Page 1

Yagi Dipole

Vertical

(Patent #6,677,914)

40m - 30m Dipole Kit

nstruction Manual for the 2-3-4 Element Yagi

I

teppIR Antennas

S

112 -116th Ave NE, Suite 2-5 , Bellevue, WA 98004

2

Tel: 425-453-1910 Fax: 425-462-4415

Tech Support: 425-891-6134

www.steppir.com

Rev: Q 01/16/08

Page 2

SteppIR Antennas 40m - 30m Dipole Kit

2

EST

A

bbreviations

EST Element Support Tube

EHU Element Housing Unit

FTP Fiberglass Telescoping Pole

QDB Quick Disconnect Boots (rubber)

ERT Element Return Tube

QDB

EHU

FTP

ERT

SteppIR Antenna Information Web Sites (as of 8/03/06)

http://steppir.com/

http://groups.yahoo.com/group/steppir/

Page 3

SteppIR Antennas 40m - 30m Dipole Kit

3

40m - 30m Dipole Overview

T

he 40m - 30m dipole is simply a driven element that functions as a dipole from 6.8 MHz to

13.8 MHz and as the driven element for the yagi array from 13.8 MHz to 54 MHz. It has no

effect on the performance of the yagi. The yagi works the same with or without this option.

A dipole for 40m would normally be about 64 feet long but we have shortened it to 39 feet

by looping the element tip back towards the boom. This is a form of linear loading and is

very efficient, however, nothing comes for free and with this dipole you lose about .37 db on

40m over a full size dipole. This is hardly measurable at the receiving station end so it is a

very reasonable trade off. On 30m since the copper tape barely turns the corner back toward

the boom it essentially performs like a full sized dipole.

On 40m folding the element back nearly double (the tape comes within about 3.5 feet of the

boom on each side) very conveniently makes the impedance 25 ohms, a 1.0:1 match for our

yagi Balun/Unun. On the 30m, however, we have a full sized dipole whose impedance is

very much dependant on the height above ground so there is a varying degree of mismatch.

Below 40 feet or so you will find the SWR as high as 2.6:1 but at greater heights it can drop

to as low as 1.6:1 SWR.

This small amount of mismatch can easily be handled by the internal tuners on most trans-

ceivers. At 10 MHz SWR values in this range result in insignificant loss, so the antenna will

perform very well on 30m. You will find that on 40m even at heights below 40 feet you will

get a very good match with this type of shortened dipole. If the SWR seems to be too high

try adjusting the driven element length using the “Create Modify” function.

Note: By using the “Create Modify” function to fully extend either the reflector or director 1

on 30m you can create a very short director for the dipole resulting in .5 db gain and

lowering the SWR by about .2. You can then save it and it will be permanent. You

could also save it in both directions (180

180° and the director 1 in the normal direction and now have it reversible. If SWR is

the biggest concern try

lengthening both the reflector and director 1 to

get the lowest SWR.

Warm Regards,

First Prototype Sweep

°

and normal), lengthen the reflector in the

Mike Mertel

Mi

chael (Mike) Mertel - K7IR

President

Page 4

SteppIR Antennas 40m - 30m Dipole Kit

Boom

Element Support Tube

4

Stepper Drive Motor

Copper Beryllium Tape

Element Housing Unit

Element Return Tube

Page 5

SteppIR Antennas 40m - 30m Dipole Kit

5

Topic Page

Abbreviations 2

40m - 30m Dipole Overview 3

Table of Contents 5

Parts List 6

For Upgrade of Existing Antenna

Remove Existing Driven Element - 2 Element 7

- 3 Element 8

- 4 Element 9

Install 40m - 30m Return Loop

Install the Element Return Mounting Bracket 10

Assemble the Return Mounting Kit 11

Install Boom Counter-weights (4 Element Retrofit ONLY) 12

Install the Element Housing Unit 14

Install CPVC Liner Tubes 14

Prepare the Fiberglass Telescoping Poles (FTP) 16

Assemble the Sweeps to the Poles 18

Attach the 40 - 30 EST’s to the EST & ERT 21

Antenna Layout Drawing - 2 Element 22

- 3 Element 23

- 4 Element 23

New Antenna Specifications 24

Appendix A - 6m Passive (Early 3 Element Reconfiguration) 25

Appendix B - Controller (Upgrade) 26

Appendix C - CPU (Firmware chip) Replacement Procedures 27

Appendix D - Controller Firmware Version 6.7 or Later 30

Appendix E - Troubleshooting Guide 33

Appendix F - Replacing the Driven Element Bracket 39

SteppIR Warranty 41

Page 6

SteppIR Antennas 40m - 30m Dipole Kit

40m - 30m Dipole Kit

(

RETROFIT 3E)

ITEM QTY PART # DESCRIPTION

PARTS LIST

6

1

BOX 1 1 72-0027-01 ELEMENT HOUSING UNIT (DRIVEN)

1 72-0009-03 PVC GLUE PACK

2 72-0027-02 SWEEP ASSEMBLY (RETURN LOOP)

2 72-xxxx-01 COUNTER-WEIGHT BAR 2-1/2” x 12” x 1/2” (4 Element Retrofit Only)

1 72-0027-03 FIBERGLASS TUBE, 1.75" OD x 12"

BOX 2 4 70-2025-02 3/4” CPVC LINER TUBE WITH COUPLING (2-43.5” & 2- 49” LONG)

BAG 1 16 60-0014-01 6-32 X 7/8 PANHEAD SCREWS

1 10-1505-01 ELEMENT RETURN BRACKET

4 72-0023-06 FIBERGLASS TELESCOPING POLE (FTP), 18 FOOT

72-0009-02

40M - 30M DIPOLE KIT

DRIVEN ELEMENT KIT

ELEMENT RETURN TUBE KIT

HARDWARE

16 60-0014 6/32 NYLOK NUT

4 60-0014 4-40 X 3/4 PANHEAD SCREW

2 60-0003 1-3/4 U-BOLT W/SADDLES

2 60-0093 5/16 X 2-3/4 BOLTS

6 60-0046 5/16 NYLOK NUTS

BAG 2 4 60-1006-01 QUICK DISCONNECT (RUBBER BOOT) 1.5” TO 1.25” - W/CLAMPS

8 60-0021-01 4-40 X 5/8 PANHEAD SCREW

12 60-0022 4-40 NYLOK NUT

7 60-0019 10-32 NYLOK NUTS

2 60-0091 1/4-20 X 3-3/4 BOLT (4 Element Retrofit Only)

2 60-0030 1/4 NYLOK NUT (4 Element Retrofit Only)

8 60-0041 1/4 FLAT WASHER (4 Element Retrofit Only)

1 09-0002 CW 85 ELECTRICAL TAPE (66 ft)

1 20-4003-01 CPU CHIP W/LATEST FIRMWARE & 40 - 30 BUTTON LABEL

Page 7

SteppIR Antennas 40m - 30m Dipole Kit

7

Remove Existing Driven Element: (F

• Retract all elements:

sing the controller:

• U

• Go to “Setup” mode and press ‘Select’

• Using the ‘Up’ - ‘Dn’ buttons find “Retract Elements” and press ‘Select’

• Using the ‘Up’ - ‘Dn’ buttons find “Yes” and press ‘Select’

• Wait for the “ * ” to stop flashing

• The elements are now retracted

• Disconnect the coax and control cable for the driven

• Loosen the clamps holding the two rubber boots securing the fiberglass poles

• Remove the two fiberglass telescoping poles (FTPs) from the driven element

housing (Drawing 1 - 3 or 5)

• Remove the driven element housing (EHU) unit from its mounting plate

(Drawing 1 - 3 or 5)

Note: For customers who purchased a 3 element anten

housing brackets may have been of a different design. If you have the original style

element housing bracket (approximately 4-1/4” across the top) you will need to install a new style element housing bracket on your boom before you can mount the

new 40m - 30m dipole driven element housing unit (see Appendix F).

or Retrofit Installation ONLY)

element

na before March 2003 your element

REMOVE

iven FTPs & EHU

Dr

2 Element 20m - 6m

New 40m - 30m Dipole Loop

2 Element 40m - 6m

Driven

Director

Driven

Director

Drawing 1

rawing 2

D

Page 8

SteppIR Antennas 40m - 30m Dipole Kit

Director

EMOVE

R

iven FTPs & EHU

Dr

3 Element 20m - 6m

Driven

8

Drawing 3

New 40m - 30m Dipole Loop

Reflector

Director

Drawing 4

Driven

3 Element 40m - 6m

Reflector

Page 9

SteppIR Antennas 40m - 30m Dipole Kit

Reflector

R

D

EMOVE

riven FTPs & EHU

Drawing 5

Driven

Director 1

9

4 Element 20m - 6m

New 40m - 30m Dipole Loop

Director 2

Reflector

Driven

Drawing 6

Director 1

4 Element 40m - 6m

Director 2

Page 10

SteppIR Antennas 40m - 30m Dipole Kit

Install 40m - 30m Return Loop:

In

stall the Element Return Mounting Bracket: (For Retrofit Kit ONLY)

10

Note

• Drilling instructions

Warning:

Keep the drill straight while drilling to produce a clean round hole.

he element return bracket comes installed when ordered with a new antenna.

: T

• M

easure

• Secure

• Make sure to level

ither a level or actually mounting the element and eyeballing it.

e

• Drill

sing the pre-drilled pilot holes in the bracket as a guide (Picture 1).

u

& mark the boom to install the return bracket per D

the return bracket firmly in place with some type of clamp (P

the bracket with respect to the driven element bracket using

four 5/16” holes, two in from each side, through the bracket and the boom

rawing 7, 8 or 9.

icture 1).

Make sure that the bracket does not slip or twist while drilling.

It may be helpful to drill both holes for one bolt and then install

that bolt providing more positive alignment for the second hole.

• Install the two 5/16” bolts with Nylok nuts & tighten

snug as possible in the holes.

Note: For the 2 element boom only you will need to move the mast plate from its original

position in the center of the boom to make room for the return bracket. It can be located in any of the four (4) positions indicated in Drawing 7. It only needs to be

moved enough to clear the return bracket. If you will be installing the optional 6m

passive element - only positions #2 or #3 can be used.

. These bolts should fit as

irector

D

.75 12.00

4 8.0 0

2 .2 5

Director

Drawing 8

9 4.0

2

3

8" splice

Drawing 7

19 6 .5 0

4 8.0 0

Driven

Return

4 .2 5

4

48.00

2 0.7 5

2 5.0 0

18.60

Driven

1

18.60

2 Element

.75

3 Element

Reflector

4 8.0 0

Return

10 2 .5 0

4 8.0 0

5 0.2 5

Page 11

SteppIR Antennas 40m - 30m Dipole Kit

11

R

eflector

Return

84.00 114.00 186.50

25.00

Driven

Drawing 9

42.5067.5046.25

72.00

Director 1

42.50 67.50

* Not Actual Spacing *

Return

racket

B

Level

Pre-Drilled

ilot Holes (4)

P

(2 Per Side)

• A

ssemble the Return Mounting Kit

nstall return element cross tube and U-bolts as seen in Picture 3 (center an

• I

aluminum sleeve under each U-bolt but do not tighten yet).

Note: Some of the U-bolt saddles have come from the supplier with the ears bent out-

ward (Picture 2-A). It is recommended that you bend then straight so that they

center on the reinforcing ring more securely and safer (Picture 2-B). The sad-

dles will need to be pressed on securely (or tapped on with a hammer) until

they bottom out.

• Measure the return tube offset to

ma

tch the offset of the driven ele-

ment housing tube (Drawing 10).

• Tighten the U-bolts securely.

Drill Bit

A B

4 Element

Picture 1

Driven Bracket

Return Kit

Picture 2

Director 2

46.25

Page 12

SteppIR Antennas 40m - 30m Dipole Kit

12

Picture 3

Drawing 10

6

7

5

4

3

1

2

nstall Boom Counter-weights (4 Element ONLY):

I

On the 4 element antenna ONLY you will need to install a pair of counter-weights to the side

of the Director 2 element mounting bracket (Picture 3B) to balance the boom after the in-

stallation of the 40m - 30m dipole kit. These are powder coated steel bars weighing approxi-

mately a total of 8.2 pounds.

Locate: (Picture 3A)

• Two steel bars 2-1/2” x 12” x 1/2” (counter-weigh

• Two 1/4-20 x 3-3/4” bolts

• Two 1/4-20 Nylok nuts

• Eight 1/4” flat washers

Suggested Installation Steps (retrofit only):

• On a retrofit installation you should not need to remove the element housing unit

(EHU) from the element mounting bracket but do be careful with the weight of

the EHU and the FTP’s attached when you remove the existing bolts.

• Remove the first 1/4” bolt from the Di

stall it back into its hole from the other side of the bracket. This will support the

bracket while you remove the second bolt.

• Remove the second 1/4” bolts from the Director 2 element mounting bracket.

• Put two 1\4” flat washers on each of the new 1/4-20 x 3-3/4” bolts.

• Position the first counter-weight by lining up the holes so that the end of the

weight is even with the end of the element mounting bracket (Picture 3B) and in-

stall a new 1/4-20 x 3-3/4” bolts with the two flat washers through the empty

hole.

• Now install the second new 1/4-20 x 3-3/4” bolts with

through the second hole pushing out the old bolt that you temporarily installed

from the other side.

• Put the second counter-weight over the two new bolts sticking out.

• Install two flat washers on each bolt and then the new Nylok nuts and tighten.

• The end results should look like Pi

• This completes the installation of the counter-weights.

rector 2 element mounting bracket and in-

cture 3B.

ts)

the two flat washers

Page 13

SteppIR Antennas 40m - 30m Dipole Kit

Director 2 - Element Mounting Bracket

13

Picture 3A

Director 2 - Element

ounting Bracket

M

ounter-Weight Bar (2)

C

4 Element Counter-Weight Assembled

or the 40m - 30m Dipole Option

f

Counter-Weight

ars Installed

B

Picture 3B

Page 14

SteppIR Antennas 40m - 30m Dipole Kit

Install the Element Housing Unit (EHU):

Wa

rning: (For a retrofit installation only) Mount the new 40m - 30m driven element hous-

ing unit (EHU) in the SAME

r

efer to Drawing 2 - 4 or 6.

• Install the driven element housing unit onto the element bracket with bolts in

holes 1 through 7 (Drawing 10) and tighten. Use the seven (7) new 10-32

Nylok nuts and the existing screws. (For a retrofit installation only) hole # 7 will

need to be drilled through the aluminum element bracket (with a # 6 or a 13/64”

bit) before the bolt can be installed and tightened.

• If the mounting holes in the new EHU do not line up w

mounting bracket you may need to loosen the two horizontal bolts [Picture 1

(Driven Bracket)] that secure the element mounting bracket to the boom and

then insert the screws in the EHU and tighten. Be sure to retighten the two horizontal bolts when you are finished mounting the EHU.

• The remaining three bolts do not pass through the aluminum element plate but be

sure they are tight also.

Note: With a retrofit installation

he control cable and run the “Test Motors

t

ain antenna installation manual to verify the wiring is correct and eve-

m

rything is functioning before final assembly.

Installing CPVC Liner Tubes:

Locate:

• Four pieces of 3/4” CPVC liner extension tubing

(pi

cture 4 & 5 only has 2 shown in picture) with

CPVC coupling installed, two poles for each side.

• One CPVC glue kit

• One or more good assistants

• Using the supplied glue and cotton tips, apply the

glue onto any area where there is a CPVC connection. Be sure and place the glue

onto the outside of the CPVC tubing and NOT ON THE INSIDE OF THE COU-

PLER. Then slide the coupler onto the CPVC so that none of the glue goes onto the

inside of the CPVC, this would cause a potential blockage inside the tube.

• Glue the two CPVC sections together so that the 43.5”

element housing and the 49” will slide into the Fiberglas Telescoping Pole first. Let

it dry for ten minutes.

• Repeat this process for the other side.

orientation as the old unit that you removed. Also

ith the holes in the element

this is the point where you want to reconnect

” procedure outlined in the

section can be glued to the

14

Picture 4

43.5” CPVC

49”

CPVC

Page 15

SteppIR Antennas 40m - 30m Dipole Kit

Note: You may need to prop up the CPVC until the glue sets.

W

arning: This will leave you with the two liner ext

not to hit or catch anything on these liners as this could damage the CPVC.

These liners will be covered with the installation of the Fiberglass Telescoping

Poles in the next operation. Be equally careful when sliding them into place.

• Prepare the special EST’s marked 30 - 40 as described in the “Prepare the Fi-

berglass Telescoping Poles (FTP)” section and “Assemble the Sweeps to the

Poles:” sections.

• Read the “Attach the 40 - 30 FTP’s to the EST & ERT”

ing.

• Slide the entire CPVC extension into the Fiberglass Telescoping Pole, except for

6” to allow for gluing to the CPVC in the element housing, as shown in Drawing

11.

Note: It may take a number of attempts to get the CPVC liner tube to go past the second

section of the Fiberglass Telescoping Pole, allowing it to go in all the way (Drawing

11). Gently shaking the CPVC can be helpful. Take your time and be careful with it.

• Then you will glue the CPVC extension tube to the int

housing (Picture 6)

ensions sticking out. Be very careful

section before continu-

ernal CPVC of the driven

15

EST Ho usin g

Drawing 11

ib erg la ss Telescoping Pole with Inte rna l C PV C for 40/30m Diag ram

F

Rubbe r boot sh o u ld b e place onto th e Fiberg las s

Tele scoping Pole s o that it slid e s o n to the ES T

CP VC Co up ler

43 .5 Inn er C PV C

• After the glue has been dried, then finish

th

e assembly as described in the “Attach

the 40 - 30 FTP’s to the EST & ERT”

section.

• Repeat these instructions for the other

si

de to finish the installation of the 40m -

30m loop assembly.

CPVC Liner

49 Inn er C PVC

Picture 6

EHT

Bullet

EHU

Page 16

S

teppIR Antennas 40m - 30m Dipole Kit

Prepare the Fiberglass Telescoping Poles

L

ocate:

• Four dark green fiberglass telescoping poles (Pi

• Four quick disconnect boots with clamps (Picture 5)

• One roll of black vinyl electrical tape (Picture 11)

• Your tape measure

Note: The steel reinforcing rings on the first two pole sections provide extra strength in

potential high stress conditions.

The green fiberglass telescoping poles are all assembled in the same manner and, when

extended, keep the copper -beryllium tape safe from the weather. The copper-beryllium tape

is shipped retracted inside their respective element housing units (EHUs).

Repeat the following procedure for each telescoping pole

elescope a pole to full length by jerking each section out very

T

aggressively with a twisting motion until it is extended as far as

possible. Each segment is tapered and should lock (jam) se-

curely in place when fully extended. It is especially important

on the 40 - 30 driven element that the poles are very firmly telescoped. You don’t want them potentially twisting out of level

in the wind - that would not look good. Each poles length, when

fully extended, must be 17’ 8” +/- 1”

from the butt (large) end of the pole to the tip. (Picture 13)

Caution: Verify the length for each pole before

f a pole comes up a little short try collapsing the pole and start-

I

Picture 5

n length as measured

i

cture 13)

Picture 11

Picture 13

proceeding.

16

ing over, this time aggressively

stead of twisting. The pole cannot be damaged and you may

gain a minimum of 1/2” or more.

jerk” each section out in-

“

17’8” +/- 1”

Page 17

SteppIR Antennas 40m - 30m Dipole Kit

If you have trouble collapsing a pole try carefully striking one end on a piece of wood or

o

ther similar surface placed on the ground. If necessary you can use a hard plastic faced

mallet to drive the sections in.

At the factory when we quality check the poles to verify that they meet minimum

ength we hold the butt (large) end and whip it like we were casting a fishing pole

l

with considerable force. This procedure can produce a significant difference in the

extended length of some poles as a last resort if nothing else works.

DO BE CAREFUL !!!

17

Warning:

Next wrap each joint on the fiberglass poles (Picture 15) with the vinyl electrical tape

(Picture 11). Use approximately: 40 in. On the first (large) joint

31 in. On the second (middle) joint

22 in. On the third (small) joint.

For each joint, stretch the tape tight (up to 50 %) as you wrap it. This should make at least

two passes. This new tape replaces the old electrical tape and silicone tape process we

used before. E

joint.

Exception: On joints with reinforcing rings, the tape must continue further so it extends a

heck all four sections of each pole for packing popcorn or any other

C

foreign object that could interfere with the copper tape movement.

There are NO

reen telescoping poles as there are in a regular pole. This is the correct

g

configuration for the four 40 - 30 poles.

ach joint should have at least the full width of the tape on both sides of the

minimum of one full tape width beyond the metal ring and onto the fiberglass

pole.

foam plugs glued in the small end of these four special dark

Picture 15

Start the tape with one complete wrap of electrical tape around the fiberglass telescoping

pole. The tape should be applied in half-lapped layers with sufficient tension to produce a

uniform wind (for most applications this tension will reduce the tape’s width to approximately 5/8 of its original width). In the beginning wrap the tape up-hill, taping from a

smaller diameter surface to a larger diameter surface then back down smoothing the tape

with your fingers as you go. Apply the tape with no tension on the last full wrap to prevent

flagging. At the end of the run, cut the tape with a knife or scissors and press it down flat.

Then run your hand over the tape again a couple of times to smooth it and firm up the bond-

Page 18

SteppIR Antennas 40m - 30m Dipole Kit

Picture 19

18

Assemble the Sweeps to the Poles:

ocate: 2 Sweep Assemblies (Picture 19)

L

2 3/8 x 28” White Fiberglass Rods

4 #4 x 3/4” Screws w/Nylok nuts

8 #4 x 5/8” Screws w/Nylok nuts

16 #6 x 7/8” Screws w/Nylok nuts

4 Telescoping Fiberglass Poles

1 Small container of silicone grease (Picture 25.5)

Layout two poles (fully extended and taped) parallel about 30” apart. The tip of each pole

will have an “O” ring seal (glued on) and a piece of adhesive non-skid attached to it (Picture

21). Their will also be one extra strip (spare) of non-skid tape in the hardware kit in case a

repair is needed. This material is to provide a very secure grip for the return loop fitting to

grab on to.

Get one of the sweep assemblies, making sure the label [THIS WAY UP] is on top (Picture

19) and the drain holes in the tip of the loop are to the bottom. Insert one of the pole tips into

each of the sweep fittings (Picture 25) making sure that they go in until they bottom out

(approximately 2-3/8”). The non-skid tape should go completely inside the fitting (Picture

27). It may be a good idea to mark the poles so you can see when they are fully seated.

WARNING: Petroleum base lubricants WI

25). We recommend that you apply a thin film of the NON PETROLEUM

ased silicone grease - (provided

b

serted in the fitting.

LL

damage the polycarbonate fittings (P

- Picture 25.5)

to the “O” ring as it is in-

Picture 21

icture

Picture 25

Picture 25.5

inished Assembly

F

Picture 26

Page 19

SteppIR Antennas 40m - 30m Dipole Kit

Caution: Inserting the pole tip into the sweep fitting may be very tight. You may need to

i

nsert a screwdriver into the gap on the edge of the fitting (Picture 25) and pry it

apart enough to push the pole home. Be careful not to damage the “O” ring seal or

the non-skid tape when inserting the poles.

Now insert one of the white fiberglass rods, one end into each fitting (Picture 26 & 29), into

the assembly and line up the holes.

Repeat this procedure for the other side.

19

“O” Ring

Grip Tape

Cut-Away View of Return

acket Fitting

Br

Pole

Picture 27

is a cut-away to show the position of the pole tip and its components

s they fit together inside the sweep fitting.

a

Page 20

SteppIR Antennas 40m - 30m Dipole Kit

20

Now, as seen in P

and tighten to secure the fitting to the green poles. Be sure to place the nut into the side of

the fitting that is molded to capture the nut (Picture 28), Do not tighten yet.

Next insert the #4 screws and Nylok nuts used to properly secure the 3/8” white fiberglass

rod that stiffens the return loop assembly. The center screw is #4 x 3/4 and the other two

screws are #4 x 5/8 (Picture 29). When inserting the middle screw through the fiberglass

rod you may need to screw it in with a screw driver to get it to go through. Again observe

the correct side of the fitting to place the nuts. Now tighten all the screws.

Note: You may need to hold the nut down in the pocket with your finger when you first be-

gin tightening each screw.

When both return loop assemblies are properly mounted to the ends of the fiberglass telescoping poles the two resultant assemblies are ready for final preparation and installation to

the element housing tube and the return bracket tube (Drawing 13).

icture 29, insert the four #6 screws and Nylok nuts in each of the fittings

Picture 28

Picture 29

(4) # 6 Screws

# 4 x 3/4 Screws

This Side Molded

o Hold a Nut

t

# 4 x 5/8 Screws

EHU

Not Used

Drawing 13

EHT

Reinforcing Rings

ERT

Page 21

teppIR Antennas 40m - 30m Dipole Kit

S

21

Attach the 40 - 30 FTPs to the EST & ERT:

T

he butt (large) ends of the green fiberglass telesco

ameter. Some of them may have been sanded, while others were not. The colors at the ends will be either natural, or black. The difference in colors has no affect on performance. Do not be concerned if

they vary slightly in tightness when being installed in the EST’s. This is normal. All poles are tested at

the factory prior to shipping, however in the event that a specific pole just won’t fit sanding it is okay.

The EST’s on the EHU’s have aluminum reinforcing rings (Drawing 13) attached to provide extra

strength in high wind conditions.

Locate the four quick disconnect boots (rubber) and repeat the following procedure for each of the four

fiberglass telescoping poles.

ping poles (FTPs) may vary slightly in outside di-

Picture 35

Picture 31

• Place the narrow end of a rubber boot onto the butt (

assembly and slide them about 6” up each pole (Figure 31).

• Insert the butt ends of each of the two pole assemblies into one side of the EST and the ERT

(Drawing 9).

Caution: It is very important to ensure that the butt (large)

pole firmly bottoms out (is seated) inside the driven element EST.

n the element return tube (ERT) the pole (FTP) may be adjusted in or out a small

O

amount to get the tips of the two poles even (where the sweep is attached - Picture 27),

just make sure the black raised ring on the FTP is covered by the rubber boot.

ush each rubber boot firmly onto its EST until the h

• P

and will clamp down onto the fiberglass telescoping pole (Picture 35). It is imperative that

the stainless steel hose clamp be located so that the clamp on the outside of the rubber boot on

the EHU side of the connection is completely PAST

ures that the hose clamp can grip onto the fiberglass and the ring will prevent the rubber

s

boot from ever coming off.

Note: Before tightening the rubber boots ensure the 40m - 30m driven element loop tip is level by ro-

tating the butts of each EST until the element tip is level.

• Firmly tighten both stainless steel hose clamps, one

test the connection by pulling and twisting it. There should be no slippage at the joints.

Picture 33

large) end of each of the two poles of the first

end of each fiberglass telescoping

ose clamp is past the aluminum ring

the aluminum reinforcing ring. This en-

over the EST and the other over the FTP. Then

Page 22

SteppIR Antennas 40m - 30m Dipole Kit

• F

inally wrap each of the quick disconnect boots (rubber) between the clamps with two

layers of the premium all weather electrical tape the same way as you wrap the joints on

the FTP’s (Picture 15). Remember to stretch the tape tight and smooth it down while

wrapping. This tape will help protect the rubber from UV radiation.

After installing both return loop assemblies and double checking that all connections are

made and fittings are properly tightened the assembly of the 40m - 30m dipole section is

complete.

If this is a retrofit kit

he antenna otherwise return to the main

t

assembly manual.

it is time to mount

Electrical Tape

22

30 in. From center of

riven element to center

d

of return element

Boom / Mast Plate

Mast

Splice

40m - 30m Return

ounting Plate

M

22 in. From center of driven

lement to center of 6m

e

passive element

57in.

Drawing 15

Optional 6m Passive

114 in. Long

Picture 19

Director

D

riven

2 Element Yagi Spacing and Installation Layout

(not to scale)

Page 23

SteppIR Antennas 40m - 30m Dipole Kit

23

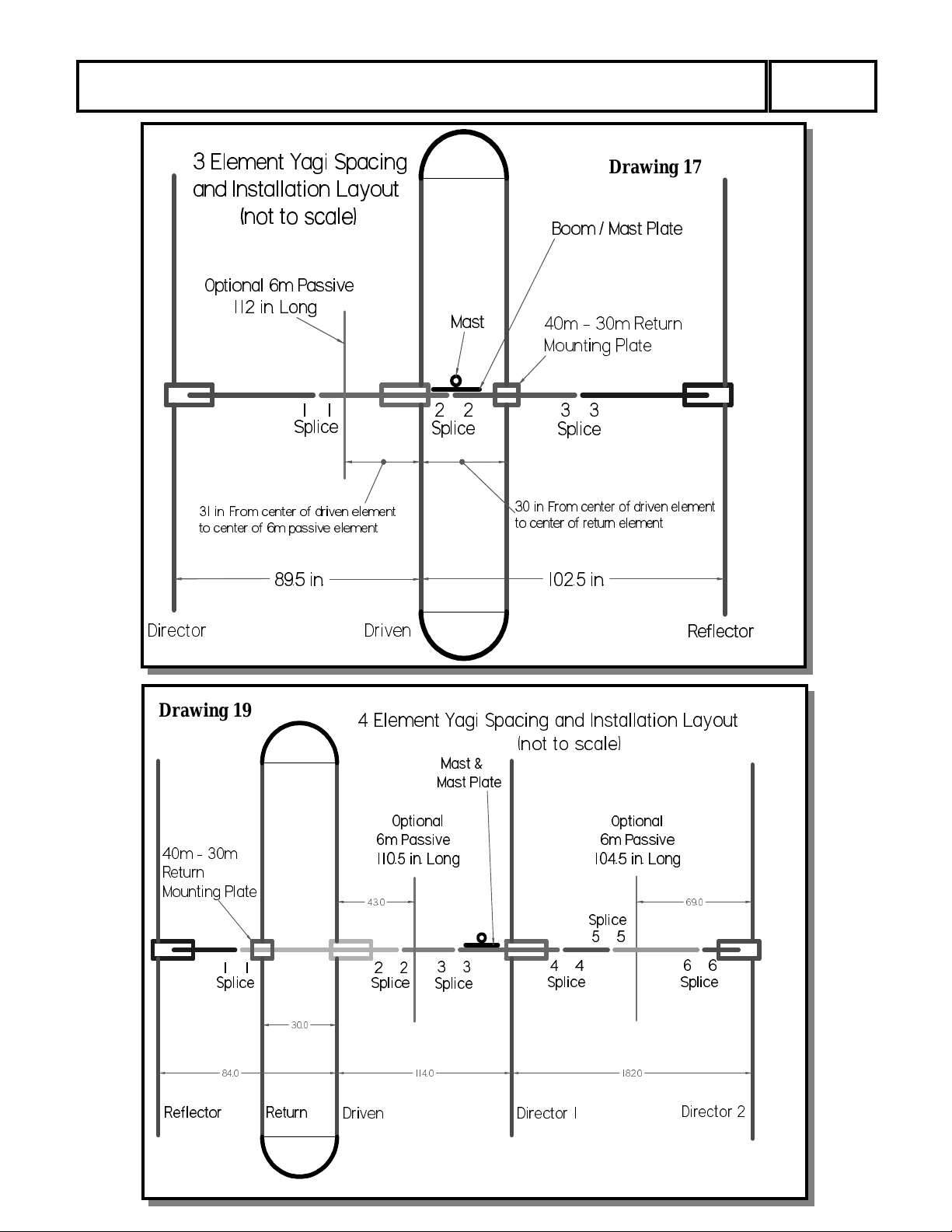

3 Element Yagi Spacing

nd Installation Layout

a

(not to scale)

Optional 6m Passive

112 in. Long

Splice

31 in. From center of driven element

o center of 6m passive element

t

89.5 in. 102.5 in.

Mast

2 2

Splice

Drawing 17

Boom / Mast Plate

40m - 30m Return

ounting Plate

M

31 1

3

Splice

30 in. From center of driven element

o center of return element

t

Director D

Drawing 19

40m - 30m

eturn

R

Mounting Plate

1 1

Splice

84.0 114.0 182.0

30.0

4 Element Yagi Spacing and Installation Layout

riven

(not to scale)

Mast &

Ma

st Plate

Optional

6m Passive

110.5 in. Long

43.0 69.0

4

2 2

Splice

3 3

Splice

4

Splice

Optional

6m Passive

104.5 in. Long

Sp

lice

5

5

Reflector

6 6

Splice

Reflector

Return

Driven

Director 1

Director 2

Page 24

SteppIR Antennas 40m - 30m Dipole Kit

New Antenna Specifications With

24

Specifications

/ 40m - 30m

W

eight

W

Max. Wind

urface Area

S

ind Rating

W

Longest

lement

E

ower Rating

P

T

he 40m - 30m Dipole Installed

→

2 Element Yagi 3 Element Yagi 4 Element Yagi

→

37 lb / 16.8 kg 58 lb / 23.1 kg 108 lb / 49.0 kg

→

6.0 ft2 /

→

100 MPH EIA-

→

39 ft / 11.88 m 39 ft / 11.88 m 39 ft / 11.88 m

→

3000 Watts

Ke

.56m2

222-C

y Down

8.1 ft² / 0.75 m² 11.7 ft² / 1.09 m²

100 MPH EIA-

222-C

3000 Watts

Key Down

100 MPH EIA-

222-C

3000 Watts

Key Down

Boom Length

oom Diameter → 1.75 in

B

Mast Diameter

requency

F

Coverage

Turning Radius

able

C

Requirements

Tuning Rate

→

57 in / 1.44 m 16 ft / 4.87 m 32 ft / 9.75 m

4.5 cm

→

2.0 in / 5.08 cm 2.0 in / 5.08 cm 2.0 in / 5.08 cm

→

40m - 6m

Continuous

18.15 ft / 5.53 m 19.7 ft / 6 m 24.1 ft / 7.35 m

→

→

12 conductor

22

AWG

(shielded)

→

1.33 ft/ sec

1.75 in

4.5 cm

40m - 6m

Continuous

12 conductor

22 AWG

(shielded)

1.33 ft/ sec

2.50 - 1.75 in

6.35 - 4.5 cm

40m - 6m

Continuous

16 conductor

22 AWG

(shielded)

1.33 ft/ sec

Balun Included

40 m/sec

.

→

Yes Yes Yes

40 m/sec

.

40 m/sec

.

Page 25

SteppIR Antennas 40m - 30m Dipole Kit

Appendix A:

25

6 M

eter Passive Installation (3 Element)

e use of the optional 6m passive element on 3 element antennas configured at the end of

Th

2003 and later (Drawings 17) or earlier antennas modified to the new configuration do not

present any problems working with the new 40m - 30m dipole kit.

Antennas configured earlier (Drawings 21) that have not been modified to the new configuration will need to be modified before the new 40m - 30m dipole kit can be installed.

With the early 3 element antennas the direction on 6m was 180 degrees different from the

other bands (what were we thinking? - actually, you get very slightly better gain the other

way, about .2 dB - not worth the confusion).

The six meter aluminum element now mounts between the driven element and the director

(the elements that are approximately 89” apart). The center of the 6m element should be 31”

from the center of the driven element. (Drawings 17)

This change also necessitated adding 2” to each side of the aluminum element, for a total of

112” from tip to tip. The beam still works very well and without the mental gymnastics of

keeping track of your real direction on 6 meters!

The 6m element has enough 3/8 tubing inside to extend it to the new length of 112 inches.

All you will have to do is drill new holes.

The controller is all ready to go with the new firmware. All you need to do is enable the option using the “Options” menu.

This should be all you need to swap the 6m element position to the Normal direction.

3 Element Yagi Spacing

nd Installation Layout

a

(not to scale)

Boom / Mast Plate

Splice

30 in. From center of driven element

o center of return element

t

89.5 in. 102.5 in.

Director

Drawings 21

1

D

riven

Mast

2 2 3 31

Splice

OLD 6 meter

Passive Instalation

late 2003 & earlier

Optional 6m Passive

108

in. Long Must be

modified and relocated

to work with the 40 - 30

dipole loop system.

Splice

40m - 30m Return

ounting Plate

M

Reflector

Page 26

SteppIR Antennas 40m - 30m Dipole Kit

26

Appendix B:

C

ontroller (Upgrade)

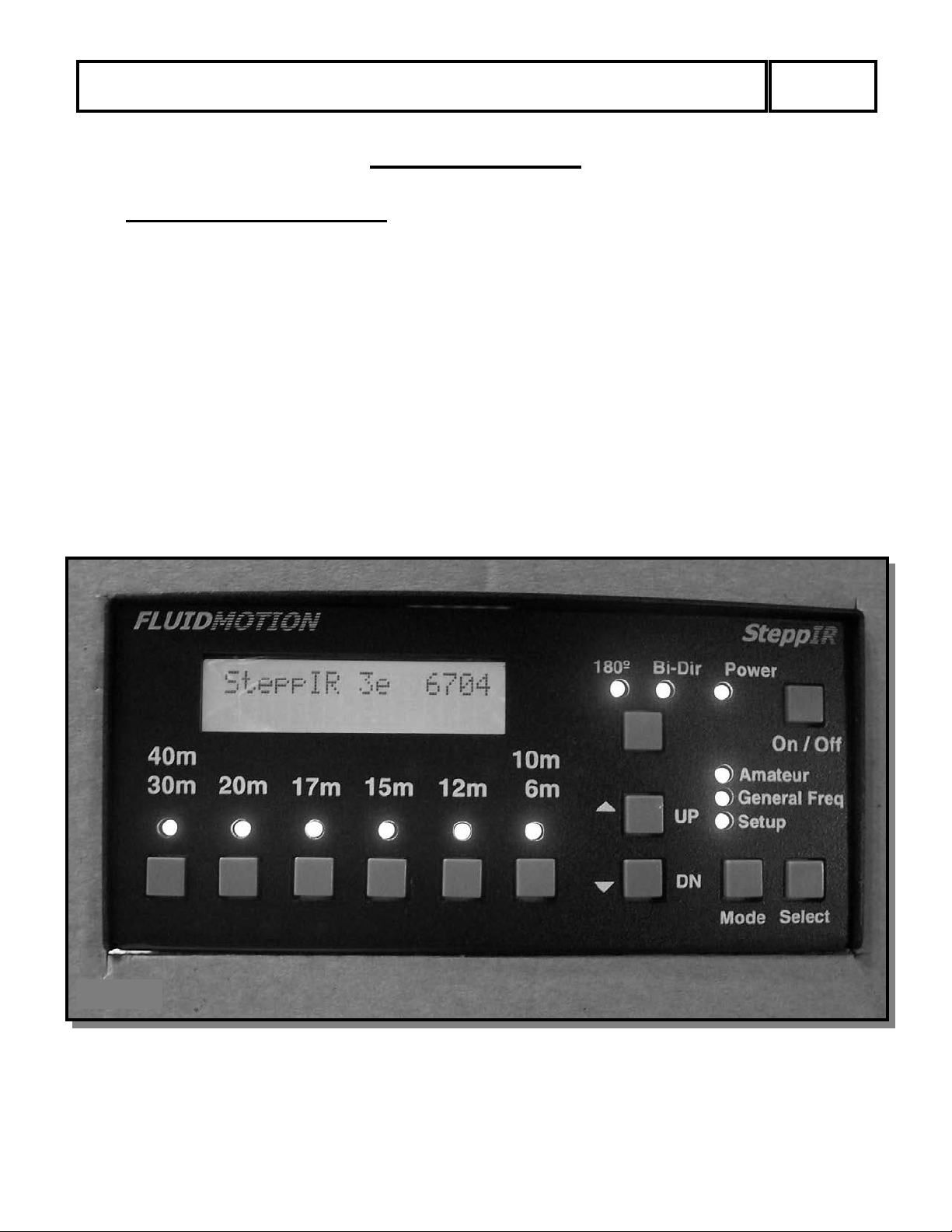

less your firmware is version 6.704 or later you will need to update your controller firm-

Un

ware with the provided chip. If you do not know what version of firmware you have on your

controller the version number will appear in the upper right hand corner of the controller display (Picture A) when you first turn it on. If your controller does not have a 40m band button you will need to install the provided label to properly identify the band buttons for the

new firmware. Look over the software options carefully, the frequency offset will need to be

adjusted in most cases to center your antenna with the new firmware. Remember to enable

the 40/30 option in the menu.

Instructions for controller firmware version 6704 or later will be in with your new chip, in the

back of your antenna manual or both.

Picture A

Page 27

CPU (chip) Replacement Procedures

Appendix C:

●

Retract elements

○

Press 'Mode' button until you see 'Setup Mode' (Setup light will also come on)

○

Press 'Select' button (within 4 seconds)

○

Press 'Up' or 'Dn' button to scroll to 'Retract Elements'

○

Press 'Select' button and 'Home Now ?' will display

○

Press 'Up' or 'Dn' button to select 'Yes' (flashing)

○

Press 'Select' button and the elements will retract (wait until the '*' stops flashing)

●

Power off and unplug the controller

●

Remove the controller top cover (Picture 1)

○

Remove four Phillips head screws (two on each side)

○

Remove the 2 jack screws from the 25 pin D sub connector (and 4 jack screws from

27

the (2) 9 pin D sub connectors if you have the interface option on your controller)

○

Remove the nut and lock washer from the ground stud on the back of the controller

○

Lift the top cover off

Display Board

Driver Board

• Unplug the driver board from the display board (Pi

Picture 1

cture 1)

Page 28

CPU (chip) Replacement Procedures

28

Chip Extractor

Picture 2

●

Use a chip extractor (P

tiny “claws” on the extractor fit at the chip corners, and hook under the chip. Gently

pull the chip upwards, rocking slightly as necessary until it is free.

icture 2 & 3) to carefully pull the chip out of its socket. The

Picture 3

Chip Extractor

Picture 4

Driver Board

Display Board

Firmware chip shown properly aligned but out of its socket

●

Caution: U

●

Align the arrow on the replacement chip to the arrow in the chip socket (P

sing any other tool to remove the chip may damage the pins on the chip

icture 4)

Page 29

C

PU (chip) Replacement Procedures

29

Picture 5

Firmware chip in its socket

●

Center the chip in the socket and press the chip down vertically with your thumb

icture 5). Press evenly until the chip is firmly seated on all sides.

(P

●

Reinstall the driver board to the display board (Picture 1)

●

Reassemble the controller cover

Page 30

New SteppIR Controller Firmware

Appendix D:

30

N

ew SteppIR Controller Firmware

V

ersion 6.7 or later

n a effort to improve the operation of the Steppir antenna and to address the problems that

I

can come up in the myriad of installations we have a new version of firmware for all of our

Yagis.

Feature list:

●

Moved Band defaults to more common frequencies in the

●

Moved the center frequency to better center the best SWR.

●

Cleaned up messages so they are clearer.

●

Frequency is common between Amateur and General Freq Modes.

●

Changed Band segments so there is one segment per band.

●

Applied changes done in Create Modify to entire band.

●

Added New Options menu.

●

Added 6M passive selection.

●

Added Transceiver Frequency tracking Disable Key.

HAM mode.

●

Added Global Frequency Offset adjustment.

●

Added Global SWR correction.

●

Made it possible to program a single button for the H

●

Added 40/30 Dipole selection.

Am

ateur Mode

ome position.

When the controller is in the Amateur Mode the band buttons 20M-6M (1 through 6) are

pre-programmed to get the antenna close to the desired frequency. On the larger bands the

buttons have several presets in the band which the controller will cycle through each time

the band button is pressed. If the the controller is switched between bands using the band

buttons it will return to the last preset frequency the button was at.

The Bandwidth will depend on which model antenna you have but it will be at least 100Khz,

if you want to fine tune the antenna the UP/DN Keys will shift the antenna frequency in

50Khz steps.

The button below the 180 and Bi-dir LEDs cycles the Steppir through the 3 directions. When

both the 180 and Bi-dir LEDs are OUT the antenna is in the Forward or Normal direction.

The transceiver interface does not change the frequency in this Mode.

Page 31

New SteppIR Controller Firmware

General Freq Mode

W

hen the controller is in this mode there are several options:

●

The Transceiver Interface sets the operating frequency.

●

The Options menu is selectable in this mode.

●

The Band buttons are programmable in this Mode.

If the transceiver interface is disabled or disconnected the band buttons can be used as

presets to your favorite frequencies or to Retract (Home) the elements. To save a preset first

use the band buttons and UP/DN keys to select the desired frequency. Next Hold the band

button in until the LED over it starts to blink. Release the button and press it once more

before the LED stops blinking.

In the Case of saving the Home position first use the setup Menu retract elements command.

After the elements are Home Press and hold the Band button as before. When you press it the

second time the Controller will display 0000Mhz.

The transceiver interface will update the frequency if it is enabled with the radio or computer

on overriding the band buttons almost immediately. If using a Band button to home the

antenna turn off the Radio first.

31

Options Menu- This menu is entered by holding the Select Key Down for 3 seconds while

the controller is in the General Freq Mode. Due to limited program space the the only sure

indication this mode is active will be some of the band LEDs lighting (LED 5 will always

light). Also since we have 2 different boxes we will refer to the Band buttons as 1 through 6

with 1 being the 20M or 40/30M button on the far left.

1) Driven Element Offset- Band button #1 works with the #2 band button Ad-

just the Driven element to Correct for feed point interactions. Each time the

#1 button is pressed the driven element is moved .2” longer. The opposite

happens when the #2 button is pressed. The band LED’s for these buttons indicate which way the driver has been adjusted (Both Off indicates the default

position). This adjustment can correct for higher than normal SWRs when

other antennas are interacting and changing the feed point impedance. It will

have little to no effect if the antenna is in the clear.

2) 6M passive selection- Button #3 will toggle between having the 6M passive

installed or not. The band LED will be lit when the passive element is selected. The lengths for the 6M passive element will be active for the Normal

and 180 positions in the frequency range of 50 MHz through 51 MHz. There

will be a small “p” in the same location as the saved segment indicator on the

LCD display when the 6M passive element lengths are being used. The 6M

passive antenna always faces forward even in the 180 mode, Bi-Dir mode will

reduce the front to back but the antenna will still have forward gain. This does

not effect any other band.

Page 32

New SteppIR Controller Firmware

3

) 40/30 Dipole selection- Button #4 toggles between having the 40/30 Dipole

option installed or not. The band LED needs to be lit when the Dipole option

is present to use it. CAUTION do not enable this option if the Dipole is not

installed, it may be possible to damage your driven element if you do.

4) Frequency Tracking disable- Band Button #6 is the Transceiver Interface

Frequency tracking control toggle. When its band LED is lit the antenna will

follow the radio frequency. This only effects frequency tracking, the computer

Port (Data Out) can still send commands to the controller.

5) Frequency Offset ADJ- Using the UP and DN keys the antenna display fre-

quency can be offset from the antenna frequency. There will be a number in

the range of +/- 15 displayed in the upper right of the LCD display indicating

the offset value. This is a global adjustment to all bands and is based on a percent of frequency. The number is for reference only and does not scale directly. When making this adjustment it is possible to move off the best performance point so some experimentation may be necessary to find the best

value.

The changes made in this menu will be saved when the controller power is switched

off or after about 3 minutes.

Some notes about adjusting the antenna:

●

The firmware frequency is set to what we have determined to be proper for each band,

t

he lowest SWR point may still be at a higher frequency.

●

The SWR should be less than 1.5:1 if the antenna is working correctly.

●

If the antenna is working properly the SWR in the Normal Mode (Direction) and the 180

Mode should be very close to being the same. Bi-dir Mode SWR varies a lot, do not expect it to be the same or close to the SWRs in the other modes, as it is difficult to create

this type of antenna.

●

If you are upgrading from older firmware (3x04) you will need to adjust the frequency

o

ffset to get the proper frequency display

32

Page 33

Yagi Troubleshooting Guide

●

Miss

-

wir

e causing the stepper motor on one or more elements to run backwards

Appendix E:

Th

e Most Common Problems

ead this First!

(R

The antenna is out of calibration, perform the calibration as described in the manual.

●

●

The factory defaults have been inadvertently changed, reset factory defaults “all”. There

are two default modes, “all” and “current”. “Current” only resets the band segment you

are currently on.

●

The control cable is miss-wired.

●

Interaction between power lines, other antennas, metal roofs, house wiring, gutters, etc,

and the antenna.

●

The automatic tuner is enabled on your rig, your linear or your external tuner that is in-

line.

●

Your antenna selector is on the wrong antenna, check the coax cable at the shack end with

an ohm meter, it should read very close to a dead short.

)

33

●

Your rig is in the split mode and worse case, to a different band!

●

A low pass filter is in-line and 6 meters has very high SWR.

●

Your in-line linear has a transmit / receive switch some of which may be poorly designed

or faulty. This can make the SWR give incorrect higher readings. Remove as many things

in-line on the coax as possible so you get a more accurate SWR reading.

●

Low cost SWR meters, especially those built into transceivers, can give incorrect readings,

both higher and lower than reality. They also can be drastically affected by the length of

the coax line. Removing a few feet of line can cause drastic differences in the reading

ranging from 10% to as much as 100%! Directional couplers such as the Bird watt meter

or antenna analyzers are much more reliable. Make sure you really have a problem before

you hit the panic button.

●

Blown driver board from shorting any of the wires in the control cable with power plugged

i

nto the controller. Even with the power button pushed “off” the cable is energized.

●

Broken or damaged control cable or connector. See Cable Problems section.

●

Bad coax or coax connector. We have seen bad coax that an analyzer said was good. Sub-

stitution is the sure way.

●

Damaged driver board is pulling power supply voltage down causing the microprocessor

t

o malfunction. Check to see if the green LED is lit on power supply

●

Ground the controller, this prevents crashes of the microprocessor and provides a path

for static discharge.

●

The rubber plugs that were installed in the telescoping poles for shipping and handling

urposes were not removed.

p

●

PL-259 was not tightened with PLIERS

roblem

p

– Do NOT trust your fingers – This is a common

Page 34

Yagi Troubleshooting Guide

34

GENERAL:

B

e aware that just because the controller display say

no guarantee that it is, the motor could be running backwards due to a miss-wire, the element

could have mechanical problems, or a broken wire in the control cable (the motor will run

with only one winding driven in some cases) or a faulty driver board. The controller runs

open loop and has no way of knowing if the element is really moving. The motors in the

elements make three

A ratcheting sound lasting 1 – 2 seconds at the start and finish of the motor running. This

1.

is the rpm ramp-up the stepper motors require and is normal.

2. A smooth whirring sound indicating normal operation.

3.

A loud rattling sound that sounds like gears slipping indicates the stepper is stalling.

This occurs during the middle portion of a “calibrate” with the smooth running sound before and after it and is normal. Any other time (even for brief durations) this noise indicates unwanted stalling of the motor and should be investigated.

Check the resistance with an ohmmeter between the center conductor and ground of the coax

connected to the antenna, it should read zero

distinct noises:

ohms.

s an element is a certain length there is

IGH SWR:

H

Wh

enever the antenna has a problem you will most likely observe higher than expected

SWR. However, this is not always the case, as there are many situations where the SWR

looks good but one element on the antenna may not be working at all. This is what makes it

so difficult to diagnose problems and why we emphasis building and wiring the antenna

carefully.

SWR will not be at the same frequency as the best performance. This is because we have

optimized the antenna for performance first, SWR second.

If the problem is with the driven element the SWR can be very high (over 3:1 and as high as

10:1). If the problem is with a passive element the SWR will not be over about 3:1 no matter

how far off the passive element is.

In our experience an SWR of 1.4:1 or less is normal. In most cases the lowest

INTERACTION PROBLEMS:

The most common reason for higher than expected or shifted SWR is unexpected interactions. Usually only one or two bands are affected but not always and the antenna will probably have reasonable gain and front to back. It is important to take good notes so if you need

to call us we can do a better job of helping you. Record the SWR on each band and each direction mode at least one place in the band, this is a good idea anyway so you can assess the

health of your antenna over time. Rotate the antenna and look for changes in SWR greater

than .2 or so, this indicates interaction if it changes very much. The usual culprits are wire

antennas, other nearby antennas, gutters, power lines, house wiring, metallic guy wires, etc.

If the SWR is not too high you can “tune” it out by using the “Create, Modify” mode to adjust only the driven element

djust the passive elements to improve SWR it will degrade the performance. Adjusting the

a

driven element won’t. Otherwise you will need to change your installation to reduce the interaction to an acceptable level.

for best SWR and save it as described in the manual. Don’t

Page 35

Yagi Troubleshooting Guide

35

CABLE PROBLEMS:

T

he control cable uses 4 wires per motor (one motor in each element housing). Each motor

has two wires for each of its two motor windings. This test assumes the antenna is connected

to one end of the control cable and the measurements are taken at the 25-pin connector that

mates to the controller. You need a ohmmeter capable of measuring 15 – 35 ohms with reasonable resolution or at least one that you can tell the difference between a dead short and 15

ohms. Remove the 25-pin D sub control cable connector from the controller. Hold it so you

are looking at the pins with them pointing at you. Orient the connector so the row with 13

pins is on top, now the upper left-hand pin is pin 1. You should read between about 18 ohms

to 30 ohms depending on cable length between the pins listed below. (100’ is about 23 ohms)

=====================================================

=========================

The Dipole: (has a driven only)

Pin Numbers

Driven 1 – 2 20 ohms (approximately)

3 – 4 20 ohms

===============================================================================

The 2 Element: (has a driven & director)

Pin Numbers

Driven 1 – 2 20 ohms (approximately)

3 – 4 20 ohms

Director 5 – 6 20 ohms

7 – 8 20 ohms

===============================================================================

The 3 Element: (has a driven, director & reflector)

Pin Numbers

Driven 1 – 2 20 ohms (approximately)

3 – 4 20 ohms

Director 5 – 6 20 ohms

7 – 8 20 ohms

Reflector 9 – 10 20 ohms

11 – 12 20 ohms

=====================================================

==========================

Page 36

Yagi Troubleshooting Guide

36

The 4 Element & MonstIR:

tor)

Pin Numbers

Driven 1 – 2 20 ohms (approximately)

3 – 4 20 ohms

Director 1 5 – 6 20 ohms

7 – 8 20 ohms

Reflector 9 – 10 20 ohms

11 – 12 20 ohms

Director 2 14 – 15 20 ohms

16 – 17 20 ohms

=====================================================

Next make sure there is an open

ohms is bad)

K

●

Connector case to

circuit between the following pins. (Any reading less than 100

(each have a driven, director 1, director 2 & reflec-

==========================

any pin

pin 1 to

●

pin 3 to

●

pin 5 to

●

pin 7 to

●

pin 9 to

●

pin 11 to

●

pin 14 to

●

pin 16 to

●

pin 13 is NOT used

●

If your antenna passes this test it does not mean it is wired correctly. You could still have

swapped two elements or even wired the whole thing backwards (started at the wrong end of

the terminal strip) and it will still measure correctly because each connector pair has a motor

winding connected to it but it is the wrong one. This test just takes you to the next step of trying to determine if the antenna is wired correctly and then finally determining if the elements

are physically moving. This is an open loop system and the controller has no way of knowing if

the elements are really moving when commanded to.

any pin except pin 2

any pin except pin 4

any pin except pin 6

any pin except pin 8

any pin except pin 10

any pin except pin 12

any pin except pin 15

any pin except pin 17

MISS-WIRED CABLE:

It can be a difficult to figure out what exactly has

it is likely you have a miss-wire, it is advisable to go up on the tower and check the terminal

wiring. Since there are many combinations of incorrect wiring we will give just a few examples

of common miss-wires and the symptoms they cause.

been miss-wired. Once you have determined

Page 37

Yagi Troubleshooting Guide

●

T

wo or More Elements are Swapped:

37

This is easy to do if you don’t mark the 4 conductor cables before you tape them along the

boom. The SWR will usually be high on every band. Often by changing the controller

frequency, while keeping the transmit frequency fixed, the SWR may go quite low at a

higher or lower controller frequency. In any case of SWR problems don’t be surprised if the

SWR is okay when you switch to the 180 degree mode. If it isn’t good in the forward mode

you have a problem.

●

If you Suspect Elements are Swapped:

Fi

rst try to identify which one is the driven element. You can identify the driven element

easily because it has a much greater effect on SWR than the passives do. The driven element

is also very easy to identify by retracting all of the elements and then use “Create, Modify”

to extend each element individually until signals are heard in the receiver. Obviously you

will only hear signals when the driven element is extended. The best way to determine if the

passives are switched is to point the antenna in the normal mode at a station you know the

location of and then switch the antenna to 180-degree mode, if he gets stronger you probably

have switched the passives. If it seems like they are switched you can use “Create, Modify”

mode to “swap” the elements back by first recording what the controller says each one

should be and then go put the reflector length into the director and vice-versa for the director.

If the antenna now works normally you have swapped the cables of the two passives and will

need to correct the wiring.

●

One or More Elements are not Moving:

If

the driven is not moving you will have very high SWR at all frequencies. However, it may

have stopped at some length and you might have good SWR only at one particular

frequency. Set the controller to 14.200 Mhz and monitor the SWR at that frequency. Next

go into the “Create, Modify ” mode and vary each element length and monitor the SWR

while you do it (100 watts or less is okay) and watch for dramatic changes (.5 SWR change,

minimum). When you adjust the driven element driven you should be able to get an SWR of

5:1 or greater. Always return the element you have just tested to its original length before

testing the next one. The passive elements can only cause an SWR of 3.5:1 maximum no

matter what length you make them. Adjust the passive elements from minimum length to

maximum length and you should see at least a .5 change at some point. When the passive

element is near the length of the driven element interaction is the greatest and you should see

very noticeable change in SWR. You will find that Director 2 (on 4 element models) has

much less of an affect on the SWR because it is so far away from the driven element, but you

should still see at least a .4 change in the SWR reading. A classic symptom of one passive

element not moving is a high SWR in the normal direction and a markedly better SWR in the

180 direction.

If any element does not affect the SWR the cause is one of the following:

●

Bad or intermittent cable, check it again.

●

Damaged driver board in the controller

●

Mechanical problem with the element

aware that lightning or shorting the cable can partially disable a driver chip and it will

Be

still limp along moving the tape but you will see inconsistent SWR when changing from

band to band.

Page 38

Yagi Troubleshooting Guide

Mechanical problems can range from an obstruction in the element, usually in the tip, such as packing

m

aterial or in rare cases fiberglass bumps or imperfections. We check this by running a gauge in the tip

but once in a great while that doesn’t catch it. DO NOT ever tape or block the end of the element tip,

water can collect and freezing can cause a blockage or trap the element. The foam plug must be left

in the tip so wind driven rain and bugs are kept out but the element can breathe.

●

Stepper Motor Running Backwards:

A

simple miss-wire can cause one or more element stepper motors to run backwards. Simply swapping

the Black and Red

ackwards. If both pairs get swapped the motor will run normally.

b

wires or the Green and White in the 4 conductor cable will cause the motor to run

38

Motor Runs:

o-------- Black o-------- Black

o-------- Red o-------- Green

o-------- Green Normal

o-------- White o-------- White

o-------- Red

o-------- Black

o-------- Green Backwards

o-------- White

o-------- White

o-------- Green

o-------- Red Backwards

o-------- Black

M

o

-------- Red Driver Board Damaged

otor Doesn't Runs:

o-------- Red

o-------- Black

o-------- White Normal

o-------- Green

If the driven is wired backwards when you first command the antenna to go to a specific band the driven

tries to go in (retract) and it can't so you hear no signal (unless it is an S9 + ++ signal) and the SWR will

be very

als and band noise. The SWR will probably be terrible but with a little imagination you can see that you

n

might hit some combination where the SWR looks good, so this type of miss-wire can be very confusing.

The driven is the easiest to diagnose in this case. Passives are a little tougher. Run the element you want

to test all the way out then all the way in using the “Create Modify” function and carefully look for a

good SWR. If a director starts working at 4.5” or at very short lengths you can be sure that motor is running backwards

high. If you retract or go to a higher band the driven will start going out and you will hear sig-

Page 39

SteppIR Antennas - 3 Element

39

Appendix F:

R

eplacing the Driven Element Bracket (Original 3 element only)

Fo

r customers who purchased a 3 element antenna before March 2003 your element housing brackets

may have been of a different design (Figure 3-C). If you have the original style element housing bracket

you will need to install a new style element housing bracket on your boom (Figure 3) before you can

mount the new 40m - 30m driven element housing unit.

A 3 element boom layout drawing (Figure 1) is provided to give you the necessary dimensions to install

the new element housing bracket as well as the new element return bracket.

Remove Existing Driven Element & its Bracket:

• Retract all elements:

sing the controller:

• U

• Go to “Setup” mode and press ‘Select’

• Using the ‘UP’ - ‘DN’ buttons find “Retract Elements” and press ‘Select’

• Using the ‘UP’ - ‘DN’ buttons find “Yes” and press ‘S

• Wait for the “ * ” to stop flashing

• The elements are now retracted

• Disconnect the coax and control cable for the driven element

• Loosen the clamps holding the two quick disconnect rubber boots securing the fiberglass tele-

scoping poles

• Remove the two fiberglass telescoping poles (FTPs) from the driven element housing

• Remove the driven element housing unit from its mount

• Remove the driven element housing mounting bracket from the boom

elect’

ing bracket

Install the New Element Mounting Bracket:

• Drilling instructions

easure

• M

• Secure

ake sure to level

• M

evel or actually mounting the element and eyeballing it.

l

• Drill

NOT be using the original holes in the boom.

arning:

W

Keep the drill straight while drilling to produce a clean round hole. It may be helpful to

Make sure that the bracket does not slip or twist while drilling.

drill both holes for one bolt and then install that bolt providing more positive alignment

for the second pair of holes.

• Install the two 5/16” bolts with Nylok nuts & tighten

possible in the holes.

& mark the boom to install the new bracket per F

the return bracket firmly in place with some type of clamp

four 5/16” holes, two in from each side, through the bracket and the boom. You will

igure 1.

the bracket with respect to the other element brackets using either a

. These bolts should fit as snug as

Page 40

2.25

48.00

teppIR Antennas - 3 Element

S

48.00

4.25

48.00

40

48.00

Figure 1

Figure 2

94.0

Make Section with return bracket like this

Make both (2) end sections like this

10-1018-01

1/4-20 x 2-1/4 Bolt

10-1020-01

" splice

8

30.00

25.00

102.5

Make Center section like this

Note: In this drawing you are looking down on the

so that the element housings would be up

boom

A - Return bracket for the 40/30 loop

- Current element housing bracket

B

C - Original element housing bracket

50.25

Figure 3

C

Original Bracket

A

Return Bracket

B

Current Production Bracket

Page 41

teppIR Antennas 40m - 30m Dipole Kit

S

www.steppir.com

41

i m i t e d W a r r a n t y

L

hese products have a limited warranty against manufacturer's

T

defects in materials or construction for two (2) years from date of

sale. Do not modify this product or change physical construction

without the written permission of SteppIR Antennas Inc. This

limited warranty is automatically void if the following occurs:

improper installation, unauthorized modifications, physical abuse or

damage from severe weather, beyond the manufacturer's control.

Manufacturer's responsibility is strictly limited to repair, or

replacement of defective components. The shipping instructions

will be issued to the buyer for defective components, and shipping

charges will be paid for by the buyer to the manufacturer. The

manufacturer assumes no further liability.

Page 42

40m - 30m Dipole Option

Yagi

Dipole

Vertical

www.steppir.com

Loading...

Loading...