Steelcase 8, 5 Series Series Manual

®

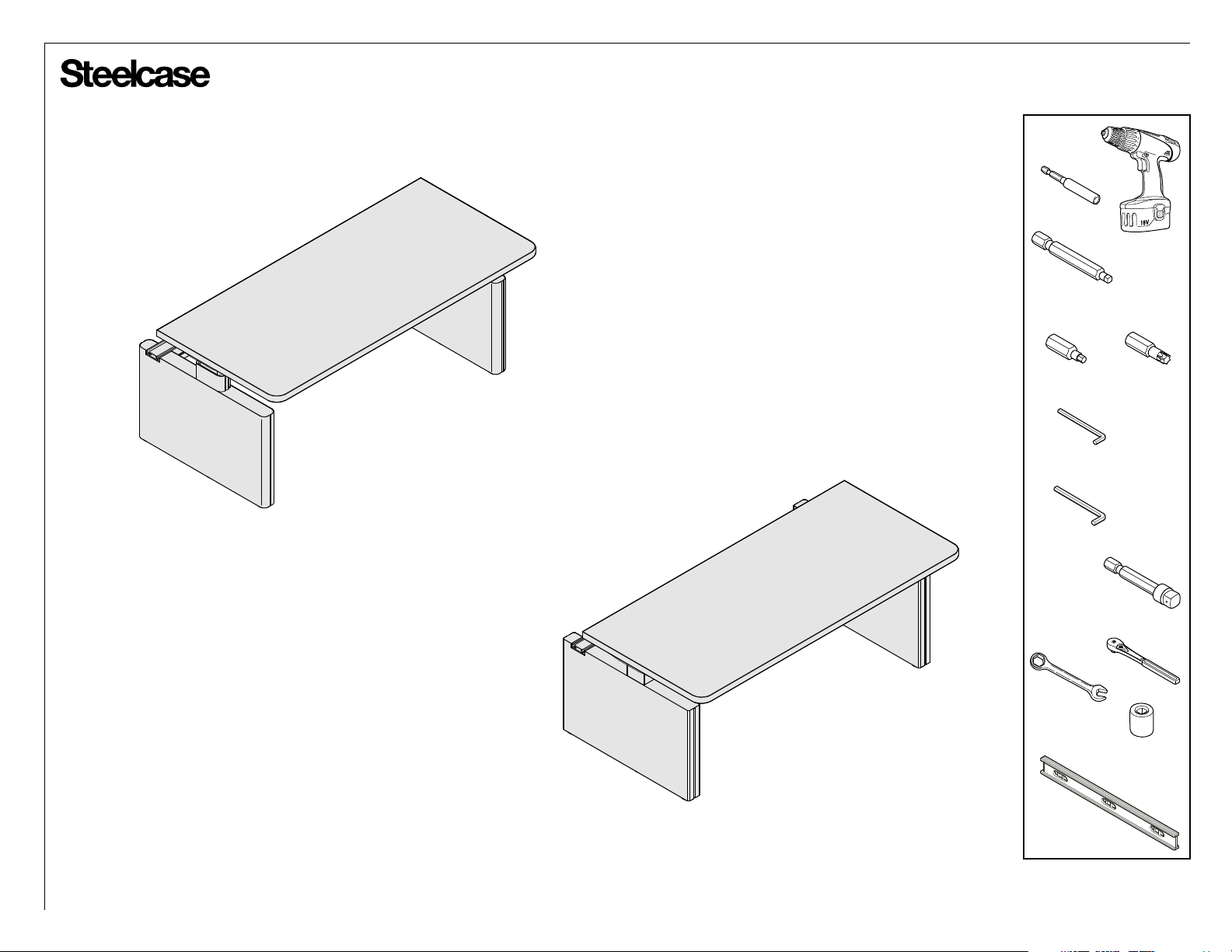

Single Sided Height Adjustable Benching

Bit Holder

Power Drill

Long #2 Square

Drive Bit

SERIES 5

If you have a problem, question, or request, call

your local dealer, or Steelcase Line 1 at

888.STEELCASE (888.783.3522)

for immediate action by people who want to help you.

(Outside the U.S.A., Canada, Mexico, Puerto Rico,

and the U.S. Virgin Islands, call: 1.616.247.2500)

Or visit our website: www.steelcase.com

©

2015 Steelcase Inc.

Grand Rapids, MI 49501

U.S.A.

Printed in U.S.A.

SERIES 8

5mm

Hex Drive Bit

Hex Key - 2.5mm

(Provided)

Hex Key - 3mm

10mm

Wrench

T-30

Torx Drive Bit

Socket Adaptor

(or)

Ratchet

8mm & 10mm

Sockets

Level

Page 1 of 38

939564909 Rev B

®

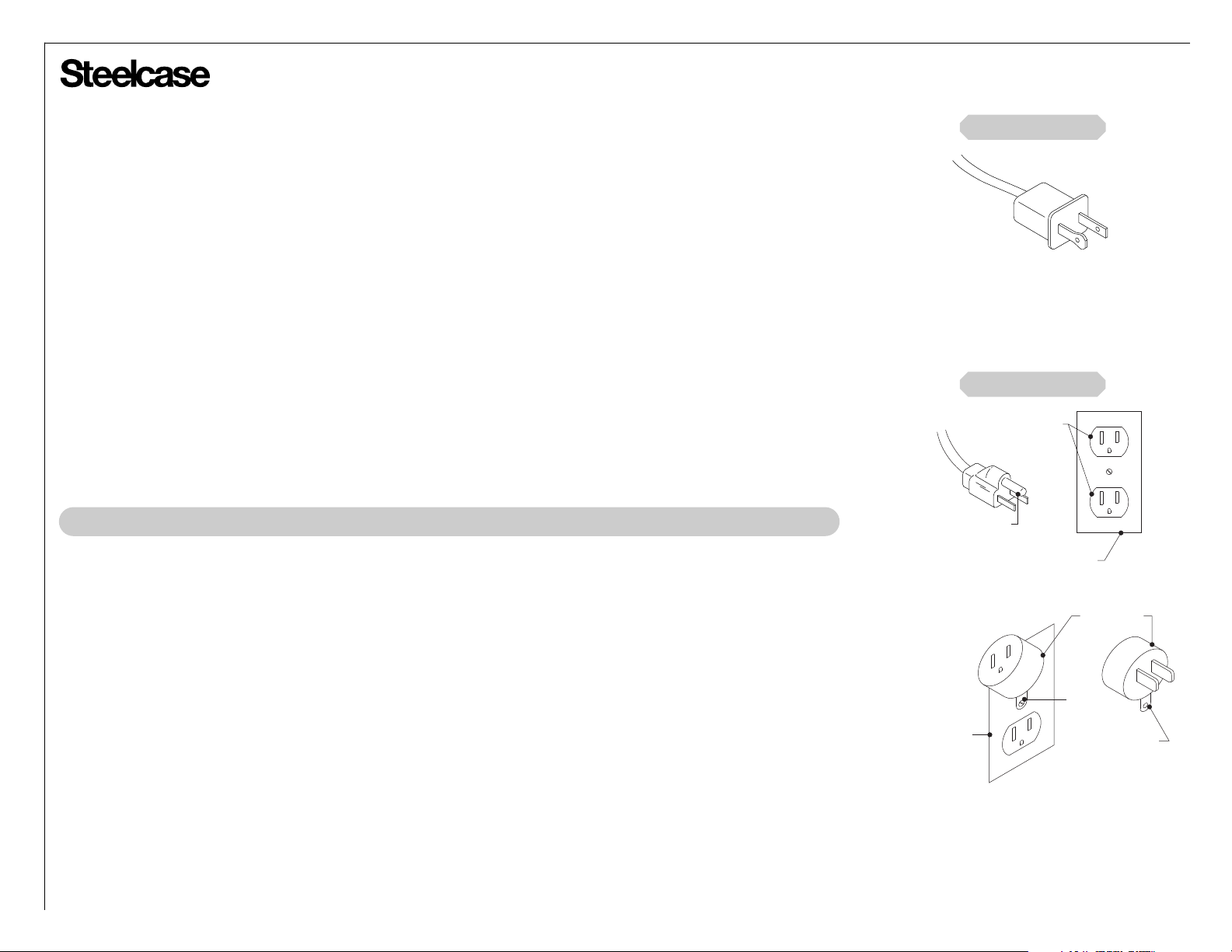

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical furnishing, basic precautions should always be followed, including the following:

Read all instructions before using (this furnishing).

DANGER - To reduce the risk of electric shock:

1. Always unplug this furnishing from the electrical outlet before cleaning.

WARNING - To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Always unplug this furnishing from the electrical outlet before cleaning.

2. Close supervision is necessary when this furnishing is used by, or near children, invalids, or disabled persons.

3. Use this table only for its intended use as described in these instructions. Do not use attachments not

recommended by the manufacturer.

4. Never operate this table if it has a damaged cord or plug, if it is not working properly, if it has been dropped or

damaged, or dropped into water.

5. Keep the cord away from heated surfaces.

6. Never drop or insert any object into any opening.

7. Do not use outdoors.

8. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

9. For loading always put heavier items at the bottom and not near the top in order to help prevent the possibility

of the furnishing tipping over.

SAVE THESE INSTRUCTIONS

The power socket/outlet shall be installed near the equipment and shall be easily accessible.

OPERATING INSTRUCTIONS - Please refer to the attached Installation Instructions and the provided User Guide.

USER-MAINTENANCE INSTRUCTIONS - The receptacle power block is equipped with a circuit breaker that will shut

off power in an overload condition. Press to reset the circuit breaker to restore power.

POLARIZED PLUG INSTRUCTIONS (Series 8 only) - To reduce the risk of electrical shock, this furnishing has a

polarized plug (one blade is wider than the other) like the plug illustrated in Figure 1. This plug will fit in a polarized

outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified

electricial to install the proper outlet. Do not change the plug in any way.

GROUNDING INSTRUCTIONS (Series 5 only) - This product must be grounded. Connect this appliance to a properly

grounded outlet only. If it should malfunction or breakdown, grounding provides a path of least resistance for electric

current to reduce the risk of electric shock. This product is equipped with a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

DANGER - Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with

a qualified electrician or serviceman if you are in doubt as to whether the product is properly grounded. Do not modify

the plug provided with the product - if it will not fit the outlet, have a proper outlet installed by a qualified electrician.

This product is for use on a nominal 120-V circuit and has a grounding plug that looks like the plug illustrated in

sketch A in Figure 2. Make sure that the product is connected to an outlet having the same configuration as the plug.

No adapter should be used with this product.

GROUNDING

(A)

GROUNDED

OUTLET BOX

(B)

SERIES 8 ONLY

Figure 1

Polarized Plug

SERIES 5 ONLY

GROUNDED

OUTLET

PIN

GROUNDED

OUTLET BOX

ADAPTER

METAL

SCREW

TAB FOR

GROUNDING

SCREW

Figure 2

Grounding methods

Page 2 of 38

939564909 Rev B

®

TABLE OF CONTENTS:

Lets Get Started!............................................................................................

Attaching Mounting Plate to Lifting Columns (Series 5 & 8)......................

Mounting Lifting Columns to Worksurfaces (Series 5 & 8)........................

Series 5 Table Assembly

- Determine Switch Position on your Table...............................................

- Identify the Master & Slave Motors.........................................................

- Installing Driveshafts..............................................................................

- Installing Switch & Power Supply............................................................

- Attaching Driveshaft Covers & Wire Managers......................................

- Connect and Route All Cables................................................................

- Connecting the Table Assemblies & Installing the Center Beam............

- Finishing the Table Assembly..................................................................

Series 8 Table Assembly

- Attaching Control Box & Wire Managers................................................

- Connecting & Routing Cables................................................................

- Attaching the Controller..........................................................................

- Finishing the Lifting Column Installation.................................................

- Connecting the Table Assemblies & Installing the Center Beam............

- Finishing the Table Assembly..................................................................

Installing the Inline Connector........................................................................

Assembling & Attaching the Modular Power Blocks......................................

Assembling & Attaching the Hardwire Power Blocks.....................................

PAGE(S):

4

5

6 - 7

8

9

10 - 13

14

15

16

17

19

20

21

22

23

24

26 - 27

28

29 - 30

31

STOP - Electrical Inspection Required before moving on!

Attaching the Power Trays & Data Tray.........................................................

Attaching Interior Covers...............................................................................

32 - 35

36 - 37

Page 3 of 38

939564909 Rev B

®

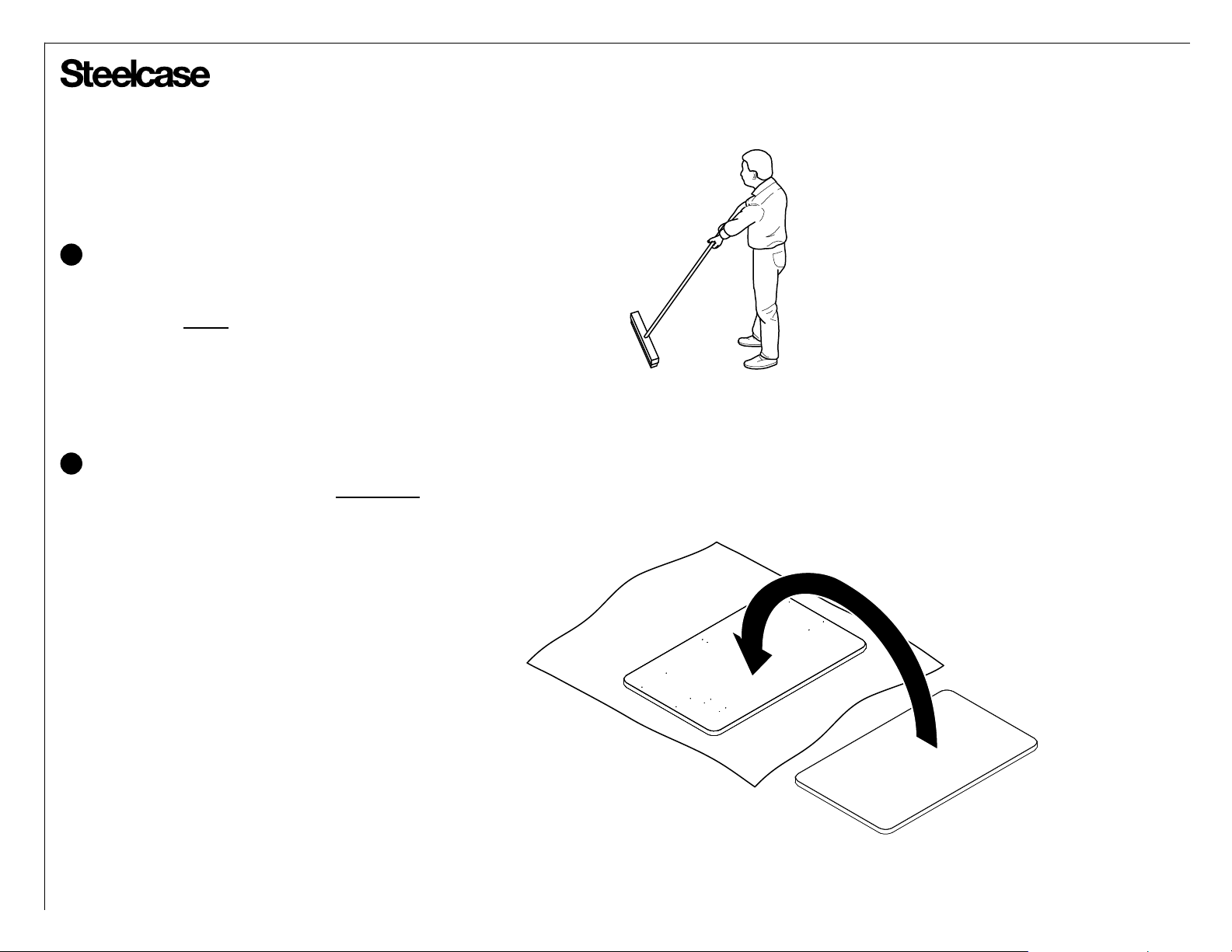

Prepare a large open space to assemble the table.

1

• Sweep the floor! Screws and small parts can damage

the worksurface.

• Put down a CLEAN shipping blanket to protect the worksurfaces.

Unpack the worksurfaces and place on the shipping blanket upsid e-down.

2

• REMEMBER - You're looking at the UNDERSIDE of the worksurfaces.

Are you sure which side is left or right and front or rear?

Page 4 of 38

939564909 Rev B

®

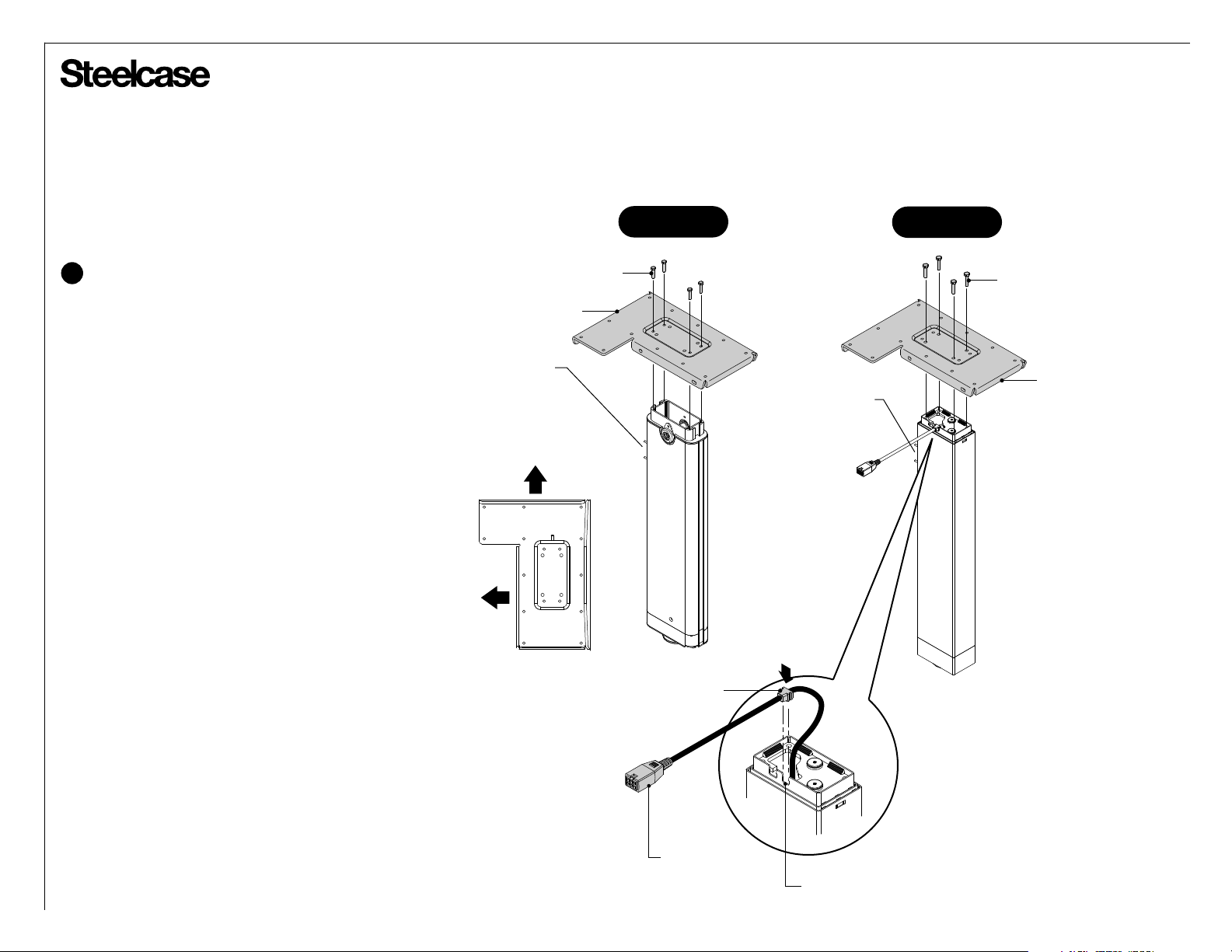

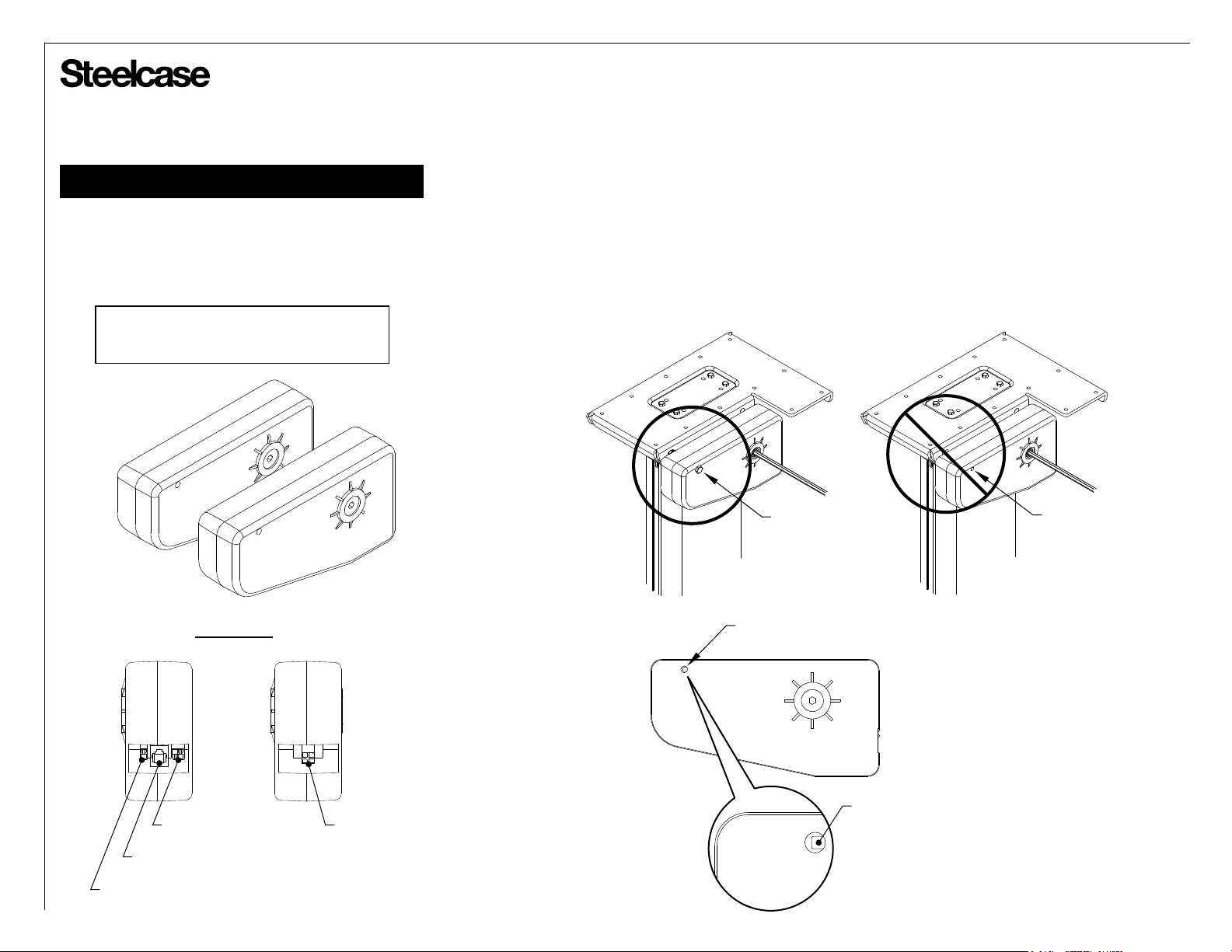

Attaching Mounting Plate to Lifting Columns

3

Series 8 lifting columns are handed.

Secure the plastic strain relief block in

the notch provided in each lift column

before assembling mounting plate.

Locate and install each mounting plate

using 5mm (for Series 5) or 6mm (for

Series 8) hex head fasteners provided.

Do not over-tighten.

TOWARD CENTER

OF WORKSURFACE

8mm HEX HEAD M5 x 25 BOLTS

STUDS ON BACK OF

(TIGHTEN GENTLY WITH

3mm HEX KEY IF LOOSE)

MOUNTING PLATE

LIFTING COLUMN

TOWARD BACK

OF WORKSURFACE

Series 5

Series 8

10mm HEX HEAD M6 x 25 BOLTS

MOUNTING PLATE

STUDS ON BACK OF

LIFTING COLUMN

(TIGHTEN GENTLY WITH

3mm HEX KEY IF LOOSE)

PLASTIC STRAIN RELIEF

WIRING

HARNESS,

TOWARD CENTER

OF WORKSURFACE

NOTCH

Page 5 of 38

939564909 Rev B

®

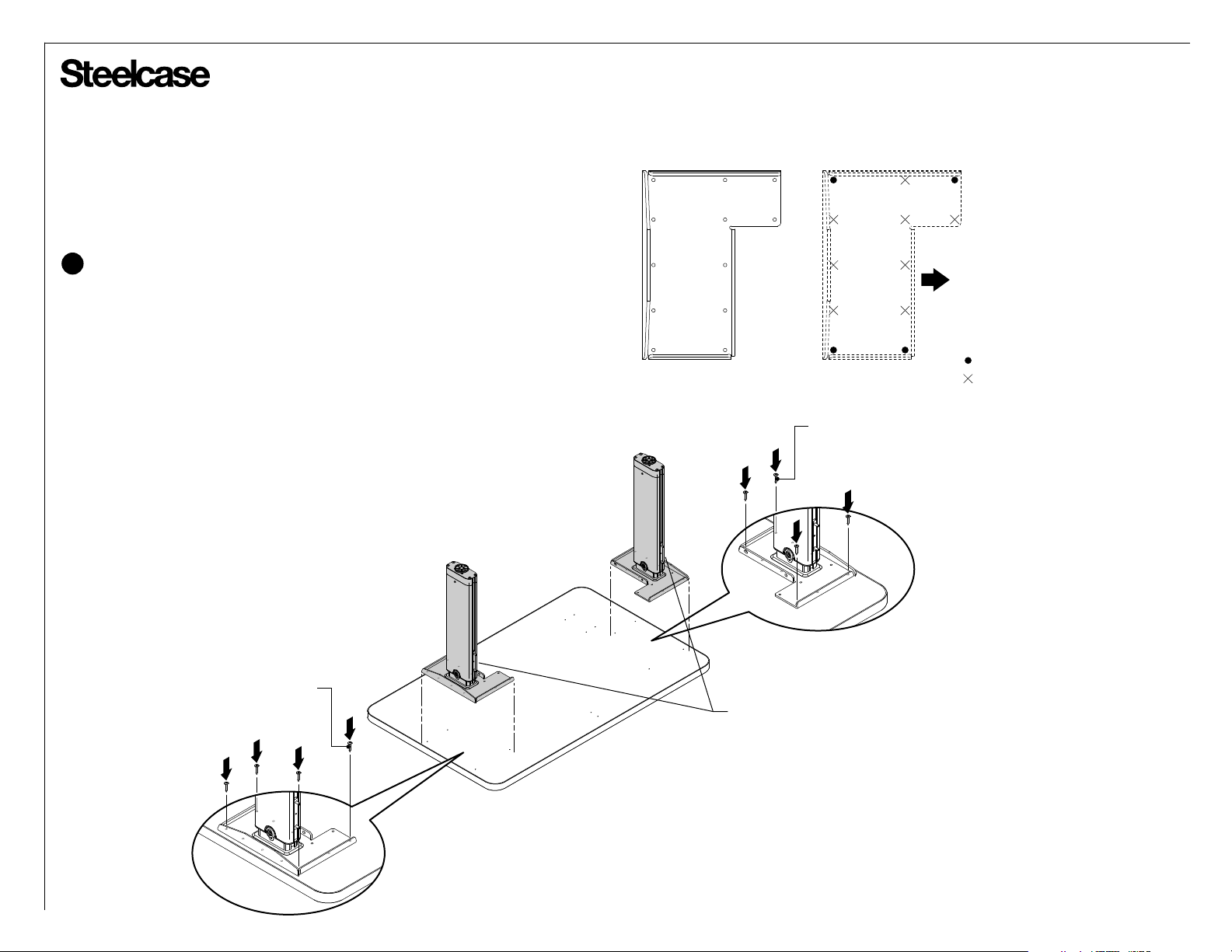

Mounting Lifting Columns to Worksurfaces

4

With the top still upside down on the floor,

turn each leg assembly over and align the

mounting plates to the pre-drilled holes in

the top.

Mounting Plate

Worksurface

Pilot Holes

TOWARD CENTER

OF WORKSURFACE

Install one fastener in each of the

pre-drilled pilot holes.

#2 SQUARE DRIVE

WORKSURFACE

SCREW

= PILOT HOLE

= NO PILOT HOLE PROVIDED

#2 SQUARE DRIVE

WORKSURFACE

SCREW

STUDS FACING BACK

OF WORKSURFACE

Page 6 of 38

939564909 Rev B

®

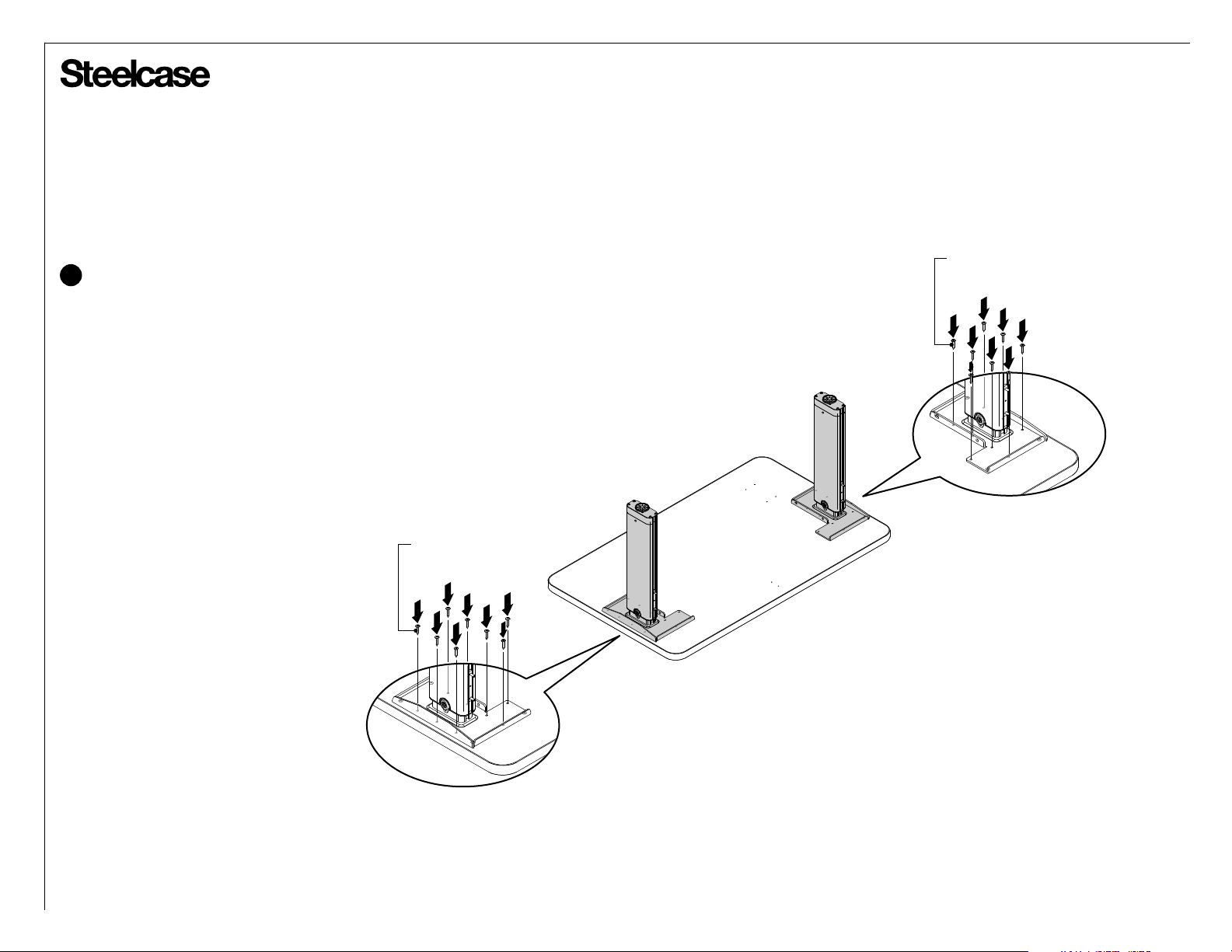

Mounting Lifting Columns to Worksurfaces (cont.)

5

Install one fastener in each of the

remaining holes in the lifting column

mounting plate holes.

#2 SQUARE DRIVE

WORKSURFACE

SCREW

#2 SQUARE DRIVE

WORKSURFACE

SCREW

CAUTION: All holes in the lifting column mounting

plates MUST be filled with screws. Failure to install

all screws may result in structural instability.

Page 7 of 38

939564909 Rev B

®

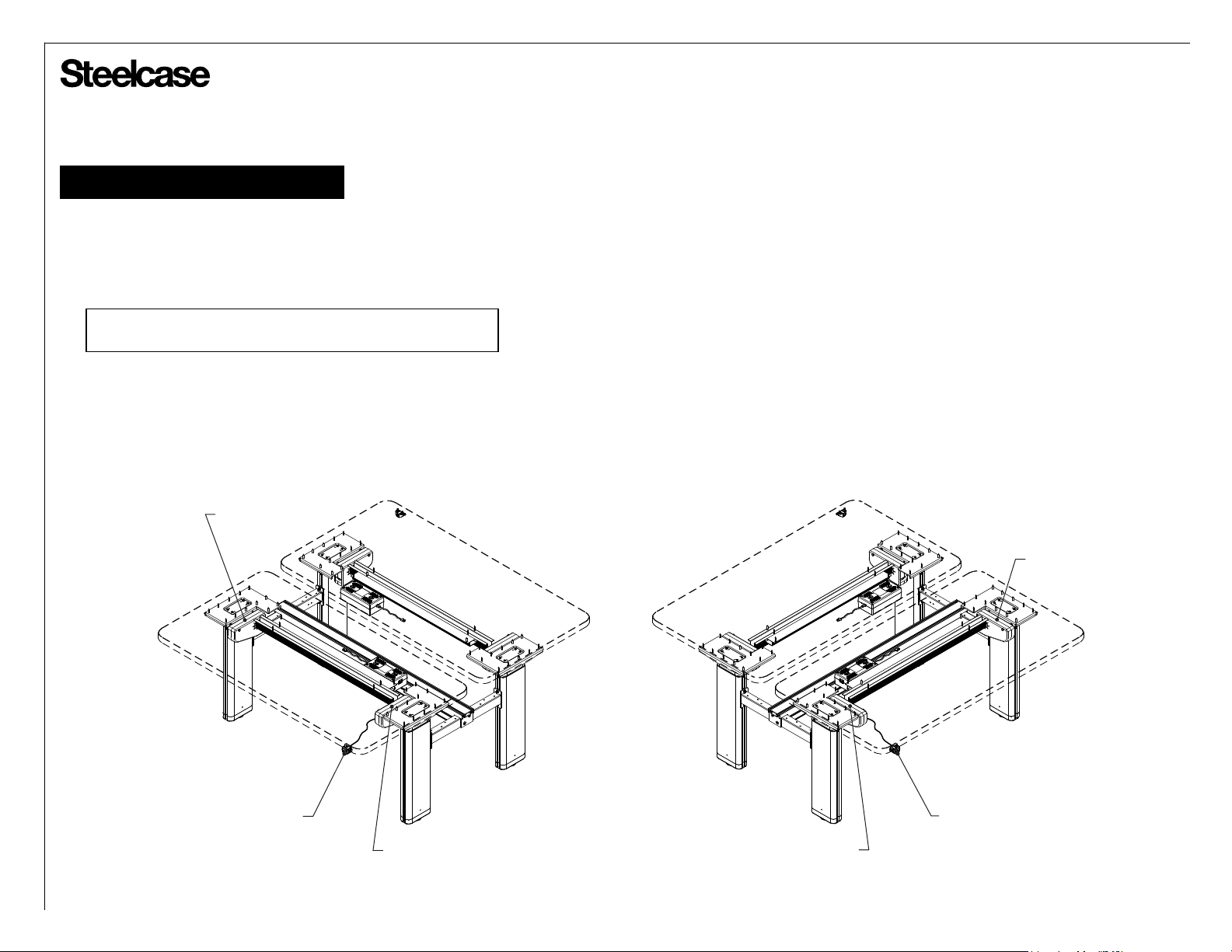

Series 5 Table Assembly

Determine Switch Position on your Table

• The switch can be located on either on either side of your table,

but the switch comes with a short cable to minimize clutter. So,

be sure to always locate the master motor near the switch loc ation.

NOTE: It does not matter which side of the table the master or

slave motor goes on.

SLAVE MOTOR

SWITCH

Switch & Master Motor on Right:

MASTER MOTOR

Switch & Master Motor on Left:

SLAVE MOTOR

SWITCH

MASTER MOTOR

Page 8 of 38

939564909 Rev B

®

Series 5 Table Assembly (cont.)

Identify the Master and Slave Motors

The master motor and slave motor look the same,

except for the connection panel at the back.

NOTE: The power supply converts 120V AC

from the wall outlet to 24V DC. The series 5

motors operate on 24V DC.

Slave

Rear View

Master

Slave

Master

IMPORTANT! The master motor has one other key difference.

It also has a hidden kill switch. This kill switch is inside the

front mounting hole. If the front mounting bolt is not properly

installed, the table will not operate!

CORRECT!

FRONT MOUNTING HOLE

(Table will not operate)

MOUNTING

BOLT

WRONG!

NO MOUNTING

BOLT

4-WIRE CONNECTOR

TO SLAVE MOTOR

RJ-11 SOCKET

FROM SWITCH

2-WIRE CONNECTOR

FROM POWER SUPPLY

KILL SWITCH

SINGLE 4-WIRE

CONNECTOR FROM

MASTER MOTOR

Page 9 of 38

939564909 Rev B

®

Series 5 Table Assembly (cont.)

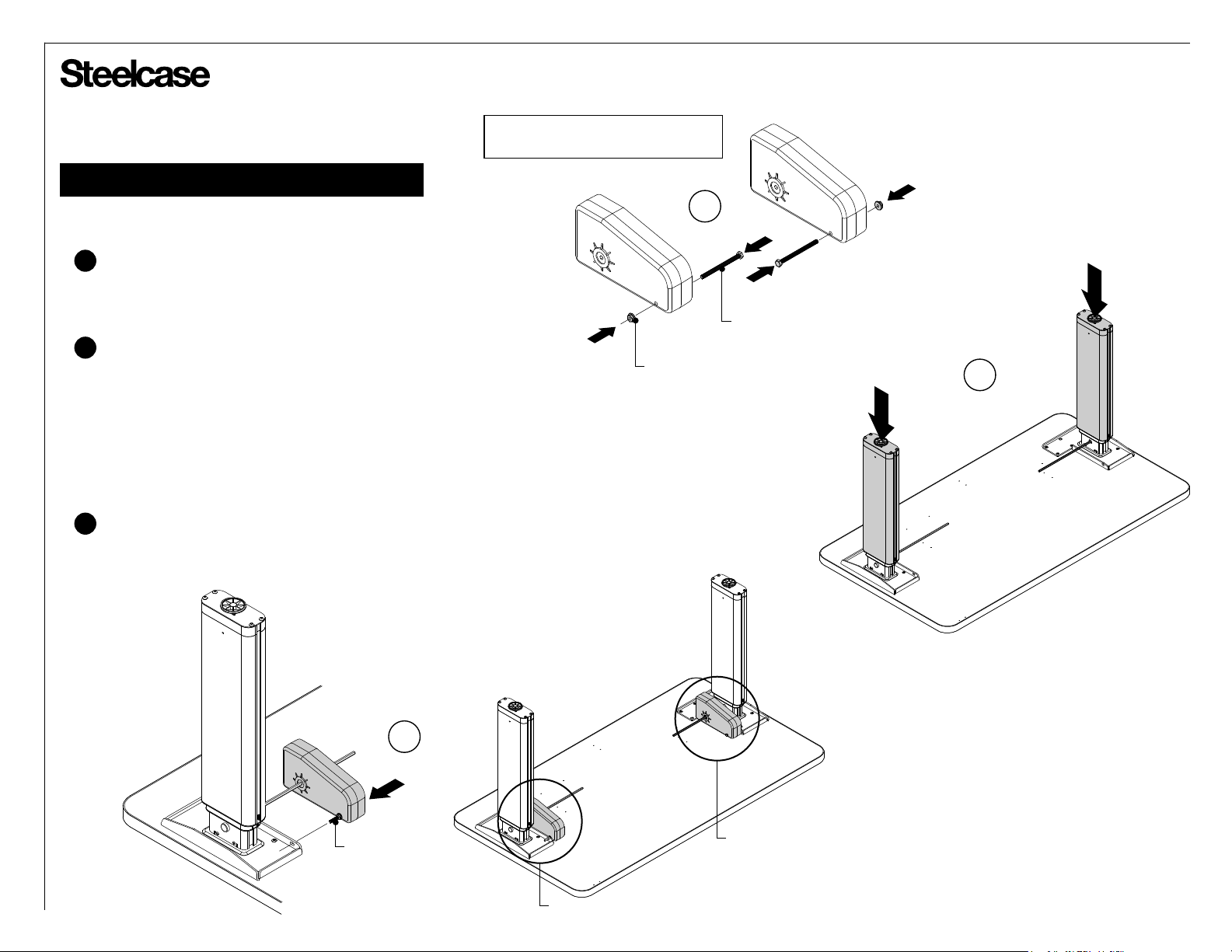

Installing Driveshafts

Driveshafts are retained using cap nuts, which

grip the driveshaft ends and prevent them from

backing out of the lifting columns.

Tables require one cap nut mounted outside of

each lifting column. The driveshaft assembly is

thus retained in both directions.

Place cap nut on a flat, hard surface and push

1

driveshaft into it.

With lifting columns pushed all the way down, feed

2

driveshaft through each lifting column, from outside,

until cap nut bottoms out on each lifting column.

CAP NUT

(with plastic cover)

CAP

NUT

1

CAP

NUT

FINISHED ASSEMBLY

2

Page 10 of 38

939564909 Rev B

®

Series 5 Table Assembly (cont.)

Installing Driveshafts (cont.)

Determine on which side of the table

3

each motor will go. (see page 16)

Install M6 x 80 bolts & M6 nuts to

each motor as shown.

Driveshafts and Lifting Column Synchronization

4

Series 5 lifting columns and motors must be synchronized

before installing the driveshafts.

Series 5 motors are shipped from the factory in the

"all the way down" position.

Before inserting the driveshafts, ensure ALL

LIFTING COLUMNS are pushed all the way down

(fully compressed).

Insert the exposed stud from each motor

5

into the side mounting slot of the outboard

leg mounting plates.

Example: Master motor and switch

on user's right-hand side.

Master Motor

3

10mm M6 HEX NUT

Slave Motor

10mm M6 x 80 HEX HEAD BOLT

4

5

EXPOSED STUD

MOTOR

MOTOR

Page 11 of 38

939564909 Rev B

®

Series 5 Table Assembly (cont.)

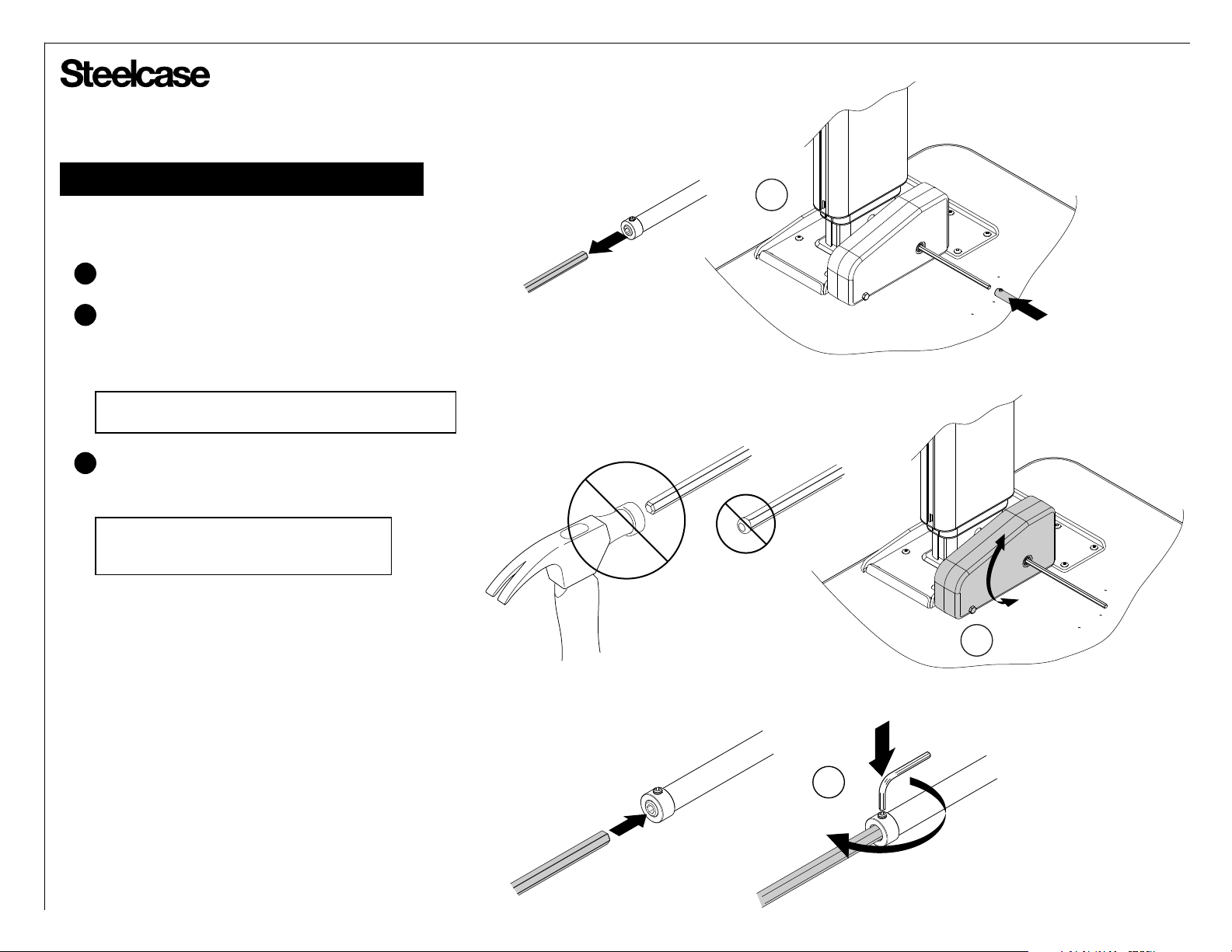

Installing Driveshafts (cont.)

Insert hex shafts into driveshaft tube.

6a

If the hexagon openings are not perfectly aligned,

6b

rotate the motor up and down to align the hex

shaft with the driveshaft tube, until the driveshaft

slides through with ease.

NOTE: DO NOT pound the hex shafts through with a

hammer. This will mushroom the end of the hex shaft.

Ensure all driveshafts are inserted into driveshaft

6c

tubes. Tighten set screws very tightly with

a 3mm hex wrench.

NOTE: DO NOT overtighten the set screws.

Overtightening can strip the threads in the

driveshaft tube.

6a

6c

6b

Page 12 of 38

939564909 Rev B

Loading...

Loading...