Page 1

INSTALLATION AND SERVICE MANUAL

HORIZONTAL COMBUSTION AIR INLET KITS

CATEGORY III VENTING FOR SEPARATED COMBUSTION

TUBULAR GAS FIRED UNIT HEATERS

USE 5 INCH KIT FOR UNITS WITH CAPACITIES 100,000 TO 250,000 BTU/HR

USE 6 INCH KIT FOR UNITS WITH CAPACITIES 300,000 TO 400,000 BTU/HR

Supplement to unit installation instructions – STPIM or STBII

Improper installation, adjustment, alteration,

service or maintenance can cause property damage, injury or

death. Read this supplement and the unit heater installation,

operating and maintenance instructions thoroughly before

installing or servicing this equipment.

This Combustion Air Inlet Kit utilizes one 5 or 6 inch termination in which both the

discharge fl ue gas and the combustion air inlet pass.

HCAK-IOM-3

J30-09025

The location of the vent terminal must be in accordance with the National Fuel Code ANSI Z223.1 (NFPA 54) in

the U.S. or the Natural Gas Installation Code CSA-B149.1 or the Propane Gas Installation Cade CSA-B149.2 in

Canada. Minimum clearances are shown in Table 1 and Figure 3.

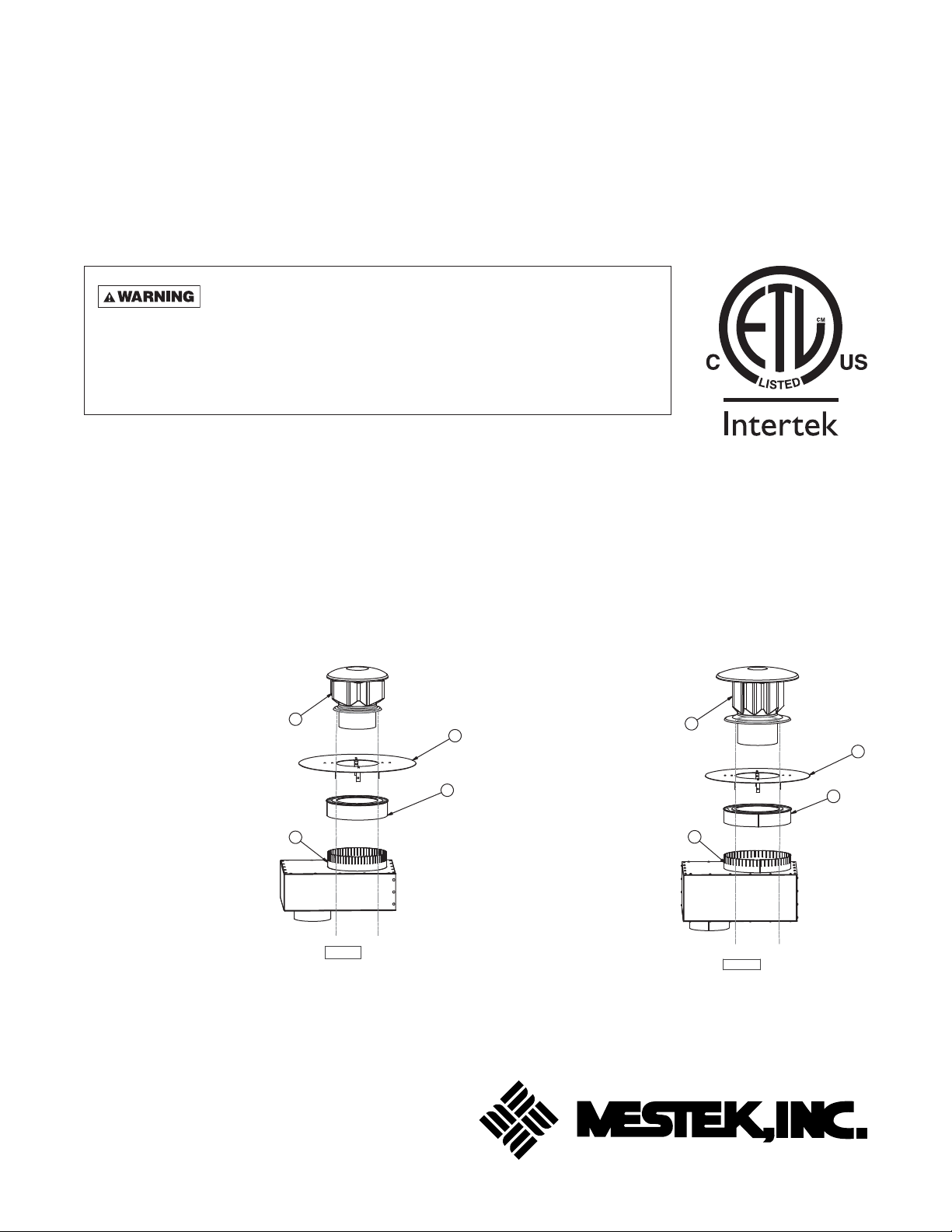

KIT CONTENTS:

Figure 1a – 5 Inch Combustion Air Inlet Kit

#1 – Part No. 11J37R02222-002

(1) Flue Vent Terminal

#2 – Part No. 11507R08560

(1) Combustion Air Inlet Box

Assembly (see Figure 2a

for dimensional data)

#3 – Part No. 11J37R08572

(1) Air Inlet Screen

#4 – Part No. 11507R08569

(1) Defl ector Disk

Also Included:

(1) Part No. J30-09025

Installation Instructions

(1) Part No. 11H03R03612-002

Tube of High Temp Silicone

Sealant

1

2

D8981B

Figure 1b – 6 Inch Combustion Air Inlet Kit

#1 – Part No. 11J37R02222-003

(1) Flue Vent Terminal

#2 – Part No. 11507R08951

(1) Combustion Air Inlet Box

4

3

Assembly (see Figure 2b

for dimensional data)

#3 – Part No. 11J37R08957

(1) Air Inlet Screen

#4 – Part No. 11507R09012

(1) Defl ector Disk

Also Included:

(1) Part No. J30-09025

Installation Instructions

(1) Part No. 11H03R03612-002

Tube of High Temp Silicone

Sealant

1

2

3

D9014B

4

08/13

260 NORTH ELM ST., WESTFIELD, MA 01085

TEL: (413) 568-9571 FAX: (413) 562-8437

www.mestek.com

Page 2

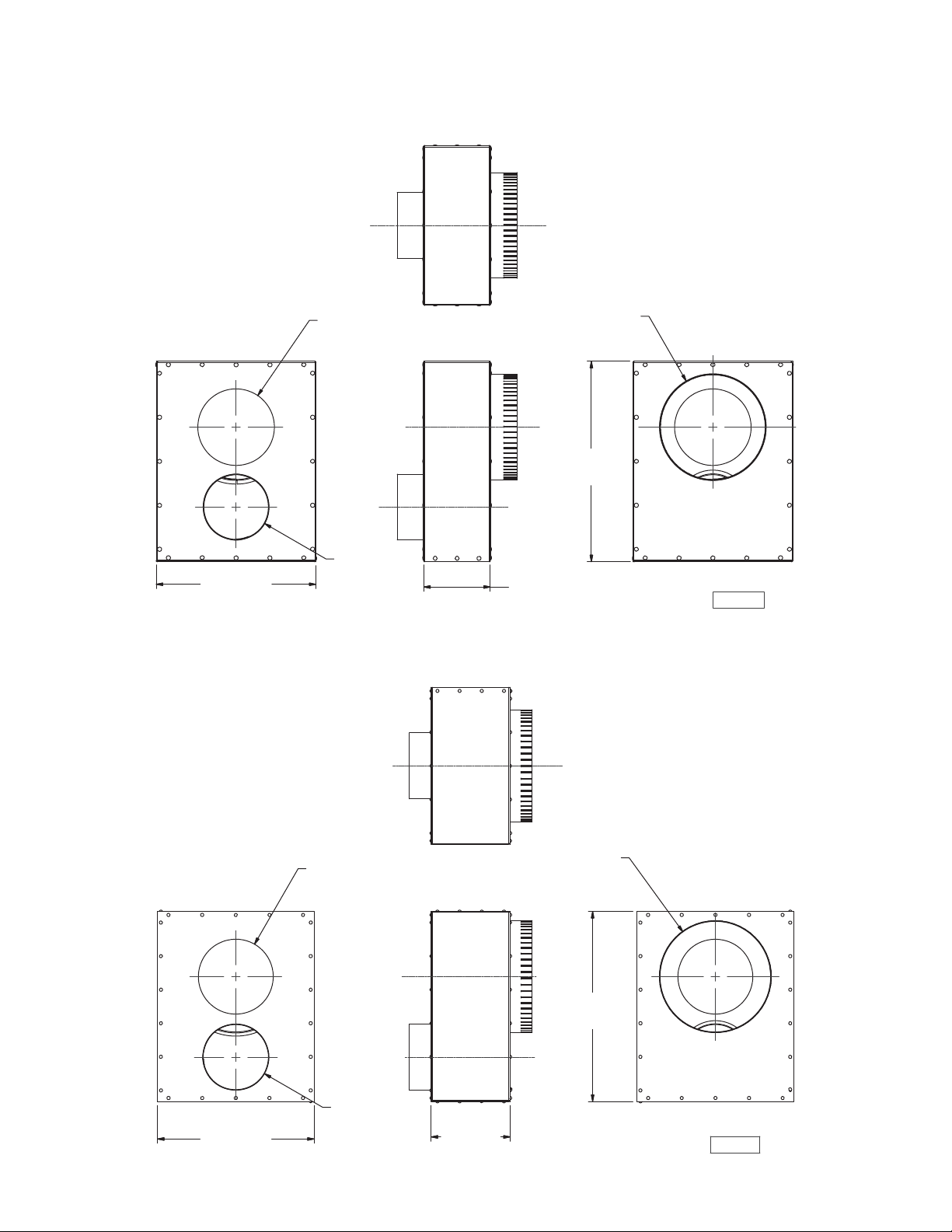

DIMENSIONAL DATA

Figure 2a – 5 Inch Combustion Air Inlet Box Assembly

5.75"

(146.1mm)

5"

12"

(304.8mm)

Figure 2b – 6 Inch Combustion Air Inlet Box Assembly

(127mm)

5"

(127mm)

8"

(203.2mm)

15"

(381mm)

D9015B

2

14.125"

(358.8mm)

6.75"

(171.45mm)

6"

(152.4mm)

7.125"

(181mm)

10"

(254mm)

17.125"

(435mm)

D9016B

Page 3

VENTING – GENERAL GUIDELINES

All unit heaters must be vented! All Venting installations shall be in accordance with the latest edition of Part 7,

Venting of Equipment of the National Fuel Gas Code, ANSI Z223.1 (NFPA 54), or applicable provisions of local

building codes. Refer to notes* below for Canadian installations.

CARBON MONOXIDE! Your venting system must not be blocked by any snow, snow drifts, or

any foreign matter. Inspect your venting system to ensure adequate ventilation exists at all times! Failure to

heed these warnings could result in Carbon Monoxide Poisoning (symptoms include grogginess, lethargy,

inappropriate tiredness, or fl u-like symptoms).

When an existing heater is removed or replaced in

venting system, the venting system may not be properly

sized to vent the attached appliances. An improperly

sized vent system can cause formulation of condensate

or leakage or spillage of fl ue gases.

The following steps shall be followed with each appliance

connected to the venting system placed in operation,

while any other appliances connected to the venting

system are not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and

horizontal pitch, as required in the National Fuel

Gas Code, ANSI Z223.1 (NFPA 54) and these

instructions. Determine that there is no blockage or

restriction, leakage, corrosion and other

defi ciencies, which could cause an unsafe

condition.

3. In so far as practical, close all building doors and

windows and all doors between the space in which

the appliance(s) connected to the venting system

are located and other spaces of the building. Turn

on clothes dryers and any exhaust fans, such as

range hoods and bathroom exhausts, so they

shall operate at maximum speed. Do not operate

a summer exhaust fan. Close fi replace damper.

4. Follow the lighting instructions. Place the appliance

being inspected in operation. Adjust thermostat so

that the appliance will operate continuously.

5. After it has been determined that each appliance

connected to the venting system properly vents

when tested as outline above, return doors,

windows, exhaust fans, fi replace dampers,

and any other gas-burning appliance to their

previous condition of use.

6. If improper venting is observed during any of the

above tests, the venting system must be corrected

immediately so that the system conforms with the

National Fuel Gas Code, ANSI Z223.1 (NFPA 54).

When resizing any portion of the venting system, the

venting system should be resized to approach the

minimum size as determined using the appropriate

tables in Appendix G of the National Fuel Gas Code,

ANSI Z223.1 (NFPA 54).

The unit heater shall be connected to a factory built

chimney or vent complying with a recognized standard,

or a masonry or concrete chimney lined with a lining

material acceptable to the authority having jurisdiction.

Venting into an unlined masonry chimney is

prohibited.

ADDITIONAL REQUIREMENTS FOR CANADIAN INSTALLATIONS

*The following instructions apply to Canadian installations in addition to installation and operating instructions.

1. Installation must conform with local building codes,

or in the absence of local codes, with current

CSA-B149.1, Installation Codes for Natural

Gas Burning Appliances and Equipment, or

CSA-B149.2, Installation Codes for Propane

Gas Burning Appliances and Equipment.

2. Any reference to U.S. standards or codes in these

instructions are to be ignored and the applicable

Canadian standards or codes applied.

3

Page 4

VENTING – GENERAL GUIDELINES (continued)

Do not damper or add heat recovery devices to the fl ue

piping. Failure to open such a damper prior to operating

the gas unit heater will result in the spillage of fl ue gas

into the occupied space.

Avoid installing units in areas under negative pressure.

When required, a fl ue vent fan should be installed in

accordance with the instructions included with the fan.

Vent connectors serving Category I and Category II

heaters shall not be connected into any portion of

mechanical draft systems operating under positive vent

pressure.

Maintain 1-inch (25.4mm) clearance between the vent

pipe and combustible materials.

Figure 3 – Side View Horizontal Vent

ANSI now organizes vented appliances into four

categories:

Venting Categories

Non

Condensing Condensing

Negative

Vent Pressure

Positive

Vent Pressure

III

III

IV

Category I

Includes non-condensing appliances with negative vent

pressure, like the traditional atmospheric unit heater.

Category II

Groups condensing appliances with negative vent

pressure.

Category III

Appliances are non-condensing and operate with a

positive vent pressure.

Category IV

Covers condensing appliances with positive vent

pressure.

NOTICE: Category II and IV do not apply to equipment

specifi ed within this manual.

Table 1

Vent SystemsTermination Clearance Requirements

Minimum Clearances for

Structure/Object

Termination Locations

USA CANADA

1 ft. (0.3m) for 100,000 BTUH

input or less. 3 ft. (0.9m) for

input exceeding 100,000

BTUH

Door, window or gravity vent inlet or

combustion air inlet for other appliances

4 ft. below

4 ft. horizontally

1 ft. above

Forced air inlet within 10 ft. 3 ft. above 6 ft. (1.8m)

Adjoining building or parapet 10 ft. 10 ft. (3.04m)

Adjacent public walkways 7 ft. above grade 7 ft. (2.1m) above grade

3 ft. (0.9m) horizontally from

meter/regulator assembly. 6

Electric, gas meters & regulators 4 ft. horizontal

ft. (1.8m), any direction, from

a gas service regulator vent

outlet

Above grade level* 1 ft. 1 ft. (0.3m)

4

* Minimum above maximum snow depth, or per local code, whichever is greatest.

Page 5

INSTALLATION

HORIZONTAL TERMINATION, 5 INCH KIT

FOR USE WITH 100-250 MBH UNITS ONLY

Select a location on outside wall for vent terminal.

In most applications, the terminal should be on level

with the fl ue outlet of the unit, less a 1/4 inch per foot

(21mm/m) pitch for condensate drainage toward the

outside of the building. See Table 1 and Figures 3 and 4.

Cut hole through wall for 8 inch (203mm) combustion

air pipe. Install thimble if required by local codes or

type of wall construction.

Combustion air inlet box may be fastened directly to

wall or spaced away from wall using suitable brackets

(fi eld supplied). Cut length of 8 inch UL 1738 listed pipe

so that it will protrude 4 inches (102mm) through the

wall when the box is mounted in position. Fasten pipe

to box with sheet metal screws, using at least 3 screws

per joint. Seal joint with high temperature silicone

sealant.

Never use pipe other than 5 inch

diameter. Never use PVC, ABS or any other nonmetallic pipe for venting! To do so may result in

serious damage to the unit and or severe personal

injury or death!

Insert pipe through wall and fasten adaptor box in place

so that the pipe pitches downward 1/4 inch per foot

(21mm/m) toward the outside. Flash and/or caulk

8 inch pipe on outside wall. Install inlet air screen

assembly and fasten to 8 inch pipe with screws. Insert

a continuous length of 5 inch UL 1738 listed vent pipe

through the 5-3/4 inch opening with the “UP” arrow

pointing toward the outside. Position the pipe to extend

a minimum of 12 inches (305mm) beyond the inlet air

screen. Seal the space between the UL 1738 listed

vent pipe and 5-3/4 inch opening of the combustion air

inlet box using high temperature silicone sealant. Install

defl ector disk on UL 1738 listed vent pipe 2-1/2 inches

(63.5mm) from inlet air screen and fasten with screws.

Install vent terminal on end of UL 1738 listed vent pipe,

fasten with screws and seal joint (see Figure 4).

Connect fl ue pipe and combustion air pipe from

combustion air inlet box to unit following Combustion

Air and Exhaust Venting instructions on pages 7 and

8. Joint between UL 1738 listed vent pipe and single

wall vent pipe must be sealed with high temperature

silicone sealant (see Figure 4).

Collars on unit and on combustion air inlet box are

sized so that crimped ends of combustion air pipes go

toward the unit and crimped ends of fl ue pipes go away

from the unit.

HORIZONTAL TERMINATION, 6 INCH KIT

FOR USE WITH 300-400 MBH UNITS ONLY

Select a location on outside wall for vent terminal. In

most applications, the terminal should be on level

with the fl ue outlet of the unit, less a 1/4 inch per foot

(21mm/m) pitch for condensate drainage toward the

outside of the building. See Table 1 and Figures 3 and 4.

Cut hole through wall for 10 inch (254mm) combustion

air pipe. Install thimble if required by local codes or type

of wall construction.

Combustion air inlet box may be fastened directly to

wall or spaced away from wall using suitable brackets

(fi eld supplied). Cut length of 10 inch UL 1738 listed

pipe so that it will protrude 4 inches (102mm) through

the wall when the box is mounted in position. Fasten

pipe to box with sheet metal screws, using at least 3

screws per joint. Seal joint with high temperature

silicone sealant.

Never use pipe other than 6 inch

diameter. Never use PVC, ABS or any other nonmetallic pipe for venting! To do so may result in

serious damage to the unit and or severe personal

injury or death!

Insert pipe through wall and fasten adaptor box in

place so that the pipe pitches downward 1/4 inch per foot

(21mm/m) toward the outside. Flash and/or caulk 10 inch

pipe on outside wall. Install inlet air screen assembly and

fasten to 10 inch pipe with screws. Insert a continuous

length of 6 inch UL 1738 listed vent pipe through the

6-3/4 inch opening with the “UP” arrow pointing toward

the outside. Position the pipe to extend a minimum of 12

inches (305mm) beyond the inlet air screen. Seal the

space between the UL 1738 listed vent pipe and 6-3/4

inch opening of the combustion air inlet box using h igh

temperature silicone sealant. Install defl ector disk on UL

1738 listed vent pipe 2-1/2 inches (63.5mm) from inlet

air screen and fasten with screws.

Install vent terminal on end of UL 1738 listed vent pipe,

fasten with screws and seal joint (see Figure 4).

Connect fl ue pipe and combustion air pipe from

combustion air inlet box to unit following Combustion

Air and Exhaust Venting instructions on pages 7 and 8.

Joint between UL 1738 listed vent pipe and single wall

vent pipe must be sealed with high temperature silicone

sealant (see Figure 4).

Collars on unit and on combustion air inlet box are

sized so that crimped ends of combustion air pipes go

toward the unit and crimped ends of fl ue pipes go away

from the unit.

5

Page 6

INSTALLATION (continued)

Figure 4 – Horizontal Combustion Air Inlet Kit Installation

Note: Separated Combustion Blower Type Unit Shown

4" min.

Inlet Air Screen

Wind Deflector Disk

Approved Breidert

Type L or

Fields StarKap

Vent Terminal

(101.6mm )

9-1/2" Min.

(241mm)

UL 1738 Listed Vent

(One Piece, Field Supplied)

Single Wall Air Inlet

6" min to 1st Joint

(152.4 mm)

Flue Pipe

Inlet Air Pipe

**Seal All Joints!

*Secure with a minimum of 3 corrosion resistant screws!

Condensate Drain

with Trap

(If Required by

local authorites)

1FT. *

(304.8mm)

1/4" Min. *

(21mm/m) Min. Slope

12" (305mm) Min.

Above Grade Plus

Max. Snow Depth

or Per Local Code,

Whichever is Greater.

2-1/2"

(63.5mm)

Wall

Combustion Air Inlet Box

D9017C

6

Page 7

INSTALLATION (continued)

COMBUSTION AIR VENTING

Never operate unit heaters without

combustion air and fl ue gas piping in place or severe

personal injury or death may occur!

CARBON MONOXIDE!

Your venting system must not be blocked by any

snow, snow drifts, or any foreign matter. Inspect

your venting system to ensure adequate ventilation

exists at all times! Failure to heed these warnings

could result in Carbon Monoxide Poisoning (symptoms include grogginess, lethargy, inappropriate

tiredness, or fl u-like symptoms).

1. The combustion air system installation must be in

accordance with the current edition of the National

Fuel Gas Code-NFPA 54 or ANSI Z223.1 National

Fuel Gas Code. In Canada, installation must be in

accordance with CSA-B149.1 “Installation Code for

Natural Gas Burning Appliances and Equipment”

and CSA-B149.2 “Installation Code for Propane

Burning Appliances and Equipment.”

2. The combustion air inlet box, inlet air screen,

defl ector disk, and vent terminal provided with the

unit heater must be installed at the termination

point of the combustion air/vent system. See

Figures 1a/1b, 2a/2b and 4.

3. Each unit heater MUST have its own combustion

air system. It MUST NOT be connected to other

air intake systems.

4. Use UL 1738 listed single wall pipe for the vent

system. For installations in Canada, use corrosion

resistant and gas-tight, listed vent pipe conforming

with local building codes, or in the absence of local

building codes, with current CSA-B149.1, Installation

Codes for Natural Gas Burning Appliances and

Equipment or CSA-B149.2, Installation Codes for

Propane Gas Burning Appliances and Equipment.

For residential installations in the United States, vent

pipe approved for Category III appliances must be

used between the appliance and the combustion air

inlet box.

Never use pipe other than 5 or 6 inch

diameter with respective Combustion Air Inlet Kits.

Never use PVC, ABS or any other nonmetallic pipe

for venting! To do so may result in serious damage

to the unit and or severe personal injury or death!

5. Long runs of single wall combustion air piping

passing through an unheated space may require

insulating if condensation becomes noticeable.

6. The combustion air system must be installed to

prevent collection of condensate. Pitch horizontal

pipes downward 1/4 inch per foot (21 mm/m)

toward the inlet cap to facilitate drainage.

7. The equivalent length of the combustion air system

must not be less than 5 feet (1.5m) and must not

exceed 50 feet (15.2m). Equivalent length equals

the total length of straight pipe plus 10 feet (3.05m)

for each 90° elbow and 4 feet (1.22m) for each

45° elbow.

NOTICE: For optimum performance keep the combustion air system as straight as possible.

8. Each joint must be secured with at least three

corrosion resistant screws. Two full turns of 3M #425

Aluminum Foil Tape or its equivalent must then be

used to seal each joint. General Electric RTV-108,

Dow-Corning RTV-732 or an equivalent silicone

sealant with a temperature rating of 500°F may

be used instead of the tape.

9. For horizontal combustion air systems longer than

5 feet (1.5m), the system must be supported from

overhead building structures at 4 foot (1.2m)

intervals in the U.S. and at 3 foot (0.91m) intervals

in Canada.

7

Page 8

INSTALLATION (continued)

EXHAUST VENTING

Never operate unit heaters without

combustion air and fl ue gas piping in place or severe

personal injury or death may occur!

1. Vent system installation must be in accordance

with the current National Fuel Gas Code-NFPA 54

or ANSI Z223.1 National Fuel Gas Code. In

Canada installation must be in accordance with

CSA-B149.1 “Installation Code for Natural Gas

Burning Appliances and Equipment” and

CSA-B149.2. “Installation Code for Propane

Burning Appliances and Equipment”.

2. A factory supplied Combustion Air Inlet Kit (which

includes a combustion air inlet box, air inlet screen,

defl ector disk, vent terminal and inlet air collar)

MUST be installed at the termination point of the

combustion air/vent system. See Figures 1a/1b,

2a/2b, and 4.

3. Each unit heater MUST have its own vent system.

It MUST NOT be connected to other vent systems

or to a chimney.

4. Use UL 1738 listed single wall pipe for the vent

system. For installations in Canada, use corrosion

resistant and gas-tight, listed vent pipe conforming

with local building codes, or in the absence of local

building codes, with current CSA-B149.1, Installation

Codes for Natural Gas Burning Appliances and

Equipment or CSA-B149.2, Installation Codes for

Propane Gas Burning Appliances and Equipment.

For residential installations in the United States,

vent pipe approved for Category III appliances

must be used between the appliance and the

combustion air inlet box.

5. Any run of single wall vent pipe passing through an

unheated space must be insulated with insulation

suitable to 550°F.

6. The vent system must be installed to prevent

collection of condensate. Pitch horizontal pipes

downward 1/4 inch per foot (21mm per meter)

toward the vent cap to facilitate drainage.

7. The equivalent length of the vent system must

not be less than 5 feet (1.5m) and must not

exceed 50 feet (15.2m). The equivalent length

equals the total length of straight pipe plus

10 feet (3.05m) for each 90° elbow and 4 feet

(1.22m) for each 45° elbow.

8. Each joint must be secured with at least three

corrosion resistant screws. Two full turns of 3M

#425 Aluminum Foil tape or its equivalent must

then be used to seal each joint. High temperature

silicone sealant may be used instead of the tape.

Silicone sealant must be used to seal the joint

between the double wall vent pipe and the single

wall pipe.

9. For horizontal vent systems longer than 5 feet

(1.5m), the system must be supported from

overhead building structures at 4 foot (1.2m)

intervals in the U.S. and at 3 foot (0.91m)

intervals in Canada.

10. The exhaust vent system must remain at a

minimum distance of 1 inch (25mm) from all

combustible materials. Any part of the vent

system that passes through a combustible

material must be properly insulated.

NOTICE: Increasing the clearance distances may be

necessary if there is a possibility of distortion or

discoloration of adjacent materials.

8

Loading...

Loading...