Page 1

PINBALL MACHINE

SERVICE AND OPERATION MANUAL

WARNING

IMPORTANT HEALTH WARNING: PHOTOSENSITIVE SEIZURES - A very small percentage of people may experience a seizure when exposed to

certain visual images, including ashing lights or patterns. Even people with no history of seizures of epilepsy may have an undiagnosed condition that

can cause “photosensitive epileptic seizures” due to certain visual images, ashing lights or patterns. Symptoms can include light-headedness, altered

vision, eye or face twitching, jerking or shaking of arms or legs, disorientation, confusion, momentary loss of awareness, and loss of consciousness or

convulsions that can lead to injury from falling down or striking nearby objects.

IMMEDIATELY STOP PLAYING AND CONSULT A DOCTOR IF YOU EXPERIENCE ANY OF THESE SYMPTOMS.

Stern Pinball machines are assembled in Melrose Park, Illinois, USA; each pinball machine has unique characteristics that make it a one-of-a-kind

American-made product. Each machine will have variations in appearance resulting from differences in the machine’s particular wood parts, individual

silk screened art and mechanical assemblies. Stern Pinball has inspected each game element to insure it meets our quality standards.

© 2015 KISS Catalog, Ltd. Under License to Epic Rights.

Games congured for North America operate on 60 cycle electricity only. These games will not operate in countries with 50 cycle electricity (Europe

UK, Australia).

1-800-KICKERS - PARTS.SERVICE@STERNPINBALL.COM

WWW.STERNPINBALL.COM - FACEBOOK.COM/STERNPINBALL

KISS PRO

KISS PRO #500-55H1-01

MANUAL #780-50H1-01

Page 2

TABLE OF CONTENTS

1. Setup and Moving .................................. 3

1.1 First-time Setup Instructions................................ 3

1.2 Transporting the Game ........................................ 6

1.3 Maintenance ........................................................ 7

1.4 Maintenance Kits ................................................. 7

1.5 Common Parts ..................................................... 7

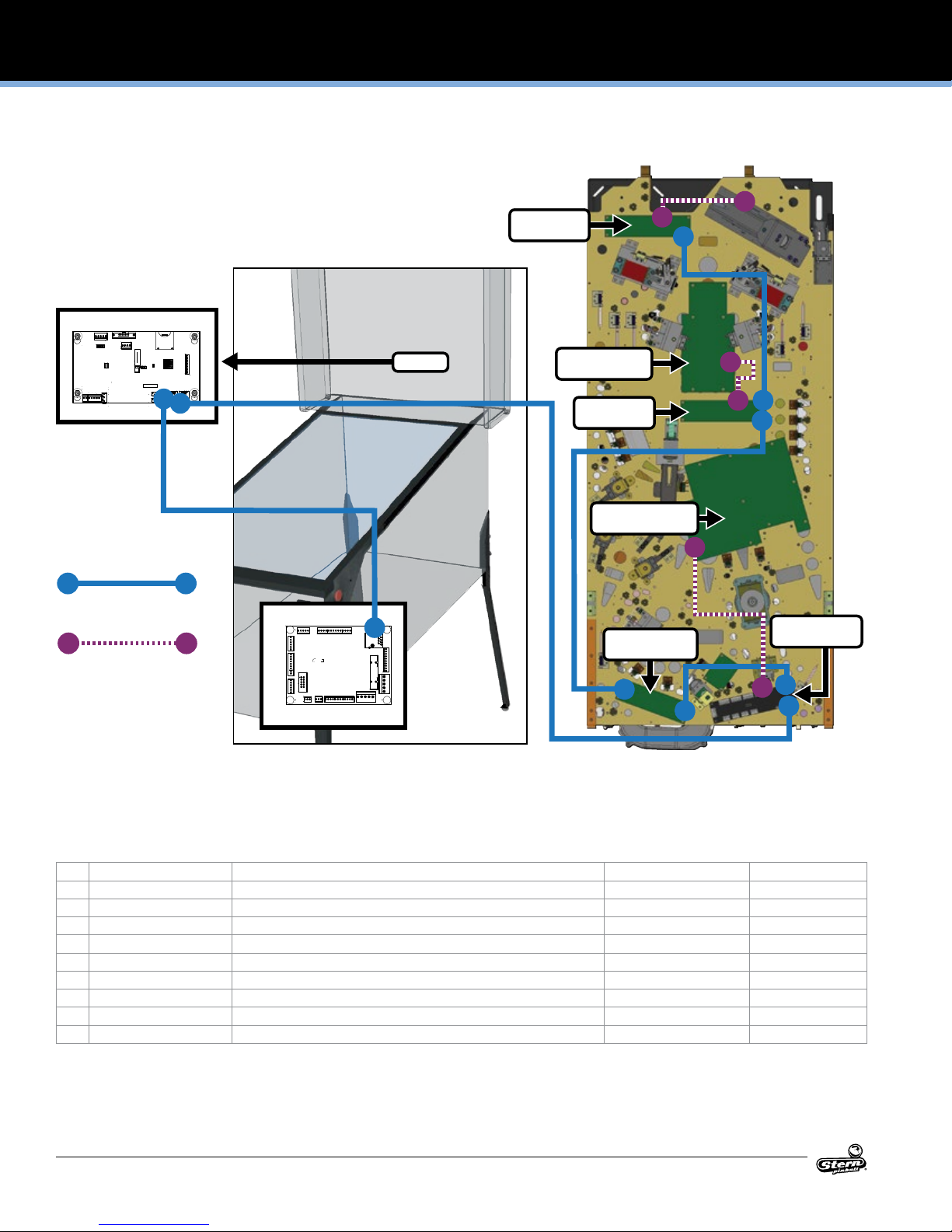

2. SPIKE System and Node Guide ............ 8

2.1 SPIKE System Overview ...................................... 8

2.2 Node Bus Cabling ................................................ 8

2.3 System Power ...................................................... 8

2.4 SPIKE Node addresses ........................................ 8

2.5 SPIKE Node Programming................................... 8

2.6 SPIKE System Terminology ................................. 9

2.7 Common SPIKE Node Boards ............................. 9

3. Light, Switch, and Driver Reference ... 10

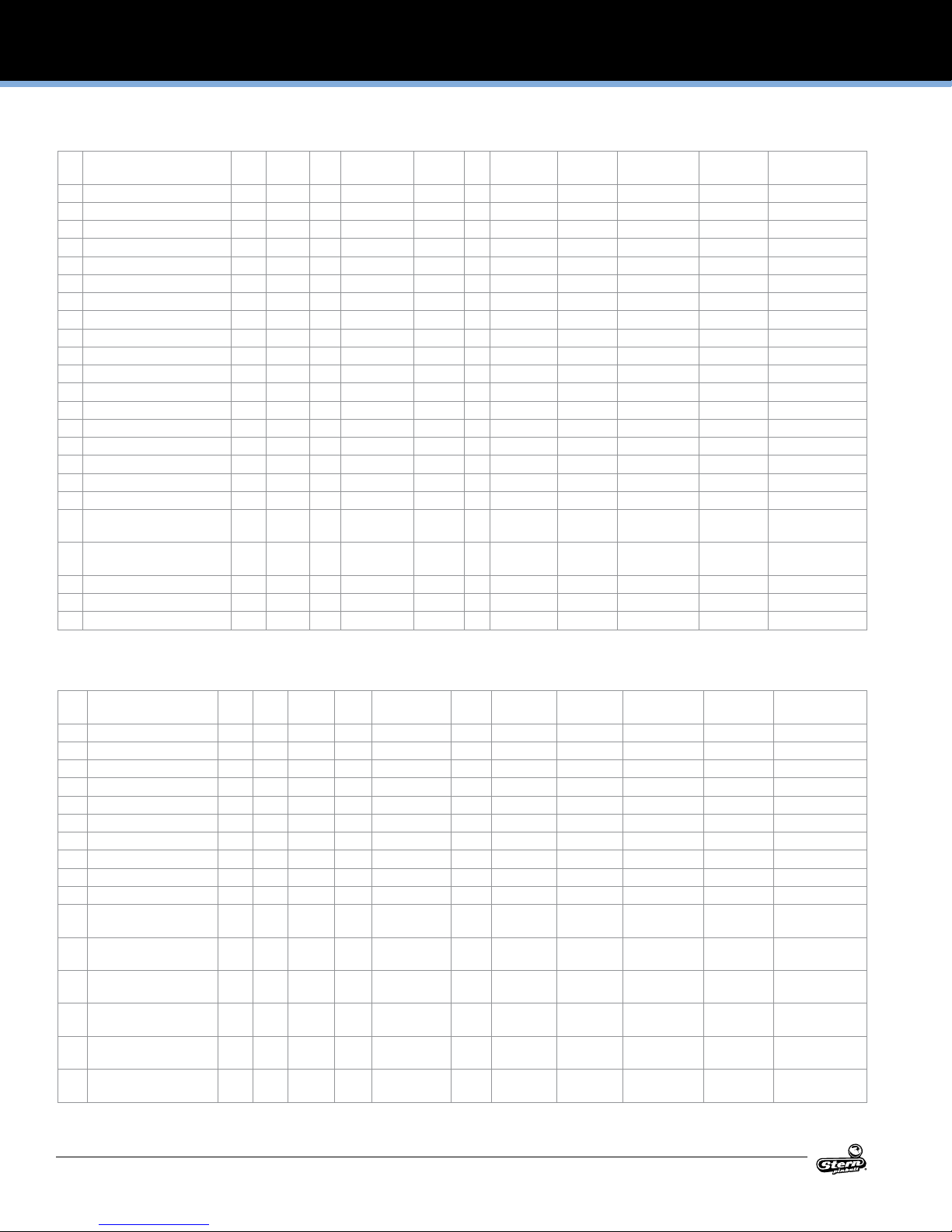

3.1 SPIKE Node Boards ........................................... 10

3.2 Driver Reference ................................................ 11

3.3 Switch Reference ............................................... 12

3.4 Light Reference .................................................. 15

4. Electronic Pinouts and Schematics.... 19

4.1 SPIKE CPU Node 0 ............................................ 19

4.2 Node 1 Cabinet .................................................. 21

4.3 Lower Playeld 48V 8-Driver Pinout Node 8 ..... 22

4.4 Node 9 Mid Playeld 8-Driver 48V Pinout ......... 23

4.5 Node 10 Upper Playeld 8-Driver 48V Pinout .. 24

4.6 Node 11 Upper Playeld 32-Light and Switch

Pinout .......................................................................... 25

4.7 Dual Motor Driver ............................................... 27

4.8 Main Power Supply ............................................ 27

4.9 Trough Opto Transmitter .................................... 27

4.10 Trough Opto Receiver ........................................ 27

4.11 Star Lower Playeld Grid LED ........................... 28

4.12 Star Upper Playeld LED ................................... 28

4.13 Power Distribution Board ................................... 29

4.14 Power Plug Wiring.............................................. 29

5. Parts Reference .................................... 30

5.1 Playeld Rubber Parts ....................................... 30

5.2 Rubber Size Chart .............................................. 30

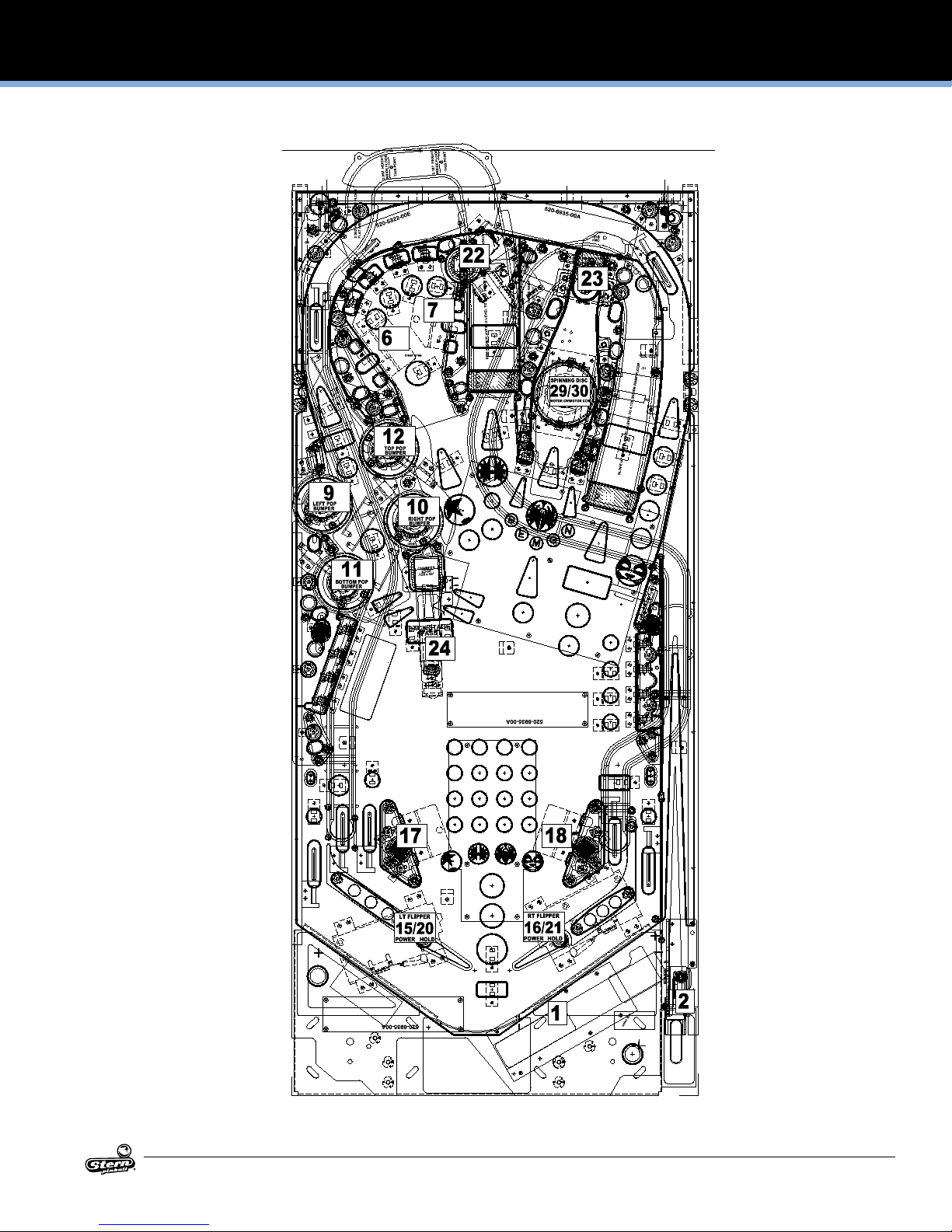

5.3 Playeld assemblies, Top ................................... 31

5.4 Playeld assemblies, Bottom ............................. 32

5.5 Backbox Parts.................................................... 33

5.6 Speaker Panel Parts .......................................... 33

5.7 Cabinet Parts ..................................................... 34

5.8 Auto Launch Assembly ...................................... 35

5.9 Ball Trough Assembly......................................... 35

5.10 Flipper Assembly, Left ........................................ 36

5.11 Flipper Assembly, Right ..................................... 36

5.12 Sling shot Assemblies ........................................ 37

5.13 Slingshot Flash Assy - 02 .................................. 37

5.14 Slingshot Flash Assy- 04 ................................... 37

5.15 Power Scoop ..................................................... 38

5.16 Up-Post Vuk Assembly ...................................... 38

5.17 Pop Bumper Assembly ...................................... 39

5.18 Right Ramp Pro Assy ......................................... 40

SPIKE PINBALL SOFTWARE UPDATE INSTRUCTIONS

1. Obtain game software update le (lename ends

in “.spk”) from www.sternpinball.com or from

authorized Stern distributor.

2. Place game software update le ( “.spk”) in root

directory of a blank FAT32-formatted USB ash

drive

3. Use backbox power switch to turn off game

4. Plug in USB ash drive to CPU board USB connector (CN20 or CN21). Refer to www.sternpinball.com

5. Turn on game

6. The game will automatically begin software

update

7. Select the correct .spk update le from list.

8. Press Enter on the service switches to start

update

9. When the display indicates “Update Complete”,

turn off game

10. Remove USB ash drive from CPU board

11. Turn game on to complete the update and play

pinball!

12. Detailed instructions and troubleshooting tips

are available in the game manual, www.sternpinball.com and authorized Stern distributors.

5.19 Amplier Assembly ............................................ 40

5.20 Left Ramp Assy .................................................. 40

5.21 Paul Assembly, Pro ............................................ 40

5.22 Plastic Flash Assy - 05 ....................................... 41

5.23 Plastic Assy - 06 ................................................ 41

5.24 Plastic Assy - 08 ................................................ 41

5.25 Plastic Assy - 09 ................................................ 41

5.26 Plastic Assembly - 10 ........................................ 41

5.27 Plastic Assembly - 11 ........................................ 42

5.28 Ball Guide Assembly - 03................................... 42

5.29 Plastic Flash Assembly - 28 ............................... 42

5.30 Ball Guide Assembly - 04................................... 42

5.31 Gene Head Assy ................................................ 43

5.32 Spinning Disk Assembly .................................... 43

6. Specications ....................................... 44

6.1 Game Dimensions .............................................. 44

7. Warranty ................................................ 45

7.1 Warnings, Compliance, and Legal Notices ........ 45

2

KISS PRO MANUAL #500-55H1-01

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

Page 3

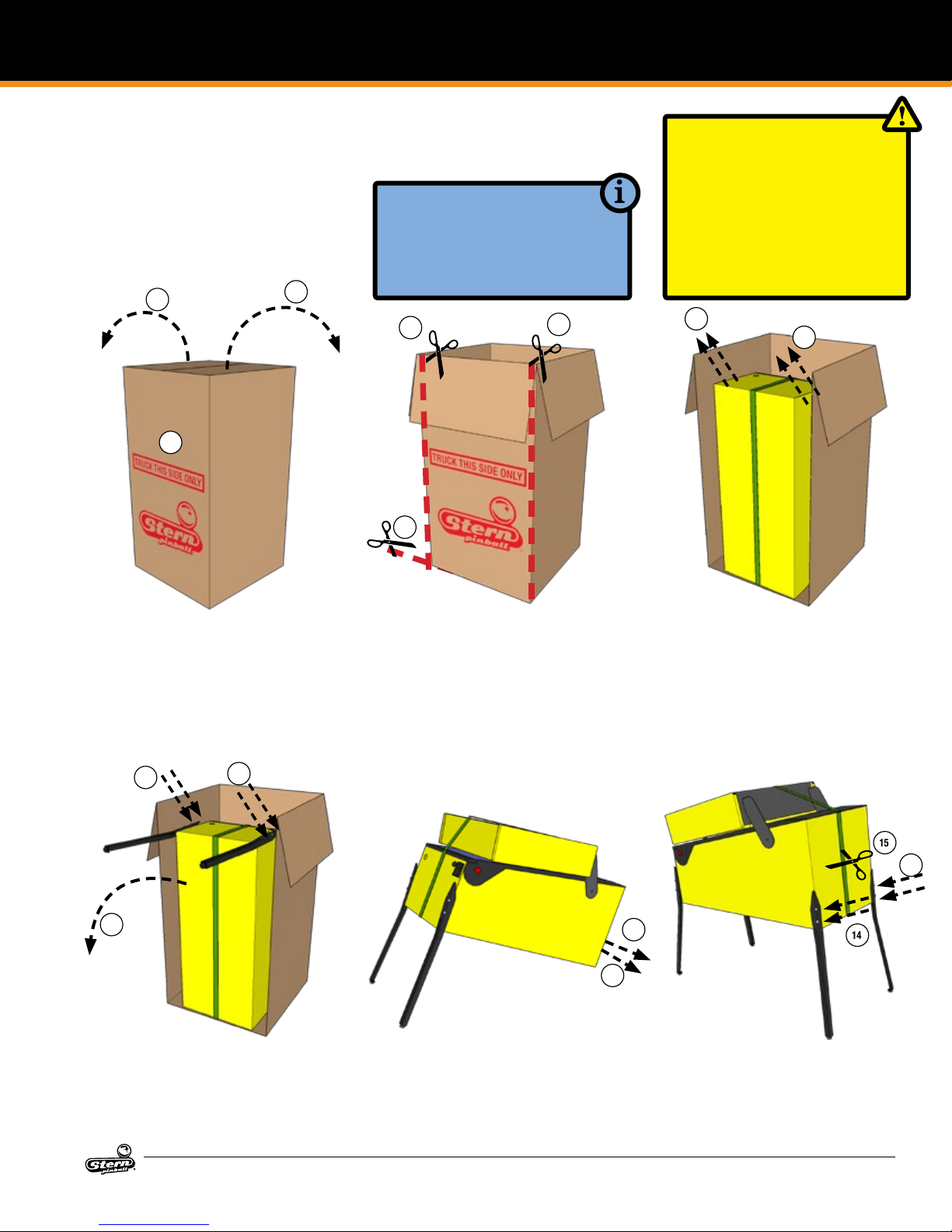

1. SETUP AND MOVING

1.1 FIRST-TIME SETUP

INSTRUCTIONS

Your brand new Stern Pinball Machine is

carefully packed for safety and security.

For your safety, exercise caution and use

the correct tools and sufcient help when

setting up your new game.

2

1

2

TOOLS REQUIRED

• 5/8” Socket Wrench

• Utility Knife

• Snips

• A helper

5

SETUP AND MOVING

CAUTION: AT LEAST TWO (2)

PEOPLE ARE REQUIRED TO

MOVE AND MANEUVER THE

GAME. USE PROPER MOVING

EQUIPMENT AND EXTREME

CARE WHILE HANDLING.

STERN PINBALL MACHINES

WEIGH OVER 250LBS BOXED.

5

7

7

1. Locate the side labeled “TRUCK

THIS SIDE ONLY”. The bottom of

the game faces this side.

2. Open the top box aps by pulling

hard in an upward motion on each

ap. If the aps are taped, cut the

tape rst, taking care to avoid the

box staples.

8

9

8

6

3. Remove the four (4) foam pieces and two (2) narrow box tubes

which contain the four (4) identical

legs with levelers.

4. DO NOT CUT STRAPPING YET.

Keep backbox secured in the

down position.

5. With the utility knife, carefully cut

down the left and right corners of

the box.

11

6. Let the face fall forward and

remove the entire side by carefully

cutting the bottom.

7. With the game still in its folded

position, use a ⅝” wrench to loosen and remove the 2 leg bolts on

each side of the front cabinet. Ensure the leg levelers are screwed

all the way in to the legs.

15

14

11

14

8. Install front legs using the bolts

removed from Step 5. Secure

tightly.

9. Use a helper to carefully set the

game down on the front legs.

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

10. Set aside the open box.

11. With the ⅝” socket wrench, loosen

and remove the 2 leg bolts on

each side of the rear cabinet, 4

total.

KISS PRO MANUAL #500-55H1-01

12. Using supports or two people,

prop the rear of the cabinet up.

13. Ensure the rear leg levelers are

screwed all the way into the legs.

14. Install rear legs using the 4 bolts

removed from step 11.

3

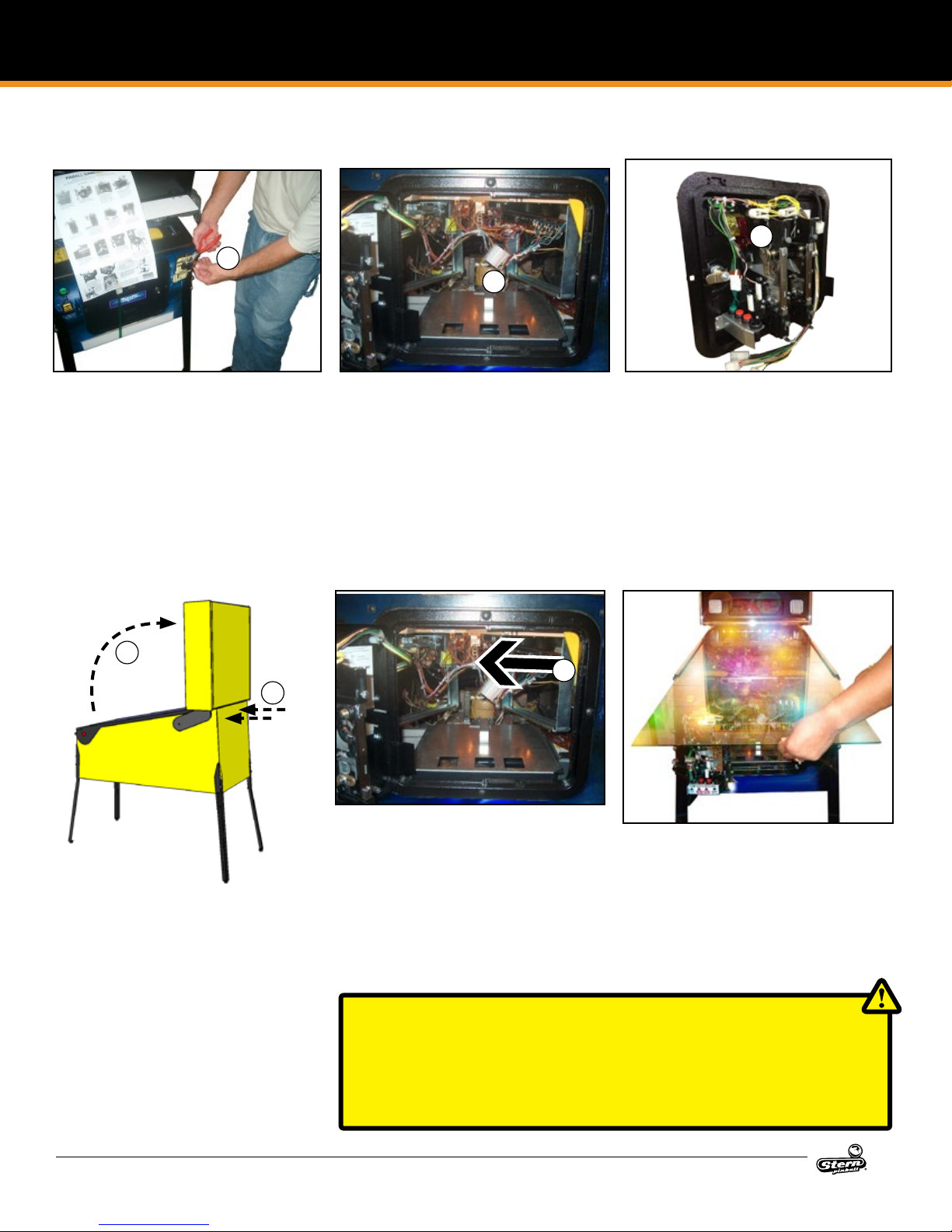

Page 4

SETUP AND MOVING

FIRST-TIME SETUP CONTINUED

17

21

19

15. Cut nylon strapping and remove

protective strap corner guards

16. Locate the factory keys, either on

the shooter rod or taped to the

playeld glass.

17. Using the snips, cut the tie-wrap

securing the keys if required. One

set of keys is for the front coin

door, the other set of keys is for

accessing components in the

backbox

25

26

24. Locate the two (2) backbox bolts in

the cash box.

25. Carefully raise backbox to upright

position while ensuring that cables

are not pinched.

26. Use the ⅝” wrench to Install the

two (2) backbox bolts to secure the

backbox as indicated on the back

of the cabinet.

18. Open the front coin door.

19. Reach into the game and remove

the retaining clip at the rear of the

cash box.

20. Remove the cash box lid by sliding

it toward you.

21. Store the backbox keys, if desired,

on the metal hook located in the

coin door.

22. Locate and remove the pinballs,

plumb bob, and backbox bolts

from the cash box.

23. Replace the cash box lid and

retaining clip for future use.

27

27. Reach inside the cabinet and

move and hold the yellow top

molding lock handle to the left.

28. Remove the front top molding and

then release the handle.

29. Remove the playeld glass by

sliding it toward you and carefully

place it in a safe location.

Remove all playeld shipping

tie downs, shipping blocks, and

packing foam, and follow any

game-specic unpacking instructions included in the playeld, if

present.

CAUTION: PLAYFIELD GLASS IS MADE FROM HIGH-STRENGTH TEMPERED GLASS.

TEMPERED GLASS IS SENSITIVE TO EXTREME TEMPERATURE SHIFTS AND CORNER NICKS, WHICH CAN CAUSE THE GLASS TO FAIL CATASTROPHICALLY. TAKE

CARE TO STORE THE GLASS ON A SOFT, ROOM-TEMPERATURE SURFACE AND

PREVENT THE CORNERS FROM BEING DAMAGED.

4

KISS PRO MANUAL #500-55H1-01

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

Page 5

FIRST-TIME SETUP CONTINUED

30. If pinballs were already installed into the lower ball trough,

remove them before lifting the playeld.

31. Raise the playeld and rest it against the backbox.

32. Grasp the lower arch between the ippers, and rmly but

gently pull directly up to raise the playeld 8-12 inches.

33. While holding the playeld up, pull the playeld toward

you until the two playeld supports are over the front

edge of the cabinet.

34. Rest the playeld on the front edge of the cabinet.

35. Visually inspect all cabinet cables and connector terminations; ensure no wires or cables are pinched and that

cable harnesses are not pulled tight.

36. Locate the plumb bob in the parts bag in the cash box

37. Slide plumb bob onto the hanger wire. Note: the vertical

position of the plumb bob affects tilt sensitivity - higher

makes the game more sensitive to tilting.

38. Tighten the Thumb Screw nger-tight.

39. Install the correct number of pinballs. Refer to the decal

on the lock down assembly for the correct number of

pinballs.

LOCATING, LEVELING, AND FINAL SETUP

1. Select a location that is indoors, out of direct sunlight,

and climate controlled. Excessive moisture/humidity can

cause long-term damage to your game.

2. Adjust the front or rear levelers as necessary to position

the playeld level bubble, located on the front right of the

playeld next to the shooter lane, to oat between the two

(2) black lines. This will place the playeld at the recommended 6.5° pitch. Playeld angles greater than 6.5°

can be achieved by turning out the rear leg leveler(s) for

increased difculty and faster gameplay.

3. Use a pinball to roll down the center of the playeld for

side-to-side leveling, or use an external bubble level,

digital level, or smartphone level app.

4. Plug into a grounded outlet and check for proper operation through DIAGNOSTICS.

5. Check the coin door: With the door closed, insert coins to

verify proper operation.

6. Play game: Check for satisfactory operation and adjust

game volume (push the Red Buttons inside the Coin

Door).

7. If desired, perform any game diagnostics, game adjustments, and pricing settings at this time.

SETUP AND MOVING

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

KISS PRO MANUAL #500-55H1-01

5

Page 6

SETUP AND MOVING

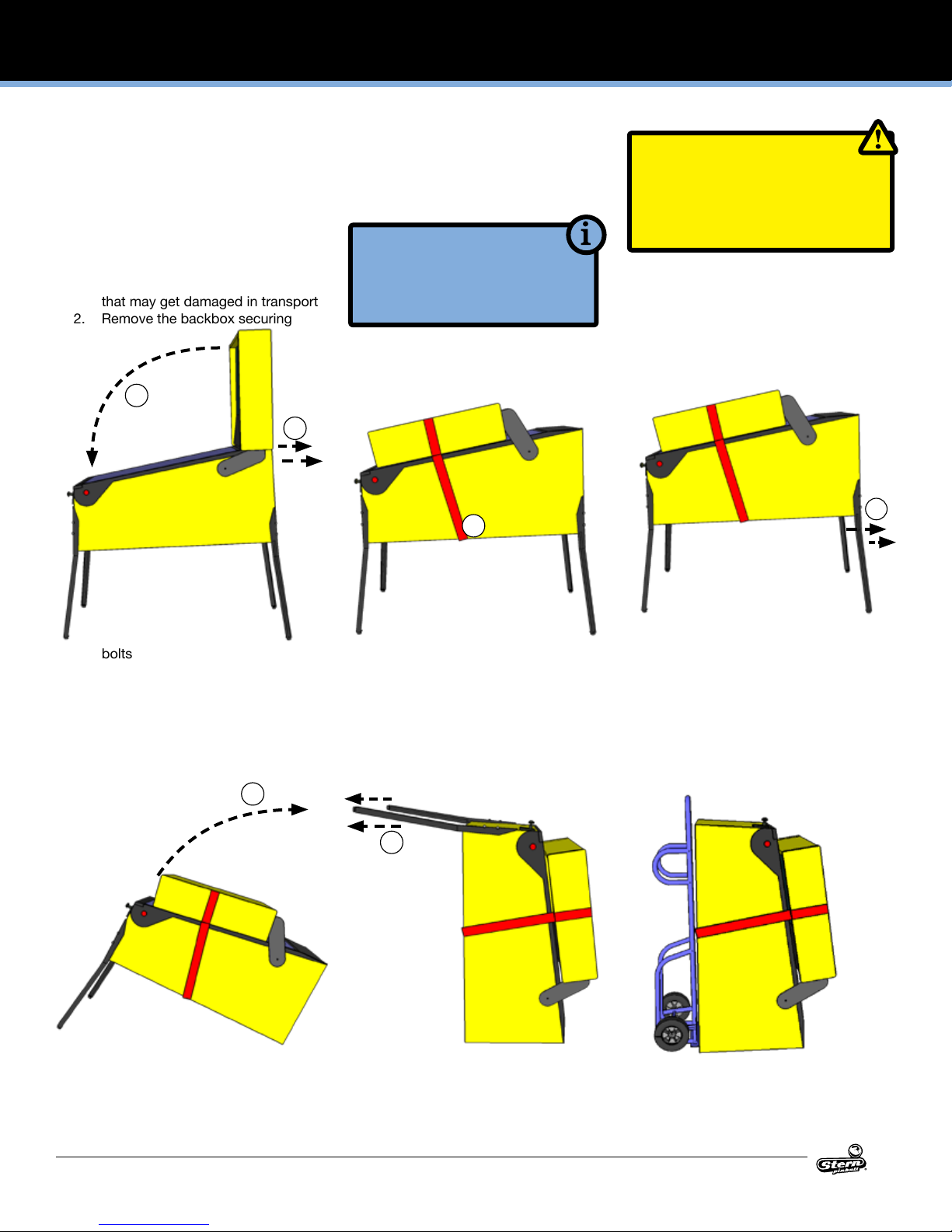

1.2 TRANSPORTING THE GAME

When transporting the game, such as in the back of a truck or with a hand truck, the

game’s backbox must be secured to prevent damage to the side rails.

1. SECURE THE BACKBOX

1. Ensure that the pinballs are removed from the playeld, and secure any free-moving mechanisms

that may get damaged in transport

2. Remove the backbox securing

3

2

TOOLS REQUIRED

• STRAP (500LB OR GREATER)

• A HELPER

• HAND TRUCK

4

NEVER TRANSPORT THE GAME IN A

MOVING VEHICLE WITH THE BACKBOX RAISED! TWO PEOPLE ARE REQUIRED TO REMOVE THE LEGS!

STAND UP

6. Remove the legs, rear legs rst.

Use a stool or a friend to support

6

bolts

3. Carefully lower the backbox onto

the side rails. Use a piece of cardboard or suitable padding between

the backbox and the game.

4. Securely strap the back box to the

8

10. Secure all loose parts and trans-

game

5. The game may be transported with

the legs on. If the legs must be removed, follow the remaining steps.

2. REMOVE THE LEGS AND

9

port with a hand truck in the

the rear of the game.

7. Rest the rear of the game on the

ground.

8. Stand the game up on its back.

9. Remove the front two legs.

upright position.

CAUTION

6

KISS PRO MANUAL #500-55H1-01

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

Page 7

1.3 MAINTENANCE

SETUP AND MOVING

REGULAR MAINTENANCE - (MONTHLY/500

GAMES)

• Remove the playeld glass

• Enter the software diagnostics menu, start lamp test, then

clean and wax the playeld.

• While cleaning the playeld, identify and repair malfunctioning

lights, loose parts, cracked plastics and worn rubber parts.

• While in diagnostics, enter the switch test (Select the "SW"

Icon, then "TEST" Icon).

• Use a pinball to actuate all switches and verify the correct

switch registers with the switch test.

• The game will play a sound to conrm the switch.

• Lift the playeld and inspect all assemblies for loose parts,

broken wires or excessive wear. Look at the bottom of the

cabinet for any parts that may have worked loose, then nd

the source.

• Check all coin door mechanisms and bill acceptor (if installed)

for proper operation

• Play the game to ensure all coils and features are working

• Check the playeld to ensure it is level and set to the proper

pitch using the bubble level on the right side wood rail.

• Check game audits: Replay % and Ball Time and note abnormal values which can indicate problems.

• Ensure game volume is set appropriately for the location.

• Clean both sides of the playeld glass and reinstall.

• Check and clean pinballs and replace if excessively worn or

scuffed. Dirty pinballs accelerate game wear.

OVERHAUL MAINTENANCE (5000 GAMES)

• Verify latest game software is installed

• Check ippers for excessive wear. Excessive ipper sloppi-

ness (vertical or horizontal) or weakness indicates a ipper

rebuild is required.

• Clean machine inside and out and check leg levelers for free

operation.

• Visual check for loose or broken playeld and cabinet parts

and repair as necessary.

• Electrical check: Plug into grounded outlet and check for

proper operation through DIAGNOSTICS.

• Replace worn or dirty rubbers.

• Replace pinballs.

• Check all playeld switches with a pinball.

• Check all settings (refer to manual for factory settings).

• Check coin door: With door closed, insert coins to verify

proper operation.

• Check for proper adjustment of the plumb bob tilt.

• Play game: Check for satisfactory operation.

COMMON PINBALL TOOLS

• Common nut drivers (¼”, 5/16”, 11/32", ⅜”)

• Phillips screw driver

• Standard Allen wrench/Hex key set

• ⅝” Socket with ratchet

• Adjustable wrench (5/8" & 9/16")

• 6" Torpedo Level (or use a pinball

• Flashlight or headlampv

• Soldering Iron (60w with at tip), lead-free solder

• Wire cutter

• Wire stripper

• Long nose (“needle nose”) pliers

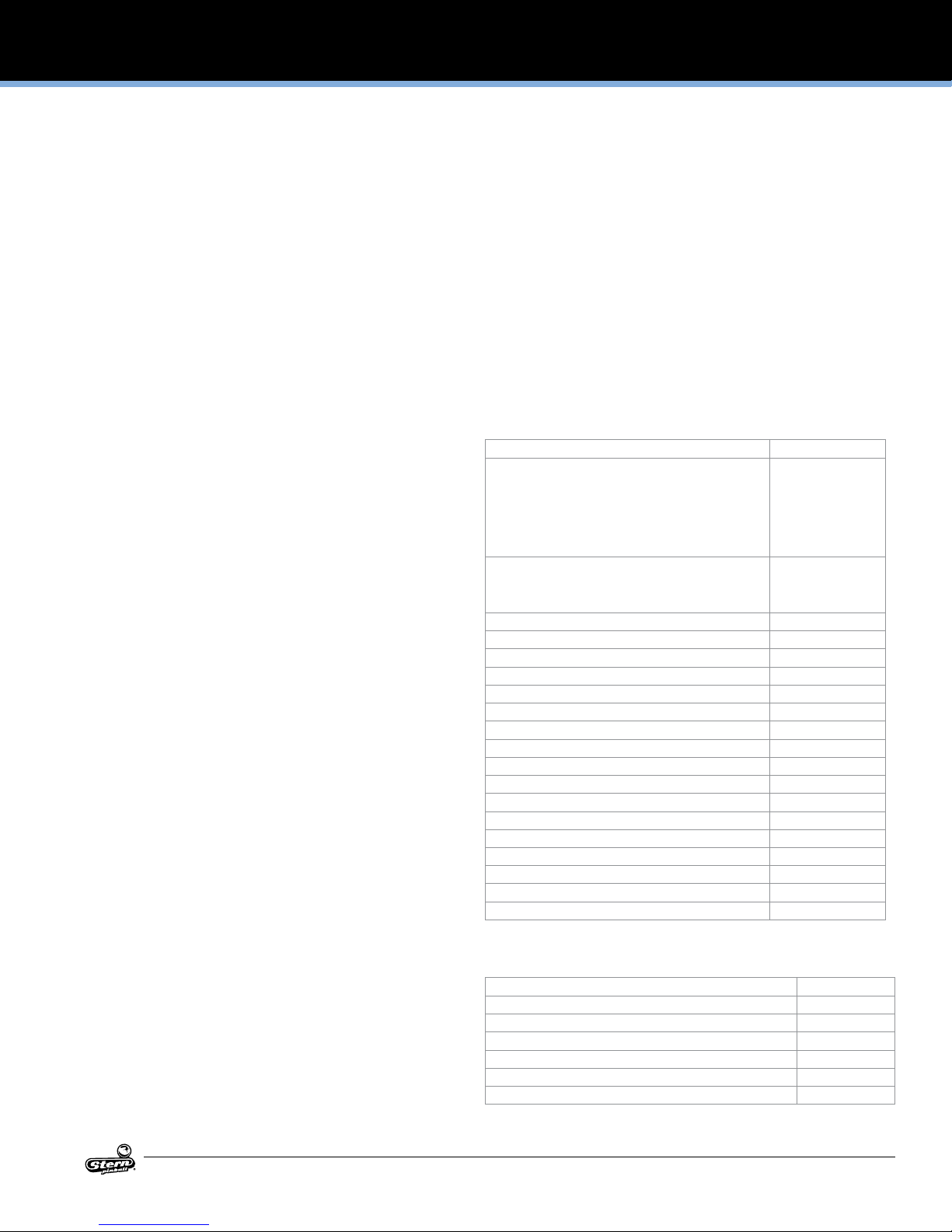

1.4 MAINTENANCE KITS

Description Part Number

KISS Pro Maintenance Kit

• 8 oz pinball playeld wax (Novus # 2) (675-0003-01)

• Standard Pinball (260-5000-00)

• Cleaning Cloth

• All Playeld Rubber Rings

• Spare Fuses

KISS Pro Deluxe Maintenance Kit

• All standard kit items, plus:

• Flipper rebuild kits, Left and Right (500-6307-10,-00)

KISS Playeld Plastics Kit 803-5000-H1

KISS Playeld Decals Kit 802-5000-H1

KISS Playeld Decals Kit (Germany) 802-5000-H1-GER

KISS Pro Cabinet Decal Left 820-66H1-01

KISS Pro Cabinet Decal Left (Germany) 820-66H1-01G

KISS Pro Cabinet Decal Right 820-66H1-02

KISS Pro Cabinet Decal Right (Germany) 820-66H1-02G

KISS Pro Cabinet Decal Left 820-66H1-03

KISS Pro Cabinet Decal Left (Germany) 820-66H1-03G

KISS Pro Cabinet Decal Right 820-66H1-04

KISS Pro Cabinet Decal Right (Germany) 820-66H1-04G

KISS Pro Cabinet Decal Front 820-66H1-05

KISS Pro Cabinet Decal Front (Germany) 820-66H1-05G

KISS Pro Playeld, Bare 830-5000-H1

KISS Pro Playeld, Bare (Germany) 830-5000-H1G

KISS Pro Translite 830-52H1-01

KISS Pro Translite (Germany) 830-52H1-GER

502-6002-H1

502-6003-H1

1.5 COMMON PARTS

Description Part Number

8 oz Pinball Playeld wax (Novus # 2) 675-0003-01

Standard Pinball, 1-1/16 in 260-5000-00

Flipper Rebuild Kit Left (Standard) 500-6307-10

Flipper Base Plate Kit Left 515-6617-01

Flipper Rebuild Kit Right 500-6307-00

Flipper Base Plate Kit Right 515-6617-00

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

KISS PRO MANUAL #500-55H1-01

7

Page 8

SPIKE SYSTEM AND NODE GUIDE

2. SPIKE SYSTEM AND NODE GUIDE

2.1 SPIKE SYSTEM OVERVIEW

The SPIKE Pinball system is a rugged, distributed, and embedded platform custom-designed for the rigors of the pinball

machine environment. SPIKE takes advantage of modern technologies to deliver an immersive pinball experience that supports

modern features, reduces cabling, and increases serviceability

and reliability.

A Stern Pinball machine based on the SPIKE system will have at

least two nodes networked together with the SPIKE node bus,

a custom industrial pinball control bus that is designed around

industry standards and optimized for the pinball environment.

The primary CPU node is networked to one or more input/output

nodes over standard Category 5 UTP (unshielded twisted pair)

ethernet cabling.

There are ve primary types of nodes that are found in the game.

• CPU node (Node 0) - The primary node that controls other

nodes in the system. Contains the primary game software

for the system and provides SPIKE node bus power for other

nodes.

• Cabinet 48V node (Node 1) - Specialized node with specic

inputs and outputs for coin doors, tilt mechanisms, and other

bottom-cabinet devices.

• 48V playeld node - Controls high power devices such

as coils and ashers, and also supports a few switch and

low-power outputs. Powered by the system 48V power

supply.

• Light and switch node - High-density switch and low-power

LED outputs, bus-powered from the node bus. These boards

contain as many 32 switch inputs and light outputs.

• Node extensions - These sub-nodes add additional low-power input and outputs to a specic Power or I/O node and are

connected with simple serial bus.

2.2 NODE BUS CABLING

The SPIKE node bus utilizes standard Ethernet-style RJ45 8-pin

modular jacks, and off-the-shelf Category 5e or better ethernet

cabling. The node bus is electrically different from Ethernet and

does not not utilize Ethernet or TCP/IP protocols or signaling

standards. SPIKE nodes are not compatible with standard computer networking equipment.

CAUTION: Plugging a SPIKE Node or CPU board into a standard

Ethernet port may damage one or both devices and void your

warranty.

2.3 SYSTEM POWER

The SPIKE System is powered from an 48V DC power supply

bus. Each SPIKE node converts this voltage to lower voltages

required by the node and its specic components. A SPIKE 48V

node typically controls high-power outputs such as game coil

mechanisms and high-brightness LEDs. These powered nodes

are supplied directly with 48V system power. SPIKE standard I/O

nodes are low-power nodes that read switch inputs and output

to standard-brightness LEDs. Standard I/O nodes use the node

bus power, which is supplied by the main CPU node over the

node bus modular jack connectors.

COIN-DOOR SAFETY INTERLOCK

To protect the system and for user safety, power to the playeld

is disabled when the front coin door is opened. 48V system power and 9V node bus power is disabled to all playeld components

until the switch is closed.

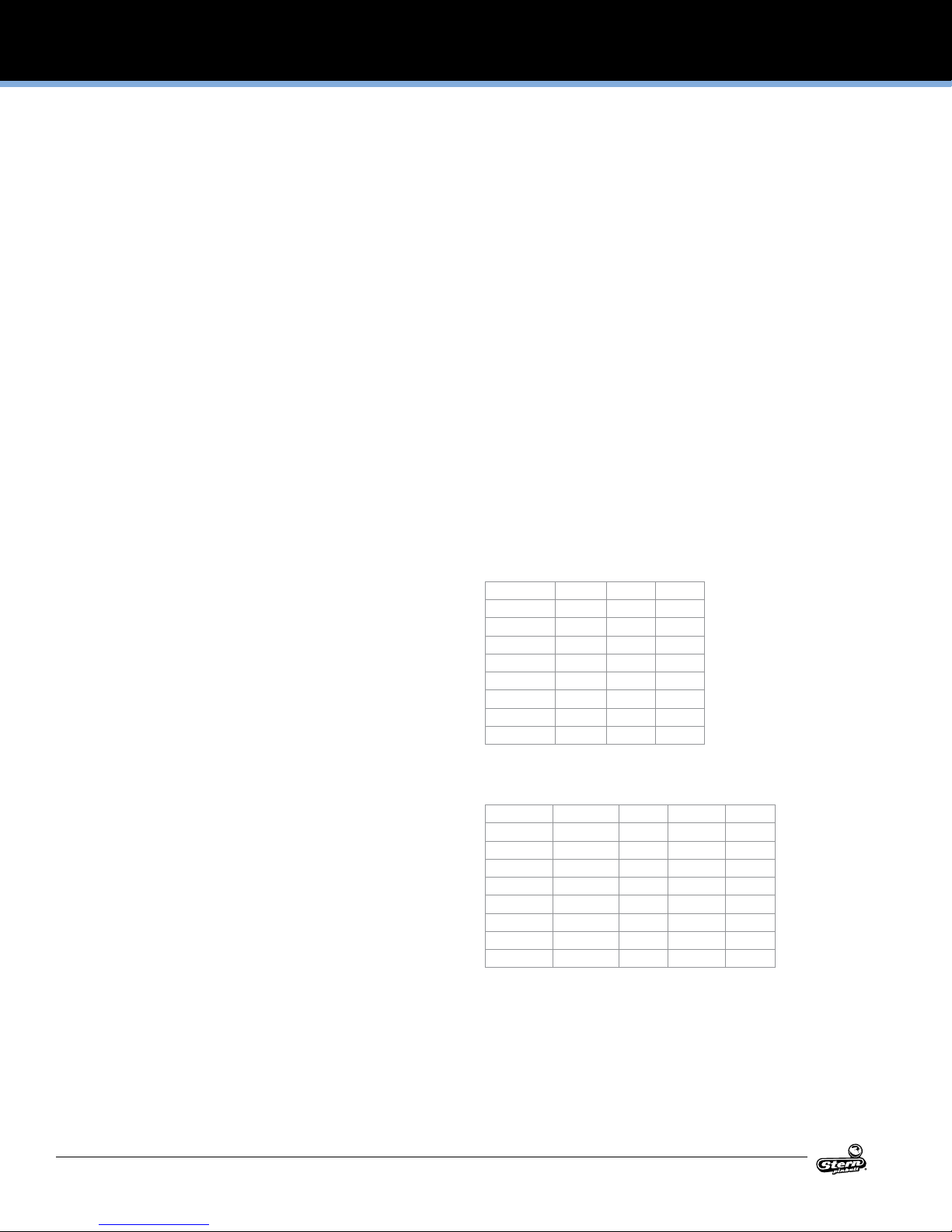

2.4 SPIKE NODE ADDRESSES

Each SPIKE node has a unique address ranging from 0 to 15. Not

all addresses are used in all games. Nodes can be of the same

part number, so the address is specied on the DIP switches on

each node. When replacing a node, be certain that the correct

address is set. Nodes can have 3-position and 4-position DIP

switches. Refer to the appropriate table to set the address for

each type of Node. The correct address for a node can be found

in the SPIKE node reference section of the manual or in the game

diagnostic software. Address 0 is reserved for the backbox CPU

node, where the game software resides. Address 1 is reserved for

the cabinet node, located inside the coin door. These two nodes

do not have DIP switches as their address is not congurable.

Address 1 2 3

8 OFF OFF OFF

9 OFF OFF ON

10 OFF ON OFF

11 OFF ON ON

12 ON OFF OFF

13 ON OFF ON

14 ON ON OFF

15 ON ON ON

Figure 2.4.1. SPIKE node addresses for nodes with 3-position DIP

switches. Addresses 0-7 are not used by SPIKE nodes with 3-position DIP switches.

Address 1 2 3 4

8 OFF OFF OFF OFF

9 OFF OFF ON OFF

10 OFF ON OFF OFF

11 OFF ON ON OFF

12 ON OFF OFF OFF

13 ON OFF ON OFF

14 ON ON OFF OFF

15 ON ON ON OFF

Figure 2.4.2. SPIKE node addresses for nodes with 4-position DIP

switches. Addresses 0-7 are reserved for xed-function nodes and

do not require conguration.

2.5 SPIKE NODE PROGRAMMING

The SPIKE nodes are smart nodes that have on-board processors and run embedded code. The nodes are programmed

8

KISS PRO MANUAL #500-55H1-01

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

Page 9

SPIKE SYSTEM AND NODE GUIDE CONTINUED

SPIKE SYSTEM AND NODE GUIDE

automatically by the CPU node whenever software updates are

installed to the CPU. When replacing a node, the CPU node will

detect and update the node to the latest software with no user

intervention. Always replace nodes with the power to the game

turned OFF.

2.6 SPIKE SYSTEM TERMINOLOGY

MULTI GENERAL ILLUMINATION LIGHTING

General Illumination Lighting is two or more lights powered by

one control source. These are often a number of LEDs connected in parallel and the system controls these as one large LED. A

missing LED will not affect these circuits, however a shorted LED

can cause the entire string of LEDs to turn off.

SINGLE LIGHTS

Single lights and LEDs are direct-controlled from SPIKE node

boards. A common power source is grounded by individual

transistors to turn individual LEDs on and off. Groups of LEDs,

usually by node connector, share a common power source, so if

a group of LEDs is out, check the wiring for the power source.

FLASHERS

SPIKE games treat ashers the same as single LEDs that draw

more power. Flashers are controlled from the same circuits that

power regular lights.

DRIVERS

A driver is a circuit that controls a high power-device such as a

coil, magnet, or motor. Each device has a common 48V power

source that is then connected to ground by a dedicated control

transistor. Each driver is protected against shorting, static electricity, and over-current conditions. Take caution as 48V is always

present on a device even when it is not energized.

OPTOS

Certain types of optical switches (“optos”) require external signal

conditioning. For these optos, they will interface to a SPIKE node

via an opto signal conditioning board. Other optical switches

connect directly to the Spike node board.

System Protections

CAUTION: Unless explicitly directed by an Authorized Stern Repair technician, perform ALL work on your pinball machine with

the power disabled!

INPUT/OUTPUT PROTECTIONS

SPIKE features built-in short-circuit, static electricity, and other

protections to maximize reliability. If an LED, coil or other device

shorts, it will be disabled but will not shut down the entire system

in most circumstances. Groups of LEDs, coils, and switches often

share common power supplies or other circuits, so it is possible

that a bad device will affect the group of related devices and

require removal or repair to x the group. The system diagnostics

will inform the technician of shorted or otherwise malfunctioning

devices whenever possible. While the system is protected against

permanent damage, it is strongly recommended to repair or

replace these bad components as soon as possible to minimize

downtime and maximize game earnings.

FUSES

Nodes that have 48 V power are fused individually. Fuse voltage

ratings are a safety rating and always must be higher than the

circuit the fuse is protecting. Never replace a fuse with a lower

voltage-rated fuse. Fuse current ratings must be replaced with

the same current value. A higher current value fuse could cause

catastrophic failures, and a lower-value fuse will cause premature

fuse failures.

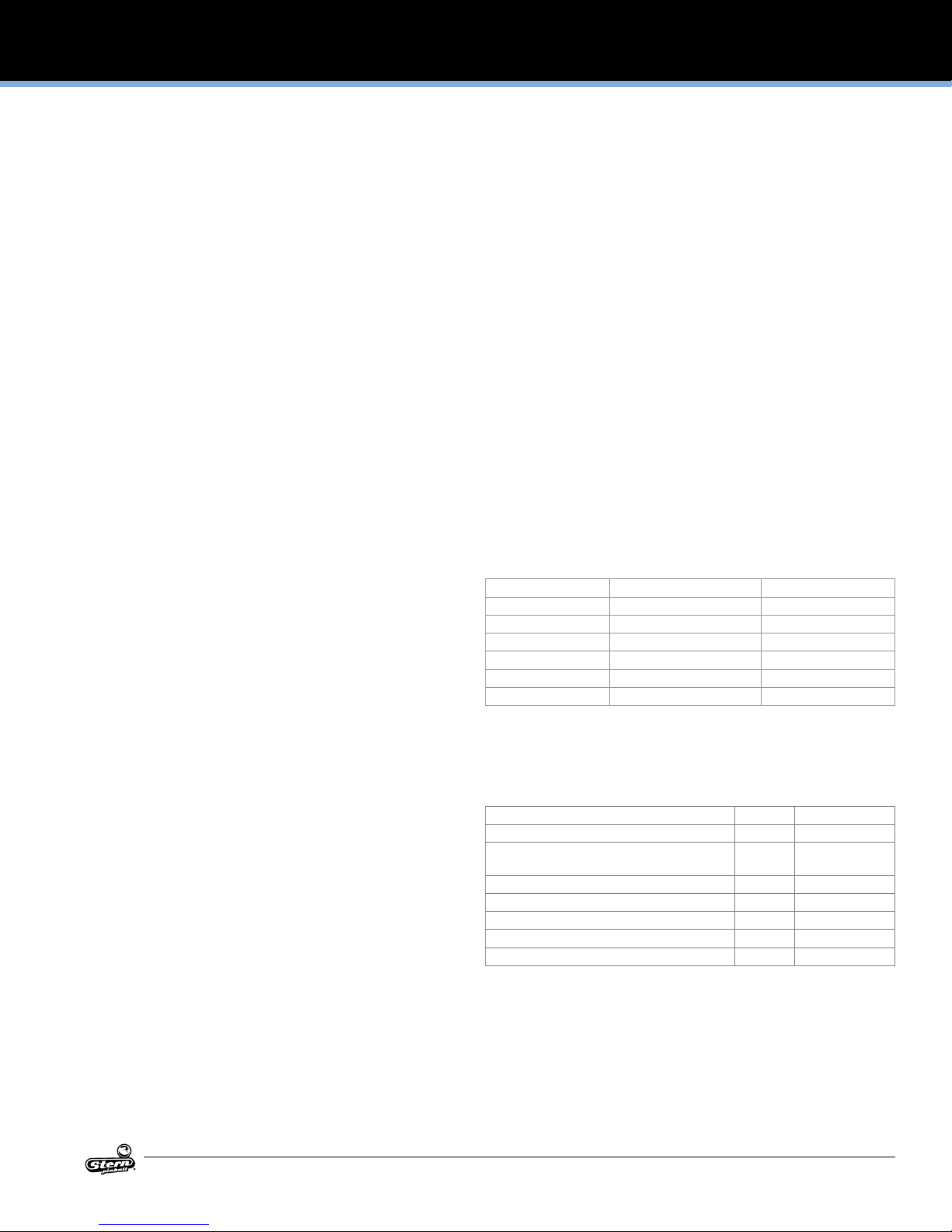

Common fuses

Fuse Rating (Amps) Type Part Number

3/4 A Slow Blow MDL 200-5000-17

3 A Slow Blow MDL 200-5000-08

4 A Slow Blow MDL 200-5000-06

5 A Slow Blow MDL 200-5000-01

7 A Slow Blow MDL 200-5000-03

8 A Slow Blow MDL 200-5000-05

CAUTION: Always replace fuses with the exact current specications.

2.7 COMMON SPIKE NODE BOARDS

Description Type Part Number

SPIKE CPU Node Node 520-6936-00

SPIKE CPU Node w/ Video Out Support (Back-

ward compatible with -00) Node 520-6936-10

Cabinet Node Node 520-5319-00

48V 8-Driver Node Node 520-6935-00

48V 4-Driver Node Node 520-5329-00

SPIKE 32 Light and Switch Node Node 520-5322-00

Trough Serial Opto Receiver Extension Extension 520-5345-00

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

KISS PRO MANUAL #500-55H1-01

9

Page 10

LIGHT, SWITCH, AND DRIVER REFERENCE

NODE BOARD ID INSTRUCTION SHEET

3. LIGHT, SWITCH, AND DRIVER REFERENCE

CN14

CN3

KISS PRO

NODE 8

PLAYFIELD FRONT

CN1

BACKBOX

POWER

1

IN

CN7

D30D29D28

D13

1

+48V

24V

5V

48V

9V

LINE

OUT

520-6936-00A

SPIKE CPU

AMPLIFIED AUDIO

OUT

HEADPHONE

CN18

CN4

CN1

1

1

L+ L-

R+R-

C+ C-

CPU NODE 0

Node Bus Cable (RJ45)

GND

SCL

SDA

RST

1

CN23

SD CARD

CN24

BT1

CN25

BATTERY

1

STATUS

NETSTAT

TxD

RxD

S1

RESET

SPIKE NODE BUS

DIP S2

CN3 CN22

USB

CN21

CN20

CN3

CN22

Serial Data Cable

When replacing node boards,

ensure DIP address switches

are set correctly!

CABINET

CN11

1

FLIPPER

INPUTSLEDS

TICKET

1

CABINET LEFT

CN9

STERN

DBA

Pinball

1

CN5

COIN DOOR

CN1

520-5319-00F

Cabinet Node

1

MENU BUTTONS

CN10

CN8

CABINET RIGHT

CN7

SHAKER MOTOR

FLIPPER

INPUTS LEDS

METER 2

METER 1

1

CN3

CN4

1

1

CABINET NODE 1

NODE 0

NODE 9a

NODE 9

CN2

CN2

CN14

CN3

NODE 10a

CN2

CN13

CN13

CN6

1

CN12

TO CPU

3A 125V

1

TIME LAG FUSE

POWER

CN14

1

CN2

1

NODE 11

CN10

CN9

NODE 10

CN2

CN14

CN3

3.1 SPIKE NODE BOARDS

ID DIP SW1 Address Description Location Part Number

0 n/a SPIKE CPU Node Backbox 520-6936-00

1 n/a Cabinet Node Cabinet 520-5319-00

8 OFF-OFF-OFF-OFF Lower Playeld 48V 8-Driver Node Lower playeld 520-6935-00

8a n/a Trough Serial Opto Receiver Extension Lower playeld ball trough 520-5345-01

9 OFF-OFF-ON-OFF Mid Playeld 48V 8-Driver Node Mid playeld 520-6935-00

9a n/a Star Grid LED Extension Lower playeld 520-6969-00

10 OFF-ON-OFF-OFF Upper Playeld 48V 8-Driver Node Upper playeld 520-6935-00

10a n/a Star LED Extension Mid playeld 520-6970-00

11 OFF-ON-ON Upper Playeld S/L I/O Node Upper playeld 520-5322-00

10

KISS PRO MANUAL #500-55H1-01

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

Page 11

3.2 DRIVER REFERENCE

STAR PRO

COIL MAP

.062

DEEP

.062

DEEP

BOTTOM

W

BOTTOM

LIGHT, SWITCH, AND DRIVER REFERENCE

W

BD.#11

-13

-24

-18

BD.#10

-29

W

W

WHITE

A

WHITE

T

W

WHITE

S

NEW

W

DEEP

ROUT

.125

CLEAR

CLEAR

LITE

BACK STAGE

PASS

COLLECT

INSTRUMENT

ORANGE

WHITE

white

W

W

AMBER

EXTRA BALL

YELLOW

W

KISS ARMY

W

W

YELLOW

LITE

ARMY

LITE

TARGETS

BUMPER

SHOT

WHITE

AMBER

E

PAHS M

TOP

.093 DEEP

DEEP

.062

BOTTOM

W

-20

W

.062

DEEP

BOTTOM

W

DEEP

.062

BOTTOM

W

TOP

.093 DEEP

-24

WHITE

R

SUPER

JACKPOT

CLEAR

.070

ROUT

CLEAR

CLEAR

WHITE

YELLOW

ARMY

MILLIONS

WHITE

COLLECT

INSTRUMENT

ORANGE

COLLECT

INSTRUMENT

ORANGE

ORANGE

ADD A BALL

CLEAR

ROCK CITY

CLEAR CLEAR CLEAR

YELLOW YELLOW YELLOW YELLOW

WHITE WHITE WHITE WHITE

ORANGE ORANGE ORANGE ORANGE

WHITE

WHITE

BLUE FILTER

PURPLE FILTER

2X

ORANGE

3X

ORANGE

COLOSSAL

BONUS

CLEAR

W

W

W

DEEP

LITE

CLEAR

L

O

C

GREEN

K

RED

WHITE

RED

RED

RED

L

O

GREEN

C

K

COLLECT

INSTRUMENT

ORANGE

INSTRUMENT

ORANGE

BD.#9

CLEAR

LITE

L

O

C

K

GREEN

RED

WHITE

KISS

MILLION TARGETS

MULTIBALL

PURPLE

COLLECT

START

-01

CLEAR

W

W

JACKPOT

ROUT

.070

YELLOW

A

YELLOW

R

YELLOW

M

YELLOW

Y

DOUBLE

KISS

WHITE

DEEP

.062

BOTTOM

SUPER

CLEAR

DEEP

WHITE

BUMPER

WHITE

ROUT

CLEAR

LITE

CAT

BUMPER

WHITE

LITE

SPACE

BUMPER

WHITE

LITE

STAR

BUMPER

WHITE

LITE

DEMON

-06

W

W

-29

RED

W

TOP

WHITE

RED FILTER

WHITE

GREEN FILTER

W

DEEP

.062

BOTTOM

TOP

.093 DEEP

.093 DEEP

DEEP

.062

BOTTOM

W

-29

W

TOP

.093 DEEP

.125

DEEP

Figure 3.2.1. Playeld top component view

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

color bar

BD.#8

ROCK

AMBER

AGAIN

KISS PRO MANUAL #500-55H1-01

.062

BOTTOM

DEEP

11

Page 12

LIGHT, SWITCH, AND DRIVER REFERENCE

DRIVER REFERENCE CONTINUED

ID Name Node Con-

1 Trough 8 CN8 5 ORG-GRY 48V 6 GRY-ORG Playeld Coil - 27-1500 8-DR-5 090-5004-ND

2 Auto Plunger 8 CN6 5 ORG-WHT 48V 6 GRY-ORG Playeld Coil - 23-800 8-DR-4 090-5001-ND

6 Up Left Sling 9 CN5 3 YEL-BLU 48V 4 GRY-BLK Playeld Coil - 26-1200 9-DR-0 090-5044-ND

7 Up Right Sling 9 CN7 3 YEL-GRY 48V 4 GRY-BLK Playeld Coil - 26-1200 9-DR-1 090-5044-ND

8 Shaker Motor 1 CN2 1 BLU 48V 5 RED Cabinet Motor 1-DR-0 041-5029-04

9 Left Pop Bumper 9 CN6 5 ORG-BLK 48V 6 GRY-BLK Playeld Coil - 26-1200 9-DR-4 090-5044-ND

10 Right Pop Bumper 9 CN8 5 ORG-BRN 48V 6 GRY-BLK Playeld Coil - 26-1200 9-DR-5 090-5044-ND

11 Bottom Pop Bumper 9 CN10 5 ORG-RED 48V 6 GRY-BLK Playeld Coil - 26-1200 9-DR-6 090-5044-ND

12 Top Pop Bumper 9 CN12 5 ORG 48V 6 GRY-BLK Playeld Coil - 26-1200 9-DR-7 090-5044-ND

15 Left Flipper 8 CN5 3 ORG-YEL 48V 4 GRY-ORG Playeld Coil - 24-850 8-DR-0 090-5083-03-ND

16 Right Flipper 8 CN7 3 ORG-GRN 48V 4 GRY-ORG Playeld Coil - 24-850 8-DR-1 090-5083-03-ND

17 Left Sling 8 CN12 5 ORG-BLU 48V 6 GRY-ORG Playeld Coil - 26-1200 8-DR-7 090-5044-ND

18 Right Sling 8 CN10 5 ORG-VIO 48V 6 GRY-ORG Playeld Coil - 26-1200 8-DR-6 090-5044-ND

20 Left Flipper Hold 8 CN9 3 YEL-ORG 48V 4 GRY-ORG Playeld Coil - 31-3500 8-DR-2 090-5083-03-ND

21 Right Flipper Hold 8 CN11 3 YEL-GRN 48V 4 GRY-ORG Playeld Coil - 31-3500 8-DR-3 090-5083-03-ND

22 Eject 10 CN5 3 YEL-BLK 48V 4 GRY-BRN Playeld Coil - 26-1200 10-DR-0 090-5044-ND

23 Vertical Upkicker 10 CN7 3 YEL-BRN 48V 4 GRY-BRN Playeld Coil - 23-800 10-DR-1 090-5001-ND

24 Scoop 10 CN9 3 YEL-RED 48V 4 GRY-BRN Playeld Coil - 23-800 10-DR-2 090-5001-ND

29 Motor-Spin Disc 1 10 10a-

30 Motor-Spin Disc 2 10 10a-

31 Meter 1 1 CN3 2 BLK 12V 1 RED Cabinet Digital Out 1-DR-2 500-9946-00

32 Meter 2 1 CN4 2 BLK 12V 1 RED Cabinet Digital Out 1-DR-3 500-9946-00

33 Ticket Dispenser 1 CN11 3 12V 1 Cabinet Digital Out 1-DR-4

Ret.

nector

CN9

CN9

Ret. Wire Voltage V+

Pin

4 BLU-ORG 5V 1 RED Playeld Motor 10-LP-41 511-5190-00

5 BLU-YEL 5V 1 RED Playeld Motor 10-LP-42 511-5190-00

V+ Color Location Type Address Part Number

Pin

Figure 3.3.1. Driver reference table.

3.3 SWITCH REFERENCE

Name Node Node

1 Return Lane L 11 - CN7 3 WHT-RED 10 BLK-VIO Playeld Rollover 11-SW-1 500-9935-04

2 Return Lane R 11 - CN1 6 TAN-GRN 10 BLK-ORG Playeld Rollover 11-SW-28 500-9935-03

3 Left Outlane 11 - CN7 2 WHT-BRN 10 BLK-VIO Playeld Rollover 11-SW-0 500-9935-04

4 Right Outlane 11 - CN1 7 TAN-BLU 10 BLK-ORG Playeld Rollover 11-SW-29 500-9935-04

5 Left Slingshot 8 - CN12 4 GRY-BLU 3 BLK-GRN Playeld Leaf 8-SW-7 180-5231-00

6 Right Slingshot 8 - CN10 4 GRY-VIO 3 BLK-GRN Playeld Leaf 8-SW-6 180-5231-00

10 Flipper Button L 8 - CN9 2 GRY-BRN 1 BLK-GRN Cabinet Leaf 8-SW-2 500-5160-01

11 Flipper Button R 8 - CN11 2 GRY-RED 1 BLK-GRN Cabinet Leaf 8-SW-3 500-5160-01

14 Left Orbit 11 - CN7 5 WHT-YEL 10 BLK-VIO Playeld Rollover 11-SW-3 500-9935-04

15 Tournament Start 1 - CN6 9 GRY-WHT 5 BLK-WHT Cabinet Micro 1-SW-12 180-5174-00

16 Trough 6 8 8a CN14 - - - - Playeld Opto 8a-SW-9 520-5344-00 tx

17 Trough 5 8 8a CN14 - - - - Playeld Opto 8a-SW-10 520-5344-00 tx

18 Trough 4 8 8a CN14 - - - - Playeld Opto 8a-SW-11 520-5344-00 tx

19 Trough 3 8 8a CN14 - - - - Playeld Opto 8a-SW-12 520-5344-00 tx

20 Trough 2 8 8a CN14 - - - - Playeld Opto 8a-SW-13 520-5344-00 tx

21 Trough 1 8 8a CN14 - - - - Playeld Opto 8a-SW-14 520-5344-00 tx

Ext

Conn. Input

Pin

Input Wire GND

Pin

Ground

Wire

Location Type Address Part Number

520-5345-01 rx

520-5345-01 rx

520-5345-01 rx

520-5345-01 rx

520-5345-01 rx

520-5345-01 rx

12

KISS PRO MANUAL #500-55H1-01

Continued on next page...

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

Page 13

STAR PRO

SWITCH MAP

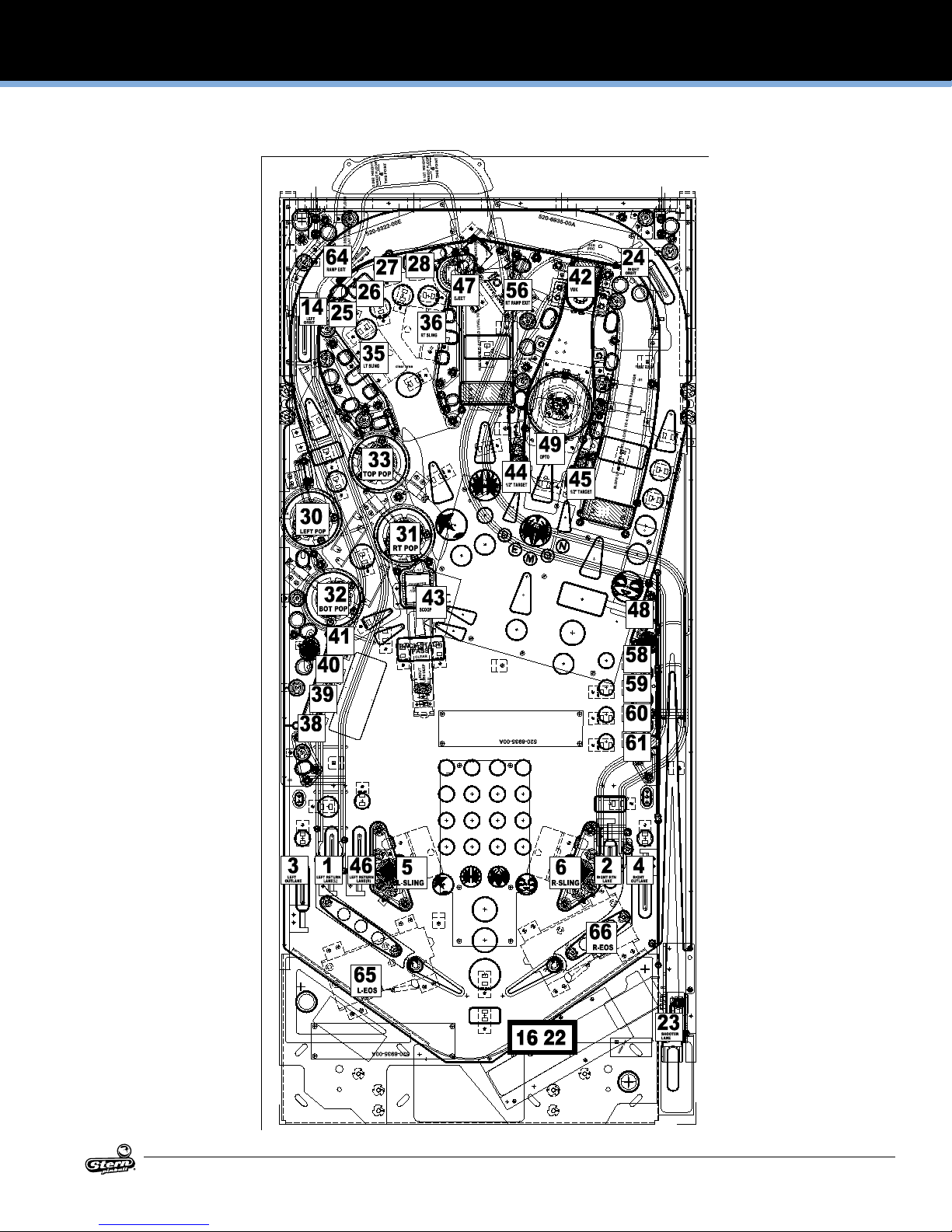

SWITCH REFERENCE CONTINUED

.062

DEEP

BOTTOM

W

.062

DEEP

BOTTOM

W

BD.#11

-13

LIGHT, SWITCH, AND DRIVER REFERENCE

W

BD.#10

-18

-24

-29

W

WHITE

A

WHITE

T

W

WHITE

S

NEW

W

DEEP

ROUT

.125

CLEAR

CLEAR

LITE

BACK STAGE

PASS

COLLECT

INSTRUMENT

ORANGE

WHITE

white

W

W

AMBER

EXTRA BALL

YELLOW

W

KISS ARMY

W

W

YELLOW

LITE

ARMY

LITE

TARGETS

BUMPER

SHOT

AMBER

M SHAPE

WHITE

TOP

.093 DEEP

DEEP

.062

BOTTOM

W

-20

W

.062

DEEP

BOTTOM

W

DEEP

.062

BOTTOM

W

TOP

.093 DEEP

-24

WHITE

R

SUPER

JACKPOT

CLEAR

.070

ROUT

CLEAR

CLEAR

WHITE

YELLOW

ARMY

MILLIONS

WHITE

COLLECT

INSTRUMENT

ORANGE

COLLECT

INSTRUMENT

ORANGE

ORANGE

ADD A BALL

CLEAR

ROCK CITY

CLEAR CLEAR CLEAR

YELLOW YELLOW YELLOW YELLOW

WHITE WHITE WHITE WHITE

ORANGE ORANGE ORANGE ORANGE

WHITE

WHITE

PURPLE FILTER

BLUE FILTER

2X

ORANGE

ORANGE

3X

COLOSSAL

BONUS

CLEAR

RED FILTER

W

W

W

DEEP

LITE

CLEAR

L

O

C

GREEN

K

RED

WHITE

RED

RED

RED

L

O

GREEN

C

K

COLLECT

INSTRUMENT

ORANGE

INSTRUMENT

ORANGE

LITE

L

O

C

K

GREEN

RED

START

WHITE

KISS

MILLION TARGETS

MULTIBALL

PURPLE

COLLECT

-01

CLEAR

W

W

SUPER

JACKPOT

CLEAR

ROUT

DEEP

.070

WHITE

YELLOW

A

YELLOW

DEMON

BUMPER

WHITE

BUMPER

LITE

.125

DEEP

ROUT

CLEAR

LITE

CAT

BUMPER

WHITE

LITE

SPACE

BUMPER

WHITE

LITE

STAR

WHITE

-06

W

R

YELLOW

M

DOUBLE

WHITE

BOTTOM

BOTTOM

W

Y

KISS

-29

RED

TOP

.093 DEEP

-29

W

TOP

.093 DEEP

BD.#9

CLEAR

YELLOW

DEEP

.062

W

WHITE

WHITE

GREEN FILTER

W

DEEP

.062

DEEP

.062

BOTTOM

W

TOP

.093 DEEP

Figure 3.3.2. Playeld switch locations (top view).

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

color bar

ROCK

AMBER

AGAIN

BD.#8

.062

BOTTOM

DEEP

KISS PRO MANUAL #500-55H1-01

13

Page 14

LIGHT, SWITCH, AND DRIVER REFERENCE

SWITCH REFERENCE CONTINUED

Name Node Node

22 Trough Jam 8 8a CN14 - - - - Playeld Opto 8a-SW-15 520-5344-00 tx

23 Shooter Lane 8 - CN6 4 GRY-WHT 3 BLK-GRN Playeld Rollover 8-SW-4 180-5157-01

24 Right Orbit 11 - CN3 9 PNK-VIO 10 BLK-RED Playeld Rollover 11-SW-23 500-9935-03

25 (S)TAR Target 11 - CN7 6 WHT-GRN 10 BLK-VIO Playeld Leaf, Target 11-SW-4 515-9783-00-00

26 S(T)AR Target 11 - CN7 7 WHT-BLU 10 BLK-VIO Playeld Leaf, Target 11-SW-5 515-9783-00-00

27 ST(A)R Target 11 - CN7 8 WHT-VIO 10 BLK-VIO Playeld Leaf, Target 11-SW-6 515-9783-00-00

28 STA(R) Target 11 - CN7 9 WHT-GRY 10 BLK-VIO Playeld Leaf, Target 11-SW-7 515-9783-00-00

30 Left Pop Bumper 9 - CN6 4 LGN-BLK 3 BLK-BRN Playeld Leaf 9-SW-4 180-5232-00

31 Right Pop Bumper 9 - CN8 4 LGN-BRN 3 BLK-BRN Playeld Leaf 9-SW-5 180-5232-00

32 Bottom Pop Bumper 9 - CN10 4 LGN-RED 3 BLK-BRN Playeld Leaf 9-SW-6 180-5232-00

33 Top Pop Bumper 9 - CN12 4 LGN-ORG 3 BLK-BRN Playeld Leaf 9-SW-7 180-5232-00

35 Up Left Sling 9 - CN5 2 LGN-YEL 1 BLK-BRN Playeld Leaf 9-SW-0 180-5231-00

36 Up Right Sling 9 - CN7 2 LGN-BLU 1 BLK-BRN Playeld Leaf 9-SW-1 180-5231-00

38 4 Bank (K)ISS 10 - CN6 4 WHT-BRN 3 BLK-BLU Playeld Leaf, Target 10-SW-4 515-9783-00-00

39 4 Bank K(I)SS 10 - CN8 4 WHT-RED 3 BLK-BLU Playeld Leaf, Target 10-SW-5 515-9783-00-00

40 4 Bank KI(S)S 10 - CN10 4 WHT-ORG 3 BLK-BLU Playeld Leaf, Target 10-SW-6 515-9783-00-00

41 4 Bank KIS(S) 10 - CN12 4 WHT-YEL 3 BLK-BLU Playeld Leaf, Target 10-SW-7 515-9783-00-00

42 Verticual Upkicker 10 - CN7 2 WHT-BLU 1 BLK-BLU Playeld Rollover 10-SW-1 180-5209-00

43 Scoop 10 - CN9 2 WHT-VIO 1 BLK-BLU Playeld Rollover 10-SW-2 180-5057-00

44 Left Lock Target 11 - CN5 2 LGN-BLK 10 BLK-GRY Playeld Leaf, Target 11-SW-8 515-9785-00-00

45 Right Lock Target 11 - CN5 3 LGN-BRN 10 BLK-GRY Playeld Leaf, Target 11-SW-9 515-9785-00-00

46 Left Return Lane (R) 11 - CN7 4 WHT-ORG 10 BLK-VIO Playeld Rollover 11-SW-2 500-9935-04

47 Eject 10 - CN5 2 WHT-GRN 1 BLK-BLU Playeld Micro 10-SW-0 180-5186-01

48 Spinner 10 - CN11 1 WHT-GRY 1 BLK-BLU Playeld Micro 10-SW-3 180-5010-04

49 Demon Entrance Opto 11 - CN5 4 LGN-RED 10 BLK-GRY Playeld Opto 11-SW-10 515-0215-00 tx

56 Right Ramp Exit 11 - CN3 7 PNK-GRN 10 BLK-RED Playeld Micro 11-SW-21 180-5087-00

58 (A)RMY Target 11 - CN1 2 TAN-BLK 10 BLK-ORG Playeld Leaf, Target 11-SW-24 515-9783-00-00

59 A(R)MY Target 11 - CN1 3 TAN-RED 10 BLK-ORG Playeld Leaf, Target 11-SW-25 515-9783-00-00

60 AR(M)Y Target 11 - CN1 4 TAN-ORG 10 BLK-ORG Playeld Leaf, Target 11-SW-26 515-9783-00-00

61 ARM(Y) Target 11 62 Start Button 1 - CN6 10 GRY 5 BLK-WHT Cabinet Micro 1-SW-11 500-6388-44-

64 Left Ramp Exit 11 - CN3 3 PNK-BRN 10 BLK-RED Playeld Micro 11-SW-17 180-5087-00

65 Left Flipper EOS 8 - CN5 2 GRY-YEL 1 BLK-GRN Playeld Leaf 8-SW-0 180-5149-00

66 Right Flipper EOS 8 - CN7 2 GRY-GRN 1 BLK-GRN Playeld Leaf 8-SW-1 180-5149-00

67 Left Coin 1 - CN5 9 PNK-BRN 3 BLK Cabinet Micro 1-SW-16

68 Right Coin 1 - CN5 8 PNK-RED 3 BLK Cabinet Micro 1-SW-18

69 Center Coin 1 - CN5 7 PNK-ORG 3 BLK Cabinet Micro 1-SW-17

70 Fourth Coin 1 - CN5 6 - - - Cabinet - 1-SW-19

71 Fifth Coin 1 - CN5 5 - - - Cabinet - 1-SW-20

72 Tilt Pendulum 1 - CN6 7 WHT 5 BLK-WHT Cabinet Plumb Bob 1-SW-14

-

73 Launch Button (Re

served)

76 Ticket Notch 1 - CN11 5 - - - Cabinet - 1-SW-8

77 Slam Tilt 1 - CN5 4 LGN-RED 3 BLK Cabinet - 1-SW-21

C1 DIP 1 0 - - - - - - CPU Node 0-SW-0 C2 DIP 2 0 - - - - - - CPU Node 0-SW-2 C3 DIP 3 0 - - - - - - CPU Node 0-SW-3 C4 DIP 4 0 - - - - - - CPU Node 0-SW-4 C5 DIP 5 0 - - - - - - CPU Node 0-SW-5 -

1 - CN7 8 PNK-BLU 5 BLK Cabinet Micro 1-SW-2

Conn. Input

Ext

CN1 5 TAN-YEL 10 BLK-ORG Playeld Leaf, Target 11-SW-27 515-9783-00-00

Input Wire GND

Pin

Pin

Ground

Wire

Location Type Address Part Number

520-5345-01 rx

515-0215-01 rx

LED

Continued on next page...

14

KISS PRO MANUAL #500-55H1-01

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

Page 15

SWITCH REFERENCE CONTINUED

LIGHT, SWITCH, AND DRIVER REFERENCE

Name Node Node

C6 DIP 6 0 - - - - - - CPU Node 0-SW-6 -

C7 DIP 7 0 - - - - - - CPU Node 0-SW-7 -

C8 DIP 8 0 - - - - - - CPU Node 0-SW-8 -

C9 Service Select 0 - CN25 1 LGN-GRY 11 BLK-WHT Coin Door 0-SW-9 180-5192-04

C10 Service Plus 0 - CN25 2 LGN-VIO 11 BLK-WHT Coin Door 0-SW-10 180-5192-02

C11 Service Minus 0 - CN25 3 LGN-BLU 11 BLK-WHT Coin Door 0-SW-11 180-5192-02

C12 Service Back 0 - CN25 4 LGN-BLK 11 BLK-WHT Coin Door 0-SW-12 180-5192-00

C16 Power Interlock Sense 0 - CN7 4 GRY-RED 1 BLK Cabinet Interlock 0-SW-16 180-5136-00

Ext

Conn. Input

Pin

Input Wire GND

Pin

Ground

Wire

Location Type Address Part Number

3.4 LIGHT REFERENCE

ID Name Node Node

1 Start Button 1 - CN6 3 YEL BRN 1 RED Cabinet Feature White 1-LP-2 112-5033-08

2 Tournament Button 1 - CN6 2 YEL RED 1 RED Cabinet Feature White 1-LP-3 112-5033-08

6 Left Outlane 11 - CN8 8 BRN GRN 2/3 RED Playeld Feature White 11-LP-28 520-5307-00

7 Left Return Lane L 11 - CN8 9 BRN BLU 2/3 RED Playeld Feature White 11-LP-29 520-5307-00

8 Left Return Lane R 11 - CN8 10 BRN VIO 2/3 RED Playeld Feature White 11-LP-30 520-5307-00

9 Bonus (K)ISS 9 9a CN14 - - - - Playeld Feature White 9a-LP-39 520-6969-00

10 Bonus K(I)SS 9 9a CN14 - - - - Playeld Feature White 9a-LP-36 520-6969-00

11 Bonus KI(S)S 9 9a CN14 - - - - Playeld Feature White 9a-LP-27 520-6969-00

12 Bonus KIS(S) 9 9a CN14 - - - - Playeld Feature White 9a-LP-30 520-6969-00

13 Bonus (A)RMY 9 9a CN14 - - - - Playeld Feature White 9a-LP-45 520-6969-00

14 Bonus A(R)MY 9 9a CN14 - - - - Playeld Feature White 9a-LP-33 520-6969-00

15 Bonus AR(M)Y 9 9a CN14 - - - - Playeld Feature White 9a-LP-24 520-6969-00

16 Bonus ARM(Y) 9 9a CN14 - - - - Playeld Feature White 9a-LP-21 520-6969-00

17 Bonus Pop Starchild 9 9a CN14 - - - - Playeld Feature White 9a-LP-48 520-6969-00

18 Bonus Pop Spaceman 9 9a CN14 - - - - Playeld Feature White 9a-LP-42 520-6969-00

19 Bonus Pop Demon 9 9a CN14 - - - - Playeld Feature White 9a-LP-18 520-6969-00

20 Bonus Pop Catman 9 9a CN14 - - - - Playeld Feature White 9a-LP-15 520-6969-00

21 Bonus Inst Starchild 9 9a CN14 - - - - Playeld Feature White 9a-LP-54 520-6969-00

22 Bonus Inst Spaceman 9 9a CN14 - - - - Playeld Feature White 9a-LP-51 520-6969-00

23 Bonus Inst Demon 9 9a CN14 - - - - Playeld Feature White 9a-LP-9 520-6969-00

24 Bonus Inst Catman 9 9a CN14 - - - - Playeld Feature White 9a-LP-12 520-6969-00

25 Bonus Starchild 9 9a CN14 - - - - Playeld Feature White 9a-LP-61 520-6969-00

26 Bonus Spaceman 9 9a CN14 - - - - Playeld Feature White 9a-LP-58 520-6969-00

27 Bonus Demon 9 9a CN14 - - - - Playeld Feature White 9a-LP-57 520-6969-00

28 Bonus Catman 9 9a CN14 - - - - Playeld Feature White 9a-LP-56 520-6969-00

29 Bonus 2X 9 9a CN14 - - - - Playeld Feature White 9a-LP-59 520-6969-00

30 Bonus 3X 9 9a CN14 - - - - Playeld Feature White 9a-LP-60 520-6969-00

31 Bonus Colossal 9

32 Rock Again 9 9a 9a-CN3 3 ORG YEL 4 RED Playeld Feature White 9a-LP-63 520-5307-00

33 Right Return Lane 10 10a 10a-CN8 4 BRN YEL 8 RED Playeld Feature White 10-LP-61 520-5307-00

34 Right Outlane 10 10a 10a-CN8 5 BRN GRN 8 RED Playeld Feature White 10-LP-62 520-5307-00

35 (K)ISS 11 - CN8 4 BRN BLK 2/3 RED Playeld Feature White 11-LP-24 520-5307-00

36 K(I)SS 11 - CN8 5 BRN RED 2/3 RED Playeld Feature White 11-LP-25 520-5307-00

37 KI(S)S 11 - CN8 6 BRN ORG 2/3 RED Playeld Feature White 11-LP-26 520-5307-00

38 KIS(S) 11 - CN8 7 BRN YEL 2/3 RED Playeld Feature White 11-LP-27 520-5307-00

39 Extra Ball 11 - CN6 10 ORG BLU 2/3 RED Playeld Feature White 11-LP-22 520-5307-00

40 KISS Army 11 - CN6 11 ORG VIO 2/3 RED Playeld Feature White 11-LP-23 520-5307-00

41 Backstage Pass LT 11 - CN4 10 ORG BLK 2/3 RED Playeld Feature White 11-LP-14 520-5307-00

42 Backstage Pass RT 11 - CN4 11 ORG BRN 2/3 RED Playeld Feature White 11-LP-15 520-5307-00

Conn. Ret.

Ext.

9a 9a-CN3 2 ORG RED 4 RED Playeld Feature White 9a-LP-62 520-5307-00

Ret. Wire Src.

Pin

Pin

Src.

Location Type Light

Wire

Color

Address Part Number

Continued on next page...

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

KISS PRO MANUAL #500-55H1-01

15

Page 16

LIGHT, SWITCH, AND DRIVER REFERENCE

color bar

DEEP

ROUT

.125

DEEP

.125

ROUT

DEEP

ROUT

DEEP

.062

BOTTOM

TOP

.093 DEEP

.093 DEEP

TOP

BOTTOM

DEEP

.062

.062

DEEP

BOTTOM

TOP

.093 DEEP

.062

DEEP

BOTTOM

.062

DEEP

BOTTOM

.062

DEEP

BOTTOM

-20

M SHAPE

.093 DEEP

TOP

.093 DEEP

TOP

ROUT

.070

CAT

STAR

BUMPER

LITE

BUMPER

DEMON

LITE

BUMPER

SPACE

LITE

BUMPER

LITE

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

.070

DEEP

S

T

A

R

RED

AMBER

WHITE

GREEN FILTER

WHITE

PURPLE FILTER

WHITE

RED FILTER

WHITE

BLUE FILTER

YELLOW

CLEAR CLEAR CLEAR

WHITE

WHITE

CLEAR

CLEAR

RED

RED

RED

RED

RED

GREEN

GREEN

GREEN

CLEAR

ROCK

AGAIN

WHITE

WHITE

WHITE

WHITE

WHITE

CLEAR

A

CLEAR

CLEAR

YELLOW

ARMY

MILLIONS

WHITE

START

KISS

MILLION TARGETS

JACKPOT

JACKPOT

WHITE

WHITE

WHITE

WHITE

CLEAR

WHITE

DOUBLE

KISS

LITE

SHOT

WHITE

AMBER

BUMPER

A

R

M

Y

WHITE

SUPER

SUPER

YELLOW YELLOW YELLOW YELLOW

WHITE

LITE

TARGETS

ARMY

ORANGE

INSTRUMENT

COLLECT

ORANGE

INSTRUMENT

COLLECT

ORANGE

INSTRUMENT

COLLECT

LITE

L

O

C

K

LITE

L

O

C

K

CLEAR

CLEAR

CLEAR

.062

BOTTOM

DEEP

L

O

C

K

-29

-29

-06

-24

-24

NEW

-01

-29

-13

COLOSSAL

R

M

BACK STAGE

.062

DEEP

BOTTOM

.062

DEEP

BOTTOM

CLEAR

2X

3X

BONUS

Y

YELLOW

LITE

PASS

ADD A BALL

ORANGE

EXTRA BALL

AMBER

ROCK CITY

CLEAR

KISS ARMY

YELLOW

WHITE WHITE WHITE WHITE

ORANGE ORANGE ORANGE ORANGE

-18

W

W

W

W

W

W

W

W

W

INSTRUMENT

COLLECT

MULTIBALL

white

ORANGE

INSTRUMENT

COLLECT

YELLOW

YELLOW

YELLOW

ORANGE

ORANGE

PURPLE

ORANGE

BD.#10

BD.#9

BD.#8

BD.#11

LIGHT REFERENCE CONTINUED

16

KISS PRO MANUAL #500-55H1-01

Continued on next page

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

Page 17

LIGHT REFERENCE CONTINUED

LIGHT, SWITCH, AND DRIVER REFERENCE

ID Name Node Node

43 Rock City 10 10a CN14 - - - - Playeld Feature White 10-LP-15 520-6970-00

44 New Track 10 10a CN14 - - - - Playeld Feature White 10-LP-17 520-6970-00

46 BOT Pop bumper-RED 11 - CN4 4 RED YEL 2/3 RED Playeld Feature Red 11-LP-8 520-6971-00

47 BOT Pop bumper-GRN 11 - CN4 5 GRN YEL 2/3 RED Playeld Feature Green 11-LP-9 520-6971-00

48 BOT Pop bumper-BLU 11 - CN4 6 BLU YEL 2/3 RED Playeld Feature Blue 11-LP-10 520-6971-00

49 LT Pop bumper-RED 11 - CN2 4 RED BRN 2/3 RED Playeld Feature Red 11-LP-0 520-6971-00

50 LT Pop bumper-GRN 11 - CN2 5 GRN BRN 2/3 RED Playeld Feature Green 11-LP-1 520-6971-00

51 LT Pop bumper-BLU 11 - CN2 6 BLU BRN 2/3 RED Playeld Feature Blue 11-LP-2 520-6971-00

52 TOP Pop bumper-RED 11 - CN4 7 RED GRN 2/3 RED Playeld Feature Red 11-LP-11 520-6971-00

53 TOP Pop bumper-GRN 11 - CN4 8 GRN 2/3 RED Playeld Feature Green 11-LP-12 520-6971-00

54 TOP Pop bumper-BLU 11 - CN4 9 BLU GRN 2/3 RED Playeld Feature Blue 11-LP-13 520-6971-00

55 RT Pop bumper-RED 11 - CN2 7 RED ORG 2/3 RED Playeld Feature Red 11-LP-3 520-6971-00

56 RT Pop bumper-GRN 11 - CN2 8 GRN ORG 2/3 RED Playeld Feature Green 11-LP-4 520-6971-00

57 RT Pop bumper-BLU 11 - CN2 9 BLU ORG 2/3 RED Playeld Feature Blue 11-LP-5 520-6971-00

58 LT Orbit Arrow-RED 11 - CN6 4 RED GRY 2/3 RED Playeld Feature Red 11-LP-16 520-5333-00

59 LT Orbit Arrow-GRN 11 - CN6 5 GRN GRY 2/3 RED Playeld Feature Green 11-LP-17 520-5333-00

60 LT Orbit Arrow-BLU 11 - CN6 6 BLU GRY 2/3 RED Playeld Feature Blue 11-LP-18 520-5333-00

61 Super Bumpers 11 - CN6 7 ORG RED 2/3 RED Playeld Feature White 11-LP-19 520-5307-00

62 Collect Catman Inst 11 - CN6 8 ORG YEL 2/3 RED Playeld Feature White 11-LP-20 520-5307-00

64 (S)TAR 9 - CN6 1 ORG BLK 2 YEL Playeld Feature White 9-LP-0 520-5307-00

65 S(T)AR 9 - CN8 1 ORG BRN 2 YEL Playeld Feature White 9-LP-1 520-5307-00

66 ST(A)R 9 - CN10 1 ORG RED 2 YEL Playeld Feature White 9-LP-2 520-5307-00

67 STA(R) 9 - CN12 1 ORG YEL 2 YEL Playeld Feature White 9-LP-3 520-5307-00

68 Starchild Arrow-RED 10 10a 10a-CN7 7 RED BLU 10 RED Playeld Feature Red 10-LP-49 520-5333-00

69 Starchild Arrow-GRN 10 10a 10a-CN7 8 GRN BLU 10 RED Playeld Feature Green 10-LP-50 520-5333-00

70 Starchild Arrow-BLU 10 10a 10a-CN7 9 BLU 10 RED Playeld Feature Blue 10-LP-51 520-5333-00

71 Starchild 10 10a CN14 - - - - Playeld Feature White 10-LP-21 520-6970-00

72 Collect Starchild Inst 10

73 LT Ramp Arrow-RED 10 10a 10a-CN7 4 RED VIO 10 RED Playeld Feature Red 10-LP-46 520-5333-00

74 LT Ramp Arrow-GRN 10 10a 10a-CN7 5 GRN VIO 10 RED Playeld Feature Green 10-LP-47 520-5333-00

75 LT Ramp Arrow-BLU 10 10a 10a-CN7 6 BLU VIO 10 RED Playeld Feature Blue 10-LP-48 520-5333-00

76 Spaceman 10 10a CN14 - - - - Playeld Feature White 10-LP-19 520-6970-00

77 ARMY 10 10a CN14 - - - - Playeld Feature White 10-LP-20 520-6970-00

78 Collect Spaceman Inst 10 10a CN14 - - - - Playeld Feature White 10-LP-22 520-6970-00

79 Demon Arrow-RED 10 10a 10a-CN7 1 RED GRY 10 RED Playeld Feature Red 10-LP-43 520-5333-00

80 Demon Arrow-GRN 10 10a 10a-CN7 2 GRN GRY 10 RED Playeld Feature Green 10-LP-44 520-5333-00

81 Demon Arrow-BLU 10 10a 10a-CN7 3 BLU GRY 10 RED Playeld Feature Blue 10-LP-45 520-5333-00

82 LT Lock target 10 10a CN14 - - - - Playeld Feature White 10-LP-29 520-6970-00

83 Demon 10 10a CN14 - - - - Playeld Feature White 10-LP-27 520-6970-00

84 RT Lock target 10 10a CN14 - - - - Playeld Feature White 10-LP-26 520-6970-00

85 (D)EMON 10 10a CN14 - - - - Playeld Feature White 10-LP-30 520-6970-00

86 D(E)MON 10 10a CN14 - - - - Playeld Feature White 10-LP-31 520-6970-00

87 DE(M)ON 10 10a CN14 - - - - Playeld Feature White 10-LP-28 520-6970-00

88 DEM(O)N 10 10a CN14 - - - - Playeld Feature White 10-LP-24 520-6970-00

89 DEMO(N) 10 10a CN14 - - - - Playeld Feature White 10-LP-25 520-6970-00

90 LOCK 10 10a CN14 - - - - Playeld Feature White 10-LP-18 520-6970-00

91 Collect Demon Inst. 10 10a CN14 - - - - Playeld Feature White 10-LP-14 520-6970-00

92 RT Ramp Arrow-RED 10 10a CN14 - - - - Playeld Feature Red 10-LP-32 520-6970-00

93 RT Ramp Arrow-GRN 10 10a CN14 - - - - Playeld Feature Green 10-LP-33 520-6970-00

94 RT Ramp Arrow-BLU 10 10a CN14 - - - - Playeld Feature Blue 10-LP-34 520-6970-00

95 Super Targets 10 10a CN14 - - - - Playeld Feature White 10-LP-16 520-6970-00

Conn. Ret.

Ext.

10a CN14 - - - - Playeld Feature White 10-LP-23 520-6970-00

Ret. Wire Src.

Pin

Pin

Src.

Location Type Light

Wire

Color

Address Part Number

Continued on next page

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

KISS PRO MANUAL #500-55H1-01

17

Page 18

LIGHT, SWITCH, AND DRIVER REFERENCE

LIGHT REFERENCE CONTINUED

ID Name Node Node

96 LOVE GUN 10 10a CN14 - - - - Playeld Feature White 10-LP-8 520-6970-00

97 Lite Inst. RT ramp 10 10a CN14 - - - - Playeld Feature White 10-LP-13 520-6970-00

98 RT Orbit Arrow-RED 10 10a 10a-CN6 1 RED WHT 8 RED Playeld Feature Red 10-LP-52 520-5333-00

99 RT Orbit Arrow-GRN 10 10a 10a-CN6 2 GRN WHT 8 RED Playeld Feature Green 10-LP-53 520-5333-00

100 RT Orbit Arrow-BLU 10 10a 10a-CN6 3 BLU WHT 8 RED Playeld Feature Blue 10-LP-54 520-5333-00

101 RT Orbit Catman 10 10a 10a-CN6 4 ORG GRY 8 RED Playeld Feature White 10-LP-55 520-5307-00

102 RT Orbit Spaceman 10 10a 10a-CN6 5 ORG WHT 8 RED Playeld Feature White 10-LP-56 520-5307-00

103 RT Orbit Starchild 10 10a CN14 - - - - Playeld Feature White 10-LP-11 520-6970-00

104 RT Orbit Demon 10 10a CN14 - - - - Playeld Feature White 10-LP-10 520-6970-00

105 Catman 10 10a CN14 - - - - Playeld Feature White 10-LP-9 520-6970-00

106 (A)RMY 10 10a CN14 - - - - Playeld Feature White 10-LP-12 520-6970-00

107 A(R)MY 10 10a 10a-CN8 1 BRN BLK 8 RED Playeld Feature White 10-LP-58 520-5307-00

108 AR(M)Y 10 10a 10a-CN8 2 BRN RED 8 RED Playeld Feature White 10-LP-59 520-5307-00

109 ARM(Y) 10 10a 10a-CN8 3 BRN ORG 8 RED Playeld Feature White 10-LP-60 520-5307-00

113 Sling Flash 10 10a 10a-CN8 6 YEL GRN 8 RED Playeld Flash White 10-LP-63 520-6785-00

114 Mid Pd Flash Left 11 - CN8 11 YEL BLK 2/3 RED Playeld Flash White 11-LP-31 520-6785-00

115 Pop ash 11 - CN6 9 ORG GRN 2/3 RED Playeld Flash White 11-LP-21 520-6785-00

116 STAR Flash 10 10a 10a-CN4 2 YEL BRN 5 RED Playeld Flash White 10-LP-36 520-6785-00

117 Paul Flash 10 10a 10a-CN4 1 YEL RED 5 RED Playeld Flash White 10-LP-35 113-5032-08

118 Left Ramp Flash 10 10a 10a-CN4 3 ORG GRN 5 RED Playeld Flash White 10-LP-37 520-6785-00

120 Mid Plfd Flash Rt 11 - CN2 11 YEL VIO 2/3 RED Playeld Flash White 11-LP-7

121 Gene Flash 10 10a 10a-CN4 4 YEL ORG 5 RED Playeld Flash White 10-LP-38 113-5032-08

122 Right Ramp Flash 10 10a 10a-CN6 6 ORG BLU 8 RED Playeld Flash White 10-LP-57 520-6785-00

123 Backpanel Flash 1 L 10 - CN6 1 YEL BLK 2 YEL Back Pnl Flash White 10-LP-0 520-6785-00

124 Backpanel Flash 2 10 - CN8 1 YEL BRN 2 YEL Back Pnl Flash White 10-LP-1 520-6785-00

125 Backpanel Flash 3 10 - CN10 1 YEL RED 2 YEL Back Pnl Flash White 10-LP-2 520-6785-00

126 Backpanel Flash 4 R 10 - CN12 1 YEL ORG 2 YEL Back Pnl Flash White 10-LP-3 520-6785-00

132 Coin Door GI(x2) 1 -

133 Pd GI White Lower 8 - CN13 1 WHT BLK 3 YEL

134 Pd GI White Mid 9 - CN13 1 RED BLK 3 YEL

135 Pd GI White Upper 10 - CN13 1 BLU BLK 3 YEL

136 Coin Enable 1

Conn. Ret.

Ext.

CN5 2 YEL 1 YEL

Ret. Wire Src.

Pin

BLK GRY 2 GRY

- CN8 6

Src.

Pin

Wire

WHT

BLK

RED

BLU

RED Coin Door

Location Type Light

Coin Door G.I. White 1-LP-1 112-5033-08

Playeld G.I. White 8-LP-4 112-5034-08

Playeld G.I. Red 9-LP-4 112-5034-08

Playeld/

Back Pnl

G.I. Blue 10-LP-4 112-5034-08

Color

Address Part Number

Digital

Out 1-LP-0

18

KISS PRO MANUAL #500-55H1-01

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

Page 19

D30D29D28

D13

SDA

RST

GND

SCL

RESET

CN18

LINE

OUT

TxD

NETSTAT

STATUS

RxD

5V

48V

24V

9V

S1

+48V

CN23

1

1

CN20

POWER

HEADPHONE

CN25

IN

L+ L-

C+ C-

R+ R-

CN21

CN7

CN3 CN22

CN4

CN1

CN24

520-6936-00A

SPIKE CPU

1

1

1

1

BT1

AMPLIFIED AUDIO

OUT

SPIKE NODE BUS

USB

SD CARD

BATTERY

DIP S2

ELECTRONIC PINOUTS AND SCHEMATICS

4. ELECTRONIC PINOUTS AND SCHEMATICS

4.1 SPIKE CPU NODE 0

520-6936-00

AUDIO PINOUTS

ID Type Pin Description Minimum

CN18 TRS 3.5mm

Headphone

Jack

CN1 .156" 5-pin

Header

Tip Headphone Left 8 Ohms 200mW

Ring Headphone Right 8 Ohms 200mW

Sleeve Audio Ground - 1 Speaker Right Ground

(-)

2 Speaker Right (+) 4 Ohms 20W

3 n/c - -

4 Speaker Left Ground

(-)

5 Speaker Left (+) 4 Ohms 20W

CN4 .156" 2-pin

Header

CN27 .100" 3-pin

header

1 Woofer Ground (-) 8 Ohms 2 Woofer Out (+) 8 Ohms 40W

1 Line Out Left (+) 600 Ohms -

2 Line Out Ground - -

3 Line Out Right (-) 600 Ohms -

Figure 3.4.3. Audio Pinouts

CONNECTORS

ID Connector Type Description

CN1 5-Pin .156” Header Backbox 2-channel amplied speaker out

CN3 RJ45 SPIKE node bus - to cabinet node N1

CN4 2-Pin .156” Cabinet 1-channel amplied speaker out

CN7 5-Pin .156” Header 48V supply from main power supply

CN18 3.5mm Stereo TRS jack Headphone Jack

CN20 USB USB connector - for software updates,

audit dumps, and expansion modules

CN21 USB USB connector - for software updates,

audit dumps, and expansion modules

CN22 RJ45 SPIKE node bus - to playeld node, N8

CN23 14-Pin .100” Header Dot matrix display connector

CN24 4-Pin .156” Header 5V DC and ground out to the LED display

CN25 12-Pin .100” Header Dedicated switch inputs - service, volume

switches

COMPONENTS

ID Name

S1 Resetv Switch

S2 DIP Switches

SD CARD For system SD card. Note: only to be removed if instructed to by

Stern Service.

BT1 CR232 3V Lithium battery for game clock between power cycles

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

Impedance

Power

(RMS)

4 Ohms -

4 Ohms -

COUNTRY CODES (DIP S2)

Figure 3.4.2. Country code DIP switch settings.

KISS PRO MANUAL #500-55H1-01

Max

Figure 3.4.1. SPIKE CPU Node connector detail.

DIP S2

Country 1 2 3 4 5 6 7 8

USA OFF OFF OFF OFF OFF OFF OFF OFF

Austria ON OFF OFF OFF OFF OFF OFF OFF

Australia ON OFF ON ON OFF OFF OFF OFF

Belgium OFF ON OFF OFF OFF OFF OFF OFF

Canada 1 ON ON OFF OFF OFF OFF OFF OFF

Canada 2 OFF ON OFF ON ON OFF OFF OFF

Croatia OFF ON ON OFF ON OFF OFF OFF

Denmark ON OFF OFF ON OFF OFF OFF OFF

Finland ON OFF ON OFF OFF OFF OFF OFF

France OFF ON ON OFF OFF OFF OFF OFF

Germany ON ON ON OFF OFF OFF OFF OFF

Greece ON ON ON ON OFF OFF OFF OFF

Italy OFF OFF OFF ON OFF OFF OFF OFF

Japan ON OFF ON OFF ON OFF OFF OFF

Middle East ON ON ON OFF ON OFF OFF OFF

Netherlands OFF OFF ON OFF OFF OFF OFF OFF

New Zealand OFF OFF OFF OFF ON OFF OFF OFF

Norway OFF ON OFF ON OFF OFF OFF OFF

Portugal ON OFF OFF OFF OFF ON OFF OFF

Russia ON OFF OFF ON ON OFF OFF OFF

S. Africa OFF OFF ON OFF ON OFF OFF OFF

Spain OFF ON OFF OFF ON OFF OFF OFF

Sweden ON ON OFF ON OFF OFF OFF OFF

Switzerland OFF OFF ON ON OFF OFF OFF OFF

Taiwan OFF OFF OFF ON ON OFF OFF OFF

United Kingdom OFF ON ON ON OFF OFF OFF OFF

19

Page 20

ELECTRONIC PINOUTS AND SCHEMATICS

SPIKE CPU NODE 0 CONTINUED

STATUS LEDS

LED ID Name Color Description

48V +48V Supply In Red ON: Main system power is connected, OFF: No 48V system power. Check power supply

24V +24V Audio Power Red ON: Audio power supply is good, OFF: Audio power supply off, call tech support.

9V +9V Node Bus Power Red ON: Node bus power supply is good, OFF: Node bus power supply bad, call tech support.

5V Red ON: Logic power supply is good. OFF: Logic power supply bad, call tech support.

TxD Node bus transmit Red Node bus transmit activity

RxD Node bus receive Red Node bus receive activity

Status System status Red Constant double blink - game software running

Netstat Network status Red Communication bridge activity

DIRECT SWITCH MAPPING (CN25)

The coin-door diagnostic switches are connected directly to the CPU node via the Cabinet Node. Note that both the CPU and

Cabinet nodes are required for diagnostic switch operation.

connections, cables, and fuses.

ID Name Conn. Input

C1 DIP 1 - - - - - CPU Node 0-SW-0 C2 DIP 2 - - - - - CPU Node 0-SW-2 C3 DIP 3 - - - - - CPU Node 0-SW-3 C4 DIP 4 - - - - - CPU Node 0-SW-4 C5 DIP 5 - - - - - CPU Node 0-SW-5 C6 DIP 6 - - - - - CPU Node 0-SW-6 C7 DIP 7 - - - - - CPU Node 0-SW-7 C8 DIP 8 - - - - - CPU Node 0-SW-8 C9 Service Select CN25 1 LGN-GRY 11 BLK-WHT Coin Door 0-SW-9 180-5192-04

C10 Service Plus CN25 2 LGN-VIO 11 BLK-WHT Coin Door 0-SW-10 180-5192-02

C11 Service Minus CN25 3 LGN-BLU 11 BLK-WHT Coin Door 0-SW-11 180-5192-02

C12 Service Back CN25 4 LGN-BLK 11 BLK-WHT Coin Door 0-SW-12 180-5192-00

C16 Playeld Power Interlock CN7 4 GRY 5 GRY-RED Cabinet Interlock 0-SW-16 180-5136-00

Pin

Input Wire GND

Pin

Ground Wire Location Type Address Part Number

COIN DOOR SERVICE SWITCH WIRING

Figure 4.1.1. Service switch wiring. Note that the Cabient Node must be present and CN10 and CN12 connected for the Coin Door

Service Switches to function correctly.

20

KISS PRO MANUAL #500-55H1-01

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

Page 21

4.2 NODE 1 CABINET

ELECTRONIC PINOUTS AND SCHEMATICS

520-5319-00

ID Type Pin Description Wire Color

CN2 .156" 5-Pin

Header

Shaker Motor

CN3 .100" 3-Pin

Header

Meter 1

CN4 .100" 3-Pin

Header

Meter 2

CN5 .100" 9-Pin

Header

CN6 .100" 14-Pin

Header

Cabinet Left

CN7 .100" 12-Pin

Header

Cabinet Right

CN9 .100" 6-Pin

Header

Dollar Bill Acceptor

1 Shaker Motor (-) BLU

2 Shaker Motor (-) -

3 Shaker Motor (+) -

4 Key Key

5 Shaker Motor (+) RED

1 Meter 12V (+) RED

2 Meter (-) BLK

3 N/C -

1 Meter 12V (+) RED

2 Meter (-) BLK

3 N/C -

1 5V Out YEL-WHT

2 Coin LED Out YEL

3 Ground BLK

4 Slam Tilt In LGN-RED

5 Coin 5 PNK-GRN*

6 Coin 4 PNK-YEL*

7 Coin 3 PNK-ORN*

8 Coin 2 PNK-RED*

9 Coin 1 PNK-BRN*

1 5V LED Power RED

2 Start 2 LED YEL-RED

3 Start 1 LED YEL-BRN

4 Spare LED 5 Ground BLK-WHT

6 Spare Left -

7 Tilt Input WHT

8 Door Open -

9 Start 2 Switch GRY-WHT

10 Start 1 Switch GRY

11 N/C 12 N/C 13 N/C 14 N/C 1 5V LED Power -

2 Plunge 2 LED -

3 Plunge 1 LED -

4 Spare LED 2 5 Ground 6 Spare Right In -

7 Plunge 2 Switch -

8 Plunge 1 Switch -

9 N/C -

10 N/C 11 N/C 12 N/C 1 Coin Enable/DBA Inhibit (-) -

2 Coin Enable/DBA Inhibit (+) -

3 Key Key

4 DBA 12V 5 Coin 6 / DBA Credit 6 Ground -

CN13

1

1

CN9

DBA

TICKET

CN11

1

CABINET LEFT

FLIPPER

INPUTSLEDS

CN6

1

CN5

CN10

COIN DOOR

1

MENU BUTTONS

1

CN3

CN8

METER 1

1

CN1

METER 2

CN4

1

520-5319-00F

Cabinet Node

CABINET RIGHT

CN7

FLIPPER

INPUTS LEDS

SHAKER MOTOR

1

ID Type Pin Description Wire Color

CN10 .100" 6-Pin

Header

Service Switch In

1 Service Back (To Coindoor) LGN-BLK

2 Service Down (To Coindoor) LGN-BLU

3 Service Up (To Coindoor) LGN-VIO

4 Service Select (To Coindoor) LGN-GRY

5 Key Key

6 Service Ground (To Coindoor) BLK

CN11 .100" 5-Pin

Header

Ticket Dispenser

1 12V RED

2 N/C -

3 Ticket Dispenser Enable WHT

4 Ground BLK

5 Ticket Dispenser Notch BLU

CN12 .100" 10-Pin

Header

CPU Direct

Switches

1 Service Back (To CPU) LGN-BLK

2 Service Down (To CPU) LGN-BLU

3 Service Up (To CPU) LGN-VIO

4 Service Select (To CPU) LGN-GRY

5 Power Present LGN-ORG

6 Service Ground (To CPU) BLK-WHT

7 N-C -

8 N/C -

9 N/C -

10 N/C -

-

CN14 .156" 5-Pin Head

er Power Input

1 Ground BLK

2 Key Key

3 N/C -

4 N/C 5 48VDC In GRY-YEL

*Varies by country model

CN12

TO CPU

3A 125V

TIME LAG FUSE

CN14

1

CN2

1

POWER

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

KISS PRO MANUAL #500-55H1-01

21

Page 22

ELECTRONIC PINOUTS AND SCHEMATICS

4.3 LOWER PLAYFIELD 48V 8-DRIVER PINOUT NODE 8

520-6935-00

CN3

CN2

ID Type Pin Description Wire Color

SW1 Address DIP - Node 8 - OFF-OFF-OFF-OFF CN2 RJ45 - SPIKE Node Bus n/a

CN3 RJ45 - SPIKE Node Bus Multi

CN4 .156" 5-Pin

Header Node

Power

CN5 .156" 4-Pin

Header (White)

CN6 .156" 6-Pin

Header (White)

CN7 .156" 4-Pin

Header (Black)

CN8 .156" 6-Pin

Header (Black)

CN9 .156" 4-Pin

Header (Orange)

CN13

520-6935-00

CN1

8-Driver Node

CN14

CN12 CN10

GREEN ORANGE NEUTRALBLACK

1 Ground BLK

2 Key Key

3 N/C -

4 N/C 5 48VDC In GRY

1 Switch Ground BLK-GRN

2 8-SW-0 Switch Return GRY-YEL

3 8-DR-0 Driver Return ORG-YEL

4 48V Driver Power GRY-ORG

1 8-LP-0 Light Return -

2 LED V+ -

3 Switch Ground BLK-GRN

4 8-SW-4 Switch Return GRY-WHT

5 8-DR-4 Driver Return ORG-WHT

6 48V Driver Power GRY-ORG

1 Switch Ground BLK-GRN

2 8-SW-1 Switch GRY-GRN

3 8-DR-1 Driver Return ORG-GRN

4 48V Driver Power GRY-ORG

1 8-LP-1 Light Return -

2 LED V+ -

3 Switch Ground -

4 8-SW-5 5 8-DR-5 Driver Return ORG-GRY

6 48V Driver Power GRY-ORG

1 Switch Ground BLK-GRN

2 8-SW-2 Switch GRY-BRN

3 8-DR-2 Driver Return YEL-ORG

4 48V Driver Power -

GREEN ORANGE NEUTRALBLACK

CN9

ON

1 2 3 4

CN10 .156" 6-Pin

Header (Orange)

CN11 .156" 4-Pin

Header (Green)

CN12 .156" 6-Pin

Header (Green)

CN13 .100" 3-Pin

Header

CN14 .100" 6-Pin

Header, Node

Extension Bus

F1 Fuse - 7A SB, 125V n/a

CN7CN11

CN8

1 8-LP-2 Light Return -

2 LED V+ -

3 Switch Ground BLK-GRN

4 8-SW-6 Switch Return GRY-VIO

5 8-DR-6 Driver Return ORG-VIO

6 48V Driver Power GRY-ORG

1 Switch Ground BLK-GRN

2 8-SW-3 Switch GRY-RED

3 8-DR-3 Driver Return YEL-GRN

4 48V Driver Power 1 8-LP-3 Light Return -

2 LED V+ -

3 Switch Ground BLK-GRN

4 8-SW-7 Switch Return GRY-BLU

5 8-DR-7 Driver Return ORG-BLU

6 48V Driver Power GRY-ORG

1 8-LP-4 GI Return (1A Max) WHT-BLK

2 GI Ground -

3 LED V+ YEL-BLK

1 Ground BLK

2 DIN VIO-BLK

3 DOUT -

4 SCK VIO-RED

5 RCK VIO-ORG

6 V+ RED

CN5

CN6

F1A

125V 7A

TIME LAG

F1B

TOP

CN4

22

KISS PRO MANUAL #500-55H1-01

© 2015 KISS Catalog, Ltd.

Under License to Epic Rights.

Page 23

ELECTRONIC PINOUTS AND SCHEMATICS

4.4 NODE 9 MID PLAYFIELD 8-DRIVER 48V PINOUT

520-6935-00

GREEN ORANGE NEUTRALBLACK

CN3

CN13

520-6935-00

8-Driver Node

CN1

CN9

ON

1 2 3 4

F1A

CN7CN11

CN5

125V 7A

TIME LAG

CN4

CN14

CN12 CN10

CN2

GREEN ORANGE NEUTRALBLACK

ID Type Pin Description Wire Color

SW1 Address DIP - Node 9 - OFF-OFF-ON-

CN2 RJ45 - SPIKE Node Bus Multi

CN3 RJ45 - SPIKE Node Bus Multi

CN4 .156" 5-Pin Header

Node Power

CN5 .156" 4-Pin Header

(White)

CN6 .156" 6-Pin Header

(White)

CN7 .156" 4-Pin Header

(Black)

CN8 .156" 6-Pin Header

(Black)

CN9 .156" 4-Pin Header

(Orange)

OFF

1 Ground BLK

2 Key Key

3 N/C -

4 N/C 5 48VDC In GRY

1 Switch Ground BLK-BRN

2 9-SW-0 Switch Return LGN-YEL

3 9-DR-0 Driver Return YEL-BLU

4 48V Driver Power GRY-BLK

1 9-LP-0 Light Return ORG-BLK

2 LED V+ YEL

3 Switch Ground BLK-BRN

4 9-SW-4 Switch Return LGN-BLK

5 9-DR-4 Driver Return ORG-BLK

6 48V Driver Power GRY-BLK

1 Switch Ground BLK-BRN

2 9-SW-1 Switch LGN-BLU

3 9-DR-1 Driver Return YEL-GRY

4 48V Driver Power GRY-BLK

1 9-LP-1 Light Return ORG-BRN

2 LED V+ YEL

3 Switch Ground BLK-BRN

4 9-SW-5 LGN-BRN

5 9-DR-5 Driver Return ORG-BRN

6 48V Driver Power GRY-BLK

1 Switch Ground -

2 9-SW-2 Switch -

3 9-DR-2 Driver Return -

4 48V Driver Power -

-

Max)

CN6

F1B

TOP

RED-BLK

CN8

ID Type Pin Description Wire Color

CN10 .156" 6-Pin Header

(Orange)

CN11 .156" 4-Pin Header

(Green)

CN12 .156" 6-Pin Header

(Green)

CN13 .100" 3-Pin Header 1 9-LP-4 GI Return (1A