Steelkor AC-FA User Manual

SUGGESTED SPECIFICATIONS FOR CONVEYOR

MODEL AC-FA

Soiled Dish Accumulator Conveyor to be

SOUTHERN ENGINEERING SYSTEMS by Duke Mfg

Co., model ACFA, UL and ETL Listed, and NSF approved commercial kitchen conveyor.

Conveyor Belt to be 16” wide, heavy duty, polyester synthetic woven carcass with PVC coating. Belt is

FDA approved for food service use. Belt edges are sealed. Belt to operate at a variable speed of 5 to 40

feet per minute.

Conveyor Bed to be constructed on #14 gauge, 300 series stainless steel with 3” high x 1-1/4” wide

rolled rim on exposed sides and 10” high x 2-1/2” wide splash along walls. Polish stainless steel to a #3

finish. Slider pan , under belt, embossed with raised round disks to prevent vacuum drag between belt and

pan. Belt returned via flanged non-friction PVC roller assemblies.

Drive Housing to be a welded stainless steel frame with hinged, lift off, double wall, #16 gauge stainless

steel access door exposing oversized, removable stainless steel scrap pan. Drive housing to be supported

by four 1-5/8" O.D., #16 gauge stainless steel legs and stainless steel adjustable bullet feet.

Drive Type to be 90-volt DC, ½ H.P. variable speed with 120volt-60 cycle service, internal torque limit

adjustment and ramp acceleration start. Controlled by one (1) on/off switch station and variable speed

control.

Drive end of conveyor furnished with anti-jam Silver Saver switch plate to prevent foreign material from

jamming drive system.

Flush Wash System to be provided standard, with 1-1/2” drain and strainer at drive housing and fulllength, adjustable height, stainless steel drip pan. (Optional Auto-Wash system available).

Conveyor supported by 1-5/8” 16gauge stainless steel tubing Legs with welded stainless steel cross rails.

Leg frames fitted into enclosed, round stainless steel gussets welded to stainless steel channel braces, and

fitted with stainless steel adjustable bullet feet.

Conveyor to be pre-wired and factory tested.

Conveyor to carry UL and ETL listing and shall be NSF approved. E

quipment built in an ISO

9001:2000 approved manufacturing facility.

2305 N. Broadway

St. Louis, MO 63012

Ph 314-231-1130

Fax 314-231-5074

www.dukemfg.com

5/07

BY

"Your Solutions Partner"

Optional Accessories

20” Fabric Belt Sloped Rack Shelf – Wall Mount

Flanged Feet Sloped Rack Shelf – Cantilevered

SS Window Frame & Sill Flat Storage Shelf – Wall Mount

Removable Skirting Panels – SS Flat Storage Shelf – Wall Mount

Removable Skirting Panels - Laminate Stationary Under Shelf

Sight & Sound Barrier Removable Under Shelf

Security or Fire Door 3” High x 1-1/2” Channel Rim Sides

Prison Security Package 7/8” High x 1-1/4” Marine Edge

Additional Start-Stop Station Pre-Rinse Sink

Limit Switch – Bed Mount Disposer Sink

Limit Switch – Splash Mount Scrapping Trough

Foot Switch (Momentary Stop) Trough Wheel

Hip Switch (Constant Stop) Recessed SS Roller Section

Power Tray Discharge (Drive End) Pre-Rinse Spray – Splash Mount

Tray Storage Platform (Tail End) Pre-Rinse Spray – Bed Mount

Auto-Wash System (HW,CW & Detergent Inject)

Other _____________________________

_____________________________

Design Option (Pick One)

32” Long Drive Housing (Standard)

40” Long Drive Housing (Optional)

COMMENTS/NOTES _____________________________________________________

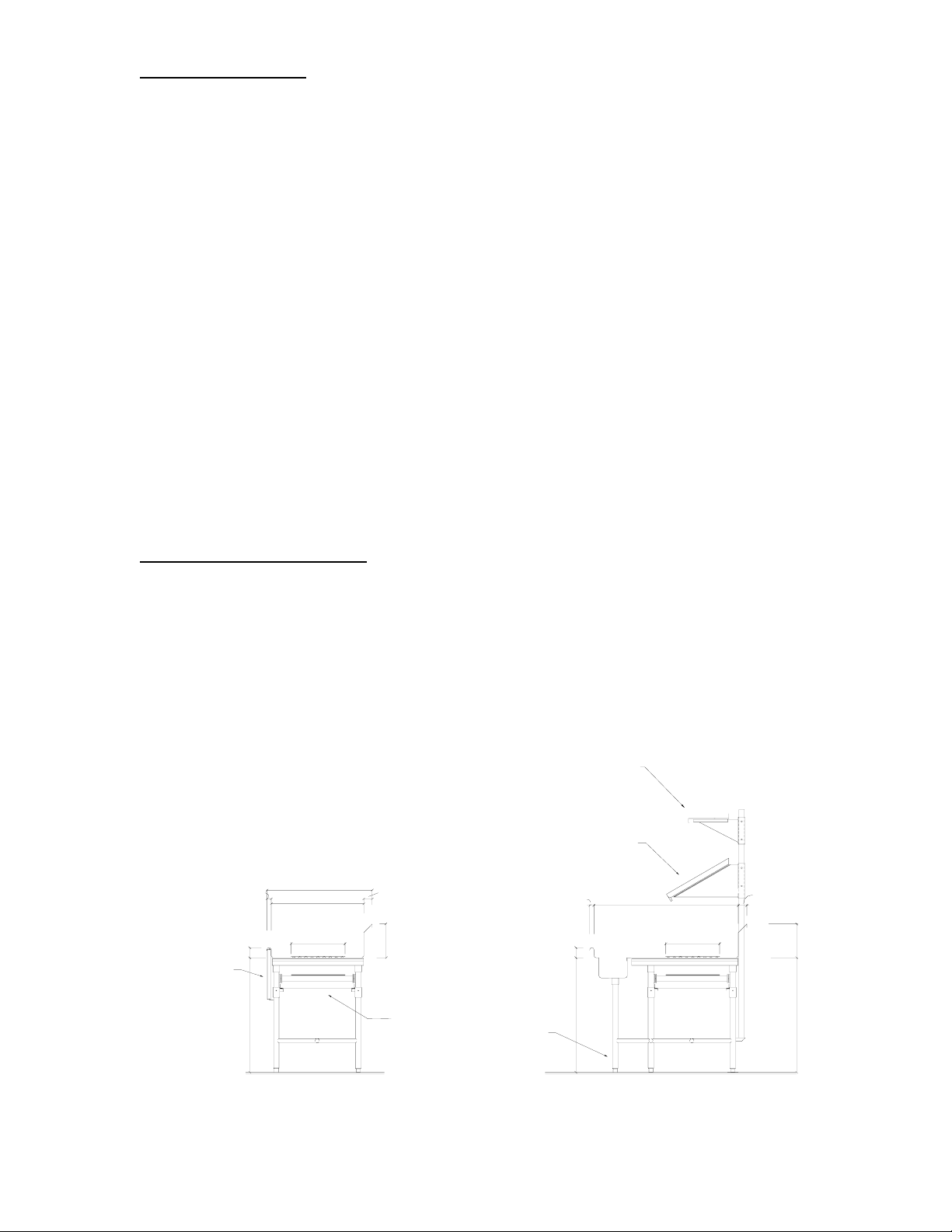

14GA SS FLAT STORAGE SHELF W/

ADJ 14GA SS SLEEVED BRACKETS

& 16GA SS TUBING SUPPORTS

14GA SS SLOPED RACK SHELF W/

ADJ 14GA SS SLEEVED BRACKETS

& 16GA SS TUBING SUPPORTS

31-1/4"

27-1/2"

16"

BELT

2 1/2"

10"

ADJ SS DRIP PAN

16GA SS LEGS WITH

ADJ SS BULLET FEET

1 1/4"

2 1/2"

16"

3"

2'-10" A.F.F.

BELT

2'-10" A.F.F. 10"

REMOVABLE 16GA SS

ENCLOSURE PANELS

1 1/4"

3"

2'-10" A.F.F.

Loading...

Loading...