Page 1

BP800 Series Beside-the-Press Granulators

Models BP810, BP814, BP818

Effective: 8.13.2008

Write Down Your Serial Numbers Here For Future Reference:

_________________________ _________________________

_________________________ _________________________

_________________________ _________________________

We are committed to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual are subject to change without notice.

DCN No. ____________

© Copyright 2011

All rights reserved.

Page 2

ii

Shipping Info

Unpacking and Inspection

You should inspect your granulator for possible shipping damage.

Thoroughly check the equipment for any damage that might have occurred in transit, such as

broken or loose wiring and components, loose hardware and mounting screws, etc.

In the Event of Shipping Damage

According to the contract terms and conditions of the Carrier, the responsibility of the

Shipper ends at the time and place of shipment.

Notify the transportation company’s local agent if you discover damage.

Hold the damaged goods and packing material for the examining agent’s inspection. Do not

return any goods before the transportation company’s inspection and authorization.

File a claim with the transportation company. Substantiate the claim by referring to the

agent’s report. A certified copy of our invoice is available upon request. The original Bill of

Lading is attached to our original invoice. If the shipment was prepaid, write us for a

receipted transportation bill.

Advise customer service regarding your wish for assistance and to obtain an RMA (return

material authorization) number.

If the Shipment is Not Complete

Check the packing list as back-ordered items are noted on the packing list. You should have:

! Bill of lading

! Packing list

! Operating and Installation packet

! Electrical schematic and panel layout drawings

! Component instruction manuals

Re-inspect the container and packing material to see if you missed any smaller items during

unpacking.

If the Shipment is Not Correct

If the shipment is not what you ordered, contact the parts and service department

immediately at [262] 641-8600. Have the order number and item number available.

Hold the items until you receive shipping instructions.

Returns

Do not return any damaged or incorrect items until you receive shipping instructions from the

shipping department.

Page 3

iii

Table of Contents

CHAPTER 1: SAFETY 5

1-1 How to Use This Manual ............................................................................................. 5

Safety Symbols Used in this Manual ..................................................................... 5

1-2 General Safety Regulations ........................................................................................ 6

1-3 Responsibility .............................................................................................................. 6

1-4 Warnings and Precautions .......................................................................................... 7

CHAPTER 2: FUNCTIONAL DESCRIPTION ............................. 9

2-1 Models Covered in This Manual .................................................................................. 9

2-2 Typical Features and Components ............................................................................. 9

Main Components of Standard Granulators………………………………………….8

Optional Equipment………………………………………………………… ………… ..9

2-3 Safety Features ......................................................................................................... 10

CHAPTER 3: INSTALLATION .................................................. 13

3-1 Uncrating the Equipment ........................................................................................... 13

3-2 Installing the Granulator ............................................................................................ 14

3-3 Electrical Connections ............................................................................................... 14

3-4 Initial Start-up ............................................................................................................ 15

CHAPTER 4: OPERATION ....................................................... 20

4-1 Start-up ..................................................................................................................... 20

4-2 Operation Procedures ............................................................................................... 20

4-3 Shut-down ................................................................................................................. 21

CHAPTER 5: MAINTENANCE .................................................. 22

5-1 Preventative Maintenance Schedule ......................................................................... 22

5-2 Preventative and Corrective Maintenance ................................................................ 23

Monthly Maintenance Operations……………………………………………………22

Inspection and Adjustment of Knives……………………… …………… …………..24

Removing and Replacing Bed Knives………………………………… ……… …….26

Removing and Replacing Rotating Blades………………………………………….27

Specifications for Re-sharpening Bed Knives……………………… …… … … … … 28

Specifications for Re-sharpening Rotor Knives………………………… … … … ….29

CHAPTER 6: TROUBLESHOOTING ........................................ 31

6-1 Introduction ............................................................................................................... 31

General Problems……………………………………………………… ………… …..30

Electrical Problems……………………………… …… …… …… …… ……… …… …31

CHAPTER 7: APPENDIX .......................................................... 33

7-1 Returned Material Policy ........................................................................................... 32

7-2 Technical Specifications ............................................................................................ 33

7-3 Drawings and Diagrams ............................................................................................ 34

Page 4

iv

7-4 Spare Parts List ......................................................................................................... 40

7-5 Technical Assistance ................................................................................................ 41

Page 5

Chapter 1: Safety 5 of 41

Chapter 1: Safety

1-1 How to Use This Manual

Use this manual as a guide and reference for installing, operating, and maintaining your

granulator. The purpose is to assist you in applying efficient, proven techniques that enhance

equipment productivity.

This manual covers only light corrective maintenance. No other maintenance should be

undertaken without first contacting a service engineer.

The Functional Description section outlines models covered, standard features, and safety

features. Additional sections within the manual provide instructions for installation, preoperational procedures, operation, preventive maintenance, and corrective maintenance.

The Installation chapter includes required data for receiving, unpacking, inspecting, and setup

of the granulator. We can also provide the assistance of a factory-trained technician to help

train your operator(s) for a nominal charge. This section includes instructions, checks, and

adjustments that should be followed before commencing with operation of the granulator.

These instructions are intended to supplement standard shop procedures performed at shift,

daily, and weekly intervals.

The Operation chapter includes a description of electrical and mechanical controls, in

addition to information for operating the granulator safely and efficiently.

The Maintenance chapter is intended to serve as a source of detailed assembly and

disassembly instructions for those areas of the equipment requiring service. Preventive

maintenance sections are included to ensure that your granulator provides excellent, long

service.

The Troubleshooting chapter serves as a guide for identification of most common problems.

Potential problems are listed, along with possible causes and related solutions.

The Appendix contains technical specifications, drawings, schematics, parts lists, and

available options. A spare parts list with part numbers specific to your machine is provided

with your shipping paperwork package. Refer to this section for a listing of spare parts for

purchase. Have your serial number and model number ready when ordering.

Safety Symbols Used in this Manual

The following safety alert symbols are used to alert you to potential personal injury hazards.

Obey all safety messages that follow these symbols to avoid possible injury or death.

DANGER! DANGER indicates an imminently hazardous situation

that, if not avoided, will result in death or serious injury.

WARNING! WARNING indicates a potentially hazardous situation or

practice that, if not avoided, could result in death or

serious injury.

CAUTION indicates a potentially hazardous situation or practice that, if

not avoided, may result in minor or moderate injury or in property damage.

Page 6

Chapter 1: Safety 6 of 41

1-2 General Safety Regulations

This machine uses knives for the performance of its intended use. Consequently, it can be a

dangerous machine to operate and maintain unless these safety regulations are followed.

These regulations should be read, understood and periodically reviewed by all personnel

involved in any way with this machine.

Never operate or remove any machine components that are secured by wrench-type fasteners

unless the motor is electrically locked out and the rotor is motionless.

Never operate the machine or jog the rotor unless the cutting chamber covers, discharge

chute, or any guards or covers are in place and secure. Do not circumvent the safety

interlocks.

Prior to clearing a jam or performing any maintenance, the motor should be turned off and

electrically locked out. Be sure that the rotor has come to a stop. Hands must not be inserted

into the machine to clear the jam.

Do not extend any part of the body into feed roll openings or discharge area unless the motors

are electrically locked out and the rotor and feed rolls are motionless.

Never extend fingers through holes in screen.

Be sure that the v-belts are properly aligned and that tension is at its maximum.

Extreme care should be taken to see that all bolts are properly tightened at all times. During

the operation of the machine, rotor knife bolts may come loose. Although fine threads are

used on the rotor knife bolts because vibration does not easily loosen them, you should

inspect the tightness of the bolts frequently.

This machine is designed for the granulation of plastic materials. Do not feed any other

materials into the machine.

1-3 Responsibility

These machines are constructed for maximum operator safety when used under standard

operating conditions and when recommended instructions are followed in the maintenance

and operation of the machine.

All personnel engaged in the use of the machine should become familiar with its operation as

described in this manual.

Proper operation of the machine promotes safety for the operator and all workers in its

vicinity.

Becoming familiar with materials, inspection, speed limitations, screens, and guard

maintenance and total user responsibility will assist you in learning potential areas in need of

observation for danger.

Each individual must take responsibility for observing the prescribed safety rules as outlined.

All caution, warning and danger signs must be observed and obeyed. All actual or potential

danger areas must be reported to your immediate supervisor.

Page 7

Chapter 1: Safety 7 of 41

1-4 Warnings and Precautions

Our granulators are designed to provide safe and reliable operation when installed and

operated within design specifications, following national and local safety codes.

To avoid possible personal injury or equipment damage when installing, operating, or

maintaining this granulator, use good judgment and follow these safe practices:

! LEARN AND OBEY your company’s safety policy regarding granulating

equipment.

! MOVING OR LIFTING THE GRANULATOR: Although our equipment is built

and engineered for great ruggedness in operation, care must be taken when moving

the machine along the floor or lifting it. Damage may occur to sheet metal covers,

electrical cabinets, or small brackets if pressure is applied to them when moving the

granulator. When lifting the granulator, be certain of total machine weight and the

capability of the lifting equipment. (See the Granulator Specification Sheets for

machine weights and dimensions.)

! GRANULATOR LOCATION: Adequate area for routine maintenance should be

provided in order to open the machine for knife, screen, or cleanout service. Proper

service area clearances also should allow people who are working on the machine to

be clearly visible to others, thereby reducing the potential safety hazards.

! SAFE HOUSEKEEPING: The work area must be kept clean and uncluttered during

periods of operation or maintenance. No hand tools or other metal objects should be

left on or around the machine. Any tools or other metal objects that mistakenly fall

into the hopper feed opening can cause severe damage to internal cutting chamber,

rotor and screen components.

! SAFETY GLASSES OR A FACE SHIELD MUST ALWAYS BE WORN when

servicing or operating the machine. Although our machines are designed for the

maximum in flyback control, caution must be used when operating near the hopper

feed opening in order to guard against unexpected material flyback.

! EAR PROTECTION may be required when operating the machine during

granulation of very hard or noisy materials. The Occupational Safety and Health Act

of 1970 has established guidelines for Permissible Noise Exposures (OSHA 1910.95)

that should be followed.

! NEVER attempt to operate the granulator unless it is fully assembled with all guards

and interlocks in place and functional.

! OBSERVE all danger, warning, caution and safety labels on the equipment.

! Upon completion of any machine maintenance, be certain ALL SAFETY GUARDS

AND COVERS are securely and properly fastened prior to resuming machine

operation. All fasteners must be in place and properly tightened. ANY

SHORTCUTS MAY RESULT IN INJURY TO PERSONNEL OR DAMAGE

TO EQUIPMENT.

! NEVER wear any loose fitting clothes, neckties, or dangling items such as earrings,

belts, or shoestrings. Jewelry, such as wristwatches, bracelets, or rings should

NEVER be worn. Long hair must be tied back or placed in a tight fitting hairnet.

NEVER lean against or rest hands or feet on the granulator when it is in operation or

open for maintenance. NEVER stand on the granulator when it is in operation.

Page 8

Chapter 1: Safety 8 of 41

! ROTATION OF MOTORS: The correct rotating direction for the granulator motor

is clearly marked on the machine. Always check for proper rotation of motors.

Incorrect rotation direction can cause severe damage.

! ELECTRICAL GROUNDING: All electrical equipment on the granulator must be

grounded in accordance to all local codes and Article 250 of the National Electric

Code.

! ALWAYS DISCONNECT AND LOCKOUT the main electrical power to the

granulator before performing any service.

! SAFETY INTERLOCKS MUST NOT BE BYPASSED. The mechanical and

electrical safety interlocks ensure the safety of personnel. They should never be

tampered with or removed for ANY reason. They should be checked frequently by a

qualified mechanic for proper operation.

! NEVER modify the machine configuration or any individual component without

written notice from the factory.

For further information on granulator safety, installation, and operation, see the American

National Standard for Plastics Machinery!Granulators, Pelletizers, and Dicers Used for

Size Reduction of Plastics!Construction, Care, and Use. ANSI B151.11-1982.

We have long recognized the importance of safety and have designed and manufactured our

equipment with operator safety as a prime consideration. We expect you, as a user, to abide

by the foregoing recommendations in order to make operator safety a reality.

Page 9

Chapter 2: Functional Description 9 of 41

Chapter 2: Functional Description

2-1 Models Covered and General Description

The models covered in this operational manual include, from the 800 Series Beside-thePress Granulators, BP810, BP814, and BP818. This family of granulators has been

designed to granulate plastic material such as sprues, runners, and small reject parts.

The granulator is comprised of an in-feed hopper into which the material to be granulated

is fed, mounted on a cutting chamber in which a series of rotary and bed knives reduce the

material to granules, the size of which is determined by the screen holes. The granules fall

and collect in the bin below. The operation of the granulator is controlled by a control

panel and powered by an electric motor.

2-2 Typical Features and Components

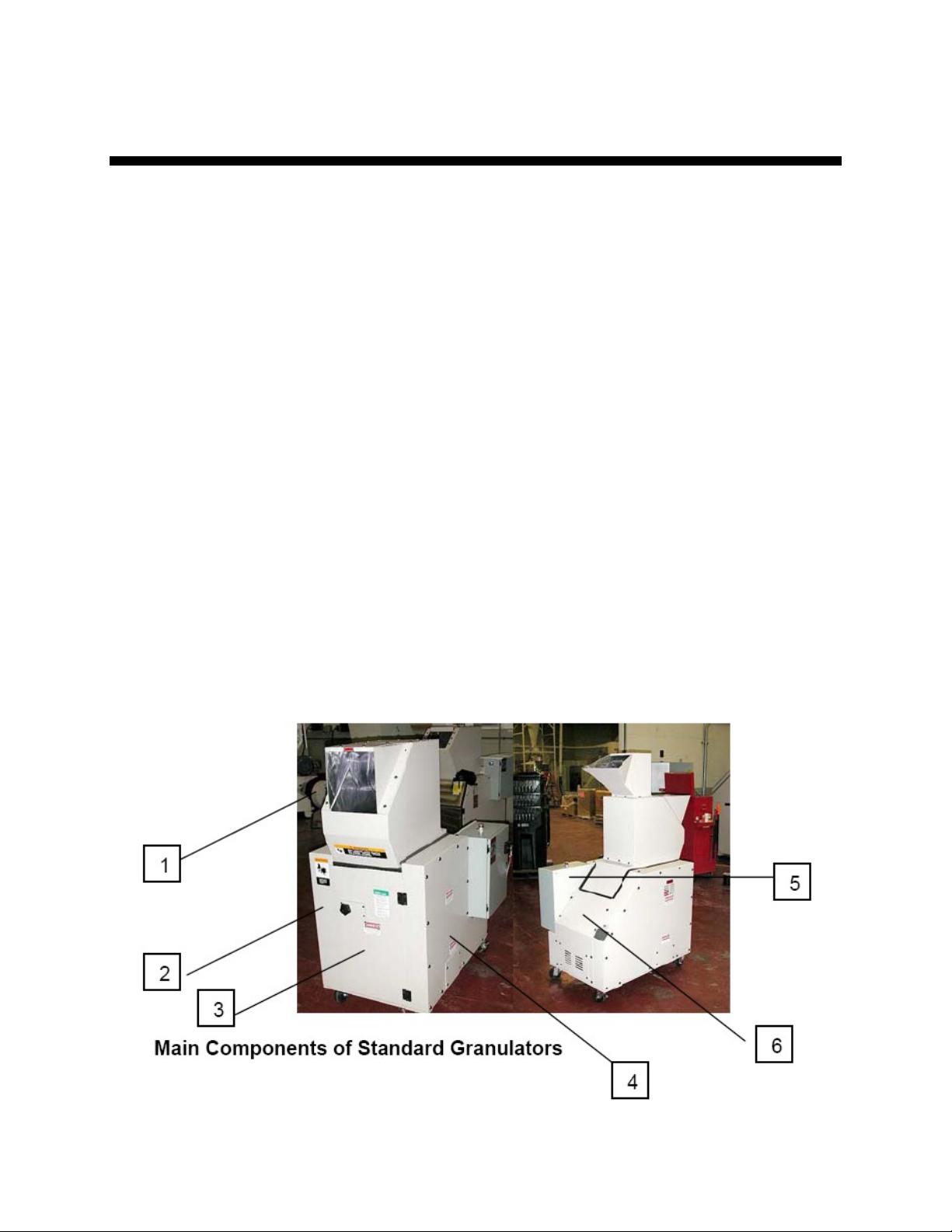

Main Components of Standard Granulators

Please refer to the following list and figure.

1. In-feed hopper

2. Cutting chamber

3. Bin for granulated material

4. Belt drive

5. Control panel

6. Electric motor

Page 10

Chapter 2: Functional Description 10 of 41

Optional Equipment

The 800 Series Beside-the-Press granulators offer the following options:

• Conveyor

• Other screen hole sizes

• Blower/airveying system

• Vacuum bin

• Special operating voltages

Technical Data

In-feed

Front or top entry

In-feed hopper

For manual feeding

Cutting chamber

Upright bolted type

Rotor

3-knife rotor w/ lateral disks

Cutting system

Scissor action with double angle

cutting

Knives

Tool steel

NOTE: Refer to Drawings and Diagrams chapter for more information.

2-3 Safety Features

The granulators are equipped with safety features intended to protect personnel and the

granulator. DO NOT remove or tamper with such equipment.

Safety Features Fitted on Granulator

All moving drive parts, including the two pulleys and the belt, are contained in a guard,

which may only be removed using specific tools and cannot be fixed in the correct

position without special fastenings.

WARNING! Always make sure that the guard is in position before

starting the granulator!

The upper part of the cutting chamber is protected by the feed hopper, used to insert

material to be granulated, while the lower part is protected by the screen and screen

support. These components are fixed by a screw knob; unscrewing releases a safety

switch key (see figure below), which cuts off the electric supply to the motor and causes

the rotor to stop.

Page 11

Chapter 2: Functional Description 11 of 41

The method of opening the granulator has been designed to restrict the operator access,

which allows the rotor and all moving knives to stop completely. Allowing operating

access more quickly could be dangerous because it is possible to make contact with the

granulator knives while they are still rotating.

Figure: Safety Switch

Opening the Granulator

The Start/Stop lighted push-button provide on the control panel (see figure below) is used

to operate the granulator. The button must be pressed to stop the granulator and pulled

out to start.

Before performing any maintenance or opening the granulator, follow the procedure

below:

2. Turn off the granulator using the provided push-button.

3. Turn the disconnect switch to OFF and lock out power. (If you cannot lock out

power, then remove the power fuses in the control panel.)

4. Tag the machine as “Out of Service”.

5. Make sure the rotor has come to a complete stop.

WARNING! Wear protective gloves when exposed to knives!

Page 12

Chapter 2: Functional Description 12 of 41

Figure: Control Panel

Start/Stop PushButton

Disconnect

switch

Page 13

Chapter 3: Installation 13 of 41

Chapter 3: Installation

3-1 Uncrating the Equipment

Prepare in advance the site you have selected for installation of the granulator. Be sure

the area the machine will occupy is clean, level, and free of obstruction. The selected site

must have a floor rating to adequately support the weight of the machine.

The granulator is mounted on a wooden skid and blocked and banded to secure it for

shipment. All non-painted items subject to corrosion are coated with a quality rust

preventative, and the machine is covered with heavy-duty polyethylene to protect it from

moisture and dirt. Granulators are normally shipped completely assembled unless the

size of the machine or an agreement for special shipping arrangements prompts partial

assembly.

If an inspection after shipment has revealed no shipping damage, unpack the unit by

removing the polyethylene protective covering and banding. Remove the envelope with

the parts list, assembly drawings, electrical schematics, and manual from the base

evacuation area.

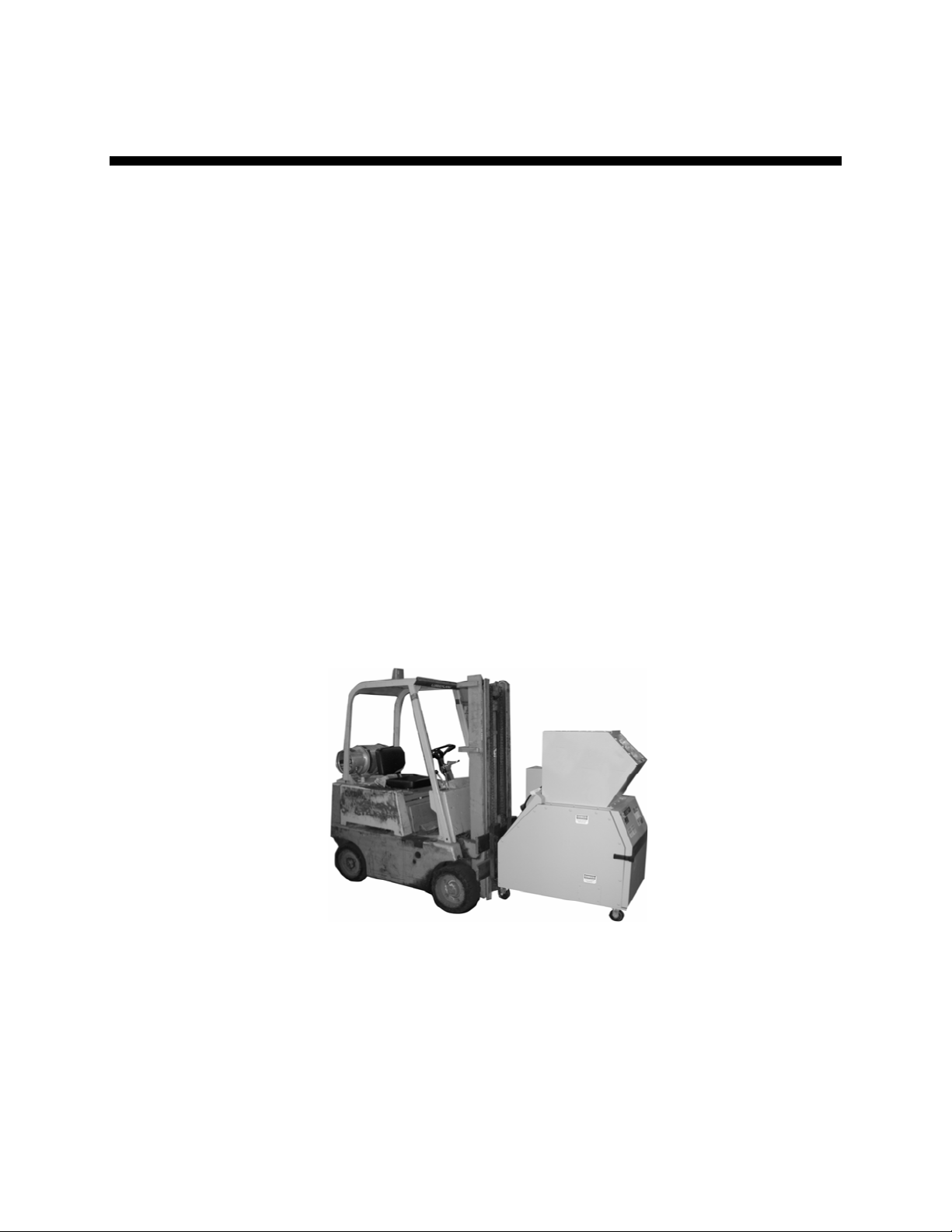

You can now have the machine lifted from the skid. A forklift is ideal for this process,

but make sure to properly position the forks between the casters and the centrally

mounted evacuation pipe from the side of the machine (see figure below).

Figure: Lifting the granulator

CAUTION! Do not attempt to lift the granulator with a shaft or protruding member—

ESPECIALLY THE HOPPER!

Page 14

Chapter 3: Installation 14 of 41

3-2 Installing the Granulator

NOTE: Before lifting or moving the granulator, check the relative weight shown on the

shipping papers.

To facilitate the lifting operation using forklift trucks, the drop box has been removed

from the granulator and is packed with any spare parts.

When using a forklift to move the granulator, make sure it is suitable for the weight and

dimensions of the granulator. When moving the machine, make sure NOT to damage

delicate parts. To lift the machine with a forklift, place the carriage forks under its base

(see below figures). When a forklift truck is not available, it is possible to use cables or

belts provided that they are strong enough to support the weight of the granulator to carry

out the lifting procedure.

NOTE: When moving the granulator, the load must remain I the horizontal position,

regardless of the type of equipment used.

Positioning the Granulator

NOTE: Make sure that the base supporting the granulator is solid and completely level

the granulator can be supported without being subject to vibration. It is recommended

that the floor be reinforced concrete with a very smooth surface.

Place the granulator in an area large enough to allow sufficient space on all sides

for the operator to carry out maintenance.

Although the granulator controls and electrical components comply with CEE

and NEMA codes and regulations, the machine must be placed in an area free of

humidity, dampness, and water. The proper environment for a granulator is a

weather-proof, covered, in-door area where water cannot collect on the floor.

Once the granulator is in position, the front panel must be opened I order to insert

the bin as shown in the figure below.

Page 15

Chapter 3: Installation 15 of 41

3-3 Electrical Connections

It is extremely important that the machine is correctly wired into the plant power source

by a licensed electrician. (See wiring diagram.)

All electrical equipment must be properly grounded in accordance with local and national

codes to protect personnel from electrical shock. A fusible, lockable disconnect between

the plant power source and the machine electrical cabinet is highly recommended.

CAUTION! Before connecting the power, check that the power cable size and capacity

corresponds to the horsepower and amp load indicated on the granulator label and that the

disconnect switch is in the OFF position.

Unless otherwise specified, the granulator has been wired for 480 volts, 60 Hz, 3 ph.

The power cable from the plant source can be run directly to the control panel or through

the base of the machine. To run the power cable through the base of the granulator,

perform the following steps:

1. Open the back cover and insert the power cable from underneath the granulator.

2. Pass the power cable through the appropriate hole and insert it into the control

panel through a connector placed at the base.

3. Connect the three-phase wires to the appropriate terminals of the main switch and

connect the ground wire to the provided terminal near the main disconnect

switch. (See figure below.)

Figure: Electrical Connections

Phase wire

terminals

Page 16

Chapter 3: Installation 16 of 41

3-4 Initial Start-up

Start-up Checks

Checking the Cutting Chamber

Before starting the granulator, open the cutting chamber to ensure that no foreign

objects have fallen in during transportation and installation. The use of heavy

gloves is recommended to avoid injury when exposed to knives in the cutting

chamber.

NOTE: This operation must be carried out by an operator/mechanical

maintenance engineer.

Check that the cutting chamber is free of foreign objects by following these

steps:

1. Turn OFF and lock out the machine power to the granulator or remove

fuses from the main control panel.

2. Open the front panel and remove the bin.

3. Unscrew the screw knob and carefully lower the screen. (See figure

below.)

4. Pivot back the feed hopper to gain free access to the cutting chamber.

5. Check that there are no foreign objects in the cutting chamber.

6. Check to make sure the bed knife and rotor knife bolts are at the proper

torque and the knife gap is set according to the specifications.

7. After completing the checks, close the hopper and screen and fasten them

with the corresponding knob.

8. Reinsert the bin and close both the rear cover and the front panel.

Page 17

Chapter 3: Installation 17 of 41

9. Remove the drive belt guard by unscrewing the ten (10) fastening

screws.

10. Manually give the rotor at least one complete turn using the rotor pulley.

11. If there are no warning noises or signs of friction, then the cutting

chamber is completely clear. Replace the belt guard, remove lock out

devices, and turn power ON.

Checking Rotation Direction

Check to make sure the direction of the rotor is correct using the following steps:

1. Turn the main disconnect switch to ON.

2. Pull the Start button until the motor comes up to speed.

3. Push the button to stop the granulator motor.

4. Using the appropriate window, check that the rotor direction corresponds

to that shown on the arrow label located above the guard.

If the rotation direction is correct, the granulator is ready for use. If the rotation

direction is incorrect, reverse the rotor directing using the following steps:

WARNING! A LICENSED ELECTRICIAN must carry out this

operation!

1. Disconnect and lock out the power to the machine at the incoming power

source. If the disconnect is not lockable, remove the fuses.

2. Reverse any two of the three power line conductors to the machine. If

there is more than one motor on the machine and only one is turning in

the wrong direction, reverse any two of the three line conductors at the

overload relay for that motor.

3. Unlock the power and switch the electrical disconnect switch to ON.

(Replace the fuses if necessary.)

4. Re-check the rotation direction of the motors.

Page 18

Chapter 3: Installation 18 of 41

Test the Interlock Switch

With the cutting chamber and screen cradle closed and power ON, perform the

following tests:

1. Push the Start button to start the granulator.

2. With the granulator running, loosen the hand knob on the front access

door to verify the safety interlock switch shuts the machine off. If the

hand knob is completely loose and the power does not disconnect, the

interlock switch is not working and the cause of malfunction must be

determined.

3. Turn OFF and lock out the power.

4. Have an electrician check the interlock switch on the hopper to correct

the malfunction.

5. If necessary, engage the screen cradle interlock actuator screw.

After completing the above procedures, close the control panel. Unlock the

power or return the fuses in the supply panel, turning the disconnect switch to

ON. Pull the start button and release only when the motor has started, and check

again that the rotor is turning in the correct direction.

Checking Knife Position

NOTE: This operation must be carried out by an operator or mechanical

maintenance engineer.

Before undertaking any type of work o the machine, use a feeler gauge to check

the distance between the bed knives and the rotor knives (the knife gap).

To access the cutting chamber, follow the same procedure and observe the

precautionary steps outlined in “Checking the Cutting Chamber.” Before

proceeding to the checks, it is recommended to block the rotor to avoid any

inadvertent rotation.

Once you have safety accessed the cutting chamber, check the current distance

between the bed knives and the rotor knives using a feeler gauge (see figure

below).

Figure: Checking

the knife gap

Page 19

Chapter 3: Installation 19 of 41

NOTE: The distance set by the manufacturer for normal application is 0.006"

to 0.008" (0.15 mm to 0.20 mm). If the gap between the bed knives and the

rotor knives is greater than this range, an adjustment must be made. (See

“Inspection and Adjustment of Knives”.)

Once you have checked the knife gap, close the hopper and secure it with the

appropriate swing bolt. Reinsert the bin and close the front panel.

Page 20

Chapter 4: Operation 20 of 41

Chapter 4: Operation

4-1 Start-up

Pre-operational Checklist

To ensure the granulator is ready for operation, perform the outlined tasks in the

following pre-operational checklist. All electrical and mechanical machine elements

MUST be inspected and any defects MUST first be corrected.

" Make sure the operational manual has been read and followed.

" Make sure that all necessary personnel (granulator operators, cleanout,

maintenance, service personnel) have been fully trained on machine operation

and all machine safety mechanisms.

" Make sure all necessary personnel have read and understand the operational

manual.

" Make sure sufficient location clearances have been allowed.

" Make sure the equipment is grounded in accordance with local codes and/or

Article 250 of the National Electric Code.

" Make sure all motors have been checked for proper rotation.

" Make sure all machine controls, push-buttons, and limit switch interlocks have

been checked for proper function.

" Make sure the cutting chamber has been checked for foreign matter.

" Make sure the drive components have been checked for alignment and tension.

" Make sure the machine is properly closed with all visible fasteners tight.

" Make sure all accessory components are electrically and mechanically connected

with proper support and fasteners tightened.

" Make sure electrical enclosure boxes are tightly closed and clamped shut.

" Make sure all personnel are clear of the machine.

4-2 Operation Procedures

The granulator can be operated in a vertical top-feed position or in a horizontal front-feed

position.

Before starting the granulator, always check for and remove tools or any other objects

placed on the granulator. Turn the Power disconnect switch to ON, pull the Start button,

and release it when the motor has started.

It is normal for the motor not to start immediately, as the electronic system must check all

the micro switches before enabling start-up procedures. Wait for the electric motor to

reach normal rotating speed before feeding the granulator.

Page 21

Chapter 4: Operation 21 of 41

WARNING! Never push material into the hopper with hands!

If the hopper becomes blocked, the granulator must be turned OFF, and the power must

be locked out or the fuses removed.

4-3 Shut-down

Before stopping the granulator for the end of a working shift or for any other reason, stop

feeding the material and leave the granulator running for several minutes to allow the

cutting chamber to completely granulate and empty the material inside. Press the lighted

Start/Stop button to immediately turn off the granulator.

NOTE: If the granulator stalls frequently during use, it may be necessary to adjust the

calibration of the “overload.” (Refer to the values shown in the electrical diagram.)

Page 22

Chapter 5: Maintenance 22 of 41

Chapter 5: Maintenance

5-1 Preventative Maintenance Schedule

Before carrying out any work on the granulator, carefully read the instructions provided in

this manual.

NOTE: Only specialist and competent personnel should carry out these operations.

All maintenance work must be carried out with the granulator switched OFF and with the

power supply disconnected and locked out.

Conduct that is not in accordance with safety instructions outlined in this manual may pose a

threat to both personnel and equipment.

Once the maintenance work in completed and before re-starting the granulator, make sure to

check the following:

" Any parts that may have been replaced and/or tools that have been used are removed

from the granulator.

" All safety equipment is in proper working condition.

Periodic Maintenance Schedule

Mechanical Check

Frequency

Knife clearance and wear

Weekly

Rotor knife retaining screws for tightness

Weekly

Downstroke bed knife and shield retaining screws for

tightness

Weekly

Upstroke bed knife retaining screws for tightness

Weekly

Screen cradle arm screws for tightness

Weekly

In-feed chute and cutting chamber screws for tightness

Monthy

NOTE: After the granulator has been used for the first day, adjust the drive belt

tension. Correct tension for use should be the minimum at which the belt does not slip.

Make sure the pulleys are correctly aligned.

Page 23

Chapter 5: Maintenance 23 of 41

5-2 Preventative and Corrective Maintenance

Monthly Maintenance Operations

Drive Belt Tension

NOTE: This operation should be carried out by an operator or mechanical

maintenance engineer.

For the granulator to function correctly, it is extremely important that the

drive belt is always tight. Correct tension reduces the load of the rotor

bearings and minimizes wear and stretching of the belt. To check and adjust

belt tension, use the following procedure:

1. Turn OFF the machine and lock out power by using the disconnect

switch, or remove the fuses from the electrical control panel.

2. Remove the belt guard by unscrewing the ten (10) screws that hold it

in place.

3. Open the front panel.

4. Remove the bin.

5. Open the rear panel.

6. Loosen the nuts that lock the motor base slide.

7. Loosen the tie rod.

8. Adjust the belt tension by turning the tie rods forward.

9. Turn the tie rod to bring the motor square to the belt axis.

10. After the adjustment is made, lock the nuts back in place and close

the rear panel, refitting the proper locking latch.

11. Reinsert the bin and close the front panel.

12. Refit the belt guard and unlock the power or replace the fuses in the

control panel.

Proper Belt Tension

Measure the belt span and divide by 64 to get the allowable belt deflection.

With a belt gauge, measure the force it takes to deflect the belt the amount

calculated.

NOTE: Check your belt gauge’s instructions for proper scale settings. Belt

tension gauges are available from the customer service department.

Compare the gauge reading the chart value for the belt cross-section used

(see table below.).

Page 24

Chapter 5: Maintenance 24 of 41

Belt Cross-Section

Small O.D. Range

Deflection Force, lbs/V-belt **

Run-in

Normal running

3VX

3.65 – 4.12,

4.50 – 5.60

6.4

7.5

5.7 – 4.4,

6.6 – 5.1

** The Deflection Force Value shown is for each belt and must be multiplied by the number

of V-belt elements if all are deflected.

Belt Replacement

NOTE: It is very important to replace all belts at the same time!

If the drive belts have to be replaced, follow the procedure from “Drive Belt

Tension” through Step 6. When the point is reached, release the belt from

tension by fully unscrewing the tie rods. Slip off the belts and replace them

with new ones. Continue with the procedure for adjusting the belt tension.

Removal and Replacement of the Screen

NOTE: A qualified operator/maintenance mechanic should carry out this procedure!

1. Switch the machine OFF and lock out power by turning the disconnect

switch or remove the fuses from the main control panel.

2. Open the front panel.

3. Remove the bin.

4. Remove the screw knob that holds the hopper on top of the cutting

chamber. Carefully lower the screen cradle assembly, resting it on the

base.

Deflection = Beltspan

______

64

Beltspan

Belt Deflection Gauge

Page 25

Chapter 5: Maintenance 25 of 41

5. Remove the screen, keeping it in a horizontal position (see figure below).

6. Replace the screen with a new one; tighten the screw knob, reposition the

bin and close the front panel. Unlock the power and turn the machine

ON.

Inspection and Adjustment of Knives

NOTE: This operation must be performed by a qualified operator or mechanical

maintenance technician.

NOTE: Before carrying out any maintenance on the cutting chamber, the operator must

put on work gloves thick enough to avoid injury to the hands while touching sharp parts

and the cutting edges of blades.

To inspect the blades, remove the screen following the procedure in “Removal and

Replacement of Screen.” Then proceed as follows:

1. Open the rear-closing panel by releasing the locking latch.

2. Pivot the in-feed hopper completely back to gain clear access to the cutting

chamber.

3. Clear any process material or foreign objects between the knives.

4. Turn the rotor slowly until the first row of rotor knives are in close proximity to

the bed knife cutting edge. Turn the rotor backwards, keep hands and fingers

from directly contacting sharp knife edges.

5. Using a feeler gauge, measure the gap between the rotor and knife cutting edges.

Check each rotor knife to find the “high knife”, or the knife that measures the

smallest gap. If the gap is substantially greater than the specified 0.006 in. to

0.008 in. (0.15 mm to 0.2 mm), the knives need readjustment.

6. Loosen the bed knife shield; hold down the screws and remove the shield.

Figure:

Removing the

screen

Page 26

Chapter 5: Maintenance 26 of 41

7. Leave the screws that hold the bed knife just tight enough to allow the bed knife

to move.

8. Loosen the adjustment screws and lock nuts.

9. Insert a 0.006 in. to 0.008 in. (0.15 mm to 0.2 mm) thickness gauge between the

cutting edge of the bed knife and that of the high rotor knife.

10. Adjust the bed knife into the rotor knife using the adjustment screws. Make sure

to leave enough space for the thickness gauge to move.

NOTE: Check that the distance between the fixed and rotating knife is the same at

both ends of each knife. Move the bed knife using the push adjusting screws a

little at a time on each end.

11. When adjustment is complete, tighten the lock nuts on the adjustment screws.

12. Torque the bed knife and bed knife shield bolts to 95 lbs/ft. (13 kg/m, 128 Nm)

using a torque wrench.

13. Repeat the steps 4-11 to adjust the rear (or downstroke) bed knife. Turn the rotor

slowly for one complete revolution, checking the exact distance between all the

rotary knives and bed knives.

14. Close the hopper and replace the screen and screen cradle, securing them in place

using the swing bolt provided.

15. Close the front and rear doors and unlock the power or replace the fuses in the

control panel. Turn the disconnect switch to ON.

Rotor knife locking bolts

Bed knife locking bolts

Bed knife adjusting

screws

Figure: Inspection of Knives

Page 27

Chapter 5: Maintenance 27 of 41

Removing and Replacing Bed Knives

NOTE: This procedure should be performed only be a qualified operator or maintenance

engineer. Protective gloves must be worn to avoid injury when handling the cutting knives!

To remove and replace bed knives, use the following procedure.

1. Open the granulator by following the steps “Removal and Replacement of the

Screen.”

2. Open the rear-closing panel by releasing the locking latch.

3. Pivot the in-feed hopper completely back to gain clear access to the cutting

chamber; clear any process material or foreign objects from between the knives.

4. Rotate the rotor so that the rotor knives will not interfere with the removal of the

bed knife. Using a wooden block, block the rotor to prevent it from rotating

while removing the knives.

5. Loosen the lock nuts and back off the adjustment screws.

6. Loosen and remove the bed knife shield bolts and remove the shield, positioned

above the knife. The remaining bed knife bolts and bed knife may now be

removed.

7. Perform the above steps to remove the rear (upstroke) bed knife as well.

NOTE: Before replacing the bed knife with new or sharpened knives, whip the

knife seats on the knife block, being sure to clean off all process material. The

tapped holes in the knife block (used for holding the knives in place) should be

clear of any dirt, oil, or process material.

8. Install new or sharpened bed knives on each knife seat, making sure that the rotor

is blocked to prevent it from rotating while installing each knife. Be sure to place

the bed knives in the correct positions:

a. The rear (upstroke) bed knife must be placed with the extended cutting

edge on the bottom.

b. The front (downstroke) bed knife should be placed with the cutting edge

on the top.

9. Before re-installing the knife bolts, whip them clean with a light oil-damp cloth.

Do not leave an oil film on the bolt since lubrication can adversely affect the

stress on the bolt when torqued to the specified values.

Page 28

Chapter 5: Maintenance 28 of 41

NOTE: It is recommended that the knife bolts be replaced with each new set of

knives. This will reduce the risk of bolt failure due to overstretching. Always use

the specified replacement bolts.

10. Tighten the bolts that hold just the bed knife enough to keep the knife in place at

the same time allowing the adjusting screws to move the knife forward.

11. Adjust the knife gaps with the rotor knives following steps 8-12 in “Inspection

and Adjustment of Knives.”

12. Replace the shields in position above the bed knives. The shield on the front

(downstroke) bed knife should be positioned so that the inside edge is set back

approximately 1/32" from the cutting edge below it. Replace the remaining bolts

and torque.

13. Close the machine while following steps 12-14 in “Inspection and Adjustment of

Knives.”

Removal and Replacement of Rotating Blades

NOTE: Only a qualified operator or maintenance engineer should perform this operation.

Protective gloves MUST be worn to avoid injury when handling the cutting knives.

To remove and replace rotor knives, complete the following procedure:

1. Open the granulator following the steps in “Removal and Replacement of the

Screen.”

2. Open the rear-closing panel by releasing the locking latch.

3. Pivot the in-feed hopper completely back to gain clear access to the cutting

chamber; clear any process material or foreign objects from between the knives.

4. Rotate the rotor so that the knife bolts are in a convenient position to remove the

bolts with the appropriate wrench. Using a wooden block, block the rotor to

prevent it from rotating while removing knives or after a knife as been removed.

5. Loosen and remove the knife bolts and lift the knife off the knife seat removing it

from the cutting chamber.

6. Perform the above steps until all the rotor knives are removed.

NOTE: Before replacing the rotor knife with new or sharpened knives, wipe the

knife seats on the rotor making sure to clean off all process material. The tapped

holes in the rotor (used for holding the knives in place) should be clear of any dirt,

oil, or process material.

7. Loosen the bed knife bolts and adjusting screws and pull back the bed knife so

the rotor knives will collide as they are installed and rotated.

Page 29

Chapter 5: Maintenance 29 of 41

8. Install knew or sharpened knives on each knife seat, making sure that the rotor is

still blocked to prevent it from rotating while installing the knives.

9. Before re-installing the knife bolts, wipe them clean with a light, oil-damped

cloth. Do not leave an oil film on the bolt since lubrication can adversely affect

the stress on the bolt when torqued to the specified values.

NOTE: It is recommended that the knife bolts be replaced with each new set of

knives. This will reduce the risk of bolt failure due to overstretching. Always use

the specified replacement bolts.

10. Tighten each set of the knife bolts, making sure that the knife is seated against

the back heel in the rotor seat. Before setting the torque of the bolts, check that a

0.001" feeler gauge cannot fit between the heel and the back of the knife.

11. Torque the rotor knife bolts to 100 lbs/ft. (14 kg/m, 135 Nm).

12. Adjust the knife gap with the bed knives and close the machine, following steps

8-12 in “Inspection and Adjustment of Knives.”

Specifications for Re-sharpening Bed Knives

Every bed knife has two cutting edges, one on each side. When a blade becomes worn,

the knives can be rotated. To regrind these knives, refer to Bed Knife Specifications.

Replacement of these knives is necessary when their length fails below the recommended

tolerance.

Model

X

Y

BP810

2.43 in.

61.8 mm

2.75 in.

69.9 mm

BP814

BP818

Grind these surfaces only

20°

Minimum length, X

New knife length, Y

.158", (4 mm)

Page 30

Chapter 5: Maintenance 30 of 41

Specifications for Re-sharpening Rotor Knives

All the rotor knives must be re-sharpened in sets. Each knife within a set must have a

tolerance within 0.003" (0.05 mm) for the total height, heel to cutting edge. Greater

variations within a set will result in improper knife gap settings and other operational

problems. (See “Rotor Knife Specifications.”)

Knives below the minimum dimension specified must not be used! Using knives below

the specified minimum can cause interference resulting in serious damage to the rotor and

cutting chamber.

When using a surface grinder to re-sharpen the rotor or bed knives, it is not harmful to

allow a few small nicks to remain on the cutting edge. Grinding the knife so that the

cutting edge is free from all nicks can be wasteful.

Figure: Rotor Knife Specifications

.382” ± .003

(9.5 mm ± .05)

30°

20°

Minimum Length 2.305” (58.5 mm)

New Knife Length 2.480” (63 mm)

Page 31

Chapter 6: Troubleshooting 31 of 41

Chapter 6: Troubleshooting

6-1 Introduction

The utmost in safety precautions should be observed at all times when working on or around

the machine and the electrical components. All normal trouble-shooting must be

accomplished with the power off, line fuses removed, and with the machine tagged as out of

service.

The use of good quality test equipment cannot be over-emphasized when troubleshooting is

indicated. Use a good ammeter that can measure at least twice the AC and DC current that

can be encountered for the machine. Be sure that the voltmeter has at least minimum

impedance of 5,000 OHMS-per-volt on AC and 20,000 OHMS-per-volt on DC scales.

Popular combination meters, VOM and VTVM can be selected to provide the necessary

functions.

Before making haphazard substitutions and repairs when defective electrical components are

malfunctioning, we recommend that you check the associated circuitry and assemblies for

other defective devices. It is common to replace the obviously damaged component without

actually locating the real cause of the trouble. Such hasty substitutions will only destroy the

new component. Refer to wiring diagrams and schematics.

Locating mechanical problems, should they occur, is relatively straightforward. When

necessary, refer to the parts catalog section.

General Problems

Problem

Possible Cause

Possible Remedy

Overheating of bearings

Dirt or contamination in the

bearing

Correct source of contamination

Excessive belt tension

Adjust belt tension

No lubrication

Check bearing seals

Knives moving in their seats

May be foreign matter on the

knives

Carefully clean seat

Knife screws loose

Tighten screws with torque

wrench at values specified

Knife screws weakened

Screws must not be used more

than 6 times

Broken Knife

Improper re-sharpening

Check knife grinding method

used

Extremely hard material

Contact supplier

Incorrect rotor direction

Check rotor direction

Foreign body in the cutting

chamber

Look for cause with operator

Faulty fitting of screen

Check assembly procedure

Excessive knife wear

Incorrect knife position

Correct the gap or distance

between bed knives and rotor

knives

Page 32

Chapter 6: Troubleshooting 32 of 41

Improper knife re-sharpening

Check dimensions with figures

included in this manual.

Abrasive material

Contact the supplier for special

knives

Abnormal screen wear

Incorrect fitting of screen

Check that the screen is

correctly seated in its rear

position and that it fits perfectly

at the front

Abrasive material

Contact the supplier for special

knives

Rotor jamming

Excessive in-feed material

Reduce amount of material

being fed to the machine

Total or partial obstruction of the

screen holes

Remove the screen and clear

the holes

Insufficient belt tension

Check and/or adjust belt tension

Knives worn

Replace with new knives

Distance between the knives too

small or large

Check distance between knives

Screen holes too small

Increase screen hole diameter

Failure of air conveying system

or discharge system

Check fan rotation and make

sure pipes are not obstructed

Electrical Problems

Problem

Possible Cause

Possible Remedy

Machine stops for no apparent

reason

Safety switch has stopped

power

Check that the knobs that

operate the safety switch are

tightened

Electric motor does not start

No power

Check fuses

Overload failure

Check amperage of electric

motor

Safety switch not working

Check and replace

Cutting chamber too full

Empty cutting chamber

Motor starts but does not speed

up or take a load

Excessive drive belt tension

Check belt tension and adjust

Motor connected to power

source incorrectly

Reconnect correctly

Defective starter winding

Check current in each phase. If

substantial difference between

phases, contact motor

manufacturer

Motor starts, but does not gain

speed

Bearing excessively worn

Replace bearings

Cutting chamber full

Empty cutting chamber

Page 33

Chapter 7: Appendix 33 of 41

Chapter 7: Appendix

7-1 Returned Material Policy

Credit Returns

Prior to the return of any material, authorization must be given by the manufacturer. A

RMS number will be assigned for the equipment to be returned.

Reason for requesting the return must given.

All returned material purchased from the manufacturer is subject to 15% ($75.00

minimum) restocking charge.

All returns are to be shipped prepaid.

The invoice number and ate or purchase order number and date must be supplied.

No credit will be issued for material that is not within the manufacturer’s warranty period

and/or in new and unused condition, suitable for resale.

Warranty Returns

Prior to the return of any material, authorization must be given by the manufacturer. A

RMS number will be assigned for the equipment to be returned.

Reason for requesting the return must given.

All returns are to be shipped prepaid.

The invoice number and ate or purchase order number and date must be supplied.

After inspecting the material, a replacement or credit will be given, at the

manufacturer’s discretion, if the item is found to be defective in materials or

workmanship. Purchased components are covered under their specific warranty terms.

Page 34

Chapter 7: Appendix 34 of 41

7-2 Technical Specifications

Overall Dimensions (CA039016)

Page 35

Chapter 7: Appendix 35 of 41

7-3 Drawings and Diagrams

Cutting Chamber—Vertical Cross Section (CA039060S2)

Page 36

Chapter 7: Appendix 36 of 41

Cutting Chamber—Longitudinal Cross Section (CA039060S1)

Page 37

Chapter 7: Appendix 37 of 41

Cutting Chamber—Front View (CA039060S3)

Page 38

Chapter 7: Appendix 38 of 41

Cutting Chamber—Rear View (CA039060S4)

Page 39

Chapter 7: Appendix 39 of 41

Typical Wiring Diagram

Page 40

Chapter 7: Appendix 40 of 41

7-4 Spare Parts List

Recommended Spare Parts

Item

BP810

Quantity

BP814

Quantity

BP818

Quantity

Material

Rotor Knife

3 3 3

HCHC

Rotor Knife Screw

9

12

15

GR 10.9 M12 x 40MM

Bed Knife

2 2 2

HCHC

Bed Knife Screw

8

10

10

GR 10.9 M12 x 60MM

Bed Knife Washer

8

10

10

Hardened

Screen 1 1

1

Specify Hole Size Required

Rotor Bearing

2 2 2

65MM Bore

Drive Belt

2 2 2

Qty. Depends on HP

Bed Knife Adj. Screw

4 4 4

GR

Interlock Switch

1 1 1

*When ordering a screen, always specify the diameter of the holes required.

Page 41

Chapter 7: Appendix 41 of 41

7-5 Technical Assistance

Parts Department

Call toll-free 7am–5pm CST [800] 423-3183 or call [847] 273-7700, Fax [847] 273-7812

The ACS Customer Service Group will provide your company with genuine OEM quality parts

manufactured to engineering design specifications, which will maximize your equipment’s

performance and efficiency. To assist in expediting your phone or fax order, please have the

model and serial number of your unit when you contact us. A customer replacement parts list

is included in this manual for your convenience. ACS welcomes inquiries on all your parts

needs and is dedicated to providing excellent customer service.

Service Department

Call toll-free 8am–5pm CST [800] 423-3183 or call [847] 273-7700

Emergencies after 5pm CST, call [847] 439-5655

We have a qualified service department ready to help. Service contracts are available for most

of our products.

Sales Department

Call [847] 273-7700 Monday–Friday, 8am–5pm CST

Our products are sold by a worldwide network of independent sales representatives. Contact

our Sales Department for the name of the sales representative nearest you.

Contracting Department

Call [847] 273-7700 Monday–Friday, 8am–5pm CST

Let us install your system. The Contracting Department offers any or all of these services:

project planning; system packages including drawings; equipment, labor, and construction

materials; and union or non-union installations.

Sterling, Inc.

2900 S. 160th Street

New Berlin, WI 53151

www.sterlco.com

Loading...

Loading...