Page 1

CHIPPER / SHREDDER

Model CS312

Starting Serial No. 1001

CHIPPER / SHREDDER BLOWER

Model CS313

Starting Serial No. 1001

Owner/Operator's Manual

& Illustrated Parts List

CAUTION

Avoid injuries. Read and understand Operator’s manual

before operating tractor or equipment.

It contains instructions for safe operation.

Form # 09-282C

Page 2

CAUTION

• READ AND UNDERSTAND OPERATORS MANUAL

BEFORE OPERATING OR SERVICING.

• OBEY ALL SAFETY INSTRUCTIONS. FAILURE TO DO SO

MAY RESULT IN INJURY TO YOU OR OTHERS.

• BE SURE MACHINE IS IN SAFE OPERATING CONDITION

BEFORE USE.

• INSPECT MACHINE DAILY. REPLACE ALL WORN OR

DAMAGED PARTS.

• KEEP ALL GUARDS AND SHIELDS IN PLACE.

• CHECK OPERATION OF ALL SAFETY INTERLOCK

SWITCHES DAILY.

• DO NOT OVERRIDE INTERLOCK SYSTEM, IT IS FOR YOUR

PROTECTION.

• DO NOT ALLOW MINORS OR THE INEXPERIENCED TO

OPERATE MACHINE.

• KEEP PEOPLE AND PETS A SAFE DISTANCE AWAY FROM

MACHINE USING POWER DRIVEN ATTACHMENTS.

INJURY COULD RESULT FROM FLYING DEBRIS.

Date of Purchase: Month ________________Day____________________Year _______________

Dealer Name _________________________Phone__________________

Serial Number ________________________

Model Number ________________________

ALWAYS GIVE MODEL AND SERIAL NUMBER WHEN ORDERING SERVICE PARTS

STEINER TURF EQUIPMENT, INC.

289 N. Kurzen Rd., P.O. Box 504

Dalton, Ohio 44618

Telephone: (330) 828-0200

FAX: (330) 828-1008

Page 3

TABLE OF CONTENTS

INTRODUCTION SECTION 1 page

Description ..........................................1-1

Specifications .........................................1-2

SAFETY SECTION 2

General Safety.........................................2-1

Safety Operating Instructions .................................2-2

INSTALLATION SECTION 3

Mounting Instructions .....................................3-1

OPERATION SECTION 4

Operating Precautions ....................................4-1

Operating Instructions ....................................4-1

Shredding, Chipping & Stopping Instructions ........................4-2

SERVICE SECTION 5

Service Schedule .......................................5-1

Adjustments ..........................................5-2

Trouble Shooting Chart ....................................5-4

PARTS SECTION 6

Parts List and Illustrations Index ...............................6-1

ASSEMBLY SECTION 7

Assembly Instructions.....................................7-1

WARRANTY ......................................last page

3/96 1 - 0 09-282C

Page 4

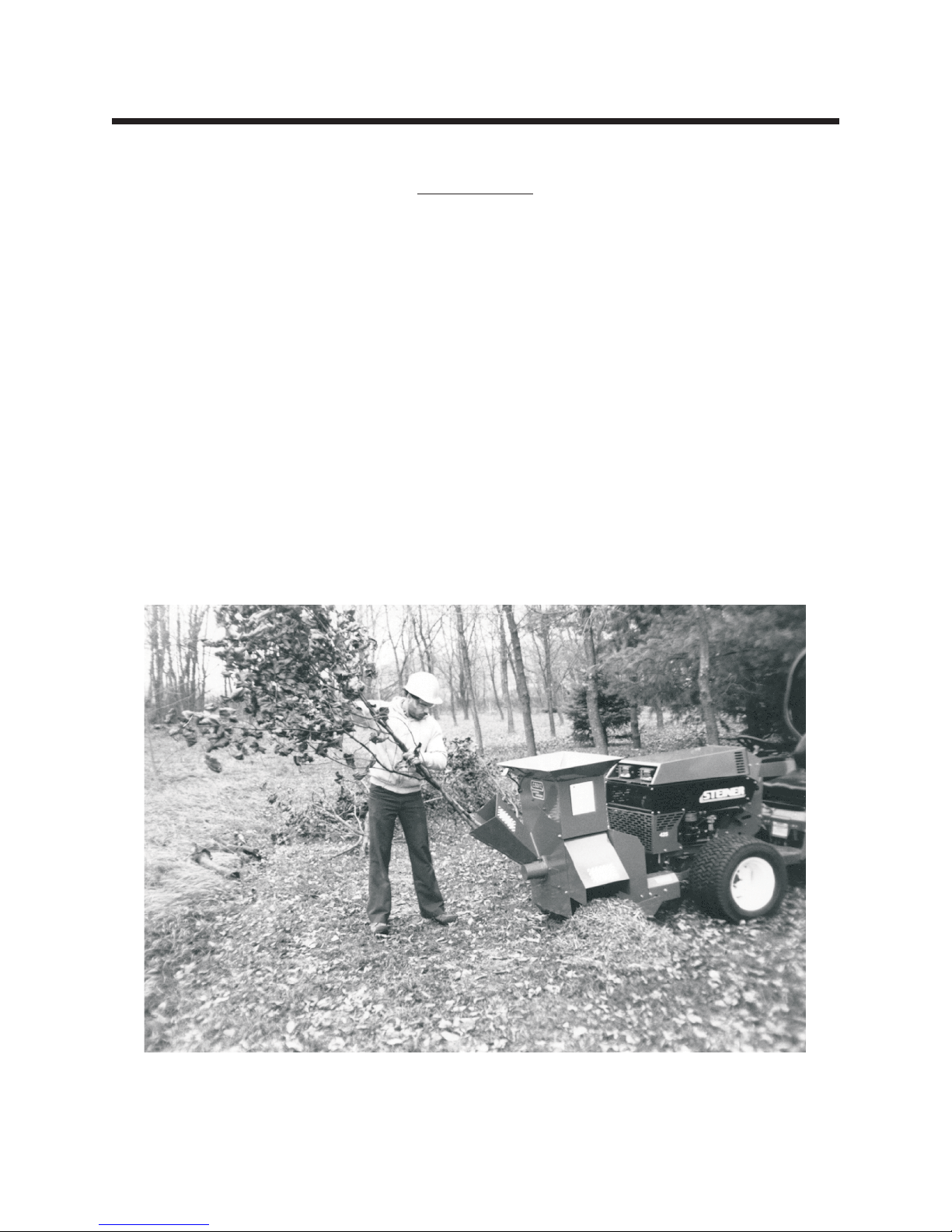

INTRODUCTION section 1

Description

The Steiner Chipper/Shredder is designed to grind, shred, and chip a variety of materials into a use

able processed material to enrich, beautify and landscape. Mounted on the front of the Steiner 4-wheel

drive articulated frame tractor enables the chipper/shredder to be used in a variety of locations.

Small materials such as leaves, yard and garden debris (cornstalks, plants, prunings, vines, etc.) can

easily be processed through the shredder inlet. Sticks and branches should be limited to 1-1/2 inches in di

ameter and no longer than 24 inches to avoid excess whipping and wrapping. The processed material can

be placed in a compost pile or spread on the ground as mulch, giving a professionally landscaped look.

The chipper inlet can chip branches up to 4 inches in diameter. Several small branches can be

grouped and fed into the chute together. The chipper can reduce a pile of branches and brush into useful

and attractive decorative landscape chips.

-

-

09-282C 1 - 1 3/96

Page 5

INTRODUCTION section 1

Specification

Overall width ________________35-5/8"

Overall height _______________44-1/2"

Overall length _______________53-1/4"

Chipper Knives _______________4hardened

Shredder Sections _____________72hardened

Rotor Diameter _______________18"

Rotor Width ________________12"

Rotor Speed (maximum) ___________1550 RPM

Shredder Throat Opening __________9-1/2" x 11"

Maximum material size for Shredder ______1-1/2" diameter x 24" long

Maximum material size for Chipper ______4"diameter

Application ________________Steiner 420, 425, 525

Power Units only

Weight __________________430lbs.

Specifications are subject to change without notice.

3/96 1 - 2 09-282C

Page 6

SAFETY section 2

ATTENTION: This symbol

identifies potential health

and safety hazards. It

marks safety precautions.

ATTENTION: Your safety

and the safety of others is

involved.

BE ALERT!

SIGNAL WORD DEFINITIONS

DANGER- Indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury. This signal word is limited to the most extreme cases.

WARNING- Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION- Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury and/or property damage. It may also be used to alert against unsafe

practices.

GENERAL SAFETY

1. Read and understand the owner's manual,

before attempting to operate this machine.

4. Do not leave equipment unattended. STOP

the engine and remove the key.

2. Operate all controls from the operator's

seat. NO RIDERS.

3. Keep all shields in place and safety switches

adjusted properly.

OPERATING SAFETY

1. STOP ENGINE to install drive belt.

2. DO NOT attempt to work on unit or any

attachments with the engine running. STOP

ENGINE!

3. Before leaving the tractor seat:

1. Disengage PTO.

2. Set PARKING brake.

3. Stop Engine.

5. Do not allow minors or the inexperienced to

operate this machine.

6. Keep people and pets a safe distance away

from machine using power driven attachments. Injury

could result from flying debris.

CAUTION!

ALWAYS WEAR SAFETY

GLASSES WHEN OPERATING

CHIPPER/SHREDDER.

DANGER!

DO NOT OPERATE WITH

PERSONS IN THE AREA.

CHIPPER/SHREDDER MAY

PROPEL OBJECTS CAUSING

POSSIBLE INJURY OR DEATH.

09-282C 2 - 1 3/96

Page 7

SAFETY section 2

Safety Operating Instructions

1. Wear safety glasses at all times while operating the machine.

BE ALERT!

2. The operator should also wear heavy boots, gloves and other ade

quate clothing to protect himself from branches and other sharp or

harmful objects. Avoid wearing loose-fitting clothing.

3. Keep proper balance and footing at all times. Do not overreach.

4. Keep face and body away from the feed opening. Do not allow

hands, feet, or clothing inside the feeding chamber or discharge chute.

5. Move machine to a clear level area outdoors before starting. Do not

operate machine on a paved, concrete or hard gravel surface. Discharged material may rebound.

6. Emergency stop switch must have cable plugged into outlet on

power unit. Do not operate machine without this emergency stop

switch connected.

7. When feeding shreddable material into the machine, be extremely

careful that pieces of metal, rocks, bottles, cans or other foreign objects

are not fed into the feeding chamber.

-

8. If the machine becomes clogged, disengage PTO, stop engine and

allow machine to come to a complete stop before clearing debris.

9. The chipper/shredder rotor may continue to rotate even with the en

gine stopped. Do not attempt any repairs or adjustments until the entire

machine has come to a complete stop. Never operate this machine

without the discharge screen in place.

3/96 2 - 2 09-282C

-

Page 8

INSTALLATION Section 3

Mounting Instructions

The chipper/shredder should be used only on the Steiner 420, 425 and 525 power units equipped

with the required chipper/shredder electrical outlet. (This electrical outlet is shipped with each chip

per/shredder. See Section 7 for electrical outlet installation.)

NOTE: The PTO drive line is subject to shock loads while using the chipper/shredder. Therefore, the

chipper/shredder is not recommended for use on the Steiner 220 power unit. Damage to the hydrostatic

pump may result.

To mount the Chipper/Shredder do the following steps:

1. Open quick hitch latches. Drive tractor into position, aligning the quick hitch. Be sure that both

•

latches are fully engaged and locked.

2. Stop engine! Do not attempt to install drive belt with engine running.

•

• 3. Release double idler assembly to facilitate easy installation of the B-41 drive belt. Put belt over

drive pulley and engage or adjust double idler assembly. (See Power Unit Operator's Manual for

PTO belt tension adjustment.)

-

• 4. Plug emergency stop cable into chipper/shredder electrical outlet on tractor. Be certain the

Emergency Stop Switch is pulled out for normal operation. Do not operate the Chipper/Shredder

without this cable plugged in.

• 5. Remove clip pin and rotate stand to highest position. Reinsert clip pin.

•

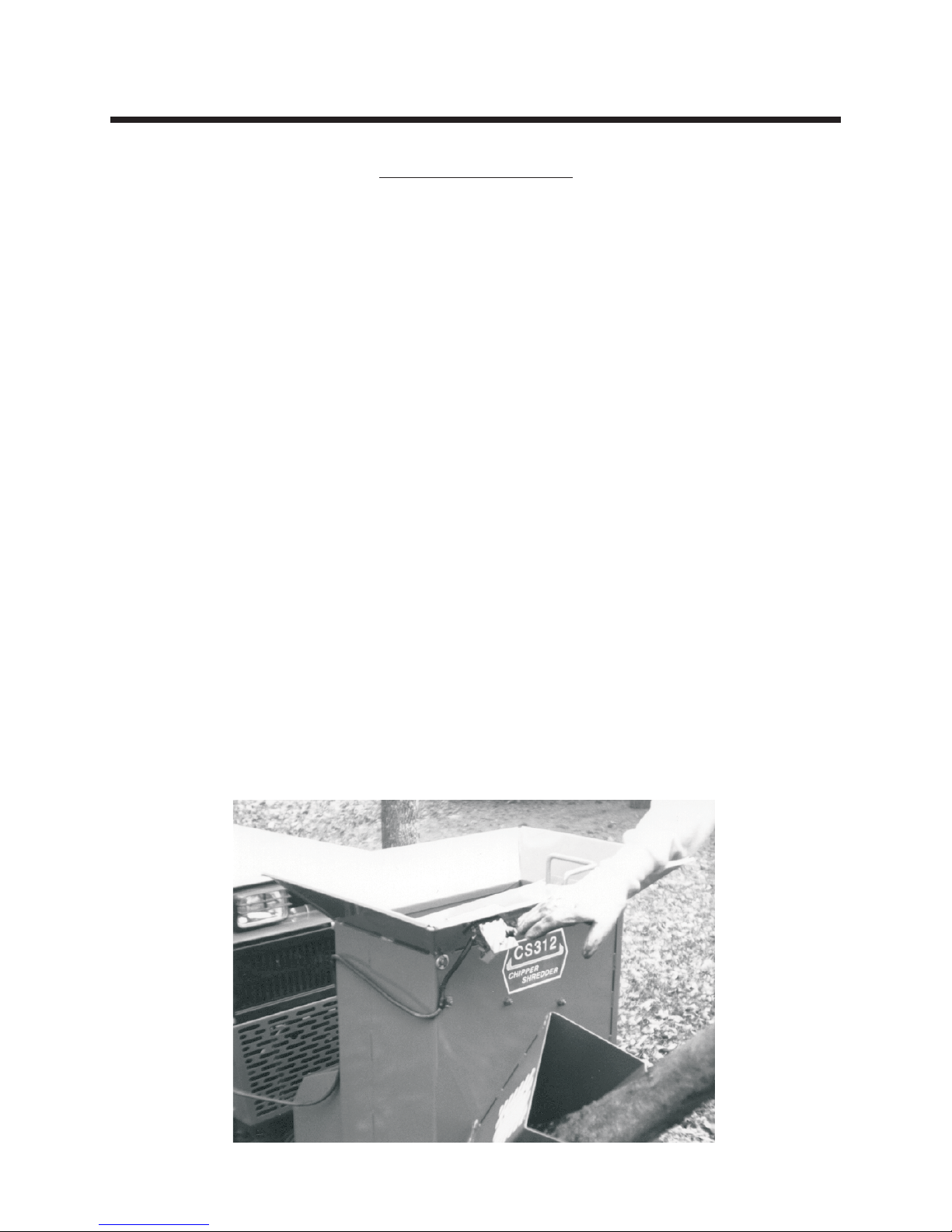

6. A rear weight bar with 4 weights is recommended to provide additional stability in transport.

•

7. Start engine, engage PTO and check operation of Emergency Stop Switch. (See photo below)

09-282C 3 - 1 3/96

Page 9

OPERATION Section 4

Operating Precautions

This chipper/shredder is designed and tested to offer reasonably safe service, however, failure to

operate it in accordance with the following instructions may result in personal injury or death.

Operating Instructions

1. Mount the chipper/shredder according to instructions in Section 3.1.

A rear weight bar with 4 weights is recommended.

2. Wear safety glasses at all times while operating the machine. Also wear heavy boots, gloves, and

adequate clothing to protect from branches and other sharp or harmful objects. Avoid wearing

loose-fitting clothing.

3. Do not operate the chipper/shredder in the vicinity of bystanders. Do not allow minors or the

inexperienced to operate this machine.

4. By using the front lift to transport the machine, move it to a clear level area outdoors. Set the parking brake

on the tractor. Do not operate the chipper/shredder on a paved, concrete or hard gravel surface.

Discharged material may rebound. Lower machine before operating. Do not operate in transport

position.

5. Before starting the machine, make sure the cutting chamber is empty.

6. When feeding shreddable material into the machine, be extremely careful that pieces of metal, rocks,

bottles, cans or other foreign objects are not fed into the feeding chamber.

7. If the cutting mechanism strikes any foreign object, or if the machine should start making an unusual

noise or vibration or become clogged, immediately push the emergency stop switch, stop engine and

allow the machine to come to a complete stop. Take the following steps:

a. Inspect for damage.

b. Clear the debris.

c. Replace or repair any damaged parts.

d. Check for and tighten any loose parts.

8. Keep face and body away from the feed opening. Do not allow hands, feet or clothing inside the feeding

chamber or discharge chute. Do not overreach. Keep proper balance and footing at all times.

3/96 4 - 1 09-282C

Page 10

OPERATION Section 4.2

Shredding Instructions

1. Place material to be shredded (leaves, garden

debris, sticks and branches up to 1-1/2"

diameter and 24" long, etc.) into the hopper.

2. Feed material evenly into the shredder so that the

tractor does not lug down or the shredder

become clogged. If necessary, use the hopper

lid to push the material through the inlet guards.

If the machine becomes plugged it may be

necessary to remove the discharge shield and

screen to clean rotor. Branches or items that

plug or cause the machine to stall should be fed

slowly and carefully.

3. If equipped with a blower, it is recommended to

alternate between dry and green material to

avoid blower plugging.

Chipping Instructions

1. Select limbs that are up to 4 inches in diameter.

Trim side branches that do not fit into the

chipper chute. Small diameter branches can be

held together in a bundle and fed in

simultaneously.

2. Place limb, butt end first, into the chipper chute

until it contacts the chipper blades. The actual

feed rate of the limb into the chipper will depend

on the type of material fed, and sharpness of the

cutting blades. Alternately insert and retract the

limb or insert continuously at a rate that will not

stall the tractor. Rotating the branch as it is fed

will improve cutting action. The chipping knives

will dull with use and require periodic

sharpening. Refer to Service Section 5.2 for

instructions to sharpen chipper knives.

Stopping Instructions

Do not leave machine unattended, or attempt any

inspection or service unless the PTO is disengaged

and tractor engine is shut off. Allow machine to

come to a complete stop.

To stop machine proceed as follows:

1. Move tractor throttle to slow position.

2. Disengage PTO and shut off tractor engine.

3. Allow machine to come to a complete stop.

09-282C 4 - 2 3/96

The rotor is heavy and has inertia that will make the

rotor continue to turn for some time after the tractor

has been shut off. The stopping time can be short

ened by inserting a branch in the chipper chute so

that it contacts the knives and slows the rotor to a

complete stop.

-

Page 11

SERVICE section 5

SERVICE SCHEDULE

Daily:

Check for any signs of loose bolts and tighten as needed.

•

Check chipper knives and sharpen or adjust as needed. (See Page 5-2)

•

25 Hour:

In addition to daily service, remove belt shields and check drive belts for wear or cracking. Replace if

•

worn. (See Section 5.3)

Grease rotor bearings and drive shaft bearings.

•

100 Hour or Annual:

• Remove discharge shield and discharge screen and check rotor. Inspect chipper knives and shredder

sections for wear. Replace worn parts for efficient operation. (See Page 5-2 & 5-3)

Storage:

• Thoroughly clean the machine and store in a dry place to prevent rusting of rotor parts.

3/96 5 - 1 09-282C

Page 12

SERVICE section 5

MAINTENANCE AND ADJUSTMENTS

ADJUSTING KNIFE CLEARANCE

Before inspecting or servicing any part of the

machine, disengage PTO and make sure all

moving parts have come to a complete stop.

The chipping knives and shredding sections

are sharp! Use care when working on machine

to avoid injury.

SHARPENING CHIPPER KNIVES

It is recommended that the chipper knives are

sharpened every 5 to 15 hours of chipper

operation, depending on the type of wood fed

into the chipper.

To remove the chipper knives for sharpening, first

remove the discharge shield and the discharge

screen. Remove the two 5/16 inch retaining bolts

and pull the screen outward. Remove the knife

access cover. Rotate the rotor so that the bolts

holding the chipper knife are accessible. Remove

the two bolts holding the knife and the knife itself.

Repeat for all 4 knives.

Grind the knife at 45 degrees.(See Figure A) The

knives can be ground on a bench grinder or by a

professional. Be careful when grinding so that the

knife material does not get too hot and change

color, this will remove the knife's special heat

treated properties. Use short grinding times and

cool with water. Try to remove an equal amount

off each knife to maintain balance. Replace the

chipper knives and tighten bolts to 20 foot

pounds. Replace the discharge screen.

The chipper knife should clear the chipping block

by 1/8 inch.(See Figure B) To adjust the knife

clearance, proceed as follows:

A. Remove the belt shield, discharge shield, and

the discharge screen. Remove the shaft cover

on the front side.

B. Loosen the two set screws holding the set collar

at the front rotor bearing. Loosen the set

screws holding the lock collars on the front and

rear rotor bearings.

C. Use a punch and hammer and tap the collars in

a direction opposite shaft rotation so they can

rotate freely.

D. Using a soft face mallet, tap the end of the rotor

shaft to obtain 1/8" clearance between the

chipper knife and the chipper block.(See

Figure B) Knife clearance can be checked at

the chipper inlet chute. Rotate the rotor and

check the clearance on all chipper knives.

E. When the clearance has been set, tighten the

eccentric lock collars on the bearings by

rotating them in the direction of shaft rotation.

Using a punch and hammer, “set” them with a

positive hammer tap. Tighten the lock collar set

screws. Slide the set collar against the front

bearing lock collar and tighten the two set

screws.

F. Check the double drive belts for proper

alignment. It may be necessary to move the

pulley on the rotor shaft an equal distance the

rotor was moved.

G. Make sure all set screws are tight and replace

discharge screen and all shields which were

removed.

Figure A

09-282C 5 - 2 3/96

Figure B

Page 13

SERVICE section 5

MAINTENANCE AND ADJUSTMENTS

Before inspecting or servicing any part of the

machine, disengage PTO and make sure all

moving parts have come to a complete stop.

The chipping knives and shredding sections are

sharp! Use care when working on machine to

avoid injury.

SHREDDER SECTIONS

E. See also Cleaning Plugged Blower.

The serrated self sharpening shredder sections

are designed to offer long life and can be

reversed if they become dull. To remove or

replace the sections, proceed as follows:

A. Remove discharge shield, discharge screen and

knife access cover.

B. Work with one section shaft at a time. Remove

the #10-24 bolt from the section shaft. The shaft

can be removed through the access hole.

C. Remove sections and section spacers. Be

careful to keep track of the order the spacers

were installed on the shafts so they can be

returned to the original locations. If the spacers

are not installed properly, the rotor will be out of

balance and also will not have proper

shredding action.

D. Reverse or replace sections and reassemble

into the rotor. Reinstall #10-24 bolt and locknut

through spacer and torque to 36 inch pounds.

E. Complete service of all 6 shafts and replace the

knife access cover, discharge screen and

discharge shield.

BELT REPLACEMENT

Check the condition of the double drive belts

every 30 hours of operation or annually,

whichever occurs first. Only replace belts in sets.

To replace belts proceed as follows:

A. Disengage PTO and stop engine.

B. Remove belt shields.

C. Remove belt idler spring and remove belts from

pulleys.

D. Remove 4 bolts attaching hitch assembly to

main frame and completely remove belts.

E. Place new belts around the hitch frame and

attach the hitch assembly to the main frame.

F. Position belts on the pulleys and attach the idler

arm spring.

G. Check the attachment drive belt and replace if

needed. Replace belt shields.

CLEANING PLUGGED ROTOR

If too large of material or too much material is fed

into the chipper/shredder, it may become

plugged. To clear plugged rotor, proceed as

follows:

A. Disengage PTO and stop engine.

B. Remove discharge shield and discharge screen.

C. Clean debris out of the shredding rotor. Turn the

rotor by hand to be sure it is free to rotate.

D. Replace discharge screen and discharge shield.

3/96 5 - 3 09-282C

CLEANING PLUGGED BLOWER

If too much green material is fed into the

chipper/shredder the blower may become

plugged. To clear the blower, proceed as follows:

A. Disengage PTO and stop engine.

B. Remove blower drive belt guard, and remove

drive belt.

C. Remove the Blower discharge tube.

D. Tilt the blower away from the main frame and

clean debris out of blower housing.

Page 14

SERVICE section 5

TROUBLE SHOOTING

SYMPTOM: Rotor stops or engine stalls.

Possible Cause Remedy

1. Obstructed discharge.

2. Plugged rotor.

SYMPTOM: Hard to feed chipper or excessive power needed to chip.

Possible Cause Remedy

1. Obstructed discharge.

2. Dull chipper knives.

3. Improper knife clearance.

SYMPTOM: Shredder requires excessive power or stalls

Possible Cause Remedy

1. Obstructed discharge.

2. Plugged rotor.

3. Green material will not discharge.

SYMPTOM: Drive belts squealing or smoking

Possible Cause Remedy

1. Use branch or similar object to clear discharge.

2. Clear rotor. (See Section 5.3)

1. Use branch or similar object to clear discharge.

2. Sharpen knives. (See Section 5.2)

3. Adjust knife clearance. (See Section 5.2)

1. Use branch or similar object to clear discharge.

2. Clear rotor, feed material into hopper more

slowly. (See Section 5.3)

3. Alternately feed dry material, or allow material to

dry before shredding.

1. Plugged rotor.

2. Loose or worn belts.

SYMPTOM: PTO will not engage or engine stops when PTO is engaged

Possible Cause Remedy

1. Emergency stop switch is “IN”. 1. Pull emergency stop switch “OUT” for normal

09-282C 5 - 4 3/96

1. Clear rotor. (See Section 5.3)

2. Adjust belt tension or replace belts if needed.

operation.

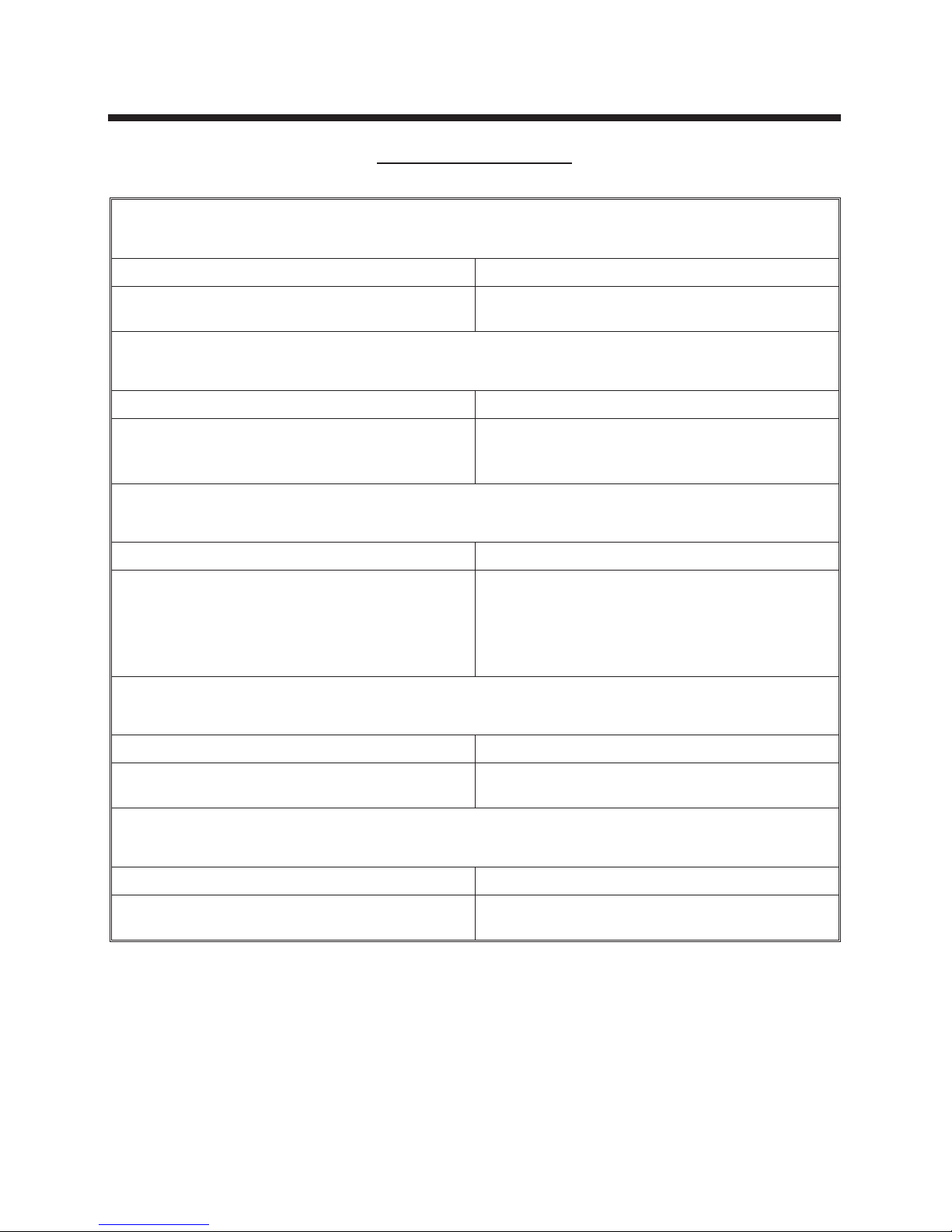

Page 15

PARTS section 6

PARTS INDEX

GROUP FIGURE PAGE

Hitch & Drive Parts ............Figure 1 ......................6-2

Frame Parts ...............Figure 2 ......................6-4

Emergency Stop Switch Parts ......Figure 3 ......................6-6

Chipper/Shredder Blower Parts .....Figure 4 ......................6-8

ALWAYS GIVE MODEL AND SERIAL NUMBER WHEN ORDERING SERVICE PARTS.

Model CS312 begins with Serial Number 1001

Model CS313 begins with Serial Number 1001

3/96 6 - 1 09-282C

Page 16

PARTS section 6

Hitch and Drive Parts

Figure 1

rev 8/98 6 - 2 09-282C

Page 17

PARTS section 6

Parts List for Figure 1

Ref Part no. Description Quantity

1 83-2TB124 Pulley, 2-groove 12-3/4 diameter 1

2 81-B054 Belt, B54 2

3 83-Q124 Bushing, Q1 x 1-1/2 1

4 85-K0612 Key, 3/8 x 1-1/2 1

5 99-K26 Flange Bolt, 1/4 x 3/4 5

6 00-093 Decal, Warning Read Owner's Manual 1

7 60-576 Shield, Belt 1

8 92-08 Nut, 1/2 5

9 96-08 Lock Washer, 1/2 5

10 90-0810 Bolt, 1/2 x 1-1/4 4

11 02-PP0524 Presto Pin, 5/32 x 2-15/16 1

12 99-F36 Bolt, Special 1/2 x 1-1/2 1

13 62-757 Hitch Frame 1

14 99-E20 Flange Nut, 1/4 1

15 90-0822 Bolt, 1/2 X 2-3/4 1

16 80-244 Drive Shaft 1

17 55-FB23016 Flange Bearing, 2 Bolt, 1" 2

18 90-0610 Bolt, 3/8 X 1-1/4 4

19 83-BK52H Pulley 1

20 83-H16 Bushing, 1" 2

21 85-K0410 Key, 1/4 X 1-1/4 2

22 62-758 Support Stand 1

23 99-E12 Flange Nut, 5/16 5

24 99-K19 Bolt, Flange 5/16 x 3/4 1

25 83-028 Flat Idler 1

26 99-K02 Bolt, Flange 5/16 X 1 4

27 96-06 Lock Washer, 3/8 6

28 92-06 Nut, 3/8 7

29 83-2BK50H Pulley 1

30 60-575 Shield, Drive Pulley 1

31 00-025 Decal, Warning Keep Hands Away 1

32 41-010 Spring, 5" 1

33 90-0612 Bolt, 3/8 X 1-1/2 1

34 99-A06 Locknut, 3/8 1

35 95-08 Flat Washer, 1/2 SAE 2

36 99-A08 Locknut, 1/2 Stover 1

37 40-300 Idler Arm 1

38 95-06 Flat Washer, 3/8 SAE 2 or A/R

39 90-0622 Bolt, 3/8 x 2-3/4 1

* 81-B041 Drive Belt, B41 1

* 30-004B Terminal, Female Spd. 1

* Not Illustrated

09-282C 6 - 3 rev 5/00

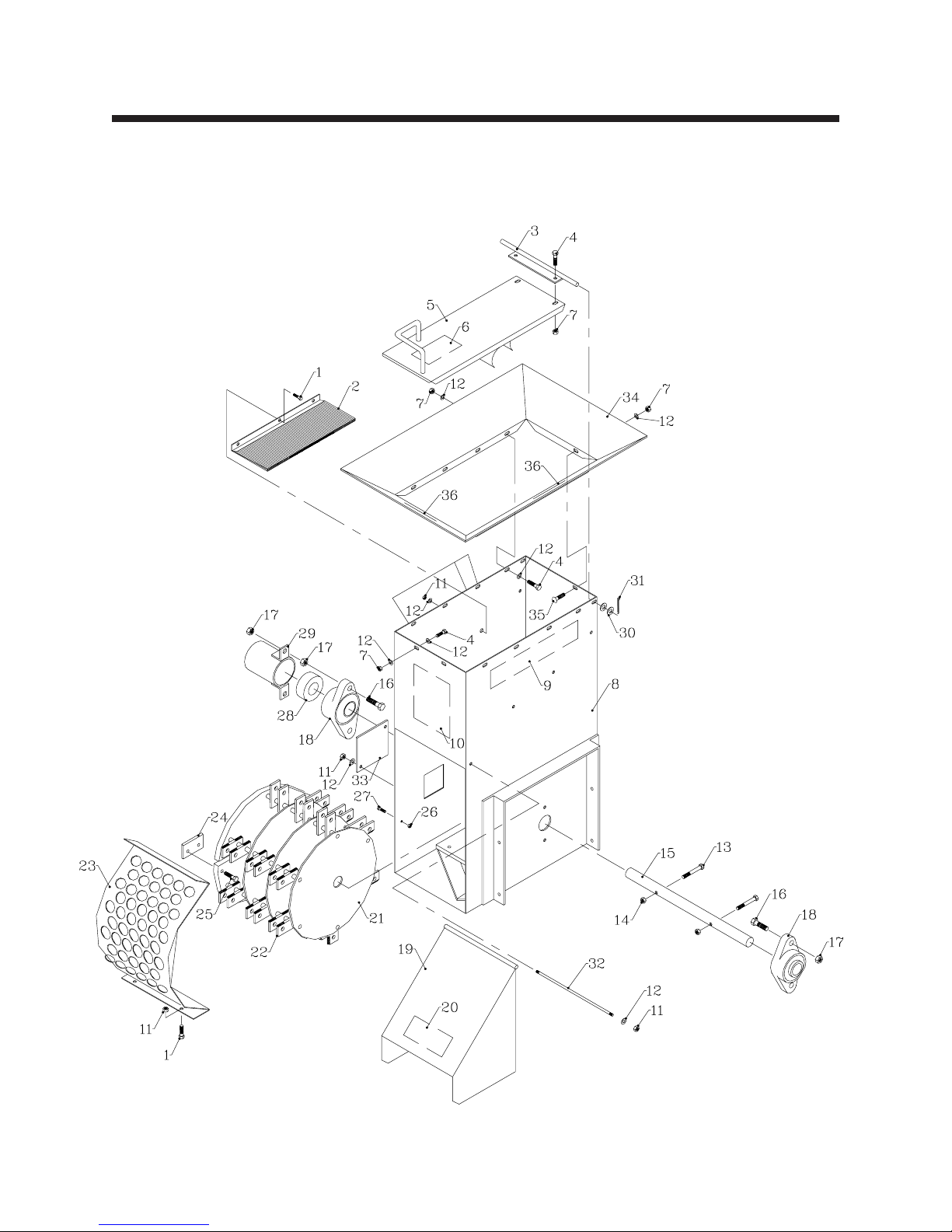

Page 18

PARTS section 6

Frame Parts

Figure 2

rev 5/00 6 - 4 09-282C

Page 19

PARTS section 6

Parts List for Figure 2

Ref Part no. Description Quantity

1 90-0506 Bolt, 5/16 X 3/4 8

2 87-CS16068 Brush, Inlet 2

3 64-732 Hinge Rod, Lid 1

4 99-K19 Flange Bolt, 5/16 x 3/4 12

5 60-578 Hopper Lid 1

6 00-093 Decal, Warning Read Owner's Manual 1

7 99-E12 Flange Nut, 5/16 13

8 62-756 Main Frame Housing (Serial No. 1001 - 1035) 1

62-787 Main Frame Housing (Serial No 1036 - ) 1

9 00-004 Decal, Steiner 1

10 00-156 Decal, Caution and Operating Instructions 1

11 87-CS15356 Locknut, 5/16 NYL 12

12 95-05 Flat Washer, 5/16 SAE 29

13 90-0620 Bolt, 3/8 x 2-1/2 2

14 87-CS15388 Locknut, 3/8 NYL 2

15 87-CS70379 Shaft, Rotor 1

16 90-0816 Bolt, 1/2 X 2 4

17 99-AC08 Locknut, Center 1/2 6

18 87-CS16004 Bearing, 2 BLT FLG 1-1/2" 2

19 60-577 Discharge Chute 1

20 00-153 Decal, Discharge Shield 1

21 87-CS70583 Rotor, Assembly (incl. Ref 22 and 24)(Ser. No. 1001 - 1159) 1

87-CS70969 Rotor, Assembly (incl. Ref 22 and 24)(Ser. No. 1160 - ) 1

87-CS70584 Weldment, Rotor (Ser. No. 1001 - 1159) 1

87-CS72689 Weldment, Rotor (Ser. No. 1160 - ) 1

22 87-CS70972 Shredder Kit, Consists of: 1

87-CS70856 Shredder Knife 36

87-CS70381 Shaft, Section Knife 6

87-CS70367 Spacer, 0.75 x 0.59 10

87-CS70368 Spacer, 0.75 x 0.59 w/hole 2

87-CS70369 Spacer, 0.75 x 1.18 8

87-CS70370 Spacer, 0.75 x 1.18 w/hole 4

87-CS70371 Spacer, 0.75 x 1.47 18

87-CS17898 Cap Screw, Socket Head 10-24x1-1/4 6

87-CS15397 Locknut, 10-24 NYL 6

23 87-CS70332 Coarse Screen 1

24 87-CS70453 Knife Kit (set of 4, with Ref. 25)(Ser. No. 1001 - 1159) 1

87-CS72493 Knife Kit (set of 4, with Ref. 25)(Ser. No. 1160 - ) 1

25 90-0508 Bolt, 5/16 X 1 8

26 99-E20 Flange Nut, 1/4 1

27 99-K26 Flange Bolt, 1/4 x 3/4 1

28 86-049 Set Collar, Special 1

29 87-CS70426 End Cap 1

30 95-08 Flat Washer, 1/2 SAE 4

31 02-CP0408 Cotter Pin, 1/8 x 1 2

32 87-CS70397 Rod, Discharge Shield 1

33 87-CS70396 Cover, Knife Access 1

34 60-596 Hopper (Serial No. 1036 - ) 1

35 97-0506 Carriage Bolt, 5/16 x 3/4 1

36 00-152 Decal, Danger Keep Hands..Inlet

* 00-155 Decal, Model CS312 1

* Not Illustrated

(2 shown&2onchipper chute) 4

09-282C 6 - 5 rev 5/00

Page 20

PARTS section 6

Emergency Stop Switch Parts

Figure 3

rev 8/98 6 - 6 09-282C

Page 21

PARTS section 6

Parts List for Figure 3

Ref Part no. Description Quantity

1 31-020A Knob, Black for 31-020 1

2 99-K26 Flange Bolt, 1/4 x 3/4 2

3 99-E20 Flange Nut, 1/4 6

4 64-731 Safety Switch Bracket 1

5 00-154 Decal, Emergency Stop 1

6 31-020 Switch, Push-Pull 1

7 11-016 Wire Clip, 13/32 2

8 30-173 Cable, 3-wire Switch to Plug - 60" 1

9 30-163 Connector Plug, 4 pole 1

10 30-164 Connector Socket, 4 pole 1

11 64-733 Mounting Bracket, Electrical Socket 1

12 30-174 Wiring Harness, All Model 420 & 425 w/o electric clutch 1

30-175 Wiring Harness, Model 425 with electric clutch 1

30-187 Wiring Harness, Model 525 with electric clutch 1

13 30-112 Connector, for 35-067 1

14 35-067 Relay 1

15 99-K31 Flange Bolt, 1/4 x 1/2 4

09-282C 6 - 7 rev 8/98

Page 22

PARTS section 6

MODEL CS313

Chipper/Shredder Blower Parts

Figure 4

rev 5/00 6 - 8 09-282C

Page 23

PARTS section 6

MODEL CS313

Parts List for Figure 4

Ref Part no. Description Quantity

1 87-CS70521 Hinge Pin, 5/16 x 14" 1

2 95-05 Flat Washer, 5/16 SAE 9

3 87-CS15356 Locknut, 5/16 NYL 11

4 87-CS70471 Impeller 1

5 87-CS70604 Shaft, Blower 1

6 90-0516 Bolt, 5/16 x 2 1

7 87-CS70586 Housing, Blower 1

8 87-CS17960 Clamp, 4-1/4" ID 1

9 87-CS70249 Blower Tube 1

10 97-0506 Carriage Bolt, 5/16 x 3/4 2

11 87-CS70253 Spout, Blower Tube 1

12 87-CS15321 Knob 1

13 90-0508 Bolt, 5/16 X 1 1

14 90-0506 Bolt, 5/16 X 3/4 10

15 00-002 Decal, Steiner Small 1

16 00-138 Decal, Danger-Rotating Blades 1

17 87-CS15402 Speed Nut, 5/16 4

18 87-CS17692 Spring, Extension 3/4" OD 1

19 87-CS69126 Spacer, Idler Pivot 1

20 87-CS15060 Carriage Bolt, 3/8 x 2 1

21 87-CS70475 Idler Plate, Blower 1

22 87-CS17740 Pulley, Idler 3-1/2" 1

23 87-CS15388 Locknut, 3/8 NYL 1

24 87-CS17831 Bearing, 1" Flushmount, 3 Bolt 2

25 87-CS15391 Key, Square 1/4 x 2" 1

26 87-CS17958 Pulley, Cast 1" Bore, 4" OD 1

27 87-CS70602 Belt Guard 1

28 87-CS16086 V-Belt, BX49 1

29 87-CS16016 Bushing, 1-1/2 1

30 87-CS16499

31 87-CS15441 Key, 3/8 x 1/4 x 2" 1

32 99-AC08 Locknut, 1/2 1

33 87-CS70496 Bracket, Belt Guard 1

34 00-093 Decal, Warning Read Owner’s Manual 1

Pulley, 3.6 x 1B-SH

1

09-282C 6 - 9 rev 8/02

Page 24

ASSEMBLY section 7

INSTALLATION INSTRUCTIONS FOR EMERGENCY STOP SWITCH OUTLET ON MODEL 420

Model 420 (Serial No. 1001 -- 2999)

1. Disconnect the battery ground cable.

2. On model 420 with Onan engine, mount the

electrical outlet on the left side of the black

upper grille panel with two 1/4 x 3/4 flange bolts

and nuts. Choose a location using the existing

slots in the panel. On models with Kubota

engines, the outlets are mounted on the right

side.

3. Connect the new harness (Part No. 30--174) to

the electrical outlet following the wiring diagram

on Page 3. Connect the brown wire to the “W”

terminal, the green wire to the “G” terminal and

the black wire to the “BK” terminal.

4. Locate the black module under the dash and

find the brown wire in the bulk connector.

Remove the bulk connector and carefully

release the brown wire from the connector with

a small blade pocket screwdriver. Place the

single black plastic connector on this brown

wire and connect to the new harness matching

connector. This is the seat switch wire.

5. Locate the brown jumper wire on the wiring

harness. (connected with a blue 3M connector)

Plug the end of the brown jumper wire into the

module bulk connector where the brown wire

was removed in step 3. Connect the bulk

connector to the module.

6. Route the white wire to the ignition switch. Find

the accessory terminal (white wire). Remove

the wire and place the double male spade

adapter on the switch. Replace the wire and

connect the white wire to the other terminal of

the double spade. NOTE: On Kubota tractors,

cut the spade terminal off the white wire, crimp

the enclosed ring terminal to the white wire and

attach it to the accessory terminal of the ignition

switch.

7. Check the wiring diagram and snap the brown

seat switch wire in the relay bulk connector

aligned with 87A on the relay. The brown wire

from the module aligns with 30. The black wire

aligns with 85 and the white wire with 86. Snap

these in place and push the connector on the

relay.

8. Mount the relay using one of the module

mounting screws.

9. Connect the green wire ring terminal to a

suitable ground. Tie all wires to keep them from

contact with moving parts or exhaust system.

10. Reconnect the battery cable, plug in the

chipper/shredder cable and test the

emergency stop switch for proper operation.

Pull the switch out for normal operation. Start

engine and engage the PTO. Push in for

emergency stop.

Model 420 (Serial No. 3000 -- )

1. Disconnect the battery ground cable.

2. On model 420 with Onan engine, mount the

electrical outlet on the left side of the black

upper grille panel with two 1/4 x 3/4 flange bolts

and nuts. Choose a location using the existing

slots in the panel. On models with Kubota

engines, the outlets are mounted on the right

side.

3. Connect the new harness (Part No. 30--174) to

the electrical outlet following the wiring diagram

on Page 3. Connect the brown wire to the “W”

terminal, the green wire to the “G” terminal and

the black wire to the “BK” terminal.

4. Locate the safety interlock relay under the dash

and find the brown wire in the bulk connector.

Remove the bulk connector and carefully

release the brown wire from the connector with

a small blade pocket screwdriver. Place the

single black plastic connector on this brown

wire and connect to the new harness matching

connector. This is the seat switch wire.

5. Locate the brown jumper wire on the wiring

harness. (connected with a blue 3M connector)

Plug the end of the brown jumper wire into the

safety relay bulk connector where the brown

wire was removed in step 3. Connect the bulk

connector to the safety relay.

6. Route the white wire to the ignition switch. Find

the accessory terminal (white wire). Remove

the wire and place the double male spade

adapter on the switch. Replace the wire and

connect the white wire to the other terminal of

the double spade. NOTE: On Kubota tractors,

cut the spade terminal off the white wire, crimp

the enclosed ring terminal to the white wire and

attach it to the accessory terminal of the ignition

switch.

7. Check the wiring diagram and snap the brown

seat switch wire in the new relay bulk connector

aligned with 87A on the new relay. The brown

wire from the safety relay aligns with 30. The

black wire aligns with 85 and the white wire with

86. Snap these in place and push the connector

on the relay.

8. Mount the new relay by drilling a hole in the

battery tray of the Onan power units. On Kubota

units, drill a hole at a suitable location on the

side of the dash panel.

9. Connect the green wire ring terminal to a

suitable ground. Tie all wires to keep them from

contact with moving parts or exhaust system.

10. Reconnect the battery cable, plug in the

chipper/shredder cable and test the

emergency stop switch for proper operation.

Pull the switch out for normal operation. Start

engine and engage the PTO. Push in for

emergency stop.

09-282C 7 - 1 rev 8/97

Page 25

ASSEMBLY section 7

INSTALLATION INSTRUCTIONS FOR EMERGENCY STOP SWITCH OUTLET ON MODEL 425

Model 425 Tractors without

1. Disconnect the battery ground cable.

2. Mount the Electrical outlet on the right side of

the black upper grille panel with two 1/4 x 3/4

flange bolts and nuts. Choose a location using

the existing slots in the panel.

3. Connect the new harness (Part No. 30--174) to

the electrical outlet following the wiring

diagram on Page 3. Connect the brown wire to

the “W” terminal, the green wire to the “G”

terminal and the black wire to the “BK” terminal.

4. Locate the black module under the dash and

find the brown wire in the bulk connector.

Remove the bulk connector and carefully

release the brown wire from the connector with

a small blade pocket screwdriver. Place the

single black plastic connector on this brown

wire and connect to the new harness matching

connector. This is the seat switch wire.

5. Locate the brown jumper wire on the wiring

harness. (connected with a blue 3M connector)

Plug the end of the brown jumper wire into the

module bulk connector where the brown wire

was removed in step 3. Connect the bulk

connector to the module.

6. Route the white wire to the ignition switch. Find

the accessory terminal (white wire). Remove

the wire and place the double male spade

adapter on the switch. Replace the wire and

connect the white wire to the other terminal of

the double spade. NOTE: On Kubota tractors,

cut the spade terminal off the white wire, crimp

the enclosed ring terminal to the white wire and

attach it to the accessory terminal of the ignition

switch.

7. Check the wiring diagram and snap the brown

seat switch wire in the relay bulk connector

aligned with 87A on the relay. The brown wire

from the module aligns with 30. The black wire

aligns with 85 and the white wire with 86. Snap

these in place and push the connector on the

relay.

8. Mount the relay using one of the module

mounting screws.

9. Connect the green wire ring terminal to a

suitable ground. Tie all wires to keep them from

contact with moving parts or exhaust system.

10. Reconnect the battery cable, plug in the

chipper/shredder cable and test the

emergency stop switch for proper operation.

Pull the switch out for normal operation. Start

engine and engage the PTO. Push in for

emergency stop.

11. Proper operation will stop the engine when the

emergency stop switch is pushed “IN”. To

restart, disengage PTO and pull emergency

knob “OUT”.

electric clutch:

Model 425 Tractors with

1. Disconnect the battery ground cable.

2. Mount the Electrical outlet on the right side of

the black upper grille panel with two 1/4 x 3/4

flange bolts and nuts. Choose a location using

the existing slots in the panel.

3. Connect the new harness (Part No. 30--175) to

the electrical outlet following the wiring

diagram on Page 3. Connect the brown wire to

the “W” terminal, the green wire to the “G”

terminal and the black wire to the “BK”

terminal.

4. Locate the clutch relay behind the grille and find

the brown wire in the bulk connector. Remove

the bulk connector and carefully release the

brown wire from the connector with a small

blade pocket screwdriver. This is the seat

switch wire. Insert the brown jumper wire (the

one connected with a blue 3M connector) from

the new harness in its place and push the bulk

connector on the clutch relay as before.

5. Route the white wire to the ignition switch. Find

the accessory terminal (white wire). Remove

the wire and place the double male spade

adapter on the switch. Replace the wire and

connect the white wire to the other terminal of

the double spade. NOTE: On Kubota tractors,

cut the spade terminal off the white wire, crimp

the enclosed ring terminal to the white wire and

attach it to the accessory terminal of the

ignition switch.

6. Check the wiring diagram and snap the brown

seat switch wire in the relay bulk connector

aligned with 87A on the relay. The brown wire

from the new harness aligns with 30. The black

wire aligns with 85 and the white wire with 86.

Snap these in place and push the connector on

the relay.

7. Mount the relay on the rear side of panel using

the clutch relay mounting screw.

8. Connect the green wire ring terminal to a

suitable ground. Tie all wires to keep them from

contact with moving parts or exhaust system.

9. Reconnect the battery cable, plug in the

chipper/shredder cable and test the

emergency stop switch for proper operation.

Pull the switch out for normal operation. Start

engine and engage the PTO. Push in for

emergency stop.

10. Proper operation will disengage the electric

PTO clutch when the emergency stop switch is

pushed “IN”. Do not use the emergency stop

switch as a PTO operational switch. To restart,

disengage tractor PTO switch, pull emergency

knob “OUT” and engage PTO in the normal

manner.

electric clutch:

rev 8/97 7 - 2 09-282C

Page 26

ASSEMBLY section 7

Typical Emergency Stop Switch Wiring Diagram

Two wiring harnesses are shipped with each Chipper/Shredder to adapt to the following tractors:

Model 420 and 425 Tractors without electric clutch

Part No. Description

30-174 Harness with 44" black and brown wires,...and 20" white wire.

Model 425 Tractors with electric clutch

Part No. Description

30-175 Harness with 33" black and brown wires,...and 57" white wire.

09-282C 7 - 3 rev 8/97

Page 27

ASSEMBLY section 7

INSTALLATION INSTRUCTIONS FOR EMERGENCY STOP SWITCH OUTLET ON MODEL 525

Diagram No. 2 for Model 525 Tractors w/o 2 Second Delay

(before serial no. 1197)

Model 525 Tractors:

1. Disconnect the battery ground cable.

2. Mount the electrical outlet on the left side of the

black upper grille panel with two 1/4 x 3/4

flange bolts and nuts. Choose a location using

the existing slots in the panel.

3. Remove the dash access panel. Starting at the

dash area, route the new harness (the end

without terminals) along the existing wiring

harness through the center pivot area of the

tractor. Continue routing until the wires reach

the electrical outlet.

4. Connect the new harness (Part No. 30--187) to

the electrical outlet following the wiring

diagram on this page. Connect the blue wire to

the “W” terminal, the green wire to the “G”

terminal and the black wire to the “BK”

terminal.

5. Locate the clutch relay and circiut breakersin

the dash area. Near the breakers find the

harness with two blue wires that comes from

the seat switch. Disconnect the bullet

connector on the blue seat switch wire and

connect the female bullet connector of the 5

inch brown wire to the male bullet connector on

the blue seat switch wire. Connect the male

bullet of the new green wire to the female bullet

connector of the blue wire that goes to the front

lift limit switch.

6. Route the blue wire from the new harness to the

PTO switch. Find the PTO switch terminal with

the blue wire attached. Remove the wire and

place the double male spade adapter on the

switch. Replace the wire and connect the new

blue wire to the other terminal of the double

spade.

7. Check the wiring diagram and snap the 5 inch

brown seat switch wire in the relay bulk

connector aligned with 87A on the relay. The

green wire from the new harness aligns with 30.

The black wire aligns with 85 and the 10 inch

black wire with ring terminal with 86. Snap

these in place and push the connector on the

safety relay.

8. Mount the safety relay on the left side of

mounting panel using the clutch relay

mounting screw.

9. Connect the black wire ring terminal to a

suitable ground. Tie all wires to keep them from

contact with moving parts or exhaust system.

10. Reconnect the battery cable, plug in the

chipper/shredder cable and test the

emergency stop switch for proper operation.

Pull the switch out for normal operation. Start

engine and engage the PTO. Push in for

emergency stop.

11. Replace all shields.

12. Proper operation will disengage the electric

PTO clutch when the emergency stop switch is

pushed “IN”. To restart, pull emergency knob

“OUT” and engage PTO in the normal manner.

rev 8/97 7 - 4 09-282C

Page 28

ASSEMBLY section 7

INSTALLATION INSTRUCTIONS FOR CHIPPER/SHREDDER WIRE HARNESS ON MODEL 525

EQUIPPED WITH 2 SECOND DELAY RELAY

Wiring Diagram for Model 525 Tractors w/2 Second Delay

(after serial number 1197)

Model 525 Tractors:

1. Disconnect the battery ground cable.

2. Mount the electrical outlet on the left side of the

black upper grille panel with two

bolts and nuts. Choose a location using the

existing slots in the panel.

3. Remove the dash access panel. Starting at the

dash area, route the new harness (the end

without terminals) along the existing wiring

harness through the center pivot area of the

tractor. Continue routing until the wires reach

the electrical outlet.

4. Connect the new wire harness (Part # 30--301)

to electrical outlet installed in Step 2, following

the wiring diagram on this page. Connect the

black wire to the BK terminal, the blue wire to

the W terminal, the gray wire to the R terminal,

and the green wire to the G terminal.

5. Install the supplied relay to the same bolt that

fastens the top of the 30 amp breaker. Position

the relay so that the relay plug will clear the

other bolts on the electrical mounting plate.

6. Remove the blue wire from the load terminal of

the lift cut--off delay relay and install that wire in

the new relay plug so that it connects with the

#87a terminal of the new relay.

7. Install one of the gray wires from the new

harness (30--301) to the load terminal of the lift

cut--off delay relay. Either gray wire can be

used.

8. Install the other gray wire from the new harness

(30--301) into the new relay plug so that it will

connect with the #30 terminal of the new relay.

x flange

9. Install the supplied black wire (approx. 11” long)

to the new relay plug so that it will connect with

the #85 terminal of the new relay. Install the

eyelet end to the ground bolt on the dash. Also

install the black wire from the new harness to

the ground bolt.

10. Install the green wire from the new harness

(30--301) to the new relay plug so that it

connects with the #86 terminal of the new

relay. Install the relay plug onto the new relay.

11. Locate the light blue wire that goes to the

control terminal of the seat switch delay relay.

Cut this wire 3” to 4” from the delay relay plug

and install the supplied male bullet terminals to

both wire ends. Install both ends into the

supplied 3--way electrical connector, also

install the blue wire from the new harness

(30--301) into the 3--way connector.

12. Change the wiring on the emergency stop

switch following the wiring diagram on this

page. The white wire connects to the #4

terminal, the black wire connects to the #5

terminal, the green wire connects to the #2

terminal, and the gray wire connects to the #3

terminal.

13. Reconnect the battery cable, plug in the

chipper/shredder cable and test the

emergency stop switch for proper operation.

Pull the switch out for normal operation. Start

engine and engage the PTO. Push in for

emergency stop.

14. Replace all shields.

15. Proper operation will disengage the electric

PTO clutch when the emergency stop switch is

pushed “IN”. To restart, pull emergency knob

“OUT” and engage PTO in the normal manner.

09-282C 7 - 5 rev 8/97

Page 29

ASSEMBLY section 7

Assembly Instructions for: MODEL CS313 CHIPPER / SHREDDER BLOWER

Refer to Section 6 Parts

Drawing for Identification of

Parts.

1. Remove hinge pin (Fig. 4, Ref. 1)

and remove discharge chute.

2. Remove the end cap from the

rotor shaft.

3. Hold blower up to the main frame

and secure with the new hinge

pin (Fig, 4, Ref. 1) supplied with

the blower assembly.

Photo 1

4. Install pulley, bushing and key

(Fig. 4, Ref. 29, 30, 31) onto the rotor shaft. Do not

secure to shaft at this time.

5. Install belt onto the inside groove on the rotor shaft

pulley, and onto the blower pulley. Idler should run

on the inside of belt for correct tension. (See Photo

1) Align pulleys to within 1/16". Tighten all pulleys on

shafts.

6. Install belt guard support bracket (Fig. 4, Ref.33)

onto top 1/2" bolt for bearing on main frame and

secure with 1/2" lock nut. (Fig. 4, Ref. 32)

7. Install belt guard (Fig. 4, Ref. 27) with (4) 5/16" x 3/4"

bolts and washers.

8. Install blower spout (Fig. 4, Ref. 11) on the blower

tube with (2) 5/16" x 3/4" carriage bolts, (1) 5/16"

locknut and (1) spout knob. Install blower tube onto

blower assembly and secure with clamp. (See

Photo 2)

Photo 2

rev 11/97 7 - 6 09-282C

Page 30

Loading...

Loading...