Page 1

M2B+ Controller

M2B+ Controller

Part Number: 682.92011.00

Bulletin Number: SC1-630.8

Effective: 12/10/07

Write Down Your Serial Numbers Here For Future Reference:

_________________________ _________________________

_________________________ _________________________

_________________________ _________________________

We are committed to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual are subject to change without notice.

DCN No. ____________

© Copyright 2007

All rights reserved.

Chapter 1: Safety 1 of 65

Page 2

M2B+ Controller

Shipping Information

Unpacking and Inspection

You should inspect your equipment for possible shipping damage. Thoroughly check the

equipment for any damage that might have occurred in transit, such as broken or loose wiring

and components, loose hardware and mounting screws, etc.

In the Event of Shipping Damage

According to the contract terms and conditions of the Carrier, the responsibility of the

Shipper ends at the time and place of shipment.

Notify the transportation company’s local agent if you discover damage

Hold the damaged goods and packing material for the examining agent’s inspection.

return any goods before the transportation company’s inspection and authorization.

File a claim with the transportation company. Substantiate the claim by referring to the

agent’s report. A certified copy of our invoice is available upon request. The original Bill of

Lading is attached to our original invoice. If the shipment was prepaid, write us for a

receipted transportation bill.

Advise customer service regarding your wish for assistance and to obtain an RMA (return

material authorization) number.

If the Shipment is Not Complete

Check the packing list as back-ordered items are noted on the packing list. In addition to the

equipment itself, you should have:

; Bill of lading

; Packing list

; Operating and Installation packet

; Electrical schematic and panel layout drawings

; Component instruction manuals (if applicable)

Re-inspect the container and packing material to see if you missed any smaller items during

unpacking.

Do not

If the Shipment is Not Correct

If the shipment is not what you ordered, contact the parts and service department

immediately at (262) 641-8610. Have the order number and item number available.

Hold the items until you receive shipping instructions.

Returns

Do not return any damaged or incorrect items until you receive shipping instructions from the

shipping department.

2 of 65 Chapter 1: Safety

Page 3

M2B+ Controller

Table of Contents

CHAPTER 1: SAFETY................................................................6

1-1 How to Use This Manual.............................................................................................6

Safety Symbols Used in this Manual.....................................................................6

1-2 Warnings and Precautions..........................................................................................7

1-3 Responsibility..............................................................................................................7

CHAPTER 2: FUNCTIONAL DESCRIPTION.............................9

2-1 Models Covered in This Manual..................................................................................9

2-2 General Description...................................................................................................10

2-3 Standard Features.....................................................................................................11

2-4 Optional Features......................................................................................................11

2-5 Panel Layout and Keypad.........................................................................................12

LED Indicator Lights............................................................................................12

LCD Display ........................................................................................................12

LCD Messages....................................................................................................13

Keypad................................................................................................................14

2-6 Menu Structure..........................................................................................................16

Primary Menu......................................................................................................16

Secondary Menu .................................................................................................16

Secure Menu.......................................................................................................16

2-7 Passwords and Security............................................................................................17

CHAPTER 3: INSTALLATION..................................................19

3-1 Location.....................................................................................................................19

3-2 Electrical Connections...............................................................................................19

CHAPTER 4: BASIC OPERATION ..........................................21

4-1 Turning the Power On...............................................................................................21

4-2 Starting and Stopping Water TCUs...........................................................................22

Starting the Unit (Local).......................................................................................22

Stopping the Unit.................................................................................................22

Starting the Unit (Remote)...................................................................................22

4-3 Starting and Stopping Hot Oil TCUs..........................................................................23

Starting the Unit (Local).......................................................................................23

Stopping the Unit.................................................................................................23

Starting the Unit (Remote)...................................................................................24

4-4 Tuning .......................................................................................................................24

Autotuning...........................................................................................................24

Manual Tuning (Zeigler-Nichols PID Method) .....................................................25

4-5 Selecting a Local Probe ............................................................................................26

Using a Remote Input Probe for Monitoring........................................................26

4-6 Setting Up Cascade Control......................................................................................27

4-7 Adjusting the Automatic Venting Timer.....................................................................28

4-8 Using Crash Cool......................................................................................................28

Chapter 1: Safety 3 of 65

Page 4

M2B+ Controller

CHAPTER 5: ADVANCED OPERATION.................................29

5-1 Using the Analog Remote Input ................................................................................29

5-2 Retransmission Analog Signal ..................................................................................30

Setting the Analog Signal Source to FLOW ........................................................31

Using Analog Output for Heating and Cooling.....................................................31

5-3 Using the Flow Monitor..............................................................................................32

5-4 Programming the Alarms...........................................................................................33

Temperature........................................................................................................33

Flow Alarm ..........................................................................................................34

Open Sensor .......................................................................................................34

Low Pressure ......................................................................................................34

Low Fluid Level Alarm.........................................................................................35

High Fluid Level Alarm........................................................................................35

Pump Failure Alarm.............................................................................................35

Safety Thermostat Alarm.....................................................................................35

Welded Contactor Alarm .....................................................................................35

5-5 Using the Second Setpoint Function.........................................................................36

5-6 Using the Remote Start Function..............................................................................36

5-7 Changing the Temperature Display Units .................................................................37

5-8 Setting the Temperature Display Precision...............................................................37

5-9 Using the Elapsed Time Meter..................................................................................38

5-10 Programming Ramp/Soak.........................................................................................39

Controlling Ramp/Soak .......................................................................................41

Monitoring Ramp/Soak........................................................................................41

5-11 Setting the Approach Rate........................................................................................42

5-12 Level Input Operation (Water Units)..........................................................................42

5-13 Adjusting the LCD Display Contrast..........................................................................42

5-14 Adjusting the Auto Shutdown Temperature Setpoint ................................................42

5-15 Calibrating the T/C, RTD, and V Inputs.....................................................................43

5-16 Accessing the Debug Menu ......................................................................................45

5-17 Reloading Factory Defaults.......................................................................................46

5-18 Serial Communications Operation.............................................................................47

Port Address........................................................................................................47

Baud Rate and Data Format ...............................................................................47

Protocols .............................................................................................................47

MODBUS Protocol ..............................................................................................48

SPI Protocol ........................................................................................................51

CHAPTER 6: TROUBLESHOOTING .......................................53

6-1 Operating Mode and Error Display Messages ..........................................................55

CHAPTER 7: APPENDIX..........................................................56

7-1 Electrical Specifications.............................................................................................56

General................................................................................................................56

Normal Operating Environment...........................................................................56

Storage Environment...........................................................................................56

Primary, Power Supply (Line Power)...................................................................56

Alarm Outputs .....................................................................................................56

External System Outputs.....................................................................................56

4 of 65 Chapter 1: Safety

Page 5

M2B+ Controller

User Interface......................................................................................................56

Temperature Sensor Inputs.................................................................................57

Flow Sensor Inputs..............................................................................................57

System Inputs......................................................................................................57

Optional Analog Output Modules ........................................................................57

7-2 Menu Structure* ........................................................................................................58

7-3 Control Board Layout ................................................................................................64

7-4 DAC Board Layout (Optional)....................................................................................64

7-5 Technical Assistance.................................................................................................65

Parts Department ................................................................................................65

Service Department.............................................................................................65

Sales Department................................................................................................65

Contract Department...........................................................................................65

Chapter 1: Safety 5 of 65

Page 6

M2B+ Controller

Chapter 1: Safety

1-1 How to Use This Manual

Use this manual as a guide and reference for installing, operating, and maintaining your

equipment. The purpose is to assist you in applying efficient, proven techniques that enhance

equipment productivity.

This manual covers only light corrective maintenance. No other maintenance should be

undertaken without first contacting a service engineer.

The Functional Description section outlines models covered, standard features, and optional

features. Additional sections within the manual provide instructions for installation, preoperational procedures, operation, preventive maintenance, and corrective maintenance.

The Installation chapter includes required data for receiving, unpacking, inspecting, and setup

of the equipment. We can also provide the assistance of a factory-trained technician to help

train your operator(s) for a nominal charge. This section includes instructions, checks, and

adjustments that should be followed before commencing with operation of the equipment.

These instructions are intended to supplement standard shop procedures performed at shift,

daily, and weekly intervals.

The Operation chapter includes a description of electrical and mechanical controls, in

addition to information for operating the equipment safely and efficiently.

The Maintenance chapter is intended to serve as a source of detailed assembly and

disassembly instructions for those areas of the equipment requiring service. Preventive

maintenance sections are included to ensure that your equipment provides excellent, long

service.

The Troubleshooting chapter serves as a guide for identification of most common problems.

Potential problems are listed, along with possible causes and related solutions.

The Appendix contains technical specifications, drawings, schematics, and parts lists. A

spare parts list with part numbers specific to your machine is provided with your shipping

paperwork package. Refer to this section for a listing of spare parts for purchase. Have your

serial number and model number ready when ordering.

Safety Symbols Used in this Manual

The following safety alert symbols are used to alert you to potential personal injury hazards.

Obey all safety messages that follow these symbols to avoid possible injury or death.

Danger! DANGER indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

Warning! WARNING indicates a potentially hazardous situation or practice which, if not

avoided, could result in death or serious injury.

Caution! CAUTION indicates a potentially hazardous situation or practice which, if not

avoided, may result in minor or moderate injury or in property damage.

6 of 65 Chapter 1: Safety

Page 7

M2B+ Controller

1-2 Warnings and Precautions

Our equipment is designed to provide safe and reliable operation when installed and operated

within design specifications, following national and local safety codes.

To avoid possible personal injury or equipment damage when installing, operating, or

maintaining this equipment, use good judgment and follow these safe practices:

; Follow all SAFETY CODES.

; Wear SAFETY GLASSES and WORK GLOVES.

; Disconnect and/or lock out power before servicing or maintaining the equipment.

; Use care when LOADING, UNLOADING, RIGGING, or MOVING this

equipment.

; Operate this equipment within design specifications.

; OPEN, TAG, and LOCK ALL DISCONNECTS before working on equipment.

You should remove the fuses and carry them with you.

; Make sure the equipment and components are properly GROUNDED before you

switch on power.

; When welding or brazing in or around this equipment, make sure VENTILATION is

ADEQUATE. PROTECT adjacent materials from flame or sparks by shielding with

sheet metal. An approved FIRE EXTINGUISHER should be close at hand and

ready for use if needed.

; Refrigeration systems can develop refrigerant pressures in excess of 500 psi (3,447.5

kPa/ 34.47 bars). DO NOT CUT INTO THE REFRIGERATION SYSTEM. This

must be performed by a qualified service technician only.

; Do not restore power until you remove all tools, test equipment, etc., and the

equipment and related components are fully reassembled.

; Only PROPERLY TRAINED personnel familiar with the information in this

manual should work on this equipment.

We have long recognized the importance of safety and have designed and manufactured our

equipment with operator safety as a prime consideration. We expect you, as a user, to abide

by the foregoing recommendations in order to make operator safety a reality.

1-3 Responsibility

These machines are constructed for maximum operator safety when used under standard

operating conditions and when recommended instructions are followed in the maintenance

and operation of the machine.

All personnel engaged in the use of the machine should become familiar with its operation as

described in this manual.

Proper operation of the machine promotes safety for the operator and all workers in its

vicinity.

Each individual must take responsibility for observing the prescribed safety rules as outlined.

All warning and danger signs must be observed and obeyed. All actual or potential danger

areas must be reported to your immediate supervisor.

Chapter 1: Safety 7 of 65

Page 8

Page 9

M2B+ Controller

Chapter 2: Functional Description

2-1 Models Covered in This Manual

This manual provides operation, installation, and maintenance instructions for the M2B+

Controller. The M2B+ Controller is available for use with several models of temperature

control units (TCUs). A separate manual describes operation, installation, and maintenance

instructions for the TCU itself.

Chapter 2: Functional Description 9 of 65

Page 10

M2B+ Controller

2-2 General Description

The M2B+ is a microprocessor-based process controller designed for use with temperature

control units. The M2B+ monitors and maintains the temperature of the fluid in any given

process to a selected setpoint using a unique proportional integral derivative (PID) autotuning program. The controller employs PID algorithms to automatically tune the system to

heat or cool the fluid as required by the process.

The M2B+ has a Liquid Crystal Display (LCD) that provides all operational status and

programming menus. The controller includes self-diagnostics to check hardware functions.

All diagnostic information is displayed in the second line of the Liquid Crystal Display.

The M2B+ is panel-mounted and has a membrane keypad with tactile feedback. When

properly installed with a sealing gasket, the M2B+ meets NEMA 4 or IP66 integrity.

10 of 65 Chapter 2: Functional Description

Page 11

M2B+ Controller

2-3 Standard Features

• PID Control for both heating and cooling

• 4 line x 20 character LCD Display Screen

• Setpoint, To Process, From Process, and DT displays

• System status

• Password protection

• Selectable sensor types (Type K, J, & T thermocouples; 100 ohm and 1000 ohm RTDs)

• Autovent sequence (adjustable from 1 to 10 minutes)

• Sixteen segment Ramp/Soak program

• Start, stop, vent, and alarm silence switches

• D.C. dry contact inputs for pressure switch, pump rotation/phase loss, safety thermostat,

second setpoint/remote start, weld contact, and for pump tank applications high and low

water level

• Cascade control with remote input sensor

• Triac outputs for heating and cooling

• Crash (Quick) cool feature

• Alarm outputs for temperature (absolute and deviation), low or high flow (with optional

flow meter), open temperature sensor, low water pressure, pump failure, over

temperature, contactor weld, high and low water level (for pump tank units)

• Analog setpoint temperature input (current or voltage)

2-4 Optional Features

• Analog output for heating (SCRs) and cooling (modulating valves)

• Analog retransmission of Setpoint or To Process temperature

• Analog retransmission of flow (with optional flow meter)

• Flow sensor input, pulse or analog, with voltage excitation

• RS-232 or RS-485 Modbus communications

• RS-485 SPI communications

Chapter 2: Functional Description 11 of 65

Page 12

M2B+ Controller

2-5 Panel Layout and Keypad

See

Figure 1 on page 15 for an illustration of the control panel and its buttons. The LCD backlight

lights up whenever any key is pressed. The backlight turns off after five minutes if no other

key activity occurs.

LED Indicator Lights

The M2B+ has one LED that will light up to indicate the control process has been started.

This LED is located inside the Start button of the controller’s front panel. When power is

applied, the LED will remain off until the Start button is pushed. The LED will then

illuminate green.

LCD Display

A 4-line by 20-character liquid crystal display (LCD) will show operational status, alarms

and programming menus.

1st Line. The first line of the LCD continuously displays the ‘To Process’ temperature.

2nd Line. The second line of the LCD continuously displays the ‘Setpoint’ temperature.

3rd Line. The third line of the LCD continuously displays the ‘From Process’ temperature;

the delta temperature of the ‘To Process’ and the ‘From Process’; and the flow in GPM or

LPM, if applicable.

4th Line. The fourth line of the LCD will display all menu items used in the controller setup.

Also displayed are the status of the pump, outputs for the heater, as well as cooling and

elapsed time for the vent cycle. The fourth line will also explain all alarm conditions and

operating status.

12 of 65 Chapter 2: Functional Description

Page 13

M2B+ Controller

LCD Messages

Autotuning. Appears while tuning is in process.

High Water Alarm. Appears if the option is selected and the switch is closed

Water Pressure/Low Level Alarm. Appears when the Low Water Pressure switch is open

or the optional Low Water switch is closed.

Auto Vent Indicator. Appears in the LCD display when the unit is in Auto Vent mode. The

vent time remaining will also be displayed.

Pump Rotation/Loss Indicator. Appears in the LCD display when the Pump Rotation

switch is open.

Safety Thermostat Indicator. Appears in the LCD display when the Safety Thermostat

switch is open.

‘To Process’ Sensor Open Indicator. “999” appears in the process LED displays when the

‘To Process’ probe is open.

‘From Process’ Sensor Open Indicator. “999” appears in the LCD display for return

temperature (RT) when the ‘From Process’ probe is open.

Remote Probe Sensor Open Indicator. “999” appears in the LCD display for mold

temperature (MT) when the Remote probe is open.

High Alarm Indicator. Appears in the LCD display when a High Alarm condition occurs.

Low Alarm Indicator. Appears in the LCD display when a Low Alarm condition occurs.

‘From Process’ Temp Indicator. Appears in the LCD display when the temperature display

is showing the ‘To Process’ temperature.

Delta Temp Indicator. Appears in the LCD display when the temperature display is showing

temperature differential.

High Heat Output Indicator. Displays status in the LCD display when full power heat

output is applied.

Low Heat Output Indicator. Displays status in the LCD display when half power heat

output is applied. When the optional proportional output is installed, the display will show the

percentage of output.

Cool Output Indicator. Displays status in the LCD display when the cool output is applied.

When the optional proportional output is installed, the display will show the percentage of

output.

Ramp/Soak Indicator. Displays the ramp/soak segment status and remaining time in the

LCD display.

Second Setpoint/Remote Start. Displays status in the LCD display when either function is

selected.

Communications Local/Remote.

Weld Contact. Appears in the LCD Display when a Weld Contact Alarm condition occurs.

Chapter 2: Functional Description 13 of 65

Page 14

M2B+ Controller

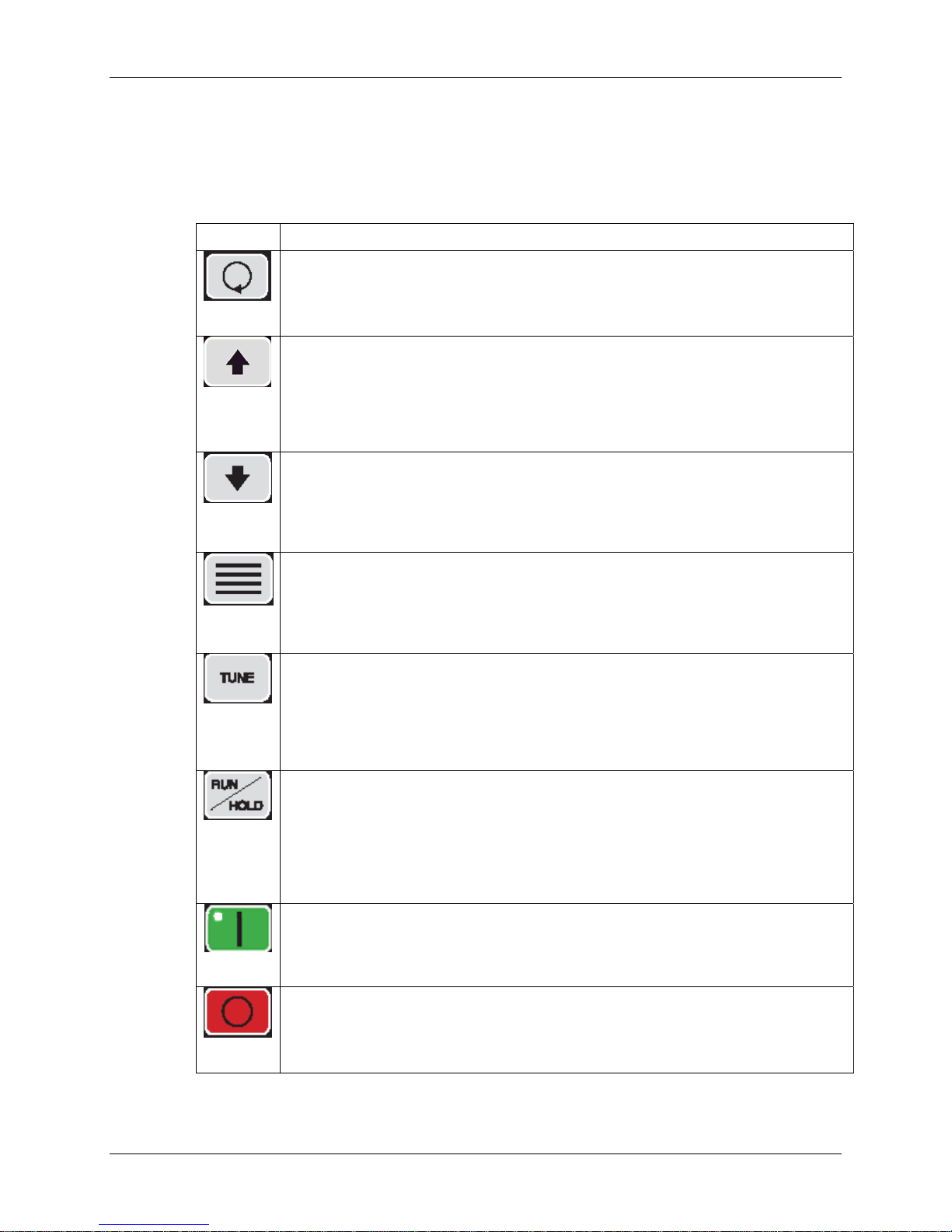

Keypad

Four keys, ‘Index’, ‘Up’, ‘Down’, and ‘Enter’ are used primarily to gain access to the menu

structure and modify the controller’s parameters and features. The remaining six keys are

used to direct the controller to start or stop a process.

Button Function

• Used to advance to one of the three setup menus.

• Used to advance to the next menu item when in a setup mode.

• Used in conjunction with the Down button to go back to a previous menu item when

Index

Up

Down

Enter

Tune

Run/Hold

Start

Stop

in a setup mode.

• Used in conjunction with the Enter button at power-on to break into Factory mode.

• Used to increment the current setpoint value while system is in the normal running

mode. Note that the rate speeds up when the key is held down.

• Used to increment the current parameter value when in a setup mode. Note that

the rate speeds up when the key is held down.

• If pressed when the oil unit is in the “PmpRev” Shutdown mode, the Vent Output

and the Alarm2 Output will be energized while the key is pressed. Use this function

to reverse the pump in order to purge the mold of hot oil.

• Used to decrease the current setpoint value while the system is in the normal

running mode. Note that the rate speeds up when the key is held down.

• Used to decrease the current parameter value when in a set up mode. Note that the

rate speeds up when the key is held down.

• If pressed when the Index button is being held down, returns to the previous menu

item when in a setup mode.

• Used to select one of the three setup modes.

• Used to accept (save/write to EEPROM) the current indicated parameter value.

• Note: No save/write occurs unless the Enter key is pressed before going to the

next/previous item or Setup mode is terminated.

• Used in conjunction with the INDEX key at power-on to enter into the Factory

mode.

• If no Autotune operation is in progress, this button starts an Autotune operation. If

an Autotune operation is in progress, pressing this button will immediately stop the

Autotune operation. While the Autotune is running, the “Autotune” message is

displayed on the LCD in place of the normal “Running” message.

• This key will not function if the Security Level is less than 3.

• This key will not function if the Ramp/Soak operation is in progress.

• This key will not function while in the Factory mode.

• This key controls the Ramp/Soak process. If no Ramp/Soak operation is in

progress, it starts the Ramp/Soak operation. When Ramp/ Soak is running, this key

puts the Ramp/Soak operation into a hold condition. While the Ramp/Soak is

running, the “Ramp/Soak” message is displayed on the LCD in place of the normal

“Running” message.

• This key will not function if the Security Level is less than 3.

• This key will not function if the Ramp/Soak operation is in progress.

• This key will not function while in the Factory mode.

• When system is powered-on, the controller initializes and then displays the

“[SYSTEM OFF]” message on the LCD. The controller is not functioning at this

point. Pressing this START key enables all controller functions and lights the green

power-on LED. After the system has been started, the “[Running]” message is

displayed on the LCD.

• Stops all controller functions and turns off the green power-on LED (ov errides

Remote Start input). After the system has been stopped, the “Stopped” message is

displayed on the LCD.

• This key will override an existing Remote Start input switch closure.

14 of 65 Chapter 2: Functional Description

Page 15

M2B+ Controller

Button Function

Vent

Alarm

Silence

Figure 1: Panel Layout

2-6

• When the system is first powered-on and the “Power Available - System Off”

message is displayed, pressing the VENT key will turn on the Vent Output for a

period of 8 seconds. The message “VENT” will be displayed during this period.

• When the system is running, pressing the VENT key shall manually turn on the

Vent Output for as long as the key is held down, provided the ‘To Process’

temperature is below 150

unit. The message “Vent Time = MANUAL” will be displayed while the key is held

down.

• Turns off the Alarm 1 Output. The cause of the alarm will continue to appear in LCD

until the fault is cleared.

• Used to immediately terminate any of the three Setup modes without having to

cycle through to the end of the menu items. Note that the current displayed

parameter value is not saved to EEPROM when this key is pressed.

• Can be used as a means of turning on the LCD backlight without affecting any

operation.

o

F (65.5oC) for a water unit and 250oF (121oC) for an Oil

Chapter 2: Functional Description 15 of 65

Page 16

M2B+ Controller

Menu Structure

The parameter menu structure is organized into three basic menus: Primary, Secondary, and

Secure. To access the menus, press the Index button until the menu label appears in the

second line of the LCD display. Additional menus display when an option is selected;

however, the options are non-functional unless the appropriate menu option or option board

has been installed. See the Menu Parameter Tables in the Appendix of this manual for more

information.

Continuing to press the Index button scrolls from menu to menu. Press the Enter button to

enter the menu, and use the Index button to scroll through the parameters of the menu. Once

you find the parameter that needs to be changed, use the Up and Down buttons to change the

parameter. Press the Enter button to accept the new value.

You can exit the setup menus by scrolling through the menu to its end or by pressing the

Alarm Silence button. The controller will automatically exit the setup menu if no buttons

have been pressed for more than one minute.

Primary Menu

The Primary menu includes all non-critical parameters for standard operation including but

not limited to standby mode, mold temperature, alarm trip points, ramp/soak settings, and

high heat.

Secondary Menu

The Secondary menu includes all non-critical parameters for optional equipment including

but not limited to degrees F/C, Alarm parameters, ramp/soak segments, remote setpoint

scaling, communication setup, and retransmission scaling.

Secure Menu

The Secure menu includes all critical parameters for setting up the controller including but

not limited to controller function, select either Water TCU or Oil TCU default values, flow

meter on/off, remote control probe on/off, pressure switch, high and low level, safety

thermostat on/off, output parameters, and scale limits.

16 of 65 Chapter 2: Functional Description

Page 17

M2B+ Controller

2-7 Passwords and Security

The controller provides four levels of security. Depending on the security level, some or all of

the setup menus may be locked. The security level must be changed in order to unlock these

menus. The current security level is displayed in the lower right corner of the menu display.

The default security level is 3.

Security levels are changed by changing the password value using the Up and Down buttons

and pressing the Enter button. Values in the setup menus can be changed only when the

correct security level is set. Note that the security level value itself can be changed in any

security level.

Use the following procedure to change the security level:

1. Press the Index button three times to access the Secure menu.

2. Press the Enter button. The LCD screen will display the current security level.

3. Use the Up or Down buttons to change the value in the display line to the password

of the new desired security level.

4. Press the Enter button to select this new security level and retain the value in

EEPROM. The display will change from the password value to the selected security

level for that password.

Level Password Menu Status Description

1 110

2 101

3 011

4 111

Primary Locked

Secondary Locked

Secure Locked

Primary

Secondary Locked

Secure Locked

Primary

Secondary

Secure Locked

Primary

Secondary

Secure

Unlocked

Unlocked

nlocked

U

nlocked

U

nlocked

U

nlocked

U

No parameter values can be

changed.

Setpoint cannot be changed.

Only the primary menu values

can be changed.

Setpoint can be changed.

Only the primary and secondary

menu values can be changed.

Setpoint can be changed.

All parameter values can be

changed.

Setpoint can be changed.

Chapter 2: Functional Description 17 of 65

Page 18

Page 19

M2B+ Controller

Chapter 3: Installation

3-1 Location

Mount the instrument in a location that will not be subject to excessive temperature, shock or

vibration. All models are designed for mounting in an enclosed panel.

When properly mounted in an enclosed panel using a gasket at the panel/controller interface,

the keypad can be washed down with water. Do not use high-pressure fluids.

3-2 Electrical Connections

Microprocessor-based instruments require a “clean” source of power that is steady and free of

noise. Electrical noise may be caused by line faults, power switching, motors, motor

controllers, or power controllers containing SCR devices. Without a clean source, any

microprocessor is prone to failure. If your power source is not from a clean line, your system

can be protected by installing a line filter.

Where external contactors or solenoids are used with relay output instruments, an R/C

Snubber Network should be used. The snubber installs easily directly across the field coil

terminals of the relay or solenoid.

Do not run thermocouples, RTD’s or other class 2 wiring in the same conduit or area as the

power leads. Maintain separation between wiring of sensors, process signals and other power

and control wiring.

Chapter 3: Installation 19 of 65

Page 20

Page 21

M2B+ Controller

Chapter 4: Basic Operation

4-1 Turning the Power On

When AC power is first applied to the unit, the following sequence of events will occur:

1. The LCD backlight lights up.

2. The LCD displays dashes: LEDs have all segments on.

3. The LCD displays the PROM Rev/Date.

4. The LCD displays “SelfTest in Progress.”

5. If the ‘Debug’ parameter is enabled, the following messages about Option Cards can

be displayed:

• Re-Transmit Detected

• Cool Analog Detected

• Heat Analog Detected

• Serial Comm Detected

• None Installed

6. The LED segments turn off.

7. The LCD backlight turns off.

8. The LCD displays “Power Available/System OFF.”

At this point, a Manual Vent Operation can be initializeed for 8 seconds by pressing the Vent

button.

The unit is now in a standby mode of operation. No system process control will occur until

the Start button is pressed.

Chapter 4: Basic Operation 21 of 65

Page 22

M2B+ Controller

4-2 Starting and Stopping Water TCUs

Starting the Unit (Local)

Press the Start button to begin the following sequence of events:

1. The green LED inside the Start button lights up.

2. The LCD backlight lights up.

3. The Pump Output turns on.

4. The LCD displays the setpoint value, process temperature, return temperature, and

delta temperature.

5. If the Auto Vent Cycle parameter is enabled, the Vent Output turns on, and the LCD

displays “Vent Time = mm:ss.”

6. When the Auto Vent timer expires or if the Auto Vent Cycle parameter is disabled,

the LCD displays “RUNNING,” and system control begins.

Stopping the Unit

While the system is running, press the Stop button to shut down the system. If the process

temperature is below 150ºF, the system will immediately shut down. If the current process

temperature is above 150ºF, pressing the Stop button will begin the following sequence of

events:

7. The LCD displays “SHUTDOWN [Cool Down].”

8. The setpoint changes to 150

º

F.

9. The Heat Outputs will turn off.

10. The Cool Output will turn on.

11. The system waits for the process temperature to drop down to 150

Note: Shutdown temperature is adjustable from 90

º

F.

°

F to 180°F. See

Section 5-14 for procedure.

12. At 150

º

F, the LCD displays “SHUTTING DOWN.”

13. All outputs immediately turn off.

14. The system re-cycles to the “Power Available/System OFF” state.

Note: Pressing the Stop button a second time while the controller is

in the “SHUTDOWN [Cool Down]” mode will abort this cool

down operation and the system will immediately go into the

“SHUTTING DOWN” phase of the operation.

Starting the Unit (Remote)

REMOTE START option, the controller start sequence will be initiated by a maintained dry

contact closure on pins 5 & 6 of header J6. The controller may be turned off by two means;

open the maintained contact input or depress the controller stop button.

The controller may also be started or stopped locally by depressing the controller start button

or stop buttons.

22 of 65 Chapter 4: Basic Operation

Page 23

M2B+ Controller

4-3 Starting and Stopping Hot Oil TCUs

Starting the Unit (Local)

Press the Start button to begin the following sequence of events:

1. The green LED inside the Start button lights up.

2. The LCD backlight lights up.

3. The Pump Output turns on.

4. The LCD displays the setpoint value, process temperature, return temperature, and

delta temperature.

5. If the Auto Vent Cycle parameter is enabled, the Vent Output turns on, the green

LED blinks, and the LCD alternates between “Mode is OFF,” “Press START to

Run,” and “Vent Time = mm:ss.”

6. When the Auto Vent timer expires or if the Auto Vent Cycle parameter is disabled,

the LCD alternates between “Mode is Off” and “Press START to Run.”

7. Press the Start button. The display reads “Vent Time = mm:ss.”

8. When the vent time expires, the LCD displays “RUNNING,” and system control

begins.

Stopping the Unit

While the system is running, press the Stop button to shut down the system. If the current

process temperature is above 150ºF, pressing the Stop button will begin the following

sequence of events:

9. The LCD displays “SHUTDOWN [Cool Down].”

10. The setpoint changes to 150ºF.

11. The Heat Outputs will turn off.

12. The Cool Output will turn on.

13. The system waits for the process temperature to drop down to 150ºF.

Note: Shutdown temperature is adjustable from 90

5-14 for procedure.

14. At 150ºF, the LCD displays “SHUTTING DOWN.”

15. All outputs immediately turn off.

16. The system re-cycles to the “Power Available/System OFF” state.

Note: Pressing the Stop button a second time while the controller is in the

“SHUTDOWN [Cool Down]” mode will abort this cool down operation

and the system will immediately go into the “SHUTTING DOWN” phase

of the operation.

If the process temperature is below 150ºF, all outputs will turn off, and the controller will

enable Pump Reverse mode. The LCD will display “Shutdown [PmpRevOff]” for 30 seconds

before the system re-cycles to the “Power Available/System OFF” state.

8

F to 1808F. See Section

During the 30-second “Shutdown[PumpRevOff] mode, press the Up button to reverse the

pump and purge oil from the mold. During pump reverse, the Vent Output and Pump

Reverse outputs will turn on. The LCD will display “Shutdown[PmpRevON] until the Up

Chapter 4: Basic Operation 23 of 65

Page 24

M2B+ Controller

button is released, at which time the 30-second time-out will restart. After 30-seconds, the

system will recycle to the “Power Available/System OFF” state.

Starting the Unit (Remote)

REMOTE START option is similar to the water process sequence. Closure of pins 5 and 6 of

header J6 initiates the start sequence. The display flashes MODE IS OFF, PRESS START

TO RUN. THE VENT/FILL timer counts down from 10 minutes. After the VENT/FILL

timer has elapsed, the controller will automatically go to the second vent operation for 10

minutes. Upon completing the second vent operation the controller will automatically go to

the run mode.

The controller may also be started or stopped locally by depressing the controller start button

or stop buttons.

4-4 Tuning

Autotuning

Caution! The factory default for the controller is automatic half/full heat for water units,

and full heat for oil units. If an autotune cycle is completed, do not switch to

low heat without performing a new autotune cycle. Failure to autotune will

result in poor control of the process. Subsequent changes from one heat setting

to another require autotune to be run.

The Tune button is used to toggle the autotune process. If no autotune operation is in

progress, pressing the Tune button starts the autotune operation. The “AutoTune” message is

displayed on the LCD. If an autotune operation is already in progress, pressing this button

again will immediately stop the autotune operation. The display will return to the “Running”

message.

During the autotune process, the control point is the ‘To Process’ probe or the ‘Remote

Selected’ probe. The tuning constants (i.e. rate, reset and gain) can be altered in setup mode.

The unit’s cycle time is selectable in one-second increments. The heat and cool cycles have a

minimum pulse of one second.

24 of 65 Chapter 4: Basic Operation

Page 25

M2B+ Controller

Manual Tuning (Zeigler-Nichols PID Method)

This tuning method may be used if the spread between ambient temperature and process

operating temperature is small. For best results, use a recording device when tuning with this

method.

1. Disable the cooling valve by removing the output signal to the device. For solenoid

valves, remove plug from the solenoid. For modulating valves, remove the J7 plug

located on the back of the controller.

2. Press the Index button one time to access the Primary Menu.

3. Press the Enter button.

4. In the Primary Menu, change the Reset Time and Rate Time OFF, and change the

Prop Band Heat to 100.

5. Adjust setpoint to the desired value.

6. While monitoring the process temperature or recording device, decease the

proportional value by repeatedly halving the value until a small, sustained

temperature oscillation is observed. Measure the period of one cycle of oscillation

“T”.

7. Divide the period of oscillation “T” by eight; the resulting number is the correct Rate

Time in seconds.

8. Multiply the Rate Time by four. This is the correct Reset Time in seconds.

9. Multiple the bandwidth value “T” by 1.66, and enter this as the new Prop Band Heat

value.

10. Re-enable the cooling valve by reversing step 1.

Chapter 4: Basic Operation 25 of 65

Page 26

M2B+ Controller

4-5 Selecting a Local Probe

The controller has two standard temperature probe inputs for delivery (to process) and return

(from process). The probes are typically set up at the factory, but they can be re-configured in

the field. To set up this feature you must have access to the Secure Menu. See Section 2-6 on

page 16 to review accessing the Secure Menu.

Use the following procedure to select a local probe:

1. Press the Index button three times to access the Secure menu.

2. Press the Enter button.

3. Press the Index button until the display reads “Sensor type = RTDIK.”

4. Use the Up and Down buttons to select the sensor type.

5. Press the Enter button to accept the value.

When changing the sensors from RTDs to thermocouples, you must also change the

jumpers JMP1 and JMP3 to pins 2 and 3.

6. Press the Alarm Silence button to return to Running mode.

Using a Remote Input Probe for Monitoring

The Remote Probe Input can be used for two different functions: To control or monitor the

temperature of a process outside of the temperature control loop. To set up this feature you

must have access to the Secure Menu. See Section 2-6 on page 16 to review accessing the

Secure Menu.

This option can be purchased with or without the manufacturer supplying the actual

temperature-sensing device. If the manufacturer supplies the probe, the controller is

preconfigured, and the user needs to set up the controller as local or remote input.

Use the following procedure to monitor the process from the remote probe:

1. Press the Index button three times to access the Secure menu.

2. Press the Enter button.

3. Press the Index button until the display reads “Sensor Monitor.”

4. Press the Enter button.

5. Use the Up and Down buttons to select the type of input desired. Select “MON” for

monitor. The LCD display will change to have MT display the monitored

temperature from the probe.

If the display reads “999,” the probe is not plugged into the back of the controller at

pins 3 and 4 of the 8-pin connector.

6. Press the Enter button to save the sensor monitor parameter.

7. Press the Index button until the display reads “Mold Sensor Type.”

8. Press the Enter button.

9. Use the Up and Down buttons to select the type of mold sensor (Type J, K, or T

thermocouples or 100 or 1000 ohm RTD).

10. Press the Enter button to save the mold sensor type.

11. Press the Alarm Silence button to return to Running mode.

26 of 65 Chapter 4: Basic Operation

Page 27

M2B+ Controller

4-6 Setting Up Cascade Control

The controller is provided with an internal cascade control feature. Cascade control is used to

enable a process having multiple lags to be controlled with the fastest possible response to

process disturbances. The system uses a remote control probe in the downstream process and

a local delivery and return probe in the TCU. The controller uses the remote probe to drive

the heating and cooling outputs, while the local delivery probe is the process fluid

temperature limit control. To set up this feature you must have access to the Secure Menu.

See Section 2-6 on page 16 to review accessing the Secure Menu.

V1.09C-V2.01 Cascade Set-up

• Turn Power on. The controller will go through an initialization sequence.

• After the sequence is complete, turn the controller on with the start button. The

controller will be defaulted to SECURE 3; To access parameters in the secure

menu the controller must be in SECURE 4.

• Index to secure menu, press enter, Use the up arrow to scroll to “111”, press

enter. The controller secure menu is unlocked.

• Scroll down to the SENSOR MONITOR menu, default is OFF. Depress the up

arrow to display=CNTL depress enter. The controller is now set for cascade

control.

• Scroll to the menu MOLD SENSOR type. Press the up arrow to display = RTD.

This is the setting for a 100 ohm RTD for the remote probe. For 1K ohm, select

RTD1K.

• Continue to scroll through the menu until the control goes back to the run menu.

Or wait one minute without touching a key. The controller will return to the run

mode automatically.

• The remote probe input is wired to Header J5, pins 3 and 4 on the back of the

controller. The remote probe is factory defaulted for a Type J T/C input. Move

the jumper “JMP2” to pins 1 and 2 for a RTD input.

• The controller process display will reflect the customer’s remote temperature. DT

(local to process temperature) will appear to the right of the Delta T temperature.

• If the local PID parameters are known, enter them for the inner loop parameters.

If they are unknown, take the controller out of the cascade mode by setting the

SENSOR monitor selection to OFF. Press the TUNE button. The parameters will

be written into the primary menu.

• Return the controller to the cascade mode.

• Press the TUNE button again to tune the controller to the customer’s process.

When the tune is completed, the PID parameters will be written into the

PRIMARY menu.

• Both the inner and outer loops can be viewed or adjusted in the PRIMARY

menu.

Chapter 4: Basic Operation 27 of 65

Page 28

M2B+ Controller

4-7 Adjusting the Automatic Venting Timer

When the Auto Vent Cycle Timer is set, the controller will open the venting valve for the set

time at the startup of the unit. The Auto Venting Timer can be turned off, or it can be set to a

specified time period. For water TCUs, Auto Vent can be set between 1 and 10 minutes. For

hot oil TCUs, the vent time can be set between 1 and 60 minutes. TCUs are programmed at

the factory to Auto Vent for 1 minute for water units and 10 minutes for oil units.

Use the following procedure to adjust the Auto Vent Cycle parameter:

1. Press the Index button one time to access the Primary menu.

2. Press the Enter button.

3. Press the Index button until the display reads “Auto Vent Cycle.”

4. Press the Enter button.

5. Use the Up and Down buttons to set the cycle time to the desired time.

6. Press the Enter button to save the cycle time.

7. Press the Alarm Silence button to return to Running mode.

4-8 Using Crash Cool

The Crash Cool feature allows the user to quickly cool the process down. Once Crash Cool is

turned on, the setpoint is automatically adjusted to 0ºF, and the cooling valve is opened. Oil

TCUs not equipped with the optional heat exchanger will cool only through convection and

radiation.

Use the following procedure to being “Crash Cool”:

1. Press the Index button one time to access the Primary menu.

2. Press the Enter button

3. Press the Index button until the display reads “Crash Cool.”

4. Press the Enter button.

5. Use the Up and Down buttons to set the “Crash Cool” parameter to “ON.”

6. Press the Enter button to begin crash cooling. The setpoint will change to 0, and the

cool output will turn on.

7. Press the Alarm Silence button to return to Running mode.

28 of 65 Chapter 4: Basic Operation

Page 29

M2B+ Controller

Chapter 5: Advanced Operation

5-1 Using the Analog Remote Input

This feature is typically setup at the factory, but can be installed as a retrofit in the field. It is

used to accept a remote analog setpoint value or flow value. If the analog signal is set up for

remote setpoint input, the Up and Down arrow keys are locked out for changing the setpoint

at the controller. The analog signal can be configured to be 0-20 mA, 4-20 mA, 0-5 VDC, 15 VDC, 0-10 VDC, or 2-10 VDC via jumper 4 and menu selection.

Use the following procedure to set up the Analog Remote Input:

1. Press the Index button two times to access the Secondary menu.

2. Press the Enter button.

3. Press the Index button until the display reads “Remote Input.”

4. Press the Enter button.

5. Use the Up and Down buttons to change value to either SETP for setpoint or FLOW

for flow.

6. Press the Enter button.

7. Press the Index button one time to access the “Remote Signal” parameter.

8. Press the Enter button.

9. Use the Up and Down buttons to change the range of the analog input.

10. Press the Enter button.

11. Press the Alarm Silence button to return to Running mode.

From the factory, the remote setpoint temperature range is set up to be the same as the range

of the controller (Water: 0°F to 250°F; Oil: 0°F to 550 °F). These parameters can be changed

through the Secondary Menu.

Use the following procedure to adjust the remote setpoint temperature range:

1. Press the Index button two times to access the Secondary menu.

2. Press the Enter button.

3. Press the Index button until the display reads “Remote SetPtLo” for the low limit, or

“Remote SetPtHi” for the high limit.

4. Press the Enter button.

5. Use the Up and Down buttons to change the value.

6. Press Enter to accept the value change.

7. Press the Alarm Silence button to return to Running mode.

Note: If there is no signal present, the controller’s setpoint will automatically

default to 0 °F.

Chapter 5: Advanced Operation 29 of 65

Page 30

M2B+ Controller

5-2 Retransmission Analog Signal

This feature is typically set up at the factory, but it can also be installed as a retrofit in the

field. It is used to transmit an analog signal for process temperature, setpoint temperature, and

flow. The analog signal can be configured to be 0-20mA, 4-20mA, 0-5VDC, 1-5VDC, 010VDC, and 2-10VDC.

Note: The Process Output Low and High values must match the high and low

limits of the controller setup in the Secure menu.

Use the following procedure to set up the analog retransmission output:

1. Insert the analog retransmission card (P/N 691-00537-00) into header “J9.” The card

must be inserted into the header to activate the analog output setpoint menus.

2. Press the Index button two times to access the Secondary menu.

3. Press the Enter button.

4. Press the Index button until the display reads “Analog Out=Process Signal Type.”

5. Use the Up and Down buttons to change the value.

6. Press the Enter button to accept the value.

7. Press the Index button until the display reads “Process Outlow.”

8. Use the Up and Down buttons to change the low limit value.

9. Press the Enter button to accept the value.

10. Press the Index button until the display reads “Process OutHig.”

11. Use the Up and Down buttons to change the high limit value.

12. Press the Enter button to accept the value.

13. Press the Index button until the display reads “Process Out SrC.”

14. Use the Up and Down buttons to change the analog signal source to PROC, SETP, or

FLOW.

Note: Selecting “FLOW” requires additional setup. See the next procedure.

15. Press the Enter button to accept the value.

16. Press the Alarm Silence button to return to Running mode.

30 of 65 Chapter 5: Advanced Operation

Page 31

M2B+ Controller

Setting the Analog Signal Source to FLOW

If the analog signal source is set to “FLOW,” follow steps 1 through 15 on page 30, and then

complete the following procedure:

1. Press the Index button until the display reads “Remote Input.”

2. Use the Up and Down buttons to change the value to “FLOW.”

3. Press the Enter button to accept the value.

4. Press the Index button until the display reads “Remote Signal.” Do not alter this

value; use the default setting.

5. Press the Enter button to accept the default setting.

6. Press the Index button until the display reads “Remote Flowslo=Minimum Flow

Value.”

7. Use the Up and Down buttons to change the value to 0.

8. Press the Enter button to accept the value.

9. Press the Index button until the display reads “Remote Flowshi=Maximum Flow

Value.”

10. Press the Enter button to accept the default value.

11. Press the Alarm Silence button to return to Running mode.

12. Press the Index button two times to access the Secondary menu.

13. Press the Enter button.

14. Press the Index button until the display reads “Remote Input.”

15. Use the Up and Down buttons to select “OFF.”

16. Press the Enter button to accept the value.

17. Press the Alarm Silence button to return to Running mode.

Using Analog Output for Heating and Cooling

This feature is typically set up at the factory, but it can also be installed as a retrofit in the

field. It is used to control a modulating valve or heating SCR proportionally. The analog

signal can be configured to be 0-20mA, 4-20Ma, 0-5VDC, 1-5VDC, 0-10VDC, and 210VDC. Inserting the card into header “J5” for cooling or “J6” for heating automatically

configures the controller to direct its outputs through these boards.

Use the following procedure to set up the analog outputs:

1. Insert the analog card (P/N 691-00537-00) into the appropriate header.

2. Press the Index button two times to access the Secondary menu.

3. Press the Enter button.

4. Press the Index button until the display reads “Cool Output” or “Heat Output.”

5. Use the Up and Down buttons to select the analog signal type.

6. Press the Enter button to accept the value.

7. Press the Alarm Silence button to return to Running mode.

Chapter 5: Advanced Operation 31 of 65

Page 32

M2B+ Controller

5-3 Using the Flow Monitor

The controller is set up to accept a pulsed or current input from a flow sensor. The controller

translates the pulse or current into either gpm (gallons per minute) or lpm (liters per minute).

If the flow sensor is of the pulsed variety, it is connected to block J1 on the main controller

board. For analog signal sensors, see Section Chapter 5: on page 29.

Use the following procedure to set up a pulsed flow sensor:

1. Press the Index button three times to access the Secure menu.

2. Press the Enter button.

3. Press the Index button until the display reads “Flow Monitor.”

4. Press the Enter button.

5. Use the Up or Down buttons to change the value to PUL for pulsed input.

6. Press the Enter button to accept the value.

7. Press the Index button one time to access the “Flow Constant B” parameter.

8. Press the Enter button.

9. Use the Up and Down buttons to change the offset of the displayed flow reading.

This value should be determined by using a certified sensor to determine the offset.

10. Press Enter to accept the value.

11. Press the Index button one time to access the “Flow Constant K” parameter.

12. Press the Enter button.

13. Use the Up and Down buttons to change the scaling factor to the K factor (pulses per

gallon) provided by the sensor manufacturer. If the K factor isn’t known, use the

GPM flow rate and frequency. (A factor = GPM/Hz, K factor = 60 sec./A factor)

14. Press the Enter button to accept the value.

15. Press the Alarm Silence button to return to Running mode.

At this point, the controller should display the flow as “FL=X.X.” The user can now set up as

many as two alarms that will annunciate when the flow drops below or rises above a set value.

Use the following procedure to set up the flow alarm:

1. Press the Index button one time to access the Primary menu.

2. Press the Enter button.

3. Press the Index button until the display reads “Flow Alarm Low” for a low flow

alarm or “Flow Alarm High” for a high flow alarm.

4. Press the Enter button.

5. Use the Up and Down buttons to change the value.

6. Press the Enter button to accept the value.

7. Press the Alarm Silence button to return to running mode.

Use the following procedure to change the units of the displayed flow:

1. Press the Index button two times to access the Secondary menu.

2. Press the Enter button.

3. Press the Index button until the display reads “Flow Display.”

4. Press the Enter button.

5. Use the Up and Down buttons to change the value between GPM and LPM.

6. Press the Enter button to accept the change.

7. Press the Alarm Silence button to return to Running mode.

32 of 65 Chapter 5: Advanced Operation

Page 33

M2B+ Controller

5-4 Programming the Alarms

The controller is set up to monitor both critical and non-critical operations within the process.

Based on the severity of the condition, the controller will alarm and perform a specific

function based on the type of unit being controlled. If an alarm is tripped, the LCD display

will flash the backlight and if an audible alarm is present, turn it on. Below is a brief

explanation of each of the eight areas that the controller monitors and how to set them up.

Temperature

This alarm is used to monitor the difference between the setpoint and the “to process”

temperatures. The alarm can be configured as an absolute or deviation alarm. When setting

the alarm value for an absolute alarm (Alarm1 Mode = ABS), simply set the value at which

the alarm is to occur.

When setting the value for the deviation alarm (Alarm1 Mode = DEV), set the difference in

value from the Setpoint desired. For example if you want to configure Alarm 1 as a high and

low deviation alarm (Alarm1 Cfg = HILO and Alarm1 Mode = DEV), and you want the low

alarm to be 5 degrees below the setpoint, then set Alarm 1 Low = 5. If a high alarm is to be

20 degrees above the setpoint, then set Alarm 1 High = 20. If the setpoint is changed, the

alarm will continue to maintain that deviation.

Use the following procedure to set up the temperature alarm to be either an absolute alarm or

a deviation alarm:

1. Press the Index button two times to access the Secondary menu.

2. Press the Enter button.

3. Press the Index button until the display reads “Alarm1 Cfg.”.

4. Press the Enter button.

5. Press the Up and Down buttons to select the alarm type: low, high, hilo, or evnt.

6. Press the Enter button.

7. Press the Index button one time to see “Alarm1 Mode.”

8. Use the Up and Down buttons to select ABSL for absolute or DEV for deviation.

9. Press the Enter button.

10. Press the Alarm Silence button to return to the Running mode.

11. Press the Index button one time to access the Primary menu.

12. Press the Enter button.

13. Press the Index button until the alarm type you selected in Step 5 appears (example

Alarm 1 Low).

14. Press the Enter button.

15. Use the Up and Down buttons to select the temperature for the configured alarm.

16. Press the Enter button.

17. Repeat Steps 15 and 16 until all of the alarm configurations are set up.

18. When finished, press the Alarm Silence button to return to Running mode.

Note: The factory setup of the alarms is to be in an On/Off reset mode (Alarm1 Reset =

ONOF). The reset declares how the controller is supposed to function when the

alarm is tripped. The On/Off mode allows the controller to reset the alarm when

the offending parameter is cleared. The HOLD mode makes the alarm a critical

one in which the user has to turn the controller off and then on to clear the alarm.

Chapter 5: Advanced Operation 33 of 65

Page 34

M2B+ Controller

Flow Alarm

This alarm is used to monitor the flow rate input from either a pulse or analog style flow

meter. Once the Flow Monitor is turned on (in the Secure Menu; Flow Monitor = PUL or

CUR) either a low flow alarm or high flow alarm or both can be set up.

Use the following procedure to set up the Flow Alarm:

1. Press the Index button one time to access the Primary menu.

2. Press the Enter button.

3. Press the Index button until the display reads “Flow Alarm Low.”

4. Press the Enter button.

5. Use the Up and Down buttons to adjust the value of the alarm.

6. Press the Enter button to accept the value.

7. Press the Index button until the display reads “Flow Alarm High.”

8. Press the Enter button.

9. Use the Up and Down buttons to adjust the value of the alarm.

10. Press the Enter button to accept the value.

11. Press the Alarm Silence button to return to Running mode.

Open Sensor

This alarm occurs when the controller loses the signal from the To Process (process display

999), From Process (return display 999), or Remote probes (mold display 999). This alarm is

critical. The pump will remain operating and cooling is enabled. Turn the controller off,

correct the condition and start the controller to clear the fault. There are no menu items that

affect this function.

Low Pressure

This alarm occurs when the controller loses the signal from the pressure switch. In water

units, this alarm immediately disables the pump motor, heat, and cool outputs. In the water

unit, this alarm is not critical and will automatically reset the controller once the pressure

signal is regained.

In water units with manual fill reservoir tanks, the pressure switch input can be bypassed

during initial start-up with an adjustable timer located in the Secure menu. This time period

should be kept as short as possible to prevent damage to the pump seal.

In oil units, during the Auto Mode, the loss of the pressure switch disables the heater output

and the pump motor output will remain on for a preset time period (Pressure Timer = OFF,

2sec, 5sec, 30sec, or 1 to 10 minutes).

Use the following procedure to change the Pressure Timer for oil TCUs:

1. Press the Index button three times to access the Secure menu.

2. Press the Enter button.

3. Press the Index button until the display reads “Pressure Timer.”

4. Press the Enter button.

5. Use the Up and Down buttons to adjust the value of the timer.

6. Press the Enter button to accept the change.

7. Press the Alarm Silence button to return to Running mode.

34 of 65 Chapter 5: Advanced Operation

Page 35

M2B+ Controller

Low Fluid Level Alarm

This factory-set alarm occurs when the low level switch is in a closed condition. This is not a

critical alarm and will reset once the condition is cleared. For water TCUs the Low Level

alarm disables the heater and the pump motor outputs. For oil TCUs it disables the heater

output. There are no menus that affect this alarm.

High Fluid Level Alarm

This factory-set alarm occurs when the high level switch is in a closed condition. This alarm

is only applicable for water TCUs. This is not a critical alarm and will reset once the

condition is cleared. It is an alarm only and no outputs are disabled.

Pump Failure Alarm

This critical, factory-set alarm occurs when one of three conditions occurs: phase loss, phase

reversal, or motor overload trip. If any of these occur, the heat, cool, and pump motor

outputs are disabled. Turn the unit off and then on again to reset the fault.

Safety Thermostat Alarm

This critical, factory-set alarm occurs when the thermostat sensor opens on a high

temperature condition. For both water and oil TCUs, the heater output is disabled, but the

pump and cooling outputs are still active. For water TCUs, the cooling output will latch on.

Turn the unit off and then on again to reset the fault.

Welded Contactor Alarm

This critical factory-set alarm occurs when the controller senses that an auxiliary contact has

remained closed after a preset time period after the heater output has been turned off. The

heater output is disabled, and the cool and pump motor outputs are enabled to prevent

temperature runaway. This alarm is an option for water TCUs and is standard for oil units.

Turn the unit off and then on again to reset the fault.

Chapter 5: Advanced Operation 35 of 65

Page 36

M2B+ Controller

5-5 Using the Second Setpoint Function

With this function, the user can send the controller a dry contact closed signal to activate the

second setpoint. Opening the dry contact causes the controller to revert to the primary

setpoint. To reinitiate the second setpoint, the switch must be closed again.

Use the following procedure to enable the second setpoint function:

1. Press the Index button three times to access the Secure menu.

2. Press the Enter button.

3. Press the Index button until the display reads “SP2/RmtStart.”

4. Press the Enter button.

5. Use the Up and Down buttons to change the value to “SP2.”

6. Press the Enter button to accept the change.

7. Press the Alarm Silence button to return to Running mode.

8. Press the Index button to access the Primary menu.

9. Press the Enter button.

10. Press the Index button until the display reads “Aux Set Point.”

11. Press the Enter button.

12. Use the Up and Down buttons to change the value. The range is between the

SetPtLoLimit and the SetPtHiLimit in the Secure menu.

13. Press the Enter button to accept the change.

14. Press the Alarm Silence button to return to Running mode.

5-6 Using the Remote Start Function

With this function, the user can send the controller a dry contact closed signal to activate the

controller. Stopping the unit can be done one of two ways: removing the signal or pressing

the Stop button on the face of the controller. Either method will initiate the Automatic

Shutdown routine within the controller. The remote contact must be opened to reset the

controller.

36 of 65 Chapter 5: Advanced Operation

Page 37

M2B+ Controller

5-7 Changing the Temperature Display Units

The controller is set up to display the temperature, and all related temperature settings, in

either degrees Fahrenheit or degrees Celsius. Use the following procedure to change the

display units:

1. Press the Index button two times to access the Secondary menu.

2. Press the Enter button.

3. Press the Index button one time to access the “Degrees (F/C)” parameter.

4. Use the Up and Down buttons to change the value.

5. Press the Enter button to accept the change.

6. Press the Alarm Silence button to return to Running mode.

5-8 Setting the Temperature Display Precision

The controller is factory-set to display the temperature, and all related settings, as an integer.

The user has the ability to change the display precision to tenths of a degree. Use the

following procedure to change the display precision:

1. Press the Index button two times to access the Secondary menu.

2. Press the Enter button.

3. Press the Index button until the display reads “Precision.”

4. Use the Up and Down buttons to change the value.

5. Press the Enter button to accept the change.

6. Press the Alarm Silence button to return to Running mode.

Chapter 5: Advanced Operation 37 of 65

Page 38

M2B+ Controller

5-9 Using the Elapsed Time Meter

The controller is equipped with an elapsed time meter that keeps track of the time that the

pump motor has run in hours. The meter is enabled or reset in the Secure menu and viewed

in the Primary menu.

Use the following procedure to enable the elapsed time meter:

1. Press the Index button three times to access the Secure menu.

2. Press the Enter button.

3. Press the Index button until the display reads “ElapsedTimeMode.”

4. Use the Up and Down buttons to change the value to “ON.”

5. Press the Enter button to accept the value.

6. Press the Alarm Silence button to return to Running mode.

Use the following procedure to view the elapsed time meter:

1. Press the Index button one time to access the Primary menu.

2. Press the Enter button.

3. Press the Index button until the display reads “ElapsedTime.”

4. Press the Alarm Silence button to return to Running mode.

Use the following procedure to reset the elapsed time meter:

1. Press the Index button three times to access the Secure menu.

2. Press the Enter button.

3. Press the Index button until the display reads “ElapsedTimeMode.”

4. Use the Up and Down buttons to change the value to “RST.”

5. Press the Enter button to accept the value.

6. Press the Alarm Silence button to return to Running mode. At this point the meter has

been reset to zero hours.

38 of 65 Chapter 5: Advanced Operation

Page 39

M2B+ Controller

5-10 Programming Ramp/Soak

The controller has a 16-segment, front-face programmable Ramp/Soak feature. Unused

alarms can be programmed as a segment.

Caution! Do not attempt to auto-tune the controller during a ramp/soak program. The

Tune button will not function during this process.

Instead of requiring the operator to calculate an approach rate, the controller does the

calculation automatically. The operator needs to program the target setpoint and the time

desired to reach that setpoint. When the controller executes the ramp segment, it calculates

the ramp required to reach the process temperature from starting setpoint to the programmed

setpoint in the time allowed. (See Figure 2 for sample ramp/soak program.)

Dwells (or soaks) are ramp segments with target setpoint equal to starting process

temperature. This allows for multistage ramps without wasting intermediate soak steps.

Note: Before programming Ramp/Soak, evaluate your program on paper.

Test any program for best results before running production material.

Caution! Make sure to run auto-tune before operating Ramp/soak because Ramp

functions will interfere with the operation of the auto-tune

Segment Prompt Function Time (min.) Setpoint, ºF

1TI 1st Event 1

1SP 50

2TI 2nd Event 2

2SP 150

3TI 3rd Event 2

3SP 150

4TI 4th Event 2

4SP 100

5TI 5th Event 1

5SP 100

6TI 6th Event 2

5SP 50

7TI Un-Used 0

7SP Hold Last Setpoint 50

↓

GTI Un-Used 0

GSP 50

END Stay at present setpoint (GSP) HOLD

END Revert to SP1 value SETP