Page 1

Op er at ing In struc tions

Sin gle Con veyor Unit

SSV 05/2R

016-4MS

Ster ling Ma te rial Pro cess ing

Page 2

Ster ling Ma te rial Pro cess ing

5200 West Clinton Ave.

Mil wau kee, WI 53223

Tele phone: (414) 354-0970

Fax: (414) 354-6421

www.sterlco.com

Technical service:

Ser vice de part ment

Tele phone: (800) 423-3183

Edition: 08/99

SSV 05/2R

This operation manual is for*:

(* Please fill in personally)

Serial number:

Built in:

Date of delivery:

Number of delivery:

Date of commissioning:

Location:

016-4MS

Group of machines:

2

Page 3

SSV 05/2R

Ster ling Ma te rial Pro cess ing re tains all rights to change the in for ma tion in these

op er at ing in struc tions at any time with out notice.

We as sume no li a bil ity for any er rors or di rect or in di rect dam age re sult ing in con text with these op er at ing instructions.

Copy ing, trans la tion or pub li ca tion in any form ex cept for per sonal use of pur chaser re quires ap proval from Ster ling Ma te rial Processing.

016-4MS

All rights re served.

3

Page 4

Please note that our address and phone information has changed.

Please reference this page for updated contact information.

These manuals are obsolete and are provided only for their technical information, data and capacities.

Portions of these manuals detailing procedures or precautions in the operation, inspection, maintenance

and repair of the products may be inadequate, inaccurate, and/or incomplete and shouldn’t be relied

upon. Please contact the ACS Group for more current information about these manuals and their

warnings and precautions.

Parts and Service Department

The ACS Customer Service Group will provide your company with genuine OEM quality parts manufactured to engineering

design specifications, which will maximize your equipment’s performance and efficiency. To assist in expediting your phone

or fax order, please have the model and serial number of your unit when you contact us. A customer replacement parts list

is included in this manual for your convenience. ACS welcomes inquiries on all your parts needs and is dedicated to

providing excellent customer service.

For immediate assistance, please contact:

• North, Central and South America, 8am – 5pm CST +1 (800) 483-3919 for drying, conveying, heating and cooling

and automation. For size reduction: +1 (800) 229-2919.

North America, emergencies after 5pm CST (847) 439-5855

North America email: acsuscanadacustserv@corpemail.com

• Mexico, Central & South America

Email: acslatinamericacustserv@corpemail.com

• Europe, Middle East & Africa +48 22 390 9720

Email: acseuropecustserv@corpemail.com

• India +91 21 35329112

Email: acsindiacustserv@corpemail.com

• Asia/Australia +86 512 8717 1919

Email: acsasiacustserv@corpemail.com

Sales and Contracting Department

Our products are sold by a worldwide network of independent sales representatives. Contact our Sales Department for the

name of the sales representative nearest you.

Let us install your system. The Contract Department offers any or all of these services: project planning; system packages

including drawings; equipment, labor, and construction materials; and union or non-union installations.

For assistance with your sales or system contracting needs please Call:

North, Central and South America +1 (262) 641-8600 or +1 (847) 273-7700 Monday–Friday, 8am–5pm CST

Europe/Middle East/Africa +48 22 390 9720

India +91 21 35329112

Asia/Australia +86 512 8717 1919

Facilities:

ACS offers facilities around the world to service you no matter where you are located. For more information, please visit us at

www.acscorporate.com

United States:

ACS Schaumburg – Corporate Offices

1100 E. Woodfield Road

Suite 588

Schaumburg, IL 60173

Phone: + 1 847 273 7700

Fax: + 1 847 273 7804

ACS New Berlin – Manufacturing Facility

2900 S. 160th Street

New Berlin, WI 53151

Phone : +1 262 641 8600

Fax: + 1 262 641 8653

Asia/Australia:

ACS Suzhou

109 Xingpu Road SIP

Suzhou, China 215126

Phone: + 86 8717 1919

Fax: +86 512 8717 1916

Europe/Middle East/Africa:

ACS Warsaw

Ul. Działkowa 115

02-234 Warszawa

Phone: + 48 22 390 9720

Fax: +48 22 390 9724

India

ACS India

Gat No. 191/1, Sandbhor Complex

Mhalunge, Chakan, Tal Khed,

Dist. Pune 410501, India

Phone: +91 21 35329112

Fax: + 91 20 40147576

Page 5

SSV 05/2R

Tab le of con tents

1. Sa fe ty in struc tions ............................................6

1.1. War nings and sym bols ..................................7

1.2. Ex pla na tions and in for ma ti on .............................8

1.3. For your sa fe ty ........................................9

1.4. For the sa fe ty of the units ...............................12

2. In stal la ti on in struc tions .......................................13

2.1. Ge ne ral in for ma ti on ...................................14

2.2. In stal ling the con vey or hop per ...........................15

2.3. In stal ling the con trol and main ten an ce unit .................16

2.4. Con nec ting the com pres sed-air supp ly ....................17

2.5. Elec tri cal con nec ti on ...................................18

3. Functio nal des crip ti on ........................................19

3.1. Me thod of functio ning ..................................20

3.2. Con trol and main ten an ce unit ...........................20

4. Set-up ......................................................21

4.1. Pre pa ra tions .........................................22

4.2. Set ting the mi xing ra tio of the com po nents .................22

4.3. Ba sic set ting of the fil ling le vel in the con vey or hop per .......23

4.3.1. Fine ad just ment of the fil ling le vel in the

con vey or hop per ..............................24

5. Main ten an ce.................................................25

5.1. Main ten an ce in ter vals ..................................27

5.2. Clea ning/re pla cing the fil ter car trid ge .....................28

5.3. Ad ju sting the le vel pro be ...............................29

5.4. Trou ble-shooting ......................................30

016-4MS

4

Page 6

SSV 05/2R

6. Tech ni cal data ...............................................31

6.1. Di men si on sheet ......................................32

6.2. Spa re parts list .......................................33

016-4MS

5

Page 7

1. Safety in struc tions

SSV 05/2R

»

These safety in struc tions ap ply to all per sons within the range of

ac tion of the equip ment.

Please in form all per sons within the range of ac tion of the equip ment of the di rect and in di rect haz ards con nected with the

equip ment.

These op er at ing in struc tions are to be used by all per sons as signed ac tiv i ties con nected with the equip ment.

Knowl edge of the Eng lish lan guage is pre req ui site.

En sure in each case that the op er at ing per son nel are fa mil iar

with the op er at ing in struc tions and the function of the

equipment.

016-4MS

Safety in struc tions 6

Page 8

SSV 05/2R

1.1. Warn ings and sym bols

The fol low ing warn ings and sym bols are used in these op er at ing in struc tions:

»

L

F

This sym bol in di cates dan ger to life! Fa tal or se ri ous in jury is

pos si ble if the cor re spond ing in struc tions, reg u la tions or warn ings are not observed.

This sym bol in di cates that se ri ous in jury is pos si ble if the cor re spond ing in struc tions, reg u la tions or warn ings are not

observed.

This sym bol in di cates that ex ten sive dam age to equip ment

is pos si ble if the cor re spond ing in struc tions, reg u la tions or

warn ings are not observed.

&

$

016-4MS

This sym bol in di cates in for ma tion im por tant for be com ing fa mil iar with the equip ment, i.e. tech ni cal correlations.

This sym bol in di cates that a tech ni cal term is ex plained at

this point.

Safety in struc tions 7

Page 9

SSV 05/2R

1.2. Ex pla na tions and in for ma tion

Var i ous terms and des ig na tions are used fre quently in these op er at ing in struc tions to en sure clar ity. There fore please note that the terms used in the text stand

for the cor re spond ing ex pla na tions listed below.

Equip ment

·

”Equip ment” can mean an in di vid ual unit, a ma chine or an in stal la tion.

Op er at ing per son nel

·

The ”op er at ing per son nel” are per sons op er at ing the equip ment on their own re spon si bil ity or ac cord ing to in struc tions (minimum age: 16).

Op er a tor

·

The ”op er a tor” of the equip ment (pro duc tion man ager, fore man, etc.) is the per son re spon si ble for all pro duc tion se quences. The op er a tor in structs the op er at ing per son nel of what is to be done.

Op er at ing in struc tions

·

The ”plant op er at ing in struc tions” de scribe the in ter ac tion of the equip ment, pro duc tion se quences or meth ods. The plant op er at ing in struc tions must be com piled by the op er a tor of the equipment.

Equip ment fore man

·

When sev eral op er at ing per son nel work on one ma chine, the ”equip ment fore man” co or di nates the se quences. The equip ment fore man must be ap pointed by

the operator.

Trained per son nel

·

”Trained per son nel” are per sons who, due to their train ing, are au tho rized to carry

out the re quired work in good prac tice.

016-4MS

Safety in struc tions 8

Page 10

SSV 05/2R

1.3. For your safety

The op er a tors of this unit must be at least 16 years old.

·

Be fore ini tial op er a tion, read this op er at ing man ual care fully. Ob serve all points.

·

In quire in case of un cer tain ties.

This will avoid dan ger to per sons and dam age of material!

Store this op er at ing man ual in such a way that it is al ways avail able on the site of

·

op er a tion for the unit. Faulty op er a tion may lead to accidents!

Note that, for rea sons of clar ity, not ev ery pos si ble case of op er a tion or main te -

·

nance can be men tioned.

Note the in struc tions for safety and the dan ger signs on the unit.

·

This will avoid dan ger to per sons and dam age of ma te rial!

All work on the unit may only be car ried out by per sons whose qual i fi ca tion cor re -

·

sponds with the in di vid ual chap ters of the op er at ing man ual.

Faulty op er a tion may lead to accidents!

For all types of work on the unit, proper work ing clothes must be worn.

·

This will avoid dan ger to per sons!

Com pare the con nected loads to those of the mains sup ply.

·

Dan ger of elec tri cal shock!

When us ing lift ing gear, ob serve the spe cific in struc tions.

·

Dan ger of ac ci dents!

Ob serve the lo cal reg u la tions and re quire ments con cern ing the plant.

·

In ter rupt the mains sup ply for all types of work on elec tri cal com po nents.

·

Dan ger to life due to elec tri cal shock!

016-4MS

Safety in struc tions 9

Page 11

SSV 05/2R

Do not carry through mod i fi ca tions, at tach ments or al ter ations of the unit with out

·

the man u fac turer’s per mis sion. Dan ger of accidents!

By means of this op er at ing man ual, pre pare pre cise in struc tions for use of this

·

unit. Faulty op er a tion may lead to ac ci dents!

Des ig nate a unit leader re spon si ble for the unit.

·

In any case, the op er a tors of this unit must be thor oughly in structed.

·

Faulty op er a tion may lead to ac ci dents!

If the unit has been switched off for rea sons of safety, it must be pro tected from

·

unathorised ac ti va tion. Dan ger of ac ci dents!

Be fore be gin ning main te nance work, des ig nate a su per vi sor.

·

Be fore be gin ning main te nance work, in form the re spon si ble op er at ing per son nel.

·

Dan ger of accidents!

Be fore be gin ning main te nance work, in ter rupt the mains sup ply so that the unit is

·

not switched on un in ten tion ally. Dan ger of accidents!

Re pair work may only be car ried through by trained per son nel.

·

Dan ger of ac ci dents!

The unit may never be op er ated when it is par tially dis as sem bled.

·

Limbs may be drawn in! Elec tri cal shock!

In case of func tional dis tur bances, switch off the unit im me di ately. Er rors must be

·

elim i nated im me di ately. Dan ger of accidents!

The unit is ex clu sively in tended for con vey ing plas tic gran ules and regrind. Any

·

other us age is not per mit ted.

016-4MS

This unit is not suit able for pro cess ing foods.

·

Safety in struc tions 10

Page 12

SSV 05/2R

At tach ments which are not de liv ered by Ster ling must be con structed ac cord ing

·

to the safety stan dard EN 294. Dan ger of ac ci dents!

Check all lines, hoses and cou pling pieces in reg u lar in ter vals for leak ages and

·

dam age. Any er rors must be elim i nated im me di ately.

Dan ger of accidents!

Be fore be gin ning main te nance work, set all com pressed-air lines on the unit at

·

zero pres sure. Dan ger of ac ci dents!

The unit may only be op er ated if all cor re spond ing com po nents have been prop -

·

erly con nected and are in ac cor dance with the rel e vant reg u la tions.

Ob serve the safety in struc tions for the con nected units.

·

016-4MS

Safety in struc tions 11

Page 13

SSV 05/2R

1.4. For the safety of the units

The unit may only be used for con vey ing cy lin dri cal plas tic gran ules and regrind

·

on in jec tion mould ing ma chines.

Never change set tings un less you are able to pre cisely fore see the con se -

·

quences.

Use only orig i nal Ster ling spare parts.

·

Ob serve the main te nance in ter vals.

·

Keep a book on all main te nance and re pair work.

·

Note that elec tronic sub as sem blies may be dam aged by static dis charge.

·

Be fore ini tial op er a tion and in reg u lar in ter vals, check all elec tri cal con nec tions for

·

proper fit.

Never mod ify sen sors with out know ing their pre cise func tions.

·

Make sure that all plugs are con nected prop erly.

·

Ob serve the car ry ing ca pac ity of the ma chine flange.

·

Ob serve the op er at ing man u als of the con nected units.

·

016-4MS

Safety in struc tions 12

Page 14

2. In stal la tion in struc tions

SSV 05/2R

»

L

These in stal la tion in struc tions are in tended for per sons with

skills in elec tri cal and me chan i cal ar eas due to their train ing, ex pe ri ence and re ceived in struc tions.

Per son nel us ing these in stal la tion in struc tions must be in structed in the reg u la tions for the pre ven tion of ac ci dents, the

op er at ing con di tions and safety reg u la tions and their im ple men ta tion.

En sure in each case that the per son nel are in formed.

The in stal la tion in struc tions pro vided in the cor re spond ing op er at ing in struc tions ap ply for all con nected equip ment.

Ob serve safety reg u la tions with re gard to lift ing gear han dling.

All in stal la tion work must be car ried out with the equipment

disconnected from electrical power and compressed air supply.

For in stal la tion work tak ing place at heights of over approx.

1829 mm. (6 ft), use only lad ders or sim i lar equip ment and

work ing plat forms in tended for this pur pose. At greater

heights, the proper equip ment for pro tec tion against fall ing

must be worn.

Use only suit able lift ing gear which is in proper work ing or der

and load sus pen sion de vices with suf fi cient car ry ing ca pac ity. Do not stand or work un der sus pended loads!

Use suitable workshop equipment.

In stall the equip ment such that all parts are eas ily ac ces si ble; this fa cil i tates main te nance and re pair work.

F

016-4MS

In stal la tion in struc tions 13

Page 15

SSV 05/2R

1

0

2

4

1

3

2.1. Gen eral in for ma tion

Un pack all parts of the sin gle con veyor unit and make sure that ev ery thing is

avail able:

con veyor hop per with level probe (1)

·

con trol and main te nance unit (2)

·

2 x in jec tor tube (3)

·

2 x sup ply hose (4) with 4 hose clamps

·

com pressed-air hose

·

op er at ing in struc tions

·

016-4MS

In stal la tion in struc tions 14

Page 16

SSV 05/2R

2.2. In stall ing the con veyor hop per

The sin gle con veyor unit is not sen si tive to shocks and can be in stalled di rectly on

the pro cess ing ma chine.

Make sure that all con nec tions are tight so that the con vey ing per for mance is not

im paired.

The con veyor hop per is equipped with a uni ver sal flange.

De pend ing on the po si tion, drill the holes for fas ten ing the con veyor hop per to the

pro cess ing machine.

Mount the con veyor hop per on the pro cess ing ma chine.

In stall the sup ply hoses on the con veyor hop per and on the in jec tor tubes by

means of the hose clamps which are part of the sup ply.

F

Note that the hop per may not touch any other com po nent.

016-4MS

In stal la tion in struc tions 15

Page 17

2.3. In stall ing the con trol and main te nance unit

1

0

In stall the con trol and main te nance

unit at a freely ac ces si ble site.

Ob serve the length of the con nec tion

ca ble.

Ob serve the length of the sup plied

hoses to the in jec tor tubes.

Dur ing in stal la tion, ob serve the length of the sup ply lines.

SSV 05/2R

F

016-4MS

In stal la tion in struc tions 16

Page 18

SSV 05/2R

2.4. Con nect ing the com pressed-air sup ply

Check com pressed-air pip ing for cor rect in stal la tion and as sem bly.

Check fit tings, length and qual ity of the hose con nec tions for agree ment with re quire ments.

Check all com pressed-air lines for leak ages.

You need a com pressed-air sup ply with 5 - 6 bar

(72.52-87.02 PSI) sys tem overpressure. The air

should be free from oil and wa ter, if pos si ble.

Con nect the com pressed-air hose, which is part

of the sup ply, to the in jec tor tube and to the con trol

and main te nance unit. To this end, the com pressed-air hose is firmly pressed into the con nect ing sockets.

Con nect the con trol and main te nance unit to the com pressed-air sup ply (max. in put pres sure 10 bar (145.04 PSI) sys tem overpressure).

Set the pres sure on the pres sure re ducer at 5 - 6 bar (72.52-87.02 PSI).

Max i mum in put pres sure 10 bar (145.04 PSI) (sys tem

overpressure).

F

Max i mum out put pres sure 6 bar. (87.02 PSI)

016-4MS

In stal la tion in struc tions 17

Page 19

2.5. Elec tri cal con nec tion

SSV 05/2R

»

Ob serve the reg u la tions of the lo cal elec tric ity board.

The op er at ing volt age is 230 V, AC, PE, 50/60 Hz.

Spe cial volt ages avail able on re quest.

The con nected load is approx. 15 W.

The con nec tion takes place by means of a mains con nec tor.

A sep a rate pro tec tion of the socket is not nec es sary.

Con nect the plug of the probe ca ble to the con trol unit.

Plug the mains con nec tor into a cor re spond ing socket.

016-4MS

In stal la tion in struc tions 18

Page 20

3. Func tional de scrip tion

SSV 05/2R

»

F

This func tional de scrip tion is in tended for the op er at ing per son nel of the equip ment.

Gen eral knowl edge of op er at ing con veyor units is pre req ui site.

En sure in each case that the op er at ing per son nel are

sufficiently informed.

The sin gle con veyor unit SSV 05/2R is de signed for con vey ing 2 dust-free com po nents (plas tic gran ules and/or regrind)

di rectly on the in jec tion mould ing machine.

016-4MS

Func tional de scrip tion 19

Page 21

3.1. Method of func tion ing

A

C

B

1

0

The sin gle con veyor unit works ac cord ing

to the venturi prin ci ple. An ex ter nal com pressed-air sup ply is needed.

A venturi me ter (A) is in te grated in the in jec tor tube. The venturi me ter as pi rates

the ma te rial in the lower part of the tube (C)

and then con veys the ma te rial into the con veyor hop per by means of com pressed air

in the up per part (B). In the hop per loader,

the ma te rial is sep a rated from the air.

The fill ing level in the con veyor hop per is

mon i tored and con trolled by means of a

level probe.

SSV 05/2R

3.2. Con trol and main te nance unit

The unit is switched on and off at the con trol and main te nance unit.

On the pres sure re duc ers, the op er at ing pres sure and the mix ing ra tio be tween com po nent 1 and com po nent 2

is adjusted.

A wa ter sep a ra tor is in te grated.

016-4MS

Func tional de scrip tion 20

Page 22

4. Set-up

SSV 05/2R

»

This chap ter is in tended for the op er at ing per son nel of the

equip ment.

Gen eral knowl edge of op er at ing con veyor units is pre req ui site.

The func tional de scrip tion must have been read and un der stood.

En sure in each case that the op er at ing per son nel are

sufficiently informed.

016-4MS

Set-up 21

Page 23

SSV 05/2R

4.1. Prep a ra tions

Check whether the in jec tor tubes are in serted in the ma te rial to be con veyed.

Switch on the com pressed-air sup ply.

Switch on the con veyor unit at the con trol and main te nance unit.

The con veyor unit should now con vey un til the con veyor hop per is filled up to the

level probe.

4.2. Set ting the mix ing ra tio of the com po nents

The mix ing ra tio of the com po nents is ad justed on the pres sure re duc ers.

&

The ad just ment on the pres sure re duc ers will vary ac cord ing

to the ma te rial, flow prop er ties, par ti cle size and con vey ing

distance.

016-4MS

Set-up 22

Page 24

SSV 05/2R

A

4.3. Ba sic set ting of the fill ing level in the con veyor hop per

The fill ing level in the con veyor hop per is mainly de ter mined by the level probe.

Filling level too low

By means of a screw driver, turn the ad just ment screw of the level probe (A)

¼ ro ta tion coun ter clock wise.

Ob serve the fill ing level dur ing the next con vey ing pro ce dure.

Re peat the pro cess un til the de sired fill ing

level in the con veyor hop per is reached.

Filling level too high

By means of a screw driver, turn the ad just ment screw (A) of the level probe ¼ ro ta tion clock wise.

Ob serve the fill ing level dur ing the next con vey ing pro ce dure.

Re peat the pro cess un til the de sired fill ing level in the con veyor hop per is

reached.

016-4MS

Set-up 23

Page 25

4.3.1. Fine ad just ment of the fill ing level in the con veyor hop per

A

SSV 05/2R

&

Dur ing op er a tion, care fully turn the ad just ment screw (A) of the level probe by

means of a screw driver un til the de sired fill ing level is reached.

&

If the fill ing level in the con veyor hop per can not be low ered far enough by means

of the level probe, the pres sure on the con trol and main te nance unit can be re duced step by step.

Be fore the fine ad just ment, carry through a ba sic ad just ment.

Clock wise ro ta tion makes

the fill ing level fall.

Coun ter clock wise ro ta tion makes the fill ing level rise.

016-4MS

Set-up 24

Page 26

5. Main te nance

SSV 05/2R

»

This chap ter is in tended for per sons with skills in elec tri cal and

me chan i cal ar eas due to their train ing, ex pe ri ence and re ceived

in struc tions.

Per son nel us ing the in struc tions in this chap ter must be in structed of the reg u la tions for the pre ven tion of ac ci dents, the

op er at ing con di tions and safety reg u la tions and their im ple men ta tion.

En sure in each case that the per son nel are in formed ac cord ingly.

For main te nance work tak ing place at heights of over approx

1829 mm.(6 ft.), use only lad ders or sim i lar equip ment and

work ing plat forms in tended for this pur pose. At greater heights,

the proper equip ment for pro tec tion against fall ing must be

worn.

Use only suit able lift ing gear which is in proper work ing or der

and load sus pen sion de vices with suf fi cient car ry ing ca pac ity.

Do not stand or work un der sus pended loads!

En sure that the elec tric mo tors/switch cab i nets are suf fi ciently

pro tected against mois ture.

Use only suit able work shop equip ment.

Be fore start ing main te nance work, ap point a su per vi sor.

In form the re spon si ble per son nel be fore main te nance work on

the sys tem is started.

Never op er ate the equip ment when par tially dis man tled.

All main te nance and re pair work not de scribed in this chapter

may only be carried out by Sterling service personnel or

016-4MS

authorized personnel (appointed by Sterling).

Main te nance 25

Page 27

SSV 05/2R

L

F

Dis con nect the equip ment from mains sup ply be fore start ing

main te nance pro ce dures to en sure that it can not be

switched on un in ten tion ally.

Depressurize all com pressed air pip ing of the equip ment be fore start ing maintenance work.

Please ob serve the main te nance in ter vals.

Be fore start ing main te nance work, clean the equip ment of

oil, fuel or lu bri cants.

En sure that ma te ri als and in ci den tals re quired for op er a tion

as well as spare parts are dis posed of prop erly and in an en vi ron men tally sound man ner.

Use only orig i nal Ster ling spare parts.

Keep re cord of all main te nance and repair procedures.

016-4MS

Main te nance 26

Page 28

SSV 05/2R

5.1. Main te nance in ter vals

daily: Check the set ting of the pres sure re ducer.

Empty the wa ter sep a ra tor.

Check the dan ger signs on the unit for leg i bil ity

and com plete ness.

monthly: Clean the fil ter and sieve

(de pend ing on ac cu mu la tion of dust!).

Blow out the fil ter from the in side out by means

of com pressed air.

Check the unit plugs for proper func tion ing.

ev ery six months: Check all elec tri cal and me chan i cal con nec tions

for proper fit.

Re place the fil ter and the sieve

(de pend ing on ac cu mu la tion of dust!).

The given main te nance in ter vals are av er age val ues.

F

016-4MS

Check whether in your in di vid ual case the main te nance in ter vals must be shortened.

Main te nance 27

Page 29

5.2. Clean ing/re plac ing the fil ter car tridge

C

B

A

A

SSV 05/2R

»

Switch off the unit.

Dis con nect the mains plug.

Disassembly

Re move the fil ter car tridge (A).

Blow out the fil ter car tridge (A) from the in side out by means of com pressed air or

re place the fil ter.

Open the tog gle-type fas tener (B) and fold the hop per lid up wards.

Check the sieve (C) within the lid for ma te rial res i due. Dis as sem bling the sieve for

clean ing: draw the sieve out of the fit of the seal ing ring.

Clean the sieve (C) by means of com pressed-air.

Re place the sieve and seal ing ring in case of dam age.

016-4MS

Main te nance 28

Page 30

Assembly

As sem ble the sieve and the seal ing ring.

Check the sieve for proper fit.

Clean the hop per loader by means of a vac uum cleaner.

Close the hop per lid.

Close the tog gle-type fas tener.

As sem ble the fil ter car tridge.

SSV 05/2R

&

5.3. Ad just ing the level probe

Or der num ber

fil ter car tridge: ID 98171

Sieve: ID 29252

Seal ing ring: ID 28628

See chap ter “set-up”.

F

&

Or der num ber

level probe: ID 85480

016-4MS

Main te nance 29

Page 31

5.4. Trou ble-shoot ing

Prob lem Rem edy

The unit is not con vey ing

and is not ac tive a, b, g, h

The unit is not con vey ing;

the com pressed-air valve is switched

when the de vice is switched on c, f

The unit is not con vey ing,

the com pressed air is flow ing au di bly c, d, e, f, i, j, k

The unit is over filled g, l, m

The unit is not filled prop erly c, d, e, f, i, j, k, l

Test steps

a) Check whether the unit is switched on.

SSV 05/2R

b) Check whether the mains con nec tor is con nected and mains volt age is pres ent.

c) Check whether suf fi cient com pressed air is avail able.

d) Check whether the in jec tor tube is in serted in the ma te rial.

e) Check whether the com pressed-air hose is prop erly con nected to the in jec tor

tube.

f) Check whether the com pressed-air hose is prop erly con nected to the main te nance unit.

g) Check whether the level probe is prop erly ad justed.

h) Check whether the ca ble of the level probe is prop erly con nected.

i) Check whether the fil ter is clogged.

j) Check whether the sieve is clogged.

k) Check whether the con veyor hose is prop erly con nected.

l) Check whether the com pressed-air sup ply is prop erly ad justed.

016-4MS

Main te nance 30

Page 32

SSV 05/2R

6. Tech ni cal data

Max. per mis si ble shot weight

of the in jec tion mould ing ma chine: ............... 100 kg/h (with 0.6 kg/l)

(220.56 lbs/hr) (1.32 lbs./l)

Weight: ..............................................approx. 3 kg

(6.61 lbs.)

Op er at ing volt age: ...........................230 V, AC, PE, 50/60 Hz

Spe cial volt age on re quest

Con nected load: ......................................approx. 15 W

To tal noise level: .......................................< 75 dB (A)

Com pressed-air sup ply: ..................5-6 bar (sys tem overpressure)

(72.52-87.02 PSI)

Max. prod uct tem per a ture: .................................... 80 °C

( 176°F)

016-4MS

Tech ni cal data 31

Page 33

6.1. Di men sion sheet

SSV 05/2R

Di men sions and data are not bin ding. All di men sions are in mm. (in.) All data are sub ject to chan ge.

016-4MS

Tech ni cal data 32

Page 34

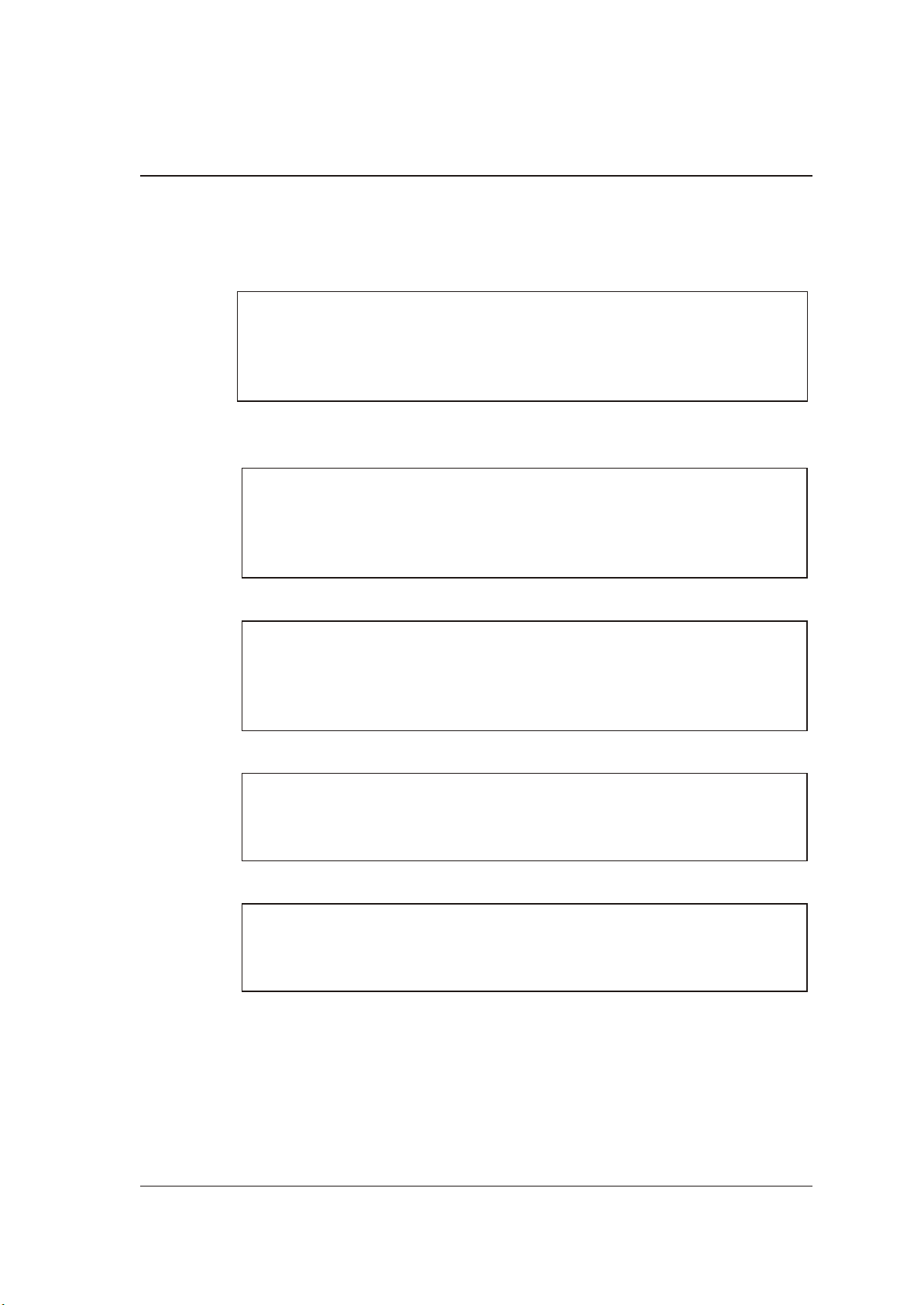

6.2. Spare parts list

3

5

1

0

4

6

2

1

SSV 05/2R

016-4MS

Tech ni cal data 33

Page 35

Pos. ID-No. Des ig na tion

1 85480 level probe

2 98171 fil ter car tridge

29252 sieve

28628 seal ing ring

3 84426 con veyor hose

97784 hose clamp

4 31683 in jec tor tube

5 31177 main te nance and con trol unit

6 88351 com pressed-air hose

SSV 05/2R

016-4MS

Tech ni cal data 34

Loading...

Loading...