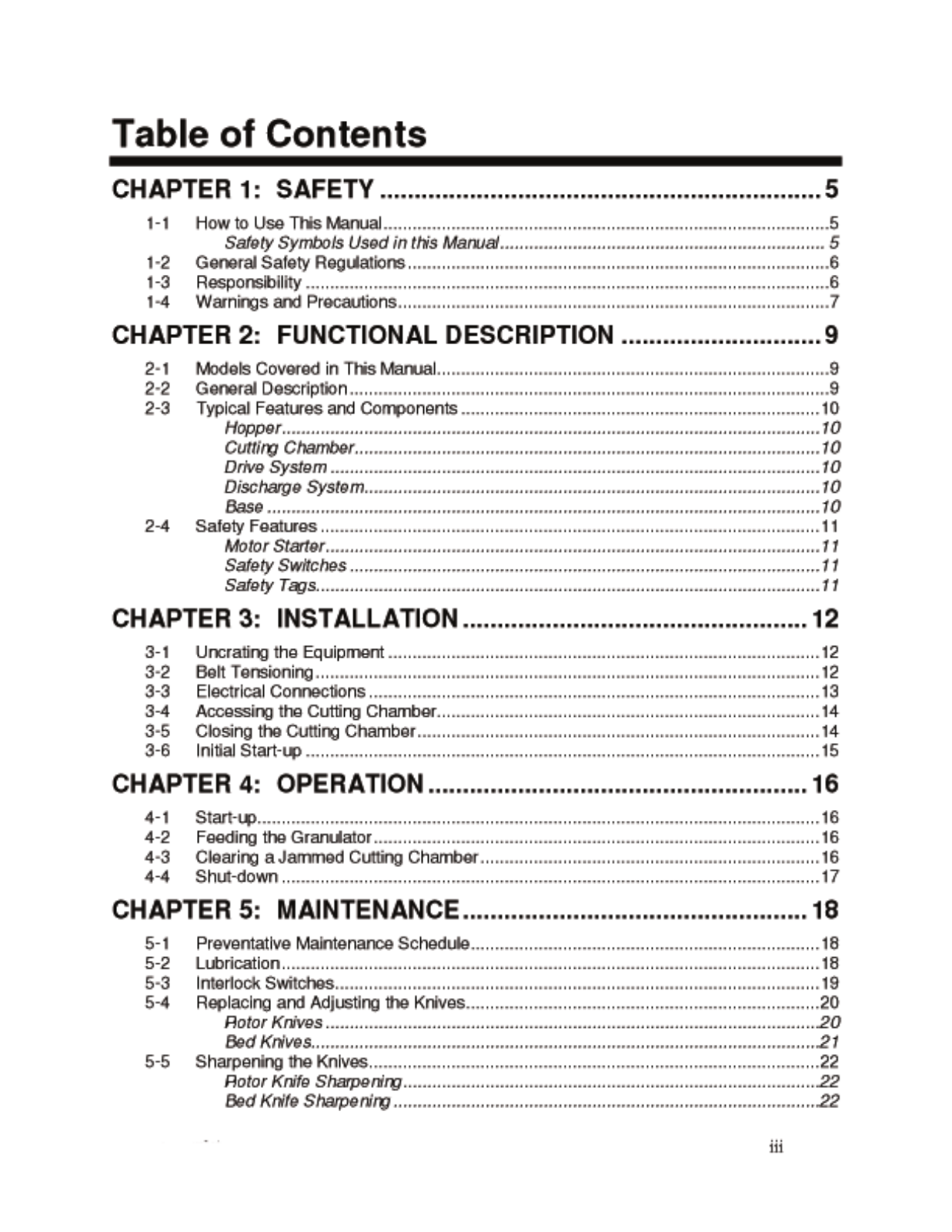

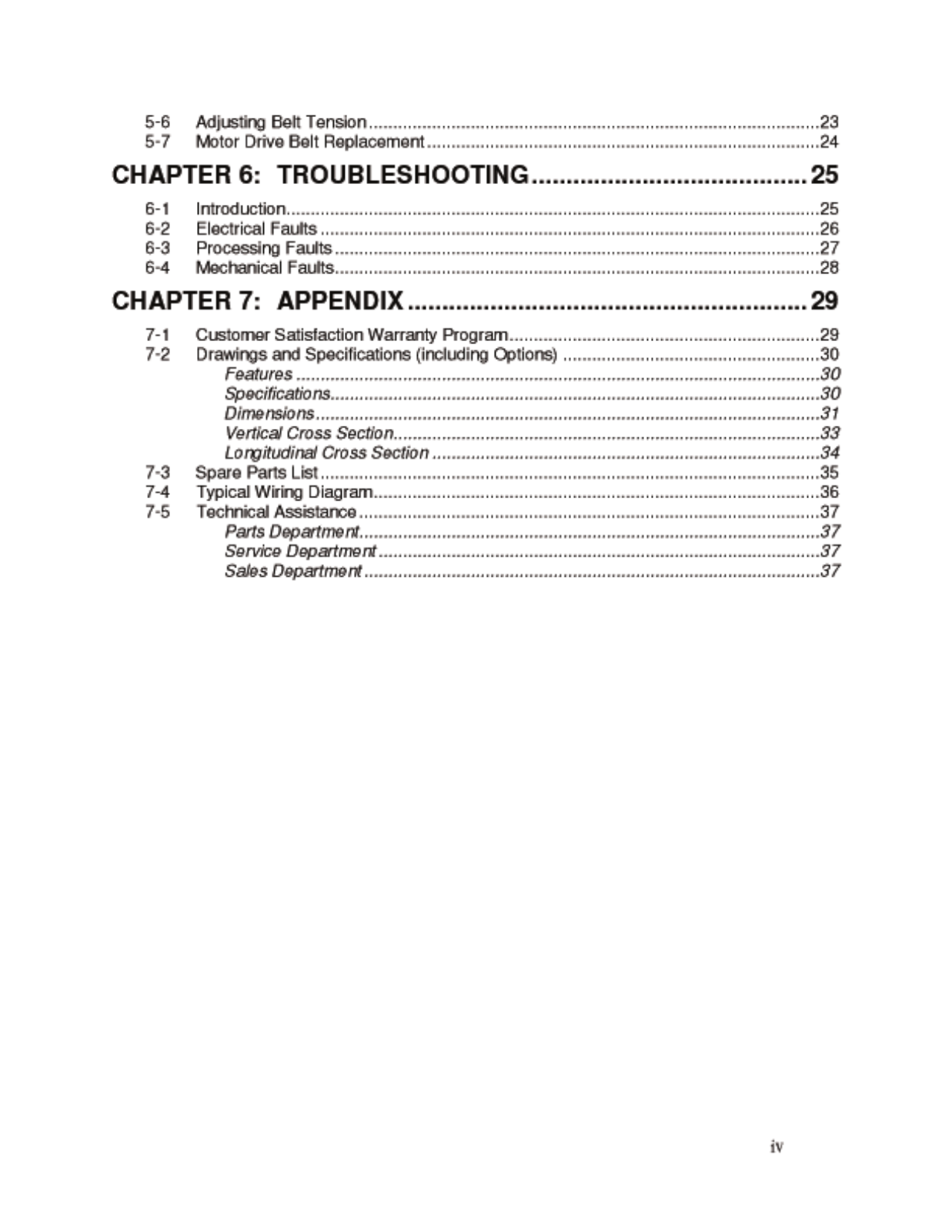

Specifications and Main Features

- Distinguishing no: D-391210

- Size of throat: 14x26 or 356 x 660 mm.

- Diameter of cutting circle: 419 mm or 16.57 inches.

- Throughput: 544 kg or 1200ong per hour.

- Approximately weight under estimation: 2609kg or 5750 lbs.

- Options for Feed: Tray Feed, Conveyor feed, Side feed, Box hopper.

- Cutting Chamber: 7 bed knives, Twinshear system are equipped with this type.

- Rotor: 3 knife Twinshear rotors.

- Rotor Knives: HCHC 55 degrees steep angle HCHC keen edge.

- Bed knives: 4 edge HCHC.

- Screen: For screen, a 3/8 inch diameter swing is also available in 3/16 inch diameter or 3 inches size, which are treated with heat and have perforated stainless steel.

- Base: Type bin constructed of tube mounted hold construction with the use of forklift pick up,

- Discharge: Airveyor chutes are available with chute discharge.

- Motor: 100hp at 1600rpms while a suggestion of 50-75HP optional sizes are also available.

- Drive System: Sufficient V belt driven adjustable motor bases are available with the use of belt tension.

- Electrical Components: NEMA 12 coupled with safety measures combines the use of interlocks into one unit.

- Noise level: 85 DBA is the average value measured for most applications.

- Magnetic motor starter or failure switches on access covers unit serve as safety features.

Frequently Asked Questions

Q1: What is the maximum throughput of the BP1426 Twin-Shear Granulator?

A1: A maximum of 544kg of BP 1426 twin shear up to 1200 lbs/hr will be available at my disposal.

Q2: Which materials can be used with this granulator?

A2: With this model, only granulation of plastics is possible.

Q3: What safety features are included with the granulator?

A3: The safeties added on include a magnetic motor starter and safety switches on all access covers. This also meets NEMA 12 standards.

Q4: How much does the BP1426 weigh?

A4: The BP1426 weighs approximately 5,750 lbs. or 2609 kgs.

Q5: What is the motor for the granulator?

A5: A 100HP TEFC motor can be used with the granulator unit or a custom fitted motor with up to 75 HP may also be used.

Q6: How is the maintenance of the rotor knives conducted?

A6: In relation to wear and clearance, rotator knives are recommended to be checked every week, replaced or re-ground when necessary.

Q7: Are there any available modifications to the discharge system?

A7: Of course, depending on processing requirements different Airveyor chute options can be fitted to the discharge system.

User Manual

Loading...

Loading...