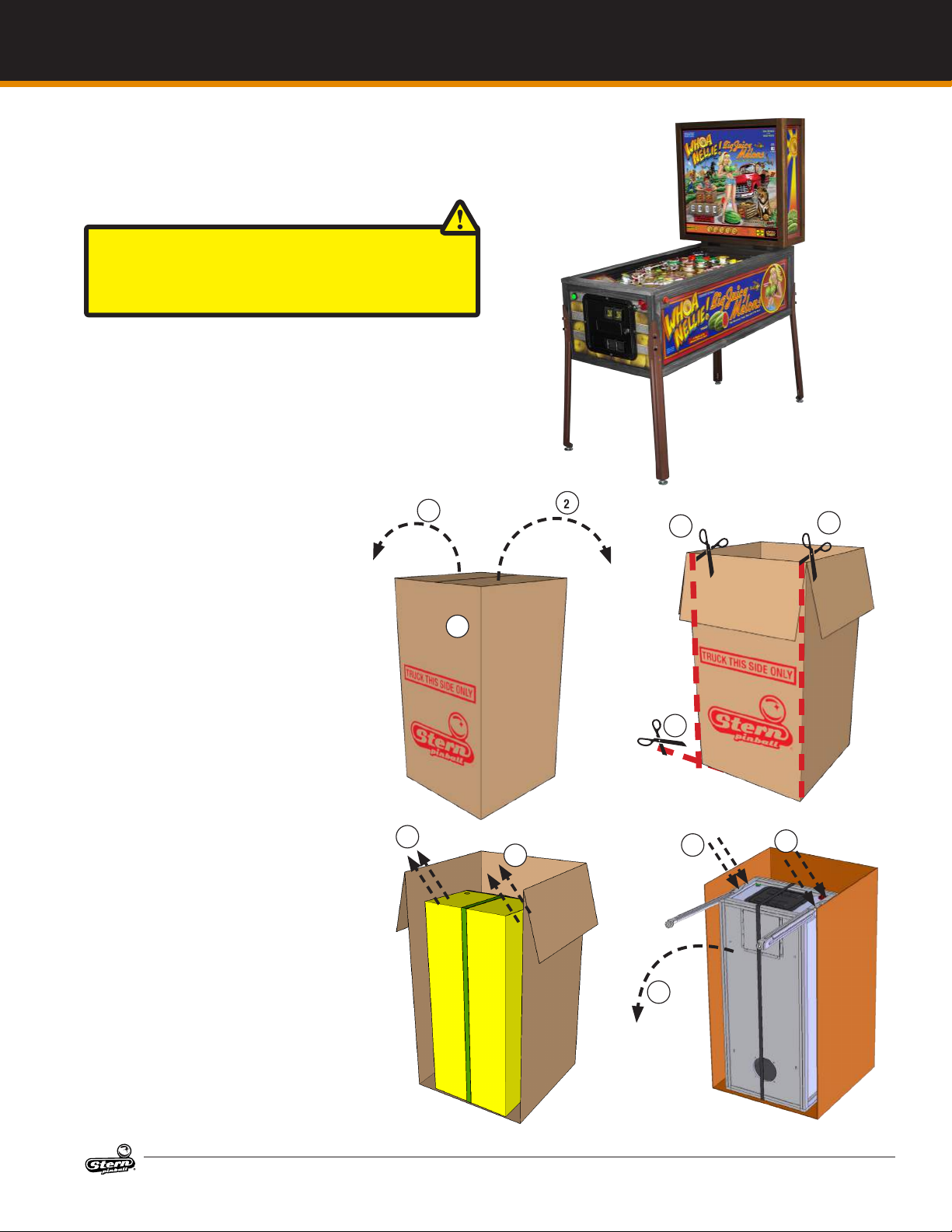

1. GAME SETUP

1.1 FIRST-TIME SETUP INSTRUCTIONS

500-55D7-01 Whoa Nellie

CAUTION: AT LEAST TWO (2) PEOPLE ARE REQUIRED TO

MOVE AND MANEUVER THE GAME. USE PROPER MOVING

EQUIPMENT AND EXTREME CARE WHILE HANDLING. STERN

PINBALL MACHINES WEIGH OVER 250LBS BOXED.

GAME SETUP

Your brand new Stern Pinball Machine is

carefully packed for safety and security.

For your safety, exercise caution and use

the correct tools and sucient help when

setting up your new game.

1. Locate the side labeled “TRUCK

THIS SIDE ONLY”. The bottom of

the game faces this side.

2. Open the top box aps by pulling

hard in an upward motion on

each ap. If the aps are taped,

cut the tape rst, taking care to

avoid the box staples.

3. Remove the foam pieces and

narrow box tubes which contain

the four (4) identical legs with

levelers.

4. DO NOT CUT STRAPPING YET.

Keep backbox secured in the

down position.

5. With the utility knife, carefully cut

down the left and right corners of

the box.

6. Let the face fall forward and remove the entire side by carefully

cutting the bottom.

7. With the game still in its folded

position, use a ⅝” wrench to

loosen and remove the 2 leg bolts

on each side of the front cabinet.

8. Ensure the leg levelers are fully

screwed into the legs.

9. Install front legs using the bolts

removed from the cabinet. Secure tightly.

10. Use a helper to carefully set the

game down on the front legs.

11. Set aside the open box.

12. With the ⅝” socket wrench, loosen and remove the 2 leg bolts on

each side of the rear cabinet, 4

total.

13. Using supports or two people,

prop the rear of the cabinet up.

14. Ensure the rear leg levelers are

screwed all the way into the legs.

TOOLS REQUIRED

5/8” Socket Wrench

⅜” Nut driver or wrench

Utility Knife

Diagonal Cutters

No. 2 Phillips™ Screw-

driver

A helper

2

1

7

2

5

6

7

8

9

5

8

WHOA NELLIE! MANUAL #780-50D7-00

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

3

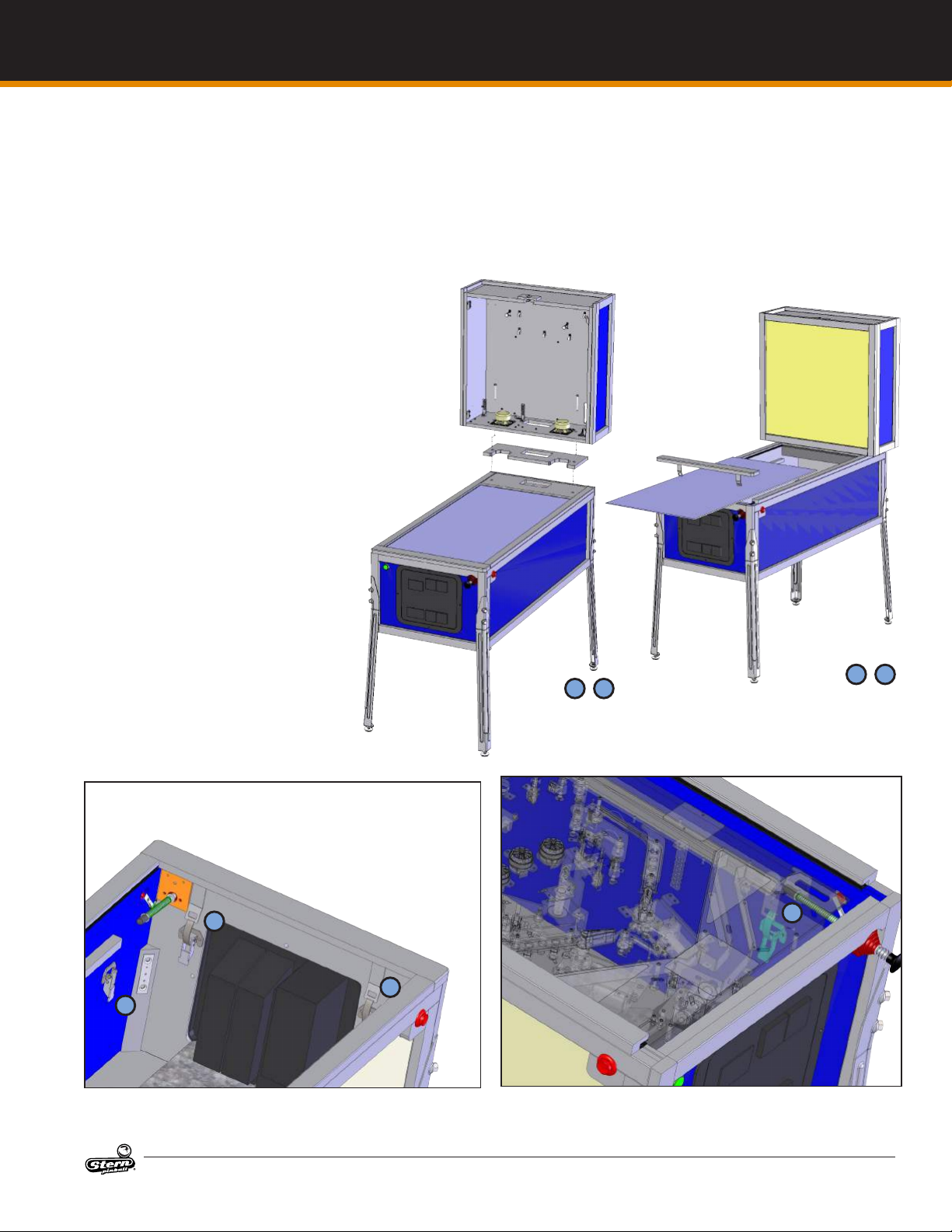

GAME SETUP

FIRST-TIME SETUP CONTINUED

15. Install the two rear legs using the

4 bolts previously removed from

the cabinet.

16. Note that the backbox assembly is not attached to the game

cabinet. While supporting the

backbox, cut the strap holding

the parts together.

17. Using a helper, set the back box

and the Fruit Crate parts box on

the oor.

18. Open the Fruit Crate parts box to

access the assembly hardware,

crate and cabinet components.

19. Locate the factory keys, either on

the shooter rod or taped to the

playeld glass.

20. If you will not be assembling the

Fruit Crate, store the Fruit Crate

parts box.

21. Using the diagonal cutters, cut

the tie-wrap securing the keys if

required. One set of keys is for

the front coin door, the other set

of keys is for accessing components in the backbox

22. Using the backbox key, locate

the backbox lock on top of the

backbox and unlock the lock.

23. Gently remove the backglass

frame assembly by lifting the

backglass frame vertically and

pulling away from the backbox.

24. Place the two backbox spacers

on the cabinet and orient the bolt

holes over the cabinet bolt holes.

25. With the helper, position the

backbox with the glass removed

over the spacers and align the

holes.

26. Install the two 3/8-16 x 3.00”

bolts in the (2) backbox holes

and tighten with the ⅝” wrench.

27. Open the front coin door.

28. Reach into the game and remove

the retaining clip at the rear of

the cash box.

29. Remove the cash box lid by

sliding it toward you.

30. Locate and remove the pinball,

plumb bob, and backbox bolts

from the cash box.

31. Replace the cash box lid and

retaining clip for future use.

32. Store the backbox keys on the

metal hook located in the coin

door.

33. Reach inside the cabinet and lift

the two latches, toward the back

of the game.

34. Remove the front top molding.

10

15

23

17

4

WHOA NELLIE! MANUAL #780-50D7-00

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

FIRST-TIME SETUP CONTINUED

GAME SETUP

35. Remove the playeld glass by

sliding it toward you and carefully

place it in a safe location.

Remove all playeld shipping

tie downs, shipping blocks, and

packing foam, and follow any

game-specic unpacking instructions included in the playeld, if

present.

36. CAUTION: Playeld glass is made

from high-strength tempered

glass. Tempered glass is sensitive

to extreme temperature shifts and

corner nicks, which can cause

the glass to fail catastrophically.

Take care to store the glass on a

soft, room-temperature surface

and prevent the corners from

being damaged.

37. Unlatch and raise the playeld

and rest it against the backbox.

38. Grasp the lower arch between the

ippers, and rmly but gently pull

directly up to raise the playeld

8-12 inches.

39. While holding the playeld up,

pull the playeld toward you

about 1 foot.

40. Pivot the playeld vertically and

rest it against the backbox.

41. Visually inspect all cabinet cables

and connector terminations;

ensure no wires or cables are

pinched and that cable harnesses

are not pulled tight.

42. Locate the plumb bob in the

parts bag in the cash box

43. Slide plumb bob onto the hanger

wire. Note: the vertical position

of the plumb bob aects tilt sensitivity - higher makes the game

more sensitive to tilting.

24 25

44. Tighten the Thumb Screw nger-tight.

45. Install the correct number of

pinballs. Refer to the decal on

the lock down assembly for the

correct number of pinballs.

34

35

33

33

37

WHOA NELLIE! MANUAL #780-50D7-00

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

37

5

GAME SETUP

FIRST-TIME SETUP CONTINUED

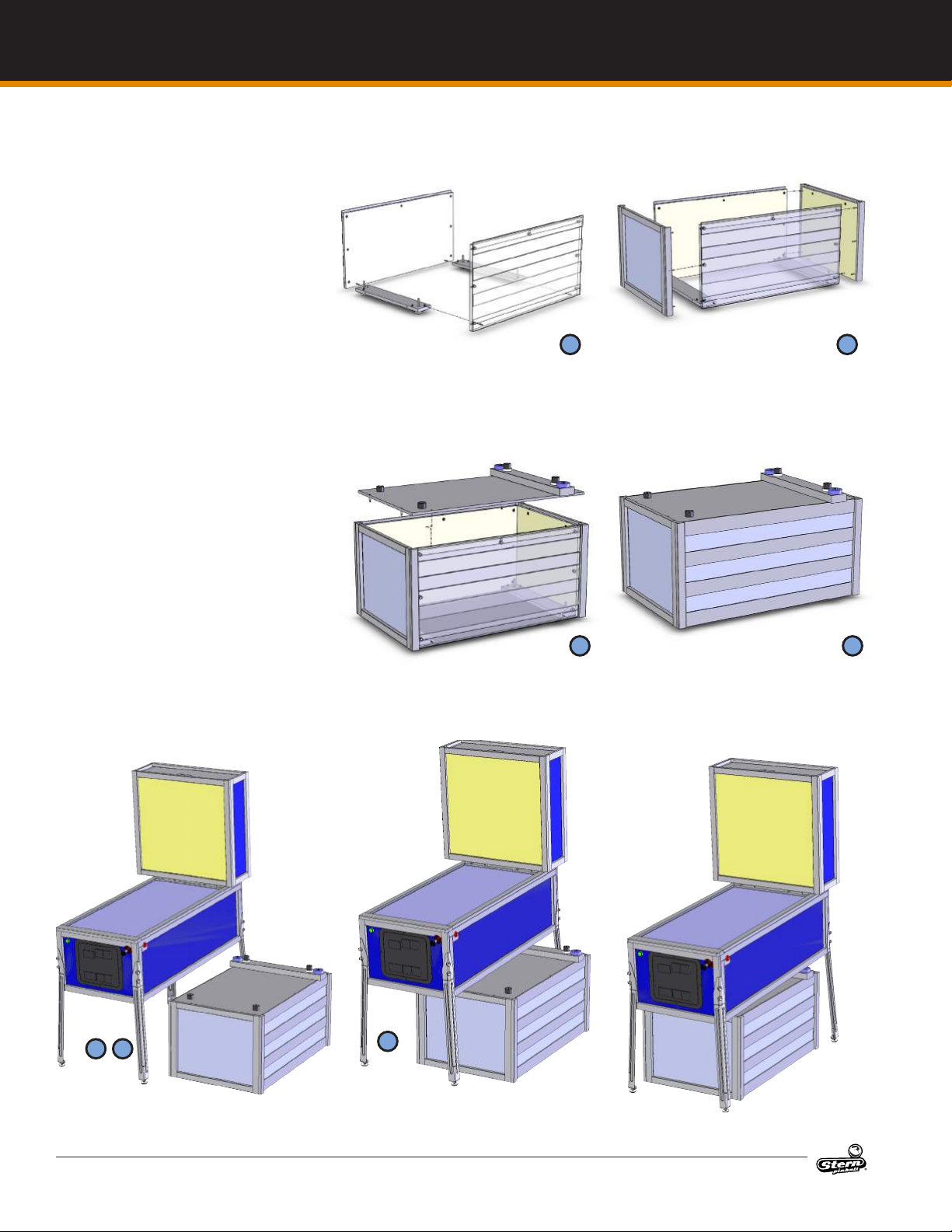

OPTIONAL: ASSEMBLING WHOA NELLIE

CABINET WITH FRUIT CRATE BASE

1. Open the Fruit Crate parts box and locate the Fruit

Crate hardware and panels.

2. Assemble the hardware in the 7 panels. Refer to

explosion diagrams 1.2-1.5 for details.

3. Using a Phillips screwdriver, hand-tighten a connecting bolt (#2) into each Fruit Crate panel hole for each

of the 7 panels: End panel (x2), Side Panel (x2), Leg

plates (x2), and Top Panel.

4. Connect the two leg plates with the side plates.

5. Push the pins xed to the side panel into the hole on

the leg plate and rotate the locking cam ¼ turn to

lock it.

6. Connect the side panel to the parts from step 5. Do

one side at a time.

7. Use the Phillips screwdriver to turn each cam ¼ turn

to lock

8. Connect the Top Plate to the parts from step 6

9. Use the Phillips screwdriver to turn each cam ¼ turn

to lock the remaining six connecting bolts.

10. Position the pinball machine in its desired location

11. Set the crate next to the pinball machine

12. Raise the leg leveler plates all the way up to allow the

crate assembly to slide under the pinball machine.

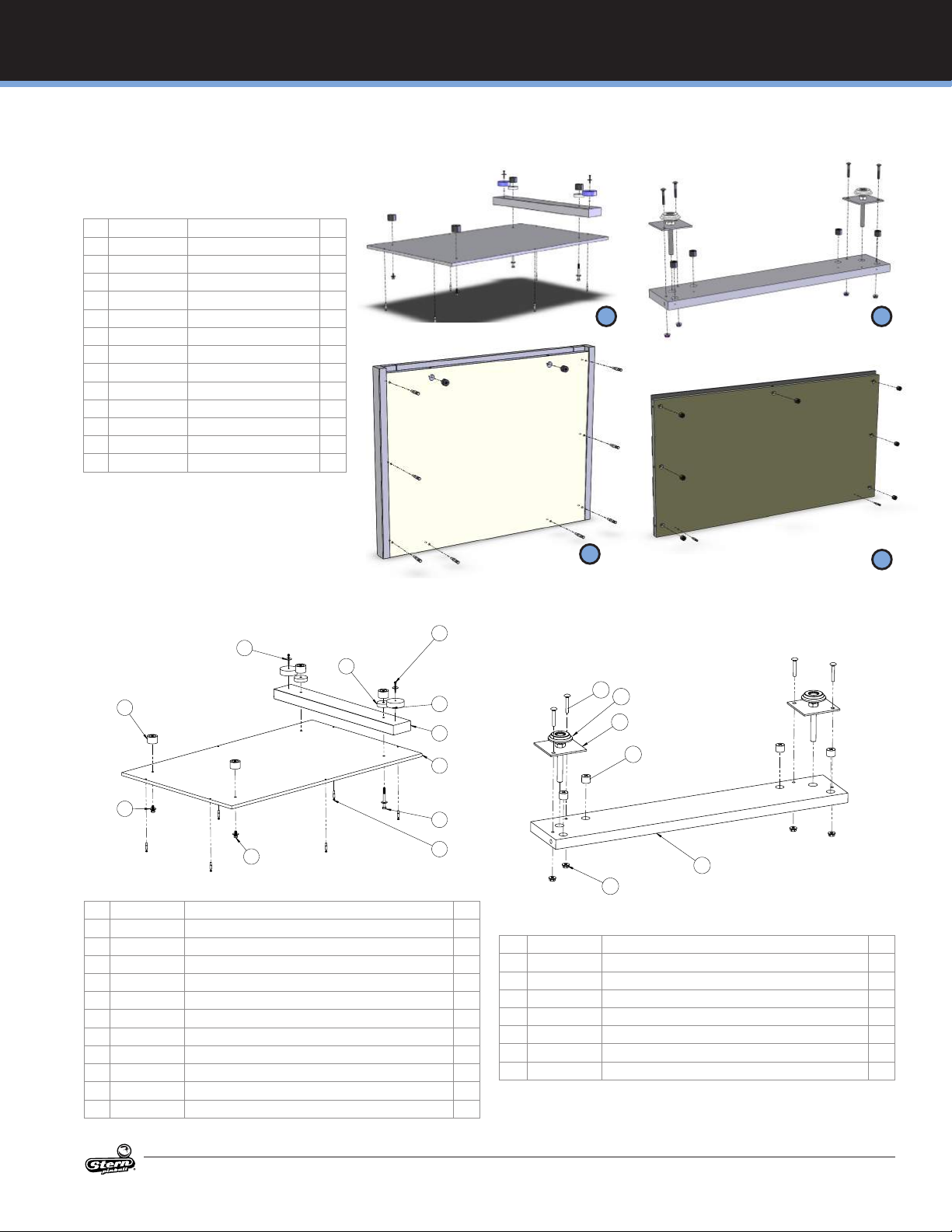

1.2 CRATE END PANEL

511-7650-00

1

3

2

Figure 1.2.1. Crate End Panel 511-7650-00 diagram.

ID Part Number Description Qty

1 511-7650-00 CRATE: END PANEL, WN 1

2 237-6297-00 CONNECTING BOLT 8

3 240-5410-00 15/16 CAM 2

Figure 1.2.2. Crate End Panel 511-7650-00 bill of materials.

1.3 CRATE SIDE PANEL

525-1014-03

1 3

2

Figure 1.3.1. Crate Side Panel 525-1014-03 diagram.

ID Part Number Description Qty

1 525-1014-03 CRATE: SIDE PANEL 1

2 237-6297-00 CONNECTING BOLT 2

3 240-5410-00 15/16 CAM 7

Figure 1.3.2. Crate Side Panel 525-1014-03 bill of materials.

6

WHOA NELLIE! MANUAL #780-50D7-00

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

FRUIT CRATE SETUP CONTINUED

WHOA NELLIE CRATE HARDWARE CONTENTS

ID Part Number Description Qty

1 280-5028-00 Cabinet Shock Mounts 4

2 515-0205-00 Leg Leveler Plate 4

3 500-5017-00 Leg Leveler, 3" 4

4 535-1097-00 Whoa Nellie Beer Cans 2

5 545-0653-00 Crate Spacers 2

6 231-5012-00 10-24 X 1 1/4 CB 8

7 242-5010-00 Washer #1010 13/ 8

8 240-5207-00 Nut, 10-24 Washer Nut 8

9 237-6297-00 Connecting Bolt, 1.38" 26

10 240-5410-00 Cam lock 26

11 231-5545-00 Hex Bolt 5/16"-24 x 3/4" 6

12 231-5546-00 Hex Bolt 5/16"-24 x 3" 2

13 242-5077-00 Washer, 11/32"ID 8

GAME SETUP

2 2

1.4 CRATE TOP PANEL

525-1014-01

3

7

11

6

4

10

5

2

1

9

8

Figure 1.4.1. Crate Top Panel 525-1014-01 diagram.

ID Part Number Description Qty

1 525-1014-01 CRATE: TOP PANEL 1

2 525-1019-00 CRATE: WN, 2x4 1

3 280-5028-00 MACHINE MOUNT 4

4 545-0653-00 SPACER, CRATE, WN 2

5 535-1097-00 BEER CAN: CRATE, WN 2

6 231-5545-00 HEX BOLT: 5/16"-24 x 3/4" 6

7 242-5077-00 FLAT WASHER: 5/16" 8

8 237-6297-00 CONNECTING BOLT 6

9 231-5546-00 HEX BOLT: 5/16"-24 x 3.00" 2

10 237-5969-00 #8 x 1.50" HWH 2

11 242-5059-00 3/16 I.D. X 7/8 O.D. X .045 WASHER 2

Figure 1.4.2. Crate Top Panel 525-1014-01 bill of materials.

2

1.5 CRATE LEG PLATE

525-1014-04

5

2

3

4

1

6

Figure 1.5.1. Crate Leg Plate 525-1014-04 diagram.

ID Part Number Description Qty

1 525-1014-04 CRATE: LEG PLATE 1

2 500-5017-00 LEG LEVELER - 3/8-16 X 3" - ZINC PLATED 2

3 515-0205-00 PLATE: LEG LEVELER 2

4 240-5410-00 262.23.373; 15/16 Minix CAM 4

5 231-5012-00 CARRIAGE BOLT, 10-24 X 1-1/4", BLACK 4

6 240-5207-00 # 10-24 KEPS NUT 4

7 242-5010-00 #10 WASHER, .50 O.D. X .047 THK 4

Figure 1.5.2. Crate Leg Plate 525-1014-04 bill of materials.

2

WHOA NELLIE! MANUAL #780-50D7-00

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

7

GAME SETUP

FRUIT CRATE SETUP CONTINUED

13. Slide the crate under the game.

14. Remove the glass and raise the

playeld against the backbox.

While looking into the cabinet

align the Fruit Crate mounts

threaded holes with the cabinet

oor holes.

15. Install and hand-tighten the

5/16-24 X ¾” hex bolts with at

washer into the mounts located

on the crate.

16. There are two holes in the cabinet oor near the front and two

slots in the cabinet oor near the

real of the cabinet.

17. Once all four bolts are started,

tighten them with a wrench.

18. Once the crate is lined up under

the game, lower the leg levelers

until the game comes into contact with the crate.

19. Remove the pinball legs from the

game.

20. Remove the wood trim in the

front and rear of the game with

the leg bolt holes and replace

with the solid trim pieces.

21. Use a Phillips screwdriver to remove screws for front trim piece.

Be careful to not damage the

side cabinet decal when removing and installing the screws.

3 5

7 7

9

10

8

WHOA NELLIE! MANUAL #780-50D7-00

12

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

FRUIT CRATE SETUP CONTINUED

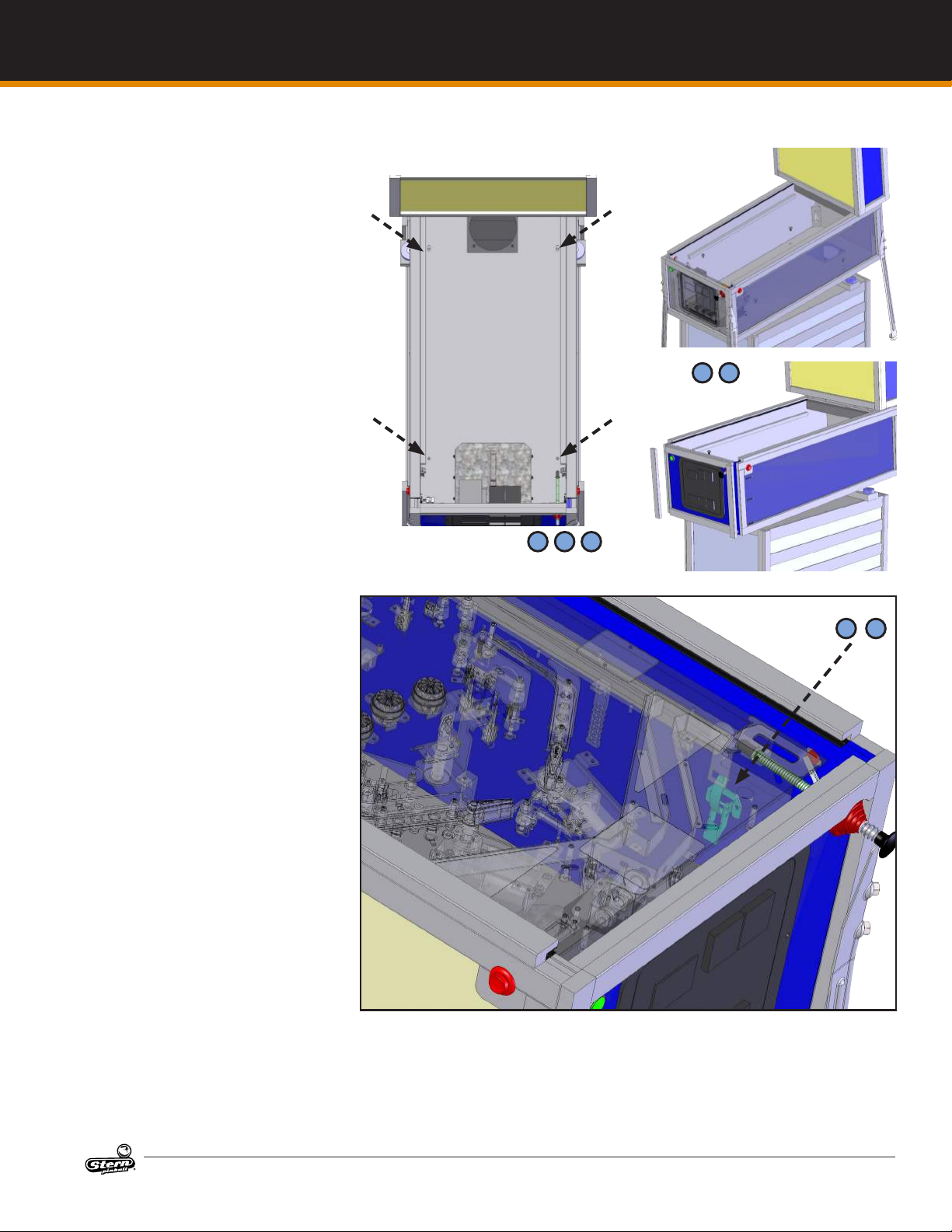

LOCATING, LEVELING, AND

FINAL SETUP

1. Select a location that is indoors,

out of direct sunlight, and climate

controlled. Excessive moisture/

humidity can cause long-term

damage to your game.

2. Use a pinball to roll down the

center of the playeld for side-toside leveling, or use an external

bubble level, digital level, or

smartphone level app.

3. Plug into a grounded outlet

and check for proper operation

through DIAGNOSTICS.

4. Check the coin door: With the

door closed, insert coins to verify

proper operation.

5. Play game: Check for satisfactory operation and adjust game

volume (push the Red Buttons

inside the Coin Door).

6. If desired, perform any game

diagnostics, game adjustments,

and pricing settings at this time.

PLAYFIELD REMOVAL

The playeld is held in place by two

basset clamps located on each side on

the game.

7. Loosen the basset clamps by

lifting them away from cabinet.

8. Lift the playeld and pull toward

you.

9. Tilt up and rest the playeld

against the backbox if necessary.

PLAYFIELD INSTALLATION

10. If the playeld has been completely removed, set the playeld

on the wood rails in the base

cabinet.

11. Ensure the cables are reconnected correctly.

12. Slide the playeld forward into

the base cabinet until it stops.

13. Latch the basset clamps on each

side of the base cabinet.

13 14 15

19 20

GAME SETUP

7

13

WHOA NELLIE! MANUAL #780-50D7-00

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

9

GAME SETUP

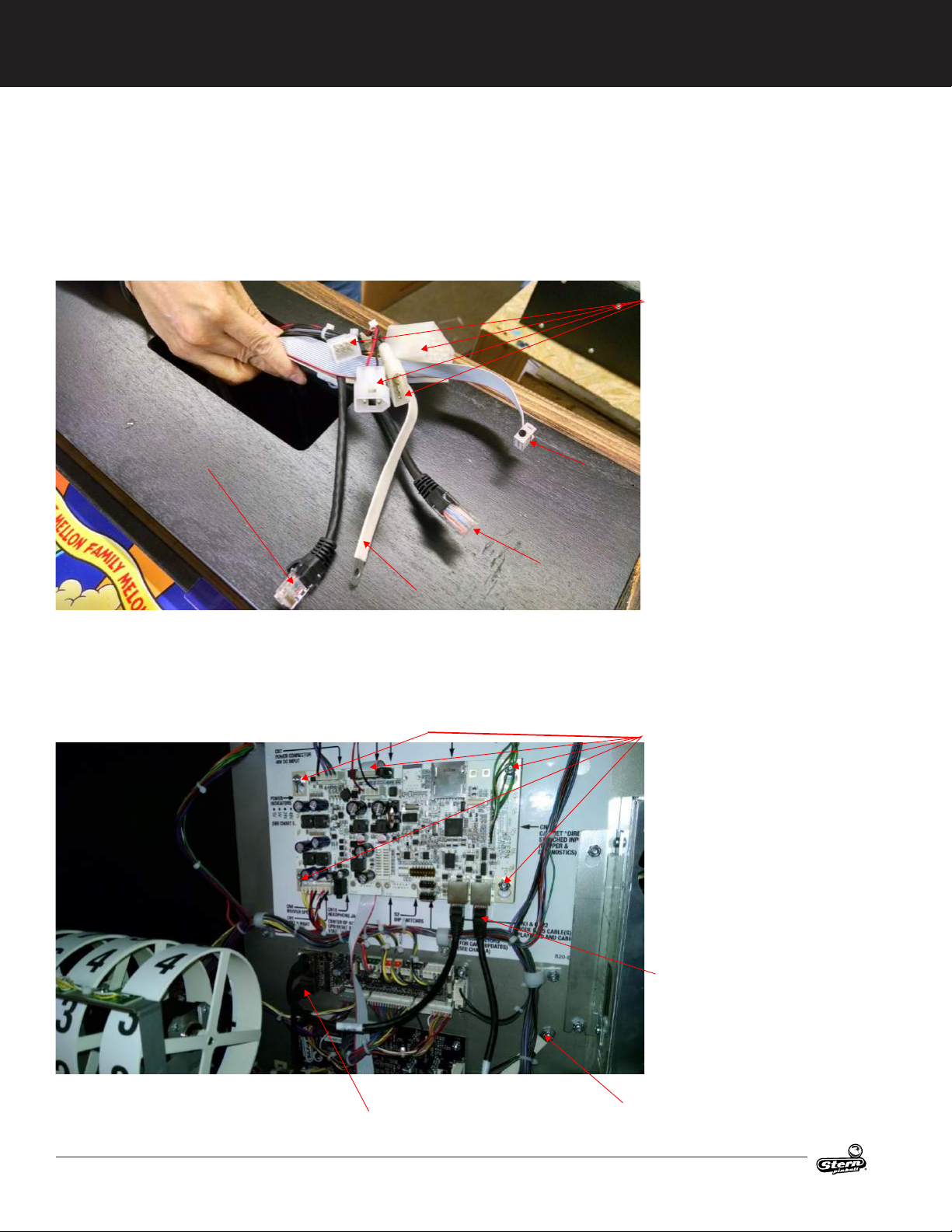

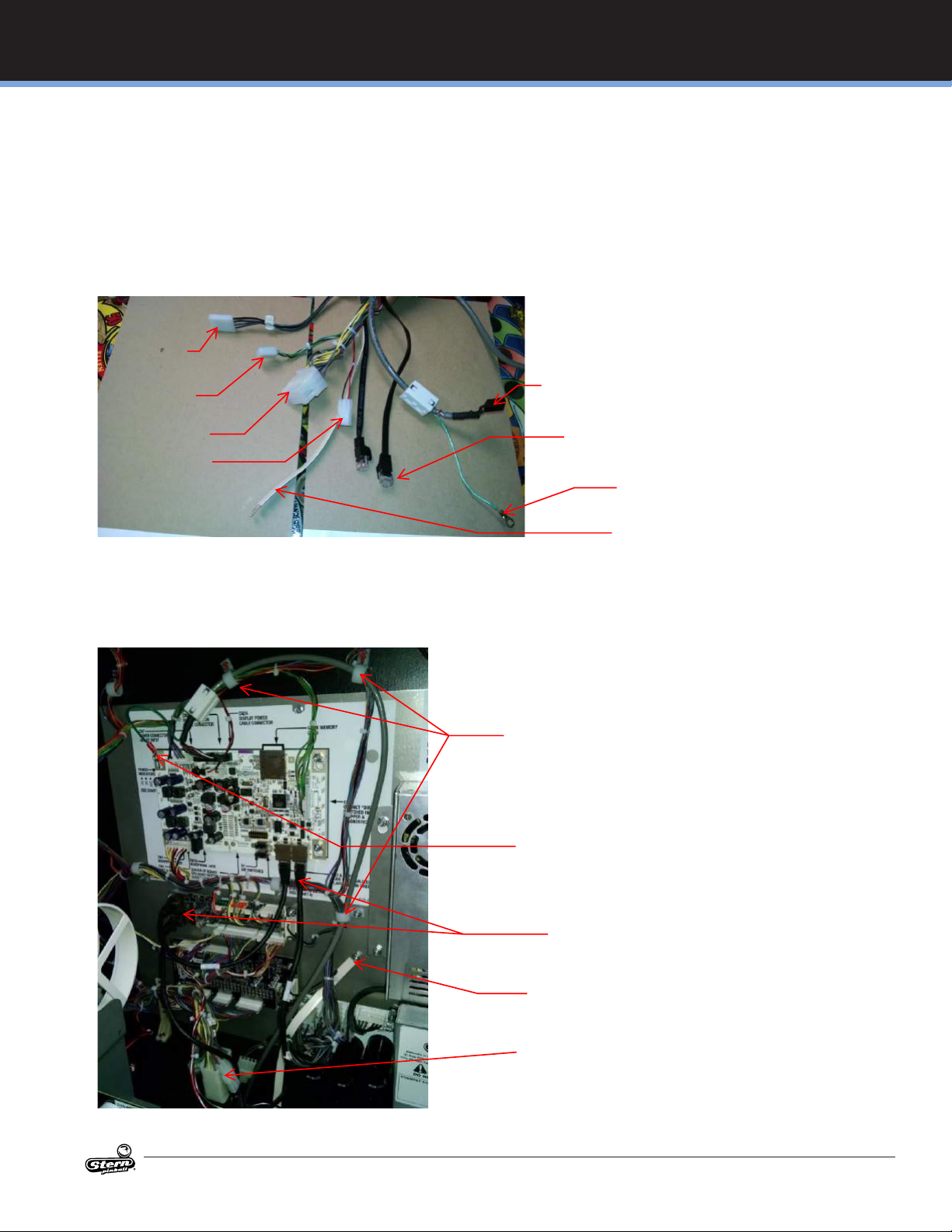

RJ45 cable

Ribbon Cable

Ground Strap

white connector cables

RJ45 cable

RJ45 cable goes here

RJ45 cable goes here

Remove nut with 11/32 driver

Connect ground strap

Replace nut

Loosen 4 nuts-do not remove

Note location of stripe

FIRST-TIME SETUP CONTINUED

1.6 USA CABLE CONNECTIONS

Making cable connection from base game to backbox

Make sure the backbox has been properly attached to the base game

Reach into the base cabinet through the large rectangular hole in the backbox and retrieve the bundle of cables. Pull the

bundle into the back box

3 pin, 4 pin, 6 pin, 12 pin

Connect the four cables from the base cabinet to the matching cables in the backbox, these are the white connectors.

There is: a 3 pin plug, 4 pin plug, 6 pin plug, and 12 pin plug.

There are two black RJ 45 cables one gets connected to the CPU the other to the 4-coil driver circuit board.

The ribbon cable gets connected to the CPU

The ground strap to the stud as shown

Slide CPU up and off

Run ribbon cable behind CPU

as shown

Place CPU back on studs

Tighten nuts

Connect ribbon connector

10

WHOA NELLIE! MANUAL #780-50D7-00

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

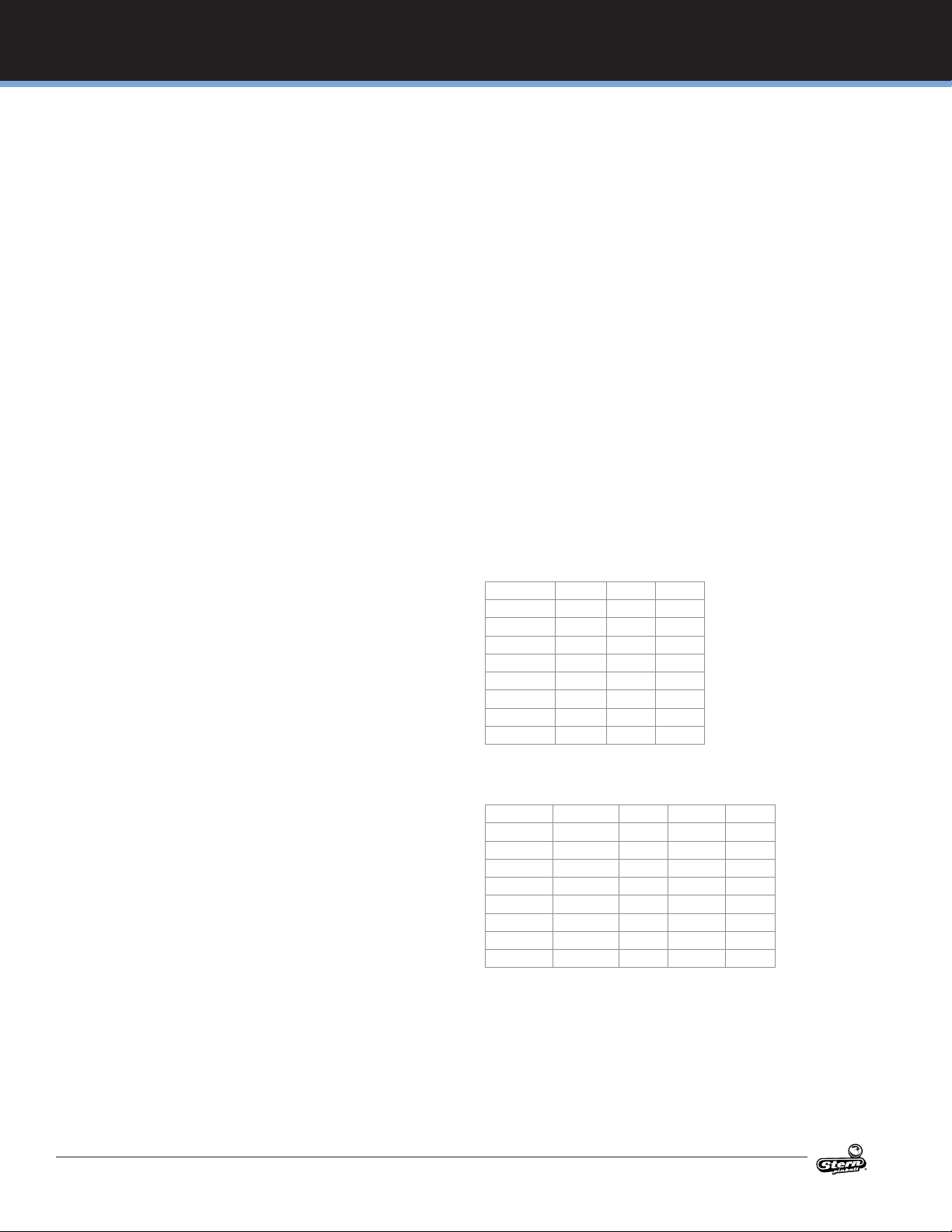

FIRST-TIME SETUP CONTINUED

RJ45 Cables

Back Box Ground Strap

6 Pin

4 Pin

3 Pin

Display Cable Ground Strap

Cables from base game pulled

up through hole in back box

1.7 INTERNATIONAL CABLE CONNECTIONS

Making cable connection from base game to backbox

Make sure the backbox has been properly attached to the base game

Reach into the base cabinet through the large rectangular hole in the backbox and retrieve the bundle of cables. Pull the

bundle into the back box

Display Cable

12 Pin

GAME SETUP

Connect the four cables from the base cabinet to the matching cables in the backbox, these are the white connectors.

There is: a 3 pin plug, 4 pin plug, 6 pin plug, and 12 pin plug.

There are two black RJ 45 cables one gets connected to the CPU the other to the 4-coil driver circuit board.

The ribbon cable gets connected to the CPU

The ground strap to the stud as shown

Dress display cable in

cable clamps as shown

Remove nut with 11/32 driver

Connect display cable ground strap

Replace nut

RJ45 cables go here

Remove nut with 11/32 driver

Connect ground strap

Replace nut

WHOA NELLIE! MANUAL #780-50D7-00

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

11

GAME SETUP

12

WHOA NELLIE! MANUAL #780-50D7-00

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

1.8 MAINTENANCE

GAME SETUP

REGULAR MAINTENANCE - EVERY MONTH, OR

EVERY 500 GAMES

Remove the playeld glass

Enter the software diagnostics menu, start lamp test, then

clean and wax the playeld.

While cleaning the playeld, identify and repair malfunctioning

lights, loose parts, cracked plastics and worn rubber parts.

While in diagnostics, enter the switch test (Select the "SW"

Icon, then "TEST" Icon).

Use a pinball to actuate all switches and verify the correct

switch registers with the switch test.

The game will play a sound to conrm the switch functional-

ity.

Lift the playeld and inspect all assemblies for loose parts,

broken wires or excessive wear. Look at the bottom of the

cabinet for any parts that may have worked loose, then nd

the source.

Check all coin door mechanisms and bill acceptor (if installed)

for proper operation

Play a game or two to ensure all coils and features are work-

ing

Check the playeld to ensure it is level and set to the proper

pitch using the bubble level on the right side wood rail.

Check game audits: Replay % and Ball Time and note abnor-

mal values which can indicate problems.

Ensure game volume is set appropriately for the location.

Clean both sides of the playeld glass and reinstall.

Check and clean pinballs and replace if excessively worn or

scued. Dirty pinballs accelerate game wear.

OVERHAUL MAINTENANCE - EVERY 5000

GAMES

Verify latest game software is installed

Check ippers for excessive wear. Excessive ipper sloppi-

ness (vertical or horizontal) or weakness indicates a ipper

rebuild is required.

Clean machine inside and out and check leg levelers for free

operation.

Visual check for loose or broken playeld and cabinet parts

and repair as necessary.

Electrical check: Plug into grounded outlet and check for

proper operation through DIAGNOSTICS (enter the Service

Menu).

Clean playeld.

Replace worn or dirty rubbers.

Replace pinballs.

Playeld switch adjustments: Check all playeld switches

with a pinball.

Check all settings (refer to manual for factory settings).

Check coin door: With door closed, insert coins to verify

proper operation.

Check for proper adjustment of the plumb bob tilt.

Play game: Check for satisfactory operation.

COMMON PINBALL TOOLS

Common nut drivers (¼”, 5/16”, 11/32", ⅜”)

Phillips screw driver

Standard Allen wrench/Hex key set

⅝” Socket with ratchet

Adjustable wrench (5/8" & 9/16")

6" Torpedo Level (or use a pinball

Flashlight or headlamp

Soldering Iron (60w with at tip), lead-free solder

Wire cutter

Wire stripper

Long nose (“needle nose”) pliers

1.9 MAINTENANCE KITS

Description Part Number

Whoa Nellie! Big Juicy Melons Standard Pinball Location Maintenance Kit

• 8 oz pinball playeld wax (Novus # 2) (675-0003-01)

• Standard Pinball (260-5000-00)

• Cleaning Cloth

• All Playeld Rubber Rings

• Spare Fuses

Whoa Nellie! Big Juicy Melons Deluxe Pinball Location

Maintenance Kit

• All standard kit items, plus:

• Flipper rebuild kits, Left and Right (500-6307-10,-00)

Whoa Nellie! Big Juicy Melons Playeld Plastics Kit 803-5000-D7

Whoa Nellie! Big Juicy Melons Cabinet Decals Kit 802-5000-D7

502-6002-D7

502-6003-D7

1.10 COMMON MAINTENANCE PARTS

Description Part Number

8 oz Pinball Playeld wax (Novus # 2) 675-0003-01

Standard Pinball, 1-1/16 in 260-5000-00

Flipper Rebuild Kit Left (Standard) 500-6307-10

Flipper Base Plate Kit Left 515-6617-01

Flipper Rebuild Kit Right 500-6307-00

Flipper Base Plate Kit Right 515-6617-00

WHOA NELLIE! MANUAL #780-50D7-00

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

13

SPIKE SYSTEM AND NODE GUIDE

2. SPIKE SYSTEM AND NODE GUIDE

2.1 SPIKE SYSTEM OVERVIEW

The SPIKE Pinball system is a rugged, distributed, and embedded platform custom-designed for the rigors of the pinball

machine environment. SPIKE takes advantage of modern technologies to deliver an immersive pinball experience that supports

modern features, reduces cabling, and increases serviceability

and reliability.

A Stern Pinball machine based on the SPIKE system will have at

least two nodes networked together with the SPIKE node bus,

a custom industrial pinball control bus that is designed around

industry standards and optimized for the pinball environment.

The primary CPU node is networked to one or more input/output

nodes over standard Category 5 UTP (unshielded twisted pair)

ethernet cabling.

There are ve primary types of nodes that are found in the game.

CPU node (Node 0) - The primary node that controls other

nodes in the system. Contains the primary game software

for the system and provides SPIKE node bus power for other

nodes.

Cabinet 48V node (Node 1) - Specialized node with specic

inputs and outputs for coin doors, tilt mechanisms, and other

bottom-cabinet devices.

48V playeld node - Controls high power devices such

as coils and ashers, and also supports a few switch and

low-power outputs. Powered by the system 48V power

supply.

Light and switch node - High-density switch and low-power

LED outputs, bus-powered from the node bus. These boards

contain as many 32 switch inputs and light outputs.

Node extensions - These sub-nodes add additional low-pow-

er input and outputs to a specic Power or I/O node and are

connected with simple serial bus.

2.2 NODE BUS CABLING

The SPIKE node bus utilizes standard Ethernet-style RJ45 8-pin

modular jacks, and o-the-shelf Category 5e or better ethernet

cabling. The node bus is electrically dierent from Ethernet and

does not not utilize Ethernet or TCP/IP protocols or signaling

standards. SPIKE nodes are not compatible with standard computer networking equipment.

CAUTION: Plugging a SPIKE Node or CPU board into a standard

Ethernet port may damage one or both devices and void your

warranty.

2.3 SYSTEM POWER

The SPIKE System is powered from an 48V DC power supply

bus. Each SPIKE node converts this voltage to lower voltages

required by the node and its specic components. A SPIKE 48V

node typically controls high-power outputs such as game coil

mechanisms and high-brightness LEDs. These powered nodes

are supplied directly with 48V system power. SPIKE standard I/O

nodes are low-power nodes that read switch inputs and output

to standard-brightness LEDs. Standard I/O nodes use the node

bus power, which is supplied by the main CPU node over the

node bus modular jack connectors.

COIN-DOOR SAFETY INTERLOCK

To protect the system and for user safety, power to the playeld

is disabled when the front coin door is opened. 48V system power and 9V node bus power is disabled to all playeld components

until the switch is closed.

2.4 SPIKE NODE ADDRESSES

Each SPIKE node has a unique address ranging from 0 to 15. Not

all addresses are used in all games. Nodes can be of the same

part number, so the address is specied on the DIP switches on

each node. When replacing a node, be certain that the correct

address is set. Nodes can have 3-position and 4-position DIP

switches. Refer to the appropriate table to set the address for

each type of Node. The correct address for a node can be found

in the SPIKE node reference section of the manual or in the game

diagnostic software. Address 0 is reserved for the backbox CPU

node, where the game software resides. Address 1 is reserved for

the cabinet node, located inside the coin door. These two nodes

do not have DIP switches as their address is not congurable.

Address 1 2 3

8 OFF OFF OFF

9 OFF OFF ON

10 OFF ON OFF

11 OFF ON ON

12 ON OFF OFF

13 ON OFF ON

14 ON ON OFF

15 ON ON ON

Figure 2.4.1. SPIKE node addresses for nodes with 3-position DIP

switches. Addresses 0-7 are not used by SPIKE nodes with 3-position DIP switches.

Address 1 2 3 4

8 OFF OFF OFF OFF

9 OFF OFF ON OFF

10 OFF ON OFF OFF

11 OFF ON ON OFF

12 ON OFF OFF OFF

13 ON OFF ON OFF

14 ON ON OFF OFF

15 ON ON ON OFF

Figure 2.4.2. SPIKE node addresses for nodes with 4-position DIP

switches. Addresses 0-7 are reserved for xed-function nodes and

do not require conguration.

2.5 SPIKE NODE PROGRAMMING

The SPIKE nodes are smart nodes that have on-board processors and run embedded code. The nodes are programmed

14

WHOA NELLIE! MANUAL #780-50D7-00

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

SPIKE SYSTEM AND NODE GUIDE CONTINUED

SPIKE SYSTEM AND NODE GUIDE

automatically by the CPU node whenever software updates are

installed to the CPU. When replacing a node, the CPU node will

detect and update the node to the latest software with no user

intervention. Always replace nodes with the power to the game

turned OFF.

2.6 SPIKE SYSTEM TERMINOLOGY

MULTI GENERAL ILLUMINATION LIGHTING

General Illumination Lighting is two or more lights powered by

one control source. These are often a number of LEDs connected in parallel and the system controls these as one large LED. A

missing LED will not aect these circuits, however a shorted LED

can cause the entire string of LEDs to turn o.

SINGLE LIGHTS

Single lights and LEDs are direct-controlled from SPIKE node

boards. A common power source is grounded by individual

transistors to turn individual LEDs on and o. Groups of LEDs,

usually by node connector, share a common power source, so if

a group of LEDs is out, check the wiring for the power source.

FLASHERS

SPIKE games treat ashers the same as single LEDs that draw

more power. Flashers are controlled from the same circuits that

power regular lights.

DRIVERS

A driver is a circuit that controls a high power-device such as a

coil, magnet, or motor. Each device has a common 48V power

source that is then connected to ground by a dedicated control

transistor. Each driver is protected against shorting, static electricity, and over-current conditions. Take caution as 48V is always

present on a device even when it is not energized.

INPUT/OUTPUT PROTECTIONS

SPIKE features built-in short-circuit, static electricity, and other

protections to maximize reliability. If an LED, coil or other device

shorts, it will be disabled but will not shut down the entire system

in most circumstances. Groups of LEDs, coils, and switches often

share common power supplies or other circuits, so it is possible

that a bad device will aect the group of related devices and

require removal or repair to x the group. The system diagnostics

will inform the technician of shorted or otherwise malfunctioning

devices whenever possible. While the system is protected against

permanent damage, it is strongly recommended to repair or

replace these bad components as soon as possible to minimize

downtime and maximize game earnings.

FUSES

Nodes that have 48 V power are fused individually. Fuse voltage

ratings are a safety rating and always must be higher than the

circuit the fuse is protecting. Never replace a fuse with a lower

voltage-rated fuse. Fuse current ratings must be replaced with

the same current value. A higher current value fuse could cause

catastrophic failures, and a lower-value fuse will cause premature

fuse failures.

Common fuses

Fuse Rating (Amps) Type Part Number

3/4 A Slow Blow MDL 200-5000-17

3 A Slow Blow MDL 200-5000-08

4 A Slow Blow MDL 200-5000-06

5 A Slow Blow MDL 200-5000-01

7 A Slow Blow MDL 200-5000-03

8 A Slow Blow MDL 200-5000-05

CAUTION: Always replace fuses with the exact current specications.

OPTOS

Certain types of optical switches (“optos”) require external signal

conditioning. For these optos, they will interface to a SPIKE node

via an opto signal conditioning board.

System Protections

CAUTION: Unless explicitly directed by an Authorized Stern Repair technician, perform ALL work on your pinball machine with

the power disabled!

WHOA NELLIE! MANUAL #780-50D7-00

MANUFACTURED UNDER LICENSE BY STERN PINBALL, INC.

™ & © 2015 WHIZBANG PINBALL LLC. ALL RIGHTS RESERVED.

2.7 COMMON SPIKE NODE BOARDS

Description Type Part Number

SPIKE CPU Node Node 520-6936-00

SPIKE CPU Node w/ Video Out Support (Back

ward compatible with -00) Node 520-6936-10

Cabinet Node Node 520-5319-00

48V 8-Driver Node Node 520-6935-00

48V 4-Driver Node Node 520-5329-00

SPIKE 32 Light and Switch Node Node 520-5322-00

Trough Serial Opto Receiver Extension Extension 520-5345-00

-

15

Loading...

Loading...