$30.

00

Operation

and

Installation Manual

EX Series Screenless Granulator

Important! Read Carefully Before Attempting to Install or Operate Equipment

Bulletin No. BJ1-625

Write down your granulator ________________ ________________

serial numbers here ________________ ________________

for future reference ________________ ________________

Ball & Jewell can advise you on proper selection and sizing of systems for your

operating environment.

Ball & Jewell is committed to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual are subject to

change without notice.

Bulletin No. BJ1-625 Effective 7/10/02

DCN No. ____________

© Copyright Ball & Jewell Corp. 2002

All rights reserved.

Page ii

Safety Considerations

Ball & Jewell EX Series Granulator Sprue and Runner Cutters are

designed to provide safe and reliable operation when installed and

operated within design specifications, following national and local

safety codes.

To avoid possible personal injury or equipment damage when

installing, operating, or maintaining this granulator, use good

judgment and follow these safe practices:

LEARN AND OBEY your company’s safety policy regarding

;

granulating equipment.

MOVING OR LIFTING THE GRANULATOR: Although

;

our equipment is built and engineered for great ruggedness in

operation, care must be taken when moving the machine along

the floor or lifting it. Damage may occur to sheet metal covers,

electrical cabinets, or small brackets if pressure is applied to

them when moving the granulator. When lifting the granulator,

be certain of total machine weight and the capability of the

lifting equipment (see the Granulator Specification Sheets for

machine weights and dimensions).

GRANULATOR LOCATION: Adequate area for routine

;

maintenance should be provided in order to open the machine

for knife, screen, or cleanout service. Proper service area

clearances also should allow people who are working on the

machine to be clearly visible to others, thereby reducing the

potential safety hazards.

SAFE HOUSEKEEPING: The work area must be kept clean

;

and uncluttered to allow personnel safe movement around the

granulator during periods of operation or maintenance. No

hand tools or other metal objects should be left on or about the

machine. Any tools or other metal objects which mistakenly

fall into the hopper feed opening can cause severe damage to

internal cutting chamber and screen chamber components.

SAFETY GLASSES OR A FACE SHIELD MUST

;

ALWAYS BE WORN when servicing or operating the

machine. Although our machines are designed for the

maximum in flyback control, caution must be used when

operating near the area of the hopper feed opening in order to

guard against unexpected material flyback.

Page iii

EAR PROTECTION may be required when operating the

;

machine during granulation of very hard/noisy materials. The

Occupational Safety and Health Act of 1970 has established

guidelines for Permissible Noise Exposures (OSHA 1910.95)

that should be followed.

NEVER attempt to operate the granulator unless it is fully

;

assembled with all guards and interlocks in place and

functional.

OBSERVE all danger, warning, caution and safety labels on

;

the equipment.

Upon completion of any machine maintenance, be certain ALL

;

SAFETY GUARDS AND COVERS are securely and

properly fastened prior to resuming machine operation. All

fasteners must be in place and properly tightened. ANY

SHORTCUTS MAY RESULT IN INJURY TO

PERSONNEL OR DAMAGE TO EQUIPMENT.

NEVER wear any loose fitting clothes, neckties, or dangling

;

items such as earrings, belts or shoestrings. Jewelry such as

wristwatches, bracelets, or rings should NEVER be worn.

Long hair must be tied back or placed in a tight fitting hairnet.

NEVER lean against or rest hands/feet on the granulator when

it is in operation or open for maintenance. NEVER stand on

the granulator when it is in operation.

ROTATION OF MOTORS: All rotating items in the

;

granulator are clearly marked on the machine. Always check

for proper rotation of motors.

ELECTRICAL GROUNDING: All electrical equipment on

;

the granulator must be grounded in accordance to all local

codes and Article 250 of the National Electric Code.

ALWAYS DISCONNECT AND LOCKOUT THE MAIN

;

ELECTRICAL POWER TO THE GRANULATOR BEFORE

PERFORMING ANY SERVICE.

SAFETY INTERLOCKS MUST NOT BE BYPASSED.

;

The mechanical and electrical safety interlocks ensure the

safety of personnel. They should never be tampered with or

removed for ANY reason. They should be checked frequently

by a qualified mechanic for proper operation.

NEVER modify the machine configuration or any individual

;

component without written consent from Cumberland

Engineering Corp.

Page iv

For further information on granulator safety, installation, and

operation, see the American National Standard for Plastics

Machinery - Granulators, Pelletizers, And Dicers Used For Size

Reduction of Plastics - Construction, Care, and Use. ANSI

B151.11-1982.

Ball & Jewell has long recognized the importance of safety and has

designed and manufactured its equipment with operator safety as a

prime consideration. We expect you, as a user, to abide by the

foregoing recommendations in order to make operator safety a

reality.

SAFETY IS NO ACCIDENT

Page v

Table of Contents

Error! No table of contents entries found.

1 General Information 11

1-1 Introduction 11

1-1-1 How to Use This Manual 11

1-1-2 Safety Symbols Used in This Manual 12

1-2 Granulator Specifications 13

1-3 Standard Features 13

1-4 Available Options 14

2 Shipping Information 15

2-1 Unpacking and Inspection 15

2-2 In the Event of Shipping Damage 15

2-3 If the Shipment is Not Complete 16

2-4 If the Shipment is Not Correct 16

2-5 Returns 16

2-6 Uncrating Your Granulator 16

3 Installation 18

3-1 Scope 18

3-2 General Set-Up 18

3-3 Inspecting and Cleaning Granulator Components 18

3-4 Completing the Installation of Your Granulator 19

3-5 Electrical Considerations 20

3-6 Electrical Service Connections 21

3-7 Electrical Testing 21

3-7-1 Hopper Safety Disconnect 22

3-7-2 Motor Rotation Direction 22

3-7-3 Accessory Equipment 22

4 General Operation 23

4-1 Scope 23

4-2 Pre-Operational Checklist 23

4-3 Granulator Operation 24

4-4 Cleaning Out the Granulator 24

4-5 Shutdown Conditions 25

4-5-1 Emergency Stops 25

4-5-2 Temporary Machine Stops 25

4-5-3 Final Machine Stops 25

Page vi

5 Maintenance 26

5-1 Maintaining Drive Components 26

5-2 Replacing Timing Belts 27

5-3 Lubrication Specifications and Considerations 27

5-4 Knife Recommendations and Adjustments 28

5-4-1 Removing, Replacing and Adjusting Granulator Combs

28

5.4.1.a. Removing Rotor Combs: 28

5.4.1.b. Removing Bed Combs: 29

5.4.1.c. Installing Bed Combs: 29

5-5 Adjusting the Sensitivity of the Optional Bin Level Monitor 30

5-6 Recommended Spare Parts List 31

6 Troubleshooting 33

7 Charts and Figures 39

Page vii

List of Figures

1.

Belt Tensioning Chart 27

2.

Recommended Spare Parts List Categories 32

3.

S Series Screenless Granulator (Front) 39

4.

S Series Screenless Granulator (Back) 39

5.

Segregation Chamber Access 40

6.

Cutting Chamber Detail 40

7.

Discharge Options 41

8.

Knife Bolt/Screw Tightening Torque Specifications 42

Page viii

Ball & Jewell Warranty Information

Thank you for your purchase of your new EX Series Screenless Granulator. We are confident

that you will have excellent results and trouble-free operation with this machine.

When the machine arrives at your plant, inspect it carefully for shipping damage before

uncrating and immediately report any damage to your transportation company. All shipments

are FOB South Attleboro, Massachusetts.

Customer Satisfaction Warranty Program for EX Series Screenless Granulator.

The terms and conditions of the warranty set forth are for one (1) year from the original date of

purchase by the original purchaser.

Ball & Jewell warrants to the original purchaser the product and/or goods to which this

disclaimer is attached, and manufactured by us, to be free from defects in material and

workmanship under normal use and service. THIS WARRANTY IS EXPRESSLY IN LIEU OF

ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, AND ALL

OTHER OBLIGATIONS AND LIABILITIES ON OUR PART.

This warranty shall not apply to any goods or product manufactured by us which has been

subject to accident, negligence, alteration of any kind, abuse or misuse. We further make no

warranty whatsoever in respect to accessories or parts not supplied by us. Any warranty of any

nature shall apply only to an “original purchaser” which shall be deemed to mean that person or

entity for whom the goods and/or product were originally ordered and installed.

We neither assume nor authorize any person to assume for us any liability in connection with the

sale or use of the products and goods sold hereunder, and shall not be responsible for damages

for which a purchaser may be liable to other persons, damages to property, or injuries to any

other persons.

Our sole obligation under this warranty shall be limited to replacing, repairing, or exchanging

any part or parts of goods and/or products sold which we determine are defective under normal

use and service within one (1) year of date of installation by the original purchaser. We shall not

be liable for any loss or damage resulting directly or indirectly from the use or loss of the goods

and/or products purchased. In no event shall we be liable for any general, direct, consequential,

incidental or special damages of any kind.

We do not warrant any of our products that are installed in other machines or apparatus as

meeting requirements of any safety code of any nature. The purchaser assumes all risks and

liabilities resulting from the installation and use of product sold by us in combination with other

machines or apparatus.

Page ix

Ball & Jewell Warranty Information

We warrant our product to be of the kind and quality quoted, and no other warranty except of

title shall be implied. Our company shall repair or replace, at our discretion, any manufactured

item on your S Series granulator without charge FOB factory, within one (1) year after date of

original purchase, which is proved to be defective when shipped. Claims for labor or

consequential damages are not allowed.

Excluded from the above are knives, screens, and belts. Purchased items, including electrical

components, motors, etc., shall carry the warranty of the supplier and no extension of that

warranty is allowed.

Refer to this manual for assistance in installing and maintaining a highly efficient machine.

Questions regarding areas that are not covered in the manual should be referred to the Customer

Service Manager at the factory at (800) 229-2919.

Page x

1 General Information

1-1 Introduction

The Ball & Jewell EX Series Screenless Granulators are designed

to uniformly and consistently size-reduce solid material scrap.

They have been engineered to consistently deliver clean granulate

with a minimum of fines and longs.

The rotor on which the combs and breaker bars are mounted is a

machined steel unit supported by bearings mounted outside the

cutting chamber. The rotor is driven by a gear motor capable of

producing high torque loads. The granulator is equipped with a

magnetic reversing starter protected by manually resettable

overload heaters. The rotor combs and bed combs create a

shearing cutting action, producing a very consistent particle size.

Motors are individually fused for maximum protection in

compliance with the National Electric Code. The control enclosure

houses all of the necessary wiring, fuses, overload heaters, and

motor starter coils, along with the 115V control transformer and

granulator operating controls. The control enclosure is built to

meet NEC regulations and also contains a fused disconnect switch.

1-1-1 How to Use This Manual

Use this manual as a guide and reference for installing, operating,

and maintaining your EX Series Granulator. The purpose is to

assist you in applying efficient, proven techniques that enhance

equipment productivity.

The General Information section outlines models covered, standard

features, and available options. Additional sections within the

manual provide instructions for installation, pre-operational

procedures, operation, preventive maintenance, and corrective

maintenance.

Installation instructions include all required data for receiving,

unpacking, inspecting, and setup of the granulator. We can

provide the assistance of a factory-trained technician to help train

your operator(s) for a nominal charge.

Pre-operational procedures include instructions, checks, and

adjustments that should be followed before operating the

granulator. These instructions are intended to supplement

Page 11

standard shop procedures performed at shift, daily, and weekly

intervals.

The Operation chapter includes a description of electrical and

mechanical controls, in addition to information for operating the

granulator safely and efficiently.

The Maintenance chapter is intended to serve as a source of

detailed assembly and disassembly instructions for those areas of

the equipment requiring service. Preventive maintenance sections

are included to ensure that your EX Series Granulator provides

excellent, long service. The Customer-Recommended Spare Parts

section in the Maintenance chapter contains a list of parts that may

require replacement. A spare parts list with part numbers specific

to your machine is provided with your shipping paperwork

package. Refer to this section for a listing of spare parts for

purchase. Have your serial number and model number ready when

ordering.

The Troubleshooting chapter serves as a guide for identification of

most common problems. Potential problems are listed, along with

possible causes and related solutions.

1-1-2 Safety Symbols Used in This Manual

The following safety alert symbols are used to alert you to

potential personal injury hazards. Obey all safety messages that

follow these symbols to avoid possible injury or death.

DANGER indicates an imminently hazardous situation, which, if

not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation or practice

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation or practice

which, if not avoided, may result in minor or moderate injury, or in

property damage.

Page 12

1-2 Granulator Specifications

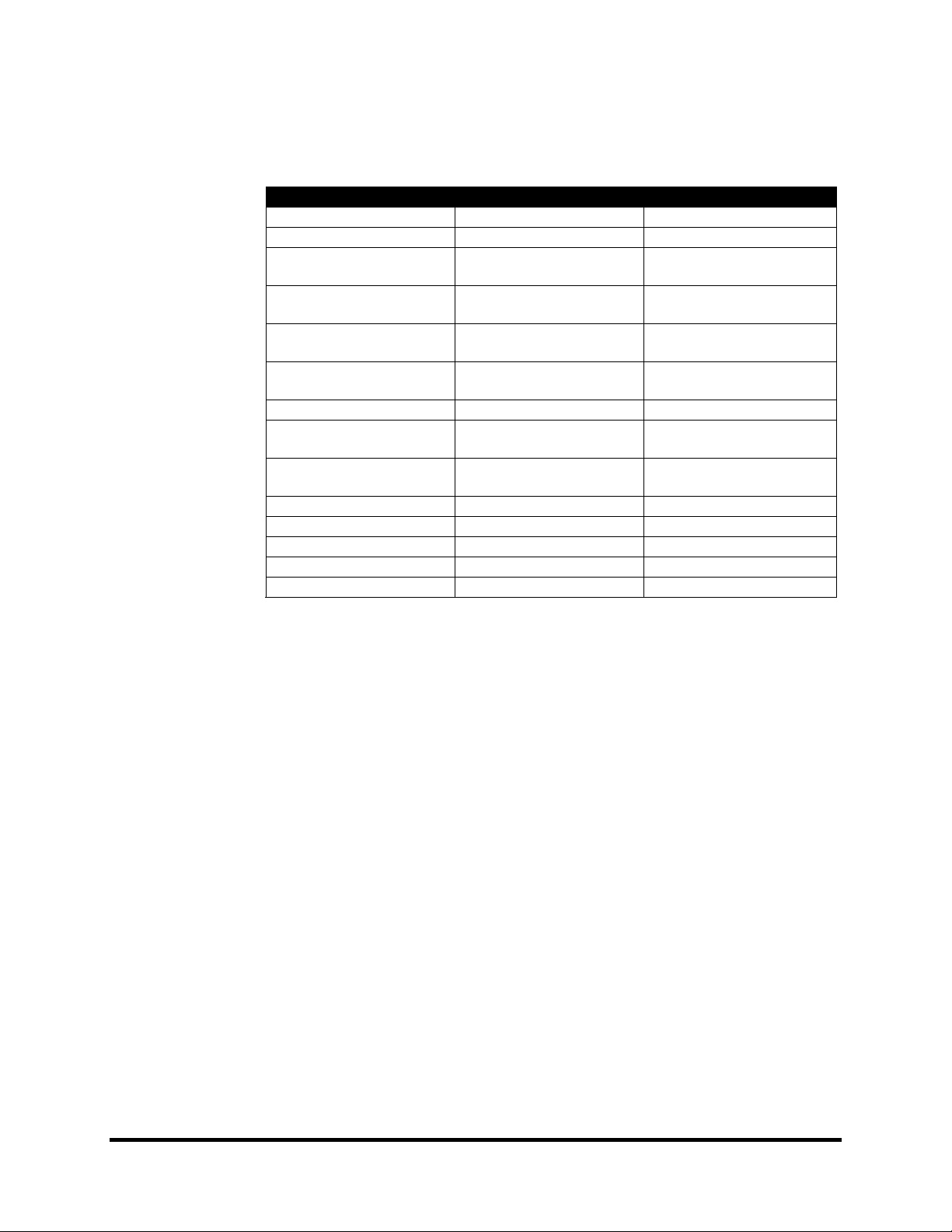

Table 1: Granulator Specifications

EX909 EX913 EX918

Cutting Circle 9.7” (247 mm) 9.7” (247 mm) 9.7” (247 mm)

Throughput 30 lbs./hr (14 kg/hr) 40 lbs./hr (18 kg/hr) 50 lbs./hr (23 kg/hr)

Cutting Chamber 9” x 9” (229 mm x 229

mm)

Rotor Knives Hardened 8620 alloy

steel

Bed Comb Reversible 1/4” (6.4 mm)

comb

Discharge Bin 0.70 cu. ft. (.0198 cu.

meters)

Motor 1 hp (.75 kW) 2 hp (1.5 kW) 2 hp (1.5 kW)

Drive Cyclodial speed reducer

– 34rpm

Electrical

Components

Controls NEMA type 12 NEMA type 12 NEMA type 12

Feed Height 52” (1321 mm) 52” (1321 mm) 52” (1321 mm)

Length 25.25” (641 mm) 25.25” (641 mm) 25.25” (641 mm)

Width 19” (483 mm) 23” (584 mm) 28” (711 mm)

Weight 550 lbs (250 kg) 650 lbs (295 kg) 750 lbs (341 kg)

Start/stop pushbutton Start/stop pushbutton Start/stop pushbutton

9” x 13” (229 mm x 330

mm)

Hardened 8620 alloy

steel

Reversible 1/4" (6.4 mm)

comb

0.85 cu. ft. (.0241 cu.

meters)

Cyclodial speed reducer

– 34rpm

9” x 18” (229 mm x 457

mm)

Hardened 8620 alloy

steel

Reversible 1/4" (6.4 mm)

comb

1.00 cu. ft. (.0283 cu.

meters)

Cyclodial speed reducer

– 34rpm

1-3 Standard Features

Standard features of the EX Series Granulator are

• 34 RPM rotor speed

• 230 or 460 voltages

• Segmented rotor comb design

• Timing belt drive system with taper lock bushings

• Totally-enclosed fan-cooled gear motor

• Front hopper cleanout door

• NEMA 1 drop-down rear access electrical enclosure with fused

disconnect switch

• Start-stop control button mounted on NEMA 12 box

• Front-access bed comb cam adjusting system

• 8620 heat treated cutter segments

• Manual discharge bin

• Positive break safety switch to interlock hopper and chute doors

Page 13

• No Tools Required to open the cutting chamber/segment

chamber/hopper chute

• Four (4) swivel casters

1-4 Available Options

Available standard options for EX Series Granulators include:

• Alternate feed chutes.

• Alternative voltages: 208/3/60, 380/3/50, 415/3/50, 575/3/60

• Alternate comb tooth sizes .185”(~5MM) and .220”(~6MM),

• Vacuum bin design

• Bin level-sensing proximity switch and light

• Abrasion resistance package

• Compressed air venturi

Page 14

Loading...

Loading...