Page 1

BBPP22440000 SSEERRIIEESS GGRRAANNUULLAATTOORRSS

SStte

e

rrlli

nngg,,

nncc

R

R

R

R

i

I

I

OOPPEERRAATTIIOONN AANNDD MMAAIINNTTEENNAANNCCEE MMAANNUUAALL

Y

CCOOPPY

IIGGHHTT 22000099

JJuullyy 2299,, 22000099

AALLLL RRIIGGHHTTSS RREESSEERRVVEEDD

,

0

IInnc

tth

h

c

SSttrreeeett

A

PPA

BBuulllleettiinn NNoo.. GGRRNN33--660000

TT NNOO.

.

DD4488116600s

s

SStteerrlliinngg,

SSiizzee RReedduuccttiioonn DDiivviissiioonn

22990000 SSoouutthh 11660

1

Page 2

Sterling, Inc.

th

2900 South 160

New Berlin, WI 53151

Tel: 1-262-641-8600

Fax: 1-262-641-8653

Parts and Service

1-800-229-2919

Street

MACHINE DATA

MODEL ___________________________________________________________

SERIAL NUMBER _____________________________________________________

CUMBERLAND CUSTOMER ORDER NUMBER___________________________________

REFER TO THIS SHEET WHEN ORDERING PARTS.

2

Page 3

TABLE OF CONTENT

S

TTOOPPIICC::

FFaaccttoorryy aaddddrreessss..

IINNTTRROODDUUCCTTIIOON

WWhhaatt iiss aa ggrraannuullaattoorr??……..……………………………………………………..……………………………………………………..……..…

AA ggrraannuullaattoorr iiss……..

TThhee ggrraannuullaattiinngg ooff ppllaassttiiccss……

SSiizzee ooff tthhee ggrraannuullaattee……

TThhee ddiissppoossaall ooff ppllaassttiicc ggrraannuullaattee……

SSeeccttiioonn 11 –– SSAAFFEETTYY

SSaaffeettyy ssyymmbboollss aanndd ppllaatteess………………………………………………………………………………………………………………………………………

LLeeaarrnn mmaacchhiinnee ssaaffeettyy

SSaaffeettyy aalleerrtt ssyymmbbooll

UUnnddeerrssttaanndd tthhee ssiiggnnaall wwoorrddss

FFoollllooww ssaaffeettyy iinnssttrruuccttiioonnss……………………………………………………....…………………………………………………………………

RRoottaattiinngg kknniivveess ssaaffeettyy ppllaattee

WWaarrnniinngg--PPaauussee aafftteerr sshhuuttddoowwnn

OOppeenniinngg hhooppppeerr,, gguuaarrddss,, ccoovveerrss ssaaffeettyy ppllaattee

RRoottaattiinngg mmaacchhiinneerryy ssaaffeettyy ppllaattee…………………………………………..………………………………………………………

OOppeenniinngg hhooppppeerr ssaaffeettyy ppllaattee

RRoottaattiinngg kknniivveess ssaaffeettyy ppllaattee

WWaarrnniinngg sshheeaarr hhaazzaarrdd

JJaacckkssccrreeww rreevveerrssiinngg ooppeerraattiioonn…………………………………………………………………………………………………………...

GGuuaarrdd’’ss ssaaffeettyy ppllaattee

SSaaffeettyy iinnssttrruuccttiioonn ppllaattee………………………………………………………………………………………………………………………………....…

HHaazzaarrddoouuss vvoollttaaggee ssaaffeettyy ppllaattee

RRoottaattiinngg kknniivveess ssaaffeettyy ppllaattee………………………………………………………………………………………………………………………

MMoottoorr rroottaattiioonn ssaaffeettyy ppllaattee

SSAAFFEETTYY -- ccllootthhiinngg aanndd pprraaccttiiccees

WWeeaarr hheeaarriinngg pprrootteeccttiioonn

WWeeaarr ssaaffeettyy ggllaasssseess

WWeeaarr pprrootteeccttiivvee ccllootthhiinngg………………………………………………………………………………………………………………....…………………

KKeeeepp yyoouurr wwoorrkk aarreeaa ssaaffee KKeeeepp ccoo--wwoorrkkeerrss ooffff tthhee mma

WWoorrkk ssaaffeellyy……………………………………………………………………………………………………………………………………………………………………....11--99

MMaacchhiinnee ooppeenniinngg ddeevviicceess

BBee ssuurree tthhee rroottoorr iiss mmoottiioonnlleessss bbeeffoorree ooppeenniinngg mmaacch

SSaaffeellyy cclleeaarriinngg aa jjaam

WWoorrkk ssaaffeellyy

JJaacckkssccrreeww ooppeerraattiioonn

OOppeenn ccuuttttiinngg cchhaammbbeerr

CClleeaarr tthhee jjaamm………………………………………………………………………………………………………………………………………………………………......11--1111

MMaallffuunnccttiioonn cchheecckklliisstt

RReessttaarrtt ggrraannuullaattoorr

N

……………………………………………………………….………2

m

…………....……………………………………......……………………………………………………………………………………11--1100

SSEECCTTIIOONN//PPAAGGEE

…

…11--11

……………....11--22

………....………………11--33

.………………......11--44

………....11--55

…......……....11--66

s

………………………………..………………....…………………………………………………………..………………....11--77

………11--88

acchhiinnee

hiinnee

1111

3

Page 4

TTAABBLLEE OOFF CCOONNTTEENNTTSS

TOPIC SECTION/PAGE

SECTION 2 – MACHINE PARTS AND CONTROLS…………………………………….…2-1

BP-Series granulators left front quarter view

BP-Series granulators, right front quarter view..…………………………………………………….….2-2

BP-Series granulators, machine open front view

BP-Series granulators, left rear quarter view …………………………..………………………………2-3

BP-Series granulators, right rear quarter view

SECTION 3 INSTALLATIONS

Overview…………………………………………………………………………………………….…..3-1

Machine weights

Uncrate the granulator

Move the granulator to its

worksite……………………………………………………………………………………………….…3-2

Allow adequate workspace

Level the granulator

Work safely

Remove protective coating………………………………………………………………………….…...3-3

Check knives and screen

Power considerations

Electrical wiring…………………………………………………………………………………………3-4

Work safely

Check for mechanical interferences……………………………………………………………………..3-5

Set up the machine functions

Check the rotation of motors

If necessary, reverse the motor rotation

Interlock switch test procedure………………………………………………………………………….3-6

Alternate test for the interlock switches

Test the zero speed sensor………………………………………………………………………………3-7

Lubrication……………………………………………………………………………………………...3-8

SECTION 4 – SETTINGS AND ADJUSTMENTS

Adjusting or replacing the bed knives…………………………………………………………………..4-1

Basic facts about the knives

Check all settings and adjustments before granulating any material

Malfunction check

Work safely

Open the cutting chamber interlock…………………………………………………………………….4-2

Release the cutting chamber fasteners

Care in handling knives ..…………………………………………………………………………….…4-3

Install the rotor-locating pin

4

Page 5

TTAABBLLEE OOFF CCOONNTTEENNTTSS

TOPIC SECTION/PAGE

SECTION 4 – SETTINGS AND ADJUSTMENTS (Continued from previous page)

Adjusting or replacing the bed knives (Continued from previous page)

Loosen the mounting screws……………………………………………………………………………..4-4

Remove the first knife clamp or shield

Remove the bed knives

Clean the knife mounting surfaces……………………………………………………………………….4-5

Mounting screws

Replace the upstroke bed knife

Replace the upstroke knife clamp

Remove the down stroke bed knife………………………………………………………………………4-6

Replace the down stroke knife shields

Check the bed knives

Gap adjustment tips

Measure the knife gap……………………………………………………………………………………4-7

Set the downstream knife shield

Check the knife gap

Tighten the screws to final torque………………………………………………………………………..4-8

Finalize installation of upstroke bed knife

Fasten the cutting chamber……………………………………………………………………………….4-9

Close the cutting chamber safety interlock

Restart the granulator

Adjusting or replacing rotor knives……………………………………………………………….4-10

Basic facts about the knives

Work safely

Open the cutting chamber interlock

Release the cutting chamber fasteners…………………………………………………………………...4-11

Care in handling knives………………………………………………………………………………….4-12

Lock the rotor

Remove the mounting screws

Remove the rotor knives

Clean parts for reassembly……………………………………………………………………………....4-13

Mounting screws

Rotors with replaceable knife seats

Tighten the rotor knives to final torque…………………………………………………………………4-14

Check the bed knives

Gap adjustment tips

Measure the knife gap

5

Page 6

TTAABBLLEE OOFF CCOONNTTEENNTTSS

TOPIC SECTION/PAGE

SECTION 4 – SETTINGS AND ADJUSTMENTS (continued from previous page)

Adjusting or replacing the bed knives (Continued from previous page)

Set the down stroke knife shield…………………………………………………………………...4-15

Check the knife gap

Tighten the screws to final torque

Fasten the cutting chamber …………………………………..……………………………………4-16

Close the cutting chambers safety interlock

Restart the granulator

Drive belt replacement and adjustment….……………………………………………..…..4-17

Overview

Work safely

Remove the drive guard cover

Inspect the drive belts……………………………………………………………………………..4-18

Remove the belts

Install the matched belts

Tighten the belt tension

Check the pulley alignment…………………………………………………………………..…...4-19

Measure the belt span

Calculate the allowable belt deflection

Measure the deflection force

Compare the measured force to the recommended force…………………………………………4-20

Adjust the belt tension

Tighten the motor base bolts

Replace the driver guard cover……………………………………………………………………4-21

Restart the granulator

Setting and adjusting the chamber jackscrews………………………….………………..4-22

Overview

Work safely

Open the cutting chamber interlock

Release the cutting chamber fasteners…………….………………...…………………….………4-23

Jackscrew operation

Cutting chamber open set point

Open the cutting chamber…………………………………………………………………….…...4-24

Adjust the jackscrew open position limit switch

Jackscrew operation

Close the cutting chamber…………………………………………………………………….…..4-25

If the motor stops before the cutting chamber closes

Set the jackscrew closed position limit switch

6

Page 7

TTAABBLLEE OOFF CCOONNTTEENNTTSS

TOPIC SECTION/PAGE

SECTION 4 – SETTINGS AND ADJUSTMENTS (Continued from previous page)

Setting and adjusting the chamber jackscrew (Continued from the previous page)

The chamber stops before it closes but the motor continues to run……………………………..…..4-26

Set and test the mounting bracket limit switch

Close the cutting chamber………………………………………………………………………..….4-27

Fasten the cutting chamber

Close the cutting chamber safety interlock……………………………………………………….....4-28

Setting and adjusting the cradle jackscrew………………………………………………….4-29

Overview

Jackscrew operation

Open the screen cradle interlock

Retract the screen cradles retainers

Jackscrew operation…………………………………………………………………………………4-30

Cradle open position

Beware of rotor knives

Lower the screen cradle

Adjust the cradle open-position limit switch……………………………………………………..…4-31

Jackscrew operation

Check the cradle closed-position limit switch……………………………………………...……….4-32

Raise the screen cradle

Adjust the cradle closed position limit switch………………………………...…………………….4-33

Close the screen cradle retainers

Close the screen cradle interlock

Zero speed sensors……………………………………………………………………….………4-34

Zero speed sensors operation

Adjust the sensor position

Control Circuit

Adjustable Rotor Knives…………………………………………………………………4-35

Rotor Knife Preparation

Rotor Knife Installation Into Fixture

Knife Length Setting, Knife Length Setting-Inspection

Adjustable Rotor Knife Installation

Hydraulic opening position switches ………………………………………………………………4-36

Hydraulic pump operation

SECTION 5 – OPERATION

Initial startup………………………………………………………………………………..…….…5-1

Safety check

Work safely

Check for mechanical interferences

Check the motor rotation direction……………………………………………………………….....5-2

Run the motor

Discharge air adjustment

7

Page 8

TTAABBLLEE OOFF CCOONNTTEENNTTSS

TOPIC SECTION/PAGE

SECTION 5 - (Continued from previous page)

Normal operation……………………………………………………………………………………..5-4

Feed the machine

Shut down the machine

Discharge cleanout safety

Cleaning the discharge transition

Safely clearing the jam……………………………………………………………………….5-5

Work safely

Jackscrew operation

Open the cutting chamber

Clear the jam……………………………………………………………………………………………..5-6

Malfunction check

Restart the granulator

SECTION 6 – MAINTENANCE

Periodic maintenance…………………………………………………………………………………….6-1

Periodic maintenance schedule

Lubrication……………………………………………………………………………………………….6-2

Knife screw torque

Belt tension

Screen condition

Infeed flap condition……………………………………………………………………………………..6-3

Upper chamber pivot arms – screws

Hydraulic cylinder/jackscrew inspection pivot pins & lockouts

Screen replacement…………………………………………………………………………………...6-4

Work safely

Open the screen cradle interlock

Retract the screen cradle retainers

Jackscrew operation………………………………………………………………………………………6-5

Lower the screen cradle

Beware of rotor knives

Remove the screen………………………………………………………………………………………..6-6

Replace the screen

Raise the screen cradle……………………………………………………………………………………6-7

Close the screen cradle retainers

8

Page 9

TTAABBLLEE OOFF CCOONNTTEENNTTSS

TOPIC SECTION/PAGE

SECTION - 6 – MAINTENANCE (continued)

Screen replacement (Continued from previous page)

Close screen cradle interlock……………………………………………………………………………6-8

Restart granulator

Cutting chamber access…………………………………………………………………………….6-9

Work safely

Open the cutting chamber interlock

Release the cutting chamber fasteners

Jackscrew operation…………………………………………………………………………………….6-10

Open the cutting chamber with jackscrews

Open the cutting chamber with hydraulics

Close the cutting chamber with jackscrews…..………………………………………………………..6-11

Close the cutting chamber with hydraulics

Fasten the cutting chamber

Close the cutting chamber safety interlock

Restart the granulator

Jackscrew operation ……………………………………………………………………………………6-12

Lowering the screen cradle with jackscrews

Lowering the screen cradle with hydraulics

Jackscrew operation ……………………………………………………………………………………6-13

Raising the screen cradle with jackscrews

Raising the screen cradle with hydraulics

Knife sharpening ………………..………………………………………………………………….6-14

Rotor knife sharpening

Bed knife sharpening…………………………………………………………………………………..6-15

SECTION – 7 - TROUBLESHOOTING

Overview…………………………………………………………………………………………..…..7-1

Test equipment

Locating trouble

Troubleshooting chart

Processing faults……………………………………………………………………………..………….7-2

Mechanical faults……………………………………………………………………………..…………7-3

Electrical faults………………………………………………………………………………..………...7-4

9

Page 10

TTAABBLLEE OOFF CCOONNTTEENNTTS

TOPIC SECTION/PAGE

SECTION – 8 PARTS LISTS AND DRAWINGS

Recommended spare parts………………………………………………………………………………… 8-1

Parts identification Sterling drawing no. A-48050 ……………………………………………………..….8-2

Overall dimensions Sterling drawing no. A-48150 ……………………………………………………......8-3

Parts identification Sterling drawing no. 348070C ………………………………………………………..8-4

Parts identification Sterling drawing no. 348185…………………………………………….…………….8-5

Parts identification Sterling drawing no. 1554-460 ……...…………………………………….………..…8-6

Wiring diagram Sterling no. A-399598 ……………………………………………………………….…...8-7

Parts identification Sterling drawing no. 348078-1………………………………………….………..……8-8

Wiring diagram for Hydraulics Sterling no. D-499061………………………………………………..…...8-9

Wiring diagram Sterling no. D-499044 …………………….……………………………………………..8-10

Metric knife bolt/screw tighten torque specifications ………..…………………………………………....112

S

10

Page 11

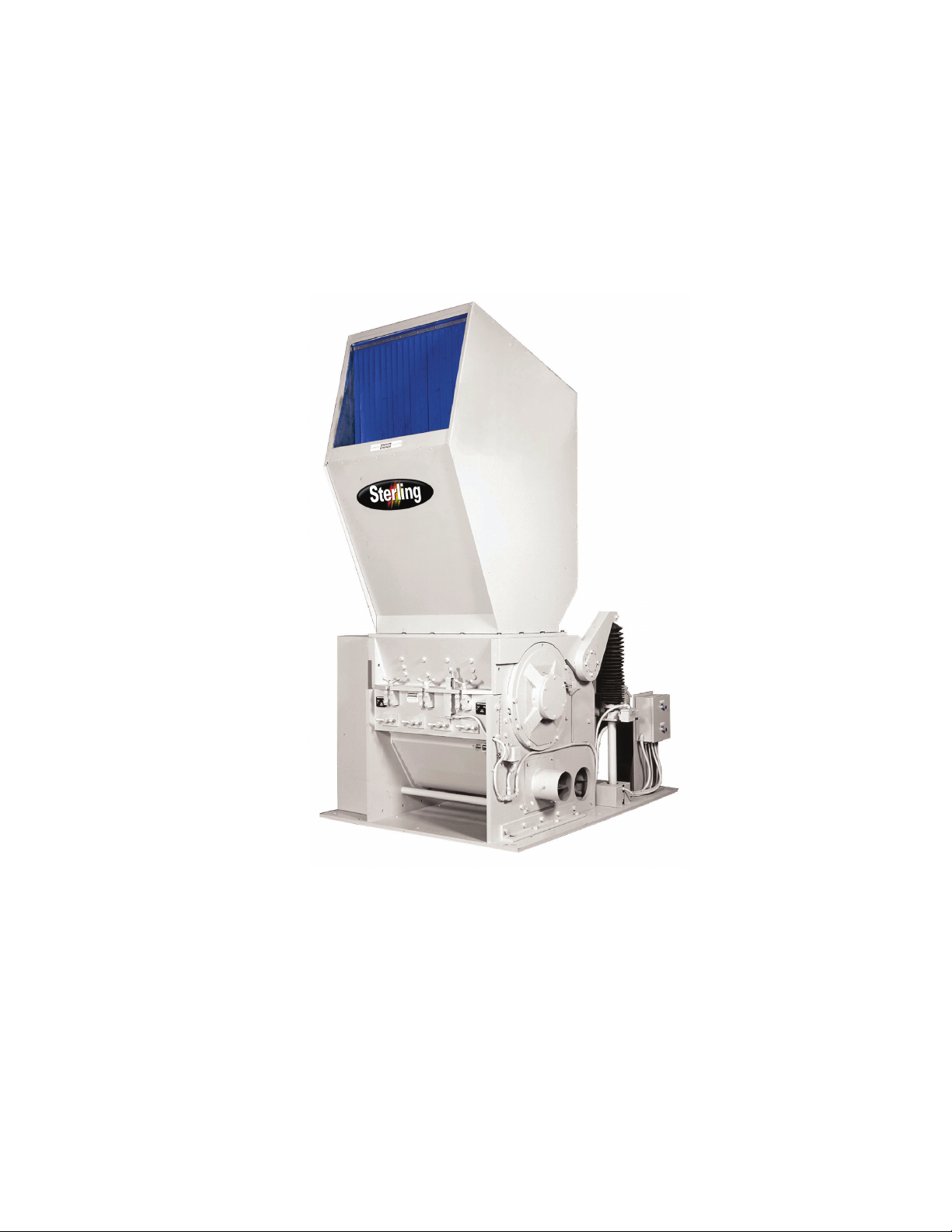

THANK YOU FOR PURCHASING AN STERLING BP2400 SERIES GRANULATOR.

READ THIS MANUAL to learn how to operate and service your granulator safely. It covers the

family of granulators called the BP2400. This series of Sterling Granulators is designed for the

big jobs in reclamation of large blow-molded and thin walled, injection molded plastic parts as

well as film.

This revision of the manual covers the improvements made since the introduction of the

BP2400 Series Machines in 1993.

NOTE: This manual covers light maintenance only. No further maintenance should be performed

without first contacting the Sterling Service Department at the mailing address and phone number

shown on page 2.

When calling the factory for service information and parts, please have the model and serial

number of your machine on hand. The serial number is stamped on the plate mounted on the

center at the back of the granulator just below the hopper.

11

Page 12

T

R

ROODDUUCCTTIIOONN

IINNT

WHAT IS A GRANULATOR?

A GRANULATOR is a machine that is designed to size-reduce plastic materials to chips or granulate.

The machine can be fed either by hand through a hopper opening in the front or automatically from a special

hopper opening, which can be specially designed.

DISPOSAL OF THE PLASTIC GRANULATE takes place after it passes through the screen and

drops into the discharge area, where it is removed from the machine by a discharge blower and conveyed by

air to a remote side of the machine. This discharge blower is available as optional equipment.

THE GRANULATING OF PLASTIC is achieved by the cutting action of sharp rotating knives in

close adjustment to one or more stationary knives called bed knives. The rotary knife assembly is called a

rotor. You will see the references to it as you read through this manual. There are two bed knives in the

machines covered by this manual. The heavy-duty rotor and bed knife assemblies, combined with the screen

(explained below) and their enclosing cutting chamber are the heart of the granulator.

THE SIZE OF THE GRANULATE resulting from the cutting action described is controlled by a

screen, which fits tightly around the rotary knives in the cutting chamber. This screen retains the plastic

granulate until it is reduced to a small enough size to fall through the holes in the screen. Screens with

various hole sizes are available for the granulator. The standard screen hole size for the X-Series is 3/8”

diameter. Screens are available with either smaller or larger hole sizes. For a given machine, the throughput

capacity of the granulator is dependent upon the size of the screen utilized.

12

Page 13

SAFETY SECTION 1-1

Safety Symbols and Plates

LEARN MACHINE SAFETY

Read this manual.

Learn how to operate and how to use the control.

DO NOT ALLOW ANYONE TO OPERATE THIS MACHINE WITHOUT PROPER INSTRUCTIONS.

THIS SAFETY alert symbol MEANS ATTENTION…BE ALERT!

YOUR SAFETY IS INVLOVED!

This symbol appears frequently in this manual and on your machine. It is used to alert you to the possibility

of personal injury or death. Follow the instructions in the safety messages identified with this symbol.

UNDERSTAND THE SIGNAL WORDS….

A signal words such as – DANGER, WARNING OR CAUTION, is always used with the safety alert

symbol to indicate the level of hazard. These safety words are in accordance with ANSI Z535.5.

DDAANNGGEERR

DDiissrreeggaarrdd ooff tthhiiss hhaazzaarrdd wwiillll rreessuulltt iinn sseevveerree ppe

oorr ddeeaatthh.. TThhiiss ssiiggnnaall wwoorrdd iiss pprriinntteedd oovveerr aa rreedd bbaacckkggrroouunndd.

WWAARRNNIINNGG iiddeennttiiffiieess aa ppootteennttiiaall hhaazzaarrdd oorr uunnssaaffee pprra

DDiissrreeggaarrdd ooff tthhiiss hhaazzaarrdd ccoouulldd rreessuulltt iinn sseevveerree iin

ddeeaatthh.. TThhiiss ssiiggnnaall wwoorrdd iiss pprriinntteedd oovveerr aa rreedd bbaacckkggrroouunnd

CCAAUUTTIIOONN

DDiissrreeggaarrdd ooff tthhiiss hhaazzaarrdd ttoo rreessuulltt iinn mmiinnoorr ppeerrsso

pprroodduucctt oorr pprrooppeerrttyy ddaammaaggee.. TThhiiss ssiiggnnaall wwoorrdd mmaayy aallssoo bbee

uusseedd ttoo aalleerrtt aaggaaiinnsst

pprriinntteedd oovveer

iiddeennttiiffiieess aann iimmmmiinneennttllyy hhaazzaarrddoouuss ssiittuuaattiioonn..

errssoonnaall iinnjjuurryy

njjuurryy oorr

iiddeennttiiffiieess aa ppootteennttiiaall hhaazzaarrdd oorr uunnssaaffee pprraaccttiiccee..

onnaall iinnjjuurryy,,

t uunnssaaffee pprraaccttiicceess.. TThhee ssiiggnnaall wwoorrdd iiss

r

aa yyeellllooww bbaacckkggrroouunndd..

accttiiccee..

.

d

.

.

13

Page 14

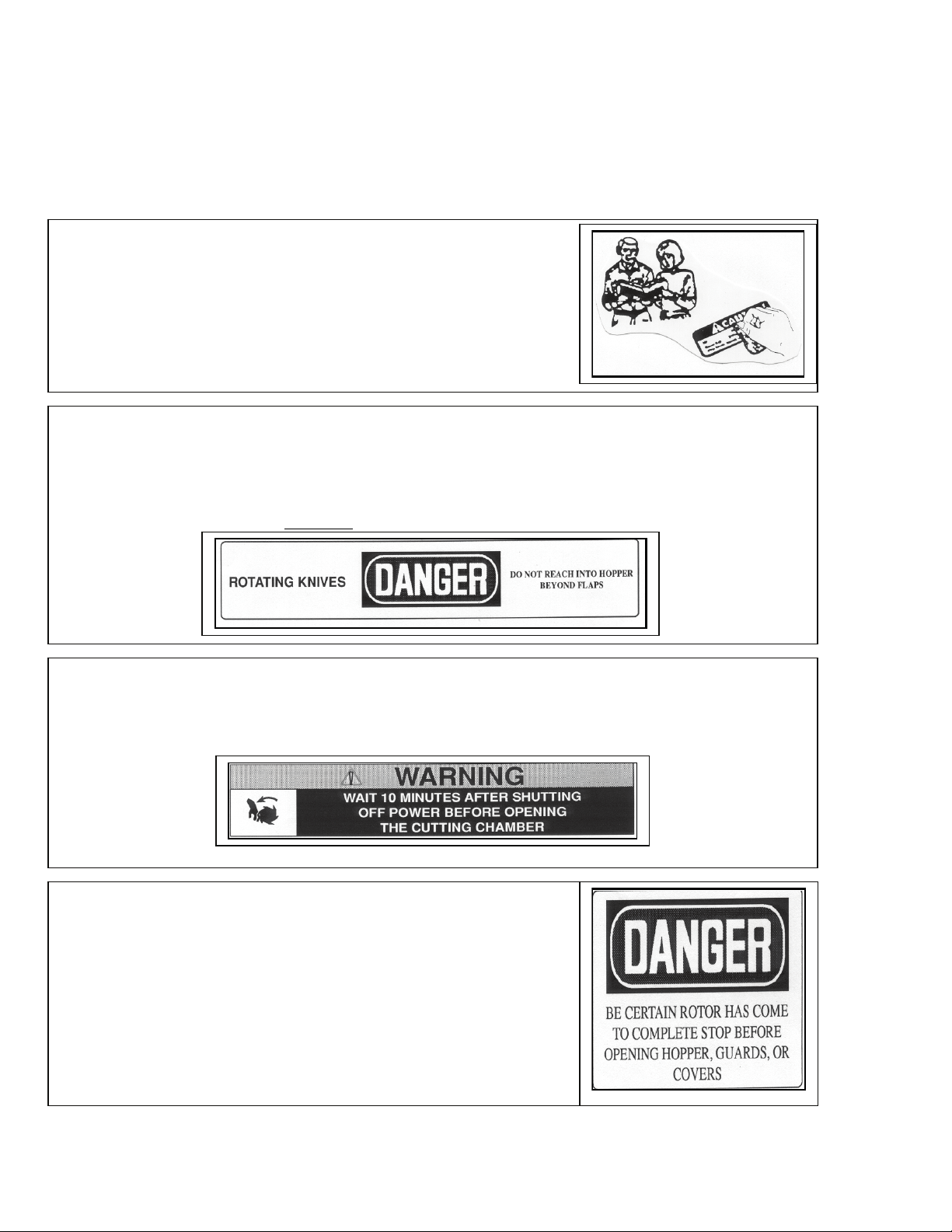

SAFETY

SECTION 1-2

Safety Symbols and Plates

FOLLOW THE SAFETY INSTRUCTIONS:

Read all safety messages in this manual and on your machine safety plates.

Follow the recommended precautions and safe operating practices.

Keep safety plates in good condition. Replace missing or damaged plates.

ROTATING KNIVES SAFETY PLATE

(Located below the infeed opening at the front of the machine)

DO NOT, UNDER ANY CIRCUMSTANCES, place your hands into the feed opening beyond the curtain

while the machine is capable of running.

Disconnect and lock out all power when it becomes necessary to work beyond this point.

Make sure the rotor has come to a full stop

before reaching through the curtain.

WARNING–PAUSE AFTER SHUT-DOWN (Located at the front of the cutting chamber)

Pause, as suggested, after shutting the machine down and locking out the power even though safety

interlocks are in place to prevent injury. Develop good safety habits by adhering to the messages on all the

warning plates. The best safety provision is your own careful concentration of safety.

OPENING HOPPER, GUARDS, COVERS SAFETY PLATE

(Located on the screen cradle on the front panel, left of the machine

center.) The hopper, guards and safety covers are in place for your

protection during machine operation. Be sure not to remove them until

the rotor has come to a complete stop and you have disconnected and

locked out all power. Be sure to replace all guards before reconnecting

power.

14

Page 15

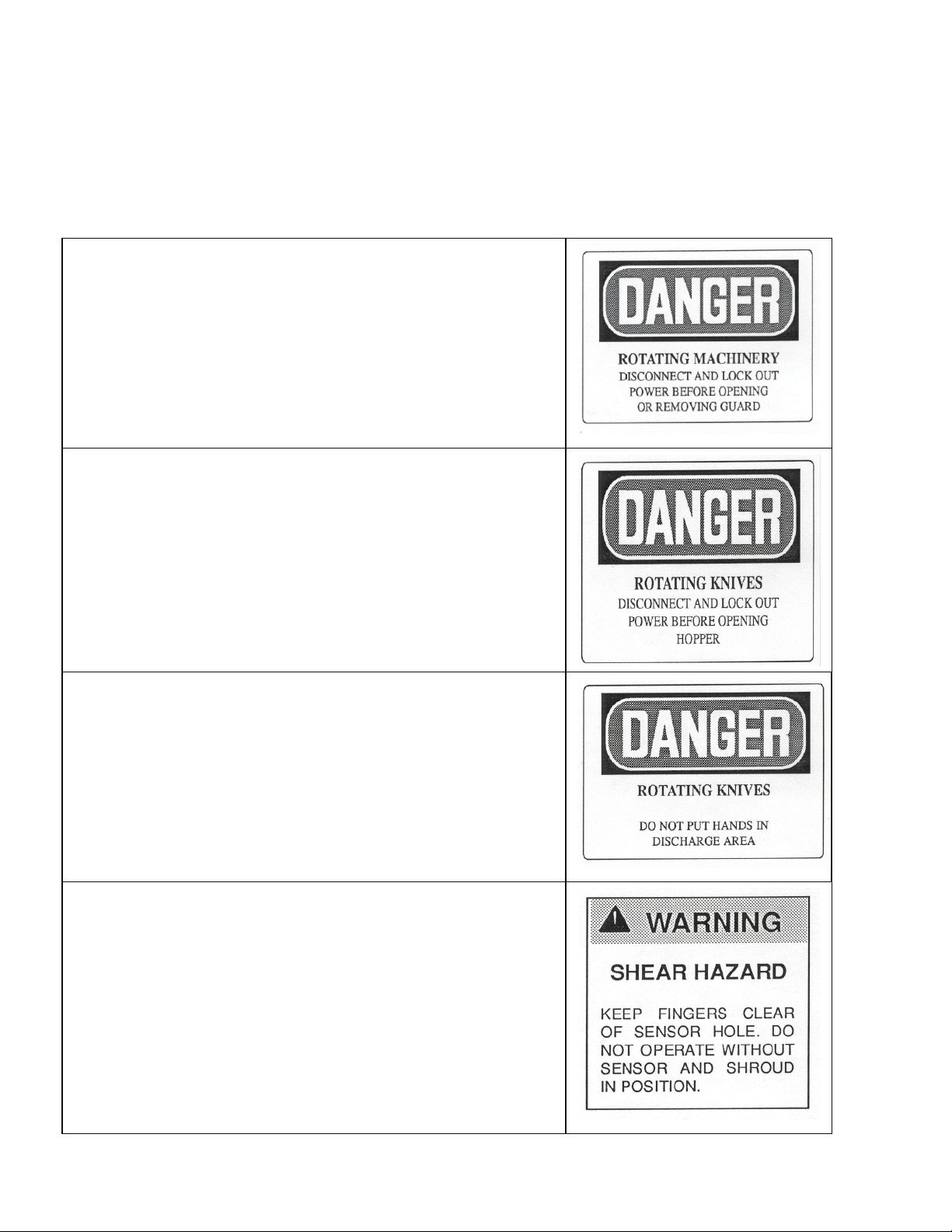

SAFETY

y

ROTATING MACHINERY SAFETY PLATE (One located

on the machine guard on the left side of the machine, one on the

screen cradle on the front panel, to the right of the machine center.)

Avoid personal injury by making sure that the rotor is stopped and the

power is disconnected and locked out before removing a machine

guard.

A motion sensor monitors the rotor and disables the jackscrew motors

if there is rotor movement. If you see the rotor spinning after opening

the machine, immediatel

OPENING HOPPER SAFETY PLATE

(Located on center at the lower, front side of the hopper)

Take the time for safety by disconnecting and locking out the

power before opening the hopper. Work carefully and beware of all

hazards with the hopper open and the knives exposed.

shut down and call for service.

SECTION 1-3

Safety Symbols and Plates

ROTATING KNIVES SAFETY PLATE (One located near the

discharge port and one located near the vent port on each side of the

machine.)

Never reach into the vent or discharge areas without shutting down

the machine and locking out the power. Wear protective gloves

whenever you work around the rotor knives and do not open the

access doors to them until you are certain that the rotor has stopped

and you have disconnected and locked out the power. To clear a jam,

refer to the topic entitled Safely Clearing a Jam later in this section.

WARNING SHEAR HAZARD (Located on the right side of the

machine near the zero speed sensor to the rear of the right rotor

bearing housing)

With the zero speed sensor removed, there is a potential hazard

because the sensor probe extends into close proximity of the rotor. If

you should place anything within this hole while the machine is

running, the passing rotor would likely shear it off. In addition,

without this component installed the safety interlock, which disables

the jackscrew motors, is out of service, thus creating another serious

safety hazard.

15

Page 16

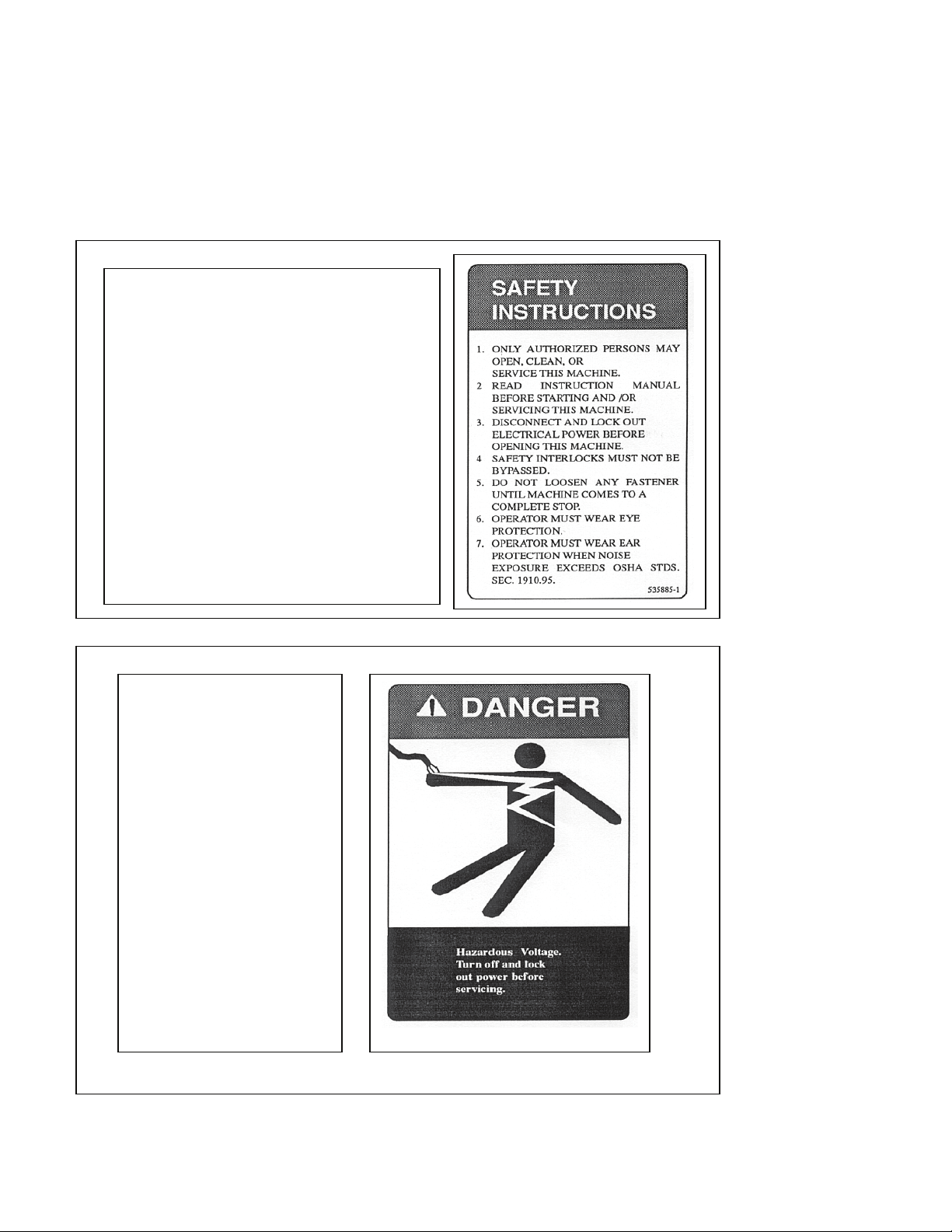

SAFETY

SECTION 1-4

Safety Symbols and Plates

JACKSCREW REVERSING OPERATION

(Located on the jackscrew operating console)

This information plate reminds you of the important procedure for reversing the direction of

jackscrew operation. Be sure to pause as advised. This allows the jackscrew drive the necessary

time to coast to a stop before reversing. Without this pause, the jackscrew may be severely

damaged.

GUARDS SAFETY PLATE

(Located on the drive guard cover on the left side as you face the machine)

By keeping the guards in place at a11 times you are promoting good safety practices and avoiding

needless hazard and injury.

16

Page 17

SAFETY INSTRUCTION PLATE

(Located on the front of the drive guard)

The safety instruction plate summarizes the

most important safety rules that you need to

operate this machine safely. Read it carefully and observe it always to promote safe

machine operation.

SAFETY

SECTION 1-5

Safety Symbols and Plates

HAZARDOUS

VOLTAGE SAFETY

PLATE

(Located on the door of the

jackscrew console)

Always call for the services

of a licensed electrician

when you think that there is

an electrical problem. Never

open any electrical panel if

you are not a licensed

electrician. Touching the

wrong terminals may result

in serious injury or death.

17

Page 18

SAFETY

ROTATING KNIVES SAFETY PLATE

(One located on the front of the cutting chamber and

one on the front of the cradle)

The rotating knives are razor-sharp to the touch.

Always verify that the rotor is not moving. Avoid

personal injury by making sure that the rotor is

stopped and the power is disconnected and locked

out before opening the machine. A motion sensor

monitors the rotor and disables the hydraulic

cylinder/jackscrew controls if there is movement. If

you see the rotor spinning after opening the machine,

immediately shut down the machine and call for

service.

Wear protective gloves whenever you work around

the rotor knives. To avoid jamming your fingers

between the rotor knives and the bed knives, refer to

the information for safely clearing a jammed cutting

chamber later in this section.

SECTION 1-6

Safety Symbols and Plates

MOTOR ROTATION SAFETY PLATE

(Located on the door of the jackscrew console)

A REMINDER TO THE ELECTRICIAN to

check the motor rotation. It is important to check

the motor rotation whenever electrical

connections to the motor are being made or have

been disturbed for maintenance. The wrong

rotation direction can cause personal injury (by

throwing debris back toward the feed hopper

opening) and/or by damaging the knives.

NOTE: The drive motor direction arrow plate is

located on the top surface of the drive guard

toward the front of the machine.

18

Page 19

SAFETY

SECTION 1-7

Safety Clothing & Practices

(Located above the infeed opening at the front of the

machine)

It is recommended that hearing protection be used at

all times when operating this equipment. It is

mandatory that hearing protection be worn when

noise exposure exceeds OSHA Standards Section

1910.95.

(Located above the infeed opening at the front of the machine)

Always wear proper eye protection when operating and/or servicing this equipment. Wear safety glasses with

side shields or full-face safety shields.

19

Page 20

SAFETY

SECTION 1-8

Safety Clothing & Practices

WEAR PROTECTIVE CLOTHING

Never wear neckties, dangling jewelry,

loose-fitting clothing, watches, bracelets,

or rings. Tie back long hair or restrain it

with a hair net to ensure your safety.

KEEP YOUR WORK AREA SAFE

Keep your work area clean and uncluttered. Store your maintenance tools away from the granulator to

prevent them from falling into the machine and causing severe internal damage to the cutting chamber.

KEEP CO-WORKERS OFF THE MACHINE

Never lean or rest on the granulator. Do not let co-workers lean on your machine while it is running. A

moving part or shower of material many cause unexpected injury.

20

Page 21

SAFETY

SECTION 1-9

Safety Clothing & Practices

TURN OFF AND LOCKOUT

(Lockout/Tag-out of Energy Sources).

If it is not possible to lock out the power, have an electrician remove the fuses.

Make sure the rotor has come to a complete stop.

The hydraulic cylinders or jackscrews, which open the machine, should not operate until the rotor is

completely stopped.

If you discover that the hydraulic cylinders or jackscrews DO operate while the rotor is still turning,

immediately shut down the machine and call for maintenance to adjust it.

Wear gloves to protect against injury from the rotor or bed knives.

the power per OSHA 1910.147 OR ANSI Z244.1-1982

MACHINE OPENING DEVICES

The BP 2400 Series of granulators have been supplied with two different types of opening devices. These

devices provide access to the Cutting Chamber for both the area above the rotor, mainly for cleaning/knife

maintenance and below the rotor for cleaning/screen maintenance.

The system supplied on your machine may be either an electro-mechanical design (electric jackscrews) or

of a hydraulic design (hydraulic cylinders & power supply). References to both systems appear throughout

this manual. Be sure to follow the instructions that pertain to the system as supplied on your machine.

BE SURE THE ROTOR IS MOTIONLESS BEFORE OPENING MACHINE

Never open or remove any machine components unless the motor is electrically locked out and the

rotor is completely motionless.

The BP 2400 Series machine has a zero speed sensor that detects motion of the rotor. This sensor is

inter- locked to the controls of the two hydraulic cylinders or jackscrews. If it detects motion in the

rotor, it cuts the power to the hydraulic cylinder/jackscrew controls.

If you ever notice that the hydraulic cylinders or jackscrews operate while the rotor is turning, have a

mechanic and electrician check the speed sensor per the procedure in Section 4, entitled Zero Speed

Sensor.

21

Page 22

SAFETY

SECTION 1-10

Safely Cleaning A Jam

TURN OFF AND LOCKOUT the power per OSHA 1910.147 OR ANSI Z244.1-1982

(Lockout/Tag-out of Energy Sources).

If it is not possible to lock out the power, have an electrician remove the fuses.

Make sure the rotor has come to a complete stop.

The hydraulic cylinders or jackscrews, which open the machine, should not operate until the

rotor is completely stopped.

If you discover that the hydraulic cylinders or jackscrews DO operate while the rotor is still

turning, immediately shut down the machine and call for maintenance to adjust it.

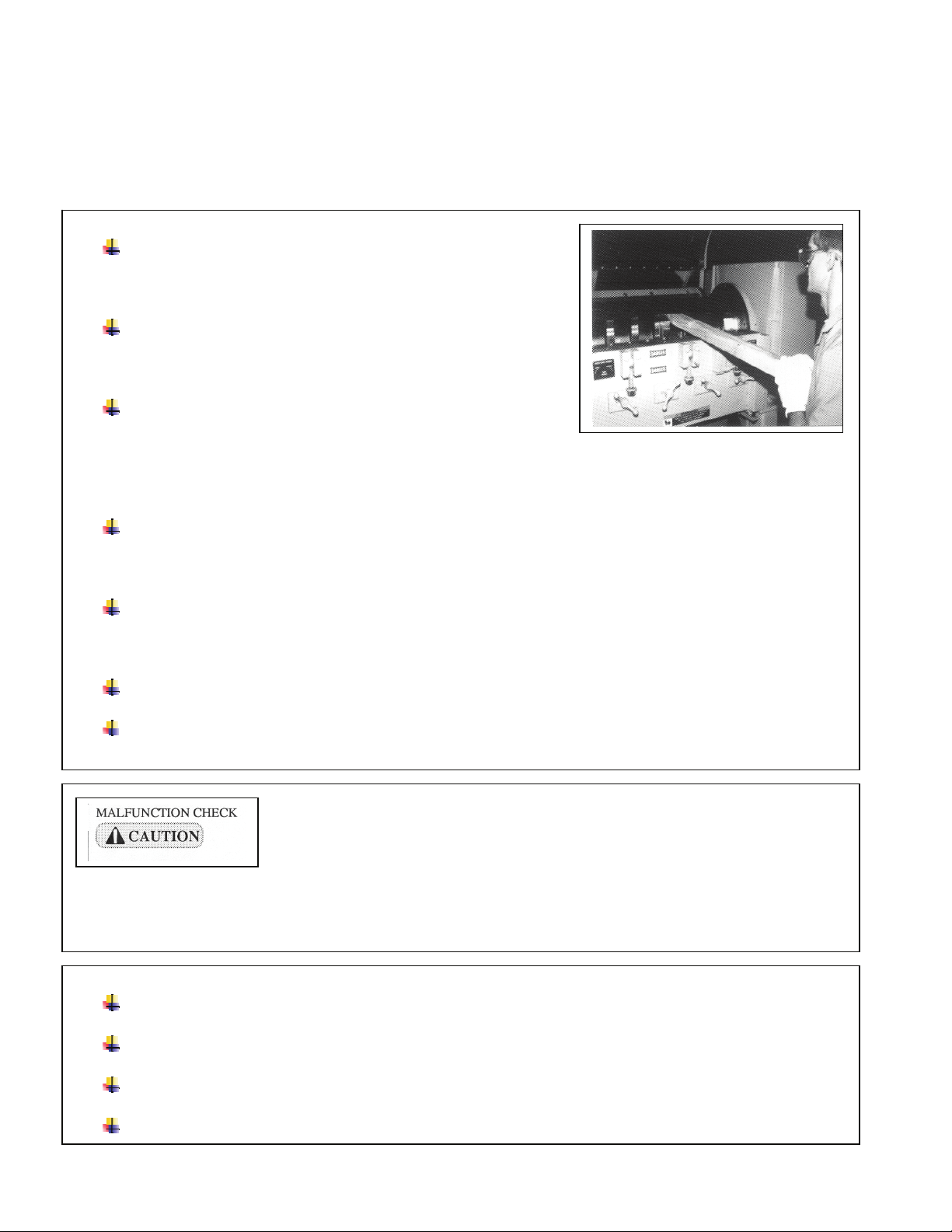

When you REVERSE the jackscrew operating direction, always ALLOW THE JACKSCREW

MOTOR TO COME TO A COMPLE1E STOP. Release the control switch and allow a

minimum of 5 seconds before switching to the opposite operating position. If you don't allow

this pause, the JACKSCREW AND OTHER COMPONENTS MAY BE SEVERELY

DAMAGED.

OPEN THE CUTTING CHAMBER

Open the screen cradle per instructions in Section 6-6 entitled Screen Replacement.

Open the cutting chamber per instructions in Section 6-9 entitled Cutting Chamber Access.

NEVER ATTEMPT TO FREE A JAMMED MACHINE BY PLACING YOUR HANDS ON

THE ROTOR, ON THE KNIVES, OR INSIDE THE CUTTING CHAMBER.

KEEP YOUR HANDS CLEAR OF THE ROTATIONAL PATH OF THE ROTOR

KNIVES.

22

Page 23

SAFETY

g

SECTION 1-11

Safely Cleaning A Jam

CLEAR THE JAM

A leather mallet and block of wood of sufficient length to keep

hands away from the path of the knives can be used if required.

Use the block of wood to exert force on the rotor, usually in the

direction opposite normal rotation.

Make sure you have secure footing on a clean floor and keep

your body well braced while prying on the rotor. Guard against

loss of balance should the jammed condition suddenly come free.

Use pliers to remove material from the cutting chamber, keep in mind that the removal of material may

cause rotation of the rotor and rotor knives.

If prying on the rotor is unsuccessful, remove the bed knife and the rotor knife at the jam. For

information about bed knives, refer to Section 4, Settings and Adjustments.

Close the screen cradle per instructions in Section 6-4 entitled Screen Replacement.

Close the cutting chamber per instructions in Section 6-9 entitled Cutting Chamber Access.

A malfunction of the machine, such as a jam, may cause undue strain or damage to any part. Do not restart the

machine after such a malfunction without checking to see whether damage was done or whether settings were

ed by the malfunction.

chan

RESTART THE GRANULATOR

If necessary to replace the fuses, call an electrician to do it.

UNLOCK AND TURN ON the main power.

Remove the OUT OF SERVICE tag

Start the granulator by depressing the start pushbutton on the electrical cabinet.

23

Page 24

MACHINE AND CONTROLS

SECTION 2-1

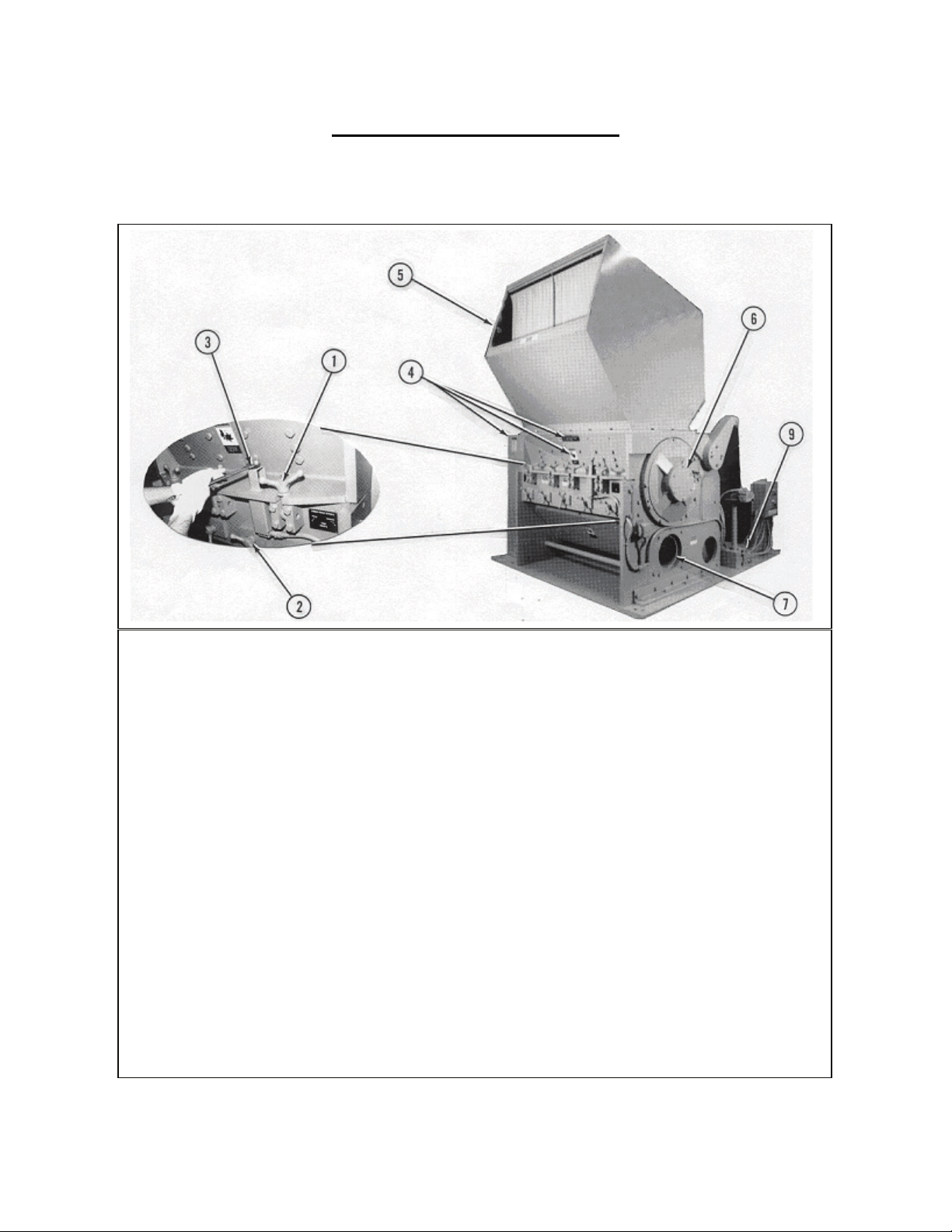

BP 2400 Series Granulator -Left Front Quarter View

1.

Hold-down clamps - cutting chamber

2. Screen cradle retainers

3. Interlock actuator screw - cutting chamber

4. Safety plates

5. Feed hopper

6. Rotor bearing housing

Discharge duct (pipe not shown-optional mount to either side)

7.

8. Start/stop pushbuttons are located on the electrical cabinet, not shown. (The electrical cabinet is

optional equipment.)

9. Cover, mounting bracket limit switch, jackscrew opening only.

BP 2400 Series Granulators The BP 2400 Series Granulators have a common cutting diameter of

23.6"(600mm) and a common throat size of 24" (610mm) by widths ranging up to 56" (1420mm).

They are designed for reclamation of large blow-molded and thin-walled injection molded-parts,

films, and fibers.

The machines in the BP-Series can be fitted with screens having hole sizes to suit the particular

application. The BP-Series machines conform to ANSI Standards: B 151.11 and NFPA 79.

24

Page 25

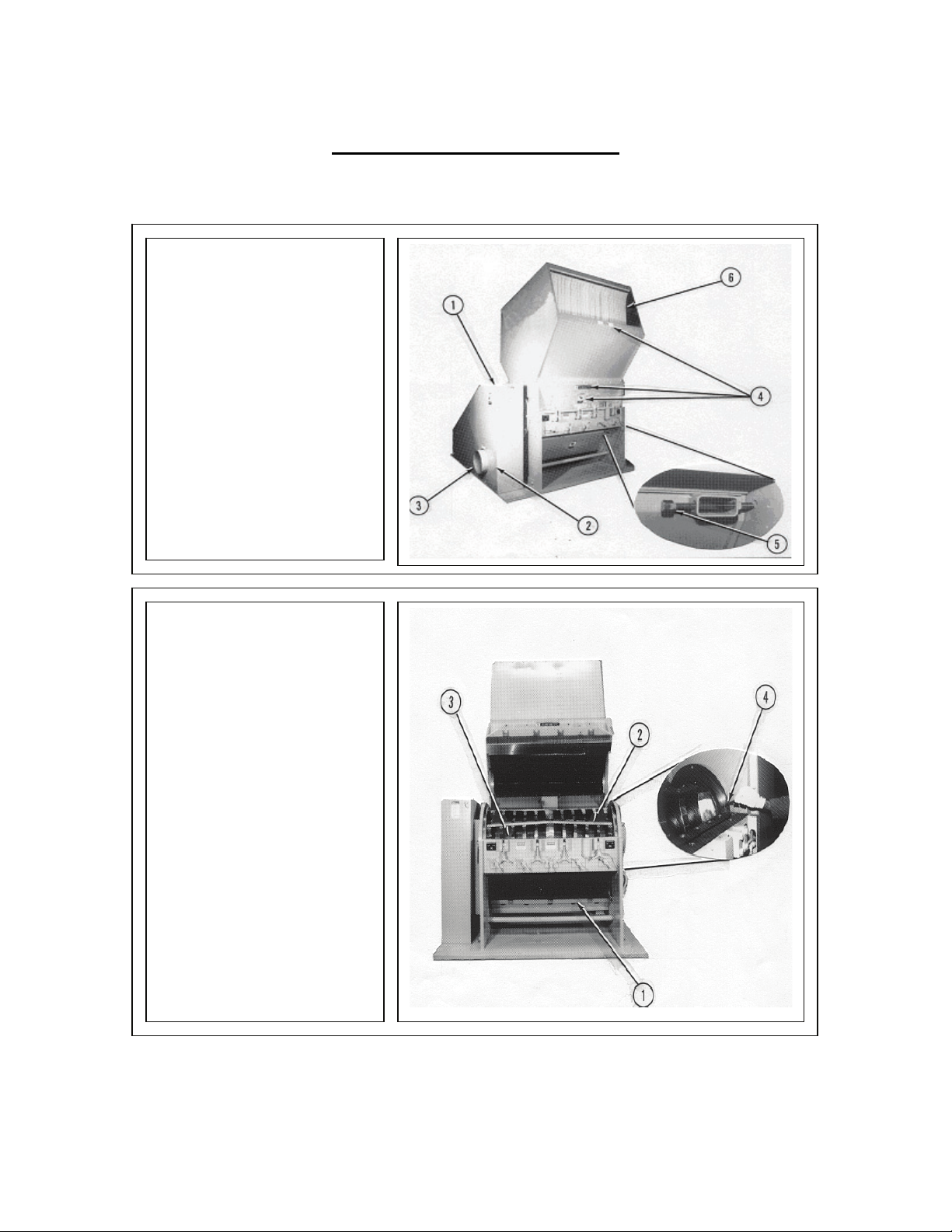

BP 2400 Series Granulator

Right Front Quarter View

1. Drive guard

2. Drive guard cover

3. Inlet vent -discharge

blower

4. Safety plates

5. Interlock actuator

screw screen cradle

6. Infeed flap

MACHINE AND CONTROLS

SECTION 2-2

BP 2400 Series Granulator

Machine Open Front View

1. Screen

2. Rotor Knife

3. Bed knife (down

stroke)

4. Rotor locating pin

25

Page 26

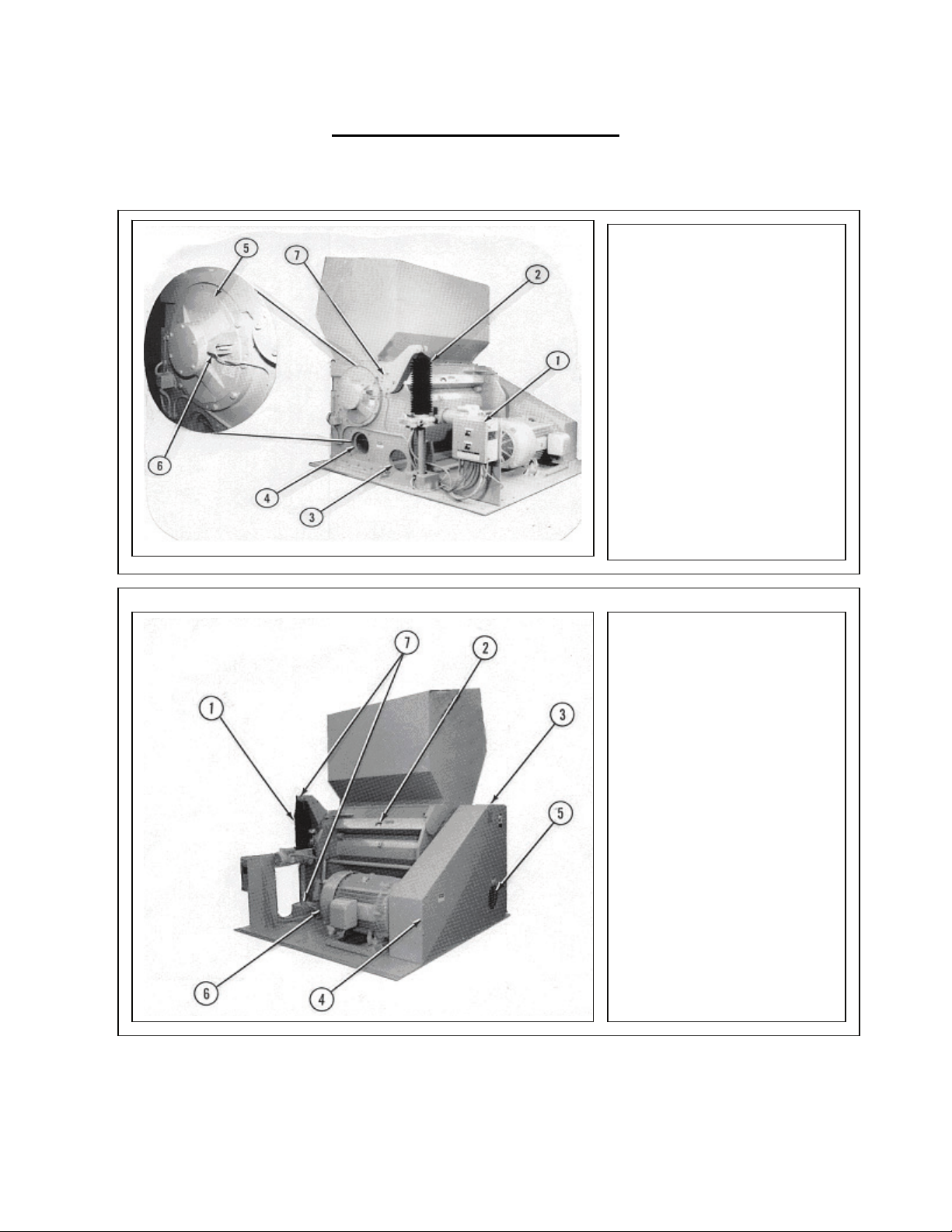

MACHINE AND CONTROLS

SECTION 2-3

BP 2400 Series Granulator Left

Rear Quarter View

I. Hydraulic cylinder/

jackscrew console

2. Hydraulic cylinder or

jackscrew- cutting chamber

3. Cleanout- discharge

transition

4. Discharge outlet (pipe not

shown-optional mount to

either side)

5. Rotor bearing housing

6. Rotor zero speed sensor

7. Upper chamber pivot arm

screws

BP 2400 Series Granulator

Right Rear Quarter View

1. Hydraulic cylinder or

jackscrew -cutting

chamber

2. Machine serial

number plate

3. Drive guard

4. Drive guard cover

5. Inlet vent, discharge

blower

6. Drive motor

7. Hydraulic cylinder or

jackscrew pivot pins

and locknuts

26

Page 27

INSTALLATION

SECTION 3-1

OVERVIEW

This section deals with the procedures required to place your BP 2400 Series Granulator into

service after you receive it at your plant. The following basic steps need to be accomplished.

Uncrating the machine

Accounting for all necessary parts

Inspecting for damage and reporting any damage to the carrier

Cleaning the protective coating from the machine

Moving the machine to its service location

Checking and, if necessary, adjusting mechanical parts before applying electrical power

Connecting electrical power to the machine control panel and hydraulic

cylinder/jackscrew control panel located on the machine

Performing the start-up procedure

PLEASE FOLLOW THESE STEPS, AS OUTLINED TO ACHIEVE A SAFE AND

SUCCESSFUL START- UP OF YOUR GP-SERIES GRANULATOR.

The machine weights for the BP-Series Granulators are as follows: BP 2428-10000 pounds

BP 2439-13000 pounds

BP 2456-16000 pounds

UNCRATE THE GRANULATOR

As shipped, the granulator and the hopper are securely bolted onto separate skids and covered

with a wooden crate. The electrical cabinet, an optional item, is similarly packaged when ordered.

Remove the strapping.

Remove the packages and parts from the skid or inner sides of the crate. Remove the hold-

down bolts, nuts, etc.

Inspect for damage during transit and notify the carrier immediately of any damage.

Check the packing list and notify Sterling if there are any shortages.

27

Page 28

INSTALLATION

SECTION 3-2

MOVE THE GRANULATOR TO ITS WORK SITE

If lifting the machine is necessary, use appropriately rated lifting equipment. Always lift the unit

from beneath the base plate.

The machine weights for the BP-Series Granulators are as follows: BP 2428-10000 pounds

ALLOW ADEQUATE WORK SPACE

Adequate clearance must be maintained so that all areas of the granulator are accessible and

unobstructed for servicing, maintaining, or operating the equipment. Space must be allowed for

removing guards and screens.

Allow three feet (91 cm) on all sides of the machine for access.

BP 2439-13000 pounds

BP 2456-16000 pounds

LEVEL THE GRANULATOR

Once the granulator is at its final installation site, ensure that the machine is on a level surface and

resting firmly on its base plate. If necessary, use shims to level it.

It can be mounted on isolation pads or it can be lagged to the floor through holes provided in the

base plate.

TURN OFF AND LOCKOUT the power per OSHA 1910.147 OR ANSI Z244.1-1982

(Lockout/Tag-out of Energy Sources).

If it is not possible to lock out the power, have an electrician remove the fuses. Make sure the

rotor has come to a complete stop.

(Continued on next page)

28

Page 29

INSTALLATION

SECTION 3-3

The hydraulic cylinders or jackscrews, which open the machine should not operate until the

rotor is completely stopped. If you discover that the hydraulic cylinders or jackscrews DO

operate while the rotor is still turning, immediately shut down the machine and call for

maintenance to adjust it.

Wear gloves to protect against injury from the rotor or bed knives.

REMOVE THE PROTECTIVE COATING

The machine is shipped with a protective wax coating, which must be removed prior to start-up.

The coating can be removed with an acceptable solvent, such as mineral spirits.

Clean the following areas:

Inside the feed hopper

Inside the cutting chamber (knives, rotor, etc.)

Inside the discharge area.

Be sure that the screens are properly installed into the cutting chamber and that nothing has

fallen into the cutting chamber during transportation and/or installation. Refer to Section 6,

Maintenance, for the procedure entitled Screen Replacement and Cutting Chamber Access.

Check to be sure the bed knife and rotor knife hold-down screws are tight and knife clearances

are correct. Refer to Section 4, Settings and Adjustments.

Before operating the granulator, it is extremely important that a licensed electrician correctly

wires the machine into the plant power source. See Section 8, for wiring diagram.

All electrical equipment must be properly grounded in accordance with local and national codes

to protect personnel from electrical shock.

A fusible, lockable disconnect between the plant power source and the machine electrical

cabinet is highly recommended.

29

Page 30

INSTALLATION

SECTION 3-4

ELECTRICAL WIRING

To wire the granulator, run power (of the proper voltage) from the plant source through a lockable,

fusible disconnect to the machine electrical control panel.

To wire the jackscrew motors, run power (of proper voltage) from the plant source through a fusible disconnect to

the machine-mounted jackscrew control panel.

From the main electrical control panel, make the necessary control circuit connections to the hydraulic

cylinders/jackscrew control panel. Refer to the wiring diagrams supplied with the machine.

Wiring from the hydraulic cylinders/jackscrew console to the safety switches, zero speed sensor and

hydraulic pump/valves or cutting chamber/screen cradle jackscrew is done at the factory.

From the main electrical panel, make the necessary wiring connections to the main drive motor and any

auxiliary motors or control connections.

Refer to the wiring diagram appended to this manual for wiring connections for typical machine

applications. Check the wiring diagram supplied for any wiring that is specific to your application. This

diagram is part of the documentation shipped with the machine.

After power is connected, do not make any adjustments to the machine without performing the

following operations.

TURN POWER OFF and LOCK IT OUT per OSHA 1910.147 OR ANSI Z244.1-1982 (Lockout/Tagout of Energy Sources).

If you cannot lock out the power, have an electrician remove the fuses.

Tag the machine as OUT OF SERVICE.

Make sure the rotor has come to a complete stop.

The hydraulic cylinders/jackscrews, which open the machine, should not operate until the rotor is

completely stopped. If you discover that the hydraulic cylinders/jackscrews DO operate while the rotor

is still turning, immediately shut down the machine and call for maintenance to adjust it.

Wear gloves to protect against injury from the rotor or bed knives.

30

Page 31

INSTALLATION

CHECK FOR MECHANICAL INTERFERENCES

TURN POWER OFF and LOCK IT OUT per OSHA 1910.147 OR ANSI Z244.1-1982

(Lockout/Tag-out of Energy Sources).

Open the cutting chamber. Refer to the procedures entitled Screen Replacement and Cutting

Chamber Access in Section 6.

Turn the rotor slowly with gloved hands, at least one full revolution, to verify that there are no

interferences between the rotor knives and bed knives and/or with the screen.

SET UP THE MACHINE FUNCTIONS

Set and torque the rotor knives and bed knives as shown in Section 4, Settings and

Adjustments.

Adjust the V-belt drive per the procedure in Section 4 entitled Drive Belt Replacement or

Adjustment

SECTION 3-5

CHECK ROTATION OF MOTORS

With the cutting chamber closed, jog the drive motor by pushing the start and stop buttons in

quick succession. This starts and stops the granulator motor. Be alert for mechanical

interferences between parts. Stop the machine immediately if you hear unexpected sounds.

Jog the motor to check the rotational direction. The V-belt sheave must rotate in the direction

shown by the arrow located on top of the belt guard. Have a helper confirm the direction by

looking at the V-belt through the viewing window on the side of the belt guard cover.

If your unit has the optional discharge blower located on either the right or left side of the

machine, check the direction of rotation of the blower.

It is extremely important that a licensed electrician performs these steps.

If any motor rotates in the wrong direction, stop the machine by depressing the stop button.

TURN OFF AND LOCK OUT the power at the disconnect switch which supplies power to the main

electrical control panel per OSHA 1910.147 OR ANSI Z244.1-1982 (Lockout/Tag-out of Energy

Sources). If the disconnect is not lockable, remove the fuses.

(Continued on next page)

31

Page 32

INSTALLATION

SECTION 3-6

With all power to the electrical control panel disconnected and locked out, reverse any two of the three

power line conductors to the machine. If there is more than one motor on the machine, and one is

turning in the wrong direction, and one isn't: reverse any two of the three line conductors at the overload

relay of the motor that you wish to reverse.

Unlock the power and switch it on at the electrical disconnect (if necessary, replace the fuses).

Re-check the rotation direction of the motor(s).

INTERLOCK SWITCH TEST PROCEDURE

With the machine stopped, perform the following steps.

TURN OFF and LOCK OUT THE POWER per OSHA 1910.147 OR ANSI Z244.1-1982 (Lockout/

Tag-out of Energy Sources).

U se the wiring diagram appended to this manual to locate the interlock switch terminal strip in the jack-

screw control panel-

The wires for the upper chamber interlock switch are numbers 1 and 16.

The wires for the screen cradle interlock switch are numbers 16 and 5.

Connect an ohmmeter across each interlock switch terminal or across all interlock switch terminals (wire

numbers1 and 5).

Switch the ohmmeter resistance to the lowest scale.

When the interlock actuator screws are in place and properly activating their switches, the ohmmeter

should read zero resistance.

When either or both actuator bolts are withdrawn, the ohmmeter should read infinite resistance.

Loosen ONE actuator screw 3 to 4 turns.

If the meter reads INFINITY, before the screw can be completely removed, the INTERLOCK IS

WORKING.

If the meter reads ZERO RESISTANCE when the actuator screw is completely REMOVED the

interlock IS NOT working.

REPLACE THE FIRST ACTUATOR SCREW TESTED BEFORE TESTING THE SECOND ONE. If

an interlock does not work, the complete mechanism, including the switch, must be removed and

disassembled to determine the cause of the malfunction.

ALTERNATE TEST FOR THE INTERLOCK SWITCHES

With the cutting chamber and screen cradle closed and power on, perforn1 the following steps.

Push the start button to start the granulator.

Retract the screen cradle interlock actuator screw by turning it counterclockwise. Make sure that the end

of the actuator screw is visible and clear of any contact. The granulator should stop.

If the machine continues to run, TURN OFF AND LOCK OUT THE POWER per OSHA 1910.147 OR

ANSI Z244.1-1982 (Lockout/Tag-out of Energy Sources).

Have the electrician check the interlock switch on the screen cradle to correct the malfunction.

32

Page 33

INSTALLATION

SECTION 3-6

With all power to the electrical control panel disconnected and locked out, reverse any two of the three

power line conductors to the machine. If there is more than one motor on the machine, and one is

turning in the wrong direction, and one isn't: reverse any two of the three line conductors at the overload

relay of the motor that you wish to reverse.

Unlock the power and switch it on at the electrical disconnect (if necessary, replace the fuses).

Re-check the rotation direction of the motor(s).

INTERLOCK SWITCH TEST PROCEDURE

With the machine stopped, perform the following steps.

TURN OFF and LOCK OUT THE POWER per OSHA 1910.147 OR ANSI Z244.1-1982 (Lockout/

Tag-out of Energy Sources).

U se the wiring diagram appended to this manual to locate the interlock switch terminal strip in the jack-

screw control panel-

The wires for the upper chamber interlock switch are numbers 1 and 16.

The wires for the screen cradle interlock switch are numbers 16 and 5.

Connect an ohmmeter across each interlock switch terminal or across all interlock switch terminals (wire

numbers1 and 5).

Switch the ohmmeter resistance to the lowest scale.

When the interlock actuator screws are in place and properly activating their switches, the ohmmeter

should read zero resistance.

When either or both actuator bolts are withdrawn, the ohmmeter should read infinite resistance.

Loosen ONE actuator screw 3 to 4 turns.

If the meter reads INFINITY, before the screw can be completely removed, the INTERLOCK IS

WORKING.

If the meter reads ZERO RESISTANCE when the actuator screw is completely REMOVED the

interlock IS NOT working.

REPLACE THE FIRST ACTUATOR SCREW TESTED BEFORE TESTING THE SECOND ONE. If

an interlock does not work, the complete mechanism, including the switch, must be removed and

disassembled to determine the cause of the malfunction.

ALTERNATE TEST FOR THE INTERLOCK SWITCHES

With the cutting chamber and screen cradle closed and power on, perforn1 the following steps.

Push the start button to start the granulator.

Retract the screen cradle interlock actuator screw by turning it counterclockwise. Make sure that the end

of the actuator screw is visible and clear of any contact. The granulator should stop.

If the machine continues to run, TURN OFF AND LOCK OUT THE POWER per OSHA 1910.147 OR

ANSI Z244.1-1982 (Lockout/Tag-out of Energy Sources).

Have the electrician check the interlock switch on the screen cradle to correct the malfunction.

33

Page 34

INSTALLATION

SECTION 3-7

ALTERNATE TEST FOR THE INTERLOCK SWITCHES (Continued from previous page).

After the test or repair, engage the screen cradle interlock actuator screw.

If necessary, unlock and turn on the power.

Push the start button to start the granulator.

Retract the cutting chamber interlock actuator screw by turning it counterclockwise. Make

sure that the end of the actuator screw is visible and clear of any contact. The granulator

should stop.

If the machine continues to run, TURN OFF AND LOCK OUT THE POWER per OSHA

1910.147 OR ANSI Z244.1-1982 (Lockout/Tag-out of Energy Sources).

Have the electrician check the interlock switch on the cutting chamber to correct the

malfunction.

After the test or repair, if necessary, engage the cutting chamber interlock actuator screw.

TEST THE ZERO SPEED SENSOR

Cutting Chamber Jackscrew

Depress the start button to start the granulator.

When the machine reaches full speed, depress the stop button to stop the granulator.

Open the cutting chamber interlock using the procedure in Section 6 entitled Cutting

Chamber Access.

Release the cutting chamber hold-down clamps using the procedure in Section 6 entitled

Cutting Chamber Access.

While the rotor is still turning, actuate the cutting chamber hydraulic cylinder or

jackscrew from the control console by turning the CC/Hopper selector switch to the

RAISE POSITION.

The hydraulic cylinder or jackscrew should NOT operate until the rotor has come to a

complete stop.

If the hydraulic cylinder or jackscrew operates before the rotor stops, TURN OFF AND

LOCKOUT THE POWER per OSHA 1910.147 OR ANSI Z244.1-1982 (Lockout/Tag-out

of Energy Sources).

34

Page 35

INSTALLATION

SECTION 3-8

TEST THE ZERO SPEED SENSOR {Continued from previous page)

Screen Cradle Jackscrew

Push the start button to start the granulator

When the machine reaches full speed, push the stop button to stop the granulator.

Open the screen cradle interlock using the procedure in Section 6-4 entitled Screen

Replacement.

Release the cradle retainers using the procedure in Section 6-9 entitled Screen Replacement.

While the rotor is still turning, actuate the screen cradle hydraulic cylinder or jackscrew

from the control console by turning the CC/screen cradle selector switch to the LOWER

POSITION.

The hydraulic cylinder or jackscrew should NOT operate until the rotor has come to a

complete stop.

If the hydraulic cylinder or jackscrew operates before the rotor stops, TURN OFF AND

LOCKOUT THE POWER per OSHA 1910.147 OR ANSI Z244.1-1982 (Lockout/Tag-out

of Energy Sources).

LUBRICATION

The machine is pre-lubricated except for the motor. For motor lubrication, check the tag supplied by

the motor manufacturer.

After the BP2400 Series Granulator has been in service for some time, the jackscrews and the main

bearings should be lubricated periodically.

Refer to Section 6, Maintenance, for further information.

35

Page 36

SETTINGS AND ADJUSTMENTS

g

SECTION 4-1

Adjusting or Replacing Bed Knives

BASIC FACTS ABOUT THE KNIVES

All of the rotor knives are ground in sets to equal dimensions. Mount and service them as sets.

The rotor knives must be mounted tightly against the backs of the knife seats, in order to make it

possible to achieve consistent knife clearances.

Rotors with adjustable rotor knives require setting of the knife length prior to installation on to the

rotor. Knife length setting is accomplished by using the fixture supplied with the machine, see

Section 4-35.

Accurate cutting clearance is obtained by setting the bed knives to a 0.006 in. to 0.008 in. (0.15

mm to 0.20 mm) gap from the rotor knives.

The bed knives are adjusted by turning captive adjusting screws. For best results, start with the bed

knives adjusted to a wide gap from the rotor knife, and slowly adjust them

turning the screws in the same direction; avoid reversals. Reversals introduce inaccuracies due to

backlash.

to the required gap by

CHECK ALL SETTINGS AND ADJUSTMENTS BEFORE GRANULATING ANY

MATERIAL

Proper adjustments and settings are made prior to shipment, however the machine may require

readjustment. The standard knife gap setting is between six and eight thousandths of an inch (0.006 in. to

0.008 in. or 0.15 mm to 0.20 mm).

NOTE: These instructions apply to both the upstroke (the bed knife furthest from you when you service the

cutting chamber) and the down-stroke bed knives.

A malfunction of the machine, such as a jam, may cause undue strain or damage to any part. Do not restart

the machine after such a malfunction without checking to see whether damage was done or whether settings

were chan

ed by the malfunction.

TURN OFF AND LOCKOUT the power per OSHA 1910.147 OR ANSI Z244.1-1982 (Lockout/Tag-out of

Energy Sources).

If it is not possible to lock out the power, have an electrician remove the fuses. Make sure the rotor has

come to a complete stop.

36

Page 37

SETTINGS AND ADJUSTMENTS

Adjusting or Replacing Bed Knives

(Continued from previous page)

The hydraulic cylinders or jackscrews, which open the machine, should not operate until the rotor is

completely stopped. If you discover that the hydraulic cylinders or jackscrews DO operate while the rotor

is still turning, immediately shut down the machine and call for maintenance to adjust it.

Wear gloves to protect against injury from the rotor or bed knives.

OPEN THE CUTTING CHAMBER INTERLOCK

Disengage the interlock actuator screw with a box

wrench or a ratchet wrench.

Make sure the end of the interlock actuator screw is

visible and clear of any contact.

When disengaged, the interlock opens the electrical

control circuit to the motor and prevents the machine

from running.

SECTION 4-2

RELEASE THE CUTTING CHAMBER

FASTENERS

Turn the hold-down clamps counterclockwise to

loosen them.

Swing the hold-down clamps toward you until they

are disengaged from the cutting chamber housing.

SEE SECTION 6-10 PAGE 87 FOR CUTTING CHAMBER OPENING INSTRUCTIONS.

37

Page 38

SETTINGS AND ADJUSTMENTS

SECTION 4-3

Adjusting or Replacing Bed Knives

The rotor knives and bed knives are very sharp wear heavy gloves to avoid injury.

Use the rotor-locating pin to lock the rotor in the position that is least likely to cause injury as you

work. The pin keeps the rotor from turning.

If the rotor knives and the bed knives are to be removed, remove the rotor knives first

(and replace them last) to reduce the chance of injury.

INSTALL THE ROTOR LOCATING PIN

Insert the rotor-locating pin into the hole in the

right side of the bearing housing.

While applying light pressure, turn the rotor pin

until the pin drops deeper into the locating hole.

The pin keeps the rotor from turning while the pin

is in place.

NOTE: The locating pin allows you to engage several hole

locations so that you can position the knives in the least

hazardous position.

38

Page 39

SETTINGS AND ADJUSTMENTS

LOOSEN THE MOUNTING SCREWS

Select either the upstroke knife or the down-stroke knife

for first removal.

Loosen the bed knife screws with a 30 mm socket

mounted on a breaker bar. These screws are tightened to

a torque of 472 ft Ibs (640 Nm) so make sure you have

the proper breaker bar (a four foot long (1.2 m) bar with a

3/4 inch (19 mm) drive is suggested). Make sure you

have solid footing while you apply the breaking force.

REMOVE THE FIRST KNIFE CLAMP OR SHIELD

Remove the screws on one half of the selected bed

knife using a 30 mm socket or equivalent wrench.

NOTE: When removing the knife clamp on the upstroke knife

(the similar piece on the down-stroke knife is called knife

shield), hold the clamp while removing the last screw to keep it

from slipping off its inclined mounting surface. The knives will

not slip off because they are, secured by the captive adjusting

screws.

Keep the screws for reinstallation or use new factory-

sup- plied screws of the same specification for

replacement.

Repeat the removal procedure for the remaining knife

clamps and shields.

SECTION 4-4

Adjusting or Replacing Bed Knives

REMOVE THE BED KNIVES

Remove the bed knives by lifting each half until the

captive screws are clear of their slots.

Remove the second bed knife using the same

procedure.

39

Page 40

SETTINGS AND ADJUSTMENTS

SECTION 4-5

Adjusting or Replacing Bed Knives

CLEAN THE KNIFE MOUNTING SURFACES

Clean the knife mounting surfaces with a

stone or other non-marring tool and wipe

them with a clean cloth.

Make sure they are free of all material,

dust, and dirt.

DO NOT REPLACE THE MOUNTING SCREWS WITH ANY TYPE OF SCREW

OTHER THAN THAT SPECIFIED BY CUMBERLAND. Substitution of improper screws

could lead to premature failure, equipment damage, and serious injury to personnel.

When regrinding the knives, you may re-use the same screws and washers but do not re-use

them more than six times. When installing new knives, replace the screws and washers with

those furnished by the factory.

REPLACE THE UPSTROKE BED KNIFE

Wipe the screws with a lightly oiled cloth; do

not leave an oil film since lubrication can

adversely affect the stress on a screw

installed to a fixed torque.

Install the upstroke knife making sure to

install it with the knife-edge on the lower

side.

Engage the captive screws in the slots on the

far side of the knife bed and lower the knife

onto the knife bed-

Repeat these steps for the second half of the

knife.

REPLACE THE UPSTROKE KNIFE CLAMP

Place the clamp over one half of the knife

and hold it in position until you fasten the

first two screws and washers finger-tight.

Place the second clamp over the second half

of the knife and hold it while you fasten it.

Install the remaining mounting screws and

washers and tighten them finger-tight.

40

Page 41

SETTINGS AND ADJUSTMENTS

REPLACE THE DOWNSTROKE BED KNIFE

Install the down-stroke bed knife (located on the near

side of the rotor) making sure to install it with the knifeedge on the upper side.

Engage the captive screws in the slots on the near side of

the knife bed and lower the knife onto the knife bed.

Repeat these steps for the second half of the down-stroke

knife.

REPLACE THE DOWNSTROKE KNIFE SHIELDS

Back off the captive screws on both halves of the bed

knife so that they will not interfere with the rotor.

Place the shields over the bed knife.

Install the mounting screws and washers and tighten them

finger-tight.

SECTION 4-6

Adjusting or Replacing Bed Knives

CHECK THE BED KNIVES

Check both halves of the upstroke knife (the bed knife on the far side of the rotor) to be sure

that the cutting edges face down.

Check both halves of the down-stroke knife (the bed knife on the near side of the rotor) to

be sure that the cutting edges face up.

GAP ADJUSTMENT TIPS

It is best to keep the adjustments on the captive screws moving in the same direction. This

eliminates the effect of backlash in the adjusting screw.

Make the screw adjustments in small steps to keep the bed knife adjustment even over the width of

the machine.

To avoid cutting the shim stock, turn the rotor backward during the adjustment procedure.

Use the rotor knife with the largest dimension from rotor centerline as the reference, i.e., the highest

knife.

41

Page 42

SETTINGS AND ADJUSTMENTS

MEASURE THE KNIFE GAP

If you are changing the rotor knives, do that now,

otherwise, continue with this procedure.

Use brass shim stock to set the knife gap to the cutting

clearance of 0.006 in. to 0.008 in. (0.15 mm to 0.20

mm).

Remove the rotor-locating pin.

Rotate the rotor backward, by hand, and measure the

gap between it and the bed knife at the point of shear.

You can work on each half of the bed knife

independent of the other half but keep them in step

with each other by working from side-to-side.

SET THE DOWNSTROKE KNIFE SHIELD

SECTION 4-7

Adjusting or Replacing Bed Knives

Position the knife-shield so that it sets back from the

bed knife-edge about 1/32 in. for film and 1/16 in. for

thicker materials. Use a plastic or leather mallet, if

necessary, to tap the shield or knife-

The upstroke knife clamp does not need this

adjustment.

Carefully adjust the bed knife clearance to its final

setting and snug down the mounting screws with a 30

mm socket wrench.

CHECK THE KNIFE GAP

Snug the screws down in stages keeping them about even as you progressively tighten them.

Recheck the knife gap after snugging down the mounting screws.

After setting up to one rotor knife (usually the highest knife), rotate the remaining knives slowly

by the bed knife and quickly verify the knife gap.

42

Page 43

SETTINGS AND ADJUSTMENTS

SECTION 4-8

Adjusting or Replacing Bed Knives

TIGHTEN THE SCREWS TO FINAL TORQUE

When the knife gap is adjusted to the proper

dimension, tighten the mounting screws to a torque of

472 ft lbs (640 Nm).

For safety, make sure that you have solid footing when

you apply this final torque.

Recheck the gap after tightening the screws to the final

torque.

Make sure that both halves of the bed knife are

adjusted.

FINALIZE INSTALLATION OF UPSTROKE BED KNIFE

To complete the installation of the upstroke bed knife, use the same procedures as for the down-stroke knife.

The titles follow:

Measure the knife gap.

Unlike the knife shield, the knife clamp does not need to be adjusted.

Check the knife gap.

Tighten the screws to final torque.

SEE SECTION 6-11 PAGE 88 FOR CUTTING CHAMBER CLOSING INSTRUCTIONS.

43

Page 44

SETTINGS AND ADJUSTMENTS

FASTEN THE CUTTING CHAMBER

Raise the hold-down clamps to their upright

positions

Turn the knobs clockwise until they are tight

against the chamber housing.

CLOSE THE CUTTING CHAMBER SAFETY

INTERLOCK

Engage the safety interlock by turning the

actuator screw clockwise with a box wrench or

a ratchet wrench

Make sure the screw is fully seated against the

top surface of its housing.

When engaged, the interlock closes the electrical

control circuit to the motor and allows the machine to

run.

SECTION 4-9

Adjusting or Replacing Bed Knives

RESTART THE GRANULATOR

If necessary to replace the fuses, call an electrician to do it.

UNLOCK AND TURN ON the main power.

Remove the OUT OF SERVICE tag.

Start the granulator by depressing the start pushbutton on the electrical cabinet.

44

Page 45

SETTINGS AND ADJUSTMENTS

SECTION 4-10

Adjusting or Replacing Rotor Knives

BASIC FACTS ABOUT THE KNIVES

All of the rotor knives are ground in sets to equal dimensions. Mount and service them as sets. .

The rotor knives must be mounted tightly against the backs of knife seats in order to make it possible

to achieve consistent knife clearances.

Rotors with adjustable rotor knives require setting of the knife length prior to installation on to the

rotor. Knife length setting is accomplished by using the fixture supplied with the machine,

see Section 4-35.

Accurate cutting clearance is obtained by setting the bed knives to a 0.006 in. to 0.008 in. (0.15 mm

to 0.20 mm} gap from the rotor knives.

The bed knives are adjusted by turning captive adjusting screws. For best results, start with the bed

knives adjusted to a wide gap from the rotor knife, and slowly adjust them to the required gap by

turning the screws in the same direction; avoid reversals. Reversals introduce inaccuracies due to

backlash.

TURN OFF AND LOCKOUT the power per OSHA 1910.147 OR ANSI Z244.1-1982 (Lockout/Tag-

out of Energy Sources).

If it is not possible to lock out the power, have an electrician remove the fuses.

Make sure the rotor has come to a complete stop.

The hydraulic cylinders or jackscrews, which open the machine, should not operate until the rotor is

completely stopped. If you discover that the hydraulic cylinders or jackscrews DO operate while the

rotor is still turning, immediately shut down the machine and call for maintenance to adjust it.

Wear gloves to protect against injury from the rotor or bed knives.

OPEN THE CUTTING CHAMBER INTERLOCK

Disengage the interlock actuator screw with a box wrench or a ratchet

wrench.

Make sure the end of the interlock actuator screw is visible and clear of

any contact.

When disengaged, the interlock opens the electrical control circuit to the

motor and prevents the machine from running.

45

Page 46

SETTINGS AND ADJUSTMENTS

RELEASE THE CUTTING CHAMBER

FASTENERS

Turn the hold-down clamps counterclockwise to loosen

them.

Swing the hold-down clamps toward you until they are

disengaged from the cutting chamber housing.

SEE SECTION 6-10 PAGE 87 FOR CUTTING CHAMBER

OPENING INSTRUCTIONS.

SECTION 4-11

Adjusting or Replacing Rotor Knives

46

Page 47

SETTINGS AND ADJUSTMENTS

SECTION 4-12

Adjusting or Replacing Rotor Knives

The rotor knives and bed knives are very sharp wear heavy gloves to avoid injury.

Use the rotor-locating pin to lock the rotor in the position that is least likely to cause injury as you work. The

pin keeps the rotor from turning.

If the rotor knives and the bed knives are to be removed, remove the rotor knives first {and replace them

last) to reduce the chance of injury.

LOCK THE ROTOR

Position the rotor so that a blade is at top dead center.

Insert the rotor-locking pin into the hole in the right side

bearing housing.

Apply light pressure against the pin while turning the rotor

toward you approximately 10 degrees. The pin will drop into

the hole when it is properly aligned.

The pin locks the rotor in place until the pin is removed.

REMOVE THE MOUNTING SCREWS

Loosen the rotor knife screws with a 30 mm socket mounted

on a breaker bar (These screws are tightened to a torque of

472 ft lbs (640 Nm) so make sure you have the proper

breaker bar (a four foot long (1.2 m) bar with a 3/4 inch (19

mm) drive is suggested. Make sure you have solid footing

while you apply the breaking force.

Remove the mounting screws from the right rotor knife with

a suitable socket wrench.

REMOVE THE ROTOR KNIVES

Lift the right knife off from the rotor and repeat the process

with the left rotor knife.

Remove the rotor-locating pin, turn the rotor to bring the next

knives into position for removal, insert the locating pin to

hold the rotor in this position. Repeat the process for the

remaining knives.

47

Page 48

SETTINGS AND ADJUSTMENTS

q

SECTION 4-13

Adjusting or Replacing Rotor Knives

CLEAN PARTS FOR REASSEMBLY

Clean the rotor knife seats with a stone or other

non-mar- ring tool. Make sure that the backs of the

knife seats are clean so that the rotor knife can be

placed squarely against them.

Wipe the screws with lightly oiled cloth, do not

leave an oil film since lubrication can adversely

affect the stress on a screw installed to a fixed

tor

ue value.

DO NOT REPLACE THE MOUNTING SCREWS WITH ANY TYPE OF SCREW

OTHER THAN THAT SPECIFIED BY STERLING. Substitution of improper screws could

lead to premature failure, equipment damage, and serious injury to personnel.

When regrinding the knives, you may re-use the same screws and washers but do not re-use them

more than six times. When installing new knives, replace the screws and washers with those

furnished by the factory.

ROTORS WITH REPLACEABLE KNIFE SEATS

Check the replaceable knife seat screws for proper torque. PHOTO

Rotor with replace seats

The proper torque value for these screws is 235 ft lbs.

This should be carried out at regular set maintenance intervals.

48

Page 49

SETTINGS AND ADJUSTMENTS

TIGHTEN THE ROTOR KNIVES TO FINAL TORQUE

Use a 30 mm socket wrench to tighten the mounting

screws on each knife in small steps keeping them about

even as you increase the torque on them.

Use a torque wrench to apply the final torque of 472 ft

lbs (640 Nm) to the mounting screws. Make sure your

footing is secure before you apply the final torque.

Check with a 0.0015" (0.04 mm) feeler gage to ensure

that each knife is snug against the knife seat.

CHECK THE BED KNIVES

If the bed knives have been removed, check them as follows:

Check both halves of the upstroke knife (the bed knife on the far side of the rotor) to be sure

that the cutting edges face down.

Check both halves of the down-stroke knife (the bed knife on the near side of the rotor) to

be sure that the cutting edges face up.

SECTION 4-14

Adjusting or Replacing Rotor Knives

GAP ADJUSTMENT TIPS

It is best to keep the adjustments on the captive screws moving in the same direction. This

eliminates the effect of backlash in the adjusting screw.

Make the screw adjustments in small steps to keep the bed knife adjustment even over the

width of the machine.

To avoid cutting the shim stock, turn the rotor backward during the adjustment procedure.

Use the rotor knife with the largest dimension from rotor centerline as the reference, i.e., the

highest knife.

MEASURE THE KNIFE GAP

Use brass shim stock to set the knife gap to the cutting

clearance of 0.006 in. to 0.008 in. (0.15 mm to 0.20 mm).

Remove the rotor-locating pin.

Rotate the rotor backward, by hand, and measure the gap

between it and the bed knife at the point of shear. You

can work on each half of the bed knife independent of the

other half but keep them in step with each other by

working from side-to-side.

49

Page 50

SETTINGS AND ADJUSTMENTS

SET THE DOWNSTROKE KNIFE SHIELD

Position the knife shield so that it sets back from the bed

knife edge about 1/32 in. for film and 1/16 in. for thicker

materials. Use a plastic or leather mallet, if necessary, to

tap the shield or knife-

The upstroke knife clamp does not need this adjustment.

Carefully adjust the bed knife clearance to its final setting

and snug down the mounting screws with a 30 mm socket

wrench.

CHECK THE KNIFE GAP

Snug the screws down in stages keeping them about even

as you progressively tighten them. Recheck the knife gap

after snugging down the mounting screws.

After setting up to one rotor knife (usually the highest

knife), rotate the remaining knives slowly by the bed

knife and quickly verify the knife gap.

SECTION 4-15

Adjusting or Replacing Rotor Knives

TIGHTEN THE SCREWS TO FINAL TORQUE

When the knife gap is adjusted to the proper dimension,

tighten the mounting screws to a torque of 472 ft lbs (640

Nm). For safety, make sure that you have solid footing

when you apply this final torque.

Recheck the gap after tightening the screws to the final

torque.

Make sure that both halves of the bed knife are adjusted.

SEE SECTION 6-11 PAGE 88 FOR CUTTING CHAMBER

CLOSING INSTRUCTIONS.

50

Page 51

SETTINGS AND ADJUSTMENTS

R

Adjusting or Replacing Rotor Knives

FASTEN THE CUTTING CHAMBE

Raise the hold-down clamps to their upright positions.

Turn the knobs clockwise until they are tight against the

chamber housing.

CLOSE THE CUTTING CHAMBER SAFETY

INTERLOCK

Engage the safety interlock by turning the actuator screw

clockwise with a box wrench or a ratchet wrench.

Make sure the screw is fully seated against the top surface of

its housing.

When engaged, the interlock closes the electrical control circuit to the

motor and allows the machine to run.

SECTION 4-16

RESTART THE GRANULATOR

If necessary to replace the fuses, call an electrician to do it.

UNLOCK AND TURN ON the main power.

Remove the OUT OF SERVICE tag.

Start the granulator by depressing the start pushbutton on the electrical cabinet.

51

Page 52

SETTINGS AND ADJUSTMENTS

SECTION 4-17

Drive Belt Replacement Or Adjustment

OVERVIEW

Belt tension is important to the proper operation of the drive system of your granulator.

Improper belt tension can lead to excessive belt wear and/or undue bearing wear on the rotor and

motor bearings.

This procedure shows you how to access the drive belts and how to adjust the tension to

recommended levels. It also shows you how to replace the belts.

TURN OFF AND LOCKOUT the power per OSHA 1910.147 OR ANSI Z244.1-1982

(Lockout/Tag-out of Energy Sources).

If it is not possible to lock out the power, have an electrician remove the fuses.

Make sure the rotor has come to a complete stop.

The hydraulic cylinders or jackscrews, which open the machine, should not operate until the

rotor is completely stopped. If you discover that the

operate while the rotor is still turning, immediately shut down the machine and call for

maintenance to adjust it.

Wear gloves to protect against injury from the rotor or bed knives.

hydraulic cylinders or jackscrews DO

REMOVE THE DRIVE GUARD COVER

Use a socket wrench to remove the fasteners that retain the drive guard cover.

Remove the cover.

52

Page 53

SETTINGS AND ADJUSTMENTS

SECTION 4-18

Drive Belt Replacement Or Adjustment

INSPECT THE DRIVE BELTS

Check the belts for cracks in the V-sections that ride in the pulley grooves as well as on the outside

surface of the belts. Also look for signs of excessive wear.

If replacement is necessary, continue with the steps that follow.

If it is not necessary to replace the belts, skip ahead to the step entitled Measure the Belt Span.

REMOVE THE BELTS

Loosen the motor mount locking screws.

Loosen the belt tension on the V-belts by turning the

adjusting screws on the motor base counterclockwise-

When the tension has been released sufficiently, slip the belts