GB/US ....LP8 Lifting platform

Vers. 4.00

LP8 Lifting platform

Item no.:

3091xx

1.00 ........Purpose and use ..............................................3

1.01 ........Manufaturer ...................................................3

1.02 ........Purpose and use ...............................................3

1.03 .........Important/warnings .............................................4

1.04 ........Components ..................................................5

2.00 ........Description of functions ........................................6

2.01 ........Control panel ..................................................6

2.02 ........Operating Instructions ...........................................6

2.03 ........Markings and symbols on the product ...............................8

3.00 ........Connections ..................................................9

3.01 ........Electrical connections ...........................................9

4.00 ........Installation of accessories .....................................10

5.00 ........Safety measures .............................................10

6.00 ........Maintenance .................................................12

7.00 ........Troubleshooting ..............................................14

8.00 ........Technical specications .......................................15

9.00 ........EC-declaration of conformity ...................................15

. . . . . . . . . . . . . USA and countries outside the EU ..............................16

A. ...........Users guide ..................................................16

B. ..........WARRANTY ..................................................16

2

© Guldmann GB/US-1412/01/18 • # 30901020

1.00 Purpose and use

1.01 Manufaturer

V. Guldmann A/S

Graham Bells Vej 21-23A

DK-8200 Aarhus N

Denmark

Tel. + 45 8741 3100

Fax + 45 8741 3131

1.02 Purpose and use

Purpose of the manual

The manual describes the standard model with a lifting height from 0-3 metres.

Use

The LP8 is a vertical lifting platform designed for permanent installation indoors

and outdoors. The lifting platform may be used in temperatures from -40° to

+50°C. At temperatures below the freezing point a heating cable cassette

(accessory) is recommended.

The lifting platform is designed to move individuals with limited mobility (e.g.

the walking-impaired, wheelchair users, pram and sack trolley users, etc.)

vertically from one level to another. Entry and exit is at opposite ends of the

lifting platform. The lifting platform is designed and produced in accordance

with current standards for negotiating height differences of up to 3 metres.

Great importance is attached to the design and implementation to achieve

attractive and harmonious installation in different environments, private and

public. Public environments are institutions, public buildings, etc., where the

lifting platform is subject to a certain amount of supervision. In these environments, the lifting platform should be locked, protecting it against unintentional

use or games.

When the lifting platform is in use, it is understood that the user has been

instructed on its use, or that a skilled personnel is present to assist.

Assembly

The lifting platform is delivered ready-assembled from the factory. The

platform must be mounted on a suitable and stable foundation. The lifting

platform must be installed by a qualied technician, in accordance with

Guldmann’s instructions.

The motor housing must be placed in a suitable location to facilitate service

and minimise noise.

© Guldmann GB/US-1412/01/18 • # 30901020

3

Testing and checks

The area around the lifting platform must meet all applicable requirements in

order to eliminate crush hazards.

The lifting platform is supplied fully assembled and factory tested. The platform is tested at 1.1 x nominal capacity, and test loaded at 1.25 x nominal

capacity.

Storing the lifting platform when not in use

• The lifting platform must be stored upright and with the lift basket in the lower

position.

• The lifting platform must be disconnected from the power supply.

• If the lifting platform is dismantled and stored, it is important that the lifting

platform is stable so that it cannot tip over and cause injury or damage its

surroundings.

• The hydraulics system of the lifting platform contains oil that must be collected and disposed of in accordance with applicable regulations. In the event

of an oil leak/spill, an appropriate clean-up must be performed. The lifting

platform contains electronic parts that must also be disposed of in accordance with applicable regulations.

1.03 Important/warnings

• Read the instructions carefully before using the product.

• The LP8 must be assembled by the Guldmann Service Team or by an

engineer approved by Guldmann.

• The accompanying safety bar must be used when the service engineer

moves around beneath the lifting platform.

• The safety gear shall only be released and reset by a competent person.

• The MAX. load of 350 kg must not be exceeded.

• The lifting platform and access ramp must be swept clean of gravel, fallen

leaves, snow etc. before use.

• The lifting platform is to be used to transport people only, and must be used

in accordance with the descriptions of this manual.

• All playing by and with the lifting platform is forbidden.

• The lifting platform must not be used during re.

• A simple and usable “Emergency Procedure” must be described and agreed

between the user and the helper. This must ensure that the user does not

become trapped on the platform in the event of an electrical or a mechanical

failure. In this connection it should also be decided if a two-way voice communication is necessary.

4

© Guldmann GB/US-1412/01/18 • # 30901020

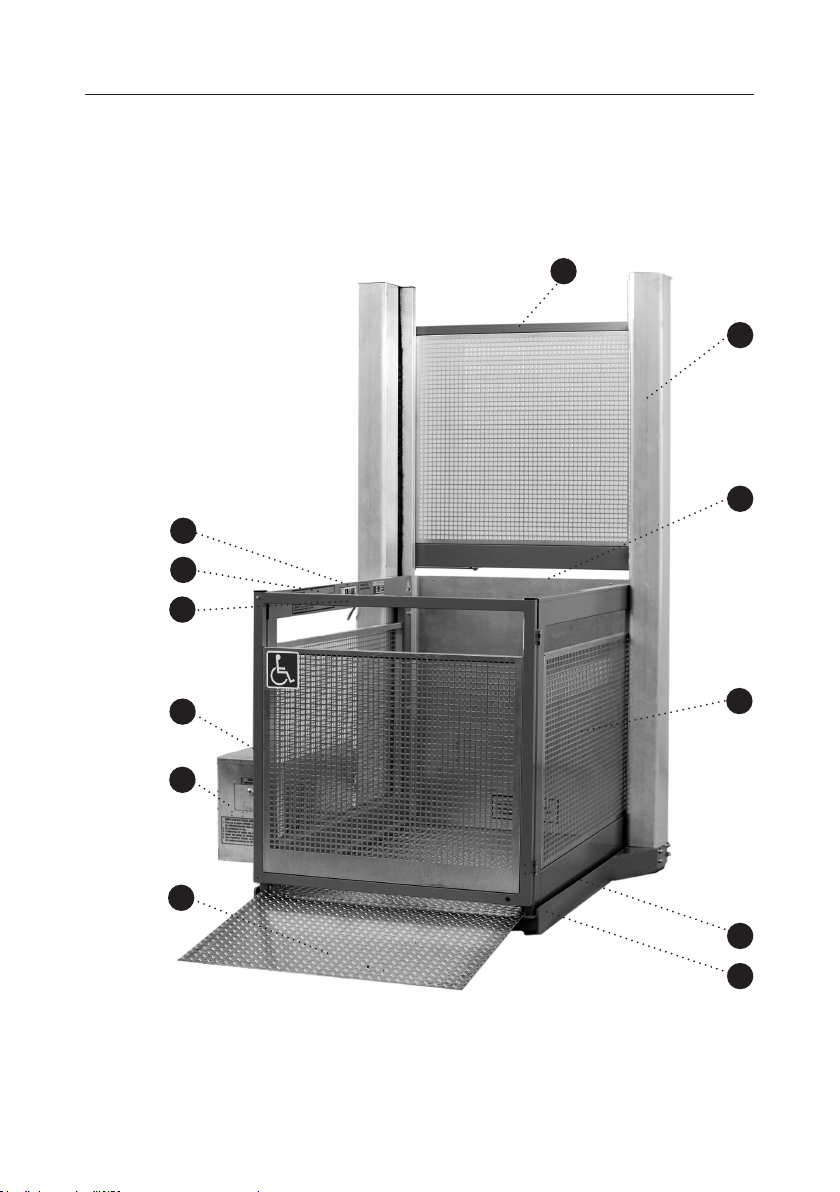

1.04 Components

1 Lower door

2 Upper door

3 Access ramp

4 Control panel

5 Emergency lowering valve behind cover

(adjusting screw for emergency lowering)

6 Production sign

7 Tower

8 Lift basket

9 Base frame

10 Exit ramp

11 Safety cut-out board

12 Motor housing

4

6

1

2

7

10

5

12

3

© Guldmann GB/US-1412/01/18 • # 30901020

8

11

9

5

2.00 Description of functions

2.01 Control panel

The lifting platform is operated by means of a

control panel.

The lifting platform is logical and unproblematic to operate and use, even with

no prior knowledge.

1. Raise

2. Emergency stop

3. Lower

4. Overload signal

2.02 Operating Instructions

Before operating the lifting platform, it must be ensured that no persons or

objects are situated beneath the platform. Always ensure that the platform is

stopped at the lower level after use.

Operating instructions:

1. Ensure that no one is situated at the doors, as the doors open and close

automatically.

2. UP. Press and hold the Up button in until the lifting platform stops and the

door opens.

3. DOWN. Press and hold the Down button in until the lifting platform stops

and the door opens.

4. EMERGENCY STOP BUTTON. In the event of an unexpected situation

arising: Press the emergency stop switch.

5. PARKING. The lift basket must be parked in the lower position after use.

4

3

2

1

If the lifting platform is overloaded, an indicator lamp (4) will turn on and give

a signal - and the platform will not lift or lower. After the overload has been

removed, the platform can operate again.

6

© Guldmann GB/US-1412/01/18 • # 30901020

Emergency lowering device: (It is not possible to activate the emergency

lowering device from the lift basket.)

1. Ensure that no one is situated below the platform, as the safety board

does not work during emergency lowering.

2. Open the motor housing with the key. Open the hatch, and press and hold

the red button until the platform reaches the lower level.

3. The lower door can be opened when the lifting platform is in the lower position.

4. If the emergency lowering device has been used, the cause must be

identied. If necessary, the platform must be inspected by a service technician.

Emergency call: (if installed)

To call for help, push the alarm button; after

10 seconds, the automatic emergency calling

device will dial a pre-set number to summon

assistance.

FÄLTCOM

© Guldmann GB/US-1412/01/18 • # 30901020

7

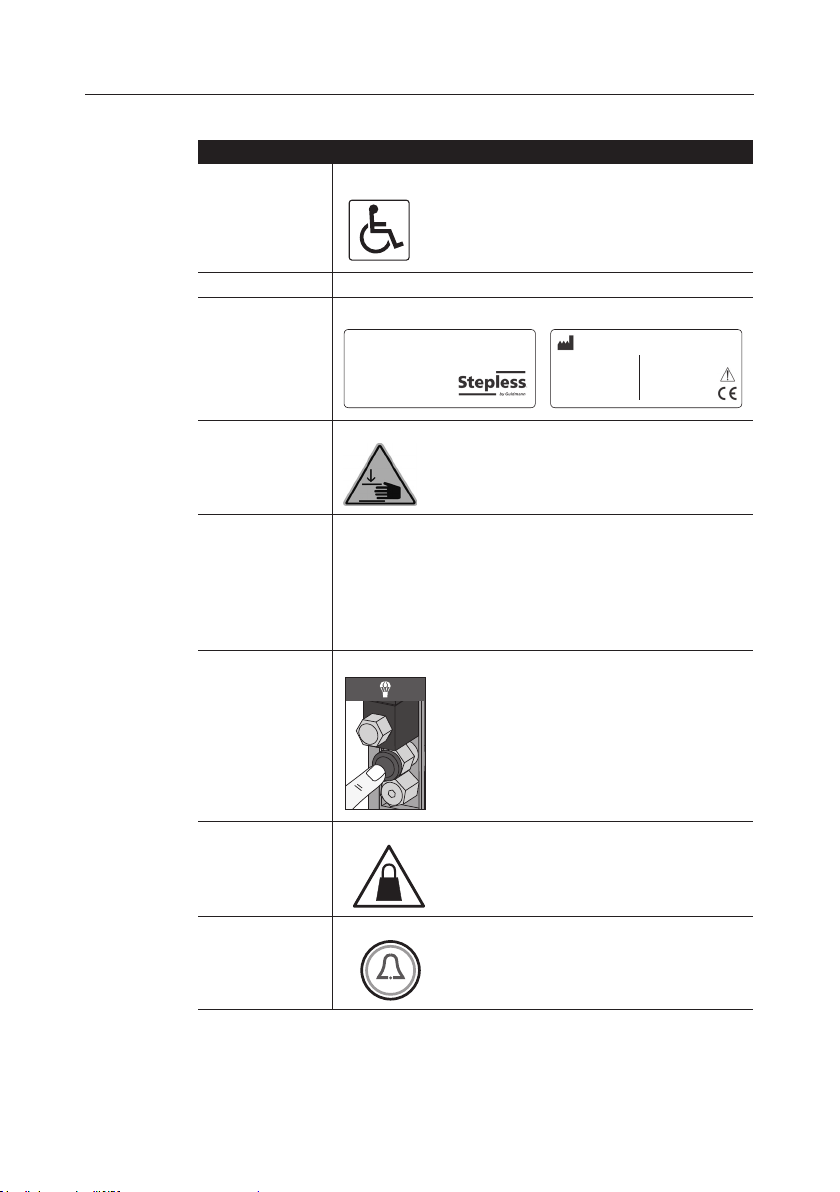

2.03 Markings and symbols on the product

max 350 kg / 770 lbs

Lifting Platform LP8

Type Description

Disabled label Disabled label.

Parking instructions PARKING. The lift basket must be parked in the lower position after use.

Manufacturer’s sign Manufacturer’s sign with CE label

V. Guldmann A/S

Graham Bells Vej 21-23A

DK-8200 Aarhus N

Made in Denmark

yyyy-mm-dd

Crush risk Illustrated label on lift tower and inside the lift basket

Emergency lowering

instructions.

On the motor housing

At the emergency lowering valve on the motor

housing

Overload label Placed in the lift basket by the overload indicator

Emergency call Symbol for emergency call button.

1. The emergency lowering device is available behind the hatch.

2. Ensure that no one is under the platform, as the safety board does not

work during emergency lowering.

3. Open the hatch.

4. Press and hold the red button until the platform reaches the lower level.

5. The lower door can be opened when the lifting platform is in the lower

position.

6. Call a service technician.

DANGER emergency lowering device

MAX

Part no. 3091xx

Serial no. xx xx xxxxx x

230V, 50Hz, 1.1kW

Internally powered

equipment 24V DC

8

© Guldmann GB/US-1412/01/18 • # 30901020

3.00 Connections

3.01 Electrical connections

The lifting platform is delivered with a cable and plug connected to the lifting

platform’s motor housing. This is only a temporary solution in order to be able

to run the lift during assembly, until an authorised electrician connects the lifting platform permanently.

Circuit: The lifting platform has a single-phase motor which uses maximum

7.8A and possibly also a heating cable (accessory) of 220W. The lifting platform

therefore needs as a minimum a 10 A single-phase circuit with fuses (alternatively a 13A circuit). The circuit must have a residual current device in accordance with directives on electrical building installations etc.

The main switch shall always be placed in the vicinity of the lifting platform. The

main switch and the heating cable switch are often placed indoors to avoid unintended interruption of the platform.

Electrical connection of lifting platform: The power supply must be connected to the terminal block located in a switch box in the motor housing. The

heating cable (if mounted) is also connected to the terminal block. The heating

cable can with advantage be equipped with a thermostat, so that it switches on

only when the temperature gets below the freezing point.

The connection diagram is found inside the motor housing.

Lighting: A minimum of 50 lux lighting must be provided for the lifting platform and control panel.

Main power switch: The lifting platform must have a lockable main power

switch that breaks the voltage supply to the lifting platform, normally placed

together with the switch for heating cables indoors. This is to enable the lifting

platform to be without voltage during ser vicing, and when the lifting platform

should not be used. The normal solution is to pull a 4+earth wire cable from

the lift’s socket on the motor housing to the main switch and heating cable

switch which is normally placed indoors.

The main power switch shall be marked with:

THE MAIN POWER SWITCH MUST NOT BE SWITCHED OFF BEFORE

THE LIFTING PLATFORM IS AT THE LOWER LEVEL

© Guldmann GB/US-1412/01/18 • # 30901020

9

4.00 Installation of accessories

Heating cables: The lifting platform is delivered as standard without heating

cables. In the base frame space has been made for a heating cable cassette.

For outdoor assembly, it is recommended that heating cables are always built

into the lifting platform’s base. Alternatively, heating cables can be cast into

a concrete base below the lift plate. The purpose of the cable is to keep the

base free of snow and ice. Assembly must be carried out by the supplier.

Two-way voice communication: It is possible to establish two-way voice

communication. If assistance is needed, press the alarm button and the automatic emergency call will after 10 seconds be transferred to a preset phone

number.

Extension cable set for external motor housing: The motor housing can

as standard be placed 2,5 metres from the left tower. The extension set consists of a hydraulic hose and an electric cable of 3 metres.

Perforated steel: Side plates of lift basket and doors are available in perforated steel instead of glass.

Remote control: As an option the lifting platform can be supplied with infrared remote control.

5.00 Safety measures

Operating switches. The UP or DOWN switches must be held in while the

lifting platform is running.

Emergency stop switches. The lifting platform is equipped with an easyaccess, self-locking emergency stop switch, which is placed between the

operating switches.

Overload signal. The lifting platform has both a visual and acoustic signal

that will be activated when the lifting platform is overloaded.

Main power switch. The lifting platform has a lockable main power switch.

This is placed inside the house in the vicinity of or beside the lifting platform.

The main power switch is used during servicing or to prevent unwanted use.

Automatic doors. In order to be able to operate the lifting platform, both

doors must be in the closed position. The doors are opened and closed automatically, when the operating switch is activated.

10

© Guldmann GB/US-1412/01/18 • # 30901020

Safety cut-out board. A safety cut-out board has been tted under the lift

basket, which means that the lifting platform stops if it comes into contact with

anything. If an object appears below the lift basket and the lifting platform has

stopped, the lifting platform must be taken slightly up in order to remove the

object before the lifting platform can be operated normally again.

When the emergency lowering device is being used, the safety cut-out board

will not work.

Automatic stop. The lifting platform stops automatically at the preset height.

On the upper level an extra safety switch is mounted that stops the platform if

the normal end stop should fail.

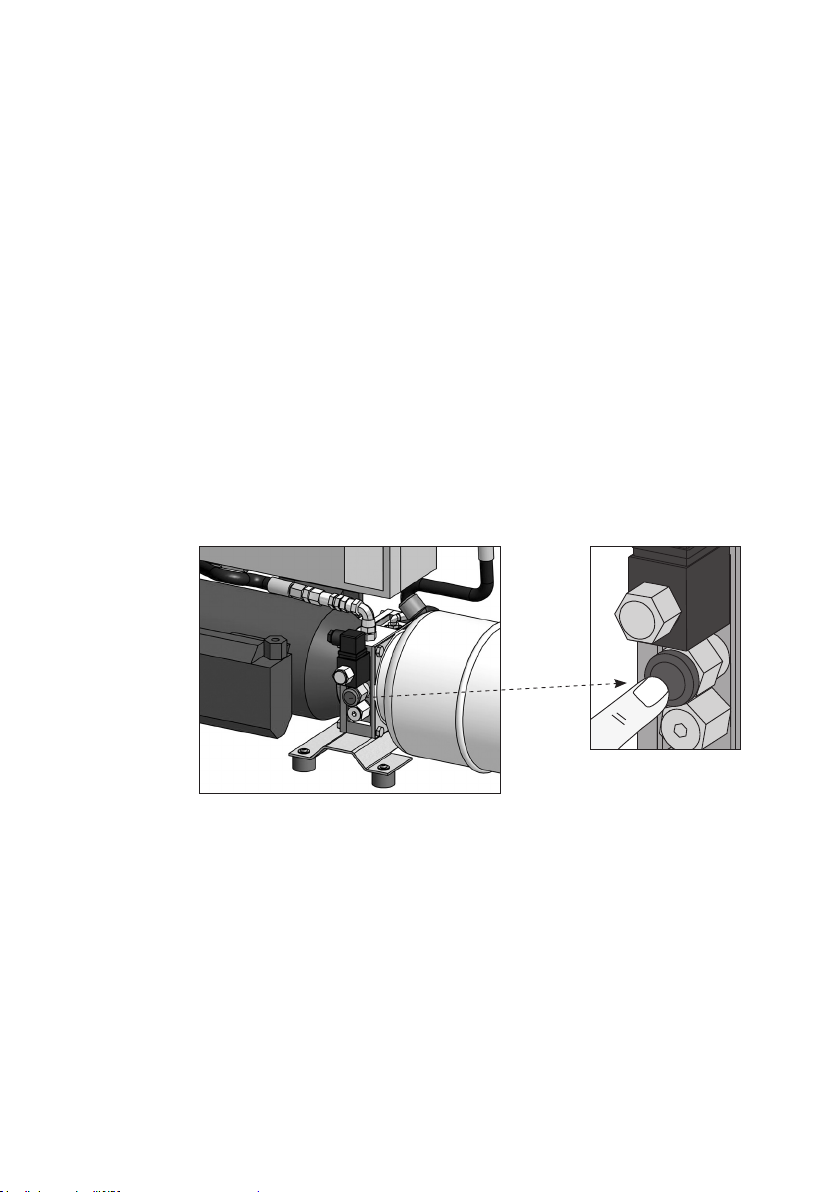

Emergency lowering device. The lifting platform is equipped with an emergency lowering device. In the event of unwanted stops or power failures, the

lifting platform can be lowered by using the emergency lowering device. The

emergency lowering device is locked in and is placed in the motor housing

which is either behind the lifting platform or at the side depending on the customer’s requirements and available space. We therefore recommend that the

user carries a mobile phone or safety alarm when the lifting platform is used

without someone to assist. See also the Operating Instructions.

Great care must be taken when using the emergency lowering device

because the safety cut-out board does not work when this is activated.

Read the instructions on the motor housing carefully before use.

External control panels. The lifting platform is equipped with external control

panels which makes it possible to retrieve the lifting platform at the desired

level.

Parking the lifting platform. The lifting platform must be parked at the lower

level in order to prevent snow, leaves and other foreign objects from getting

below the lifting platform when not in use. This will also ensure that heating

cables keep the safety cut-out board free from ice and snow, and prevent the

drying out of the hydraulic cylinder’s piston rod and stufng boxes.

© Guldmann GB/US-1412/01/18 • # 30901020

11

Heating cable. Lifting platforms installed outdoors are normally tted with a

heating cable of 220 Watt. This should be left on whenever there is a danger

of frost.

The following points must be adhered to:

• There is a risk of getting jammed at the moving parts of the platform, for

instance the automatic doors.

• Fingers must not be placed in the gaps in the lifting platform’s columns/tower

as this can lead to them being crushed.

• Parts and components must not be removed from the lifting platform.

• Contact the supplier in the event of faults or defective components. Use only

original spare parts.

• The control panel must not be covered.

• Signs must not be removed or covered.

• Great care must be taken in the winter because of the risk of slipping on the

lifting platforms oor and access ramp.

• Great care must be taken when using the emergency lowering device.

6.00 Maintenance

Exercise caution while working beneath the platform, as a crush hazard may

arise between the platform’s moving parts.

Important! A blocking beam must always be used while working beneath the

platform.

The following safety advice must be adhered to:

• Run the platform all the way to the upper level.

• Next, disconnect the platform’s power source in

order to prevent the risk of electrical shock and

crushing.

• Insert the blocking beam beneath the platform

beside the left post, as shown in the drawing. It

is now safe to work beneath the platform.

• The lifting platform may NOT be raised/lowered

while work is being performed beneath the

platform. This rule applies even if the blocking

beam or other safety devices are in place.

• Only one person is allowed to work on the lifting platform once it has been

installed, connected and can be raised/lowered.

12

© Guldmann GB/US-1412/01/18 • # 30901020

Maintenance: Ensure that the safety cut-out board under the lifting platform

is always hanging freely and that foreign objects do not get lodged in the

board. The base frame must be kept free of sand, gravel, leaves and other

objects. This is crucial so that the lifting platform can be run all the way down

without the safety cut-out board being pressed up and thereby preventing the

lifting platform from going all the way down.

Cleaning: The lifting platform can be cleaned with soap and water.

NB: High-pressure washers and scourers cannot be used.

Service inspection: The LP8 must be inspected in accordance with the

national law and at least once a year. The platform must be inspected by a

qualied technician or by Guldmann Service Team.

It is the owner’s responsibility to arrange such service inspections.

In the event of faults that can cause dangerous situations, the lifting platform

shall be shut down immediately until the problems are solved.

© Guldmann GB/US-1412/01/18 • # 30901020

13

7.00 Troubleshooting

Fault Possible cause Solution

None of the electrical functions

works.

The lifting platform does not go

all the way down.

The lifting platform drops a few

centimetres when parked in the

upper position.

The lifting platform is sinking. The emergency lowering

The lifting platform shows

overload.

The lifting platform won’t start

after the lower door has been

closed.

The lifting platform does not go

down after the upper door has

been closed.

The emergency stop button

has been pressed.

The main power switch has

been turned off.

The fuse has blown. Change the fuse or reset the

Foreign objects below the lifting platform/lift basket.

Hydraulic leak. Press the UP button and the

device has been used.

Remove some of the load from

the lifting platform.

The lower door does not indicate closed and locked.

The upper door shows no sign

that it has been closed and

locked.

Turn all emergency stop buttons to the right.

Turn the switch on.

residual current device.

The safety cut-out board is

activated. Clear away snow/ice

or other foreign objects.

platform will go to the upper

level. Contact the supplier for

repair of the lifting platform.

Turn the adjusting screw for

emergency lowering to its

original position.

Do not exceed the maximum

load of the platform.

Press the DOWN button until

the door is completely open.

Check that there are no foreign

objects between the door and

the lifting platform. Run the

lifting platform as normal. If the

problem continues, contact the

supplier to adjust the door lock.

Press the UP button until the

door is open. Check that there

are no foreign objects between

the door and the lifting platform. Run the lifting platform

as normal. If the problem continues, contact the supplier to

adjust the door lock.

14

© Guldmann GB/US-1412/01/18 • # 30901020

8.00 Technical specications

Data

The lifting platform’s net weight 650 kg

Highest speed 0.08 m/s

Average lifting speed 0.07 m/s

Lifting height in mm 0–3000

Max. load, one person

incl. wheelchair 350 kg

Materials Aluminium and powder coated / electro-

Noise level 65 dB(A)

Electrical parts

Frequency 50Hz

Phases 1-phase

Circuit 10A fuses

Voltage 230 Volt

Control power 24 Volt

Heating cable 220 Watt

Doors

Door motor 24 Volt DC

Motor unit

AC motor 1.1kW, 230 Volts, 1400 r/min.

Operating pressure max. 86 Bar

Oil volume 0-1.6 m: min. 4.5 litres

2-3 m: min 8 litres

galvanized / hot-galvanized steel

Oil type Shell Tellarctic 32

9.00 EC-declaration of conformity

The product is manufactured in compliance with the Council Directive

2006/42/EC of May 17th 2006 on machinery and amending Directive

95/16/EC.

© Guldmann GB/US-1412/01/18 • # 30901020

15

USA and countries outside the EU

A. Users guide

Before using the product, read the entire operation manual

including warranty.

B. WARRANTY

Guldmann warrants its equipment is free from material defects under normal

use, and will perform substantially in accordance with the specications set

forth in documentation provided with the equipment.

This express warranty shall be in effect for one year from the date of original

purchase and installation (the “Warranty Period”). If a valid claim is made

during the Warranty Period for malfunction or equipment defect, Guldmann will

repair or replace the equipment at no additional cost to you. Guldmann retains

sole discretion as to whether the equipment will be repaired or replaced.

This warranty shall be null and void if the equipment is operated and maintained in any manner inconsistent with its intended use or the instructions

provided with the product. Further, in order for the warranty to remain in effect

for the full Warranty Period, all service to the equipment must be provided

by a Guldmann designated technician. Any parts or components repaired or

replaced by a Guldmann designated technician will be guaranteed for the

remainder of the Warranty Period.

The warranty does not cover any part of the equipment which has been subject to damage or abuse by the user or others. The warranty does not cover

any part of the equipment which has been altered or changed in any way by

the user or others. Guldmann does not warrant that the lifting device functions

will meet your requirements, be uninterrupted or error free.

The warranty set forth is in lieu of all other express and implied warranties,

whether oral, written or implied, and the remedies set forth above are your

sole and exclusive remedies. Only an authorized ofcer of Guldmann may

make modications to this warranty, or additional warranties binding on Guld-

mann. Accordingly, additional statements such as advertising or presentations, whether oral or written, do not constitute warranties by Guldmann.

Service or Repair

Contact Guldmann Repair for an authorization to return any defective item

during the Warranty Period. You will be provided with a return authorization

number and address for returning the item for warranty service or replacement. Do not return items to Guldmann under warranty without receiving a

Return Authorization Number.

If mailing the item, pack it carefully in a sturdy carton to prevent damage. Include

your Return Authorization Number, a brief description of the problem and your

return address and phone number. Guldmann does not assume the risk of loss

or damage while in transit, so it is recommended you insure the package.

16

© Guldmann GB/US-1412/01/18 • # 30901020

© Guldmann GB/US-1412/01/18 • # 30901020

17

18

© Guldmann GB/US-1412/01/18 • # 30901020

© Guldmann GB/US-1412/01/18 • # 30901020

19

V. Guldmann A/S

Tlf. +45 8741 3100

Fax +45 8741 3131

E-mail info@guldmann.com

www.stepless.com

© Guldmann GB/US-1412/01/18 • # 30901020

Loading...

Loading...