Page 1

INSTALLATION INSTRUCTIONS AND PARTS IDENTIFICATION

TUBULAR GAS-FIRED BLOWER STYLE UNIT HEATER

ATTENTION: READ THIS MANUAL AND ALL LABELS ATTACHED TO THE UNIT CAREFULLY BEFORE

ATTEMPTING TO INSTALL, OPERATE OR SERVICE THESE UNITS! CHECK UNIT DATA PLATE FOR TYPE OF GAS

AND ELECTRICAL SPECIFICATIONS AND MAKE CERTAIN THAT THESE AGREE WITH THOSE AT THE POINT OF

INSTALLATION. RECORD THE UNIT MODEL AND SERIAL No.(s) IN THE SPACE PROVIDED. RETAIN FOR FUTURE

REFERENCE.

TBII-3

J30-08867

Unit No.

Serial No.

FOR YOUR SAFETY

The use and storage of gasoline or other fl ammable vapors and liquids in open containers in

the vicinity of this appliance is hazardous.

R

T

E

E

K

T

N

I

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open fl ame.

4. Immediately contact your gas supplier.

V

E

CM

D

E

R

I

I

F

ENERGY

PERFORMANCE

VERIFIED

RENDEMENT

ENERGETIQUE

VERIFIE

Improper installation, adjustment, alteration, service, or maintenance

can cause property damage, injury, or death. Read the installation, operating, and

maintenance instruction thoroughly before installing or servicing this equipment.

APPROVED FOR USE IN CALIFORNIA

APPROVED FOR USE IN CALIFORNIA

Install, operate, and maintain unit in accordance with the manufacturer's

instructions to avoid exposure to fuel substances, or substances from incomplete

combustion, which can cause death or serious illness. The state of California

has determined that these substances may cause cancer, birth defects, or other

reproductive harm.

08/13

INSTALLER'S RESPONSIBILITY

Installer Please Note: This equipment has been test fired and inspected. It has been

shipped free from defects from our factory. However, shipment and installation

problems such as loose wires, leaks, or loose fasteners may occur. It is the installer's

responsibility to inspect and correct any problem that may be found.

RECEIVING INSTRUCTIONS

Inspect shipment immediately when

received to determine if any damage

has occurred to the unit during

shipment. After the unit has been

uncrated, check for any visible

damage to the unit. If any damage

is found, the consignee should sign

the bill of lading indicating such

damage and immediately file claim

for damage with the transportation

company.

260 NORTH ELM ST., WESTFIELD, MA 01085

TEL: (413) 568-9571 FAX: (413) 562-8437

www.mestek.com

Page 2

TABLE OF CONTENTS

DESCRIPTION………………. ....................................... 2

GENERAL SAFETY INFORMATION

Installation Codes………………………………… 2, 3

Special Precautions………………………………. 2, 3

PERFORMANCE AND DIMENSIONAL DATA .............. 4

INSTALLATION

Locating Units………………………………………… 5

Combustion Air……………………………………… . 5

Heat Throw Data……………………………………. . 6

Clearances…………………………………….. ......... 7

Suspension of Units………………………………. ....7

Gas Piping……………………………………… ........ 8

Pipe Installation……………………………………. ... 9

BLOWER SET UP AND ADJUSTMENT……………...10

NOTICE: It is the equipment owners responsibility to provide any scaffolding or other apparatus required to

perform emergency service or annual/periodic maintenance to this equipment.

MOTOR AND PULLEY .............................................. 11

ELECTRICAL CONNECTIONS…………………. ...12-16

VENTING ..............................................................17-21

OPERATION

Explanation of Controls…………………………… . 22

Start-Up, Shut Down………………......…………....22

Main Burner Orifi ce Schedule…………….……….23

Gas Input Rate and Adjustments…………….. 23, 24

TROUBLESHOOTING GUIDE ..............................25-28

LED Indicator Troubleshooting .............................. 29

MAINTENANCE… ...................................................... 30

WARRANTY…............................................................31

IDENTIFICATION OF PARTS ................................32-33

UNIT NUMBER DESCRIPTION ................................. 35

START-UP INSPECTION SHEET ............................... 36

DESCRIPTION

The Power Vented Gas Fired Blower Unit Heaters are

factory assembled, high static pressure type, centrifugal

blower units designed for heavy duty applications such

as continuous operation or where a single unit heater

must do the entire heating job in a large area.These

blower type unit heaters may be used with the standard

adjustable louvers, with short duct runs or discharge

nozzles for spot heating. These blower type unit heaters

may be used where low sound levels are required. The

designs are certified by ETL as providing a minimum

of 83% thermal efficiency, and approved for use in

California. Do not alter these units in any way. If you

have any questions after reading this manual, contact

the manufacturer.

Figure 1 - Tubular Blower Unit Heater

See Identifi cation of Parts, Figures 12 through 18.

The following terms are used throughout this manual, in addition to the ETL requirements to bring attention to the

presence of potential hazards, or to important information concerning the product:

Indicates an imminently hazardous

situation which, if not avoided, will result in

death, serious injury, or substantial property

damage.

Indicates an imminently hazardous situation which, if not avoided, could result

in death, serious injury, or substantial property

damage.

situation which, if not avoided, may result in minor

injury or property damage.

NOTICE: Used to notify of special instructions on

installation, operation, or maintenance which are

important to equipment but not related to personal

injury.

2

Indicates an imminently hazardous

Page 3

GENERAL SAFETY INFORMATION

Failure to comply with the general

safety information may result in extensive

property damage, severe personal injury, or

death.

This product must be installed by

a licensed plumber or gas fi tter when installed

within the Commonwealth of Massachusetts.

Installation must be made in accordance with local

codes, or in absence of local codes, with the latest

edition of the ANSI Standard Z223.1 (N.F.P.A. No. 54)

National Fuel Gas Code. All of the ANSI and NFPA

Standards referred to in these installation instructions

are those that were applicable at the time the design

of this appliance was certified. The ANSI Standards

are available from CSA Information Services, 1-800463-6727. The NFPA Standards are available from the

National Fire Protection Association, Batterymarch Park,

Quincy, MA 02269. These unit heaters are designed for

use in airplane hangars when installed in accordance

with ANSI/NFPA No. 409, and in public garages when

installed in accordance with NFPA No. 88A and NFPA

No.88B.

If installed in Canada, the installation must conform with

local building codes, or in the absence of local building

codes, with CSA-B149.1 “Installation Codes for Natural

Gas Burning Appliances and Equipment” or CSA-B149.2

“Installation Codes for Propane Gas Burning Appliances

and Equipment.” These unit heaters have been designed

and certifi ed to comply with CSA 2.6. Also see sections

on installation in AIRCRAFT HANGARS and PUBLIC

GARAGES.

Do not alter the unit heater in any

way or damage to the unit and/or severe personal

injury or death may occur!

Disconnect all power and gas

supplies before installing or servicing the heater.

If the power disconnect is out of sight, lock

it in the open position and tag it to prevent

unexpected application of power. Failure to do

so could result in fatal electric shock, or severe

personal injury.

Do not attempt to convert the

heater for use with a fuel other than the one

intended. Such conversion is dangerous, as it

will create the risks previously listed.

Make certain that the power source conforms to the

electrical requirements of the heater.

Do not depend upon a thermostat

or other switch as sole means of disconnecting

power when installing or servicing heater.

Always disconnect power at main circuit breaker

as described above. Failure to do so could result

in fatal electric shock.

Special attention must be given to any grounding

information pertaining to this heater. To prevent the risk of

electrocution, the heater must be securely and adequately

grounded. This should be accomplished by connecting

a ground conductor between the service panel and the

heater. To ensure a proper ground, the grounding means

must be tested by a qualifi ed electrician.

Do not insert fi ngers or foreign objects into heater or its

air moving device. Do not block or tamper with the heater

in any manner while in operation, or just after it has been

turned off, as some parts may be hot enough to cause

injury.

This heater is intended for general heating applications

ONLY. It must NOT be used in potentially dangerous

locations such as fl ammable, explosive, chemical-laden,

or wet atmospheres.

In cases in which property damage may result from

malfunction of the heater, a back-up system or

temperature sensitive alarm should be used.

The open end of piping systems being

purged shall not discharge into areas where there

are sources of ignition or into confined spaces

UNLESS precautions are taken as follows: (1) by

ventilation of the space, (2) control of the purging

rate, (3) elimination of all hazardous conditions. All

precautions must be taken to perform this operation

in a safe manner!

Ensure that all power sources conform

to the requirements of the unit heater, or damage to

the unit will result!

Follow installation instructions CAREFULLY to avoid

creating unsafe conditions. All wiring should be done

and checked by a qualifi ed electrician, using copper wire

only. All gas connections should be made and leak-tested

by a suitably qualifi ed individual, per instructions in this

manual. Also follow procedures listed on “Gas Equipment

Start-Up Sheet” located in this manual.

Use only the fuel for which the heater is designed (see

rating plate). Using LP gas in a heater that requires

natural gas, or vice versa, will create risk of gas leaks,

carbon monoxide poisoning, and explosion.

Unless otherwise specifi ed, the following conversions

may be used for calculating SI unit measurements:

1 foot = 0.305 m

1 inch = 25.4 mm

1 gallon = 3.785 L

1 pound = 0.453 kg

1 psig = 6.894 kPa

1 cubic foot = 0.028m

1000 BTU/cu. ft. = 37.5 MJ/m

1000 BTU per hour = 0.293 kW

1 inch water column = 0.249 kPa

1 litre/second = CFM x 0.472

1 meter/second = FPM ÷ 196.8

3

3

3

Page 4

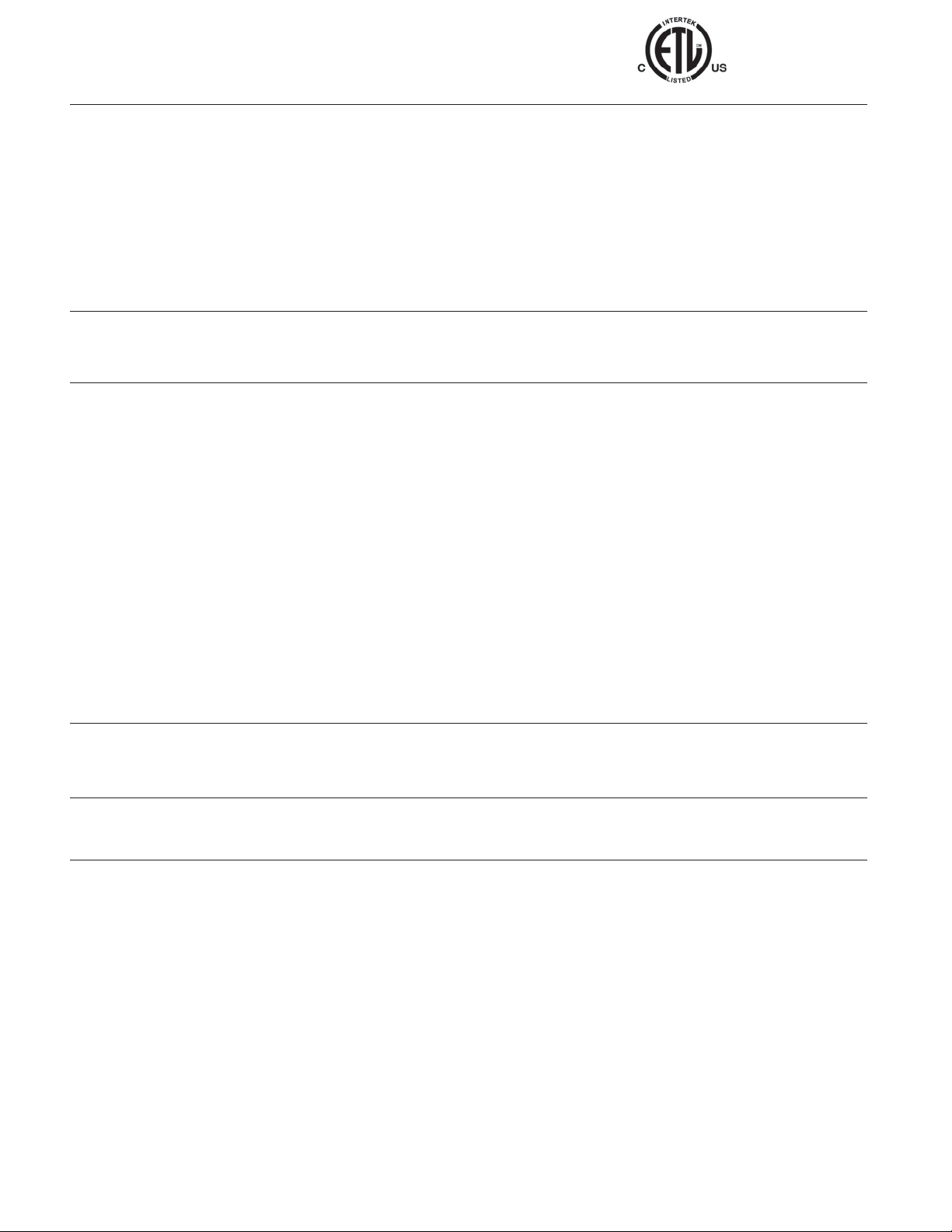

Table 1 - Performance and Dimensional Data - Tubular Blower Unit Heater

Unit Size 100 125 150 175 200 250 300 350 400

PERFORMANCE DATA†

Input - BTU/Hr. 100,000 125,000 150,000 175,000 200,000 250,000 300,000 350,000 400,000

(kW) (29.3) (36.6) (44.0) (51.3) (58.6) (73.3) (87.9) (102.6) (117.2)

Output - BTU/Hr. 83,000 103,750 124,500 145,250 166,000 207,500 246,000 290,500 332,000

(kW) (24.3) (30.4) (36.5) (42.6) (48.6) (60.8) (72.1) (85.1) (97.3)

Thermal Effi ciency - % 83 83 83 83 83 83 82 83 83

Free Air Delivery - CFM 1,181 1,476 1,771 2,067 2,362 2,953 3,501 4,134 4,724

(cu. m/s) (0.557) (0.697) (0.836) (0.976) (1.115) (1.394) (1.652) (1.951) (2.230)

Air Temperature Rise - Deg. F 65 65 65 65 65 65 65 65 65

(Deg. C) (36) (36) (36) (36) (36) (36) (36) (36) (36)

Outlet Velocity - FPM 370 463 555 395.0 451.0 564.0 422 498 570

(m/s) (1.879) (2.351) (2.819) (2.006) (2.291) (2.864) (2.143) (2.529) (2.895)

Full Load Amps at 115V 7.3 9.4 9.4 14.2 14.2 15.6 15.6 20.8 20.8

Maximum Circuit Ampacity 8.6 11.2 11.2 17.1 17.1 18.9 18.9 25.4 25.4

MOTOR DATA: Motor HP 1/4 1/2 1/2 3/4 3/4 1 1 1-1/2 1-1/2

Motor kW 0.19 0.37 0.37 0.56 0.56 0.75 0.75 1.11 1.11

Motor Type ODP** SPH SPH SPH SPH SPH Cap. Start Cap. Start Cap. Start Cap. Start

RPM 1,725 1,725 1,725 1,725 1,725 1,725 1,725 1,725 1,725

Amps @ 115V 5.1 7.2 7.2 11.6 11.6 13.0 13.0 18.2 18.2

DIMENSIONAL DATA - inches (mm)

"A" Height to Top of Flue 33-3/4 33-3/4 33-3/4 33-3/4 33-3/4 33-3/4 34 34 34

(857) (857) (857) (857) (857) (857) (864) (864) (864)

"B" Jacket Width of Unit 20-3/4 20-3/4 20-3/4 32-3/4 32-3/4 32-3/4 50-3/4 50-3/4 50-3/4

(527) (527) (527) (832) (832) (832) (1289) (1289) (1289)

"C" Width to Centerline Flue 13-3/8 13-3/8 13-3/8 19-3/8 19-3/8 19-3/8 28-3/8 28-3/8 28-3/8

(340) (340) (340) (492) (492) (492) (721) (721) (721)

"D" Depth to Front Hanger 21 21 21 21 21 21 21 21 21

(533) (533) (533) (533) (533) (533) (533) (533) (533)

"E" Hanging Distance Width 18-5/8 18-5/8 18-5/8 30-5/8 30-5/8 30-5/8 48-5/8 48-5/8 48-5/8

(473) (473) (473) (778) (778) (778) (1235) (1235) (1235)

"F" Hanging Distance Depth 19 19-1/2 19-1/2 32-3/4 32-3/4 32-3/4 23-1/2 32-3/4 32-3/4

(483) (495) (495) (832) (832) (832) (597) (832) (832)

"G" Discharge Opening Width 18-3/4 18-3/4 18-3/4 30-3/4 30-3/4 30-3/4 48-3/4 48-3/4 48-3/4

(476) (476) (476) (781) (781) (781) (1238) (1238) (1238)

"H" Depth to Centerline Flue 4-3/4 4-3/4 4-3/4 4-3/4 4-3/4 4-3/4 5-1/8 5-1/8 5-1/8

(121) (121) (121) (121) (121) (121) (130) (130) (130)

"L" Discharge Opening Height 24-1/2 24-1/2 24-1/2 24-1/2 24-1/2 24-1/2 24-1/2 24-1/2 24-1/2

(622) (622) (622) (622) (622) (622) (622) (622) (622)

"M" Overall Unit Width 25-1/4 25-1/4 25-1/4 37-1/4 37-1/4 37-1/4 55-1/4 55-1/4 55-1/4

(641) (641) (641) (946) (946) (946) (1403) (1403) (1403)

"P" Overall Unit Depth 49-3/4 49-3/8 49-3/8 56-1/8 56-1/8 56-1/8 53-3/8 56-1/8 56-1/8

(1264) (1254) (1254) (1426) (1426) (1426) (1356) (1426) (1426)

*Flue Size Diameter - in 5 5 5 5 5 5 6 6 6

(mm) (127) (127) (127) (127) (127) (127) (152) (152) (152)

Blower Size - inches (Qty) 9 10 10 12 12 12 10 (2) 12 (2) 12 (2)

Gas Inlet, Natural Gas - in 1/2 1/2 1/2 1/2 1/2 3/4 3/4 3/4 3/4

Gas Inlet, LP Gas - in 1/2 1/2 1/2 1/2 1/2 1/2 OR 3/4 1/2 OR 3/4 1/2 OR 3/4 1/2 OR 3/4

Approximate Unit Weight - lb 171 175 202 245 264 289 370 390 429

(kg) (78) (79) (92) (111) (120) (131) (168) (177) (195)

Approximate Ship Weight - lb 256 261 289 381 400 425 520 547 595

(kg) (116) (118) (131) (173) (181) (193) (236) (248) (270)

† Ratings shown are for unit installations at elevations between 0 and 2,000 ft (0 to 610m). For unit installations in U.S.A. above 2,000 ft. (610m), the unit input must be fi eld derated 4%

for

each 1,000 ft. (305m) above sea level; refer to local codes, or in absence of local codes, refer to the latest edition of the National Fuel Gas Code, ANSI Standard Z223.1 (N.F.P.A. No. 54).

For installations in Canada, any reference to deration at altitudes in excess of 2,000 ft. (610m) are to be ignored. At altitudes of 2,000 ft. to 4,500 ft. (610 to 1372m), the unit must be

fi eld derated to 90% of the normal altitude rating, and be so marked in accordance with the ETL certifi cation. See Table 8A for fi eld deration information.

* Flue collar is factory supplied with unit; to be fi eld installed per included instructions.

** LEGEND: SPH = SPLIT PHASE CAP. START = CAPACITOR START ODP = OPEN DRIP PROOF

4

Page 5

INSTALLATION

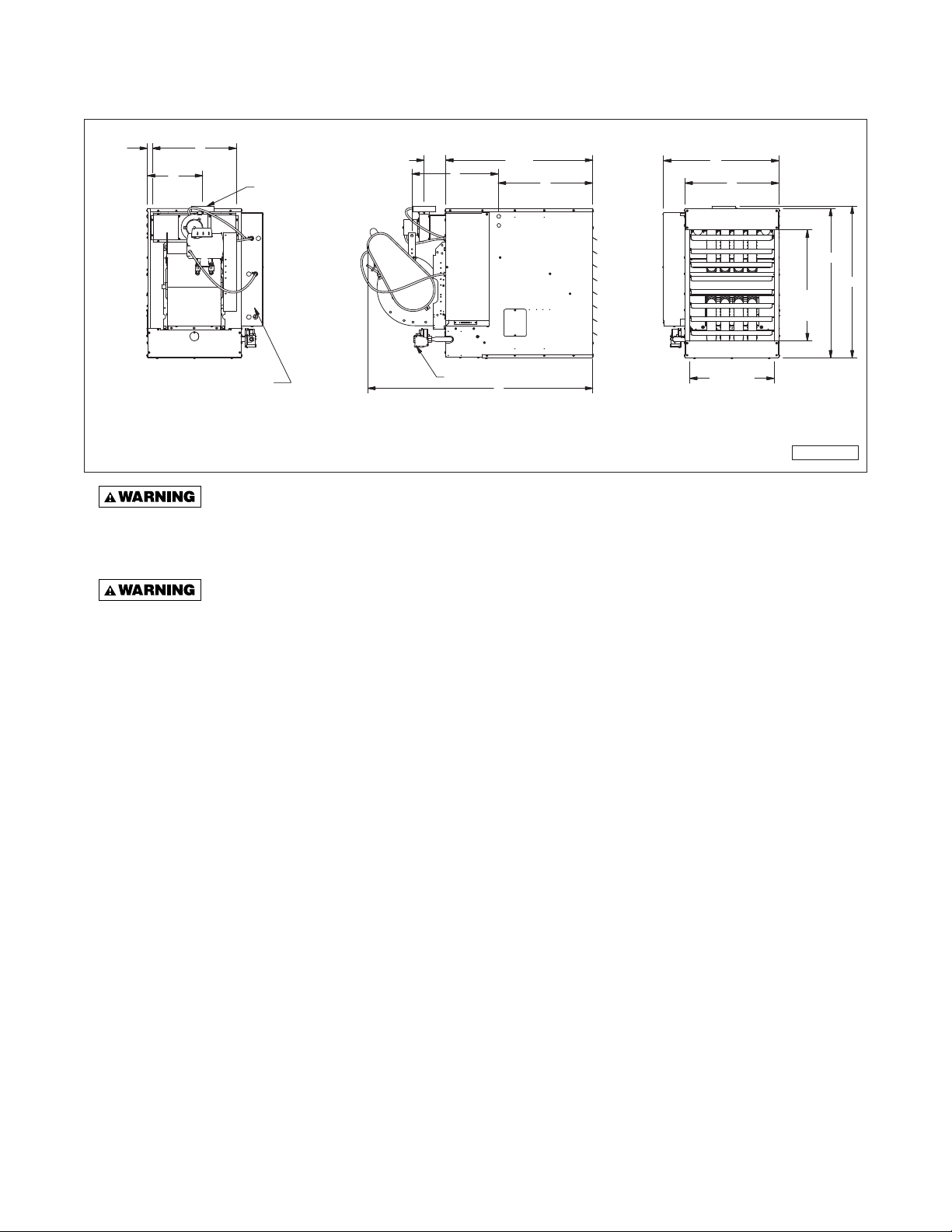

Figure 2 - Dimensional Drawing – Tubular Blower Unit Heater

1 1/8

D8931B

E

C

Electrical Control Panel

Rear View

Flue

H

F

Gas Valve

Do not install unit heaters in

corrosive or fl ammable atmospheres! Premature

failure of, or severe damage to the unit will

result!

Avoid locations where extreme

drafts can affect burner operation. Unit heaters

must not be installed in locations where air for

combustion would contain chlorinated, halogenated or acidic vapors. If located in such an

environment, premature failure of the unit will

occur!

Since the unit is equipped with an automatic gas ignition

system, the unit heater must be installed such that the

gas ignition control system is not directly exposed to

water spray, rain or dripping water.

NOTICE: Location of unit heaters is related directly to

the selection of sizes. Basic rules are as follows:

MOUNTING HEIGHT: Unit Heaters equipped with

standard fan guards must be installed at a minimum

of 8' (2.4m) above the fl oor, measured to the bottom of

the unit. For mounting heights above 8', see Table 2 to

compare unit height to heat throw distance.

AIRCRAFT HANGARS: Unit Heaters must be installed

in aircraft hangars as follows: In aircraft hangars, unit

heaters must be at least 10' (3.0m) above the upper

surface of wings or engine enclosures of the highest

aircraft to be stored in the hangar, and 8' (2.4m) above

the floor in shops, offices and other sections of the

hangar where aircraft are not stored or housed. Refer

to current ANSI/NFPA No. 409, Aircraft Hangars. In

Canada, installation is suitable in aircraft hangars when

acceptable to the enforcing authorities.

32 1/2

D

P

Side View

M

B

G

(Discharge

Opening)

Front View

L

(Discharge

Opening)

D8931B

33

PUBLIC GARAGES: In repair garages, unit heaters must

be located at least 8' (2.4m) above the fl oor. Refer to the

latest edition of NFPA 88B, Repair Garages.

In Canada, installation must be in accordance to the

latest edition of CSA B149 “Installation Codes for Gas

Burning Appliances and Equipment.”

AIR DISTRIBUTION: Direct air towards areas of

maximum heat loss. When multiple heaters are involved,

circulation of air around the perimeter is recommended

where heated air fl ows along exposed walls. Satisfactory

results can also be obtained where multiple heaters are

located toward the center of the area with heated air

directed toward the outside walls. Be careful to avoid

all obstacles and obstructions which could impede the

warm air distribution patterns. Heat throw distances are

presented in Table 2.

Unit heaters should not be installed to maintain low

temperatures and/or freeze protection of buildings.

A minimum of 50°F (10°C) thermostat setting must

be maintained. If unit heaters are operated to maintain

lower than 50°F (10°C), hot flue gases are cooled

inside the heat exchanger to a point where water

vapor (a fl ue gas by-product) condenses onto the heat

exchanger walls. The result is a mildly corrosive acid that

prematurely corrodes the aluminized heat exchanger and

can actually drip water down from the unit heater onto

fl oor surface. Additional unit heaters should be installed

if a minimum 50°F (10°C) thermostat setting cannot be

maintained.

A

5

Page 6

INSTALLATION (continued)

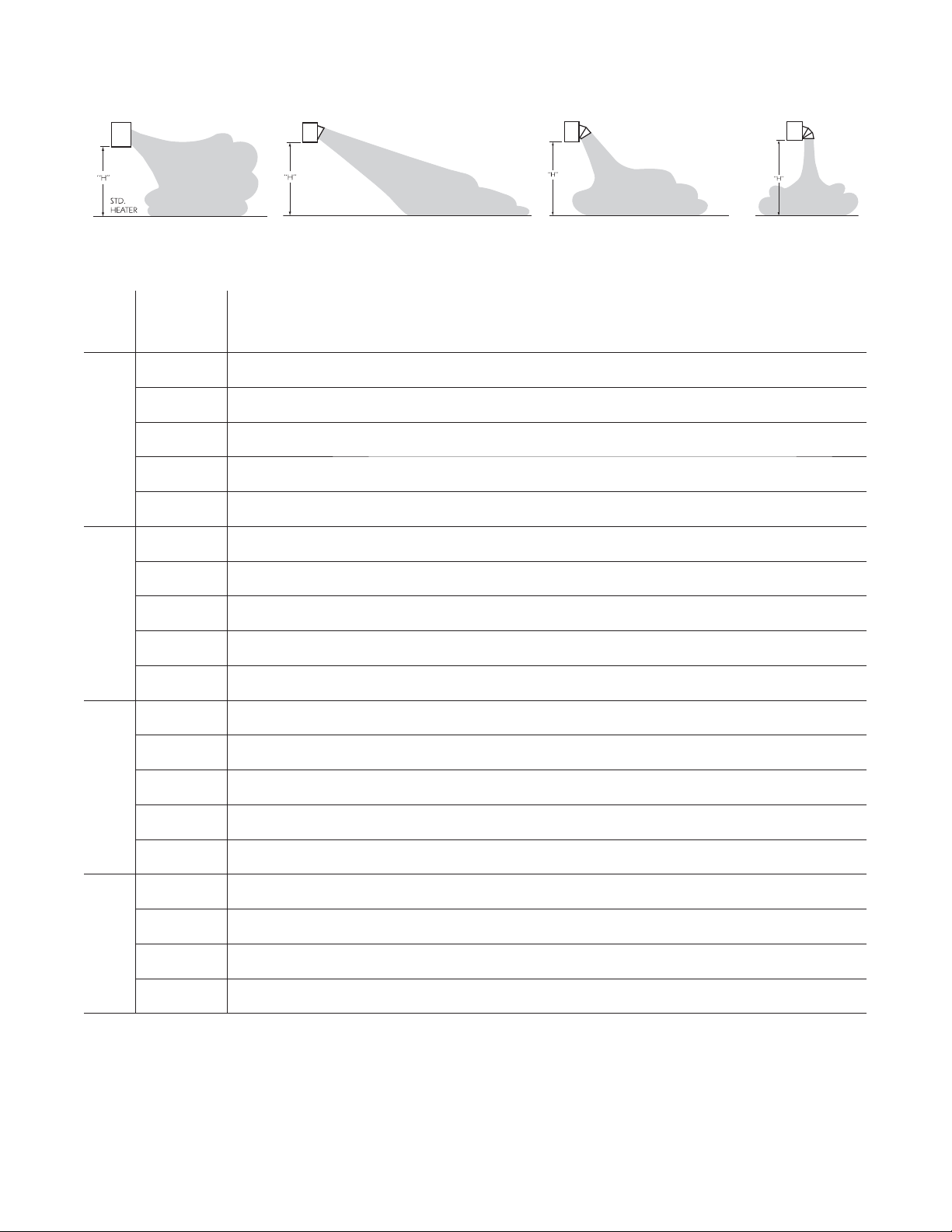

Table 2 - Heat Throw Data

Standard Heater 30° Nozzle 60° Nozzle 90° Nozzle

Degree

Nozzle

None 8 60 65 70 75 80 90 105 110 120

90°* 15 30 x 25 35 x 30 40 x 35 45 x 40 50 x 40 60 x 45 70 x 45 80 x 50 100 x 50

* It is not recommended to mount a unit with a 90 nozzle under 10 feet.

Notes: 1. All throw data fi gures are approximations. Allowances should be made for optimum performance, altitude, etc.

2. NR - Units not recommended at these mounting heights.

3. 30°, 60° and 90° nozzles are shipped unassembled.

Distance From

Floor to Bottom

of

of Unit "H" - ft

(m)

(2.4) (18.3) (19.8) (21.3) (22.9) (24.4) (27.4) (32.0) (33.5) (36.6)

10 54 56 60 64 68 78 90 95 100

(3.0) (16.5) (17.1) (18.3) (19.5) (20.7) (23.8) (27.4) (29.0) (30.5)

12 44 46 49 57 61 68 80 84 90

(3.7) (13.4) (14.0) (14.9) (17.4) (18.6) (20.7) (24.4) (25.6) (27.4)

15

(4.6) (13.7) (14.9) (15.8) (18.3) (21.3) (22.6) (24.4)

20

(6.1) (14.0) (16.5) (19.2) (20.1) (21.3)

30° 8 65 70 75 80 85 95 115 120 125

(2.4) (19.8) (21.3) (22.9) (24.4) (25.9) (29.0) (35.1) (36.6) (38.1)

10 57 60 64 68 72 86 99 105 110

(3.0) (17.4) (18.3) (19.5) (20.7) (21.9) (26.2) (30.2) (32.0) (33.5)

12 50 54 57 60 64 77 88 94 100

(3.7) (15.2) (16.5) (17.4) (18.3) (19.5) (23.5) (26.8) (28.7) (30.5)

15

(4.6) (13.7) (14.6) (15.2) (16.2) (19.5) (22.6) (24.1) (25.6)

20

(6.1) (13.4) (14.3) (17.7) (20.1) (21.6) (22.9)

60° 8 75 80 85 90 95 110 125 130 138

(2.4) (22.9) (24.4) (25.9) (27.4) (29.0) (33.5) (38.1) (39.6) (42.1)

10 65 70 75 79 83 95 109 115 120

(3.0) (19.8) (21.3) (22.9) (24.1) (25.3) (29.0) (33.2) (35.1) (36.6)

12 60 64 68 72 76 84 100 103 108

(3.7) (18.3) (19.5) (20.7) (21.9) (23.2) (25.6) (30.5) (31.4) (32.9)

15 50 54 56 61 65 71 85 88 94

(4.6) (15.2) (16.5) (17.1) (18.6) (19.8) (21.6) (25.9) (26.8) (28.7)

20

(6.1) (14.9) (15.8) (16.8) (18.0) (19.8) (23.5) (24.7) (25.9)

(4.6) (9.1) (7.6) (10.7) (9.1) (12.2) (10.7) (13.7) (12.2) (15.2) (12.2) (18.3) (13.7) (21.3) (13.7) (24.4) (15.2) (30.5) (15.2)

20

(6.1) (12.2) (10.7) (17.1) (12.2) (19.8) (12.2) (21.3) (13.7) (24.4) (13.7)

25

(7.6) (15.2) (10.7) (18.3) (10.7) (19.8) (12.2) (22.9) (12.2)

30

(9.1) (16.8) (10.7) (18.3) (10.7) (19.8) (12.2)

100,000 125,000 150,000 175,000 200,000 250,000 300,000 350,000 400,000

Approximate Distance of Heat Throw - Feet (Meters)

NR NR

NR NR NR NR

NR

NR NR NR

NR

NR NR NR NR

NR NR NR NR NR

NR NR NR NR NR NR

45 48 50 53 64 74 79 84

49 52 55 59 65 77 81 85

45 49 52 60 70 74 80

UNIT SIZE BTU/Hr

46 54 63 66 70

44 47 58 66 71 75

40 x 35 56 x 40 65 x 40 70 x 45 80 x 45

50 x 35 60 x 35 65 x 40 75 x 40

55 x 35 60 x 35 65 x 40

6

Page 7

INSTALLATION (continued)

AIR FOR COMBUSTION: The unit heater shall be

installed in a location in which the facilities for

ventilation permit satisfactory combustion of gas,

proper venting, and the maintenance of ambient

temperature at safe limits under normal conditions of

use. The unit heater shall be located in such a manner

as not to interfere with proper circulation of air within the

confi ned space. When buildings are so tight that normal

infi ltration does not meet air requirements, outside air

shall be introduced per Sections 1.3.4.2 and 1.3.4.3 of

ANSI Z223.1 for combustion requirements. A permanent

opening or openings having a total free area of not less

than one square inch per 5,000 BTU/Hr (1.5 kW) of total

input rating of all appliances within the space shall be

provided.

NOTICE: Unit Heater sizing should be based on heat

loss calculations where the unit heater output equals

or exceeds heat loss.

CLEARANCES: Each Gas Unit Heater shall be

located with respect to building construction and other

equipment so as to permit access to the Unit Heater.

Clearance between vertical walls and the vertical sides

of the Unit Heater shall be no less than 6" (152mm).

To ensure access to the control box, a minimum of 18"

(457mm) is required for the control box side. A minimum

clearance of 6" (152mm) must be maintained between

the top of the Unit Heater and the ceiling. The bottom of

the Unit Heater must be no less than 12" (305mm) from

any combustible. The distance between rear of unit and

vertical wall should be no less than 18" to maintain inlet

air fl ow. The distance between the fl ue collector and any

combustible must be no less than 6" (152mm). Also see

AIR FOR COMBUSTION and VENTING sections.

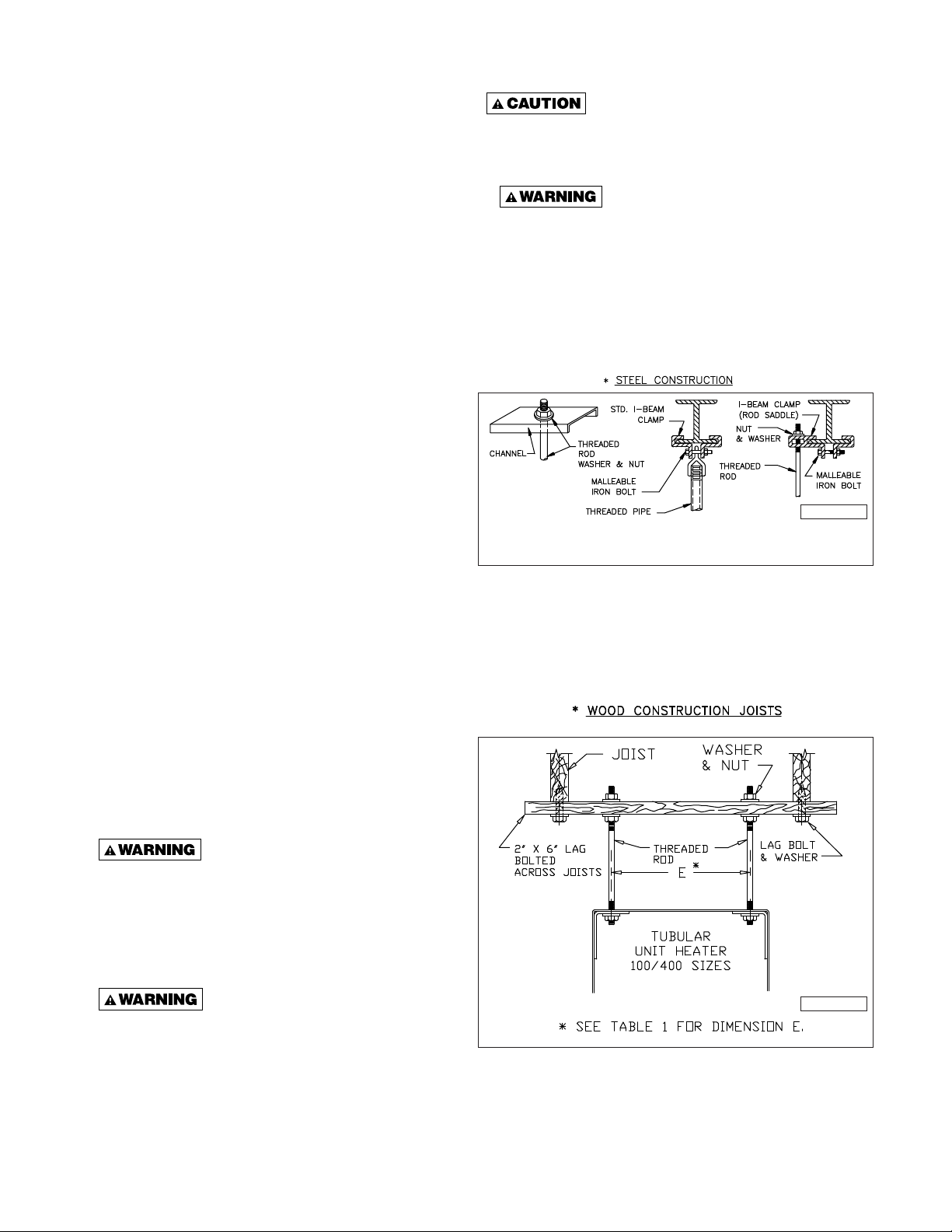

Unit Heaters must be hung level

from side to side and from front to back, see Figure

3A and 3B. Failure to do so will result in poor

performance and/or premature failure of the unit.

Ensure that all hardware used in

the suspension of each unit heater is more than

adequate for the job. Failure to do so may result

in extensive property damage, severe personal

injury, or death!

Refer to Figures 3A and 3B for suspension of units.

Figure 3A - Heater Mounting*

D2788A

*All hanging hardware and wood is not included with the unit (To

be fi eld supplied).

Figure 3B - Heater Suspension

NOTICE: Increasing the clearance distances may

be necessary if there is a possibility of distortion or

discoloration of adjacent materials.

Make certain that the lifting

methods used to lift the heater and the method

of suspension used in the fi eld installation of the

heater are capable of uniformly supporting the

weight of the heater at all times. Failure to heed

this warning may result in property damage or

personal injury!

Make sure that the structure

to which the unit heater is to be mounted is

capable of safely supporting its weight. Under

no circumstances must the gas lines, the venting

system or the electrical conduit be used to

support the heater; or should any other objects

(i.e. ladder, person) lean against the heater gas

lines, venting system or the electrical conduit for

support. Failure to heed these warnings may result

in property damage, personal injury, or death.

D4804

7

Page 8

INSTALLATION (continued)

GAS PIPING

To avoid damage or possible personal injury, do not connect gas piping to this unit

until a supply line pressure/leak test has been completed. Connecting the unit before completing the

pressure/leak test may damage the unit gas valve and result in a fi re hazard.

Do not rely on a shut-off valve to isolate the unit while conducting gas pressure/leak tests.

These valves may not be completely shut off, exposing the gas valve to excessive pressure and damage.

PIPE SIZING

To provide adequate gas pressure to the gas unit heater,

size the gas piping as follows:

by the same piping arrangement, the total cu. ft./hr.

input and length of pipe must be considered.

1. Find the cu. ft./hr. by using the following formula:

Cu. ft./hr. =

Input BTU/Hr.

1000

2. Refer to Table 3. Match “Length of Pipe in Feet”

with appropriate “Gas Input - Cu. Ft./Hr.” fi gure. This

fi gure can then be matched to the pipe size at the

top of the column.

Example:

It is determined that a 67 foot (20.4m) run of gas

pipe is required to connect a 200 MBTU gas unit

heater to a 1,000 BTU/cu ft. (0.29kW) natural gas

supply.

200,000 BTU/Hr

1,000 BTU/cu. ft.

= 200 Cu. ft./hr.

Using Table 3, a 1 inch pipe is needed.

NOTICE: If the gas unit heater is to be fi red with LP

gas, consult your local LP gas dealer for pipe size

information.

NOTICE: HEATER INSTALLATION FOR USE WITH

PROPANE (BOTTLED) GAS MUST BE MADE BY

A QUALIFIED L.P. GAS DEALER OR INSTALLER.

HE/SHE WILL INSURE THAT PROPER JOINT

COMPOUNDS ARE USED FOR MAKING PIPE

CONNECTIONS; THAT AIR IS PURGED FROM

LINES; THAT A THOROUGH TEST IS MADE FOR

LEAKS BEFORE OPERATING THE HEATER; AND

THAT IT IS PROPERLY CONNECTED TO THE

PROPANE GAS SUPPLY SYSTEM.

Before any connection is made to the existing line

supplying other gas appliances, contact the local gas

NOTE: See General Safety Information section for

English/Metric unit conversion factors.

company to make sure that the existing line is of adequate

size to handle the combined load.

NOTICE: If more than one unit heater is to be served

Table 3 - Gas Pipe Size

Maximum Capacity of Pipe in Cubic Feet of Gas per Hour (Cubic Meters per Hour) for Gas Pressures of 0.5 psig (3.5 kPa) or Less,

and a Pressure Drop of 0.5 Inch Water Column (124.4 Pa)

(Based on a 0.60 Specifi c Gravity Gas)

Nominal

Iron Internal Length of Pipe, Feet (meters)

Pipe Size

Dia. 10 20 30 40 50 60 70 80 90 100 125 150 175 200

in. in. (3.0) (6.1) (9.1) (12.2) (15.2) (18.3) (21.3) (24.4) (27.4) (30.5) (38.1) (45.7) (53.3) (61.0)

1/2 0.622 175 120 97 82 73 66 61 57 53 50 44 40 37 35

(4.96) (3.40) (2.75) (2.32) (2.07) (1.87) (1.73) (1.61) (1.50) (1.42) (1.25) (1.13) (1.05) (0.99)

3/4 0.824 360 250 200 170 151 138 125 118 110 103 93 84 77 72

(10.2) (7.08) (5.66) (4.81) (4.28) (3.91) (3.54) (3.34) (3.11) (2.92) (2.63) (2.38) (2.18) (2.04)

1 1.049 680 465 375 320 285 260 240 220 205 195 175 160 145 135

(19.3) (13.2) (10.6) (9.06) (8.07) (7.36) (6.80) (6.23) (5.80) (5.52) (4.96) (4.53) (4.11) (3.82)

1 1/4 1.380 1400 950 770 660 580 530 490 460 430 400 360 325 300 280

(39.6) (26.9) (21.8) (18.7) (16.4) (15.0) (13.9) (13.0) (12.2) (11.3) (10.2) (9.20) (8.50) (7.93)

1 1/2 1.610 2100 1460 1180 990 900 810 750 690 650 620 550 500 460 430

(59.5) (41.3) (33.4) (28.0) (25.5) (22.9) (21.2) (19.5) (18.4) (17.6) (15.6) (14.2) (13.0) (12.2)

2 2.067 3950 2750 2200 1900 1680 1520 1400 1300 1220 1150 1020 950 850 800

(112) (77.9) (62.3) (53.8) (47.6) (43.0) (39.6) (36.8) (34.5) (32.6) (28.9) (26.9) (24.1) (22.7)

2 1/2 2.469 6300 4350 3520 3000 2650 2400 2250 2050 1950 1850 1650 1500 1370 1280

(178) (123) (99.7) (85.0) (75.0) (68.0) (63.7) (58.0) (55.2) (52.4) (46.7) (42.5) (38.8) (36.2)

3 3.068 11000 7700 6250 5300 4750 4300 3900 3700 3450 3250 2950 2650 2450 2280

(311) (218) (177) (150) (135) (122) (110) (105) (97.7) (92.0) (83.5) (75.0) (69.4) (64.6)

4 4.026 23000 15800 12800 10900 9700 8800 8100 7500 7200 6700 6000 5500 5000 4600

(651) (447) (362) (309) (275) (249) (229) (212) (204) (190) (170) (156) (142) (130)

1. Determine the required Cu. Ft./Hr. by dividing the input by 1000. For SI/Metric measurements: Convert BTU/Hr. to kilowatts. Multiply the units

inputs (kW) by 0.0965 to determine Cu. Meters./Hr. 2. FOR NATURAL GAS: Select pipe size directly from the table. 3. FOR PROPANE GAS:

Multiply the Cu. Ft./Hr. value by 0.633; then, use the table. 4. Refer to the metric conversion factors listed in the General Safety section for SI Unit

measurement conversions.

8

Page 9

INSTALLATION (continued)

D3631C

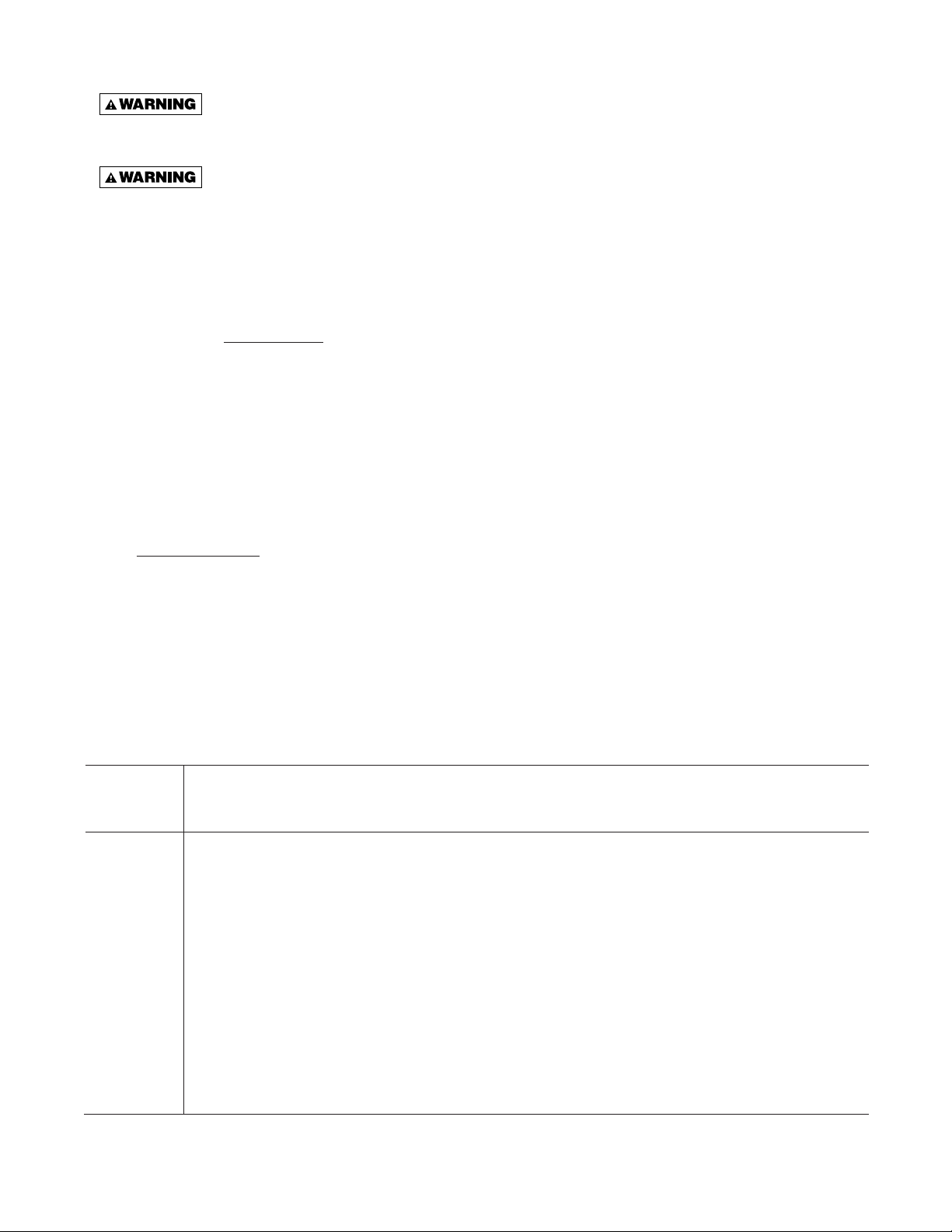

PIPE INSTALLATION

1. Install the gas piping in accordance with applicable

local codes.

2. Check gas supply pressure. Each unit heater must

be connected to a manifold pressure and a gas

supply capable of supplying its full rated capacity as

specifi ed in Table 4. A fi eld LP tank regulator must

be used to limit the supply pressure to a maximum

of 14" W.C. (3.5 kPa). All piping should be sized in

accordance with the latest edition of ANSI Standard

Z223.1 (NFPA54), National Fuel Gas Code; in

Canada, according to CSA B149. See Tables 1

& 3 for correct gas piping size. If gas pressure is

excessive on natural gas applications, install a

pressure regulating valve in the line upstream from

the main shutoff valve.

3. Adequately support the piping to prevent strain on

the gas manifold and controls.

4. To prevent the mixing of moisture with gas, run the

take-off piping from the top, or side, of the main.

5. Standard Unit Heaters, optional two-stage units are

supplied with a combination valve which includes:

a. Manual "A" valve

b. Manual "B" valve

c. Solenoid valve

d. Pressure regulator

Pipe directly into the combination valve (see Figure

4).

6. Gas valve has a pressure test post requiring a

3/32" hex head wrench to read gas supply and

manifold pressures. Open 1/4 turn counterclockwise

to read, turn clockwise to close and reseat. A 5/16"

ID hose fi ts the pressure post.

7. Provide a drip leg in the gas piping near the gas

unit heater. A ground joint union and a manual gas

shutoff valve should be installed ahead of the unit

heater controls to permit servicing. The manual

shutoff valve must be located external to the jacket

(See Figure 4).

8. Make certain that all connections have been

adequately doped and tightened.

Do not over tighten the inlet gas

piping into the valve. This may cause stresses that

will crack the valve!

NOTICE: Use pipe joint sealant resistant to the

action of liquefied petroleum gases regardless of

gas conducted.

Figure 4 - Pipe Installation, Standard Controls

D3631C

Never use an open fl ame to detect

gas leaks. Explosive conditions may exist which

may result in personal injury or death!

The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system in excess of 1/2 psig

(3.5 kPa).

The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psig (3.5 kPa).

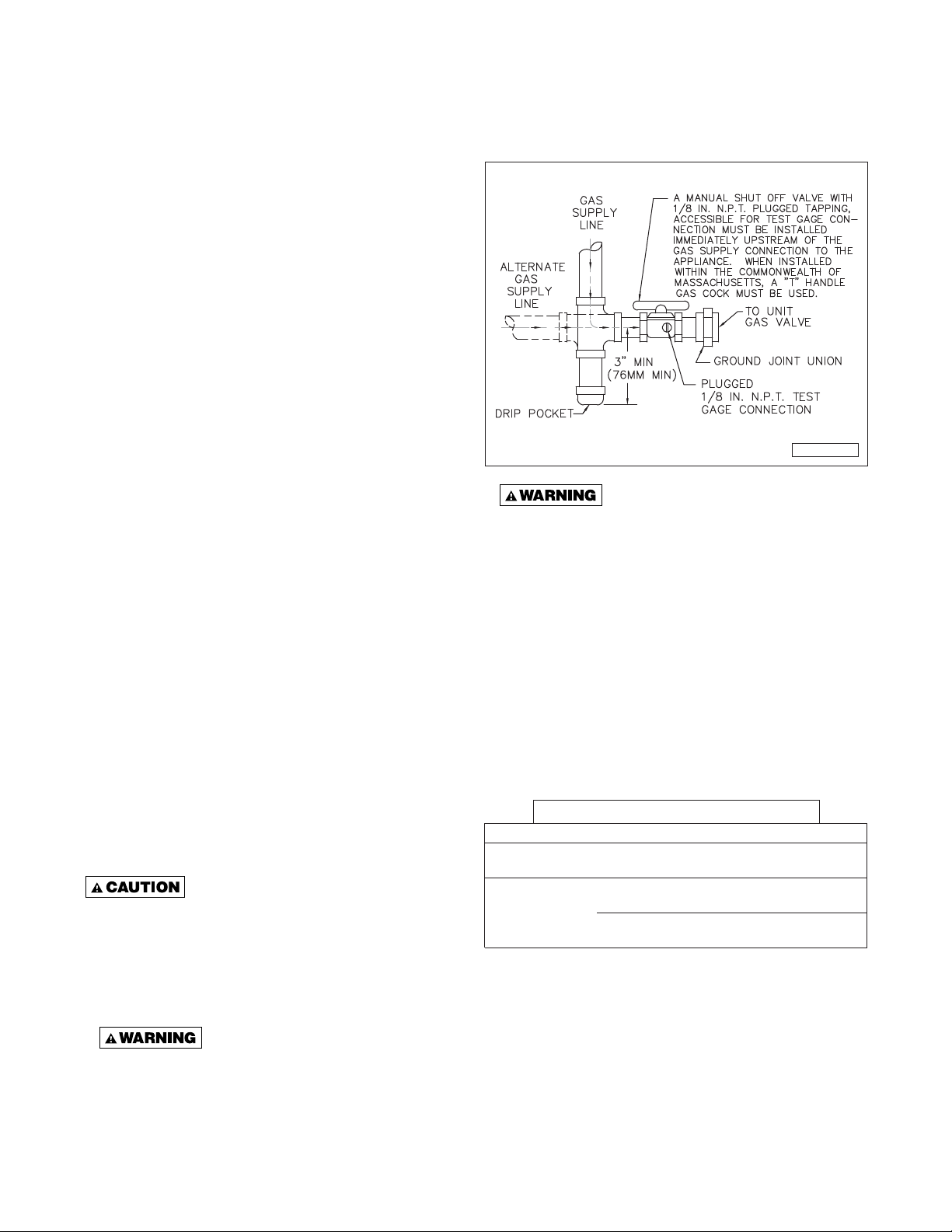

Table 4 - Gas Piping Requirements

SINGLE STAGE GAS PIPING REQUIREMENTS*

GasType Natural Gas Propane (LP) Gas

Manifold 3.5 in. W.C. 10.0 in. W.C.

Pressure (0.9 kPa) (2.5 kPa)

14.0 in. W.C. Max. 14.0 in. W.C. Max.

Supply Inlet (3.5 kPa) (3.5 kPa)

Pressure

(1.2 kPa) (2.7 kPa)

*For single stage application only at normal altitudes.

5.0 in. W.C. Min. 11.0 in W.C. Min.

Check all pipe joints for leakage

using a soap solution or other approved method.

Never use an open flame or severe personal

injury or death may occur!

9

Page 10

BLOWER SET UP AND ADJUSTMENT

BLOWER SET UP

BLOWER DRIVE ADJUSTMENT

The drive ratio of the motor and blower sheaves has

been preset at the factory for a temperature rise of 65°F

at .2" W.C. If the unit is to be operated under different

static air fl ow or pressure requirements, the drive ratio

must be altered by means of the adjustable sheave on

belt without fi rst disconnecting all electrical

power to the unit or severe personal injury may

result!

Never attempt to adjust the drive

the blower motor.

1. Ensure that all packing material, support blocks, etc.

have been removed from the unit.

2. Adjust the blower drive belt tension by means of the

two tension bolts on the blower motor base. When

proper tension has been achieved, the mid-point

defl ection of the belt will be 3/4" when subjected to a

5 lb. force.

3. Recheck all electrical connections.

4. When power is applied, ensure that the motor and

blower are rotating in a counter clockwise direction

when viewed from the drive side.

1. Remove the belt guard and loosen the belt tension

bolts on the blower motor base.

2. Loosen the set screw on the adjustable half of the

motor sheave. To increase the blower speed, turn

the adjustable half of the sheave clockwise, counter

clockwise to slow the blower. Retighten the set

screw.

3. Realign the blower and motor sheaves if necessary.

4. Adjust the belt tension as specifi ed in the BLOWER

SET UP section under step 2.

5. Replace the belt guard.

5. Measure the current draw of the motor.

Never operate the unit without

The "at speed" current draw of the

motor must never exceed that specified on the

the belt guard in place or severe personal injury

may result!

motor rating plate or severe damage to the motor

will result!

6. Check that the air flow of the unit, the rpm

and current draw of the blower motor and the

temperature rise are within the limits specified in

Table 1, the blower motor rating plate and the rating

plate on the unit, respectively (also see Motor Data

on page 11).

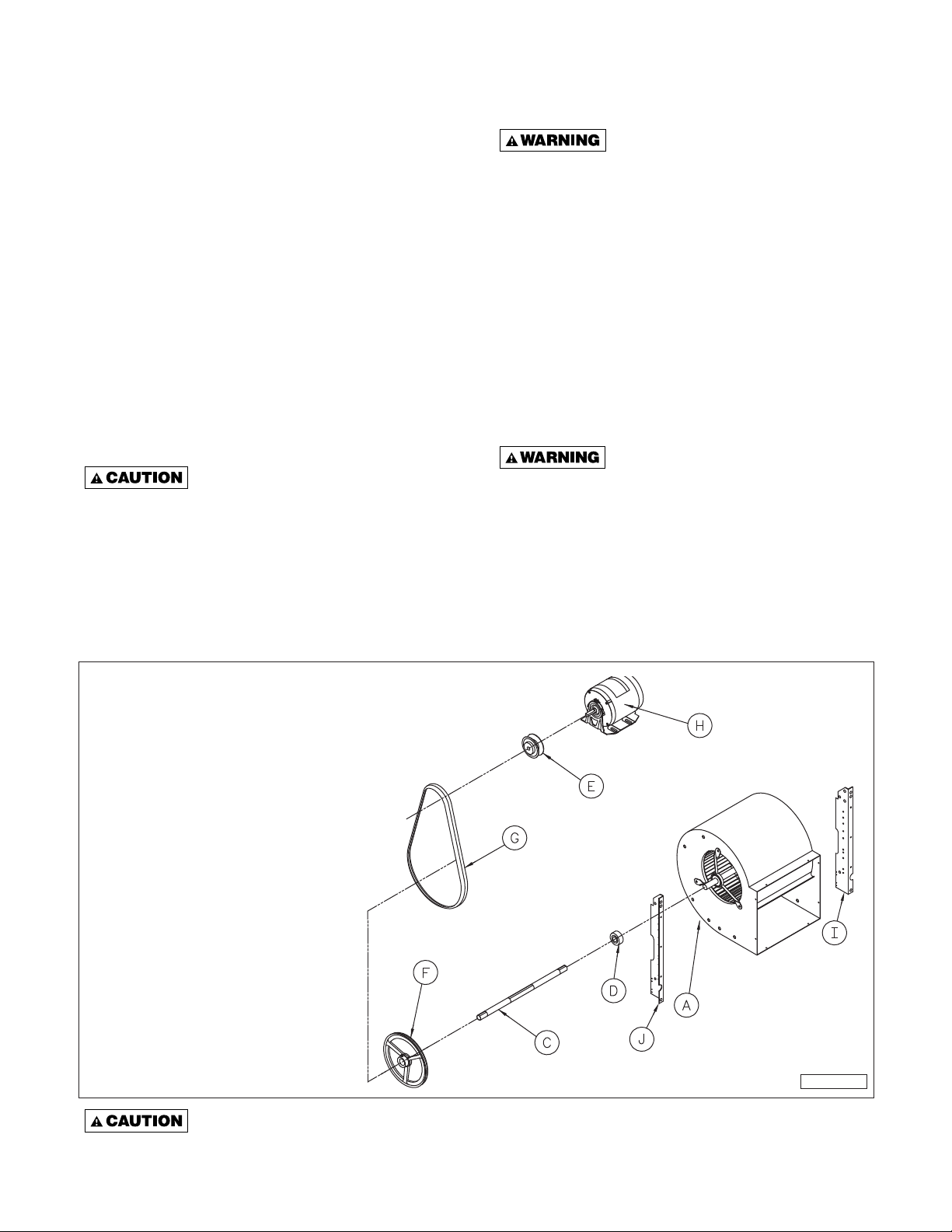

Figure 5 - Motor & Blower Assembly *

* PART DESCRIPTION

A. Blower Housing and Wheel

C. Blower Shaft

D. Bearings

E. Drive Pulley

F. Driven Pulley

G. V-Belt

H. Blower Motor

I. Blower Housing Support (LH)

H. Blower Housing Support (RH)

Never operate the unit beyond

the specified limits or severe damage to, and or

premature failure of, the unit will result!

D9000

* NOTICE: THE BLOWER ASSEMBLY FOR THE 100/250 UNITS

CONSISTS OF 1 WHEEL, 1 HOUSING, 1 SHAFT AND 2 BEARINGS.

FOR 300/400 UNITS THE BLOWER ASSEMBLY CONSISTS OF 2

WHEELS, 2 HOUSINGS, 1 SHAFT AND 3 BEARINGS.

10

Page 11

MOTOR AND PULLEY

All motor data based on standard ODP Motors.

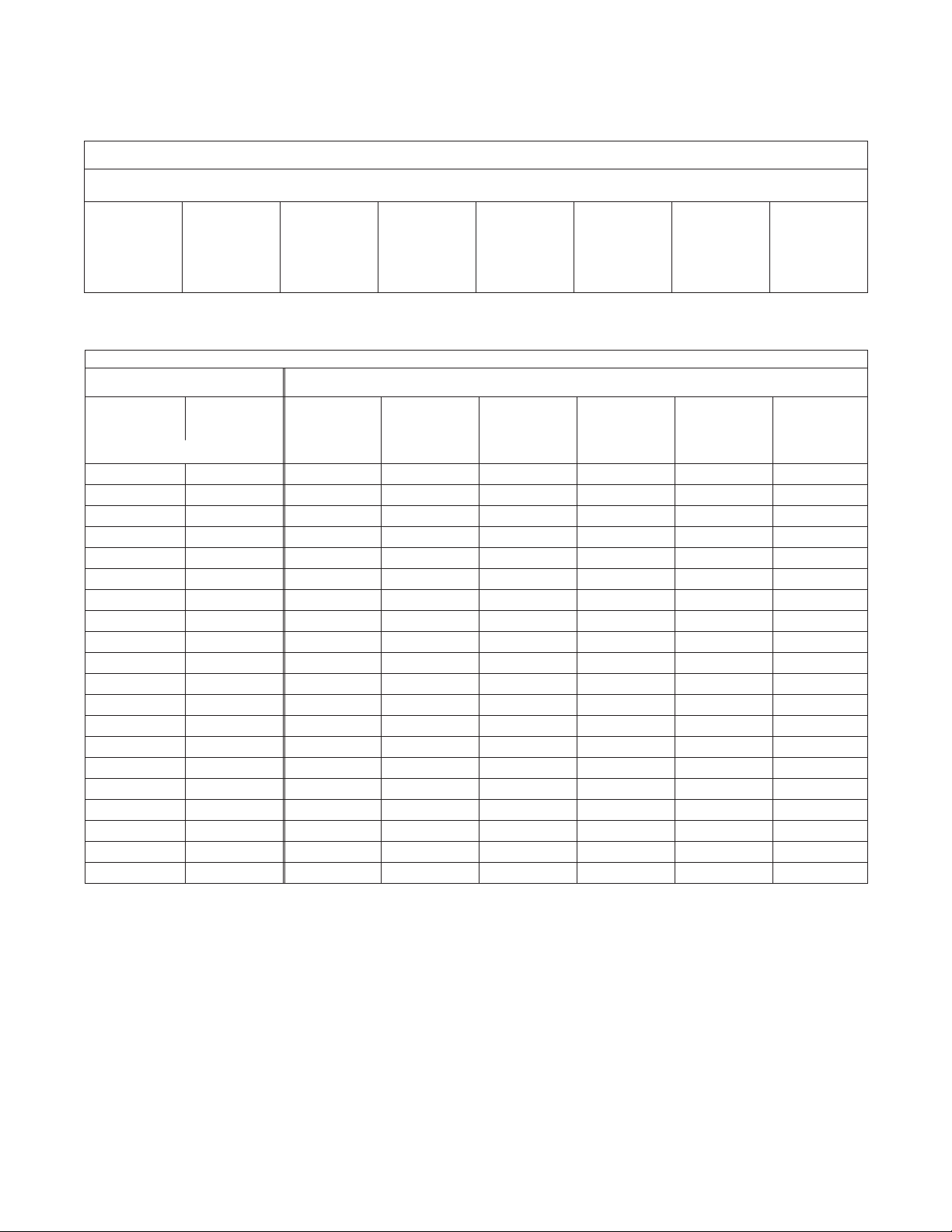

Table 5

Motor Full Load Amps*

VOLTAGE - PHASE

HP 115-1 208-1 230-1 208-3 230-3 460-3 575-3

1/4 5.1 2.2 2.3 1.7 1.3 0.7 N/A

1/2 7.2 3.7 3.8 2.3 2.2 1.1 0.8

3/4 11.6 5.2 5.0 3.0 3.4 1.7 1.1

1 13.0 6.6 6.5 3.4 3.4 1.7 1.3

1-1/2 18.2 9.1 9.1 5.1 5.2 2.6 1.7

2 21.0 11.3 10.5 6.2 6.0 3.0 N/A

* Average value, all speeds and frequencies.

Table 6

Pulley Table 1725 RPM Motors (1/3 to 2 H.P.)

MOTOR PULLEYS

BLOWER PULLEYS

IVL34

1.9-2.9

Turns Open

5

4-1/2

4

3-1/2

3

2-1/2

2

1-1/2

1

1/2

0

IVL44

2.8-3.8

5

4-1/2

4

3-1/2

3

2-1/2

2

1-1/2

1

1/2

0

AK51

4.7

697

734

771

807

844

880

918

954

991

1027

1064

1101

1137

1174

1211

1247

1284

1321

1357

1394

AK56

5.2

630

663

697

730

763

796

829

863

896

928

962

995

1028

1061

1094

1127

1161

1194

1227

1260

AL64

6.0

546

575

603

633

661

690

719

748

776

805

834

863

891

920

949

978

1006

1035

1064

1093

AL74

7.0

468

493

517

542

567

591

616

641

665

690

715

739

764

789

813

838

863

887

912

936

AL84

8.0

410

431

453

474

496

517

539

560

582

604

625

647

668

690

712

733

755

776

798

819

AL104

10.0

327

345

362

380

397

414

431

448

466

483

500

518

535

552

569

587

604

621

638

656

11

Page 12

ELECTRICAL CONNECTIONS

HAZARDOUS VOLTAGE!

DISCONNECT ALL ELECTRIC

POWER INCLUDING REMOTE

DISCONNECTS BEFORE

SERVICING. Failure to

disconnect power before

servicing can cause severe

personal injury or death.

Figure 6a Low-voltage

Thermostat Wiring

Single Stage

D4788

Figure 6b -

Low-voltage

Thermostat Wiring

Two Stage

Standard units are shipped for use on 115 volt, 60 hertz,

single phase electric power. The motor name-plate and

electrical rating of the transformer should be checked

before energizing the unit heater electrical system. All

external wiring must conform to the latest edition of

ANSI/NFPA No. 70, United States National Electrical

Code, and applicable local codes; in Canada, to the

Canadian Electrical Code, Part 1, CSA Standard C22.1.

Do not use any tools (i.e. screwdriver,

pliers, etc.) across terminals to check for power. Use

a voltmeter.

It is recommended that the electrical power supply to

each unit heater be provided by a separate, fused, and

permanently live electrical circuit. A disconnect switch of

suitable electrical rating should be located as close to

the gas valve and controls as possible. Each unit heater

must be electrically grounded in accordance with the

latest edition of the United States National Electrical

Code, ANSI/NFPA No. 70, or CSA Standard C22.1. Refer

to Figures 6a, 6b, 6c, 6d, 6e, 6f and 6g.

THERMOSTAT WIRING AND LOCATION:

Figure 6c -

D8541

Low-voltage

T834H or T834N

(or equivalent)

Thermostat Wiring

Single Stage

D8922C

NOTICE: The start-up fan delay should not exceed

30 seconds from a cold start.

IMPORTANT: For all wiring connections, refer to the

wiring diagram shipped with your unit (either affi xed

to the side jacket or enclosed in the installation

instructions envelope). Should any original wire

supplied with the heater have to be replaced, it

must be replaced with wiring material having a

temperature rating of at least 105°C.

Should any high limit wires have to be replaced,

they must be replaced with wiring material having a

temperature rating of 200°C minimum.

NOTICE: The thermostat must be mounted on a

vertical, vibration-free surface, free from air currents,

and in accordance with the furnished instructions.

Mount the thermostat approximately 5' (1.5m) above

the floor, in an area where it will be exposed to a free

circulation of average temperature air. Always refer to

the thermostat instructions, as well as our unit wiring

diagram, and wire accordingly. Avoid mounting the

thermostat in the following locations:

1. Cold Areas - Outside walls or areas where drafts

may affect the operation of the control.

2. Hot Areas - Areas where the sun's rays, radiation,

or warm air currents may affect the operation of

the control.

3. Dead Areas - Areas where the air cannot circulate

freely, such as behind doors or in corners.

12

Page 13

ELECTRICAL CONNECTIONS (continued)

Figure 6d - Tubular Blower Units 100-150 with Single Stage Ignition, Natural Gas and Propane (LP) Gas

13

Page 14

ELECTRICAL CONNECTIONS (continued)

Figure 6e - Tubular Blower Units 100-150 with Two Stage Ignition, Natural Gas and Propane (LP) Gas

14

Page 15

ELECTRICAL CONNECTIONS (continued)

Figure 6f - Tubular Blower Units 175-400 with Single Stage Ignition, Natural Gas and Propane (LP) Gas

15

Page 16

ELECTRICAL CONNECTIONS (continued)

Figure 6g - Tubular Blower Units 175-400 with Two Stage Ignition, Natural Gas and Propane (LP) Gas

16

Page 17

VENTING

ANSI now organizes vented

appliances into four categories.

Category I

Includes non-condensing

appliances with negative vent

Venting Categories

Non

Condensing Condensing

Negative

Vent I II

Pressure

Positive

Vent III IV

Pressure

pressure, like the traditional

atmospheric unit heater.

Category II

Groups condensing appliances

with negative vent pressure.

Category III

Appliances are non-condensing

and operate with a positive vent

Category IV

Covers condensing appliances with

positive vent pressure.

NOTICE: Category II and IV do

not apply to equipment specifi ed

within this manual.

pressure.

All unit heaters must be vented! All Venting installations shall be in accordance with the latest edition of Part 7,

Venting of Equipment of the National Fuel Gas Code, ANSI Z223.1 (NFPA54), or applicable provisions of local

building codes. Refer to page 19 for Canadian installations. Refer to Figures 7, 8, 9A, 9B, 10A and 10B.

CARBON MONOXIDE! Your venting system must not be blocked by any snow, snow

drifts, or any foreign matter. Inspect your venting system to ensure adequate ventilation exists at all

times! Failure to heed these warnings could result in Carbon Monoxide Poisoning (symptoms include

grogginess, lethargy, inappropriate tiredness, or fl u-like symptoms).

Do not damper or add heat recovery devices to the fl ue piping. Failure to open such a damper prior to operating

gas unit will result in the spillage of fl ue gas into the occupied space.

VERTICALLY VENTED UNIT HEATERS (CATEGORY I)

Observe the following precautions when venting the unit:

1. Use fl ue pipe of the same size as the fl ue connections

on the gas unit heater (See Table #1). All heaters

should be vented with double wall or single wall vent,

a factory built chimney, or a lined brick and mortar

chimney that has been constructed in accordance

with the National Building Code. Type B vent should

only be used for vertical rise portions of a Category

I vent pipe system. Type B vent pipe should not be

used for horizontal runs of vent pipe.

2. Provide as long a vertical run of fl ue pipe at the gas

unit heater as possible. A minimum of 5' (1.5m) of

vertical flue is required. The top of the vent pipe

should extend at least 2' (0.61m) above the highest

point on the roof. Install a weather cap over the

vent opening. Consideration should be made for

anticipated snow depth.

3. Slope horizontal runs upward from the gas unit

heater at least 1/4" per foot (21mm/m) minimum.

Horizontal runs should not exceed 75% of the

vertical height of the vent pipe, or chimney, above

the fl ue pipe connection, up to a maximum length of

10' (3m). Horizontal portions of the venting system

shall be supported at minimum intervals of 4' (1.2m).

In Canada, support at minimum intervals of 3' (1m).

5. Seal all vent pipe joints and seams to prevent

leakage. Use General Electric RTV-108, Dow

Corning RTV-732, or equivalent silicone sealant

with a temperature rating of 500 degrees F, or 3M

#425 aluminum foil tape (or equivalent).

6. Avoid running vent pipe through unheated spaces.

7. When this cannot be avoided, insulate the pipe to

prevent condensation of moisture on the walls of the

pipe.

8. Do not damper the fl ue piping. Failure to open such

a damper prior to operating the gas unit heater will

result in the spillage of flue gas into the occupied

space.

9. Avoid installing units in areas under negative

pressure due to large exhaust fans or air

conditioning. When required, a fl ue vent fan should

be installed in accordance with the instructions

included with the fan.

10. Vent connectors serving Category I and Category

II heaters shall not be connected into any portion of

mechanical draft systems operating under positive

pressure.

4. Use as few elbows as possible.

17

Page 18

VENTING (continued)

HORIZONTALLY VENTED UNIT HEATERS

(CATEGORY III)

Horizontal venting arrangements are designed to be used

with single wall vent pipe. Horizontal venting arrangements

must terminate external to the building using UL 1738

Listed single wall or double wall vent. For installations in

Canada, use corrosion resistant and gas-tight, listed vent

pipe conforming with local building codes, or in the absence

of local building codes, with current CSA-B149.1, Installation

Codes for Natural Gas Burning Appliances and Equipment

or CSA-B149.2, Installation Codes for Propane Gas

Burning Appliances and Equipment. See Figures 8, 9A and

10A for special installation requirements regarding these

venting conditions.

Do not use Type B (double wall)

vent internally within the building on horizontally

vented power vented units! This can result in

death, serious injury or substantial property

damage.

If double wall venting is used, components which are UL

Listed and approved for Category III positive pressure

venting systems MUST be used.

A Breidert Type L, Fields Starkap, or equivalent vent cap

must be supplied by the customer for each power vented

unit. The vent pipe diameter MUST be as specified in

Table 1. All unit sizes are factory equipped with the

required fl ue size collar; attach in place (if not mounted

to outlet); refer to included vent collar instruction sheet

for additional requirements.

Table 7

Vent Systems

Termination Clearance Requirements

Minimum Clearance

Structure/Object

Door, window, or gravity vent

inlet; combustion air inlet for

other appliances

Forced air inlet within 10 feet 3 feet above 6 feet (1.8m)

Adjoining Building or parapet 6 feet 6 feet (1.8m)

Adjacent public walkways

Electric, gas meters

& regulators

Above grade level* 1 foot* 1 foot (0.3m)*

*Above maximum anticipated snow depth.

for Termination Locations

USA CANADA

9 inch for 10,000 to

50,000 BTU/Hr

input; 12 inch for

input exceeding

50,000 BTU/Hr.

7 feet above

grade

4 feet horizontal

9 inch (230mm) for

10,000 to 50,000

BTU/Hr input;

12 inch (305mm)

for input exceeding

50,000 BTU/Hr.

7 feet (2.1m) above

grade

3 feet (0.9m)

horizontally from

meter/regulator

asembly. 6 feet

(1.8m), any

direction, from

a gas service

regulator vent outlet

The vent terminal must be at least 12" (305mm) from

the exterior of the wall that it passes through to prevent

degradation of the building material by fl ue gases.

Through the wall vent for these appliances shall NOT

terminate over public walkways, or over an area where

the condensate or vapor could create a nuisance or

hazard or could be detrimental to the operation of

regulators, relief valves, or other equipment.

The vent pipe equivalent length must not exceed 50'

(15.2m). Equivalent length is the total length of straight

sections PLUS 10' (3.05m) for each 90° elbow and

4' (1.22m) for each 45° elbow.

Maintain clearance between the vent pipe and combustible materials according to vent pipe manufacturers

instructions

Seal all vent pipe joints and seams to prevent leakage.

Use General Electric RTV-108, Dow-Corning RTV-732

silicone sealant or equivalent sealant with a temperature

rating of 500° F; or 3M #425 aluminum foil tape (or

equivalent). The vent air system must be installed to

prevent collection of condensate. Pitch horizontal pipes

downward 1/4" per foot (21mm per meter) toward the

outlet for condensate drainage.

Horizontal portions of the venting systems shall be

supported at maximum intervals of 4' (1.2m) to prevent

sagging (in Canada, support at 3' (1m) maximum

intervals).

Insulate single wall vent pipe exposed to cold air or

running through unheated areas.

Each unit must have an individual vent pipe and vent

terminal! Each unit MUST NOT be connected to other

vent systems or to a chimney.

18

Page 19

VENTING (continued)

Figure 7 - Vertically Vented Tubular Unit Heater – Category I

Figure 8 - Horizontally Vented Tubular Unit Heater – Category III

D8929

D8930

ADDITIONAL REQUIREMENT FOR CANADIAN INSTALLATIONS

* The following instructions apply to Canadian installations in addition to installation and operating instructions.

1. Installation must conform with local building codes, or in the absence of local codes, with current CSA B149.1, Installation Codes for Natural

Gas Burning Appliances and Equipment, or CSA B149.2, Installation Codes for Propane Gas Burning Appliances and Equipment.

2. Any reference to U. S. standards or codes in these instructions are to be ignored, and the applicable Canadian standards or codes applied.

REFER TO SPECIFICATION TABLE AND INSTALLATION MANUAL FOR PROPER USAGE.

19

Page 20

Figure 9A

VENTING (continued)

Figure 9B

D3620F

20

D3619C

Page 21

Figure 10A

VENTING (continued)

Figure 10B

D3661F

21

D3662D

Page 22

OPERATION

POWER VENTED BLOWER UNITS

DIRECT SPARK IGNITION

EXPLANATION OF CONTROLS:

1. The unit heater is equipped with a power vent system

that consists of a power venter motor and blower,

pressure switch, and sealed fl ue collector in place of

the conventional draft diverter.

2. The power venter motor is energized by the room

thermostat through the integrated control board when

a demand for heat is sensed. The pressure switch

measures the flow through the vent system and

energizes the direct spark ignition system beginning

the pre-purge timing when the fl ow is correct.

The pressure switch MUST NOT be

bypassed. The unit MUST NOT be fi red unless the

power venter is operating. An unsafe condition

could result.

3. The direct ignition system consists of an ignition

control module and a gas valve. When the prepurge period ends, the spark ignition system is

energized, and the gas valve opens to supply gas

to the burners. When the thermostat is satisfi ed, the

vent system is de-energized and the valve closes to

stop the fl ow of gas to the unit. (See Figure 11.)

4. The limit switch interrupts the fl ow of electric current

to the control board, interrupting the fl ow of gas to the

gas valve if the unit heater becomes overheated.

5. Once the thermostat is satisfi ed, or the limit switch

interrupts the fl ow of electric current to the control

board, the unit will begin a post-purge period. When

the post-purge period ends, the power venter motor

is de-energized.

6. The fan operation is delayed 30 seconds once the

thermostat is closed, and continues operation for 30

seconds after the thermostat opens.

7. The wall thermostat, supplied optionally, is a

temperature sensitive switch that operates the vent

and ignition system to control the temperature of

the space being heated. The thermostat must be

mounted on a vertical, vibration-free surface free

from air currents and in accordance with the furnished

instructions (also refer to Electrical Connections).

START-UP (Also refer to lighting instruction plate

equipped on the unit)

1. Open the manual gas valve in the gas supply line to

the unit heater. Loosen the union in the gas line to

purge it of air. Tighten the union and check for leaks.

Never use an open flame to detect gas leaks. Explosive conditions may exist

which could result in personal injury or death.

2. Open the manual valve on the unit heater.

3. Turn ON the electrical power.

4. The unit should be under the control of the thermostat.

Tur n the thermostat to the highest point and determine

that the power venter motor starts and the burners

ignite. Turn the thermostat to the lowest point and

determine that the power venter motor shuts off and

the burners are extinguished.

5. Turn the thermostat to the desired position.

6. See Gas Input Rate and Adjustments sections.

SHUT DOWN

1. Turn the valve selector lever to the “OFF” position.

2. Turn off the electricity.

3. To relight, follow “start-up” instructions.

See Figures 11-17 for parts/identifi cation.

NOTICE: The start-up fan delay must not exceed 30

seconds from a cold start.

Figure 11 - Direct Spark Ignition

System, Bottom View

D6923B

22

Page 23

OPERATION

PRIMARY AIR SHUTTER ADJUSTMENT

Primary air adjustment is made at the factory. No fi eld adjustments are necessary.

GAS INPUT RATE

Check the gas input rate as follows (Refer to General

Safety Information section for metric conversions).

Never overfi re the unit heater, as this

may cause unsatisfactory operation, or shorten the

life of the heater.

1. Turn off all gas appliances that use gas through the

same meter as the unit heater.

2. Turn the gas on to the unit heater.

3. Clock the time in seconds required to burn 1 cubic

foot of gas by checking the gas meter.

4. Insert the time required to burn one cubic foot of

gas into the following formula and compute the input

rate.

3600 (Sec. per Hr.) X BTU/Cu. Ft.

= Input Rate

Time (Sec.)

For example:

Assume the BTU content of one cubic foot of gas is

1000, and that it takes 18 seconds to burn one cubic

foot of gas.

3600 x 1000

= 200,000

18

NOTICE: If the computation exceeds, or is less than

95% of the gas BTU/hr. input rating (see Table 1),

adjust the gas pressure.

Adjust the gas pressure as follows:

1. NATURAL GAS: Best results are obtained when

the unit heater is operating at its full rated input

with the manifold pressure of 3.5" W.C. (0.9 kPa).

Adjustment of the pressure regulator is not normally

necessary since it is preset at the factory. However,

fi eld adjustment may be made as follows:

a. Attach manometer at the pressure tap plug

adjacent to the control outlet.

b. Remove the regulator adjustment screw cap,

located on the combination gas valve.

c. With a small screwdriver, rotate the adjustment

screw counterclockwise to decrease pressure, or

clockwise to increase pressure.

d. Replace regulator adjustment screw cap.

2. PROPANE GAS: An exact manifold pressure of

10.0" W.C. (2.5 kPa) must be maintained for proper

operation of the unit heater. If the unit is equipped

with a pressure regulator on the combination gas

valve, follow steps "a" through "d" above. If the unit

is not so equipped, the propane gas supply system

pressure must be regulated to attain this manifold

operating pressure.

3. The adjusted manifold pressure should not vary

more than 10% from pressure specifi ed in Table 8.

Table 8 - Main Burner Orifi ce Schedule*

TYPE OF GAS NATURAL PROPANE

INPUT

HEATING VALUE

IN

1,000

BTU

100

125

150

175

200

250

300

350

400

*This schedule is for units at operating at normal altitudes of 2000 ft. (610m)

or less.

When installed in Canada, any references to deration at altitudes in excess

of 2000 ft. (610m) are to be ignored. At altitudes of 2000 to 4500 ft. (610 to

1372m), the unit heaters must be fi eld derated to 90% of the normal altitude

rating, and be so marked in accordance with ETL certifi cation. See Table 8A

for fi eld deration information.

MANIFOLD

PRESSURE

FT3/HR 93 40

ORIFICE DRILL 42 53

FT3/HR 116 50

ORIFICE DRILL 42 53

FT3/HR 140 60

ORIFICE DRILL 42 53

FT3/HR 163 70

ORIFICE DRILL 42 53

FT3/HR 186 80

ORIFICE DRILL 42 53

FT3/HR 233 100

ORIFICE DRILL 42 53

FT3/HR 280 120

ORIFICE DRILL 42 53

FT3/HR 326 140

ORIFICE DRILL 42 53

FT3/HR 372 160

ORIFICE DRILL 42 53

1050 BTU/Ft3

(39.1 MJ/m3)

3.5" W.C. 10" W.C.

(0.87kPA) (2.49kPA)

2500 BTU/Ft3

(93.1 MJ/m3)

NO. OF

BURNER

ORIFICES

4

5

6

7

8

9

10

11

12

23

Page 24

OPERATION (continued)

TUBULAR UNIT HEATER

HIGH ALTITUDE DERATION

This Tubular Unit Heater has been manufactured utilizing

standard burner orifi ces and a normal manifold pressure

setting as per the specifi cations shown on your unit rating

plate.

are made in the fi eld, attach label #J17-06459 to the unit,

and record adjusted manifold pressure, altitude of the

unit installation and the technician’s name and date on

the label using a permanent marker.

All unit deration must be done through fi eld adjustments

by a qualifi ed technician. Once the proper adjustments

Refer to Installation Instruction section on AdjustmentsGas Input Rate for adjusting the manifold pressure.

Table 8A

High Altitude Deration - United States

Altitude

Feet Meters Inches W.C. Pa Inches W.C. Pa Percentage

0-2,000 0-610 3.5 872 10 2,491 100%

2,001-3,000 611-915 3.2 797 9.2 2,292 96%

3,001-4,000 916-1,220 2.9 722 8.4 2,092 92%

4,001-5,000 1,221-1,525 2.7 673 7.7 1,918 88%

5,001-6,000 1,526-1,830 2.4 598 7 1,744 84%

6,001-7,000 1,831-2,135 2.2 548 6.4 1,594 80%

7,001-8,000 2,136-2,440 2 498 5.7 1,420 76%

8,001-9,000 2,441-2,745 1.8 448 5.1 1,270 72%

9,001-10,000 2,746-3,045 1.6 399 4.6 1,145 68%

Notes: 1. Deration based on ANSI Z223.1 (NFPA 54).

2. Table based on heating value of 1,050 BTU/Cu. ft. at sea level.

3. Table based on heating value of 2,500 BTU/Cu. ft. at sea level.

4. Consult local utility for actual heating value.

Natural Gas

Manifold Pressure

2

Liquid Propane

3

High Altitude Deration - Canada

Altitude

Feet Meters Inches W.C. Pa Inches W.C. Pa Percentage

0-2,000 0-610 3.5 872 10 2,491 100%

2,001-3,000 611-915 3.2 797 9.2 2,292 96%

3,001-4,000 916-1,220 2.9 722 8.4 2,092 92%

4,001-4,500 1,221-1,371 2.8 697 7.9 1,968 90%

Notes: 1. Deration based on CGA 2.17-M91

2. Table based on heating value of 1,050 BTU/Cu. ft. at sea level.

3. Table based on heating value of 2,500 BTU/Cu. ft. at sea level.

4. Consult local utility for actual heating value.

Natural Gas

Manifold Pressure

2

Liquid Propane

3

BTU Output

BTU Output

1

1

24

Page 25

Table 9 - Tubular Blower Troubleshooting Guide

SYMPTOMS POSSIBLE CAUSE(S) CORRECTIVE ACTION

A. Flame pops back. 1. Burner orifi ce too small. 1. Check with local gas supplier for proper orifi ce

B. Noisy Flame. 1. Irregular orifi ce causing whistle or resonance.

size and replace. Refer to "Gas Input Rate."

1. Replace orifi ce.

2. Excessive gas input.

C. Yellow tip fl ame (some yellow

tipping on LP gas is permissible).

D. Floating fl ame. 1. Blocked venting.

E. Gas odor 1. Gas leak. Shut off gas supply immediately!

F. Delayed ignition. 1. Improper ground.

1 Clogged main burners.

2. Misaligned orifi ces.

3. Insuffi cient combustion air.

4. Possibly over fi red.

2. Insuffi cient combustion air.

3. Blocked heat exchanger.

4. Air leak into combustion chamber or fl ue

collector.

2. Leaking gas test port on valve.

3. Blocked heat exchanger.

4. Blocked fl ue collector.

5. Negative pressure in the building.

2. Bad or broken spark cable.

3. Faulty control.

2. Test and reset manifold pressure (see Table

4 - "Gas Piping Requirements").

1. Clean main burner ports.

2. Replace manifold assembly.

3. Refer to "Installation - Clearances" and

"Venting" to ensure unit is properly mounted

and vented.

4. Check gas input and manifold pressures.

1. Clean fl ue. Refer to "Installation."

2. Clean combustion air inlet openings.

3. Clean heat exchanger. Refer to "Installation."

4. Determine leak and repair accordingly.

1. Inspect all gas piping and repair accordingly.

2. Check to ensure gas test ports are sealed.

3. Clean heat exchanger. Refer to "Installation."

4. Clean fl ue collector. Refer to "Installation."

5. See "Installation."

1. Check grounding wires and spark bracket

connections.

2. Inspect spark cable connections and cuts.

Replace if necessary.

3. Check to ensure spark is energized after prepurge period.

4. Pressure regulator set too low.

5. Main burner orifi ces dirty.

6. Improper venting.

G. Failure to ignite. 1. Gas leak. Shut off gas supply immediately!

2. No power supply to unit.

3. Thermostat not calling.

4. Defective high limit.

5. Defective draftor prove switch.

6. Defective spark ignitor, gas valve, thermostat

or transformer.

7. Loose wiring.

8. Improper ground.

9. Improper thermostat or transformer wiring.

4. Test and reset manifold pressure.

5. Clean or replace orifi ces.

6. Refer to "Installation."

1. Open all manual valves, check for leaks.

2. Turn on power supply, check fuses and

replace if bad.

3. Turn up thermostat. Check for 24V on

terminals R and W1 on terminal strip.

4. Check switch for continuity if open with no

heat present; replace.

5. Check switch operation to ensure switch

closes after draftor purge period. If it does not

make, check tubing connections for blockage.

6. Check for continuity and voltage in safety

and control circuits; replace an item where

continuity or voltage not found.

7. Check all wiring per diagram.

8. Check all ground wires and connections.

9. Check both for wiring according to diagram;

check for 24V at gas valve terminals during

trial for ignition period. If present and valve

does not open, replace valve.

25

Page 26

Table 9 - Tubular Blower Troubleshooting Guide (continued)

SYMPTOMS POSSIBLE CAUSE(S) CORRECTIVE ACTION

H. Condensation. 1. Improper venting.

2. Unit under fi red.

3. Building/space too cold.

I. Burners will not shut off. 1. Thermostat located improperly.

2. Improper thermostat wiring.

3. Shorted circuit.

4. Defective thermostat.

5. Defective/sticking gas valve.

6. Defective control board.

7. Excessive gas supply pressure.

J. Rapid burner cycling. 1. Loose electrical connections at thermostat or

K. Blower will not run. 1. Loose electrical connections.

L. Blower motor turns on and off while

burner is operating.

M. Blower motor will not stop. 1. Control board is in fl ame failure mode.

gas valve.

2. Excessive thermostat heat anticipator setting.

3. Unit cycling on high limit.

4. Thermostat located improperly.

2. Defective motor or overload.

3. Defective control board.

4. Contactor or starter overload tripped.

5. Broken belt.

1. Motor overload protection is tripping.

2. Loose wiring or connection.

3. Control board is defective.

2. Improperly wired blower circuit.

3. Control board is defective.

1. Refer to "Installation."

2. Check gas supply pressures to unit. Refer to

"Installation."

3. Refer to "Installation."

1. Relocate thermostat away from outside wall

or drafts.

2. Check thermostat circuit for open and close

on heater terminal strip "R" and "W."

3. Check thermostat circuit for shorts or any

staples piercing wires.

4. If thermostat is calling after set point has

been satisfi ed, replace.

5. Check for 24V on gas valve terminals when

thermostat not calling. Replace if necessary.

6. Check for 24V at terminals "R" and "W." If not

present and board is not in fl ash code mode,

replace board.

7. Refer to "Pipe Installation" and Table 4 - "Gas

Piping Requirements."

1. Tighten all electrical connections.

2. Adjust heat anticipator setting for longer

cycles. Refer to "Electrical Connections."

3. Check for proper air supply across heat

exchanger and proper gas supply.

4. Relocate thermostat away from outside wall

or drafts.

1. Check and tighten wires on blower circuit.

2. Test for 115V on terminal ACB Heat and "L2."

If voltage is present, replace motor.

3. Test for 115V on terminal ACB Heat and "L2."

If voltage is not present 45 seconds after trial

for ignition, replace board.

4. Test for 115V on coil of contactor. Check if

overload has tripped; reset. Check amp draw

to motor. Check incoming for power and

contactor operation.

5. Replace belt.

1. Check motor amp against the motor name

plate, check voltage, replace if found

defective.

2. Check for 115V between motor leads.

3. Check terminal ACB Heat for voltage. If

voltage not constant, replace board.

1. Turn 115V power off to the unit, wait 10

seconds and reapply voltage to the unit.

2. Check wiring of blower circuit to wiring

diagram.

3. If unit is not calling for heat and board is not

in fl ash code mode, replace board.

26

Page 27

Table 9 - Tubular Blower Troubleshooting Guide (continued)

SYMPTOMS POSSIBLE CAUSE(S) CORRECTIVE ACTION

N. Not enough heat. 1. Incorrect gas input.

2. Heater undersized.

3. Thermostat malfunction.

4. Heater cycling on limit.

5. Incorrect orifi ce sizes.

O. Too much heat. 1. Unit is over fi red.

2. Thermostat malfunction.

3. Heater runs continuously.

4. Defective gas valve.

5. Excessive gas supply pressure.

6. Excessive static pressure.

P. Noisy blower/motor. 1. Blower wheel loose.

2. Blower wheel is dirty.

3. Blower wheel is rubbing on housing.

4. Bearings are dry.

5. Pulley is loose.

Q. Cold air is delivered during heater

operation.

R. High limit is tripping. 1. Unit is over fi red.

1. Incorrect manifold pressure or input.

2. Air throughput too high.

2. Air fl ow is too low.

3. Defective high limit.

4. Defective control board.

1. Refer to "Gas Input Rate"

2. Is the heater output sized correctly for the

heat loss of the space? Has the space been

enlarged? Is the heater located in the space

properly (see "Installation")?

3. Check thermostat circuit; 24V on terminals

"R" and "W" on terminal strip.

4. Check air movement across heat exchanger.

Check voltage and amps at the blower motor.

Check gas input to ensure unit is not over

fi red. Check heat exchanger to ensure unit is

not dirty.

5. Check orifi ce size (Refer to "Gas Input Rate"),

replace if necessary.

1. Refer to "Gas Input Rate." Check orifi ce size.

Replace if too large.

2. Check thermostat for operation, to ensure

circuit open and closes.

3. Check wiring per diagram. Check operation at

the gas valve. Look for a short in thermostat

circuit.

4. Replace valve and check pressure setting

(See Table 4 "Gas Piping Requirements").

5. Refer to "Pipe Installation" and Table 4 - "Gas

Piping Requirements."

6. Adjust blower sheave to correct RPM - See

"Blower Set Up and Adjustment."

1. Replace or tighten.

2. Clean blower wheel.

3. Realign blower wheel.

4. Oil bearings on blower motor. (Refer to label

on motor.)

5. Check Blower and Motor pulleys. Replace or

tighten as necessary.

1. Test and reset manifold pressure (see Table

4 - "Gas Piping Requirements").

2. Check Blower and Motor pulleys. Replace or

tighten as necessary.

1. Refer to "Gas Input Rate." Check orifi ce size.

Replace if too large.

2. Check for proper voltage; ensure blower

assembly is correct.

3. Check operation of switch. If switch is open

during operation, check gas pressure and/

or CFM; adjust accordingly. If switch is open

during start-up, replace switch.

4. Check for 24V on line side of high limit.

Constant voltage should be recorded. If not,

control board is suspect. Check fl ash code.

27

Page 28

Table 9 - Tubular Blower Troubleshooting Guide (continued)

SYMPTOMS POSSIBLE CAUSE(S) CORRECTIVE ACTION

S. Power ventor will not run. 1. No power supply to unit.

2. Thermostat not calling.

3. Loose wiring or connection.

4. Motor overload protection is tripping or bad

motor.

5. Defective control board.

T. Power ventor turns on and off

during operation.

U. Power ventor will not stop. 1. Power ventor improperly wired.

V. Noisy power ventor. 1. Power ventor wheel loose.

1. Power ventor improperly wired.

2. Motor overload cycling or defective motor.

3. Defective control board.

2. Main burner did not light on call for heat.

3. Defective control board.

2. Power ventor wheel is dirty.

3. Power ventor wheel is rubbing on housing.

1. Turn on power supply, check fuses and

replace if bad.

2. Turn up thermostat. Check for 24V on

terminals R and W1 on terminal strip.

3. Check all wiring in the power vent circuit to

ensure good connection, including "Neutral."

4. Check for 115V between motor leads

and check amp draw of motor. Replace if

necessary.

5. Check for continuous 115V on terminal

"CBM" Blower" and neutral during call for

heat. If not present and all checks are normal,

replace.

1. Check power ventor circuit per wiring

diagram.

2. Check motor voltage and amp draw to motor

name plate, replace if motor found defective.

3. Check for continuous 115V on terminal

"CBM" Blower" and neutral during call for

heat. If not present and all checks are normal,

replace.

1. Check power ventor circuit per wiring

diagram.

2. Heater is in lockout mode; check fl ash code

table for problem.

3. If no fl ash codes present along with no call for

heat, replace control board.

1. Replace or tighten.

2. Clean power ventor wheel.

3. Realign power ventor wheel.

28

Page 29

Table 9A - Tubular Blower Troubleshooting with LED Indicator Assistance

No Cycling or appliance power

or thermostat call for heat

since appliance failure has

occured.

Line voltage power can

cause product damage,

severe injury or death.

Only a trained experienced

service technician should

perform this troubleshooting.

1. Check the system thermostat to make sure it is calling for heat. (Do not cycle

the thermostat on and off at

this time.)

2. Remove the appliance

burner compartment door.

Do not interrupt power

to the control board by

opening any electrically

interlocked panels.

3. Observe the LED indicator

on the control board (a

greem LED labeled “OK”

indicates system faults);

check and repair system

as noted in the chart to the

right.

*NOTICE: Air flow proving

switch and power ventor

hose barbs must be free

of any dust or debris at all

times. Periodically check

these openings and/or if any

problems occur.

LED STATUS

Slow Flash

Fast Flash

Steady Off

Steady On

2 Flashes

3 Flashes

4 Flashes

5 Flashes

6 Flashes

INDICATES CHECK/REPAIR

Control OK, no call for heat.

Control OK, call for heat present.

Internal control fault, or no power.

Control internal failure or bad ground.

In lockout from failed ignitions

or fl ame losses.

Pressure Switch open with inducer on

or closed with inducer off.

Limit or rollout switch is open.

Flame sensed while gas valve is off.

On-board microprocessors disagree.

Not Applicable

Not Applicable

1. Line voltage on terminals 120

and C on transformer.

2. Low voltage (24V) on terminals

24 and C on transformer.

3. 5 Amp fuse on circuit board.

1. Common side of transformer

grounded to chassis.

2. Loose spark ignitor.

1. Gas supply off or gas supply

pressure too low.

2. Flame sense rod contaminated

or loose wire.

3. Gas valve switch is off or wires

are not connected.

4. Broken or cracked porcelain on

fl ame probe or spark ignitor.

1. Obstructions or restrictions

in appliance air intake or fl ue

outlet are preventing proper

combustion airfl ow.

2. Moisture or debris in tubing that

connects pressure switch and

draft inducer.