Page 1

Ope ra ting In struc tions

P/N 882.00608.00

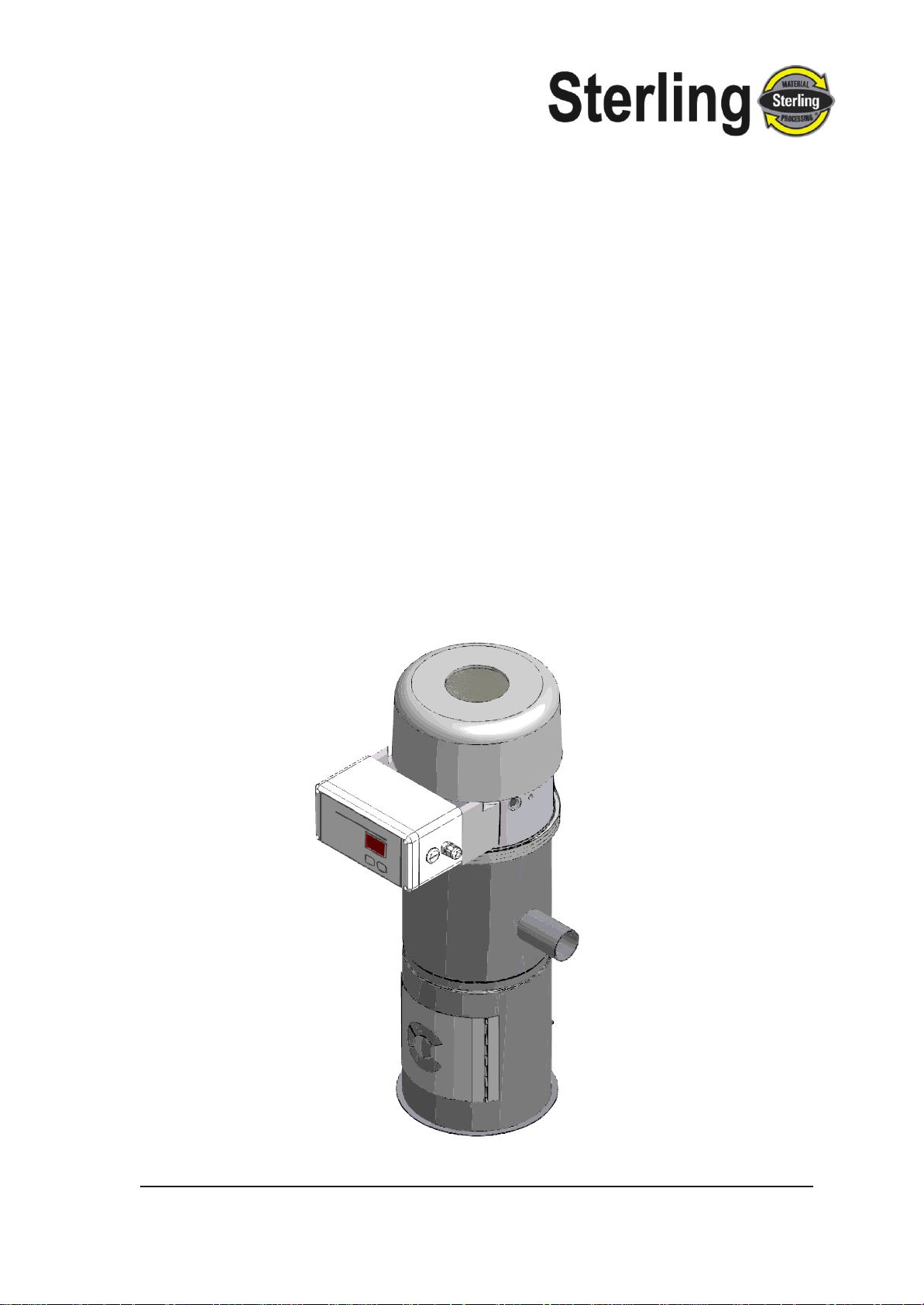

Sing le Con vey or Unit

SSE-2

516-4MS

Ster ling Ma te rial Pro cess ing

Page 2

Ster ling Ma te rial Pro cess ing

5200 West Clinton Ave.

Mil wau kee, WI 53223

Tele phone: (414) 354-0970

Fax: (414) 354-6421

www.sterlco.com

Tech ni cal ser vi ce:

Ser vice de part ment

Tele phone: (800) 423-3183

Edi ti on: 07/02

Con fir ma tion num ber: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

SSE-2

These op er at ing in struc tions are for:*

(* Plea se fill in per so nal ly)

Se ri al num ber:

Built in:

Date of de li very:

Num ber of de li very:

Date of com mis sio ning:

Lo ca ti on:

516-4MS

Group of ma chi nes:

2

Page 3

SSE-2

Ster ling Ma te rial Pro cess ing re tains all rights to chan ge the in for ma ti on in the se

ope ra ting in struc tions at any time wit hout no ti ce.

We as su me no lia bi li ty for any er rors or di rect or in di rect da ma ge re sul ting in con text with the se ope ra ting in struc tions.

Co py ing, trans la ti on or pub li ca ti on in any form ex cept for per so nal use of pur cha -

516-4MS

ser re qui res ap pro val from Ster ling Ma te rial Pro cess ing.

All rights re ser ved.

3

Page 4

Please note that our address and phone information has changed.

Please reference this page for updated contact information.

These manuals are obsolete and are provided only for their technical information, data and capacities.

Portions of these manuals detailing procedures or precautions in the operation, inspection, maintenance

and repair of the products may be inadequate, inaccurate, and/or incomplete and shouldn’t be relied

upon. Please contact the ACS Group for more current information about these manuals and their

warnings and precautions.

Parts and Service Department

The ACS Customer Service Group will provide your company with genuine OEM quality parts manufactured to engineering

design specifications, which will maximize your equipment’s performance and efficiency. To assist in expediting your phone

or fax order, please have the model and serial number of your unit when you contact us. A customer replacement parts list

is included in this manual for your convenience. ACS welcomes inquiries on all your parts needs and is dedicated to

providing excellent customer service.

For immediate assistance, please contact:

• North, Central and South America, 8am – 5pm CST +1 (800) 483-3919 for drying, conveying, heating and cooling

and automation. For size reduction: +1 (800) 229-2919.

North America, emergencies after 5pm CST (847) 439-5855

North America email: acsuscanadacustserv@corpemail.com

• Mexico, Central & South America

Email: acslatinamericacustserv@corpemail.com

• Europe, Middle East & Africa +48 22 390 9720

Email: acseuropecustserv@corpemail.com

• India +91 21 35329112

Email: acsindiacustserv@corpemail.com

• Asia/Australia +86 512 8717 1919

Email: acsasiacustserv@corpemail.com

Sales and Contracting Department

Our products are sold by a worldwide network of independent sales representatives. Contact our Sales Department for the

name of the sales representative nearest you.

Let us install your system. The Contract Department offers any or all of these services: project planning; system packages

including drawings; equipment, labor, and construction materials; and union or non-union installations.

For assistance with your sales or system contracting needs please Call:

North, Central and South America +1 (262) 641-8600 or +1 (847) 273-7700 Monday–Friday, 8am–5pm CST

Europe/Middle East/Africa +48 22 390 9720

India +91 21 35329112

Asia/Australia +86 512 8717 1919

Facilities:

ACS offers facilities around the world to service you no matter where you are located. For more information, please visit us at

www.acscorporate.com

United States:

ACS Schaumburg – Corporate Offices

1100 E. Woodfield Road

Suite 588

Schaumburg, IL 60173

Phone: + 1 847 273 7700

Fax: + 1 847 273 7804

ACS New Berlin – Manufacturing Facility

2900 S. 160th Street

New Berlin, WI 53151

Phone : +1 262 641 8600

Fax: + 1 262 641 8653

Asia/Australia:

ACS Suzhou

109 Xingpu Road SIP

Suzhou, China 215126

Phone: + 86 8717 1919

Fax: +86 512 8717 1916

Europe/Middle East/Africa:

ACS Warsaw

Ul. Działkowa 115

02-234 Warszawa

Phone: + 48 22 390 9720

Fax: +48 22 390 9724

India

ACS India

Gat No. 191/1, Sandbhor Complex

Mhalunge, Chakan, Tal Khed,

Dist. Pune 410501, India

Phone: +91 21 35329112

Fax: + 91 20 40147576

Page 5

SSE-2

Tab le of con tents

1. Ge ne ral in struc tions .......................................................1-1

1.1. War nings and sym bols.............................................1-2

1.2. Ex pla na tions and in for ma ti on .......................................1-3

1.3. Le gal ba sis ......................................................1-3

1.4. Fields of ap pli ca tions ..............................................1-3

1.5. No tes on usa ge...................................................1-3

2. Sa fe ty in struc tions ........................................................2-1

2.1. For your sa fe ty ...................................................2-2

2.2. For the ope ra ting sa fe ty of the equip ment .............................2-5

3. Put ting into op er a tion......................................................3-1

3.1. Chec king the pipe sys tem ..........................................3-2

3.2. Ad ju sting the suc ti on pi pes .........................................3-3

3.3. Set ting the con trol ler ..............................................3-4

3.4. In iti al con vey ing ope ra tions .........................................3-5

3.5. Swit ching off the unit ..............................................3-5

4. Er ror and er ror cor rec tion ..................................................4-1

5. Main te nance .............................................................5-1

5.1. Main ten an ce in ter vals .............................................5-3

5.2. Ser vi cing the con vey or.............................................5-3

5.2.1. Chan ging the sea ling ring of the out let flap ...................5-4

5.2.2. Ad ju sting the flap switch ..................................5-5

5.2.3. Clea ning the unit ........................................5-6

5.3. Re pla cing car bon brus hes at tur bi ne .................................5-8

6. Functio nal de scrip tion .....................................................6-1

6.1. Ge ne ral .........................................................6-2

6.2. Con trol ler........................................................6-3

7. Trans port, As sem bly and Stor age ...........................................7-1

7.1. Trans port and Pac king .............................................7-2

516-4MS

7.2. As sem bly........................................................7-2

7.3. Sto ra ge .........................................................7-2

4

Page 6

SSE-2

8. As sem bly in struc tions .....................................................8-1

8.1. As sem bly........................................................8-2

8.2. Moun ting on the pro ces sing ma chi ne .................................8-4

8.3. Moun ting onto a ma chi ne hop per ....................................8-4

8.4. Moun ting onto mi xing hop pers with la te ral in let .........................8-5

8.5. Moun ting onto do sing sta ti on DT 30 ..................................8-5

8.6. Ma te ri al feed .....................................................8-6

8.7. Moun ting the suc ti on pipe MV .......................................8-6

8.8. Pi pe work ........................................................8-7

8.9. Elec tri cal con nec ti on ..............................................8-7

8.9.1. In stal la ti on of the “flap switch” sig nal line ....................8-8

8.9.2. In stal la ti on of the sig nal line of the SKW (op tio nal).............8-8

8.9.3. In stal la ti on of the alarm in di ca ting de vi ce (op tio nal) ............8-9

8.10. Com pres sed-air supp ly (only SSE-2 with ac ti ve clea ning) .............8-10

8.11. In stal ling the ac ces so ries ........................................8-10

9. Tech ni cal data ............................................................9-1

10. Spa re parts list .........................................................10-1

10.1. SSE-2, 230 V, 50 Hz ............................................10-3

10.2. SSE-2, 110 V, 60 Hz ............................................10-4

10.3. SSE-2, 230 V, 50 Hz with ac ti ve clea ning ...........................10-5

10.4. SSE-2, 110 V, 60 Hz with ac ti ve clea ning ...........................10-5

10.5. Ac ces so ries....................................................10-6

11. Ac ces so ries ............................................................11-1

o _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

o _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

o _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

12. Elec tri cal man ual .......................................................12-1

o Con nec ti on dia gram no.: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

o Cur rent ly not avai la ble; will be de li ver ed at a la ter date !

516-4MS

5

Page 7

1. Gener al in struc tions

The se in struc tions ap ply to all per sons wit hin the ran ge of ac ti on of the equip ment.

»

The se ope ra ting in struc tions are to be used by all per sons as sig ned ac ti vi ties con nec ted with the equip ment.

SSE-2

516-4MS

Gener al in struc tions 1-1

Page 8

1.1. War nings and sym bols

The fol lo wing war nings and sym bols are used in the se ope ra ting in struc tions:

This sym bol in di ca tes dan ger to life! Fa tal or se ri ous in ju ry is pos si ble if the

cor re spon ding in struc tions, re gu la tions or war nings are not ob ser ved.

»

SSE-2

L

F

&

$

This sym bol in di ca tes that se ri ous in ju ry is pos si ble if the cor re spon ding

in struc tions, re gu la tions or war nings are not ob ser ved.

This sym bol in di ca tes that ex ten si ve da ma ge to equip ment is pos si ble if

the cor re spon ding in struc tions, re gu la tions or war nings are not ob ser ved.

This sym bol in di ca tes in for ma ti on im por tant for be co ming fa mi li ar with

the equip ment, i.e. tech ni cal cor re la tions.

This sym bol in di ca tes that a tech ni cal term is ex plai ned at this point.

516-4MS

Gener al in struc tions 1-2

Page 9

SSE-2

1.2. Ex pla na tions and in for ma ti on

Va ri ous terms and de sig na tions are used in the se ope ra ting in struc tions to en su re cla ri ty. The re fo re plea se note that the terms used in the text stand for the cor re spon ding ex pla na tions lis ted be low.

Equip ment

•

”Equip ment” can mean an in di vi du al unit, a ma chi ne or an in stal la ti on.

Ope ra ting per son nel

•

The ”ope ra ting per son nel” are per sons ope ra ting the equip ment on their own re spon si bi li ty or ac cor ding to in struc tions.

Ope ra tor

•

The ”ope ra tor” of the equip ment (pro duc ti on ma na ger, fo re man, etc.) is the per son re spon si ble for

all pro duc ti on se quen ces. The ope ra tor in structs the ope ra ting per son nel of what is to be done.

Ope ra ting in struc tions

•

The ”ope ra ting in struc tions” des cri be the in ter ac ti on of the equip ment, pro duc ti on se quen ces or

me thods. The ope ra ting in struc tions must be com pi led by the ope ra tor of the equip ment.

Equip ment fo re man

•

When se ve ral ope ra ting per son nel work on one ma chi ne, the ”equip ment fo re man” coor di na tes

the se quen ces. The equip ment fo re man must be ap poin ted by the ope ra tor.

Trai ned per son nel

•

”Trai ned per son nel” are per sons who, due to their trai ning, are aut ho ri zed to car ry out the re qui red

work.

1.3. Le gal ba sis

See “Ma nu fac tu rer’s Cer ti fi ca te” resp. “Cer ti fi ca te of Con for mi ty”.

1.4. Fields of ap pli ca tions

Ster ling sing le con vey ing units are de sig ned for use in fa ci li ties in which re qui re in de pen dent ma chi ne con vey ing sys tems. The sing le con vey ing units have been de ve lo ped for con vey ing ther mo plas tic gra nu les. A ty pi cal area of ap pli ca ti on is for pro ces sing ma chi nes and dry ing hop pers

with throughputs of up to 180 kg/h (396 lbs/hr).

1.5. No tes on usa ge

Ex pe rien ced ope ra tors can be gin di rect ly with the chap ter on “Start-up” if the unit has been pro -

•

per ly in stal led.

516-4MS

If the unit has not been in stal led yet, ob ser ve the in struc tions in the chap ters “Trans port, As sem bly

•

and Sto ra ge” and “As sem bly In struc tions”.

Gener al in struc tions 1-3

Page 10

2. Sa fe ty in struc tions

The se sa fe ty in struc tions ap ply to all per sons wit hin the ran ge of ac ti on of the

equip ment.

»

Plea se in form all per sons wit hin the ran ge of ac ti on of the equip ment of the

di rect and in di rect ha zards con nec ted with the equip ment.

The se ope ra ting in struc tions are to be used by all per sons as sig ned ac ti vi ties con nec ted with the equip ment.

Knowled ge of the En glish langua ge is pre re qui si te.

En su re in each case that the ope ra ting per son nel are fa mi li ar with the ope ra ting in struc tions and the functi on of the equip ment.

SSE-2

516-4MS

Sa fe ty in struc tions 2-1

Page 11

SSE-2

2.1. For your sa fe ty

Ge ne ral

The ope ra ting per son nel of this equip ment must be at least 16 ye ars old.

Plea se read the se ope ra ting in struc tions ca re ful ly be fo re ta king into ope ra ti on for the first time.

Con tact us should que stions ari se. This avoids in ju ry and da ma ge to equip ment!

The se ope ra ting in struc tions must be kept avai la ble at all ti mes at the pla ce of ope ra ti on of the

equip ment. Im pro per ope ra ti on re sults in dan ger of ac ci dents!

Plea se note that, for rea sons of cla ri ty, not all con cei va ble ca ses re gar ding ope ra ti on or main ten an ce of the equip ment can be co ver ed in the se ope ra ting in struc tions.

Plea se ob ser ve all sa fe ty in struc tions and war nings on the equip ment. This avoids in ju ry and da ma ge to equip ment!

All work on the equip ment is to be car ried out by per sons who se qua li fi ca tions are spe ci fied in the

per tai ning chap ters of the ope ra ting in struc tions. Im pro per ope ra ti on re sults in dan ger of ac ci dents!

The pro per wor king clot hes are to be worn du ring any work on the equip ment. This avoids in ju ry!

The lo cal re gu la tions and re qui re ments per tai ning to this equip ment must be ob ser ved.

Dis con nect elec tri cal com po nents from the mains supp ly be fo re work is car ried out on the se com po nents Cau ti on: Dan ger to life through elec tri cal shock!

Com pi le de tai led ope ra ting in struc tions ba sed on the se Ope ra ting in struc tions for the se quen ce

of pro ce du res to be car ried out on this equip ment. Im pro per ope ra ti on re sults in dan ger of ac ci dents!

Plea se note that sound le vels ex cee ding 85 db(A) may in the long term da ma ge your he alth. Use

the ap pro pria te ear muffs. This avoids im pair ment of hea ring!

516-4MS

Sa fe ty in struc tions 2-2

Page 12

SSE-2

As sem bly

Com pa re the con nec ted lo ads with tho se of the mains supp ly. Dan ger of in ju ry through elec tri cal

shock!

When using lif ting gear, plea se ob ser ve the per tai ning re gu la tions. Cau ti on: Dan ger of ac ci dents!

Do not mo di fy, add ot her equip ment or chan ge the de sign of the equip ment wit hout the ap pro val

of the ma nu fac tu rer. Cau ti on: Dan ger of ac ci dents!

At tach ments not supp lied by Ster ling must be ma nu fac tur ed in ac cor dan ce with sa fe ty re gu la ti on

EN 294. Dan ger of ac ci dents!

The equip ment may only be ope ra ted when all the as so cia ted com po nents are pro per ly con nec ted up and in ac cor dan ce with the re le vant re gu la tions. This avoids in ju ry and da ma ge to equip ment!

Ope ra te the de vi ce only if all its com po nents are groun ded. Dan ger: ac ci dent through elec tri cal

shock!

So lid par ti cles and dust must be se pa ra ted be fo re en try to the va cu um ge ne ra tor. This avoids da ma ge to equip ment!

If PVC ho ses are used for con vey ing, they must be groun ded. This avoids in ju ry and da ma ge to

equip ment!

An acous tic co ver should be in stal led when va cu um ge ne ra tors are lo ca ted in work rooms. This

avoids im pair ment of hea ring!

516-4MS

Sa fe ty in struc tions 2-3

Page 13

SSE-2

Ope ra ti on

Ap point an equip ment fo re man to be re spon si ble for the equip ment.

En su re that the ope ra ting per son nel are pro vi ded de tai led in struc ti on in the ope ra ti on of the

equip ment. Im pro per ope ra ti on re sults in dan ger of ac ci dents!

When the main switch is swit ched off for rea sons per tai ning to sa fe ty, it must be se cu red against

un aut ho ri zed ac ti vat ion. Cau ti on: Dan ger of ac ci dents!

Re pair work may be car ried out by trai ned per son nel only. Cau ti on: Dan ger of ac ci dents!

Ne ver ope ra te the equip ment when parti al ly dis mant led! Dan ger! Limbs may be caught in ma chi ne ry! Elec tric shock!

In case of mal functi on, shut down the equip ment im me di ate ly. Have mal functions cor rec ted im me di ate ly. Dan ger of ac ci dents!

The equip ment is in ten ded only for con vey ing gra nu la ted plas tics and re grinds. Any ot her or ad di tio nal use is con tra ry to spe ci fi ca tions.

This equip ment is not suit ab le for food pro ces sing.

The sa fe ty in struc tions of the con nec ted ma chi nes must be fol lo wed.

Ex plo si ve ga ses and mix tu res of gas and air must not be con vey ed. Dan ger of ex plo si on! Avoids

in ju ry or da ma ge to equip ment!

Main ten an ce

Be fo re star ting main ten an ce work, ap point a su per vi sor.

In form the re spon si ble per son nel be fo re main ten an ce work on the sys tem is start ed. Cau ti on:

Dan ger of ac ci dents!

Dis con nect the equip ment from mains supp ly be fo re star ting main ten an ce pro ce du res to en su re

that it can not be swit ched on un in ten tio nal ly. Cau ti on: Dan ger of ac ci dents!

All pi pes, ho ses and scre wed con nec tions should be che cked re gu lar ly for le aks and da ma ge.

Any faults which ari se should be cor rec ted im me di ate ly. Dan ger of ac ci dents!

De pres su ri se all com pres sed air pi ping be fo re star ting main ten an ce work. Dan ger of ac ci dents!

516-4MS

Sa fe ty in struc tions 2-4

Page 14

SSE-2

2.2. For the ope ra ting sa fe ty of the equip ment

Ne ver chan ge set tings if the con se quen ces are not pre ci se ly known.

Use only ori gi nal Ster ling spa re parts.

Plea se ob ser ve the main ten an ce sche du le.

Keep re cord of all main ten an ce and re pair work.

Plea se note that elec tro nic com po nents may be da ma ged by sta tic disch ar ge.

Check all elec tri cal con nec tions for pro per fit be fo re the equip ment is ta ken into ope ra ti on for the

first time and at re gu lar in ter vals.

Plea se en su re that the per mit ted ope ra ti on tem pe ra tu re lies bet ween 0 °C and +45 °C

(32 to +113 °F).

Plea se en su re that the per mit ted sto ra ge tem pe ra tu re lies bet ween -25 °C and +55 °C

(-13 to +131 °F).

Note down all data which you have en te red into the con trol sys tem.

Plea se en su re that all plugs are cor rect ly plug ged in.

The ope ra ting in struc tions of the con nec ted ma chi nes must be fol lo wed.

Ope ra te the de vi ce only if all its com po nents are groun ded.

Ne ver ad just sen sors wit hout ex act knowled ge of their functi on.

Plea se note that a com pres sed air supp ly is re qui red for the ope ra ti on of the unit (only SSE-2 with

ac ti ve clea ning, op tio nal).

Ne ver set a hig her ope ra ting pres su re than 6 bar for the hop per loa ders (sys tem over pres su re,

only SSE-2 with ac ti ve clea ning, op tio nal).

Align the suc ti on tu bes cor rect ly.

The unit should be in stal led in such a way that the out let flap os cil la tes at right an gles to the mo ving di rec ti on of the equip ment.

The load-bea ring ca pa ci ty of the ma chi ne flan ge should be ad he red to.

Plea se ob ser ve that a le vel in di ca tor is re qui red when con vey ing from gra nu la tors.

Ob ser ve that the ma xi mum con vey ing ca pa ci ty is up to 180 kg/hr (390 lbs/hr) at 100% ope ra ting

time.

Ob ser ve that the ty pi cal con vey ing ca pa ci ty is up to 90 kg/hr (195 lbs/hr) at 50 % ope ra ting time.

516-4MS

Sa fe ty in struc tions 2-5

Page 15

3. Put ting into ope ra ti on

This chap ter is in ten ded for ope ra ting per son nel.

SSE-2

»

F

Pre re qui si te for this chap ter is ge ne ral knowled ge of the ope ra ti on of con vey ing sys tems.

Also pre re qui si te for this chap ter is that the functio nal des crip ti on has been

read and un ders tood.

En su re in each case that the ope ra ting per son nel are suf fi cient ly in form ed.

Make sure the plas tic stop per has been re mo ved from the ma te ri al in let

nozzle.

Make sure the ad he si ve tape has been re mo ved from the exit flap.

516-4MS

Put ting into ope ra ti on 3-1

Page 16

3.1. Chec king the pipe sys tem

Re mo ve the fle xi ble hose from the con nec ted ma te ri al ta keup.

Clo se the open end of the hose with your hand.

Con nect the unit to mains supp ly by the de vi ce plug.

If the tur bi ne is ope ra ting, your hand must feel the suc ti on wit hin few se conds.

If you don’t feel the va cu um it me ans that the pipe sys tem is not tight.

Check the pipe sys tem and seal any un tight points you may have iden ti fied.

Re con nect the con vey ing hose.

Dis con nect the unit from mains supp ly by the de vi ce plug.

SSE-2

516-4MS

Put ting into ope ra ti on 3-2

Page 17

3.2. Ad ju sting the suc ti on pi pes

The suc ti on pi pes have to be ad jus ted ex act ly to en su re trou ble free ope ra ti on.

1. Set the suc ti on pi pes to their home po si ti on.

SSE-2

&

2. Start a con vey ing ope ra ti on.

Con nect the unit to mains supp ly by the de vi ce plug.

3. Ob ser ve the fle xi ble hose at the suc ti on pipe.

The fle xi ble hose must not show any pul sa ting mo ve ment.

4. Ob ser ve the fle xi ble hose at the se pa ra tor.

The con vey ing hose must only move du ring in-feed.

If the con di tions (points 3 + 4) are not met:

Pull the in ner pipe furt her out of the ou ter pipe un til the re is no more jer ky con vey an ce.

If the con di tions (points 3 + 4) are met:

Push the in ner pipe slowly into the ou ter pipe un til pul sa ting of the fle xi ble hose or shock con vey an ce oc curs.

Now pull the in ner pipe slight ly back again un til the hose stop pul sa ting.

At home po si ti on the in ner pipe of the suc ti on pipe pro tru des about

120-160 mm (4.75" - 6.25") from the ou ter pipe at the top end.

Se lect a set ting bet ween the two pi pes to en su re that enough air can flow into the ma te ri al pipe.

Once you have rea ched a sa tis fac to ry con vey ing re sult turn the wing screw at the suc ti on pipe

tight.

516-4MS

Put ting into ope ra ti on 3-3

Page 18

3.3. Set ting the con trol ler

The fil ling ca pa ci ty of the hop per loa der may not ex ceed the ma te ri al in let.

F

SSE-2

&

Set ting the con vey ing time

Press the “ar row key”.

&

The con vey ing ca pa ci ty is too highlow (the se pa ra tor is over crowded):

Re du ce the con vey ing time.

The set ting is in de pen dent of the con vey ing line and the ma te ri al to be

con vey ed.

It is only pos si ble to set the con vey ing time/line cle ar time when the unit is

not con vey ing any ma te ri al.

The con vey ing time which was last se lec ted ap pe ars in the dis play.

1-99 se conds may be set for the con vey ing time.

The con vey ing ca pa ci ty is too low:

In crea se the con vey ing time.

516-4MS

Put ting into ope ra ti on 3-4

Page 19

Set ting the line cle ar time

Press the “chan ge-over” key and

then the “ar row key”.

SSE-2

&

The line cle ar time which was last se lec ted ap pe ars in the dis play.

0-99 se conds may be set for the line cle ar time.

If no line cle ar val ve has been in stal led en ter “0".

F

3.4. In iti al con vey ing ope ra tions

Me tal sha vings may be in si de the pipe from cut ting down pi pes into lengths. The se are pul led du ring the first con vey ing pro cess and col lec ted in the se pa ra tor.

This ma te ri al should not be used again.

F

3.5. Swit ching off the unit

Dis con nect the unit from mains supp ly by the de vi ce plug.

516-4MS

Put ting into ope ra ti on 3-5

Page 20

4. Er ror and er ror cor rec ti on

This chap ter is in ten ded for the ope ra ting per son nel of the equip ment.

SSE-2

»

Pre re qui si te for this chap ter is ge ne ral knowled ge of the ope ra ti on of con vey ing sys tems

The “Start-up” des crip ti on must have been read and un ders tood.

En su re in each case that the ope ra ting per son nel are suf fi cient ly in form ed.

516-4MS

Er ror and er ror cor rec ti on 4-1

Page 21

SSE-2

If a dis tur ban ce oc curs in the unit, an alarm mes sa ge will be is su ed (op ti on, only if the alarm in di ca ting de vi ce has been ac ti vat ed).

&

An “E” ap pe ars in the dis play and an er ror num ber.

The alarm in di ca ting de vi ce (sig nal si ren, horn) re acts.

The con trol sys tem can only res tart ope ra ti on when the mal functi on has

been cor rec ted.

F

Press the “ack nowled ge ment key”.

&

The fol lo wing er ror mes sa ges can be dis play ed:

The cau se of the mal functi on will not be cor rec ted by pres sing the “ack nowled ge ment key”.

“E1"

The alarm mes sa ge “E1" is dis play ed when no ma te ri al has been con vey ed du ring 3 con se cu ti ve

con vey ing cy cles.

Check that suf fi cient ma te ri al is being con vey ed.

Check that the flap switch is set cor rect ly.

When the mal functi on has been cor rec ted press the key.

F

516-4MS

Er ror and er ror cor rec ti on 4-2

Page 22

SSE-2

“E2"

If the con trol sys tem be comes too hot dur ing op er a tion (>70°C, 158°F) the “E2" alarm mes sage is

dis played and the unit is switched off.

En su re that the con trol sys tem is suf fi cient coo led.

&

The unit starts au to ma ti cal ly af ter the coo ling down pha se.

516-4MS

Er ror and er ror cor rec ti on 4-3

Page 23

5. Ma in ten an ce

This chap ter is in ten ded for per sons with skills in elec tri cal and me cha ni cal

are as due to their trai ning, ex pe rien ce and re cei ved in struc tions.

Per son nel using the in struc tions in this chap ter must be in struc ted of the re gu la tions for the pre ven ti on of ac ci dents, the ope ra ting con di tions and sa fe ty

re gu la tions and their im ple men ta ti on.

En su re in each case that the per son nel are in form ed.

For main ten an ce work ta king pla ce at heights of over ap prox. 6 feet, use only

lad ders or si mi lar equip ment and wor king plat forms in ten ded for this pur po se. At grea ter heights, the pro per equip ment for pro tec ti on against fal ling

must be worn.

Use only suit ab le lif ting gear which is in pro per wor king or der and load sus pen si on de vi ces with suf fi cient car ry ing ca pa ci ty. Do not stand or work un der

sus pen ded lo ads!

SSE-2

L

En su re that the elec tric mo tors/switch ca bi nets are suf fi cient ly pro tec ted

against moi stu re.

Use only suit ab le work shop equip ment.

Be fo re star ting main ten an ce work, ap point a su per vi sor.

In form the re spon si ble per son nel be fo re main ten an ce work on the sys tem is

start ed.

Ne ver ope ra te the equip ment when parti al ly dis mant led.

All main ten an ce and re pair work not des cri bed in this chap ter may only be

car ried out by Ster ling ser vi ce per son nel or aut ho ri zed per son nel (ap poin ted

by Ster ling).

Dis con nect the equip ment from mains supp ly be fo re star ting main ten an ce pro ce du res to en su re that it can not be swit ched on un in ten tio nal ly.

De pres su ri ze all sys tem sec tions of the equip ment be fo re car ry ing out

any re pair work.

516-4MS

Ma in ten an ce 5-1

Page 24

Plea se ob ser ve the main ten an ce in ter vals.

SSE-2

F

Be fo re star ting main ten an ce work, cle an the equip ment of oil, fuel or lu bri cants.

En su re that ma te ri als and in ci den tals re qui red for ope ra ti on as well as

spa re parts are dis po sed of pro per ly and in an en vi ron men tal ly sound

man ner.

Use only ori gi nal Ster ling spa re parts.

Keep re cord of all main ten an ce and re pair pro ce du res.

516-4MS

Ma in ten an ce 5-2

Page 25

5.1. Main ten an ce in ter vals

Dai ly: Check war ning signs on equip ment for good

le gi bi li ty and com ple te ness

Cle an the sie ve / fil ter (= units with ac ti ve clea ning):

Use com pres sed air to blow through the sie ve / fil ter

(ac cor ding to the ac cu mu la ti on of dust)

Month ly: Check functi on of the de vi ce plug

Every 6 months: Check all elec tri cal and me cha ni cal con nec tions for tight fit

Check set ting of the le vel sen sor (if pre sent, op tio nal)

Re pla ce the sie ve / fil ter (= units with ac ti ve clea ning)

(ac cor ding to the ac cu mu la ti on of dust)

An nu al ly: Re pla ce out let val ve sea ling.

Ad just val ve switch

Af ter 1000

ope ra ting hours: Re pla ce car bon brus hes

SSE-2

The gi ven main ten an ce in ter vals are aver age va lu es.

F

5.2. Ser vi cing the con vey or

»

Dis as sem bly the unit.

516-4MS

Check whet her in your in di vi du al case the main ten an ce in ter vals must be

shor te ned.

Dis con nect the unit from mains supp ly by the de vi ce plug.

De pres su ri ze all sys tem sec tions of the equip ment (only units with ac ti ve

clea ning).

Ma in ten an ce 5-3

Page 26

5.2.1. Chan ging the sea ling ring of the out let flap

CC

A

B

A

B

Open the tog gle-type fa ste ners (A) and

the flap (B) of the hop per loa der.

Draw the old sea ling ring (C) off the

nozzle of the ma te ri al out let.

In stall the new sea ling ring (C).

Ob ser ve the di rec ti on of in stal la ti on (C).

F

SSE-2

In stal la ti on sea ling ring

Clo se the flap (B) and the tog gle-type fa ste ners (A).

In stall the hop per loa der.

&

516-4MS

Or der num ber sea ling ring “ma te ri al out let”: ID 29258

Ma in ten an ce 5-4

Page 27

5.2.2. Ad ju sting the flap switch

3O3O

C B AC B A

Re mo ve the con nec ting plug “flap switch”

from the con nec ti on hou sing of the hop per.

Con nect an ohm me ter to PINS 2 and 3 of

the con nec ting plug “flap switch”.

Re lea se the nuts (A) of the flap switch (B)

un til the sup port can be dis pla ced.

Open the out let flap (C) so far that the front

tip of the out let flap is ap prox. 30 mm (1.2")

away from the sea ling sur fa ce.

Dis pla ce the flap switch (B) un til the con tact of the mag net switch is clo sed.

Tighten the nuts (A) of the flap switch.

Check the ad just ment:

In case of free han ging out let flap (emp ty

hop per loa der) the con tact of the mag net

switch must be clo sed.

SSE-2

Out let flap

If the out let flap can not be pro per ly ad jus ted, re pla ce the flap switch or the out let flap with mag net.

In stall the hop per.

&

Or der num bers

switch with plug: ID 29570

out let flap with mag net: ID 28647

516-4MS

Ma in ten an ce 5-5

Page 28

5.2.3. Clea ning the unit

Open the ten si on ring.

Fold the tur bi ne head up wards.

Re mo ve the sie ve.

Cle an the sie ve by me ans of com pres sed-air.

Cle an the hop per loa der by me ans of a va cu um clea ner.

Mount the sie ve. Pay at ten ti on for pro per fit.

Mount the tur bi ne head.

Mount the ten si on ring.

or op tio nal, ac ti ve clea ning

SSE-2

Open the ten si on ring.

Fold the tur bi ne head up wards.

Re mo ve the fil ter.

Cle an the fil ter by me ans of com pres sed-air.

Cle an the hop per loa der by me ans of a va cu um clea ner.

Mount the fil ter. Pay at ten ti on for pro per fit.

Mount the tur bi ne head.

Mount the ten si on ring.

&

516-4MS

Or der num ber

sie ve with sea ling ring: ID 35014

fil ter with sealing: ID 37755

Ma in ten an ce 5-6

Page 29

Open the tog gle-type fa ste ners (A) and

A

B

A

B

C DC D

the flap (B) of the hop per loa der.

Check the fil ter cloth (C) and the wire cloth

(D) for ma te ri al re si due. Cle an the fil ter by

me ans of com pres sed air.

Clo se the flap (B) and the tog gle-type fa ste ners (A) on the flap of the hop per loa der.

In stall the unit.

SSE-2

SSE-2

&

516-4MS

Or der num bers

Fil ter cloth: ID 28626

Wire cloth: ID 23091

Ma in ten an ce 5-7

Page 30

5.3. Re pla cing car bon brus hes at tur bi ne

B

A

D

C

This work must be car ried out by qua li fied per son nel only.

SSE-2

»

Dis as sem bly the unit.

Re mo ve the screws (A) at the lid.

Re mo ve the lid (B).

Re mo ve the lat chet ca re ful ly from the

brush hol der (C).

Re mo ve the co ver (D).

Loo sen the brush hol der lock.

Pull out the brush hol der.

In stal la ti on

Push the lat chet with the con nec ting line

on to the new brush hol der.

Dis con nect the unit from mains supp ly by the de vi ce plug be fo re you be gin

with works on the con trol ler. Dan ger to life!

De pres su ri ze all sys tem sec tions of the equip ment (only units with ac ti ve

clea ning).

516-4MS

Mount the brush hol der.

Plea se be ca re ful with the lat chet con nec ting line.

Mount the co ver.

Mount the lid.

Mount the screws at the lid.

In stall the unit.

SSE-2

Ma in ten an ce 5-8

Page 31

Ob ser ve that no ca bles will be squee zed.

SSE-2

F

&

Car bon brus hes can be re pla ced twi ce.

Af ter that the tur bi ne has to be com ple te ly re pla ced.

Or der num bers

Tur bi ne (230 V, 800 W): ID 85629

Car bon brus hes (swit ching off): ID 85628

Tur bi ne (110 V, 800 W): ID 85844

Car bon brus hes (swit ching off): ID 84716

516-4MS

Ma in ten an ce 5-9

Page 32

6. Functio nal des crip ti on

This functio nal des crip ti on is in ten ded for all ope ra ting per son nel of the

equip ment.

»

Pre re qui si te for this functio nal des crip ti on is ge ne ral knowled ge of con vey ing sys tems.

En su re in each case that the ope ra ting per son nel are suf fi cient ly in form ed.

SSE-2

516-4MS

Functio nal des crip ti on 6-1

Page 33

6.1. Ge ne ral

The sing le con vey or unit functions ac cor ding to the prin ci ple of suc ti on con vey an ce.

A high-per for man ce tur bi ne, moun ted per ma nent ly on the de vi ce, pro vi des for the

va cu um that is re qui red to con vey the ma te ri al into the se pa ra tor.

In the se pa ra tor the ma te ri al is se pa ra ted

from air. Af ter the con vey ing time is fi nis hed the tur bi ne is swit ched off and the ma te ri al emp tied into the ma te ri al in ter me di ate hop per. If the fil ling le vel re mains be low

the out let flap of the sing le con vey or unit, a

star ting pul se is trig ge red and sent to the

con trol ler.

The fil ter will be clea ned (pas si ve clea ning)

or blo wed off using com pres sed-air (op tio nal, ac ti ve clea ning). Then the con vey an ce

is res tar ted. This pro cess re pe ats so of ten

un til the ma te ri al in ter me di ate hop per is fil led. Af ter wards the con vey an ce is stop ped

un til a new star ting pul se is trig ge red and

sent to the con trol ler.

SSE-2

516-4MS

Functio nal des crip ti on 6-2

Page 34

SSE-2

6.2. Con trol ler

The con trol sys tem is moun ted on the se pa ra tor lid.

The set ting for the con vey ing time and the line cle ar time are made via the keys (A1: “chan ge-over” key, A2: “ar row key”) on the front of the con trol sys tem. The va lu es which have been set

will be dis play ed on the dis play (B). The va lu es which have been set are main tai ned af ter the ma chi ne has been shut off.

3 LEDs in di ca te the re spec ti ve mo des of ope ra ti on: clea ning (C), con vey ing (D), line clea ring (E).

&

The con vey ing time can be set from 1 to 99 se conds.

The line cle ar time can be set from 0 to 99 se conds.

The clea ring time con sists of 2 se conds.

The emp ty ing time con sists of 8 se conds.

When the unit is swit ched on all LEDs blink and the soft wa re ver si on is

dis play ed.

C

D

E

B

A1 A2

516-4MS

Con trol ler

Functio nal des crip ti on 6-3

Page 35

SSE-2

Op tio nal:

If a ma te ri al clea ring val ve has been in stal led re si du es of flo wing ma te ri al will be clea ned from the

con vey ing line du ring the line cle ar time.

If a dis tur ban ce oc curs in the unit, an alarm mes sa ge will be is su ed (only if the alarm in di ca ting de vi ce has been ac ti vat ed).

&

An “E” ap pe ars in the dis play and an er ror num ber.

The alarm in di ca ting de vi ce (sig nal si ren, horn) re acts.

516-4MS

Functio nal des crip ti on 6-4

Page 36

7. Tran sport, As sem bly and Sto ra ge

This chap ter is in ten ded for all ope ra ting per son nel of the equip ment.

SSE-2

»

Per son nel using the se in struc tions must be in struc ted in the re gu la tions for

the pre ven ti on of ac ci dents, the ope ra ting con di tions and sa fe ty re gu la tions

and their im ple men ta ti on.

En su re in each case that the ope ra ting per son nel are suf fi cient ly in form ed.

Plea se in form all per sons wit hin the ran ge of ac ti on of the equip ment of the

di rect and in di rect ha zards con nec ted with the equip ment.

Plea se ob ser ve all sa fe ty re gu la tions for the ope ra ti on of lif ting equip ment.

516-4MS

Tran sport, As sem bly and Sto ra ge 7-1

Page 37

SSE-2

7.1. Tran sport and Pac king

Plea se en su re ade qua te car ry ing ca pa ci ty of the lif ting equip ment.

»

The equip ment pass a ri go rous ope ra ting test in the fac to ry and are pa cked ca re ful ly to avoid

trans port da ma ge.

Plea se check pac king on de li very for trans port da ma ge.

The in let and disch ar ge flan ges are sea led with plugs, so that no dirt can en ter du ring trans port.

Plugs must be re mo ved be fo re as sem bly.

Pac king ma te ri als should be dis po sed of ac cor ding to en vi ron men tal laws or reu sed.

Only use for trans port of the equip ment a suit ab le lif ting de vi ce (e. g. a fork lift truck or a work shop

cra ne).

Trans port must be shock-proo fed and free from vi brat ions.

7.2. As sem bly

Plea se en su re ade qua te car ry ing ca pa ci ty of the lif ting equip ment.

»

7.3. Sto ra ge

The con trol sys tem may only be sto red at tem pe ra tu res from -25 to +55°C (-13 to +131 °F).

Bet ween de li very and ma chi ne com mis sio ning the equip ment should be sto red in a dry, dust-free

and vi brat ion-free room.

Check the car ry ing ca pa ci ty of the point of in stal la ti on, par ti cu lar ly if in stal led

on a plat form.

The pla ce se lec ted for in stal la ti on should be as free of vi brat ions as pos si ble.

The main switch must be free ly ac ces si ble.

Ground the equip ment against elec tro sta tic char ging.

516-4MS

Tran sport, As sem bly and Sto ra ge 7-2

Page 38

8. As sem bly in struc tions

The se in stal la ti on in struc tions are in ten ded for per sons with skills in elec tri cal and me cha ni cal are as due to their trai ning, ex pe rien ce and re cei ved in -

»

struc tions.

Per son nel using the se in stal la ti on in struc tions must be in struc ted in the re gu la tions for the pre ven ti on of ac ci dents, the ope ra ting con di tions and sa fe ty

re gu la tions and their im ple men ta ti on.

En su re in each case that the per son nel are in form ed.

The in stal la ti on in struc tions pro vi ded in the cor re spon ding ope ra ting in struc tions ap ply for all con nec ted equip ment.

Plea se ob ser ve all sa fe ty re gu la tions for the ope ra ti on of lif ting gear.

All in stal la ti on work must be car ried out with the equip ment dis con nec ted

from elec tri cal po wer an com pres sed air supp ly.

SSE-2

L

For in stal la ti on work ta king pla ce at heights of over ap prox. 6 feet, use

only lad ders or si mi lar equip ment and wor king plat forms in ten ded for this

pur po se. At grea ter heights, the pro per equip ment for pro tec ti on against

fal ling must be worn.

Use only suit ab le lif ting gear which is in pro per wor king or der and load

sus pen si on de vi ces with suf fi cient car ry ing ca pa ci ty. Do not stand or

work un der sus pen ded lo ads!

Use only suit ab le work shop equip ment.

In stall the equip ment such that all parts are ea si ly ac ces si ble; this fa ci li ta tes main ten an ce and re pair work.

F

516-4MS

As sem bly in struc tions 8-1

Page 39

SSE-2

8.1. As sem bly

The sing le con vey or unit is in sen si ti ve to shocks and can be moun ted di rect ly onto the pro ces sing

ma chi ne, on a ma chi ne hop per, a dry ing hop per or a do sing and blen ding unit.

The equip ment is de li ver ed as a com ple te as sem bly.

Un pack the equip ment.

Re mo ve the plas tic stop per (A) from the ma te ri al in let nozzle.

Open the flap (B) and re mo ve the ad he si ve tape from the exit flap.

The con trol ler must be free ly ac ces si ble.

F

A

B

516-4MS

As sem bly in struc tions 8-2

Page 40

SSE-2

J

L

Moun ting on fi xed ma chi ne thro ats or in ter me di ate con tai ners is done by me ans of strap re tai ners.

Plea se check du ring as sem bly that the ad mis si ble bea ring lo ads are not ex cee ded.

Mount the con vey or in such a way that the out let flap swings in a right an gle to the di rec ti on of ma chi ne mo ve ment.

Plea se check that all con nec ting points are tight to en su re that the con vey ing per for man ce is not

im pai red.

As sem bly

516-4MS

As sem bly in struc tions 8-3

Page 41

8.2. Moun ting on the pro ces sing ma chi ne

A ma te ri al hop per VT 1,0 is re qui red:

Mount the material hop per onto the flan ge of the pro ces sing ma chi ne.

Mount the unit onto the ma te ri al hop per.

Ob ser ve the bea ring ca pa ci ty of the ma chi ne flan ge.

F

8.3. Moun ting onto a ma chi ne hop per

SSE-2

VT 1,0

A wel ding flan ge EF 190 is re qui red:

L

Weld the wel ding flan ge into the ma chi ne hop per lid.

Mount the unit onto the flan ge.

Plea se ob ser ve all sa fe ty re gu la tions for the ope ra ti on of wel ding equip ments.

Al ways wear a sa fe ty gog gle.

EF 190

516-4MS

As sem bly in struc tions 8-4

Page 42

8.4. Moun ting onto mi xing hop pers with la te ral in let

A ma te ri al hop per VT 1,0 is re qui red:

Mount the ma te ri al hop per onto the swan-neck of the

mi xing hop per.

Mount the unit onto the in ter me di ate hop per.

Ob ser ve the bea ring ca pa ci ty of the ma chi ne flan ge.

F

SSE-2

VT 1,0

8.5. Moun ting onto do sing sta ti on DT 30

A do sing hop per DT 30 (320 mm high) is re qui red:

Mount the do sing hop per di rect ly onto the do sing con tai ner of the do sing sta ti on DT 30.

Mount the unit onto the do sing hop per.

Ob ser ve the bea ring ca pa ci ty of the ma chi ne flan ge.

F

DT 30

516-4MS

As sem bly in struc tions 8-5

Page 43

SSE-2

8.6. Mate ri al feed

Suc ti on pi pes type MV may be til ted by ap prox. 45 de grees in eit her di rec ti on to the ver ti cal. Ad di tio nal fas te ning is not re qui red.

When con vey ing from the bot tom of sto ra ge con tai ners (si los), a suc ti on box with 1-3 suc ti on pi pes is re qui red.

The con nec ti on of the suc ti on pi pes must be car ried out with a pie ce of fle xi ble line to pro vi de suf fi cient mo ve ment.

Plea se ob ser ve that the length of the hose should not ex ceed 3 me ters (10 feet). Push the free

pipe end into the fle xi ble line to a depth of ap prox. 4-5 cm (1.5" - 2"). Con nect both parts by me ans

of a hose clamp.

8.7. Moun ting the suc ti on pipe MV

The suc ti on pipe con sists of an in ner pipe (A) and an ou ter pipe (B) which can be off set against

each ot her.

Con nect the in ner pipe with the straight end to a fle xi ble hose:

Push the free pipe end into the fle xi ble line to a depth of ap prox. 4-5 cm (1.5" - 2").

Con nect both parts by me ans of a hose clamp.

Plea se ob ser ve that the length of the hose should not ex ceed 3 me ters (10 feet).

Plea se check that the ou ter pipe is not co ver ed as it pro vi des for un hin de red ac cess of am bient

air.

When con vey ing from si los, ma te ri al hop pers and sto ra ge con tai ners, a

suc ti on box with 1-3 suc ti on pi pes is re qui red.

F

B A

516-4MS

MV

As sem bly in struc tions 8-6

Page 44

SSE-2

8.8. Pi pe work

If PVC ho ses are used for con vey ing, they must be groun ded: draw out the cop per lead on both

ends of the hose and jam it bet ween hose and tube. For fas te ning, use threa ded clamps.

8.9. Elec tri cal con nec ti on

The re gu la tions of the lo cal Elec tri ci ty Board must be ob ser ved.

»

The ope ra ting vol ta ge is 230 V/50 Hz.

Spe ci al vol ta ges on re quest.

The con nec ted load is ap prox. 800 W.

The equip ment is con nec ted to mains supp ly by a de vi ce plug.

Se pa ra te fuse pro tec ti on of the wall so cket is re qui red (max. 16 A).

Be fo re con nec ti on to the elec tri ci ty supp ly, it should be en su red that the

supp ly vol ta ge and the po wer fre quen cy are in ac cor dan ce with the data on

the name pla te of the ma chi ne.

The elec tri cal con nec ti on may only be car ried out by Ster ling ser vi ce staff or

trai ned per son nel aut ho ri sed by Ster ling.

It is not per mit ted for ot her per sons to un der ta ke the elec tri cal con nec ti on.

The main switch must be free ly ac ces si ble.

Ground the equip ment against elec tro sta tic char ging.

516-4MS

As sem bly in struc tions 8-7

Page 45

SSE-2

B A

8.9.1. In stal la ti on of the “flap switch” sig nal line

In sert the ap pli an ce plug of the “flap switch” sig nal line into the “flap switch” con nec tor (A) on the

lo wer side of the con trol ler.

8.9.2. In stal la ti on of the sig nal line of the SKW (op tio nal)

In sert the ap pli an ce plug of the "SKW (= Two Com po nent Pro por tio ning Val ve)” sig nal line into the

“SKW” con nec tor (B) on the lo wer side of the con trol ler.

Lo wer side of the controller

516-4MS

As sem bly in struc tions 8-8

Page 46

8.9.3. In stal la ti on of the alarm in di ca ting de vi ce (op tio nal)

This work must be car ried out by qua li fied per son nel only.

SSE-2

»

&

Ter mi nals:

X2 = Po wer supp ly

X4 = Blo wer

X5 = Clea ning

X6 = Clea ring

X9 = Alarm

Dis con nect the unit from mains supp ly by the de vi ce plug be fo re you be gin

with works on the con trol ler. Dan ger to life!

The con nec ti on is po ten ti al-free and ra ted for no more

than 100 VA.

An ad di tio nal alarm in di ca ting de vi ce (e.g. horn, sig nal light) can be con nec ted.

You need an “ack nowled ge ment key” for 24 V (e.g. by Rafi Com pa ny).

X3 = PE

516-4MS

X5 = Flap switch

X6 = ack nowled ge ment key

As sem bly in struc tions 8-9

Page 47

SSE-2

8.10. Com pres sed-air supp ly (only SSE-2 with ac ti ve clea ning)

For ope ra ting the clea ning de vi ce, a com pres sed-air supp ly is ne ces sa ry.

Check com pres sed-air pi ping for cor rect in stal la ti on and as sem bly.

Check fit tings, length and qua li ty of the hose con nec tions for agree ment with re qui re ments.

The ope ra ting pres su re is 5-6 bar (72-87 PSI) (sys tem over pres su re).

Check the com pres sed-air supp lied by the plant’s supp ly net work.

Ad just com pres sed-air pres su re to 5-6 bar (72-87 PSI) (sys tem over pres su re).

Con nect the unit to the plant’s supp ly net work by me ans of a hose.

L

F

8.11. In stal ling the ac ces so ries

De pres su ri ze com pres sed-air supp ly li nes which must be ope ned.

Com pres sed air must be de wa te red, dust free and oil free.

In stall a main ten an ce unit if re qui red.

Ad just pres su re to a max. va lue of 6 bar (87 PSI) (sys tem over pres su re).

See chap ter “Ac ces so ries”.

F

516-4MS

As sem bly in struc tions 8-10

Page 48

9. Tech ni cal data

The se in struc tions ap ply to all per sons wit hin the ran ge of ac ti on of the equip ment.

»

The se ope ra ting in struc tions are to be used by all per sons as sig ned ac ti vi ties con nec ted with the equip ment.

SSE-2

516-4MS

Tech ni cal data 9-1

Page 49

SSE-2

SSE-2

Ba sic Ver si on

• In te gra ted con trol with:

- LED-dis play

- in di ca ti on of the re spec ti ve mo des of ope ra ti on

- ad jus tab le con vey ing time

- ad jus tab le line clea ring time

- two com po nent val ve out put

• In te gra ted va cu um pump

• In te gra ted fil ter-sie ve

• Parts co ming in con tact with ma te ri al are made of stain less steel

• Simp le moun ting to do sing and blen ding units due to com pact and weight sa ving de sign

Op tio nal Fea tu res

• In te gra ted fil ter with au to ma tic clea ning

• Alarm in di ca ting de vi ce

- dis play of er ror codes

- alarm out put

- au to ma tic shut-down with lack of ma te ri al

• Le vel sen sor in put when in use with gra nu la tors

-au to ma tic clea ring pre vents over char ging of the gra nu la tor

• Ma te ri al clea ring val ve

Per for man ce

• Con vey ing ca pa ci ty max. up to 180 kg/hr (390 lbs/hr) at 100 % ope ra ting time

• Hop per loa der ca pa ci ty: ca. 2 l (.07 cu. ft.)

• Con nec ted load: 230 V, AC, N, PE, 50/60 Hz, 0,8 kW; 110 V, AC, N, 60 Hz

• Ma te rial tem per a ture max. 80 °C (176°F)

• Noi se le vel max. ap prox. 80 db(A)

• Weight ap prox. 10 kg (22 lbs.)

• Air con sump ti on (only with ac ti ve clea ning): max. 10 l at 6 bar / per clea ning cy cle (.35 cu. ft. at

87 PSI)

516-4MS

Tech ni cal data 9-2

Page 50

Di men si on Sheet

SSE-2

Di men sions and data wit hout ob li ga ti on. Di men sions in mm. Spe ci fi ca tions may be sub ject to al te ra tions.

516-4MS

Tech ni cal data 9-3

Page 51

10. Spa re parts list

This spa re parts list is in ten ded to be used only by trai ned per son nel.

SSE-2

»

&

Ot her per sons are not per mit ted to mo di fy or re pair the equip ment.

Wear Code:

A = Wea ring part, fast used up

B = Wea ring part

C = Spa re part, sto re kee ping for 1 year

D = Spa re part, sto re kee ping for 2 ye ars

E = Spa re part, sto re kee ping for more than 2 ye ars

516-4MS

Spa re parts list 10-1

Page 52

SSE-2, 230 V, 50 Hz / 110 V, 60 Hz

SSE-2

516-4MS

Spa re parts list 10-2

Page 53

SSE-2

10.1. SSE-2, 230 V, 50 Hz

Pos. Or der no. De sig na ti on Wear Code

1 37767 Tur bi ne head com ple te, with tur bi ne

and controller

2 37765 Co vering cap

3 18491 Sieve

4 34197 Iso la ti on

5 37768 Support

6 85629 Tur bi ne (800 W) D

85628 Car bon brus hes (swit ching off) B

7 24679 Iso lation

8 26384 Fil ter round

9 37764 Tur bi ne lo wer part

98194 Ca ble bushing

10 83098 Controller

11 35014 Sie ve with sea ling ring A

12 28626 Fil ter cloth C

13 23091 Wire cloth C

14 28625 Sea ling C

15 29258 Sea ling ring A

16 28647 Out let flap with mag net

17 28839 Flap switch with plug C

26462 Co ve ring C

18 37761 Separator

19 85481 Ten si on ring

29299 Sea ling ring B

26451 Lock

516-4MS

Spa re parts list 10-3

Page 54

SSE-2

10.2. SSE-2, 110 V, 60 Hz

Pos. Or der no. De sig na ti on Wear Code

1 37777 Tur bi ne head com ple te, with tur bi ne

and con trol ler

2 37765 Co ve ring cap

3 18491 Sieve

4 34197 Iso lation

5 37768 Support

6 85844 Tur bi ne (800 W) D

84716 Car bon brus hes (swit ching off) B

7 24679 Iso lation

8 26384 Fil ter roun d

9 37764 Tur bi ne lo wer part

98194 Ca ble bus hing

10 83097 Controller

11 35014 Sie ve with sea ling ring A

12 28626 Fil ter cloth C

13 23091 Wire cloth C

14 28625 Sea ling C

15 29258 Sea ling ring A

16 28647 Out let flap with mag net

17 28839 Flap switch with plug C

26462 Co ve ring C

18 37761 Se pa ra tor

19 85481 Ten si on ring

29299 Sea ling ring B

26451 Lock

516-4MS

Spa re parts list 10-4

Page 55

SSE-2

10.3. SSE-2, 230 V, 50 Hz with ac ti ve cleaning

Pos. Or der no. De sig na ti on Wear Code

1 37755 Fil ter with sea ling A

2 37222 Basket

3 82593 So le noid val ve B

4 97745 Bush D

5 37800 Bre at her tube D

10.4. SSE-2, 110 V, 60 Hz with ac ti ve clea ning

Pos. Or der no. De sig na ti on Wear Code

1 37755 Fil ter with sea ling A

2 37222 Basket

3 82592 So le noid val ve B

4 97745 Bush D

5 37800 Bre at her tube D

516-4MS

Spa re parts list 10-5

Page 56

10.5. Ac ces so ries

Plea se ob ser ve the ope ra ting ma nu als in chap ter 11.

F

SSE-2

516-4MS

Spa re parts list 10-6

Page 57

11. Ac ces so ries

o _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

o _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

o _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

SSE-2

516-4MS

Ac ces so ries 11-1

Page 58

12. Elec tri cal ma nu al

This elec tri cal ma nu al is in ten ded to be used only by Ster ling ser vi ce per son nel and trai ned per son nel aut ho ri zed by Ster ling.

»

Ot her per sons are not per mit ted to mo di fy or re pair the equip ment.

o Con nec ti on dia gram no.: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

o Cur rent ly not avai la ble; will be de li ver ed at a la ter date !

SSE-2

516-4MS

Elec tri cal ma nu al 12-1

Loading...

Loading...