Page 1

Op er ating In struc tions

SDD 1 SGM

with S 150 con trol unit

176-1MS

Ster ling Ma te rial Pro cess ing

Page 2

Ster ling Ma te rial Pro cess ing

5200 West Clinton Ave.

Mil wau kee, WI 53223

Tele phone (414) 354-0970

Fax: (414) 354-6421

www.sterlco.com

Parts & Ser vice de part ment:

Tele phone: (800) 423-3183

Edi tion: 07/01

SDD 1 SGM

This op er a tion man ual is for*:

(* Please fill in personally)

Serial number:

Built in:

Date of delivery:

Number of delivery:

Date of commissioning:

Location:

176-1MS

Group of machines:

2

Page 3

SDD 1 SGM

Ster ling Ma te rial Pro cess ing re tains all rights to change the in for ma tion in these

op er at ing in struc tions at any time with out no tice.

We as sume no li a bil ity for any er rors or di rect or in di rect dam age re sult ing in con text with these op er at ing in struc tions.

Copying, trans la tion or pub li ca tion in any form ex cept for per sonal use of pur -

176-1MS

chaser re quires ap proval from Ster ling Ma te rial Pro cess ing.

All rights re served.

3

Page 4

SDD 1 SGM

Ta ble of con tents

1. Safety in struc tions ........................................................1-1

1.1. For your safety ...................................................1-2

1.2. For the op er at ing safety of the equip ment .............................1-4

2. Con cern ing these Op er ating In struc tions ....................................2-1

2.1. Warn ing Mes sages and Sym bols ....................................2-2

2.2. Ex pla na tions and Def i ni tions ........................................2-3

2.3. Notes on Us age ..................................................2-3

3. Putting into op er a tion......................................................3-1

3.1. Con trol Sys tem S 150 .............................................3-2

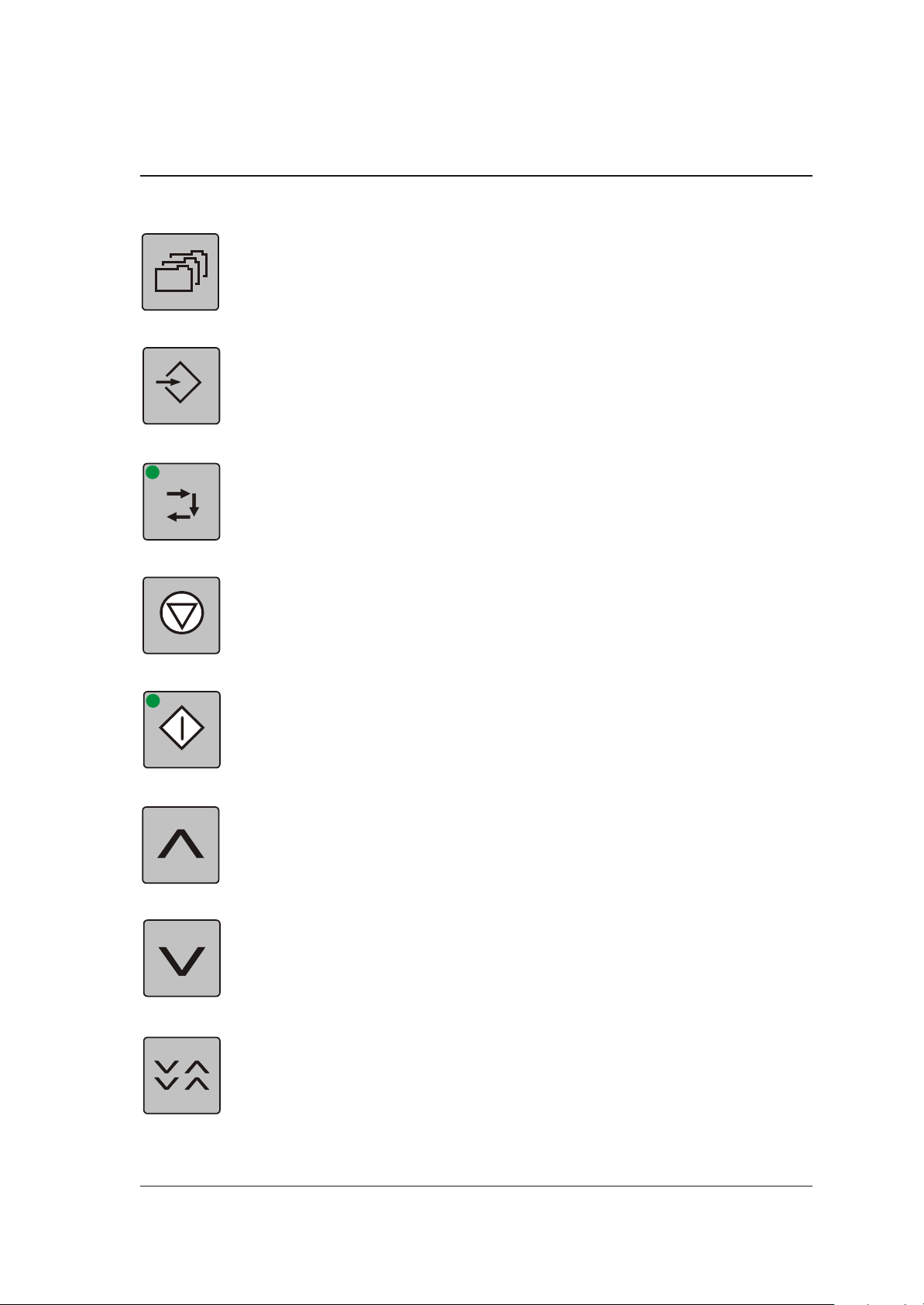

3.1.1. Key As sign ment .........................................3-3

3.1.2. Sym bols ...............................................3-4

3.2. Ini tial op er a tion pro ce dure ..........................................3-5

3.3. Ba sic Pa ram e ter Set ting ...........................................3-9

3.4. Cal i bra tion ......................................................3-12

3.4.1. Prep a ra tions ...........................................3-12

3.4.2. De ter mining the Cal i bra tion Weight ........................3-14

3.4.3. Pre paring the Feed Sta tion for Nor mal Op er a tion.............3-16

3.5. Mod ify/Cre ate Rec ipe.............................................3-17

3.5.1. Save Rec ipe ...........................................3-20

3.6. Starting mode ...................................................3-21

3.7. Starting the Con tin u ous Op er a tion ..................................3-21

3.8. Viewing the Ac tual Values .........................................3-22

3.9. Stopping the Con tin u ous Op er a tion .................................3-22

3.10. Call ing up the rec ipe ............................................3-23

3.11. Switching off the De vice .........................................3-23

3.12. Alarm Mes sages ................................................3-24

4. Main te nance ..............................................................4-1

4.1. Main te nance in ter vals .............................................4-3

4.2. Re moving/re plac ing scraper in the SDD dos ing sta tion ..................4-4

4.3. Cleaning the SDD dos ing sta tion ....................................4-6

4.4. Changing the dos ing disc in the SDD dos ing sta tion.....................4-8

4.4.1. In stalling Dif fer ent Types of Dosing Discs ...................4-10

4.5. Re moving/re plac ing the scraper in the SDT dos ing sta tion ..............4-11

176-1MS

4.6. Cleaning the SDT dos ing sta tion....................................4-13

4.7. Ex change able sta tions ............................................4-15

4.8. Ex changing Fuses ...............................................4-16

4

Page 5

SDD 1 SGM

5. As sem bly in struc tions .....................................................5-1

5.1. Trans port ........................................................5-2

5.2. SDD 1 SGM......................................................5-2

5.2.1. Mount ing on the pro cess ing ma chine........................5-3

5.3. Con trol sys tem S 150 ..............................................5-4

5.4. Elec tri cal Con nec tion ..............................................5-5

6. Func tional de scrip tion .....................................................6-1

6.1. SDD 1 SGM......................................................6-2

6.2. Con trol Unit S 150 ................................................6-2

7. Tech ni cal Data ............................................................7-1

7.1. SDD 1 SGMI .....................................................7-1

7.2. Con trol unit S 150.................................................7-2

7.3. Di men sion sheet ..................................................7-3

8. Spare parts list ...........................................................8-1

9. Ac ces sories ..............................................................9-1

o Drilling jig

o Values re quired for the ba sic pa ram e ter

o Level probe KCB-M32GP/015

o _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

o _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

10. Elec tri cal man ual........................................................10-1

176-1MS

5

Page 6

1. Safety in struc tions

These safety in struc tions ap ply to all per sons within the range of ac tion of the

»

equip ment.

Please in form all per sons within the range of ac tion of the equip ment of the

di rect and in di rect haz ards con nected with the equip ment.

These op er at ing in struc tions are to be used by all per sons as signed ac tiv i ties con nected with the equip ment.

Knowl edge of the Eng lish lan guage is pre req ui site.

En sure in each case that the op er at ing per son nel are fa mil iar with the op er at ing in struc tions and the func tion of the equip ment.

SDD 1 SGM

176-1MS

Safety in struc tions 1-1

Page 7

SDD 1 SGM

1.1. For your safety

Gen eral

The op er at ing per son nel of this equip ment must be at least 16 years old.

Please read these op er at ing in struc tions care fully be fore tak ing into op er a tion for the first time.

Con tact us should ques tions arise. This avoids in jury and dam age to equip ment!

These op er at ing in struc tions must be kept avail able at all times at the place of op er a tion of the

equip ment. Im proper op er a tion re sults in dan ger of ac ci dents!

Please note that, for rea sons of clar ity, not all con ceiv able cases re gard ing op er a tion or main te nance of the equip ment can be cov ered in these op er at ing in struc tions.

Please ob serve all safety in struc tions and warn ings on the equip ment. This avoids in jury and

dam age to equip ment!

All work on the equip ment is to be car ried out by per sons whose qual i fi ca tions are spec i fied in the

per tain ing chap ters of the op er at ing in struc tions. Im proper op er a tion re sults in dan ger of ac ci dents!

The proper work ing clothes are to be worn dur ing any work on the equip ment.

This avoids in jury!

The lo cal reg u la tions and re quire ments per tain ing to this equip ment must be ob served.

Dis con nect elec tri cal com po nents from the mains sup ply be fore work is car ried out on these com po nents. Cau tion: Dan ger to life through elec tri cal shock!

Com pile de tailed op er at ing in struc tions based on these Op er ating in struc tions for the se quence

of pro ce dures to be car ried out on this equip ment. Im proper op er a tion re sults in dan ger of ac ci dents!

As sem bly

Com pare the con nected loads with those of the mains sup ply. Dan ger of in jury through elec tri cal

shock!

When us ing lift ing gear, please ob serve the per tain ing reg u la tions. Cau tion: Dan ger of ac ci dents!

Do not mod ify, add other equip ment or change the de sign of the equip ment with out the ap proval

of the man u fac turer. Cau tion: Dan ger of ac ci dents!

At tach ments not sup plied by Ster ling must be man u fac tured in ac cor dance with safety in struc tion

EN 294. Cau tion: Dan ger of ac ci dents!

The equip ment may only be op er ated when all the as so ci ated com po nents are prop erly con nected up and in ac cor dance with the rel e vant reg u la tions. This avoids in jury and dam age to

equip ment!

Op er ate the de vice only if all its com po nents are grounded. Dan ger: ac ci dent through elec tri cal

shock!

176-1MS

Please note for in stal la tion that the equip ment is top-heavy. Dan ger ex ists that it may top ple over!

Safety in struc tions 1-2

Page 8

SDD 1 SGM

Op er a tion

Ap point an equip ment fore man to be re spon si ble for the equip ment.

En sure that the op er at ing per son nel are pro vided de tailed in struc tion in the op er a tion of the

equip ment. Im proper op er a tion re sults in dan ger of ac ci dents!

When the main switch is switched off for rea sons per tain ing to safety, it must be se cured against

un au tho rized ac ti va tion. Cau tion: Dan ger of ac ci dents!

Re pair work may be car ried out by trained per son nel only. Cau tion: Dan ger of ac ci dents!

Never op er ate the equip ment when par tially dis man tled. Cau tion! Dan ger ex ists that limbs may

be caught; dan ger of elec tri cal shock!

In case of mal func tion, shut down the equip ment im me di ately. Have mal func tions cor rected im me di ately. Cau tion: Dan ger of ac ci dents!

The equip ment is in tended only for dos ing gran u lated plas tics and ad di tives. Other use of the

equip ment is con trary to its spec i fi ca tions.

This equip ment is not suit able for foods pro cess ing.

Ob serve the safety in struc tions for con nected equip ment.

The de vice may only be started up if all feed sta tions and blind lids have been mounted or if there

is a weigh ing con tainer in the in ter me di ate piece for pro por tion ing. Dan ger: Limbs may be caught

in ma chin ery!

Main te nance

Be fore start ing main te nance work, ap point a su per vi sor.

In form the re spon si ble per son nel be fore main te nance work on the sys tem is started. Cau tion:

Dan ger of ac ci dents!

Dis con nect the equip ment from mains sup ply be fore start ing main te nance pro ce dures to en sure

that it can not be switched on un in ten tion ally. Cau tion: Dan ger of ac ci dents!

Check all lines, hoses and screwed conections reg u larly for leaks and ob vi ous dam age. Re pair

dam age im me di ately. Cau tion: Dan ger of ac ci dents!

Never reach into a dos ing sta tion or an in ter me di ate piece for dos ing while the con trol sys tem is

still con nected to the power sup ply. Dan ger of squeez ing!

When han dling the scraper be care ful, the scraper is sharp. Dan ger of in jury ex ists!

Wait at least one min ute be fore start ing to work at the switch ing cab i net. Dan ger to life! Dis charge

of high-voltage pos si ble!

176-1MS

Safety in struc tions 1-3

Page 9

SDD 1 SGM

1.2. For the op er at ing safety of the equip ment

Never change set tings if the con se quences are not pre cisely known.

Use only orig i nal Ster ling spare parts.

Please ob serve the main te nance in ter vals.

Keep re cord of all main te nance and re pair pro ce dures.

Ob serve pre cau tions for han dling elec tro static sen si tive de vices.

Check all elec tri cal con nec tions for proper fit be fore the equip ment is taken into op er a tion for the

first time and at reg u lar in ter vals.

The con trol sys tem may be op er ated only at tem per a tures from 0 to 50 °C (32 to 120 °F).

The con trol sys tem may only be stored at tem per a tures from -20 to +70 °C (-4 to +160 °F).

Note down all set ting data en tered in the con trol sys tem.

Check the ro ta tional di rec tion of the dos ing mo tor be fore tak ing into op er a tion (see ro ta tional di rec tion ar row).

En sure that all plugs are prop erly con nected.

Never con nect con vey ing equip ment with the dos ing sta tions with out the cor re spond ing sup ports.

En sure that the ma chine flange has suf fi cient car ry ing ca pac ity.

Please note that the dos ing mo tor may reach tem per a tures of up to 70 °C (160°F) dur ing con tin u ous op er a tion.

Please ob serve the op er at ing in struc tions of the con nected equip ment.

All com po nents must be suf fi ciently grounded.

In case the tem per a ture within the hous ing of the con trol sys tem ex ceeds 85°C (185°F), the con trol sys tem will be au to mat i cally switched off.

176-1MS

Safety in struc tions 1-4

Page 10

2. Con cer ning the se Ope ra ting In struc tions

The se ope ra ting in struc tions are ad dres sed to all users of the de vi ce.

»

The se ope ra ting in struc tions must be used by every per son char ged with

work on the unit.

SDD 1 SGM

176-1MS

Con cer ning the se Ope ra ting In struc tions 2-1

Page 11

SDD 1 SGM

2.1. War ning Mes sa ges and Sym bols

The fol lo wing war ning mes sa ges and sym bols are used in the se ope ra ting in struc tions:

This sym bol in di cates dan ger to life! Fa tal or se ri ous in jury is pos si ble if the

»

cor re spond ing in struc tions, reg u la tions or warn ings are not ob served.

L

F

&

$

This sym bol in di cates that se ri ous in jury is pos si ble if the cor re spond ing

in struc tions, reg u la tions or warn ings are not ob served.

This sym bol in di cates that ex ten sive dam age to equip ment is pos si ble if

the cor re spond ing in struc tions, reg u la tions or warn ings are not ob served.

This sym bol in di cates in for ma tion im por tant for be com ing fa mil iar with

the equip ment, i.e. tech ni cal cor re la tions.

This sym bol in di cates that a tech ni cal term is ex plained at this point.

176-1MS

Con cer ning the se Ope ra ting In struc tions 2-2

Page 12

SDD 1 SGM

2.2. Ex pla na tions and De fi ni tions

In this ope ra ting ma nu al, cer tain terms are used re pea ted ly for bet ter cla ri ty. The re fo re plea se

keep in mind that the se terms stand for the ex pla na tions gi ven here.

Unit

·

“Unit” may de sig na te eit her a sing le de vi ce, a ma chi ne or a plant.

User

·

The user is the per son who uses the unit on his or her own re spon si bi li ty or on the re spon si bi li ty of

so meo ne else.

Ope ra tor

·

The ope ra tor of a unit (pro duc ti on ma na ger, fo re man etc.) is the per son re spon si ble for the sum of

the pro ces ses. The ope ra tor in structs the users to do so me thing.

Ope ra ting ma nu al

·

The ope ra ting ma nu al des cri bes the cor re la tions bet ween se ve ral units, pro ces ses or ma nu fac tu ring pro ce du res. The ope ra ting ma nu al must be pre pa red by the ope ra tor of the units.

Co-ordinator

·

If se ve ral users work on one unit, the “co-ordinator” co-ordinates the pro ces ses. The co-ordinator

must be de sig na ted by the ope ra tor.

Trai ned per son nel

·

Trai ned per son nel are peo ple who are qua li fied by their trai ning to car ry out the re spec ti ve work in

a pro fes sio nal man ner.

2.3. No tes on Usa ge

Ex pe rien ced ope ra tors of do sing sys tems can be gin di rect ly with the chap ter on “Put ting into Ope -

·

ra ti on” if the unit has been pro per ly in stal led.

If the unit has not been in stal led yet, ob ser ve the in struc tions in the chap ter on “Assembly In struc -

·

tions”.

176-1MS

Con cer ning the se Ope ra ting In struc tions 2-3

Page 13

3. Put ting into op er a tion

This chap ter is in ten ded for ope ra ting per son nel.

»

Pre re qui si te for this chap ter is ge ne ral knowled ge of the ope ra ti on of do sing

and blen ding units on in jec ti on moul ding ma chi nes.

Also pre re qui si te for this chap ter is that the functio nal des crip ti on has been

read and un ders tood.

En su re in each case that the ope ra ting per son nel are suf fi cient ly in form ed.

S 150

&

LED = light emit ting di ode

“bzw.” = “or”

176-1MS

Put ting into op er a tion 3-1

Page 14

S 150

lb

min

g

kg

%

s

Input

Run

Stop

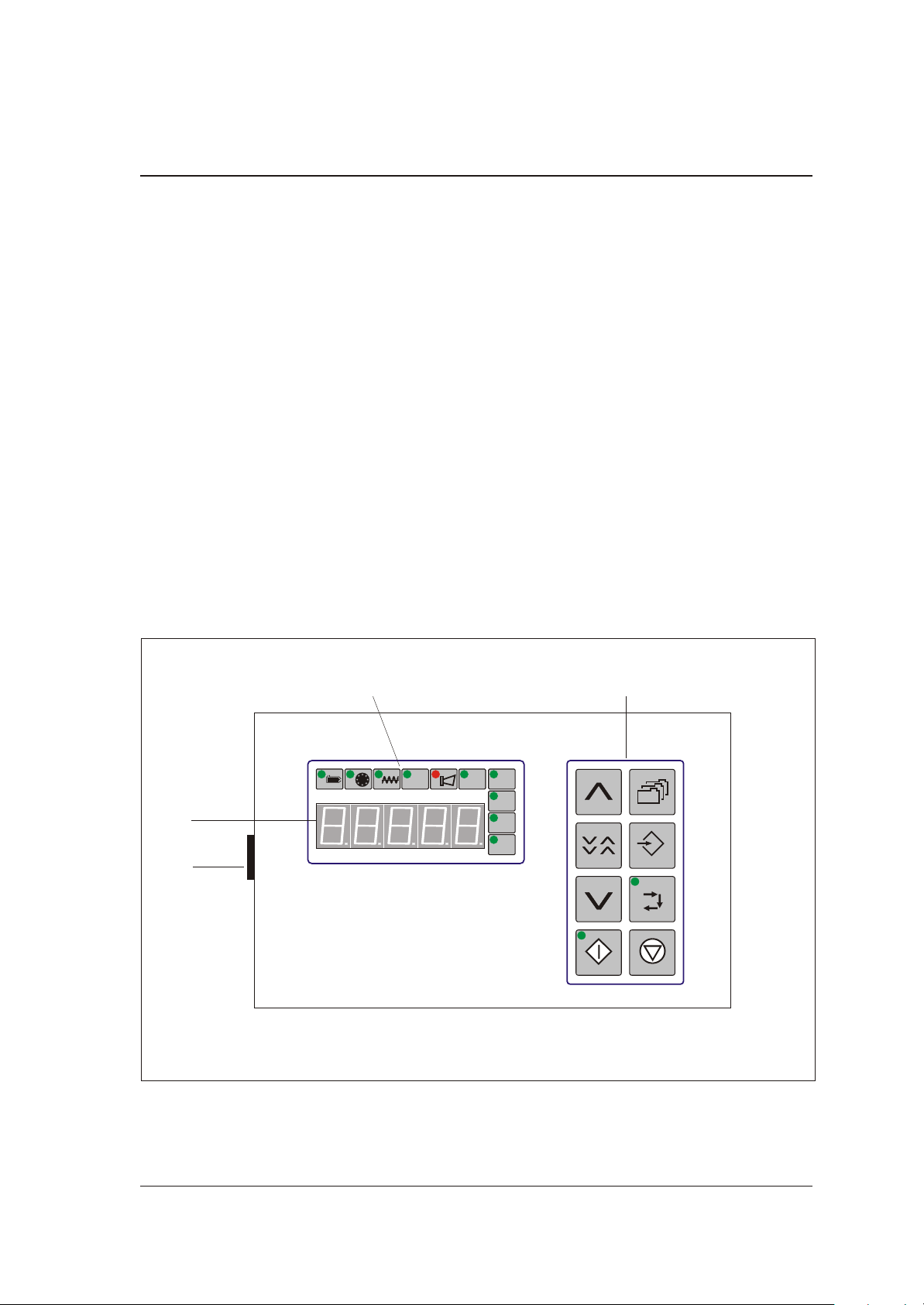

3.1. Con trol Sys tem S 150

The Con trol sys tem is swit ched on by me ans of the On/Off switch (switch set in po si ti on “1"). The

con trol sys tem is ope ra ted via the key board (B). The in di vi du al ope ra ting mo des are in di ca ted by

sym bols (C). Mes sa ges ap pe ar on a 4-digit dis play (D). Up to ten re ci pes can be sa ved and read

on re quest. re ci pes can be as sig ned re spec ti ve num bers.

C B

D

A

176-1MS

S 150

Put ting into op er a tion 3-2

Page 15

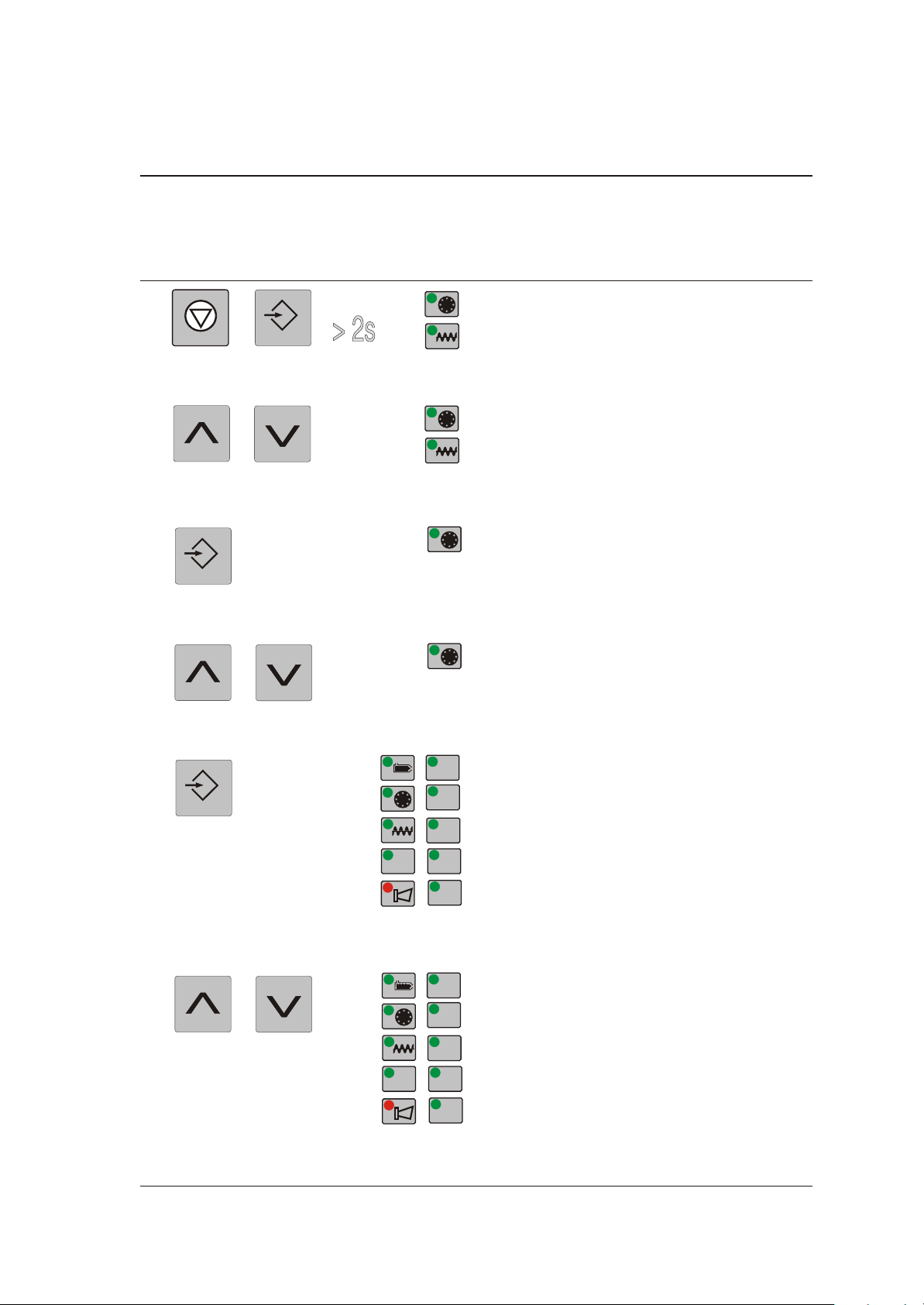

3.1.1. Key As signment

Input

Run

Stop

“re ci pe”

For sa ving, cal ling up or mo di fy ing re ci pes

“in put”

For the in put of pro gram pa ram e ters

“cal i bra tion”

Switches to the cal i bra tion mode, the LED flashes in case the cal i bra tion pro cess

was started by press ing the “run” key.

Starts the start ing mode if the key is de pressed for more than 2 sec onds.

S 150

“stop”

Stops the con ti nu ous ope ra ti on or the weig hing pro ce du re; will set the me te red

amount of ad di ti ve to zero if the key is de pres sed for more than 2 se conds.

“run”

Starts the con ti nu ous ope ra ti on (the LED is lit up) or the ca li brat ion mode (the LED

flas hes).

ar row key

for in crea sing the set va lue

ar row key

for de crea sing the set va lue

ar row key

for quick in- or de crea sing of the set va lue (the key must be pres sed si mul ta ne ous -

176-1MS

ly with the key for in- or de crea sing the set va lue).

Put ting into op er a tion 3-3

Page 16

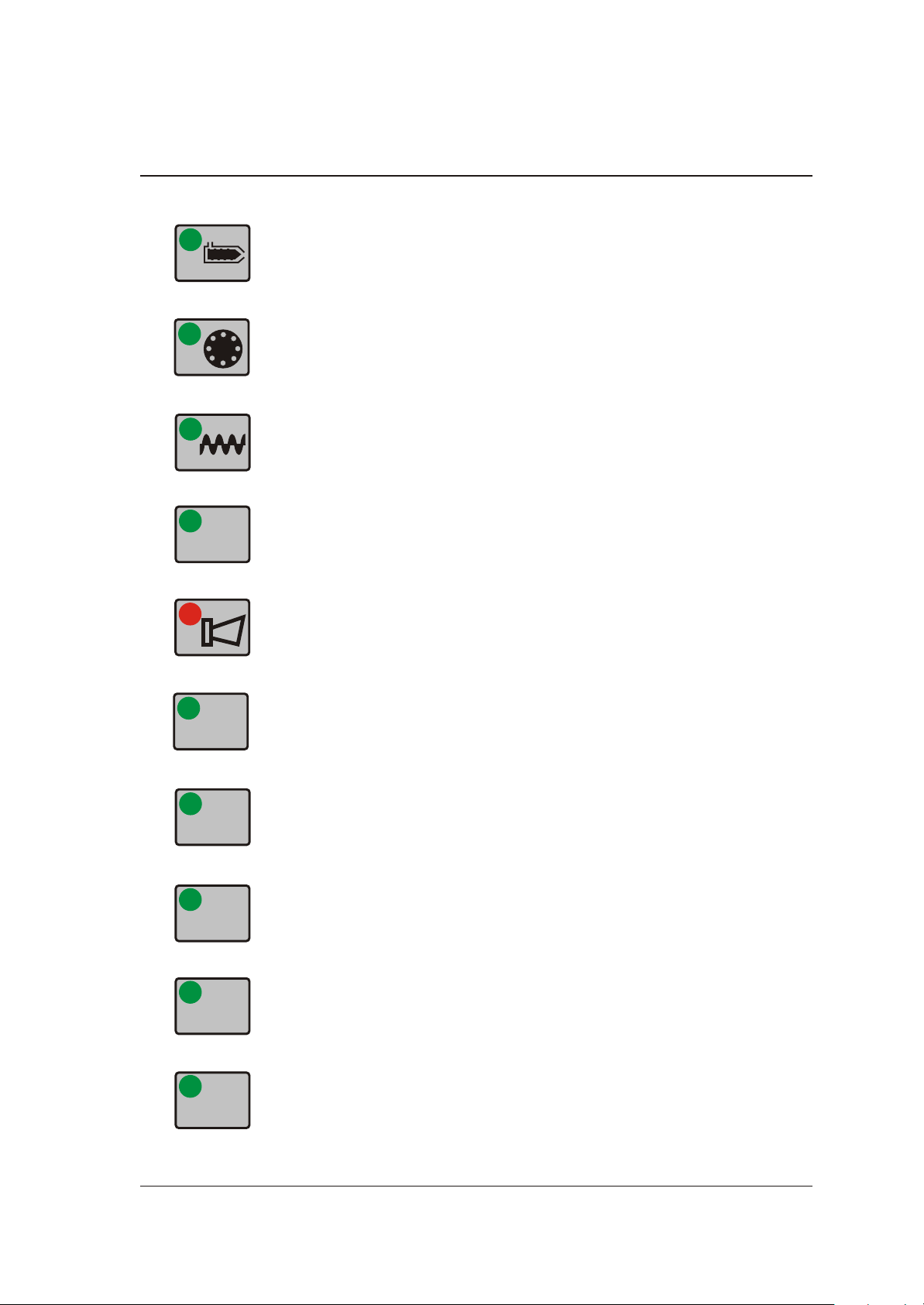

3.1.2. Sym bols

lb

min

g

kg

%

s

S 150

“Screw re tract time”

“Do sing disc”

“Screw speed”

“Per cent”

“Alarm”

176-1MS

“Se conds”

“Mi nu tes”

“Grams”

“Ki lo grams”

“Pound”

Put ting into op er a tion 3-4

Page 17

S 150

3.2. In iti al ope ra ti on pro ce du re

The con trol sys tem is fac to ry-programmed. Ne ver the less, spe ci fic va lu es have to be pre de fi ned

or to be che cked (ba sic pa ra me ter set ting).

The in put va lu es will be sa ved and will still be avai la ble af ter ha ving swit ched off the sys tem or a

po wer fai lu re.

The fol lo wing va lu es are re qui red (in the ap pen dix, the re is a copy of the list whe re the va lu es can be en te red):

Pul ses of the en co der: ..........................................................

&

Nom i nal cur rent of the mo tor for the dos ing mo tor (see name plate): ....................

&

Con fig u ra tion value (see De ter mining the Con fig u ra tion Value): ........................

Only in case of moun ting on a Mico mi xing-hopper:

Ma te rial con tents of the mix ing-hopper (g): .........................................

BI SON mo tor (= black mo tor)

14103 for mo tors with 12 rpm

4387 for mo tors with 38 rpm

Bauer mo tor (= blue mo tor)

11739 for mo tors with 6.5 rpm

2135 for mo tors with 35.5 rpm

2100 for SDD S

If the va lue has been ex cee ded, an alarm mes sa ge will be sent.

&

176-1MS

Vol ume mix ing-hopper MN*: 5.25 l

Vol ume mix ing-hopper MV*: 13.25 l

*mea sured up to the up per edge of the free ma te rial in let (swan-neck in let)

Put ting into op er a tion 3-5

Page 18

S 150

Only in case of ex ter nal de si red va lue spe ci fi ca ti on:

Min. in put fre quen cy (see Fre quen cy Out put of the Ex tru der):..........................

or if a vol ta ge sig nal is avai la ble (0 - 10 V):

Frequency [Hz] =

or if a cur rent sig nal is avai la ble (0 - 20 mA):

Frequency [Hz] =

Span fac tor: ..................................................................

Sp an factor [Hz/rpm] =

Only in case of con nec ti on to a HOST:

Com mu ni ca ti on ad dress: ........................................................

Inp ut voltage [V] x 10000 [Hz]

10 [V]

Inp ut current [mA] x 10000 [Hz]

20 [mA]

Frequency [Hz]

D

Rotation

D al speed of the extruder [rpm] x 10

If there is no ex ter nal de sired value spec i fi ca tion and/or con nec tion to a

host, use the val ues for the stan dard reg u la tion.

F

176-1MS

Put ting into op er a tion 3-6

Page 19

S 150

De ter mi ning the Configura tion Va lue

Mark the functions re quired. Move the nu me ri cal value to the emp ty field. Add the val ues at the

bot tom for use in ba sic pa ram e ter setting.

&

Af ter Ster ling con sul ta tion ad di tional con fig u ra tions will be pos si ble for

spe cial ap pli ca tions.

o raw ma te ri al pro be ................................................. 1 ... ___

o ad di ti ve pro be ..................................................... 2 ... ___

o blen ding unit.......................................................8....___

o throughput in lb ...................................................16 ... ___

o through put g/shot (1-6500 g) (0.001-6.5 kg) .............................0 ... ___

or

o through put g/shot (1-6500 g) (0.001-6.5 kg) x fac tor 10 ..................32 ... ___

or

o through put g/shot (1-6500 g) (0.001-6.5 kg) x: fac tor 10 .................128 ... ___

o ex ter nal re lea se starts do sing........................................64 ... ___

o moun ting on a Mico mix ing-hopper ..................................256 ....___

o alarm out put is also swit ched in case of po wer fai lu re .................. 512 ....___

o prin ter avai la ble ................................................16348 ....___

Con fig u ra tion value: ................................................. .._____

176-1MS

Put ting into op er a tion 3-7

Page 20

S 150

Ex am ple:

le vel pro bes: raw ma te ri al pro be

ad di ti ve pro be

throughput: 10 through 65 kg/shot

throughput: dis play ed in lb (kg)

n raw ma te ri al pro be ................................................. 1 ... __1

n ad di ti ve pro be ..................................................... 2 ... __2

o blen ding unit.......................................................8....___

n throughput in lb (kg) ...............................................16 ... _16

o through put g/shot (1-6500 g) (0.001-6.5 kg) .............................0 ... ___

or

n through put g/shot (1-6500 g) (0.001-6.5 kg) x fac tor 10...................32 ... _32

or

o through put g/shot (1-6500 g) (0.001-6.5 kg) : fac tor 10 ..................128 ... ___

o ex ter nal re lea se starts do sing........................................64 ... ___

o mount ing on a Mico mix ing-hopper ..................................256 ....___

o alarm out put is also swit ched in case of po wer fai lu re .................. 512 ....___

o printer avail able ................................................16348 ....___

Con fig u ra tion value: ................................................. ..___51

176-1MS

Put ting into op er a tion 3-8

Page 21

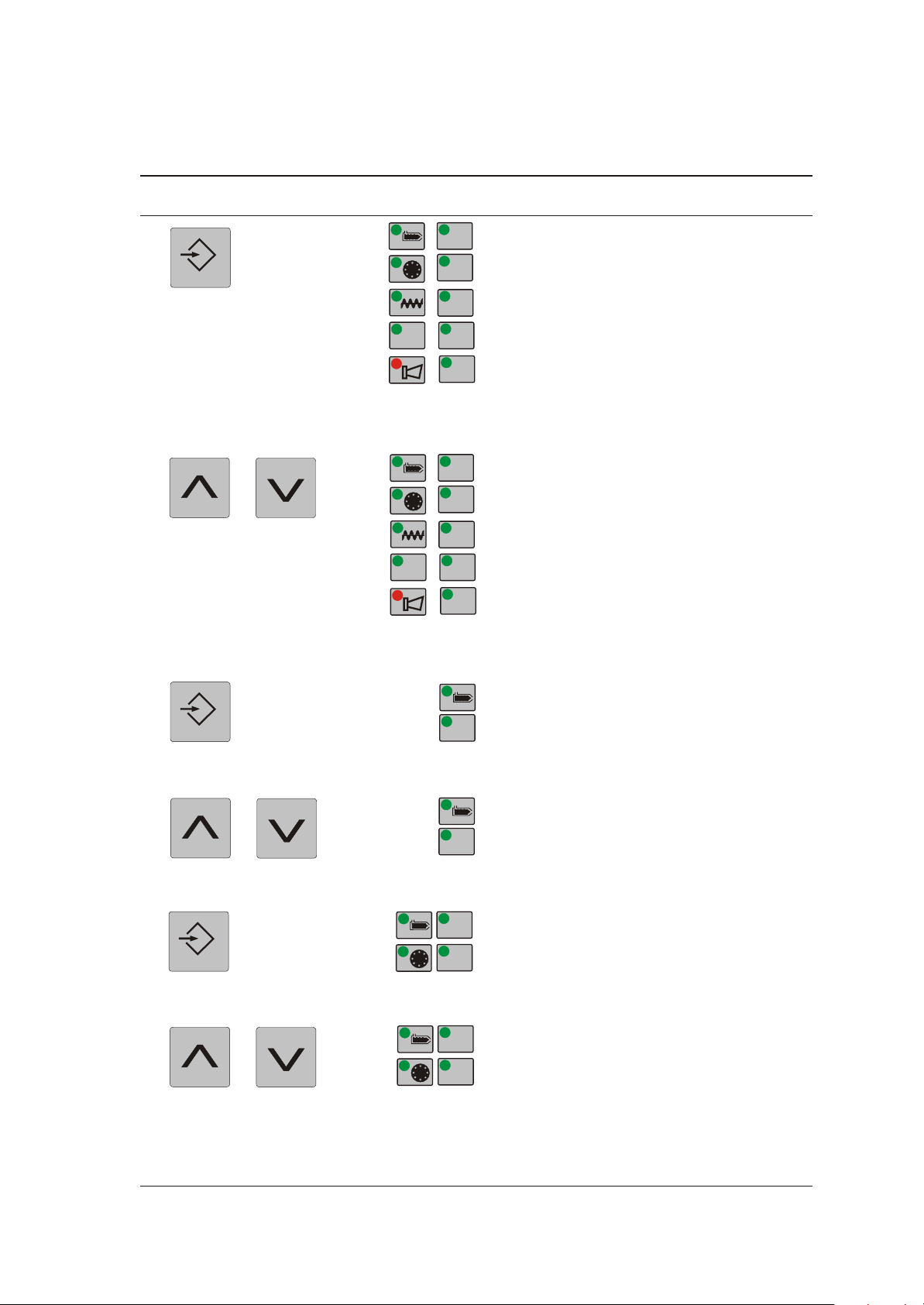

3.3. Ba sic Pa ra me ter Set ting

Input

Stop

Input

Input

lb

g

kg

%

s

min

lb

g

kg

%

s

min

Press key LED dis play dis play

“7"

pulses of the en coder reg u la tion:

14103 (12 rpm), 4387 (38 rpm),-black

motor

11739 (6.5 rpm), 2135 (35.5 rpm)-blue

motor

or 2100 (SDD S) re spec tively

en ter the im pulses of the en coder

S 150

“8"

nom i nal cur rent of the mo tor

Bauer mo tor: 0.7 A - blue motor

Bi son mo tor: 0.5 A - black motor

SDD S: 0.5 A

en ter the nom i nal cur rent of the mo tor

“9"

con fig u ra tion value

see list “De ter mining the Con fig u ra tion

Value”

176-1MS

en ter con fig u ra tion value

Put ting into op er a tion 3-9

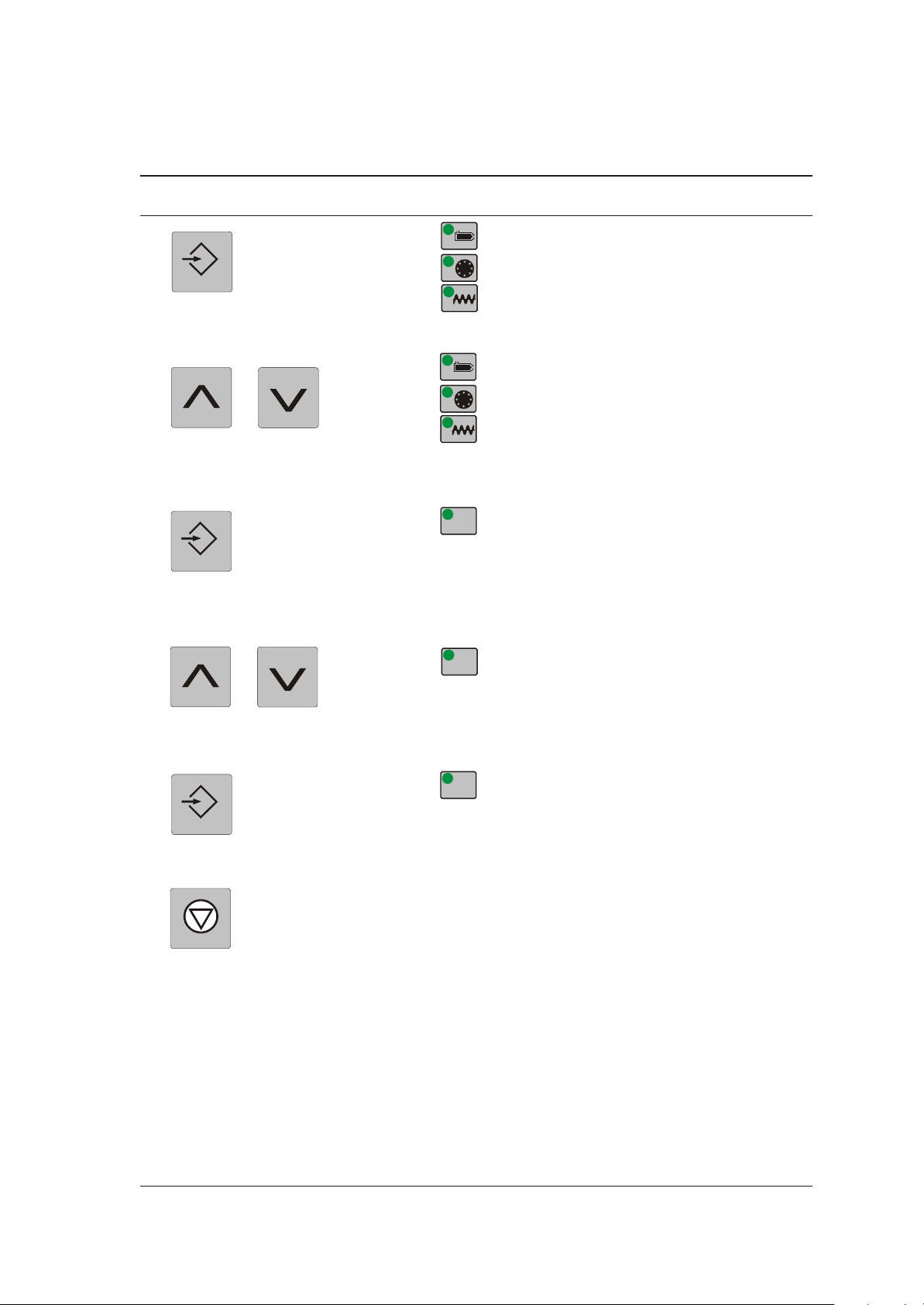

Page 22

Press key LED dis play dis play

Input

lb

g

kg

%

s

min

lb

g

kg

%

s

min

Input

s

s

s

min

Input

s

min

“10"

con fig u ra tion value: 1, if Bauer mo tor pres ent

S 150

en ter con fig u ra tion value

“11”

min i mum in put fre quency or num ber of ma chine cy cles per dosing

stan dard reg u la tion: 50 Hz

Only in jec tion mold ing op er a tion af ter con tact with Ster ling Ser vice

en ter in put fre quency / num ber of ma chine

cy cles

176-1MS

“12"

span fac tor

stan dard re gu la ti on: 5.56 rpm/Hz

en ter span fac tor

Put ting into op er a tion 3-10

Page 23

Input

Input

Stop

Input

kg

g

g

S 150

Press key LED dis play dis play

“13"

com mu ni ca tion ad dress

stan dard re gu la ti on: 1

Only if Eu ro map17-report is in use

en ter com mu ni ca ti on ad dress

“14”

material con tents of the mix ing hop per,

stan dard reg u la tion: 5000 g (5 kg)

Only in case of mount ing on a Mico mix ing-hopper

176-1MS

en ter ma te rial con tents

pulses of the en coder reg u la tion

or

quit the menu at any time whi le ta king on

the en te red va lu es

Put ting into op er a tion 3-11

Page 24

3.4. Ca li brat ion

The ca li brat ion pro ce du re has to be re-determined for each ma te ri al to be

me te red sin ce the ca li brat ion weight dif fers from ma te ri al to ma te ri al.

F

S 150

$

The fol lo wing is re qui red:

a sca le which per mits weig hing to at least the nea rest 0.01 g (0.00001 kg)

·

the weig hing con tai ner which is part of the de li very

·

Fill the feed sta ti on with suf fi cient ma te ri al.

3.4.1. Pre pa ra tions

Ca li brat ion weight

me te red ma te ri al weight for one re vo lu ti on of the do sing disc

The de vice may only be started up if all com po nents have been prop erly

in stalled. Dan ger: Limbs may be caught in ma chin ery!

Feed Sta tion with In ter me di ate Piece for Pro por tioning

Re move the blind lid at the in ter me di ate piece for pro por tion ing.

Slide the weigh ing con tainer in the in ter me di ate piece for pro por tion ing.

176-1MS

Put ting into op er a tion 3-12

Page 25

S 150

Stan dard Feed Sta ti on

Open the sa fe ty screws at the tog gle-type fas te ner.

Open the two tog gle-type fas te ner at the do sing mo tor.

Lift the feed sta ti on from the do sing mo tor and turn the feed sta ti on (180°) so that the out put points

away from the mi xing hop per.

Put the feed sta ti on back on the do sing mo tor.

Pla ce the weig hing con tai ner un der the out let ope ning/out let flan ge of the feed sta ti on.

Clo se the tog gle-type fa ste ners.

F

SDD 1 SGM S feed sta tion

Turn the feed sta tion approx. 45° clock wise.

Lift the feed sta tion from the dos ing mo tor and turn the feed sta tion so that the out put of the dos ing

disc points away from the div ing hose in the hop per piece.

Put the feed sta tion back on the dos ing mo tor (pay at ten tion to the guide pins).

Press the feed sta tion on the dos ing mo tor and turn the feed sta tion approx. 45° coun ter-clockwise.

Mount the sa fe ty screws.

The de vice may only be started up if all com po nents have been prop erly

in stalled. Dan ger: Limbs may be caught in ma chin ery!

176-1MS

Put ting into op er a tion 3-13

Page 26

3.4.2. De ter mi ning the Ca li brat ion Weight

Be fo re the ac tu al weig hing, a fil ling pro cess ta kes pla ce which is no ta ken

into ac count.

F

It is re com men ded to car ry out at least five weig hing pro ce du res.

Weigh the emp ty weig hing con tai ner and note the weight (= tare weight).

“Pro por tio ning”

Re mo ve the weig hing con tai ner.

Weigh the weig hing con tai ner.

Sub tract the tare weight of the weig hing con tai ner from the de ter min ed va lue.

S 150

Sli de the weig hing con tai ner back in the in ter me di ate pie ce for pro por tio ning

or

pla ce the weig hing con tai ner un der the out let ope ning/out let flan ge of the feed sta ti on.

176-1MS

Put ting into op er a tion 3-14

Page 27

Press key LED dis play dis play

Run

Run

g

g

g

g

Run

Run

Stop

g

— — — —

fil ling pro ce du re

S 150

If cal i bra tion weight “0" in the rec ipe:

The dos ing mo tor turns for one rev o lu tion

at half of the max i mum ro ta tional speed.

“pro por tio ning” and en try of the weight

start pro por tio ning pro ce du re:

The do sing mo tor turns for one re vo lu ti on

at the cal cu la ted speed.

“pro por tio ning” and en try of the weight.

re pe at pro por tio ning, ma xi mum of five pro por tio ning pro ce du res.

176-1MS

or

ter mi nate pro por tion ing while not tak ing

on the cal i bra tion weight

or

ter mi nate pro por tion ing while tak ing on

the cal i bra tion weight

Put ting into op er a tion 3-15

Page 28

S 150

3.4.3. Pre pa ring the Feed Sta ti on for Nor mal Ope ra ti on

The de vice may only be started up if all com po nents have been prop erly

in stalled. Dan ger: Limbs may be caught in ma chin ery!

Stan dard Feed Sta ti on

Open the sa fe ty screws at the tog gle-type fas te ner.

Open the two tog gle-type fas te ner at the do sing mo tor.

Lift the feed sta ti on from the do sing mo tor and turn the feed sta ti on (180°) so that the out put points

away from the mi xing hop per.

Put the feed sta ti on back on the do sing mo tor.

Clo se the tog gle-type fa ste ners.

F

Feed Sta ti on with In ter me di ate Pie ce for Pro por tio ning

Re mo ve the weig hing con tai ner.

Mount the blind lid at the in ter me di ate pie ce for pro por tio ning.

Co lor blend S feed sta ti on

Turn the feed sta tion approx. 45° clock wise.

Lift the feed sta tion from the dos ing mo tor and turn the feed sta tion so that the out put of the dos ing

disc is lo cated over the div ing hose in the hop per piece.

Put the feed sta tion back on the dos ing mo tor (pay at ten tion to the guide pins).

Mount the sa fe ty screws.

The de vice may only be started up if all com po nents have been prop erly

in stalled. Dan ger: Limbs may be caught in ma chin ery!

Press the feed sta tion on the dos ing mo tor and turn the feed sta tion approx. 45° coun -

176-1MS

ter-clockwise.

Put ting into op er a tion 3-16

Page 29

3.5. Mo di fy/Crea te Re ci pe

S 150

&

The fol lo wing is re qui red:

the de si red co lou ring (%)

·

the shot weight (g, op tio nal ly: lb)

·

the screw re tract time/plas ti fi ca ti on time of the pro ces sing ma chi ne (s)

·

the ca li brat ion weight (g, op tio nal ly: lb)

·

&

By press ing the “stop” key, you can quit the menu at any time while tak ing

on the en tered val ues.

In case the steps des cri bed in the chap ter “De ter mi ning the Ca li brat ion

Weight” have been car ried out just be fo re, the de ter min ed va lue is dis play ed.

the main tai ned run ning time of the blen ding unit (s, op tio nal if the re is only one blen ding unit)

·

a printer (op tional, only if you wish to print rec ipe pa ram e ters)

·

176-1MS

Put ting into op er a tion 3-17

Page 30

Input

Input

Input

%

lb

g

bzw.

lb

g

bzw.

s

Input

%%

lb

g

bzw.

lb

g

bzw.

s

S 150

Press key LED dis play dis play

“1"

parts of the ad di ti ve (co lou ring) in %

en ter parts of the ad di ti ve

“2"

shot weight in g or lb re spec ti ve ly

en ter shot weight

“3"

plastification time of the ma chi ne in se conds

en ter plas ti fi ca ti on time

“4"

cal i bra tion weight in g or lb re spec tively,

if ”0": Set to value in di cated in sec tion 4.7,

then carry out cal i bra tion.

en ter ca li brat ion weight

176-1MS

Put ting into op er a tion 3-18

Page 31

Press key LED dis play dis play

Input

Input

kg

Input

s

s

“5"

main tained run ning time of the blen ding

unit in se conds

en ter main tai ned run ning time of the blen ding unit

S 150

“6”

printer

Only if a printer (op tional) is avail able

en ter printer parameters

0 = no prin ting

1 = print ing setpoints

2 = print ing parameters

3 = page change

4 = print ing each event

5 = print ing alarms

to tal throughput in kg (lbs.)

176-1MS

Put ting into op er a tion 3-19

Page 32

3.5.1. Save Re ci pe

lb kg

bzw.

Press key LED dis play dis play

“L (= load)” and the most re cent ly cal led up

re ci pe num ber

“S (= save)” and the most re cent ly sa ved

re ci pe num ber

se lect re ci pe num ber (1 - 10)

save re ci pe

S 150

&

176-1MS

If you want to save the re ci pe un der a num ber that al rea dy exists, the re ci pe sto red un der that num ber will be over writ ten.

Put ting into op er a tion 3-20

Page 33

3.6. Starting mode

lb kg

bzw.

Run

Run

g

g

lb kg

bzw.

Stop

Only in case of moun ting on a Mico mix ing-hopper.

F

Press key LED dis play dis play

ma te rial con tents of the mix ing-hoppe

mixing the material

S 150

total through put

3.7. Star ting the Con ti nu ous Ope ra ti on

Press key LED dis play dis play

to ta li zer

176-1MS

Put ting into op er a tion 3-21

Page 34

3.8. Vie wing the Ac tu al Va lu es

lb

g

bzw.

min

%

min

kg

lb kg

bzw.

Stop

Press key LED dis play dis play

to ta li zer

throughput

ro ta tio nal speed of the do sing mo tor

S 150

no mi nal cur rent of the mo tor in %

3.9. Stop ping the Con ti nu ous Ope ra ti on

Press key LED dis play dis play

to ta li zer

If the “stop” key is pres sed for more than 2 se conds, the weights are re set

to zero.

F

176-1MS

Put ting into op er a tion 3-22

Page 35

3.10. Cal ling up the re ci pe

lb kg

bzw.

Stop

lb kg

bzw.

lb kg

bzw.

Stop

Press key LED dis play dis play

to ta li zer

“L (= load)” and the most re cent ly cal led up

re ci pe num ber

se lect re ci pe num ber (1 - 10)

call up re ci pe

S 150

3.11. Swit ching off the De vi ce

Press key LED dis play dis play

to ta li zer

Switch off the de vi ce by pres sing the On/Off switch.

176-1MS

Put ting into op er a tion 3-23

Page 36

3.12. Alarm Mes sa ges

In case a mal functi on oc currs, an alarm mes sa ge will be dis play ed.

S 150

&

An A and an er ror num ber will be shown in the dis play.

The LED “alarm” is lit up.

The con trol sys tem can not re su me the ope ra ti on, un less the mal functi on

has been re me died.

F

Press the “stop” key.

&

By me ans of pres sing the stop key the rea son for the mal functi on will not

be re sol ved.

176-1MS

Put ting into op er a tion 3-24

Page 37

S 150

“A0001"

Strap “sa fe ty switch” is mis sing.

Ster ling Ser vi ce.

“A0002"

The no mi nal cur rent of the do sing mo tor (= 100 %, see name pla te) is being ex cee ded for more

than 2 se conds by 30 % or for a ma xi mum of 0.5 se conds by 80 %.

Do sing mo tor de fec ti ve or jam med. Check the do sing mo tor and ex chan ge it if ne ces sa ry.

Check whet her the do sing disc is jam med by ma te ri al and re mo ve the ma te ri al if ne ces sa ry.

“A0003"

The no mi nal cur rent of the do sing mo tor (= 100 %, see name pla te) is being ex cee ded for more

than one mi nu te.

Do sing mo tor de fec ti ve or jam med. Check the do sing mo tor and ex chan ge it if ne ces sa ry.

Check whet her the dos ing disc is jam med by ma te ri al and re mo ve the ma te ri al if ne ces sa ry.

“A0004"

Ex cess tem per a ture

The tem per a ture within the hous ing is > 85°C (185°F).

Check whet her the coo ling pla te at the back of the de vi ce is suf fi cient ly coo led down.

“A0005"

The en co der (pul se ge ne ra tor) does not emit any pul ses for ap prox. 2 se conds.

The do sing mo tor does not turn. Check whet her the do sing disc is jam med by ma te ri al and re mo ve the ma te ri al if ne ces sa ry.

De fect at the do sing mo tor. Check do sing mo tor, ex chan ge if ne ces sa ry.

De fect at the en co der. Check en co der, ex chan ge if ne ces sa ry.

“A0006"

For ap prox. 4 se conds, the re is a de via ti on of the mo tor speed of more than 20 % from the no mi nal

ro ta tio nal speed.

De fect at the do sing mo tor. Check do sing mo tor, ex chan ge if ne ces sa ry.

Check whet her the do sing disc is jam med by ma te ri al and re mo ve the ma te ri al if ne ces sa ry.

Po wer supp ly part or con trol out of or der. Ster ling Ser vi ce.

“A0007"

Do sing mo tors stops or does not work.

176-1MS

Bra ke at the do sing mo tor out of or der.

Con trol sys tem out of or der. Ster ling Ser vi ce.

Put ting into op er a tion 3-25

Page 38

“A0008"

The screw re tract time of the pro cess ing ma chine in shorter than 0.1 sec onds.

The unit can not be ope ra ted in com bi na ti on with this pro ces sing ma chi ne.

“A0009"

The cal cu la ted speed of the mo tor is eit her too high or too low.

Check ba sic pa ra me ter set ting and re ci pe, mo di fy if ne ces sa ry.

“A0010"

The feed sta ti on is not able to me ter the de si red re ci pe.

Check ba sic pa ra me ter set ting and re ci pe, mo di fy if nec es sary.

“A0011"

The raw ma te ri al pro be is not co ver ed.

Re fill ma te ri al.

S 150

“A0012"

The ad di ti ve pro be is not co ver ed.

Re fill ma te ri al.

The do sing pro cess will not be in ter rup ted.

F

“A0014"

Po wer fail ure.

“A0015"

EE PROM data loss, EE PROM not pro gram med.

Ster ling Ser vi ce.

“A0016”

No com mu ni ca tion be tween HOST and unit.

176-1MS

Check ca ble fit tings.

Ster ling Ser vice.

Put ting into op er a tion 3-26

Page 39

4. Main te nance

This chap ter is in tended for per sons with skills in elec tri cal and me chan i cal

»

ar eas due to their train ing, ex pe ri ence and re ceived in struc tions.

Per son nel us ing the in struc tions in this chap ter must be in structed of the reg u la tions for the pre ven tion of ac ci dents, the op er at ing con di tions and safety

reg u la tions and their im ple men ta tion.

En sure in each case that the per son nel are in formed.

For main te nance work tak ing place at heights of over approx. 6 feet (1829

mm), use only lad ders or sim i lar equip ment and work ing plat forms in tended

for this pur pose. At greater heights, the proper equip ment for pro tec tion

against fall ing must be worn.

Use only suit able lift ing gear which is in proper work ing or der and load sus pen sion de vices with suf fi cient car ry ing ca pac ity. Do not stand or work un der

sus pended loads!

SDD 1 SGM

En sure that the elec tric mo tors/switch cab i nets are suf fi ciently pro tected

against mois ture.

Use only suit able work shop equip ment.

Be fore start ing main te nance work, ap point a su per vi sor.

In form the re spon si ble per son nel be fore main te nance work on the sys tem is

started.

Never op er ate the equip ment when par tially dis man tled.

All main te nance and re pair work not de scribed in this chap ter may only be

car ried out by Ster ling ser vice per son nel or au tho rized per son nel (ap pointed

by Ster ling).

176-1MS

Main te nance 4-1

Page 40

SDD 1 SGM

L

F

Dis con nect the equip ment from mains sup ply be fore start ing main te nance pro ce dures to en sure that it can not be switched on un in ten tion ally.

Depressurize all com pressed air pip ing of the equip ment be fore start ing

main te nance work.

Please ob serve the main te nance in ter vals.

Be fore start ing main te nance work, clean the equip ment of oil, fuel or lu bri cants.

En sure that ma te ri als and in ci den tals re quired for op er a tion as well as

spare parts are dis posed of prop erly and in an en vi ron men tally sound

man ner.

Use only orig i nal Ster ling spare parts.

Keep re cord of all main te nance and re pair pro ce dures.

Ob serve that a dos ing and blend ing unit may only be put into op er a tion if

all dos ing sta tions and cov ers are in place. Dan ger of squeez ing!

176-1MS

Main te nance 4-2

Page 41

4.1. Main te nance in ter vals

Daily: Check warn ing signs on equip ment for good

leg i bil ity and com plete ness

Weekly: Check func tion of the on/off switch

Ev ery 3 months: Check scraper in dos ing sta tion DD/DT

Ev ery 6 months: Check all elec tri cal and me chan i cal con nec tions

for tight fit

Check ad just ment of the level probes (op tional),

see chap ter “Ac ces sories”

An nually: Check dos ing disc in dos ing sta tion DD/DT

Each time af ter

ma te rial is changed: Clean dos ing sta tion

Check scraper

Check dos ing disc

SDD 1 SGM

&

F

176-1MS

This main te nance sched ule is cal cu lated for 3-shift op er a tion.

The given main te nance in ter vals are av er age val ues.

Check whether in your in di vid ual case the main te nance in ter vals must be

short ened.

Main te nance 4-3

Page 42

4.2. Re moving/re plac ing scraper in the SDD dos ing sta tion

Re moving the scraper

Empty the dos ing sta tion.

Switch the con trol unit off by means of the on/off switch.

»

Open the tight en ing strap (B) on

the dos ing hop per.

Re move the dos ing hop per from

the dos ing unit.

Open the safety screws at the tog gle-type fas ten ers.

Dis con nect from mains volt age.

SDD 1 SGM

Open the tog gle-type fas ten ers on

the dos ing mo tor.

Re move the dos ing unit from the

dos ing mo tor.

Re move the cover from the con nect ing piece (D).

Loosen the two screws (C) on the

un der side of the dos ing unit hous ing (E).

Re move the scraper (A).

L

When han dling the scraper be care ful, the scraper is sharp.

Dan ger of in jury ex ists!

Dosing unit (side view)

176-1MS

Main te nance 4-4

Page 43

In stalling the scraper

Place the new scraper in the dos ing unit hous ing.

En sure that the scraper is po si tioned cor rectly.

Screw the scraper in place by means of 2 hexa gon socket screws (M5 x 16).

Turn the dos ing disc to check for smooth move ment.

Mount the cover on the con nect ing piece.

Po si tion the dos ing unit on the dos ing mo tor (note guide pins).

Close the tog gle-type fas ten ers on the dos ing mo tor.

SDD 1 SGM

F

Po si tion the dos ing hop per on the dos ing unit.

F

&

Mount the safety screws.

Mount the tight en ing strap.

Mount the screw at the tight en ing strap.

Ob serve that a dos ing and blend ing unit may only be put into op er a tion if

all dos ing sta tions and cov ers are in place. Dan ger of squeez ing!

Or der num ber scraper: ID 21392

176-1MS

Main te nance 4-5

Page 44

4.3. Cleaning the DD dos ing sta tion

D

B

C

A

A

B

Dis man tling the dos ing sta tion

Empty the dos ing sta tion.

Switch the con trol unit off by means of the on/off switch.

»

Open the tight en ing strap on the

dos ing hop per.

Re move the dos ing hop per from the

dos ing unit.

Dis man tle the dos ing unit and re move the scraper (D).

Dis con nect from mains volt age.

SDD 1 SGM

Loosen the two hexa gon socket

screws (B, M6 x 30) on the top side of

the dos ing disc (A).

Loosen the cen ter hexa gon socket

screw (C, M6 x 12) and re place by an

M6 x 60 screw.

Lift the dos ing disc (A) from the dos ing unit hous ing (B) by this screw.

Clean the scraper us ing a cot ton

cloth.

Clean the dos ing hop per and the

dos ing disc in soapy wa ter.

The dos ing unit hous ing may also be

cleaned with soapy wa ter.

En sure that soapy wa ter does not

en ter the ball bear ings.

Dry all parts thor oughly.

176-1MS

Dosing unit (top view)

Dosing unit (side view)

Main te nance 4-6

Page 45

In stalling the dos ing sta tion

Place the dos ing disc in the dos ing unit hous ing.

Re move the screw (M6 x 60).

Screw the dos ing disc in place by means of 2 hexa gon socket screws (M6 x 30).

Mount the cen ter hexa gon socket screw (M6 x 12).

In stall the scraper and then the dos ing unit.

Turn the dos ing disc to check for smooth move ment.

Po si tion the dos ing hop per on the dos ing unit.

Tighten the tight en ing strap.

Ob serve that a dos ing and blend ing unit may only be put into op er a tion if

all dos ing sta tions and cov ers are in place. Dan ger of squeez ing!

SDD 1 SGM

176-1MS

Main te nance 4-7

Page 46

SDD 1 SGM

4.4. Changing the dos ing disc in the SDD dos ing sta tion

Re moving the dos ing disc

Empty the dos ing sta tion.

Switch the con trol unit off by means of the on/off switch.

»

Open the tight en ing strap on the dos ing hop per.

Re move the dos ing hop per from the dos ing unit.

Dis man tle the dos ing unit and re move the scraper.

Loosen the two hexa gon socket screws (M6 x 30) on the top side of the dos ing disc.

Loosen the cen ter hexa gon socket screw (M6 x 12) and re place by an M6 x 60 screw.

Dis con nect from mains volt age.

Lift the dos ing disc from the dos ing unit hous ing by this screw.

Installating the dos ing disc

Change and place the dos ing disc in the dos ing unit hous ing.

Re move the screw (M6 x 60).

Screw the dos ing disc in place by means of 2 hexa gon socket screws (M6 x 30).

Mount the cen ter hexa gon socket screw (M6 x 12).

In stall the scraper and then the dos ing unit.

Turn the dos ing disc to check for smooth move ment.

Po si tion the dos ing hop per on the dos ing unit.

Tighten the tight en ing strap.

176-1MS

Main te nance 4-8

Page 47

SDD 1 SGM

Ob serve that a dos ing and blend ing unit may only be put into op er a tion if

all dos ing sta tions and cov ers are in place. Dan ger of squeez ing!

&

Or der num bers

Dosing disc

72 cham bers: ID 31447

40 cham bers: ID 21710

25 cham bers: ID 21711

18 cham bers: ID 23057

Dosing disc, wear resistant

40 cham bers: ID 28214

25 cham bers: ID 27141

18 cham bers: ID 27142

176-1MS

Main te nance 4-9

Page 48

SDD 1 SGM

4.4.1. In stalling Dif fer ent Types of Dosing Discs

Dosing discs of the same type may be ex changed for each other with out any prob lems.

If dos ing discs with a dif fer ent com part ment num ber are in stalled, this has to be en tered in the

con trol sys tem.

En ter the (pre lim i nary) cal i bra tion value of the freshly in stalled dos ing disc

(* = bulk den sity 550 g/l (1.21 lbs/l), ** = bulk den sity 700 g/l) (1.54 lbs/l).

Dosing disc Pre lim i nary cal i bra tion value

SDD30-030672 *1.5 , **2.0

SDD30-051040 *4.0 , **5.0

SDD30-051725 *7.0 , **9.0

SDD30-051818 *13.0 , **17.0

Ex e cute “cal i bra tion” to de ter mine the fi nal cal i bra tion value.

When sav ing rec i pes, note the dos ing disc by means of which the cal i bra tion was re leased.

F

Mind that the ap pro pri ate dos ing disc has to be in stalled when call ing up

stored rec i pes.

176-1MS

Main te nance 4-10

Page 49

4.5. Re moving/re plac ing the scraper in the SDT dos ing sta tion

Empty the dos ing sta tion.

Switch the con trol unit off by means of the on/off switch.

»

Open the tight en ing strap (C) of the dos ing con tainer.

Re move the tight en ing strap (C).

Re move the dos ing con tainer (B) along with the

dos ing hop per (A).

Dis con nect from mains volt age.

SDD 1 SGM

A

Loosen the 3 plas tic screws on the strip per

(DT-t: metal screws).

Re move the scraper and hold ing plate.

B

C

DT 30

176-1MS

Main te nance 4-11

Page 50

SDD 1 SGM

In stall the new scraper along with the hold ing plate.

Tighten down the 3 plas tic screws. Make sure that the strip per is fit ted par al lel to the dos ing plate.

Use only plas tic screws (DT-t: metal screws).

F

In stall the dos ing con tainer along with the dos ing hop per on the dos ing hous ing (pay at ten tion to

the guide pins).

Mount the tight en ing strap.

F

&

Mount the screwat the tight en ing strap.

Ob serve that a dos ing and blend ing unit may only be put into op er a tion if

all dos ing sta tions and cov ers are in place. Dan ger of squeez ing!

Or der num bers

Plas tic screws: ID 96039

Scraper: ID 05334

Holding plate: ID 05353

Dosing disc

20 cham bers: ID 23056

12 cham bers: ID 23060

10 cham bers: ID 18405

176-1MS

Main te nance 4-12

Page 51

4.6. Cleaning the SDT dos ing sta tion

Empty the dos ing sta tion.

Switch the con trol unit off by means of the on/off switch.

»

Open the tight en ing strap (C) of the dos ing con tainer.

Re move the tight en ing strap (C).

Re move the dos ing con tainer (B) along with the

dos ing hop per (A).

Open the safety srews at the tog gle-type fas ten ers.

Open the tog gle-type fas ten ers.

Re move the dos ing hous ing (D) from the mix ing

hop per.

Dis con nect from mains volt age.

SDD 1 SGM

A

B

C

D

Clean the dos ing hous ing (D) with a paint brush.

Clean the dos ing con tainer (B) and the dos ing

hop per (A) in soapy wa ter.

Dry all parts thor oughly.

Tog gle-type fas tener

176-1MS

Main te nance 4-13

Page 52

Mount the dos ing hous ing onto the dos ing mo tor.

Ob serve that the guide pins are locked into po si tion.

Close the tog gle-type fas ten ers.

SDD 1 SGM

F

In stall the dos ing con tainer along with the dos ing hop per on the dos ing hous ing (pay at ten tion to

the guide pins).

F

Mount the safety srews.

Mount the tight en ing strap.

Mount the screw at the tight en ing strap.

Ob serve that a dos ing and blend ing unit may only be put into op er a tion if

all dos ing sta tions and cov ers are in place. Dan ger of squeez ing!

176-1MS

Main te nance 4-14

Page 53

SDD 1 SGM

4.7. Ex change able sta tions

Dosing discs of the same type may be ex changed for each other with out any prob lems.

If dos ing discs with a dif fer ent com part ment num ber are in stalled, this has to be en tered in the

con trol sys tem.

En ter the (pre lim i nary) cal i bra tion value of the freshly in stalled dos ing disc

(* = bulk den sity 550 g/l (35lbs/ft3), ** = bulk den sity 700 g/l) (44lbs/ft3).

Feed sta tion Num ber of dos ing com part ments Pre lim i nary cal i bra tion value

SDD30-030672 72 *1.5 , **2.0

SDD30-051040 40 *4.0 , **5.0

SDD30-051725 25 *7.0 , ** 9.0

SDD30-051818 18 *13.0 , **17.0

SDT30-101820 20 *28.0 , **35.0

SDT30-203012 12 *93.0 , **118.0

SDT30-204010 10 *148.0 , **190.0

Ex e cute “cal i bra tion” to de ter mine the fi nal cal i bra tion value.

When sav ing rec i pes, note the dos ing disc by means of which the cal i bra tion was real ised.

F

Mind that the ap pro pri ate dos ing disc has to be in stalled when call ing up

stored rec i pes.

176-1MS

Main te nance 4-15

Page 54

4.8. Ex changing Fuses

These tasks may be car ried out by trained per son nel only.

»

Stop the con tin u ous op er a tion.

Wait un til the dos ing unit has come to a stand still.

Switch off the de vice by means of the On/Off switch.

Cut off the volt age sup ply.

Wait at least one min ute be fore start ing to work at the switch ing cab i net.

Dan ger to life! Dis charge of high-voltage pos si ble!

Never try to re pair a de fec tive fuse.

SDD 1 SGM

176-1MS

Main te nance 4-16

Page 55

Open the screws (A) and re move the lid (B).

Re move the blind lid (C) and open the screws.

Move the lid (D) aside.

SDD 1 SGM

176-1MS

S 150

Main te nance 4-17

Page 56

Re move the de fec tive fuse from the fuse car rier.

In stall the new fuse (while ob serv ing the value).

Mount the lid (D).

Fas ten the screws and the blind lids (C).

Mount the lid (B).

Mount the screws (A).

SDD 1 SGM

&

Pur chase or der num bers

Fuse

F1, 5 AT: ID 84773

F2, 4 AF: ID 84770

F3, 0,5 AF: ID 83670

F4, 2 AT: ID 99815

F5, 2 AT: ID 99815

F7, 5 AT: ID 84773

176-1MS

Main te nance 4-18

Page 57

5. As sem bly in struc tions

These in stal la tion in struc tions are in tended for per sons with skills in elec tri -

»

cal and me chan i cal ar eas due to their train ing, ex pe ri ence and re ceived in struc tions.

Per son nel us ing these in stal la tion in struc tions must be in structed in the reg u la tions for the pre ven tion of ac ci dents, the op er at ing con di tions and safety

reg u la tions and their im ple men ta tion.

En sure in each case that the per son nel are in formed.

The in stal la tion in struc tions pro vided in the cor re spond ing op er at ing in struc tions ap ply for all con nected equip ment.

Ob serve all safety reg u la tions for the op er a tion of lift ing gear.

All in stal la tion work must be car ried out with the equip ment dis con nected

from elec tri cal power and com pressed air sup ply.

SDD 1 SGM

L

For in stal la ti on work ta king pla ce at heights of over ap prox. 6 feet (1829

mm), use only lad ders or si mi lar equip ment and wor king plat forms in ten ded for this pur po se. At grea ter heights, the pro per equip ment for pro tec ti on against fal ling must be worn.

Use only suit ab le lif ting gear which is in pro per wor king or der and load

sus pen si on de vi ces with suf fi cient car ry ing ca pa ci ty. Do not stand or

work un der sus pen ded loads!

Use only suit ab le work shop equip ment.

In stall the equip ment such that all parts are ea si ly ac ces si ble; this fa ci li ta tes main ten an ce and re pair work.

F

176-1MS

As sem bly in struc tions 5-1

Page 58

SDD 1 SGM

5.1. Trans port

The equip ment is de li ver ed as a com ple te as sem bly.

Only use for trans port of the equip ment a suit ab le hoist (e. g. a fork lift truck or a work shop cra ne).

Plea se en su re ade qua te car ry ing ca pa ci ty of the lif ting gear.

»

5.2. SDD 1 SGM

SDD 1 SGM is vi bra tion-proof. It can be mounted di rectly on the pro cess ing ma chine.

En su re af ter as sem bly that the do sing sta ti on does not knock against ot her com po nents (also

when the pro ces sing ma chi ne is in ope ra ti on).

Note that the equip ment is top-heavy.

Plea se ob ser ve all sa fe ty re gu la tions for the ope ra ti on of lif ting gear.

176-1MS

As sem bly in struc tions 5-2

Page 59

5.2.1. Mount ing on the pro cess ing ma chine

Re mo ve the ma chi ne hop per from the pro ces sing ma chi ne.

Check the car ry ing ca pa ci ty of the ma chi ne flan ge.

If the car ry ing ca pa ci ty is not suf fi cient, a sup port must be moun ted.

F

Check whet her the hop per piece fits on the

ma chi ne flan ge.

Mount the hop per pie ce on the pro ces sing

ma chine if the dia me ter of the in let of the

ma chi ne flan ge is big ger than the dia me ter

of the out let of the hop per pie ce.

Ob serve the di men sion sheet.

SDD 1 SGM

Mount the adap ter pla te or pre pa re an

adap ter pla te, if the dia me ter of the in let of

the ma chi ne flan ge is smal ler than the dia me ter of the out let of the hop per pie ce.

Mount the hop per pie ce on the adap ter pla te.

Ob ser ve the di men si on sheet.

L

At tach ments not supp lied by Ster ling must be ma nu fac tur ed in ac cor dan ce with sa fe ty in struc tion EN 294. Cau tion: Dan ger of ac ci dents!

The dia me ter of the in let of the ma chi ne flan ge must be big ger than the

dia me ter of the out let of the hop per pie ce.

F

Di men sion sheet (all di men sions in mm (in))

176-1MS

En sure that all scre wed con nec tions are tight.

As sem bly in struc tions 5-3

Page 60

5.3. Con trol sys tem S 150

158

13

7

2O5

c

a

b

The con trol sys tem may be in stal led eit her di rect ly at the hop per pie ce or se pa ra te ly (ver ti cal in stal la ti on).

The con trol sys tem has to be fi xed at the pre de ter min ed fas te ning sta ti on.

De sign an ap pro pria te dril ling jig and drill the

re spec ti ve ho les.

Ob ser ve the in di ca ted di men sions (see

Chap ter “Tech ni cal Data”).

Fix the con trol sys tem at the fas te ning sta tions a, b, and c:

Hang up the con trol sys tem in po si ti on “a” and

screw it tight in po si ti on “b” and “c”.

Make sure that the coo ling pla te (D) is suf fi cient ly coo led down at the back of the coo ling

sys tem.

SDD 1 SGM

D

Nei ther ex pose the con trol sys tem to heat

(max. am bi ent tem per a ture: 50°C) (122°F)

nor to mois ture.

In case the tem per a ture within the hous ing of the con trol sys tem ex ceeds

85°C (185°F), the con trol sys tem will be au to mat i cally switched off.

F

S 150

176-1MS

As sem bly in struc tions 5-4

Page 61

5.4. Elec tri cal Con nec ti on

The elec tri cal con nec ti on may be car ried out by trai ned per son nel only.

»

Ot her per sons are not per mit ted to car ry out the elec tri cal con nec ti on.

The re gu la tions of the lo cal elec tri ci ty board must be ob ser ved.

Be fo re ha ving the elec tri cal con nec ti on estab lis hed, plea se make sure that

the supp ly vol ta ge as well as the po wer fre quen cy are iden ti cal with the data

in di ca ted on the name pla te.

All work should be car ried out when the re is no vol ta ge or pres su re to be me su red at the de vi ce.

Ob ser ve the in struc tions in the con nec ti on dia gram.

SDD 1 SGM

F

The ope ra ting vol ta ge amounts to 230 VAC ± 10 %, 50/60 Hz.

Spe ci al vol ta ges on re quest.

The con nec ted load amounts to ap prox. 200 Watt.

176-1MS

As sem bly in struc tions 5-5

Page 62

6. Functio nal des crip ti on

This functio nal des crip ti on is in ten ded for all ope ra ting per son nel of the

»

equip ment.

Pre re qui si te for this functio nal des crip ti on is ge ne ral knowled ge of do sing

and blen ding units.

En su re in each case that the ope ra ting per son nel are suf fi cient ly in form ed.

SDD 1 SGM

176-1MS

Functio nal des crip ti on 6-1

Page 63

SDD 1 SGM

6.1. SDD 1 SGM

The SDD 1 SGM is a syn chro nized, dig i tal dos ing sys tem de signed to pre cisely dose plas tic ad di tives (ei ther in pel let or pow der form) on any plas tics pro cess ing ma chine, whether in jec tion mold ing, blow mold ing, or all ex tru sion ap pli ca tions.

The prcise dos ing of ad di tives is ac com plished us ing a cor rectly sized dos ing disc in com bi na tion

with a spe cial DC drive mo tor and our easy to op er ate con trol. This com bi na tion al lows for ad di tives to be dosed in synch with the pro cess ing ma chine and the flow of the main com po nent ma te rial. When the ad di tive and main ma te rial hit the pro cess ing screw, they will be mixed at ex actly

the right pro por tion, ac cord ing to your inputted rec ipe. The SDD 1 SGM con trol lers are connected

to the pro cess ma chine and mon i tor the screw re cov ery time for in jec tion, in jec tion blowmolding

and the screw speed of an ex trud er. Ster ling guar an tees de liv ery of a ho mo ge neous mix ev ery

time with out risk of de-mix ing even with the use of mi cro-batch (or mi cro pel lets).

Our de sign makes ma te rial change over al most ef fort less. Sim ply lift two quick dis con nects and

lift off the ad di tive sta tion. By the use of a spare sta tion, change over is im me di ate. If you elect not

to pur chase a spare sta tion, clean up and ma te rial change oc curs off the ma chine in min utes, re duc ing down time and risk of in jury. Ad di tive may also be au to mat i cally loaded by the use of one of

Ster ling’s hop per load ers.

The SDD 1 SGM is mounted di rectly in the throat of the pro cess ing ma chine. We have var i ous

sizes and adapt ers to ac com mo date ma chine sizes and hop per loader con fig u ra tions.

6.2. Con trol Unit S 150

The Ster ling S150 con trol ler is a mi cro pro ces sor based con trol ler to op er ate the SDD 1 SGM au to matic dos ing sta tion for in jec tion mold ing ap pli ca tions.

To con trol the vari able speed AC mo tors, we uti lize pulse width mod u la tion tech nol ogy. This tech nol ogy keeps the mo tor torque con stant over the en tire con trol range of op er a tion. The drive op er ates with a built-in quartz cy cle, dig i tal con trol cir cuit, di rectly tied into the im pulse speed trans mit ter in the dos ing mo tor. This holds the inputted mo tor speed at an ac cu racy level of 1 min ute. A

sturdy key pad al lows op er a tional in puts. Op er ating con di tions are dis played by sym bols.

The ad di tive is dosed syn chro nously to the main com po nent and plasticization time of the in jec tion mold ing ma chine. The dos ing mo tor speed is mon i tored con tin u ously and, if nec es sary, ad justed in a fully au to matic way.

176-1MS

Functio nal des crip ti on 6-2

Page 64

SDD 1 SGM

7. Tech ni cal Data

7.1. SDD 1 SGM

Ba sic Ver sion

• Com po nents to dose gran u late, mi cro-batch/pel lets or pow der (please spec ify re quire ment)

• Quick dis con nect for change over/clean ing

• Sam pling tube for sim ple cal i bra tion

• Abil ity to han dle ma te ri als up to 80 °C (176 °F)

• Con nec tion wire to pro cess ing ma chine

• Op er ating volt age ei ther 230 +/- 10 %, AC, Sin gle phase, 50/60Hz

• 0.2 kW op er at ing load

• Weight 23 kg/51 lbs

• Noise level with gran ules/pow der max. 65 dB(A) (de pend ing on the ma te rial)

• Min. shot weight* 5 g (0.01 lbs)

• Max. shot weight* 6500 g (6.5 lbs.)

*All feed rates are ap prox i mate, ac tual feed rates will vary ac cord ing to the feed sta tion, ma te rial,

flow prop er ties and par ti cle size.

Op tional Fea tures

• Spare sta tion for im me di ate change over for pel lets or pow ders

• Op tion for abra sive ma te ri als

• Hop per load ers for au to matic re fill

• Extern re fill ing sys tems

• Low level sen sors

• Spe cial volt age

176-1MS

Tech ni cal Data 7-1

Page 65

7.2. Con trol unit S 150

Ba sic equip ment

• 5 digit LED dis play

• Mem ory backup for rec ipe and data stor age

• Dry con tact cy cle sig nal in put

• In put for level probe for both raw ma te rial and ad di tives

• IP64 shield ing

• short cir cuit proof out puts

• Op er ates be tween 0°C to +50°C (32 to 120° F)

• Stor age tem per a ture range -20 to +70° C (-4 to +160°F)

• Op er ating volt age 230 VAC ±10 %, 50/60 Hz

• Con nected load of 100 W max i mum dur ing op er a tion

SDD 1 SGM

• Dry con tact alarm out put

• Ther mal de vice pro tec tion

Op tional equip ment

• RS422/465 for Euromap 17 pro to col in ter face

• Spe cial volt age avail able

Func tion al ity

• Di rect in put of de sired ad di tive per cent ages

• Au to matic cal cu la tion of cal i bra tion val ues for dos ing

• Op er ating con di tions shown via sym bols

• Dis play of ad di tive con sump tion

• Stor age of up to 10 rec i pes

176-1MS

Tech ni cal Data 7-2

Page 66

7.3. Di men sion sheet

SDD 1 SGM

176-1MS

All di men sions in mm (in.). Spec i fi ca tions may be sub ject to al ter ations.

Tech ni cal Data 7-3

Page 67

8. Spa re parts list

This spa re parts list is in ten ded to be used only by trai ned per son nel.

»

Ot her per sons are not per mit ted to mo di fy or re pair the equip ment.

SDD 1 SGM

176-1MS

Spa re parts list 8-1

Page 68

Dosing sta tion SDD

F4F4

F5F5

F3F3

F2F2

F1F1

F7F7

J14J14

J15J15

J17J17

J13J13

J9J9

J10J10 J12J12J11J11

J8J8

J16J16

**

J 10 (110 V)J 10 (110 V)

J 11 (230 V)J 11 (230 V)

De scrip tion Or der-Num ber

Scraper 21392

Dosing disc

72 cham bers: 31447

40 cham bers 21710

25 cham bers 21711

18 cham bers 23057

Dosing disc, wear re sis tant

40 cham bers 28214

25 cham bers 27141

18 cham bers 27142

Dosing sta tion SDT

De scrip tion Or der-Num ber

Scraper 05334

Plas tic screws 96039

SDD 1 SGM

Holding plate 05353

Dosing disc

20 cham bers: 23056

12 cham bers: 23060

10 cham bers: 18405

Con trol sys tem

De scrip tion Or der-Num ber

Fuse

F1 / F7, 5 AT 84773

F2, 4 AF 84770

F3, 0,5 AF 83670

F4 / F5, 2 AT 99815

176-1MS

Spa re parts list 8-2

Page 69

9. Ac ces so ries

o Drilling jig

o Values re quired for the ba sic pa ram e ter

o Le vel probe KCB-M32GP/015

o _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

o _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

SDD 1 SGM

176-1MS

Ac ces so ries 9-1

Page 70

SDD 1 SGM

176-1MS

Ac ces so ries 9-2

Page 71

SDD 1 SGM

Values re quired for the ba sic pa ram e ter:

Max. nom i nal cur rent of the mo tor: ................................................

Pulses of the en coder: ..........................................................

Con fig u ra tion value: ............................................................

In case of ex ter nal de sired value spec i fi ca tion:

Min. in put fre quency: ...........................................................

Span fac tor: ..................................................................

In case of con nec tion to a HOST:

Com mu ni ca tion ad dress: ........................................................

176-1MS

In case of mount ing on a Mico mix ing-hopper:

Ma te rial con tents of the mix ing-hopper (g): .........................................

Ac ces so ries 9-3

Page 72

Ac ces so ries

Le vel pro be

KCB-M32GP/015

176-1MS

Ster ling Ma te rial Pro cess ing

Page 73

Ad just ment of the le vel pro bes

Do not cle an the le vel pro bes be fo re the ad just ment.

F

Fill the do sing sta ti on un til 1/3 of the le vel pro be is co ver ed.

Re mo ve the plas tic screw.

Turn the trim-pot un til the yel low con trol lamp is swit ched off.

Don’t turn furt her un til the con trol lamp has swit ched off.

SDD 1 SGM

Blind lid

Ca ble

LED green (le vel pro be) LED yel low (sta ti on)

on: Po wer supp ly avai la ble on: Sta ti on fil led

off: Po wer supp ly not avai la ble off: Sta ti on emp tied

176-1MS

npn nor mal ly clo sed npn nor mal ly open

pnp nor mal ly open pnp nor mal ly clo sed

Pro tec ti ve screw

Trim-pot with plas tic screw

Level probe

2

Page 74

SDD 1 SGM

&

Fill the do sing sta ti on un til 2/3 of the le vel pro be is co ver ed. The yel low con trol lamp must now

switch on again.

Mount the plas tic screw.

Check the set ting du ring ope ra ti on.

&

Tur ning the trim-pot to the left de crea ses - tur ning the trim-pot to the right

in crea ses the swit ching-distance.

Or der num bers

Level probe: ID 85871

Level probe : ID 27546

(com plete with ca ble)

176-1MS

3

Page 75

10. Elec tri cal ma nu al

This elec tri cal man ual is ex clu sively de ter mined for the use by Ster ling Ser -

»

vice per son nel or by trained per son nel author ised by Ster ling only.

Other per sons are not al lowed to per form mod i fi ca tions or re pairs on the de vices.

All work should be car ried out when there is no volt age to be mesured at the

de vice.

Wait at least one min ute be fore start ing to work at the switch ing cab i net.

Dan ger to life! Dis charge of high-volt age pos si ble!

Be fore con nec tion of an ex ter nal power sup ply switch the equip ment off.

Un plug the mains plug.

Re move the fuses F4 (= blend ing unit) or F5 (= alarm).

SDD 1 SGM

176-1MS

Elec tri cal ma nu al 10-1

Page 76

Switch off the de vi ce by me ans of the On/Off switch.

»

Loosen the screws (A) and re mo ve the lid.

Cut off the vol ta ge supp ly.

Wait at least one mi nu te be fo re star ting to work at the swit ching ca bi net.

Dan ger to life! Disch ar ge of high-voltage pos si ble!

SDD 1 SGM

176-1MS

Elec tri cal ma nu al 10-2

Page 77

SDD 1 SGM

F4F4

F5F5

F3F3

F2F2

F1F1

F7F7

J14J14

J15J15

J17J17

J13J13

J9J9

J10J10 J12J12J11J11

J8J8

J16J16

**

J 10 (110 V)J 10 (110 V)

J 11 (230 V)J 11 (230 V)

J 15

Power sup ply

J 16

1: Dosing mo tor 2: Dosing mo tor +

J 8

1: 230 V, N

2: PE

3: Alarm COM

(230 V, L1)

4: Alarm NO

J 9

1: 230 V, N

2: PE

3: Mixer COM

(230 V, L1)

4: Mixer NO

176-1MS

J 10 (RS485/422)

1: Ex ter nal feed

max. 7 V

2: GND extern

3: TX+

4: TX5: RX+

6: RX-

J 11

1: Start

2: GND

3: Alarm

ac knowl edge ment

4: GND

J 12

1: Re serve In put

2: +15 V

3: Speed Con trol

4: GND

J 13

1: +15 V

2: Raw ma te rial probe

3: GND

4: +15 V

5: Ad di tive probe

6: GND

J 14

1: +15 V

2: Ro tary valve

3: Cal i bra tion switch

4: Ta chom e ter-In

5: Safety switch

6: Tacho

J 17

1: GND

2: Ta chom e ter-In

3: +5 V

Elec tri cal ma nu al 10-3

Page 78

Ter mi nal As sign ment S150 (115/230 V), from

J9

1

2

3

4

4

3

2

230V: N

Mischer

230V: L1

2AT

PE

F4

5

J8

1

2

3

4

4

3

2

230V: N

Alarm

230V: L1

2AT

PE

F5

5

se rial num ber 031.03-0108162090 on wards

From the se rial num ber cited above on wards the

blend ing unit and alarm re lay is once again im ple mented as a change-over con tact on the J9 or J8

ter mi nal.

The max. ter mi nal load con sists of 230 V/2A.

When the blend ing unit is con fig ured

(from soft ware P2.08, E2.08 on wards):

ac ti vated J9 3-4 closed, 3-5 open,

non-op er a tive sta tus: J9: 3-4 open, 3-5 closed

(If C150 is be ing me tered and dur ing the run on

time)

When the blend ing unit is not con fig ured

(from soft ware P2.08, E2.08 on wards):

ac ti vated J9 3-4 closed, 3-5 open,

non-op er a tive sta tus: J9: 3-4 open, 3-5 closed

(When the ‘RUN’ key is pressed (ready for op er a tion)

&

SDD 1 SGM

Mischer = mixer

Alarm = alarm

Alarm (from soft ware P2.08, E2.08 on wards):

ac ti vated J8: 3-4 open, 3-5 closed

If an er ror oc curs: J8: 3-4 closed, 3-5 open

An open ing func tion for the alarm re lay can also

be set in the equip ment con fig u ra tion:

Mark the func tion “alarm out put is

F

also switched in case of power fail ure” see page 7, chap ter 3: de ter min ing the con fig u ra tion value”.

Alarm (from soft ware P2.08, E2.08 on wards):

ac ti vated J8: 3-4 closed, 3-5 open

If an er ror oc curs J8: 3-4 open, 3-5 closed

176-1MS

Elec tri cal ma nu al 10-4

Page 79

De fault set ting:

J15 J16 J8 J9 J10 J11

J12

J13 J14 J17

Ju7

1

Ju2

Ju3

1

1

Ju5

1

Ju4

Ju6

1

1

Ju1

F2

F3

Ju10

115V

Ju11

230V

F7

F1

F5

F4

* *

* from serial number 031.03-0108162090

onwards 5 terminals

Injection

Extrusion

·

In jec tion or ex tru sion with ex ter nal set value 0-10 kHz

SDD 1 SGM

S 150 jumper as sign ment

Ju1: 1-2: Mi cro pro ces sor in power save mode, open (stan dard)

Ju2/3: 1-2 + 2-4: Ma te rial sen sor with open col lec tor out put

Ju4/6: 1-2: Ex ter nal RS422 sup ply

2-3 + 4-5: Ma te rial sen sor with source driver (stan dard)

2-3: In ter nal RS422 sup ply (stan dard)

Ju5: 1-2: Set value 0-10 kHz (stan dard),

2-3: Set value 0-10 V, 0-20 mA

Ju7: 1-2: Set value 0-20 mA,

2-3: Set value 0-10 kHz (stan dard) or 0-10 V

Ju10: Equip ment sup ply volt age 115 V

Ju11: Equip ment sup ply volt age 230 V (stan dard)

176-1MS

Elec tri cal ma nu al 10-5

Page 80

Ex tru sion with ex ter nal set value 0-10 V

J15 J16 J8 J9 J10 J11 J12 J13 J14 J17

Ju7

1

Ju2

Ju3

1

1

Ju5

1

Ju4

Ju6

1

1

Ju1

F2

F3

Ju10

115V

Ju11

230V

F7

F1

F5

F4

* *

U

0-10V

+

-

* from serial number 031.03-0108162090 onwards 5 terminals

·

SDD 1 SGM