Page 1

OWNER/OPERATOR’S MANUAL

& ILLUSTRA TED PARTS LIST

MODELS:

75-70855 MOWER DECK-48” MD448

75-70860 MOWER DECK-60" MD460

75-70865 MOWER DECK-72" MD472

WARNING: If incorrectly used this machine can cause severe injury . Those who use

and maintain this machine should be trained in its proper use, warned of its dangers

and should read the entire manual before attempting to set up, operate, adjust or

service the machine.

09-254B REV D

Page 2

CALIFORNIA

Proposition 65 Warning

WARNING

Diesel engine exhaust and some of

its constituents are known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Californie Proposition 65

Avertissement

Les échappements des moteurs diesel

et certains de leurs composés sont

reconnus par l’Etat de Californie pour

être cancérigènes, provoquer des

défauts congénitaux et d’autres dangers

en matière de reproduction.

California Advertencia

de la Proposicion 65

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

AVERTISSEMENT

L’émission du moteur de ce matériel

contient des produits chimiques que

l’Etat de Californie considère être

cancérigènes, provoquer des défauts

congénitaux et d’autres dangers en

matière de reproduction.

ADVERTENCIA

El estado de California hace saber que

los gases de escape de los motores

diesel y algunos de sus componentes

producen cáncer, defectos de

nacimiento y otros daños en el

proceso de reproducción humana.

© 2003, TEXTRON INC

El estado de California hace saber

que los gases de escape de este

producto contienen productos

quÍmicos que producen cáncer,

defectos de nacimiento y otros daños

en el proceso de reproducción

humana.

Page 3

ROTARY

MOWER

IMPORTANT MESSAGE

Thank you for purchasing this Jacobsen product. You have purchased a world class product, one of the best

designed and built anywhere.

This product comes with an Owner/Operator's Manual. The useful life and good service you receive from this

product depends to a large extent on how well you read and understand this manual. Treat this product properly

and adjust it as instructed, and it will give you many years of reliable service.

See a Jacobsen dealer for any service or parts needed. Jacobsen service ensures that you continue to receive

the best results possible from Jacobsen products. You can trust Jacobsen replacement parts because they are

manufactured with the same high precision and quality as the original parts.

Jacobsen designs and builds its equipment to serve many years in a safe and productive manner. For longest

life, use this product only as directed in the manual, keep it in good repair and follow safety warnings and

instructions. You'll always be glad you did.

Jacobsen, a Textron Company

One Bob Cat Lane

Johnson Creek, WI 53038-0469

TABLE OF CONTENTS FIGURES PAGE

INTRODUCTION ........................................................................................................................................... 2

SPECIFICATIONS ......................................................................................................................................... 3

SAFETY ...................................................................................................................................................... 4-7

DECALS ..................................................................................................................................................... 8, 9

ASSEMBLY INSTRUCTIONS ...................................................................................................................... 10

INSTALLATION .............................................................................................................................................11

OPERATION ................................................................................................................................................ 12

SERVICE ................................................................................................................................................ 13-17

DECK PARTS 48" .............................................. FIGURE 1 ................................................................. 18, 19

DECK PARTS 60" .............................................. FIGURE 2 ................................................................. 20, 21

DECK PARTS 72" .............................................. FIGURE 3 ................................................................. 22, 23

FRAME PARTS 48" ............................................ FIGURE 4 ................................................................. 24, 25

FRAME PARTS 60" ............................................ FIGURE 5 ................................................................. 26, 27

FRAME PARTS 72" ............................................ FIGURE 6 ................................................................. 28, 29

HITCH & DRIVE PARTS .................................... FIGURE 7 ................................................................. 30, 31

SPINDLE PARTS ............................................... FIGURE 8 ................................................................. 32, 33

FLIP-UP DECKS ................................................ FIGURE 9 ................................................................. 34, 35

9-2004

1

Page 4

INTRODUCTION

ROTARY

MOWER

DESCRIPTION

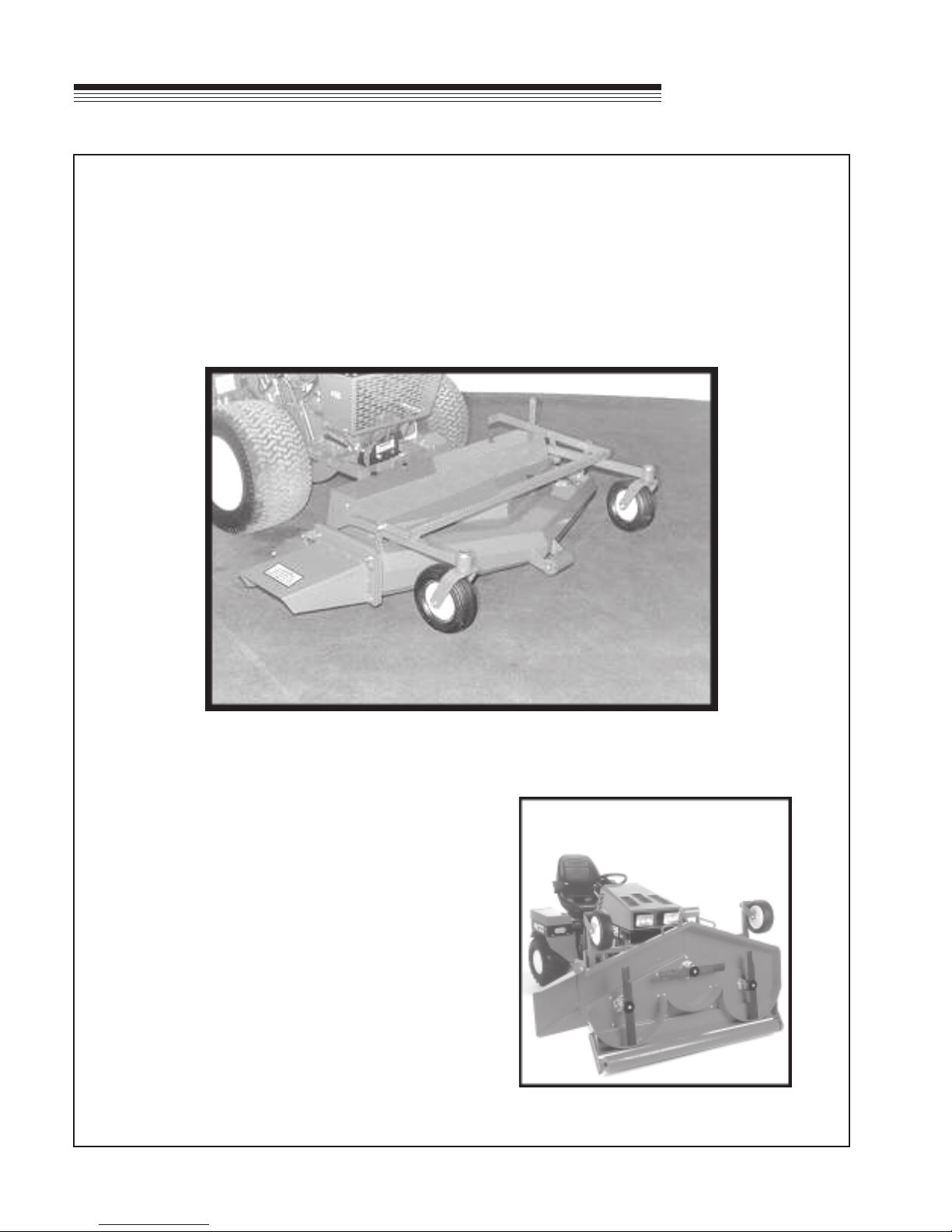

A full-floating rotary mower deck is designed to fit all Steiner power units with the quick hitch front lift.

Three sizes match the power unit to the application. These decks are easy to attach and detach allowing

interchange with the many other front mounted attachments. The side discharge rotary mower provides

even distribution of clippings while the full-floating deck follows the contours of the terrain for an even cut

with cutting height controlled by the front caster wheels and full width rear roller. The deck can be safely

serviced and cleaned while still attached to the tractor. Convenient handles enable the deck to be lifted

vertically over 90 degrees so the blades are fully exposed. Exceptional visibility and maneuvering is

possible with this front mounted design mower.

NOTE: The flip-up deck feature was added

beginning with the following Serial Numbers:

75-70855 ----------------------- 1494

75-70860 ----------------------- 4728

75-70865 ----------------------- 1970

2

Page 5

ROTARY

SPECIFICATIONS

MOWER

SPECIFICATIONS

Model 75-70855 75-70860 75-70865

Overall Width with Chute: ......... 60-1/2" ......................... 73" ................................ 85"

Overall height:........................... 19" ............................... 19" ................................ 19"

Overall length:........................... 49-1/2" ......................... 48-3/4" ......................... 55"

Cutting Width: ...........................47" ............................... 59-3/8" ......................... 72"

Cutting Height: ..........................1" to 4-1/2". .................. 1" to 4-1/2" ...................1" to 4"

Blades: ...................................... 3 - 16-1/4" blades ........ 3 - 20-1/2" blades ........ 3 - 24-3/4" blades

Weight:...................................... 330 lbs. ........................ 360 lbs. ........................ 470 lbs.

3

Page 6

SAFETY

ROTARY

MOWER

NOTICE !!!

Unauthorized modifications may present extreme

safety hazards to operators and bystanders and

could also result in product damage.

Jacobsen, a Textron Company strongly warns

against, rejects and disclaims any modifications,

add-on accessories or product alterations that are

not designed, developed, tested and approved by

Jacobsen Engineering Department. Any Jacobsen

product that is altered, modified or changed in any

manner not specifically authorized after original

manufacture–including the addition of “after-market”

accessories or component parts not specifically

approved by Jacobsen–will result in the Jacobsen

Warranty being voided.

Any and all liability for personal injury and/or property

damage caused by any unauthorized modifications,

add-on accessories or products not approved by

Jacobsen will be considered the responsibility of

the individual(s) or company designing and/or

making such changes. Jacobsen will vigorously

pursue full indemnification and costs from any party

responsible for such unauthorized post-manufacture

modifications and/or accessories should personal

injury and/or property damage result.

This symbol means:

ATTENTION!

BECOME ALERT!

Your safety and the safety of others is involved.

Signal word definitions:

The signal words below are used to identify levels

of hazard seriousness. These words appear in this

manual and on the safety labels attached to

Jacobsen machines. For your safety and the safety

of others, read and follow the information given with

these signal words and/or the symbol shown above.

DANGER indicates an imminently hazardous

situation which, if not avoided, WILL result in death

or serious injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, MAY result in minor

or moderate injury. It may also be used to alert

against unsafe practices or property damage.

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, MAY result in property damage

MODEL NUMBER: This number appears on

sales literature, technical manuals and price

lists.

SERIAL NUMBER: This number appears only

on your mower. It contains the model number

followed consecutively by the serial number.

Use this number when ordering parts or seeking

warranty information.

4

Page 7

ROTARY

SAFETY

MOWER

GENERAL SAFETY

1. Read and understand the Owner’s Manual before attempting to operate this machine.

2. Operate all controls from the operator’s seat, (if so equipped). NO RIDERS.

3. Keep all shields in place and safety switches adjusted properly.

4. Do not leave equipment unattended. Park on a level surface, set parking brake, STOP the engine and

remove the key.

5. Do not allow minors or the inexperienced to operate this machine.

6. Keep people and pets a safe distance away from machine using power driven attachments. Injury

could result from flying debris.

7. Do not attempt to work on unit or any attachments with engine running!

8. Wear all the necessary protective clothing and personal safety devices to protect your head, eyes,

ears, hands and feet. Operate the machine only in daylight or in good artificial light.

5

Page 8

SAFETY

ROTARY

MOWER

IMPORTANT

Safe Operation Practices for

Mowers

This cutting machine is capable of amputating

hands and feet and throwing objects. Failure to

observe the following safety instructions could

result in serious injury or death.

I GENERAL OPERATION

• Read, understand, and follow all instructions

in the manual and on the machine before

starting.

• Only allow responsible adults, who are

familiar with the instructions, to operate the

machine.

• Clear the area of objects such as rocks, toys,

wire, etc., which could be picked up and

thrown by the blade.

• Be sure the area is clear of other people

before mowing. Stop the machine if anyone

enters the area.

• Do not operate the machine while under the

influence of alcohol or drugs.

• Watch for traffic when operating near or

crossing roadways.

• Use extra care when loading or unloading the

machine into a trailer or truck.

• Always wear safety goggles or safety glasses

with side shields when operating mower.

II SLOPE OPERATION

Slopes are a major factor related to

loss-of-control and tip-over accidents, which can

result in severe injury or death. All slopes

require extra caution. If you feel uneasy on it, do

not mow it.

DO:

• Mow up and down slopes, not across.

• Remove obstacles such as rocks, tree limbs,

etc.

• Never carry passengers.

• Do not mow in reverse unless absolutely

necessary. Always look down and behind

before and while backing.

• Be aware of the mower discharge direction

and do not point it at anyone. Do not operate

the mower without the discharge chute in

place.

• Slow down before turning.

• Never leave a running machine unattended.

Always turn off blades, set parking brake, stop

engine, and remove keys before dismounting.

• Turn off blades when not mowing.

• Stop engine before unclogging discharge

chute.

• Mow only in good light, keeping away from

holes and hidden hazards.

• Watch for holes, ruts, or bumps. Uneven

terrain could overturn the machine. Tall grass

can hide obstacles.

• Use slow speed on slopes.

• Follow the manufacturers recommendations

for wheel weights or counterweights to

improve stability.

• Use extra care with grass catchers or other

attachments. These can change the stability

of the machine.

• Keep all movement on the slope slow and

gradual. Do not make sudden changes in

speed or direction.

• Avoid stopping or starting on a slope. If tires

lose traction, disengage the blades and

proceed slowly straight down the slope.

6

Page 9

ROTARY

MOWER

SAFETY

DO NOT:

• Do not turn on slopes unless necessary, and

then, turn slowly and gradually downhill, if

possible.

• Do not mow drop-offs, ditches, or

embankments. The mower could suddenly

turn over if a wheel is over the edge of a cliff

or ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction

could cause sliding.

• Do not try to stabilize the machine by putting

your foot on the ground.

• Do not use grass catcher on steep slopes.

III CHILDREN

Tragic accidents can occur if the operator is not

alert to the presence of children. Children are

often attracted to the machine and the mowing

activity. Never assume that children will remain

where you last saw them.

IV SERVICE

• Use extra care in handling gasoline and other

fuels. They are flammable and the vapors are

explosive.

- Use only an approved container.

- Never remove gas cap or add fuel with

engine running. Allow engine to cool before

refueling.

- Do not smoke.

- Never add or drain fuel with machine

indoors.

- Never store the machine or fuel container

inside where there is an open flame, such

as in a water heater.

• Never run the machine in a closed area.

• Keep nuts and bolts, especially blade

attachment bolts, tight and keep equipment in

good condition.

• Never tamper with safety devices. Check their

proper operation regularly.

• Keep machine free of grass, leaves, and other

debris build-up. Clean up oil or fuel spillage.

Allow machine to cool before storing.

• Keep children out of the mowing area and

under the watchful eye of another responsible

adult.

• Be alert and turn machine off if children enter

the area.

• Before and when backing, look behind and

down for small children.

• Never carry children as passengers, even

with the blades off. They may suddenly fall

off and be seriously injured or interfere with

safe machine operation.

• Never allow children to operate the machine.

• Use extra care when approaching blind

corners, shrubs, trees, or other objects that

may obscure vision.

• Stop and inspect the equipment if you strike

an object. Repair, if necessary, before

re-starting.

• Never make adjustments or repairs with the

engine running.

• Discharge chute components are subject to

wear, damage, and deterioration, which could

expose moving parts or allow objects to be

thrown. Frequently check components and

replace with manufacturer’s recommended

parts, when necessary.

• Mower blades are sharp and can cut. Wrap

the blade(s) or wear gloves, and use extra

caution when servicing them.

• Check brake operation frequently (if

equipped). Adjust and service as required.

7

Page 10

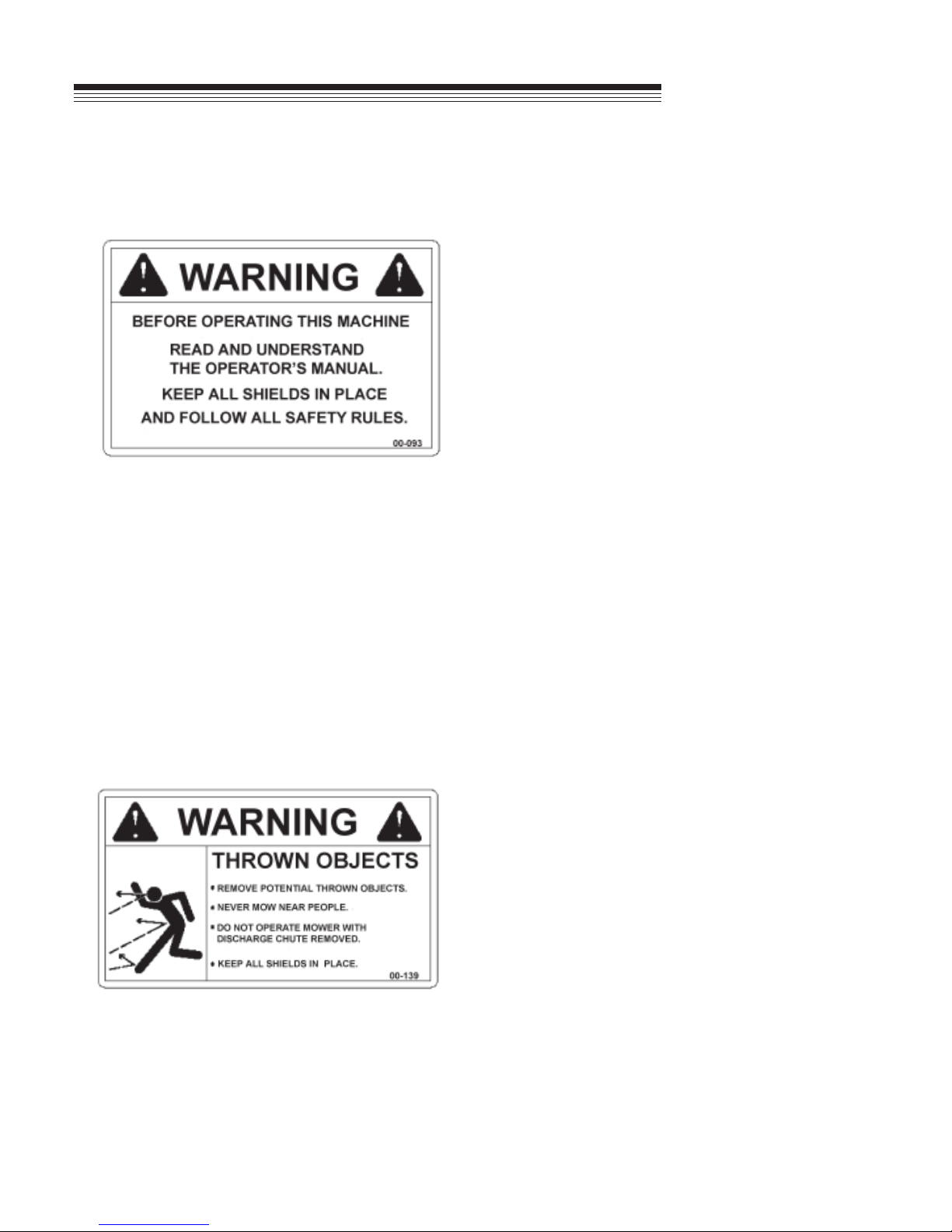

DECALS

ROTARY

MOWER

Location:

On mower deck, front center.

8

Location:

On mower deck and discharge chute.

Page 11

ROTARY

MOWER

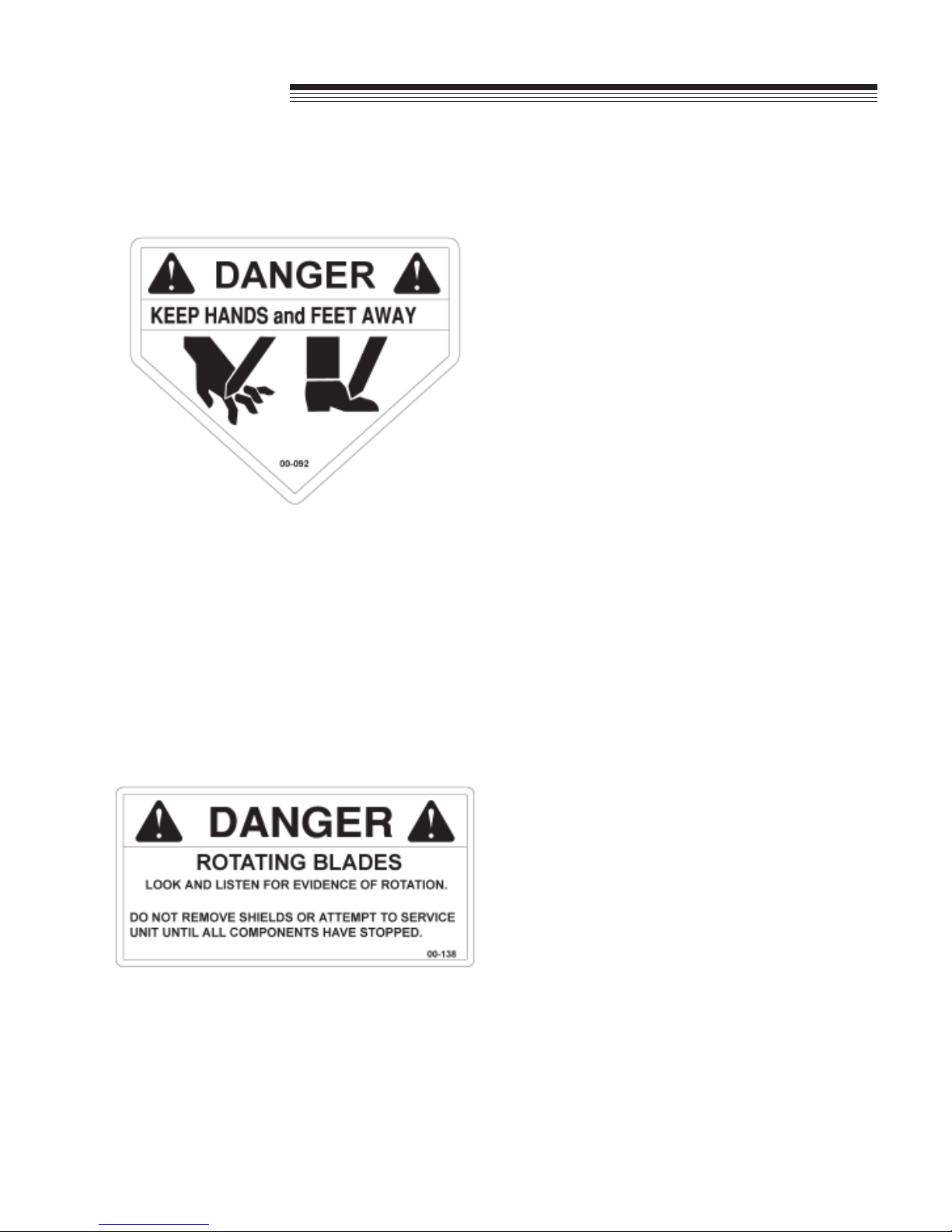

DECALS

Location:

On mower deck top front center and both sides.

Location:

On mower deck top shield.

9

Page 12

ASSEMBLY INSTRUCTIONS

ROTARY

MOWER

1. Remove the mower from the shipping crate.

2. Remove top shield.

3. Install both left and right hitch arms as shown in Figure 7. Torque the 1/2" attaching bolts to 85 ft. lbs.

Serial Numbers:

75-70855: 1001-1493, 75-70860: 1001-4727, 75-70865: 1001-1969

Install the 1/2" locknut, which holds the two hitch arms together. Tighten and back off 1/2 turn. This

allows some independent movement of the hitch arms.

Serial Numbers:

75-70855: 1494 & Up, 75-70860: 4728 & Up, 75-70865: 1970 & Up

Install the 1/2" nut and the 1/2" lockwasher, which holds the two hitch arms together. Torque to 85 ft. lbs.

4. Be sure that the mower main drive belt is installed correctly on all pulleys. Check spring-loaded idler

arm position. Choose a mounting hole in the deck which allows the idler arm to lean toward the drive

shaft, with the spring attached. Fasten spring to chain and idler arm as shown on Page 16.

Serial Numbers:

75-70855: 1001-1493, 75-70860: 1001-4727, 75-70865: 1001-1969

Choose a chain link that stretches spring to an overall length of 8-9 inches.

Serial Numbers:

75-70855: 1494 & Up, 75-70860: 4728 & Up, 75-70865: 1970 & Up

Choose a chain link that stretches spring approximately 1" on 75-70860 or 1-1/2" on 75-70855 &

75-70865.

5. Check bolts mounting spindles to the deck. Torque should be 35-40 ft. lbs.

6. Check blade bolts. Torque should be 75 - 85 ft. lbs.

7. Check 1/4" cap screws on pulley bushings (Figure 1, Item 9). Torque should be 95 inch pounds.

Tighten these cap screws in alternating sequence 10-12 times to assure equal torque on all cap

screws.

8. Reinstall the top shield.

9. Remove 1/2" locknut on height adjustment lever and position correctly as shown on Page 12. Replace

locknut.

10. Remove the drive pulley shield and install the proper drive belt for the power unit. Replace shield.

11. Attach mower to power unit. See Page 11 for installation instructions. See Pages 6 & 7 for safety

instructions and Page 12 for operating instructions.

10

Page 13

ROTARY

MOWER

ATTACHING MOWER TO TRACTOR:

- Operate latch control to open hitch latches.

- Drive tractor into position aligning the quick hitch.

- Be sure both latches engage fully and and are placed in the locked position.

- Stop engine! Do not attempt to install drive belt with engine running.

- Release idler assembly to facilitate easy installation of the drive belt.

- Put belt over drive pulleys and engage or adjust idler assembly.

(See Power Unit Operator’s Manual for PTO belt tension adjustments.)

- Set mower to desired cutting height.

- Start engine and engage PTO slowly to prevent shock load on mower components.

INSTALLATION

- Mow with front lift lever in “FLOAT” position only.

REAR WEIGHT REQUIREMENTS

The table of requirements for rear weights is based upon average mowing conditions and operator’s weight

of 150 lbs. The recommendations may vary with the weight of the operator, other accessories, and the

mowing conditions. It is the operator’s responsibility to determine the correct amount of weight needed to

improve stability. All weights must be removed when the mower is removed. (See Caution in Power Unit

Operator’s manual.)

ledoMtinUrewoPkceD"84kceD"06kceD"27

032/022sthgiew0sthgiew0sthgiew2

014sthgiew2sthgiew4

034/024sthgiew2sthgiew4sthgiew5

tonsikcedsihT

dednemmocer

524sthgiew2sthgiew2sthgiew4

525sthgiew0sthgiew0sthgiew0

11

Page 14

OPERATION

Observe all safety decals.

Keep all shields in place. Do not operate mower with discharge chute removed.

Do not operate mower with other persons in the area. Irregularities in ground surface

can permit foreign material to be propelled from beneath deck to cause serious injury

or death.

Before leaving tractor, stop on a level surface, move Forward - Reverse control to

neutral position, disengage PTO, set parking brake, lower mower deck and stop

engine.

Remove key from ignition if maintenance procedures are to be performed or tractor is

to be left unattended.

OPERATING INSTRUCTIONS

ROTARY

MOWER

- Do not operate mower with discharge chute removed.

- Mow with front lift lever in “FLOAT” position only.

- Engage PTO slowly at low engine r.p.m.

- Mower is designed to operate at full throttle for mowing heavy turf, but 3/4 throttle is adequate for

average conditions. Set mower blade speed with throttle and control ground speed with Forward Reverse control.

- Use extreme caution when operating on hills. Mow up and down whenever possible.

- See Page 11 for weight recommendations.

SETTING MOWER CUTTING HEIGHT

- Lift mower deck off the ground and shut off tractor engine.

- Remove clevis pin at location A from height adjustment link.

- Raise or lower deck to desired height.

- Replace clevis pin into height adjustment link.

12

Page 15

ROTARY

MOWER

MAINTENANCE

Daily maintenance:

Visual inspection for loose parts and accumulation of grass and dirt.

Clean accumulation of grass clippings from beneath deck daily for better mowing performance.

Keep blades sharp. Check the tips of the blades for wear.

25 hour maintenance:

In addition to daily maintenance, grease roller and all bearings.

Spindle housings must be kept full of grease. Grease spindles until grease “shows” at the relief

hole under the spindle drive pulley.

NOTE: The relief hole is under the spindle hub and is not visible. As grease enters the spindle

housing you can hear the sound of escaping air at the relief hole. Stop greasing when the sound of

escaping air ceases.

SERVICE

Check drive belt tension. See Drive Belt Installation on Page 16.

Check 1/4" cap screws on pulley bushings. Torque should be 95 inch pounds. Tighten these cap

screws in alternating sequence 10-12 times to assure equal torque on all cap screws.

Check blade bolts. Torque should be 75-85 ft. lbs.

Annual Maintenance:

In addition to daily and 25 hour maintenance, remove the drive belt and check for cracks or wear.

Rotate each spindle to check for roughness which would indicate bearing wear. Remove and

sharpen blades, clean and wash deck prior to storage. The acid in grass clippings causes

premature corrosion and rusting of mower parts.

Grease all bearings after washing.

13

Page 16

SERVICE

ROTARY

MOWER

ADJUSTMENTS

Sharpening blades

Be careful while sharpening blades that the corners of the blade do not become rounded at the tips. This

reduces the blades overlap and will cause skipping. While sharpening, it is essential to ensure the balance

of the blades is maintained to prevent vibration. Blade bolt torque should be 75-85 ft. lbs. Rotate blades

after re-installing to check for bent or bowed blades and blade alignment.

Blade alignment

When installing sharpened blades or new blades be sure the mating surfaces are clean and the retaining

washer is not bent. Check for bent blades by rotating blades until tips are near each other. (It is easier to

do this with main drive belt idler spring unhooked.)

Leveling mower deck

The front to rear leveling adjustment is provided by two slots in the linkage which supports the front of the

deck. This allows each side to be adjusted independently. Check the blade level with mower resting on a

level floor and the cutting height set at about 2-1/2" setting. Measure to the tip of the left blade at the rear,

then rotate the blade 180 degrees and measure again to the tip of the blade at the front. The cutting height

should be equal or 1/16" lower at the front. Change adjustment in the left slot as required and measure

again until proper setting is reached. Repeat procedure for blade at right end of the deck and adjust right

slot.

14

Page 17

ROTARY

SERVICE

MOWER

TO REMOVE BELT:

Serial Numbers:

75-70855 1001-1493

75-70860 1001-4727

75-70865 1001-1969

Remove top shield and the bolts which fasten the hitch arms to the deck brackets. No further disassembly

is necessary.

Serial Numbers:

75-70855 1494 & Up

75-70860 4728 & Up

75-70865 1970 & Up

Remove the six 1/4" X 3/4" bolts from the flip-up braces and remove the pivot stop pin and the idler spring.

Remove the braces.

• With the idler spring released, move the idler toward the drive shaft.

• Slip belt off the outer spindle pulleys.

• Slip belt off the front center idler and spindle.

• Remove belt.

15

Page 18

SERVICE

TO INSTALL BELT:

• Form loop for drive pulley and idler pulley as

shown. (Photos 2 & 3)

• Slip loop over drive pulley on left hitch arm.

(Photos 2 & 3)

• Form a loop around the center spindle

pulley and fixed idler pulley. (Photos 2 & 3)

• Position belt on the outer spindle pulleys.

(Photos 2 & 3)

Serial Numbers:

75-70855 1001-1493

75-70860 1001-4727

75-70865 1001-1969

ROTARY

MOWER

PHOTO 2

Re-install hitch arms and bushings in place .

Serial Numbers:

75-70855 1494 & Up

75-70860 4728 & Up

75-70865 1970 & Up

Re-install hitch arms and pivot braces. Torque 1/2"

attaching bolts to 85 ft. lbs. (Photos 2 & 3)

Hook idler spring in place.

Serial Numbers:

75-70855 1001-1493

75-70860 1001-4727

75-70865 1001-1969

Choose chain link that stretches spring to an overall

length of 8-9 inches.

Serial Numbers:

75-70855 1494 & Up

75-70860 4728 & Up

75-70865 1970 & Up

PHOTO 3

Choose chain link which stretches spring

approximately one inch on 75-70860 or 1-1/2" on

75-70855 & 75-70865.

• Re-install top shield.

16

Page 19

ROTARY

SERVICE

MOWER

USING THE FLIP-UP OPTION ON THE 75-70855, 75-70860 AND 75-70865 ROTARY MOWERS

1. Stop on a level surface, set parking brake and shut off the tractor.

2. Lift the deck.

3. Remove the top deck shield and set aside.

4. Standing at the front of the deck, pull the handle on the idler arm so the belt comes loose.

5. Remove the belt from the drive pulley.

6. Remove the presto pin and slide pin from holes.

7. Grasp the handles and lift the deck up and back until you hear a click. This indicates that the latch has

engaged.

8. Lower the deck until the roller touches the ground. This gives stability when working on the deck.

9. Complete your work under the deck.

10. Start the tractor and lift the deck again. Shut off the tractor.

11. Grasp the handles at the front of the deck. Push the deck back slightly and release the catch.

12. Pull the deck forward and down, keeping a firm grip on the handles.

13. Lower the deck to the ground.

14. Replace the pin and clip in the hole above the lift arm.

15. Grasp the idler arm handle again and pull to stretch the spring. Place the belt onto the drive pulley.

16. Make sure the belt is around all pulleys. Release the idler arm.

17. Replace the top shield and secure with the rubber latches.

18. Moving the power unit with the deck in the flipped up position is not recommended. Serious injury and

or damage could result.

17

Page 20

DECK PARTS 48"

ROTARY

FIGURE 1

MOWER

18

Page 21

ROTARY

DECK PARTS 48"

MOWER

ITEM PART NO. DESCRIPTION QTY

1-1 47-050 KNOB 4

64002-04 LOCKWASHER, EXT. 5/16 4

(SN 1001 - 1433)

1-2 60-535 SHIELD-TOP 1

(SN 1001 - 1009)

60-567 SHIELD-TOP DECK 1

(SN 1010 - 1433)

60-652 SHIELD-TOP DECK 1

(SN 1434 - )

1-3 41-052 SPRING-EXT 0.875 X 6.750 1

1-4 6107645 CHAIN, IDLER ARM STOP 1

(SN 1001 - 1577)

1-5 64-534 HOOK-SPRING 1

(SN 1001 - 1577)

1-6 64141-2 NUT-WLF 1/4-20 4

1-7 29-010 GREASE FITTING-1/4 3

1-8 64164-12 KEY-1/4X1/4X1 SQ END 3

1-9 83-H16SPL BUSHING-H X 1" SPLIT TYPE3

1-10 83-BK50H PULLEY-5" H1 BUSHING 3

1-11 64123-117 BOLT-HEX 1/2-13X1-1/2 1

1-12 83-012 IDLER-"V" 1/2" ID X 4-1/2" OD 2

1-13 99-B12 WASHER-1/4 X 17/32 X 1-1/8 2

1-14 62-723 DECK-TOP 1

(SN 1001 - 1433)

62-843 DECK-TOP 1

(SN 1434 - 1577)

62-872 UPR DK WLDMT 1

(SN 1578 - )

1-15 64025-09 HEX, NUT 1/2-13 2

1-16 64006-05 LOCKWSHR-HELICAL 1/2 2

1-17 64163-67 WASHER-.516X1X12GA 1

1-18 85-B29 BUSHING-.406 X .740 X .258 1

1-19 90-0814 BOLT-1/2 X 1-3/4 1

1-20 40-290 IDLER ARM 1

(SN 1001 - 1577)

40-329.7 IDLER ARM 1

(SN 1578 - )

1-21 64141-4 NUT-WLF 3/8-16 18

1-22 64139-18 BLT-WLF 3/8-16X1-1/4 12

1-23 64139-21 BLT-WLF 3/8-16X3/4 5

1-24 62-716 DECK-MOWER 1

(SN 1001 - 1433)

62-844 DECK-MOWER 1

(SN 1434 - )

1-25 60-534 CHUTE-SIDE DISCHARGE 1

1-26 87-143 SPINDLE 3

1-27 79-062 BLADE-16-1/4" .700 AIR LIFT 3

79-064 BLADE-16-1/4" 1-3/8 AIR LIFT3

(OPTIONAL)

1-28 99-B14 WASHER-1/4 X 1/2 ID X 3 OD3

1-29 91-0810 BOLT-1/2 X 1-1/4 NF 3

FIGURE 1

ITEM PART NO. DESCRIPTION QTY

1-30 64123-50 BOLT-HEX 3/8-16X1 1

1-31 64-799 WASHER-13/32 X 1-9/32 1

1-32 99-K38 BOLT-1/4 X 1-1/4 BH 2

(SN 1010 - )

1-33 64163-03 WSHR-.256IDX.62ODX18 2

(SN 1010 - )

1-34 64-687.7 SPACER 2

(SN 1010 - )

1-35 00-137 DECAL-SPIRAL INDICATOR 1

(SN 1010 - )

60-568 SUPPORT 1

(SN 1010 - )

1-36 56-059-17 TRIM-LOC-RUBBER 17" 1

(SN 1010 - )

1-37 06-010 CAP PLUG-1" 1

(SN 1010 - )

1-38 64-866 SHIM-SPINDLE 22 GA. 1

(1 PAIR OPTIONAL)

64-867 SHIM-SPINDLE 16 GA. 1

(1 PAIR OPTIONAL)

64-868 SHIM-SPINDLE 12 GA. 1

(1 PAIR OPTIONAL)

1-39 47-090 LATCH-RUBBER 3" LONG 3

(SN 1434 - )

1-40 04-008 POP RIVET-1/8 X 1/4 SS 6

(SN 1434 - )

1-41 04-007 POP RIVET-1/8 X 1/8 SS 6

(SN 1434 - )

1-42 64-900.7 BRKT-TOP SHIELD LATCH 1

(SN 1434 - )

1-43 64139-02 BLT-WLF 1/4-20X1/2 2

(SN 1434 - )

1-44 64123-15 BOLT-3/8-16X3/4 3

1-45 64025-05 NUT-3/8-16 3

1-46 64006-03 LOCKWASHER-3/8 3

1-47 00-092 DECAL-HANDS & FEET 2

1-48 00-139 DECAL-WARNING 2

1-49 00-138 DECAL-DANGER 1

1-50 00-129 DECAL-BELT INSTALL 1

(LOCATED UNDERNEATH TOP SHIELD)

1-51 4128363 DECAL-STEINER LOGO 1

1-52 00-140 DECAL-ANSI CERT. 1

1-53* 00-093 DECAL 1

1-54* 4112761 LABEL-MADE IN USA 1

* NOT ILLUSTRATED

19

Page 22

DECK PARTS 60"

ROTARY

FIGURE 2

MOWER

20

Page 23

ROTARY

DECK PARTS 60"

MOWER

ITEM PART NO. DESCRIPTION QTY

2-1 47-050 KNOB 4

64002-04 LOCKWASHER, EXT. 5/16 4

(SN 1001 - 4188)

2-2 60-526 SHIELD-TOP DECK 1

(SN 1001 - 1224)

60-544 SHIELD-TOP DECK 1

(SN 1225 - 4188)

4133299.17 SHIELD-TOP DECK 1

(SN 4189 - )

2-3 41-052 SPRING-EXT 0.875 X 6.750 1

2-4 6107645 CHAIN, IDLER ARM STOP 1

(SN 1001 - 1577)

2-5 64-534 HOOK-SPRING 1

(SN 1001 - 1577)

2-6 64141-2 NUT-WLF 1/4-20 4

2-7 29-010 GREASE FITTING-1/4 3

2-8 64164-12 KEY-1/4X1/4X1 SQ END 3

2-9 83-H16SPL BUSHING-H X 1" SPLIT TYPE 3

2-10 83-BK72H SHEAVE- BK72H 3

2-11 64123-117 BOLT-HEX 1/2-13X1-1/2 1

2-12 83-012 IDLER-"V" 1/2" ID X 4-1/2" OD 2

2-13 99-B12 WASHER-1/4 X 17/32 X 1-1/8 2

2-14 62-700 DECK-TOP 1

(SN 1001 - 1194)

62-729 DECK-TOP 1

(SN 1195 - 4188)

62-835 DECK-TOP 1

(SN 4189 - 5456)

62-868.7 UPR DK WLDMT 1

(SN 5457 - )

2-15 64025-09 HEX, NUT 1/2-13 2

2-16 64006-05 LOCKWSHR-HELICAL 1/2 2

2-17 64163-67 WASHER-.516X1X12GA 1

2-18 85-B29 BUSHING-.406 X .740 X .258 1

2-19 90-0814 BOLT-1/2 X 1-3/4 1

2-20 40-289 IDLER ARM 1

(SN 1001 - 1194)

40-290 IDLER ARM 1

(SN 1195 - 5456)

40-329.7 IDLER ARM 1

(SN 5457 - )

2-21 64141-4 NUT-WLF 3/8-16 18

2-22 64139-18 BLT-WLF 3/8-16X1-1/4 12

2-23 64139-21 BLT-WLF 3/8-16X3/4 5

2-24 62-694 DECK-MAIN 1

(SN 1001 - 1194)

62-727 DECK-MAIN 1

(SN 1195 - 4188)

62-834.17 DECK-MAIN 1

(SN 4189 - )

FIGURE 2

ITEM PART NO. DESCRIPTION QTY

2-25 62-696.17 CHUTE-SIDE DISCHARGE 1

2-26 87-143 SPINDLE-MOWER 3

2-27 79-050 BLADE-20-1/2" .700 AIR LIFT 3

79-053 BLADE-20-1/2" 1-3/8 AIR LIFT3

2-28 99-B14 WASHER-1/4 X 1/2 ID X 3 OD3

2-29 91-0810 BOLT-1/2 X 1-1/4 NF 3

2-30 64123-50 BOLT-HEX 3/8-16X1 1

2-31 64-799 WASHER-13/32 X 1-9/32 1

2-32 99-K38 BOLT-1/4 X 1-1/4 BH 2

(SN 1225 - )

2-33 64163-03 WSHR-.256IDX.62ODX18 2

(SN 1225 - )

2-34 64-687.7 SPACER 2

(SN 1010 - )

2-35 00-137 DECAL-SPIRAL INDICATOR 1

(SN 1225 - )

60-568.7 SUPPORT 1

(SN 1010 - )

2-36 56-059-17 TRIM-LOC-RUBBER 17" 1

(SN 1225 - )

2-37 06-010 CAP PLUG-1" 1

(SN 1225 - )

2-38 64-866 SHIM-SPINDLE 22 GA. 1

(1 PAIR OPTIONAL)

64-867 SHIM-SPINDLE 16 GA. 1

(1 PAIR OPTIONAL)

64-868 SHIM-SPINDLE 12 GA. 1

(1 PAIR OPTIONAL)

2-39 47-090 LATCH-RUBBER 3" LONG 3

(SN 4189 - )

2-40 04-008 POP RIVET-1/8 X 1/4 SS 6

(SN 4189 - )

2-41 04-007 POP RIVET-1/8 X 1/8 SS 6

(SN 4189 - )

2-42 64-900.7 BRCKT-TOP SHIELD LATCH 1

(SN 4189 - )

2-43 64139-02 BLT-WLF 1/4-20X1/2 2

(SN 4189 - )

2-44 64123-15 BOLT-3/8-16 X 3/4 3

2-45 64025-05 NUT-3/8-16 3

2-46 64006-03 LOCKWASHER-3/8 3

21

Page 24

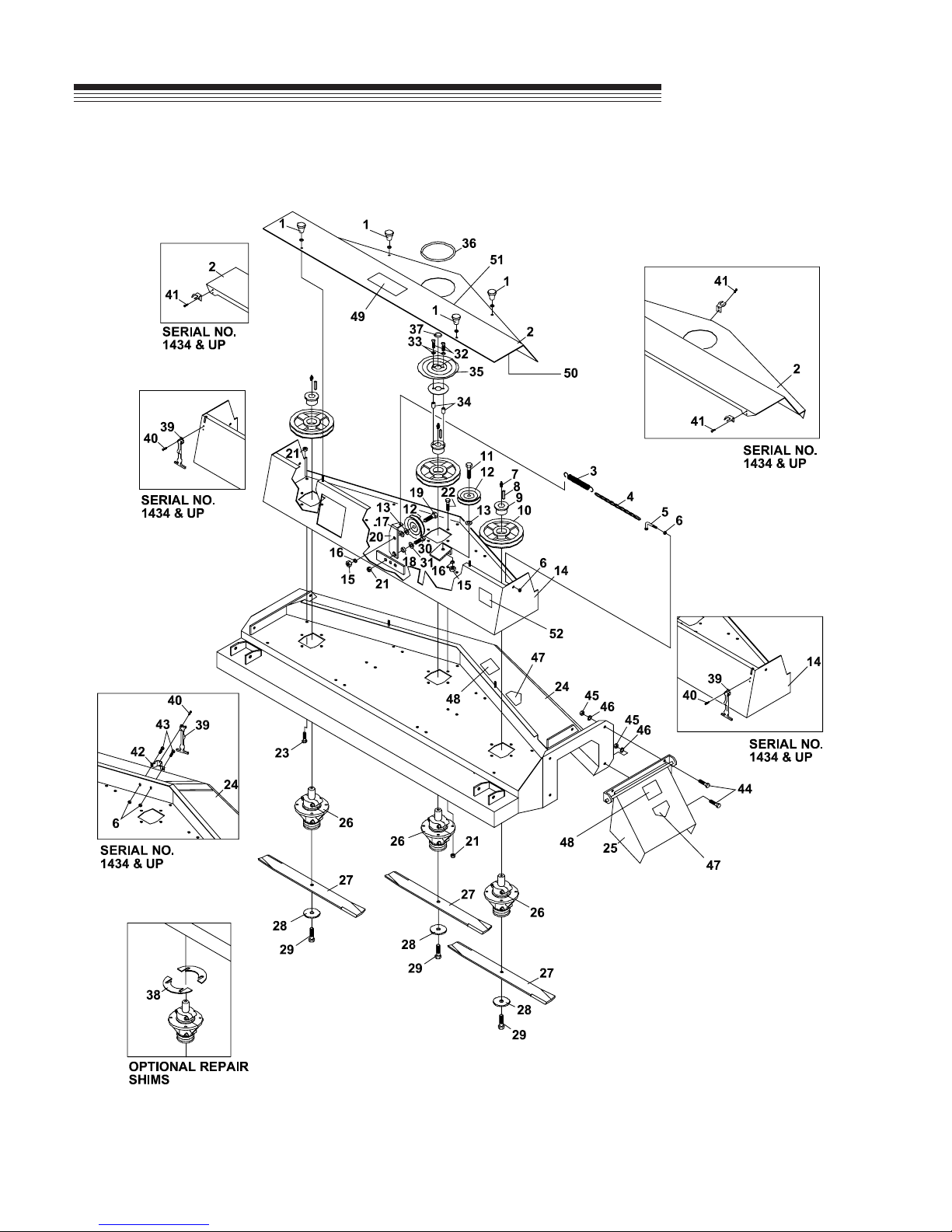

DECK PARTS 72"

ROTARY

FIGURE 3

MOWER

22

Page 25

ROTARY

DECK PARTS 72"

MOWER

ITEM PART NO. DESCRIPTION QTY

3-1 47-050 KNOB 4

64002-04 LOCKWASHER, EXT. 5/16 4

(SN 1001 - 1837)

3-2 60-540.17 SHIELD-TOP DECK 1

(SN 1001 - 1016)

60-545.17 SHIELD-TOP DECK 1

(SN 1017 - 1837)

4133301.17 SHIELD-TOP DECK 1

(SN 1838 - )

3-3 41-051 SPRING-EXT 1.0 X 6.750 1

3-4 56-055-22 CHAIN-IDLER 1

(SN 1001 - 2301)

3-5 64-534 HOOK-SPRING 1

(SN 1001 - 2301)

3-6 64141-2 NUT-WLF 1/4-20 4

3-7 29-010 GREASE FITTING-1/4 3

3-8 64164-12 KEY-1/4X1/4X1 SQ END 3

3-9 83-H16SPL BUSHING-H X 1" SPLIT TYPE 3

3-10 83-BK80H PULLEY- BK80H 3

3-11 64123-70 BOLT-HEX 3/8-16X1-1/2 1

3-12 83-034 IDLER-"V" 3/8" ID X 5" OD 2

3-13 64163-61 WSHR .81X.406X16GA 5

3-14 62-733 DECK-TOP 1

(SN 1001 - 1837)

62-840.7 DECK-TOP 1

(SN 1838 - 2301)

62-873.7 UPR DK WLDMT 1

(SN 2302 - )

3-15 64141-4 NUT-WLF 3/8-16 22

3-16 64-900 BRKT-TOP SHIELD LATCH 2

(SN 1838 - )

3-17 04-007 POP RIVET-1/8 X 18 SS 8

(SN 1838 - )

3-18 85-B29 BUSHING-.406X.740X.258 1

3-19 64123-87 BOLT-HEX 3/8-16X1-3/4 1

3-20 40-292 IDLER ARM 1

(SN 1001 - 2301)

40-329 IDLER ARM 1

(SN 2302 - )

3-21 64139-02 BLT-WLF 1/4-20X1/2 4

(SN 1838 - )

3-22 64139-18 BLT-WLF 3/8-16X1-1/4 12

3-23 64139-21 BLT-WLF 3/8-16X3/4 7

3-24 62-730.17 DECK-MOWER 1

(SN 1001 - 1837)

62-841.17 DECK-MOWER 1

(SN 1838 - )

3-25 60-54117 CHUTE-SIDE DISCHARGE 1

3-26 87-143 SPINDLE 3

FIGURE 3

ITEM PART NO. DESCRIPTION QTY

3-27 79-068 BLADE-24-3/4" .700 AIR LIFT 3

79-069 BLADE-24-3/4" 1-3/8 AIR LIFT3

(OPTIONAL)

3-28 99-B14 WASHER-1/4X1/2IDX3OD 3

3-29 91-0810 BOLT-1/2 X 1-1/4 NF 3

3-30 64123-50 BOLT-HEX 3/8-16X1 1

3-31 64-799 WASHER-13/32 X 1-9/32 1

3-32 99-K39 BOLT-1/4 X 1-1/2 BH 2

(SN 1017 - )

3-33 453023 FLATWASHER, 1/4 4

(SN 1017 - )

3-34 64-688.7 SPACER 2

(SN 1017 - )

3-35 00-137 DECAL-SPIRAL INDICATOR 1

(SN 1017 - )

60-568.7 SUPPORT 1

(SN 1010 - )

3-36 56-059-17 TRIM-LOC-RUBBER 17" 1

(SN 1017 - )

3-37 06-010 CAP PLUG-1" 1

(SN 1017 - )

3-38 64-866 SHIM-SPINDLE 22 GA. 1

(1 PAIR OPTIONAL)

64-867 SHIM-SPINDLE 16 GA. 1

(1 PAIR OPTIONAL)

64-868 SHIM-SPINDLE 12 GA. 1

(1 PAIR OPTIONAL)

3-39 47-090 LATCH-RUBBER 3" LONG 3

(SN 1838 - )

3-40 04-007 POP RIVET, 1/8 X 1/4 SS 6

(SN 1838 - )

3-41 64123-15 BOLT-3/8-16 X 3/4 3

3-42 64025-05 NUT-3/8-16 3

3-43 64006-03 LOCKWASHER-3/8 3

23

Page 26

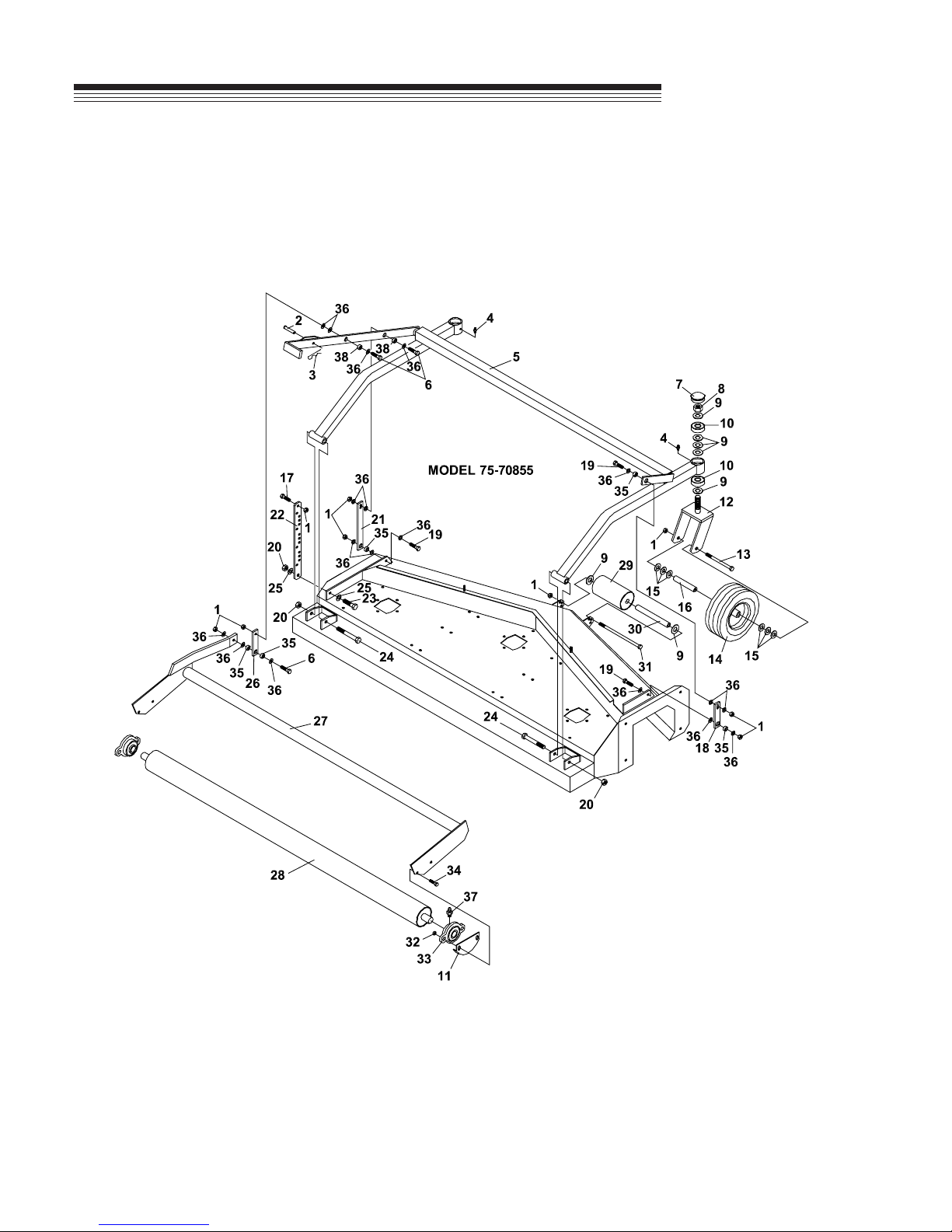

FRAME PARTS 48"

ROTARY

FIGURE 4

MOWER

24

Page 27

ROTARY

FRAME PARTS 48"

MOWER

ITEM PART NO. DESCRIPTION QTY

4-1 64141-4 NUT-WLF 3/8-16 13

4-2 03-0610 CLEVIS PIN-3/8 X 1-1/4 1

4-3 02-PP0318 PRESTO PIN-3/32 X 2-5/16 1

4-4 29-010 GREASE FITTING-1/4 2

4-5 62-725.7 FRAME-HEIGHT ADJ 1

4-6 64123-70 BOLT-HEX 3/8-16X1-1/2 5

4-7 53-060 HUB CAP-FOR MOWER 2

4-8 99-AC12NFLOCKNUT-CENTER 3/4 NF 2

4-9 64163-06 WASHER-.768/.756X1.25X14 12

4-10 55-Z9504AB BALL BEARING-3/4 ID 4

4-11 64-807 SPACER 2

(SN 1001 -11310)

64-845.7 SHIELD-BEARING 2

(SN 1311 - )

4-12 4132783.7 CASTER, MOWER 2

4-13 64123-93 BLT-HEX 3/8-16X5 2

4-14 53-104 WHEEL-CASTER 2

(SN 1001 - 1711)

55-G527 BEARING-BALL 2

55-107 BEARING-5/8 ID X 1-3/8 OD 2

(OPT HD)

53-186 WHEEL-10.25 X 3.25 2

(SN 1712 - )

55-112 BRG-ROLLER 5/8 ID X 1-3/8 1

53-187 RETAINER 2

FIGURE 4

ITEM PART NO. DESCRIPTION QTY

4-28 50-078.7 ROLLER-REAR 1

4-29 50-105 ROLLER-FRONT 1

85-B11 BEARING-3/4" WOOD RLR 2

4-30 50-074 AXLE-ANTI SCALP ROLLER 1

4-31 64123-219 BOLT-HEX 3/8-16X6 1

4-32 64141-6 NUT, 5/16-18 4

4-33 55-FB16016 BEARING-160 FLANGE 1" 2

4-34 64018-15 BLT-CRG 5/16-18X1 4

90-0510 BOLT-5/16 X 1-1/4 4

(SN 1001 - 1118)

99-K62 BOLT-FLANGE 5/16 X 1-1/4 4

(SN 1578 - )

4-35 64-663 BUSHING-ADJUSTER LINK 5

4-36 64-799 WASHER-13/32 X 1-9/32 18

4-37 29-045 GREASE FITTING-1/4 45 1

4-38 64-662 BUSHING-ADJUSTER LINK 2

4-15 64163-16 WASHER-41/64X1, 3/8X12GA12

4-16 50-062 AXLE TUBE-CASTER WHL 2

4-17 64139-21 BLT-WLF 3/8-16X3/4 1

4-18 42-440.7 LINK-RIGHT LIFT 1

4-19 64123-16 BLT-HEX 3/8-16X1-1/4 3

4-20 64229-05 LOCKNUT, 1/2-13 NYLON 3

4-21 42-445.7 LINK-LEFT FRONT 1

4-22 42-443.7 LINK-HEIGHT ADJUSTMENT 1

4-23 64123-117 BOLT-HEX 1/2-13X1-1/2 1

4-24 90-0832 BOLT-1/2-13 X 4 2

4-25 64163-67 WASHER-.516X1X12GA 2

4-26 42-442 LINK-MIDDLE 1

4-27 62-724 FRAME-REAR ROLLER 1

(SN 1001 - 1577)

62-869.7 FRAME-REAR ROLLER 1

(SN 1578 - )

25

Page 28

FRAME PARTS 60"

ROTARY

FIGURE 5

MOWER

26

Page 29

ROTARY

FRAME PARTS 60"

MOWER

ITEM PART NO. DESCRIPTION QTY

5-1 64141-4 NUT-WLF 3/8-16 10

5-2 03-0610 CLEVIS PIN-3/8 X 1-1/4 1

5-3 02-PP0318 PRESTO PIN-3/32 X 2-5/16 1

5-4 29-010 GREASE FITTING-1/4 2

5-5 62-695 FRAME-TUBE 1

(SN 1001 - 1194)

62-726.7 FRAME-TUBE 1

(SN 1195 - )

5-6 64123-70 BOLT-HEX 3/8-16X1-1/2 3

5-7 53-060 HUB CAP-FOR MOWER 2

5-8 99-AC12NFLOCKNUT-CENTER 3/4 NF 2

5-9 64163-06 WASHER-.768/.756X1.25X14 12

5-10 55-Z9504AB BALL BEARING-3/4 ID 4

5-11 64-807 SPACER 2

(SN 1001 - 3246)

64-845 SHIELD-BEARING 2

(SN 3247 - )

5-12 4132783.7 CASTER, MOWER 2

5-13 90-0640 BOLT,3/8-16 X 5 2

5-14 53-104 WHEEL-10.25X3.25 CASTER 2

(SN 1001 - 6813)

55-G527 BRG-BALL F/53-104 WHL 2

55-107 BEARING-5/8 ID X 1-3/8 OD 2

OPT HD)

53-186 WHEEL-10.25X3.25 CASTER 2

(SN 6814 - )

55-112 BRG-ROLLER 5/8 ID X 1-3/8 1

53-187 RETAINER-FLANGED 2

5-15 64163-16 WASHER-41/64X1, 3/8X12GA12

5-16 50-062 AXLE TUBE-CASTER WHL 2

5-17 64-799 WASHER-13/32 X 1-9/32 18

5-18 42-428 LINK-RIGHT 1

(SN 1001 - 1194)

42-444.7 LINK-RIGHT 1

(SN 1195 - )

FIGURE 5

ITEM PART NO. DESCRIPTION QTY

5-23 64123-117 BOLT-HEX 1/2-13X1-1/2 1

5-24 90-0832 BOLT-1/2 X 4 2

5-25 64163-67 WASHER-.516X1X12GA 2

5-26 42-429 LINK-MID LEFT 1

(SN 1001 - 1194)

42-446.7 LINK-MID LIFT 1

(SN 1195 - )

5-27 62-697 FRAME-ROLLER 1

(SN 1001 - 1194)

62-728 FRAME-REAR ROLLER 1

(SN 1195 - 5456 )

62-870.7 FRAME-REAR ROLLER 1

(SN 5457 - )

5-28 50-067 ROLLER-REAR 1

(SN 1001 - 1194)

50-079.7 ROLLER-REAR 1

(SN 1195 - )

5-29 50-105 ROLLER-FRONT 1

85-B11 BEARING-3/4" WOOD RLR 2

5-30 50-074 AXLE-ANTI SCALP ROLLER 1

5-31 64123-219 BOLT-HEX 3/8-16X6 1

5-32 64141-6 NUT, 5/16-18 4

5-33 55-FB16016 BEARING-160 FLANGE 1" 2

5-34 64018-15 BLT-CRG 5/16-18X1 4

(SN 1001 - 2010)

64123-47 BLT-HEX 5/16-18X1-1/4 4

(SN 2011 - 5456)

99-K62 BOLT-FLANGE 5/16 X 1-1/4 4

(SN 5457 - )

99-K62 BOLT-FLANGE 5/16 X 1-1/4 4

(SN 1578 - )

5-35 64-663 BUSHING-ADJ LINK THIN 6

(SN 1195 - )

5-19 64123-16 BLT-HEX 3/8-16X1-1/4 3

5-20 64229-05 LOCKNUT, 1/2-13 NYLON 3

5-21 42-427 LINK-LEFT FRONT 1

(SN 1001 - 1194)

42-445.7 LINK-LEFT FRONT 1

(SN 1195 - )

5-22 42-430 LINK-HEIGHT ADJUST 1

(SN 1001 - 1194)

42-447.7 LINK-HEIGHT ADJUST 1

(SN 1195 - )

5-36 64123-87 BOLT-HEX 3/8-16X1-3/4 1

5-37 29-045 GREASE FITTING-1/4 45 1

5-38 64-662 BUSHING-ADJ LINK THICK 2

(SN 1195 - )

5-39 64139-21 BLT-WLF 3/8-16X3/4 1

27

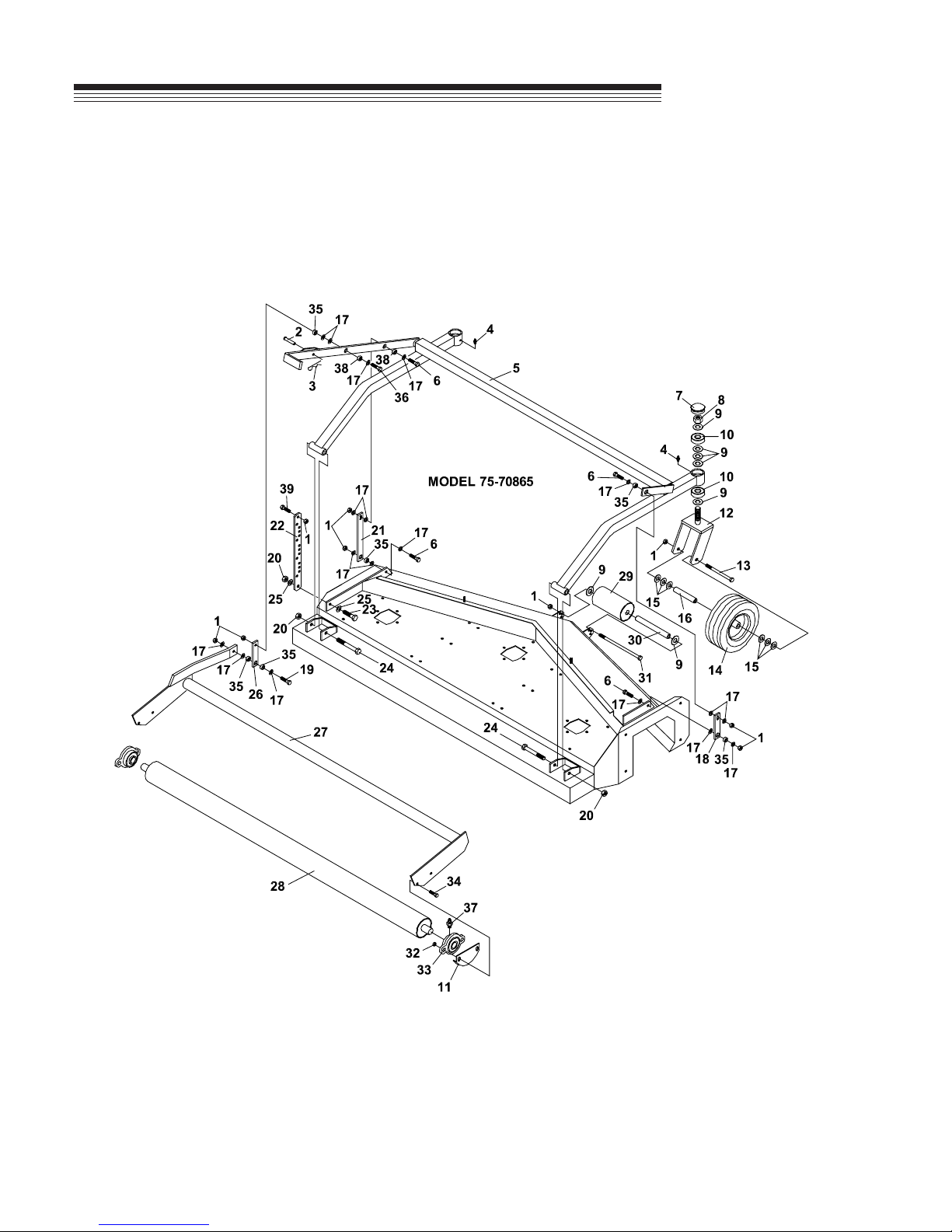

Page 30

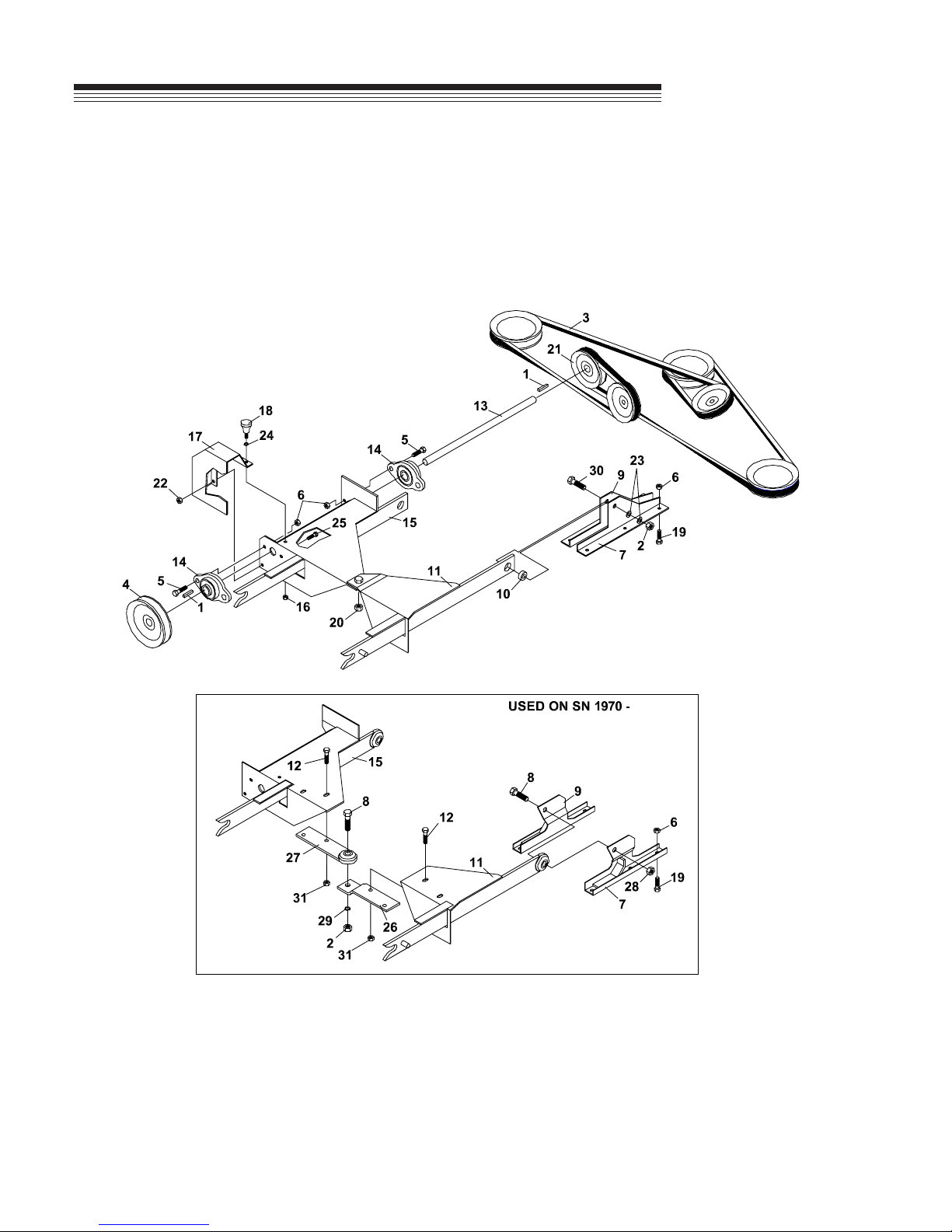

FRAME PARTS 72"

ROTARY

FIGURE 6

MOWER

28

Page 31

ROTARY

FRAME PARTS 72"

MOWER

ITEM PART NO. DESCRIPTION QTY

6-1 64141-4 NUT-WLF 3/8-16 10

6-2 03-0610 CLEVIS PIN-3/8 X 1-1/4 1

6-3 02-PP0318 PRESTO PIN-3/32 X 2-5/16 1

6-4 29-010 GREASE FITTING-1/4 2

6-5 62-731.7 FRAME-TUBE 1

6-6 99-K75 BOLT-HEX 3/8-16X1-1/2 4

6-7 53-060 HUB CAP-FOR MOWER 2

6-8 99-AC12NFLOCKNUT-CENTER 3/4 NF 2

6-9 64163-06 WASHER-.768/.756X1.25X14 12

6-10 55-Z9504AB BALL BEARING-3/4 ID 4

6-11 64-807.7 SPACER 2

(SN 1001 - 3246)

64-845.7 SHIELD-BEARING 2

(SN 3247 - )

6-12 4132783.7 CASTER, MOWER 2

6-13 90-0640 BLT-HEX 3/8-16X5 2

6-14 53-104 WHEEL-10.25 X 3.25 2

(SN 1001 - 2882)

55-G527 BEARING-BALL 2

55-107 BEARING-5/8 ID X 1-3/8 OD 2

(OPT HD)

53-186 WHEEL-10.25 X 3.25 2

(SN 2883 - )

55-112 BRG-ROLLER 5/8IDX1-3/8 1

53-187 RETAINER-FLANGED 2

FIGURE 6

ITEM PART NO. DESCRIPTION QTY

6-30 50-074 AXLE-ANTI SCALP ROLLER 1

6-31 64123-219 BOLT-HEX 3/8-16X6 1

6-32 64141-6 NUT, 5/16-18 4

6-33 55-FB16016 BEARING-160 FLANGE 1" 2

6-34 64018-15 BLT-CRG 5/16-18X1 4

(SN 1001 - 1285)

64123-47 BLT-HEX 5/16-18X1-1/4 4

(SN 1286 - 2301)

99-K62 BOLT-FLANGE 5/16 X 1-1/4 4

(SN 2302 - )

6-35 64-663 BUSHING-ADJ LINK THIN 6

6-36 64123-87 BOLT-HEX 3/8-16X1-3/4 1

6-37 29-045 GREASE FITTING-1/4 45 1

6-38 64-662 BUSHING-ADJ LINK THICK 2

(SN 1195 - )

6-39 64139-21 BLT-WLF 3/8-16X3/4 1

6-15 64163-16 WASHER-41/64X1, 3/8X12GA12

6-16 50-062 AXLE TUBE-CASTER WHL 2

6-17 64-799 WASHER-13/32 X 1-9/32 18

6-18 42-444.7 LINK-MIDDLE RIGHT 1

6-19 64123-87 BOLT-HEX 3/8-16X1-3/4 1

6-20 64229-05 LOCKNUT, 1/2-13 NYLON 3

6-21 42-449.7 LINK-HEIGHT ADJT FRT LFT 1

6-22 42-452.7 LINK-HEIGHT SELECTOR 1

6-23 64123-117 BOLT-HEX 1/2-13X1-1/2 1

6-24 90-0832 BOLT-1/2 X 4 2

6-25 64163-67 WASHER-.516X1X12GA 2

6-26 42-451.7 LINK-MID LIFT 1

6-27 62-732 FRAME-ROLLER 1

(SN 1001 - 2301)

62-871.7 FRAME-REAR ROLLER 1

(SN 2302 - )

6-28 50-080.7 ROLLER-REAR 1

6-29 50-105 ROLLER-FRONT 1

85-B11 BEARING-3/4" WOOD RLR 2

29

Page 32

HITCH & DRIVE PARTS

ROTARY

FIGURE 7

MOWER

30

Page 33

ROTARY

HITCH & DRIVE PARTS

MOWER

ITEM PART NO. DESCRIPTION QTY

7-1 64164-11 KEY-3/16X3/16X1-1/4 SQ 2

7-2 64229-05 LOCKNUT, 1/2-13 NYLON 3

64141-13 NUT WLF 1/2-13 1

7-3 81-A128 BELT-48" 1

81-A158 BELT-60" 1

81-A180 BELT-72" 1

7-4 83-BK5012 PULLEY-5" 3/4" BORE 1

7-5 64139-24 BLT-WLF 3/8-16 X 1 4

7-6 64141-4 NUT-WLF 3/8-16 16

7-7 64-660.7 ANCHOR-LFT ARM RT 2

(USED ON 48" SN 1001 - 1493)

64-934.7 ANCHOR-LFT ARM RT 2

(USED ON 48" SN 1494 - )

64-646.7 ANCHOR-LFT ARM RT 2

(USED ON 60" SN 1001 - 4727)

64-936.7 ANCHOR-LFT ARM RT 2

(USED ON 60" SN 4728 - )

64-668.7 ANCHOR-LFT ARM RT 2

(USED ON 72" SN 1001 - 1969)

64-938.7 ANCHOR-LFT ARM RT 2

(USED ON 72" SN 1970 - )

FIGURE 7

ITEM PART NO. DESCRIPTION QTY

7-18 64139-08 BOLT-5/16-18X3/4 WLF 2

47-077 KNOB-SM CLMPNG W/STUD 1

7-19 64139-21 BLT-WLF 3/8-16X3/4 12

7-20 64229-05 LOCKNUT, 1/2-13 NYLON 1

7-21 83-BK4012 PULLEY-4" 3/4" BORE 1

(USED ON 72" ONLY)

83-BK5012 PULLEY-5" 3/4" BORE 1

(USED ON 60" & 72" MODELS ONLY)

7-22 64229-02 LOCKNUT-NYLON 5/16-18 1

7-23 64163-67 WASHER-.516X1X12 2

7-24 99-G06 WASHER-1/4 1

7-25 64123-54 BOLT, 5/16-18X3/4 HEX 1

7-26 64-933.7 LIFT ARM-TOP LINK 1

7-27 64-932.7 LIFT ARM-LOWER LINK 1

7-28 64141-13 NUT WLF 1/2-13 1

7-29 64006-05 LOCKWSHR-1/2 1

7-30 64123-125 BOLT-HEX 1/2-13X2-3/4 1

7-31 64268-03 NUT-FL NYLON LOCK 3/8-16 4

* 81-A040 BELT 1

* 81-B041 BELT 1

7-8 99-K82 BOLT, FLANGE 1/2-13 X 2 1

7-9 64-661.7 ANCHOR-LFT ARM LFT 2

(USED ON 48" SN 1001 - 1493)

64-935.7 ANCHOR-LFT ARM LFT 2

(USED ON 48" SN 1494 - )

64-645.7 ANCHOR-LFT ARM LFT 2

(USED ON 60" SN 1001 - 4727)

64-937.7 ANCHOR-LFT ARM LFT 2

(USED ON 60" SN 4728 - )

64-669.7 ANCHOR-LFT ARM LFT 2

(USED ON 72" SN 1001 - 1969)

64-939.7 ANCHOR-LFT ARM LFT 2

(USED ON 72" SN 1970 - )

7-10 85-SC08 SET COLLAR-1/2" 2

7-11 62-698.7 HITCH ARM-RIGHT 1

62-858.7 HITCH ARM-RIGHT 1

7-12 64139-24 BLT-WLF 3/8-16 X 1 4

7-13 80-237 SHAFT-MOWER DRIVE 1

7-14 55-FB23012 BRG-2-BOLT FLANGE 3/4 2

7-15 62-699.7 HITCH ARM-LEFT 1

62-857.7 HITCH ARM-LEFT 1

7-16 64141-6 NUT, 5/16-18 2

7-17 64-611.7 SHIELD-DRIVE PULLEY 1

* NOT ILLUSTRATED

31

Page 34

SPINDLE PARTS

ROTARY

FIGURE 8

MOWER

32

Page 35

ROTARY

SPINDLE PARTS

MOWER

ITEM PART NO. DESCRIPTION QTY

8-1 87-235 SHAFT-SPINDLE 1

8-2 87-209843 SEAL 2

8-3 87-244643 BEARING CONE 2

8-4 87-244610 BEARING CUP 2

8-5 87-240001-5 CASTING-W/O BRTHR HLE 1

87-240001-6 CASTING-W/BRTHR HLE 1

8-6 87-240101-01 BLADE ADAPTER W/CUP 1

8-7 87-203293 RETAINING RING 2

8-8 87-203815 BOLT-3/8 X 1-1/2 SHCS 4

FIGURE 8

ITEM PART NO. DESCRIPTION QTY

33

Page 36

FLIP-UP DECKS

ROTARY

FIGURE 9

MOWER

34

Page 37

ROTARY

FLIP-UP DECKS

MOWER

ITEM PART NO. DESCRIPTION QTY

9-1 REF MAIN DECK WELDMENT 1

9-2 40-329.7 IDLER ARM-(48" & 60") 1

40-330.7 IDLER ARM-(72") 1

9-3 64141-2 NUT-WLF 1/4-20 10

9-4 6107645 CHAIN, IDLER ARM STOP 1

9-5 64123-80 BLT-HEX 1/4-20X1-1/4 1

9-6 41-092 SPRING-(60") 1

41-052 SPRING-(48") 1

41-051 SPRING-(72") 1

9-7 64-966 PIVOT STOP PIN 1

9-8 64025-09 HEX, NUT 1/2-13 2

9-9 64006-05 LOCKWSHR-HELICAL 1/2 2

9-10 F1002 NUT, JAM 1/4-20 1

9-11 83-012 IDLER-"V" 1/2" ID X 4-1/2" OD 2

9-12 90-0814 BOLT-1/2 X 1-3/4 1

9-13 64123-50 BOLT-HEX 3/8-16X1 2

9-14 64-799 WASHER-13/32IDX1-9/32OD 2

9-15 85-B29 BUSHING-.406X.740X.258 1

9-16 83-034 IDLER-"V" 3/8" ID X 5" OD 1

(USED ON 72" ONLY)

FIGURE 9

ITEM PART NO. DESCRIPTION QTY

9-31 64163-67 WASHER-.516X1X12 4

9-32 64123-125 BOLT-HEX 1/2-13X2-3/4 1

9-33 64123-87 BOLT-HEX 3/8-16X1-3/4 1

9-34 64139-21 BLT-WLF 3/8-16X3/4 2

(USED ON 72" SN 2592 - )

9-17 64163-61 WSHR .81X.406X16GA 3

(USED ON 72" ONLY)

9-18 64-967.7 FLIP-UP LATCH 1

9-19 41-013 SPRING-EXT. 0.50 X 1.938 1

9-20 64-965.7 FRONT LIFT ARM STOP 1

9-21 64229-03 LOCKNUT-NYLON 3/8-16 1

9-22 64139-04 BOLT-WLF 1/4-20X3/4 8

9-23 64-968.7 FLIP-UP DECK BRACE-LFT 1

(USED ON 60" & 72" ONLY)

64-970.7 FLIP-UP DECK BRACE-LFT 1

(USED ON 48" ONLY)

9-24 64-969.7 FLIP-UP DECK BRACE-RT 1

(USED ON 60" & 72" ONLY)

64-971.7 FLIP-UP DECK BRACE-RT 1

(USED ON 48" ONLY)

9-25 64168-1 COTTER-HAIRPIN.120X2-3/8 1

9-26 62-858.7 ARM, RIGHT HITCH 1

9-27 64-998.7 HOLD DOWN-RLR FRAME 1

(USED ON 72" SN 2592 - )

9-28 64141-4 NUT-WLF 3/8-16 2

9-29 64-939.7 ANCHOR, LIFT ARM LEFT 2

64-938.7 ANCHOR, LIFT ARM RIGHT 2

9-30 64229-05 LOCKNUT, 1/2-13 1

35

Page 38

Equipment from Jacobsen, a Textron company,

is built to exacting standards ensured by

ISO 9001 and ISO 14001 registration at all our

manufacturing locations.

A worldwide dealer network and factory-trained

technicians backed by Textron Parts Xpress

provide reliable, high-quality product support.

BOB-CAT BROUWER BUNTON CUSHMAN RYAN STEINER

Loading...

Loading...