Page 1

AC/DC

SERVICE AND OPERATION MANUAL

WARNING

IMPORTANT HEALTH WARNING: PHOTOSENSITIVE SEIZURES - A very small percentage of people may experience a seizure when exposed to certain visual images, including ashing lights or patterns. Even people with no history of seizures of epilepsy may have an undiagnosed condition that can cause “photosensitive epileptic seizures”

due to certain visual images, ashing lights or patterns. Symptoms can include lightheadedness, altered vision, eye or face twitching, jerking or shaking of arms or legs,

disorientation, confusion, momentary loss of awareness, and loss of consciousness or convulsions that can lead to injury from falling down or striking nearby objects.

IMMEDIATELY STOP PLAYING AND CONSULT A DOCTOR IF YOU EXPERIENCE ANY OF THESE SYMPTOMS.

Stern Pinball machines are assembled in Elk Grove Village, Illinois, USA; each pinball machine has unique characteristics that make it a one-of-a-kind American-made

product. Each machine will have variations in appearance resulting from differences in the machine’s particular wood parts, individual silk screened art and mechanical

assemblies. Stern Pinball has inspected each game element to ensure it meets our quality standards.

The AC/DC mark and logo are owned by LEIDSEPLEIN PRESSE B.V. Used by Stern Pinball, Inc. with permission, all rights reserved.

Games congured for North America operate on 60 cycle electricity only. These games will not operate in countries with 50 cycle electricity (Europe UK, Australia).

MANUAL #780-50C8-00

AC/DC LUCI #500-55C8-01

1-800-KICKERS - parts.service@sternpinball.com

www.sternpinball.com - facebook.com/sternpinball

Page 2

TABLE OF CONTENTS

1. Setup and Moving .................................. 3

1.1 First-Time Setup Instructions ............................... 3

1.2 Adjustments Menu ............................................... 6

1.3 Transporting the Game ...................................... 10

1.4 Maintenance ...................................................... 11

1.5 Maintenance Kits ............................................... 11

1.6 Common Parts ................................................... 11

1.7 Updating Game Code for the S.A.M. System .... 12

1.8 Fuses and Cabinet Switches ............................. 13

1.9 Service Switch & CPU DIP Switch Settings ....... 14

1.10 Diagnostic Aids .................................................. 15

1.11 CPU DIP Switch Settings ................................... 15

1.12 Switch Locations................................................ 17

1.13 Lamp Locations ................................................. 19

1.14 Coil Locations .................................................... 23

2. Service Menu System .......................... 25

2.1 Service Menu Introduction ................................. 25

2.2 Service Menu Icon Tree...................................... 26

2.3 Problem/Solution Table ...................................... 28

2.4 Diagnostics Menu .............................................. 29

3. PartsIdentication&Location ........... 37

3.1 Backbox Parts.................................................... 37

3.2 Speaker Panel Parts .......................................... 37

3.3 Cabinet Parts ..................................................... 38

3.4 Playeld Top - Main Assem. & Switches ............ 39

3.5 Playeld Bottom - Main Assem. and Switches . . 40

3.6 Playeld - Rubber Parts ..................................... 41

3.7 Rubber Size Chart .............................................. 41

4. Major Assemblies ................................. 42

4.1 Ball Shooter Assembly ....................................... 42

4.2 Auto Launch Assembly ...................................... 42

4.3 Flipper Assembly, Left ........................................ 43

4.4 Flipper Assembly, Right ..................................... 43

4.5 Pop Bumper Assembly ...................................... 44

4.6 Slingshot Assembly............................................ 45

4.7 4-Ball Trough Assembly ..................................... 45

4.8 Cannon Motor & Switch ..................................... 46

4.9 AC/DC Cannon .................................................. 46

4.10 Front Molding Assembly - Premium/LE ............. 47

4.11 LED Board Assembly ......................................... 47

4.12 Top Button Switch Assembly ............................. 47

4.13 Vertical Up-Kicker .............................................. 48

4.14 Magnet Core ...................................................... 48

4.15 Left Ramp Assembly - Premium/LE ................... 49

4.16 Right Ramp Assembly - Premium/LE ................ 49

4.17 Detonator Assembly - Premium ......................... 50

4.18 Detonator Assembly - Coil/Plunger ................... 50

4.19 Electric Ball Gate............................................... 51

4.20 3-Bank Drop Target Assembly ........................... 51

4.21 5-Bank Drop Target Assembly ........................... 52

4.22 Pivoting Bell Assembly - Premium ..................... 52

4.23 Bell & Block Assembly - Premium ..................... 53

4.24 Plunger Assembly .............................................. 53

4.25 Kicker Arm Assembly - Premium ....................... 53

4.26 Mini Playeld Fastening Items - Top .................. 54

4.27 Mini Playeld Fastening Items - Bottom ............ 55

4.28 Lower Mini Playeld ........................................... 56

4.29 Rocking Band Assembly .................................... 57

4.30 Malcolm Assembly ............................................. 58

4.31 Angus Assembly ................................................ 58

4.32 Brian Assembly .................................................. 58

4.33 Cliff Assembly .................................................... 58

4.34 Back Panel Assembly ........................................ 59

5. Schematics,Wiring&PCBs ................ 60

5.1 Backbox Wiring .................................................. 60

5.2 Playeld Wiring .................................................. 62

5.3 Cabinet and Coin Door Wiring ........................... 67

5.4 Printed Circuit Boards ........................................ 70

6. Specications ..................................... 116

6.1 Game Dimensions ............................................ 116

6.2 Warranty ........................................................... 117

6.3 Warnings, Compliance, and Legal Notices ...... 117

2

AC/DC LUCI MANUAL 500-55C8-01

Page 3

SETUP AND MOVING

1. SETUP AND MOVING

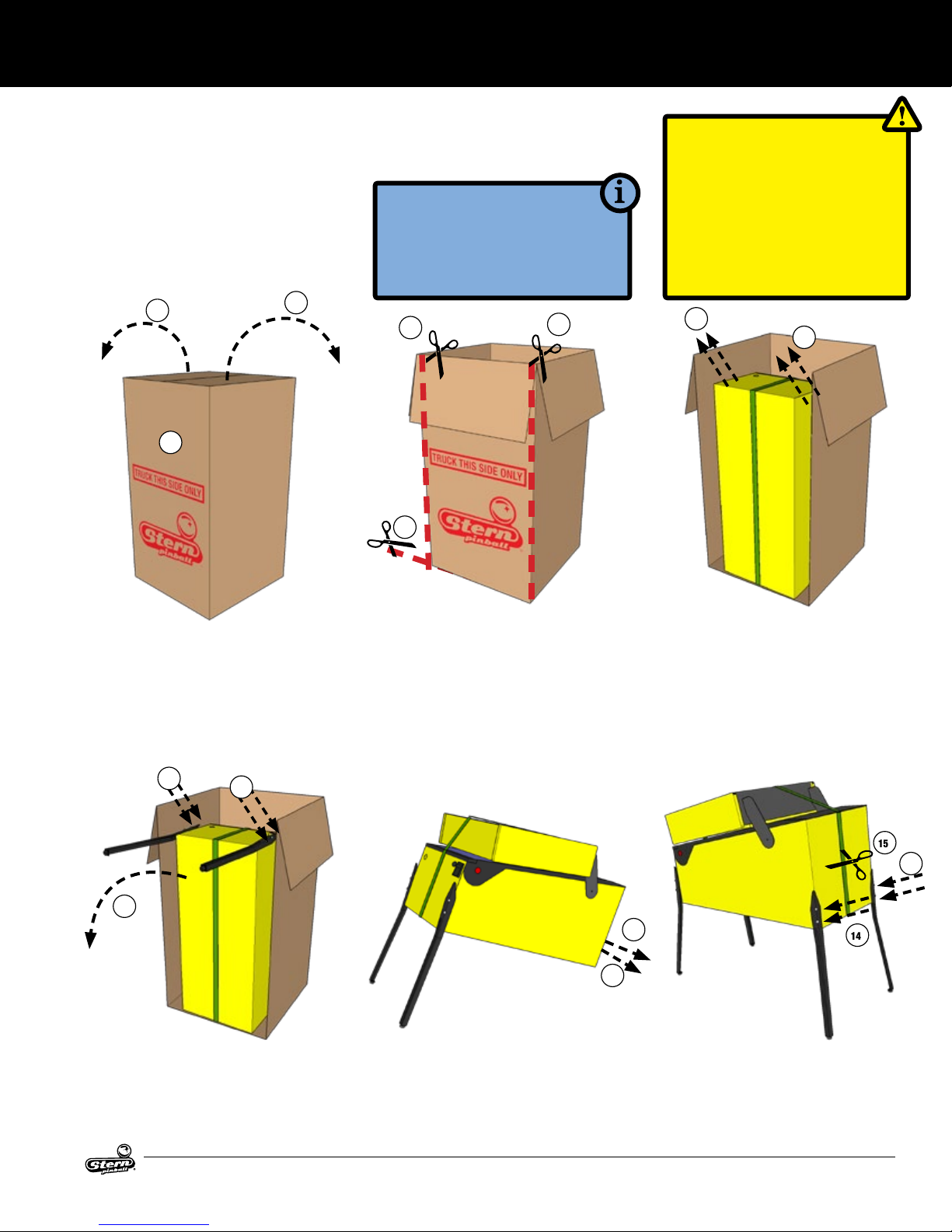

1.1 FIRST-TIME

SETUP INSTRUCTIONS

Your brand new Stern Pinball Machine is

carefully packed for safety and security.

For your safety, exercise caution and use

the correct tools and sufcient help when

setting up your new game.

2

1

2

TOOLS REQUIRED

• 5/8” Socket Wrench

• Utility Knife

• Snips

• An Assistant

5

6

CAUTION: AT LEAST TWO (2)

PEOPLE ARE REQUIRED TO

MOVE AND MANEUVER THE

GAME. USE PROPER MOVING

EQUIPMENT AND EXTREME

CARE WHILE HANDLING. STERN

PINBALL MACHINES WEIGH

OVER 250LBS BOXED.

5

7

7

1. Locate the side labeled “TRUCK

THIS SIDE ONLY”. The bottom of

the game faces this side.

2. Open the top box aps by pulling

hard in an upward motion on each

ap. If the aps are taped, cut the

tape rst, taking care to avoid the

box staples.

8

9

8. Install front legs using the bolts

removed from the cabinet. Secure

tightly.

9. Have someone help you carefully set

the game down on the front legs.

8

3. Remove the four (4) foam pieces

and two (2) narrow box tubes

which contain the four (4) identical

legs with levelers.

4. DO NOT CUT STRAPPING YET.

Keep backbox secured in the

down position.

5. With the utility knife, carefully cut

down the left and right corners of

the box.

10. Set aside the open box.

11. With a ⅝” socket wrench, loosen

and remove the 2 leg bolts on

each side of the rear cabinet, 4

total.

6. Let the face fall forward and

remove the entire side by carefully

cutting the bottom.

7. With the game still in its folded position, use a ⅝” wrench to loosen

and remove the 2 leg bolts on each

side of the front cabinet. Ensure

the leg levelers are screwed all the

way into the legs.

11

11

12. Using supports or two people,

prop the rear of the cabinet up.

13. Ensure the rear leg levelers are

screwed all the way into the legs.

14. Install rear legs using the 4 bolts

removed from step 11.

15

14

14

AC/DC LUCI MANUAL 500-55C8-01

3

Page 4

SETUP AND MOVING

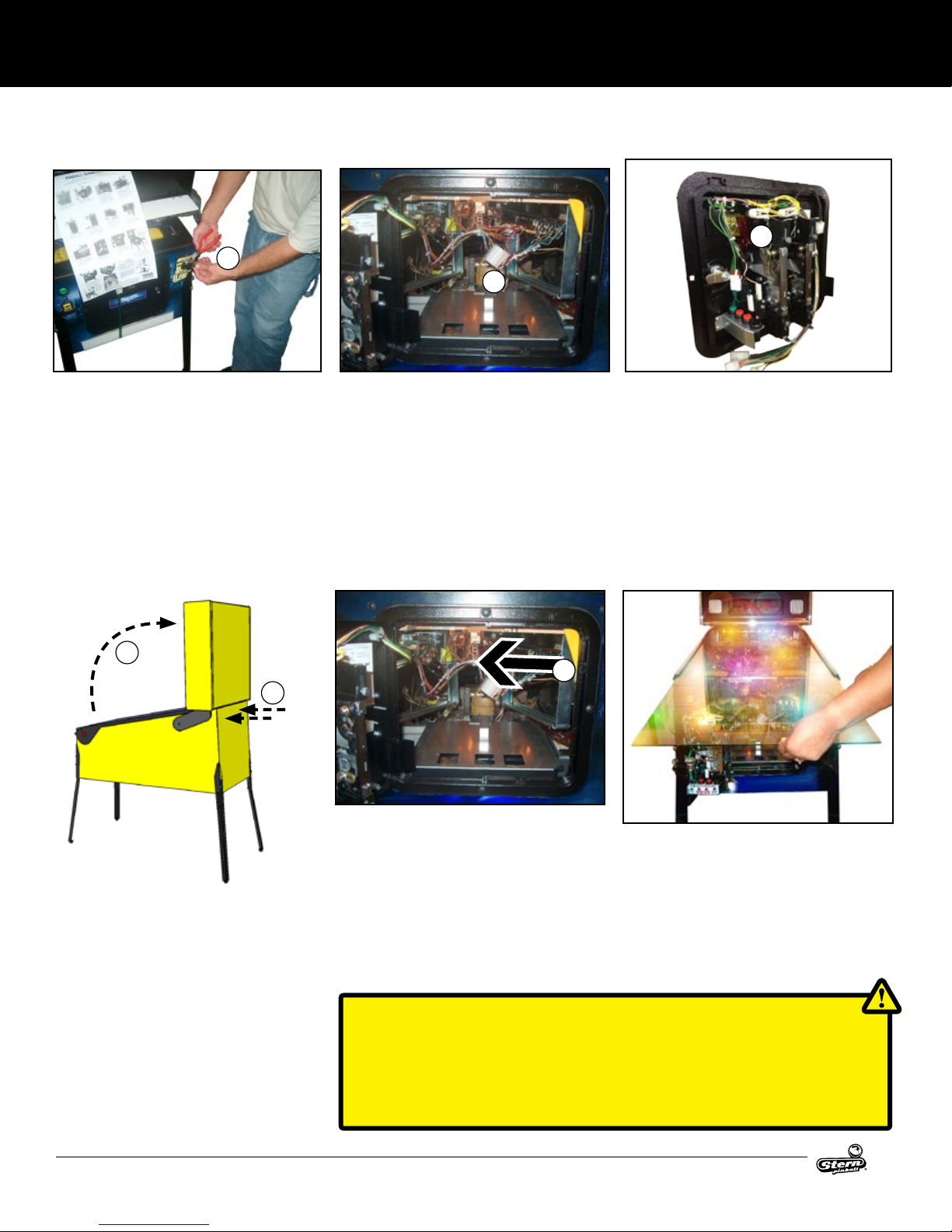

FIRST-TIME SETUP CONTINUED

17

21

19

15. Cut nylon strapping and remove

protective strap corner guards.

16. Locate the factory keys, either on

the shooter rod or taped to the

playeld glass.

17. Using snips, cut the tie-wrap securing the keys if required. One set of

keys is for the front coin door, the

other set of keys is for accessing

components in the backbox.

25

26

24. Locate the two (2) backbox bolts in

the cash box.

25. Carefully raise backbox to upright

position while ensuring that cables

are not pinched.

26. Use the ⅝” wrench to Install the

two (2) backbox bolts to secure the

backbox as indicated on the back

of the cabinet.

18. Open the front coin door.

19. Reach into the game and remove

the retaining clip at the rear of the

cash box.

20. Remove the cash box lid by sliding

it toward you.

27

27. Reach inside the cabinet and hold

and move the yellow top molding

lock handle to the left.

28. Remove the front top molding.

21. Store the backbox keys, if desired,

on the metal hook located in the

coin door.

22. Locate and remove the pinballs,

plumb bob, and backbox bolts

from the cash box.

23. Replace the cash box lid and

retaining clip for future use.

29. Remove the playeld glass by

sliding it toward you and carefully

place it in a safe location.

Remove all playeld shipping

tie downs, shipping blocks, and

packing foam, and follow any

game-specic unpacking instructions included in the playeld, if

present.

CAUTION: PLAYFIELD GLASS IS MADE FROM HIGH-STRENGTH TEMPERED

GLASS. TEMPERED GLASS IS SENSITIVE TO EXTREME TEMPERATURE SHIFTS

AND CORNER NICKS, WHICH CAN CAUSE THE GLASS TO FAIL CATASTROPHICALLY. TAKE CARE TO STORE THE GLASS ON A SOFT, ROOM-TEMPERATURE

SURFACE AND PREVENT THE CORNERS FROM BEING DAMAGED.

4

AC/DC LUCI MANUAL 500-55C8-01

Page 5

FIRST-TIME SETUP CONTINUED

30. If pinballs were already installed into the lower ball

trough, remove them before lifting the playeld.

31. Grasp the lower arch between the ippers, and rmly

but gently pull directly up to raise the playeld 8 to 12

inches.

32. While holding the playeld up, pull the playeld toward

you until the two playeld supports are over the front

edge of the cabinet.

33. Rest the playeld on the front edge of the cabinet.

34. Raise the playeld and rest it against the backbox.

35. Visually inspect all cabinet cables and connector terminations; ensure no wires or cables are pinched and that

cable harnesses are not pulled tight.

36. Locate the plumb bob in the parts bag in the cash box.

37. Slide plumb bob onto the hanger wire. Note: the vertical

position of the plumb bob affects tilt sensitivity - higher

makes the game more sensitive to tilting.

38. Tighten the thumb screw nger-tight.

39. Install the correct number of pinballs. Refer to the decal

on the lock down assembly for the correct number of

pinballs.

SETUP AND MOVING

LOCATING, LEVELING, AND FINAL SETUP

1. Select a location that is indoors, out of direct sunlight,

and climate controlled. Excessive moisture/humidity

can cause long-term damage to your game.

2. Adjust the front or rear levelers as necessary to position

the playeld level bubble, located on the front right of

the playeld next to the shooter lane, to oat between

the two (2) black lines. This will place the playeld at the

recommended 6.5° pitch. Playeld angles greater than

6.5° can be achieved by turning out the rear leg leveler(s) for increased difculty and faster gameplay.

3. Use a pinball to roll down the center of the playeld for

side-to-side leveling, or use an external bubble level,

digital level, or smartphone level app.

4. Plug into a grounded outlet and check for proper operation through DIAGNOSTICS.

5. Check the coin door: With the door closed, insert coins

to verify proper operation.

6. Play game: Check for satisfactory operation and adjust

game volume (push the Red Buttons inside the Coin

Door).

7. If desired, perform any game diagnostics, game adjustments, and pricing settings at this time.

AC/DC LUCI MANUAL 500-55C8-01

5

Page 6

SETUP AND MOVING

1.2 ADJUSTMENTS MENU

STANDARD ADJUSTMENTS

Perform the below steps to review the adjustments.

Enter the Service Menu, then enter the Standard Adjustments

Menu.

Press SELECT. Press BACK to exit or escape at any time.

Press [>]. Go to the ADJ icon. Press SELECT.

Go to the S.P.I. icon. Press SELECT.

ID Adjustment Name Default Setting

1 REPLAY TYPE AUTO

2 REPLAY PERCENTAGE 10%

3 REPLAY AWARD CREDIT

4 REPLAY LEVELS 1

5 AUTO REPLAY START 20,000,000

6 DYNAMIC REPLAY START 60,000,000

7 REPLAY LEVEL #1 15,000,000

8 REPLAY LEVEL #2 30,000,000

9 REPLAY LEVEL #3 45,000,000

10 REPLAY LEVEL #4 60,000,000

11 REPLAY BOOST YES

12 SPECIAL LIMIT 1

13 SPECIAL PERCENTAGE 10%

14 SPECIAL AWARD CREDIT

15 FREE GAME LIMIT 5

16 EXTRA BALL LIMIT 5

17 EXTRA BALL PERCENTAGE 25%

18 GAME PRICING USA 11

19 MATCH PERCENTAGE 9%

20 MATCH AWARD CREDIT

21 BALLS PER GAME 3

22 TILT WARNINGS 2

23 CREDIT LIMIT 30

24 ALLOW HIGH SCORES YES

25 HIGH SCORE AWARD CREDIT

26 GRAND CHAMPION AWARDS 1

27 HIGH SCORE #1 AWARDS 1

28 HIGH SCORE #2 AWARDS 0

29 HIGH SCORE #3 AWARDS 0

30 HIGH SCORE #4 AWARDS 0

31 GRAND CHAMPION SCORE 75,000,000

32 HIGH SCORE #1 55,000,000

33 HIGH SCORE #2 40,000,000

STANDARD ADJUSTMENT #1 appears with the adjustment

name ashing. While the adjustment name is ashing press [<]

[>] to move between adjustments.

To change the adjustment setting press SELECT. While the adjustment setting is ashing, press [<] [>] repeatedly until the desired setting appears. Press the SELECT button to “install” the

change. The adjustment comment (bottom line) will indicate if

the factory default setting is selected or will display INSTALLED

if the change is not a factory default setting.

ID Adjustment Name Default Setting

34 HIGH SCORE #3 30,000,000

35 HIGH SCORE #4 25,000,000

36 HSTD INITIALS 3 INITIALS

37 HSTD RESET COUNT 2000

38 FREE PLAY NO

39 LANGUAGE ENGLISH

40 PLAYER LANGUAGE SELECT YES

41 CUSTOM MESSAGE ON

42 FLASH LAMP POWER NORMAL

43 COIL PUSLE POWER NORMAL

44 KNOCKER VOLUME NORMAL

45 GAME RESTART YES

46 BILL VALIDATOR NO

47 MUSIC VOLUME 1

48 BALL SAVE TIME 0:05

49 TIMED PLUNGER OFF

50 FLIPPER BALL LAUNCH OFF

51 COINDOOR BALL SAVER NO

52 COMPETITION MODE NO

53 CONSOLATION BALL YES

54 FAST BOOT YES

55 Q24 OPTION COIN METER

56 TICKET DISPENSER NO

57 PLAYER COMPETITION YES

58 TEAM SCORES NO

59 LOCATION ID 0

60 GAME ID 0

61 TIME FORMAT 12-HOUR

62 COIN INPUT DELAY 30

63 LOST BALL RECOVERY YES

64 COIN DOOR DISABLE TILT NO

6

AC/DC LUCI MANUAL 500-55C8-01

Page 7

FEATURE ADJUSTMENTS

Each table has feature adjustments specic to the characteristics of that game. To access feature adjustments enter the

Service Menu and then enter the Adjustments Menu.

Press SELECT to access the Service Menu. Press BACK to exit

or escape at any time.

Press [>]. Go to the ADJ icon. Press SELECT.

Go to the game icon. Press SELECT.

FEATURE ADJUSTMENT #1 appears with the adjustment name

ashing. With the adjustment name ashing press [<] [>] to

move between adjustments. Feature adjustments are changed

similarly to standard adjustments using the SELECT button to

choose options and the [<] [>] buttons to cycle through available settings.

SETUP AND MOVING

AC/DC LUCI MANUAL 500-55C8-01

7

Page 8

SETUP AND MOVING

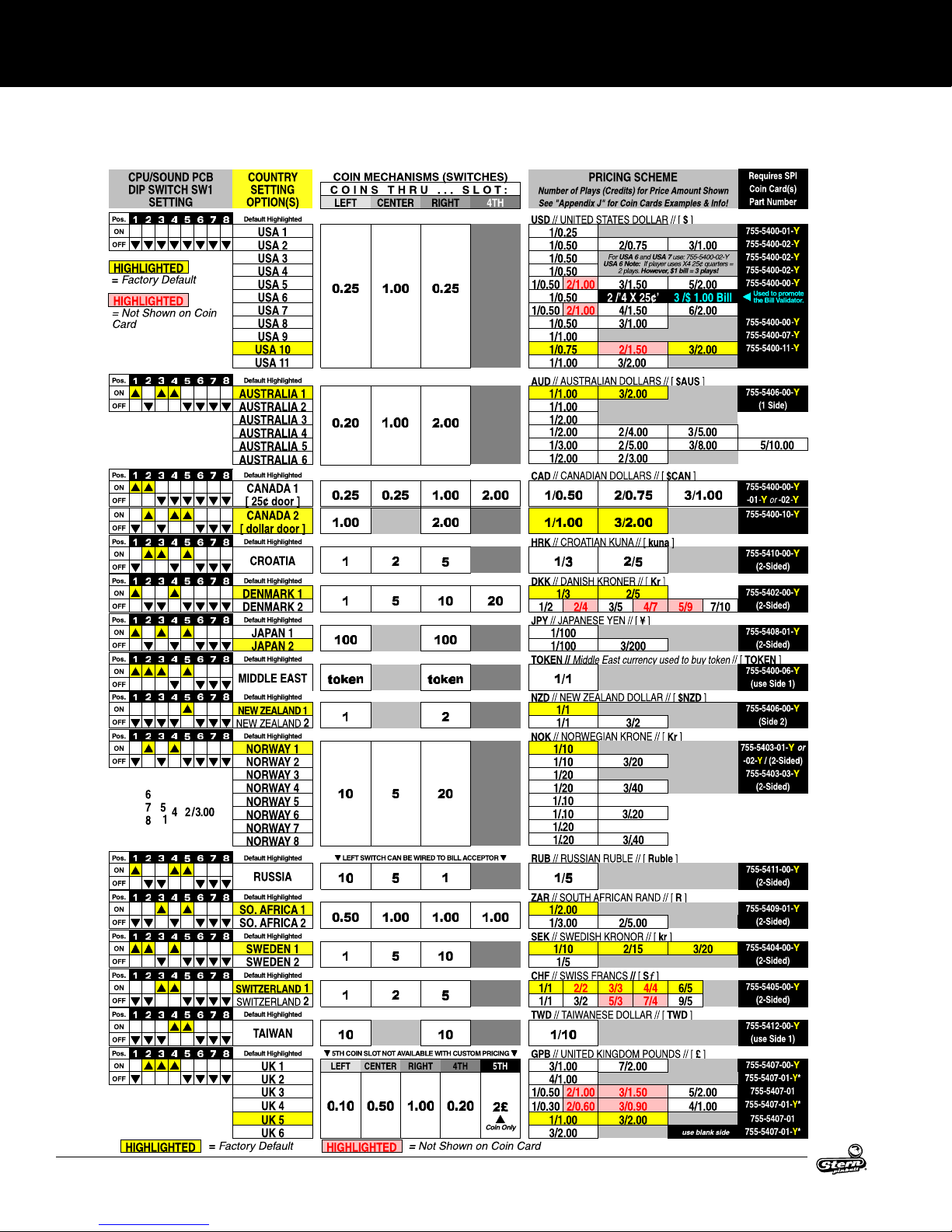

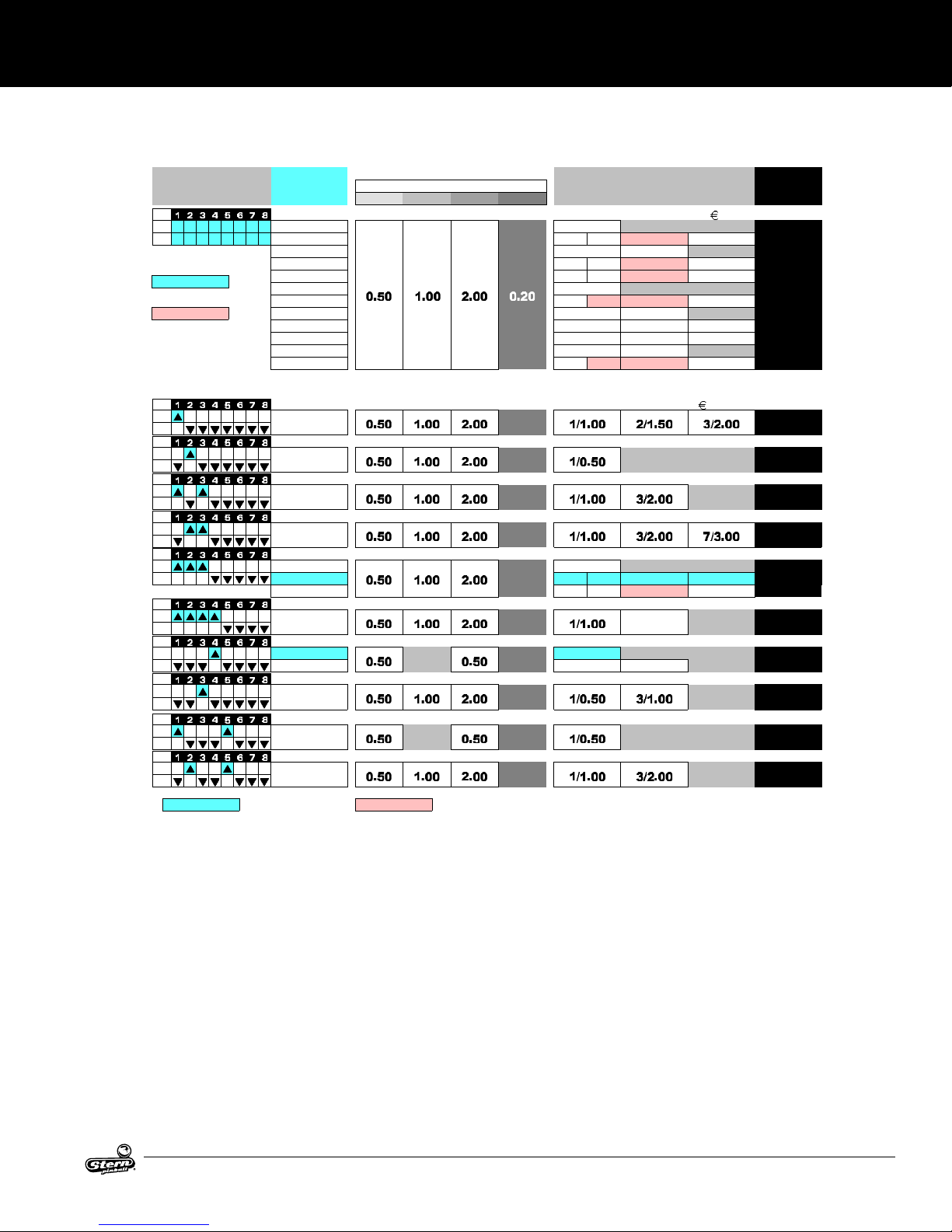

USA & INTERNATIONAL (NON-EURO)

STANDARD PRICING SELECT TABLE

8

*

AC/DC LUCI MANUAL 500-55C8-01

Page 9

EURO SUMMARY & INTERNATIONAL (EURO)

CPU/SOUND PCB

COUNTRY

COIN MECHANISMS (SWITCHES)

PRICING SCHEME

Requires SPI

STANDARD PRICING SELECT TABLE

SETUP AND MOVING

DIP SWITCH SW1

SETTING

Pos. Default Highlighted

ON

SEEBE L O W

OFF

S E T T I N G S

Euro 1-12 are alternate settings for

countries using the Euro.

HIGHLIGHTED

= Factory Default

HIGHLIGHTED

= Not Shown on Coin

Card

Euro 1-12 or CUSTOM* for new setting (reference above Euro 1-12 Summary)

Pos. Default Highlighted

ON

OFF

Pos. Default Highlighted

ON

OFF

Pos. Default Highlighted

ON

OFF

Pos. Default Highlighted

ON

OFF

Pos. Default Highlighted

ON

OFF

Pos. Default Highlighted

ON

OFF

Pos. Default Highlighted

ON

OFF

Pos. Default Highlighted

ON

OFF

Pos. Default Highlighted

ON

OFF

Pos. Default Highlighted

ON

OFF

For a different

HIGHLIGHTED

SETTING

OPTION(S)

Euro 1 1/0.50

Euro 2

Euro 3 1/0.50 3/1.00

Euro 4

Euro 5 optional

Euro 6 2/0.50

Euro 7 1/1.00 2/2.00 3/3.00 5/4.00

Euro 8 optional 1/1.00 3/2.00

Euro 9 1/1.00 2/1.50 3/2.00

Euro 10 1/1.00 3/2.00 7/3.00

Euro 11 1/1.00 4/2.00

Euro 12 2/1.00 4/2.00 6/3.00 9/4.00

Euro Pricing Scheme

AUSTRIA

Euro 9

BELGIUM

Euro 1

FINLAND

Euro 8

FRANCE

Euro 10

GERMANY 1 1/0.50

GERMANY 2

GERMANY 3

C O INS T H R U . . . SLO T :

LEFT CENTER RIGHT 4TH

(other than Factory Default listed below), scroll through

GREECE

Euro 8

ITALY 1 1/0.50

ITALY 2 1/1.00 3/2.00

NETHERLANDS

Euro 3

PORTUGAL

SPAIN

Euro 8

= Factory Default

HIGHLIGHTED

Not Shown on Coin Card

=

Number of Plays (Credits) for Price Amount Shown

See "Appendix J" for Coin Cards Examples & Info!

EUR // EUROPEAN UNION EUROS // [ ]

1/0.50 2/1.00

1/0.50 2/1.00

1/0.50 3/1.00

Keep the Country Dip Switch Setting the same as listed below.

.

3/1.50 5/2.00

3/1.50 6/2.00

4/1.50 7/2.00

Standard Adjustment 18

EUR // EUROPEAN UNION EUROS // [ ]

1/0.50 2/1.00

1/0.50 2/1.00

3/1.50 5/2.00

3/1.50 6/2.00

3/2.00

Coin Card(s)

Part Number

755-5401-01755-5401-02755-5401-03755-5401-04755-5401-05755-5401-06755-5401-07755-5401-08755-5401-09755-5401-10755-5401-11755-5401-12-

:

755-5401-09-

755-5401-01-

755-5401-08-

755-5401-10-

755-5401-01755-5401-02755-5401-04-

755-5401-08-

755-5401-01755-5401-08-

755-5401-03-

755-5401-01-

755-5401-08-

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

AC/DC LUCI MANUAL 500-55C8-01

9

Page 10

SETUP AND MOVING

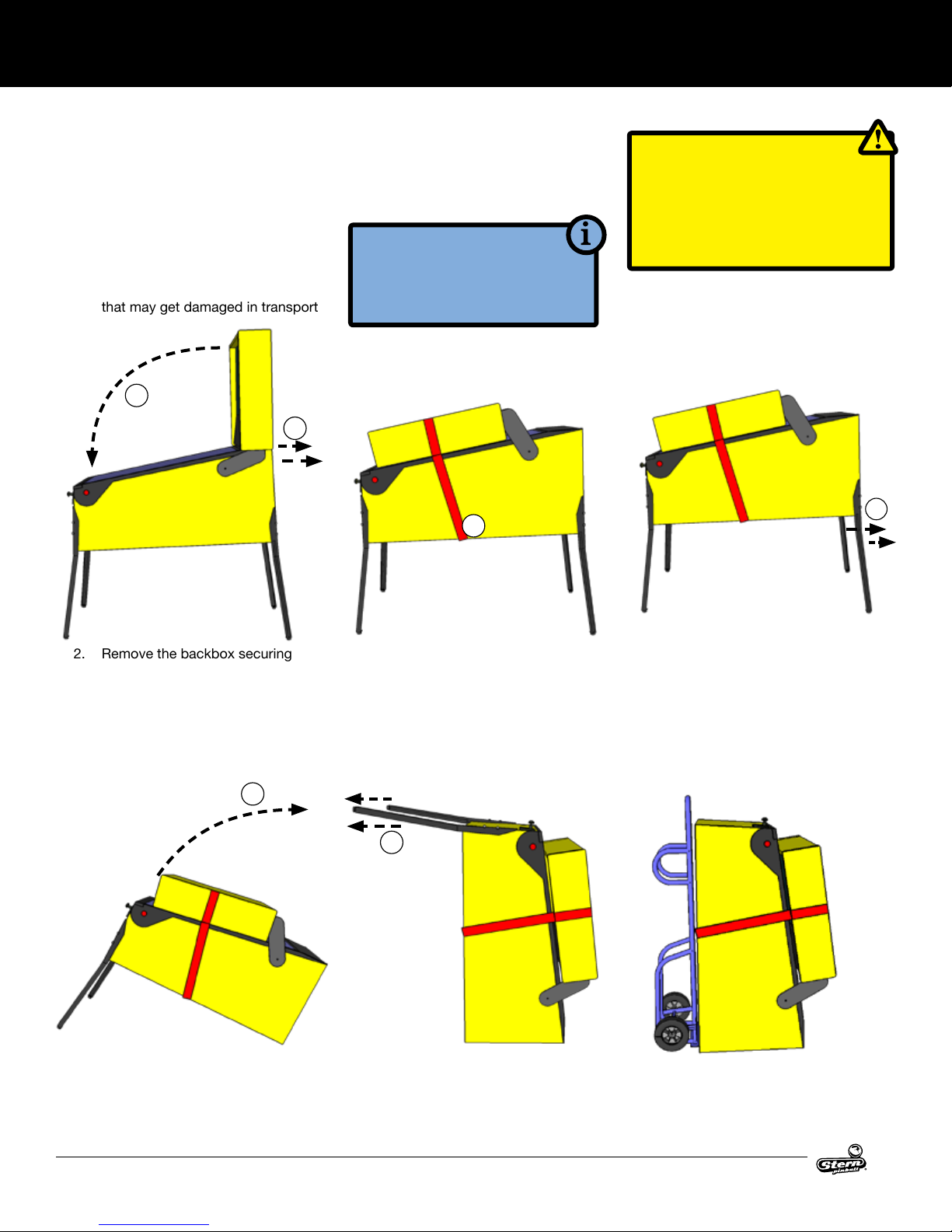

1.3 TRANSPORTING THE GAME

When transporting the game, such as in the back of a truck or with a hand truck, the

game’s backbox must be secured to prevent damage to the side rails.

1. SECURE THE BACKBOX

1. Ensure that the pinballs are removed from the playeld, and secure any free-moving mechanisms

that may get damaged in transport

3

2

TOOLS REQUIRED

• STRAP (500LB OR GREATER)

• AN ASSISTANT

• HAND TRUCK

4

CAUTION

NEVER TRANSPORT THE GAME

IN A MOVING VEHICLE WITH THE

BACKBOX RAISED! TWO PEOPLE

ARE REQUIRED TO REMOVE THE

LEGS!

2. REMOVE THE LEGS AND

STAND UP

6

2. Remove the backbox securing

bolts

3. Carefully lower the backbox onto

the side rails. Use a piece of cardboard or suitable padding between

the backbox and the game.

8

8. Stand the game up on its back.

4. Securely strap the back box to the

game

5. The game may be transported with

the legs on. If the legs must be removed, follow the remaining steps.

9

9. Remove the front two legs.

6. Remove the legs, rear legs rst. Use

a stool or a friend to support the

rear of the game.

7. Rest the rear of the game on the

ground.

10. Secure all loose parts and transport with a hand truck in the

upright position.

10

AC/DC LUCI MANUAL 500-55C8-01

Page 11

1.4 MAINTENANCE

SETUP AND MOVING

REGULAR MAINTENANCE - (MONTHLY/500

GAMES)

• Remove the playeld glass

• Enter the software diagnostics menu, start lamp test, then

clean and wax the playeld.

◊ While cleaning the playeld, identify and repair malfunctioning

lights, loose parts, cracked plastics and worn rubber parts.

• While in diagnostics, enter the switch test (Select the "SW"

Icon, then "TEST" Icon).

◊ Use a pinball to actuate all switches and verify the correct

switch registers with the switch test.

◊ The game will play a sound to conrm the switch.

• Lift the playeld and inspect all assemblies for loose parts,

broken wires or excessive wear. Look at the bottom of the

cabinet for any parts that may have worked loose, then nd

the source.

• Check all coin door mechanisms and bill acceptor (if installed)

for proper operation

• Play the game to ensure all coils and features are working

• Check the playeld to ensure it is level and set to the proper

pitch using the bubble level on the right side wood rail.

• Check game audits: Replay % and Ball Time and note abnormal values which can indicate problems.

• Ensure game volume is set appropriately for the location.

• Clean both sides of the playeld glass and reinstall.

• Check and clean pinballs and replace if excessively worn or

scuffed. Dirty pinballs accelerate game wear.

OVERHAUL MAINTENANCE (5000 GAMES)

• Verify latest game software is installed

• Check ippers for excessive wear. Excessive ipper sloppi-

ness (vertical or horizontal) or weakness indicates a ipper

rebuild is required.

• Clean machine inside and out and check leg levelers for free

operation.

• Visual check for loose or broken playeld and cabinet parts

and repair as necessary.

• Electrical check: Plug into grounded outlet and check for

proper operation through DIAGNOSTICS.

• Replace worn or dirty rubbers.

• Replace pinballs.

• Check all playeld switches with a pinball.

• Check all settings (refer to manual for factory settings).

• Check coin door: With door closed, insert coins to verify

proper operation.

• Check for proper adjustment of the plumb bob tilt.

• Play game: Check for satisfactory operation.

COMMON PINBALL TOOLS

• Common nut drivers (¼”, 5/16”, 11/32", ⅜”)

• Phillips screwdriver

• Standard Allen wrench/Hex key set

• ⅝” Socket with ratchet

• Adjustable wrench (5/8" & 9/16")

• 6" Torpedo Level (or use a pinball

• Flashlight or headlamp

• Soldering Iron (60w with at tip), lead-free solder

• Wire cutter

• Wire stripper

• Long nose (“needle nose”) pliers

1.5 MAINTENANCE KITS

Description Part Number

AC/DC Luci Maintenance Kit

8 oz pinball playeld wax (Novus # 2) (675-0003-01)

Standard Pinball (260-5000-00)

Cleaning Cloth

All Playeld Rubber Rings

Spare Fuses

AC/DC Luci Deluxe Maintenance Kit

All standard kit items, plus:

Flipper rebuild kits, Left and Right (500-6307-10,-00)

AC/DC Luci Playeld Plastics Set 830-6125-XX

AC/DC Luci Playeld Decals Set 820-7000-XX

AC/DC Luci Backbox Decal Left 820-66C8-01

AC/DC Luci Backbox Decal Right 820-66C8-02

AC/DC Luci Cabinet Decal Left 820-66C8-03

AC/DC Luci Cabinet Decal Right 820-66C8-04

AC/DC Luci Cabinet Decal Front 820-66C8-05

AC/DC Luci Playeld, Unpopulated 830-5100-M7

AC/DC Luci Playeld, Populated 505-6004-C8

AC/DC Luci Mini Playeld, Unpopulated 830-71C8-00

AC/DC Luci Mini Playeld, Populated 500-5022-C8

AC/DC Luci Translite 830-52C8-00

Pinballs (4) 260-5000-00

502-6002-C7

502-6003-C7

820-8353-XX

1.6 COMMON PARTS

Description Part Number

8 oz Pinball Playeld wax (Novus # 2) 675-0003-01

Standard Pinball, 1-1/16 in 260-5000-00

Flipper Rebuild Kit Left 500-6307-10

Flipper Base Plate Kit Left 515-6617-01

Flipper Rebuild Kit Right 500-6307-00

Flipper Base Plate Kit Right 515-6617-00

AC/DC LUCI MANUAL 500-55C8-01

11

Page 12

SETUP AND MOVING

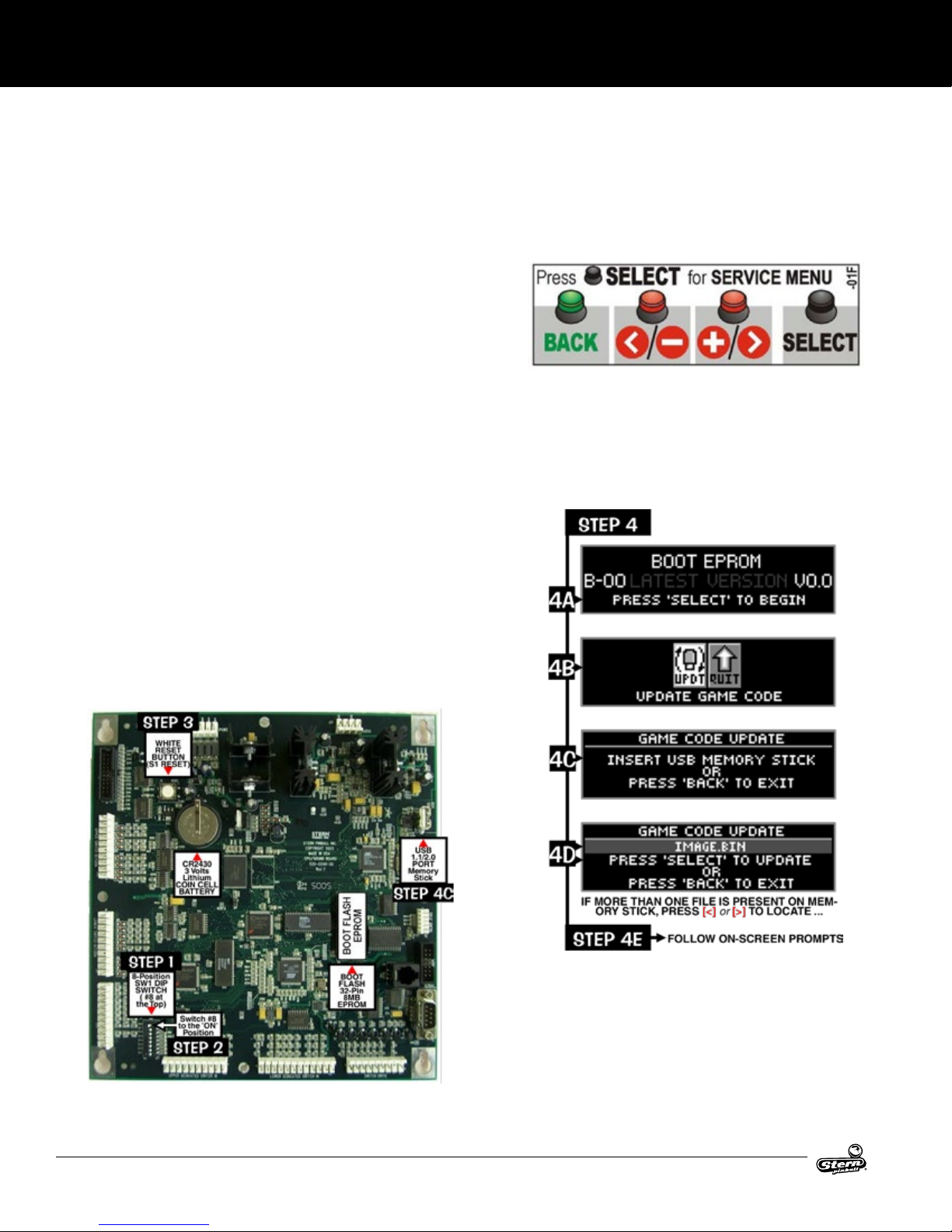

1.7 UPDATING GAME CODE FOR THE S.A.M. SYSTEM

Game code is subject to change. Update this game with the latest code downloaded from our website, from another game, or order

from your local distributor.

Upon powering up, the display will describe the version of code installed in your game. When directed to do so (via Service Bulletin or

website announcment) you will need to update your code with the boot ash EPROM installed, here’s how:

STEP 1

Open the backbox and locate the 8-position DIP switch (SW1 on

the CPI/Sound board)

STEP 2

Switch DIP switch #8 to ‘ON’ (Boot ash EPROM must be installed)

STEP 3

Press the white reset button (S1 RESET on the CPU/Sound

board) or power cycle the game OFF/ON (ON/OFF switch is

located on the outside of the cabinet bottom, front right).

STEP 4

Using the 4-button service switch set (inside the coin door):

4A: Press [SELECT] to begin.

4B: With the “UPDT” icon highlighted, press [SELECT].

4C: Insert the memory stick (with the latest les) into the USB

port.

4D: If more than one le is present on the memory stick, press [<]

or [>] to locate your le. Press [SELECT] to update.

4E: Follow on-screen prompts.

GreenButton

Press to escape

back (or exit)

RedButtons

Press to move <Left, Right>.

Press to - Decrease or +

Increase values or to change

settings.

CPU/SOUND BOARD (S.A.M. SYSTEM)

12

AC/DC LUCI MANUAL 500-55C8-01

Page 13

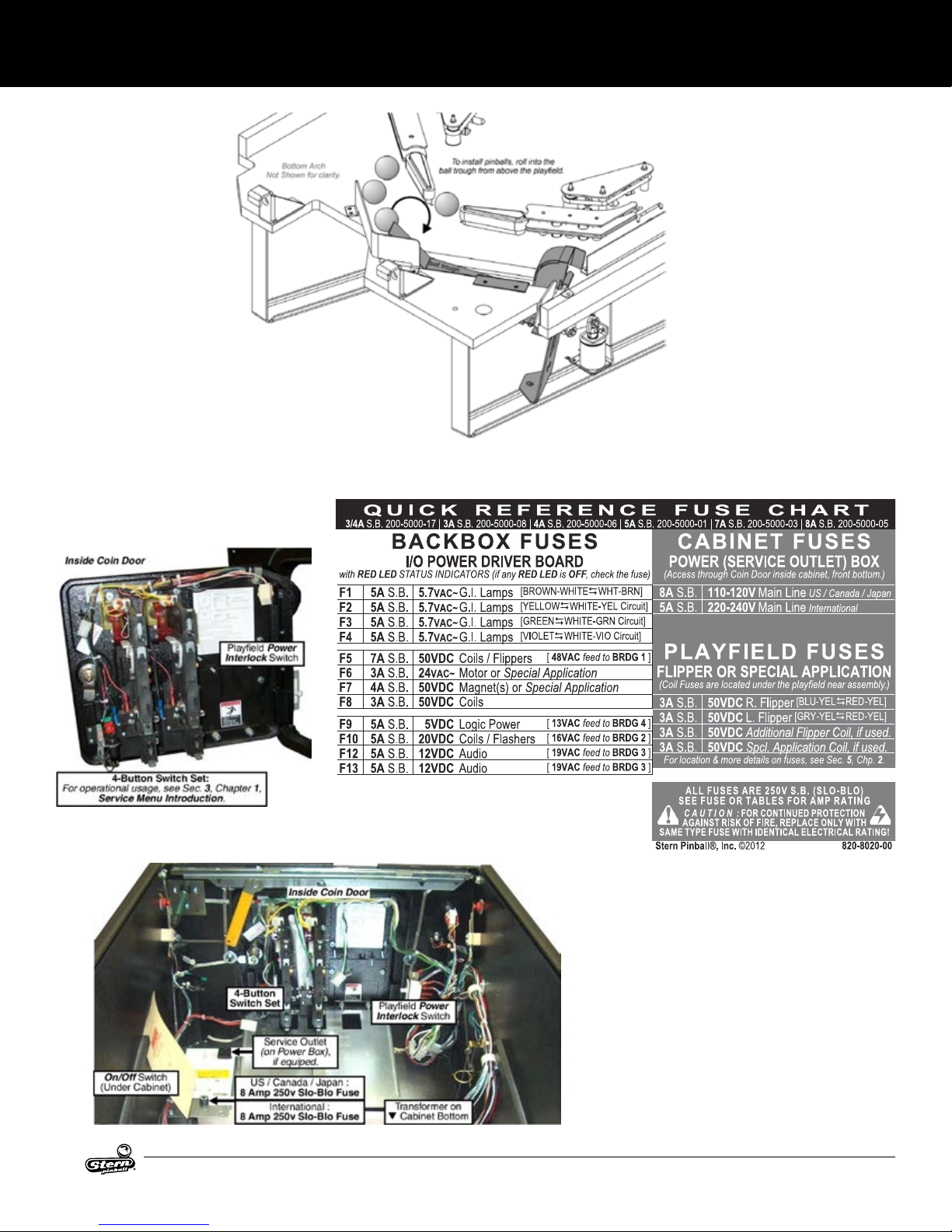

FOR PROPER OPERATION OF THIS PINBALL GAME, <4> PINBALLS MUST BE

INSTALLED IN THE 4-BALL TROUGH!

1.8 FUSES AND CABINET SWITCHES

SETUP AND MOVING

AC/DC LUCI MANUAL 500-55C8-01

13

Page 14

SETUP AND MOVING

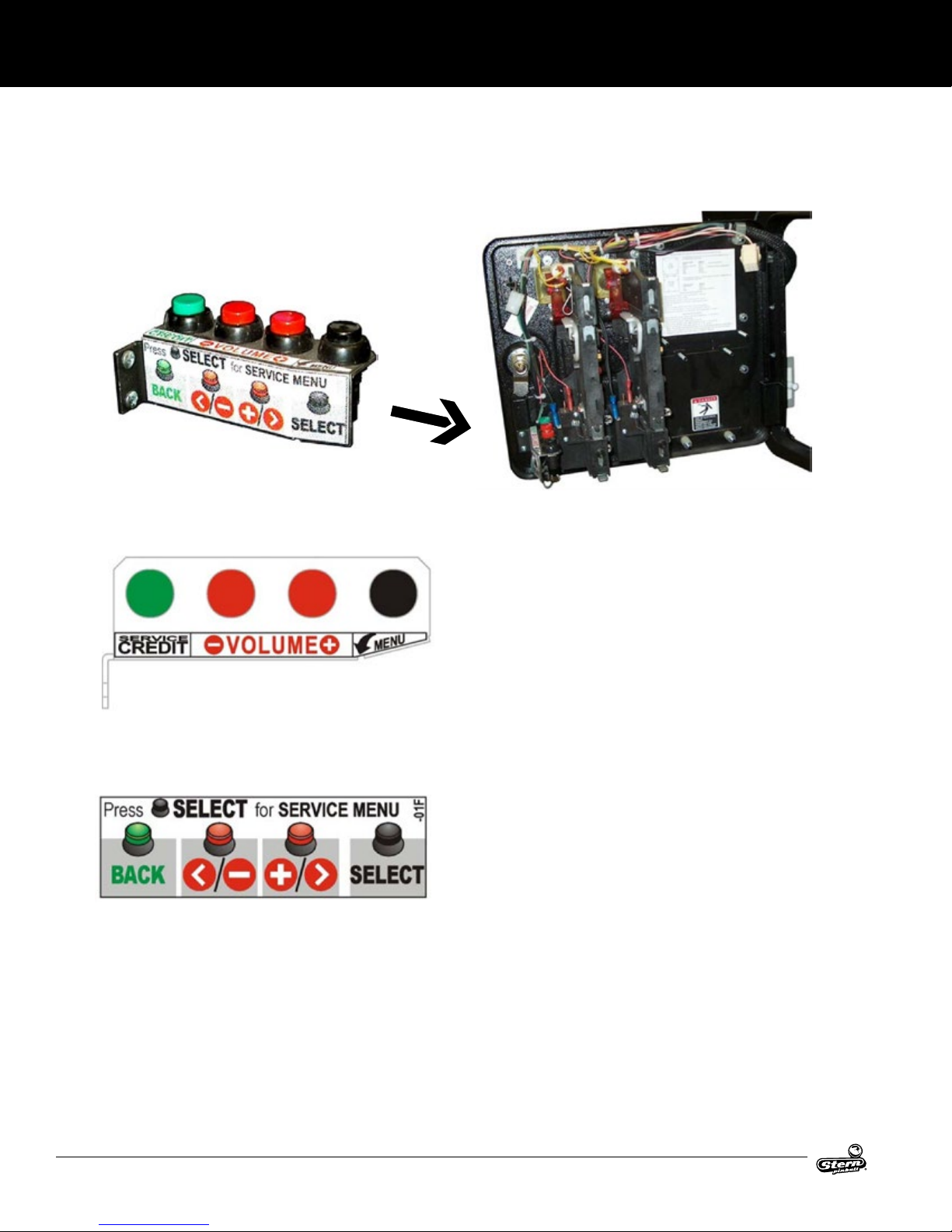

1.9 SERVICE SWITCH & CPU DIP SWITCH SETTINGS

SERVICE SWITCH X4 SET OVERVIEW

Open the coin door to access the service switch X4 set.

The fours buttons (inside the coin door) have dual functions

depending on if you have entered the Service Menu or not.

FUNCTIONS IN GAME OR ATTRACT MODE

GreenButton

Press for

Service

Credit(s).

RedButtons

Press for Volume

Adjustment

- for less (quieter)

+ for more (louder)

BlackButton

Press for

Service Menu

entry.

FUNCTIONS IN THE SERVICE MENU

GreenButton

Press to Escape

Back (or Exit).

RedButtons

Press to move

< Left , Right >

Press to - Decrease

or + Increase

values or to change

settings.

BlackButton

Press to Enter

Select (or

‘OK’).

EXAMPLE

To enter the Service Menu, then enter the Switch Test Menu via

the Diagnostics Menu, perform the below steps.

STEP 1

Press [Select].

STEP 2

With the “DIAG” icon hightlighted, press [Select].

STEP 3

With the “SW” icon highlighted, press [Select].

STEP 4

With the “TEST” icon highlighted, press [Select].

Press any switch. If wired correctly, the information in the display

will match the information in the Switch Matrix.

Press [<] or [>] to move left or right through the menus.

Press [Back] to get back a menu, exit, or escape at any time.

14

AC/DC LUCI MANUAL 500-55C8-01

Page 15

SETUP AND MOVING

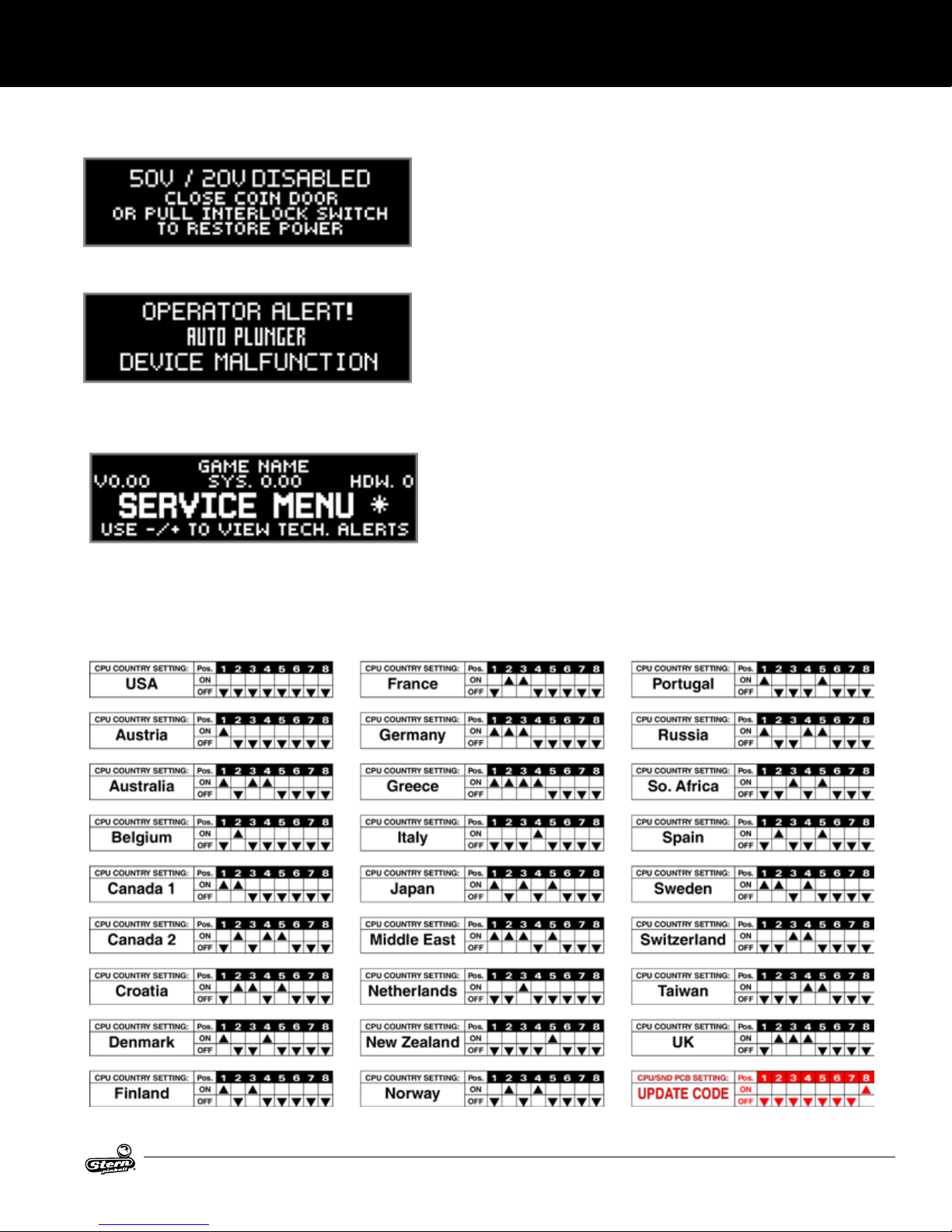

1.10 DIAGNOSTIC AIDS

This audible/visual alert display is shown when the 50V/20V power is

disabled (by opening the coin door). Pull out the interlock switch only while

in the service menu for coil, switch, or play testing when the coin door is

required to stay open for service button use! Pulling out the power interlock

switch or pressing the ‘escape’ green [BACK] button will remove the alert

display. Initial display presentation is accompanied by 3 audible tones (the

bright display warning will go dim after approximately 30 seconds).

This alert display is shown momentarily during game mode or powering up

to alert the operator of a device malfunction (device or mechanism doesn’t

energize or is energized repeatedly). OPERATOR ALERT! works by monitoring any switch activated device that has the potential to trap a ball when

disabled (e.g. in the shooter lane, scoop, or eject holes, etc.). This alert

can also appear if a switch associated with a device (e.g. ball trough, auto

plunger, etc.) is stuck closed (caused by a switch jam or stuck ball); the

game will activate the device a predetermined number of times and if the problem is still detected, this device or switch will be

noted in Switch Alerts and/or Technical Alerts.

Upon entering the service menu, if an asterisk “ * ” is displayed after the

words “SERVICE MENU”, the game has detected possible fualty devices,

switched, and/or missing pinballs. Press either of the red buttons (shortcut to the technical alerts menu) or continue into the service menu (press

the black button again), select the “DIAG” icon and “TECH” icon or the

technical alerts information.

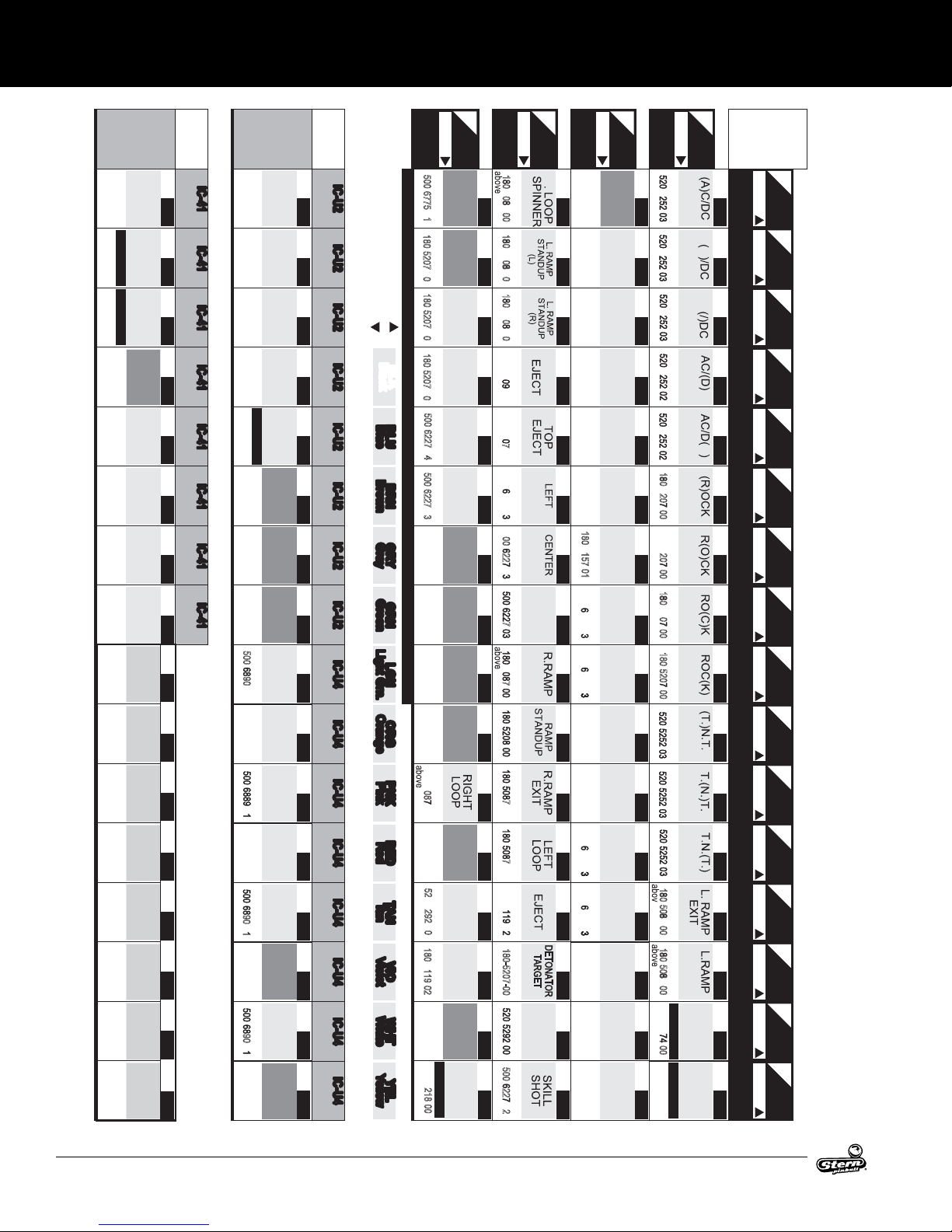

1.11 CPU DIP SWITCH SETTINGS

AC/DC LUCI MANUAL 500-55C8-01

15

Page 16

SETUP AND MOVING

OPTIONAL

502-5032-00

Optional Kit

180-5119-02

Below P/F

IF USED NOT USED

a/b playfield

180-0000-00

NOT USED NOT USED

180-5192-04

Coin Door

180-5192-02

Coin Door

NOT USED NOT USED

180-5192-02

Coin Door

180-5192-00

Coin Door

ON / OFF

#1

ON / OFF

#2

ON / OFF

#3

ON / OFF

#4

ON / OFF

#5

ON / OFF

#6

ON / OFF

#7

ON / OFF

#8

GROUND

J13-P10

(BLK)

(

PENDULUM

SW.

PLUMB BOB

TILT

D-17

)

SW.

SLAM

TILT

D-18

SW.

TICKET

NOTCH

D-19

SW.

USED

NOT

D-20

SW.

BUTTON)

(GREEN

BACK

X

D-21

SW.

(< / – RED

MINUS

BUTTON)

X

D-22

SW.

(+ / > RED

BUTTON)

PLUS

X

D-23

SW.

SELECT

BUTTON)

(BLACK

X

D-24

POSITION

SW.

SWITCH

DIP

D-25

POSITION

SW.

SWITCH

DIP

D-26

POSITION

SW.

SWITCH

DIP

D-27

POSITION

SW.

SWITCH

DIP

D-28

POSITION

SW.

SWITCH

DIP

D-29

POSITION

SW.

SWITCH

DIP

D-30

POSITION

SW.

SWITCH

DIP

D-31

POSITION

SW.

SWITCH

DIP

D-32

CPU/SND

Board

LGN-BRN

J13-P1

I

IC-41

C-41

LGN -ORG

J13-P3

I

IC-41 I

C-4

-RED

1

LGN -YEL

J13-P4

IC-41 I

C4

1

LGN -BLK

J13-P5

IC-41 I

C-4

1

LGN -BLU

J13-P6

IC-41 IC-4

C-4

1

LGN -VIO

J13-P7

IC-41 I

1

LGN GRY

J13-P8

C-41IC-41 IC-4

LGN-

J13-P9

IC-41

1

CPU/SOUND BD. SW1 DIP SWITCH (located between Connectors J3/J13)

& J3-P10

J2-P1/11

NOT USED

180-5204-00

Coin Door

SLOT

NOT USED NOT USED

180-5204-00

Coin Door

SLOT

180-5204-00

Coin Door

SLOT

NOT USED IF USED NOT USED

180-5204-00

Coin Door

SLOT

a/b playfield

180-0000-00

SLOT

a/b playfield

180-0000-00

USED

Cabinet Side

NOT USED NOT USED NOT USED

180-5160-01

USED

Cabinet Side

180-5160-01

USED

Cabinet Side

BUTTON

500- 890-01

Flipper Asm.

NOT USED

NOT USED NOT USED NOT USED NOT USED NOT USED

180-5149-00

E.O.S.

Cabinet Side

BUTTON

- -0

Flipper Asm.

180-5149-00

E.O.S.

Cabinet Side

BUTTON

-

9

0

-0

USED

Cabinet Side

NOT USED

BUTTON

- 90

.

-0

NOT USED

USED

GROUND

(BLK)

SW.

COIN

LEFT

D-1

SW.

CENTER

COIN

D-2

SW.

RIGHT

COIN

D-3

SW.

FOURTH

COIN

D-4

SW.

FIFTH

COIN

D-5

SW.

NOT

D-6

SW.

NOT

D-7

SW.

NOT

D-8

SW.

FLIPPER

L. (EFT)

D-9

SW.

FLIPPER

LEFT

D-10

SW.

R. (IGHT)

FLIPPER

D-11

SW.

FLIPPER

RIGHT

D-12

SW.

FLIPPER

U.L.

D-13

SW.

NOT

D-14

SW.

FLIPPER

U.R

D-15

SW.

NOT

D-16

CPU/SND

Board

PNK-BRN

J2-P2

I

IC-U2

CU

2

PNK

J2-P3

I

C

-U

-RED

2IC-U2 I

PNK -YEL

J2-P4

C

-

-ORG

U2IC-U2 IC-

PNK -GRN

J2-P6

IC-U2 I

U

2

PNK -BLU

J2-P7

IC-U2 I

C

-

U

2

PNK -VIO

J2-P8

IC-U2 I

C

-

U

2

PNK -GRY

J2-P9

C

-U2IC-U2 I

PNK GRY-BRN

J2-P10

C

-U2IC-U2

J3-P1

I

IC-U4

C-U

4

GRY -ORG

J3-P2

I

IC-U4 IC

C-U

-RED

4

GRY -YEL

J3-P4

IC-U4 IC

-U

4

GRY -GRN

J3-P5

IC-U4 I

-

U

4

GRY -BLU

J3-P6

IC-U4 I

CU

4

GRY -VIO

J3-P7

C-U4IC-U4 I

GRY -BLK

J3-P8

IC-U4 I

C-U4

GRY

J3-P9

IC-U4

CU

4

GRN-ORG

« D.O.T.S. » « D.O.T.S. »

1

8

0-50

8

7-00

180

-520

8-00

« D.O.T.S. »

1

8

0-5208-00

180-52 -00

180-52

7

-00

« D.O.T.S. » « D.O.T.S. » « D.O.T.S. » « D.O.T.S. » « D.O.T.S. » « D.O.T.S. » « D.O.T.S. » « D.O.T.S. »

500- 227-0

500- 22

-0

-

7

-

-5

7

-

-

-

-

7

-00

-

7

-00

180-5

1

80-5207-00 2

« D.O.T.S. »

-

-

5

0

0- 22

-0

DRIVE

Q3

TOP LANE

TOP LANE

TOP LANE

ENTER

OPTO

03

J1-P3

SW. SW. SW. S W. SW. SW. SW. SW. SW. SW. S W. SW. SW. S W. SW. SW.

Below P/F

L

# 33 # 34 # 35 # 36 # 38 # 39 # 40 # 41 # 42 # 43 # 44 # 45 # 46 # 47 # 48

below playfield

below playfield

below playfield

BELL

RX

515-0174-00

# 37

RX

515-0174-00

below playfield

below playfield

RIGHT

below playfield

2 per Asm.

R.

2 per Asm.

below playfield

below playfield

CANNON

below playfield

below playfield

BELL

below playfield

J1-P5

J1-P4

04

DRIVE

GRN-YEL

Q4

below playfield

Wire Color Abbreviations used:

50

« FOR MORE ABOUT DIODE ON TERMINAL STRIPS « D.O.T.S. », SEE SECTION 5, CHAPTER 2, PAGES 102 – 103. »

0

-677

5

-01

below playfield

1

8

0

-5

2

Black

BLK

BLK

BLU

BLU

BRN

BRN

GRY

GRY

GRN

GRN

LGN

LGN

ORG

ORG

PNK

PNK

RED

RED

TAN

TAN

VIO

VIO

WHT

WHT

YEL

YEL

0

7

-00

below playfield

a / b playfield

1

180-0000-00

8

0

-5

2

0

7

-00

below playfield

a / b playfield

180-0000-00

1

8

0

-5

2

0

7

-00

below playfield

5

0

0

-6

2

2

7

-04

below playfield

500-6227-03

a / b playfield

180-0000-00

a / b playfield

180-0000-00

180-50

playfield

8

-00

a / b playfield

180-0000-00

below playfield

520-5292-00

below playfield

1

8

0-511

9-02

180-52

In Cabinet

1

8

-0

0

Dedicated Switches [ #D-1 – #D-32 ] {Dedicated Switch Locations : next page}

Black

Blue

Brown

BrownBlue

Gray

Gray

Green

Green

Light Grn.

Light Grn.

Orange

Orange

Pink

Pink

Red

Red

Tan

Tan

Violet

Violet

White

White

Yellow

Yellow

« D.O.T.S. »

OPTO

« D.O.T.S. » « D.O.T.S. » « D.O.T.S. »

(LEFT)

(CENTER)

(RIGHT)

« D.O.T.S. » « D.O.T.S. » « D.O.T.S. » « D.O.T.S. » « D.O.T.S. » « D.O.T.S. » « D.O.T.S. » « D.O.T.S. »

USED

NOT

USED

NOT

USED

NOT

USED

NOT

USED

NOT

HOME

« D.O.T.S. »

MARK

« D.O.T.S. »

USED

NOT

« D.O.T.S. »

BUTTON

CABINET

SW. S W. SW. S W. SW. SW. SW. SW. SW. SW. S W. SW. SW. S W. SW. S W.

LOWER P.F.

KICKER

playfield

# 49 # 50 # 51 # 52 # 53 # 54 # 55 # 56 # 57 # 58 # 59 # 60 # 61 # 62 # 63 # 64

below playfield

S/U TARGET

LOWER P.F.

below playfield

S/U TARGET

LOWER P.F.

below playfield

S/U TARGET

LOWER P.F.

below playfield

LOWER P.F.

LOOP (L.)

below playfield

LOWER P.F.

LOOP (R.)

below playfield

below playfield

playfield

below playfield

above playfield

above playfield

-0 above

playfield

CANNON

above playfield

CANNON

above playfield

below playfield

FIRE

02

DRIVE

GRN-RED

Q2

SW.

NOT USED « D.O.T.S. »

180-5119-02

USED

NOT

# 17 # 19 # 20 # 21 # 22 # 23 # 24 # 25 # 26 # 27 # 28 # 29 # 30 # 31 # 32

SW.

TROUGH

180-5119-02

()

4-BALL

#4 (L)

# 18

SW. SW.

« D.O.T.S. »

TROUGH

180-5119-02

()

4-BALL

#3

« D.O.T.S. » « D.O.T.S. »

TROUGH

180-5119-02

()

4-BALL

#2

TX

TRANS. / REC.

515-0173-00

TX

TRANS. / REC.

515-0173-00

1

80-5157-01

500-

227-0

500-

227-0

180-5054-00

180-5054-00

500-

227-0

500-

227-0

180-5015-04

180-5015-04

180-5015-04

SW.

TROUGH

()

VUK OPTO

#1 (R)

()

SW. SW.

STACK OPTO

TROUGH

JAM

SHOOTER

LANE

OUTLANE

SW.

« D.O.T.S. »

LEFT

SW.

« D.O.T.S. » « D.O.T.S. » « D.O.T.S. » « D.O.T.S. » « D.O.T.S. »

RETURN

LANE

LEFT

SW.

SLING-

SHOT

LEFT

SW.

SLING-

RIGHT

SHOT

SW.

RETURN

RIGHT

LANE

OUTLANE

SW.

RIGHT

SW.

« D.O.T.S. »

BUMPER

LEFT

SW.

« D.O.T.S. »

BUMPER

RIGHT

SW.

« D.O.T.S. »

BUMPER

BOTTOM

J1-P1

below playfield

below playfield

below playfield

below playfield

below playfield

below playfield

above playfield

below playfield

below playfield

below playfield

below playfield

below playfield

e playfield

playfield

In Cabinet

In Cabinet

DRIVE

GRN-BRN

Q1

« D.O.T.S. »

-5 -

« D.O.T.S. »

-5 -

« D.O.T.S. » « D.O.T.S. » « D.O.T.S. » « D.O.T.S. »

-5 -

-5 -

-5

-

1

8

0-520

-0

0

« D.O.T.S. » « D.O.T.S. »

180-52

0

-00

1

8

0-520

-0

0

1

8

0

-5

2

0

-0

0

-

-

-

-

-

-

18

0-508

7-00

1

ENTER

8

0

-5

0

8

7-00

180-51

CABINET

START

MENT

-0

0

BUTTON

180-5174-00

CABINET

START

01

SW.

#1 #2 #3 #4 #5 #6 #7 #8 #9 #10 #11 #12 #13 #14 #15 #16

SW.

A C

SW.

AC

SW.

C

SW.

C

SW.

SW.

SW.

SW.

SW.

SW.

SW.

SW.

SW.

SW.

TOURNA-

SW.

Sound

Board

RETURN RETURN RETURN RETURN RETURN RETURN RETURN RETURN

WHT-BRN

J6-P9

RETURN

WHT-RED

J6-P8

WHT-ORG

J6-P7

WHT-YEL

J6-P6

WHT-GRN

J6-P5

WHT-BLU

J6-P3

WHT-VIO

J6-P2

WHT-GRY

J6-P1

TAN-BLK

J12-P9

RETURN RETURN

TAN-RED

J12-P8

TAN-ORG

J12-P7

RETURN

TAN-YEL

J12-P6

RETURN

TAN-GRN

J12-P4

RETURN RETURN RETURN

TAN-BLU

J12-P3

TAN-VIO

J12-P2

TAN-WHT

J12-P1

CPU/

01

IC-U22A

02

IC-U22B

03

IC-U22C

SWITCH MATRIX GRID [ #1 – #64 ] {Switch Locations : next page}

04

IC-U22D

05

IC-U16A

06

IC-U16B

07

IC-U16C

08

IC-U16D

09

IC-U36A

10

IC-U B36

11

IC-U C36

12

IC-U D36

13

IC-U40A

14

IC-U B40

15

IC-U C40

16

IC-U D40

16

AC/DC LUCI MANUAL 500-55C8-01

Page 17

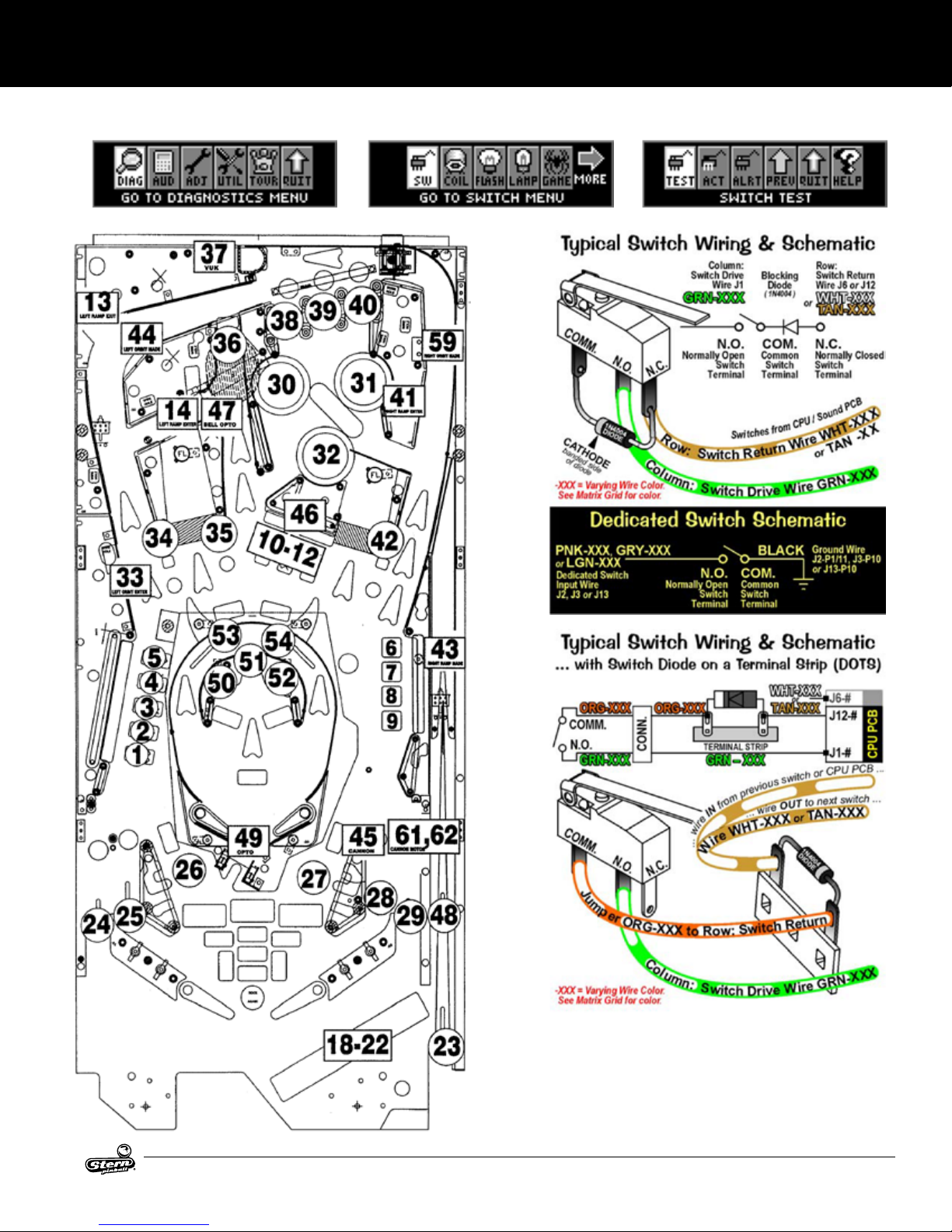

1.12 SWITCH LOCATIONS

SETUP AND MOVING

Switch Menu: Switch, Active, Single, & Service

AC/DC LUCI MANUAL 500-55C8-01

17

Page 18

SETUP AND MOVING

J5

Power

Driver

Board

I/O

« D.O.T.S. »

2

0

-53

2

4

-02

« D.O.T.S. »

2

0

-532

4

-02

« D.O.T.S. »

2

0

-532

4

-02

« D.O.T.S. »

2

0

-532

4

-02

.

N

. .

BO

OR HO

U

O

R

O K

E

H

R

N

E

B

BL K

K

N

USED

NOT

USED

NOT

USED

NOT

USED

NOT

#555 Clear

# 73

# 74

# 75

# 76 # 77 # 78

#555 Clear

# 79

#555 Clear

# 80

« D.O.T.S. »

BUTTON

START

1

1

2

-502

4

-0

« D.O.T.S. »

OU

R

RN E

B

U O

1

1

2-50

N

2

N

4-0

« D.O.T.S. »

RE

B

RE

U O

2

0

-53

N

3

3

-00

« D.O.T.S. »

R

E B

R

E

U O

EN

2

0

-533

N

3

-00

« D.O.T.S. »

R

E BU

BL

U

E

2

0

-533

O

N

3

-00

« D.O.T.S. »

BUMPER

LEFT

112-5033-08

« D.O.T.S. »

BUMPER

RIGHT

112-5033-08

« D.O.T.S. »

BOTTOM

BUMPER

112-5033-08

LED

# 57

LED

# 58

# 59

LED

# 60

LED

# 61

LED

# 62

LED

# 63

LED

# 64

LED

L

OU

L N H LON

HO

O

2

K

0

-532

# 65

4-02

E

LED

H

H O

H

E

L

L

2

0

-532

# 66

4

-02

LED

R

O

K

R N

N

R

2

0

O

-532

LL

# 67

4

-02

LED

H

O

RO E

L

E

L

O

2

0

-53

# 68

24

-02

LED

HE

B

E

LL

L

L

20-5324

# 69

-02

LED

« D.O.T.S. »

HUN ER

20-5324-02

R

U K

# 70

LED

LE

B

E

R

H

O

E

2

R

0-532

K

E

# 71

4-02

LED

HE

LL

L

E

N B

O

2

0

BE

-5324

# 72

-02

« D.O.T.S. »

.

N. .

2

0

-532

4

-03

« D.O.T.S. »

.

N. .

2

0

-53

2

4

-03

« D.O.T.S. »

.

N. .

2

0

-53

2

4

-03

« D.O.T.S. »

USED

NOT

112-5033-08

« D.O.T.S. »

J

H

UK

OR

E

N R

B

1

12

OX

-503

.

4

-02

« D.O.T.S. »

JUKE

HO

R

N L

BOX

1

1

2

.

-5034

-02

USED

NOT

USED

NOT

LED

# 49

LED

# 50

LED

# 51

LED

# 52

LED

# 53

LED

# 54

LED

#555 Clear

# 55

#555 Clear

LED

# 56

« D.O.T.S. »

R.

R

N

U

2

0

-530 -00

« D.O.T.S. »

3X

2

0

-530 -00

« D.O.T.S. »

RE

U

R H

R

N

L

2

0

-53

N

E

0

-00

« D.O.T.S. »

OU

R

L

H

N

2

0

E

-530 -00

« D.O.T.S. »

USED

NOT

112-5033-08

« D.O.T.S. »

USED

NOT

112-5033-08

« D.O.T.S. »

USED

NOT

112-5033-08

« D.O.T.S. »

USED

NOT

112-5033-08

LED

« D.O.T.S. »

2

0

-532

# 41

4

-04

LED

« D.O.T.S. »

2

0

-532

# 42

4

-04

LED

« D.O.T.S. »

2

0

-53

# 43

2

4

-04

LED

« D.O.T.S. »

2

0

-532

# 44

4

-04

LED

« D.O.T.S. »

20

-530

# 45

-00

LED

« D.O.T.S. »

2

0

-530

# 46

-00

LED

« D.O.T.S. »

112-5033-08

# 47

LED

« D.O.T.S. »

112-5033-08

# 48

RO

K

RO

K

R O K

R O K

R

L

. L

O

OO

ER

R

L .

RO

E

L

USED

NOT

E

X

R B

LL

LED

« D.O.T.S. »

20

-53

# 33

0

-00

LED

« D.O.T.S. »

112-5033-08

# 34

LED

« D.O.T.S. »

112-5033-08

# 35

LED

« D.O.T.S. »

112-5033-08

# 36

LED

« D.O.T.S. »

112-5033-08

# 37

LED

« D.O.T.S. »

112-5033-08

# 38

LED

« D.O.T.S. »

112-5033-08

# 39

LED

« D.O.T.S. »

112-5033-08

# 40

L

.

LO

O

RR

O

L

O

E

R

L

.

USED

NOT

USED

NOT

USED

NOT

USED

NOT

USED

NOT

USED

NOT

R N

« D.O.T.S. »

LED

2

0

-532

# 25

4

-0

LED

« D.O.T.S. »

2

0-532

# 26

4

-0

« D.O.T.S. »

LED

2

0

-532

# 27

4

-0

LED

« D.O.T.S. »

2

0

-532

# 28

4

-0

LED

« D.O.T.S. »

2

0

-532

# 29

4

-0

LED

« D.O.T.S. »

2

0

-530

# 30

-00

LED

« D.O.T.S. »

2

0

-530

# 31

-00

LED

« D.O.T.S. »

2

0

-530

# 32

-00

LED

L

OO

U ER

20

-53

# 17 # 18

24

#9

-01

2

LED

LED

# 19

LED

LED

« D.O.T.S. »« D.O.T.S. »

O

U

E

B

R

O

0

-532

# 10

4

-01

LED

« D.O.T.S. »

U

L

O

UR

B LL

2

0

-532

# 11

4

-01

LED

« D.O.T.S. »

OU L

L

E

NE

2

0

-530

-00

« D.O.T.S. »

2

0

-530

-00

« D.O.T.S. »

2

0-503

-00

RE

U

L

RN

E

L NE

USED

NOT

USED

NOT

# 12

LED

# 13

# 14

# 15

# 16

# 20

LED

# 21

LED

L.

N

R

U

L.

# 22

LED

L

.

N

R

U

R

# 23

.

LED

.N. .

H . NO E

R

RO

# 24

LED

« D.O.T.S. »

UL B LL

J

20

-53

24

#1

-01

« D.O.T.S. »

LED

R

U

E

E

2

R

0

-532

#2

4

-01

LED

« D.O.T.S. »

L

U E

NE

R

2

0

-53

2

#3

4

-01

LED

« D.O.T.S. »

UL B

L

B

U

2

0

L

-532

L

#4

4

-01

LED

« D.O.T.S. »

O

NN

ON

E

R

2

0

-5324

#5

-01

« D.O.T.S. »

LED

OL

NNO

LE

20

N

-5324

#6

-01

LED

« D.O.T.S. »

H O

N

NO

2

N

0

-5324

#7

-01

« D.O.T.S. »

LED

LAMP MATRIX GRID [ #1 – #80 ] {Lamp Locations : next page}

[ C. = CENTER][L. = LEFT][R. = RIGHT ]

RO

K

N

20

-5324

#8

-01

18

AC/DC LUCI MANUAL 500-55C8-01

Page 19

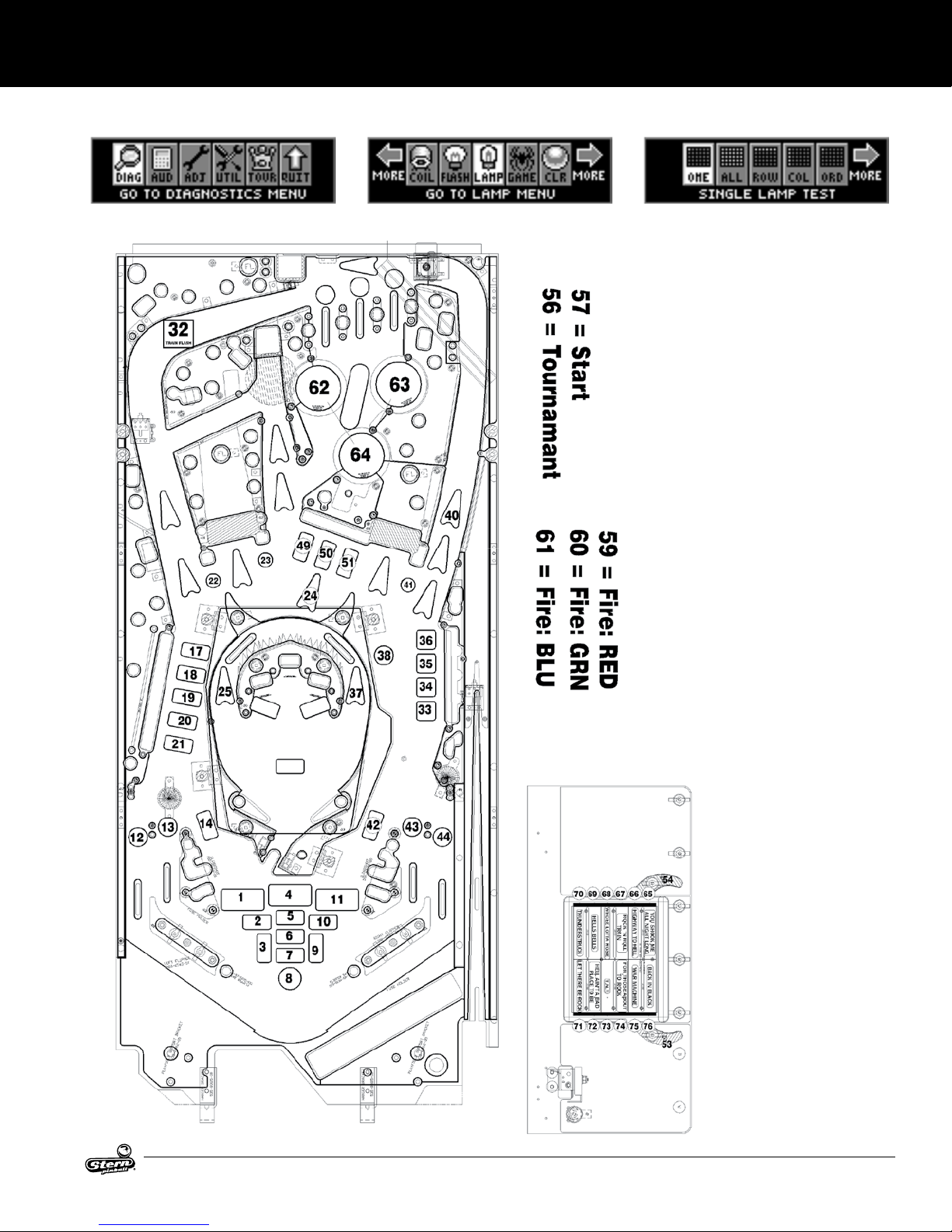

1.13 LAMP LOCATIONS

AC-DC PREMIUM SINGLE LED MAP

SETUP AND MOVING

Lamp Menu: One, All, Row, Column, & Ordered

AC/DC LUCI MANUAL 500-55C8-01

19

Page 20

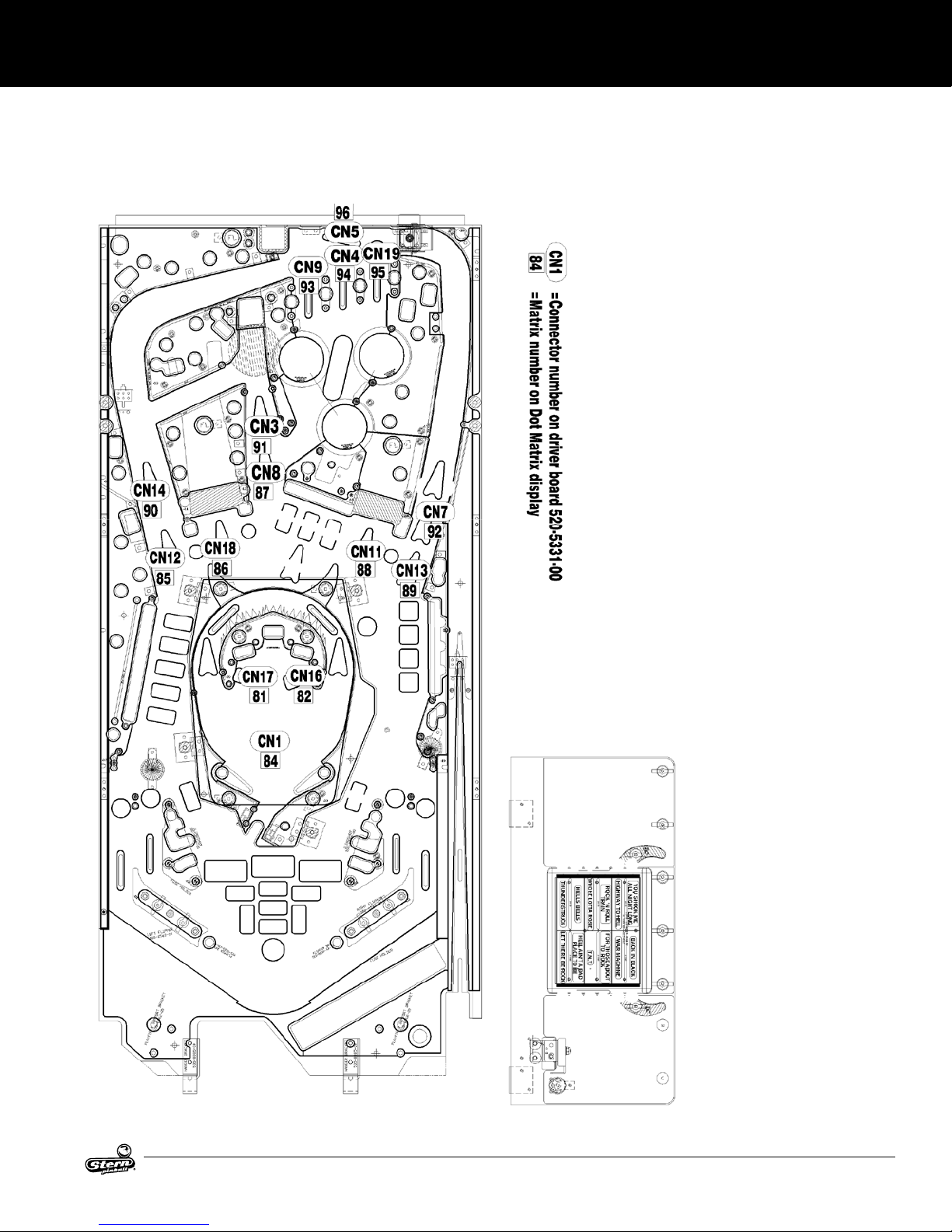

SETUP AND MOVING

LAMPNUMBER LAMPNAME CONNECTORNUMBERON

DRIVERBD.520-5331-00

81 FACE LEFT EYE CN17

82 FACE RIGHT EYE CN16

84 FACE MOUTH CN1

85 L. LOOP ARROW (BOT.) CN12

86 L. RAMP ARROW CN18

87 BELL ARROW (BOT.) CN8

88 R. RAMP ARROW CN11

89 R. LOOP ARROW (BOT.) CN13

90 L. LOOP ARROW (TOP.) CN14

91 BELL ARROW (TOP.) CN3

92 RIGHT LOOP ARROW (MID.) CN7

93 LEFT TOP LANE CN9

94 CENTER TOP LANE CN4

95 RIGHT TOP LANE CN19

96 TUNES - N - STUFF CN5

20

AC/DC LUCI MANUAL 500-55C8-01

Page 21

LAMP LOCATIONS CONTINUED

AC-DC PREMIUM TRI-COLOR LED MAP

SETUP AND MOVING

AC/DC LUCI MANUAL 500-55C8-01

21

Page 22

SETUP AND MOVING

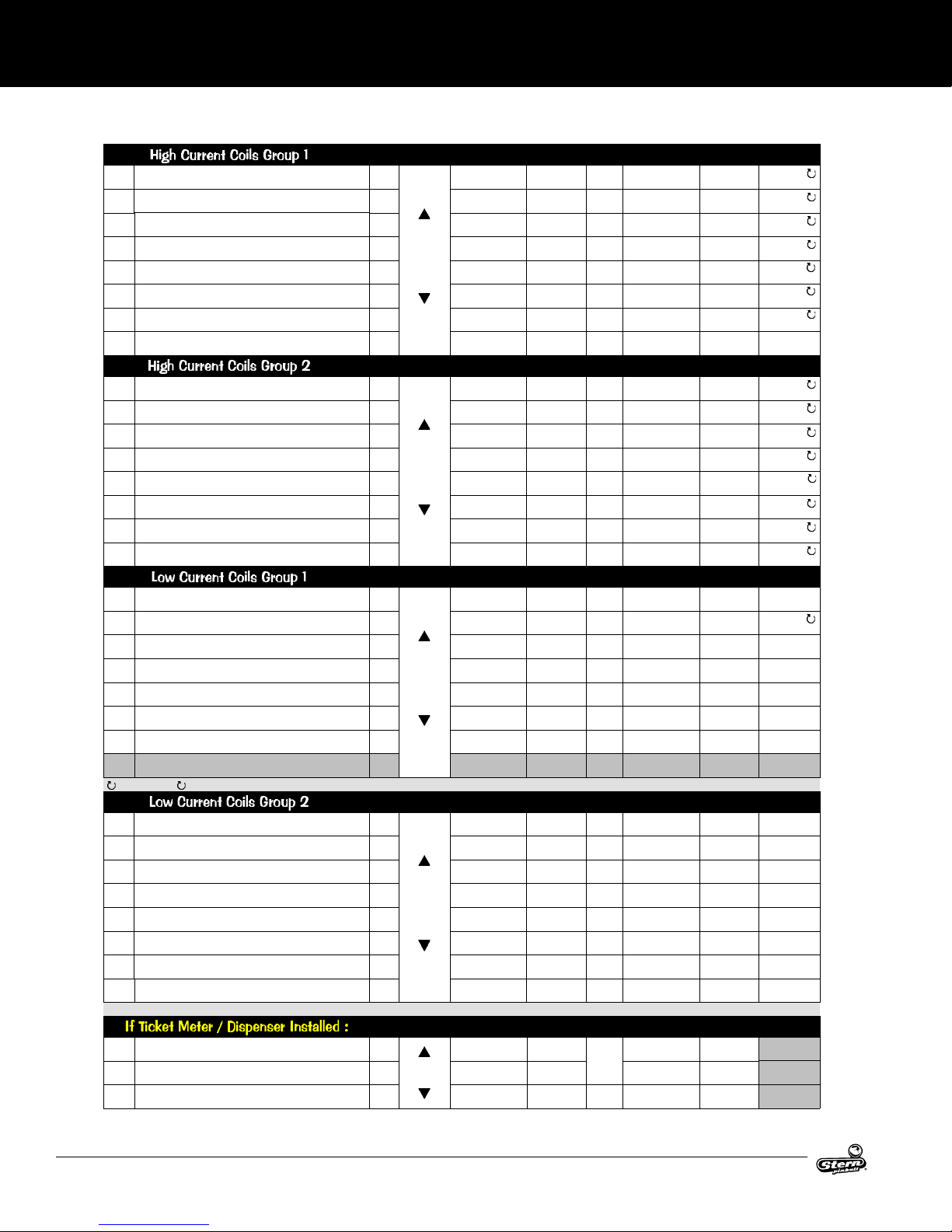

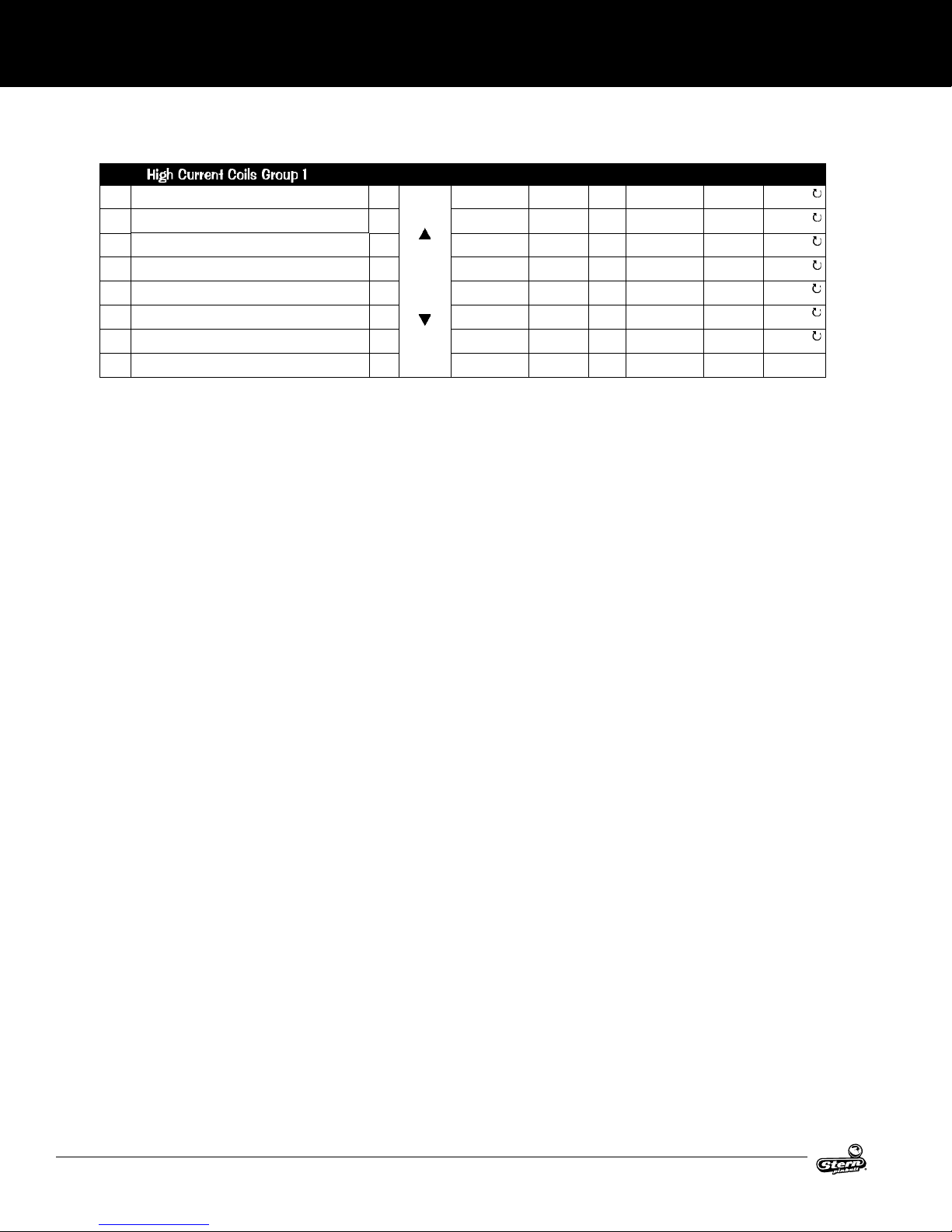

COILS DETAILED CHART TABLE

Drive

Transistor

#1 TROUGH UP-KICKER

#2 AUTO LAUNCH

#3 LOWER PLAYFIELD EJECT

#4 LOWER PLAYFIELD LEFT FLIPPER

#5 LOWER PLAYFIELD RIGHT FLIPPER

#6

LEFT 5-BANK DROP RESET (X2)

CENTER 3-BANK DROP RESET

#7

#8 SHAKER MOTOR (OPTIONAL)

#9 LEFT POP BUMPER

#10 RIGHT POP BUMPER

#11 BOTTOM POP BUMPER

#12 TOP EJECT

#13 LEFT SLINGSHOT

#14 RIGHT SLINGSHOT

#15 LEFT FLIPPER (50v RED/YEL)

#16 RIGHT FLIPPER (50v RED/YEL)

#17 TRAIN FLASHER

DETONATOR

#18

BOTTOM ARCH FLASHER (X2)

#19

#20 LEFT RAMP FLASHER

#21 LEFT SIDE FLASHER

#22 BACK PANEL FLASHER

#23 TOP EJECT FLASHER

#24 OPTIONAL (e.g. COIN METER)

Coil Note: -ND

means ’No Diode’. -00B or -00T can be used for coil replacements, but the diode must be removed. Call for more info.

#25 POP BUMPERS FLASH (X3)

#26 BELL ARROW FLASHER

#27 LEFT RAMP LEFT SIDE FLASHER

#28 LEFT RAMP RIGHT SIDE FLASHER

#29 RIGHT RAMP RIGHT SIDE FLASHER

#30 RIGHT RAMP FLASHER

#31 RIGHT SIDE FLASHER

#32 CANNON MOTOR

Note: In Test Flash Lamps Menu ("Flash" Icon), only Flashers are tested in numeric order. This Game: Q21, Q23, Q25 – Q31

#33 AUX 1: TICKET ADVANCE (ENABLE)

#34 AUX 2: TICKET METER

#35 AUX 3: SWITCHED GROUND

Q1

Q2

Q3 50VDC

Q4

Q5

Q6

Q7

Q8

Drive

Transistor

Q9

Q10

Q11

Q12

Q13 50VDC

Q14 50VDC

Q15

Q16

Drive

Transistor

Q17

Q18

Q19

Q20 20VDC

Q21

Q22 20VDC

Q23

Q24

Drive

Transistor

Q25

Q26

Q27

Q28

Q29

Q30

Q31

Q32

Drive

Trans.

Q1

Q2

Q3

Driver

Ouput PCB

I/O

Power

Driver

Driver

Ouput PCB

I/O

Power

Driver

Driver

Ouput PCB

I/O

Power

Driver

Driver

Ouput PCB

I/O

Power

Driver

Driver

Ouput PCB

Aux.

Driver

Power Line

Color

YEL-VIO J10-P9/10

YEL-VIO J10-P9/10

YEL-VIO J10-P9/10

GRY-YEL J10-P9/10

BLU-YEL J10-P9/10

YEL-VIO

YEL-VIO

RED-WHT J17-P7

Power Line

Color

YEL-VIO J10-P9/10

YEL-VIO J10-P9/10

YEL-VIO J10-P9/10

YEL-VIO J10-P9/10

YEL-VIO J10-P9/10

YEL-VIO J10-P9/10

GRY-YEL~3A

Fuse~RED-YEL

BLU-YEL~3A

Fuse~RED-YEL

Power Line

Color

ORANGE J6-P10

BROWN

ORANGE

ORANGE J6-P10

ORANGE J6-P10

ORANGE J6-P10

ORANGE J6-P10

RED J16-P4-8

Power Line

Color

ORANGE J6-P10

ORANGE J6-P10

ORANGE J6-P10

ORANGE J6-P10

ORANGE J6-P10

ORANGE J6-P10

ORANGE J6-P10

BROWN J7-P1

Power Line

Color

RED J16-P4-8

RED J16-P4-8 BROWN J2-P4

GRY-RED J16-P3

Power Line

Connection

J10-P9/10

J10-P9/10

Power Line

Connection

J10-P6/7

J10-P6/7

Power Line

Connection

J7-P1

J6-P10

Power Line

Connection

Power Line

Connection

Power

Drive Transistor

Voltage

Contro l Line Color

BRN-BLK J8-P1

50VDC

BRN-RED J8-P3

50VDC

BRN-ORG J8-P4

BRN-YEL J8-P5

50VDC

50VDC

BRN-GRN J8-P6

50VDC

BRN-BLU J8-P7

50VDC

16VDC

Voltage

50VDC

50VDC

50VDC

50VDC

BRN-VIO J8-P8

BRN-GRY J8-P9

Power

Drive Transistor

Contro l Line Color

BLU-BRN J9-P1

BLU-RED J9-P2

BLU-ORG J9-P4

BLU-YEL J9-P5

BLU-GRN J9-P6

BLU-BLK J9-P7

ORG-GRY J9-P8

50VDC

50VDC

Voltage

20VDC

20VDC

20VDC

ORG-VIO J9-P9

Power

Drive Transistor

Contro l Line Color

VIO-BRN J7-P2

VIO-RED J7-P3

VIO-ORG J7-P4

VIO-YEL J7-P6

20VDC

VIO-GRN J7-P7

VIO-BLU J7-P8

20VDC

5VDC

Voltage

20VDC

20VDC

20VDC

20VDC

20VDC

20VDC

20VDC

Vol ta ge

5VDC

1K RES.

PULL-UP

12VDC

VIO-BLK J7-P9

VIO- GRY J7-P10

Power

Drive Transistor

Contro l Line Color

BLK-BRN J6-P1

BLK-RED J6-P2

BLK-ORG J6-P3

BLK-YEL J6-P4

20DC

BLK-GRN J6-P5

BLK-BLU J6-P6

BLK-VIO J6-P7

BLK-GRY J6-P8

Power

Drive Transistor

Contro l Line Color

BLK-WHT J2-P7

WHITE J2-P3

D.T. Control

Line Connect

D.T. Control

Line Connect

D.T. Control

Line Connect

D.T. Control

Line Connect

D.T. Control

Line Connect

Coil GA -Tu rn

or Bulb Type

26-1200

090-5044-ND

23-8000

090-5001-ND

26-12000

090-5044-ND

22-1080

090-5032-ND

22-1080

090-5032-ND

25-1240

090-5034-ND

25-1240

090-5034-ND

S. Motor Kit

502-5027-00

Coil GA -Tu rn

or Bulb Type

26-1200

090-5044-ND

26-1200

090-5044-ND

26-1200

090-5044-ND

23-8000

090-5001-ND

26-1200

090-5044-ND

22-1200

090-5044-ND

22-1080

090-5032-ND

22-1080

090-5032-ND

Coil GA -Tu rn

or Bulb Type

0

LED

113-5034-08

29-1400

090-5072-03

LED0BRD

520-5328-00

LED

113-5034-08

LED

113-5034-08

LED

113-5034-08

LED

113-5034-08

Optional

5VDC

Coil GA -Tu rn

or Bulb Type

LED

113-5034-08

LED

113-5034-08

LED

112-5041-08

LED

112-5041-08

LED

112-5041-08

LED

113-5034-08

LED

113-5034-08

MOTOR

041-5111-00

Coil GA -Tu rn

or Bulb Type

Ticket

Dispenser

Ticket

Meter

Ticket

Dispenser

22

AC/DC LUCI MANUAL 500-55C8-01

Page 23

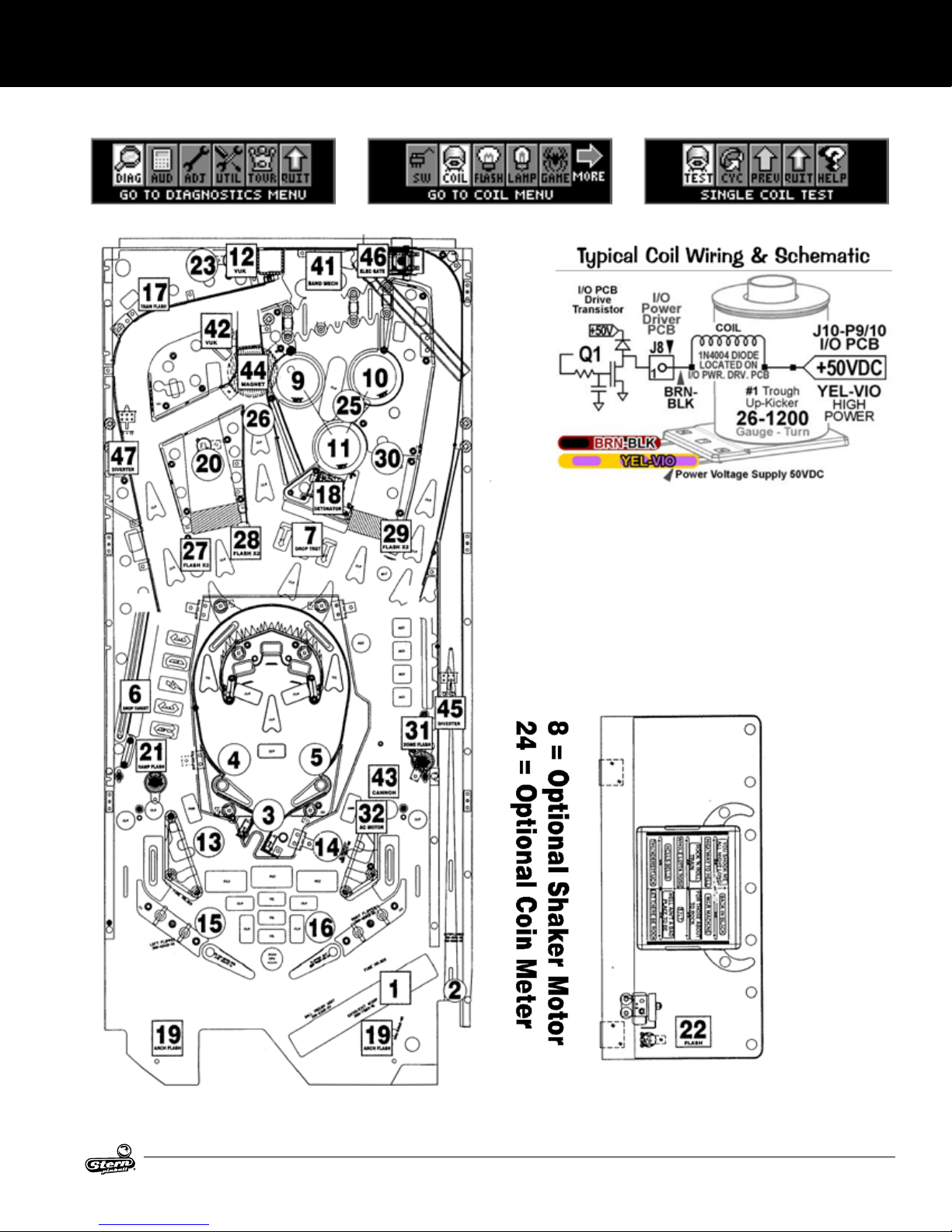

1.14 COIL LOCATIONS

SETUP AND MOVING

Coil Menu: Single Coild & Cycling Coil

AC/DC LUCI MANUAL 500-55C8-01

23

Page 24

SETUP AND MOVING

AUX COILS 41-48

#41 BAND MEMBER MECH AUX D/D0

#42 BALL EJECT

#43 CANNON EJECT

#44 BELL MAGNET

#45 RIGHT RAMP DIVERTER

#46

RIGHT CONTROL GATE

LEFT RAMP DIVERTER

#47

#48

Drive

Transistor

Driver

Ouput PCB

Q1

Q2

Q3 50VDC

I/O

Q4

Power

Driver

Q5

Q6

Q7

Power Line

Color

Power Line

Connection

YEL-VIO J2-P10

YEL-VIO J2-P10

YEL-VIO J2-P10

YEL-VIO J2-P10

YEL-VIO J2-P10

YEL-VIO

YEL-VIO

J2-P10

J2-P10

Q8

Power

Drive Transistor

Voltage

Contro l Line Color

50VDC

50VDC

BLU-BRN J2-P8

BRN-BLK J2-P7

VIO-BRN J2-P6

50VDC

50VDC

50VDC

50VDC

BLU-RED J2-P5

BRN-RED J2-P4

VIO-RED J2-P3

BLU-ORG J2-P2

D.T. Control

Line Connect

Coil GA -Tu rn

or Bulb Type

29-1400

090-5073-03

23-8000

090-5001-ND

23-8000

090-5001-ND

22-600

090-5076-ND

32-1800

515-6595-01-ND

32-1250

090-5060-01-ND

32-1800

515-6595-01-ND

24

AC/DC LUCI MANUAL 500-55C8-01

Page 25

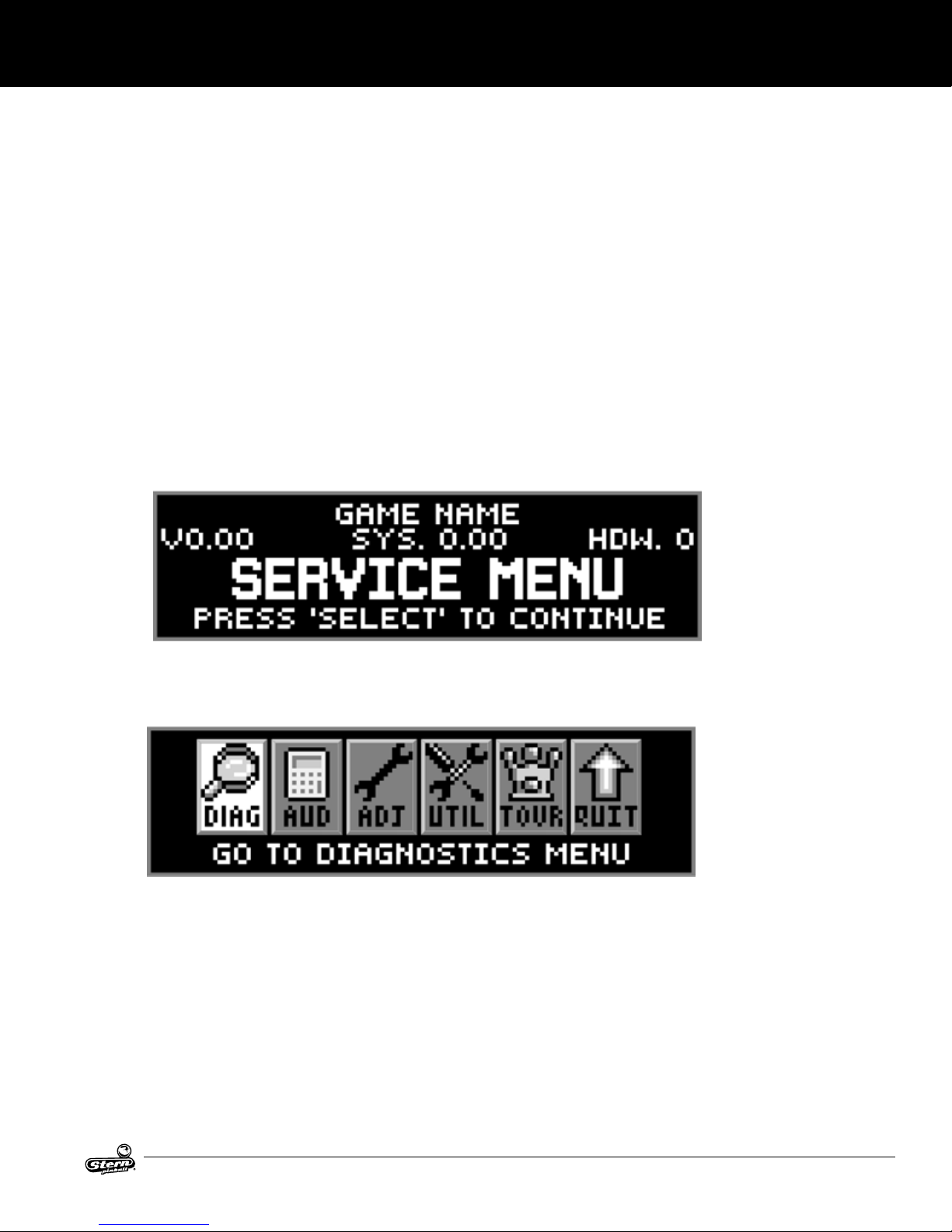

SERVICEMENUSYSTEM

2. SERVICE MENU SYSTEM

2.1 SERVICE MENU INTRODUCTION

Important: The switch bracket holds the playeld power interlock. It is located just inside the coin door frame.

The button switch for the playeld power interlock switch must be pulled out for electro-mechanical device

testing or diagnostic purposes (this is required). If this button is pushed in, the playeld power is disabled

while the coin door is open.

HOW TO USE THIS SECTION

This section will cover all functions available in the service menu in a step-by-step process. This section is

divided into chapters which coincide with the main menu (will also provide more detailed information). The

previous and following pages in this chapter will instruct the operator on how to move through the menus. It’s

simple, easy, and fun to use!

After powering up, push down the black “select” button to begin. Looking at the display you will momentarily

see “SERVICE MENU” followed by the main menu.

Use the red [</-] and [+/>] buttons to move the selected icon left or right, and the black “select” button to

activate the selected icon.

The main menu now appears with the “DIAG” icon (go to diagnostics menu) highlighted.

As the operator views the menu screen(s), the “More” [</>] symbols indicates that there are more icons to

select in each direction. The icon selected will blink. Pushing the black “select” button will select the icon

and the menu screen will change to the menu selected. Press the green “back” button to move backwards

through the menu levels. Press the green “back” button repeatedly or select the “QUIT” icon to completely

exit out of the service menu mode.

View the service menu icon tree on the next pages for a complete overview of all menus used in this

system. The “HELP” icon provides an explanation of the icon usage or any other information in the menu

where the ”HELP” icon was selected (when available).

DIAG: Go to diagnostics menu | AUD: GO to audits menu | ADJ: Go to adjustments menu | UTIL: Go to

utilities menu (Installs, Custom MSG. Custom Pricing, Set Time, Reset, & USB) | TOUR: Go to tournament

menu (Start Tournament, View Tournament Data, Sign Messages)

Use both the manual and the display to help customize, troubleshoot, and/or diagnose faults, if any.

AC/DC LUCI MANUAL 500-55C8-01

25

Page 26

SERVICEMENUSYSTEM

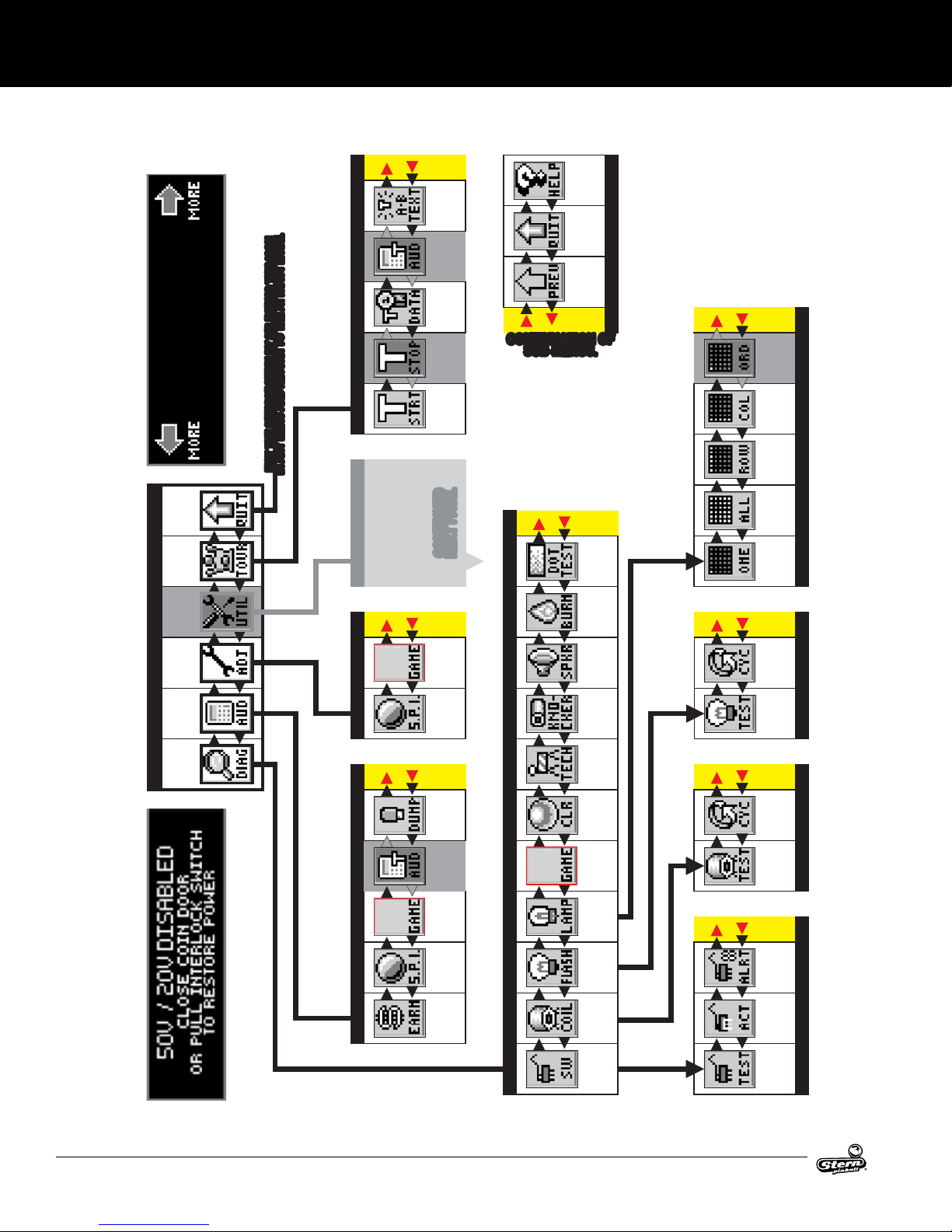

2.2 SERVICE MENU ICON TREE

snocIelbatceles-non

.noitcelesrofelbaliava

uneMdetceles

ehtotroehtot

EROM

eraerehtnehwylno

TFEL

.EDOMTCARTTAEHTOTNRUTERDNAUNEMYNANI

.EDOMTCARTTAEHTOTNRUTERDNAUNEMYNANI

NOCISIHTGNITCELESYBUNEMECIVRESEHTTIXE

NOCISIHTGNITCELESYBUNEMECIVRESEHTTIXE

ehtniraeppa

snocI

esehT

THGIR

ECIVRES

UNEM

TIXE

UNEMTNEMANRUOT

UNEMSEITILITU

YALPSID

NEERCS

PLEH

SEGASSEM

NGIS

B-A

X

TNEMAN

-RUOT

STIDUA

-ANRUOT

ATADTNEM

WEIV

X

TNEMAN

-RUOT

POTS

TNEMAN

-RUOT

TRATS

.EGAPTXEN

.EGAPTXEN

DEUNITNOC

DEUNITNOC

CONTINUATION OF

CONTINUATION OF

SUB-MENUS.

SUB-MENUS.

DEUNITNOCSUNEM...

ECIVRES

UNEM

TIXE

]UNEM[

NRUTER

...OT

DEREDRO

SPMAL

TSET

NMULOC

SPMAL

TSET

UNEMPMAL

SPMAL

TSET

WOR

SPMAL

TSET

LLA

TNEMAN

-RUOT

OTOG

UNEM

SEITILITU

UNEMNIAM

OTOG

UNEM

UNEMSTNEMTSUJDA

-TSUJDA

STNEM

OTOG

UNEM

STIDUA

OTOG

UNEM

-TSUJDA

ERUTAEF

STNEM

DRADNATS

-TSUJDA

STNEM

XIRTAM

TSET

TOD

NIGEB

NRUB

NI

REKAEPS

/DNUOS

TSET

REKCONK

TSET

ELGNIS

PMAL

TSET

UNEMSPMALHSALF

GNILCYC

HSALF

PMAL

TSET

ELGNIS

HSALF

PMAL

TSET

UNEMSCITSONGAID

SCITSON

-GAID

OTOG

UNEM

STIDUA

BSUOT

PMUD

STRELA

-HCET

NAICIN

UNEMLIOCUNEMHCTIWS

HGUORT

LLAB

TSET

GNILCYC

TSET

LIOC

ROF

.NEPOROODNIOCEHTHTIWNOITAREPO

HCTIWSKCOLRETNIREWOPEHTTUOLLUP

UNEMSTIDUA

TNEMAN

-RUOT

STIDUA

ERUTAEF

STIDUA

DRADNATS

STIDUA

SGNINRAE

STIDUA

*

CIFICEPS

-EMAG

STSET

ELGNIS

TSET

LIOC

*

OTOG

PMAL

UNEM

STRELA

SPMAL

HSALF

OTOG

UNEM

HCTIWS

*

HCTIWS

OTOG

UNEM

LIOC

EVITCA

TSET

X TSUMUOY,SUNEMDETONEHTGNIRETNENEHW

*

26

*

*

AC/DC LUCI MANUAL 500-55C8-01

HCTIWS

OTOG

UNEM

HCTIWS

TSET

Page 27

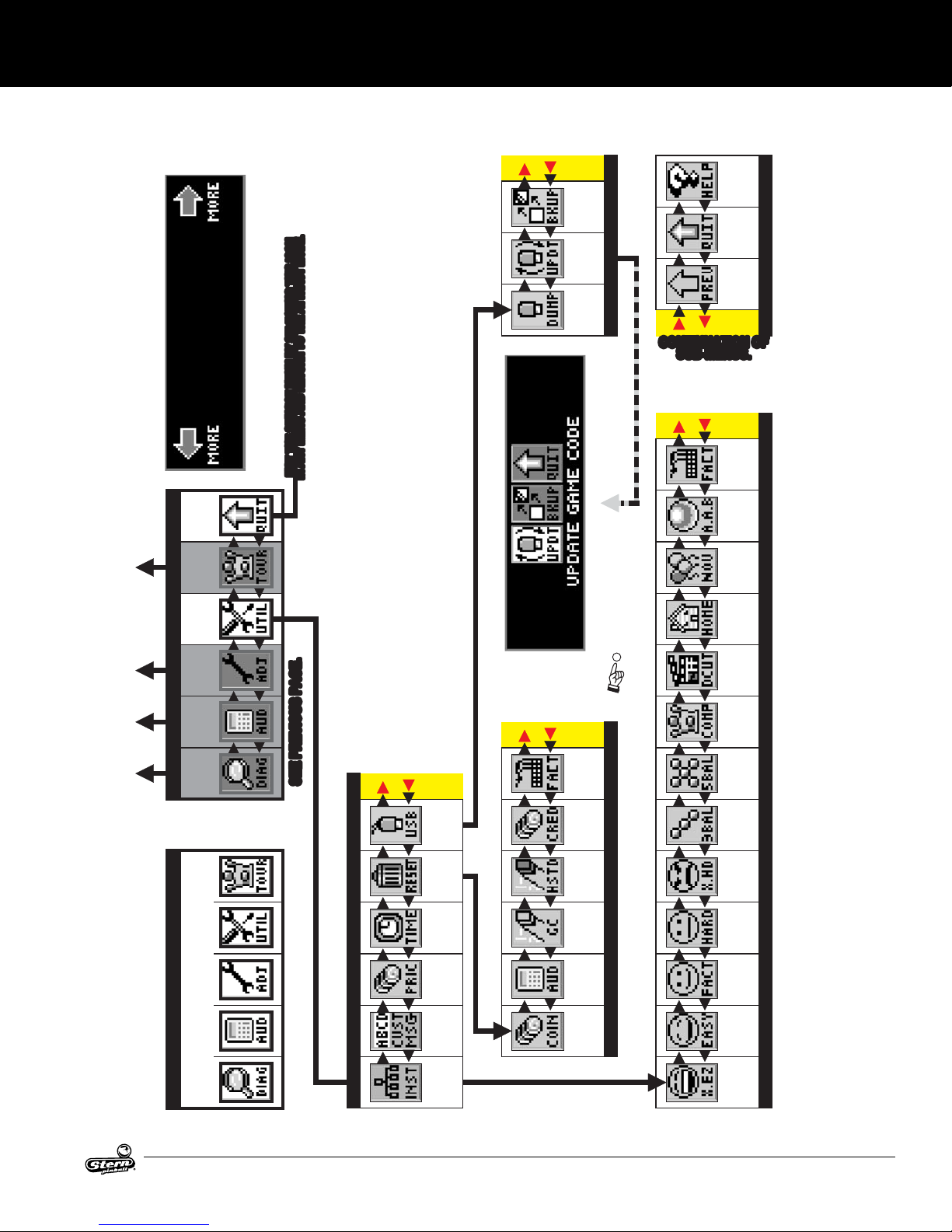

Spider-Man™ Pinball Service Menu Icon Tree Continued

SERVICE MENU ICON TREE CONTINUED

SERVICEMENUSYSTEM

nognidnepedegnahcemoS.llataraeppatonyamlanoitcnuf-nonraeppayamemos

.'RETNE'/'KO'sarotxenotehtdna,gnitteseulavaESAERCNI

snocIelbatceles-non

.noitcelesrofelbaliava

uneMdetceles

ehtotroehtot

EROM

eraerehtnehwylno

TFEL

.EDOMTCARTTAEHTOTNRUTERDNAUNEMYNANI

.EDOMTCARTTAEHTOTNRUTERDNAUNEMYNANI

NOCISIHTGNITCELESYBUNEMECIVRESEHTTIXE

NOCISIHTGNITCELESYBUNEMECIVRESEHTTIXE

ro.

snocIrosnocI

snottuBnottuB

YROMEM

PUKCAB

BSUOT

KCITS

UNEMBSU

ETADPU

EMAG

EDOC

YROMEM

BSUOT

PMUD

KCITS

]TCELES[nottuBKCALB/

ehtniraeppa

eht,epacsetixe,ogotehtesu,rebmemer ESAERCEDot

snocI

esehT

THGIR

ro

]KCAB[NEERG ]–/<[DER

syalpsidnI ,noitcnufamrofrepotedamebnacsegnahcerehw

ECIVRES

UNEM

TIXE

TNEMAN

-RUOT

OTOG

UNEM

SEITILITU

UNEMNIAM

OTOG

UNEM

gnitavitcadnagnitceleS.g.e( ehthtiwdecalpereblliw]tnemanruoTtratS[nocI"TRTS"eht

)]tnemanruoTpotS[nocI"POTS"

ro

EHTSSERP

''OT,EDOCEMAGETADPUOT

TESERBCPDNS/UPCMROFREP

8#HCTIWSPIDEVOM NO no(

.)BCPDNS/UPC

CONTINUATION OF

CONTINUATION OF

WEIVER(

STPMORPNEERCS-NOWOLLOF

.NOTTUBETIHW

.

)REVOCEDISNI

YALPSID

TIXE

NRUTER

SUB-MENUS.

SUB-MENUS.

LLATSNI

LLATSNI

LLATSNI

LLATSNI

LLATSNI

LLATSNI

LLATSNI

LLATSNI

NEERCS

PLEH

DEUNITNOCSUNEM...

ECIVRES

UNEM

]UNEM[

...OT

.puorgehtnidetcelesnocIsuoiverpynaedecrepuslliwunemsihtgnitixeerofebdetavitcanocitsalehT.ehtotsnruter

dnadellatsnisitseuqereht,ehtfoynafonoitcelesretfA.lecnacotsserP;llatsnIotsserP

YROTCAF

YROTCAF

XX

-A-DDA

-A-DDA

LLAB

LLAB

YTLEVON

YTLEVON

XX

snocIllatsnI]TCELES[:etoN

EMOH

EMOH

YALP

YALP

-TSUJDA

STNEM

OTOG

UNEM

STIDUA

OTOG

UNEM

SCITSON

-GAID

OTOG

UNEM

.EGAPSUOIVERPEES .EGAPSUOIVERPEES

.–-sretpahC,noitceSweiver,suneM-buS 623

deliatederomroF ,dnasuneMehtnonoitamrofni

2 3retpahC 4retpahC 5retpahC 6retpahCretpahC

snoitceles

:ETON ,saeraro/dnanoitacol,sgnitteshctiwSpiD,edamsnoitceles,noisreV,epyTemaGnognidnepeD

]>/+[

SGNITTES

YROTCAF

TESER

STIDERC

OTOG

UNEM

BSU

TESER

UNEMTESER

STESER

OTOG

UNEM

UNEMSEITILITU

/ETAD

EMIT

TES

MOTSUC

GNICIRP

TES

EGASSEM

MOTSUC

RETNE

SLLATSNI

OTOG

UNEM

SEROCS

TESER

HGIH

NOIPMAHC

DNARG

TESER

STIDUA

TESER

EMAG

STIDUA

TESER

NIOC

LLATSNI

LLATSNI

ROTCERID S'

ROTCERID S'

TUC

TUC

X

X

-ITEPMOC

UNEMSLLATSNI

UNEMSLLATSNI

-ITEPMOC

LLATSNI

LLATSNI

NOIT

NOIT

LLATSNI

LLATSNI

LLAB-5

LLAB-5

XX

LLATSNI

LLATSNI

LLAB-3

LLAB-3

XX

]KCAB[

LLATSNI

LLATSNI

ARTXE

ARTXE

DRAH

DRAH

LLATSNI

DRAH

DRAH

XX

NI LLATS

LLATSNI

LLATSNI

MUIDEM

MUIDEM

XX

LLATSNI

LLATSNI

YSAE

YSAE

XX

LLATSNI

LLATSNI

ARTXE

ARTXE

YSAE

YSAE

uneMllatsnI

AC/DC LUCI MANUAL 500-55C8-01

27

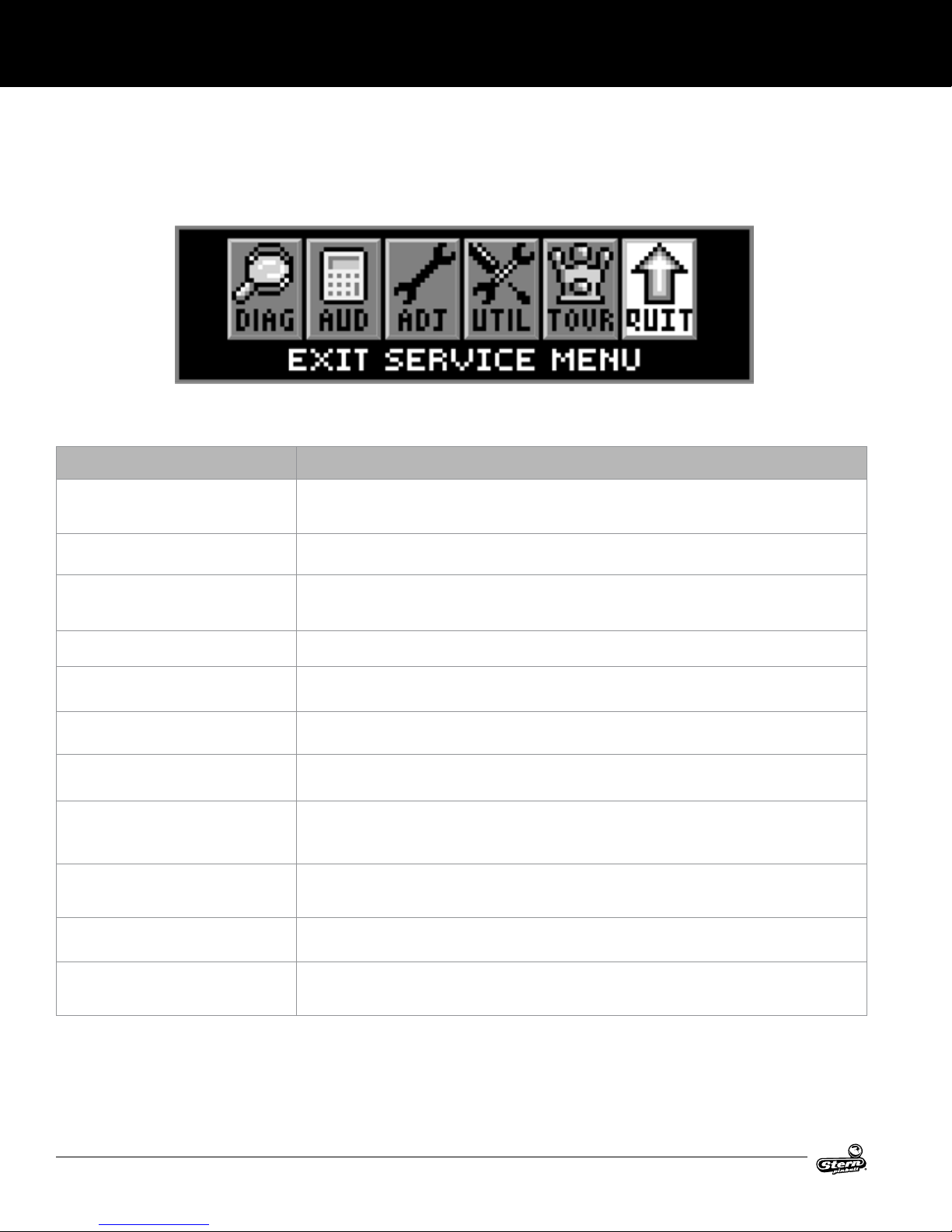

Page 28

SERVICEMENUSYSTEM

2.3 PROBLEM/SOLUTION TABLE

In the main menu and in all sub-menus (where the “QUIT” icon is present), if the “QUIT” icon is selected and activated, or the

green “BACK” button is pressed repeatedly (depending on which sub-menu you are in), the service menu session will be exited

and returned to the attract mode.

Turning the game on/off will start the power-up routine. Upon power-up, the display will indicate the country, le version, and

language(s) installed. Language/Country change via DIP switch.

Problem Solution

Will not enter the service menu after depressing the black [SELECT] button.

All the service buttons appear to be nonfunc

tional.

The green button in the attract mode will not

enter the service credits menu to add service

credits.

The display “blanks out”. • Check the dot matrix display for loose wiring harnesses, for poor or no connection, and/or broken wires.

Icons scroll along continuously in the main

menu.

• Check the service switches [Green, Red, Red, Black] for loose connections or bad ground.

• Check the associated wiring harness to/from the CPU/sound board, connector J13.

• Check the CPU/sound board for possible failure

-

• Check the service switches wiring harness for poor or no connection and/or broken wires.

• Check to make sure the game is not in Free Play. If the game is set to Free Play, adding service credits is not

required.

• Check the service switches wiring harness for poor or no connection and/or broken wires.

• Check F1 (3/4A fuse) on the display power supply board.

• Check for stuck switches on either of the red buttons.

The start and ipper buttons do not select or

activate icons in the switch test menu.

Can’t move slection of the icons with the left

and/or right ipper buttons.

Some icons appear to be non-funtional in the

menu or missing.

In the coil test menu, the coils and ashlamps

do not re after pressing the black “SELECT”

button.

In the service menu, the volume cannot be

adjusted with either of the red buttons.

In the service menu, the display seems to

lock up or the help display appears to be

non-functional

28

• This is normal. These switches are deactivated as they are part of the switch test.

• Check the ipper buttons for loose connections or bad grounding.

• This is normal only in diagnostics switch & active switch tests

• Some functionality of the service menu may not have been completed during development. If absent, it should

only be a non-critical function such as the “HELP” icon, which will explain the usage of icons. When completed,

a software update will correct the problem. Software updates are announced via Service Bulletins and on our

website (http://www.sternpinball.com/service-bulletins)

• Ensure the power interlock switch is pulled out.

• The volume adjustment can only be made when in the attract mode.

• If you cannot clear the situation by exiting back one menu, exit completely out of the service menu and re-

enter. If the problem persists, call technical support for additional help.

AC/DC LUCI MANUAL 500-55C8-01

Page 29

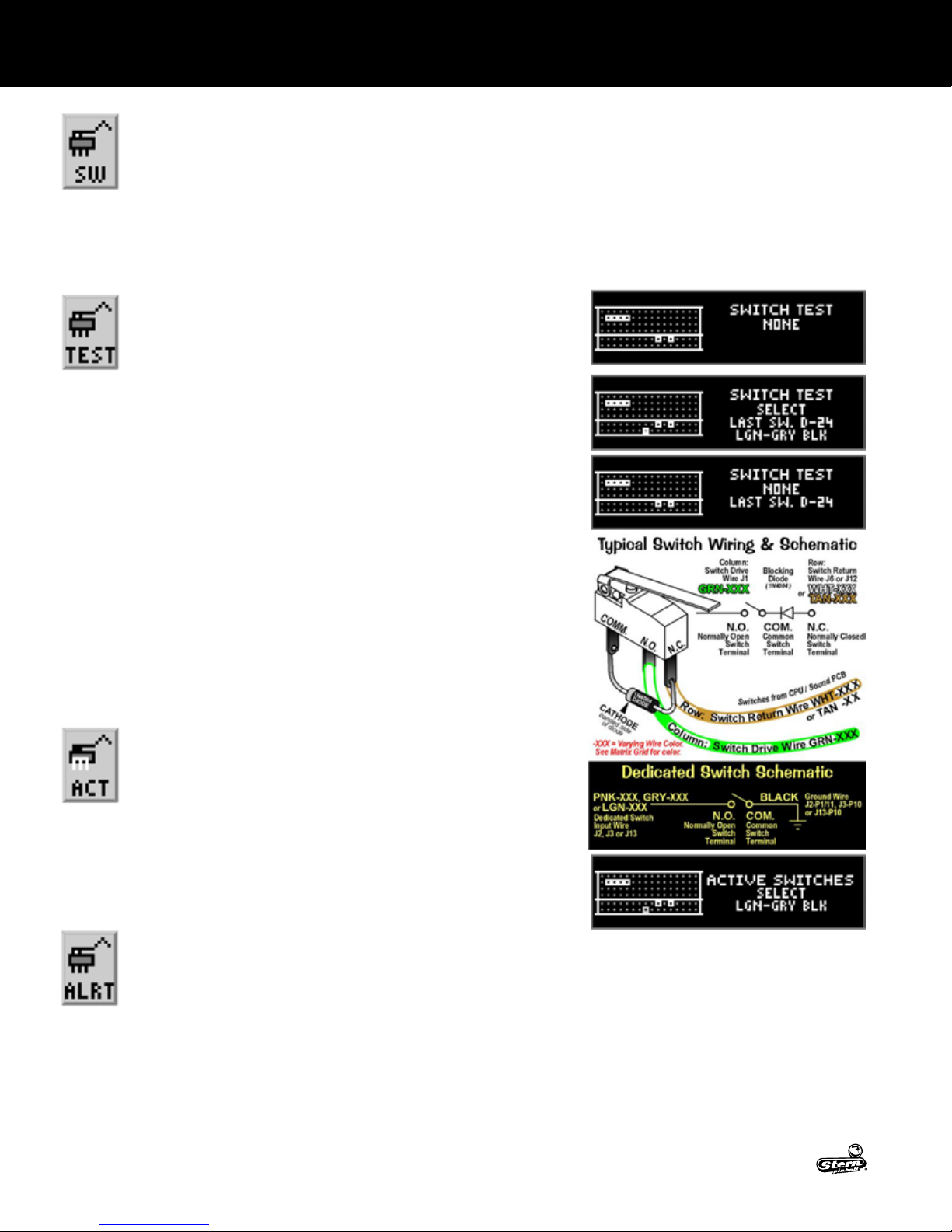

SERVICEMENUSYSTEM

2.4 DIAGNOSTICS MENU

To initiate, from the main menu select the “DIAG” icon. The diagnostics menu provides the tests for switches, coils, ash lamps,

lamps, sounds, and dots in the dot matrix display. Each feature may be tested manually or automatically after entering the service

menu. The [CYCLING COIL TEST]/[FLASH LAMP TEST] may be used for a quick verication of automatic test functions. The

[SWITCH TEST] / [SINGLE COIL TEST] / [SINGLE LAMP TEST] / [ALL LAMP TEST] / [ROW LAMPS TEST] / [COLUMN LAMPS

TEST] / [FLASH LAMP TEST] may be used for troubleshooting.

All diagnostics menu icons and their usages are explained throughout this chapter in the same order as seen in the dot matrix

display. Note: Depending on the game type, version, selections made, DIP switch settings, location and/or areas, some icons

may appear non-functional or may not appear at all. Some icons change depending on selection (e.g. Selecting and activating

the “STRT” icon [Start Tournament] will be replaced with the “STOP” icon [Stop Tournament]). Icons and/or functions, order, and

operation are subject to change.

Important: Upon power-up (game CPU reset) or opening the coin door, watch the display for any alerts.

This audible/visual alert display is shown when the 50v/20v power is disabled (by opening the coin door). Pull out the interlock switch only while in

the service menu for coil or switch testing & burn-in when the coin door is

required to stay open for service button use. Pulling out the power interlock

switch or pressing the ‘escape’ green [BACK] button will remove the alert

display. Initial display presentation is accompanied by 3 audible tones (the

bright display warning will go dim after approximately 30 seconds).

This alert display is shown momentarily during game mode or power-up to

alert the operator of a device malfunction (device or mechanism doesn’t

energize or is energized repeatedly). Operator Alert works by monitoring any

switch activated device that has the potential to trap a ball when disabled

(e.g. in the shooter lane, scoop, or eject holes, etc.). This alert can also appear if a switch associated with a device (e.g. ball trough, auto plunger, etc.)

is stuck closed (caused by a switch jam or stuck ball); the game will activate

the device a predetermined number of times and if the problem is still detected, this device will be noted in Switch Alerts and/or Technical Alerts.

Upon entering the service menu, if an asterisk “ * ” is displayed after the

words “SERVICE MENU”, the game had detected possible faulty devices,

switches, and/or missing pinballs. Press either of the red buttons (short-cut