Page 1

GP Series

Portable Chillers

Part Number: 882.93092.00

Bulletin Number: SC2-620

Effective: 5/1/2009

Write Down Your Serial Numbers Here For Future Reference:

_________________________ _________________________

_________________________ _________________________

_________________________ _________________________

We are committed to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual are subject to change without notice.

ECN No. ____________

© Copyright 2009

All rights reserved.

Page 2

Shipping Information

Unpacking and Inspection

You should inspect your equipment for possible shipping damage. Thoroughly check the

equipment for any damage that might have occurred in transit, such as broken or loose wiring

and components, loose hardware and mounting screws, etc.

In the Event of Shipping Damage

According to the contract terms and conditions of the Carrier, the responsibility of the

Shipper ends at the time and place of shipment.

Notify the transportation company’s local agent if you discover damage

Hold the damaged goods and packing material for the examining agent’s inspection. Do not

return any goods before the transportation company’s inspection and authorization.

File a claim with the transportation company. Substantiate the claim by referring to the

agent’s report. A certified copy of our invoice is available upon request. The original Bill of

Lading is attached to our original invoice. If the shipment was prepaid, write us for a

receipted transportation bill.

Advise customer service regarding your wish for assistance and to obtain an RMA (return

material authorization) number.

If the Shipment is Not Complete

Check the packing list as back-ordered items are noted on the packing list. In addition to the

equipment itself, you should have:

Bill of lading

Packing list

Operating and Installation packet

Electrical schematic and panel layout drawings

Component instruction manuals (if applicable)

Re-inspect the container and packing material to see if you missed any smaller items during

unpacking.

If the Shipment is Not Correct

If the shipment is not what you ordered, contact the parts and service department

immediately at (262) 641-8610. Have the order number and item number available.

Hold the items until you receive shipping instructions.

Returns

Do not return any damaged or incorrect items until you receive shipping instructions from the

shipping department.

GP Series Portable Chillers ii

Page 3

Table of Contents

CHAPTER 1: SAFETY................................................................5

1-1 How to Use This Manual.............................................................................................5

Safety Symbols Used in this Manual.....................................................................5

1-2 Warnings and Precautions..........................................................................................6

1-3 Responsibility..............................................................................................................6

CHAPTER 2: FUNCTIONAL DESCRIPTION.............................7

2-1 Models Covered in This Manual..................................................................................7

2-2 General Description.....................................................................................................7

Chilled Water Circuit..............................................................................................7

Refrigeration Circuit...............................................................................................7

2-3 Standard Features.......................................................................................................8

Mechanical Features.............................................................................................8

Electrical Features.................................................................................................8

Refrigeration Features...........................................................................................9

Controller Features................................................................................................9

Other Features ......................................................................................................9

2-4 Safety Devices and Interlocks.....................................................................................9

Crankcase Heater .................................................................................................9

High Pressure Cutout..........................................................................................10

Low Pressure Cutout (no switch but done through the transducer) ....................10

Flow Switch .........................................................................................................10

Remote Start/Stop Interlock ................................................................................10

2-5 Optional Features......................................................................................................10

CHAPTER 3: INSTALLATION..................................................13

3-1 Uncrating...................................................................................................................13

3-2 Electrical Connections...............................................................................................13

3-3 Process Water Connections.......................................................................................14

3-4 Bypass Valve Considerations....................................................................................14

3-5 Galvanic Corrosion Considerations...........................................................................14

3-6 Water Treatment Considerations ..............................................................................14

3-7 Condenser Considerations........................................................................................15

Water-Cooled Chiller Condensers.......................................................................15

Air-Cooled Chiller Condensers............................................................................15

3-8 Checking Motor Direction..........................................................................................16

Three-Phase Compressors .................................................................................16

Water Pumps.......................................................................................................16

Condenser Fan....................................................................................................16

3-9 Water Reservoir ........................................................................................................17

3-10 Automatic Water Make-Up Option.............................................................................19

3-11 Initial Start-Up............................................................................................................19

3-12 Finishing Setup: Setting Up Passwords....................................................................19

CHAPTER 4: OPERATION.......................................................22

GP Series Portable Chillers iii

Page 4

Panel Buttons, Indicator Lights, and Switches..........................................................22

4-1

Microprocessor Controller ...................................................................................22

4-2 Initial Start-up............................................................................................................23

4-3 Status Screens..........................................................................................................25

4-4 Access Levels ...........................................................................................................26

4-5 Controller Setpoints...................................................................................................28

4-6 Alarms.......................................................................................................................30

4-7 Optional Communications.........................................................................................30

CHAPTER 5: MAINTENANCE .................................................32

5-1 Lubrication.................................................................................................................32

5-2 Filter Cleaning...........................................................................................................32

5-3 Maintaining the Condenser .......................................................................................32

Air- and Remote Air-Cooled Chillers ...................................................................32

Water-Cooled Chillers .........................................................................................32

5-4 Maintaining the Evaporator .......................................................................................33

5-5 Evaporator Process Piping Y-Strainer.......................................................................33

5-6 Preventative Maintenance Service............................................................................33

CHAPTER 6: TROUBLESHOOTING .......................................34

CHAPTER 7: APPENDIX..........................................................36

7-1 Returned Material Policy...........................................................................................36

Credit Returns .....................................................................................................36

7-2 Technical Assistance.................................................................................................37

Parts Department ................................................................................................37

Service Department.............................................................................................37

Sales Department................................................................................................37

Contract Department...........................................................................................37

7-3 Specifications............................................................................................................38

Air-Cooled Portable Chillers................................................................................38

Water-Cooled Portable Chillers...........................................................................40

7-4 Pump Curves, Flow, and Pressure Considerations...................................................42

60 Hertz Pump Curves........................................................................................42

7-5 Electrical Schematic..................................................................................................44

GP Series Portable Chillers iv

Page 5

Chapter 1: Safety

1-1 How to Use This Manual

Use this manual as a guide and reference for installing, operating, and maintaining your

equipment. The purpose is to assist you in applying efficient, proven techniques that enhance

equipment productivity.

This manual covers only light corrective maintenance. No other maintenance should be

undertaken without first contacting a service engineer.

The Functional Description section outlines models covered, standard features, and optional

features. Additional sections within the manual provide instructions for installation, preoperational procedures, operation, preventive maintenance, and corrective maintenance.

The Installation chapter includes required data for receiving, unpacking, inspecting, and setup

of the equipment. We can also provide the assistance of a factory-trained technician to help

train your operator(s) for a nominal charge. This section includes instructions, checks, and

adjustments that should be followed before commencing with operation of the equipment.

These instructions are intended to supplement standard shop procedures performed at shift,

daily, and weekly intervals.

The Operation chapter includes a description of electrical and mechanical controls, in

addition to information for operating the equipment safely and efficiently.

The Maintenance chapter is intended to serve as a source of detailed assembly and

disassembly instructions for those areas of the equipment requiring service. Preventive

maintenance sections are included to ensure that your equipment provides excellent, long

service.

The Troubleshooting chapter serves as a guide for identification of most common problems.

Potential problems are listed, along with possible causes and related solutions.

The Appendix contains technical specifications, drawings, schematics, and parts lists. A

spare parts list with part numbers specific to your machine is provided with your shipping

paperwork package. Refer to this section for a listing of spare parts for purchase. Have your

serial number and model number ready when ordering.

Safety Symbols Used in this Manual

The following safety alert symbols are used to alert you to potential personal injury hazards.

Obey all safety messages that follow these symbols to avoid possible injury or death.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING indicates a potentially hazardous situation or practice which, if not avoided,

could result in death or serious injury.

CAUTION indicates a potentially hazardous situation or practice which, if not avoided,

may result in minor or moderate injury or in property damage.

GP Series Portable Chillers Chapter 1: Safety 5 of 44

Page 6

1-2 Warnings and Precautions

Our equipment is designed to provide safe and reliable operation when installed and operated

within design specifications, following national and local safety codes.

To avoid possible personal injury or equipment damage when installing, operating, or

maintaining this equipment, use good judgment and follow these safe practices:

9 Follow all SAFETY CODES.

9 Wear SAFETY GLASSES and WORK GLOVES.

9 Disconnect and/or lock out power before servicing or maintaining the equipment.

9 Use care when LOADING, UNLOADING, RIGGING, or MOVING this

equipment.

9 Operate this equipment within design specifications.

9 OPEN, TAG, and LOCK ALL DISCONNECTS before working on equipment.

You should remove the fuses and carry them with you.

9 Make sure the equipment and components are properly GROUNDED before you

switch on power.

9 When welding or brazing in or around this equipment, make sure

VENTILATION is ADEQUATE. PROTECT adjacent materials from flame or

sparks by shielding with sheet metal. An approved FIRE EXTINGUISHER

should be close at hand and ready for use if needed.

9 Refrigeration systems can develop refrigerant pressures in excess of 500 psi

(3,447.5 kPa/ 34.47 bars). DO NOT CUT INTO THE REFRIGERATION

SYSTEM. This must be performed by a qualified service technician only.

9 Do not restore power until you remove all tools, test equipment, etc., and the

equipment and related components are fully reassembled.

9 Only PROPERLY TRAINED personnel familiar with the information in this

manual should work on this equipment.

We have long recognized the importance of safety and have designed and manufactured our

equipment with operator safety as a prime consideration. We expect you, as a user, to abide

by the foregoing recommendations in order to make operator safety a reality.

1-3 Responsibility

These machines are constructed for maximum operator safety when used under standard

operating conditions and when recommended instructions are followed in the maintenance

and operation of the machine.

All personnel engaged in the use of the machine should become familiar with its operation as

described in this manual.

Proper operation of the machine promotes safety for the operator and all workers in its

vicinity.

Each individual must take responsibility for observing the prescribed safety rules as outlined.

All warning and danger signs must be observed and obeyed. All actual or potential danger

areas must be reported to your immediate supervisor.

GP Series Portable Chillers Chapter 1: Safety 6 of 44

Page 7

Chapter 2: Functional Description

2-1 Models Covered in This Manual

This manual provides operation, installation, and maintenance instructions for air-, water-and

remote air-cooled portable chillers. Model numbers are listed on the serial tag. Make sure you

know the model and serial number of your equipment before contacting the manufacturer for

parts or service.

Our portable chiller models are designated by approximate compressor horsepower (5,7 1/2,

10, 13 and 15 etc) and the cooling method used: -A for air-cooled, -W for water-cooled, and –

R for remote-air cooled.

2-2 General Description

Our portable chillers are reliable, accurate, and easy to use process cooling units. They are

available in air-, water-, and remote air-cooled designs in a range of sizes from 5 to 15 tons.

All are self-contained, fully portable and shipped ready to use. (Remote air-cooled chillers

require field installation by qualified technicians.)

Standard range of operation is 20ºF to 80ºF (-7ºC to 30ºC) for applications using a

water/glycol mix and 45ºF to 80ºF (7º to 30ºC) for water only applications.

A factory installed crankcase pressure regulating valve option is available for processes

requiring a leaving water temperature over 80ºF (30ºC).

Chilled Water Circuit

Cooling water “To Process” and “From Process” connections are made at the female NPT

couplings provided outside the unit. Warm coolant (water and glycol mixture) returns from

the process and goes into the reservoir tank. The coolant is then pumped through the

evaporator where it is cooled. The coolant flows to the process and returns to repeat the cycle.

A (manual) pressure actuated process water bypass valve located between the supply line and

reservoir tank (single pump models only) allows minimal flow through the unit during the

intermittent fluctuating flow conditions. It is not intended to provide continuous full bypass

flow.

This minimal flow allows the temperature sensor to signal the controller to shut down the

compressor because of the drop in process water temperature. Typically the flow switch shuts

down the chiller in this low flow condition. This valve allows enough flow for the chiller to

function when the flow is shut off to process.

Refrigeration Circuit

Air-, water-, and remote air-cooled refrigerant condensing differ only in the way the

compressed gas is condensed to a liquid.

Liquid refrigerant from the condenser heat exchanger flowing in the liquid line passes

through a shut-off valve into a filter/dryer that removes moisture and other contaminants. A

refrigerant sight glass is provided. The refrigerant then passes through the thermal expansion

valve, which allows the refrigerant to expand (boil off) and cool (remove the heat from) the

fluid inside of the evaporator. The refrigerant gas flows through the suction line back into the

compressor.

GP Series Portable Chillers Chapter 2: Functional Description 7 of 44

Page 8

The refrigerant is compressed in the compressor and flows through the discharge line as a gas

to the condenser. There it gives up its heat as it condenses to a liquid in the condenser.

An electronic hot gas bypass valve is used to control cooling capacity during intermittent or

partial load conditions. This feature contributes substantially to chiller longevity by

eliminating excessive cycling of the compressor and providing close temperature control.

2-3 Standard Features

Mechanical Features

Compressor. Hermetic scroll compressors.

Evaporator. Stainless steel copper brazed plate evaporators.

Air-Cooled Condenser. Aluminum fin/ tube with washable filters, package unit only (option

on remotes).

Water-Cooled Condenser. Tube-in-tube condensers. All come with electronic cooling

water regulating valves for cooling tower water or city water.

Remote Air-Cooled Condenser. Aluminum fin/tube with low ambient control down to –

20ºF (-29ºC) via a variable-speed primary fan.

Reservoir. 5 hp and 7.5 hp models use a 20 gallon polyethylene tank. 10 hp and 15 hp

models use a 40 gallon polyethylene tank.

Piping. Non-ferrous piping

Pump. TEFC motors (Optional 10 HP is ODP only)—horizontally mounted stamped

stainless steel construction.

Other Mechanical Features

• Low process water thermal flow switch

• NEMA-rated fan motor(s) on air-cooled models

• Galvanized structural steel frame, painted cabinetry, with 4” (locking) swivel casters

• Internal process water bypass valve for system protection only

• Fully insulated refrigeration and process water piping

• 20 mesh Y strainer on process water piping into the evaporator

• Tank level indication

• Pump pressure indication

Electrical Features

• Fully accessible NEMA 12-style electrical control enclosure

• Single-point power and ground connection

• Non-fused disconnect switch, lockable

• Branch circuit fusing

• 208-230/3/60, 460/3/60, 575/3/60 volt; 400/3/50 volt

GP Series Portable Chillers Chapter 2: Functional Description 8 of 44

Page 9

Refrigeration Features

• HFC-410a refrigerant

• Electronic hot gas bypass capacity control

• High refrigerant pressure cutout switches

• Suction and discharge pressure transducers.

• High pressure spring actuated relief valve

• Multiple refrigeration access ports

• Liquid line shut-off ball valves

• Filter-dryer

• Sight glass

• Externally equalized thermal expansion valve

• Liquid line solenoid

• Compressor crankcase heater

Controller Features

• Off-the-shelf microprocessor-based PID auto-tuning controller with To Process, From

Process and Set Point readout

• Time delay for proof of water flow/pressure (models w/pump only)

• Low refrigerant pressure time delay for low ambient start-up on remote air-cooled and

air-cooled chillers with the variable-speed fan option.

• 4 line x 20 character display with status, alarm, and service screens

Other Features

• One year labor warranty and one year compressor warranty

• Two year parts warranty

• Two year limited controller warranty

2-4 Safety Devices and Interlocks

Caution! Protect the system from freezing with glycol 20ºF below the leaving water

temperature set point. Condensation may form inside the pump tank and dilute

the mixture, therefore the freezing point should be verified periodically. See

Figure 6 on page 18 for the correct mixture.

Crankcase Heater

5 hp through 15 hp portable chillers have a crankcase heater. It is wired through the control

transformer that operates continuously whenever power is applied to the chiller.

Caution! Energize the crankcase heater for at least 24 hours before initial startup to

drive dissolved refrigerant from the compressor oil. Failure to do so will

damage the compressor.

GP Series Portable Chillers Chapter 2: Functional Description 9 of 44

Page 10

High Pressure Cutout

This electro-mechanical cutout device opens the compressor control circuit if the refrigeration

system compressor discharge pressure exceeds 575 psi..

Note: The high-pressure cutout is a manual reset device typically mounted on the

compressor discharge line inside the mechanical cabinet. Call a refrigeration

service technician to analyze the problem and reset the control.

Low Pressure Cutout (no switch but done through the transducer)

This electro-mechanical cutout device opens the compressor control circuit if refrigeration

system compressor suction pressure drops below 15 psi. It automatically resets when

refrigerant suction pressure reaches 30 psi.

Note: The low pressure cutout is an automatic reset device typically mounted on the

compressor suction line inside the mechanical cabinet. Call a refrigeration

service technician to analyze the problem and reset the control.

Flow Switch

The thermal dispersion flow switch cutout device, mounted in the process piping, shuts down

the chiller if it senses that the water/glycol flow rate through the evaporator has dropped

below an acceptable level. The flow switch opens the control circuit and shuts down the

pumps and the chiller.

Remote Start/Stop Interlock

An additional contact is provided to allow the remote starting or stopping of the chiller. To

use this feature, remove the jumper between terminals X1 and 1, and supply a switch or dry

contact interlock connected in series between these two terminals. Refer to the schematic

inside the control enclosure door.

2-5 Optional Features

Options marked with “*” indicate options that can be factory installed or retrofitted in the

field.

Automatic Water Make-Up*. Not available on chillers less reservoir tank. Includes an

electric water solenoid valve, a level sensing pressure switch mounted in the reservoir tank,

and the necessary internal piping to connect the chiller to a make-up water source. See

Appendix for typical piping diagrams.

Caution! Customer piping must provide backflow protection and venting of tank to

atmosphere to prevent over-pressurization of the reservoir tank (not needed for

open tank). See Error! Reference source not found. on page Error! Bookmark

not defined..

Process Water Sidestream Filter*. Not available on chillers less pump and reservoir tank.

Includes a 50 micron filter, flow meter, ball valve for throttling water flow, and the necessary

piping to provide constant filtering of the process water at about one gallon per minute (1

gpm/3.8lpm).

General Fault Indicator Audible/Visual Alarm*. Includes a 100 dB audible alarm horn/

visual alarm strobe and silence button with provisions for customer wiring indication

GP Series Portable Chillers Chapter 2: Functional Description 10 of 44

Page 11

interlock. The alarm signals anytime that a fault is recognized during the operation of the

chiller.

Communications Options. RS-485 serial Modbus communications.

High Pressure Fans. Provides for an additional 1.0”WC (250 Pa) of static pressure on fan

discharge. High-pressure fans are necessary and must be included in chiller installations

where exiting air exhausts through ductwork.

They can be retrofitted without sheet metal modification, but will require changing out fan

blades, and in some cases, fan motors and electrical components.

Variable Speed Fan. Reduces the speed of the fan based on entering air temperature and

system load, allowing the chiller to operate in ambient temperatures below 60ºF (15.5ºC).

This option will also reduce fan noise in ambient temperatures below 95ºF (35ºC).

Stainless Steel Reservoir. 5 hp to 15 hp models only. Manufactured from 304 stainless steel.

Mounting Features.

• Mounting rails with feet

Optional Operating Voltages. 208-230/3/60, 575/3/60, and 400/3/50 volt available

UL Labeled Electrical Subpanel. Provides for the subpanel to be listed with Underwriters

Laboratory, with UL-related benefits and features.

Optional Pumps. Pump options are available for greater pressure and flow rates. A

recirculation pump is required whenever process water flow is less than 1.2 gpm per ton or

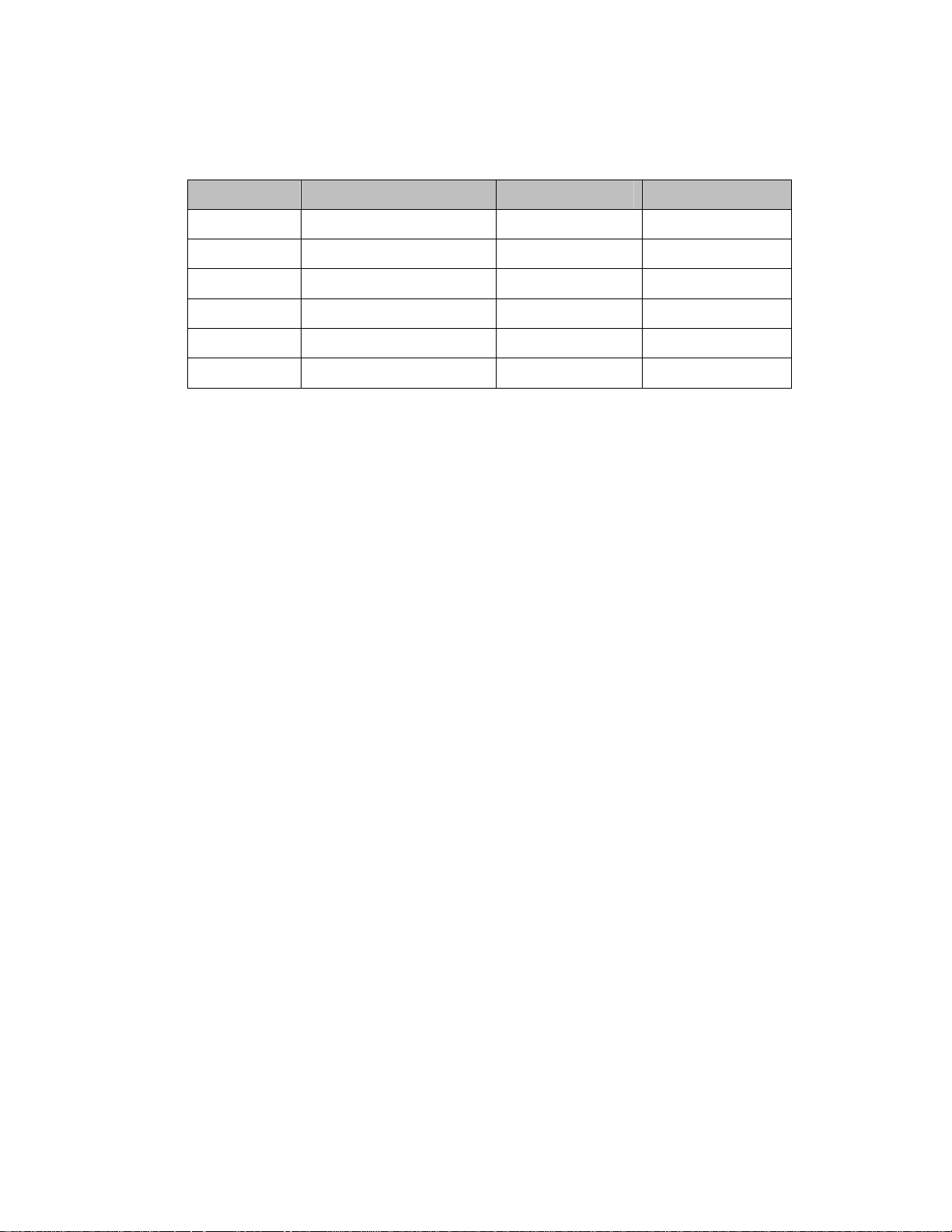

greater than 4.8 gpm per ton. See Figure 1 on page 12 for optional pump amperages.

NEMA 4 Electrical Enclosure. Provides for NEMA 4-level electrical enclosure protection.

GP Series Portable Chillers Chapter 2: Functional Description 11 of 44

Page 12

Figure 1: Optional Pump Amperages

Voltage Construction HP Full Load Amps

460/3/60 SS 1 1.7

1.5 2.3

2 4.0

3 4.2

5 8.2

10 12.0

GP Series Portable Chillers Chapter 2: Functional Description 12 of 44

Page 13

Chapter 3: Inst allation

3-1 Uncrating

All models are are shipped mounted on a skid, enclosed in a plastic wrapper, and open-crated

on all four sides and top.

1. Pry the crating away from the skid.

2. Use a pry bar to remove the blocks securing the unit to the skid.

3. Lift unit from sides, inserting forklift under the base. The forks must be equidistant

from the centerline of the unit and the unit must be balanced on the forks. Lift slowly

and only high enough to clear the skid. Use a pry bar if necessary to carefully remove

the skid from the unit.

4. Lower slowly. The unit should land on its casters or rails and can then be moved into

position.

5. Retain the crating material for reshipping the chiller in case hidden shipping damage

is found.

3-2 Electrical Connections

Supply electricity of the voltage, phase, and cycle listed on the serial tag. Total running amps

are also found in the specification tables on pages in the Appendix.

Bring properly sized power leads and ground from a fused disconnect (installed by your

electrician) to the unit. Use dual-element fuses in the disconnect switch, sized according to

the National Electrical Code recommendations. Note the outline drawings for egress into the

cabinet. Make sure all electrical connections are tight.

Refer to your local electrical requirements for proper feeder conductor and

supply disconnecting sizing. For instance, in the United States refer to

National Electric Code (NEC) Article 430-24 through 430-26, Table

Important!

310.15(B)(2)(a)

GP Series Portable Chillers Chapter 3: Installation 13 of 44

Page 14

3-3 Process Water Connections

All of our portable chillers have two chilled water connections. The chilled water supply,

labeled “To Process” is the outlet for the chilled water leading to the process being cooled.

The chilled water return, labeled “From Process” is the inlet leading from the process back

into the chiller to be cooled and re-circulated.

All external chilled water connections should be run full size to the process. Flow and

pressure information is available in the Appendix. The largest possible openings and

passages should be provided for the flow of chilled water through platens, dies, molds, or

other pieces of equipment.

Note: Be sure to reduce external pressure drop as much as possible by generously

sizing piping and tooling water passageways.

3-4 Bypass Valve Considerations

Our portable chillers have an internal manual bypass valve. If the flow is stopped to the

process while the chiller is running, the factory-set bypass valve allows a small amount of

water to flow through the chiller. This action allows the chiller to keep functioning while the

flow is stopped to process. The bypass valve is not intended to provide continuous full

bypass flow.

Caution! Do not attempt to adjust or otherwise tamper with the internal bypass. Your

warranty will be voided.

3-5 Galvanic Corrosion Considerations

The materials used in the water circuit piping of these chillers are non-ferrous and react

electro-chemically with ferrous metallic materials. Some water has dissolved minerals that

greatly accelerate the reaction between dissimilar metals.

PVC or non-ferrous piping is recommended to reduce galvanic action. If iron piping must be

used, use dielectric unions at the chiller.

3-6 Water Treatment Considerations

Water treatment is an integral part of the system. In some locations, water may cause large

deposits of scale, erosion, algae, and/or corrosion.

Note: The use of poor quality water may result in inefficient operation, heat

exchanger damage, and pump seal damage. Consult a qualified water

treatment specialist to determine whether treatment is needed.

We offer a complete line of water treatment equipment. Contact your sales representative for

water testing and treatment options.

GP Series Portable Chillers Chapter 3: Installation 14 of 44

Page 15

3-7 Condenser Considerations

Water-Cooled Chiller Condensers

Water-cooled portable chillers can use city water or tower water as a cooling medium. Make

sure that all external piping and connections supplying and discharging water to and from the

condenser are full size.

You’ll make two connections to the water-cooled condenser:

Condenser Water In. The condenser water supply, labeled “Condenser Water In”, is located

at the rear of the chiller. It is the inlet for city or tower water.

Make sure that water is supplied at a maximum temperature of 85ºF (29ºC) and a minimum

pressure of 25 psi.

Caution! The electronic water-regulating valves pressure setpoint is set at the factory.

Only a qualified refrigeration technician should adjust the pressure setting

through the service section of the controller.

Normal HFC-410a refrigerant condensing pressure is 342 psi (2,360 kPa), with 85ºF (27ºC)

water at 25 psi entering condenser water pressure

Condenser Water Out. Condenser water return, labeled “Condenser Water Out”, is located

at the rear of the chiller. It is the outlet for water after it has passed through the condenser.

It is connected to the tower water return line or to a sewer or other approved discharge

receiver. A water-regulating valve is a standard feature in the condenser water out line.

Air-Cooled Chiller Condensers

Air-cooled chillers use the surrounding air to cool the condenser. Install the chiller in an area

where there is free passage of air for condensing and provisions for removal of heated air

from the area. Do not locate air-cooled chillers in locations where steam, hot air, or fume

exhausts can be drawn into the chiller.

Caution! Clean air-cooled condensers and filters frequently. Failure to do so results in

reduced capacity, increased operating costs, and possible failure of the

equipment. Cleaning instructions can be found in the Maintenance chapter of

this manual

Normal maximum refrigerant condensing pressure with 95ºF (35ºC) air entering the

condenser is 420

Condensing Air Temperature. Our air-cooled portable chillers are designed to operate at a

minimum condenser entering air temperature of approximately 60ºF (15.5ºC). Operation of

the equipment at a lower condenser entering air temperature can cause the chiller to

malfunction. For entering air temperatures below 60ºF (15.5°C), an optional fan motor speed

control is available. We recommend maintaining a minimum 60ºF (15.5°C) ambient

temperature.

psi (2896 kPa).

GP Series Portable Chillers Chapter 3: Installation 15 of 44

Page 16

3-8 Checking Motor Direction

All of our portable chillers have their motor rotations properly phased at the factory. If

compressors, pumps, or fans are running in reverse rotation, disconnect and lock out the

power source and reverse any two power leads into the chiller disconnect switch.

Caution! Do not switch leads at the motors, motor starters, or contactors.

Three-Phase Compressors

Scroll compressors are directionally-dependent and compress in one rotational direction.

Reversing rotation direction results in an elevated sound level and a substantially-reduced

current draw.

Water Pumps

Correct pump rotation is indicated by a positive pressure of 20 to 40 psi on the pump pressure

gauge. Pump rotation should be clockwise when viewed from the motor end. For chillers with

optional pumps, check the appropriate pump curve in the Appendix.

Caution! Do not run pump dry. Doing so will result in seal damage.

Condenser Fan

Air should be drawn through the condenser and discharged vertically from the chiller.

GP Series Portable Chillers Chapter 3: Installation 16 of 44

Page 17

3-9 Water Reservoir

All portable chillers shipped during the fall, winter, or spring, or those units that are shipped

from stock are flushed at the factory with a water/ethylene glycol solution to prevent piping

components prone to retaining water from freezing. During startup and when additional

solution is required, refer to the ethylene glycol and propylene glycol curves in Figure 6 on

page 20 Add a pre-mixed solution of industrial quality (not automotive) ethylene glycol or

propylene glycol and water to provide freeze protection to a temperature 20ºF (11ºC) below

the normal chiller operating temperature set point.

Glycol and/or water, with an inhibitor, should be used to protect the materials (copper, steel,

stainless steel, and bronze) in the system from corrosion. If you intend to use straight water,

we strongly advise a minimum leaving water temperature of 45ºF (7ºC) or contact the service

department.

The following glycol products are available:

Part Number Description

A0541358 Ethylene glycol, 5 gallons (18.9 liters)

A0539637 Ethylene glycol, 55 gallons (208.2 liters)

A0542990 Propylene glycol, 5 gallons (18.9 liters)

A0542991 Propylene glycol, 55 gallons (208.2 liters)

Caution! Do not connect make-up water directly to the chilled water reservoir unless you

have an approved automatic water make-up system installed.

Caution! Do not pressurize tank. Supply and return connections must be trapped and

vented to allow vertical risers to drain into tank. Do not overfill system. Allow

enough free space in tank for vertical piping to drain.

If your application has chilled water or process piping above the reservoir fill and vent level,

trap and vent the supply and return lines to allow vertical piping to drain into tank.

Note: In applications where the process or process piping is above the reservoir, take

steps to prevent over pressurization of the reservoir. This condition can occur

on system shutdown when the water in the system drains into the reservoir. To

prevent this, a vacuum breaker should be installed at the high point of the “To

Process” and “From Process” lines.

GP Series Portable Chillers Chapter 3: Installation 17 of 44

Page 18

Figure 2: Ethylene Glycol and Propylene Glycol Curves

Perce n t G lycol Cu rvesfor Free ze Protection

40.0

30.0

20.0

10.0

0.0

-10.0

-20.0

-30.0

-40.0

-50.0

-60.0

0.0 10.0 20.0 30.0 40.0 50.0 60.0

% Gl ycol by Vol um e

Example: 45°F set point minus 20°F = 25°F.

From Figure 28, 25°F equates to 10% by volume of glycol required.

Eth ylene G lycol

Propylene Glycol

GP Series Portable Chillers Chapter 3: Installation 18 of 44

Page 19

3-10 Automatic Water Make-Up Option

The chiller may be connected to an automatic make-up system if the optional package (pipe

fittings, solenoid valve and 1/2” NPT city water make-up connection) is factory installed.

If the automatic make-up system is connected to a city water system, make provisions to

prevent backflow contamination. Install an approved backflow preventer in accordance with

local codes.

Caution! Adding straight city water into a glycol/water mixture dilutes the solution and

eventually leads to system freeze-up. Damage from freeze-up is not covered by

the warranty.

To prevent system freeze-up in automatic make-up applications, we recommend using either

a chemical feeder or make-up reservoir to replenish glycol. Contact the sales department for

more information about these configurations.

3-11 Initial Start-Up

• Check the shipping papers against the serial tag to be sure chiller size, type and voltage

is correct for the process that will be controlled. Portable chillers are built with a

voltage specific compressor and cannot be re-wired for an alternate voltage.

• Check the transformer primary voltage connections to be sure they are configured for

the electrical power you are using. The voltage at the main power connection must read

within plus or minus ten percent (±10%) of the voltage listed on the serial tag.

Electrical connections must conform to all applicable codes.

• Complete chilled water To Process and From Process connections.

• Be sure the reservoir tank and chilled water circuit piping are filled a water/glycol

mixture. The water/glycol mixture should provide for freeze protection to at least 20°F

(11ºC) below the leaving water temperature you want. Should the display show a tank

level less than 0 after the tank is filled, check the clear tube leading from the tank to the

tank level pressure switch for a blockage.

• The air-cooled condenser should have an adequate supply of 60º to 115ºF (16º to 46ºC)

air for proper operation.

• The tower or city water condenser cooling in and out connections should be completed

and an adequate supply of 85ºF (30ºC) tower or 70ºF (21ºC) city water, at 25 psi

pressure, for proper operation.

• Connect the main 3 phase incoming power to the unit making certain that line one (1)

L1 is connected to the A phase, line two (2) L2 is connected to the B phase, and line

three (3) L3 is connected to the C phase. Check for proper rotation direction of fan(s)

and pump(s).

The crankcase heater is automatically energized when the main power is applied. It

should be on for at least 24 hours before startup to force dissolved refrigerant from the

compressor oil.

3-12 Finishing Setup: Setting Up Passwords

You can establish passwords for two levels of security: operators and supervisors. The

controller comes from the factory with neither password set. This allows every user access to

all functions.

GP Series Portable Chillers Chapter 3: Installation 19 of 44

Page 20

Operator Password. If you define a password for operators, then a password will be

required to carry out any fuction (other than reviewing the status screens). Entering the

operator’s password will give the user access to the setpoints for leaving temperature, high

temperature warning, high temperature fault.

Supervisor Password. If you define a password for supervisors (or setup personnel) then

most settings can be changed only after entering the password. The password will be

required to display the extended setpoints for operating parameters and alarms. Section 4-6

shows a table of setpoints and the restrictions between Operator and Supervisor.

To set password protections:

1. Press the

2. Press the

3. Press the

or the following screen for the Supervisor Password

button to access the menu screen.

or to highlight SETPOINTS, and press .

or until the following screen appears for the Operator Password

4. Press

Password line is highlighted.

5. Press

0 and 9999.

GP Series Portable Chillers Chapter 3: Installation 20 of 44

to accept the screen, and then press until the Operator or Supervisor

or to increment or decrement the number. The password can be between

Page 21

6. Press

to accept the Password and move to the next line.

7. For either Operator or Supervisor password the time that the password will allow the

controller to be active can be set by the Operator or Supervisor Password Time. With the

PW Time value highlighted, press

or to increment or decrement the time. The

password time for either setup can be from 0 to 99 minutes.

GP Series Portable Chillers Chapter 3: Installation 21 of 44

Page 22

Chapter 4: Operation

4-1 Panel Buttons, Indicator Lights, and Switches

Microprocessor Controller

The standard chillers use a microprocessor-based PID controller. The Carel PCO controller

along with the Carel PGD1 Interface is a modular, self-contained unit that can slide from its

mounting housing. It is factory set and adjusted; no field adjustment to the internal controls is

necessary. The standard operation range is 20ºF to 80ºF (-7ºC to 27ºC).

Figure 3 - Controller Display

Button Button Description Detailed description

Menu Button

On/Off Button

Back Button

Up Arrow Button

Enter Button

Down Arrow Button

Used to access the menus structure of the PGD interface

Used to turn the entire chiller On or Off. The button is backlit and will

turn amber when the chiller is On.

Used to back up from a menu and return to the main status screen

Used to increment a data field or scroll up within a menu structure.

Used to accept a data field value or to select a menu item.

Used to decrement a data field or scroll down within a menu structure.

GP Series Portable Chillers Chapter 4: Operation 22 of 44

Page 23

4-2 Initial Start-up

1. Verify the initial start-up checklist from Chapter 3, Section 3-11.

2. With the main supply power switch in the ON position, the screen will

display the version of the software for a period of 5 seconds, and then display

the main status screen.

Figure 4 - Main Status Screen

Figure 5 - Menu Screen

3. Set the Leaving Fluid temperature by depressing the

the menu.

4. Depress the

passwords were setup (See Section 3-12 for information on the controller

passwords) the password screen will appear.

or button to highlight SETPOINTS and press . If

button to display

GP Series Portable Chillers Chapter 4: Operation 23 of 44

Page 24

Enter the established Operator Password by depressing the

position of the cursor, and then depressing the

increment or decrement the number. Once all of the numbers have been

entered depress the

appear.

Figure 6 - Operator Setpoints Screen

5. Depress

to move the

or button to

to accept the password. The following screen will

to move the cursor to the Leaving Temp line. Use the or

button to increment or decrement the value. Depress to accept the

value and move the cursor down one line.

6. Depress the

7. Depress the

8. Check pump rotation

9. Check the pump amp draw and pump pressure. Make sure that the amp draw

reading is within the running load and service factor amps.

10. Operate the chiller, looking for any leaks and listening for unusual noises or

vibrations that could indicate improper operation.

GP Series Portable Chillers Chapter 4: Operation 24 of 44

button twice to return to the main status screen.

to start the chiller.

Page 25

Elevated sound level and substantially reduced current draw indicate reverse

rotation. After several minutes of operation, the compressor internal protector

trips.

4-3 Status Screens

The controller has eight (8) preconfigured status screens. The main status screen (shown in

Figure 11) shows the main operating points of the chiller: Entering and Leaving fluid

temperatures; Leaving fluid sepoint, pump discharge pressure, tank fluid level (depth) , and

percentage of hot-gas bypass output.

Figure 7 - Main Status Screen

Depressing

I/O, and Test. The Analog and Digital I/O screens provide status of all of the inputs and

outputs for the controller. The Test aides in troubleshooting the chiller when it is not

functioning properly by displaying the basic information that a service person will need to

know to determine the problem.

cycles through the following screens (shown below) – Analog I/O, Digital

GP Series Portable Chillers Chapter 4: Operation 25 of 44

Page 26

4-4 Access Levels

The controller is setup to allow access to three distinct password groups: operator, supervisor,

and service. Operator access allows the user to modify the Leaving Water Temp, Hi Temp

GP Series Portable Chillers Chapter 4: Operation 26 of 44

Page 27

Warning, and Hi Temp Fault setpoints. Supervisor access allows the supervisor to modify the

above plus

Selecting any of the menus in the Menu Screen will display the Password Screen.

GP Series Portable Chillers Chapter 4: Operation 27 of 44

Page 28

4-5 Controller Setpoints

Variable Description

Leaving Temp Temperature of fluid out to process x x

Hi Temp Warning

Hi Temp Fault

Compressor On

Differential

Compressor Off

Differential

Pump Stop Delay

Low Temperature

Warning

Low Temperature Fault Temperature to activate Low Temperature Fault alarm x

Water Make-up On

Water Make-up Off

Water Make-up Time

Low Level Warning Tank level that will activate Low Level Warning alarm x

Setpoint for alarm to warn when leaving fluid

temperature is too high

Setpoint to shut down pump and compressor based on

leaving fluid temperature

Temperature Difference between Leaving Fluid

Temperature and Setpoint to turn on the compressor

Temperature Difference between Leaving Fluid

Temperature and Setpoint to turn off the compressor

Delay time in seconds between fault and stopping the

pump

Temperature to activate Low Temperature Warning

alarm

The tank level to turn on optional water make-up valve;

based on size of tank

The tank level to turn off optional water make-up valve;

based on size of tank.

The time in seconds that controller will allow for filling

the tank

Access Level

Operator Supervisor

x x

x x

x

x

x

x

x

x

x

Low Level Fault Tank level that will activate Low Level Warning fault x

High Level Warning Tank level that will activate High Level Warning alarm x

High Level Fault Tank level that will activate High Level Warning fault x

High Temperature

Delay

Alarm Silence Time

Operator Password

Time

Supervisor Password

Time

Delay time in minutes between fault and stopping the

compressor and pump

Time in minutes to silence alarm (with optional audible

alarm). After time alarm will reactivate.

Time in minutes for operator password to be active x

Time in minutes for supervisor password to be active x

x

x

GP Series Portable Chillers Chapter 4: Operation 28 of 44

Page 29

Figure 8 - Menu Screen

1. Set the Leaving Fluid temperature by depressing the

the menu.

button to display

2. Depress the

passwords were setup (See Section 3-12 for information on the controller

passwords) the password screen will appear.

Enter the Operator Password by depressing the

the cursor, and then depressing the

decrement the number. Once all of the numbers have been entered depress

or button to highlight SETPOINTS and press . If

to move the position of

or button to increment or

GP Series Portable Chillers Chapter 4: Operation 29 of 44

Page 30

the

Figure 9 - Operator Setpoints Screen

to accept the password. The following screen will appear.

3. Depress

button to increment or decrement the value. Depress to accept the

value and move the cursor down one line.

4. Adjust the Hi Temp Warning and Hi Temp Fault in the same manner.

5. Depress the

to move the cursor to the Leaving Temp line. Use the or

button twice to return to the main status screen.

4-6 Alarms

The controller is setup with multiple alarms, most of them configurable using the Supervisor

password. Section 4-5 Controller Setpoints gives a list of alarms that the controller is setup to

display. The alarms are broken up into two categories – warnings and faults. The warning

notifies the user that the parameter has been exceeded and the chiller is allowed to keep

operating, but should be monitored to determine the cause of the warning. The fault notifies

the user that the parameter has been exceeded and the chiller and pump has been shut down to

protect the system.

4-7 Optional Communications

The communications function allows you to monitor and set the parameters by a program

prepared and running on a host computer connected to the controller.

When using the communications function, you must add on the unit for RS-485 Modbus

communications. The communications function allows you to read/write parameters, do

operating instructions, and select the setting level.

GP Series Portable Chillers Chapter 4: Operation 30 of 44

Page 31

GP Series Portable Chillers Chapter 4: Operation 31 of 44

Page 32

Chapter 5: Maintenance

5-1 Lubrication

Grease all blower bearings, fan and blower motors, and pump motors that do not have

permanently sealed bearings. Be sure to use an all-purpose industrial grease with a

temperature reference of 185˚ F (85˚ C). Remove the grease relief plug (motors only) before

adding grease, add grease until a small amount pours out, and replace the plug when finished.

Caution! Failure to remove the grease relief plug will result in dislodging the bearing

grease seal, eventually causing bearing failure.

Refrigeration compressors are hermetically sealed and no lubrication is required.

5-2 Filter Cleaning

Air filter cleaning is important to keep your air-cooled portable chiller operating at peak

efficiency and capacity. Clean the filters whenever they appear dirty, or at regularly

scheduled intervals.

1. Turn the chiller off.

2. Slide the filter rod to release it from the frame at the top and bottom.

3. Wash down the filter with clean water (preferably with a garden hose), directing the flow

of water opposite the direction of airflow. If dirt is heavy, use a mild detergent and rinse

well. Allow the filter to dry completely before replacing it on the chiller.

Note: Keep a spare air filter set on hand. Install and use it while cleaning).

Caution! Do not use compressed air to blow off a dirty filter. It will not clean very well,

and the filter could be damaged. Never run the chiller without properly

installed filters.

5-3 Maintaining the Condenser

Dirty condenser heat exchange surfaces reduce system capacity and efficiency.

Air- and Remote Air-Cooled Chillers

Brush or vacuum light dirt accumulations off the aluminum condenser fins. Avoid bending or

damaging them. Heavy dirt accumulations on the fins may require professional cleaning.

Water-Cooled Chillers

Proper water treatment will greatly reduce cleaning intervals.

Coaxial Condensers (Standard

reverse-circulating with a mild detergent and water solution. Remove mineral deposits by

reverse circulating Liquid Inhibited Acid De-Scaling Solution (Part No. A0502600) through

the water side of the condenser. Follow the directions on the container.

Shell & Tube Condensers (Optional

side by cleaning with a nylon tube brush. Remove mineral deposits by reverse circulating

Liquid Inhibited Acid De-Scaling Solution (Part No. A0502600) through the tube water side

of the condenser. Follow the directions on the container.

). Remove dirt and slime in the condenser tube water side by

). Remove dirt and slime in the condenser tube water

The refrigerant side is sealed and requires no routine maintenance.

GP Series Portable Chillers Chapter 5: Maintenance 32 of 44

Page 33

Caution! Do not use steam or water over 140ºF (60ºC) to clean a condenser unless you

are monitoring the refrigeration circuit for excessive pressure with gauges.

Only a trained technician should use this method.

5-4 Maintaining the Evaporator

Dirty evaporator heat exchange surfaces reduce system capacity and efficiency. Remove dirt

and slime in the evaporator by reverse-circulating with a mild detergent and water solution.

Remove mineral deposits by reverse-circulating Liquid Citric Acid De-Scaling Solution (Part

No. A0536607). Follow the directions on the container.

5-5 Evaporator Process Piping Y-Strainer

The process piping Y-strainer requires periodic cleaning of its screen to insure the proper

flow through the evaporator. To clean the strainer screen, remove the access plug and

retaining cap, and pull out the screen.

Wipe, brush, or vacuum out any dirt left in the strainer body. Clean the screen and replace it

in the strainer taking care to fit it squarely into the machined seat provided.

Caution! Do not forget to re-install the screen after cleaning it. Operating the chiller

with no strainer screen can potentially plug the evaporator with dirt. The

warranty does not cover chiller failures from a dirty evaporator.

5-6 Preventative Maintenance Service

Follow a systematic preventive maintenance program to help avoid costly down time. Call

the Service Department to arrange a schedule of inspections. This service can be tailored to

fit your maintenance requirements. These inspections include, but are not limited to:

• Checking refrigerant suction and discharge pressures

• Checking safety and operating conditions

• Checking voltage and amperage of all motors

• Checking all electrical connections

• Checking quantity of refrigerant

• Checking compressor oil level

• Checking lubrication of motor and pump bearings.

• Checking circulating pump operation

• Checking flow through heat exchangers

• Checking compressor efficiency

• Checking noise levels

GP Series Portable Chillers Chapter 5: Maintenance 33 of 44

Page 34

Chapter 6: Troubleshooting

Problem Possible cause Solution

Check main disconnect, fuses, wiring,

and power lead to unit.

Voltage must be within plus or minus

10% of nameplate rating.

Replace control circuit fuse.

Check transformer.

Check for a short circuit.

Add water or water/glycol solution as

required.

Lower the leaving fluid temperature

below the leaving temperature you

desire.

Replace.

Allow time to cool and reset, then check

for high/low volt-age. It must be within

plus or minus 10% of the nameplate

rating.

Check for open fuses and loose

compressor electrical connections.

Repair or replace.

Repair or replace.

Unit does not run.

Pump runs; compressor does not.

No power.

Wrong voltage supplied to unit.

Defective on/off switch. Replace.

Control circuit fuse blown.

Defective control transformer. Replace.

Piping flow switch circuit open.

Pump motor off on overload. Reset and test.

Leaving fluid setpoint set higher

than temperature of liquid in

system.

Defective leaving fluid sensor

High/Low thermostat.

Compressor internal overload or

fuses are open.

Compressor contactor holding coil

open.

Defective compressor auxiliary

contact.

Pump runs, compressor cycles at

short intervals.

Water temperature is too high.

Broken wire in the compressor

control circuit.

Plugged Y-strainer Clean

Hot gas not coming on

Low water flow

Water/glycol mixture inadequate

for process.

Improperly set leaving fluid

temperature, warning, or fault set

point

Refrigerant charge is low.

Locate and repair.

Replace relay board on control bed hot

gas coil

Install bypass between to-and-from

process line

Make sure that the water/glycol mixture

protection is right for the process.

Adjust.

Call service to find and repair the leak,

then have refrigerant added.

GP Series Portable Chillers Chapter 6: Troubleshooting 34 of 44

Page 35

Problem Possible cause Solution

Verify rotation; if running in reverse

Pump pressure low (refer to curves

for normal pressure for various

pumps).

Pump pressure is too high. Restricted water flow.

Unit runs continuously, but not

enough cooling power.

Pump running in reverse.

Check for foreign matter. Clean the system.

Restricted condenser air flow.

Unit low on refrigerant. Check the refrigerant charge.

Compressor not operating

efficiently.

Unit under-sized for application. Call sales rep.

rotation, reverse any two main power

leads. Re-verify for correct pump

rotation.

Check for partially closed valves etc.

Make sure that all lines are properly

sized.

Clean filters.

Clean condenser.

Call service.

GP Series Portable Chillers Chapter 6: Troubleshooting 35 of 44

Page 36

Chapter 7: Appendix

7-1 Returned Material Policy

Credit Returns

Prior to the return of any material, authorization must be given by the manufacturer. A RMS number

will be assigned for the equipment to be returned.

Reason for requesting the return must be given.

All returned Material purchased from the manufacturer is subject to 15% ($75.00 minimum) restocking

charge.

All

returns are to be shipped prepaid.

The invoice number and date or purchase order number and date must be supplied.

No credit will be issued for material that is not within the manufacturer’s warranty period and/or in new

and unused condition, suitable for resale.

Warranty Returns

Prior to the return of any material, authorization must be given by the manufacturer. A RMS number

will be assigned for the equipment to be returned.

Reason for requesting the return must be given.

All returns are to be shipped prepaid.

The invoice number and date or purchase number and date must be supplied.

After inspecting the material, a replacement or credit will be given, at the manufacturer’s discretion, if

the item is found to be defective in materials or workmanship. Purchased components are covered

under their specific warranty terms.

GP Series Portable Chillers Chapter 7: Appendix 36 of 44

Page 37

7-2 Technical Assistance

Parts Department

Call toll-free 7am–5pm CST [800] 423-3183 or call [262] 641-8610, Fax [262] 641-8653

The ACS Customer Service Group will provide your company with genuine OEM quality parts

manufactured to engineering design specific ations, which will maximize your equipment’s performa nce

and efficiency. To assist in expediting your phone or fax order, please have the model and serial

number of your unit when you contact us. A customer replacement parts list is included in this manual

for your convenience. ACS welcomes inquiries on all your parts needs and is dedic ated to providing

excellent customer service.

Service Department

Call toll-free 8am–5pm CST [800] 423-3183 or call [262] 641-8610

Emergencies after 5pm CST, call [847] 439-5655

We have a qualified service department ready to help. Service contracts are available for most

products.

Sales Department

[262] 641-8610

Call

Our products are sold by a world-wide network of independent sales representatives. Co ntact our Sales

Department for the name of the sales representative nearest you.

Contract Department

[262] 641-8610

Call

Let us install your system. The Contract Department offers any or all of these services:

project planning; system packages including drawings; equipment, labor, and construction

materials; and union or non-union installations.

Monday–Friday, 8am–5pm CST

Monday–Friday, 8am–5pm CST

Sterling, Inc

th

2900 S. 160

Street

New Berlin, WI 53151

www.sterlco.com

GP Series Portable Chillers Chapter 7: Appendix 37 of 44

Page 38

7-3 Specifications

Air-Cooled Portable Chillers

Nominal operating parameters for air-cooled models are 50ºF (10ºC) leaving wa ter temperature at 2.4

gpm per ton (9.1 lpm per 3.517 kW) with 95ºF (35ºC) ambient air. For 50 Hz applications, multiply

capacity by 0.83. Nominal 60 Hz capacity flow rate must be maintained.

G-PAC-20

PERFORMANCE (NOMINAL DESIGN CONDITIONS)

COOLING CAPACITY 4.72 TONS ALTITUDE SEA LEVEL

COOLANT SUPPLY TEMPERATURE 50 °F COMPRESSOR POWER 4976 WATTS

AMBIENT AIR TEMPERATURE 95 °F EER 11.39 BTU/WATT

COOLANT WATER CONDENSER AIR FLOW 4230 CFM

COOLANT FLOW 11 GPM SOUND POWER LEVEL 86 dBA

UNIT PRESSURE DROP 7 PSID SOUND PRESSURE LEVEL @ 1 METER dBA

OPERATING PARAMETERS

COOLANT SUPPLY TEMPERATURE 20-80 °F COOLANT FLOW GPM

AMBIENT AIR TEMPERATURE 60-115 °F MINIMUM LOAD 0.944 TONS

SPECIFICATIONS

COMPRESSOR SCROLL EVAPORATOR FILTER 20 MESH

COOLANT PUMP

EVAPORATOR BRAZED PLATE CAPACITY CONTROL HOT GAS BYPASS

CONDENSER ALUMINUM REFRIGERANT 3 LBS R-410A

CONDENSER FANS

CONDENSER FAN MOTOR 1/2 HP OAO, 1140 RPM PANELS POWDER COATED STEEL

RESERVOIR 20 GALLON POLYETHYLENE WEIGHT (OPERATING) 690 LBS

POWER 460V/3PH/60HZ WEIGHT (SHIPPING) 520 LBS

CONTROL CIRCUIT 120 VDC ELECTRICAL ENCLOSURE NEMA 12

COMPRESSOR FULL LOAD AMPS 10.7 AMPS CONTROL MICROPROCESSOR

STAINLESS STEEL

CENTRIFUGAL

24 INCH

AXIAL

COOLANT CIRCUIT NON-FERROUS

FRAME GALVANIZED STEEL

G-PAC-30

PERFORMANCE (NOMINAL DESIGN CONDITIONS)

COOLING CAPACITY 7.52 TONS ALTITUDE SEA LEVEL

COOLANT SUPPLY TEMPERATURE 50 °F COMPRESSOR POWER 7634 WATTS

AMBIENT AIR TEMPERATURE 95 °F EER 11.82 BTU/WATT

COOLANT WATER CONDENSER AIR FLOW 6343 CFM

COOLANT FLOW 18 GPM SOUND POWER LEVEL 92 dBA

UNIT PRESSURE DROP 7 PSID SOUND PRESSURE LEVEL @ 1 METER dBA

OPERATING PARAMETERS

COOLANT SUPPLY TEMPERATURE 20-80 °F COOLANT FLOW GPM

AMBIENT AIR TEMPERATURE 60-115 °F MINIMUM LOAD 1.504 TONS

SPECIFICATIONS

COMPRESSOR SCROLL EVAPORATOR FILTER 20 MESH

COOLANT PUMP

EVAPORATOR BRAZED PLATE CAPACITY CONTROL HOT GAS BYPASS

CONDENSER ALUMINUM REFRIGERANT 4 LBS R-410A

CONDENSER FANS

CONDENSER FAN MOTOR 1 HP OAO, 1140 RPM PANELS POWDER COATED STEEL

RESERVOIR 20 GALLON POLYETHYLENE WEIGHT (OPERATING) 870 LBS

POWER 460V/3PH/60HZ WEIGHT (SHIPPING) 700 LBS

CONTROL CIRCUIT 120 VDC ELECTRICAL ENCLOSURE NEMA 12

COMPRESSOR FULL LOAD AMPS 16.4 AMPS CONTROL MICROPROCESSOR

STAINLESS STEEL

CENTRIFUGAL

24 INCH

AXIAL

FRAME GALVANIZED STEEL

COOLANT CIRCUIT NON-FERROUS

GP Series Portable Chillers Chapter 7: Appendix 38 of 44

Page 39

G-PAC-40

PERFORMANCE (NOMINAL DESIGN CONDITIONS)

COOLING CAPACITY 10.11 TONS ALTITUDE SEA LEVEL

COOLANT SUPPLY TEMPERATURE 50 °F COMPRESSOR POWER 9944 WATTS

AMBIENT AIR TEMPERATURE 95 °F EER 12.21 BTU/WATT

COOLANT WATER CONDENSER AIR FLOW 8458 CFM

COOLANT FLOW 24 GPM SOUND POWER LEVEL 87 dBA

UNIT PRESSURE DROP 7 PSID SOUND PRESSURE LEVEL @ 1 METER dBA

OPERATING PARAMETERS

COOLANT SUPPLY TEMPERATURE 20-80 °F COOLANT FLOW GPM

AMBIENT AIR TEMPERATURE 60-115 °F MINIMUM LOAD 2.022 TONS

SPECIFICATIONS

COMPRESSOR SCROLL EVAPORATOR FILTER 20 MESH

COOLANT PUMP

EVAPORATOR BRAZED PLATE CAPACITY CONTROL HOT GAS BYPASS

CONDENSER ALUMINUM REFRIGERANT 6 LBS R-410A

CONDENSER FANS

CONDENSER FAN MOTOR 1 HP OAO, 1140 RPM PANELS POWDER COATED STEEL

RESERVOIR 40 GALLON POLYETHYLENE WEIGHT (OPERATING) 1090 LBS

POWER 460V/3PH/60HZ WEIGHT (SHIPPING) 760 LBS

CONTROL CIRCUIT 120 VDC ELECTRICAL ENCLOSURE NEMA 12

COMPRESSOR FULL LOAD AMPS 20 AMPS CONTROL MICROPROCESSOR

G-PAC-50

STAINLESS STEEL

CENTRIFUGAL

32 INCH

AXIAL

COOLANT CIRCUIT NON-FERROUS

FRAME GALVANIZED STEEL

PERFORMANCE (NOMINAL DESIGN CONDITIONS)

COOLING CAPACITY 15.08 TONS ALTITUDE SEA LEVEL

COOLANT SUPPLY TEMPERATURE 50 °F COMPRESSOR POWER 14871 WATTS

AMBIENT AIR TEMPERATURE 95 °F EER 12.16 BTU/WATT

COOLANT WATER CONDENSER AIR FLOW 12687 CFM

COOLANT FLOW 36 GPM SOUND POWER LEVEL 93 dBA

UNIT PRESSURE DROP 7 PSID SOUND PRESSURE LEVEL @ 1 METER dBA

OPERATING PARAMETERS

COOLANT SUPPLY TEMPERATURE 20-80 °F COOLANT FLOW GPM

AMBIENT AIR TEMPERATURE 60-115 °F MINIMUM LOAD 3.016 TONS

SPECIFICATIONS

COMPRESSOR SCROLL EVAPORATOR FILTER 20 MESH

COOLANT PUMP

EVAPORATOR BRAZED PLATE CAPACITY CONTROL HOT GAS BYPASS

CONDENSER ALUMINUM REFRIGERANT 8 LBS R-410A

CONDENSER FANS

CONDENSER FAN MOTOR 2 HP OAO, 1140 RPM PANELS POWDER COATED STEEL

RESERVOIR 40 GALLON POLYETHYLENE WEIGHT (OPERATING) 1290 LBS

POWER 460V/3PH/60HZ WEIGHT (SHIPPING) 950 LBS

CONTROL CIRCUIT 120 VDC ELECTRICAL ENCLOSURE NEMA 12

COMPRESSOR FULL LOAD AMPS 30 AMPS CONTROL MICROPROCESSOR

STAINLESS STEEL

CENTRIFUGAL

32 INCH

AXIAL

COOLANT CIRCUIT NON-FERROUS

FRAME GALVANIZED STEEL

GP Series Portable Chillers Chapter 7: Appendix 39 of 44

Page 40

Water-Cooled Portable Chillers

Nominal operating parameters for water-cooled models are 50ºF (10ºC) leaving water temperature at 2.4 gpm per ton

(9.1 lpm per 3.517 kW) with 85ºF (29ºC) tower water. For 50 Hz applications, multiply capacity by 0.83. Nominal 60

Hz capacity flow rate must be maintained.

G-PWC-20

PERFORMANCE (NOMINAL DESIGN CONDITIONS, 60 HZ)

COOLING CAPACITY 5.3 TONS ALTITUDE SEA LEVEL

COOLANT SUPPLY TEMPERATURE 50 °F COMPRESSOR POWER 4251 WATTS

CONDENSER INLET WATER

TEMPERATURE

COOLANT WATER CONDENSER WATER FLOW 15.9 GPM

COOLANT FLOW 13 GPM SOUND POWER LEVEL dBA

UNIT PRESSURE DROP 7 PSID SOUND PRESSURE LEVEL @ 1 METER dBA

OPERATING PARAMETERS

COOLANT SUPPLY TEMPERATURE 20-80 °F COOLANT FLOW 15 GPM

CONDENSER INLET WATER

TEMPERATURE

SPECIFICATIONS

COMPRESSOR SCROLL EVAPORATOR FILTER 20 MESH

COOLANT PUMP

EVAPORATOR BRAZED PLATE CAPACITY CONTROL HOT GAS BYPASS

CONDENSER TUBE IN TUBE REFRIGERANT 3 LBS R-410A

FRAME GALVANIZED STEEL

PANELS POWDER COATED STEEL

RESERVOIR 20 GALLON POLYETHYLENE WEIGHT (OPERATING) 690 LBS

POWER 460V/3PH/60HZ WEIGHT (SHIPPING) 520 LBS

CONTROL CIRCUIT 120 VDC ELECTRICAL ENCLOSURE NEMA 12

COMPRESSOR FULL LOAD AMPS 10.7 AMPS CONTROL MICROPROCESSOR

G-PWC-30

COOLING CAPACITY 8.36 TONS ALTITUDE SEA LEVEL

COOLANT SUPPLY TEMPERATURE 50 °F COMPRESSOR POWER 6485 WATTS

CONDENSER INLET WATER

TEMPERATURE

COOLANT WATER CONDENSER WATER FLOW 25.08 GPM

COOLANT FLOW 20 GPM SOUND POWER LEVEL dBA

UNIT PRESSURE DROP 7 PSID

COOLANT SUPPLY TEMPERATURE 20-80 °F COOLANT FLOW 22.5 GPM

CONDENSER INLET WATER

TEMPERATURE

COMPRESSOR SCROLL EVAPORATOR FILTER 20 MESH

COOLANT PUMP

EVAPORATOR BRAZED PLATE CAPACITY CONTROL HOT GAS BYPASS

CONDENSER TUBE IN TUBE REFRIGERANT 4 LBS R-410A

FRAME GALVANIZED STEEL

PANELS POWDER COATED STEEL

RESERVOIR 20 GALLON POLYETHYLENE WEIGHT (OPERATING) 870 LBS

POWER 460V/3PH/60HZ WEIGHT (SHIPPING) 700 LBS

CONTROL CIRCUIT 120 VDC ELECTRICAL ENCLOSURE NEMA 12

COMPRESSOR FULL LOAD AMPS 16.4 AMPS CONTROL MICROPROCESSOR

G-PWC-40

COOLING CAPACITY 11.31 TONS ALTITUDE SEA LEVEL

85 °F EER 14.95 BTU/WATT

50-90 °F MINIMUM LOAD 1.06 TONS

STAINLESS STEEL

CENTRIFUGAL

PERFORMANCE (NOMINAL DESIGN CONDITIONS)

85 °F EER 15.47 BTU/WATT

OPERATING PARAMETERS

50-90 °F MINIMUM LOAD 1.672 TONS

SPECIFICATIONS

STAINLESS STEEL

CENTRIFUGAL

PERFORMANCE (NOMINAL DESIGN CONDITIONS)

COOLANT CIRCUIT NON-FERROUS

SOUND PRESSURE LEVEL @ 1

METER

COOLANT CIRCUIT NON-FERROUS

dBA

GP Series Portable Chillers Chapter 7: Appendix 40 of 44

Page 41

COOLANT SUPPLY TEMPERATURE 50 °F COMPRESSOR POWER 8323 WATTS

CONDENSER INLET WATER

TEMPERATURE

COOLANT WATER CONDENSER WATER FLOW 33.93 GPM

COOLANT FLOW 27 GPM SOUND POWER LEVEL dBA

UNIT PRESSURE DROP 7 PSID

COOLANT SUPPLY TEMPERATURE 20-80 °F COOLANT FLOW 30 GPM

CONDENSER INLET WATER

TEMPERATURE

COMPRESSOR SCROLL EVAPORATOR FILTER 20 MESH

COOLANT PUMP

EVAPORATOR BRAZED PLATE CAPACITY CONTROL HOT GAS BYPASS

CONDENSER TUBE IN TUBE REFRIGERANT 6 LBS R-410A

FRAME GALVANIZED STEEL

PANELS POWDER COATED STEEL

RESERVOIR 40 GALLON POLYETHYLENE WEIGHT (OPERATING) 1090 LBS

POWER 460V/3PH/60HZ WEIGHT (SHIPPING) 760 LBS

CONTROL CIRCUIT 120 VDC ELECTRICAL ENCLOSURE NEMA 12

COMPRESSOR FULL LOAD AMPS 20 AMPS CONTROL MICROPROCESSOR

STAINLESS STEEL

CENTRIFUGAL

85 °F EER 16.31 BTU/WATT

SOUND PRESSURE LEVEL @ 1

METER

OPERATING PARAMETERS

50-90 °F MINIMUM LOAD 2.262 TONS

SPECIFICATIONS

COOLANT CIRCUIT NON-FERROUS

dBA

G-PWC-50

PERFORMANCE (NOMINAL DESIGN CONDITIONS)

COOLING CAPACITY 16.76 TONS ALTITUDE SEA LEVEL

COOLANT SUPPLY TEMPERATURE 50 °F COMPRESSOR POWER 12789 W ATTS

CONDENSER INLET WATER

TEMPERATURE

COOLANT WATER CONDENSER WATER FLOW 50.28 GPM

COOLANT FLOW 40 GPM SOUND POWER LEVEL dBA

UNIT PRESSURE DROP 7 PSID

COOLANT SUPPLY TEMPERATURE 20-80 °F COOLANT FLOW 45 GPM

CONDENSER INLET WATER

TEMPERATURE

COMPRESSOR SCROLL EVAPORATOR FILTER 20 MESH

COOLANT PUMP

EVAPORATOR BRAZED PLATE CAPACITY CONTROL HOT GAS BYPASS

CONDENSER TUBE IN TUBE REFRIGERANT 8 LBS R-410A

FRAME GALVANIZED STEEL

PANELS POWDER COATED STEEL

RESERVOIR 40 GALLON POLYETHYLENE WEIGHT (OPERATING) 1290 LBS

POWER 460V/3PH/60HZ WEIGHT (SHIPPING) 950 LBS

CONTROL CIRCUIT 120 VDC ELECTRICAL ENCLOSURE NEMA 12

COMPRESSOR FULL LOAD AMPS 30 AMPS CONTROL MICROPROCESSOR

STAINLESS STEEL

CENTRIFUGAL

85 °F EER 15.72 BTU/WATT

SOUND PRESSURE LEVEL @ 1

METER

OPERATING PARAMETERS

50-90 °F MINIMUM LOAD 3.352 TONS

SPECIFICATIONS

COOLANT CIRCUIT NON-FERROUS

dBA

GP Series Portable Chillers Chapter 7: Appendix 41 of 44

Page 42

7-4 Pump Curves, Flow, and Pressure Considerations

60 Hertz Pump Curves

300

250

120

design 4

design 3

200

5 HP 2CDX 200/506

2CDX 120/406

150

Head [ft]

design 2

1.5 HP CDX 70/156

100

1 HP CDX 70/106

50

2 HP CDX 120/206

design 1

3 HP 2CD X 120/306

2CDX 120/206

3U 32-200-1-7.5HP

100

3U 32-200-1-10HP

80

Psi

60

40

20

0

0 1020304050607080

0

Capacity [Gal/min]

GP Series Portable Chillers Chapter 7: Appendix 42 of 44

Page 43

Calculating Chiller Nominal Flow and Pressure to Process

• Flow rate: Obtain the flow reading from the appropriate pump curve.

• Pressure: Obtain a corresponding pressure reading from the pump curve you selected,

then subtract the one-pump pressure drop listed in the above table using the

appropriate chiller hp and flow rate.

• For two-pump (Process/Recirc) chillers, do not subtract pressure drop from table above

for process pump.

GP Series Portable Chillers Chapter 7: Appendix 43 of 44

Page 44

7-5 Electrical Schematic

Please refer to your owner’s information packet for more details regarding your

specific unit.

GP Series Portable Chillers Chapter 7: Appendix 44 of 44

Loading...

Loading...