STEELGREEN SG36, SG46, SG52 Operator's Manual

OPERATOR’S MANUAL

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near

any unimproved forest-covered, brush-covered or grass-covered land unless the engine's exhaust system is

equipped with a spark arrester meeting

should be maintained in effective working order by the operator.

quired by law (Section 4442 of the California Public Resources Code). Other states may have similar laws.

Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine

authorized

PRINTED IN U.S.A.

service dealer or contact the service department, P.O. Box 361131 Anytown, US 44136-0019.

STEELGREEN LLC, 920 S STATE ROAD 39 LEBANON, IN 46025

applicable local or state laws (if any). If a spark arrester is used, it

In the State of California, the above is re-

TABLE OF CONTENTS

GENERAL INFORMATION ................................................................................................ ........................................................... 2

SAFE OPERATION ....................................................................................................................................................................... 3

CONTROLS AND OPERATION (SPREADER) ................................................................................................................................. 4

SPREADER CALIBRATION / RATE CHARTS .......................................................................................................................... 4

SPREADER CLEANING ......................................................................................................................................................... 5

SPREADER MAINTENANCE ................................................................................................................................................. 5

CONTROLS AND OPERATION (SPRAYER).................................................................................................................................... 6

SPRAYER ON/OFF CONTROLS ............................................................................................................................................ 6

SPRAYER PUMP CONTROLS ............................................................................................................................................... 7

LIQUID TANK OPTIONS ...................................................................................................................................................... 7

HOSE REEL OPERATION ..................................................................................................................................................... 8

SPRAYER CALIBRATION ...................................................................................................................................................... 8

STRIKER SETUP........................................................................................................................................................................... 9

MAINTENANCE ................................................................................................................................

........................................ 10

SPECIFICATIONS ....................................................................................................................................................................... 10

WIRE HARNESS ................................................................................................................................ ........................................ 11

GREASE POINTS ................................................................................................................................ ....................................... 12

SERVICE ................................................................................................................................................................................... 15

GENERAL INFORMATION

Serial Number: _______________________________________________________________________________________

Date Purchased: ______________________________________________________________________________________

Dealer Name: ________________________________________________________________________________________

Dealer Phone Number: _________________________________________________________________________________

2

SAFE OPERATION

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED,

COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL

INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING TO OPERATE YOUR UNIT. FAILURE TO COMPLY WITH THESE

INSTRUCTIONS MAY RESULT IN PERSONAL INJURY .

GENERAL OPERATION

•

Do not operate the machine while under the

influence of alcohol or drugs.

• Only allow responsible adults, who have

of the operator.

PARKING/BRAKE OPERATION

•

To engage the brake, pull down and in on the

of the machine.

• Lock the parking brake.

• Stop the engine.

RE-FUELING

•

ALWAYS STOP THE ENGINE and allow it to cool

before refueling. NEVER remove the gas cap to

add fuel while the engine is running, and never

fill the gas tank on an engine that has been

– gas spilled on a hot

engine can ignite.)

• Never smoke while refueling.

• Do not overfill fuel tank.

• Follow warning label on fuel tank.

SLOPE OPERATION

•

• Keep alert for hidden hazards on the terrain.

• Stay away from drop-offs, ditches and

embankments.

• Never operate on slope angles greater than 13°

BRAKE

DISENGAGED

BRAKE

ENGAGED

•

increase the risk of a rollover. (A 10° slope is a

3

CONTROLS AND OPERATION (SPREADER)

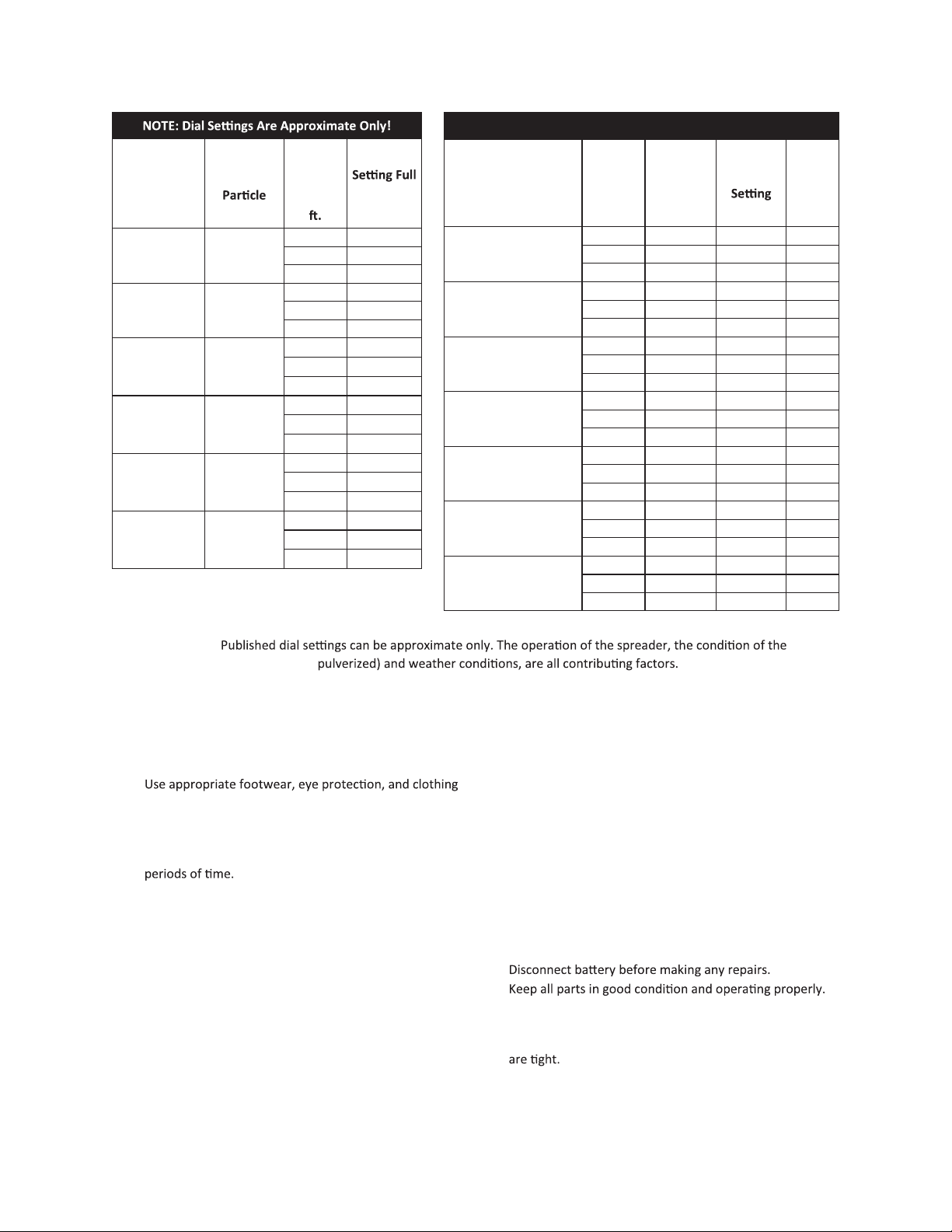

SPREADER CALIBRATION / RATE CHARTS

CAUTION! To avoid injury to hand, ensure motor is switched OFF

Wear appropriate clothing and safety equipment when applying

and handling chemicals .

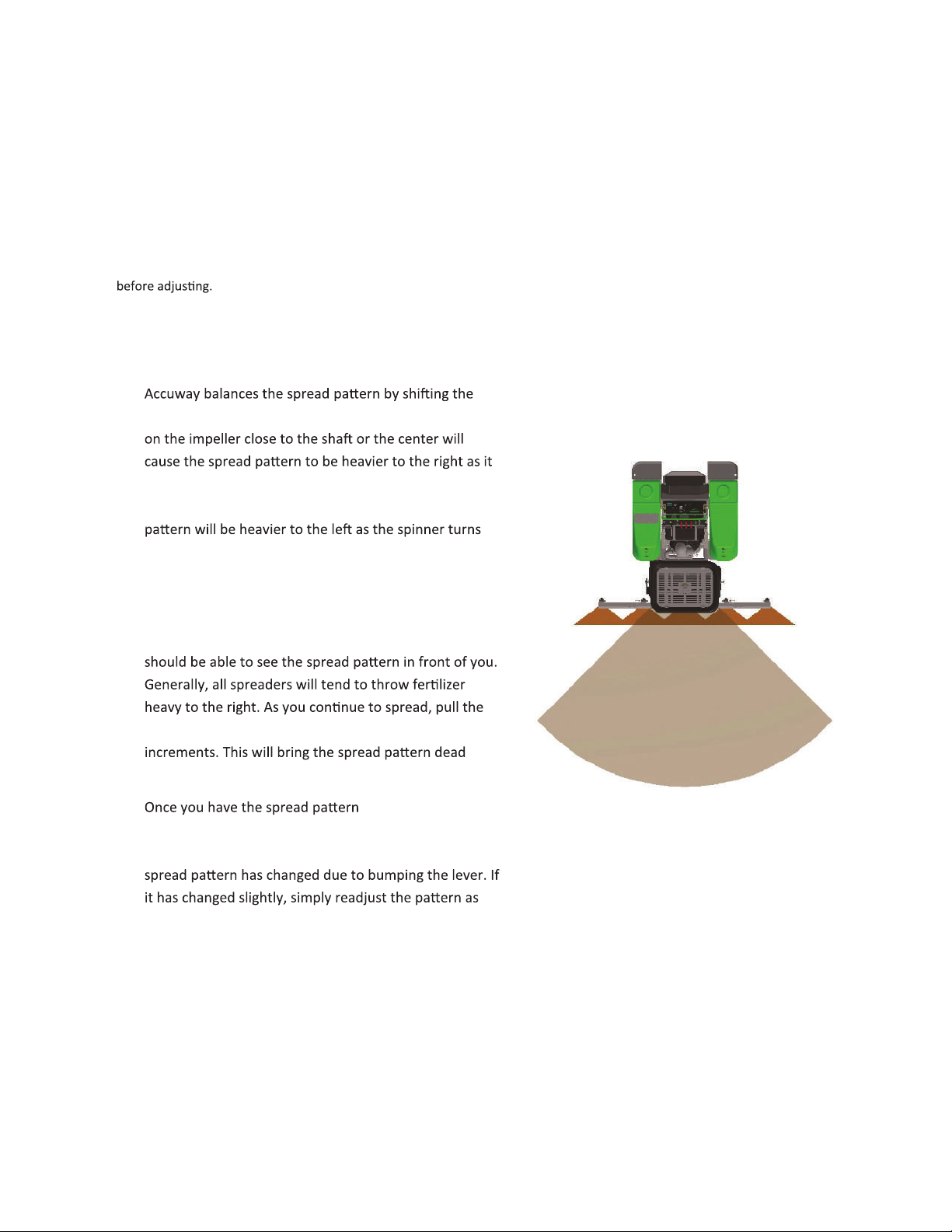

•

product placement on the spinner. Placing the product

rides the impeller for a longer period. If the product is

placed on the outer edge of the impeller, the spread

clockwise.

• Start with the Accuway control cable all the way forward

or in.

• Begin to spread the product. As you are spreading, you

Accuway control towards you very slowly in small

center in front of you.

•

the Accuway cable in place. There should be no reason

to reset the Accuway for that product unless you see the

you are spreading.

“dead center,” lock

THROW FERTILIZER

TO CENTER OF TIRE

TRACKS

4

Product

Fine Pellets

Mixed Fine

Small Pellets

Medium Size

And Granule's

Large Heavy

Pellets

Nitrogen

Pellets

Medium

Pellets

Pellets

Dial

LBS. per

1000 sq.

Size

Rate Once

1 5.6

2 6.0

3 6.2

2 5.7

4 6.7

6 7.2

Over

2 5.0

4 6.2

Product

Blue Grass or Red Top

Park, Merion, Delta,

or Kentucky Bluegrass

Hulled Bermuda

6 6.5

1 5.5

2 6.2

3 6.7

2 5.5

4 6.5

Mixtures Including

Coarse Seeds

Rye Grasses or

Tall Fescue

6 7.2

2 5.8

4 6.9

Dichondra

6 7.9

Pensacola Bahia

Grass Seed Spreading Chart

Bag

Weight

5 lbs. 1,000 3 4

1 lbs. 1,000 5 4

2lbs. 1,000 4 4

5 lbs. 1,000 4 4

1 lbs. 1,000 5 4

2 lbs. 1,000 5 4

2 lbs. 1,000 4 6

3 lbs. 1,000 5 6

4 lbs. 1,000 5 6

2 lbs. 1,000 8 6

4 lbs. 1,000 9 6

6 lbs. 1,000 9 6

2 lbs. 1,000 8 6

4 lbs. 1,000 9 6

6 lbs. 1,000 9 6

4 oz. 1,000 3 8

8 oz. 1,000 4 8

12 oz. 1,000 4 8

4 lbs. 1,000 6 7

5 lbs. 1,000 6 7

6 lbs. 1,000 7 7

Coverage

Sq. Ft

Full Rate

Dial

Spread

Width

REMEMBER!

material (damp or dry or over-

SPREADER CLEANING

•

when cleaning spreader.

• The key to years of trouble-free service is to keep your

spreader clean and dry.

• Never allow material to remain in hopper for extended

• Empty material from hopper at the end of each day.

• Use a hose or wipe excess material off spreader at the

end of each day.

• Open and close gate as you rinse to avoid buildup of

material.

• Quickly towel dry spreader.

SPREADER MAINTENANCE

• Understand service and maintenance procedure before

performing any work on this machine or spreader.

• Do not operate the engine in a confined space where

carbon monoxide and other fumes can accumulate.

• Never lubricate, service, or adjust the machine or

spreader while it

is moving or running.

• Keep hands, feet, clothing, hair, and loose items away

from any moving parts.

•

•

Fix damages immediately. Replace all worm or damaged

parts.

• Check all hardware at frequent intervals to ensure they

5

Loading...

Loading...