Page 1

SCC 7-Pump 50D & D Plus-Station Controllers

Part Number: 882.00254.00

Bulletin Number: CV3-645

Effective: 2/15/06

Write Down Your Serial Numbers Here For Future Reference:

_________________________ _________________________

_________________________ _________________________

_________________________ _________________________

We are committed to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual are subject to change without notice.

DCN No. ____________

© Copyright 2006

All rights reserved.

Page 2

Please note that our address and phone information has changed.

Please reference this page for updated contact information.

These manuals are obsolete and are provided only for their technical information, data and capacities.

Portions of these manuals detailing procedures or precautions in the operation, inspection, maintenance

and repair of the products may be inadequate, inaccurate, and/or incomplete and shouldn’t be relied

upon. Please contact the ACS Group for more current information about these manuals and their

warnings and precautions.

Parts and Service Department

The ACS Customer Service Group will provide your company with genuine OEM quality parts manufactured to engineering

design specifications, which will maximize your equipment’s performance and efficiency. To assist in expediting your phone

or fax order, please have the model and serial number of your unit when you contact us. A customer replacement parts list

is included in this manual for your convenience. ACS welcomes inquiries on all your parts needs and is dedicated to

providing excellent customer service.

For immediate assistance, please contact:

• North, Central and South America, 8am – 5pm CST +1 (800) 483-3919 for drying, conveying, heating and cooling

and automation. For size reduction: +1 (800) 229-2919.

North America, emergencies after 5pm CST (847) 439-5855

North America email: acsuscanadacustserv@corpemail.com

• Mexico, Central & South America

Email: acslatinamericacustserv@corpemail.com

• Europe, Middle East & Africa +48 22 390 9720

Email: acseuropecustserv@corpemail.com

• India +91 21 35329112

Email: acsindiacustserv@corpemail.com

• Asia/Australia +86 512 8717 1919

Email: acsasiacustserv@corpemail.com

Sales and Contracting Department

Our products are sold by a worldwide network of independent sales representatives. Contact our Sales Department for the

name of the sales representative nearest you.

Let us install your system. The Contract Department offers any or all of these services: project planning; system packages

including drawings; equipment, labor, and construction materials; and union or non-union installations.

For assistance with your sales or system contracting needs please Call:

North, Central and South America +1 (262) 641-8600 or +1 (847) 273-7700 Monday–Friday, 8am–5pm CST

Europe/Middle East/Africa +48 22 390 9720

India +91 21 35329112

Asia/Australia +86 512 8717 1919

Facilities:

ACS offers facilities around the world to service you no matter where you are located. For more information, please visit us at

www.acscorporate.com

United States:

ACS Schaumburg – Corporate Offices

1100 E. Woodfield Road

Suite 588

Schaumburg, IL 60173

Phone: + 1 847 273 7700

Fax: + 1 847 273 7804

ACS New Berlin – Manufacturing Facility

2900 S. 160th Street

New Berlin, WI 53151

Phone : +1 262 641 8600

Fax: + 1 262 641 8653

Asia/Australia:

ACS Suzhou

109 Xingpu Road SIP

Suzhou, China 215126

Phone: + 86 8717 1919

Fax: +86 512 8717 1916

Europe/Middle East/Africa:

ACS Warsaw

Ul. Działkowa 115

02-234 Warszawa

Phone: + 48 22 390 9720

Fax: +48 22 390 9724

India

ACS India

Gat No. 191/1, Sandbhor Complex

Mhalunge, Chakan, Tal Khed,

Dist. Pune 410501, India

Phone: +91 21 35329112

Fax: + 91 20 40147576

Page 3

Shipping Information

Unpacking and Inspection

You should inspect your equipment for possible shipping damage. Thoroughly check the

equipment for any damage that might have occurred in transit, such as broken or loose wiring

and components, loose hardware and mounting screws, etc.

In the Event of Shipping Damage

According to the contract terms and conditions of the Carrier, the responsibility of the

Shipper ends at the time and place of shipment.

Notify the transportation company’s local agent if you discover damage

Hold the damaged goods and packing material for the examining agent’s inspection. Do not

return any goods before the transportation company’s inspection and authorization.

File a claim with the transportation company. Substantiate the claim by referring to the

agent’s report. A certified copy of our invoice is available upon request. The original Bill of

Lading is attached to our original invoice. If the shipment was prepaid, write us for a

receipted transportation bill.

Advise customer service regarding your wish for assistance and to obtain an RMA (return

material authorization) number.

If the Shipment is Not Complete

Check the packing list as back-ordered items are noted on the packing list. In addition to the

equipment itself, you should have:

;.. Bill of lading

;.. Packing list

;.. Operating and Installation packet

; Electrical schematic and panel layout drawings

;.. Component instruction manuals (if applicable)

Re-inspect the container and packing material to see if you missed any smaller items during

unpacking.

If the Shipment is Not Correct

If the shipment is not what you ordered, contact the shipping department immediately. For

shipments in the United States and Canada, call 1 (630) 595-1060; for all other countries, call

our international desk at (630) 595-1060. Have the order number and item number available.

Hold the items until you receive shipping instructions.

Returns

Do not return any damaged or incorrect items until you receive shipping instructions from the

shipping department.

7/50D Plus or 7/50D Controller Chapter 1: Safety 2

Page 4

Table of Contents

Shipping Information .............................................................................................................. 2

Unpacking and Inspection .....................................................................................2

In the Event of Shipping Damage.......................................................................... 2

If the Shipment is Not Complete............................................................................ 2

If the Shipment is Not Correct ...............................................................................2

Returns..................................................................................................................2

Table of Contents...................................................................................................................3

CHAPTER 1: SAFETY ................................................................ 6

1-1 How to Use This Manual ............................................................................................. 6

Safety Symbols Used in this Manual.....................................................................6

1-2 Warnings and Precautions .......................................................................................... 7

1-3 Responsibility .............................................................................................................. 8

General Responsibility...........................................................................................8

Operator Responsibility .........................................................................................9

Maintenance Responsibility................................................................................... 9

Reporting a Safety Defect ..................................................................................... 9

CHAPTER 2: FUNCTIONAL DESCRIPTION............................ 10

2-1 Models Covered in This Manual................................................................................10

2-2 General Description................................................................................................... 10

2-3 Standard Features..................................................................................................... 11

Mechanical Features ...........................................................................................11

Electrical Features............................................................................................... 11

Controller Features.............................................................................................. 11

2-4 Optional Features......................................................................................................12

2-5 Safety Devices and Interlocks ................................................................................... 12

Safety Circuit Standards...................................................................................... 12

Fail Safe Operation .............................................................................................12

Safety Device Lock-Outs.....................................................................................13

CHAPTER 3: INSTALLATION .................................................. 14

3-1 Uncrating ................................................................................................................... 14

3-2 Mounting the Control Panel.......................................................................................14

3-3 System Installation Overview .................................................................................... 14

3-4 Electrical Connections............................................................................................... 15

Making Control Panel Power Drop Wiring Connections......................................15

Running KwikLink™ Cables ................................................................................15

Setting Up and Installing Mounting Plates........................................................... 17

Terminating Cable Runs...................................................................................... 18

Addressing and Installing ArmorBlocks™ ........................................................... 20

Installing KwikLink™ Connectors ........................................................................23

Connecting the Controller to the Network............................................................24

Connecting the Power Supply Enclosure to the Network....................................26

Connecting Vacuum Receivers to the Network...................................................28

Connecting Vacuum Pumps and Filter Chambers to the Network ......................30

Connecting Central Alarms to the Network .........................................................33

7/50D Plus or 7/50D Controller Chapter 1: Safety 3

Page 5

Setup ......................................................................................................................... 35

3-5

Setting Up the System......................................................................................... 36

Setting Up Stations.............................................................................................. 43

Setting Up Pumps ...............................................................................................47

Finishing Setup: Setting Up Passwords .............................................................. 51

3-6 Initial Startup............................................................................................................... 53

CHAPTER 4: OPERATION ........................................................ 54

4-1 Overview ...................................................................................................................54

4-2 Starting and Stopping the System.............................................................................54

4-3 Basic Tasks ............................................................................................................... 55

Reviewing Station Status ....................................................................................55

Reviewing Pump Status ...................................................................................... 57

Logging On and Logging Off ............................................................................... 59

Enabling and Disabling Stations and Pumps.......................................................60

Reviewing and Adjusting Basic Station Settings .................................................61

4-4 Advanced Tasks........................................................................................................64

Reviewing and Resetting a Pump Hour Meter ....................................................65

Transferring Stations to a Standby Pump............................................................66

3-5 Alarms ....................................................................................................................... 69

Reviewing Alarms................................................................................................ 69

Clearing the Alarm Log........................................................................................ 70

Silencing Alarms.................................................................................................. 71

CHAPTER 5: MAINTENANCE .................................................. 72

5-1 Preventative Maintenance......................................................................................... 72

5-2 Corrective Maintenance ............................................................................................72

Network Scanner Module Considerations ...........................................................72

CHAPTER 6: CONFIGURABLE SETTINGS............................. 73

6-1 Memory Module Considerations................................................................................ 73

6-2 Options for Station Setup .......................................................................................... 73

6-3 Options for Pump Setup ............................................................................................ 78

CHAPTER 7: TROUBLESHOOTING ........................................ 80

7-1 General Troubleshooting...........................................................................................80

7-2 Alarms.......................................................................................................................... 81

Station Alarms .....................................................................................................81

Pump Alarms.......................................................................................................82

System Alarms .................................................................................................... 83

CHAPTER 8: APPENDIX .......................................................... 84

8-1 Warranty....................................................................................................................84

8-2 Optional Components................................................................................................ 84

8-3 Drawings and Diagrams ............................................................................................ 85

8-4 Spare Parts List.........................................................................................................88

AC Voltage .......................................................................................................... 88

DC Voltage ..........................................................................................................88

8-5 Returned Material Policy ........................................................................................... 88

7/50D Plus or 7/50D Controller Chapter 1: Safety 4

Page 6

Credit Returns ..................................................................................................... 88

Warranty Returns ................................................................................................ 89

8-6 Safety Tag Information .............................................................................................. 89

Controller Safety Tags......................................................................................... 89

8-7 Controller Identification (Serial Number) Tag ............................................................ 89

8-8 Technical Assistance (Contact Information).............................................................. 90

Parts Department ................................................................................................ 90

Service Department............................................................................................. 90

Sales Department................................................................................................ 90

Contract Department ...........................................................................................90

7/50D Plus or 7/50D Controller Chapter 1: Safety 5

Page 7

Chapter 1: Safety

1-1 How to Use This Manual

Use this manual as a guide and reference for installing, operating, and maintaining your

equipment. The purpose is to assist you in applying efficient, proven techniques that enhance

equipment productivity.

This manual covers only light corrective maintenance. No other maintenance should be

undertaken without first contacting a service engineer.

The Functional Description section outlines models covered, standard features, and optional

features. Additional sections within the manual provide instructions for installation, preoperational procedures, operation, preventive maintenance, and corrective maintenance.

The Installation chapter includes required data for receiving, unpacking, inspecting, and setup

of the equipment. We can also provide the assistance of a factory-trained technician to help

train your operator(s) for a nominal charge. This section includes instructions, checks, and

adjustments that should be followed before commencing with operation of the equipment.

These instructions are intended to supplement standard shop procedures performed at shift,

daily, and weekly intervals.

The Operation chapter includes a description of electrical and mechanical controls, in

addition to information for operating the equipment safely and efficiently.

The Maintenance chapter is intended to serve as a source of detailed assembly and

disassembly instructions for those areas of the equipment requiring service. Preventive

maintenance sections are included to ensure that your equipment provides excellent, long

service.

The Troubleshooting chapter serves as a guide for identification of most common problems.

Potential problems are listed, along with possible causes and related solutions.

The Appendix contains technical specifications, drawings, schematics, and parts lists. A

spare parts list with part numbers specific to your machine is provided with your shipping

paperwork package. Refer to this section for a listing of spare parts for purchase. Have your

serial number and model number ready when ordering.

Safety Symbols Used in this Manual

The following safety alert symbols are used to alert you to potential personal injury hazards.

Obey all safety messages that follow these symbols to avoid possible injury or death.

Danger! DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Warning! WARNING indicates a potentially hazardous situation or practice which,

if not avoided, could result in death or serious injury.

Caution! CAUTION indicates a potentially hazardous situation or practice which, if

not avoided, may result in minor or moderate injury or in property

damage.

7/50D Plus or 7/50D Controller Chapter 1: Safety 6

Page 8

1-2 Warnings and Precautions

Our equipment is designed to provide safe and reliable operation when installed and operated

within design specifications, following national and local safety codes. This may include, but

is not limited to OSHA, NEC, CSA, SPI, and any other local, national and international

regulations.

To avoid possible personal injury or equipment damage when installing, operating, or

maintaining this equipment, use good judgment and follow these safe practices:

; Read and follow these operation and installation instructions when installing,

operating, and maintaining this equipment. If these instructions become

damaged or unreadable, additional copies are available from the manufacturer.

; Follow all SAFETY CODES.

; Wear SAFETY GLASSES and WORK GLOVES.

; Work only with approved tools and devices.

; Disconnect and/or lock out power before servicing or maintaining the equipment.

; Use care when LOADING, UNLOADING, RIGGING, or MOVING this

equipment.

; Operate this equipment within design specifications.

; OPEN, TAG, and LOCK ALL DISCONNECTS before working on equipment.

You should remove the fuses and carry them with you.

; Make sure the equipment and components are properly GROUNDED before you

switch on power.

; Use extreme caution when working with your conveying system. HIGH VACUUM

can be dangerous. Keep body parts, tools, clothing, and debris away from vacuum

inlets.

; When welding or brazing in or around this equipment, make sure VENTILATION is

ADEQUATE. PROTECT adjacent materials from flame or sparks by shielding with

sheet metal. An approved FIRE EXTINGUISHER should be close at hand and

ready for use if needed.

; Do not restore power until you remove all tools, test equipment, etc., and the

equipment and related components are fully reassembled.

; Only PROPERLY TRAINED personnel familiar with the information in this

manual should work on this equipment.

We have long recognized the importance of safety and have designed and manufactured our

equipment with operator safety as a prime consideration. We expect you, as a user, to abide

by the foregoing recommendations in order to make operator safety a reality.

7/50D Plus or 7/50D Controller Chapter 1: Safety 7

Page 9

1-3 Responsibility

These machines are constructed for maximum operator safety when used under standard

operating conditions and when recommended instructions are followed in the maintenance

and operation of the machine.

All personnel engaged in the use of the machine should become familiar with its operation as

described in this manual.

Proper operation of the machine promotes safety for the operator and all workers in its

vicinity.

Each individual must take responsibility for observing the prescribed safety rules as outlined.

All warning and danger signs must be observed and obeyed. All actual or potential danger

areas must be reported to your immediate supervisor.

General Responsibility

No mater who you are, safety is important. Owners, operators and maintenance personnel

must realize that every day, safety is a vital part of their jobs.

If your main concern is loss of productivity, remember that production is always affected in a

negative way following an accident. The following are some of the ways that accidents can

affect your production:

• Loss of a skilled operator (temporarily or permanently)

• Breakdown of shop morale

• Costly damage to equipment

• Downtime

An effective safety program is responsible and economically sound.

Organize a safety committee or group, and hold regular meetings. Promote this group from

the management level. Through this group, the safety program can be continually reviewed,

maintained, and improved. Keep minutes or a record of the meetings.

Hold daily equipment inspections in addition to regular maintenance checks. You will keep

your equipment safe for production and exhibit your commitment to safety.

Please read and use this manual as a guide to equipment safety. This manual contains safety

warnings throughout, specific to each function and point of operation.

7/50D Plus or 7/50D Controller Chapter 1: Safety 8

Page 10

Operator Responsibility

The operator’s responsibility does not end with efficient production. The operator usually has

the most daily contact with the equipment and intimately knows its capabilities and

limitations.

Plant and personnel safety is sometimes forgotten in the desire to meet incentive rates, or

through a casual attitude toward machinery formed over a period of months or years. Your

employer probably has established a set of safety rules in your workplace. Those rules, this

manual, or any other safety information will not keep you from being injured while operating

your equipment.

Learn and always use safe operation. Cooperate with co-workers to promote safe practices.

Immediately report any potentially dangerous situation to your supervisor or appropriate

person.

Maintenance Responsibility

Proper maintenance is essential to safety. If you are a maintenance worker, you must make

safety a priority to effectively repair and maintain equipment.

Before removing, adjusting, or replacing parts on a machine, remember to turn off all electric

supplies and all accessory equipment at the machine, and disconnect and lockout electrical

power. Attach warning tags to the disconnect switch.

Be sure that all non-current carrying parts are correctly connected to earth ground with an

electrical conductor that complies with current codes. Install in accordance with national and

local codes.

When you have completed the repair or maintenance procedure, check your work, remove

your tools. Rigging, and handling equipment.

Reporting a Safety Defect

If you believe that your equipment has a defect that could cause injury, you should

immediately discontinue its use and inform the manufacturer.

The principle factors that can result in injury are failure to follow proper operating procedures

(i.e. lockout/tagout), or failure to maintain a clean and safe working environment.

7/50D Plus or 7/50D Controller Chapter 1: Safety 9

Page 11

Chapter 2: Functional Description

2-1 Models Covered in This Manual

This manual provides operation, installation, and maintenance instructions for 7-Pump, 50D

& D Plus-Station Conveying Controllers. Model numbers are listed on the serial tag. Make

sure you know the model and serial number of your equipment before contacting the

manufacturer for parts or service.

The 7-Pump, 50D & D Plus-Station Conveying Controller is a programmable logic

controller, with 24 VDC or 115 VAC control circuit, easy-to-use touchscreen operator

interface terminal and optional audible/visual alarm.

2-2 General Description

Our material conveying systems create vacuum for the automatic conveying of most freeflowing, dry, pelletized, or granular materials. Material characteristics determine the type of

equipment needed to convey the material.

A typical use for our equipment is an in-plant distribution system for plastic processing

plants.

Our central vacuum systems are as varied as the applications they service. The tubing and

equipment furnished in our system is designed to convey the material(s) specified at the time

of purchase at specific rates and distances.

We can advise you on your system capabilities based on system makeup, distance, material,

and conveying rates you want.

System capacity is directly affected by the pressure drop in the overall system, such as

number of material line bends, pipe length, Y-tubes, T-tubes, etc.

Use the minimum effective amount of vinyl flex hose to maximize material line efficiency.

Keep material lines as straight as possible. Refer to the Mechanical Components Product

manual (Part No. A0536580) for installation recommendations.

Note: Vacuum leaks occurring anywhere in your system reduce capacity.

7/50D Plus or 7/50D Controller Chapter 2: Functional Description 10

Page 12

2-3 Standard Features

Mechanical Features

Time-fill Capability. The length of time allowed for material to drain from the station to its

receiver. During this time, the controller does not attempt to deliver any more material to the

station.

Volume-fill Capability. The length of time a station’s vacuum valve remains open to allow

material to be drawn in. The vacuum valve will close when material covers the station’s

volume-fill proximity sensor or this time elapses, whichever comes first.

Vent Valve Output. The vent valve protects the pump motor from damage during high

vacuum conditions if an undetected failure of the vacuum switch should occur. The vent

valve limits system vacuum by allowing a plunger in the valve to shift and vent the pump.

Closed-Loop Conveying. This feature allows material to be conveyed and processed

without being contaminated by outside influences (such as dust, other materials, etc.).

Common Purge Valve Output Control for Each Pump. This feature allows any remaining

material to be cleaned out of the vacuum pump or station.

Local Blowback Filter Cleaning Outputs. When this feature is enabled, the controller

periodically sends compressed air backward through the pump’s air filter to dislodge

accumulated dust and debris.

Electrical Features

• 115/1/60 or 230/1/50/60 supply voltage

• 24 VDC control voltage

• Single-point power and ground connection

• Non-fused disconnect switch, lockable

• Branch circuit fusing

• Fully accessible NEMA 4-style electrical control enclosure

Controller Features

• Allen-Bradley SLC 5/04 programmable controller with 10” color touch screen operator

interface

• Diagnostics, operating instructions and parts information are built into the interface

• Controls up to fifty (50) stations and up to seven (7) Vacuum Power Units.

• Controls up to three central alarms

• Allows operator to transfer stations to a standby pump when a pump fails

• Electronic time delay between pump startups to prevent an excessive power demand at

your facility

7/50D Plus or 7/50D Controller Chapter 2: Functional Description 11

Page 13

2-4 Optional Features

Options marked with “*” indicate options that can be factory installed or retrofitted in the

field.

230/1/60 Operation. Required to operate with a 230/1/60 supply voltage.

Additional audible/visual alarm with silence button. Alarm light and horn assembly that

can be remote mounted and wired into the controller to indicate an alarm condition.

Remote Interface.

Central Purge Capability.

Material Line Proofing

CE Package for 220/1/50 Operation. Required in Europe and other areas that need

220/1/50 supply voltage.

2-5 Safety Devices and Interlocks

This section includes information on safety devices and procedures that are inherent to the

Controller. This manual is not intended to supersede or alter safety standards established by

the user of this equipment. Instead, the material contained in this section is recommended to

supplement these procedures in order to provide a safer working environment.

At the completion of this section, the operator and maintenance personnel will be able to do

the following:

• Identify and locate specific safety devices.

• Understand the proper use of the safety devices provided.

• Describe the function of the safety device.

Safety Circuit Standards

Safety circuits used in industrial systems protect the operator and maintenance personnel

from dangerous energy. They also provide a means of locking out or isolating the energy for

servicing equipment.

Various agencies have contributed to the establishment of safety standards that apply to the

design and manufacture of automated equipment. The Occupational Safety and Health

Administration (OSHA) and the Joint Industrial council (JIC) are just a few of the

organizations that have joined with the plastics industry to develop safety standards.

Every effort has been made to incorporate these standards into the design of the controller;

however, it is the responsibility of the personnel operating and maintaining the equipment to

familiarize themselves with the safety procedures and the proper use of any safety devices.

Fail Safe Operation

If a safety device or circuit should fail, the design must be such that the failure causes a

“Safe” condition. As an example, a safety switch must be a normally open switch. The switch

must be held closed with the device it is to protect. If the switch fails, it will go to the open

condition, tripping out the safety circuit.

7/50D Plus or 7/50D Controller Chapter 2: Functional Description 12

Page 14

At no time should the safety device fail and allow the operation to continue for example, if a

safety switch is guarding a motor, and the safety switch fails, the motor should not be able to

run.

Safety Device Lock-Outs

Some safety devices disconnect electrical energy from a circuit. The safety devices that are

used in this Controller are primarily concerned with electrical power disconnection.

WARNING! Always disconnect and lockout all electrical power and pneumatic (i.e. compressed air)

sources prior to servicing the 7-Pump, 50D & D Plus-Station Controller. Failure to

do so may result in serious injury. No one but the person who installed the lockout

may remove it.

7/50D Plus or 7/50D Controller Chapter 2: Functional Description 13

Page 15

Chapter 3: Installation

3-1 Uncrating

7-Pump, 50D & D Plus-Station Controllers are shipped mounted on a skid, enclosed in a

plastic wrapper, and contained in a cardboard box.

1. Pry the crating away from the skid.

Note: Remove the nails holding the box to the skid and lift the box off

carefully; avoiding staples in the 1’ x 4’ wood supports. Cut the steel

banding.

2. Use a pry bar to remove the blocks securing the unit to the skid.

3. Lift unit from sides, inserting forklift under the base. The forks must be equidistant

from the centerline of the unit and the unit must be balanced on the forks. Lift

slowly and only high enough to clear the skid. Use a pry bar if necessary to

carefully remove the skid from the unit.

4. Lower slowly.

3-2 Mounting the Control Panel

Note: Before you mount the panel, consider how you run wiring to the

KwikLink connectors, ArmorBlocks, vacuum hoppers, the filter chamber atmospheric valve (if so equipped) and the pump motor starter(s),

vacuum switch(es), and vent valve(s).

Mount the control panel on a flat, vertical area. It should be a visible area that gives your

operator access to the control. The panel requires a low voltage power drop as listed on the

serial tag.

3-3 System Installation Overview

Installing the 7-pump 50-station controller is easy and straightforward. Because the system

uses networked distributed I/O modules, you’ll only need to run two cables for the entire

system.

The following is a typical installation sequence:

1. Run the black power and the grey data KwikLink™ flat cables from the start of the

system to the end, attaching them to vacuum tubing with nylon cable ties.

2. Set up mounting plates with tubing clamps; install KwikLink™ connectors and

ArmorBlocks onto mounting plates as required.

3. Install KwikLink connectors and ArmorBlock™ cable plates to mounting plates, and

install on vacuum tubing at each node location, just before a T-fitting or valve.

4. Install cable terminations.

5. Determine location of network system nodes, and set addresses for ArmorBlocks as

required.

6. Set up and connect to the controller and, if purchased, remote display. Connect grey

patch cords from controller terminals to KwikLink connectors installed in Step 3.

7/50D Plus or 7/50D Controller Chapter 3: Installation 14

Page 16

7. After determining quantity and location(s) of where to install system power

supply(ies) (consult factory); set up and connect to KwikLink connectors installed in

Step 3.

8. Set up and connect vacuum receiver stations to ArmorBlocks installed in Step 3,

using yellow patch cords.

9. Set up and connect vacuum pump stations and filter chambers to ArmorBlocks

installed in Step 3, using yellow patch cords.

10. Determine location(s) of central alarm(s); set up and connect alarms using yellow

patch cords.

The following sections provide detailed information on these installation steps.

3-4 Electrical Connections

Refer to local electrical codes, the schematic and connection diagrams supplied with this unit

and the serial tag for wiring considerations. Run all wiring in conduit if codes require it.

Making Control Panel Power Drop Wiring Connections

Hardwire the input power at 115/1/50-60 VAC or 230/1/50-60 VAC, depending on the

specifications, which are located on the Control Panel Serial Tag. The control enclosure

draws less than five (5) amps during normal operation at 115/1/50-60 VAC. The main power

switch is located on the right side of the enclosure.

Caution! We recommend that you protect PLC memory by providing the control

panel with a dedicated circuit, a true earth ground, and a spike/surge

protector.

Running KwikLink™ Cables

About KwikLink Flat Cables

KwikLink flat cable is physically keyed to prevent wiring mishaps. This type of cable is

unshielded and contains four conductors. Use a long-jawed straight-bladed cable cutter at

least 1½” long to cut KwikLink flat cable.

You’ll install two (2) colors of flat cable: black and grey. The black cable transmits output

power, and the grey cable transmits input power and data transmission.

Figure 1: KwikLink Cable Cross-Section, Edge Identification

Cross Section Edge Identification

7/50D Plus or 7/50D Controller Chapter 3: Installation 15

Page 17

Installing KwikLink Cable

Before you install flat cable, determine how much length you need to install black power

cable and grey data cable. Typical installations have equal lengths of each. This is a good

time to plan for the future, and run these cables to each possible location in the plant. Use a

straight-blade cable cutter to make the cut at each end.

To install KwikLink cables:

1. Cut both black and grey cables to the proper length.

2. Use cable ties to attach KwikLink cables, black cable above grey cable, on the

vacuum tubing. Attach cable to the tubing with cable ties at about three-foot (3 ft./

1 m) invervals. Make sure that cable ties are snug, but not tightened enough to bend

the flat cable.

Caution! Install KwikLink cable on vacuum tubing only. DO NOT install KwikLink

cable on material conveying tubing, as static electricity formed at material

lines could disrupt system operation.

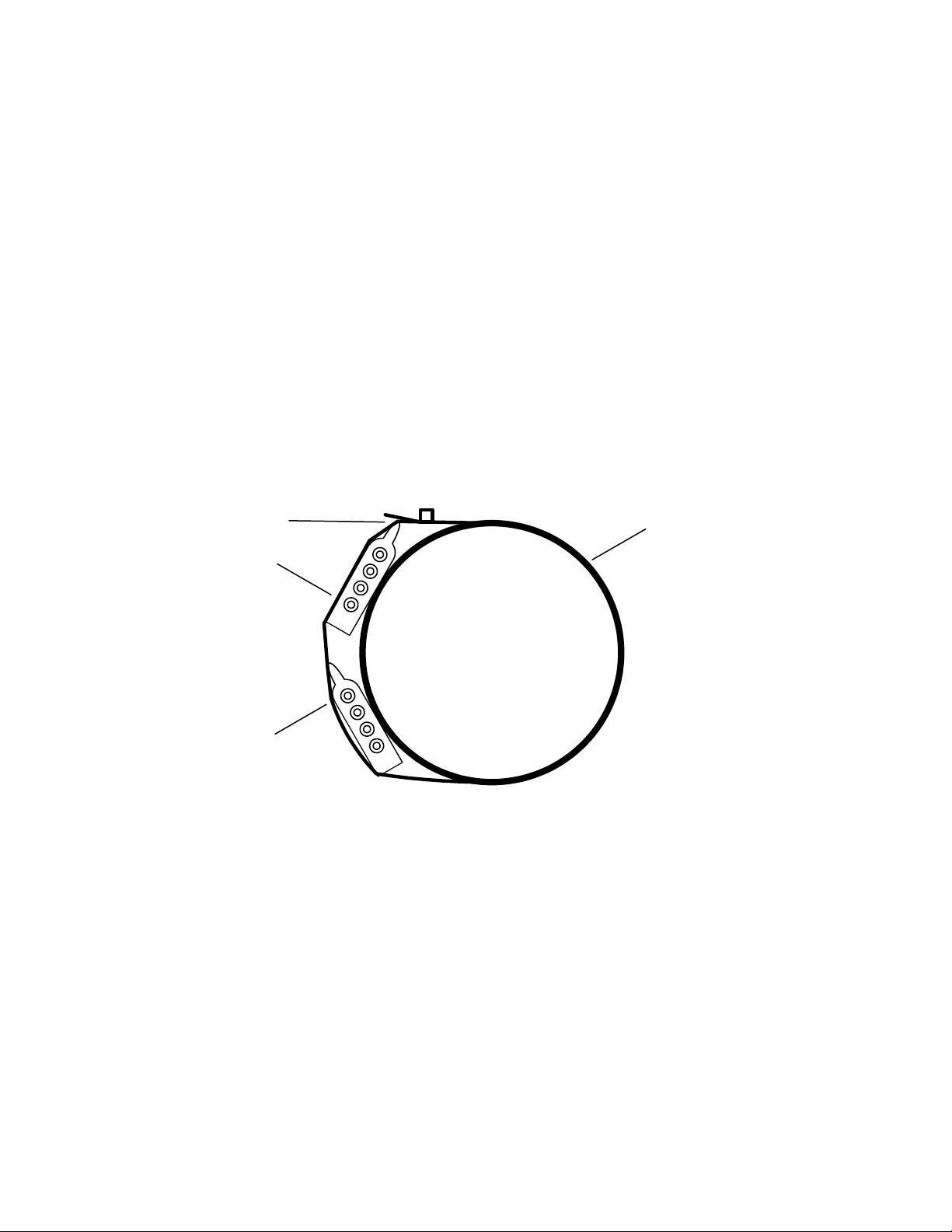

Figure 2: Side View of a Typical Power Cable and Data Cable Installation

Cable tie, buckle

Black power cable

Grey data cable

Vacuum tube

Note: When approaching a node location, stop the attachment process. Run

the cables over the node area (such as a T-valve) and make sure you

create a slight amount of slack when continuing the attachment with

cable ties. Doing so lets you install KwikLink connectors or

ArmorBlocks with greater ease, with less stress on the cable.

7/50D Plus or 7/50D Controller Chapter 3: Installation 16

Page 18

Setting Up and Installing Mounting Plates

Setting Up Mounting Plates

It’s a good idea to get all your mounting plates set up with KwikLink connector bases or

ArmorBlock cable bases before installation, as your system layout determines.

Note: ArmorBlock cable bases are installed on mounting plates

perpendicular in orientation to the flat cable runs.

Vacuum hoppers/receiver stations require 8-connector ArmorBlocks; vacuum

pumps and central alarm stations require 4-connector ArmorBlocks.

Make sure that each mounting plate has properly attached tube clamps as required. Each

mounting plate requires two (2) tube clamps. Always use locking washers, especially in

high-vibration environments.

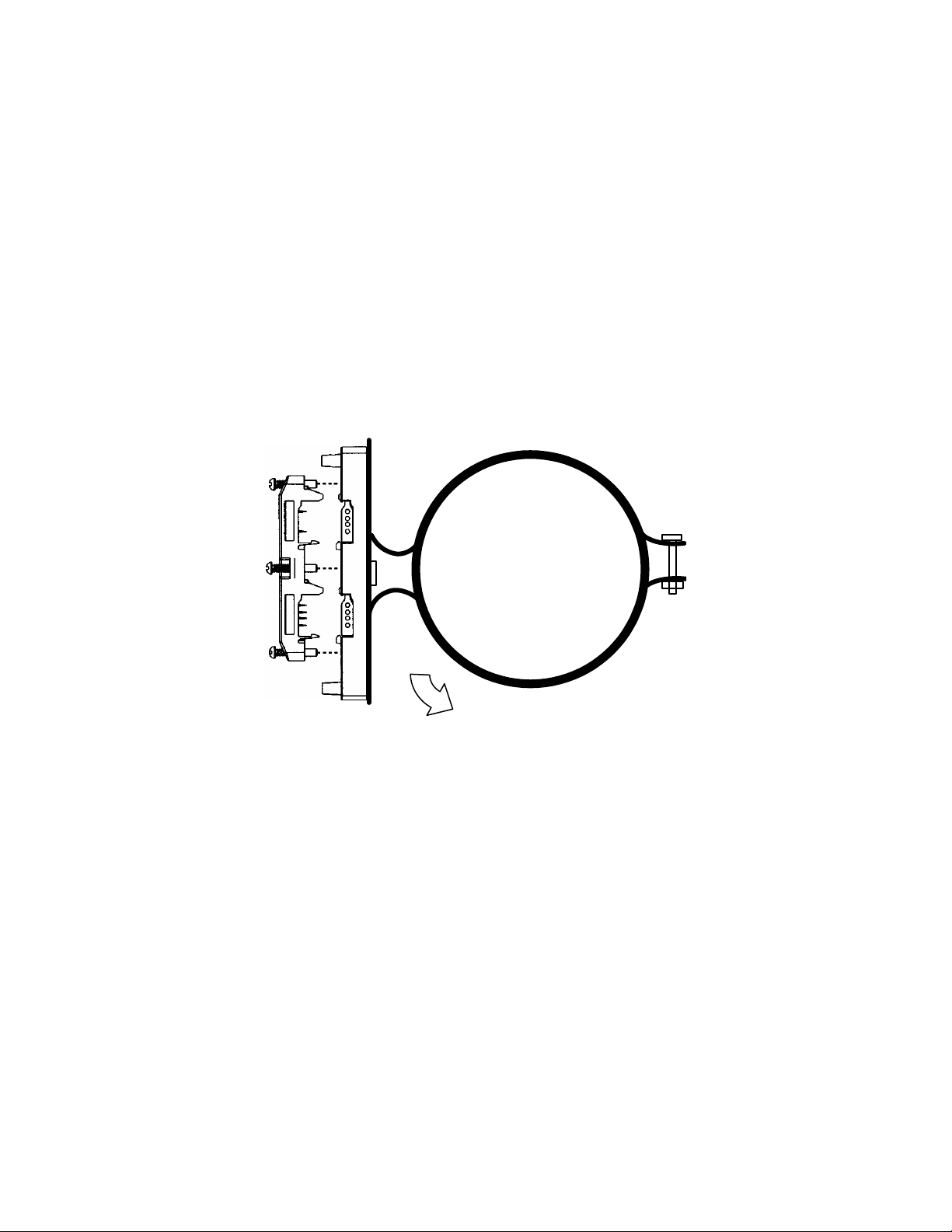

Figure 3: Side View of a Typical Mounting Plate Assembly with ArmorBlock Base

Rotate 30º to 45º downward

Installing Assembled Mounting Plates

After you’ve set up the mounting plates:

1. Install them at each node location by clipping the tubing clamps onto the vacuum

tube, just before the node area (such as a T-valve).

2. Orient the mounting plate parallel with the flat cables and at a 30º to 45º angle so the

KwikLink connector or ArmorBlock faces the operator on the floor; torque the tubing

clamp fasteners until tight.

The flat cable will be installed inside KwikLink connectors and ArmorBlocks as described in

the following sections of this chapter.

7/50D Plus or 7/50D Controller Chapter 3: Installation 17

Page 19

Terminating Cable Runs

After you’ve run the black and grey network cables, you need to properly terminate the ends

of the cables. By doing so, you’ll insure that the network runs properly. You will also have

the benefit of being able to measure voltage in the system without disrupting operation.

This section lists procedures for terminating these cables. To properly terminate a cable run:

1. Mount three standard KwikLink connectors to a mounting plate in a triangle

configuration. See Figure 4 on Page 19 for an illustration.

Make sure that each connector is installed with the hinge side down.

2. Mount the tubing clamps to the mounting plates. Each mounting plate requires two

(2) tubing clamps.

3. Mount the standard resistor cap from the KwikLink connector kit on the top center

KwikLink connector for the black power flat cable. The standard resistor cap has

metal prongs in the center.

Repeat for the outside end KwikLink connector on the grey data flat cable.

4. For the inside KwikLink connector (next to the outside end on the grey cable), mount

a separately-packaged blank cap on it instead of the standard resistor cap in the

KwikLink connector kit.

Discard the standard resistor cap to eliminate confusion.

5. Mount the mounting plate assembly on the vacuum line at the end of the cable run.

See Page 17 for more information.

6. Using the straight-blade cable cutter, carefully trim each flat cable so it sticks out past

1

the final KwikLink connector by

/4” to 3/8”.

Place a dust cap over the end of the trimmed cable.

7. Lay the dust cap and cable into the KwikLink connector so the dust cap tabs engage

in the connector slots. The dust cap tabs should fit into the connector slots perfectly.

Left Right

8. Lay the cable in the hinged base, noting the correct keyed profile; flat edge toward

the hinge, keyed edge toward the latch. Make sure that the cable and dust cap are

properly seated inside.

9. Making sure that the cable is completely straight, carefully close the hinged

assembly, and apply firm, even pressure until the first latch locks into place.

Note: Make sure that the flat cable is completely staight before continuing!!

The latch has two catches; the first loosely holds the connector on the cable, the

second requires more pressure to close the connector tightly. The cable must be in the

correct position for the connector to close properly.

7/50D Plus or 7/50D Controller Chapter 3: Installation 18

Page 20

10. Drive the two screws at the center points about halfway down; first on the latch side,

Connectors

then the hinge side.

11. Continue to tighten the screws a little at a time until fully tightened; no more than 15

inch-pounds (5.6 N

•m) of torque.

Note: You can only pierce the cable once. Once pierced, the KwikLock

connector must not be removed. This insures that the inner conductors

are not exposed to the elements.

Installing Inside KwikLink Connectors with Blank Caps

Once installed on the grey data cables, these connectors permit you to measure voltage in the

system so you can analyze how it is working. The system cannot work properly unless these

inside-mounted connectors have the blank (non-conductor) caps installed.

1. Lay the cable in the hinged base, noting the correct keyed profile; flat edge toward

the hinge, keyed edge toward the latch. Make sure that the cable is properly seated

inside.

2. Making sure that the cable is completely straight, carefully close the hinged

assembly, and apply firm, even pressure until the first latch locks into place.

Note: Make sure that the flat cable is completely straight before continuing!!

The latch has two catches; the first loosely holds the connector on the cable, the

second requires more pressure to close the connector tightly. The cable must be in the

correct position for the connector to close properly.

3. Drive the two screws at the center points about halfway down; first on the latch side,

then the hinge side.

4. Continue to tighten the screws a little at a time until fully tightened; no more than 15

inch-pounds (5.6 N

•m) of torque.

Note: You can only pierce the cable once. Once pierced, the KwikLock

connector must not be removed. This insures that the inner conductors

are not exposed to the elements.

The system should now be properly terminated. You can now continue to install components

on the system.

Figure 4: Proper Termination Connections

Dust Caps

Inside KwikLink Connector

Inside KwikLink Connector

with Blank Cap

with Blank Cap

ArmorBlock Mounting Plate Kit

ArmorBlock Mounting Plate Kit

Part No. A0556696

Inside KwikLink Connector

Inside KwikLink Connector

with Blank Cap

with Blank Cap

Standard KwikLink

7/50D Plus or 7/50D Controller Chapter 3: Installation 19

Page 21

Addressing and Installing ArmorBlocks™

Addressing Armorblocks

An ArmorBlock permits you to give it a number “address” so that the controller network

system can recognize its location and function. ArmorBlocks are used at vacuum

hopper/receiver, pump, and alarm node locations.

ArmorBlock Address Ranges

The number range of ArmorBlock addresses are as follows:

• 01 to 50 — Vacuum hopper/receiver stations; use a leading zero for

numbers 01 to 09.

• 51 to 57 — Pump stations

• 58 to 60 — Alarm stations

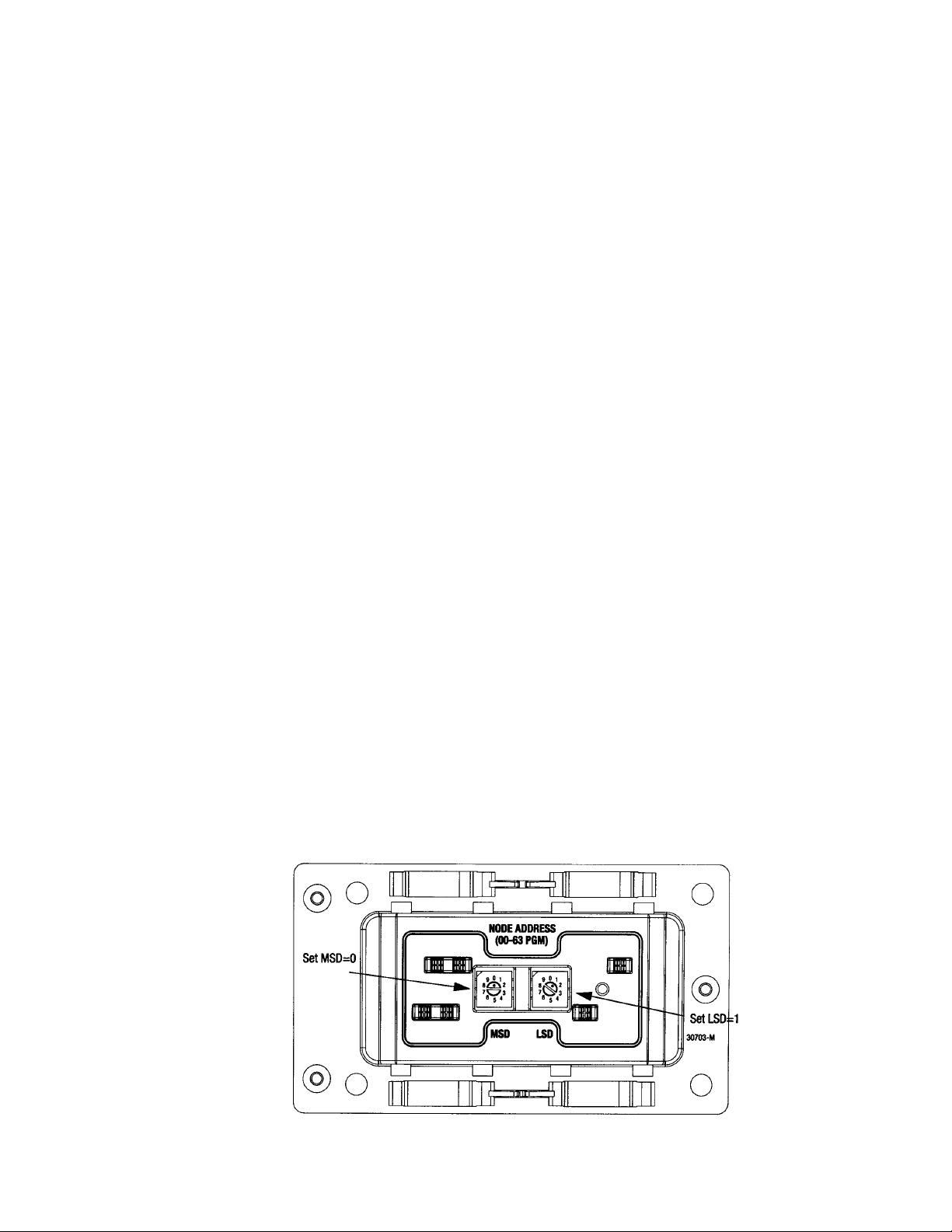

Setting Armorblock Addresses

Locate the rotary switches underneath the ArmorBlock. The two switches are:

• MSD (most significant digit) for tens

• LSD (least significant digit) for units/ones

For example, if you wanted to set an address at 36, you set the MSD rotary switch at 3 and

the LSD rotary switch at 6. To set an address of 8, set the MSD rotary switch at 0 (leading

zero), then set the LSD rotary switch at 8.

• Using a permanent black marker, write the number of the address

on the white label located on the bottom front of the ArmorBlock.

We suggest that you place numbered tags at node locations to ease

installation and reduce any confusion of locations.

To set the node address:

• Use a small straight-bladed screwdriver to rotate the switches.

Line up the small arrowhead on the switch with the number you want

to select.

The following figure shows that the address is set at 01; the MSD rotary switch is set at 0 and

the LSD rotary switch is set at 1.

Figure 5: ArmorBlock Address Node Rotary Switches

7/50D Plus or 7/50D Controller Chapter 3: Installation 20

Page 22

Installing ArmorBlocks

The ArmorBlock cable base should already be attached to the mounting plate, aligned so it is

perpendicular to the flat cables. If not, reinstall it with its proper alignment.

To install the flat cables in the ArmorBlock cable base:

1. Lay the flat cable into the ArmorBlock cable base, grey data cable on the bottom and

the black power cable on the top, making sure that the keyed edge is properly seated

toward the top.

Caution! EXERCISE CARE when handling the seal block.

Cable contacts are SHARP!

Only ONE attempt to pierce the cable is allowed for proper contact.

Figure 6: Using seal block to pierce cable

2. Align the seal block so the L-shaped tabs are towards the top, and the arrows are

matched on the bottom of the cable base and seal block. Make sure that the arrows

and the four captive screws on the seal block are properly aligned. Gently press it

into place.

Make sure that you align the seal block properly when you attach it to the base.

Doing so maintains the integrity of the sealed base.

Note: You can only pierce the cable once. Once pierced, the seal block must

not be removed. This insures that the inner conductors are not exposed

to the elements.

7/50D Plus or 7/50D Controller Chapter 3: Installation 21

Page 23

Figure 7: Securing the Seal Block to the Cable Base

To secure the seal block:

1. Start the threads of each of the four captive screws into the cable base receptacle

holes.

2. Drive each of the screws about halfway down, using the proper torque sequence:

Bottom screw, top screw, left screw, right screw. Doing so insures that the cables are

pierced evenly.

3. Using the proper torque sequence, tighten each screw, a little at a time, until the

seal block is fully seated into the cable base. Tighten to no more than 8 to 10 inchpounds (3.0 to 3.7 N

•m) of torque.

The three seat lines on the seal block should meet the cable base, indicating that the

seal block is fully seated. The seal block clips should also click into place onto the

corresponding cable base slots.

7/50D Plus or 7/50D Controller Chapter 3: Installation 22

Page 24

Installing KwikLink™ Connectors

KwikLink connectors let you connect the controller and the power supply to the system. They

are also used to electronically terminate power cable and data cable runs.

Just like ArmorBlocks, KwikLink connectors are insulation displacement connectors (IDCs).

Caution! Exercise care when installing Kwiklink connectors.

IDC blades on KwikLink connectors are SHARP!

Gently push back any protruding IDC blades before installing flat cables

inside.

The KwikLink connector should already be attached to the mounting plate, so the hinge side

is down. If not, reinstall it with its proper alignment, along the correct flat cable. See the

installation drawing located in your Customer Information Packet for further details.

To install flat cable inside KwikLink connectors:

1. Lay the cable in the hinged base, noting the correct keyed profile; flat edge toward

the hinge, keyed edge toward the latch. Make sure that the cable is properly seated

inside.

2. Making sure that the cable is completely straight, carefully close the hinged

assembly, and apply firm, even pressure until the first latch locks into place.

Note: Make sure that the flat cable is completely straight before continuing!

The latch has two catches; the first loosely holds the connector on the cable, the

second requires more pressure to close the connector tightly. The cable must be in the

correct position for the connector to close properly.

3. Drive the two screws at the center points about halfway down; first on the latch side,

then the hinge side.

4. Continue to tighten the screws a little at a time until fully tightened; no more than 15

inch-pounds (5.6 N

•m) of torque.

Note: You can only pierce the cable once. Once pierced, the KwikLink

connector must not be removed. This insures that the inner conductors

are not exposed to the elements.

7/50D Plus or 7/50D Controller Chapter 3: Installation 23

Page 25

Connecting the Controller to the Network

To connect the controller to the network, make sure that the KwikLink connector is properly

installed on the flat grey data cable. To connect:

1. Attach the keyed round connector to the terminal of the controller marked

NETWORK NO. 1. Tighten the cord grip ring until snug.

2. Align the square connector of the grey drop cable so the cable leads down from the

connector. Evenly press the square connector onto the top of the KwikLink

connector. It should make two audible snaps when properly seated.

3. Dress the excess cable with cable ties so it does not interfere with operation and gives

a pleasing appearance.

Connecting the Remote Interface to the Main Controller

After selecting a location and installing the remote interface, connect it to the main controller:

1. Determine the length of blue remote cable you need, and cut it to length.

2. Run the cable from the remote interface to the main controller, neatly dressing the

cable with cable ties so it does not interfere with system operation and to give it a

neat appearance.

3. Attach connectors at each end, following the connector manufacturer’s instructions.

4. Attach one connector to the remote interface terminal marked REMOTE DISPLAY.

Tighten the cord grip ring until snug.

5. Attach the other connector to the terminal of the controller marked REMOTE

DISPLAY. Tighten the cord grip ring until snug.

7/50D Plus or 7/50D Controller Chapter 3: Installation 24

Page 26

Figure 8: Proper Controller and Remote Interface Connections

Black Power Flat Cable

Vacuum Tube

Grey Network Flat Cable

Power or Network Tap/Cable Drop

Part No. A0555195

One (1) Cord Required & is Connected,

as Shown, to the Grey Network Flat Cable

Main Touch-Screen

Control Display

Blue Cable, 20 ft. (6 m)

One (1) Cord is Needed per Display, as Shown

Connected to the Marked Terminals

of the Main & Remote Control Boxes

ArmorBlock Mounting Plate Kit

Part No. A0556696

Remote Touch-Screen

Control Display

7/50D Plus or 7/50D Controller Chapter 3: Installation 25

Page 27

Connecting the Power Supply Enclosure to the Network

The power supply provides electrical power to make the system work. Some network layouts

require more than one power supply.

Location is also an important consideration when locating power supply enclosures on your

network. Contact the factory for determining how many power supply enclosures your system

needs, as well as where they need to be installed.

After you’ve mounted the power supply enclosure(s), you can connect them to your network.

To connect a power supply to the network:

1. Attach a KwikLink connector included in the bag with power cables to the flat

cables. One connector is used for the network grey cable and one connector is used

for the auxiliary power black cable.

2. Align the square connector of the grey drop cable so the cable leads down from the

connector. Evenly press the square connector onto the top of the bottom KwikLink

connector. It should make two audible snaps when properly seated.

3. Align the square connector of the black drop cable so the cable leads down from the

connector. Evenly press the square connector onto the top of the upper KwikLink

connector. It should make two separate, audible snaps when properly seated.

4. Attach the keyed round connectors to the receptacles on the side of the power supply

enclosure marked 24 VDC POWER SUPPLY. Tighten the cord grip ring until

snug.

5. Dress the excess cables with cable ties so they do not interfere with operation and to

give a pleasing appearance.

If more than one power supply is required to properly energize the grey network flat cable:

1. Remove the terminal block jumpers on all but the most centrally-located network

power supply enclosures.

For locations of jumpers, refer to the drawing shipped inside the power supply

enclosure

Note: Only one power supply should be connected to each section of the

black auxiliary power flat cable. Do not remove any jumpers on power

supplies that transmit energy to the black flat power cable.

7/50D Plus or 7/50D Controller Chapter 3: Installation 26

Page 28

Figure 9: Proper Power Supply Enclosure Connections

Black Power Flat Cable

Vacuum Tube

Grey Network Flat Cable

Power Cable

Part No. A0555195

Two (2) Cords Required

ArmorBlock Mounting Plate Kit

Part No. A0556696

Power Supply Enclosure

7/50D Plus or 7/50D Controller Chapter 3: Installation 27

Page 29

Connecting Vacuum Receivers to the Network

Make sure that all previous installation steps have been done first before starting this task.

To connect a vacuum receiver to the network:

1. Attach one connector of the yellow patch cord to the terminal on the vacuum receiver

terminal box. Tighten the cord grip ring until snug.

2. Attach the other connector to the upper left terminal of the ArmorBlock. Tighten the

cord grip ring until snug.

Note: Retain the terminal caps from the ArmorBlock. They may be used

later.

*** The installation steps listed above also apply to the 7/50D 4-connector

ArmorBlock.

Note the following illustrations for 4 and 8-connector ArmorBlocks:

Figure 10: 7/50D 4-Connector ArmorBlock Connections

Pump Verify (A-I0)

High Vacuum (A-I1)

Pump Fault #1 (B-I2)

Pump Fault #2 (B-I3)

4 Input / 4 Output

ArmorBlock

3. Dress the excess patch cord cable with cable ties so it does not interfere with

operation and gives a pleasing appearance.

Figure 11: 7/50D Plus 8-Connector ArmorBlock Connections

Demand Switch (A-I0)

Volume Fill Prox. (A-I1)

Bypass Switch (B-I2)

Receiver Level

Sensor (C-I4)

RPV Material 'A' Solenoid (F-O2)

RPV Material 'B' Solenoid (F-O3)

Slide Gate (G-O4)

Blowback (G-O5)

Pump Starter (C-O0)

Vent Solenoid (C-O1)

Blowback Solenoid (D-O2)

Local Alarm Light (D-O3)

T-Connector

AB#1485P-P1R4-DR4

Part No. A0555169

T-Connector

AB#1485P-P1R4-DR4

Part No. A0555169

Sequence Valve (E-O0)

Local Alarm Light (E-O1)

Not used

Purge Solenoid (H-O6)

8 Input / 8 Output

ArmorBlock

7/50D Plus or 7/50D Controller Chapter 3: Installation 28

Page 30

3. Dress the excess patch cord cable with cable ties so it does not interfere with

operation and to give a pleasing appearance.

Figure 12: Proper Vacuum Receiver Connections

Black Power Flat Cable

Vacuum Tube

Grey Network Flat Cable

Yellow Patch Cord, 20 ft. (6 m)

Part No. A0555190

ArmorBlock Mounting Plate Kit

Part No. A0556696

7/50 D Plus

Connections

8 Input / 8 Output ArmorBlock

Part No. A0555192

ArmorBlock Base

Part No. A0555191

Vacuum Receiver

OR

Make the same connections using a 4 input/ 4 output ARMORBLOCK

7/50D

Connections

7/50D Plus or 7/50D Controller Chapter 3: Installation 29

Page 31

Connecting Vacuum Pumps and Filter Chambers to the Network

Connecting Vacuum Pumps

Make sure that all previous installation steps have been done first before starting this task.

You’ll use two yellow patch cords to connect.

To connect a vacuum pump to the network:

1. Attach one connector of the first yellow patch cord to the lower terminal on the

vacuum pump terminal box. Tighten the cord grip ring until snug.

2. Attach the other connector to the upper left terminal of the ArmorBlock. Tighten the

cord grip ring until snug.

3. Attach one connector of a yellow patch cord to the upper terminal on the vacuum

pump terminal box. Tighten the cord grip ring until snug.

4. Attach the other connector to the upper right terminal of the ArmorBlock. Tighten

the cord grip ring until snug.

Note: Retain the terminal caps from the ArmorBlock. They may be used

later.

Note the following illustration for 4-connector ArmorBlocks:

Figure 13: 4-Connector ArmorBlock Connections

Pump Verify (A-I0)

High Vacuum (A-I1)

Pump Starter (C-O0)

Vent Solenoid (C-O1)

Pump Fault #1 (B-I2)

Pump Fault #2 (B-I3)

4 Input / 4 Output

ArmorBlock

Blowback Solenoid (D-O2)

Local Alarm Light (D-O3)

T-Connector

AB#1485P-P1R4-DR4

Part No. A0555169

5. Dress the excess patch cord cables with cable ties so they do not interfere with

operation and to give a pleasing appearance.

7/50D Plus or 7/50D Controller Chapter 3: Installation 30

Page 32

Figure 14: Proper Vacuum Pump Connections

Black Power Flat Cable

Vacuum Tube

Grey Network Flat Cable

Yellow Patch Cord, 20 ft. (6 m)

Part No. A0555190

Two (2) Cords Required

Vacuum Pump

ArmorBlock Mounting Plate Kit

Part No. A0556696

4 Input / 4 Output ArmorBlock

Part No. A0558296

ArmorBlock Base

Part No. A0555191

7/50D Plus or 7/50D Controller Chapter 3: Installation 31

Page 33

Connecting Filter Chambers

Make sure that all previous installation steps have been done first before starting this task.

You’ll use one yellow patch cord to connect.

To connect a filter chamber to the network:

1. Attach one connector of the yellow patch cord to the terminal on the filter chamber

terminal box. Tighten the cord grip ring until snug.

Figure 15: Proper Filter Chamber Connections

Black Power Flat Cable

Vacuum Tube

Grey Network Flat Cable

ArmorBlock Mounting Plate Kit

Part No. A0556696

8 Input / 8 Output ArmorBlock

Yellow Patch Cord, 20 ft. (6 m)

VFC Filter Chamber

Part No. A0555192

ArmorBlock Base

Part No. A0555191

Part No. A0555190

2. Attach the other connector to the lower right terminal of the ArmorBlock you used

to connect the vacuum pump. Tighten the cord grip ring until snug.

Note: Retain the terminal caps from the ArmorBlock. They may be used

later.

3. Dress the excess patch cord cables with cable ties so they do not interfere with

operation and to give a pleasing appearance.

7/50D Plus or 7/50D Controller Chapter 3: Installation 32

Page 34

Connecting Central Alarms to the Network

Make sure that all previous installation steps have been done first before starting this task.

First, determine where the best location for central alarms should be, and install the

alarm module(s) there. You’ll use two yellow patch cords to connect.

To connect an alarm module to the network:

1. Attach one connector of the first yellow patch cord to the terminal on the alarm

module. Tighten the cord grip ring until snug.

2. Attach the other connector to the upper right terminal of the ArmorBlock. Tighten

the cord grip ring until snug.

Figure 16: Proper Central Alarm Connections

Yellow Patch Cord, 20 ft. (6 m)

AEC Part No. A0555190

Vacuum Tube

Black Power Flat Cable

Grey Network Flat Cable

ArmorBlock Mounting

Plate Kit - Part

No. A0556696

4 Input / 4 Output ArmorBlock

Push to Silence Button

Part No. A0558296

ArmorBlock Base

Part No. A0555191

Yellow Patch Cord, 20 ft. (6 m)

Part No. A0555190

Remote Alarm

3. Attach one connector of a yellow patch cord to the terminal on the alarm silence

switch module. Tighten the cord grip ring until snug.

7/50D Plus or 7/50D Controller Chapter 3: Installation 33

Page 35

4. Attach the other connector to the upper left terminal of the ArmorBlock. Tighten the

cord grip ring until snug.

Note: Retain the terminal caps from the ArmorBlock. They may be used

later.

Note the following illustration for 4-connector central alarm ArmorBlocks:

Figure 17: 4-Connector ArmorBlock Connections for Central Alarms

Alarm Silence Pushbutton (A-I0)

Alarm Silence Pushbutton (A-I1)

Alarm Silence Pushbutton (B-I2)

Alarm Silence Pushbutton (B-I3)

Alarm Strobe Light (C-O0)

Alarm Horn (C-O1)

Alarm Strobe Light (D-O2)

Alarm Horn (D-O3)

4 Input / 4 Output

ArmorBlock for

Central Alarms

5. Dress the excess patch cord cables with cable ties so they do not interfere with

operation and to give a pleasing appearance.

7/50D Plus or 7/50D Controller Chapter 3: Installation 34

Page 36

3-5 Setup

This section provides the procedures for configuring your 7/50D Plus or 7/50D

controller. Configuration of your controller includes setting the number of stations and

pumps, setting variables such as convey time and blow-back interval, and setting up

passwords. We recommend that you carry out these procedures in the order given here.

Note: Before carrying out these procedures, install all equipment as

described in this section and in the Mechanical Components manual.

Figure 18 below gives an overview of the basic flow between the menus used in setting

up the system.

Figure 18: Basic Menu Flow for Setup

System

System

Pumps

Stations

System

Setup

DeviceNet

Node Status

DeviceNet

Input Status

Pump

Summary

Pump n

Setup

System

Station

Summary

hold icon hold icon

Station n

Operator

Setup

Station n

Setup

7/50D Plus or 7/50D Controller Chapter 3: Installation 35

Page 37

Setting Up the System

Setting the Number of Stations and the Number of Pumps

At the Station Summary screen (shown above), or at the Pump Summary screen:

1. Touch the icon for any station (or pump) and hold it for several seconds. (When the

controller arrives from the factory, only one icon appears.)

A Station n Operator screen similar to the following appears. (If you started at the

Pump Summary screen, the Pump n Setup screen appears instead.)

7/50D Plus or 7/50D Controller Chapter 3: Installation 36

Page 38

2. Touch System at the Station n Operator (or Pump n Setup) screen.

The System Setup screen appears:

Note: Touching Help in the lower right of this screen gives you a menu of

online help for the choices in this screen.

(7/50D Plus Screen shown)

Touching Return at the help menu brings you back to the System Setup screen.

3. Touch Stations Present in the upper left of the System Setup screen.

A keypad pops up.

4. Enter the total number of stations (1–50) to be controlled by this controller. Use ← to

erase any mistakes. Use ↵ to enter the value.

The keypad disappears and the new setting appears under Stations Present.

5. Touch Pumps Present in the upper part of the System Setup screen.

A keypad pops up.

6. Enter the total number of pumps (1–7) to be controlled by this controller. Use ← to

erase any mistakes. Use ↵ to enter the value.

7. The keypad disappears and the new setting appears under Pumps Present.

7/50D Plus or 7/50D Controller Chapter 3: Installation 37

Page 39

Checking Addressing and Wiring for System Components

Once you have set the number of stations and pumps as described previously, you should

verify that the controller is communicating with all stations, pumps, and central alarms, and

with the ArmorBlocks for all central purge valves. To do so:

1. At the System Setup screen, touch DeviceNet Node Status near the lower

right of the screen.

The DeviceNet Node Status screen appears:

2. Check that the expected components are shown as present (green) and not present

(black). (Disregard any error messages.)

For example, if you have 18 stations, boxes 01 through 18 in the Stations section

should be green and boxes 19 through 50 should be black. For central purge valves,

you should see a green box for each ArmorBlock installed.

If the screen display is not as expected, either a component’s ArmorBlock has an incorrect

address or the ArmorBlock is not correctly wired to the network.

When you have verified that the controller is communicating with the other system

components, you should verify that the inputs on all ArmorBlocks for stations and pumps are

wired correctly and are working correctly. To do so:

1. At the DeviceNet Node Status screen, touch DeviceNet Input Status near

the lower right of the screen.

7/50D Plus or 7/50D Controller Chapter 3: Installation 38

Page 40

The DeviceNet Input Status screen appears:

Station numbers are stacked vertically as column headings in this screen.

2. Check that all inputs are on (green) or off (black) as expected and that they switch on

and off as required:

a. Station demand switch: In a new installation, the box labeled Demand

Switch should be green for every station (vacuum hopper) in the system.

(All other boxes for demand switches will be black.) In a retrofit at an

existing installation, each station’s Demand Switch box should be green

unless the receiver bin under the station is in fact full.

b. Station volume-fill proximity switch: For each time-fill station, the box

labeled Volume Fill Prox should be black; no further check is needed

for these stations. For each volume-fill station, you should calibrate the

sensor now and, at the same time, check this input. To calibrate the sensor,

remove the station’s cover, extract the volume-fill proximity switch, and

place the switch in a container of the material that you will be using at this

station. Adjust the sensor according to the procedure given in the

manufacturer’s documentation for the switch. While you are doing this,

check that:

1. The box on this screen is green when the sensor indicates that no

material is present, and

2. The box is black when the sensor indicates that material is

present.

Then reinstall the switch in the station.

7/50D Plus or 7/50D Controller Chapter 3: Installation 39

Page 41

c. Station bypass switch: For every station, the box labeled Bypass Switch

should match the state of the switch at the station. Flip the switches at the

stations in order to check that:

1. Each station’s box is black when its bypass switch is in the “0”

position (station ready to convey), and

2. Each station’s box is green when its bypass switch is in the “1”

position (station bypassed).

Leave each station with its bypass switch off (in the “0” position).

d. Station receiver level: For each station whose receiver has no low-level

switch, the box labeled Receiver Level should be black; no further

check is needed for these stations. For each station whose receiver has a lowlevel switch, you should calibrate the sensor now and, at the same time,

check this input. To calibrate the sensor, remove the receiver’s cover, extract

the low-level switch, and place the switch in a container of the material that

you will be using at this station. Adjust the sensor according to the procedure

given in the manufacturer’s documentation for the switch. While you are

doing this, check that:

1. The box on this screen is green when the sensor indicates that no

material is present, and

2. The box is black when the sensor indicates that material is

present.

Note: You will not see any alarms for “receiver low level” during this

procedure. In order to prevent nuisance alarms when the system starts,

the controller’s software is designed to issue these alarms only after

material has been detected in the receiver at least once.

When you have finished calibration and checking, reinstall the switch in the

receiver.

e. Pump inputs (verify, high vacuum, fault #1, fault #2): All boxes for pump

inputs should be black. Because these inputs can turn on only when the pump

is running, it is not possible to check their operation further at this point.

If any input does not operate as expected, check the wiring on the ArmorBlock. If this does

not solve the problem, phone the Service Department for assistance.

7/50D Plus or 7/50D Controller Chapter 3: Installation 40

Page 42

Setting Up Alarm Silences

When an alarm occurs, a horn sounds and a strobe light flashes at each installed central

alarm. The lower right corner of the controller’s screen turns into a button labeled Alarm

Silence. Touching this button silences the horn(s) and turns off the light(s) for

configurable periods of time. You can set different lengths of time for keeping the horn silent

and keeping the light turned off. If a new alarm occurs, the horn sounds and the light turns on

again.

To set the lengths of time for suppressing the alarm strobe and horn:

1. Go to the System Setup screen.

To reach this screen from the DeviceNet Input Status or DeviceNet Node Status

screen, touch Return until the System Setup screen appears.

To reach this screen from the Station Summary or Pump Summary screen, touch and

hold the icon for any station or pump, until the Station n Operator or Pump n Setup

screen appears. Then touch System. The System Setup screen appears:

The current setting are displayed under Alarm Strobe Suppression and

Alarm Horn Silence.

2. Touch Alarm Strobe Suppression or Alarm Horn Silence, as appropriate.

A keypad pops up, with an entry of 0.

3. Enter the number of minutes (range: 0–99). If you want the light (or the horn) to stay

on as long as the alarm persists, simply leave its entry at 0. If you want the horn (or

the light) to stay off until a new alarm occurs, use 99 for its entry. Use ← to erase any

mistakes. Use ↵ to enter the value.

The keypad disappears and the new setting appears under Alarm Strobe

Suppression or Alarm Horn Silence.

4. Repeat for the other device (strobe or horn) as appropriate.

7/50D Plus or 7/50D Controller Chapter 3: Installation 41

Page 43

Setting Up Pump Staging

To avoid an excessive power demand at your facility when the conveying system starts up,

you can stagger the times at which pumps start. Whenever a demand would cause two pumps

to start simultaneously, your choice for pump staging sets the delay between the start of one

pump and the start of the next. The factory default is a delay of three seconds. You need to

change this setting only if this delay is too long or too short for your facility.

To set the delay between the start of one pump and the next:

1. Go to the System Setup screen if needed.

To reach this screen from the Station Summary or Pump Summary screen, touch and

hold the icon for any station or pump, until the Station n Operator or Pump n Setup

screen appears. Then touch System. The System Setup screen appears.

The current delay is displayed under Pump Staging.

2. Touch Pump Staging.

A keypad pops up, with an entry of 0.

3. Enter the number of seconds (range: 1–99). Use ← to erase any mistakes. Use ↵ to

enter the value.

The keypad disappears and the new setting appears under Pump Staging.

Setting Up Touch Switch Delay

During operation, the controller normally displays the Station Summary screen or the Pump

Summary screen, showing the current status of all stations or pumps. Briefly touching the

icon for a station or pump toggles between taking it offline (disabling it) and putting it online