Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 1

REV 1.22

4/15/2020

13406 SE 32nd Street, Bellevue, WA 98005 l Tel: 425.453.1910 l email: sales@steppir.com

This assembly manual is intended to be

printed in full COLOR. If the manual is

printed in black and white, many im-

portant details could be lost.

ASSEMBLY MANUAL

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 2

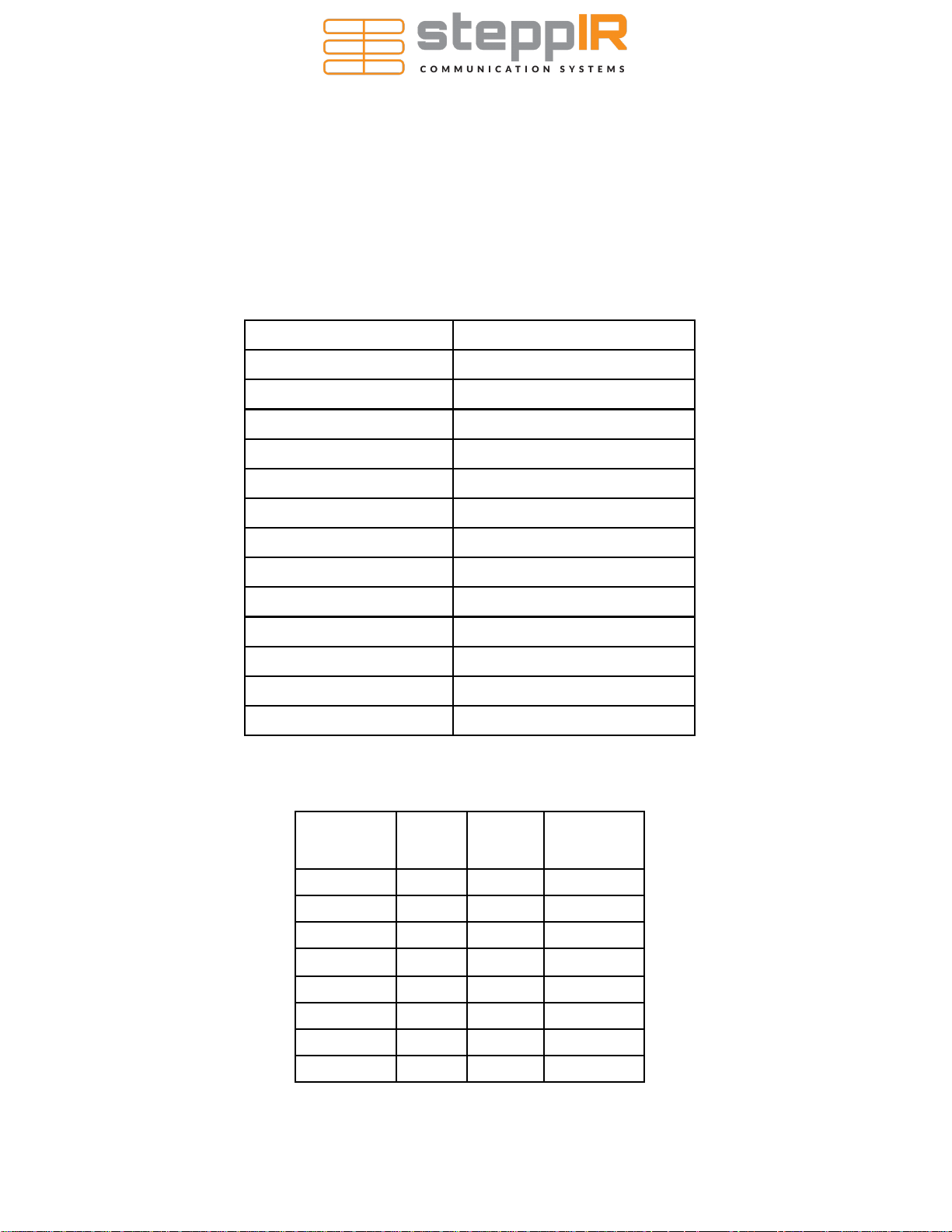

Specifications UrbanBeam Yagi

Boom length 4.0 ft / 1.22 m

Boom outside diameter 1.75 in / 4.45 cm

Longest element 30.5 ft / 9.3 m

Turning radius 15.5 ft / 4.72 m

Weight 45 lb / 20.5 kg

Wind load - EIA-222-F/G 7.9 ft2 / 0.73m2

Wind load - EIA-222-C 4.4 ft2 / 0.41m2

Wind rating 100 mph

Adjustable elements 2

Power Rating 3000 watts continuous

Feed points 1

Frequency coverage 6.8 MHz—54 MHz

Control cable 12 conductor shielded, 22AWG

Frequency Gain

dBi

Front to

Back

dB

Front to

Rear

dB

40M 1.61 9.55 (F/S)

30M 1.772 9.63 (F/S)

20M 6.50 16.5 12.0

17M 6.6 21 12.6

15M 6.6 24.6 14.0

12M 6.7 18.5 15.7

10M 6.65 14.8 14.8

6M 6.15 4.0 4.0

UrbanBeam Yagi Specifications

PREAMBLE

1

A full size dipole is referenced at 2.1dBi

2

Measured SWR is 2.3:1 for this model on 30m

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 3

TABLE OF CONTENTS Page(s)

Preamble 2-19

Antenna specifications 2

YouTube Assembly Instructions by Pascal Villenueve, VA2PV 5

Urban Beam Drawing 6

OK, NOW WHAT?? Advice from Jim Streible K4DLI (SK) 7-8

Parts Checklist 9-10

Assembly Kits—Bill of Materials 11-12

Assembly Notes (Read before you start assembly) 13

A Word About Stainless Steel and the Potential for Galling 14

Antenna Overview 15

Section 1 — Boom / Mast Plate Assembly 16-25

Overview 16

EHU Boom Locations 17

EHU Placement 18

EHU Overview 19

EHU Wiring 20-21

Director EHU Drawing 22

Attaching Director Mounting Plate & EHU to Boom 23

Driven EHU Drawing 24

Attaching Driven Mounting Plate & EHU to Boom 25

Section 2 — Mounting the Boom to the Mast Plate 25-28

Mast Plate-to-Boom Overview Drawing 26

Attaching Boom to Mast Plate 27

Mounting the Terminal Housing Tube 28

Section 3 — Boom Wiring & Initial Testing 29-31

Wiring EHUs to Control Cable 29

Connecting Control Cable to DSUB 30

Wiring Test 31

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 4

URBANBEAM TABLE OF CONTENTS (Continued) Page(s)

Section 4 — Preparing Telescoping Poles and Loop Tubes 32-41

Overview 32

Preparing Pole Tips 33-34

Sizing the Pole Tip Remnants for Loop Tubes 35

Attaching Sweep Couplers to Sweep Tubes 36-37

Attaching Poles & Loop Tubes to Sweeps 38

Joining the Loop Halves Together 39

Prepare the CPVC inner-guide tube & diverter cone 40-41

Section 5 — Final Assembly 42-45

Securing the element tubes to the EHU 42-43

Mounting the UrbanBeam to the Tower Mast 44

Last Steps 45

Section 6 — Troubleshooting 46-47

Troubleshooting tips 46-47

Section 7 — Miscellaneous 48-49

Warranty 48

Contact Information 49

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 5

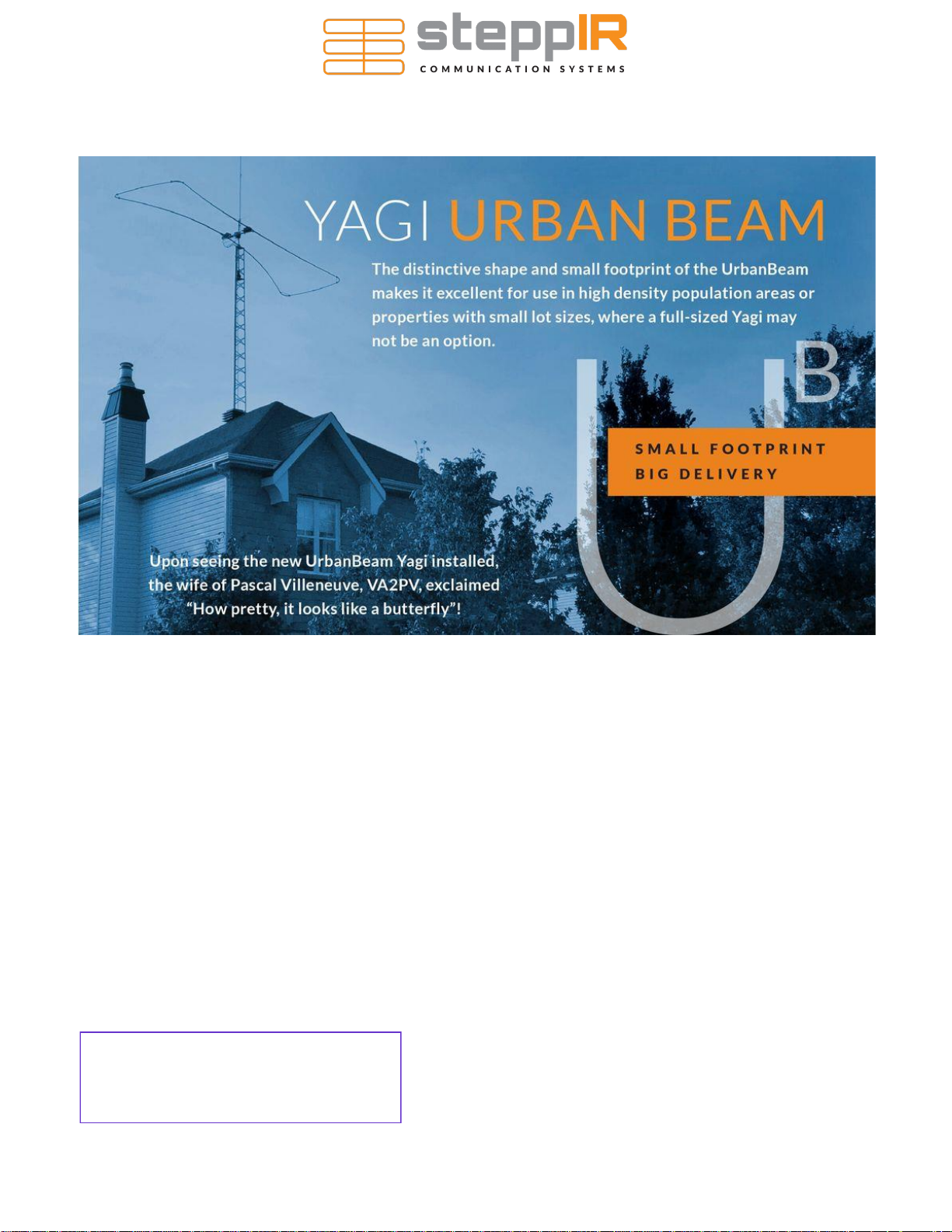

Pascal Villeneuve, VA2PV has done an excellent series on

YouTube showing the unboxing and assembly of the Urban

Beam Yagi antenna. He also did a comprehensive review of

the product including the OptimizIR controller. Below are

links that we HIGHLY recommend you review thoroughly be-

fore unboxing and assembling your Urban Beam Yagi:

Unboxing: https://www.youtube.com/watch?v=4KlkyR3S9v8

Assembly: https://www.youtube.com/watch?v=HKLnPsXhUYE

Review: https://www.youtube.com/watch?v=InKqrViwrxk

If typing these links in are laborious, simply go to www.youtube.com and then

type in Pascal Villeneuve, Urban Beam, and the three links will appear.

Special thanks to Pascal Villeneuve VA2PV for the time he spent making these in-

credible 4K HD Videos!

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 6

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 7

OK - - - NOW WHAT?

(Sage advice from Jim Streible, K4DLI, SK)

PREAMBLE

You have ordered you SteppIR Antenna and are

waiting for delivery. What do you do in the meantime?

1. Go to the SteppIR web site at www.steppir.com and download the latest manual for your antenna,

and also the Operators Manual for the controller.

2. Read the manuals from cover-to-cover ---TWICE! Don’t just read them –Study them, so you are

familiar the terminology used about the antennas and have a good idea of how the antenna is assembled and where the various parts go.

3. As you go through the manuals make notes of any instructions you may not clearly understand,

then call or email for clarifications. It is better to have it all sorted out before you start assembly.

We don’t mind answering your questions beforehand.

4. Now, wait for notification your antenna is being shipped.

Your antenna has arrived!

What is the first thing to do?

1. If the antennas is to arrive on Wednesday----DO NOT plan an antenna party for Saturday!

2. Even if you plan to install the antenna weeks later, the first thing to do is to unpack the antenna

and do a complete inspection. Make sure nothing is missing or has been damaged in shipment.

3. Do a complete inventory of every part, nut and bolt. Yes it takes time, but it also allows you to

notify SteppIR if anything is missing and allow time to get it to you before you start assembly of

the antenna. There is nothing more frustrating than realizing that something is missing, just

hours before you want to install the antenna.

4. Go back to the SteppIR website and download the latest manual. SteppIR constantly is improv-

ing and adding to the manual, so even though your paper instruction manual is going to have all

the data you need, it makes sense to check for the latest updates online. This is especially true

if you purchased the antenna and a period of time has passed between arrival and install dates.

The Manual revision is published on the front page in the lower right hand corner.

5. Take the controller and power supply out of their wrappings and connect them. The controller

does not have to be connected to the antenna in order to familiarize yourself with it. In fact, it is

best to get familiar with the controller when it is not connected to the antenna. Turn on the controller and read through the Operators Manual again while operating the controller in all of its

modes. Go through the menus so you know what each does and how to navigate through the

various menus and functions.

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 8

OK - - - NOW WHAT? (continued)

(Sage advice from Jim Streible, K4DLI, SK)

PREAMBLE

Your Antenna Has Arrived!

What is the first thing to do?

(continued)

6. When you have finished working with the controller, be sure the display indicates “Elements

Home” and the controller has been turned OFF. When the controller is connected to the anten-

na and the controller is turned back on the next time, it will assume the antenna is extended to

whatever the controller display indicates. If the antenna is in the home position the controller

needs to be set to “Home” as well before you plug in the control cable.

7. Once the antenna is completely assembled and ready to mount on the antenna tower, use an

antenna analyzer, if you have one, to test resonance of the antenna. If you don’t have an analyzer, try to borrow one. It will save you a lot of time and worry. Check the antenna on each

band for some sign of resonance within the frequency range. Leave the antenna on the default

frequency and tune the analyzer to see where the dip occurs. It will be somewhere below the

lower band edge on each band with the antenna 3 or 4 feet above the ground on saw horses.

Since it is so close to the ground, don’t expect to see a 1:1 SWR here, just look for a good indication of resonance, something in the range of 1.5:1 to 3:1.

Once it has been determined this part of the antenna is working correctly do the following: Select the lowest band and establish the dip condition by tuning the analyzer. Do not touch the

analyzer again. Retract the elements and then reselect the same band. The antenna should

come back the very near the same setting. Do this 2 or 3 times on each band. Also, try going

from the band being tested to any other band and back again and observe that the antenna

comes back to the same SWR reading. Now you know the antenna is tuning correctly from

band to band and is consistent.

8. When you are ready to use the antenna, be sure to “enable” all of the options you have pur-

chased with your controller or antenna. If you purchased the serial interface option, be sure to

set it up for your radio type and baud rate. When done enabling,

save and then turn the con-

troller off, and back on again

.

9. Enjoy the antenna!

73

Jim Streible—K4DLI

Jim passed away in early 2016, but his advice has enduring value.

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 9

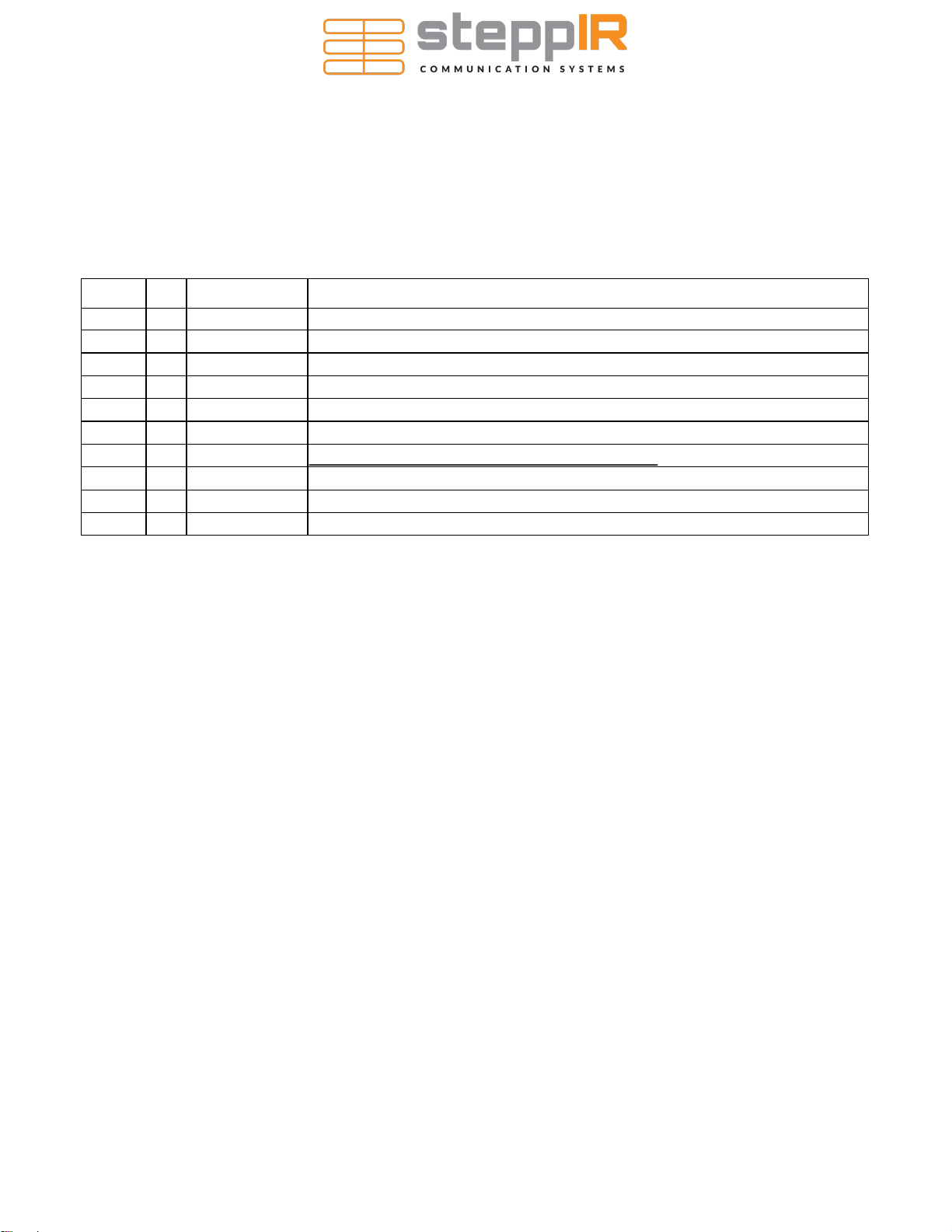

UrbanBeam PARTS CHECKLIST

✓

QTY Part # Description

1 70-3420-01 20m passive EHU (no lid - mounting plates acts as lid)

1 70-3403-01 40m driven element EHU (no lid, mounting plate acts as lid)

1 SDA100 Electronic controller

OPTIONS FOR SDA100:

1 01321 Transceiver interface

1 01324 Remote driver board

1 01323 Advanced lightning protection (ALP)

1 01322 Tuning relay

1 09002 33v___ (PN 09002)

72-0010-01 EHU Control cable wire pack consisting of:

1 Length 10’ four conductor cable

1 Coax seal (used to seal the control cable in the wire trough of EHU)

1 10-1018-11 1-3/4” Aluminum Boom (4 foot section)

4 10-1013-02 18 ft telescoping fiberglass pole

1 71-0022 UrbanBeam Instruction manual

1 71-0010 SDA 100 Instruction manual (MUSTANG Firmware)

4 60-1006-22 Quick disconnect boot 1.5" x 1.25" (connect poles to EHU)

12 10-1059-01 Polyolefin heat shrink (waterproof telescoping pole joints)

1 20-6208-01 25 pin D-SUB connector (only used if no D-SUB splice purchased)

1 20-6209-01 Backshell for 25 pin D-SUB connector

4 10-1703-01 1” OD x 18” Polyethylene sweep tube

4 10-1701-01 Metal loop struts (connects between adjacent sweep couplers)

2 70-2030-01 EHU aluminum mounting plate with foam aligning/insulating gasket

10 60-0112 10-32 SS set screw (one set screw per pair of saddles)

1 10-1021-43 8” x 8” x 0.25” Aluminum mast place (for use with aluminum saddles)

2 70-2025-23 CPVC Liner 40” without coupler

2 70-2025-13 CPVC Liner 49” with coupler

It is important that you do an inventory of the items that were shipped to you. Nothing is worse than

discovering a day before a planned installation that there are missing parts! We do our very best to ensure that you receive everything needed for construction of your antenna, but better to be safe than

sorry—inventory your parts well in advance of your installation. The items in blue represent options

available for the UrbanBeam Yagi—you will need to check these items off only if you purchased them.

PREAMBLE

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 10

UrbanBeam PARTS CHECKLIST (continued)

PREAMBLE

ASSEMBLY KITS

(a bill of materials for each kit is shown on the next page)

✓

QTY Part # Description

1 72-0060-01 UrbanBeam Loop Hardware kit

1 72-0061-01 UrbanBeam Mast Plate hardware kit

1 72-0041-01 Glue, tape and anti-seize kit (use anti-seize on ALL stainless fasteners!)

1 72-0062-01 UrbanBeam Element Hardware kit

ANTENNA OPTIONS

Voltage suppressor (lighting arrestor) OPTION

1 06112 12 pin voltage suppressor (20-8052-01)

1 01501 Connector Junction Box (70-2034)

1 03322 12 conductor control cable _______________ ft

IMPORTANT: When setting up your SDA 100 or

SDA 2000 OptimizIR electronic controller, be certain you have gone into the settings menu and ensured that the Urban Beam Yagi has been selected

and saved before you use the controller. Failure to

do so can cause damage to your antenna.

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 11

ASSEMBLY KITS - BILL OF MATERIALS

✓

QTY PART NUMBER DESCRIPTION

16 09-0013 3M Grip tape 2.3” x 1”

53 60-0014 6-32 Nylock nut

53 60-0016 6-32 Flat Washer

53 60-0186 6-32 x 2” SS Pan head Phil screw

16 halves 10-1155-01 Schedule 160 Sweep Clamps

1 09-0007 Silicone wrap, blue, 0.50” x 10mil; used for 40/30 loop; 5ft

roll

1 09-1025 11/16” conical grinding stone (pole tip preparation)

2 10-1702-01 Loop Splice 5 inch

6 60-6000-50 Type “M” (.312) #10 SS Hose Clamp .312”

UrbanBeam Loop Hardware Kit

72-0060-01

PREAMBLE

✓

QTY PART NUMBER DESCRIPTION

4 10-1601-03 1.75” x .75” Aluminum Saddle Half

4 10-1601-22 2.00” x .75” Aluminum Saddle Half

4 60-0065 5/16” x 3.5” Hex head bolt, SS

4 60-0114 5/16” x 3.75” Hex head bolt, SS

8 60-0046 5/16” -18 SS Nylock nut

UrbanBeam Mast Plate Hardware Kit

72-0061-01

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 12

✓

QTY PART NUMBER DESCRIPTION

2 72-0054-21 EHU Housing Hardware Kit

8 60-0046 5/16” Nylock nuts

8 60-0065 5/16” X 3-1/2” Stainless steel hex head bolt

8 10-1601-03 1-¾” Aluminum saddle half

UrbanBeam Element Hardware Kit

72-0062-01

ASSEMBLY KITS- BILL OF MATERIALS (continued)

PREAMBLE

✓

QTY PART NUMBER DESCRIPTION

10 60-0017 10-32 x3/4” Stainless steel machine screw

10 60-0018 # 10 SS washer

10 60-0019 10-32 Nylock nut

EHU Housing Hardware Kit

72-0054-21

✓

QTY PART NUMBER DESCRIPTION

1 72-0009-03 Glue kit

1 09-0001 66’ PVC electrical tape

1 10-1028-01 Anti-Seize

2 10-1509-02 Diverter cone

1 10-1029-01 Connector Protector

Glue, Tape & Anti-Seize Kit

72-0041-01

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 13

ASSEMBLY NOTES

PREAMBLE

Before beginning assembly of this antenna, please read the manual in its entirety to familiarize

yourself with the task at hand. Doing so will eliminate potential confusion.

Be sure to do an inventory of your parts as soon as possible after receipt of the antenna, and

well before your intended installation date - this way we can supply you any missing parts in

adequate time.

Be sure to check the insides of the aluminum tubing and the telescoping poles when unpack-

ing your boxes. In certain situations we put items inside these pieces to reduce the amount of

boxes used for shipping, which in turn reduces your shipping costs.

A large, cleared flat area is recommended for assembly of an antenna of this size and complexity. Typically, an area 10 ft x 35 ft would be ideal. We recommend using sawhorses or a

sturdy table when installing the boom. By having the boom elevated, it is easier to ensure that

the elements are level. Rubber or nitrile gloves are recommended when applying the antiseize to the stainless steel fasteners or the aluminum boom sections.

Be sure to refer to the UrbanBeam configuration drawing on the following page so that you

can fully understand how the antenna operates. In addition, the configuration drawing identifies EHU placement, which is important as you progress in your installation of the antenna.

If you have a flat surface that is at least 48” long, you can use it to make sure the two EHUs

are in the same plane. If you do not, the use of a level for adjusting the Element Housing

Units (EHUs) is highly recommended. This is a surprisingly accurate and consistent method.

When all the EHU’s are level, secure the boom to the sawhorses so that it cannot shift—this

will help considerably when you are leveling the mast plate.

Be sure to use the anti-seize compound supplied to prevent the galling of the stainless steel

fasteners. If you do not use the anti-seize, count on issues with the stainless steel hardware

galling. Heat is one of the primary culprits with galling, so if you use a ratchet, steady speed

as you tighten will help minimize galling. We have found that when the anti-seize is applied to

the bolt portion of the hardware, it will eliminate any galling issues.

NEVER ATTEMPT TO WIRE OR CHANGE WIRING ON THE ANTENNA WHEN THE

ELECTRONIC CONTROLLER IS CONNECTED TO THE CONTROL CABLE, EVEN IF IT IS

TURNED OFF. This is the number one cause of installation failures for our products. Even

with power off, damage can occur. When the power is “off” on your controller, there is still a

very small amount of power feeding to the stepper motors, to effectively “lock” them in place.

This reduces the need for calibration of the antenna.

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 14

From time to time, we get complaints from customers regarding galling of stainless steel fasteners.

Here is an excerpt from the Industrial Fastener Institute's Standards Book:

Thread galling seems to be the most prevalent with fasteners made of stainless steel, aluminum,

titanium and other alloys which self-generate an oxide surface film for corrosion protection. During

fastener tightening, as pressure builds between the contacting and sliding thread surfaces, protec-

tive oxides are broken, possibly wiped off and interface metal high points shear or lock together.

This cumulative clogging-shearing-locking action causes increasing adhesion. In the extreme, galling leads to seizing - the actual freezing together of the threads. If tightening is continued, the fastener can be twisted off or its threads ripped out.

During minor galling, the fastener can still be removed, but in severe cases of galling, a strong

bond between the bolt and nut can prevent removal of fasteners. Unfortunately, little is known on

how to control it, but here are two ways to minimize this effect:

Decreasing installation RPM speed will cause less friction and decrease heat generation. Lubrication

used prior to assembly can dramatically reduce or eliminate galling. Recommended lubricants

should contain higher amounts of molybdenum disulfide, such as graphite which is very commonly

used as a solid lubricant or special anti-galling lubricants sold by chemical companies.

We provide an anti-seize compound stick called “Thread Magic” (shown in picture below) with all of

our antennas and strongly encourage you to use it to reduce the aggravation of galling. The

Thread Magic stick is fantastic—you can get plenty of anti-seize on the fastener without getting it

on your hands!

Contrary to popular belief, galling of stainless steel is not a symptom of a "cheap" fastener - it is

prevalent in all types of stainless steel, aluminum and titanium fasteners. You can be assured that

the stainless steel fasteners we provide with our products are of very high quality.

Save yourself a lot of grief and always use a

thread lubricant when working with stainless

steel fasteners.

A WORD ABOUT STAINLESS STEEL GALLING

PREAMBLE

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 15

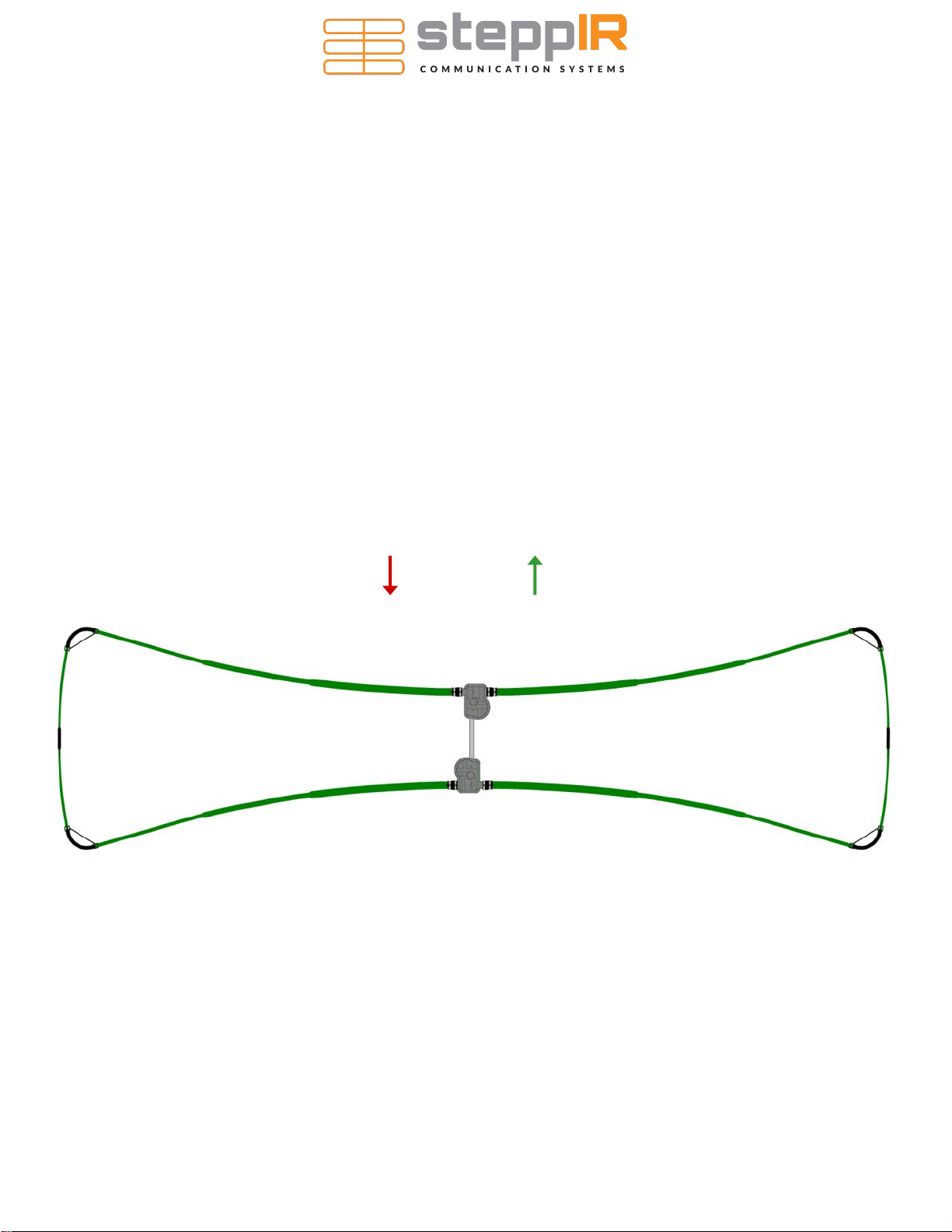

REVERSE DIRECTION (180 deg)

20m-6m Director

ANTENNA OVERVIEW

FORWARD DIRECTION (Normal)

The UrbanBeam Yagi antenna uses a loop element for 30m and 40M. The loop elements used for 40m and

30m are 50% shorter than a full size dipole element, with very little sacrifice in performance (-0.6dB).

The UrbanBeam is a dipole on 40m and 30m. The UrbanBeam performs as a 2 element Yagi on 20m-6m.

Assembly of the UrbanBeam can be broken into phases:

• Prepare the Boom with EHUs, Mast Plate, and Connector Tube (or optional Connector Box)

• Prepare the Element Tubes & Loop Tubes

• Final Assembly & Testing

40m, 20m-6m Driven

PREAMBLE

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 16

SECTION 1.0

PREPARING THE BOOM ASSEMBLY

The boom for the UrbanBeam is simple. It’s a 48 inch long aluminum tube that is 1.75” in diameter.

Place the boom on a flat surface. Take care to make sure the surface is indeed level, otherwise the

tube may roll off.

BOOM LAYOUT

Both EHUs are prepared and attached to the boom in fundamentally the same way. The control cable

connector for each EHU is plugged in, and the control wire routed in a channel weatherproofed with coax seal. The EHUs are then assembled to mounting plates, which are in turn attached to opposite ends

of the boom with clamps. It’s important to pay attention to the orientation of the EHUs on the boom,

making sure that the ESTs (where the loop elements attach) are positioned to be closest to the ends of

the boom.

EHU MOUNTING OVERVIEW

The Boom Assembly consists of the EHUs and their mounting hardware, along with the Mast Plate and Connector box. The order of assembly is:

• Lay out the Boom

• Prepare and mount Director EHU to the boom

• Prepare and mount Driven EHU to the boom

• Mount the Mast Plate to the boom

• Mount the Connector tube to the Boom (or optional connector box to the Mast Plate)

OVERVIEW

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 17

KEY Start measurement at

center-point of:

Finish measurement at

center-point of:

Measurement distance be-

tween points

A Boom edge Director EHU 3.25 inches

B Director EHU Driven EHU 41.50 inches

C Director EHU Center of Mast Plate 20.75 inches

A

B

C

SECTION 1.0

PREPARING THE BOOM ASSEMBLY

EHU Mounting Locations

EHU CENTER-TO-CENTER SPACING MEASUREMENTS

It is critically important that the center-to-center spacing is correct when assembling your SteppIR Yagi. Use Figure 1.00 for placement of each of the elements. Start from the left edge of the boom and

measure from there.

As you assemble each of the element housing units (EHU), refer to this drawing. We recommend this

sequence:

1. Secure the driven and director element mounting plates to the boom using the correct saddles and

fasteners (be sure to use anti-seize on all stainless steel fasteners). Tighten enough to hold them

in place, but loose enough so you can move the mounting plates for final tightening.

2. Wire the EHU’s and secure them to the element mounting plates (don’t forget the gasket!). The

mounting plate itself acts as the lid for the EHUs.

3. Measure the center-to-center lengths, level the mounting plates and firmly tighten.

4. Re-measure all of your lengths and correct if needed. Take your time, get it right.

All of this is covered in greater detail in this manual, but it’s important to understand the proper flow

BEFORE you start—it will save a lot of time.

FIG. 1.00

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 18

70-3403-01

Driven EHU

70-3420-01

Director EHU

SECTION 1.0

PREPARING THE BOOM ASSEMBLY

EHU Placement

ELEMENT HOUSING UNIT (EHU) PLACEMENT

The UrbanBeam Yagi has two EHUs on the boom. One is a Driven element on 40 meters through 6 meters, while the other is a Director on 20 meters through 6 meters.

For the purpose of building the antenna, we refer to the elements as Director and Driven elements as

shown in Figure 1.01 below.

All the drawings in this manual are oriented so that you are looking inward at boom with the director to

the left and the driven to the right, as shown in Figure 1.01.

FIG. 1.01

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 19

When wiring the EHUs on the UrbanBeam Yagi, it is important to know that there are two different

types of EHUs. One of the EHUs is the Driven element, and connects to the coax cable from the radio.

The other EHU is the Director which has no coaxial connector.

NEVER DO ANY WIRING WHEN THE ELECTRONIC CONTROLLER IS CONNECTED TO THE

CONTROL CABLE. Even if the power is turned off of the controller, damage can occur. This is the

number one cause of antenna installation failures, so please be sure to heed the advice.

Figure 1.02 gives an overview of the inside of a SteppIR EHU.

Control cable

tray for routing

cable out of EHU

(on edge of

case)

Element support

tube (EST)

Balun (the balun is only

inside EHUs that are

driven elements)

EHU terminal header

Spring reel for copper

strip (20m reel is

shown, 40m reel is

larger)

SO-239 connector

(for driven element only)

Sprocket / platen

assembly

SECTION 1.1

ELEMENT HOUSING UNIT (EHU) OVERVIEW

FIG. 1.02

Serial # sticker

PREPARING THE BOOM ASSEMBLY

EHU Overview

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 20

SECTION 1.1

EHU WIRING

BLACK RED GREEN WHITE

4 Pin Header Wiring Sequence

TERMINAL PLUG

TERMINAL HEADER

FIG. 1.10

FIG. 1.11

FIG. 1.12

FIG. 1.14

Trim approximately 1.5 inches of the outer jacket of the control cable (4 wires). Remove the shield material, the support thread and cut the ground wire off as shown in Figure 1.10. Attach electrical tape at the end

of the trimmed control cable jacket so that there is no chance for a short. Remove 0.25 inches of the insulation from each of the individual 22 AWG wires, leaving bare copper. Tinning of the copper wire ends

with solder is not recommended by the connector manufacturer. Figure 1.11 shows the control

cable should look like when you are finished with the trimming. Dip each of the copper wires into connector protector before inserting into the terminal plug. Figure 1.12 shows what the connector protector will

look like.

The terminal header assembly consists of the terminal header and the terminal plug as shown in Figure

1.14. The plug is shipped loosely attached to the header. Remove this plug when wiring and firmly plug

back in when completed.

Follow the wire sequence in Figure 1.14 for each EHU.

Be careful to ensure that there are no bare wires

protruding out from the terminal clamps, to avoid potential shorts. Also make sure you are clamping down

on bare wire, and not the insulation of the wire

The wiring sequence for each EHU is also imprinted on the PCB that the terminal header is mounted on

(located inside the EHU), as shown in Figure 1.13. Pay no attention to the second row of imprinted text,

these pins are for use in the manufacturing of the board itself and are of no use to you. Figure 1.13 shows

a blue line crossing out the text in question. The yellow circle shows the correct wiring sequence.

FIG. 1.13

PREPARING THE BOOM ASSEMBLY

EHU Wiring

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 21

SECTION 1.1

EHU WIRING (continued)

Check to be sure the terminal plug is firmly inserted into the terminal header.

Lay the control cable wire inside the wire tray of the EHU as shown in Figure 1.15. This trough acts as

a strain relief so that the cable will not be pulled out of the EHU. It is a good idea to leave a small

amount of slack between the plug and the point which the tray starts as shown in Figure 1.16.

Using the coax seal and cut into 1 inch strips as shown in Figure 1.17. You will need 3 strips. The remainder can be used to seal the driven element SO-239 connectors, should you wish to.

Apply coax seal on top of the control cable and work it around the cable as shown in Figure 1.18. This

will help keep water from entering into the EHU. Apply the coax seal to the remaining areas of the

wire tray as shown in Figure 1.19.

Repeat wiring and coax seal preparation for all EHUs. When finished, the EHUs will be secured to the

aluminum element mounting plates. This is covered in detail in the next chapter.

FIG. 1.15

FIG. 1.16

FIG. 1.17

FIG. 1.18

FIG. 1.19

PREPARING THE BOOM ASSEMBLY

EHU Wiring (Continued)

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 22

SECTION 1.2

DIRECTOR EHU DRAWING

A (x10)

B (x10)

C (x10)

G

H

J

J

J

J

E

E

E

E

F

D

D

D

D

The parts explosion drawing in Figure 1.20 gives you an overview of the assembly of the director EHU.

Detailed instructions follow.

Key QTY Part # Description

A 10 60-0017 #10x 3/4” Machine screw

B 10 60-0018 #10 Flat washer

C 10 60-0019 #10 Nylock nut

D 4 60-0065 5/16”x3-1/2” Hex head bolt

E 4 60-0046 5/16” Nylock nut

F 1 70-3420-01 Director EHU

G 1 10-1502-01 Element housing gasket

H 1 10-1015-11 Element mounting plate

J 4 10-1601-03 1-3/4” Aluminum saddle half

FIG. 1.20

PREPARING THE BOOM ASSEMBLY

Director EHU

These parts are in the Element Hardware Kit 72-0062-01

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 23

SECTION 1.3

SECURE DIRECTOR MOUNTING PLATE AND EHU TO BOOM

Refer to the center-to-center measurements in Figure 1.00 in Section 1.0 when installing each of the EHUs

and mounting plates to the boom. The EHU should already be wired before placing it on the aluminum

mounting plate.

Position the aluminum mounting plate (PN 10-1015-11) and align the 1-3/4” aluminum saddle halves

(PN 10-1601-03) as shown in Figure 1.31. Insert the 5/16” x 3-1/2” hex head bolts (PN 60-0065) and

thread on the 5/16” Nylock nuts (PN 60-0046). Insert a set screw on the exposed side of the aluminum

saddle. Position the aluminum saddle face to be flush with the boom end, and tighten the set screw . Be

sure to use anti-seize on all stainless steel fasteners.

Place the EHU gasket (PN 10-1502-01) onto the mounting plate as shown in Figure 1.32. Remove all chads

from the holes for the 10-32 mounting screws. Align the gasket with the holes on the mounting plate.

Place the EHU (PN 70-3420-01) onto the mounting plate and attach it using the #10 x 3/4” machine screws

(PN 60-0017), #10 flat washers (PN 60-0018) and #10 Nylock nuts (PN 60-0019) as shown in Figure 1.33.

Be sure that the flat washer is between the machine screw head and the EHU housing as shown in Figure

1.34 . Tighten the Nylock nuts enough to compress the gasket material but do not over tighten or you can

crack the plastic EHU housing. It is best to tighten the screws twice, with the final tightening being the

most aggressive. Let the EHU sit for a few moments in between tightening.

Confirm that the distance from the edge of the boom to the center point of the element is 3.5 inches as

shown in Figure 1.35.

(A tip — use the mold spline located on the EHU housing as a place to hold your tape

measure edge when measuring center-to-center as shown in Figure 1.36

)

Level the EHU as shown in Figure 1.37 and tighten the aluminum saddles firmly.

FIG. 1.31

FIG. 1.32

FIG. 1.33

FIG. 1.34

FIG. 1.35

FIG. 1.36

FIG. 1.37

PREPARING THE BOOM ASSEMBLY

Director EHU Mounting

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 24

SECTION 1.4

DRIVEN EHU DRAWING

The parts explosion drawing in Figure 1.40 gives you an overview of the assembly of the driven EHU.

Detailed instructions follow. Mounting is identical to the Director assembly.

PREPARING THE BOOM ASSEMBLY

Driven EHU

A (x10)

B (x10)

C (x10)

G

H

J

J

J

J

E

E

E

E

F

D

D

D

D

Key QTY Part # Description

A 10 60-0017 #10x 3/4” Machine screw

B 10 60-0018 #10 Flat washer

C 10 60-0019 #10 Nylock nut

D 4 60-0065 5/16”x3-1/2” Hex head bolt

E 4 60-0046 5/16” Nylock nut

F 1 70-3403-01 Driven EHU

G 1 10-1502-01 Element housing gasket

H 1 10-1015-11 Element mounting plate

J 4 10-1601-03 1-3/4” Aluminum saddle half

FIG. 1.40

These parts are in the Element Hardware Kit 72-0062-01

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 25

The Driven element is assembled in precisely the same way as the Director. We will refer to some of the

pictures for the Driven element assembly.

Refer to the center-to-center measurements in Figure 1.00 in Section 1.0 when installing each of the EHUs

and mounting plates to the boom. The EHU should already be wired before placing it on the aluminum

mounting plate.

Position the aluminum mounting plate (PN 10-1015-11) and align the 1.75” aluminum saddle halves (PN 101601-03) flush with the tube end as shown in Figure 1.00. Insert the 5/16” x 3-1/2” hex head bolts (PN 60-

0065) and thread on the 5/16” Nylock nuts (PN 60-0046). Insert a set screw on the exposed side of the

aluminum saddle. Tighten, but allow the mounting plate to be loose enough for adjusting the center-tocenter measurement. Be sure to use anti-seize on all stainless steel fasteners.

Place the EHU gasket (PN 10-1502-01) onto the mounting plate as shown in Figure 1.22. Remove all chads

from the holes for the 10-32 mounting screws. Align the gasket with the holes on the mounting plate. Place

the EHU (PN 70-3403-01) onto the mounting plate and attach it using the #10 x 3/4” machine screws (PN 60

-0017), #10 flat washers (PN 60-0018) and #10 Nylock nuts (PN 60-0019) as shown in Figure 1.23. Be sure

that the flat washer is between the machine screw head and the EHU housing as shown in Figure 1.24.

Tighten the Nylock nuts enough to compress the gasket material but do not over tighten or you can crack the

plastic EHU housing. It is best to tighten the screws twice, with the final tightening being the most

aggressive. Let the EHU sit for a few moments in between tightening.

Verify that the center-to-center length from the Director EHU to the Driven EHU is 41.5 inches.

Level the EHU as shown in figure 1.37 and tighten the aluminum saddles firmly.

Figure 1.50 shows the boom with two EHUs

SECTION 1.5

SECURE DRIVEN MOUNTING PLATE AND EHU TO BOOM

PREPARING THE BOOM ASSEMBLY

Driven EHU Mounting

FIG 1.50

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 26

SECTION 2.0

MAST PLATE-TO-BOOM OVERVIEW DRAWING

Figure 2.00 shows an exploded drawing of the boom and mast plate assembly. This parts explosion is a

useful referral tool as you complete the steps in this section. Parts for this step are included in the 72-006101 Mast Plate Hardware Kit.

E

E

E

E

F

F

F

H

H

H

H

J

F

FIG. 2.00

PREPARING THE BOOM ASSEMBLY

Mast Plate

Key QTY PART NUMBER DESCRIPTION

J 1 10-1021-43 8” x 8” x 0.250” Aluminum mast plate

Part of 72-0061-01 Mast Plate Hardware Kit

H 4 10-1601-03 1.75” x .75” Aluminum Saddle Half

4 10-1601-22 2.00” x .75” Aluminum Saddle Half

E 4 60-0065 5/16” x 3.5” Hex head bolt, SS

G 4 60-0114 5/16” x 3.75” Hex head bolt, SS

F 8 60-0065 5/16” -18 SS Nylock nut

I 2 60-0113 10-32 x 5/8” SS Pan Head Screw

G

Optional: Use screw I to hold

2” saddle halves to mast

plate for ease of attaching

antenna to mast.

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 27

SECTION 2.1

ATTACH THE BOOM TO THE MAST PLATE

Slide the 5/16” x 3.50” hex head bolts (PN 60-0114) into the mast plate, and place the first half of the 1.75”

inch aluminum saddles (PN 10-1601-01) onto the bolts as shown in Figure 2.10. Place the boom in the

saddles as shown in Figure 2.11, and attach the other half of the 1.75” aluminum saddles. Apply anti-seize

to the bolts and thread on the 5/16” Nylock nuts (PN 60-0046). Tighten the nuts until the boom is snug,

but you can still rotate it.

Use a short level to level the boom to the mast plate (The EHU plate must be level also or this won’t work).

When the mast plate is level with the boom, tighten all of the saddle nuts firmly. Don’t forget to install the

set screws in the saddles as shown in Figure 2.13. Only the exposed half of the saddles will require a set

screw.

Use the 10-32 x 5/16” SS panhead screws to hold the 2” mast saddle halves in place on the mast plate, as

in Figure 2.10. and temporarily use the 5/16” x 3.75” bolts and nuts to hold the mast saddle clamp. Figure

2.15 shows the completed assembly.

FIG. 2.10

FIG. 2.11

FIG. 2.14

FIG. 2.12

FIG. 2.13

PREPARING THE BOOM ASSEMBLY

Mast Plate Attachment to Boom

Assembly of the Boom/Mastplate is now complete.

FIG. 2.15

10-32 x 5/16” SS panhead (makes attaching

antenna to the mast much easier)

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 28

SECTION 2.2

MOUNTING THE TERMINAL HOUSING

Mounting of the Terminal Housing, and taping of the coax and control cables to the boom

should be one of the last items done before mounting the UrbanBeam onto the mast.

Note: If You purchased the optional Connector Junction Box for your antenna, the terminal housing kit will

not be included. Refer to the separate connector junction box instruction manual for installation.

The terminal housing can be installed anywhere that it fits along the boom, or even on the mast above or

below the antenna. For the UrbanBeam, the two locations where it fits are under the EHUs. We suggest

mounting the Terminal Housing under the Director EHU. Wherever it is mounted, the hose clamp is used to

go around the Terminal Housing and the location where it is mounted.

Regardless of the mounting orientation, make sure that the hole in the end cap of the terminal housing will

be facing downward when the antenna is mounted to the mast. This will allow the housing to drain and prevent water from collecting inside the housing. DO NOT SEAL THE TERMINAL HOUSING. IT SHOULD

BE ABLE TO BREATHE OUT OF THE BOTTOM DRAIN HOLE.

PREPARING THE BOOM ASSEMBLY

Terminal Housing

Key QTY PART NUMBER DESCRIPTION

A 1 70-1102-21 Terminal Housing (Connector Tube)

1 60-6000-35 SS Hose Clamp

2” saddles

View from

above antenna

looking down.

1.75” saddles

A

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 29

SECTION 3.1

CONNECTING THE EHUs TO THE TERMINAL HOUSING

NOTE: If you have purchased the connector junction box option, use the manual provided with that

option for wiring, as it is different than these instructions for the terminal housing kit

• Make sure you know where the Terminal Housing will be located, and ensure that EHU control ca-

bles can be routed along the boom to get to the Terminal Housing without strain or being pinched.

• Route and tape the control cables to the boom in a way that will avoid damage to the cables in the

event the antenna is resting on the ground, could be scraped against the mast during installation,

etc. Be especially careful around the saddle clamps and sharp corners.

• Apply a thin coat of connector protector to each of the four exposed EHU wires.

• Follow Figure 3.10 below for the correct wiring. Note that the shield wires are all connected togeth-

er as one single wire and use a single position terminal strip separate from the other terminal

blocks. Be careful not to over-tighten the screws on the terminal blocks.

PREPARING THE BOOM ASSEMBLY

WIRING EHUS TO CONTROL CABLE

Driven

EHU

Director

EHU

Black

Red

Green

White

Black

Red

Green

White

Male

25-pin

D-sub

Black

Brown

Red

Orange

Yellow

Green

Blue

Violet

White

Pink

Cream

Grey

1

2

3

4

5

6

7

8

10

11

12

9

Drain Wires

from each

element

Terminal Block 1

Terminal Block 2

Antenna Controller

Shield (drain wire)

12

conductor

cable

Figure 3.10

not used

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 30

PREPARING THE CONTROL CABLE

1. Strip the jacket and aluminum shielding off of the 12 conductor control cable as shown in figure

3.20, approximately 2.75” from end of control cable, being careful not to damage the individual

wires.

2. Strip the plastic insulation off of each of the control cable wires, approximately 0.25” in length

should be bare wire.

CONNECTING CONTROL CABLE TO THE DB25 SOLDERED CONNECTOR

If you purchased the default DB25 connector, follow the steps below to connect it to your control cable. If you purchased the optional DB25 Field Splice

upgrade, skip ahead to the next set of steps.

1. Solder each wire to the appropriate pin of the 25 pin connector. Refer to

figure 3.10 on the previous page for the correct wiring sequence.

2. Attach the clamp to the control cable approximately 1” from the connector

and secure with the provided hardware as shown in figure 3.21.

3. Place the connector between the back-shell halves as shown in figure 3.22

and secure with the provided hardware.

CONNECTING CONTROL CABLE TO THE OPTIONAL DB25 FIELD SPLICE

The optional DB25 Field replaces the standard connector with a convenient solder-less connection of the control cable to the SteppIR controller. If you purchased this option, follow the steps below to connect

it to your control cable.

1. Apply the provided dielectric grease to the exposed copper portion

of each wire.

2. Connect each wire to the appropriate terminal and tighten using a

flat head screwdriver. Note that the terminals may be closed by

default. If so, turn the terminal screw ccw ~10 turns to open it before inserting the wires. Refer to figure 3.10 on the previous page

for the correct wiring sequence.

3. Position the control cable between the cable clamp halves as shown in figure 3.23.

4. Tighten the two pan head screws until the cable is snug, but do not over-tighten.

5. Thread the two thumb screws into the connector face as shown in figure 3.23.

6. Plug the DB25 splice into the back of the controller and twist the thumb-screws to secure it.

SECTION 3.2

FIG. 3.22

FIG. 3.20

2.75”

0.25”

FIG. 3.21

FIG. 3.23

PREPARING THE BOOM ASSEMBLY

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 31

Read the SDA-100 Operators Manual so that you are familiar with operation of the controller. At this

time the controller should NOT be connected to your radio or computer. Also, the fiberglass poles and

loop elements should not be installed on the antenna.

1. With the control cable NOT CONNECTED to the controller, turn the controller on. It should read

“Manual Mode Elements Home”. If not, push the “Retract” button. After the controller is fin-

ished tuning it will turn off. You will need to turn the controller back on. The controller will now

read “Manual Mode Elements Home”.

2. The next step is to test that each of the elements will extend their copper tapes out properly.

3. ENSURE THAT ALL THE ELEMENTS ARE CLEAR OF ANY OBSTRUCTIONS. The copper tape will be

extended out from both sides of each EHU for approximately 6 inches.

4. Go into Setup mode and select “Test Motors”. Wait until the retracting element message goes

away.

5. Now CONNECT the control cable to the controller.

6. The Test Motors mode allows the user to extend the copper tape on each element just past the

EHU tube by pressing the appropriate buttons on the SDA100. The display should look like this:

The “fine” up/down buttons select which element will be moved. The “coarse” up/down buttons

allow you to manually move the element in to home or out to inspect. The “band” button allows a

complete cycle, out, then in to home, with one keystroke.

The purpose of this test is threefold:

• It determines that you have the right control cable wires connected to the correct EHU (i.e. the

Driven control wires are moving the Driven element).

• It indicates that the motors are running in the right direction — Out makes the tape move out.

If any of the four motor wires are swapped, the motor will run backwards, so instead of extending the tape, you will hear a clattering sound as the motor pulls the tape in instead of out.

• It proves the controller and driver chips are functioning as intended.

If any element fails this test, you have probably made a wiring error. Also, be aware that shorting

any of the control cable wires together while the control cable is connected to the controller and

the DC supply to the controller is energized (EVEN IF POWER IS “OFF” ON THE CONTROLLER)

can result in blown driver chips. Check and correct any wiring errors and repeat the Test Motors

procedure.

To Perform the Test Motors Procedure

• Select the desired element using the “Fine” up/down buttons.

• Press the “Coarse” up button and the selected element will extend. Pressing the “Coarse”

down button will retract the element and the display will read “All Elements In” (when

any test is ended with the down button, all elements are brought in, so you can’t inadvert-

ently leave the elements out)

• Verify that each element works correctly and then unplug the controller’s power supply be-

fore disconnecting the control cable.

SECTION 3.3

WIRING TEST

WIRING TEST

FIG. 3.20

Test Motors

Ref Out/In Cycle

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 32

TRIM THE TIP OF EACH POLE FOR AN OVERALL LENGTH OF 170.00 INCHES

SECTION 4.0

TELESCOPING POLE PREPARATION

PREPARE THE TELESCOPING POLES AND LOOP TUBES

Overview

As shipped, the telescoping poles are at least 212” when extended but must be sized to 170” for each element,

and the remnant cut-off pieces are used to complete the loop element. Sweeps and sweep couplers are used

to join the elements to the polyethylene 18” sweeps. The Driven and Driver element loop tubes are joined together with 5” long fiberglass tube loop couplers.

Preparing the telescoping pole tips

Extend the telescoping poles to full length by firmly “locking” each section of the pole in place. A good methodology is to position each half of the joint so that they are several inches apart (while still within each other),

and then pull quickly and firmly. Do this for each pole. There are rubber plugs inside the base section of each

telescoping pole. These make it easier for handling, but they MUST be removed before measuring the pole

lengths. They also need to be removed permanently when attaching the poles to the EHU’s.

With poles fully extended and as firmly ‘locked’ into the extended position as possible, trim the end of the tip

element of each pole so that the pole is 170 inches (431.8 cm) from the tip of the pole to the butt end, as

shown in Figure 4.01. Use a hack saw or similar cutting blade that is suitable for fiberglass. Circular pipe cutters used by plumbers work well too. Set aside the cut-off piece, as it will be used in Section 4.1.

Using the included conical drill bit, chamfer the ends of the poles as shown in Figure 4.02. The drawing in Fig-

ure 4.03 shows the proper depth to chamfer to. Be sure to clean out the interior of the fiberglass poles before

continuing. Debris inside the telescoping poles can lead to failure of the EHU.

Secure polyolefin heat shrink to the telescoping pole joints

On all the telescoping fiberglass elements we now include double wall polyolefin heat shrink (PN 03630). Each

telescoping pole uses 3 of the polyolefin heat shrink pieces,. Once finished, the seal is secure and waterproof.

This product requires a heat gun for activation of the adhesive. Do not attempt to use a hair dryer for this

task.

When positioning the heat shrink, place it so that the joint of the telescoping pole is centered in the middle of

the heat shrink. Figures 4.04, 4.05, 4.06 and 4.07 below show how this is done. Using a heat gun (hair dryers

will NOT work), apply heat evenly around the entire area of heat shrink. Note: There are 4 blue colored lines

imprinted on the tubing. The joint is considered done being heated and waterproof when the lines change color. Each line needs to change in color to ensure even adhesion temperatures have been reached. It is OK to

re-align the heat shrink so it is centered on the joint while heating it, as it tends to move when under

heat. Be sure to re-align while the glue is hot and viscous.

FIG. 4.01

FIG. 4.02

FIG. 4.03

FIG. 4.04

FIG. 4.05

FIG. 4.06

FIG. 4.07

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 33

Preparing the pole tips for insertion into the sweep couplers

Prepare each of the telescoping poles as shown in Figure 4.08 for insertion into the plastic sweeps and

sweep couplers.

Secure 10 wraps of electrical tape 1.70 inches from the tip, as shown in Figure 4.08, Step 1 and step 2.

This is used as a measuring stop to be certain you insert the pole in the proper depth. It is important to

NEATLY wrap the electrical tape so it has a clean edge.

Cut a 4 inch piece of blue silicone wrap off of the included roll. Wrap the silicone tape around the pole.

Try to make the silicone tape wrap so that it is flush with the electrical tape as shown in Figure 4.08,

Step 3. You should use enough tension to wrap 2 1/2 turns around the pole. The first layer is only

stretched slightly (Figure 4.09A), with the last 1 1/2 turns pulling the tape a little harder so it makes it to

2 1/2 turns (Figure 4.09B). This isn’t very critical, but it’s better to not stretch it too tight and thin. Try

to keep the edges as even as possible. Apply pressure to the wraps with your fingers for a few seconds

when you are done to ensure adhesion.

Wrap the included 3M grip tape around the pole, flush with the edge as shown in Figure 4.08, Step 4.

Be sure there is no overlap of the grip tape – it should be fine from the factory but the OD of poles varies slightly, so if there is overlap, make sure you trim the tape so there is a gap, as shown in Figure

4.08, Step 4. Figure 4.09C shows the completed tip.

SECTION 4.0

TELESCOPING POLE PREPARATION (continued)

PREPARE THE TELESCOPING POLES (continued)

FIG. 4.08

GAP

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 34

SECTION 4.0

TELESCOPING POLE PREPARATION (continued)

PREPARE THE TELESCOPING POLES FOR SWEEPS (continued)

FIG. 4.09A

FIG. 4.09C

FIG. 4.09B

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 35

Preparing the telescoping pole tips for the loop elements

The remaining piece of cut-off pole tip from the previous step will be used to complete the loop, but first it

must be cut to the proper length. The cut that was made to make the telescoping pole measure 170” is

called “cut 1.” The next cut must be made on the same end of the pole remnant. This will be called “cut 2.”

The reason is these pole sections are tapered and we want to have the thickest end go into the Loop Splice

because it makes a better fit.

Figure 4.10 is the diagram of the pole trip remnant, showing overall size, differences between the thin and

thick end, and preparations of the ends.

Cut the pole remnant to 41.5”, cutting off material from the thicker end. This is “cut 2.” See Figure 4.11.

Chamfer both ends of the tube using the supplied chamfering bit.

Prepare the thinnest end in the same way the telescoping pole tips were prepared in Section 4.0 with electrical tape, silicone tape, and grip tape. On the thicker end, use grip tape spaced 1” from the end.

Repeat this procedure for all four pole tip remnants.

SECTION 4.1

LOOP TUBE PREPARATION

SIZING THE POLE TIP REMNANT FOR LOOP TUBES

Figure 4.13

Figure 4.11

Figure 4.12

chamfer

grip tape

41.5”

1.0”

blue silicone

electrical tape

thinnest end thickest end

“cut 2”

Figure 4.10

Tube piece left over from Telescoping Tube Preparation

Section 4.0

chamfer

Cut “1”

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 36

Attach the sweep couplers to the plastic sweep tubes

Please refer to the YouTube links shown on page 5 of this manual, they are highly worth watching for

this step alone! Each of the sweep coupler halves will have a notch in the mold on one side. It is

critical that these notches are pointing towards the sweeps or they will not work properly.

See Figure 4.20 for the location of the mark. Be certain that each half of the coupler has the mark

facing the sweep tube!

Place the coupler halves on the end of the plastic sweep tubing as shown in Figure 4.21. Insert four of

the 6-32 x 2” socket head screw (PN 60-0186) with washer (PN 60-0016). Place the screws so that the

threaded portion of the screw is facing downward. Apply anti-seize to the threads and place the Nylock

nuts on. Tighten using a 5/16” wrench to hold the nut and a 7/64” Allen Key to turn the screw. Tighten

until there is approximately a 0.25” gap between the two coupler halves as shown in Figure 4.22.

For aesthetic reasons it is nice to have all of the screws in the sweeps and metal brace be oriented the

same. To do this, make two of the sweeps turn one way and two the opposite way. One of each type is

shown in Figure 4.13. Be careful not to displace the blue silicone wrap when placing the coupler onto

the pole tip. Slide the coupler on until the coupler hits the black electrical tape edge marking 1.70 inches

from the pole tip. It is acceptable for a small amount of blue silicone wrap to protrude from the joint as

shown in Figure 4.33.

SECTION 4.2

LOOP PREPARATION

ATTACH THE SWEEP COUPLERS TO THE SWEEP TUBES

FIG. 4.20

FIG. 4.21

FIG. 4.22

Sweep tubing

Mark on sweep coupler

FIG. 4.23

Helpful hint: This is not the final tightening position of the

sweeps! Later in the instructions you will want these to be as

close to flush as possible without deforming the sweep.

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 37

Connecting the telescoping poles to the plastic sweeps

Begin tightening the four screws on the outside corners of the plastic coupler. Tighten evenly, using an

X type pattern as shown in Figure 4.34 . If you do not tighten evenly, you could potentially break the

fastener. Tighten the 4 screws only until the gap between coupler halves is about 0.1” - see Figure

4.32.

It is best to let the screws sit for a while and tighten in intervals in order to allow the plastic sweep material to reform. This also will reduce the chance of damaging the clamps or snapping a screw. All six

screws will be tightened when the cross brace is installed.

The 18” polyethylene sweeps have a natural bend from the manufacturing process. Orient the curve of

the sweep to take advantage of this bend to make putting on the aluminum brace much easier.

Be sure to hand test the sweeps to ensure they are tight—if they will turn when using your hands, they

are not tight enough or installed wrong—don’t forget that the slot in the sweep coupler MUST be facing

the sweeps or they will not function correctly.

SECTION 4.3

LOOP PREPARATION (continued)

ATTACH THE FIBERGLASS TELESCOPING POLES TO THE SWEEPS

1

4

3

2

FIG. 4.34

FIG. 4.32 FIG. 4.33

Installing the Loop Tubes

Slide the TIP end of Loop Tube has been cut to 41.5” and prepped per Section XX. Repeat the steps

in section 6.2 to tighten the 6 6-32 x 2” screws.

Installing the Metal Loop Brace

Figure 4.39 shows a completed sweep assembly. To install the Loop Brace, use two 6-32 x 2” machine

screws as shown in Figure 4.35 on the sweep clamp for the 170” pole side. Tighten to match the four

previously installed screws so the gap between the clamp halves is fairly even. In the coupler on the

other end of the sweep, start two 6-32x2” screws as shown in Figure 4.36. The inside screw should

protrude about 1/4”. Grabbing both the 170” pole and pole tip as shown in Figure 4.37, bend the

sweep until the Loop Brace can be pushed down over the protruding screw. Screw the two brace

mounting screws and they will thread up into the Brace and finally clear the Brace allowing the nuts to

be put on. You can use a clamp or locking plier to seat the Brace as shown in Figure 4.38. Tighten all

six screws taking care to do it evenly. Don’t be too conservative, these screws should be tight. Stop

tightening the screws before the screw heads start deforming the plastic coupler stop.

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 38

SECTION 4.3

LOOP PREPARATION (continued)

ATTACH THE TELESCOPING POLES TO THE SWEEPS (CONT’D)

FIG. 4.39

FIG. 4.35

FIG. 4.38

FIG. 4.37 FIG. 4.36

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 39

Select two loop halves that sweep in opposite directions as shown in Figure 4.13 and connect them together using the parts shown in Figure 4.39.1 (these parts are in the Loop Hardware Kit 72-0060-01).

Slide the 5” Loop Splice tube (10-1702-01) onto one of the pole tips with the .25” drain hole on the

Splice facing down to where the ground will be until the pole tip is at the edge of the .25” drain hole as

shown in Figure 4.39.2. Now position the edge of a hose clamp 3/4” from the edge of the Loop Splice

and tighten it. Slide the remaining two hose clamps onto the Splice, the outer one will be positioned and

tightened first with the middle one left loose as shown in Figure 4.39.3. It is recommended that you put

a #2 Philips screwdriver (the shaft should be .25” diameter) into the drain hole and slide the other pole

tip into the Splice until it hits the screwdriver shaft, keep pressure on the loose pole tip while you position and tighten the other outside hose clamp as you did on the other side of the Splice. Be careful not

to damage the 3M Grip tape already in place on the pole tips. If necessary spread the slit in the Loop

Splice slightly if the fit is so tight it won’t slide onto the pole tip. Don’t spread it so aggressively as it

breaks! The last step is to position the third hose clamp so it covers the .25” drain hole and tighten it as

shown in Figure 4.39.4. Make sure you position the host clamp so the slots in the metal band of the

clamp acts as a screen that allows water out, but no bugs in! Now check that each of the three clamps

are tight, be careful, small hose clamps can easily be tightened to the point that they strip, use common

sense to get them snug but don’t overdo it. You should not be able to cause the Splice to spin or pull

out with your hands. The completed loop is shown in Figure 4.39.5. Repeat this procedure for the other

Loop Half.

SECTION 4.3

LOOP PREPARATION (continued)

JOINING THE LOOP HALVES TOGETHER

Figure 4.39.1

Figure 4.39.2

.25” drain hole

(must face the ground

for water drainage)

3/4” (.75”)

Figure 4.39.3

3/4” (.75”)

3/4” (.75”)

Figure 4.39.4

Figure 4.39.5

pole tip

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 40

SECTION 4.4

ATTACH THE ELEMENTS TO THE EHUs

PREPARE THE CPVC INNER-GUIDE TUBE & DIVERTER CONE

The loops on the URBANBEAM Yagi use a plastic tube and a diverter cone located inside the telescoping

pole, to guide the copper strip out of the EHU. The plastic tube is off-white and is made of CPVC. There are

3 pieces that make up the guide tube assembly: The diverter cone (PN 10-1509-02), the 39-7/8” section of

3/4” CPVC with no coupler (PN 70-2025-23) and the 49” section of 3/4” CPVC with a coupler attached to one

end (PN 70-2025-13). This guide tube is only required for Driven element EHU tubes. The guide tube is not

needed on the Director side of the loop. Figure 4.41 shows the three pieces in the assembly.

The smaller diameter end of the diverter cone is glued to one end of the 39-7/8” CPVC tube as shown in Fig-

ure 4.42 . Use the supplied glue and applicator as shown in Figure 4.43. Apply the glue evenly around the

outside diameter of the tube as shown in Figure 4.43. Be sure you get even coverage all the way around

the tube. Cover about 3/4” of an inch deep as shown in Figure 4.43. Firmly push the 39-7/8” CPVC tube

into the diverter cone end as shown in Figure 4.44. Let the glue dry at least 20 minutes before moving it.

Apply glue evenly around the outside diameter of the 39-7/8” CPVC tube as shown in Figure 4.45. Apply approximately 3/4” deep as per prior step. Locate the 49” CPVC tube (PN 70-2025-13) with coupler, as

shown in Figure 4.46. Push the 39-7/8” tube firmly into the coupler as shown in Figure 4.47.

Repeat above instructions for remaining guide tube assembly (two per Driven EHU only).

WARNING: Do not apply glue to the inner “female” portion of either the diverter cone or coupler. The glue

applied to the outside of the tube is sufficient to bond the two pieces, and will prevent potential for damaging obstructions being formed by dried glue.

Diverter Cone

PN 10-1509-02

39-7/8” CPVC

PN 70-2025-23

49” CPVC

PN 70-2025-13

Apply glue ONLY on the

outside diameter of the

ends of the 39-7/8” pipe

NO

GLUE

NO

GLUE

NEVER use glue on the inside “female”

portion of the diverter cone or coupler

FIG. 4.41

FIG. 4.42

FIG. 4.44

FIG. 4.45

3/4”

FIG. 4.43

FIG. 4.46

FIG. 4.47

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 41

SECTION 4.5

FINAL ASSEMBLY

FINAL ASSEMBLY

When the CPVC inner guide tubes are completed, they will need to be inserted into the telescoping

poles and secured to the Driven EHU. Figure 4.60 below gives an overview of this procedure, with detailed instructions following on the next page.

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 42

SECTION 4.6

ATTACH THE ELEMENTS TO THE EHUs (continued)

SECURING THE ELEMENTS TO THE EHU

When the CPVC inner guide tubes are completed, they will need to be inserted into the telescoping

poles and secured to the Driven EHU. Figure 4.60 below gives an overview of this procedure, with detailed instructions following on the next page.

This drawing shows the EHU placement for the Driven element, the procedure is the same for the Director element,

except the Director does NOT have the guide tubes

. The parts required in the

table below are shown for the Driven EHU assembly.

Key QTY Part # Description

A 2 10-1006-22 Quick disconnect boot

B 2 10-1013-02 Telescoping pole

C 2 NA Inner guide tube assembly consisting of diverter cone , 39-

7/8” and 49” CPVC Plastic tube, glued together.

(NOT USED FOR THE DIRECTOR)

A

A

B

B

C

C

Molded ring prevents the

pole from sliding out from

under the quick disconnect

boots — even in very high

winds.

FIG. 4.60

Driven EHU

Quick disconnect

boot

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 43

SECTION 4.6

ATTACH THE ELEMENTS TO THE EHUs (continued)

SECURING THE ELEMENTS TO THE EHU (continued)

When attaching the telescoping fiberglass poles to each of the EHUs, special care must be taken to ensure

that the rubber plugs that are in the base section of each pole are removed before placing the telescoping

poles onto the EHU. Failure to remove these plugs will result in catastrophic failure of the EHU.

Figure 4.61 shows how the plug is in place for shipping purposes.

The URBANBEAM two elements join together to form one large loop. These elements were prepared earlier

in Section 4 and should look like the ones shown in Figure 4.39.5. Be sure to put your quick disconnect

boot (PN 10-1006-22) onto the pole before inserting into the EHU.

The CPVC inner guide tube is inserted into the Driven EHU side of the loop assembly as shown in Figure

4.60. Insert the guide tube so that the edge of the diverter cone is flush with the base of the telescoping

pole as shown in Figure 4.62. Position a loop to be installed and orient it so the drain hole in the Loop

Splice will be facing down to the ground when the antenna is installed. Slide either telescoping pole into the

appropriate EHU (remember that only the poles going into the Driven EHU have the CPVC guide tubes inside

of them) until it bottoms out firmly (in very rare cases the pole butt may need sanding to allow it to slide

freely). There may be a small portion of unpainted fiberglass pole protruding as shown in Figure 4.65, this

is normal, just make sure it is bottoming out on the diverter that is inside the EST tube. The unpainted part

of the pole will be protected from the sun by the quick disconnect boot. Put a quick disconnect boot on the

other loop pole and place the pole on top of the EHU box so that it hits the round protrusion as shown in

Figure 4.63 (it will stay there pretty well but you may want someone to hold it if possible as you perform

the next step) then take a rope or cord and pull the two poles together until the butt ends of each are fairly

close to parallel, then tie it off. This allows easy insertion of the remaining pole into the appropriate EHU.

Once both poles are properly inserted as shown in Figure 4.64 you can remove the rope.

Before tightening the quick disconnect boots, twist the base sections of the telescoping poles until the loop

portion of the element is as level as possible. Tighten the quick disconnect boots firmly. Wait 20 minutes

and tighten again—the flexible material will tend to cold flow initially. It is also a good idea to do a final

tightening of all the quick disconnect boots and all fasteners as a last step before mounting the antenna

onto the mast.

FIG. 4.65

FIG. 4.61

FIG. 4.64

FIG. 4.63

FIG. 4.62

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 44

SECTION 5.0

SECURE CABLES & MOUNT URBANBEAM ON TOWER

MOUNT THE URBANBEAM ONTO THE TOWER MAST

There are many different methods and mechanisms that are used in the course of attaching an antenna to

it’s final resting spot. The most common method by far for a Yagi antenna is to mount it on a tower, with a

mast fixed in place at the top of the tower. That is the assumption with these instructions. In a best case

scenario in terms of ease of access, the antenna is being mounted on a tilt-over, crank-up tower or a crankup tower that nests at the fairly traditional 21 ft. A Yagi often times is mounted at the top of a fixed-tower,

high up in the air, where someone is strapped to the tower awaiting the antenna by means of gin-pole and

transmission line or a crane/bucket lift. With this in mind, the mast plate is set up on the URBANBEAM so

that the mating process from mast plate to tower mast is made as easy as possible.

The tower mast connection uses two sets of aluminum saddles to attach the antenna to the tower mast as

shown in figure 5.00. In most cases the tower mast is 2 inches in diameter, but occasionally the mast size

may be different, depending on the customers situation. SteppIR offers saddle sizes in 1-3/4”, 2”, 2-1/4”, 2-

1/2” and 3”. Since the vast majority of installations of the URBANBEAM comes with the standard 2 inch saddles, that is the verbiage used in the instructions that follow.

The 2 inch aluminum saddle halves (PN10-1601-22) are held in place using 5/16” x 3-3/4” hex head bolts

(PN 60-0114) and 5/16” Nylock nuts (PN 60-0046) as shown in figure 5.00. The first half of the aluminum

saddles rest against the mast plate and are held firmly to the mast plate using #10 x 5/8” machine screws,

which insert through the mast plate and thread into the portion of the aluminum saddle normally reserved

for the set screw. When connecting the saddle halves to the machine screws, be sure that the bolt holes line

up perfectly. This will be of critical importance when the antenna is connected to the tower mast.

Key QTY Part # Description

A 2 60-0113 #10x 5/8” Machine screw

B 4 60-0114 5/16” x 3-3/4” Hex head bolt

C 4 10-1601-22 2” Aluminum saddle half

D 4 60-0046 Nylock nut

FIG. 5.00

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 45

SECTION 5.1

FINAL STEPS

LAST STEPS

IT IS VERY IMPORTANT THAT YOU PERFORM EACH OF THESE

STEPS BEFORE ATTACHING THE ANTENNA TO THE TOWER MAST

1. Connect the controller to the control cable and extend the Driven element to the 40m band. Have

someone listen as the copper strip extends outward into the support tubes. As the motors extend

the copper strip, they start out moving very slowly, and then ramp up to full speed. There should

be an accompanying hum for this that should never sound harsh, or choppy.

2. If there are any obstructions stopping the copper strip from making it’s way out, you should notice

a significant sound that will not be confused with the smooth motor sound. Listen for any signifi-

cantly loud “clicks”, scraping sounds or anything that sounds out of the ordinary.

3. If there is something that outright stops the copper strip from extending or retracting, you will get

a harsh sound as the motors try to keep going but the tape is stuck.

4. If any of these “bad” sounds occur, try to locate the area where the problem is happening and in-

vestigate. Repeat these steps again. If all is OK, proceed to step 6.

5. Check all fasteners on the antenna to be certain that they are tight. This may seem redundant, but

the time to discover a loose fastener is NOW, not when that part it was supposed to hold falls out

of the sky.

6. Be sure that you have set-screws in all the saddles, where applicable. Be sure they are tightened.

7. Check all the quick disconnect boots to be sure they are as tight as possible and are in the correct

position relative to the EHU and the telescoping poles.

8. Check all wiring and coax cables to ensure that they are secured to the boom and that they are not

resting against any sharp objects.

9. Check to be sure that the elements are level with the boom— a level antenna looks much better

when suspended in the air than one that is not!

10. Get the UrbanBeam Yagi on that tower so you can work some good DX!

Support: steppir.com/support ⚫ Tel: 425.453.1910 ⚫ support@steppir.com

Page 46

SECTION 6.0

TROUBLESHOOTING THE URBANBEAM YAGI

TROUBLESHOOTING TIPS

(Instructions continued on next page)

SteppIR antennas are all powered by stepper motors, hence the name. Stepper motors function by rotating

the shaft a specific number of “steps” per revolution. The SDA 100 directs the stepper motors to extend the

elements a particular number of steps to the required length. If for some reason the antenna gets out of

calibration, the method for recalibrating is pretty simple. When you press the calibrate button, the

controller retracts each element until it assumes it is “home”, and then keeps retracting the stepper motors

for a period of time to ensure that there is no question that the elements have indeed been homed. At that

point, the controller sends the elements back out to the frequency they were at when the calibration

function started. That is why in calibration mode you will hear the antennas make a loud growling sound

towards the end of the retracting—the elements are homed but the stepper motors keep right on going for

a while longer before sending the elements back out.

It is important to note that if a problem arises with the elements, such as an obstruction that is impeding

the path of the copper strip, the SDA 100 controller will not recognize this, so just because the controller is

showing the proper length for any given band, there may still be an issue. Even though the controller may

indicate that the copper strip is moving, in a troubleshooting situation it very well may not be. The

controller does not have much say in the indicating of a problem—it’s job is to simply get the elements to

the right length. This is why we have come up with the following information for you to review when

having issues:

The antenna is out of calibration—this is something that happens from time to time and is not a

problem at all. Whenever you suspect a problem the very first thing that should be done is a calibrate. It is

always a good idea to calibrate the antenna if you are having trouble. It is best to set the UrbanBeam to

20M before doing the calibrate function. You only need to calibrate once. To be certain that the antenna

was indeed out of calibration, check the SWR before you calibrate and check it again after you calibrate to

see if there are any improvements. If the SWR is unchanged, the antenna was in calibration and is not the

issue.

The lengths of the antenna are incorrect— Using the “Cause/Effect” theory, generally the first place to

look for trouble is the last place you have been. Using this line of thinking, if there is a problem with your

antenna, we need to be sure you are using the factory default lengths for your controller. Regardless of

whether you think you have done anything that could change the lengths, as a second step in

troubleshooting (the first being the simple calibration of the antenna), be sure to reset the factory default

lengths.

There is a short or break in the antenna control cable — This is the number one ‘hard error’ that

occurs. Breaks or shorts can happen because of gnawing rodents, aggressive weed whacking, freewheeling

rotators, mechanical fatigue, cable pinched between antenna and any object, weather or UV deterioration of

antenna insulation, and dozens of other reasons. For the UrbanBeam, pairs 1-2, 3-4, 5-6, 7-8 are all

independent circuits, and should never come in contact with one another or ground. The resistance

between the pairs should be approximately 15 ohms, not including controller cable length (with 100 feet of

cable, the resistance will measure approximately 20 ohms). An intermittent short or an intermittent open

while the motors are moving can also cause a driver chip failure. There is no skimping on carefully checking

the resistance between each pair, and making sure no pairs are crossed or grounded.

The SDA 100 electronic controller has a defective or intermittent driver chip—It only takes a

momentary short to damage a driver chip. The problem with driver chips, is that a blown driver chip or a

damaged driver chip that has not failed outright can act a lot like a damaged EHU. What we don’t want you

to do, is jump to the conclusion that it is an EHU issue, only to spend time and money taking your antenna