Page 1

SMS Medium Duty Single Shaft Shredder

SMS 850, 1200, 1500, 2000

Part Number: ESS-0039-S

Bulletin Number: BJ5-615

Effective: 9.30.2008

Write Down Your Serial Numbers Here For Future Reference:

_________________________ _________________________

_________________________ _________________________

_________________________ _________________________

We are committed to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual are subject to change without notice.

DCN No. ____________

© Copyright 2008

All rights reserved.

Page 2

Shipping Info

Unpacking and Inspection

You should inspect your equipment for possible shipping damage.

Thoroughly check the equipment for any damage that might have occurred in transit, such as

broken or loose wiring and components, loose hardware and mounting screws, etc.

In the Event of Shipping Damage

According to the contract terms and conditions of the Carrier, the responsibility of the

Shipper ends at the time and place of shipment.

Notify the transportation company’s local agent if you discover damage.

Hold the damaged goods and packing material for the examining agent’s inspection. Do not

return any goods before the transportation company’s inspection and authorization.

File a claim with the transportation company. Substantiate the claim by referring to the

agent’s report. A certified copy of our invoice is available upon request. The original Bill of

Lading is attached to our original invoice. If the shipment was prepaid, write us for a

receipted transportation bill.

Advise customer service regarding your wish for assistance and to obtain an RMA (return

material authorization) number.

If the Shipment is Not Complete

Check the packing list as back-ordered items are noted on the packing list. You should have:

; Bill of lading

; Packing list

; Operating and Installation packet

; Electrical schematic and panel layout drawings

; Component instruction manuals

Re-inspect the container and packing material to see if you missed any smaller items during

unpacking.

If the Shipment is Not Correct

If the shipment is not what you ordered, contact the parts and service department

immediately at [262] 641-6410. Have the order number and item number available.

Hold the items until you receive shipping instructions.

Returns

Do not return any damaged or incorrect items until you receive shipping instructions from the

shipping department.

BJ5-615 ii

Page 3

Storage, Disposal, Transportation

Storage

Clean the machine (see “Cleaning the Machine”). Preserve all polished metal surfaces using

a suitable rust preventing agent. Store the machine in a dry, enclosed space. Cover the

machine completely with a plastic sheet.

Disposal

The disposal of machines, machine components, and process materials is partially subject to

legal controls. More detailed information is given at the relevant administrative authority

(i.e. regional and national Water Conservation Bureau and Environmental Protection

Agencies). Only deposit the material to be disposed of at authorized drop-off points.

Transportation

WARNING! Suspended load!

• Falling loads can cause serious injury or death. Only use a crane or

forklift that can withstand the weight and dimension of the load!

• Use suitable stopping means and pay attention to gravity center

location!

• Do NOT step under the suspended load!

• Wear protective helmet in addition to basic protective gear!

BJ5-615 iii

Page 4

Table of Contents

CHAPTER 1: SAFETY................................................................5

1-1 How to Use This Manual.............................................................................................5

Safety Symbols Used in this Manual.....................................................................5

1-2 General Safety Regulations ........................................................................................6

1-3 Responsibility..............................................................................................................6

1-4 Warnings and Precautions..........................................................................................7

CHAPTER 2: FUNCTIONAL DESCRIPTION...........................11

2-1 Models Covered in This Manual................................................................................11

2-2 General Description...................................................................................................11

2-3 Typical Features and Components ...........................................................................12

2-4 Safety Features.........................................................................................................20

CHAPTER 3: INSTALLATION..................................................23

3-1 Uncrating the Equipment...........................................................................................23

3-2 Electrical Connections...............................................................................................24

3-3 Initial Start-up............................................................................................................26

CHAPTER 4: OPERATION.......................................................28

4-1 Start-up......................................................................................................................28

4-2 Operation Procedures...............................................................................................28

4-3 Shut-down.................................................................................................................31

CHAPTER 5: MAINTENANCE .................................................32

5-1 Preventative Maintenance Schedule.........................................................................32

5-2 Preventative and Corrective Maintenance ................................................................33

CHAPTER 6: TROUBLESHOOTING .......................................53

6-1 Introduction................................................................................................................53

APPENDIX ............................................................................57

A-1 Returned Material Policy...........................................................................................57

A-2 Technical Specifications............................................................................................58

A-3 Drawings and Diagrams............................................................................................59

A-4 Spare Parts List.........................................................................................................63

A-5 Technical Assistance.................................................................................................84

Parts Department ................................................................................................84

Service Department.............................................................................................84

Sales Department................................................................................................84

Contract Department...........................................................................................84

BJ5-615 iv

Page 5

Chapter 1: Safety

1-1 How to Use This Manual

Use this manual as a guide and reference for installing, operating, and maintaining your

equipment. The purpose is to assist you in applying efficient, proven techniques that enhance

equipment productivity.

This manual covers only light corrective maintenance. No other maintenance should be

undertaken without first contacting a service engineer.

The Functional Description section outlines models covered, standard features, and safety

features. Additional sections within the manual provide instructions for installation, preoperational procedures, operation, preventive maintenance, and corrective maintenance.

The Installation chapter includes required data for receiving, unpacking, inspecting, and setup

of the equipment. We can also provide the assistance of a factory-trained technician to help

train your operator(s) for a nominal charge. This section includes instructions, checks, and

adjustments that should be followed before commencing with operation of the equipment.

These instructions are intended to supplement standard shop procedures performed at shift,

daily, and weekly intervals.

The Operation chapter includes a description of electrical and mechanical controls, in

addition to information for operating the equipment safely and efficiently.

The Maintenance chapter is intended to serve as a source of detailed assembly and

disassembly instructions for those areas of the equipment requiring service. Preventive

maintenance sections are included to ensure that your equipment provides excellent, long

service.

The Troubleshooting chapter serves as a guide for identification of most common problems.

Potential problems are listed, along with possible causes and related solutions.

The Appendix contains technical specifications, drawings, schematics, parts lists, and

available options. A spare parts list with part numbers specific to your machine is provided

with your shipping paperwork package. Refer to this section for a listing of spare parts for

purchase. Have your serial number and model number ready when ordering.

Safety Symbols Used in this Manual

The following safety alert symbols are used to alert you to potential personal injury hazards.

Obey all safety messages that follow these symbols to avoid possible injury or death.

DANGER! DANGER indicates an imminently hazardous situation that, if not avoided,

will result in death or serious injury.

WARNING! WARNING indicates a potentially hazardous situation or practice that, if

not avoided, could result in death or serious injury.

Caution! CAUTION indicates a potentially hazardous situation or practice that, if

not avoided, may result in minor or moderate injury or in property damage.

EJ5-615 Chapter 1: Safety 5 of 85

Page 6

1-2 General Safety Regulations

This machine uses cutters for the performance of its intended use. Consequently, it can be a

dangerous machine to operate and maintain unless these safety regulations are followed.

These regulations should be read, understood and periodically reviewed by all personnel

involved in any way with this machine.

Never operate or remove any machine components that are secured by wrench-type fasteners

unless the motor is electrically locked out and the rotor is motionless.

Never operate the machine or jog the rotor unless the cutting chamber covers, discharge

chute, or any guards or covers are in place and secure. Do not circumvent the safety

interlocks.

Prior to clearing a jam or performing any maintenance, the motor should be turned off and

electrically locked out. Be sure that the rotor has come to a stop. Hands must not be inserted

into the machine to clear the jam.

Do not extend any part of the body into feed roll openings or discharge area unless the motors

are electrically locked out and the rotor and feed rolls are motionless.

Never extend fingers through holes in screen.

Be sure that the v-belts are properly aligned and that tension is at its maximum.

Extreme care should be taken to see that all screws are properly tightened at all times. During

the operation of the machine, rotor cutter screws may come loose. Although fine threads are

used on the rotor cutter screws because vibration does not easily loosen them, you should

inspect the tightness of the screws frequently.

This machine is designed for the granulation of plastic materials. Do not feed any other

materials into the machine.

1-3 Responsibility

These machines are constructed for maximum operator safety when used under standard

operating conditions and when recommended instructions are followed in the maintenance

and operation of the machine.

All personnel engaged in the use of the machine should become familiar with its operation as

described in this manual.

Proper operation of the machine promotes safety for the operator and all workers in its

vicinity.

Becoming familiar with materials, inspection, speed limitations, screens, and guard

maintenance and total user responsibility will assist you in learning potential areas in need of

observation for danger.

Each individual must take responsibility for observing the prescribed safety rules as outlined.

All caution, warning and danger signs must be observed and obeyed. All actual or potential

danger areas must be reported to your immediate supervisor.

EJ5-615 Chapter 1: Safety 6 of 85

Page 7

1-4 Warnings and Precautions

Our granulators are designed to provide safe and reliable operation when installed and

operated within design specifications, following national and local safety codes.

To avoid possible personal injury or equipment damage when installing, operating, or

maintaining this granulator, use good judgment and follow these safe practices:

; LEARN AND OBEY your company’s safety policy regarding granulating

equipment.

; MOVING OR LIFTING THE GRANULATOR: Although our equipment is built

and engineered for great ruggedness in operation, care must be taken when moving

the machine along the floor or lifting it. Damage may occur to sheet metal covers,

electrical cabinets, or small brackets if pressure is applied to them when moving the

granulator. When lifting the granulator, be certain of total machine weight and the

capability of the lifting equipment. (See the Granulator Specification Sheets for

machine weights and dimensions.)

; SHREDDER LOCATION: Adequate area for routine maintenance should be

provided in order to open the machine for cutter, screen, or cleanout service. Proper

service area clearances also should allow people who are working on the machine to

be clearly visible to others, thereby reducing the potential safety hazards.

; SAFE HOUSEKEEPING: The work area must be kept clean and uncluttered during

periods of operation or maintenance. No hand tools or other metal objects should be

left on or around the machine. Any tools or other metal objects that mistakenly fall

into the hopper feed opening can cause severe damage to internal cutting chamber,

rotor and screen components.

; SAFETY GLASSES OR A FACE SHIELD MUST ALWAYS BE WORN when

servicing or operating the machine. Although our machines are designed for the

maximum in flyback control, caution must be used when operating near the hopper

feed opening in order to guard against unexpected material flyback.

; EAR PROTECTION may be required when operating the machine during

granulation of very hard or noisy materials. The Occupational Safety and Health Act

of 1970 has established guidelines for Permissible Noise Exposures (OSHA 1910.95)

that should be followed.

; NEVER attempt to operate the machine unless it is fully assembled with all guards

and interlocks in place and functional.

; OBSERVE all danger, warning, caution and safety labels on the equipment.

; Upon completion of any machine maintenance, be certain ALL SAFETY GUARDS

AND COVERS are securely and properly fastened prior to resuming machine

operation. All fasteners must be in place and properly tightened. ANY

SHORTCUTS MAY RESULT IN INJURY TO PERSONNEL OR DAMAGE

TO EQUIPMENT.

; NEVER wear any loose fitting clothes, neckties, or dangling items such as earrings,

belts, or shoestrings. Jewelry, such as wristwatches, bracelets, or rings should

NEVER be worn. Long hair must be tied back or placed in a tight fitting hairnet.

NEVER lean against or rest hands or feet on the granulator when it is in operation or

open for maintenance. NEVER stand on the granulator when it is in operation.

EJ5-615 Chapter 1: Safety 7 of 85

Page 8

; ROTATION OF MOTORS: The correct rotating direction for the machine motor is

clearly marked on the machine. Always check for proper rotation of motors. Incorrect

rotation direction can cause severe damage.

; ELECTRICAL GROUNDING: All electrical equipment on the granulator must be

grounded in accordance to all local codes and Article 250 of the National Electric

Code.

; ALWAYS DISCONNECT AND LOCKOUT the main electrical power to the

granulator before performing any service.

; SAFETY INTERLOCKS MUST NOT BE BYPASSED. The mechanical and

electrical safety interlocks ensure the safety of personnel. They should never be

tampered with or removed for ANY reason. They should be checked frequently by a

qualified mechanic for proper operation.

; NEVER modify the machine configuration or any individual component without

written notice from the factory.

Remaining Risks

The machine is constructed so that you are able to operate it safely. Structurally non-

avoidable dangers are prevented as well as possible by the protective devices. Certain risks

still remain. It is imperative to be aware of these risks in order to avoid accidents. To avoid

danger, please observe all safety advice provided.

Type of Danger Activity Possible

Consequences

Danger of crushing by

heavy parts falling

down/over

Cutting caused by

sharp cutters—even

when rotor is

stationary

Crushing when

opening/closing

maintenance doors on

front side of machine

Tripping over cables

and other objects

Crushing, cutting,

amputation caused by

run down of the rotor

Unloading and

transporting the

machine and/or

components

Cutter replacement,

cutter setting, cutter

sharpening and other

maintenance work

Maintenance work Serious injury

All activities Serious injury

Maintenance work Serious injury or death

Serious injury

Serious injury

particularly to hands

and fingers

Preventative Measures

• Wear personal protective gear

• Follow safety instructions in

manual

• Wear personal protective gear

• Follow safety instructions in

manual

• Make sure no persons are in the

danger area while closing the door

• Lay cables in accordance with

regulations.

• Keep work station clean and tidy.

• Maintenance doors must always

be tightly locked during operation.

• DO NOT make the run down

safety devices ineffective by using

technical aids or other

manipulations.

• NEVER use hands to check if the

rotor has stopped.

EJ5-615 Chapter 1: Safety 8 of 85

Page 9

Type of Danger Activity Possible

Consequences

Preventative Measures

Pulling in caused by

running V-belts

Direct/indirect contact

with live parts in

terminal box.

Failure of Emergency

Stop function

Fire/explosion caused

by throwing

dangerous objects

(i.e. spray cans) into

the shredder

Damage to hearing All activities Diminished hearing,

Instability of machine

caused by vibration

Loosening of the

cutting cutter

mountings caused by

vibration

Inhalation of grinding

dust

All activities Serious injury can result

from hair, jewelry, etc.

being pulled into the

machine.

Maintenance work,

start up

All activities Serious injury or death

Grinding Serious injury or death

All activities Serious injury

All activities Serious injury

All activities Diseases of the

Serious injury or death

headaches, impaired

balance, deterioration of

concentration

respiratory tract, etc.

• Never dismount V-belt protection

and window.

• Only trained electricians may carry

out all work on the electrical

equipment. If work is necessary

on parts that conduct dangerous

voltage, a second person should

be present to break the power

supply in case of emergency.

• The yellow-marked lines conduct

voltage at all times—even when

the machine is switched off.

• Only use original safety fuses with

stipulated intensity of current.

• Faulty electrical components must

be replaced immediately.

• If faults occur in the electrical

energy supply, switch machine off

immediately.

• The terminal box must be locked

during operation. Before opening

the terminal box switch too off

(“O”).

• It must be guaranteed that failure

of an Emergency Stop button is

displayed and leads to an

immediate stop.

• Only grind material which

corresponds to the agreed

customer-specific specifications in

all points.

• Reduce noise emissions by taking

suitable measures.

• Wear ear protection.

• Install the machine according to

the instructions in the manual.

• Check the cutting cutter mountings

regularly according to the

instructions in the manual.

• Mount a suitable air suction device

and wear breathing equipment if

necessary.

• When cleaning the machine, use

suction; do not blow out grinding

dust.

EJ5-615 Chapter 1: Safety 9 of 85

Page 10

Type of Danger Activity Possible

Consequences

Preventative Measures

Crushing, cutting,

amputation caused by

manipulation of

protective devices

For further information on granulator safety, installation, and operation, see the American

National Standard for Plastics Machinery

Size Reduction of Plastics

We have long recognized the importance of safety and have designed and manufactured our

equipment with operator safety as a prime consideration. We expect you, as a user, to abide

by the foregoing recommendations in order to make operator safety a reality.

All activities Serious injury or death

⎯

Granulators, Pelletizers, and Dicers Used for

⎯

Construction, Care, and Use. ANSI B151.11-1982.

• Never make the protective devices

ineffective.

• Check the protective devices

regularly for proper function

according to the manual’s

specifications.

EJ5-615 Chapter 1: Safety 10 of 85

Page 11

Chapter 2: Functional Description

2-1 Models Covered in This Manual

The models included in this manual are the Sterling SMS 850, 1200, 1500 and 2000

Medium Duty Single Shaft Shredders. The SMS Series is designed for processing scrap

from wood industries—miscellaneous trim and panel scraps, furniture, injection and

extrusion mold start-up purge, heavy wall parts, paper and cardboard, and film (baled and

loose).

2-2 General Description

Mechanical Section

After the machine has been switched ON, a hydraulically controlled “swing-style” ram

pushes a quantity of material onto the slow-running profiled rotor. The in-feed is

controlled according to load.

The material can be placed (unsorted) in the hopper mounted on top of the machine. Pay

attention to this material; it cannot contain any other metal parts except for staples and

nails. (The guarantee does not cover any damage to the machine as a result of metal parts

being fed into the machine.) The material in the hopper is shredded by the cutters on the

rotor. This shredding process is repeated as often as required until the whole diameter of

the screen below the rotor has been reached.

The shredder can also be switched off with material still in the hopper.

Control

The machine is fitted with an automatic shut-down; i.e. when set to automatic, the

machine switches off after a pre-set period in the time relay.

The ram feeds the shredding unit (rotor) with as much material as it is able to process.

Upon reaching 70 to 90 % of rated current, the feeding of the ram will be stopped and

automatically started again after the power consumption has fallen by 20% in comparison

with rated current. If the high current is applied longer than 0.7 - 1.5 seconds, the main

drive motor switches off and runs back after about 3 seconds standstill time. The ram

plate also runs back while the rotor runs back. The drive motor then stops for another 3

seconds before starting again.

Duration of pauses and return and current settings can be adjusted.

NOTE: Any alterations should only be carried out after consulting the manufacturer.

EJ5-615 Chapter 2: Functional Description 11 of 85

Page 12

Machine (Standard Execution)

(1) Base Frame

(2) Machine door

(3) Hopper door

(4) Gear Box

(5) Drive motor

(6) V-belt guards

(7) Ram hydraulic guards

(8) Discharge area

The machine housing, drive motor, gear box, hydraulic system and terminal box are

mounted on the base frame for electrical connections.

2-3 Typical Features and Components

3

7

4

2

6

5

8

1

Material In-feed

The material can be fed into the shredder in the following ways:

• Manual in-feed of the material directly into the in-feed hopper.

• Manual in-feed of the material with the help of an additional in-feed device

(e.g. hydraulic feeding unit).

• Automatic in-feed of the grinding material via an additional in-feed device

(i.e. conveyor belt).

EJ5-615 Chapter 2: Functional Description 12 of 85

Page 13

Special hopper

with hydraulic

cover

In-feed Hopper

The material in-feed flows through an in-feed hopper to ensure the grinding material is

delivered safely and correctly.

NOTE: An optional top-hinged cover to prevent in-feed material fly-back during size

reduction is available.

Additional In-feed Device

If the machine has an optional in-feed device such as a conveyor belt, please refer to the

additional information about the accessory in the manufacturer’s manual that

accompanied the accessory. A special hopper for an in-feed with conveyor arrangement

can be supplied as an option to the standard hopper.

Hopper for conveyor

belt in-feed

EJ5-615 Chapter 2: Functional Description 13 of 85

Page 14

Drive

The drive of the rotor runs using an electric motor via V-belts. The motor (mounted on

sliding rails or a motor plate) can be adjusted for regulating the tension of the V-belts

using tensioning screws. The V-belt pulley is attached to the motor shaft with a special

tensioning element.

Drive motor

NOTE: Please observe the operation manual from the manufacturer!

Rotor, Cutters, Bed Cutters

Rotor, cutters, bed cutters

• The material is shredded between the cutters assembled on the rotor and the bed

cutters; they are mounted in a fixed position in the machine lower section.

• All rotors are equipped with square cutters. These cutters make light work of the

heaviest pieces.

NOTE: The cutters have four corners so they can be easily turned once a corner has

worn out.

• The design of the rotor has a significant influence on the quality of the shredding

process and the results. The rotor construction, the type of cutter mounting and

the number of cutters have been matched to the application.

EJ5-615 Chapter 2: Functional Description 14 of 85

Page 15

(1) Rotor cutter

(2) Screen support

(hydraulic)

(3) Bed cutter

1

3

2

(1) Rotor cutter

(2) Screen support

1

2

The rotor is accessible after opening the machine door and removing the screen.

The rotor is arranged on roller bearings that situated outside the housing. The V-belt

pulley is attached to the rotor axis with a taper brush. The rotor is dynamically counterbalanced and has vibration-free concentricity.

EJ5-615 Chapter 2: Functional Description 15 of 85

Page 16

An optional feature is a water cooling system for the rotor used for special applications.

Bearing with water plug

for rotor cooling

Screen and screen support

The screen and the screen support are welded together and fixed to the housing by screws

in the standard execution.

The screen is slightly larger in radius than the cutting circle of the rotor cutters. The

screen perforation is selected according to the desired grain size of the grinding material.

All shredding material parts which are smaller than the screen perforation fall through the

screen. The screen is replaceable and can be taken out after opening the machine door.

Standard screen

EJ5-615 Chapter 2: Functional Description 16 of 85

Page 17

(1) Hydraulic cylinder

(2) Screen support

(3) Screen

Another optional feature is a screen support that can be lowered by a hydraulic system.

Discharge with

conveyor

3

1

Discharge of Shredding Material

Normally the shredded material will be discharged onto a conveyor belt. (Options

include a discharge with blower or with a screw conveyor.)

EJ5-615 Chapter 2: Functional Description 17 of 85

Page 18

Hydraulic Ram

The hydraulic ram is fixed on two arms arranged on flange bearings. Two heavy duty

hydraulic cylinders move the ram back and forth. The ram moves automatically after

switching ON the hydraulic system and the shredder when the machine is operated in

automatic mode.

NOTE: The ram can be moved by hand on the control panel when run in manual

(1) Hydraulic cylinder

(2) Flange bearing

(3) Ram arm

(4) Ram

(5) Hydraulic unit

2

4

3

mode.

(1) Serrated ram front

plate

(2) Rotor

2

1

1

5

EJ5-615 Chapter 2: Functional Description 18 of 85

Page 19

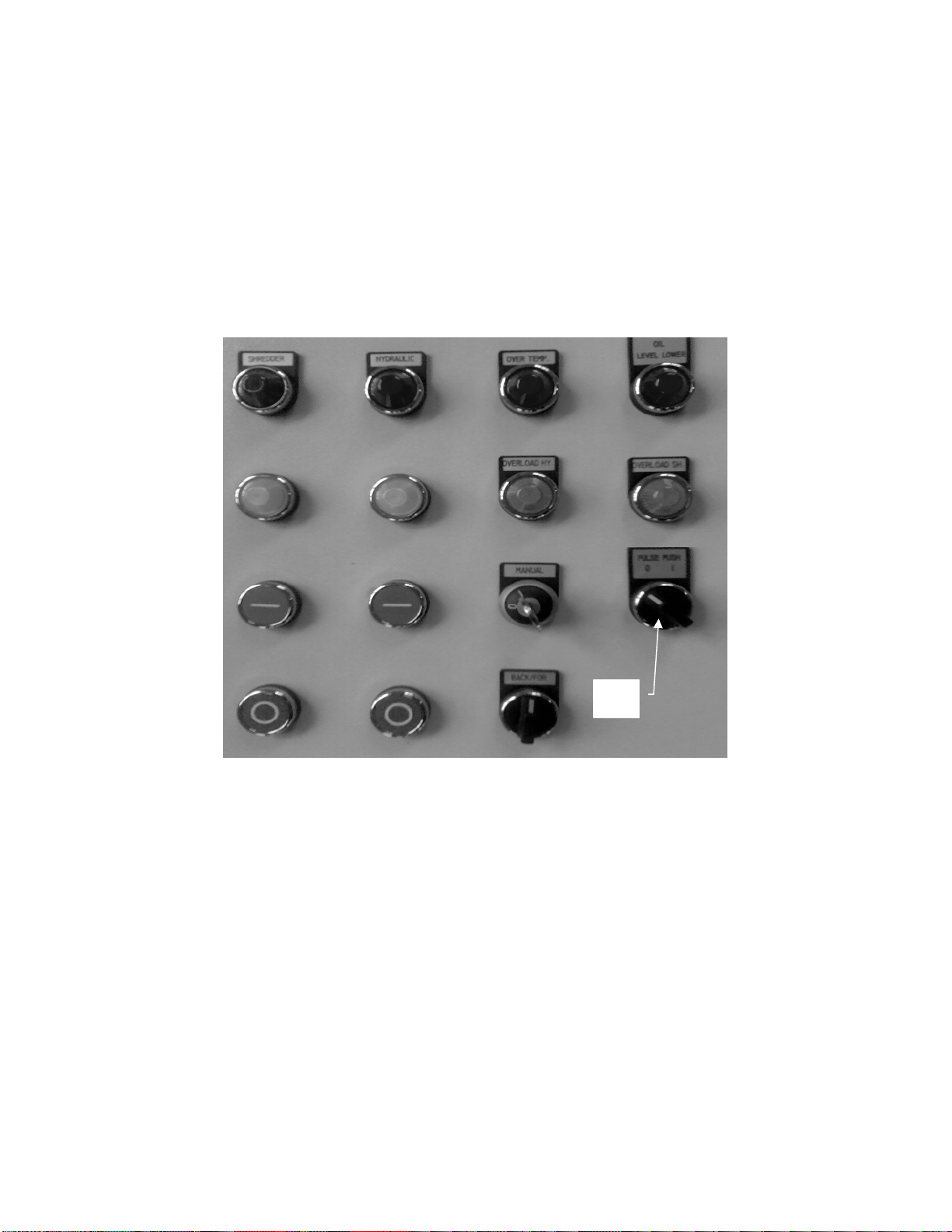

Pulse Push Function

In normal process mode, the ram pushes forward continuously until the ram arm reaches

the proximity switch, reverses the function, and the ram moves backwards.

The ram moves forward in steps when the switch (1) is changed to “Pulse Push”. This

means that after each step, the ram remains in position for a couple of seconds before it

moves forward again.

This function should be used for very heavy applications and when overloading the

system is a concern.

(1) Pulse push switch

1

EJ5-615 Chapter 2: Functional Description 19 of 85

Page 20

2-4 Safety Features

Safety device:

machine door

Protective Devices

CAUTION: The Machine may under no circumstances be operated without these

protective devices. The use of faulty or manipulated protective devices

is strongly prohibited.

Safety Device for Housing Flap

Safety device:

hopper door

The shredder can only be operated if the doors are closed—deactivating the safety switch.

The safety contact is broken when the machine or hopper door is open, thus switching off

the machine.

EJ5-615 Chapter 2: Functional Description 20 of 85

Page 21

V-Belts and Ram Guards

V-belt and ram guards are screwed to the machine. They can be dismounted for

installation and maintenance work only when all rotating parts have come to a complete

standstill and the machine is electronically locked out.

(1) Ram guarding

(2) V-belt guarding

NOTE: The operator must fit and mount the protective devices delivered with the

machine according to current legal safety regulations if a machine is delivered

without drive motors per request of the customer.

Safety Markings

Safety markings are attached to the machine. Should one of these markings

becomes detached or is no longer recognizable, it must be replaced. New safety

markings can be ordered through safety signage provides or from the

manufacturer.

Personal Protective Gear

Wear close-fitting clothing. Hair must be pulled back, and loose jewerly is

prohibited.

1

2

EJ5-615 Chapter 2: Functional Description 21 of 85

Page 22

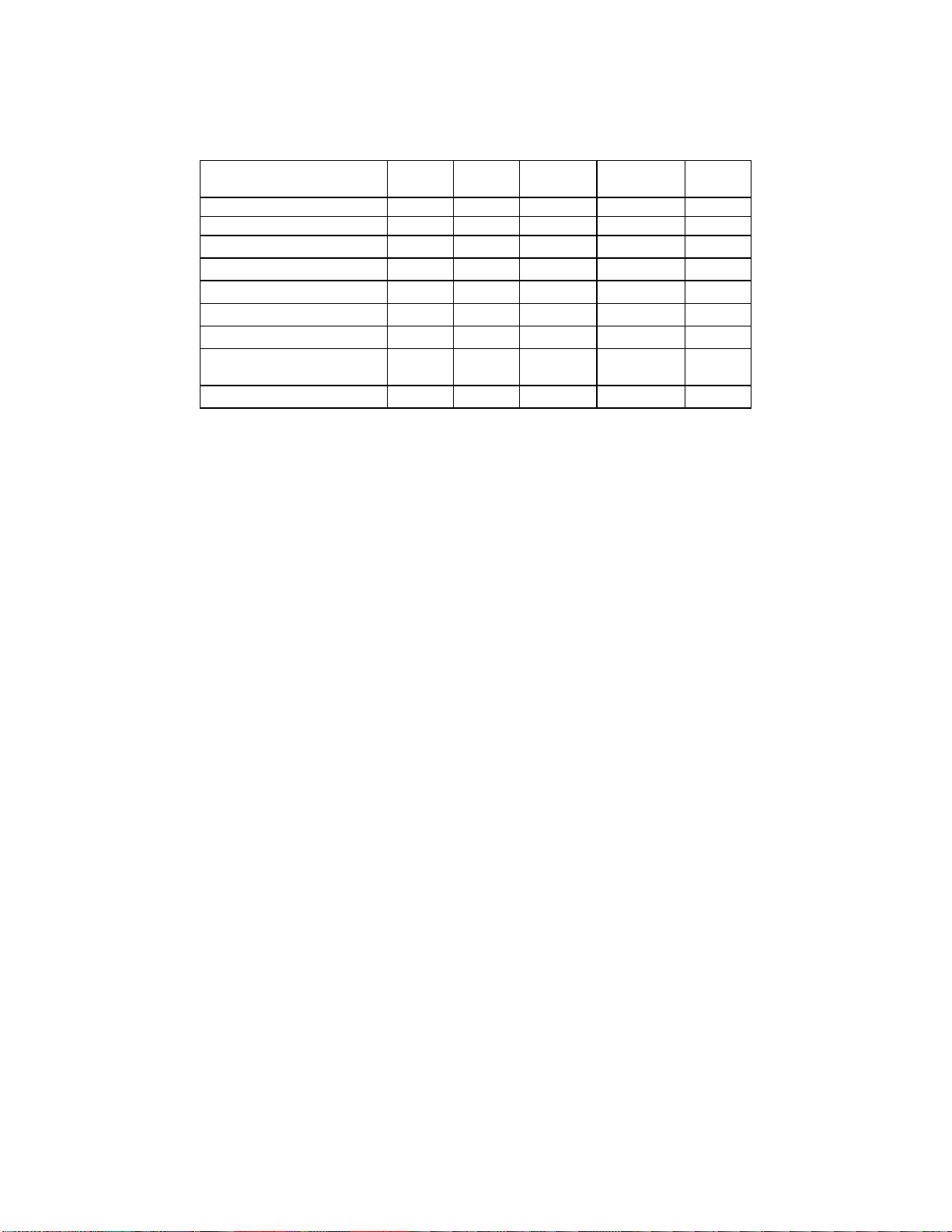

The following protective gear must be worn when carrying out the following tasks:

Unloading machine. x x x

Connecting machine. x

Operation. x x x x

Cleaning. x x x

Maintenance of bearings. x

Screen replacement. x x

Maintenance of V-belts. x

Maintenance of cutting

cutters.

Cutter sharpening. x x x x

Safety

helmet

Emergency Stop Button

The machine may only be operated with the installed Emergency Stop buttons.

An Emergency Stop Button must be mounted to the control cabinet and another

on the grinding material in-feed.

Immediately press one of the Emergency Stop buttons in case of an emergency.

CAUTION! The Emergency Stop must be activated in all situations where injury or

damage could result!

Re-operation:

Safety

boots

Safety

gloves

x x

Safety

goggles

Ear

muffs

1. Eliminate cause of Emergency Stop.

2. Unlock Emergency Stop button

3. Acknowledge fault.

4. The machine is now ready for operation.

EJ5-615 Chapter 2: Functional Description 22 of 85

Page 23

Chapter 3: Installation

3-1 Uncrating the Equipment

Requirements at Application Site

Check the application site to make sure it conforms to the qualifications listed below.

• The site is an enclosed space.

• The ground has sufficient load-bearing capacity (Refer to “Technical

Specifications” in the Appendix for machine weight). The unevenness of the

ground surface may not exceed 5 mm.

• The machine must be freely accessible from all sides.

• There must be sufficient room available for operating and service personnel.

• Spatial requirements: Refer to “Drawing and Diagrams” in the Appendix for

machine dimensions . All hinged parts must be able to be opened

completely.

• Vibration-free environment.

• The site has sufficient lighting.

• The machine may not be exposed to direct radiation caused by radiators or

the sun.

• Room temperature: +41 to 104 °F (+5° to +40°C)

• Relative atmospheric humidity according to DIN 40040:

15 to 70 % (indoor)

NOTE: By humidity levels higher than 70 %, apply anticorrosive agent

to the metallic-finished machine parts. Insulation for the

tropics is also necessary.

• The machine may not be operated within range of static discharges or strong

magnetic fields as this could lead to faults in the machine control system.

Unloading and Installing the Machine

The machine and components are packed so they arrive safely. Use a suitable crane or

forklift for unloading the packaged machine and/or components.

1. Remove the packaging material and all transportation safety devices after

unloading the machine.

2. In the case that the shredder and its accessory components have been

delivered as individual items, mount them at the site of application in

accordance with the Assembly Drawing. This is the only way to

guarantee there are sufficient piping parts, tubing, and cable connections,

and that the linking places match.

BJ5-615 Chapter 3: Installation 23 of 85

Page 24

WARNING! SUSPENDED LOAD!

• Falling loads can cause serious injury or death.

• Only use a crane or forklift suitable for the weight and the

dimensions of the load.

• Use suitable stopping equipment and pay attention to the gravity

center location.

• DO NOT step under the suspended load.

• Wear a safety helmet in addition to basic protective gear.

WARNING! OVERTURNING OR FALLING MACHINE!

• Serious injury or death can result.

• If erecting the granulator over a pit, on a frame, or on a platform,

you MUST secure the machine by putting mounting screws through

the holes on the mounting pads (see Assembly Drawing). If

assembling the machine on solid ground, this safety device is not

always necessary.

3. Align the machine horizontally with the help of a suitable spirit level.

4. Do not use blocks to place underneath the machine; use metal strips to

prevent buckling of the base frame. Make sure that an even distribution

of weight is achieved on all the points of support.

3-2 Electrical Connections

CAUTION! Electrical connections should only be made by a qualified electrician.

WARNING! DANGEROUS VOLTAGE! Touching live parts can lead to serious

injury or death. All work relating to the electricity of the machine may only be

carried out by trained electricians. Observe the currently effective EMC regulations.

Voltage, current, frequency, and protection are marked on the type plate. The voltage

tolerance is +/- 10%.

The electrical connection is to be carried out in accordance with the wiring diagram in the

terminal box for machines not pre-wired by the manufacturer.

NOTE: When making electrical connections, the regulations of the local electricity

authority must be followed. The required cable cross section required is

determined according to the rated capacity of the units.

BJ5-615 Chapter 3: Installation 24 of 85

Page 25

WARNING! Use caution when operating specific equipment to prevent electrical

shock. Installation, service, alterations, and/or modifications must only be done by

qualified personnel and with high regard for safety. Not conforming to the

requirements could result in bodily harm, death, or costly damage.

NOTE: Alterations to the wiring diagrams require approval. Failure to do this will

exclude all guarantee claims.

The wiring schematics are located in the control panel.

Connection of Emergency Stop Button

The machine may only be operated with installed Emergency Stop buttons. An

Emergency Stop button must be installed at the control cabinet and at the grinding

material in-feed if no Emergency Stop buttons have been installed at the factory.

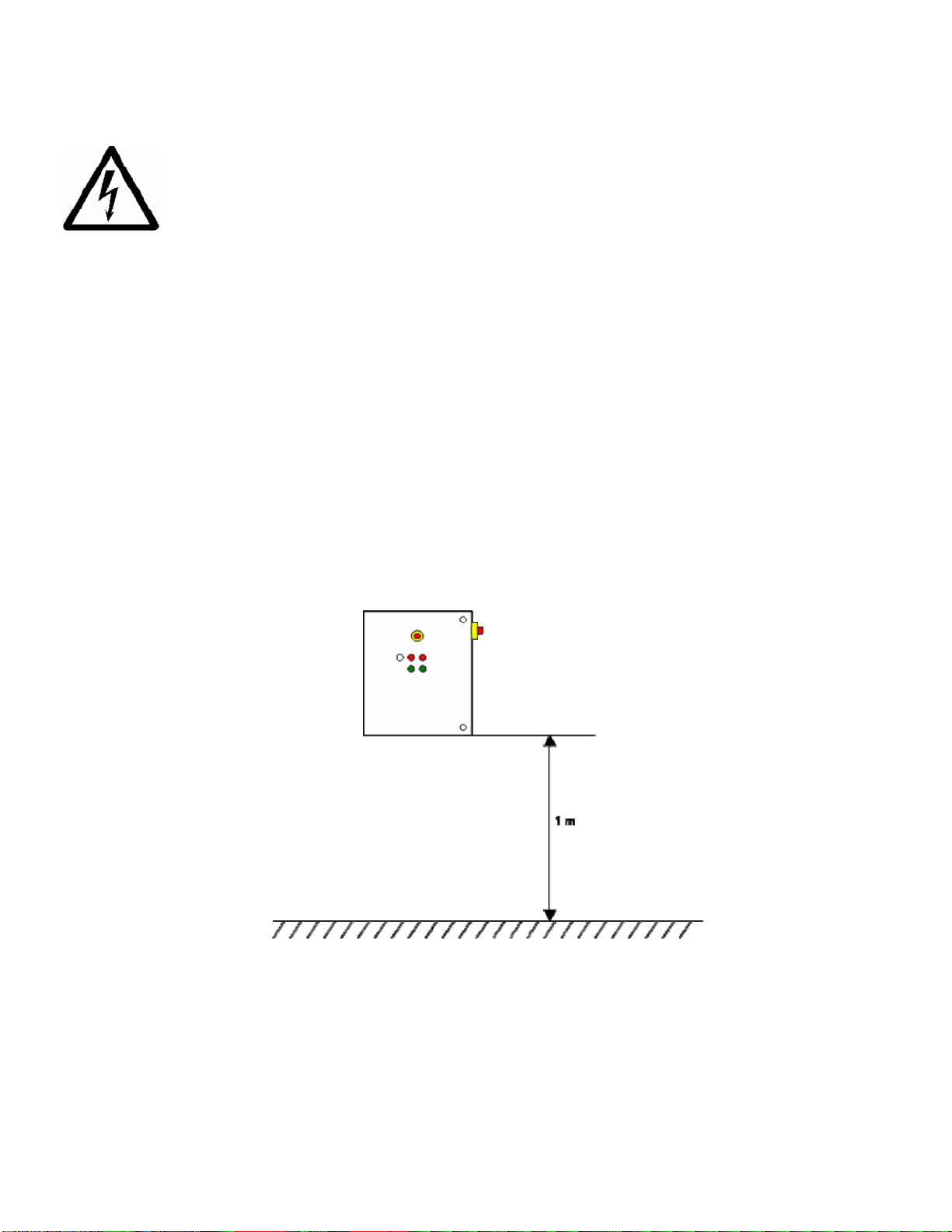

NOTE: The control panel with the switches and Emergency Stop button must be installed

near the machine. The distance should not exceed 5 m.

The distance between the floor and the lower edge of the control panel should be

at least 1 m.

The connecting cables between the control panel and the machine must be protected

against damage (cable tray, protective sleeve).

An additional Emergency Stop button has to be installed on the machine if the control

box cannot be installed according to these rules.

BJ5-615 Chapter 3: Installation 25 of 85

Page 26

Checking the Rotational Direction

Rotational direction of the motors must be checked before initial start-up. The following

steps must be completed.

1. Switch the machine ON and then immediately OFF again.

2. Observe whether the discharge air fan in the drive motor is rotating in the

direction of the direction arrow.

NOTE: If running in the wrong direction, reconnect the motor connection

immediately. Damage to the machine will result from operation in the wrong direction.

3-3 Initial Start-up

General Advice

• All work related to start-up may only be carried out by trained and specialized

personnel.

• Check the machine for possible transportation damage or other damage. If any

damage exists, confirm it with the freight company and report it to the manufacturer.

• After setting up for service and before starting up for the first time, necessary checks

must be completed.

• Check the oil level of the gear box before operating the machine.

• Fill oil into the hydraulic tank.

• Please observe the operation manual from the manufacturer

!

Machine Check Prior to Start-up

9 Use a torque wrench to check the cutter mounting screws when lower housing flap is

open.

9 Search the grinding chamber for foreign matter.

9 Open the lower housing flap and make sure the screen has been inserted in

accordance with the regulations.

9 Close upper housing flap and fasten screws tightly.

9 Check oil level of the gear box.

9 Fill oil into the hydraulic unit.

9 Examine in-feed device (accessories) for foreign matter.

9 Check that the Emergency Stop buttons are unlocked.

9 Check all safety devices for proper functioning.

BJ5-615 Chapter 3: Installation 26 of 85

Page 27

9 Switch ON machine for a short period of time and check rotational direction. The

rotational direction can be seen at the discharge air fan of the drive motor (observe

running direction arrow).

9 Switch ON hydraulic unit for a short time and check rotational direction.

9 Allow machine to run for approximately 10 minutes without shredding material.

9 Connect material discharge device and in-feed device; check rotational direction

drives.

9 Feed grinding material uniformly. Too much grinding material can lead to overload

of the machine.

9 Check the temperature of the shredded material if necessary.

9 Monitor the ammeter. This displays the present current consumption and gives

information on the load of the machine.

BJ5-615 Chapter 3: Installation 27 of 85

Page 28

Chapter 4: Operation

4-1 Start-up

WARNING! No persons should operate the machine until they have read and

understand all parts of the operation manual.

Machine Check—Before Switching Machine ON

9 Cutters and bed knives are properly set and the screws are tightened with the

specified torque.

9 Screen is inserted into the screen support according to the instructions, and the screen

support is fixed at the end position with tightened mounting screws.

9 The cutting chamber is free of foreign matter.

9 The machine and hopper doors are closed.

9 All safety devices, including those of the installed grinding material in-feed and

discharge devices, are checked and operative.

Switch ON Machine

1. Switch ON the material discharge device.

2. Switch ON the shredder (main switch to 1). Wait until the rotor has reached

its full speed and switched from star to delta.

3. Switch ON the hydraulic system.

4. Switch ON the material in-feed device (accessories).

4-2 Operation Procedures

Manual In-feed of Material

DANGER! Rotating Cutters!

Can cause serious cutting and crushing injuries that could result in

death.

Do NOT reach into the in-feed hopper or lean in while the rotor is

running. (Pay attention to the run down time). Only use approved

grinding material.

BJ5-615 Chapter 4: Operation 28 of 85

Page 29

• Throw the grinding material into the in-feed hopper.

• The machine should be fed from the front.

• If your machine has an additional in-feed device installed, please observe the

additional information for working with the in-feed device.

DANGER! Do not climb into the in-feed hopper while operating the

machine. Death will result.

Emptying the Screen (standard screen)

1. Switch OFF the shredder at the main switch

2. Safeguard main switch using a padlock.

3. Open the machine door.

4. Safeguard the machine door.

5. Hold the screen with a forklift.

2

3

(1) Screen

(2) Screen mounting screws

(3) Cutter adjusting screws

(4) Forklift

4

6. Remove the screen.

7. Empty the screen.

8. Put the screen back using a forklift.

9. Fasten the mounting screws.

10. Close the machine door.

11. Shredder can be started again.

1

BJ5-615 Chapter 4: Operation 29 of 85

Page 30

Emptying the Screen (hydraulic screen)

1. Switch OFF the shredder at the main switch.

2. Safeguard main switch using a padlock.

3. Open the lower machine door.

4. Safeguard the machine door.

5. Pivot the screen support downwards by pushing the button screen open on the control

box.

6. Remove the screen.

7. Empty the screen.

8. Put the screen back into the screen support.

9. Pivot the screen support into the working position and fasten using the mounting

screws.

10. Close the machine door.

11. Shredder can be started again.

(1) Hydraulic cylinder

(2) Screen support

(3) Screen

(4) Rotor

4

3

1

BJ5-615 Chapter 4: Operation 30 of 85

Page 31

4-3 Shut-down

Switch OFF Machine

1. Switch OFF the material in-feed device (accessories).

2. Wait until the remaining grinding material has been shredded, and then switch OFF

the shredder (main switch to 0).

3. Switch OFF the material discharge device.

BJ5-615 Chapter 4: Operation 31 of 85

Page 32

Chapter 5: Maintenance

5-1 Preventative Maintenance Schedule

Only trained and specialized personnel should carry out maintenance work

Maintenance Plan

WARNING!

• Danger caused by electrical voltage and

starting the machine during maintenance

work. Death can result!

• ALWAYS turn main switch to 0, safeguard using a padlock, and attach

a warning sign while carrying out maintenance work.

The tasks for maintenance work are described below.

Perform the following after every 8 operation hours:

• Check protective devices.

• Check cutting cutter mountings.

• Check condition of cutting cutters.

Perform the following after every 40 operation hours:

.

• Check V-belt tension force and V-belt condition.

• Check all screws of the machine for a tight fit.

• Check wearing parts.

Check hydraulic oil level and consistence.

•

Per form the following after every 2000 operation hours:

• Change hydraulic oil

•

Check gearbox oil level

Yearly maintenance:

• The purpose of yearly maintenance is primarily to check the general condition of

the machine and to arrange for the supply of any necessary replacement parts. A

service engineer can carry out this request.

BJ5-615 Chapter 5: Maintenance 32 of 85

Page 33

5-2 Preventative and Corrective Maintenance

Checking the Protective Devices

Check the safety devices for:

• Stipulated condition

• Stipulated location

• Safe mounting

• Stipulated function

WARNING! Danger due to non-functioning protective devices can cause serious injury

or death!

• Eliminate all defects before operating the machine!

• If defects occur during operation, stop the machine

immediately and eliminate the defects!

• Do NOT change or remove any protective devices. Do NOT put any

protective devices out of action by modifying them.

Cleaning the Machine

WARNING! Danger of cutting caused by sharp cutting cutters—even when the rotor is not

operating! Serious injury, especially to the hands and fingers, can result.

Wear protective gloves!

Proceed as follows:

1. Switch OFF the shredder at the main switch.

2. Safeguard main switch using a padlock.

3. Open the machine and hopper doors.

4. Safeguard the machine and hopper doors.

5. Remove the screen.

6. Empty the screen.

WARNING! Inhalation of process dust is hazardous to your health! Never blow out the

shredded material residue—always use suction instead! Wear breathing

protection if necessary!

7. Pre-clean the cutting chamber using a hand brush.

8. Vacuum the remaining shredded material residue using a suitable device.

9. Remove clinging grinding material residue using a suitable wooden scraper.

BJ5-615 Chapter 5: Maintenance 33 of 85

Page 34

10. Place the screen back into its working position and fasten with the mounting

screws.

11. Close the machine and hopper doors.

12. Machine can be started again.

Replacing the Gear Box

The gearbox is made so a replacement is only necessary in exceptional cases.

Dismounting and mounting the gear box requires specialist knowledge and a careful

working method. Please observe the instructions given in the installation manual of the

gear box manufacturer or ask the service department for help.

Replacing the Rotor

The rotor’s design is heavy duty, so a replacement is only necessary after a crash, (i.e. a

hammer fall inside). Dismounting and mounting of the rotor requires specialist

knowledge and a careful working method. Call the Service Department for assistance.

Dismounting the Rotor

1. Dismount the V-belt cover.

2. Dismount the V-belts.

3. Dismount the gearbox.

4. Remove the screen.

5. Remove the rotor mounting slot cover plates from the housing.

6. Screw in hooks on both shaft ends.

7. Remove the bearing housing mounting screw.

8. Carefully lift out the complete rotor using suitable lifting and stopping equipment.

9. Lay the rotor down in a safe location using appropriately sized timber beams.

Mounting the Rotor

1. Before starting, clean the bearing seat surfaces and check the key.

2. Lift the rotor using suitable lifting and stopping equipment and place carefully into

the bearing seats.

3. Attach the bearing housing (Pos.) to the bearing seats using screws.

4. Put the gear onto the rotor axis.

5. Put back the rotor mounting slot cover plates.

6. Put in the screen.

7. Pull on V-belts and adjust the V-belt tension force.

8. Attach the V-belt.

BJ5-615 Chapter 5: Maintenance 34 of 85

Page 35

9. Carry out a test run.

NOTE: If the spare rotor is delivered without bearings, the bearings MUST be

mounted first.

Replacing the Main Bearings

The main bearings of the machine are made so a bearing replacement is only necessary in

exceptional cases. Dismounting and mounting of the bearings requires specialist knowledge

and a careful working method. In addition to the following advice, please observe the

instructions given in the installation manual of the bearing manufacturer or ask the service

department for help.

The bearings mounted in this machine are indicated in the spare parts list. A suitable pullingoff device is a required for dismounting and mounting the bearings

Dismounting the Main Bearings

1. Dismount the V-belt cover.

2. Dismount the V-belts.

3. Dismount the gearbox.

.

4. Pull the distance sleeve off the rotor axis.

5. Remove the screen

6. Remove the rotor cover plates from the machine housing.

7. Screw in hooks on both shaft ends.

8. Hang on rotor on both shaft ends.

9. Remove the bearing housing mounting screw.

10. Carefully lift out the complete rotor using suitable lifting and stopping equipment.

11. Lay the rotor down in a safe location using timber beams of appropriate size.

12. Loosen the mounting screws on the bearings cover.

13. Pull the bearing housing off with a pulling-off device.

14. Pull the bearing off the rotor axis using a pulling-off device.

Mounting the Main Bearings

1. Before mounting, clean the bearing surfaces and the shaft surfaces thoroughly and

grease lightly.

2. Mount bearing in bearing housing.

3. Attach the bearing with the bearing housing to the rotor axis.

4. Lift the rotor using suitable lifting and stopping equipment and place carefully into

the bearing seats

BJ5-615 Chapter 5: Maintenance 35 of 85

Page 36

5. Attach the bearing housing to the bearing seats using screws.

6. Push the distance sleeve onto the rotor axis.

7. Put the gear onto the rotor axis

8. Put back the rotor cover plates

9. Put in the screen

10. Pull on V-belts and adjust the V-belt tension force.

11. Attach the V-belt cover.

12. Carry out a test run.

NOTE:

• The roller bodies will be damaged unless the mounting forces engaged into inner

ring.

• The hardened bearing rings are sensitive to impact stress; never hit the rings with

the hammer. Use a brass arbor or a striking bushing (piping piece) made from a

soft material. The inner diameter of the striking bushing should be only slightly

larger than the diameter of the bearing base.

• The bearing is then pushed onto the shaft using light blows. The force of pressure

must be evenly distributed on the circumference of the bearing ring.

Lubricating the Main Bearings

An important requirement for high operational safety and long service life of the arrangement

of bearings is the correct lubricant supply. Every machine is greased and checked in test runs

before delivery.

NOTE: Unsuitable lubricant, lubricant deficiency, excessive lubricant, or impurities in the

lubricant lead to overheating and extreme wear of the bearings.

Lubrication Intervals

Shift Operation Replace Lubricant Check

One shift operation Every 18 months Monthly

Two shift operation Every 9 months Monthly

Three shift operation Every 6 months Monthly

Check lubricant quality

You can judge whether the lubricant needs to be replaced by checking for the

following features:

• Change in consistency

• Discoloration

• Degree of soiling

BJ5-615 Chapter 5: Maintenance 36 of 85

Page 37

Replacing or Refilling Lubricant

• Fill the bearings uniformly with grease until all operating surfaces are well-greased.

• For the rotor bearings, a lubricant quantity of one third to a maximum of half of the

bearing volume per bearing is required. If too much grease is used, the lubricant will

become unusable due to excessive temperature.

• Only one type of grease may be used, mixing different types of grease is prohibited.

The bearings have been filled at the factory with lithium base saponification roller

bearing grease F3.

• Refer to the “List of Lubricants” in this section for recommended bearing grease.

Refilling lubricant

The grease reaches through the circulating grooves and bores via lubrication nipples into the

interior of the bearing.

The greasing quantity is .13 to .22 lbs (60 to 100 g) roller bearing grease F3 per bearing.

Grease Nipple

Replacing Lubricant

Renewing the lubricant between intervals is only necessary when there unusual noises or

overheating. Mounting and dismounting of the bearings must be carried out in

accordance with the instructions in this operation manual (see replacing the bearings).

1. Open the bearing.

2. Remove the bearing housing and the bearing cover.

3. Clean the bearing carefully using petroleum ether.

NOTE: Petroleum ether, petroleum, spirit, aqueous neutral or alkaline

cleaning agents may be used to clean the bearings. After washing

BJ5-615 Chapter 5: Maintenance 37 of 85

Page 38

out, the bearing must immediately be preserved using lubricant, in

order to avoid corrosion.

4. Fill bearing with approved lubricant (refer to “List of Lubricants”).

List of Recommended Lubricants

Country of Manufacturer/Manufacturer Roller Bearing Grease

ARAL ARL Grease HL 3

BP BP ENERGREASE LS 3

CASTROL CASTROL SPHEEROL AP 3

ESSO Beacon 3

FUCHS FUCHS Grease 1200

FUCHS Grease FWA 220

SHELL SHELL Alvania Grease 3

MOBIL-OIL MOBILUX 3

WISURA WISURA Liba L 3

Zeller $ Gmelin ZET GE Grease M 50

FAG FAG L 71

ANTAR ROLEXA

Holland, Beverol Beverol Multi Purpose Grease

Italy, Agip AGIP Grease 33 FD

Swede, NYNAS Nynas FI 3-42

BJ5-615 Chapter 5: Maintenance 38 of 85

Page 39

Mounting and Dismounting TAPER-LOCK Tensioning Element

The motor and the gear V-belt pulleys are attached to the shaft using a TAPER-LOCK

tensioning element. The disks must be dismounted for certain maintenance processes.

BJ5-615 Chapter 5: Maintenance 39 of 85

Page 40

Tightening Torque of the Screws

Refer to the table below.

Tensioning Screws- Screw details

element (Type) Tightening torque in Nm Number Size (BSW)

1008 5,6 2 1/4"

1108 5,6 2 1/4"

1310 20 2 3/8"

1315 20 2 3/8"

1210 20 2 3/8"

1215 20 2 3/8"

1610 20 2 3/8"

1615 20 2 3/8"

2012 31 2 7/16"

2017 31 2 7/16"

2517 48 2 1/16"

2525 48 2 1/16"

3020 90 2 5/8"

3030 90 2 5/8"

3535 60 3 1/2"

4040 102 3 5/8"

4545 155 3 3/4"

5050 185 3 7/8"

Replacing the Screen

V-Belts

The condition of the screen must be checked regularly in order to keep the throughput of

the shredder and the quality of the shredded material constant.

The screen may be damaged, dirty or not suitable for shredding material when:

• Screen holes are too fine—overheating of the shredded material can occur.

• Screen holes are too course—shredded material can have larger pieces that

are unacceptable.

Standard Screen and Hydraulic Screen

Please refer to the section “Emptying the Screen” in Chapter 4.

V-belts are wearing parts that stretch and must be re-tensioned. Regular checks on the

tension force of the V-belts and the condition of the V-belts are necessary in order to

guarantee a long service life.

BJ5-615 Chapter 5: Maintenance 40 of 85

Page 41

Checking the tension force of the V-belt

Profile section Efficiency of x in

SPA 100 - 132 20 - 27 4,4 - 5,9

SPA 140 - 200 27 - 35 5,9 - 7,7

SPB 160 - 224 35 - 50 7,7 - 11

SPB 236 - 315 50 -65 11 - 14,3

SPC 224 - 355 60 - 90 13,2 - 19,8

SPC 375 - 560 90 - 120 19,8 - 26,4

XPB 224 - 250 25 - 35 5,5 - 7,7

a: Distance between

roller centers.

b: Sag

F: Force (direction)

Re-tensioning and relaxing the V-belt

1. Remove the V-belt cover.

2. Measure the distance between the roller centers.

3. Determine the belt sag force F for each belt at 16 mm sag if sag "b" is

equal to 1 m distance between roller centers. Do this by measuring the

distance between roller centers at a right angle to the V-belt.

Force required for 1m distance between

roller centres and 16mm sag

P in Newton P in lbs

mm

4. Compare determined value with the value in the above table. If the value

lies below the lowest tolerance limit, the V-belt must be re-tensioned. If

the value lies above the highest tolerance limit, the V-belt must be relaxed.

Enlarging or decreasing the centre distance “A” tensions or relaxes the V-belt.

1. Loosen the tensioning screw.

2. Shift the drive motor as required onto the sliding rails.

BJ5-615 Chapter 5: Maintenance 41 of 85

Page 42

3. Lock the drive motor into new position using tensioning screws so the motor

shaft is parallel to the rotor axis and aligned.

4. Check the tension force of the V-belt (refer to previous section).

5. Mount the V-belt cover.

Checking V-belt condition, replacing V-belt

CAUTION! Running V-belts can pull objects into the machine! Hair, jewelry

etc. can be pulled into machine without proper precaution

resulting in serious injury. NEVER dismount the V-belt cover

and window during operation.

If a V belt is porous or ripped, it must be replaced as follows:

1. Remove the V-belt cover.

2. Loosen the front and rear tensioning screw.

3. Relax the V-belt by shifting the drive motor.

4. Put new V-belt in.

5. Tension the V-belt (refer to previous section).

6. Mount the V-belt cover.

Working on the Cutting Cutters

Correctly setting and mounting the cutting cutters is important when working with

shredders to ensure efficient and economic function.

Replacing and Checking the Cutting Cutter Mountings

Certain machine parts are subject to stress during operation as a result of vibrations that

can lead to loosening of the screw connections. Therefore, it is absolutely necessary to

check the cutter and bed knife mounting screws in accordance with the Maintenance

Plan.

1. Tighten the mounting screws on the cutters and bed knives using a torque wrench.

(Check required torque for the screw size.) The required torque for the cutter

mounting screws is 120 Nm.

NOTE: You can find out the required torque from the following table. Tightening

capacity decreases for screw when loosened and tightened again several times.

New screws of the same material quality must replace the cutting cutter

mounting screws after they have been loosened and tightened several times.

BJ5-615 Chapter 5: Maintenance 42 of 85

Page 43

Screw type Grade 8.8 Grade 10.9 Grade 12.9

M8 25 18.4 35 25.8 41 30.2

M10 49 36.1 69 50.9 83 61.2

M12 86 63.4 120 88.5 145 106

M16 210 154 295 217 355 261

M20 410 302 580 428 690 508

M24 710 523 1000 737 1200 885

Nm lbf ft Nm lbf ft Nm lbf ft

Torque

Checking the Condition of the Cutters

WARNING! Danger of cutting caused by sharp cutters at all times—even when rotor

is at standstill. Serious Injury especially to the hands and fingers can occur. Wear

protective gloves!

The cutting cutters become blunt after a certain number of operation hours; they should be

checked regularly. Using blunt cutters can affect the efficiency and performance of the

machine in the following ways:

• Decreased shredding capacity.

• Increased current consumption of the drive motor.

• Inexact cut.

• Overheating of the shredded material.

Dismounting the Cutters (see drawing below)

1. Switch OFF the shredder at the main switch.

2. Safeguard main switch using a padlock.

3. Open the machine door.

4. Safeguard the machine door.

5. Remove screen.

NOTE: Although it is possible to reach the cutting shaft by climbing into the

feeding chamber, it is recommended to access the cutters through the

machine door located at the front of the machine. The shaft can be

rotated manually by turning the motor v-belt pulley.

6. Clean the hexagon head socket of the cutter mounting screw (2).

7. Loosen the screw using a high quality Allen key (10 mm). Knock the Allen key

lightly with a hammer to loosen it if necessary.

8. Take out the cutter mounting screw, the washer, and the cutter.

BJ5-615 Chapter 5: Maintenance 43 of 85

Page 44

(1) Cutter

(2) Cutter mounting screw

(3) Cutter holder

(4) Cutter holder mounting

screws

1

Dismounting the Cutter Holders

2

3

1. Switch OFF the shredder at the main switch

2. Safeguard main switch using a padlock.

3. Open the lower machine door.

4. Safeguard the machine door.

5. Remove screen

NOTE: Although it is possible to reach the cutting shaft by climbing into the

feeding chamber, it is recommended to access the cutters through the

machine door located at the front of the machine. The shaft can be rotated

manually by turning the motor v-belt pulley.

6. Clean the hexagon head socket of the cutter mounting screw (2).

7. Loose the screw using a high quality Allen key (10 mm). If necessary knock the

Allen key lightly with a hammer to loose it.

8. Take out the cutter mounting screw, the washer and the cutter.

9. Clean the hexagon head socket of the cutter holder mounting screws (4).

10. Loose the screw using a high quality Allen key (6 mm). Knock the Allen key

lightly with a hammer to loose it if necessary.

11. Take out the cutter holder mounting screws.

12. Remove the cutter holder with the delivered Extractor.

NOTE: See previous drawing.

BJ5-615 Chapter 5: Maintenance 44 of 85

Page 45

WARNING! Danger of cutting caused by sharp cutters at all times—even when rotor is

at standstill. Serious Injury especially to the hands and fingers can occur. Wear

protective gloves!

Dismounting the Bed Cutters

1. Switch OFF the shredder at the main switch.

2. Safeguard main switch using a padlock.

3. Open the upper hopper door.

4. Safeguard the hopper door.

NOTE: Although it is possible to reach the cutters by climbing into the feeding

chamber, it is recommended to access the cutters through the front side door.

5. Clean the hexagon head socket of the cutter mounting screws (2) and the cover plates

mounting screws.

6. Loosen the cover plate mounting screws using a high quality Allen key (10 mm). Knock

the Allen key lightly with a hammer to loosen if necessary.

7. Take out the screws and cover plates.

8. Loosen the cutter adjusting screws for pulling and take them out.

9. Loosen the cutter mounting screws with Allen key (10 mm). Use a hammer to lightly

knock key if necessary.

10. Take out the cutter mounting screw and cutter.

BJ5-615 Chapter 5: Maintenance 45 of 85

Page 46

WARNING! Danger of cutting caused by sharp cutters at all times—even when rotor is at

standstill. Serious Injury especially to the hands and fingers can occur. Wear protective

gloves!

(1) Bed knife

(2) Knife mounting screws

(3) Knife holder

(4) Cover plates

(5) Knife adjusting screw for

pushing

(6) Cutter adjusting screw for

pulling

(7) Cover plate mounting

screws

Mounting the Cutter Holders

2

6

5

3

4

7

1. Clean the cutter pocket and the cutter holder.

2. Insert cutter holder into the pocket.

NOTE: Cutter holder must slide in easily. Do not damage the cutter holder

surfaces with a hammer.

3. Put in the cutter holder mounting screws (DIN912 – M8x25 – 12.9) and put some

Loctite on them.

4. Make sure that the cutter holder fits properly.

5. Tighten the cutter mounting screws using a torque wrench.

NOTE: The required torque for the cutter holder mounting screws is 39 Nm

(also see the table under “Working on Cutting Cutters”).

WARNING! Danger of cutting caused by sharp cutters at all times—even when rotor is at

standstill. Serious Injury especially to the hands and fingers can occur. Wear protective

gloves!

BJ5-615 Chapter 5: Maintenance 46 of 85

Page 47

Mounting the Cutters

1. Clean the cutter supporting surface and the hole on the cutter holder.

2. Insert sharp cutter or turn old cutter, and push against the cutter holder surface.

3. Put in the cutter mounting screw (DIN912 – M12x40 – 12.9) and the washer

(DIN433 – 13 – 300HV).

4. Screw in the mounting screws and tighten lightly first.

5. Make sure the cutter fits planar in the seat.

6. Tighten the cutter mounting screws using a torque wrench.

NOTE: The required torque for all cutter mounting screws is 120 Nm (also see

the table under “Working on Cutting Cutters”).

7. Check if the cutting gap is correct and make sure the cutters do not collide

as the rotor turns.

8. Remove tools and other objects from the cutting chamber.

9. Put back screen and fix it.

10. Switch on the shredder for a short time without material, and listen for noises. If

there are unusual noises, determine the cause and eliminate it.

NOTE: The cutting knives, in particular the cutters, should only be sharpened

Mounting the Bed Cutters

1. Clean the cutter supporting surface and the holes on the cutter holder

2. Insert sharp cutter or turn old cutter.

3. Put in the cutter adjusting screws and adjust them roughly

4. Put in the cutter mounting screws (DIN912 – M12x55 – 12.9) and tighten lightly

first

5. Adjust the gap between cutter and bed knife to 0.8-1.0 mm

6. Tighten the cutter mounting screws using a torque wrench.

or replaced in sets. There is a danger of balance error if a combination

of rotor cutters from different cutter sets is used.

Cutters are reversible and have four symmetrical cutting edges. This

makes it possible to turn the cutters and only to sharpen after every

fourth cutter change.

NOTE: The required torque for all cutter mounting screws is 120 Nm (also see the

table under “Working on Cutting Cutters”).

BJ5-615 Chapter 5: Maintenance 47 of 85

Page 48

7. Turn the rotor by hand

8. Check whether the cutting gap is correct and make sure the cutting cutters

do not collide as the rotor turns.

9. Put back the cover plates and mount them with the screws.

10. Remove tools and other objects from the cutting chamber.

11. Put screen back and mount it.

12. Switch ON the shredder for a short time without grinding material and listen for

noises. If there are unusual noises, determine the cause and eliminate it.

NOTE: Cutters are reversible and have four symmetrical cutting edges. This makes

it possible to turn the cutters and only to sharpen after every fourth cutter

change.

WARNING! Danger of cutting caused by sharp cutters at all times—even when rotor is at

standstill. Serious Injury especially to the hands and fingers can occur. Wear protective

gloves!

Sharpening Cutters and Bed Knives

Shredder cutters have 4 cutting edges. This means they can be turned 3 times. The

cutters should be replaced after the third use. Bed knives can be turned 2 times and can

be re-sharpened as long as you can mount them with the long hole.

1. Dismount the cutting cutters (see “dismounting the rotor cutters”).

2. Sharpen the cutters and bed knives.

NOTE: A specialist in accordance with the sharpening plan using particular care

should uniformly sharpen the cutting cutters mechanically. It is important to

make sure that sharpening takes place with small grinding allowance and

sufficient coolant supply. The sharpening process is finished when the cutting

edge is sharply cut. Not all indentations must be ground out; otherwise the

number of possibilities for sharpening is unnecessarily reduced. For the

sharpening process, use soft grinding wheels (Quality 40 H or 46 K). Cutters,

which have grinding cracks, are not to be reused due to danger of breakage

during operation.

3. Whet the cutting edges of the cutting cutters using a whetstone.

NOTE: the service life of the cutting cutters can be increased by taking these

measures.

4. Set the cutters and bed knives (refer to “Setting the cutters”).

5. Mount the cutters and bed knives (see “Mounting the cutters and bed knives”).

NOTE: The cutting cutters, in particular the cutters, should only be sharpened or

replaced in sets. There is a danger of balance error if a combination of cutters from

different cutter sets is used.

BJ5-615 Chapter 5: Maintenance 48 of 85

Page 49

WARNING! Danger of cutting caused by sharp cutters at all times—even when rotor is at

standstill. Serious Injury especially to the hands and fingers can occur. Wear protective gloves!

Setting the Cutting Knives

Cutters for the SMS series shredder do not have to be adjusted. All adjustments have to

be done with the bed cutters. To simplify cutter setting and shorten standstill periods

when replacing cutters, bed cutters have 4 adjusting screws, 2 each for pushing and

pulling the cutter. Having several cutter sets helps to avoid standstill periods. Correct

and careful setting of the gap between the cutters and bed knives (cutting gap) is

important for productive capacity of the shredder. Factors for the size of the cutter gap

are the size of the rotor, the design of the rotor, and the material to be ground.

(1) Bed knife

(2) Knife mounting screws

(3) Knife holder

(4) Cover plates

(5) Knife adjusting screw for

(6) Knife adjusting screw for

(7) Cover plate mounting

pushing

pulling

screws

6

5

2

3

4

1

7

1. Remove old knives (see “dismounting the bed knives”).

2. Insert sharp cutter or turn old cutter.

3. Put in the cutter adjusting screws and adjust them roughly

4. Put in the cutter mounting screws (DIN912 – M12x55 – 12.9) and tighten

lightly first

5. Adjust the gap between cutters and bed knife to 0.8-1.0 mm using a

calibre gauge.

6. Tighten the cutter mounting screws using a torque wrench.

BJ5-615 Chapter 5: Maintenance 49 of 85

Page 50

NOTE: The required torque for all cutter mounting screws is 120 Nm

(see the table under “Working on the Cutters”).

7. Turn the rotor by hand

8. Check whether the cutting gap is correct and make sure the cutters

and bed knives do not collide as the rotor turns.

NOTE: Recommended cutter gap: 0.8 mm – 1 mm

9. Mount the cutter cover plates.

Transporting and Storing the Cutting Cutters

WARNING!

• Danger of cutting caused by sharp cutting cutters.

• Serious injury, in particular to hands and fingers, can result.

• Wear protective gloves.

• Only transport and store the cutting cutters packaged.

• Grease the cutting cutters well, so that they do not rust. Protect the

cutting edges with doubled cardboard and use adhesive tape to

safeguard the cutters against slipping out of the sides of the sheath.

• After unpacking, you must degrease the cutting cutters so that they

can be gripped safely.

Hydraulic Maintenance

Hydraulic oil has to be filled into the tank before start-up of the machine. The type of oil

that should be used depends on location. Recommend oils include type DIN 51524 HLP 32

for areas with temperatures below 32°F (0°C) in the winter and HLP 46 for temperatures of

around 86°F (30°C) in the summer. For extremely hot tropical areas (i.e. Thailand,

Malaysia, Nigeria etc.) it is recommended to use HLP 68. The first oil replacement should

be done after 1,000 operating hours and then after every 2,000 operating hours. The oil filter

must be replaced too.

NOTE: Overheating of the oil and dirt in the oil will cause damage to the hydraulic

system if the oil is not replaced in the specified amount of time. This can lead to

complete standstill of the machine.

The same type of oil must be used when adding hydraulic oil. If the same type of oil is

unavailable or if it is unknown, then the oil in the tank and the entire hydraulic system has to

be removed and carefully and completely flushed. The system may only be filled with new

oil after this procedure has been done because it is necessary in preventing the valves from

gumming.

BJ5-615 Chapter 5: Maintenance 50 of 85

Page 51

Checking and Adjusting of the Hydraulic System (see figure below)

1. Start the machine in automatic running mode and wait for approximately 20

minutes.

2. When the ram moves forward the pressure gauge (1) should indicate 0 – 30 bars

depends on the adjustment of the throttle check valves (2). (Also adjust the

speed of the ram with this valve.)

3. When the ram moves backwards the pressure gauge (1) should indicate 0 – 30

bars depends on the adjustment of the throttle check valves (2).

4. The pressure gauge (1) should indicate 50 – 70 bar at the change over point of the

hydraulic cylinders other wise the spill over hand wheel (3) should be adjusted.

5. The pressure gauge (4) should indicate a maximum of 2.5 MPa other wise the

screw of the sequence valve (5) has to be adjusted.

6. The ram should run upwards in less than 10 seconds, otherwise the throttle check

valve (2) has to be adjusted.

7. When pressure gauge at the oil filter (6) indicates >5 bar, the filter should be

replaced.

Figure: Checking and adjusting the hydraulic system

4 6

5

1

3

2

BJ5-615 Chapter 5: Maintenance 51 of 85

Page 52

Hydraulic liquid recommendation

Designation to DIN 51 524 HLP 32

Ambient temperature: -7 to +70°C

Supplier Name of the oil

ARAL Aral Vitam GF 32

Aral Vitam HF 32

BP BP Energol HLP-D 32

BP Energol HLP 32

BP Energol SHF 32

ELF Elfolna 32

Hydrelf 32

ESSO Nuto H 32

HLPD-Oel 32

FINA Fina Hydran 32

FUCHS Renolin MR 10

Renolin B 10