Page 1

IIEVC-6

J30-05401

INSTALLATION SERVICE MANUAL

OUTDOOR ROOFTOP EVAPORATIVE COOLING UNITS

*Unit Type (EV) - Capacity (CA) - (10-40)

Evaporative Cooling systems meet a wide range of heating and ventilating requirements. The Evaporative Cooler

may be purchased as an individual unit in four sizes from 800 CFM to 8500 CFM (0.4 to 4.0 m3/s) or, it can be

combined with Rooftop Packaged Units (Natural or Power Vented), Air Handlers, or Make-up Air Handlers. In any

combination, the Evaporative Cooler will replace the need for 100% Outside Air Inlet Hood.

Evaporative Cooling is the simplest and most-cost effective cooling method without the use of mechanical

refrigeration.

FPO

ATTENTION: Read This manual IIEVC, manuals RISM* and RBM*, submittal/data sheets,

and all labels attached to the unit carefully before attempting to install, operate, or service the Evaporative Cooling Unit! Retain this manual for future reference.

Maintain water in sumps by proper microbicidal water treatment to minimize the risks of illness caused by Legionella Pneumophila (the bacteria that causes

Legionnaire's Disease) and other bacteria. Refer to local codes regar ding any additional

treatment or restrictions regarding water supplies and usage.

INSTALLER'S RESPONSIBILITY

Installer Please Note: This equipment has been tested and inspected. It has been shipped

free from defects from our f actory . Ho wever , during shipment and installation, problems such as

loose wires, leaks or loose fasteners ma y occur . It is the installer's responsibility to inspect

and correct any problems that may be found.

The model and serial numbers are located on the data plate attached to the side of the cooler.

Record this information in the spaces provided below.

Model No. Serial No.

*This manual may also be used for the following:

Unit Types (UT) - (RT or PV)

Rooftop Arrangements (RA) - (D or E) and

Unit Type (UT) - (AH)

Rooftop Arrangements (RA) - (P or R)

Capacity (CA) - (20 or 40)

260 NORTH ELM ST., WESTFIELD, MA 01085

TEL: (413) 568-9571 FAX: (413) 562-8437

www.mestek.com

Page 2

RECEIVING INSTRUCTIONS

Inspect shipment immediately after receiving to determine

if any damage has occurred during shipment If any

damage is found, the consignee should sign the bill of

lading, indicating such damage, and immediately fi le claim

for damage with the transportation company.

TABLE OF CONTENTS

Description Page

General Information ...........................................Cover, 2

PERFORMANCE & SPECIFICATION DATA

Evaporative Cooler - Dimensional

& Performance Data .............................................. 3

CELdek® Media Data and Effi ciency Chart .............3

Gas-Fired Rooftop Packaged Units

with Evaporative Cooler .................................... 4, 5

Air Handler with Evaporative Cooler ......................... 6

PARTS IDENTIFICATION ............................................ 7

INSTALLATION

Mounting to Roof ...................................................... 8

Connecting Water Supply ......................................... 8

Faucet Use ............................................................... 8

Adjusting Water Level and Float Valve ..................... 9

Adjusting Water Flow ................................................ 9

Bleed-Off .................................................................. 9

Electrical Connections ...................................... 10, 11

MAINTENANCE

Maintenance Schedule ........................................... 12

Changing Media ................................................12, 13

Cleaning Water Pump .............................................13

Washing Media ........................................................13

Washing Inlet Filter ..................................................13

Cabinet Cleaning and Touch-up ..............................13

Winter Shut-Down ...................................................13

Evaporative Cooler Curb Assembly Diagram ..........14

Model Number Description ......................................15

Replacement Parts ..................................................15

The following terms are used throughout this manual, in

addition to the other requirements, to bring attention to the

presence of potential hazards or to important information

concerning the product:

Indicates an imminently hazardous

situation which, if not avoided, will result in

death, serious injury or substantial property

damage.

Indicates an imminently hazardous

situation which, if not avoided, could result in

death, serious injury or substantial property

damage.

Indicates an imminently hazardous

situation which, if not av oided, ma y result in minor

injury or property damage.

NOTICE: Used to notify of special instructions on

installation, operation, or maintenance which are

important to equipment but not related to personal

injury.

Failure to comply with the General Safety Information

may result in extensive property damage, severe

personal injury, or death.

GENERAL SAFETY INFORMATION

Unless otherwise specifi ed, the following conv ersions may

be used for calculating SI/metric unit measurements:

1 lb. = 0.453 kg

1 cubic foot = 0.028m

3

1000 Btu per hour = 0.293 kW

1 foot = 0.305 m

1 inch water column = 0.249 kPa

1 inch = 25.4 mm

1 gallon = 3.785 L

1 psig = 6.894 kPa

1000 BTU/cu. ft. = 37.5 MJ/m

3

1liter/second = CFM x 0.472

meter/second = FPM ÷ 196.8

– 2 –

Disconnect all power before

installing or servicing the unit. If power disconnect

is out of sight, lock it in the open position and ta g

it to prevent unexpected application of power.

Failure to do so could result in fatal electrical

shock or severe personal injury.

Do not alter the unit in any way, or

damage to the unit and/or severe personal injury

or death may occur.

Do not depend on a thermostat or

other switch as a sole means of disconnecting

power when installing or servicing unit. Always

disconnect power at the main circuit breaker as

described above. Failure to do so could result in

fatal electrical shock.

Page 3

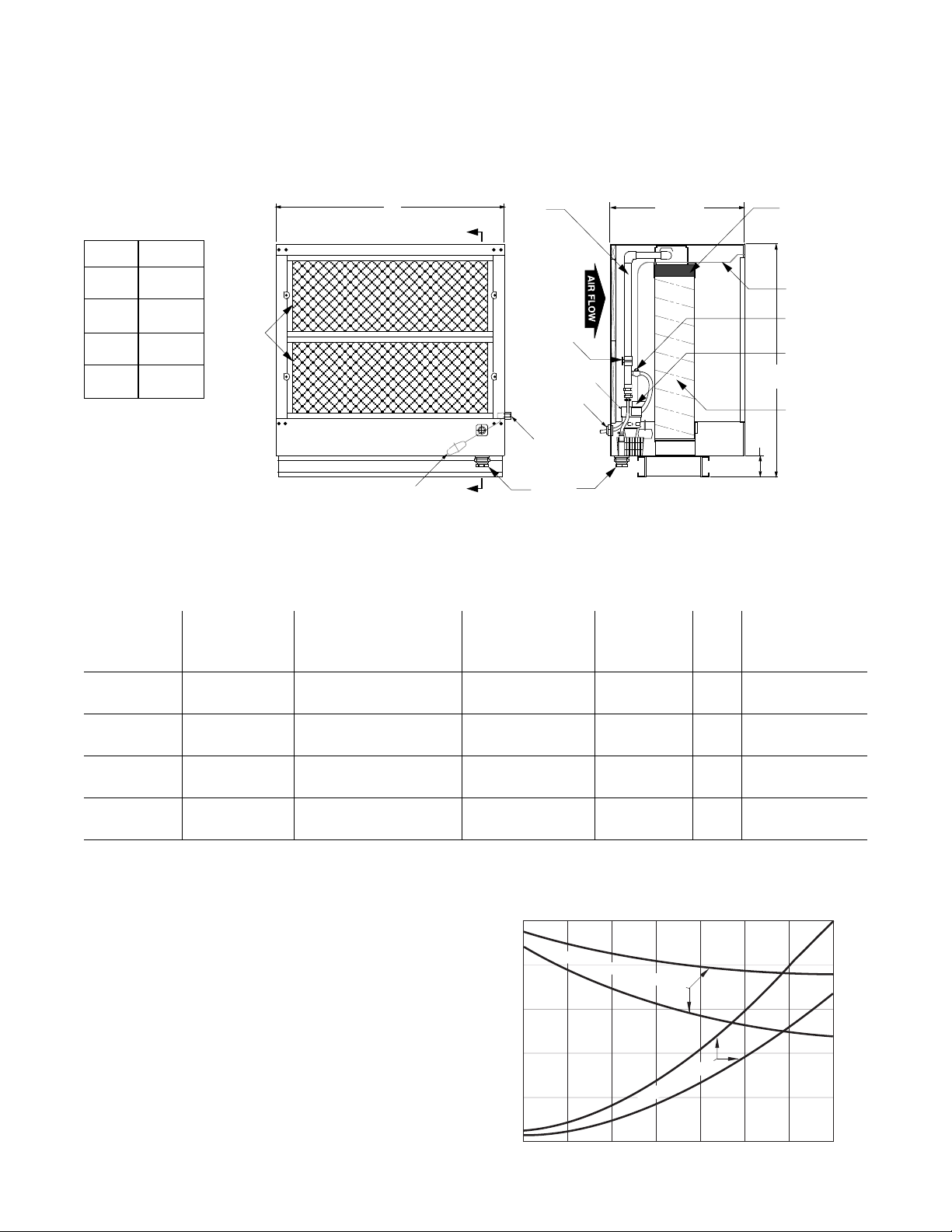

4"

(102)

8" CELdek®

(Optional 12")

2" CELdek®

Overflow

Pump

Ball

Valve

1/4" Water

Inlet

Float Valve

Bleed-off

Water

Distribution

Assembly

“A”

Intake

Filter

S

S

SECTION S-S

3/4" NPT

Drain

(Capped)

Junction Box

Liquid Tight

Electrical

Tubing

43"

(1092)

36"

(914)

Figure 1

200

0.5

100%

90%

80%

70%

60%

0.4

0.3

0.2

0.1

Air Velocity - FPM

Evaporative Cooling Efficiency

Air Pressure Drop Inches - WG

300 400 500 600 700 800

12"

8"

8"

12"

Evaporative Cooling Efficiency

Air Pressure Drop

PERFORMANCE AND SPECIFICATION DATA

Evaporative Cooling Units

Capacity

10/15

20/25/50

30/35

60/70

40/80

A

32-7/8"

(835)

43-7/8"

(1114)

54-7/8"

(1394)

60-3/8"

(1534)

Table 1 (Refer to individual unit submittals for more specifi cations.)

Performance and Dimensional Data

8" Saturation 12" Saturation 8" or 12" Media Pressure Drop “A” Unit Shipping Operating

CFM Effi ciency Effi ciency Face Area Size in W.C. Width Wt. Wt.

(cu. m/s) (cu. m/s) Range Range Ft.

*Capacity MIN. MAX. MIN. MAX. MIN. MAX. (m

10,15 800 4,500 78 88 89 92 7.01 31 x 32-9/16 0.03 0.23 32-3/4 137 301

(0.378) (2.124) (0.65) (787 x 827) (0.01) (0.06) (832) (62) (136)

20, 25, 50 1,600 5,500 77 88 88 92 9.38 31 x 43-9/16 0.03 0.20 43-3/4 166 386

(0.755) (2.596) (0.87) (787 x 1106) (0.01) (0.05) (1111) (75) (175)

30, 35, 60, 70 2,400 8,500 77 86 88 92 11.75 31 x 54-9/16 0.05 0.30 54-3/4 192 468

(1.133) (4.012) (1.09) (787 x 1386) (0.01) (0.07) (1391) (87) (212))

40, 80 3,200 8,500 77 86 87 92 12.92 31 x 60 0.07 0.28 60-1/4 206 509

(1.510) (4.012) (1.20) (787 x 1524) (0.02) (0.07) (1530) (93) (231)

*Capacities - (50, 60, 70 and 80) are for Dual Furnace Unit Types only.

2

in. (kPa) (kPa) in. lb. lb.

2

) (mm) MIN. MAX. (mm) (kg) (kg)

CELdek® EVAPORATIVE MEDIA

The Evaporative Cooler utilizes high effi ciency

CELdek® media. CELdek® is made from a special

cellulose paper, impregnated with insoluble antirot salts and rigidifying saturants. The cross fl uted

design of the pads induces highly-turbulent mixing

of air and water for optimum heat and moisture

transfer. The evaporative coolers are available

with standard 8 or optional 12 inch media which

produce high effi ciency and high face velocities,

along with a 2" distribution pad to disperse the

water evenly over the pads.

Figure 2

– 3 –

Page 4

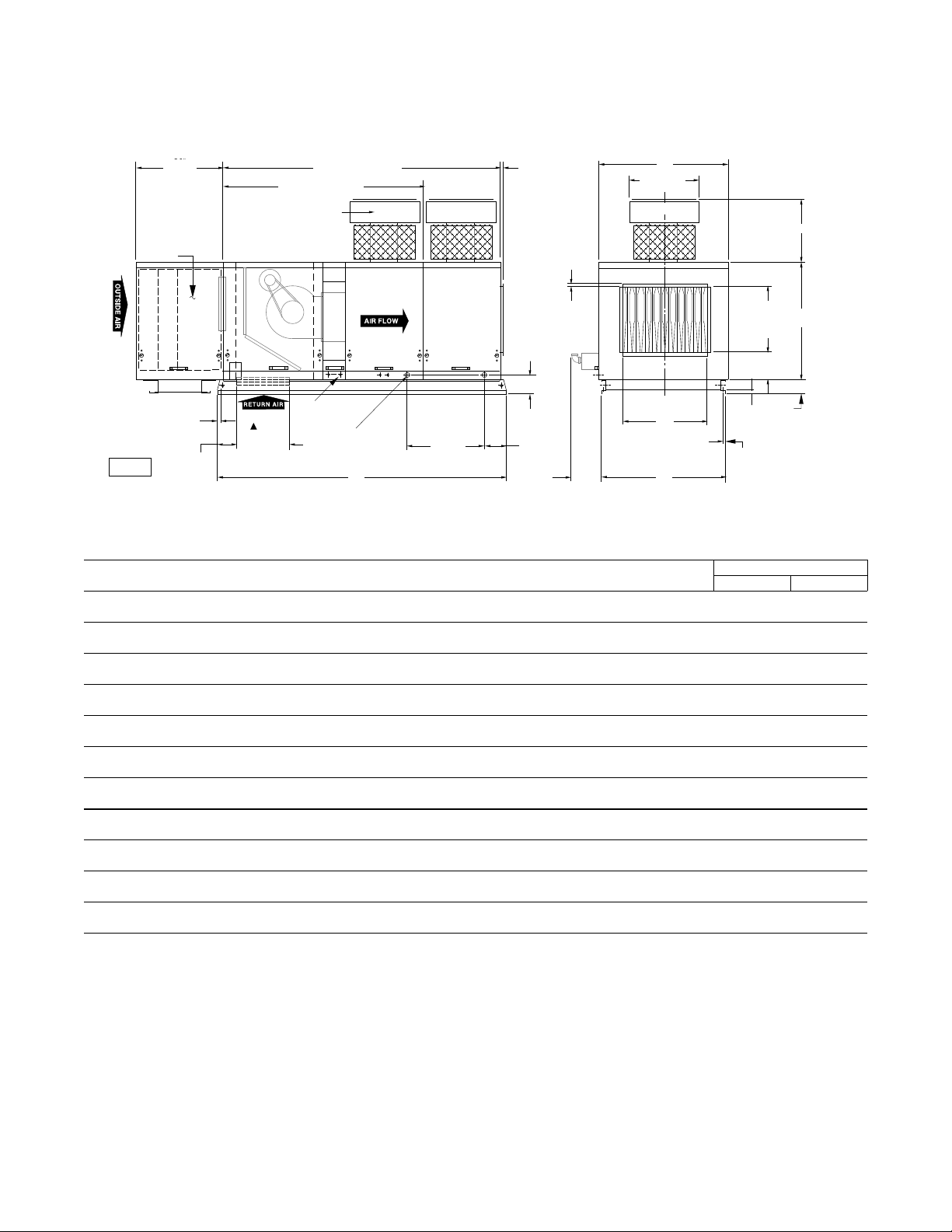

Rooftop Packaged Unit

D4163

T4160BD

B

Discharge

Opening

1-5/16" (33) Typ.

Anchor Hole

Location

5"

(127)

A

C (Typ. Sq.)

*

F

D

39"

(991)

G

Outside

1" (25)

Curb Cap

5/8" (16) Typ.

Anchor Hole

Location

6-1/16"

(154)

8-3/4

(222)

26"

(660)

Electrical

Connections

Vent Caps

Are Shipped

In Separate

Cartons

Gas

Connection

§

L

Evaporative

Cooler

18-7/8" (479)

x J Typ.

O.S. Damper

Opening

6-1/2"

(165)

36"

(914)

C

L

1-1/8" (29)

Typ. Duct

Flange

1" (25)

Typ.

19"

(483)

Discharge

Opening

10-1/8"

(257)

§

U (Capacities 10/40)

§

U (Capacities 50/80)

36"

(914)

with Evaporative Cooling

Figure 3 - Natural Vent Rooftop Unit with Evaporative Cooler (without Supply Plenum)

Table 2A

A.G.A. C.G.A. GAS INLET

CAPACITY A B C D D *F G ▲J L §U NAT LP

10 32-7/8 15-9/16 12 11 20-11/16 19-3/8 31-1/16 24 77-3/8 72-1/4 1/2 1/2

(835) (395) (305) (279) (525) (492) (789) (610) (1965) (1835)

15 32-7/8 18-5/16 21-1/2 16 25-3/16 23-1/2 31-1/16 24 77-3/8 72-1/4 1/2 1/2

(835) (465) (546) (406) (640) (597) (789) (610) (1965) (1835)

20 43-7/8 23-13/16 23-1/2 16 25-3/16 26-1/4 42-1/16 35 77-3/8 72-1/4 1/2 1/2

(1114) (605) (597) (406) (640) (667) (1068) (889) (1965) (1835)

25 43-7/8 29-5/16 23-1/2 16 25-3/16 34-1/2 42-1/16 35 77-3/8 72-1/4 3/4 1/2 OR 3/4

(1114) (745) (597) (406) (640) (876) (1068) (889) (1965) (1835)

30 54-7/8 34-13/16 26 17-1/2 26-11/16 37-1/4 53-1/16 46 77-3/8 72-1/4 3/4 1/2 OR 3/4

(1394) (884) (660) (445) (678) (946) (1348) (1168) (1965) (1835)

35 54-7/8 40-5/16 26 17-1/2 26-11/16 45-1/2 53-1/16 46 77-3/8 72-1/4 3/4 1/2 OR 3/4

(1394) (1024) (660) (445) (678) (1156) (1348) (1168) (1965) (1835)

40 60-3/8 45-13/16 26 17-1/2 26-11/16 51 58-9/16 51-1/2 77-3/8 72-1/4 3/4 1/2 OR 3/4

(1534) (1164) (660) (445) (678) (1295) (1487) (1308)

50 43-7/8 29-5/16 23-1/2 16 25-3/16 34-1/2 42-1/16 35 103-3/8 98-1/4 3/4 1/2 OR 3/4

(1114) (745) (597) (406) (640) (876) (1068) (889) (2626) (

60 54-7/8 34-13/16 26 17-1/2 26-11/16 37-1/4 53-1/16 46 103-3/8 98-1/4 3/4 1/2 OR 3/4

(1394) (884) (660) (445) (678) (946) (1348) (1168) (2626) (

70 54-7/8 40-5/16 26 17-1/2 26-11/16 45-1/2 53-1/16 46 103-3/8 98-1/4 3/4 1/2 OR 3/4

(1394) (1024) (660) (445) (678) (1156) (1348) (1168) (2626) (

80 60-3/8 45-13/16 26 17-1/2 26-11/16 51 58-9/16 51-1/2 103-3/8 98-1/4 3/4 1/2 OR 3/4

(1534) (1164) (660) (445) (678) (1295) (1487) (1308) (2626) (2496)

NOTE: REFER TO UNIT SUBMITTALS FOR MORE SPECIFICATIONS/UNIT ARRANGEMENTS.

DIMENSIONS ARE IN INCHES, DIMENSIONS IN PARENTHESIS ARE IN MILLIMETERS.

* “F” DIMENSION IS THE RECOMMENDED CLEARANCE TO SERVICE THE BURNER DRAWER(S).

▲“J” DIMENSION IS AN OUTSIDE DIMENSION FOR RETURN AIR DAMPERS.

§ “U” ALL DIMENSIONS ARE TABULATED FOR ROOFTOP ARRANGEMENTS B & D PER CAPACITIES 10 THROUGH 80 ACCORDINGLY

(CAPACITIES 50/80 ARE SHOWN PICTORIALLY).

NATURAL VENT UNIT DIMENSIONS SHOWN ABOVE; FOR POWER VENT DIMENSIONS, CONTACT CUSTOMER SERVICE FOR POWER

VENT UNIT SUBMITTAL SHEETS.

– 4 –

(1965) (1835)

2496)

2496)

2496)

Page 5

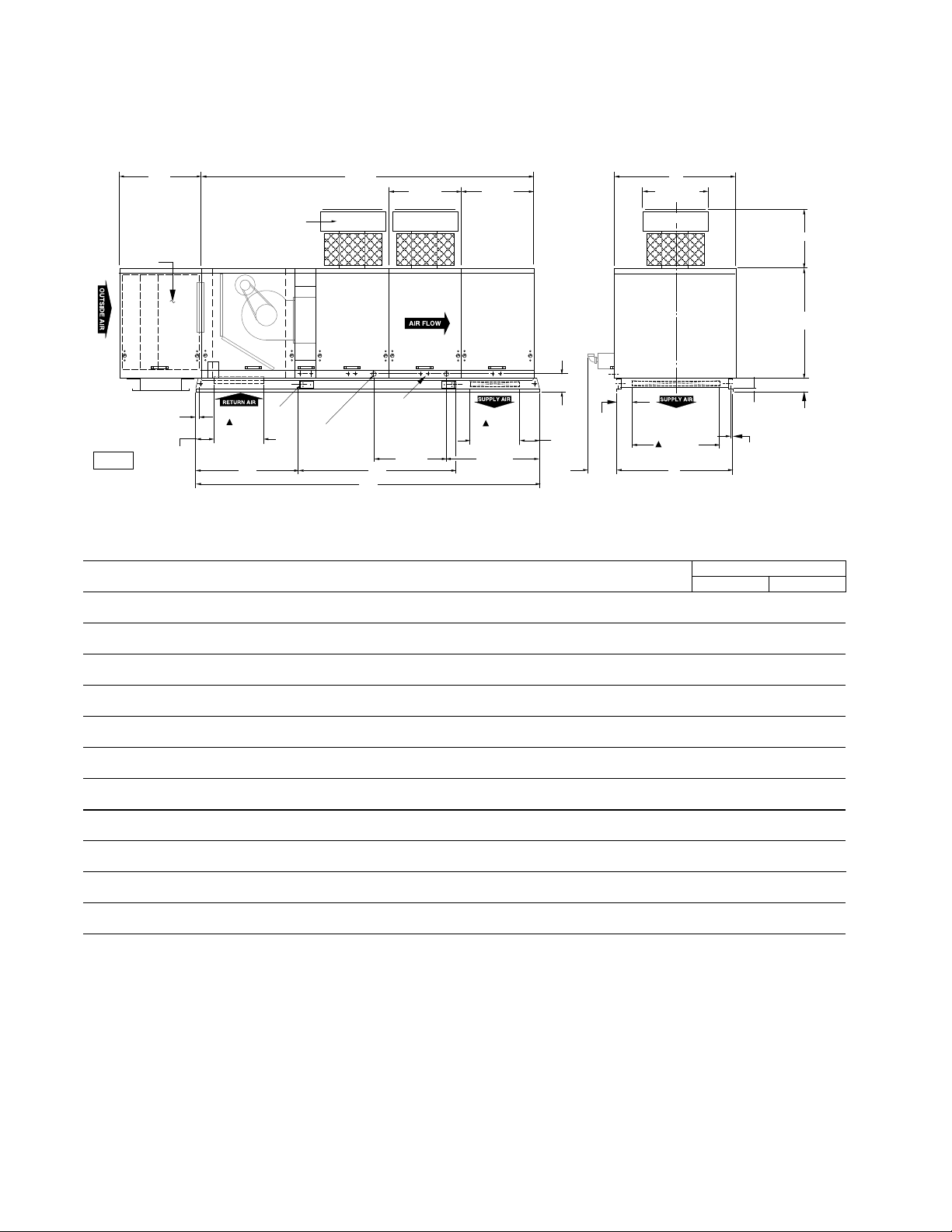

Rooftop Packaged Unit

J Inside

Supply Opening

1-5/16" (33) Typ.

Anchor Hole

Location

5"

(127)

A

C (Typ.) Sq.

*

F

C

L

D

39"

(991)

G

1" (25)

Curb Cap

D4165

T4160CE

5/8" (16) Typ.

Anchor Hole

Location

6-1/16"

(154)

Vent Caps

Are Shipped

In Separate

Cartons

Gas

Connection

6-1/16"

(154)

Evaporative

Cooler

18-7/8" (479)

x J Typ.

Inside

Opening

34-3/4"

(883)

26"

(660)

18-7/8" (479)

x J Typ.

O.S. Damper

Opening

6-1/2"

(165)

3-9/16"

(90)

Lifting

Brackets

Electrical

Connections

Outside

§

R

§

Q

§

L

§

U

26"

(660)

26"

(660)

36"

(914)

with Evaporative Cooling

Figure 4 - Natural Vent Rooftop Unit with Evaporative Cooler (with Supply Plenum)

Table 2B

A.G.A. C.G.A. GAS INLET

CAPACITY A C D D *F G ▲J L Q R §U NAT LP

10 32-7/8 12 11 20-11/16 19-3/8 31-1/16 24 103-3/8 NA NA 98-1/4 1/2 1/2

(835) (305) (279) (525) (492) (789) (610) (2626) (2496)

15 32-7/8 21-1/2 16 25-3/16 23-1/2 31-1/16 24 103-3/8 NA NA 98-1/4 1/2 1/2

(835) (546) (406) (640) (597) (789) (610) (2626) (2496)

20 43-7/8 23-1/2 16 25-3/16 26-1/4 42-1/16 35 103-3/8 NA NA 98-1/4 1/2 1/2

(1114) (597) (406) (640) (667) (1068) (889) (2626) (2496)

25 43-7/8 23-1/2 16 25-3/16 34-1/2 42-1/16 35 103-3/8 NA NA 98-1/4 3/4 1/2 OR 3/4

(1114) (597) (406) (640) (876) (1068) (889) (2626) (2496)

30 54-7/8 26 17-1/2 26-11/16 37-1/4 53-1/16 46 103-3/8 NA NA 98-1/4 3/4 1/2 OR 3/4

(1394) (660) (445) (678) (946) (1348) (1168) (2626) (2496)

35 54-7/8 26 17-1/2 26-11/16 45-1/2 53-1/16 46 103-3/8 NA NA 98-1/4 3/4 1/2 OR 3/4

(1394) (660) (445) (678) (1156) (1348) (1168) (2626) (2496)

40 60-3/8 26 17-1/2 26-11/16 51 58-9/16 51-1/2 103-3/8 NA NA 98-1/4 3/4 1/2 OR 3/4

(1534) (660) (445) (678) (1295) (1487) (1308) (2626) (2496)

50 43-7/8 23-1/2 16 25-3/16 34-1/2 42-1/16 35 129-5/16 58-3/4 38-5/8 124-1/4 3/4 1/2 OR 3/4

(1114) (597) (406) (640) (876) (1068) (889) (3285) (1492) (981) (3156)

60 54-7/8 26 17-1/2 26-11/16 37-1/4 53-1/16 46 129-5/16 58-3/4 38-5/8 124-1/4 3/4 1/2 OR 3/4

(1394) (660) (445) (678) (946) (1348) (1168) (3285) (1492) (981) (3156)

70 54-7/8 26 17-1/2 26-11/16 45-1/2 53-1/16 46 129-5/16 58-3/4 38-5/8 124-1/4 3/4 1/2 OR 3/4

(1394) (660) (445) (678) (1156) (1348) (1168) (3285) (1492) (981) (3156)

80 60-3/8 26 17-1/2 26-11/16 51 58-9/16 51-1/2 129-5/16 58-3/4 38-5/8 124-1/4 3/4 1/2 OR 3/4

(1534) (660) (445) (678) (1295) (1487) (1308) (3285) (1492) (981) (3156)

NOTE: REFER TO UNIT SUBMITTALS FOR MORE SPECIFICATIONS/UNIT ARRANGEMENTS.

DIMENSIONS ARE IN INCHES, DIMENSIONS IN PARENTHESIS ARE IN MILLIMETERS.

* “F” DIMENSION IS THE RECOMMENDED CLEARANCE TO SERVICE THE BURNER DRAWER(S).

▲“J” DIMENSION IS AN OUTSIDE DIMENSION FOR RETURN AIR DAMPERS.

▲“J” DIMENSION IS ALSO AN INSIDE DIMENSION FOR SUPPLY AIR (WITHOUT DAMPER).

§ “U” ALL DIMENSIONS ARE TABULATED FOR ROOFTOP ARRANGEMENTS C & E PER CAPACITIES 10 THROUGH 80 ACCORDINGLY

(CAPACITIES 50/80 ARE SHOWN PICTORIALLY).

NATURAL VENT UNIT DIMENSIONS SHOWN ABOVE; FOR POWER VENT DIMENSIONS, CONTACT CUSTOMER SERVICE FOR POWER

VENT UNIT SUBMITTAL SHEETS.

– 5 –

Page 6

Air Handler Packaged Unit

18-7/8" (479)

x J Typ.

Damper

Opening

39"

(991)

5"

(154)

1" (25)

Curb Cap

5/8" (16) Typ.

Anchor Hole

Location

6-1/16"

(154)

72"

(1829)

51-1/2"

(1306)

6-1/2"

(165)

36"

(883)

Electrical

Connections

Evap.

Cooler

19" (483)

x B

Discharge

Opening

10-1/8"

(257)

A

Water

Inlet 1/4"

Overflow

3/4" Npt Drain

(Capped)

Intake

Filter

D3666B

T3672FR

1" (25) Typ.

Duct Flange

18-7/8" (479)

x J Typ.

Damper

Opening

39"

(991)

5"

(127)

1" (25)

Curb Cap

6-1/16"

(154)

5/8" (16) Typ.

Anchor Hole

Location

72"

(1829)

77-3/8"

(1964)

6-1/2"

(165)

36"

(883)

Electrical

Connections

Evap.

Cooler

19" (483)

x J

Discharge

Opening

6-1/16"

(154)

A

Water

Inlet 1/4"

Overflow

3/4" NPT Drain

(Capped)

Intake

Filter

D3667B

T3672FR

with Evaporative Cooling

Figure 5 - Standard Air Handler with Evaporative Cooler (without Supply Plenum)

Table 3

CAPACITY A B C G ▲J

20 43-7/8" 23-13/16" 21-15/16 42-1/16" 35"

(1114) (605) (557) (1068) (889)

40 60-3/8" 45-13/16" 30-3/16" 58-9/16" 51-1/2"

(1534) (1164) (767) (1487) (1308)

NOTE: REFER TO UNIT SUBMITTALS FOR MORE SPECIFICATIONS/UNIT ARRANGEMENTS.

DIMENSIONS ARE IN INCHES, DIMENSIONS IN PARENTHESIS ARE IN MILLIMETERS.

▲ “J” DIMENSION IS AN OUTSIDE DIMENSION FOR RETURN AIR DAMPERS.

▲ “J” DIMENSION IS ALSO AN INSIDE OPENING FOR SUPPLY AIR (WITHOUT DAMPERS)

Figure 6 - Standard Air Handler with Evaporative Cooler (with Supply Plenum)

– 6 –

Page 7

16

15

EVAPORATIVE COOLER

PARTS IDENTIFICATION

32

4

5

14

13

6

7

8

9

10

11

112

1. Bulk Head Fitting (Drain Overfl ow)

2. Water Distribution Assembly

3. Clip Assembly (Water Distribution

Assembly)

4. Ball Valve

5. Line Filter

6. Brass Needle Cock Valve

7. Worm Clamp

8. PVC Flexible Hose

9. Pump Support Bracket

10. Pump

11. Poly Tubing - 1/4" O.D.

12. Pump Basket Screen

13. Float Valve

14. Media Pad ( 8" or Opt. 12" W)

15. Media Distribution Pad (2" x 8" x L or 2" x 12" x L)

16. Hood Water Distribution

– 7 –

Page 8

INSTALLATION

3-1/4"

FLOAT VALVE

ROD LEVEL

ADJUSTMENT SCREW

1/4" TUBING

FROM COOLER

FAUCET WITH

HOSE BIBB

BRASS NEEDLE COCK

BRASS STOP COCK

WITH DRAIN

WATER SUPPLY

ROOF LINE

NUT AND FERRULE

D3870

This manual is for Evaporative Cooler Module Installations only.

Refer to the Installation and Service Manuals for Rooftop Packaged Units

and Outdoor Furnaces for these unit installations.

Mounting to Roof

1. Before positioning the unit in its permanent

location, make certain that the roof is capable

of carrying the load of this equipment. Note that

when the cooler is fi lled with water, the unit will be

much heavier than when dry . See “Performance and

Dimension Data” table for appropriate operating

weight.

2. If unit is to be mounted on a curb, refer to the curb

specifi cations for installation requirements.

3. Make cer tain that the mounting surface is level in

all directions.

4. Make certain that you have suffi cient means for

lifting the unit into place.

5. Installation must conform to local and national

building and safety codes.

6. The units are mounted on skid rails and are suitab le

for use on combustible fl ooring. It is recommended

that the skids be mounted either on solid planking or

on steel channels, but nev er on a soft tar roof where

the skids could sink and reduce the 4" clearance

between the bottom pan and the roof.

7. Inspect all internal parts of the cooler section to

determine if any damage has occurred during

shipment. See roof curb specifi cations at the end of

the manual.

Connecting the Water Supply

NOTICE: Soft water equipment should not be

attached to water lines going to the cooler. “Soft

Water” will cause corrosion and decrease the

effective life of the cooler.

Figure 7 - Float Valve Assembly

NOTICE: There will be a slight odor during the initial

start-up of the unit. The odor will disappear within

the fi rst few days of operation if the bleed-off is

adjusted correctly.

Faucet Use

1. To connect the water line to the water supply, install

a sillcock and water valve on the faucet.

2. Place tubing nut and ferrule on tube end, and insert

valve.

3. Tighten the nuts on the valve and the tube.

NOTICE: If a faucet is not to be used for the water

supply, install the valve on the water line to be used.

Follow the procedure above for securing the tubing

to the valve.

Figure 8 - Evaporative Cooler Water Connections

1. A water valve should be installed at a convenient

2. Place tube nut and ferrule over the end of the

3. Insert tubing into factory-installed fl oat valve and

location to allow water to be turned on and off. Use

1/4" tubing to supply water to Evaporative Cooler.

A water connector kit is available at your local

wholesaler.

tubing.

tighten securely.

– 8 –

Page 9

Adjusting the Water Level and Float Valve

Fill the tank as follows:

1. Turn the water supply on. Fill the tank to a depth of

approximately 3.25" (82.6mm). While fi lling the tank,

check for good pressure and fl ow from the fl oat

valve.

2. The fl oat valve should shut down the water supply

at the 3.25" (82.6mm) level. It may be necessary to

adjust the fl oat valve by bending the rod. The rod

level adjustment screw should be set in lower notch

on lever.

3. Check the tank and all connections for leaks.

NOTE: The overfl ow fi tting is set so that the water

will begin to fl ow at the 3.25" (82.6mm) depth. It is

important that the water level not be above the pump

basket screen!

Adjusting the Water Flow

Proper water flow over the media is important.

Insufficient water flow will result in increased

accumulation of minerals on the media. Excessive water

fl ow will result in deterioration of the media and moisture

carryover.

1. Using the ball valve handle, adjust the water fl ow so

that the media is damp from the top to the bottom. If

you can see water fl owing on the entering side, your

water level is too high. Adjust the valve so that the

media is just damp on the entering side. Repeated

drying of the media will cause rapid buildup of

mineral deposits in the media. Drying is due to

improper adjustment of the water fl ow valv e, frequent

shut-down of the pump to control the evaporative

cooling/humidifi cation, or localized air velocities

across the surface of the media. The area where dry

spots occur will exhibit high mineral deposits. The

valve must be adjusted so that no dry spots appear

on entering or leaving side, and when adjusted

correctly, enough water will fl ow through the media to

wash out most of the airborne dirt and other debris.

2. Prior to start-up, it is recommended that the tank

be fi lled, and the pump turned on, allowing the

unit to run for approximately 10 minutes. Repeat

this procedure two times to help fl ush any dirt that

may have accumulated during shipping.

Bleed-Off

Bleed-Off is required to maintain the water quality of

the system. When water evaporates, minerals and

other impurities are left behind, impurities are scrubbed

from the air fl owing through the system, and make-up

water (even good quality make-up water) adds more

minerals and impurities. These form deposits on the

media during the evaporative process.Therefore, it is

important to bleed-off a small quantity of recirculating

water to keep the concentration of impurities under

control. The bleed-off rate required is dependent upon

the quality of the water used and the rate of evaporation.

As climate conditions change, the rate of evaporation

may increase, requiring an increase in the bleed-off rate.

It is recommended that the bleed-off rate be adjusted

for the maximum water evaporation. An indication of

insuffi cient bleed-off is a uniform build-up of minerals

on the entering air face of the media. If this condition is

observed, increase the rate of bleed-off until the mineral

deposits dissipate.

Adjusting the Bleed-Off

1. The bleed-off is attached to the PVC tee. This

bleed-off system will eliminate a small quantity of

water from recirculation, which will reduce scale

build-up. This water will drain through the attached

tube, and out through the overfl ow. Disposal of this

water should comply with local codes.

2. Adjust the bleed-off rate according to Table 4.

Table 4

Unit Size Seconds to Fill

Capacity 12 oz. Can

10/15 69 46

20/25/50 52 34

30/35/60/70 41 27

40/80 38 25

– 9 –

Page 10

ELECTRICAL CONNECTIONS

HAZARDOUS VOL TAGE!

DISCONNECT ALL ELECTRIC

POWER INCLUDING REMOTE

DISCONNECTS BEFORE

SERVICING. Failure to

disconnect power before

servicing can cause severe

personal injury or death.

Refer to the unit data plate to determine the supply

voltage.

Do not service before disconnecting

power or there could be a potential for an electrical

shock hazard.

The motor name-plate and electrical rating on the

transformer should be checked before energizing the

unit electrical system. All external wir ing must conform

to ANSI/NFPA No. 70-1996, National Electrical Code

(or the latest edition of) and applicable local codes; in

Canada, to the Canadian Electrical Code, Part 1 CSA

Standard C22.1

“Dashed” lines represent either fi eld wiring (by others) or

optional equipment. Ref er to optional items (shown on wiring diagram included with unit) - these will be hard wired.

Do not jumper factory wiring.

Mis-wiring of safety circuits may result in fi r e

or death.

Do not use any tools (i.e. screwdriver,

pliers, etc.) acr oss the terminals to chec k f or po wer.

Use a voltmeter.

USE COPPER CONDUCTORS ONLY!

UNIT TERMINALS ARE NOT DESIGNED TO ACCEPT

OTHER TYPES OF CONDUCTORS. Failure to do so

may cause damage to the equipment.

It is recommended that the electrical power to each

unit be provided by a separate, fused, and permanently

live electrical circuit. A disconnect switch of suitable

electrical rating for each unit should be placed as close

to the controls as possible. Each unit must be electrically

grounded in accordance with the latest edition of the

National Electrical Code, ANSI/NFPA No. 70-1996, or

CSA Standard C22.1. Sample wiring connections are

depicted in Figures 9 & 10.

NOTICE: Consult the factory before making any

changes to factory wiring.

OPTIONAL FILL AND DRAIN KIT: Optional Evaporative

Cooler Fill and Drain Kit consists of two motorized valv es,

installed in the building, and piped and wired to the roof.

The kit eliminates the need to go to the roof to fi ll or drain

the cooler for seasonal changeover, and automatically

maintains the water level. See sample Figure 10. Refer

to the kit's instruction.

GROUNDING: Install a ground wire to suitable ground

according to local codes.

NOTICE: For all wiring connections, refer to the

wiring diagram shipped with the unit (either affi xed

to the side jacket or enclosed in the unit’ s installation

instruction envelope). Should any original wire

supplied with the unit have to be replaced, it m ust be

replaced with wiring material having a temperature

rating of at least 105°C.

– 10 –

Page 11

ELECTRICAL CONNECTIONS (continued)

Figure 9

Figure 10

– 11 –

Page 12

MAINTENANCE

Open all disconnect switches

and secure in that position before servicing unit.

Failure to do so may result in personal injury or

death from electrical shock.

Because of the nature of the evaporative process, algae

buildup, biological f ouling, scale build-up, and corrosion are

distinct possibilities. Proper water treatment and regularly

scheduled maintenance will minimize or eliminate most

problems.

a.) Cooling Pad Check List:

√ Reduce the number of on/off cycles.

√ Shade the pads and pump.

√ Dry pads out completely once every 24 hours.

√ Maintain a suitable water bleed-off rate.

√ Drain and disinfect the entire water system

quarterly.

√ Avoid harmful contaminants, including dust,

fumes, harsh cleaners, and water treatment

chemicals.

√ Circulate the recommended quantity of

water over the pads.

√ Avoid dry areas on the pads.

√ Clean the fi lters regularly.

b.) Controlling Algae:

Scale and mineral deposits can form on the

cooling pad because the mineral content of

the water is too high.

Increase the water fl ow over the face of the pads.

Make certain that the fl ow of water is even from

one end of the distribution pipe to the other end.

Clean and fl ush the distributor pipe regularly;

especially if dry areas appear on the pads.

Maintain the pH of the recirculating water

between 6 and 8.

Maintain suffi cient bleed-off rate.

For more details, check MUNTERS

®

Engineering

Bulletin EB-WTM-502 (included with this manual).

c.) Preventing Algae in the Evaporative Pads:

Algae needs light, moisture, and nutrients

to survive. Eliminating, or reducing, these

elements will help to control algae. For specifi c

details, see MUNTERS® Engineering Bulletin

EB-WTM-502 (included with this manual).

d.) Biological Fouling Control:

Uncontrolled growth of organic matter can lead to

plugged media, metal deterioration, and biological contamination of the airstream. Whenever the

possibility of biological contamination of water in

an airstream exists, transmittal of Legionnaire’s

Disease should be addressed. While there are

no reported cases of Legionnaire’s Disease associated with rigid media type evaporativ e cooling

systems, the Legionella Pneumophila bacteria is

present in almost all water supplies. Howe v er , the

mere presence of the bacteria does not create a

hazard: the bacteria must be transmitted as an

aerosol in suffi cient densities to be infectious.

NOTICE: It is highly recommended that the services

of a water treatment company be retained to advise

on the proper treatment of the sump water for

biological, scale, and corrosion control. For more

information, see MUNTERS

®

Engineering Bulletin

EB-WTM-502 (included with this manual).

Maintenance Schedule

Regular maintenance is the key to successful service from

your Evaporativ e Cooler. Use the f ollowing schedule as a

guide to maintain you unit:

Maintenance Annual Annual

Requirements Start-Up Shut-Down

Changing Media At Beginning of 6th

Year or if Passages

are blocked

Cleaning Water

Pump √

Cleaning &

Touch-Up √

Adjusting Bleed-Off √

Periodic Inspection During Cooling During Cooling

Season Season

Washing Down As Required During

Media with Hose Season

Washing Inlet Filter

with Hose √ √

Drain Unit √

Following are e xplanations of the procedures outlined in

the above schedule.

Changing the Media

This should be done every 5 years or if passages become

blocked.

1. Remove fi lter/frame assemblies.

2. Disconnect the water hood panel from the top panel

by removing screws.

3. Snap out water distribution system.

4. Remove top media distribution pad.

5. Lift out media sections (Note the position of media

with respect to airfl ow. See Figure 11)

– 12 –

Page 13

®

45° TYP.

15° TYP.

AIR FLOW

D3883

6. Replace with new CELdek

media sections. (See

replacement part section).

Aspen and other evaporative media will not work.

7. When re-installing media, be sure all media

sections are installed in the proper direction. See

Figure 11.

8. Replace top media distribution pad, water dis-

tribution system, water hood panel, and fi lter/frame

assemblies.

Figure 11 - Evaporative Cooling Media Pad Section

Cleaning the Water Pump

Do not allow the pump to topple over

or become submerged. Water will damage the pump

motor. This is not a submersible pump.

Washing the Media

Avoid splashing water on the blower

motor at all times (this could cause electrical

problems)!

1. Scale and dust should be washed off the intake side of

the media annually , using a garden hose and nozzle;

this will help to unclog passages.

2. Using a stiff brush, lightly br ush the intake edges of

the media. This will not harm the openings, but will

remove any hardened scale.

3. Occasionally, there will be a b uild-up of algae or odors.

The best solution for both of these problems is to

allow the pads to dry thoroughly on a regular basis.

If cooling is not needed at night during the cooling

season, allow the blower to run for a few hours after

the pump has been shut-down to dry pads daily.

4. During the cooling season, we recommend that

the pads be shut down nightly if possible with the

blower running to dry the pads out for a few hours

before the unit is shut down.

Washing the Inlet Filter

The pre-fi lter should be cleaned periodically as follows:

1. Turn the four latches and remove filter frame

assemblies.

2. Carefully remove the aluminum fi lters. Wash the fi lters

with warm water and a mild soap, rinse thoroughly.

3. Re-install in unit.

4. If the aluminum mesh fi lters are damaged or cannot

be cleaned, replace the mesh fi lter (See replacement

parts section).

Disassemble and clean water pump as follows:

1. Disconnect power.

2. Disconnect the liquid tight connector from the

junction box to remove cord and connector.

3. Disconnect the pump mounting bracket and hose.

4. Remove the pump and basket screen.

5. To clean pump, snap out base of the pump; notice

the impeller.

6. Using a mild detergent solution, wash all deposits

from the impeller and the impeller base plate.

7. Spin the impeller to dislodge any foreign material.

Make sure that the impeller spins freely.

8. Carefully snap the impeller and impeller base plate

back onto the pump.

9. Wash the pump basket screen using the same

detergent solution, and rinsing thoroughly to remove

any debris. If unable to clean, replace with a new

screen (See replacement part section).

NOTICE: The pump motor does not require any

lubrication.

Cabinet Cleaning and Touch-Up

The cabinet and all internal parts of the Evaporative Cooler

should be cleaned annually using a soft cloth, warm water,

and a mild cleanser.

NOTE: Avoid using steel wool or sandpaper in normal

cleaning of the unit.

Winter Shut Down

1. Clean and fl ush out Evaporative Cooler media and

sump.

2. Clean water distributor holes.

3. Drain fi ll pipe and leave open. DO NOT LEAVE ANY

WATER IN THE SYSTEM. FREEZING CAN CA USE

MAJOR DAMAGE TO THE UNIT.

4. Remove and clean pump if necessary.

5. Check sump tank for leaks and repair if necessary.

Sump tank is fabricated from stainless steel.

– 13 –

Page 14

Roof Curb Kit - RC015* (-1, -2, -3, -4)

For use with:

Unit type (UT) - EV

Capacities (CA) - 10/40

*Evaporative Cooler Platform Only

(Included with Roof Curb Kit No's RC002, RC004, RC008, RC012)

Roof Curb Kit RC015

Contents:

1 Evaporative Cooler Assembly (sold separately)

2 Curb (2 platforms per kit)

3 1/4-20 “KEPS” Nut (8) required

4 1/4-20 x 5/8 LG. Hex HD. Bolt (8) required

Club Platform to Unit Assembly

Approximate Curb Kit

Shipping Weight

Curb Kit No. Capacity (CA) Weight (lbs.)

RC015-1 10/15

RC015-2 20/25/50

RC015-3 30/35/60/70

RC015-4 40/80

1 lb. = 0.453 kg

30

*One Platform Kit fi ts All Evaporative Cooler Modules/Capacities (CA) - 10/80

Capacities 50, 60, 70 and 80 are for (RT/PV) unit types only.

– 14 –

Page 15

How to order Replacement Parts

Please provide the following information to your local representative:

• Model Number

• Serial Number (if any)

• Part Description and Number as shown in Replacement Parts Literature

If further assistance is needed, please contact the manufacturer's customer service department.

Evaporative Cooler Model Number Description

Digit E X X — E V 3* 4* 0 0 0 0 0 0 11* 0 0 0 0 16* 17* +

Item Prefi x UT CA FT FM RA CO GT GC SV MT MS AI AC AS

(Internal use Only)

*See Model No. Description below.

1, 2 - Unit Type [UT]

EV - Evaporative Cooler Only

3, 4 - Capacity [CA]

10 - 100,000 BTU/HR

15 - 150,000 BTU/HR

20 - 200,000 BTU/HR

25 - 250,000 BTU/HR

30 - 300,000 BTU/HR

35 - 350,000 BTU/HR

40 - 400,000 BTU/HR

5 - Furnace Type [FT]

0 - None

6 - Furnace Construction Material [FM]

0 - None

7 - Rooftop Arrangement [RA]

0 - None

8 - Coil Options [CO]

0 - None

9 - Gas Type [GT]

0 - None

10 - Gas Control [GC]

0 - None

11 - Supply Voltage [SV]

1 - 115/1/60

2 - 208/1/60

3 - 230/1/60

12 - Motor Type [MT]

0 - None

13 - Motor Sizes [MS]

0 - None

14 - Air Inlet Confi guration [AI]

0 - None

15 - Air Control & Damper Arrangement [AC]

0 - None

16 - Accessories [AS]

C1 - Evap. Cooler - Fill & Drain Kit

C2 - Evap. Cooler - 12" Celdek

C3 - Evap. Cooler - Freezestat

D1 - Time Clock - 7 Day

D2 - Time Clock - 24 Hour

E2 - G.F .I. Conv enience Outlet 115V AC

E3 - Remote Control Panel

F1 - Ductstat - One Stage

F2 - Ductstat - T wo Stage

G1 - Thermostat - T87F w/Subbase

G2 - Thermostat - T87F w/Subbase & Guard

G3 - Thermostat - T834H w/Subbase (Sterling Stat)

G4 - Thermostat - T7300 - 7 Day Programmable

G5 - Thermostat - T874 (T wo Stage)

H1 - Return Firestat

H2 - Supply Firestat

H3 - Freezestat

L1 - 30 Amp, Fused Disconnect Switch

L2 - 30 Amp, Non Fused Disconnect Switch

L3 - 60 Amp, Fused Disconnect Switch

L4 - 60 Amp, Non Fused Disconnect Switch

0 - Other (Specify)

®

Media

LIMITED W ARRANTY

The complete unit is warranted by the manufacturer to be free from defects in material and workmanship for a

period of one (1) year from the date of manufacture.

The manufacturer will repair or replace, at its option, any component which, upon inspection, it fi nds to be

defective, provided that the unit has been operated within its listed capacity, has been installed in accordance with

the furnished instructions, has not been misused or subjected to negligence and has received reasonable and

necessary maintenance. The warranty does not cover labor costs or other costs incurred in repairing, removing,

installing, servicing or handling of parts or completed products.

The warranty does not cover loss due to corrosion by chemicals precipitated in the air such as halogenated

hydrocarbons. The manufacture will in no event be liable for incidental or consequential damages of any kind

whatsoever.

Written permission is required prior to the return of defective components. All returns must be sent with all

transportation charges prepaid to the plant designated in the written permission.

This warranty is extended only to the original owner of the unit.

– 15 –

Page 16

260 NORTH ELM ST., WESTFIELD, MA 01085

TEL: (413) 568-9571 FAX: (413) 562-8437

www.mestek.com

Loading...

Loading...