Sterling Trucks Acterra MX User Manual

ACTERRA MAINTENANCE MANUAL

Models: MX

STI-403-1 (10/07P)

Published by

Freightliner LLC

4747 N. Channel Ave.

Portland, OR 97217

Printed in U.S.A.

Foreword

When performed on a regular basis, lubricating the parts of your vehicle is the least costly way

of obtaining safe and reliable vehicle operation. Added benefits and savings occur when you

check that theengine, undercarriage, andnoise emission controlparts are ingood working order

during lubrication.

This maintenance manual explains when you should lubricate parts and what to look for when

checking for wear or damage. For daily and weekly checks, refer to the vehicle driver’s manual.

IMPORTANT:Descriptions and specificationsin this manual were in effectat the time of

printing. Sterling Truck Corporation reserves the right to discontinue models and to

change specifications or design at any time without notice and without incurring

obligation. Descriptions and specifications contained in this publication provide no

warranty, expressed or implied, and are subject to revision and editions without notice.

For additional information, please contact Freightliner LLC, Service Systems and Documentation, P.O. Box 3849, Portland, OR 97208-3849, U.S.A. or refer to www.Freightliner.com and

www.SterlingTrucks.com.

Environmental Concerns and Recommendations

Whenever you seeinstructions in this manual todiscard materials, youshould attempt to reclaim

and recycle them. To preserve our environment, follow appropriate environmental rules and

regulations when disposing of materials.

NOTICE: Parts Replacement Considerations

Do not replace suspension, axle, or steering parts (such as springs, wheels, hubs, and steering

gears) with used parts. Used parts may have been subjected to collisions or improper use and

have undetected structural damage.

© 2000-2007 Freightliner LLC

All rights reserved. No partof this publication, in whole or inpart, may be translated, reproduced,

stored in a retrieval system, or transmitted in any form by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of Freightliner LLC.

Freightliner LLC

Service Systems and Documentation (POC-SSD)

P.O. Box 3849

Portland, OR 97208–3849

Introduction

Descriptions of Service Publications

Freightliner LLC distributes the following major service publications.

Workshop Manual Workshop manuals contain service and repair information for all vehicle sys-

tems and components, except for major components such as engines, transmissions, and rear axles. Each workshop manual section is divided into subjects

that can include general information, principles of operation, removal, disassembly, assembly, installation, specifications, and troubleshooting.

Maintenance Manual Maintenance manuals contain routine maintenance procedures and intervals for

vehicle components and systems. They have information such as lubrication

procedures and tables, fluid replacement procedures, fluid capacities, specifications, procedures for adjustments and for checking the tightness of fasteners.

Maintenance manuals do not contain detailed repair or service information.

Driver’s Manual Driver’s manuals contain information needed to enhance the driver’s under-

standing of how to operate and care for the vehicle and its components. Each

manual contains a chapter that covers pretrip inspection and daily maintenance

of vehicle components. Driver’s manuals do not contain detailed repair or service information.

Parts Technical Manual Freightliner LLC publishes this manual to aid in the identification of serviceable

replacement vehicle parts. This manual is used in conjunction with the parts

book and the service parts catalog microfiche.

Service Bulletins Service bulletins provide the latest service tips, field repairs, product improve-

ments, and related information. Some service bulletins are updates to information in the workshop manual. These bulletins take precedence over workshop

manual information, until the latter is updated; at that time, the bulletin is usually

canceled. The service bulletins manual is available only to dealers. When doing

service work on a vehicle system or part, check for a valid service bulletin for

the latest information on the subject.

IMPORTANT: Before using a particular service bulletin, check the current

service bulletin validity list to be sure the bulletin is valid.

Recall Bulletins These bulletins pertain to special situations that involve service work or replace-

ment of parts in connection with a recall notice. Recall bulletins pertain to matters of vehicle safety. All bulletins are distributed to dealers; customers receive

notices that apply to their vehicles.

Field Service

Modifications

This publication is concerned with non-safety-related service work or replacement of parts. All field service modifications are distributed to dealers; customers receive notices that apply to their vehicles.

Acterra Maintenance Manual, January 2003 I–1

Introduction

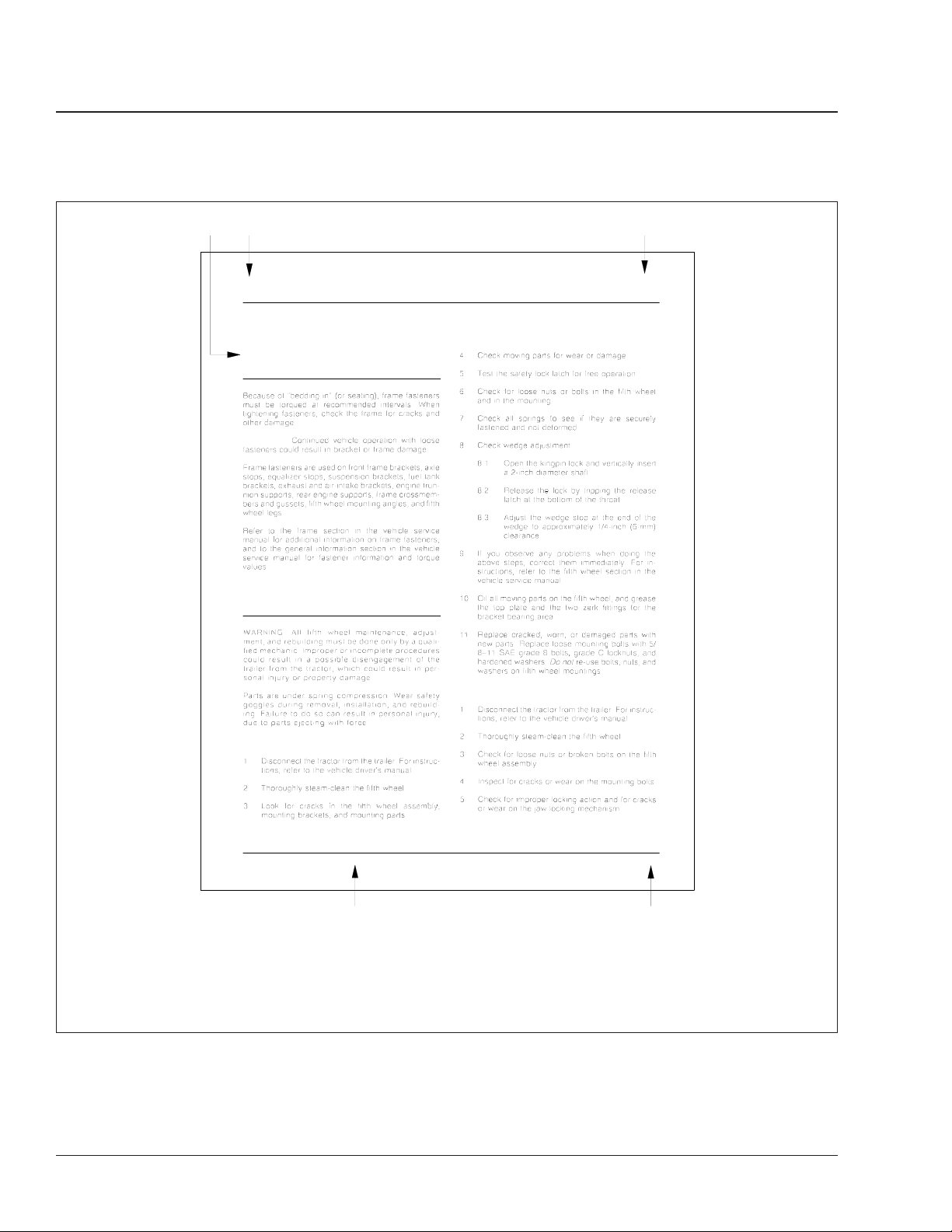

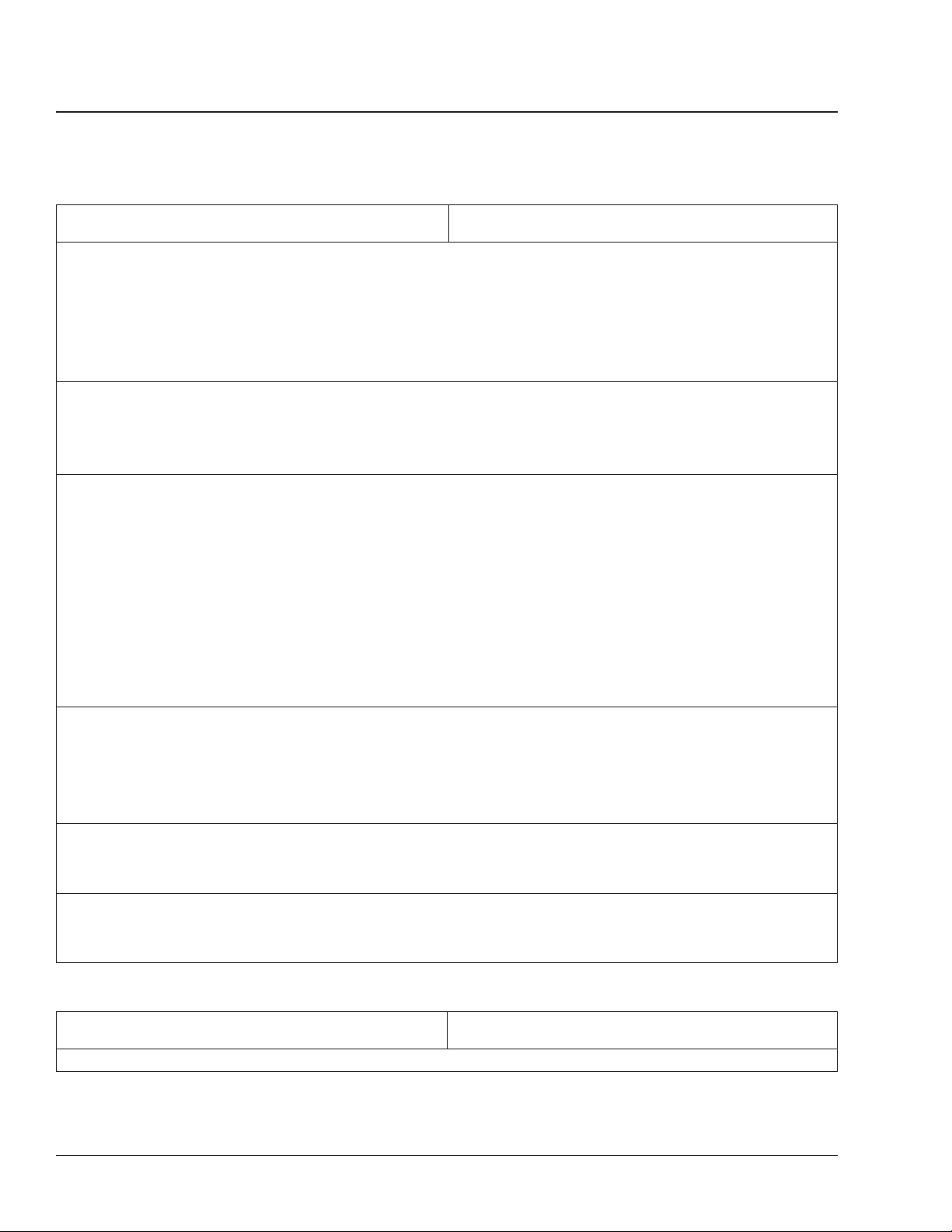

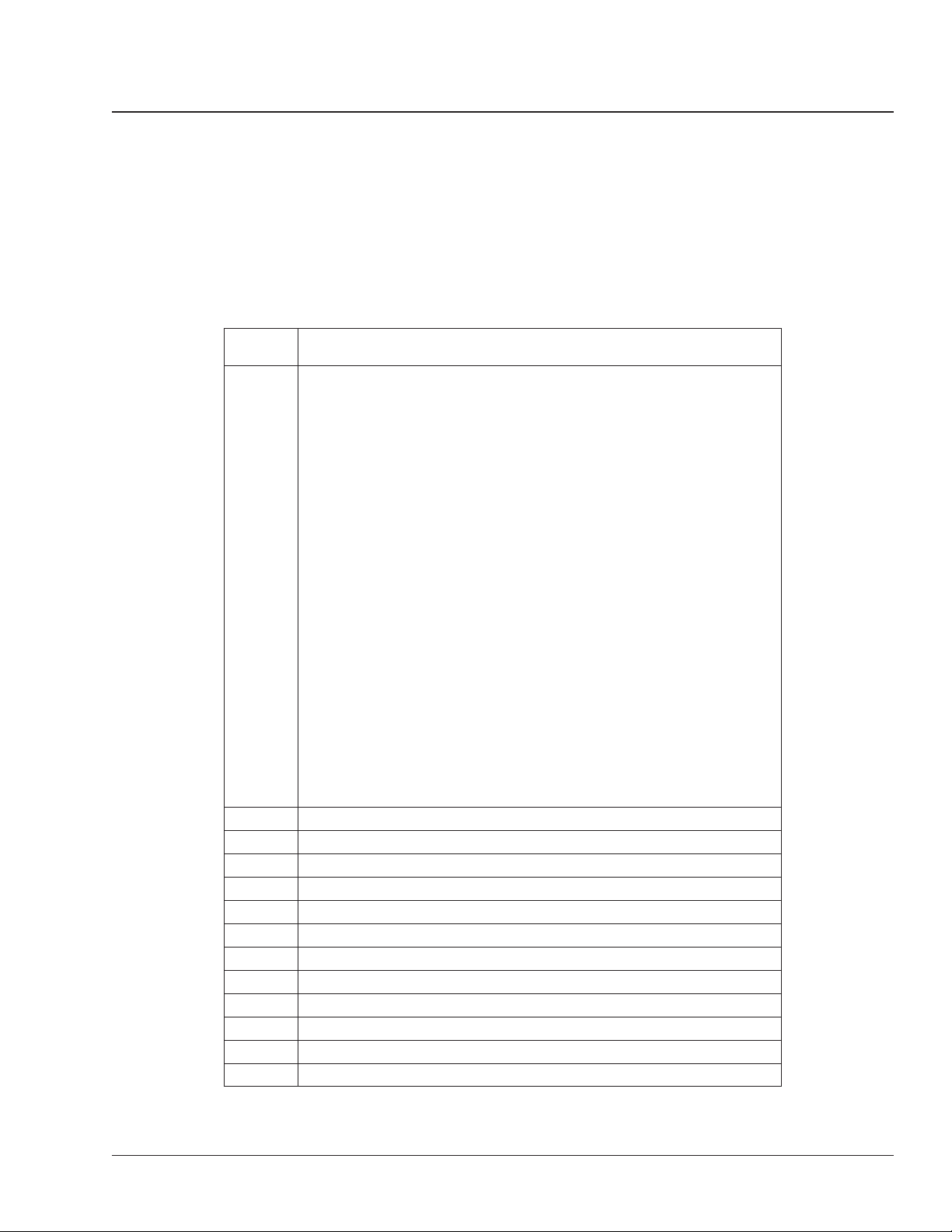

For a page example of the printed manual, see Fig. 1.

A

BC

Page Description

Frame and Fifth Wheel

31−01 Frame Fastener Torque

Checking

CAUTION:

31−02 Fifth Wheel Inspecting and

Lubricating

31

HOLLAND

FONTANE

Acterra Trucks Maintenance Manual, April 2000

D

02/11/2002

31/1

E

f020103

A. Maintenance Operation Number consists of the Group Number followed by the Sequence Number

B. Group Title

C. Group Number

D. Release Date

E. Group Number/Page Number

Fig. 1, Page Example of the Printed Manual

I–2 Acterra Maintenance Manual, January 2003

Maintenance Manual Contents

Group No. Group Title

00...................... General Information

01................................ Engine

09.............................. AirIntake

13......................... AirCompressor

15................... Alternators and Starters

20................... Engine Cooling/Radiator

25................................ Clutch

26........................... Transmission

31............. Frame and Frame Components

32............................ Suspension

33............................. Front Axle

35 ............................. Rear Axle

40........................ Wheels and Tires

41.............................. Driveline

42................................ Brakes

46............................... Steering

47 ................................. Fuel

49............................... Exhaust

54.......... Electrical, Instruments, and Controls

72................................ Doors

83................. Heater and Air Conditioner

Introduction

Acterra Maintenance Manual, January 2003 I–3

General Information 00

Index, Alphabetical

Title of Maintenance Operation (MOP) MOP Number

Initial Maintenance (IM) Operations Table................................................00–09

Lubrication and Fluid Level Check (M1)..................................................00–15

Lubrication and Fluid Level Check (M2)..................................................00–16

M1 Maintenance Interval Operations Table...............................................00–10

M2 Maintenance Interval Operations Table ............................................... 00–11

M3 Maintenance Interval Operations Table...............................................00–12

M4 Maintenance Interval Operations Table...............................................00–13

M5 Maintenance Interval Operations Table...............................................00–14

Maintenance Interval Tables..........................................................00–07

Maintenance Operation Sets Tables....................................................00–08

Maintenance Schedule Table .........................................................00–06

Metric/U.S. Customary Conversion Tables................................................00–04

Noise Emission Control Systems Maintenance ............................................00–01

Scheduled Maintenance Intervals, Description and Use......................................00–05

Torque Specifications Tables..........................................................00–03

Verification of Inspections Log.........................................................00–02

Acterra Maintenance Manual, January 2007

General Information 00

Noise Emission Control Systems Maintenance: 00–01

General Information

Federal Law, Part 205:

Transportation Equipment Noise

Emission Controls

Part 205, Transportation Equipment Noise Emission

Controls, requires the vehicle manufacturer to furnish, with each new vehicle, such written instructions

for the proper maintenance, use, and repair of the

vehicle by the ultimate purchaser to provide reasonable assurance of the elimination or minimization of

noise emission degradation throughout the life of the

vehicle. In compliance with the law, the Noise Emission Control Systems maintenance located in each

applicable group within this manual, in conjunction

with the vehicle workshop manual, provides these

instructions to owners.

Normal Vehicle Use

The maintenance instructions contained in this

manual are based on average vehicle use and normal operating conditions. Unusual vehicle operating

conditions may require service at more frequent intervals.

Recommendations for

Replacement Parts

Replacement parts used for maintenance or for the

repair of noise emission control systems should be

genuine Sterling parts. If other than genuine Sterling

parts are used for replacements or for the repair of

components affecting noise emission control, the

owner should be sure that such parts are warranted

by their manufacturer to be equivalent to genuine

Sterling parts in performance and durability.

Sterling Noise Emissions

Warranty

Tampering With the Noise

Control System Is Prohibited

Federal law prohibits the following acts or the causing thereof: (1) the removal or rendering inoperative

by any person other than for purposes of maintenance, repair, or replacement, of any device or element of design incorporated into any new vehicle for

the purpose of noise control prior to its sale or delivery to the ultimate purchaser or while it is in use, or

(2) the use of the vehicle after such device or element of design has been removed or rendered inoperative by any person. Among those acts presumed

to constitute tampering are the acts listed below:

A. Removal of engine noise-deadening panels.

B. Removal of or rendering the engine speed gover-

nor inoperative so as to allow engine speed to

exceed manufacturer’s specifications.

C. Removal of or rendering inoperative the fan

clutch, including by-passing the control on any

thermostatic fan drive to cause it to operate con-

tinuously.

D. Removal of the fan shroud.

E. Removal of or rendering inoperative exhaust sys-

tem components, including exhaust pipe clamp-

ing.

F. Removal of air intake system components.

G. Removal of hood liners (noise-deadening pan-

els).

Maintenance Instructions

Scheduled intervals are in the maintenance tables in

Group 00 of this manual. A "Verification of Inspections Log" is contained in the following table, and

should be filled in each time the noise emission controls on the vehicle are maintained or repaired.

See the vehicle owner’s warranty information book

for warranty information concerning noise emission

control systems.

Acterra Maintenance Manual, January 2007 00/1

General Information00

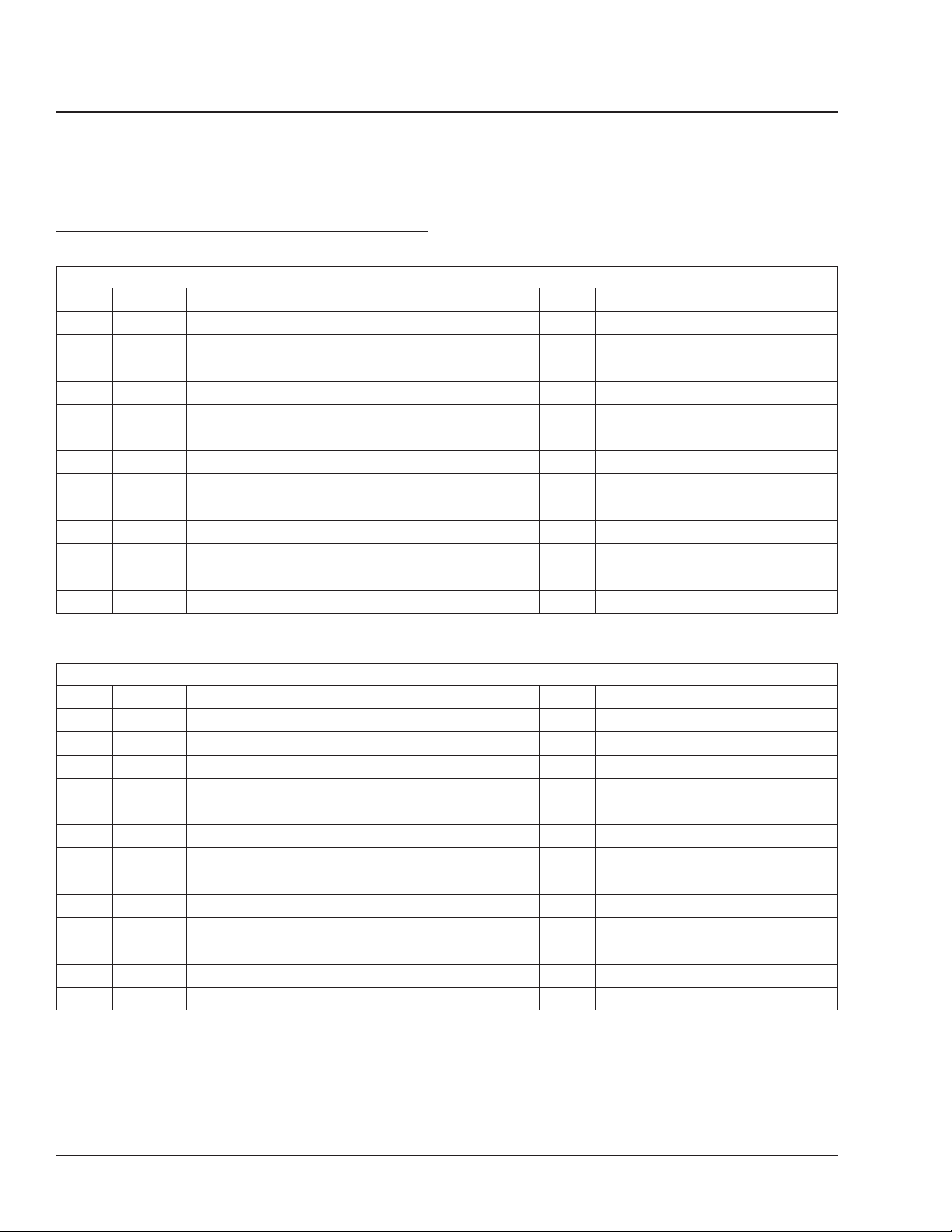

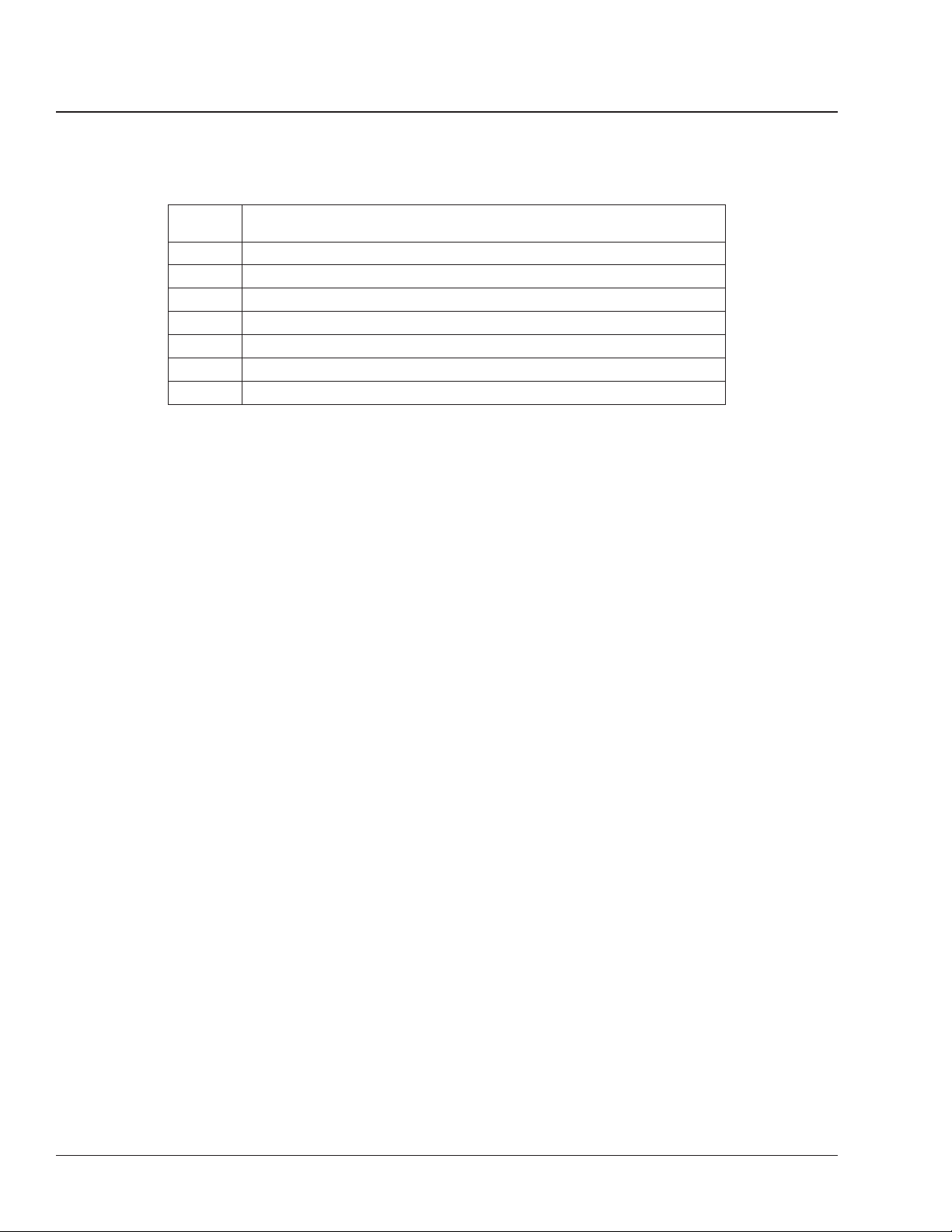

Verification of Inspections Log: 00–02

Verification of Inspections Log

Verification of Inspections Log — Group 20

Verification of Inspections Log — Group 20 — Engine Cooling/Radiator

Date Mileage Repair Description Cost Repair Facility

Verification of Inspections Log — Group 49

Verification of Inspections Log — Group 49 — Exhaust

Date Mileage Repair Description Cost Repair Facility

Acterra Maintenance Manual, January 200700/2

General Information 00

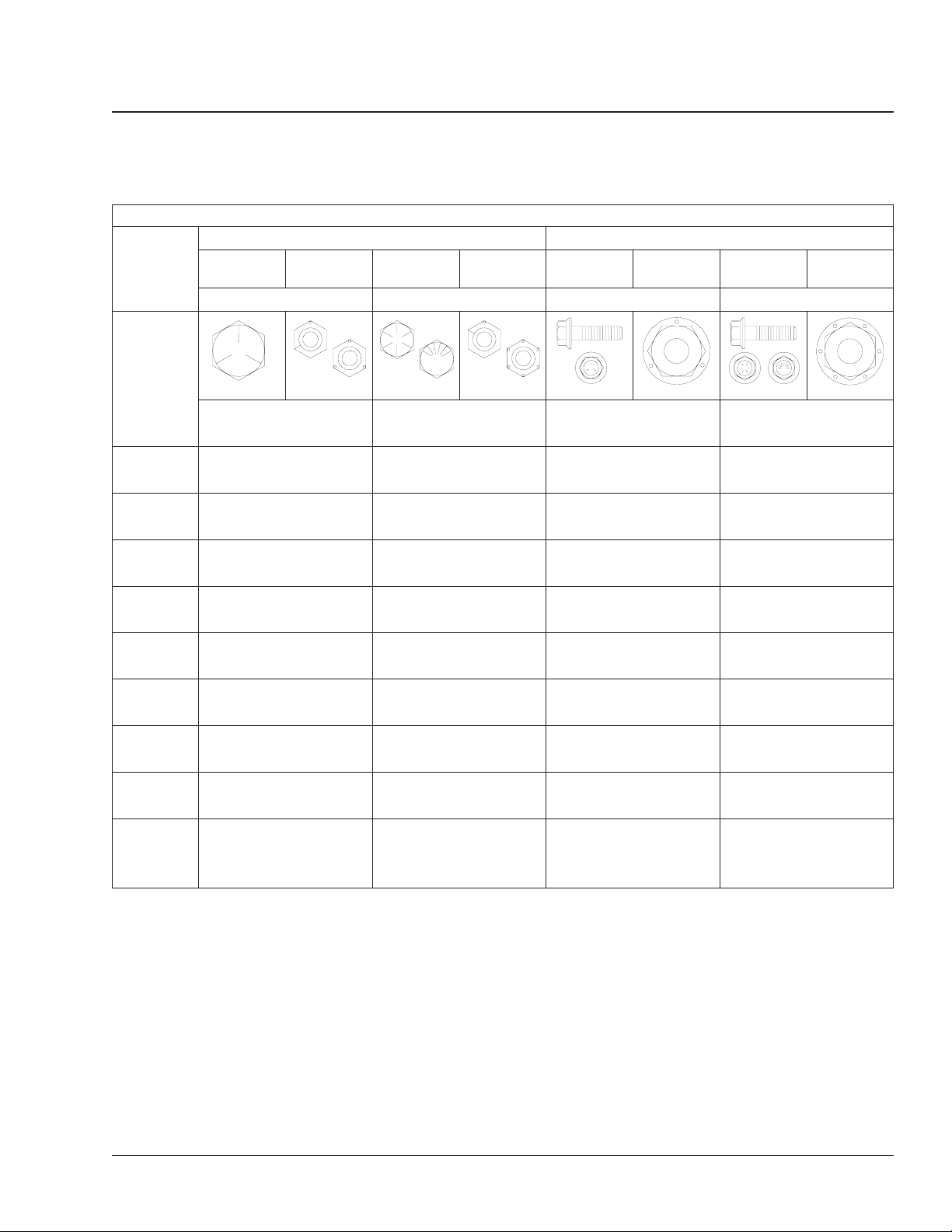

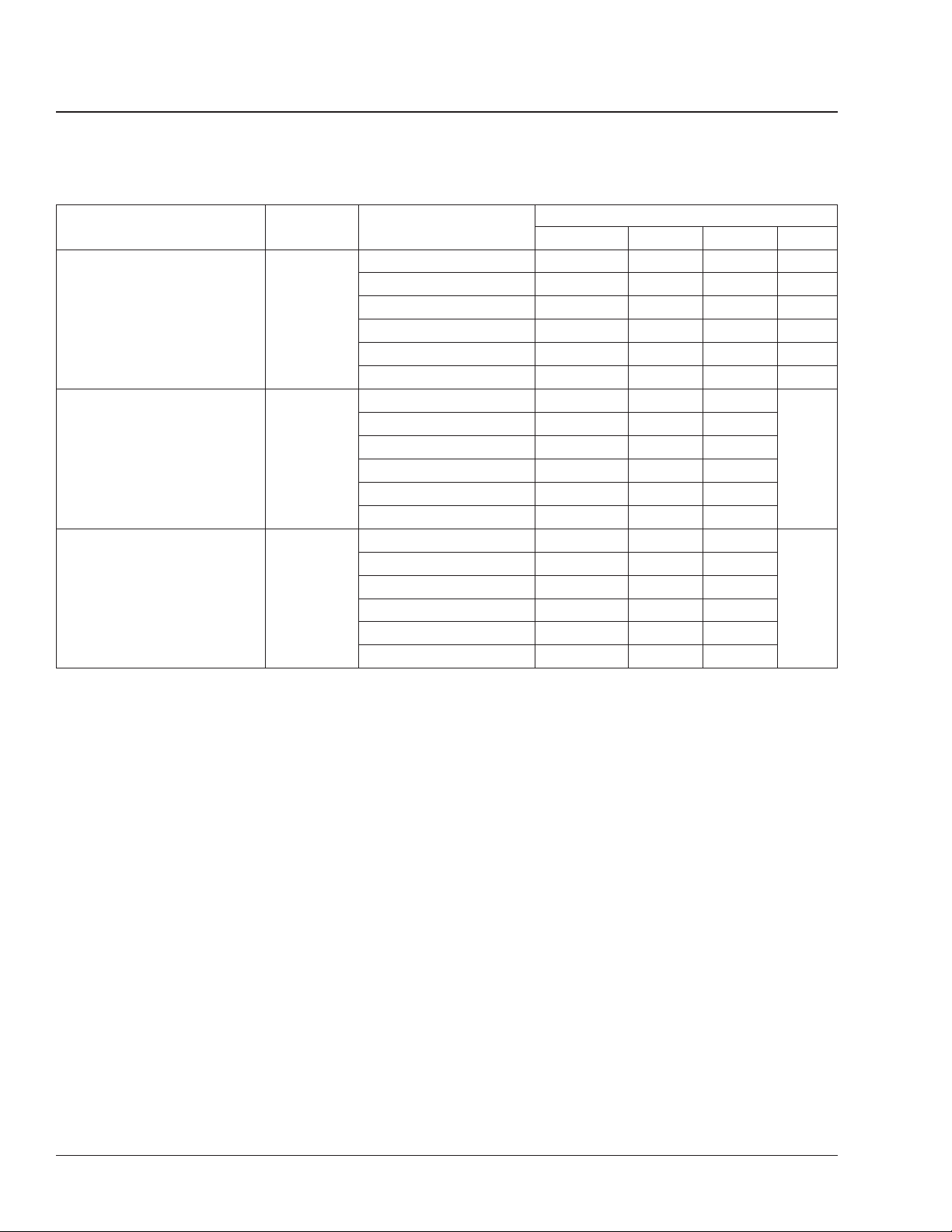

Torque Specifications Tables: 00–03

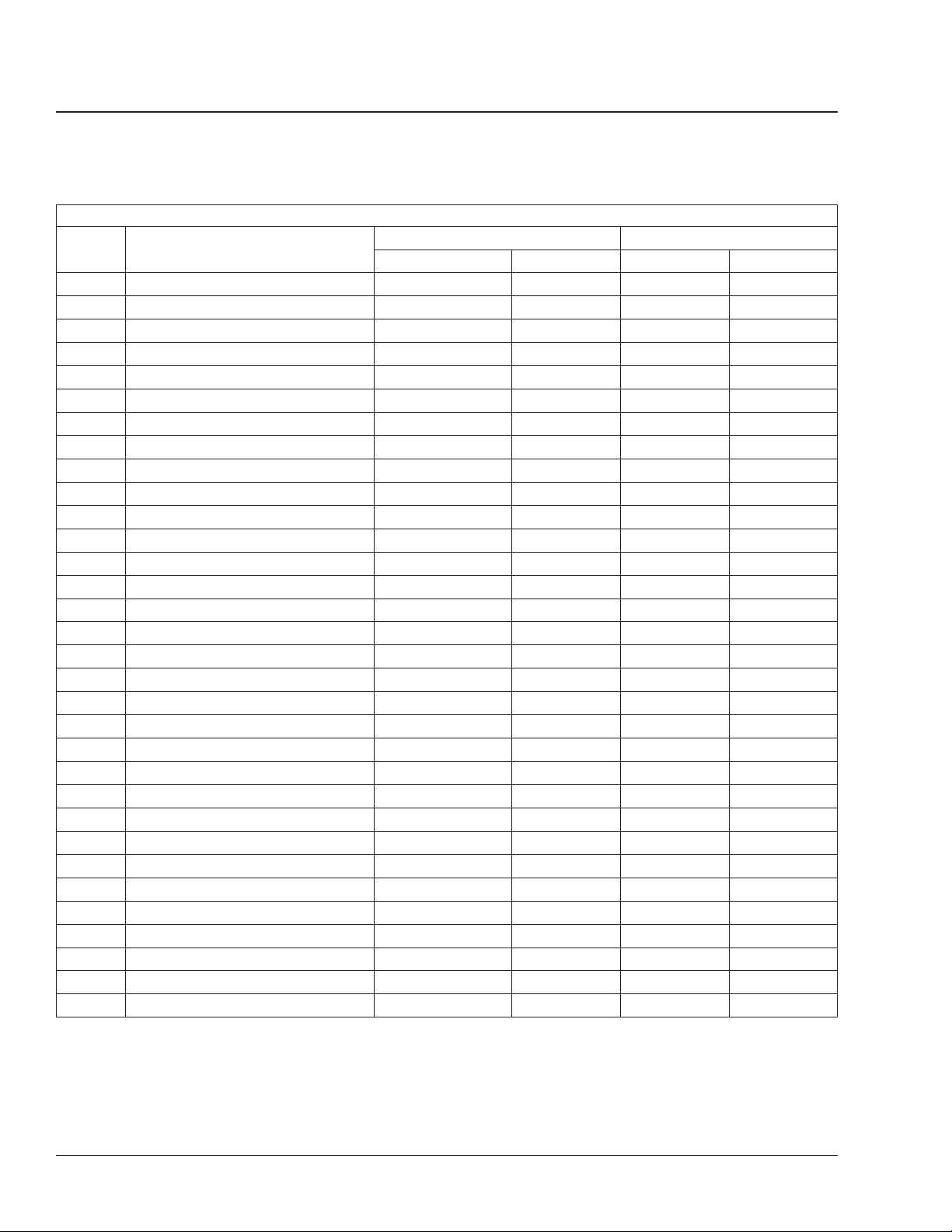

Torque Values for U.S. Customary Thread Fasteners With Lubricated*or Plated Threads

Regular Hex Flanged

Thread

Diameter–

Pitch

Grade 5

Bolt

Grade 5 or

BNut

Grade 8 or

8.2 Bolt

Grade 8 or

CNut

Grade 5

Bolt

Grade B

Nut

Grade 8 or

8.2 Bolt

Torque: lbf·ft (N·m) Torque: lbf·ft (N·m) Torque: lbf·ft (N·m) Torque: lbf·ft (N·m)

f230002

f230003

f230004

f230005

f230006

f230007

f230008

1/4–20 7 (9) 8 (11) 6 (8) 10 (14)

1/4–28 8 (11) 9 (12) 7 (9) 12 (16)

5/16–18 15 (20) 16 (22) 13 (18) 21 (28)

5/16–24 16 (22) 17 (23) 14 (19) 23 (31)

3/8–16 26 (35) 28 (38) 23 (31) 37 (50)

3/8–24 30 (41) 32 (43) 25 (34) 42 (57)

7/16–14 42 (57) 45 (61) 35 (47) 60 (81)

7/16–20 47 (64) 50 (68) 40 (54) 66 (89)

1/2–13 64 (87) 68 (92) 55 (75) 91 (123)

1/2–20 72 (98) 77 (104) 65 (88) 102 (138)

9/16–12 92 (125) 98 (133) 80 (108) 130 (176)

9/16–18 103 (140) 110 (149) 90 (122) 146 (198)

5/8–11 128 (173) 136 (184) 110 (149) 180 (244)

5/8–18 145 (197) 154 (209) 130 (176) 204 (277)

3/4–10 226 (306) 241 (327) 200 (271) 320 (434)

3/4–16 253 (343) 269 (365) 220 (298) 357 (484)

7/8–9 365 (495) 388 (526) 320 (434) 515 (698)

7/8–14 402 (545) 427 (579) 350 (475) 568 (770)

1–8 — 582 (789) — —

1–12 — 637 (863) — —

1–14 — 652 (884) — —

*

Sterling recommends that all plated and unplated fasteners be coated with oil before installation.

†

Use these torque values if either the bolt or nut is lubricated or plated (zinc-phosphate conversion-coated, cadmium-plated, or waxed).

Table 1, Torque Values for U.S. Customary Thread Fasteners With Lubricated or Plated Threads

†

Grade G

Nut

f230009

Acterra Maintenance Manual, January 2007 00/3

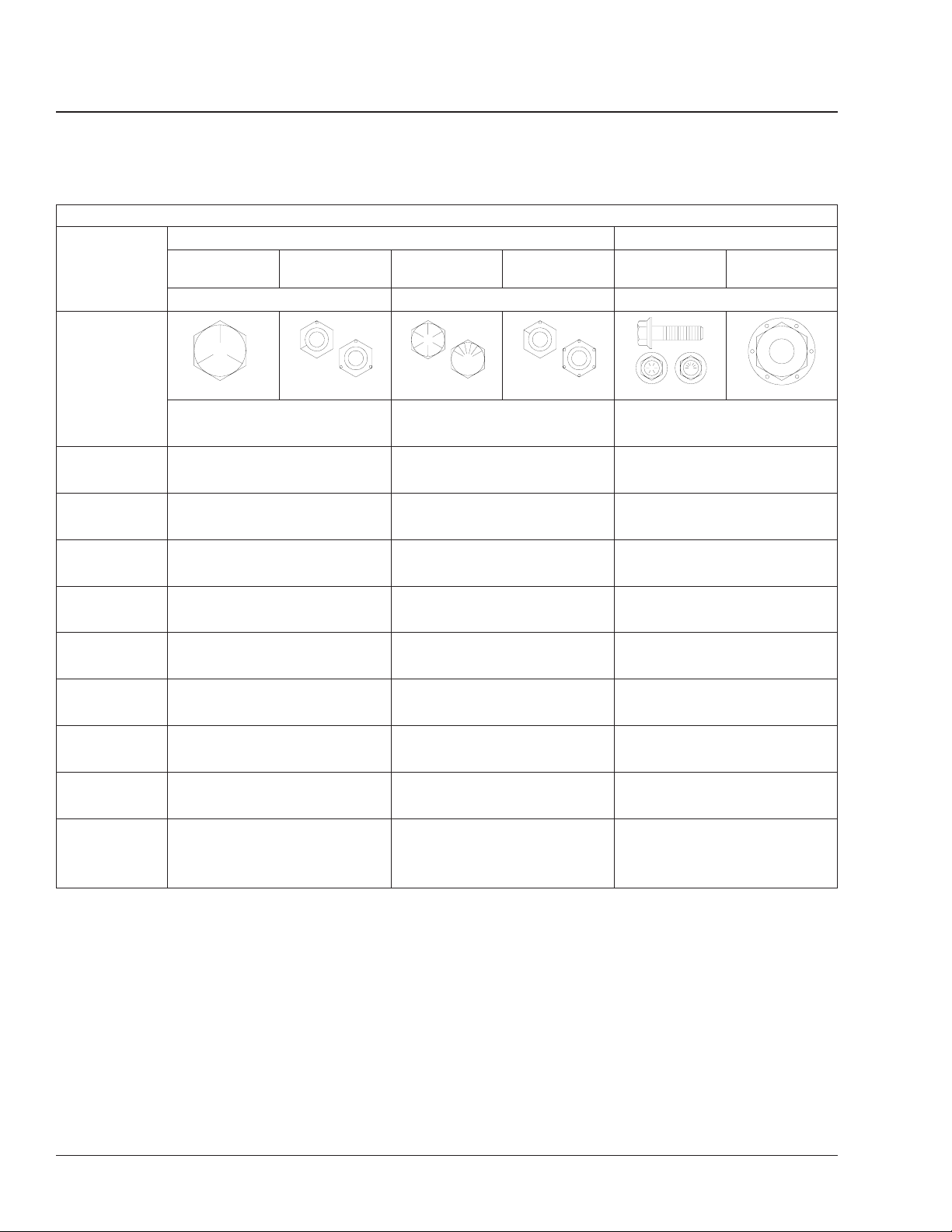

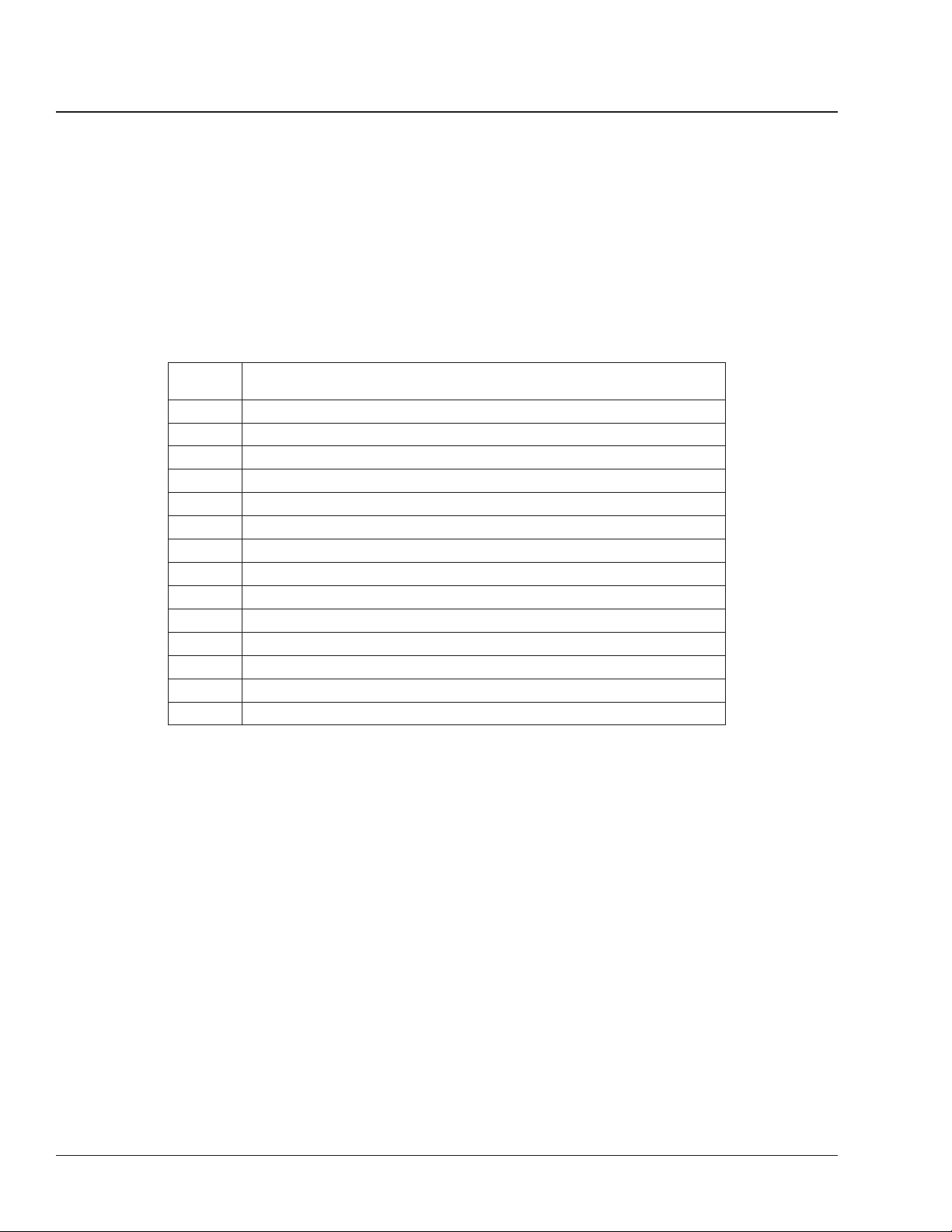

Torque Specifications Tables: 00–03

General Information00

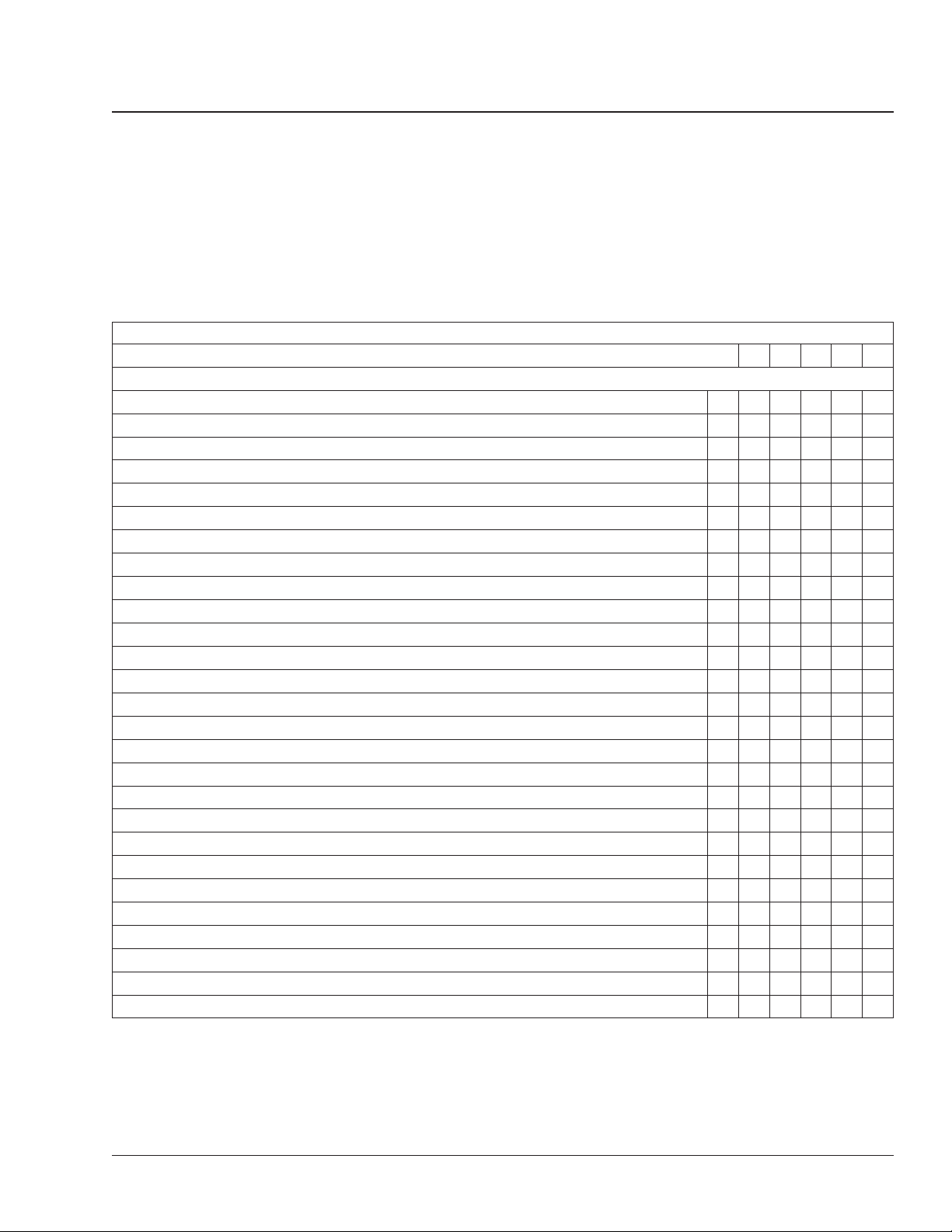

Torque Values for U.S. Customary Thread Fasteners With Dry (Unlubricated)*Plain (Unplated) Threads

†

Regular Hex Flanged

Thread

Diameter–Pitch

Grade 5 Bolt

Grade5orB

Nut

Grade 8 or 8.2

Bolt

Grade8orC

Nut

Grade 8 or 8.2

Bolt

Grade G Nut

Torque: lbf·ft (N·m) Torque: lbf·ft (N·m) Torque: lbf·ft (N·m)

f230002

f230003

f230004

f230005

f230008

1/4–20 8 (11) 10 (14) —

1/4–28 9 (12) 12 (16) —

5/16–18 15 (20) 22 (30) 22 (30)

5/16–24 17 (23) 25 (34) —

3/8–16 28 (38) 40 (54) 40 (54)

3/8–24 31 (42) 45 (61) —

7/16–14 45 (61) 65 (88) 65 (88)

7/16–20 50 (68) 70 (95) —

1/2–13 70 (95) 95 (129) 95 (129)

1/2–20 75 (102) 110 (149) —

9/16–12 100 (136) 140 (190) 140 (190)

9/16–18 110 (149) 155 (210) —

5/8–11 135 (183) 190 (258) 190 (258)

5/8–18 155 (210) 215 (292) —

3/4–10 240 (325) 340 (461) 340 (461)

3/4–16 270 (366) 380 (515) —

7/8–9 385 (522) 540 (732) —

7/8–14 425 (576) 600 (813) —

1–8 580 (786) 820 (1112) —

1–12 635 (861) 900 (1220) —

1–14 650 (881) 915 (1241) —

*

Threads may have residual oil, but will be dry to the touch.

†

Male and female threads (bolt and nut) must both be unlubricated and unplated; if either is plated or lubricated, use Table 1. Sterling recommends that all

plated and unplated fasteners be coated with oil before installation.

Table 2, Torque Values for U.S. Customary Thread Fasteners With Dry (Unlubricated) Plain (Unplated) Threads

f230009

Acterra Maintenance Manual, January 200700/4

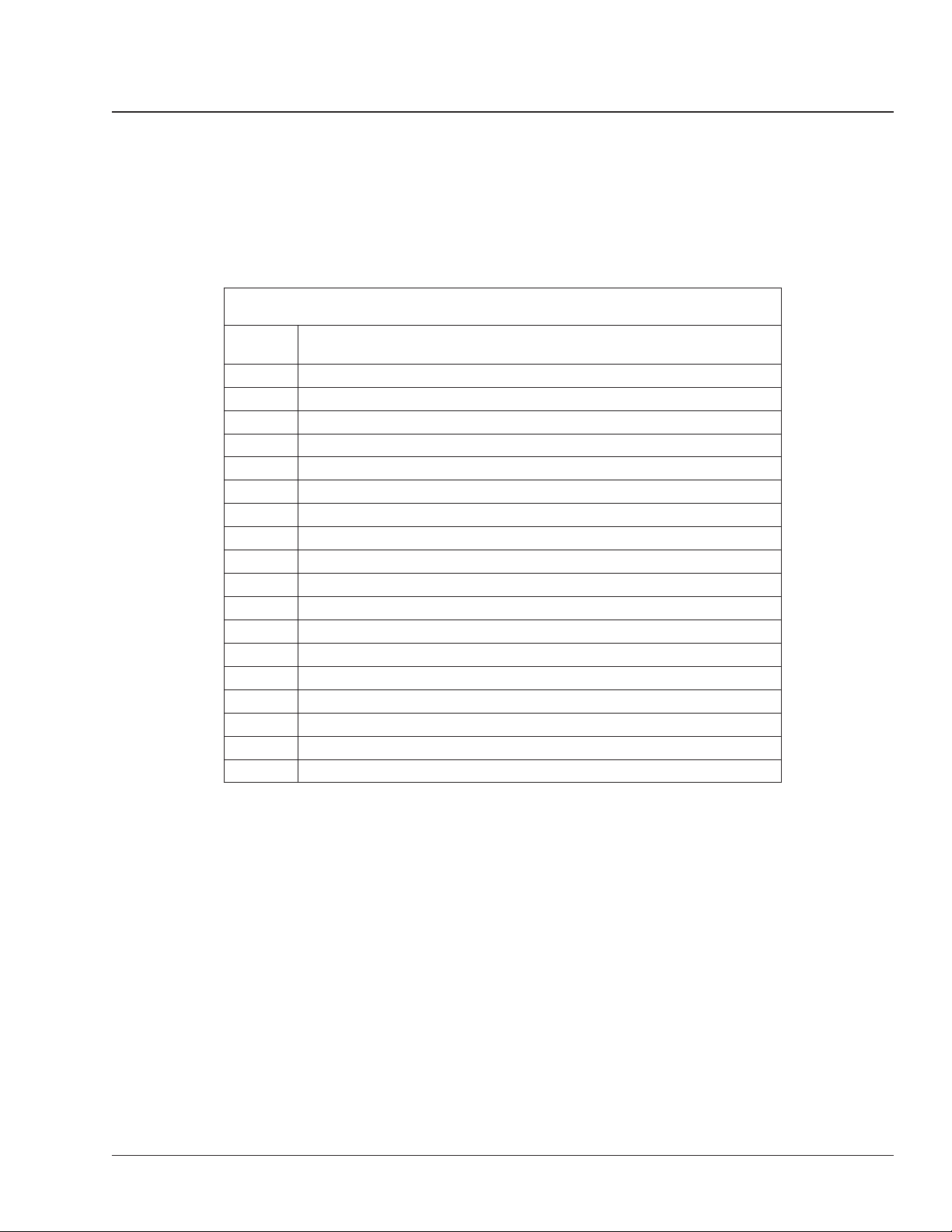

General Information 00

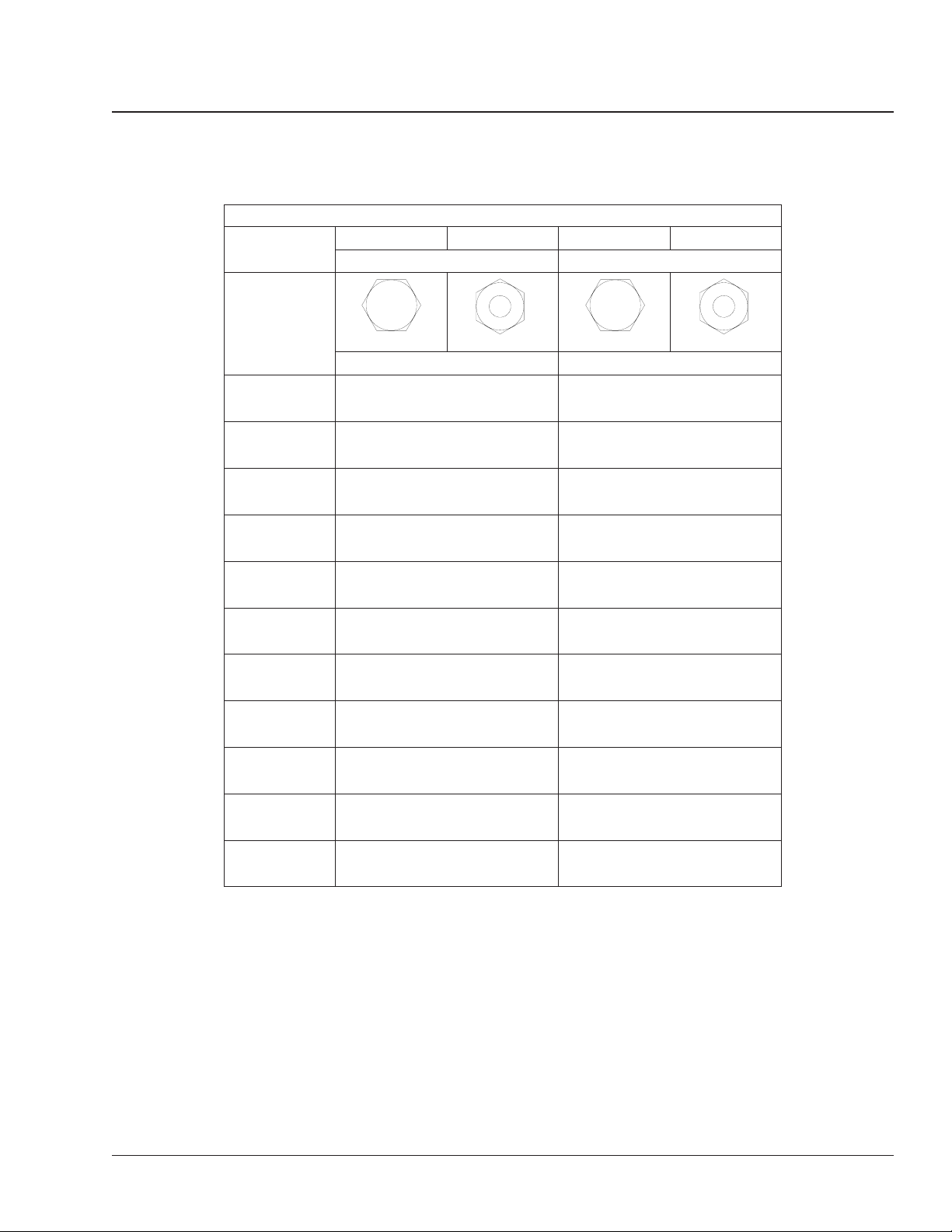

Torque Specifications Tables: 00–03

Torque Values for Metric Thread Fasteners With Lubricated*or Plated Threads

Thread

Diameter–Pitch

Class 8.8 Bolt Class 8 Nut Class 10.9 Bolt Class 10 Nut

Torque: lbf·ft (N·m) Torque: lbf·ft (N·m)

8.8

f230010

8

f230011

10.9

f230012

10

f230013

M6 5 (7) 7 (9)

M8 12 (16) 17 (23)

M8 x 1 13 (18) 18 (24)

M10 24 (33) 34 (46)

M10 x 1.25 27 (37) 38 (52)

M12 42 (57) 60 (81)

M12 x 1.5 43 (58) 62 (84)

M14 66 (89) 95 (129)

M14 x 1.5 72 (98) 103 (140)

M16 103 (140) 148 (201)

M16 x 1.5 110 (149) 157 (213)

M18 147 (199) 203 (275)

M18 x 1.5 165 (224) 229 (310)

M20 208 (282) 288 (390)

M20 x 1.5 213 (313) 320 (434)

M22 283 (384) 392 (531)

M22 x 1.5 315 (427) 431 (584)

M24 360 (488) 498 (675)

M24 x 2 392 (531) 542 (735)

M27 527 (715) 729 (988)

M27 x 2 569 (771) 788 (1068)

M30 715 (969) 990 (1342)

M30 x 2 792 (1074) 1096 (1486)

*

Sterling recommends that all plated and unplated fasteners be coated with oil before installation.

†

Use these torque values if either the bolt or nut is lubricated or plated (zinc-phosphate conversion-coated,

cadmium-plated, or waxed).

Table 3, Torque Values for Metric Thread Fasteners With Lubricated or Plated

Threads

†

Acterra Maintenance Manual, January 2007 00/5

Metric/U.S. Customary Conversion Tables: 00–04

General Information00

When You Know U.S.

Customary

Multiply

By

To Get Metric

When You

Know Metric

Multiply

By

To Get U.S. Customary

Length

inches (in) 25.4 millimeters (mm) 0.03937 inches (in)

inches (in) 2.54 centimeters (cm) 0.3937 inches (in)

feet (ft) 0.3048 meters (m) 3.281 feet (ft)

yards (yd) 0.9144 meters (m) 1.094 yards (yd)

miles (mi) 1.609 kilometers (km) 0.6215 miles (mi)

Area

square inches (in

square inches (in

square feet (ft

2

) 645.16 square millimeters (mm2) 0.00155 square inches (in2)

2

) 6.452 square centimeters (cm2) 0.155 square inches (in2)

2

) 0.0929 square meters (m2) 10.764 square feet (ft2)

Volume

3

cubic inches (in

cubic inches (in

cubic inches (in

) 16387.0 cubic millimeter (mm3) 0.000061 cubic inches (in3)

3

) 16.387 cubic centimeters (cm3) 0.06102 cubic inches (in3)

3

) 0.01639 liters (L) 61.024 cubic inches (in3)

fluid ounces (fl oz) 29.54 milliliters (mL) 0.03381 fluid ounces (fl oz)

pints (pt) 0.47318 liters (L) 2.1134 pints (pt)

quarts (qt) 0.94635 liters (L) 1.0567 quarts (qt)

gallons (gal) 3.7854 liters (L) 0.2642 gallons (gal)

cubic feet (ft

cubic feet (ft

3

) 28.317 liters (L) 0.03531 cubic feet (ft3)

3

) 0.02832 cubic meters (m3) 35.315 cubic feet (ft3)

Weight/Force

ounces (av) (oz) 28.35 grams (g) 0.03527 ounces (av) (oz)

pounds (av) (lb) 0.454 kilograms (kg) 2.205 pounds (av) (lb)

U.S. tons (t) 907.18 kilograms (kg) 0.001102 U.S. tons (t)

U.S. tons (t) 0.90718 metric tons (t) 1.1023 U.S. tons (t)

Torque/Work Force

inch–pounds (lbf·in) 11.298 Newton–centimeters (N·cm) 0.08851 inch–pounds (lbf·in)

foot–pounds (lbf·ft) 1.3558 Newton–meters (N·m) 0.7376 foot–pounds (lbf·ft)

Pressure/Vacuum

inches of mercury (inHg) 3.37685 kilo Pascals (kPa) 0.29613 inches of mercury (inHg)

pounds per square inch (psi) 6.895 kilo Pascals (kPa) 0.14503 pounds per square inch (psi)

Table 4, Metric/U.S. Customary Conversion

When You Know Subtract

Then

Divide By

To Get

When You

Know

Multiply

By

Then

Add

To Get

degrees Fahrenheit (°F) 32 1.8 degrees Celsius (°C) 1.8 32 degrees Fahrenheit (°F)

Table 5, Temperature Conversion

Acterra Maintenance Manual, January 200700/6

General Information 00

Scheduled Maintenance Intervals, Description and

Use: 00–05

Description

Schedule I (severe service) applies to vehicles that

annually travel up to 6000 miles (10 000 kilometers)

or

that operate under severe conditions. Examples of

Schedule I usage include: operation on extremely

poor roads or where there is heavy dust accumulation; constant exposure to extreme hot, cold, salt-air,

or other extreme climates; frequent short-distance

travel; construction-site operation; city operation (fire

truck, garbage truck); or farm operation.

Schedule II (short-haul transport) applies to vehicles

up to

that annually travel

meters) and operate under normal conditions. Examples of Schedule II usage are: operation primarily

in cities and densely populated areas; local transport

with infrequent freeway travel; or high percentage of

stop-and-go travel.

Schedule III (long-haul transport) is for vehicles that

annually travel

meters), with minimal city or stop-and-go operation.

Examples of Schedule III usage are: regional delivery

that is mostly freeway miles; interstate transport; or

any road operation with high annual mileage.

The table under Maintenance Schedule Table

shows three different schedules of vehicle usage. For

each schedule the appropriate distance interval is

given for performing Initial Maintenance and for repeating each maintenance operation set (M1 through

M5). For Schedule I, the appropriate time interval is

also given.

The tables under Maintenance Interval Tables show

which maintenance operation set must be performed

at the actual distances (miles and kilometers) for

each maintenance schedule (or the actual hours of

operation for Schedule I). The schedule of actual distances (and hours) is based on the intervals given in

the Maintenance Schedule Table.

The tables under Maintenance Operation Sets

Tables list, in numerical order, the text reference

numbers and descriptions of

tions, and indicates all maintenance operation sets at

which each operation must be performed.

Each Maintenance Interval Operations Table (IM

through M5) lists the appropriate text reference

numbers and descriptions of only those maintenance

operations that must be performed at that maintenance operation set. Each maintenance operation set

is listed in a separate Maintenance Operations Table.

more than

60,000 miles (100 000 kilo-

60,000 miles (100 000 kilo-

all

maintenance opera-

Use

Before placing your new vehicle in service, determine

the correct maintenance intervals that apply to your

intended use of the vehicle. Refer to the Maintenance Schedule Table to determine the distance (or

hour) interval at which each Maintenance Operation

Set must be performed to comply with your vehicle’s

schedule. For Schedule I vehicles equipped with an

hourmeter, use hours to determine maintenance intervals, rather than distance traveled.

When the vehicle reaches the actual distance (or

hours) given for an interval, refer to the Maintenance

Interval Tables to find the Maintenance Operation Set

that applies to that interval. Then perform the maintenance operations listed in the applicable Maintenance Interval Operation Table. Use the maintenance

operation reference numbers to find instructions in

the manualfor completion of each operation.

Complete each Maintenance Operation Set at the

required interval. Then, when you have completed

Maintenance Operation Set M5 under the 32nd Maintenance Number listed in the Maintenance Interval

Table, repeat the pattern. The 33rd Maintenance

Number will begin at Maintenance Operation Set M1,

under the 1st Maintenance Number listed in the

Maintenance Interval Table.

NOTE: When performing operations for the 33rd

Maintenance Number, complete the M1 operations only, not the Initial Maintenance operations.

To determine the distance/hours for the 33rd Maintenance Number, add your schedule’s distance/hours

for the 1st Maintenance Number to the

distance/hours for the 32nd Maintenance Number,

then perform the operations listed in the applicable

table in the Maintenance Operations Tables. For the

34th Maintenance Number, add the distance/hours

for the 2nd to the distance/hours for the 32nd; continue this pattern for each successive Maintenance

Number.

Acterra Maintenance Manual, January 2007 00/7

Maintenance Schedule Table: 00–06

General Information00

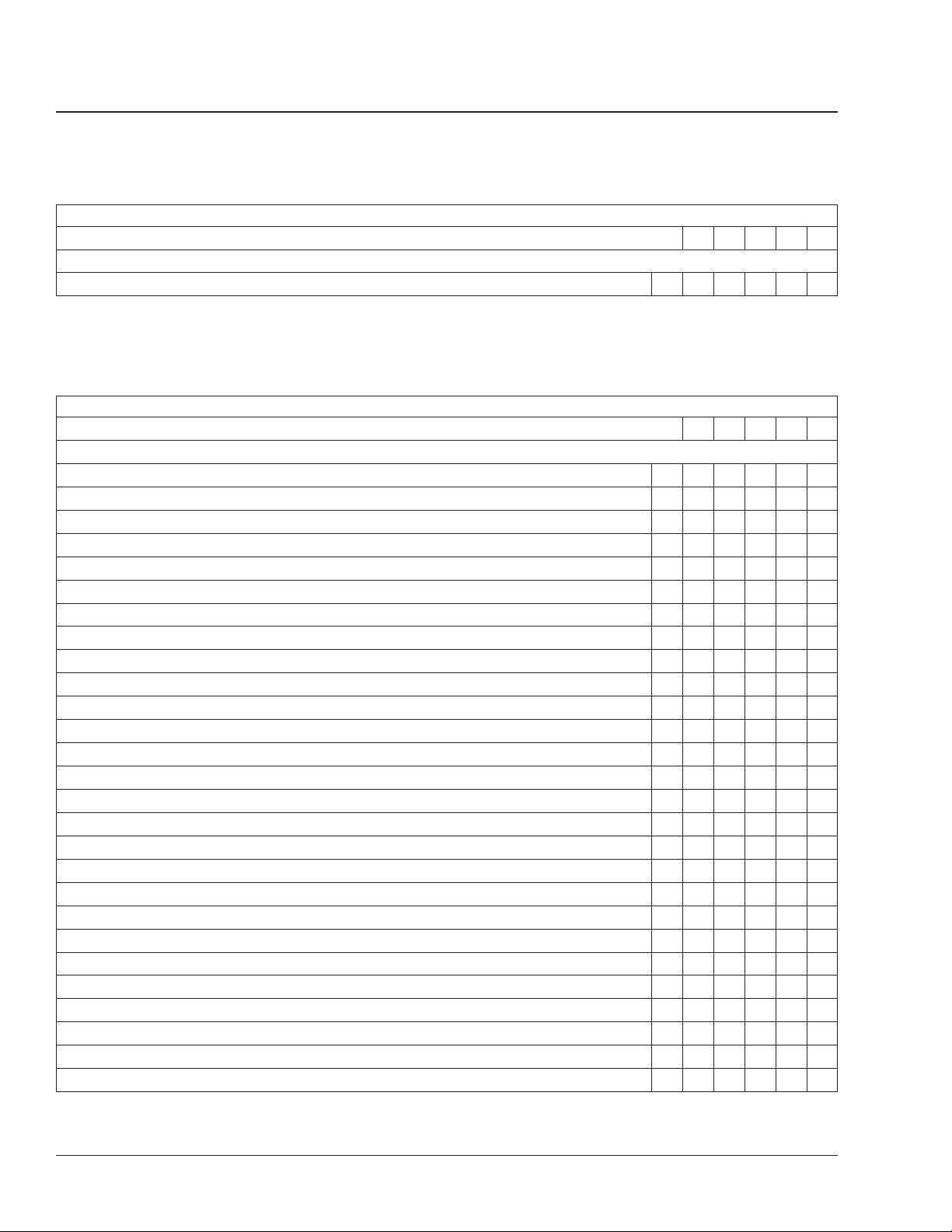

Maintenance Schedule Models

Schedule I

(Severe Service)

vehicles that annually travel up

to 6000 miles (10 000 km)

Schedule II

(Short-Haul Transport)

vehicles that annually travel up

to 60,000 miles (100 000 km)

Schedule III

(Long-Haul Transport)

vehicles that annually travel

over 60,000 miles (100 000

km)

Maintenance Interval

Operation

All Initial Maintenance (IM) first 1000 1600 100

Maintenance 1 (M1) every 1000 1600 100

Maintenance 2 (M2) every 4000 6400 400

Maintenance 3 (M3) every 8000 12 800 800

Maintenance 4 (M4) every 16,000 25 600 1600

Maintenance 5 (M5) every 32,000 51 200 3200

All Initial Maintenance (IM) first 8000 12 000

Maintenance 1 (M1) every 8000 12 000

Maintenance 2 (M2) every 16,000 24 000

Maintenance 3 (M3) every 32,000 48 000

Maintenance 4 (M4) every 64,000 96 000

Maintenance 5 (M5) every 128,000 192 000

All Initial Maintenance (IM) first 10,000 16 000

Maintenance 1 (M1) every 10,000 16 000

Maintenance 2 (M2) every 20,000 32 000

Maintenance 3 (M3) every 40,000 64 000

Maintenance 4 (M4) every 80,000 128 000

Maintenance 5 (M5) every 160,000 256 000

Table 6, Maintenance Schedule Table

Frequency Miles Km Hours

Maintenance Intervals

—

—

Acterra Maintenance Manual, January 200700/8

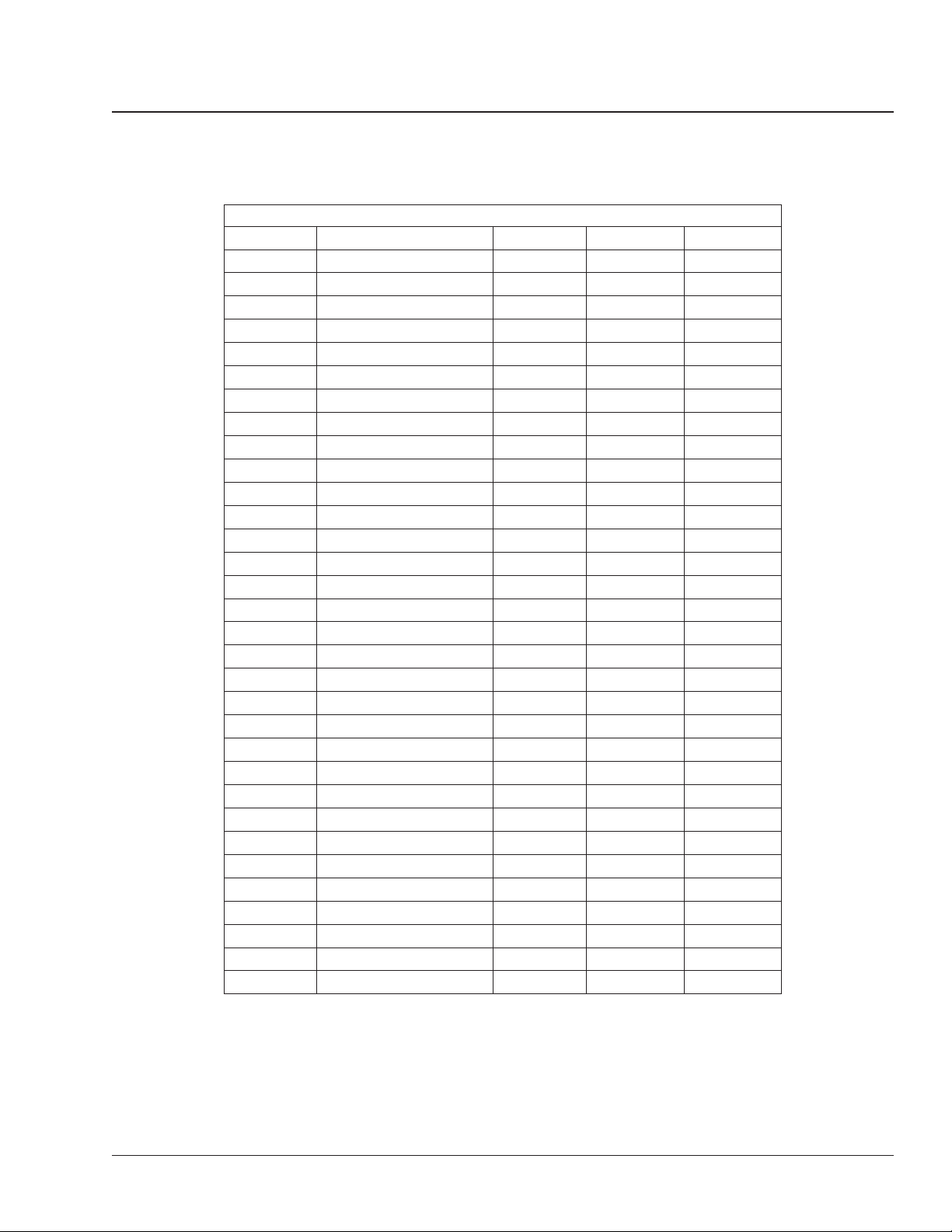

General Information 00

Maintenance Interval Tables: 00–07

Maintenance Intervals for Schedule I

Maint. No. Maintenance Interval Miles km Hours

1 IM and M1 1000 1600 100

2 M1 2000 3200 200

3 M1 3000 4800 300

4 M1and M2 4000 6400 400

5 M1 5000 8000 500

6 M1 6000 9600 600

7 M1 7000 11 200 700

8 M1, M2, and M3 8000 12 800 800

9 M1 9000 14 400 900

10 M1 10,000 16 000 1000

11 M1 11,000 17 600 1100

12 M1 and M2 12,000 19 200 1200

13 M1 13,000 20 800 1300

14 M1 14,000 22 400 1400

15 M1 15,000 24 000 1500

16 M1, M2, M3, and M4 16,000 25 600 1600

17 M1 17,000 27 200 1700

18 M1 18,000 28 800 1800

19 M1 19,000 30 400 1900

20 M1 and M2 20,000 32 000 2000

21 M1 21,000 33 600 2100

22 M1 22,000 35 200 2200

23 M1 23,000 36 800 2300

24 M1, M2, and M3 24,000 38 400 2400

25 M1 25,000 40 000 2500

26 M1 26,000 41 600 2600

27 M1 27,000 43 200 2700

28 M1 and M2 28,000 44 800 2800

29 M1 29,000 46 400 2900

30 M1 30,000 48 000 3000

31 M1 31,000 49 600 3100

32 M1, M2, M3, M4, and M5 32,000 51 200 3200

Table 7, Maintenance Intervals for Schedule I

Acterra Maintenance Manual, January 2007 00/9

General Information00

Maintenance Interval Tables: 00–07

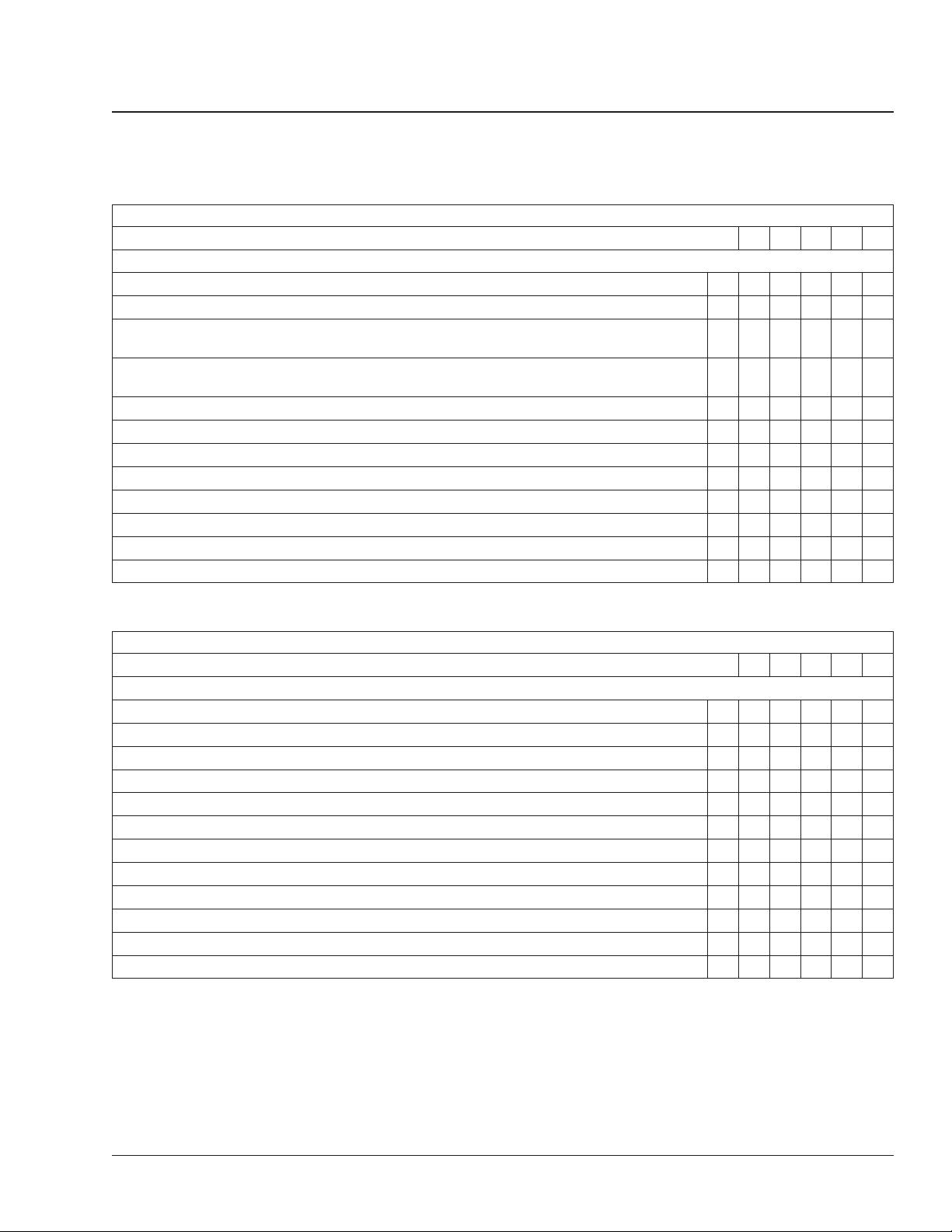

Maintenance Intervals for Schedules II and III (all models)

Maint.

No.

1 IM and M1 8000 12 000 10,000 16 000

2 M1 and M2 16,000 24 000 20,000 32 000

3 M1 24,000 36 000 30,000 48 000

4 M1, M2, and M3 32,000 48 000 40,000 64 000

5 M1 40,000 60 000 50,000 80 000

6 M1 and M2 48,000 72 000 60,000 96 000

7 M1 56,000 84 000 70,000 112 000

8 M1, M2, M3, and M4 64,000 96 000 80,000 128 000

9 M1 72,000 108 000 90,000 144 000

10 M1 and M2 80,000 120 000 100,000 160 000

11 M1 88,000 132 000 110,000 176 000

12 M1, M2, and M3 96,000 144 000 120,000 192 000

13 M1 104,000 156 000 130,000 208 000

14 M1, and M2 112,000 168 000 140,000 224 000

15 M1 120,000 180 000 150,000 240 000

16 M1, M2, M3, M4, and M5 128,000 192 000 160,000 256 000

17 M1 136,000 204 000 170,000 272 000

18 M1 and M2 144,000 216 000 180,000 288 000

19 M1 152,000 228 000 190,000 304 000

20 M1, M2, and M3 160,000 240 000 200,000 320 000

21 M1 168,000 252 000 210,000 336 000

22 M1 and M2 176,000 264 000 220,000 352 000

23 M1 184,000 276 000 230,000 368 000

24 M1, M2, M3, and M4 192,000 288 000 240,000 384 000

25 M1 200,000 300 000 250,000 400 000

26 M1 and M2 208,000 312 000 260,000 416 000

27 M1 216,000 324 000 270,000 432 000

28 M1, M2, and M3 224,000 336,000 280,000 448 000

29 M1 232,000 348 000 290,000 464 000

30 M1 and M2 240,000 360 000 300,000 480 000

31 M1 248,000 372 000 310,000 496 000

32 M1, M2, M3, M4, and M5 256,000 384 000 320,000 512 000

Maintenance Interval

Table 8, Maintenance Intervals for Schedules II and III (all models)

Schedule II Schedule III

Miles km Miles km

Acterra Maintenance Manual, January 200700/10

General Information 00

Maintenance Operation Sets Tables: 00–08

IMPORTANT: At each Maintenance Operation Set, in

addition to the maintenance operations listed in this

table, perform all daily, weekly, and monthly maintenance operations listed in the "Pretrip and Post-trip

Inspections and Maintenance" chapter of the

Acterra®Driver’s Manual

Maintenance Operation Number and Operation Description

00–15 Lubrication and Fluid Level Check ••••••

00–16 Lubrication and Fluid Level Check ••••

01–01 Engine-Support Fasteners Checking ••

01–02 Engine Drive Belt Inspecting •••

01–03 Pacbrake Inspecting and Maintenance

09–01 Air Cleaner Element Inspecting and Replacing •••

13–01 Air Compressor Inspecting, Bendix •••

13–02 Air Compressor Rebuilding/Replacing, Bendix •

15–01 Alternator, Battery, and Starter Checking ••

20–01 Radiator Cap Checking ••••

20–02 Radiator Pressure Flushing and Coolant Changing ••

20–03

25–01 Clutch Release Bearing and Release Cross-Shaft Lubricating ••••••

25–02 Clutch (Pull-Type) Inspecting and Adjusting ••••

25–03 Hydraulic Fluid Level Checking •••••

25–04 Hydraulic Fluid Replacing •

26–01 Manual Transmission Fluid Level Checking •••

26–02 Eaton Fuller and TTC Transmission Fluid Changing and Magnetic Plug Cleaning •

26–03 Allison, Eaton Fuller, and Meritor Transmission Breather Checking ••••

26–04 Allison Transmission Fluid and Filter Changing •••

26–05 Mercedes-Benz Transmission Fluid Changing and Magnetic Plug Cleaning •

26–06 Mercedes-Benz Transmission Leak Checking •

31–01 Frame Fastener Torque Checking •••

31–02 Fifth Wheel Inspecting ••••••

31–03 Fifth Wheel Lubricating ••••••

32–01 Suspension Inspecting ••••••

32–02 Suspension Lubricating ••••••

Fan Clutch Checking

.

Maintenance Operation Sets for Groups 00 through 32

REQUIRED MAINTENANCE OPERATION SET IM M1 M2 M3 M4 M5

*

NOTE: Maintenance operations appearing in italics in

this table are for noise emission control components.

Numbers in this table are maintenance operation reference numbers matching those in the text of this

manual.

•••

••••

†

••

Acterra Maintenance Manual, January 2007 00/11

General Information00

Maintenance Operation Sets Tables: 00–08

Maintenance Operation Sets for Groups 00 through 32

REQUIRED MAINTENANCE OPERATION SET IM M1 M2 M3 M4 M5

Maintenance Operation Number and Operation Description

32–03 U-Bolt Torque Checking ••••

*

With frequent use, the Pacbrake Exhaust Brake will operate free of maintenance. However, if the vehicle is used inconsistently, seasonally, or is exposed to

excess moisture, it will be necessary to perform preventative maintenance as instructed in Maintenance Operation 01–03.

†

IM interval does not apply to vehicles with a factory fill of Eaton approved synthetic lubricant.

Table 9, Maintenance Operation Sets for Groups 00 through 32

Maintenance Operation Sets for Groups 33 through 42

REQUIRED MAINTENANCE OPERATION SET IM M1 M2 M3 M4 M5

Maintenance Operation Number and Operation Description

33–01 Knuckle Pin Lubricating ••••••

33–02 Tie-Rod End Inspecting ••••••

33–03 Tie-Rod End Lubricating ••••••

33–04 All-Axle Alignment Checking •••

33–05 All-Wheel-Drive Front Axle Oil Level Checking •••

33–06 All-Wheel-Drive Front Axle Oil Changing •••

33–07 Draw Key Nut Inspecting ••••

35–01 Axle Lubricant Level Checking •••

35–02 Axle Breather Checking ••••••

35–03 Axle Lubricant Changing and Magnetic Plug Cleaning •••

35–04 Two-Speed-Axle Shift Unit Oil Level Checking ••

35–05 Two-Speed-Axle Shift Unit Oil Changing •••

40–01 Wheel Nut Checking •••

41–01 Driveline Inspecting ••••••

41–02 Driveline Lubricating ••••••

42–01 Air Dryer Inspecting, Bendix AD–9 ••••••

42–02 Air Brake Valve Inspecting and Leak Checking, Bendix BP–R1 ••••••

42–03 Foot Brake Valve Actuator Lubricating, Bendix E–8P ••••••

42–04 Air Brake Valve Operation Checking ••••••

42–05 Relay Valve Checking, Midland ••••••

42–06 Quick Release and Flipper Valves Checking, Midland ••••••

42–07 Brake Chamber Inspecting (All Models) ••••••

42–08 Camshaft Bracket Bushing Lubricating ••••

42–09 Automatic Slack Adjuster Checking, Meritor ••••••

42–10 Automatic Slack Adjuster Lubricating, Meritor ••••••

42–11 Automatic Slack Adjuster Inspecting, Meritor ••••

42–12 Air Dryer Checking, Bendix AD–9 •••

Acterra Maintenance Manual, January 200700/12

General Information 00

Maintenance Operation Sets Tables: 00–08

Maintenance Operation Sets for Groups 33 through 42

REQUIRED MAINTENANCE OPERATION SET IM M1 M2 M3 M4 M5

Maintenance Operation Number and Operation Description

42–13 Air Dryer Desiccant Replacing, Bendix AD–9 •

42–14 Air Brake Valve Leak Checking, Bendix TC–6 ••••••

42–15

42–16

42–17 Brake Lining Wear Checking, Hydraulic Disc Brakes ••••••

42–18 Brake Lines Checking, Hydraulic Disc Brakes ••••••

42–19 Power Booster Checking, Bendix Hydro-Max

42–20 Automatic Slack Adjuster Lubricating, Gunite ••••••

42–21 Automatic Slack Adjuster Inspecting, Gunite ••••••

42–22 Automatic Slack Adjuster Lubricating, Haldex ••••••

42–23 Bosch Rail-Slide Hydraulic Brake Caliper Lubricating ••••

42–24 Brake Inspection ••••••

Air Reservoir Automatic Drain Valve Disassembly, Cleaning, Inspecting, and

Lubricating, Bendix DV–2

Air Brake Valve Disassembly, Cleaning, and Inspecting, Bendix E–8P, R–12, R–14,

SR–1, ST–3, TC–6, and TP–3DC

®

Table 10, Maintenance Operation Sets for Groups 33 through 42

••••••

••••

•

Maintenance Operation Sets for Groups 46 through 83

REQUIRED MAINTENANCE OPERATION SET IM M1 M2 M3 M4 M5

Maintenance Operation Number and Operation Description

46–01 Steering Driveline Lubricating ••••

46–02 Drag Link Lubricating ••••••

46–03 Power Steering Reservoir Fluid Level Checking ••••

46–04 Power Steering Reservoir Fluid and Filter Changing ••

46–05 Power Steering Gear Lubricating ••••••

47–01 Fuel Tank Draining and Vent Checking •••

49–01

54–01 Electrical System Checking •••

54–02 Coolant Level Sensor Cleaning •

72–01 Weatherstrip, Door Latch, and Door Hinge Lubricating ••••••

83–01 Air Conditioner Inspecting ••••••

83–02 HVACAir Filter Replacing

*

Replace the HVAC filter every 6 months regardless of mileage.

Exhaust System Inspecting

Table 11, Maintenance Operation Sets for Groups 46 through 83

••••

*

Acterra Maintenance Manual, January 2007 00/13

Initial Maintenance (IM) Operations Table: 00–09

General Information00

IMPORTANT: After performing all operations in this

table, perform all daily and weekly maintenance operations listed in the "Pretrip Inspection and Daily

Maintenance" chapter of the vehicle driver’s manual.

Also, perform all M1 Maintenance Interval Operations

at the Initial Maintenance (IM).

Initial Maintenance (IM) Operations

Maint.

Oper. No.

00–10 Perform All M1 Operations

25–02 Clutch (Pull-Type) Inspecting and Adjusting

26–02 Eaton Fuller and TTC Transmission Fluid Changing and Magnetic Plug

31–01 Frame Fastener Torque Checking

32–03 U-Bolt Torque Checking

33–04 All-Axle Alignment Checking

33–07 Draw Key Nut Inspecting

35–03 Axle Lubricant Changing and Magnetic Plug Cleaning

35–04 Two-Speed-Axle Shift Unit Oil Level Checking

*

IM interval does not apply to vehicles with a factory fill of Eaton approved synthetic lubricant.

Cleaning

*

Initial Maintenance (IM) Operations

NOTE: Numbers in this table are maintenance operation reference numbers matching those in the text of

this manual. The Initial Maintenance consists of all

M1 Operations plus the other operations listed below.

Acterra Maintenance Manual, January 200700/14

General Information 00

M1 Maintenance Interval Operations Table: 00–10

IMPORTANT: After performing all operations listed in

this table, perform all daily, weekly, and monthly

maintenance operations listed in the "Pretrip and

Post-Trip Inspections and Maintenance" chapter of

Acterra®Driver’s Manual

the

M1 Maintenance Interval Operations

Maint.

Oper. No.

00–15 Lubrication and Fluid Level Check:

31–02 Fifth Wheel Inspecting

32–01 Suspension Inspecting

33–02 Tie-Rod End Inspecting

35–02 Axle Breather Checking

41–01 Driveline Inspecting

42–01 Air Dryer Inspecting, Bendix AD–9

42–02 Air Brake Valve Inspecting and Leak Checking, Bendix BP–R1

42–04 Air Brake Valve Operation Checking

42–05 Relay Valve Checking, Midland

42–06 Quick Release and Flipper Valves Checking, Midland

42–07 Brake Chamber Inspecting (All Models)

42–09 Automatic Slack Adjuster Checking, Meritor

.

M1 Maintenance Interval Operations

• Clutch Release Bearing and Release Cross-Shaft Lubricating

• Hydraulic Fluid Level Checking

• Manual Transmission Fluid Level Checking

• Fifth Wheel Lubricating

• Suspension Lubricating

• Knuckle Pin Lubricating

• Tie-Rod End Lubricating

• All-Wheel-Drive Front Axle Oil Level Checking

• Axle Lubricant Level Checking

• Driveline Lubricating

• Foot Brake Valve Actuator Lubricating, Bendix E–8P

• Automatic Slack Adjuster Lubricating, Meritor

• Automatic Slack Adjuster Lubricating, Gunite

• Automatic Slack Adjuster Lubricating, Haldex

• Drag Link Lubricating

• Power Steering Reservoir Fluid Level Checking

• Power Steering Gear Lubricating (Ross TAS Series)

• Weatherstrip, Door Latch, and Door Hinge Lubricating

NOTE: Numbers in this table are maintenance operation reference numbers matching those in the text of

this manual.

Acterra Maintenance Manual, January 2007 00/15

M1 Maintenance Interval Operations Table: 00–10

General Information00

Maint.

Oper. No.

42–14 Air Brake Valve Leak Checking, Bendix TC–6

42–17 Brake Lining Wear Checking, Hydraulic Disc Brakes

42–18 Brake Lines Checking, Hydraulic Disc Brakes

42–19 Power Booster Checking, Bendix Hydro-Max

42–21 Automatic Slack Adjuster Inspecting, Gunite

42–24 Brake Inspection

83–01 Air Conditioner Inspecting

M1 Maintenance Interval Operations

®

Acterra Maintenance Manual, January 200700/16

General Information 00

M2 Maintenance Interval Operations Table: 00–11

IMPORTANT: After performing all operations listed in

this table, perform all daily, weekly, and monthly

maintenance operations listed in the "Pretrip and

Post-Trip Inspections and Maintenance" chapter of

Acterra®Driver’s Manual

the

. Also, perform all M1

Maintenance Interval Operations at the M2 Maintenance Interval.

M2 Maintenance Interval Operations

Maint.

Oper. No.

00–10 Perform All M1 Operations

00–16 Lubrication and Fluid Level Check:

• Two-Speed-Axle Shift Unit Oil Level Checking

• Camshaft Bracket Bushing Lubricating

• Air Reservoir Automatic Drain Valve Disassembly, Cleaning, Inspect-

ing, and Lubricating, Bendix DV–2

• Bosch Rail-Slide Hydraulic Brake Caliper Lubricating

• Steering Driveline Lubricating

13–01 Air Compressor Inspecting, Bendix

20–01 Radiator Cap Checking

20–03

26–03 Allison, Eaton/Fuller, and Meritor Transmission Breather Checking

42–11 Automatic Slack Adjuster Inspecting, Meritor

49–01

83–02 HVAC Air Filter Replacing

*

Replace the HVAC filter every 6 months regardless of mileage.

Fan Clutch Checking

Exhaust System Inspecting

M2 Maintenance Interval Operations

*

NOTE: Maintenance operations appearing in italics in

this table are for noise emission control components.

Numbers in this table are maintenance operation reference numbers matching those in the text of this

manual. The M2 Maintenance consists of all M1 Interval Operations plus the other operations listed

below.

Acterra Maintenance Manual, January 2007 00/17

M3 Maintenance Interval Operations Table: 00–12

General Information00

IMPORTANT: After performing all operations listed in

this table, perform all daily, weekly, and monthly

maintenance operations listed in the "Pretrip and

Post-Trip Inspections and Maintenance" chapter of

Acterra®Driver’s Manual

the

. Also, perform all M1

and M2 Maintenance Interval Operations at the M3

Maintenance Interval.

M3 Maintenance Interval Operations

Maint.

Oper. No.

00–10 Perform All M1 Operations

00–11 Perform All M2 Operations

01–02 Engine Drive Belt Inspecting

09–01 Air Cleaner Element Inspecting and Replacing

25–02 Clutch (Pull-Type) Inspecting and Adjusting

26–04 Allison Transmission Fluid and Filter Changing

32–03 U-Bolt Torque Checking

33–06 All-Wheel-Drive Front Axle Oil Changing

33–07 Draw Key Nut Inspecting

35–05 Two-Speed-Axle Shift Unit Oil Changing

40–01 Wheel Nut Checking

42–12 Air Dryer Checking, Bendix AD–9

47–01 Fuel Tank Draining and Vent Checking

54–01 Electrical System Checking

M3 Maintenance Interval Operations

NOTE: Numbers in this table are maintenance operation reference numbers matching those in the text of

this manual. The M3 Maintenance consists of all M1

and M2 Interval Operations plus the other operations

listed below.

Acterra Maintenance Manual, January 200700/18

General Information 00

M4 Maintenance Interval Operations Table: 00–13

IMPORTANT: After performing all operations listed in

this table, perform all daily, weekly, and monthly

maintenance operations listed in the "Pretrip and

Post-Trip Inspections and Maintenance" chapter of

Acterra®Driver’s Manual

the

. Also, perform all M1,

M2, and M3 Maintenance Interval Operations at the

M4 Maintenance Interval.

M4 Maintenance Interval Operations

Maint.

Oper. No.

00–10 Perform All M1 Operations

00–11 Perform All M2 Operations

00–12 Perform All M3 Operations

01–01 Engine-Support Fasteners Checking

15–01 Alternator, Battery, and Starter Checking

20–02 Radiator Pressure Flushing and Coolant Changing

26–02 Eaton Fuller and TTC Transmission Fluid Changing and Magnetic Plug

Cleaning

31–01 Frame Fastener Torque Checking

33–04 All-Axle Alignment Checking

35–03 Axle Lubricant Changing and Magnetic Plug Cleaning

46–04 Power Steering Reservoir Fluid and Filter Changing

M4 Maintenance Interval Operations

NOTE: Maintenance operations appearing in italics in

this table are for noise emission control components.

Numbers in this table are maintenance operation reference numbers matching those in the text of this

manual. The M4 Maintenance consists of all M1, M2,

and M3 Interval Operations plus the other operations

listed below.

Acterra Maintenance Manual, January 2007 00/19

M5 Maintenance Interval Operations Table: 00–14

General Information00

IMPORTANT: After performing all operations listed in

this table, perform all daily, weekly, and monthly

maintenance operations listed in the "Pretrip and

Post-Trip Inspections and Maintenance" chapter of

Acterra®Driver’s Manual

the

. Also, perform all M1,

M2, M3, and M4 Maintenance Interval Operations at

the M5 Maintenance Interval.

M5 Maintenance Interval Operations

Maint.

Oper. No.

00–10 Perform All M1 Operations

00–11 Perform All M2 Operations

00–12 Perform All M3 Operations

00–13 Perform All M4 Operations

13–02 Air Compressor Rebuilding/Replacing, Bendix

25–04 Hydraulic Fluid Replacing

26–05 Mercedes-Benz Transmission Fluid Changing and Magnetic Plug Cleaning

26–06 Mercedes-Benz Transmission Leak Checking

42–13 Air Dryer Desiccant Replacing, Bendix AD–9

42–16 Air Brake Valve Disassembly, Cleaning, and Inspecting, Bendix E–8P,

R–12, R–14, SR–1, ST–3, TC–6, and TP–3DC

54–02 Coolant Level Sensor Cleaning

M5 Maintenance Interval Operations

NOTE: Numbers in this table are maintenance operation reference numbers matching those in the text of

this manual. The M5 Maintenance consists of all M1,

M2, M3, and M4 Interval Operations plus the other

operations listed below.

Acterra Maintenance Manual, January 200700/20

General Information 00

Lubrication and Fluid Level Check (M1): 00–15

Maintenance Operation 00–15 (see Table 12), sum-

marizes all Lubrication and Fluid Level Check operations that must be performed at the M1 Maintenance

Interval for Schedules I, II, and III

Maintenance Operation 00–15

M1 Lubrication and Fluid Level Check

Maint.

Oper. No.

25–01 Clutch Release Bearing and Release Cross-Shaft Lubricating

25–03 Hydraulic Fluid Level Checking

26–01 Manual Transmission Fluid Level Checking

31–03 Fifth Wheel Lubricating

32–02 Suspension Lubricating

33–01 Knuckle Pin Lubricating

33–03 Tie-Rod End Lubricating

33–05 All-Wheel-Drive Front Axle Oil Level Checking

35–01 Axle Lubricant Level Checking

41–02 Driveline Lubricating

42–03 Foot Brake Valve Actuator Lubricating, Bendix E–8P

42–10 Automatic Slack Adjuster Lubricating, Meritor

42–20 Automatic Slack Adjuster Lubricating, Gunite

42–22 Automatic Slack Adjuster Lubricating, Haldex

46–02 Drag Link Lubricating

46–03 Power Steering Reservoir Fluid Level Checking

46–05 Power Steering Gear Lubricating

72–01 Weatherstrip, Door Latch, and Door Hinge Lubricating

Table 12, Maintenance Operation 00-15, M1 Lubrication and Fluid Level Check

Operation Description

Maintenance operation numbers given in the table

are reference numbers used to help you find detailed

instructions in the manual on the lubrication or fluid

check.

Acterra Maintenance Manual, January 2007 00/21

Lubrication and Fluid Level Check (M2): 00–16

General Information00

Maintenance Operation 00–16 (see Table 13), sum-

marizes all Lubrication and Fluid Level Check operations that must be performed at the M2 Maintenance

Interval for Schedules I, II, and III

Maintenance Operation 00–16

M2 Lubrication and Fluid Level Check

Maint.

Oper. No.

35–04 Two-Speed-Axle Shift Unit Oil Level Checking

42–08 Camshaft Bracket Bushing Lubricating

42–15 Air Reservoir Automatic Drain Valve Disassembly, Cleaning, Inspecting,

and Lubricating, Bendix DV–2

42–23 Bosch Rail-Slide Hydraulic Brake Caliper Lubricating

46–01 Steering Driveline Lubricating

Table 13, Maintenance Operation 00-16, M2 Lubrication and Fluid Level Check

Operation Description

Maintenance operation numbers given in the table

are reference numbers used to help you find detailed

instructions in the manual on the lubrication or fluid

check.

Acterra Maintenance Manual, January 200700/22

Engine 01

Index, Alphabetical

Title of Maintenance Operation (MOP) MOP Number

Engine Drive Belt Inspecting..........................................................01–02

Engine-Support Fasteners Checking....................................................01–01

Pacbrake Inspecting and Maintenance .................................................. 01–03

Acterra Maintenance Manual, January 2007

Engine 01

01–01 Engine-Support

Fasteners Checking

Front and rear engine supports for vehicles built from

January 2007 require no periodic maintenance.

Mounts should be inspected when the engine is removed for service. For vehicles manufactured prior to

January 2007, perform the following check.

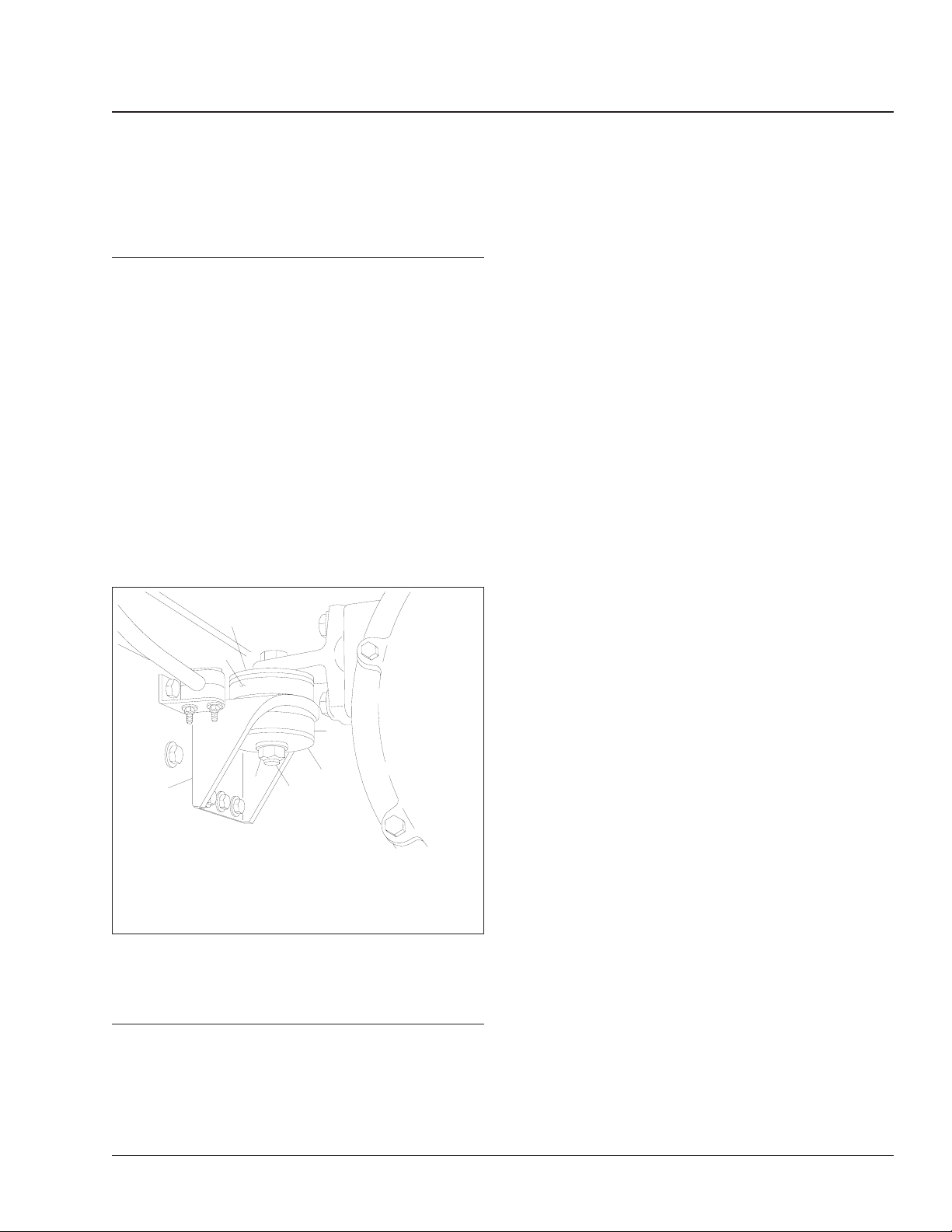

Check the rear engine-support fasteners (see Fig. 1,

Ref. 4) for tightness. Tighten the 3/4-inch fasteners

215 to 265 lbf·ft (292 to 359 N·m).

Check the front engine-support fasteners for tightness. Tighten the 5/8-inch fasteners 125 lbf·ft (170

N·m).

NOTE: At engine overhaul, and whenever the

engine has been removed, inspect the lower

and upper isolators (Refs. 1 and 6), and replace

them if they are worn. See Group 01 of the

Acterra®Workshop Manual

2

6

5

10/05/94

1. Lower Isolator

2. Engine Support

Washer

3. 3/4–10 Capscrew

4

Fig. 1, Engine Rear Mount

for instructions.

1

2

3

f220047a

4. 3/4–10 Hexnut

5. Engine Mount

6. Upper Isolator

01–02 Engine Drive Belt

Inspecting

Worn or loose drive belts may cause premature

bearing failure or engine overheating. Excessive tension, or too little tension on the belt may result in ex-

cessive and premature belt wear. Poly-V belts, or

serpentine belts, are retained by a belt tensioner that

requires no tension adjustment. Replace the engine

drive belt if any conditions described in the visual

description are found. V-belts are installed as individual belts, and as matched sets. When replacing a

matched set of belts, always replace both belts at the

same time. Matched belts must be from the same

manufacturer. To inspect a belt, gently twist the belt

to view the belt sidewalls and bottom. Inspect all

drive belts for the following conditions, then perform

the belt tension inspection.

Belt Condition Inspection

1. Inspect the belt for glazing. See Fig. 2, Ref. A.

Glazing is represented by shiny sidewalls, and is

caused by friction created when a loose belt slips

in the pulleys. It can also be caused by oil or

grease contamination on the pulleys.

2. Check the belt for ply separation. See Fig. 2,

Ref. B. Oil, grease, or belt dressing can cause

the belt to fall apart in layers. Repair any oil or

coolant leaks that are affecting the belts before

replacing the drive belts. Do not use belt dressing on any belt.

3. Check the belt for a jagged or streaked sidewall.

See Fig. 2, Ref. C. Jagged or streaked sidewalls

are the result of foreign objects, such as sand or

gravel in the pulley, or a rough pulley surface.

4. Check for tensile breaks (breaks in the cord

body). See Fig. 2, Ref. D. Cuts in a belt are usually caused by foreign objects in the pulley, or by

prying or forcing the belt during removal or installation.

5. Check for uneven ribs on serpentine (poly-V)

belts. See Fig. 2, Ref. E. Foreign objects in the

pulley will erode the undercord ribs, causing the

belt to lose its gripping power.

6. Check the drive belts for cracks. See Fig. 2, Ref.

F. Small irregular cracks are usually the signs of

an old belt.

7. Inspect the pulleys for excessive play or wobble.

Excessive play or wobble indicates a failure of

the pulley bearing. Check for belt squealing or

squeaking. Replace the bearings as necessary.

NOTE: If it is difficult to distinguish the location

of a supposed bearing noise, obtain a stethoscope and place it on the component being

Acterra Maintenance Manual, January 2007 01/1

Loading...

Loading...