Steinsvik AS Rundhaug 25, 5563 Førresfjorden, Norway | +47 52 75 47 00 | post@steinsvik.no | www.steinsvik.no

User manual

Camera System

2

Rev:

Rev. date:

By (initials):

Edits:

A1

10.04.2018

JPH

Created

A2

20.06.2018

IDFR

Added components

A3

04.07.2018

IDFR

Updated

A4

03.09.2018

IDFR

Updated spare parts

A5

23.11.2018

IDFR

Updated with Bracket V-clamp assy chap. 4.6 and 5.2.2

A6

10.12.2018

IDFR

Updated maintenance chapter

A7

21.01.2019

IDFR

Updated information regarding Orbit-310 and maintenance

3

TABLE OF CONTENT

1 Introduction ....................................................................................................................................... 5

1.1 Symbols .................................................................................................................................... 6

2 Disclaimer ......................................................................................................................................... 6

3 Safety ............................................................................................................................................... 7

3.1 Warranty limitations ................................................................................................................... 7

3.2 Waste information ..................................................................................................................... 7

3.3 Assessment of escape risk ....................................................................................................... 8

4 Technical description ........................................................................................................................ 9

4.1 Underwater camera ................................................................................................................. 10

4.2 Surface camera ....................................................................................................................... 11

4.3 PSU ......................................................................................................................................... 12

4.4 Multiwinch ............................................................................................................................... 13

4.5 Orbit-bracket for ring ............................................................................................................... 14

4.6 Orbit-bracket for ring with clamp ............................................................................................. 14

4.7 Antenna and mast ................................................................................................................... 15

4.8 Strain relief .............................................................................................................................. 16

4.9 Pulley for camera rope ............................................................................................................ 16

4.10 Pulleyblock 18 mm .............................................................................................................. 17

4.11 Camera cable ...................................................................................................................... 17

4.12 Rope Orbit XXXM ................................................................................................................ 17

4.13 Surveillance camera ............................................................................................................ 18

4.14 Fibre receiver cabinet .......................................................................................................... 20

4.15 Orbit-51X8 for wireless facilities .......................................................................................... 20

4.16 Protection cabinet for PSU .................................................................................................. 21

5 Preparation and installation ............................................................................................................ 22

5.1 Antenna ................................................................................................................................... 22

5.2 Orbit Bracket for ring ............................................................................................................... 22

5.3 Mast/Alu pipe .......................................................................................................................... 26

5.4 PSU/Protection cabinet ........................................................................................................... 27

5.5 Winch and winch rope ............................................................................................................. 28

5.6 Rope and strain relief .............................................................................................................. 29

5.7 Underwater camera ................................................................................................................. 30

5.8 Surface camera ....................................................................................................................... 32

5.9 Surveillance camera ................................................................................................................ 32

6 Operating instructions .................................................................................................................... 33

6.1 Multiwinch/underwater camera ............................................................................................... 33

6.2 Surveillance camera ................................................................................................................ 33

4

7 Maintenance ................................................................................................................................... 35

7.1 Routine inspection and periodic maintenance ........................................................................ 35

7.2 Larger reparations and modifications ...................................................................................... 36

7.3 Troubleshooting and correction of errors ................................................................................ 36

7.4 Link to troubleshooting for camera system ............................................................................. 37

7.5 Storing, preservation and maintenance .................................................................................. 37

8 Spare parts ..................................................................................................................................... 38

8.1 Underwater camera ................................................................................................................. 38

8.2 Obrit-200 (411340) and Orbit-210 (430755) ........................................................................... 38

8.3 Multiwinch (100069) ................................................................................................................ 39

8.4 Orbit-Bracket for ring (405461) ............................................................................................... 40

8.5 Orbit-bracket for ring with clamp (V-Clamp) (442778) ............................................................ 41

8.6 Antenna (411859) ................................................................................................................... 42

8.7 Strain Relief (420438) ............................................................................................................. 42

8.8 Orbit-310 (410478) .................................................................................................................. 43

9 Orbit-PSU Stainless Steel .............................................................................................................. 44

5

1 INTRODUCTION

This manual presents the installation, use and maintenance of the complete Steinsvik AS camera

system with associated components.

Consult the NeoVision or Vision user manual for the complete description of navigation and

configurations.

6

1.1 Symbols

The symbols used in this user manual, and their respective meaning, are explained below.

Information

Go to page/chapter or appendices for more information

Show caution – risk of damage to equipment and mild personal injury

Warning – may lead to personal injury

2 DISCLAIMER

Every care has been taken by the staff of Steinsvik AS in compilation of the data contained herein and

in verification of its accuracy when published, however the content of this training manual is subject to

change without notice due to factors outside the control of Steinsvik AS and this manual should therefore

be used as a guide only. For example, the products referred to in this publication are improved

continually through further research and development and this may lead to information contained in this

manual being altered without notice.

This training manual is published and distributed on the basis that the publisher is not responsible for

the results of any actions taken by users of information contained in this training manual based on the

information contained in this manual nor for any error in or omission from this manual. Steinsvik AS

does not accept any responsibility whatsoever for misrepresentation by any person whatsoever of the

information contained in this training manual and expressly disclaims all and any liability and

responsibility to any person, whether a reader of this training manual or not, in respect of claims, losses

or damage or any other matter, either direct or consequential arising out of or in relation to the use and

reliance, whether wholly or partially, upon any information contained or products referred to in this

manual.

7

3 SAFETY

3.1 Warranty limitations

Warranty according to quote.

3.2 Waste information

PSU, winch and camera house are classified as E-waste

Camera house consist mainly of POM, with small amounts of stainless steel.

Orbit-bracket for ring, mast and winch bracket

Bolts, nuts, screws and washers.

The underwater camera with depth sensor contains a small amount of glycol.

When the camera system is in storage and not in use, it will not pose any threat

with regards to pollution. All parts can be recycled.

8

3.3 Assessment of escape risk

A Steinsvik AS camera system will, under normal working conditions, not pose a risk of escape when it

is being used in a cage at a fish farm. The camera system does not consist of any parts that may, under

normal conditions, cause damage to the net, ropes or any other parts of the plastic or steel cage

construction.

Factors

1. The camera’s suspension rope breaks: The camera is designed with no sharp edges, so it poses

no risk for holes or wear on the net/cage, even if it sinks to the bottom of the cage. However, if

the camera is not retrieved after a while, or if it under pressure from the lift-up or other

equipment, this can cause wear and tear on the net.

2. Suspension on the cage edge: The Orbit bracket for ring placed on the cage edge is made out

of strong aluminium and secured with stainless steel bolts and screws. These do not normally

come in contact with the net, but if they are not fastened properly or if they come lose, they may

pose a risk of wear and tear on the net (50-80 cm above water surface)

3. Winch strength: The winch has a built-in load protection and is set to lift 10 kg at sea. Any load

above this will deactivate the engine to avoid the rope/cable/winch controlled by the winch,

getting caught and wear a hole in the net when manoeuvring the winch.

9

Antenna for wireless

connection

4 TECHNICAL DESCRIPTION

Steinsvik AS camera system is an advanced surveillance system to control the feeding of fish in

aquaculture and for general inspection of fish in cages.

The camera system consists of:

- Underwater camera

- Surface camera

- PSU

- Multiwinch

- Bracket for ring

- Antenna

- Aluminium pipe (mast)

- Strain relief (fibre installation only)

- Surveillance camera

- Camera cable

- Pulley for camera rope

- Pulleyblock 18 mm

- Counterweight

- Rope

Camera installation

Surface camera

Protection box PSU

Strain relief (only for

fiber installation)

PSU

Bracket for

ring

Multiwinch

Pulleyblock for camera rope

Rope

Underwater camera

Counterweight

Pulleyblock 18mm

Mast

Camera cable

10

4.1 Underwater camera

Steinsvik AS has five different types of underwater cameras (the Orbit-3000 series) with pan and tilt

function, both with and without active sensors. Figure 1 shows the different models and what sensors

they are equipped with.

The Orbit-3100 is eqipped with both a temperature and depth sensor, however these sensors will only

be available through a software update. This way you do not have to send the camera to service to

receive this update.

Table 1 Specifications Orbit-3000 series

Specifications

Orbit-3100

Orbit-3300

Orbit-3500

Orbit-3400

Orbit-3600

Video signal

PAL

Digital

Resolution

P50, 752x582

HD 1200p

Light sensitivity

0,003 lux

0,0003 lux

Weight

6,5 kg

6,7 kg

IP degree

IP69, down to 100 m

Temperature range

-20°C - +60°C

Effect

24 VDC

Material

POM, stainless steel and PEEK

Optic angle

77° in water

80° in water

Figure 1 Orbit-3000 series

11

4.2 Surface camera

Orbit-200B and Orbit-210 surface camera is mounted on the same aluminium pipe as the PSU on the

cage. The camera is designed as an underwater camera and is therefore waterproof and made from

corrosion resistant material. The camera is intended for permanent installation.

Table 2 Specifications Orbit-200B and Orbit-210

Specifications

Orbit-200

Orbit-210

Video signal

PAL

Digital

Resolution

768x576

1080p (Full HD)

Sensor type

Colour CCD

Colour

Zoom

36 x optic zoom

30 x optic zoom

12 x digital zoom

Lens opening

F 1.4

F1.6

Light sensitivity

0,01 lux – 50IRE

0.01 lux (using IR)

Vertical rotation

120°

120°

Horizontal rotation

360°

360°

Weight

2,5 kg

2,5 kg

IP degree

IP68

IP68

Temperature range

-20°C - +60°C

-20°C - +50°C (approved for

Nordic climate only)

Effect

11-13 VDC, 3,9 W

11-13 V (DC), 3.9 W

Material

POM

Aluminium and POM

Picture angle

60,2°

63.7°

Focus

Auto

Auto

Cable length

2 m0F1

2 m

1

Standard length. Can also be delivered with 10 m and 20 m cable

Figure 2 Orbit-200

12

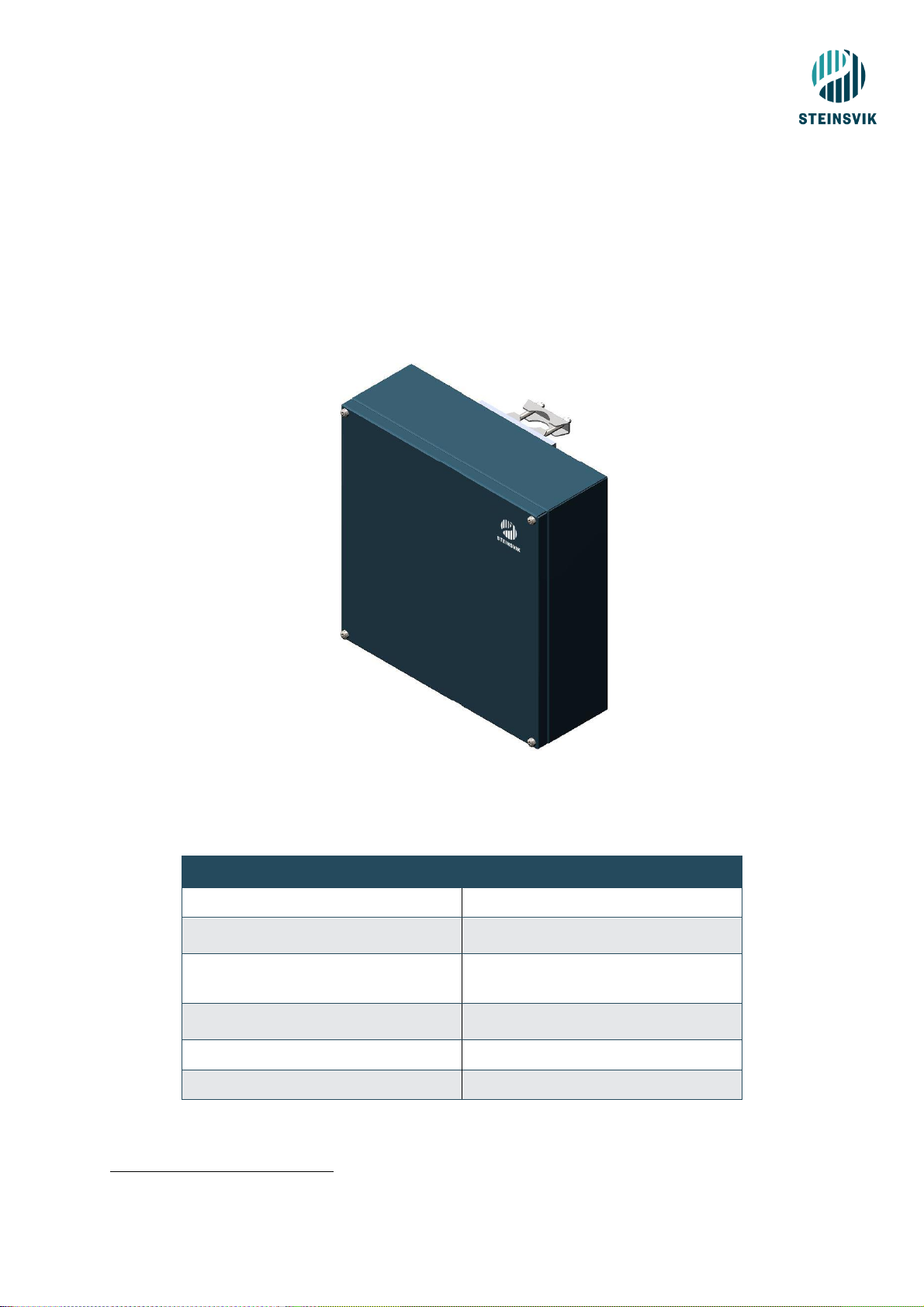

4.3 PSU

The cameras are primarily powered and controlled by the PSU at the cage. In addition, the Orbit-3100,

Orbit-3300 and the Orbit-3500 can be controlled from the control system KB-6000, which is connected

to 230 VAC and conveys low current and control signals to the connected units. The same cameras can

also be connected to the MB-3000 portable control unit which have a built-in screen, joystick and 12 V

power to the camera. See chapter 9 for more specifications.

The PSU2 also provide power to the Multiwinch.

Table 3 Specifications PSU

Specifications

Material

Stainless/aluminium/fibre glass

Possible camera connections

1, 2 or 4 – depending on which PSU

type

Nominal effect

60 W per camera

300 W when running the winch

Contacts

2 x multi contacts for sensors, surface

camera and antennas

IP degree stainless cabinets

IP67

IP degree fibre glass cabinets

IP66

2

Orbit-510/511, Orbit-515/516, Orbit-518/519, Orbit-578/579 and Orbit-520/521

Figure 3 PSU

13

4.4 Multiwinch

The Multiwinch is mounted on the cage with the Orbit – Bracket for ring and is controlled by the PSU via

a control desk or a computer with the camera software installed. The winch is connected to the PSU

with its own cable.

The winch controls the camera vertically and horizontally in the cage and has a built-in function which

prevents the rope from being driven without stretch.

Table 4 Specifications Multiwinch

Specifications

Material

Stainless steel, POM and

aluminium

Weight

11 kg

Operating voltage

50 VDC nominal

Voltage tolerance

-25% / +50% (37,5 VDC / 75 VDC)

Temperature range

-20°C - +50°C

IP degree

IP67

Fixed cable

5 m

Figure 4 Multiwinch

14

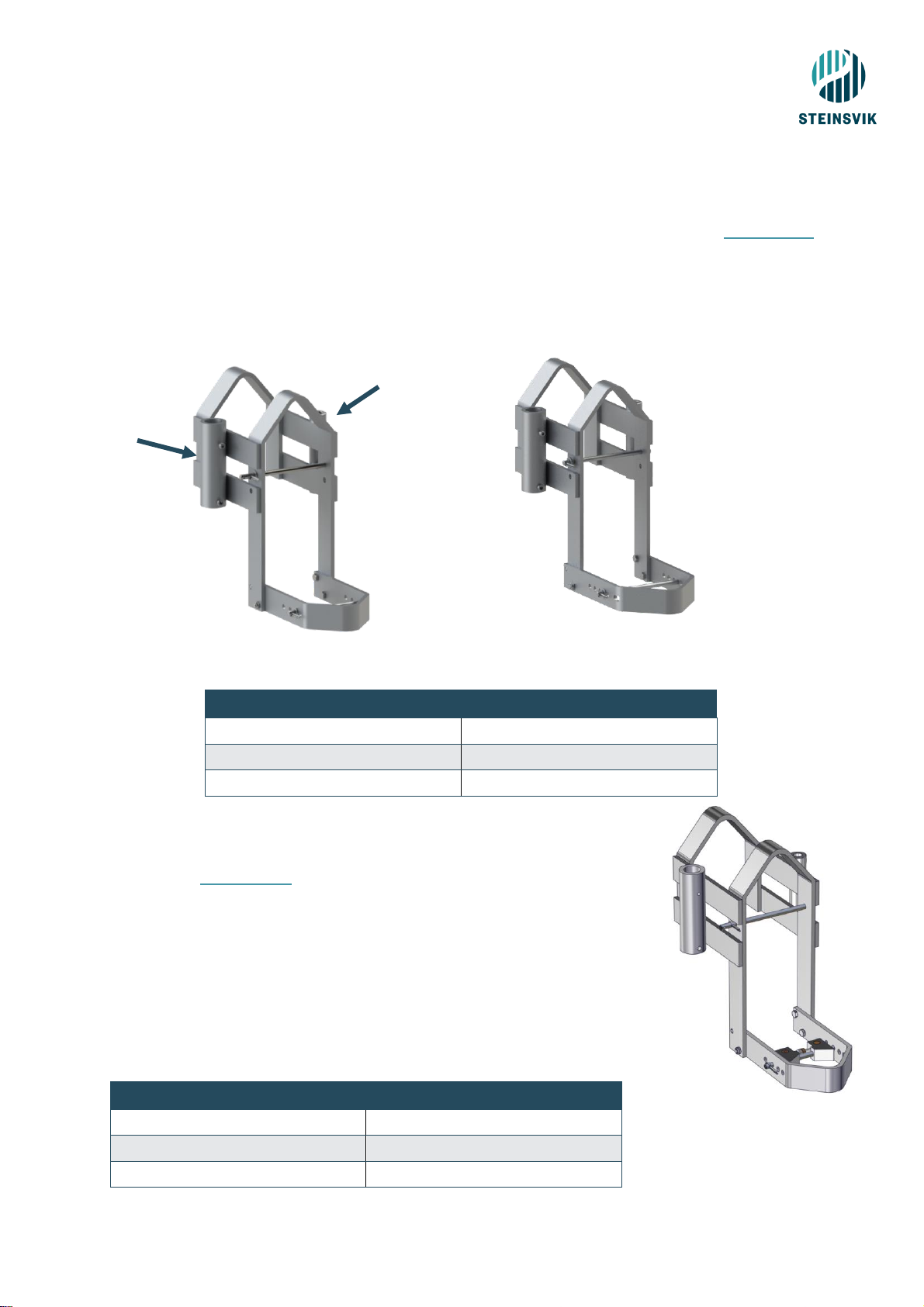

4.5 Orbit-bracket for ring

It is possible to connect the PSU, antenna and Multiwinch to the Orbit-bracket for ring. See chapter 5.2.1

for a description on how to install the bracket for ring.

Orbit-bracket for ring is delivered with a large and a small bottom mounting bracket to accommodate

most of the cages in today’s market.

Figure 5 Bracket with small clamp

Table 5 Specifications Bracket for ring

4.6 Orbit-bracket for ring with clamp

It is possible to connect the PSU, antenna and Multiwinch to the Orbit-bracket

for ring. See chapter 5.2.2 for a description on how to do install the bracket

for ring with clamp.

This version of the Orbit-bracket is delivered with a clamp mounted on the

bottom mounting bracket. This clamp makes it easy to adapt the Orbitbracket to all types/sizes of cages available in today’s market.

This bracket can also be delivered with two different sizes of the bottom

mounting bracket. Figure 7 illustrates the Orbit-bracket w/clamp and small

mounting bracket.

Table 6 Bracket for ring with clamp

Specifications

Material

Aluminium and stainless steel

Weight

7,82 kg

Dimensions (WxHxD)

315 x 502 x 553 mm

Specifications

Material

Aluminium and stainless steel

Weight

7,74 kg

Dimensions (WxHxD)

315 x 502 x 553 mm

Attachment

for mast/PSU

Attachment

for Multiwinch

Figure 6 Bracket with large clamp

Figure 7 Bracket with clamp

15

4.7 Antenna and mast

The antenna sends data from the PSU to the barge. The sticker on the antenna must face the receiving

antenna placed on the barge. For more information regarding mounting and installation, see next

chapter.

For wireless facilities, the antenna is attached to the aluminium pipe on arrival. For fibre facilities the

same aluminium pipe is used for mast to attach the fibre equipment.

Table 7 Specifications Antenna and Mast

Specifications

Antenna

Mast

Material

POM-C (white)

Aluminium

Dimensions (WxHxD)

98 x 325 x 98 mm

1500 x 40 mm

Temperature range

-20°C - +70°C

N/A

Power supply

24 V, 0,5 A (12 W),

max 5,5 W

N/A

Humidity during

operation

5-95%

condensation

N/A

Maximum power

consumption

5 W

N/A

Weight (kg)

1,63

Figure 8 Antenna and mast

16

4.8 Strain relief

The strain relief is delivered with all PSU’s and is used with the fibre cables. It is normally padded before

use.

Table 8 Specifications strain relief

Specifications

Material

Aluminium and stainless steel

Weight

1,5 kg

4.9 Pulley for camera rope3

Table 9 Specifications – Pulley for camera rope

Specifications

Material

Nylon and stainless steel

3

Strips are only for easier transportation – not used in the cage.

Figure 9 Strain relief

Figure 10 Padded strain relief

Figure 11 Pulley for camera rope

17

4.10 Pulleyblock 18 mm

Table 10 Specifications - Pulleyblock

4.11 Camera cable

Steinsvik’s camera cable transfer all signals from the PSU to the camera. The cable can be delivered in

many different lengths, depending on what is required at the locations. It is delivered either as a blue

cable or a black cable where the black cable is enhanced with Kevlar on the outside, while the blue is

not enclosed in Kevlar.

To ensure the best possible utilisation of the system, the recommended length of the cable is diagonally

from the winch to the bottom of the cage on the opposite side.

4.12 Rope Orbit XXXM

Rope Orbit-XXXM can be delivered in many different lengths, all adjusted to the cage in which it is to be

used at. The rope is held tight by the counterweight located outside of the cage, on the oposite end of

where the winch is placed. The counterweight adjust the winchrope according to the movement of the

cage.

Standard lengths for cages are:

- 120M cage: 80M

- 160M cage: 100M

- 200M cage: 120M

When using steel cages, the standard delivery is the size of the cage x2 (ie. 24; cage = 50M rope).

The importance of correct installation is due to the winch experience. The user will have a very slow

experience trying to control the winch if the rope have not been installed correctly. The rope is to be

winded out so that all white and blue lines of the rope are parralell. This might take some time to do

properly, but it is worth spending some time on it in order to save much time at a later stage.

More details about mounting is explained in chapter 5.6.

Specifications

Material

Nylon and stainless steel

Figure 12 Pulleyblock

18

4.13 Surveillance camera

Steinsvik also supplies several surveillance cameras meant for surveillance at the barge. The Orbit-351

and the Orbit-310 are reliable cameras that provides good visibility on the facility and specific parts of

the facility.

4.13.1 Orbit-310

With careful installation of the Orbit-310, you will gain maximum advantage of the camera. The camera

can easily be controlled with a gamepad and has an excellent zoom. In addition to manual control, the

camera can be pre-set to fixed positions via the software. The software allows for control of the camera

with only a keystroke where you can position the camera from the spreader in the outer most edge of

the cage, to the distribution valve at the barge. The Orbit-310 must only be installed at the barge – for

cage installation use Orbit-200/210.

Table 11 Specifications Orbit-310

Specifications

Video signal

Video over IP

Resolution

Full HD 1080p

Sensor type

Colour BSI CMOS

Zoom

30 x optic, 12 x digital

Lens opening

F 1.6

Light sensitivity

0,0015 lux – 50 IRE

Weight

10,5 kg (incl. cable)

IP degree

IP67

Temperature range

-10°C - +50°C

Effect

11-13 VDC, 24 VAC or PoE +30W

Material

Aluminium, PC and POM

Range of motion

360° (horizontal), 90° (vertical)

Focus

Auto

Cable length

30 M

Pan/tilt

Manual and Auto

Figure 13 Orbit-310

19

4.13.2 Orbit-351

The Orbit-351 Stationary Camera is a great tool to help maintain the safety of the crew in areas with

less activity, while at the same time having full monitoring of the spaces on the barge you may want.

This camera can also be used for monitoring the amount of feed in the silo. It is easy to install and

integrate in the software.

Table 12 Specifications - Orbit-351

Specifications

Video signal

Video over IP

Resolution

Full HD 1080p

Sensor type

Colour CMOS

Zoom

3x manual optic

Lens opening

F 1.4

Light sensitivity

0,03 lux – 50IRE

Weight

2 kg

IP degree

IP68

Temperature range

-20°C - +50°C

Effect

12VDC, PoE

Material

Aluminium, PC and POM

Picture angle

113° (horizontal)

Focus

Manual

Pan/tilt

Manual

Figure 14 Orbit-351

20

4.14 Fibre receiver cabinet

The Orbit-502 IP Receiver cabinet is the receiving cabinet for fibre installations on the barge. The cabinet

receive and transmit the signals given from the gamepad to the camera. It can be connected to dome

cameras and has the possibility of connecting to sensors. The sensors are not included in the standard

delivery and must be ordered separately.

Table 13 Specifications Fibre receiver cabinet

Specifications

Material

Aluminium and stainless

steel

Weight

10,10 kg

Dimensions (WxHxD)

500 x 550 x 221 mm

Connections

1 x 230 V power inn

3 x multi connector

1 x 100 Mbit/s Ethernet

2 x 100 Mbit/s Ethernet

2 x Hybrid fibre contact

4.15 Orbit-51X8 for wireless facilities

The Orbit-51X8 is the heart of wireless facilities. It receives and transmit all signals in a digital wireless

facility. The Orbit-51X8 has the possibility of connecting to dome cameras and it is possible to upgrade

the cabinet to accommodate sensor connections as well.

Table 14 Specifications Orbit-51X8

Specifications

Material

Aluminium and stainless steel

Weight

10,90 kg

Dimensions

(WxHxD)

555 x 351,3 x 408 mm

Connections

1 x 230 V power inn

2 x multi connector

7 x PoE 100 Mbit/s Ethernet

7 x 100 Mbit/s Ethernet

Figure 15 Fibre Receiver Cabinet

Figure 16 Orbit-51X8

21

4.16 Protection cabinet for PSU

Table 15 Specifications Protection cabinet

Specifications

Material

Stainless steel4

Weight

18,42 kg

Dimensions (WxHxD)

466,20 x 649 x 273 mm

4

Steinsvik AS also delivers protection cabinets for plastic PSU’s.

Figure 17 Protection cabinet for SS PSU

22

5 PREPARATION AND INSTALLATION

Perform a visual inspection before and after installation to eliminate any potential

risk for personnel and fish.

When reinstalling the equipment, (new generation) it is important to ensure that the installation

and equipment are in accordance with specifications provided by Steinsvik AS. The use will

not cause any contamination of fish.

5.1 Antenna

− Connect the antenna to the mast. The cable from the antenna is routed through the

mast.

− Attach the mast to the Orbit bracket for ring, as shown in chapter 5.3.

− The cable from the antenna is then connected to the “Multi contact” on the PSU.

Note: The antenna is marked with a TX-number. Connect the antenna to the PSU with the

same number. Example: connect the antenna marked “TX: 01” to the PSU marked “PSU:

01”. The sticker on the antenna must be faced towards the barge.

Tip: Install the antenna on the barge before you install the antenna on the cage to ensure that

the antenna is pointing in the right direction.

5.2 Orbit Bracket for ring

Find a suitable place to place the Orbit-bracket for ring:

• Place it so that the winch rope moves either with or against the current.

• Position it so that it is not placed on a post where the chains to the bottom ring emerge.

• Make sure it does not conflict with ropes for the dead fish net/lift-up.

• Position it so that it is not in the way for any live-hauling boats and other vessels that may

damage the equipment.

5.2.1 Mounting Orbit-Bracket for ring

Place the bracket over the top ring of the cage.

23

Insert the supplied bolt, washer and locking pin so that the bracket cannot fall off.

The mounting bracket goes around the support rail (picture). Fasten this with a M10x20 bolts in the

top hole (on both sides). In the bottom hole (on both sides) the M10x30 bolts and M10 nuts are

fastened.

NOTE: The bolts are fastened from the inside so that they point away from the net/cage net.

Fasten the locking bolt (196mm) in the mounting bracket. This prevents the bracket from moving

sideways on the cage ring.

Drill a new hole if the support ring is to wide.

24

5.2.2 Mounting Orbit-Bracket for ring with V-clamp

Place the bracket over the top ring of the cage.

Insert the supplied bolt, washer and locking pin so that the bracket cannot fall off.

The mounting bracket goes around the support rail (picture). Fasten this with a M10x20 bolts in the

top hole (on both sides). In the bottom hole (on both sides) the M10x30 bolts and M10 nuts are

fastened.

NOTE: The bolts are fastened from the inside so that they point away from the net/cage net.

25

Bring the clamp up to the support rail. Fasten it with the supplied locking bolt, washer and locking pin

through the bracket and clamp (see picture). Depending on the size of the support rail, the locking

bolt is placed in the hole which fits the best on the bracket

Adjust the size of the clamp so that it holds the Orbit-bracket in place by turning the nut on the right

side on the clamp (the white nut in the illustration above). Fasten the clamp by tighten the locking nut

(bronze coloured nut in the illustration to the right above).

26

5.3 Mast/Alu pipe

5.3.1 Wireless installations

Fasten the aluminium pipe into the 40 mm pipe on

the Orbit-bracket for ring.

The mast is supposed to rest on the bolt at the

bottom of the 40 mm pipe. Secure it with a set

screw (DIN 912 M8x16).

5.3.2 Fibre installations

Fasten the aluminium pipe into the 40 mm pipe

on the bracket. There must be at least 300 mm of

pipe under the bracket.

Secure the pipe with a set screw (DIN 912

M8x16) on the bracket.

Place the strain relief at the bottom of the pipe.

Fasten the strain relief with M10x80 (DIN 912)

bolt and M10 nut (through the hole on the strain

relief and into the hole at the bottom of the mast).

27

5.4 PSU/Protection cabinet

Fasten the PSU to the mast, as high up as possible. Attach the four nuts to the backside of the PSU.

If an extra protection cabinet is used, place the PSU into the cabinet before mounting it on the mast.

Remember to secure the protection cabinet with an extra bracket so that there is a total of 6 nuts fastened

on the backside.

28

5.5 Winch and winch rope

Place the washer for the winch bolt on top of the attachement point for the winch on the Orbit bracket for

ring.

Slide the winch over the washer.

Attach the bolt. The winch should be able to rotate

to both sides.

Attach the locking pin at the bottom of the bolt to

prevent the winch from falling off the bracket.

Attach the winch cable. One end is connected under

the winch, while the other is connected to the

“Winch” contact in the PSU. Make sure that the net

is not in a position for the winch cable to hook onto

and break. The winch cable should preferably be

secured around the top row before it is fastened at

both ends.

29

Apply Molykote 44 or Molykote 111 on the contact surface of the winch cable to prevent

moisture from entering.

Connect everything else before connecting to 230 V.

5.6 Rope and strain relief

The strain relief consists of a 25 kg counterweight, a rope and various blocks. The purpose is to keep

the winch rope tight even if the cage is deformed due to wind, currents or other factors.

Wind up the winch rope before it is pulled around the cage.

All white and blue lines in the rope must be parallel throughout the rope to avoid

knots/twisting of the rope.

• Fasten one end of the winch rope to the handrail of the cage and wind the rope out, either lying

in the sea or between the collar tubes.

• Pull the other end of the rope through the block hanging from the strain relief. Then tie it to the

handrail.

• Walk around the cage with the strain relief. The rope is supposed to place itself nicely out in the

cage.

Place the winch rope between the ropes for the spreader, birds net etc., and above the

rope for the dead fish handling system, lights, etc.

− Walk as far as possible with the strain relief so that the winch rope is placed where the feed

lands in the cage, preferably centred in the cage so that it is possible to lower the camera all

the way down to the dead fish handling system.

− Attach the strain relief to the handrail via the pulley.

− Attach the counterweight to the end of the strain relief and lower it into the sea. Steinsvik AS

recommend fastening a safety rope to the counterweight.

− Wind the winch rope onto the winch.

− Cut the rope to the appropriate length – the length is dependent on the size of the cage

− Tie the small block for winch rope to the rope.

− Thread the camera rope through the steering rod on the winch and through the block (which

you mounted on the winch).

− See chapter 5.7 for installation of the underwater camera and cable.

30

5.7 Underwater camera

− Connect everything else before connecting to 230 V.

− Disconnect power supply before disassembly.

− Inspect for any damage on the metal hoop on the camera before submerging the

camera

− When the camera contact is disconnected from the rest: remove all sand and growth

with isopropyl alcohol and apply Molykote before reassembly.

− Tie the camera rope from the Multiwinch to the hoop on the underwater camera.

− Apply a thin layer Molykote 44 (approx. 1/10 of the depth of the contact, approx. 1 mm).

− Attach the camera cable to the camera.

− Ensure that the camera is hanging correctly; the rope should keep the plug in the right

position.

Figure 18 Camera contact, metal hoop on

camera and camera rope

31

- The camera rope is supposed to tensions relieve the camera cable so that both the camera and

the camera cable is lifted by the rope (from the Multiwinch).

− Lower the camera into the sea and wind the camera cable out in the cage.

− Cut off some meters of the white winch rope and tie a strain relief to the camera cable. Attach

this to the handrail. This is to avoid unnecessary tension/strain to the contact/connection in the

PSU.

− Connect the camera cable to the «Camera» connection in the PSU.

Figure 19 Camera Rope

32

5.8 Surface camera

Attach the Orbit-200B/210 to the top of the mast at the cage. Place the camera in the direction you want

to look.

On PSU’s supporting surface cameras: connect the camera cable to the «Multi contact» marked with

a green circle on the PSU.

5.9 Surveillance camera

− Attach the Orbit-310 to the mast at the barge (after attaching the mast to the bracket).

− Use the 40 mm U-bolt, washers and nuts supplied.

− Attention: This camera is not supposed to be mounted at the cage edge!

− Connect the camera cable to the «Multi contact» on the receiver cabinet located at the barge.

The camera cable is equipped with a 7-pin contact and a 15-pin contact. The 7-pin contact

connects to the camera, while the 15-pin contact connects to the receiver cabinet.

Figure 20 Surface camera

Figure 21 Surveillance camera

33

6 OPERATING INSTRUCTIONS

6.1 Multiwinch/underwater camera

The camera system is primarily controlled via the NeoVision or Vision software on a computer or a

control desk located on the barge or land base.

It is also possible to operate the winch from the cage edge, this makes accessing the camera for

maintenance/inspection purposes easier. The winch has three buttons, these are marked with “up”,

“down” and “sideways”:

1. Press “Up” to: Move the camera up

2. Press “Down” to: Move the camera down

3. Press “Sideways” to: Move the camera from the winch

4. Press “Sideways” to: Move the camera towards the winch

Alternately, an older winch may only have two buttons, one to move the winch up/down, one to move it

sideways, and both buttons must be used to move the camera to/from the winch.

Consult the NeoVision/Vision user manual for a complete description of navigation and

configurations.

6.2 Surveillance camera

The surveillance camera is controlled via the NeoVision or Vision software on the PC. It can be

controlled via the gamepad, arrows on the PC’s keyboard or by clicking on the different arrows in the

camera software.

Some of the functions on the gamepad are shown in the figures below.

Consult the NeoVision/Vision user manual for a complete description of navigation and

configurations.

34

Figure 22 Gamepad

Figure 23 Gamepad backside

35

7 MAINTENANCE

7.1 Routine inspection and periodic maintenance

Table 16 Routine inspection and periodic maintenance

Component

Description

Interval

Daily

Weekly Monthly

5

Entire system (incl. cables

and antennas)

Check for any icing during the winter

months. Remove ice if found on any

equipment.

Screws on the PSU/Winch

Check that all screws for lids are fastened

and in place

Multiwinch

Wipe around cables to prevent mussels from

attaching themselves between the plate and

rope cables.

Underwater camera

Run the camera to both edges to prevent

growth.

Underwater camera

After use: park the camera centered in the

cage at a depth of 10 m with the lens facing

down to prevent growth on the lens.

Underwater camera

Wipe the camera lens

Surface/surveillance/dome

camera

Visual inspection of lenses and

cables/contacts – clean/replace if necessary

Antennas

Visual inspection of cables, contacts and

fastening equipment for any bends/damage.

Visual inspection of dome.

Rope

Scrape off all growth from the knots in the

rings

Rope

Visual inspection

Orbit bracket for ring

Check fastening point to cage; check that

bolts and suspension are properly fastened.

Winch rope

Visual inspection for damage

Winch rope

Visual inspection for growth

Sensor station

Wipe the membrane on the sensor station2F6

Strain relief

Visual inspection

Counterweight

Clean to remove growth

Suspension rings

Visual inspection

Cables

Ensure that the cables do not have any

damages/kinks

5

When possible when you are at the cage

6

Use a soft cloth/Q-tip to avoid damaging the membrane

36

PC at barge

Check that it has sufficient air flow and no

dust/dirt in the fan

Gamepad

Keep clean with a damp cloth to prevent the

buttons from sticking. N.B: Not waterproof!

7.2 Larger reparations and modifications

All service must take place at Steinsvik AS or with authorized partners.

Steinsvik AS recommend sending the underwater camera in for service after every generation, while

the winch and PSU can be sent in for service every other generation.

Calibration and/or change of oxygen film on the underwater camera must be sent in to Steinsvik AS

when needed (damage). Estimated lifetime without damage is 5 years.

7.3 Troubleshooting and correction of errors

Table 17 Troubleshooting

Problem

Possible cause

Solution

Winch will not work

Growth on the rope

Remove growth

Winch will not work

Winch rope is jammed

Loosen knots

Winch will not work

Broken winch cable

Check that the cable is whole

and without visible

marks/damages. If the cable is

broken, check for corrections on

contacts on cable and in PSU.

Winch will not work

The camera rope is on the

outside of the circlip

Thread the camera rope to the

inside of the circlip.

Winch will not work

Broken fuse

Check the fuse on the inside of

the PSU and change if this is

broken.

Note: authorized personnel only

Winch jerks or stops

before reaching the

bottom

Misplaced bottom stop switch

Raise the hoop stopper7 up and

down to the stop screw. Approx.

5 mm from the bottom position

there should be a “click” from

the switch inside the winch. If

the hoop must be raised 1 cm or

more, the bottom stop switch is

misplaced.

Winch jerks or stops

before reaching the

bottom

Error on the motor protection

on the circuit board.

The motor protection switches

on when the motor is

overloaded, and the winch will

disconnect the motor when the

camera is lifted approx. 1 m

above the water surface. This to

7

Hoop that holds the winch rope up

37

prevent the engine from tearing

the ropes or burning out.

Steinsvik recommend a service

on the winch if it fails to lift the

camera in the water.

Picture come and go

Broken camera cable

Replace camera cable or try with

a cable from a different cage.

«No video» on pc-screen

Camera is not connected to

the PSU

Ensure the camera is properly

connected

«No video» on pc-screen

Defective camera fuse

Use «camera tools» in the

software to check status on the

fuse. If the fuse is broken, verify

what caused this before

changing the fuse.

7.4 Link to troubleshooting for camera system

https://help.steinsvik.no

7.5 Storing, preservation and maintenance

Disconnect power supply before disassembly

Steinsvik AS recommend storing the equipment indoors. This includes the Orbit-bracket

for ring and ropes.

1. Clean the ropes for any growth and rinse with clean water. Check for any damages resulting

from wear and tear and order new ropes if necessary.

2. Rinse aluminium parts with clean water. To avoid oxidation, cover all contact surfaces/screw

threads with grease.

3. Rinse, clean and wipe dry all cables to remove any salt residues. Check for wear and tear,

change if necessary. Coil the cables together for storage.

4. Clean the camera to remove all growth. Steinsvik AS recommend sending the camera for

service after every generation (change gaskets, calibration of sensors).

5. Clean the winch and PSU for salt and check all contacts; Evaluate whether to submit for service

to prepare it for a new generation. Store indoors to prevent moisture from entering contacts and

lid when not in the intended position (contacts down).

6. Fibre cable: If the plug of the fibre cable has come into contact with saltwater during

disconnection, rinse it immediately in clean water. Allow to dry completely before reinstalling the

lid. When coiling the cable make sure that the cable is not heavily bent; min. bending radius is

50 cm to avoid damage to fibres.

38

8 SPARE PARTS

8.1 Underwater camera

Orbit-3100: 417854

Orbit-3300: 406632

Orbit-3500: 410481/420590

Orbit-3400: 430463

Orbit-3600: 421021

8.2 Obrit-200 (411340) and Orbit-210 (430755)

Pos. nr.

Description

Product

number

Amount

1

ISO 4762 M6 x 40 A4

2

2

Washer DIN 125 - B 6.4 300HV

2

3

Spring washer DIN 128 A6

2

4

Clamp 2

406467

1

Optional

Winter sunshade

406615

1

Pos. nr.

Description

Product

number

Amount

Silicone oil

Membrane

406293

1

39

8.3 Multiwinch (100069)

Item No.

Product

Product No.

Qty.

3

Washer for shaft

1

8

Bolt for winch

405571

1

19

Split pin

401670

1

10

Hanger

401311

1

Rope 3 mm nylon

403620

100m

12

Pan head cross recess screw M6x16

4

13

Pan head cross recess screw M4x16

1

15

Plain washer M6

4

16

Plain washer DIN 9021-4.3

1

20

Wing nut M4

401611

1

6

Locking plate

405819

1

5

Winch cover

432039

1

40

8.4 Orbit-Bracket for ring (405461)

Pos. nr.

Description

Product

number

Amount

1

Mounting Bracket (small)

Mounting bracket (large)

417314

420304

1

2

12mm locking bolt 196mm

405721

1

3

12mm locking bolt 237mm

418684

2

41

8.5 Orbit-bracket for ring with clamp (V-Clamp) (442778)

Pos. nr.

Beskrivelse

Varenummer

Antall

1

12mm locking bolt 196mm

405721

1

2

12mm locking bolt 237mm

405830

1

3

V-Clamp Assy

420297

1

4

Mounting Bracket (small)

Mounting bracket (large)

417314

420304

1

Bolt set

442197

1

42

8.6 Antenna (411859)

Pos. nr.

Description

Product

number

Amount

1

Top cover

405259

1

2

O-ring 77x4,0

405263

1

3

Antenna

411156

1

Cable (complete) 2,5m

420441

1

8.7 Strain Relief (420438)

Pos. nr.

Description

Product

number

Amount

1

DIN EN ISO 10511 - M10

5

2

DIN 912 M10 x 80

5

3

DIN 912 M8 x 16

1

43

8.8 Orbit-310 (410478)

Pos. nr.

Description

Product

number

Amount

1

Countersunk flat head

cross recess screw ISO

7046 M8x30

4

2

Baseplate

410982

1

3

Washer DIN 129-9

4

4

Prevailing torque nut DIN

EN ISO 7042 M8

4

Cable 30m

430338

1

44

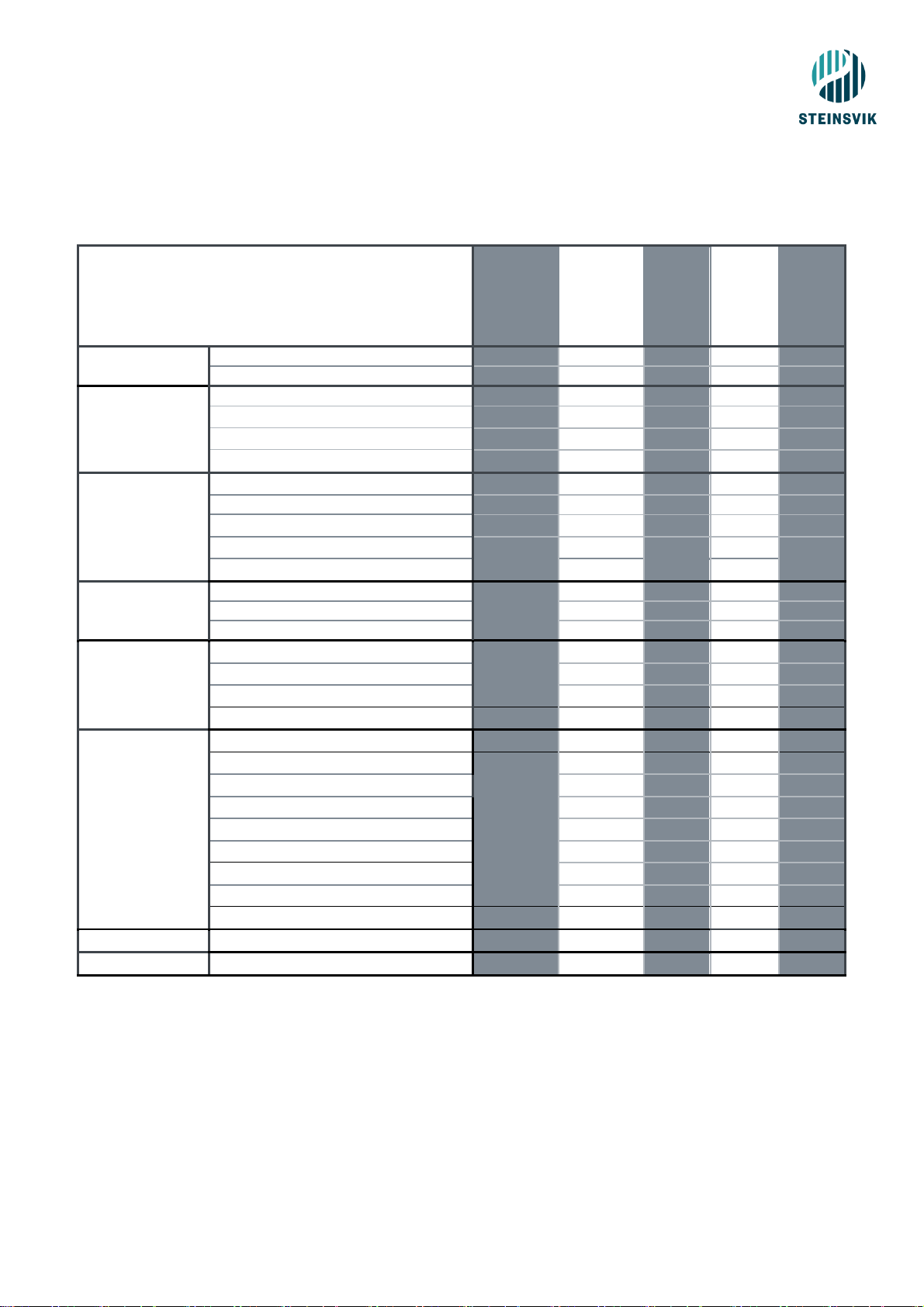

9 ORBIT-PSU STAINLESS STEEL

Orbit 542

-SS

(440221) Orbit-548SS

(100043)

Orbit-571SS

(100068)

(UK only) Orbit-578SS

(100066)

Orbit-579SS

(100067)

Video server

Siqura EVE ONE

4 1 2

Orbit-2560 1

Network switch

Korenix JetNet 4508f-m V2

Korenix JetNet 2005f

✓ ✓ ✓

Korenix JetNet 6059G

✓

Orbit-2520

✓

Contacts

Fiber & power in and out

✓

✓

1 fiber & power in, 5 fiber & power out

24 VDC PoE.

✓

Power in and out

✓

✓

Power in

✓

Connectors

Camera connector

4 4 1 1 1

Winch connector

4 4 1 1 1

Multiconnector

2 2 2 2 2

Supported by

Software

NeoVision6.0 and newer

✓ ✓ ✓

✓

NeoVision6.1 and newer

✓ ✓ ✓

✓

NeoVision6.2 and newer

✓ ✓ ✓

✓

Vision

✓

✓

✓ ✓ ✓

Supported by

Camera

Orbit-3000

✓ ✓ ✓

✓

Orbit-3100

✓ ✓ ✓ ✓

Orbit-3300

✓ ✓ ✓

✓

Orbit-3400

✓

Orbit-3500

✓ ✓ ✓

✓

Orbit-3600

✓

Orbit-200 ✓

✓

Orbit-200B ✓

✓

Orbit-210

✓

✓

✓

Material (cabinet)

Stainless steel

✓ ✓ ✓ ✓ ✓

Logging Module

Can be fitted

✓

✓ ✓ ✓

✓

45

Orbit-518SS

(100065)

Orbit-519SS

(418597)

Orbit-520SS (430992) Orbit-521SS

(430453)

Orbit-522SS (440222) Orbit-528SS

(100058)

Video server

Siqura EVE ONE

1 2 1 2 Orbit-2560

Network switch

Korenix JetNet 4508f-m V2

✓ ✓ ✓ ✓ ✓

Korenix JetNet 2005f

Orbit-2520

✓

Contacts

Fiber & power in and out

✓ ✓ ✓ ✓ ✓

✓

1 fiber & power in, 5 fiber & power out

24 VDC PoE. Power in network

Power in and out

Connectors

Camera connector

1 1 1 1 2 2 Winch connector

1 1 1 1 2 2 Multiconnector

2 2 2 2 2

2

Supported by

Software

NeoVision6.0 and newer

✓

✓

✓

NeoVision6.1 and newer

✓

✓

✓

NeoVision6.2 and newer

✓

✓

✓

Vision

✓

✓ ✓ ✓

✓

✓

Supported by

Camera

Orbit-3000

✓

✓

✓

Orbit-3100

✓

✓

Orbit-3300

✓

✓

✓

Orbit-3400

✓ ✓ ✓

Orbit-3500

✓

✓

✓

Orbit-3600

✓ ✓ ✓

Orbit-200

✓ ✓

Orbit-200B

✓ ✓

Orbit-210

✓ ✓ ✓

✓

Material (cabinet)

Stainless steel

✓ ✓ ✓ ✓ ✓

✓

Logging Module

Can be fitted

✓ ✓ ✓

✓ ✓ ✓

46

Loading...

Loading...