TPMS for Motorcycle

TP-90

Manual

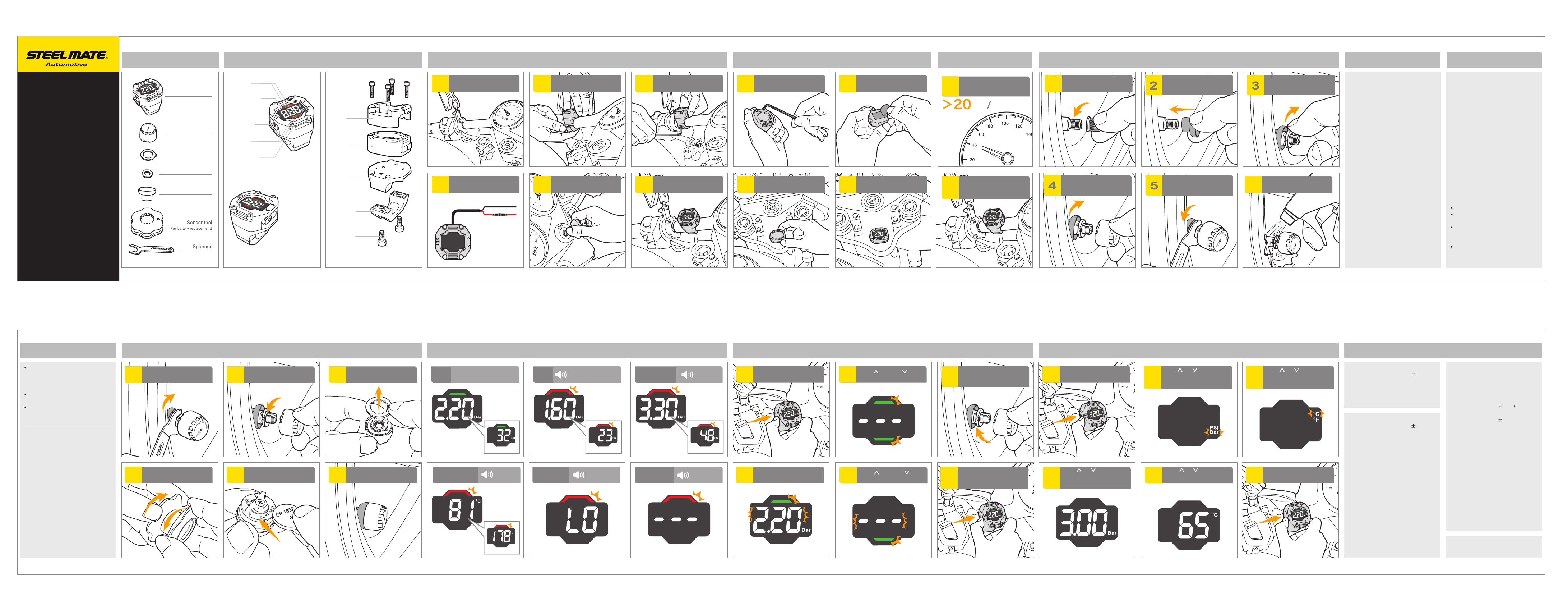

Includes Brief look of display Display installation (clip on handle bar) Display installation (stick on dash)

Display

with cradle X1

Sensor X2

Washer X3

(1 for spare)

(1 for spare)

Dustproof cover X2

(Please keep it in motorcycle carefully)

Nut X3

Front tire

indicator

Data indicator

Temperature unit

SET button

Rear tire

indicator

Pressure unit

Adjust

button

M3 screw

Cover

Display

Bottom

Holder bar

Bracket

M4 screw

Note: Tightening and loosening the M3

and M4 screws by 2.5mm and 3.0mm

hex keys respectively.

Find a place for mounting

1

Wiring the display

4

GND (Black)

ACC (Red)

Clip the cradle on the handle bar

2

ACC ON

5

Tightening the M4 screws by 3.0

3

mm hex key

Dispaly turns on

6

Loose the M3 screws on the

1

cradle by 2.5mm hex key

Stick the display on dash and

3

wiring

2

4

Tear off the sticker at the back of

display

ACC ON and display turns on

Functional test after installation

Display will show real time tire

data automatically when the

1

speed is over 20km/h ( 12.4MPH)

km h

Installation is done once 2 tire data

received and appears alternatively

2

indicator with corresponding status

every 2 seconds.

Sensor installation

Unscrew the valve cap

1

Screw on the sensor

Insert the dustproof cover

into the valve stem

Tighten up the nut to the sensor

by using the spanner

Screw on the nut

Check air leakage by spraying

6

soap water

Troubleshooting

After sensor installation, air leakage

1.

happened

The tire valves may not be universal

standard, please check from the local

workshop.

Once the installation is done, there is

2.

no tire data showed on display

Make sure ACC is on

Need tire balance after installation?

3.

No as the weight of sensor is only 9.6g

and it is located on the inner rim of wheel.

Sensor lost Please buy a new sensor.

4.

Sensor battery is low

5.

Please replace the battery of CR1632.

Location of tire changed

6.

Please reprogram the corresponding

sensors.

FCC warning statement

1.This equipment has been tested and found

to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide

reasonable protection against harmful

interference in a residential installation.

2.This equipment generates uses and can

radiate radio frequency energy and, if not

installed and used in accordance with the

instructions, may cause harmful interference

to radio communications.

3. However, there is no guarantee that

interference will not occur in a particular

installation.

4.If this equipment does cause harmful

interference to radio or television reception,

which can be determined by turning the

equipment off and on, the user is

encouraged to try to correct the interference

by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the

equipment and receiver.

Connect the equipment into an outlet on

a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio

/ TV technician for help.

Disclaimer

TPMS (Tire pressure Monitoring System) is

designed for monitoring tire irregularities.

Driver has responsibility to maintain tires

regularly.

Driver should react promptly once warning

from this unit alerted.

Steelmate does not guarantee or assumes

liability for the loss of sensors.

Notes:

This system is for 12V vehicle with tire

1.

pressure within 3.5Bar/50PSI.

All sensors in this unit have been pre-set

2.

individually for each tire in the factory.

Whenever the location of tire changed, the

3.

sensors must be changed to the

corresponding tire.

The display will turn off after the car flame

4.

out even the cigarette lighter is kept

powering.

The brightness on the display will become

5.

dimmer after the first 30 seconds.

The sensor battery life related with the driving

6.

mileage.

Sensor battery replacement

Unscrew the nut

1

Unscrew the sensor cover by

4

using the sensor tool

Unscrew the sensor

2

Replace new battery

5

Take out the washer

3

Repeat steps in

6

"Sensor installation"

Different scenarios

Normal Showing 2 tires data

PSI unit

High temperature

Bi-Bi-

PSI unit

Leakage

Low battery Bi-Bi-

Fast leakage: Bi--Bi-Slow leakage: Bi-Bi-

PSI unit

High pressure

Sensor failure

Bi---

Bi-Bi-Bi-

PSI unit

Sensor programming (reminder: all sensors pre-set in factory)

Press the "SET" button for 5 times,

the display beeps once to enter the

1

program mode

Tire pressure will show on the

corresponding tire data position

4

and press "SET" button to save data

Press " " button or " " button

2

to select front and rear tire

Press " " button or " " button

5

once to program the next sensor

Screw the new/marked sensor to

the corresponding tire (to avoid

3

confusion) and secure it with the

nut

Press and hold SET button for 3

seconds, it will have twice beep

6

sounds for save and exit the

program mode

Settings

Press and hold "SET" button for 3

seconds, the display beeps once

1

and enters system programing mode

Press

" " or " "

the recommended pressure value

4

and press SET button to save and

exit

button to adjust

Press " " or " " button to select

the pressure unit and press "SET"

2

button to save and enter next

setting

Press

" " or " "

the temperature alarm value and

5

press SET button to save and exit

button to adjust

Press " " or " " button to select

the temperature unit and press

3

SET button to save and enter

next setting.

Press and hold "SET" for 3S, it will

have twice beep sounds for save

6

and exit the setting mode.

Specifications

Sensor:

Operating frequency:

Operating voltage:

Operating temperature:

Pressure range:

Display:

Operating frequency:

Operating voltage:

Operating temperature:

Defalut:

Pressure Unit:

Temperature Unit:

Recommended

pressure:

High pressure value:

Low pressure value:

High temperature value:

Adjustable pressure range:

Pressure:

Temperature:

433.92

2.0V ~ 3.3V

-20oC ~ +60oC /

-4oF ~ +140oF

0~3.5Bar / 0~50PSI

433.92

9V ~ 16V

-40oC ~ +70oC /

-40oF ~ +140oF

Bar

o

2.5Bar / 36PSI

3.3Bar / 47PSI

1.7Bar / 25PSI

+80oC / +176oF

2~3.5Bar / 29~50PSI

+50

+122oF~+176oF

C

o

0.05MHz

0.05MHz

C~+80oC /

Monitoring:

Pressure range:

Temperature range:

Precision:

Temperature:

Pressure:

-20~0oC:

0~+50oC:

+50~+70oC:

Air pressure unit:

1 Bar = 14.5 PSI = 100K Pa = 1.02 Kgf / cm

0~4.5Bar / 0~65PSI

o

+30

C~+80oC /

+22oF~+176oF

1oC / 2oF

0.4Bar / 5.8PSI

0.2Bar / 2.9PSI

0.4Bar / 5.8PSI

PPI0191R/A

2

****50 x 120

Loading...

Loading...