Page 1

INSTALLATION INSTRUCTIONS

AIR INLET KITS

CATEGORY III VENTING FOR SEPARATED COMBUSTION

TUBULAR GAS FIRED DUCT FURNACES

USE 5" KIT FOR UNITS WITH CAPACITIES 100,000 TO 200,000 BTU/HR

USE 6" KIT FOR UNITS WITH CAPACITIES 250,000 TO 400,000 BTU/HR

Supplement to unit installation instructions – TDII

Improper installation, adjustment, alteration,

service or maintenance can cause property damage, injury or

death. Read this supplement and the unit heater installation,

operation and maintenance instructions thoroughly before

installing or servicing this equipment.

This Air Inlet Kit utilizes a 5 or 6 inch collar and gaskets to allow a tubular indoor duct

furnace to be converted to separated combustion. Included in the kit is a vent cap to

be placed at the termination of the new air inlet pipe. Note: a vent cap is also required

for the exhaust pipe termination and is available for purchase separately from this kit.

AIK-IOM-1

J30-09444X9

The location of the vent terminal must be in accordance with the National Fuel Code ANSI Z223.1 in the U.S.

or the Natural Gas Installation Code CSA-B149.1 or the Propane Gas Installation Cade CSA-B149.2 in Canada.

Minimum clearances are shown in Table 1.

KIT CONTENTS:

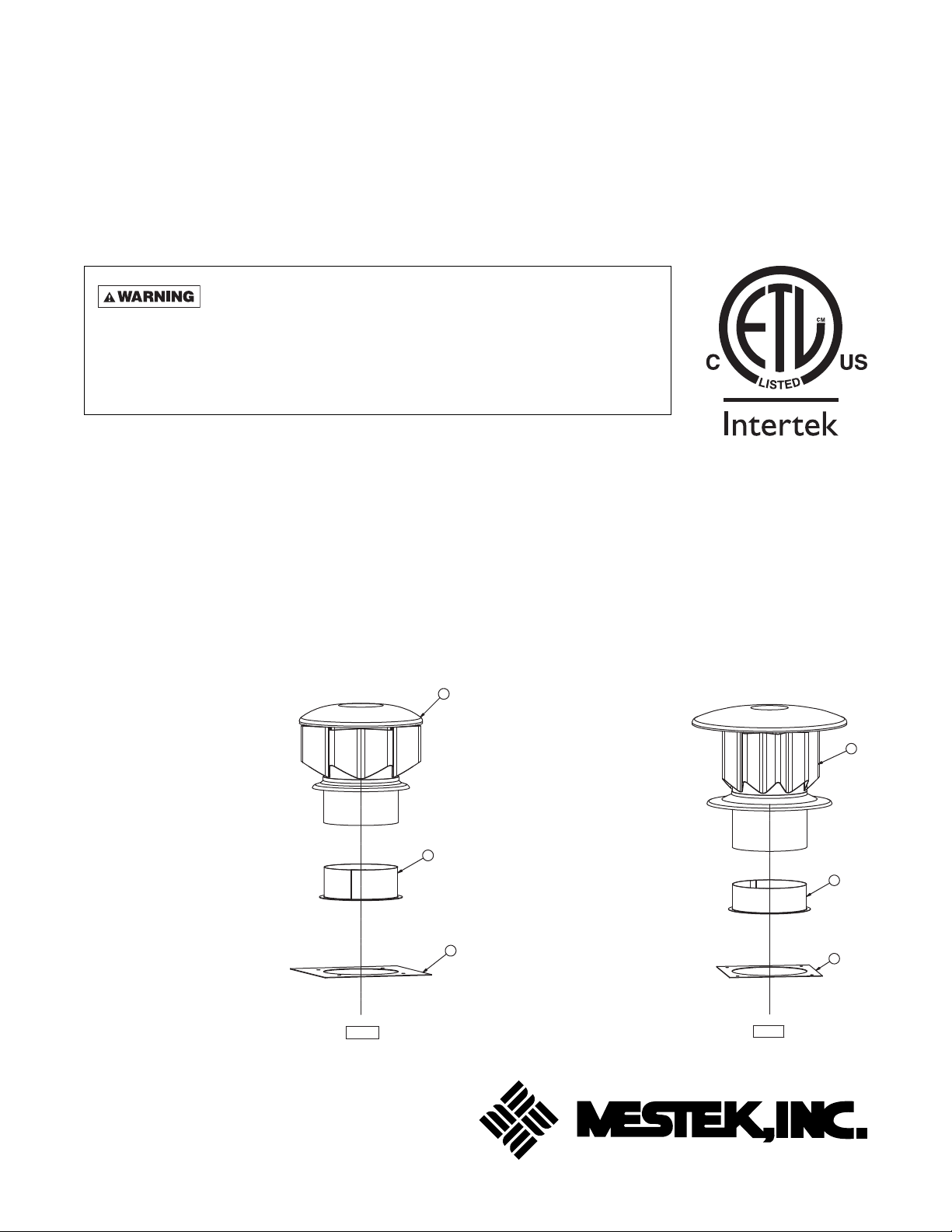

Figure 1a – 5 Inch Air Inlet Kit Figure 1b – 6 Inch Air Inlet Kit

#1 – Part No. 11J37R02222-002

(1) Vent Cap

#2 – Part No. 11257R08567

(1) Air Inlet Collar – 5"

#3 – Part No. 11252R09198-001

(1) Air Inlet Collar Gasket – 5"

Also Included:

(1) Part No. J30-09444X9

Installation Instructions

(1) Part No. 11H03R03612-002

Tube of High Temp Silicone

Sealant

(1) Part No. 11262R08614-006

Access Panel Gasket –

86.75"

1

#1 – Part No. 11J37R02222-003

(1) Vent Cap

#2 – Part No. 11257R08956

(1) Air Inlet Collar – 6"

#3 – Part No. 11252R09198-002

(1) Air Inlet Collar Gasket – 6"

Also Included:

(1) Part No. J30-09444X9

2

3

Installation Instructions

(1) Part No. 11H03R03612-002

Tube of High Temp Silicone

Sealant

(1) Part No. 11262R08614-007

Access Panel Gasket –

112.75"

2

3

1

03/14

D9460

D9461

260 NORTH ELM ST., WESTFIELD, MA 01085

TEL: (413) 568-9571 FAX: (413) 562-8437

www.mestek.com

Page 2

VENTING FOR POWER VENTED DUCT FURNACES (CATEGORY III)

GENERAL GUIDELINES

All duct furnaces must be vented! All venting installations shall be in accordance with the latest edition of Part

7, Venting of Equipment of the National Fuel Gas Code, ANSI Z223.1 (NFPA 54), or applicable provisions of local

building codes for power vented units. Refer to Figures 3a, 3b, 4a, 4b, 5a, and 5b. For installations in Canada, see

page 3.

CARBON MONOXIDE! Y our venting system m ust not be bloc ked by an y snow , snow drifts, or

any foreign matter . Inspect y our venting system to ensure adequate ventilation e xists at all times! Failure to

heed these warnings could result in Carbon Monoxide Poisoning (symptoms include grogginess, lethargy,

inappropriate tiredness, or fl u-like symptoms).

NOTICE: All vertical and horizontal venting arrangements for the Tubular Duct Furnace are Category III

venting.

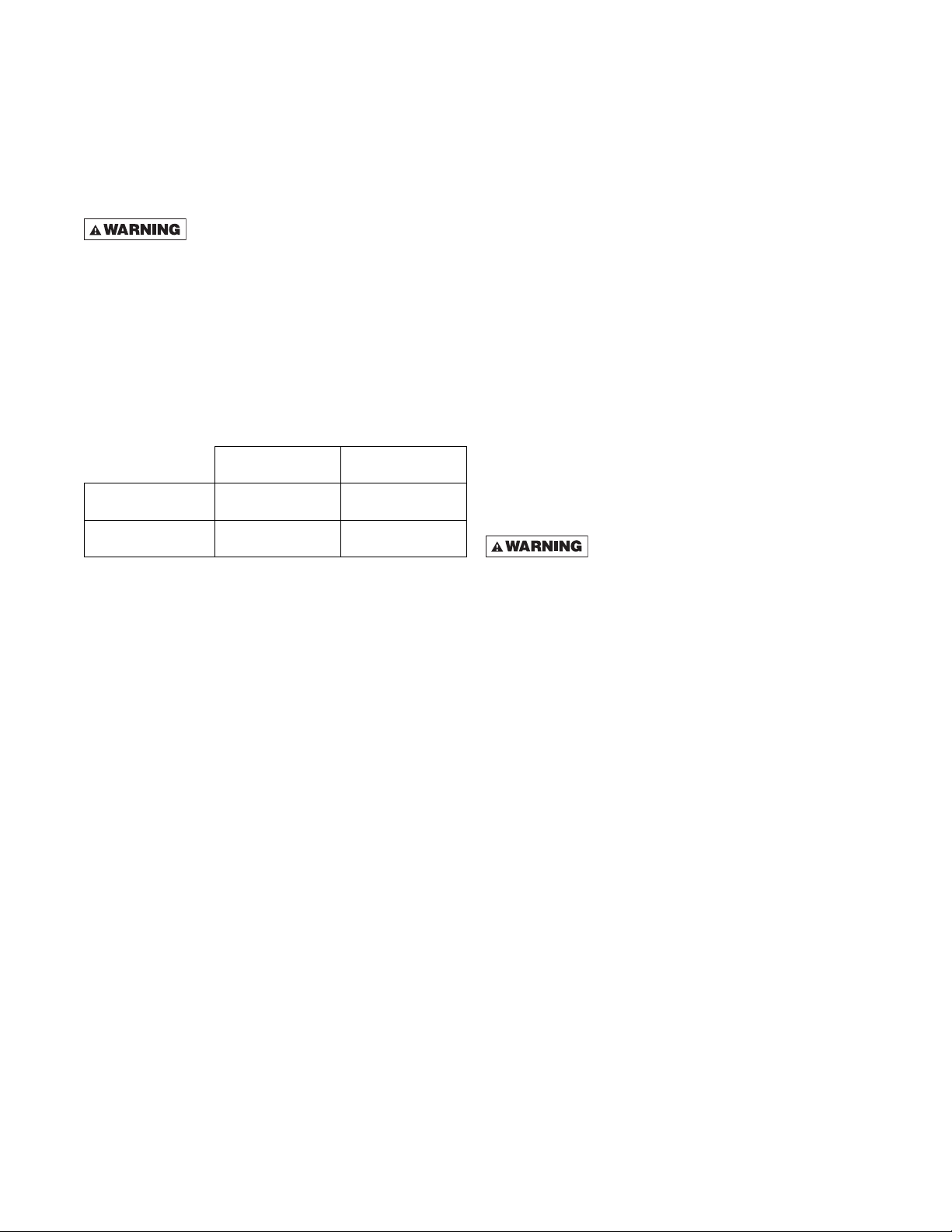

ANSI now organizes vented appliances into four

categories.

Venting Categories

Non

Condensing Condensing

Negative

Vent Pressure

Positive

Vent Pressure

III

III

IV

Category I

Includes non-condensing appliances with negative vent

pressure, like the traditional atmospheric unit heater.

Category II

Groups condensing appliances with negative vent

pressure.

Category III

Appliances are non-condensing and operate with a

positive vent pressure.

Category IV

Covers condensing appliances with positive vent

pressure.

Do not damper or add heat recovery devices to the fl ue

piping. Failure to open such a damper prior to operating

gas unit will result in the spillage of fl ue gas into the

occupied space.

Vent pipe material must be in compliance with UL 1738

for installations in the United States, and UL S636 for

installations in Canada.

Refer to Table 1 for vent termination clearance

requirements.

The vent pipe equivalent length must be 5 feet (1.5m)

minimum and must not exceed 50 feet (15.2m).

Equivalent length is the total length of straight

sections PLUS 10 feet (3.05m) for each 90 degree

elbow, and 4 feet (1.22M) for each 45 degree elbow.

Maintain 6 inch (152mm) between vent pipe and

combustible materials. A minimum of 12 inch (305mm)

of straight pipe is required from the venter outlet before

installing an elbow in the vent system. An elbow should

never be attached directly to the venter!

Never use a pipe of a diameter other

than that specifi ed in T able 1! Never use PVC or other

nonmetallic pipe for venting! To do so may result in

serious damage to the unit, severe personal injury,

or death.

Any run of single wall vent pipe exposed to cold air or

passing through an unheated space must be insulated

with insulation suitable to 550°F (288°C).

The vent system must be installed to prevent collection

of condensate. Vertical vent pipes should be equipped

with condensate drains. Pitch horizontal pipes downward 1/4 inch per foot (21mm/m) toward outlet for

condensate drainage.

Horizontal portions of the venting system shall be

supported at maximum intervals of 4 feet (1.2m) to

prevent sagging. In Canada, support at a maximum

of 3 feet (1m) intervals.

Each unit must have an individual vent pipe and

vent terminal per furnace section! Each unit MUST

NOT be connected to other vent systems or to a

chimney.

Through the wall vents for these appliances shall NOT

terminate over public walkways, or over an area where

condensate or vapor could create a nuisance or hazard

or could be detrimental to the operation of regulators,

relief valves, or other equipment.

2

Page 3

VENTING FOR POWER VENTED DUCT FURNACES (CATEGORY III)

GENERAL GUIDELINES (CONTINUED)

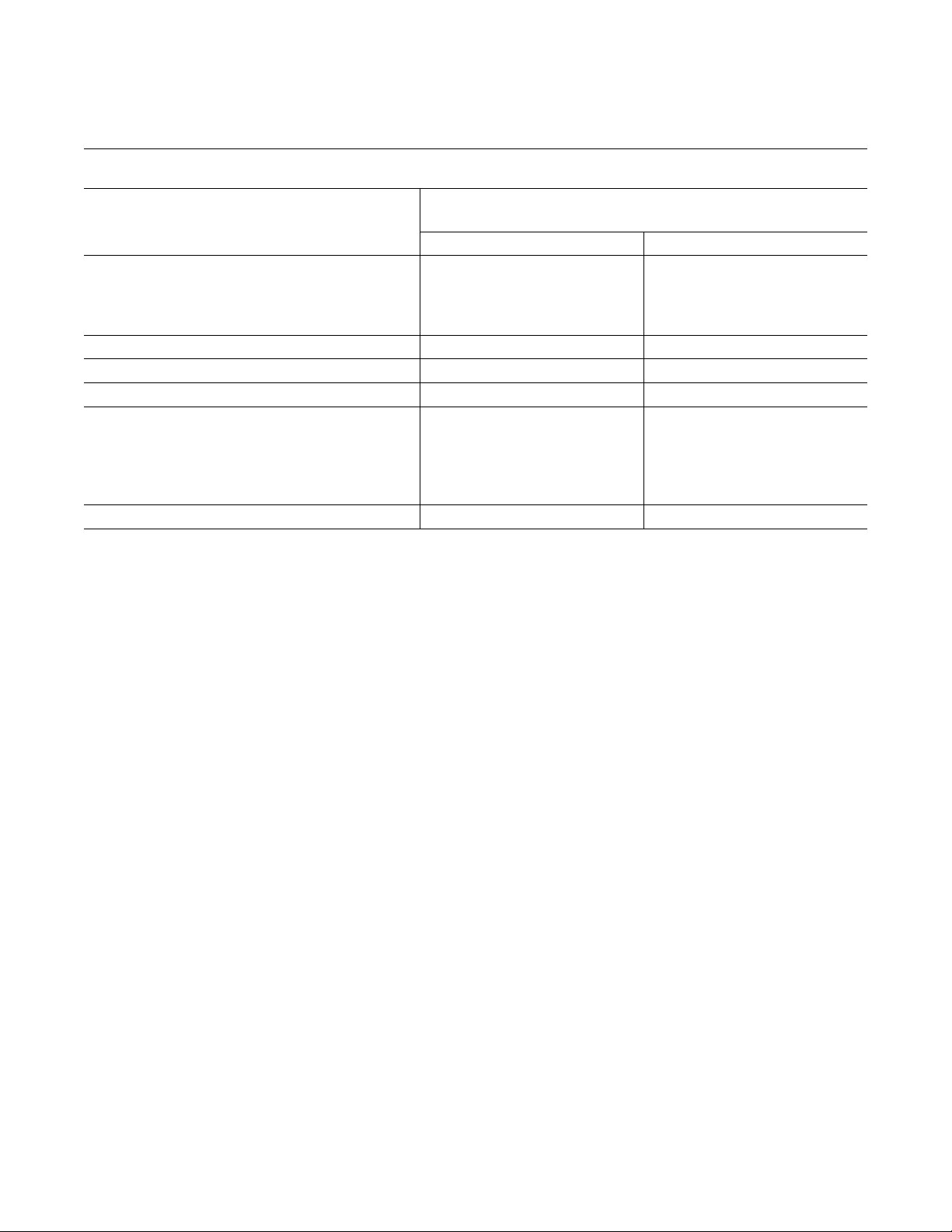

Table 1

Vent Systems Termination Clearance Requirements

Minimum Clearances for

Structure/Object

9 in. for 10,000

Door, window or gravity vent inlet; combustion

air inlet for other appliances

Forced air inlet within 10 ft. 3 ft. above 6 ft. (1.8m)

Adjoining building or parapet 10 ft. 10 ft. (3.04m)

Adjacent public walkways 7 ft. above grade 7 ft. (2.1m) above grade

Electric, gas meters & regulators 4 ft. horizontal

Above grade level* 1 ft. 1 ft. (0.3m)

to 50,000 BTU/Hr input;

12 in. for input

exceeding 50,000 BTU/Hr

Termination Locations

USA CANADA

9 in. (230mm) for 10,000

to 50,000 BTU/Hr input;

12 in. (305mm) for input

exceeding 50,000 BTU/Hr

3 ft. (0.9m) horizontally from

meter/regulator assembly.

6 ft. (1.8m), any direction,

from a gas service regulator

vent outlet

* Minimum above maximum snow depth, or per local code, whichever is greater.

ADDITIONAL REQUIREMENTS FOR CANADIAN INSTALLATIONS

REFER TO SPECIFICATION TABLE AND INSTALLATION MANUAL FOR PROPER USAGE

The following instructions apply to Canadian installations in addition to installation and operating instructions.

1. Installation must conform with local building codes,

or in the absence of local codes, with current

CSA-B149.1, Installation Codes for Natural

Gas Burning Appliances and Equipment, or

CSA-B149.2, Installation Codes for Propane

Gas Burning Appliances and Equipment.

2. Any reference to U.S. standards or codes in these

instructions are to be ignored, and the applicable

Canadian standards or codes applied.

3

Page 4

INSTALLATION INSTRUCTIONS

AIR INLET COLLAR

Remove screen and mounting plate from air inlet on top

panel of unit by removing 4 screws. Secure inlet collar

and gasket to inlet opening by reusing the 4 screws

removed in previous step.

ACCESS PANEL SEAL

Cut gasket to lengths listed in Table 2. Remove paper

backing and adhere to access panel making certain

that the entire perimeter is covered (Figure 2).

Table 2 – Gasket Lengths

Unit

Size

100 8-3/4 2 28-1/8 2

150 12 2 28-1/8 2

200 15-1/4 2 28-1/8 2

250 18-1/2 2 28-1/8 2

300 21-3/4 2 28-1/8 2

350 25 2 28-1/8 2

400 28-1/4 2 28-1/8 2

Top/Bottom

Gasket Length

(In) Qty

Right/Left

Gasket Length

(In) Qty

Figure 2 – Access Panel Seal

TOP

28.125

SIDE

BOTTOM

D9451

POWER SUPPLY INLET

After supply power line is run to main control board,

seal the gap between the cord and the hole in rear

panel with silicone sealant.

SIDE

VENTING FOR SEPARATED COMBUSTION DUCT FURNACES

(CATEGORY III)

COMBUSTION AIR

Never operate separated combustion

duct furnaces without combustion air and fl ue gas

piping in place or severe personal injury or death

may occur!

CARBON MONOXIDE!

Your venting system must not be blocked by any

snow, snow drifts, or any foreign matter. Inspect

your venting system to ensure adequate ventilation

exists at all times! Failure to heed these warnings

could result in Carbon Monoxide Poisoning (symptoms include grogginess, lethargy, inappropriate

tiredness, or fl u-like symptoms).

1. In the United States, the combustion air system

installation must be in accordance with the latest

edition of ANSI Z223.1 (NFPA 54) National Fuel

Gas Code. In Canada, installation must be in

accordance with CSA-B149.1 “Installation Code for

Natural Gas Burning Appliances and Equipment”

and CSA-B149.2 “Installation Code for Propane

Burning Appliances and Equipment.”

2. A Breidert Type L or Fields Starkap, furnished by

the customer, must be installed at the termination

point of the combustion air system. See Figures

3a and 3b.

3. Each duct furnace MUST have its own combustion

air system. It MUST NOT be connected to other air

intake systems.

4. Combustion air intake duct may be PVC, CPVC,

Type B vent, single wall, double wall or other

material approved by local code authority.

Never use duct size other than the diameter

stated in these instructions.

5. Long runs of single wall combustion air piping

passing through an unheated space may require

insulating if condensation becomes noticeable.

6. The combustion air system must be installed to

prevent collection of condensate. Pitch horizontal

pipes downward 1/4" per foot (21mm/m) toward the

inlet cap to facilitate drainage. Vertical combustion

air pipes should be piped as depicted in Figure 3a.

7. The equivalent length of the combustion air system

must not be less than 5 feet (1.5m) and must not

exceed 50 feet (15.2m). Equivalent length equals

the total length of straight pipe, plus 10 feet (3.05m)

for each 90° elbow and 4 feet (1.22m) for each

45° elbow.

NOTICE: For optimum performance keep the combustion air system as straight as possible.

4

Page 5

VENTING FOR SEPARATED COMBUSTION DUCT FURNACES

(CATEGORY III) (CONTINUED)

8. Each slip joint must be secured with at least three

corrosion resistant screws. Two full turns of 3M

#425 Aluminum Foil Tape or its equivalent must

then be used to seal each joint. General Electric

RTV-108, Dow-Corning RTV-732 or an equivalent

may be used instead of tape.

9. For horizontal combustion air systems longer than

5 feet (1.5m), the system must be supported from

overheard building structures at 4 feet (1.22m)

maximum intervals in the United States and at

3 feet (1m) maximum intervals in Canada.

EXHAUST VENTING

Never operate separated combustion

duct furnaces without combustion air and fl ue gas

piping in place or severe personal injury or death

may occur!

CARBON MONOXIDE!

Your venting system must not be blocked by any

snow, snow drifts, or any foreign matter. Inspect

your venting system to ensure adequate ventilation

exists at all times! Failure to heed these warnings

could result in Carbon Monoxide Poisoning (symptoms include grogginess, lethargy, inappropriate

tiredness, or fl u-like symptoms).

1. In the United States, vent system installation

must be in accordance with the latest edition of

ANSI Z223.1 (NFPA 54) National Fuel Gas Code.

In Canada, installation must be in accordance

with CSA-B149.1 “Installation Code for Natural

Gas Burning Appliances and Equipment” and

CSA-B149.2 “Installation Code for Propane

Burning Appliances and Equipment.”

2. A Breidert Type L or Fields Starkap, furnished by

the customer, must be installed at the termination

point of the vent system. See Figures 3a and 3b.

3. Each duct furnace MUST have its own vent system.

It MUST NOT be connected to other vent systems

or to a chimney.

4. Use UL 1738 listed single wall pipe for the vent

system. For installations in Canada, use UL S636

listed vent pipe conforming with local building

codes, or in the absence of local building codes,

with current CSA-B149.1 “Installation Codes for

Natural Gas Burning Appliances and Equipment”

or CSA-B149.2, “Installation Codes for Propane

Gas Burning Appliances and Equipment.”

Never use pipe of a diameter other

than that specifi ed in these instructions! Never use

PVC, ABS, or any other non-metallic pipe for e xhaust

venting! To do so may result in serious damage to

the unit and/or severe personal injury or death!

5. Any run of single wall vent pipe passing through

an unheated space must be insulated with an

insulation suitable to 550°F (288°C).

6. The vent system must be installed to prevent

collection of condensate. Pitch horizontal pipes

downward 1/4" per foot (21mm/m) towards the

vent cap to facilitate drainage. Vertical vent pipes

should be piped as depicted in Figure 3a.

7. The equivalent length of the vent system must not

be less than 5 feet (1.5m) and must not exceed

50 feet (15.2m). Equivalent length equals the total

length of straight pipe plus 10 feet (3.05m) for each

90° elbow and 4 feet (1.22m) for each 45° elbow.

8. For horizontal combustion air systems longer than

5 feet (1.5m), the system must be supported from

overheard building structures at 4 feet (1.22m)

maximum intervals in the United States and at

3 feet (1m) maximum intervals in Canada.

9. The exhaust vent system must remain at a

minimum distance of 6 inch (152mm) from all

combustible materials. Any part of the vent system

that passes through a combustible material must

be properly insulated.

NOTICE: Increasing the clearance distances may be

necessary if there is a possibility of distortion or

discoloration of adjacent materials.

For a VERTICAL vent pipe section that passes through

a fl oor or roof, an opening 4 inch (102mm) greater in

diameter is required. The opening must be insulated

and fl ashed in accordance with applicable installation

codes. Also see Figures 4a and 5a.

A HORIZONTAL section of an exhaust vent system that

passes through a combustible wall must be constructed

and insulated as shown in Figures 4b and 5b.

5

Page 6

VENTING FOR SEPARATED COMBUSTION DUCT FURNACES

(CATEGORY III) (CONTINUED)

Figure 3a – Vertical Inlet/Vent Locations, Separated Combustion

10 ft. (3.04m) Min. to Wall

Breidert Type L

or Fields

Approved Terminal

Exhaust

Vent

Roof Flashing

→

t

s

u

a

h

x

E

Combustion Air

Inlet

2 ft. (.609m) Min Plus Max Snow

Depth for Area

Combustion Air

→

or Adjoining Building

12 in. Min. (305 mm)

3 ft. (1m) Min Plus Max

Snow Depth

Tee with Drip Leg

and Cleanout Cap

2 ft.

(.609m)

Min.

18 in.

(457mm)

Min @ CL

Figure 3b – Horizontal Inlet/Vent Locations, Separated Combustion

D9380

D9380

6

2765C

Page 7

VENTING FOR SEPARATED COMBUSTION DUCT FURNACES

(CATEGORY III) (CONTINUED)

Figure 4a – Vertical Arrangement, Single Wall Vent System to Single Wall Termination

D3619C

Figure 4b – Horizontal Arrangement, Single Wall Vent System to Single Wall Termination

D3620F

7

Page 8

VENTING FOR SEPARATED COMBUSTION DUCT FURNACES

(CATEGORY III) (CONTINUED)

Figure 5a – Vertical Arrangement, Single Wall Vent System to Double Wall Termination

D3662D

Figure 5b – Horizontal Arrangement, Single Wall Vent System to Double Wall Termination

D3661F

8

Loading...

Loading...