Steele SP-PB101 Owner’s Manual

OWIleF'S Manual

S_PB 1O1 ........... ton8Enwc_CALL:_ _== _._,

230181

MustRead And UnderstandInstructionManual

PAnAS£RV_(CXeLLAME:_,_U--_U--_ &

Owner's Manual

Table of Contents

Technical data ............................................. 2

General safety rules ......................................... 3

Specific safety rules for the table saw ........................... 5

Electrical information ....................................... 7

Know your table saw ....................................... 9

Assembly and adjustments .................................. 10

Operation ............................................... 20

Maintenance .............................................. 26

Troubleshooting ........................................... 28

Replacement parts ......................................... 29

Push stick pattern ......................................... 30

Warranty ................................................ 32

Push stick pattern ......................................... 34

Technicaldata

Motor : 120V, 15A, 6OHz

Motor speed : 5OOORPM(no load)

Overloadprotection: Yes

Table size : 16" x 26" (406 x 660mm)

Blade : 10" (254mm) carbide-tipped;

5/8" (15.9mm) arbor

Maximum depth of cut at 90° : 3" (76,2mm)

Maximum depth of cut at 45° : 2-1/2" (63.5mm)

Maximum width of dado : 1/2" (12.7mm)

Netweight : 501b(23kg)

Owner's Manual

General safety rules

Safety is a combination of common sense, staying alert and knowing how your table saw works.

SAVE THE SESAFETYINSTRUCTIONS.

WARNING:To avoid mistakes that could cause serious injury, do not plug in the table saw

until the following steps have been read and understood.

1 .READand become familiar with this entire instruction manual. LEARN the tool's applications,

limitations, and possible hazards.

2.AVOID DANGEROUSCONDITIONS. Do not use power tools in wet or damp areas or expose them

to rain. Keep work areas weIMit.

3.DO NOT use power tools in the presence of flammable liquids or gases.

4.ALWAYS keep your work area clean, uncluttered, and weIMit. DO NOT work on floor surfaces that

are slippery with sawdust or wax.

5.KEEP BYSTANDERS AT A SAFE DISTANCEfrom the work area, especially when the tool is

operating.NEVER allow children or pets near the tool.

6.DO NOT FORCETHE TOOL to do ajob for which it was not designed.

7.DRESS FOR SAFETY. Do not wear loose clothing, gloves, neckties, or jewelry (rings,watches, etc.)

when operating the tool. Inappropriate clothing and items can get caught in moving parts and draw

you in. ALWAYS wear non-slip footwear and tie back long hair.

8.WEAR A FACEMASK OR DUSTMASK as the sawing operation produces dust.

WARNING: Dust generated from certain materials can be hazardous to your health. Always

_i_ operate the saw in a well-ventilated area and provide for proper dust removal. Use dust

collection systems whenever possible.

9.ALWAYS remove the power cord plug from the electrical outlet when making adjustments, changing

parts, cleaning or working on the tool.

IO.KEEP GUARDS IN PLACEAND IN WORKING ORDER.

11.AVOID ACCIDENTAL START-UPS. Make sure the power switch is inthe OFFposition before plugging

in the power cord.

12.REMOVE ADJUSTMENT TOOLS. Always make sure all adjustment tools are removed from the saw

before turning it on.

1&NEVER LEAVE ARUNNING TOOL UNATTENDED. Turn the power switch to OFF.Do not leave the

tool until it has come to a complete stop.

OWRGF'S MaNual

O_ler's MaNua]

General safety rules(continued)

14.NEVER STAND ON A TOOL. Serious injury could result if the tool tips or is accidentally hit.DO NOT

store anything above or near the tool.

15.D0 NOT OVER REACH.Keep proper footing and balance at all times. Wear oil-resistant rubber-

soled footwear. Keep the floor clear of oil, scrap, and other debris.

1&MAINTAIN TOOLS PROPERLY. ALWAYS keep tools clean and in good working order. Follow

instructions for lubricating and changing accessories.

17.CHECK FOR DAMAGED PARTS. Check for alignment of moving parts, jamming, breakage,

improper mounting, or any other conditions that may affect the tool's operation. Any part that

is damaged should be properly repaired or replaced before use.

18MAKE THEWORKSHOP CHILDPROOF. Use padlocks and master switches and ALWAYS

remove starter keys.

19.D0 NOT operate the tool if you are under the influence of drugs, alcohol, or medication that could

affect your ability to use the tool properly.

20.USE SAFETYGOGGLESAT ALLTIMES--that comply with ANSI Z87.1.

Normal safety glasses only have impact resistant lenses and are not

designed for safety. Wear a face or dust mask when working in adusty

environment. Use ear protection, such as plugs or muffs, during

extended periods of operation.

Specificsafety rulesfor the table saw

,_ WARNING: Do not operate the table saw until it is completely assembled and installed 1

according to the instructions.

01.Always usethe splitter and anti-kickback pawls for all operations, including through-sawing.

Through-sawing operations are those in which the blade cuts completely through the

workpiece when ripping or cross-cutting.

02.Always hold the workpiece firmly against the miter gauge or rip fence.

03.Use a push stick when required. Always use a push stick for ripping narrow stock. Refer to ripping

applications in the instruction manual where the push stick is covered in detail. See the push stick

pattern included in this instruction manual.

04.Never perform any operation"free hand"(using only your hands to support or guide the workpiece).

Always useeither the fence or the miter gauge to position and guide the work.

05.Never stand or place any part of your body in line with the path of the saw blade. Keepyour hands

out of the line of the saw blade.

O&Never reach behind or over the table saw.

07.Remove the rip fence when cross-cutting.

08.Feed the workpiece into the blade against the direction of rotation only.

09.Never use the fence as a cut-off gauge when cross-cutting.

1&Never attempt to free a stalled saw blade without first turning the saw OFF.Turn off the power

switch immediately to prevent motor damage.

11.Provide adequate support to the rear and sides of the saw table for wide or long workpieces.

12.Avoid kickbacks (work thrown back toward you) by keeping the blade sharp, keeping the rip fence

parallel to the saw blade, and keeping the splitter, anti-kickback pawls, and guard inplace and

operating.Do not releasework before it is pushed all the way past the saw blade. Do not rip work

that is twisted, warped, or does not have a straight edge to guide along the fence.

1&Avoid awkward operations and hand positions where a sudden slip could put you r hand inthe

cutting path.

/

O_er's Manual

Specificsafety rulesfor the table saw (continued)

14.Never use solvents to clean plastic parts. Solvents could dissolve or otherwise damage the

material. Use only a soft damp cloth to clean plastic parts.

15.Never cut metals or materials which may create hazardous dust.

16.Always use in a well-ventilated area. Remove sawdust frequently. Clean out sawdust from the

interior of the saw to prevent a possible fire hazard.

17.To operate properly, this saw must be mounted on the leg stand or on a suitable work surface.

Failure to provide a sawdust fall-through and removal hole will allow sawdust to build up in the

motor area, which is a fire hazard and may cause motor damage.

18.Make sure there are no nails or foreign objects in the part of the workpiece to be cut.

19.Make sure there is no debris between the workpiece and its supports.

20.Use only sharp, clean blades with properly setteeth.

21.Do not usethe saw without the proper blade insert.

O_mer's Manual

Electricalinformation

Grounding Instructions

IN THE EVENT OFAMALFUNCTION OR BREAKDOWN,grounding provides the path of least resistance

for electric current and reduces the risk of electric shock. This tool is equipped withan electric cord

that has anequipment grounding conductor and a grounding plug. The plug MUST be plugged into a

matching outlet that is properly installed and grounded in accordance with ALL local codes and

ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not fit the outlet, have the proper outlet installed by

an electrician.

IMPROPER CONNECTIONof the equipment grounding conductor can result in electric shock. The

conductor with the green insulation (with or without yellow stripes) is the equipment grounding

conductor. If repair or replacement of the electric cord or plug is necessary, DO NOTconnect the

equipment grounding conductor to alive terminal.

CHECK with a licensed electrician or service personnel if you do not completely understand

thegrounding instructions, or if you are not sure if the tool is properly grounded.

USE ONLY THREE-WIRE EXTENSION CORDS that have 3-pronged Fig. A

plugs and outlets that accept the tool's plug as shown in Fig. A.

Repair or replace a damaged or worn cord immediately.

1 3-pronge(I _lLIg 2 Properly grounded outlet

3 Grounding prong

CAUTION: In all case, make certain the outlet in question isproperly grounded. If you are not sure

if it is, havea licensed electrician check the outlet.

OWRGF'S MaNual

O_ler's MaNua|

Electricalinformation(continued)

[_JL ARNING: This tablesaw is for indoor use only. Do not expose to rain or use in damp Ilocations.

Guidelinesforusingextensioncords

Makesureyourextensioncordisingoodcondition.Whenusingan extensioncord, besuretouse

oneheavyenoughto carrythecurrentyour productwill draw.Anundersizedcordwill causea drop

in linevoltageresultinginloseofpowerandoverheating.Thetablebelowshowsthecorrectsizeto

be usedaccordingto cord lengthandnameplateampererating.If indoubt, usethenextheavier

gauge.Thesmallerthe gaugenumber,the heavierthecord.

Minimum Gauge for Extension Cords (AWG)

AmpereRating TotalLengthefCordin feet!meters)

MoreThan

lO

12

Be sure your extension cord is properly wired and in good condition. Always replace a damaged

extension cord or have it repaired by a qualified person before using it.

Protect your extension cords from sharp objects, excessive heat and damp or wet areas.

Use aseparate electrical circuit for your tools. This circuit must not be less than a#12 wire and

should be protected with a 15 Atime-delayed fuse. Before connecting the motor to the power line,

make sure the switch is in the OFFposition and the electric current is rated the same as the current

stamped on the motor nameplate. Running at a lower voltage will damage the motor.

NetMoreThan 25(7.6) 50(15) 100(30.4) 150(45.7)

o

6

electricshock.

WARNING: This tool must be grounded while in use to protect the operator from J

6 18 16 16 14

10 18 16 14 12

12 16 16 14 12

16 14 12 NotRecommended

(when using 120 V only)

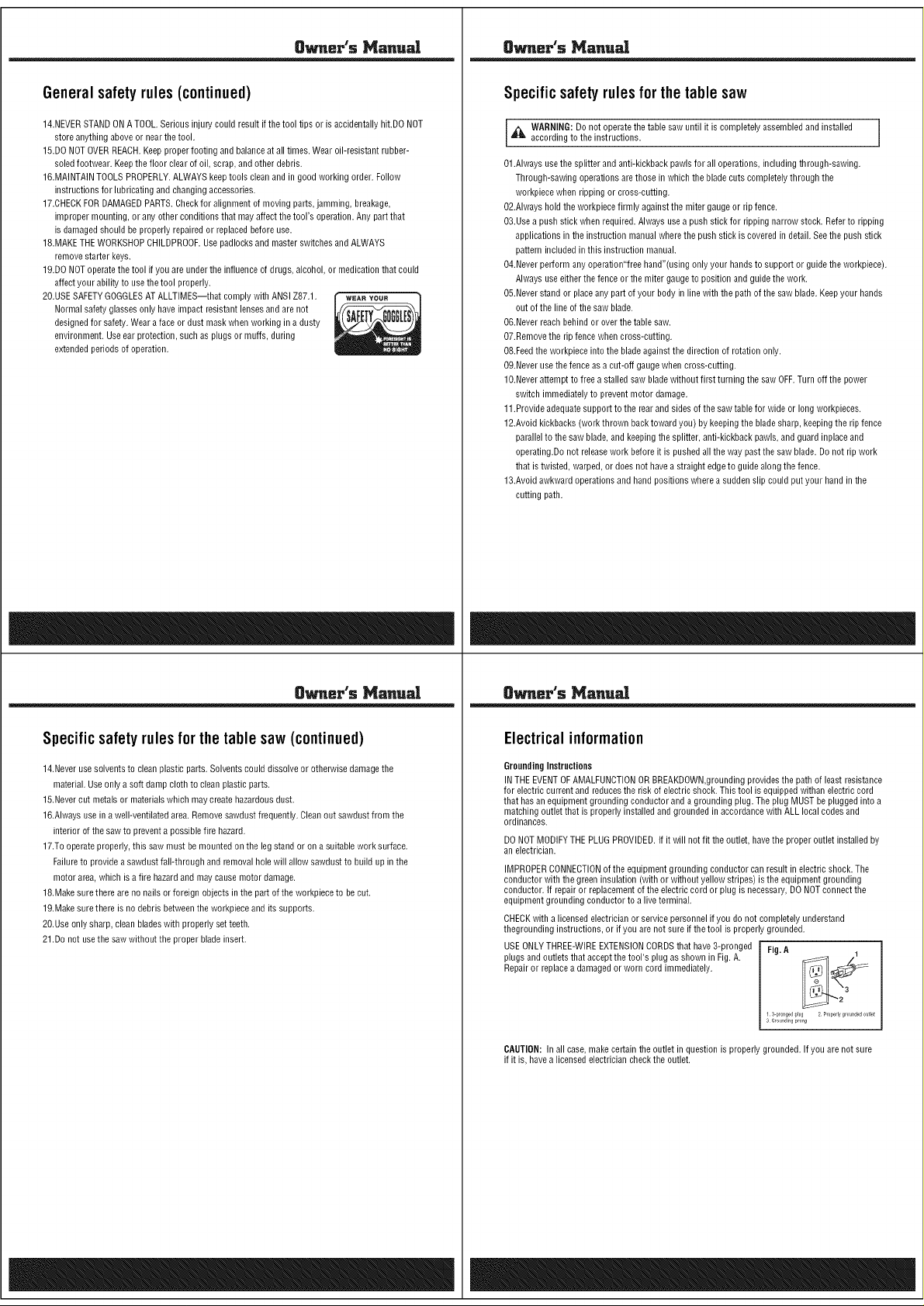

Knowyourtable saw

J

1

A\

\

J

A Sliding miter gauge

B Blade guard

C Blade

D Table insert

E Rip fence

F Table

G Blade elevation/tilting control

wheel

H Base

I Overload reset switch

J ON/OFF switch with safety key

K Blade bevel scale

L Blade bevel lock knob

M Anti-kickback pawl

N Splitter bracket

0 Sawdust port

PSplitter

Q Leg stand

O_er's Manual

Assemblyand adjustments

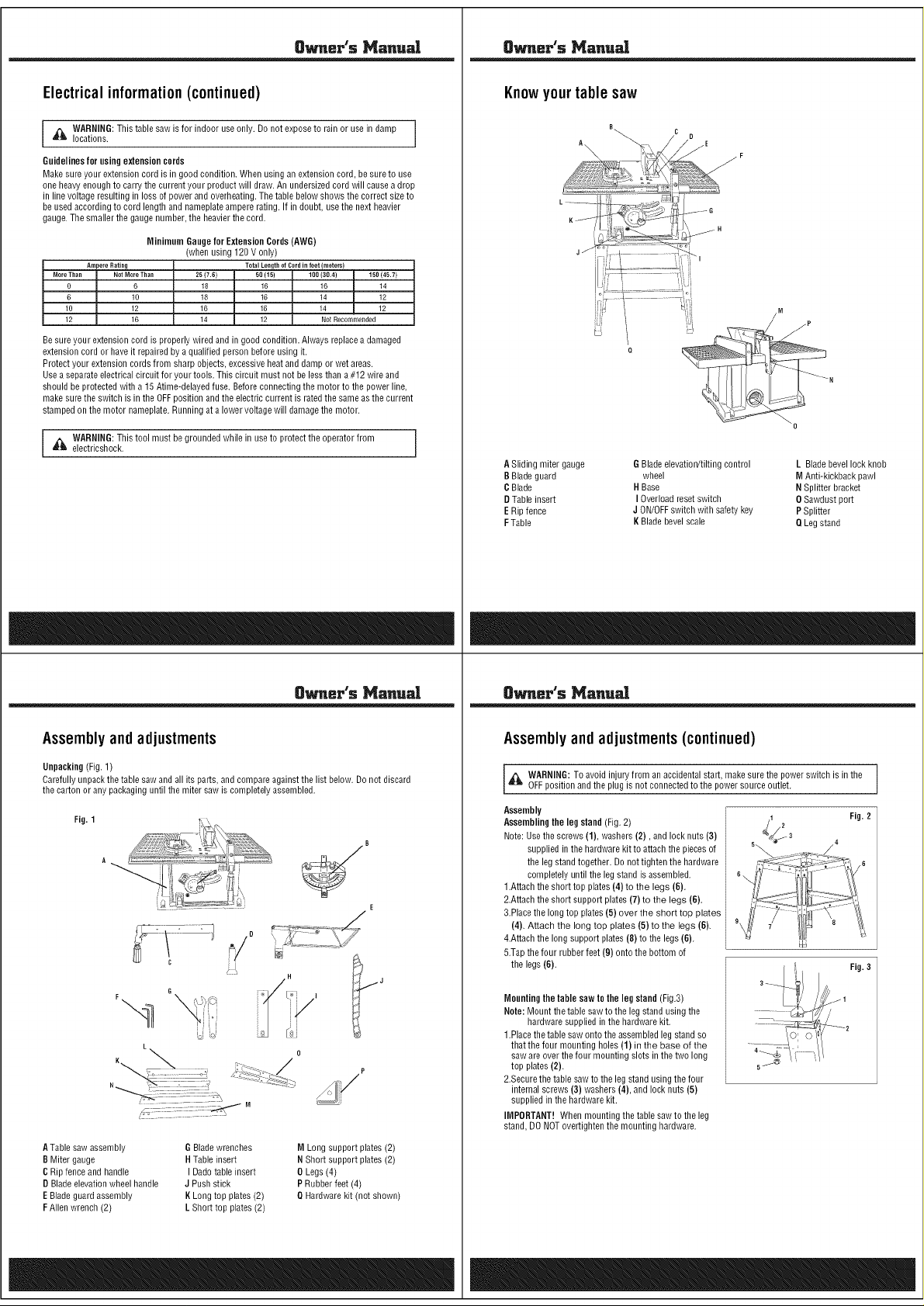

Unpacking (Fig. 1)

Carefully unpack the table saw and all its parts, and compare against the list below. Do not discard

the carton or any packaging until the miter saw is completely assembled.

Fig. 1

A _ 0

E

0

. /o

A Table saw assembly G Blade wrenches M Long support plates (2)

B Miter gauge H Table insert N Short support plates (2)

C Rip fence and handle I Dado table insert 0 Legs (4)

D Blade elevation wheel handle J Push stick P Rubber feet (4)

E Blade guard assembly K Long top plates (2) Q Hardware kit (not shown)

FAllen wrench (2) L Short top plates (2)

/J

Owner's Manual

Assemblyand adjustments(continued)

WARNING: To avoid injury from an accidental start, make sure the power switch is in the

OFFposition and the plug is not connected to the power source outlet.

Assembly

Assembling the leg stand (Fig. 2)

Note: Use the screws (1), washers (2), and lock nuts (3)

supplied in the hardware kit to attach the pieces of

the leg stand together. Do not tighten the hardware

completely until the leg stand is assembled.

1 .Attach the short top plates (4) to the legs (B)

2.Attach the short support plates (7) to the legs (6)

3.Place the long top plates (5) over the short top plates

(4), Attach the long top plates (5) to the legs (6),

4.Attach the long support plates (8) to the legs (B).

5.Tap the four rubber feet (9) onto the bottom of

the legs (B).

Mounting the table saw to the leg stand (Fig.3)

Note: Mount the table saw to the leg stand using the

hardware supplied inthe hardware kit.

1 .Place the table saw onto the assembled legstand so

that the four mounting holes (1) in the base of the

saw are over the four mounting slots in the two long

top plates (2).

2.Secure the table saw to the leg stand using the four

internal screws (3) washers (4), and lock nuts (5)

supplied in the hardware kit.

IMPORTANT! When mounting the table saw to the leg

stand, DO NOT overtighten the mounting hardware.

/2

Fig. 2

Fig. 3

Loading...

Loading...