Steelcase 5, A5BQ, A5JL, A5CQ, A5JR Series Manual

...

®

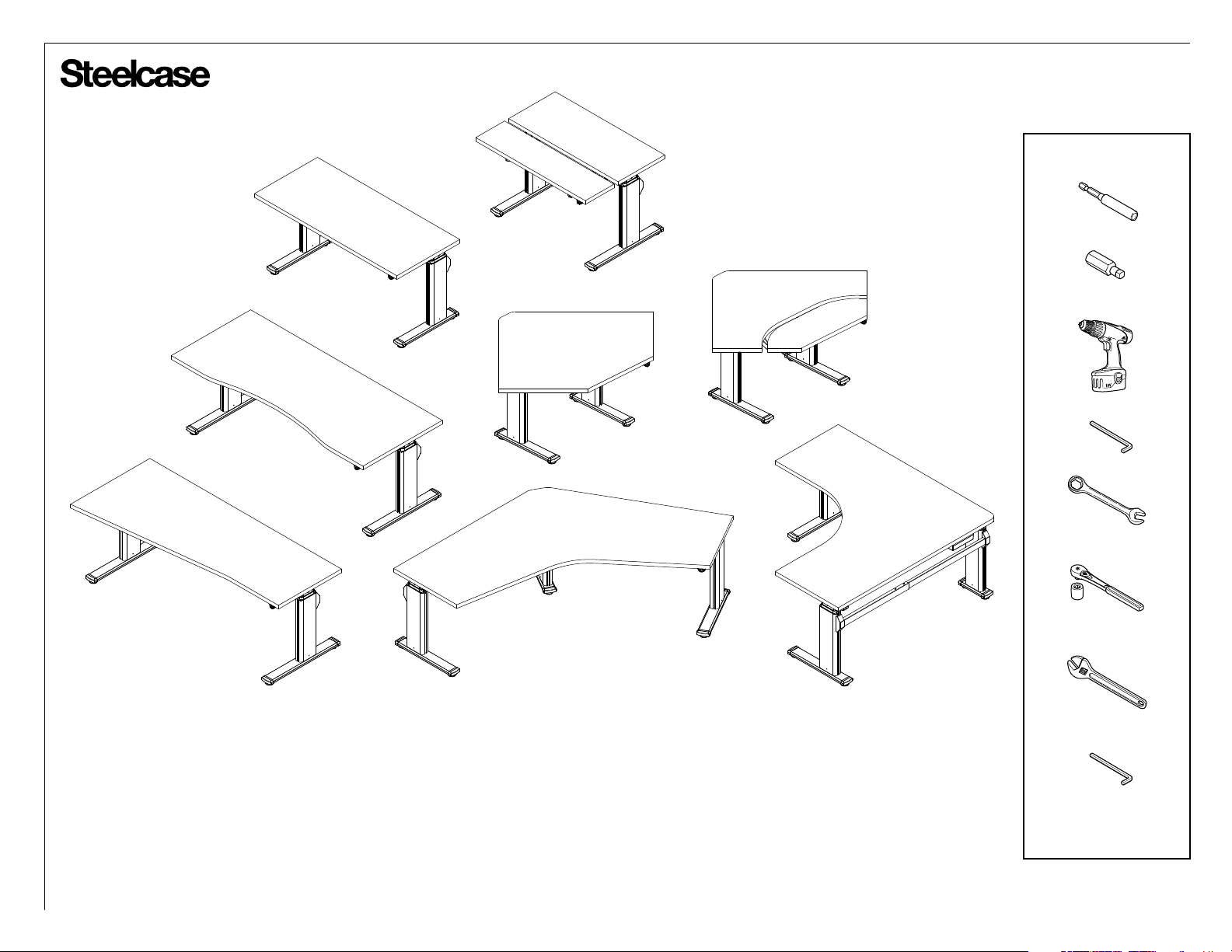

Series 5 Adjustable Height Tables

#2

M3

888.STEELCASE (888.783.3522)

www.steelcase.com

©

2018 Steelcase Inc.

Grand Rapids, MI 49501

U.S.A.

10mm & 14mm

10mm

2.5mm

Page 1 of 35

004231D Rev T

®

Max.

Min.

X

X

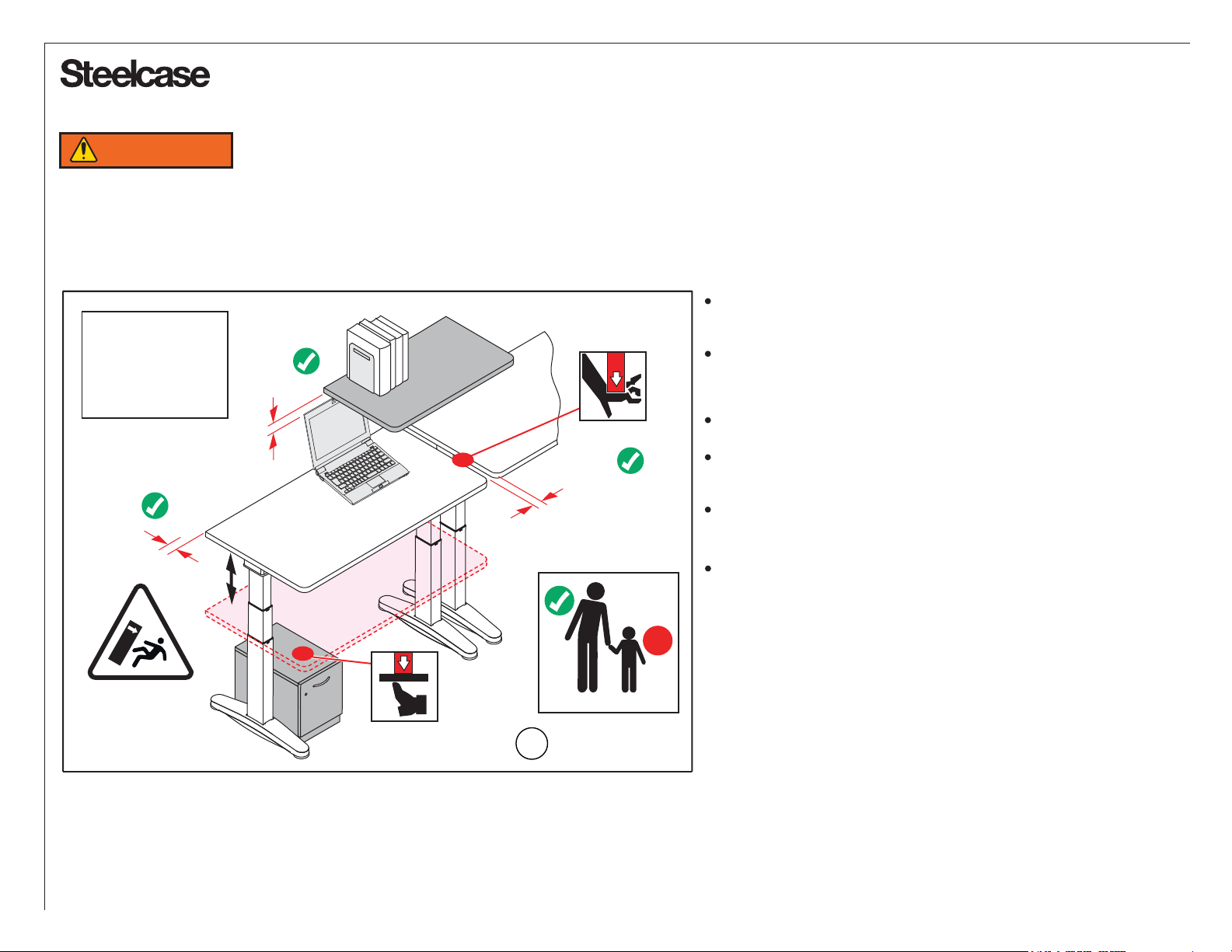

WARNING

This powered, adjustable height desk appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

NOTE: Desk image

is for reference only.

Table shape and leg

quantity may change

based on the style

and configuration.

>1"

(25mm)

RISK OF SERIOUS INJURY DUE TO PINCH POINTS, TIPOVER, OR POTENTIAL COLLAPSE.

RISK OF DEATH OR SERIOUS INJURY. Raising or lowering desk can

trap, pinch or crush body parts or property.

CRUSH HAZARD - DO NOT PLACE FEET, LEGS OR OTHER BODY

>1"

(25mm)

>1"

(25mm)

X

PARTS ON OBJECTS PLACED UNDER TABLE TOP OR BELOW

MODESTY PANEL.

DO NOT OPERATE THIS EQUIPMENT Unless Properly Trained.

DO NOT ALLOW USE BY CHILDREN or people unable to understand

the risks and to safely adjust the desk height.

INSPECT REGULARLY. Stop using if product is damaged or has

loose parts. Only repair with Steelcase authorized parts and methods.

MAINTAIN >1” (25mm) GAP ABOVE OBJECTS ON DESK AT MAX

HIEGHT AND BETWEEN THE DESK & ADJACENT OBJECTS.

Locate desk, accessories, and nearby objects to allow movement of

desktop through full range without pulling cords, trapping body parts,

or colliding with anything (shelves, electrical plugs and cords, door

knobs, window sills, storage cabinets, etc.)

1/888.783.3522

?

www.steelcase.com

Page 2 of 35

004231D Rev T

®

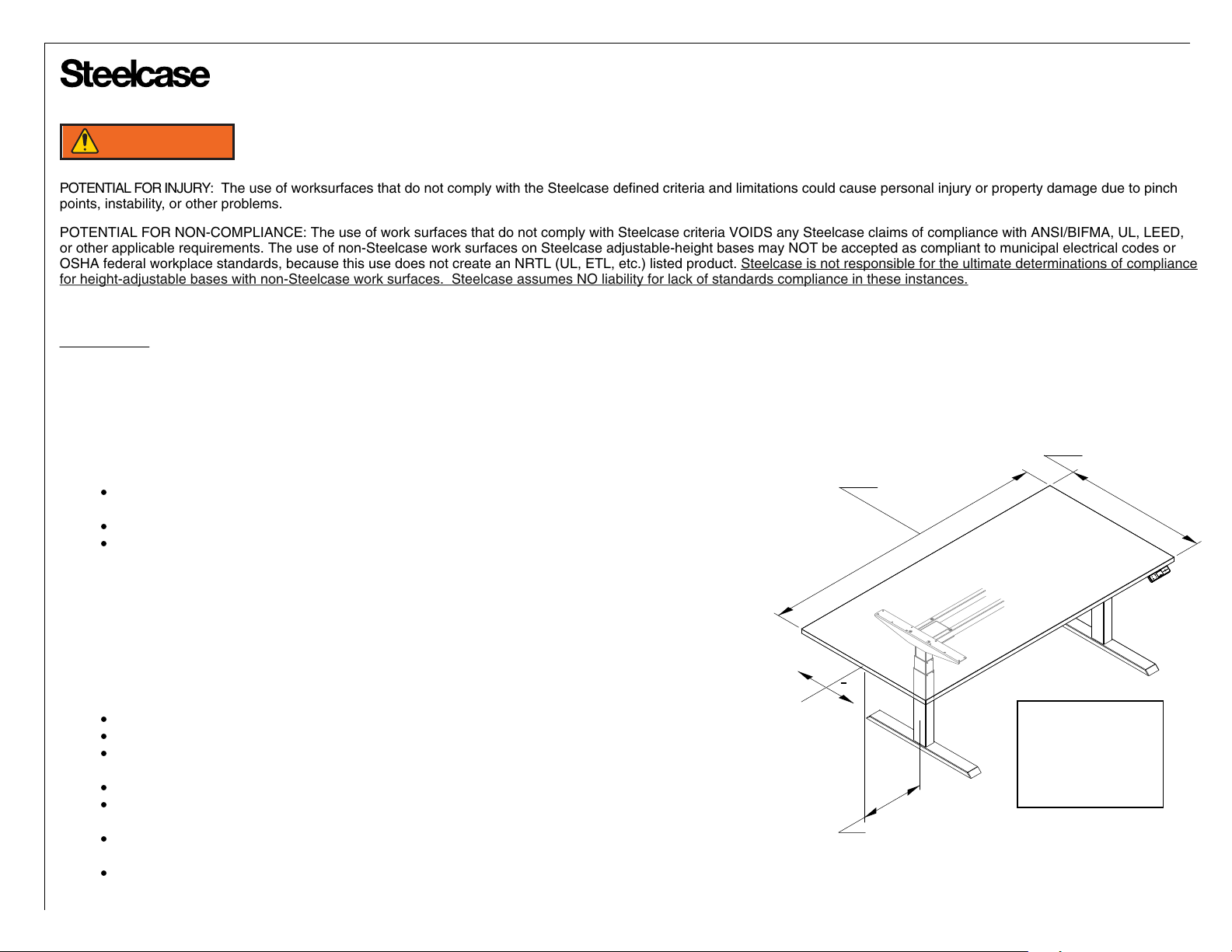

POTENTIAL FOR INJURY

: The use of worksurfaces that do not comply with the Steelcase defined criteria and limitations could cause personal injury or p

roperty damage due to pinch

points, instabilit

y

, or other problems.

POTENTIAL FOR NON-COMPLIANCE: The use of work surfaces that do not comply with Steelcase criteria VOIDS any Steelcase claims of

compliance with ANSI/BIFMA, UL, LEED,

or other applicable requirements. The use of non-Steelcase work surfaces on Steelcase adjustable-height bases may NOT be accept

ed as compliant to municipal electrical codes or

OSHA federal workplace standards, because this use does not create an NRTL (UL, ETL, etc.) listed product.

Steelcase is not responsible for the ultimate determinations of compliance

for height-adjustable bases with non-Steelcase work surfaces. Steelcase assumes NO liability for lack of standards compliance

in these instances.

BASE-ONLY

WARNING

WARRANTY RESTRICTIONS: The use of non-Steelcase supplied work surfaces VOIDS all Steelcase warranties, expressed or implied.

DISCLAIMER: The use of non-Steelcase work surfaces is NOT recommended. Any use of a non-Steelcase work surface requires additional investigation by the customer regarding the

appropriateness for use. It is the sole responsibility of the customer to determine the suitability and safety of the selected work surface construction and attachment means. The following

information is provided as a guideline, but does not address all potential issues. Customers should seek professional guidance as to the appropriateness of their chosen work surface.

MANDATORY REQUIREMENTS REGARDLESS OF WORK SURFACE MATERIAL OR CONSTRUCTION:

FASTENERS: Adjustable-height bases include fasteners intended for use with Steelcase work surfaces.

These fasteners may potentially also be suitable for work surfaces meeting the following criteria:

Medium-density or higher particleboard or fiberboard cores with High-pressure laminate (HPL), Low pressure laminate (LPL) or veneer & backers

Thickness of .984” (25.0 mm) or greater

Fasteners located a minimum distance of .984” (25.0 mm) from any edge

Any other work surface construction will require different and/or additional fastening means and these means

must be determined by the project’s designer, architect, or engineer. For example, solid-surface materials

should use appropriate threaded inserts and corresponding fasteners or similar attachment means.

RISK OF SERIOUS INJURY:

WORKSURFACE

DEPTH

WORKSURFACE

WIDTH

In all cases, all fastener locations provided in the base attachment features MUST be used (e.g. if attachment

cantilever has 6 screw holes, all 6 holes must be used for attachment).

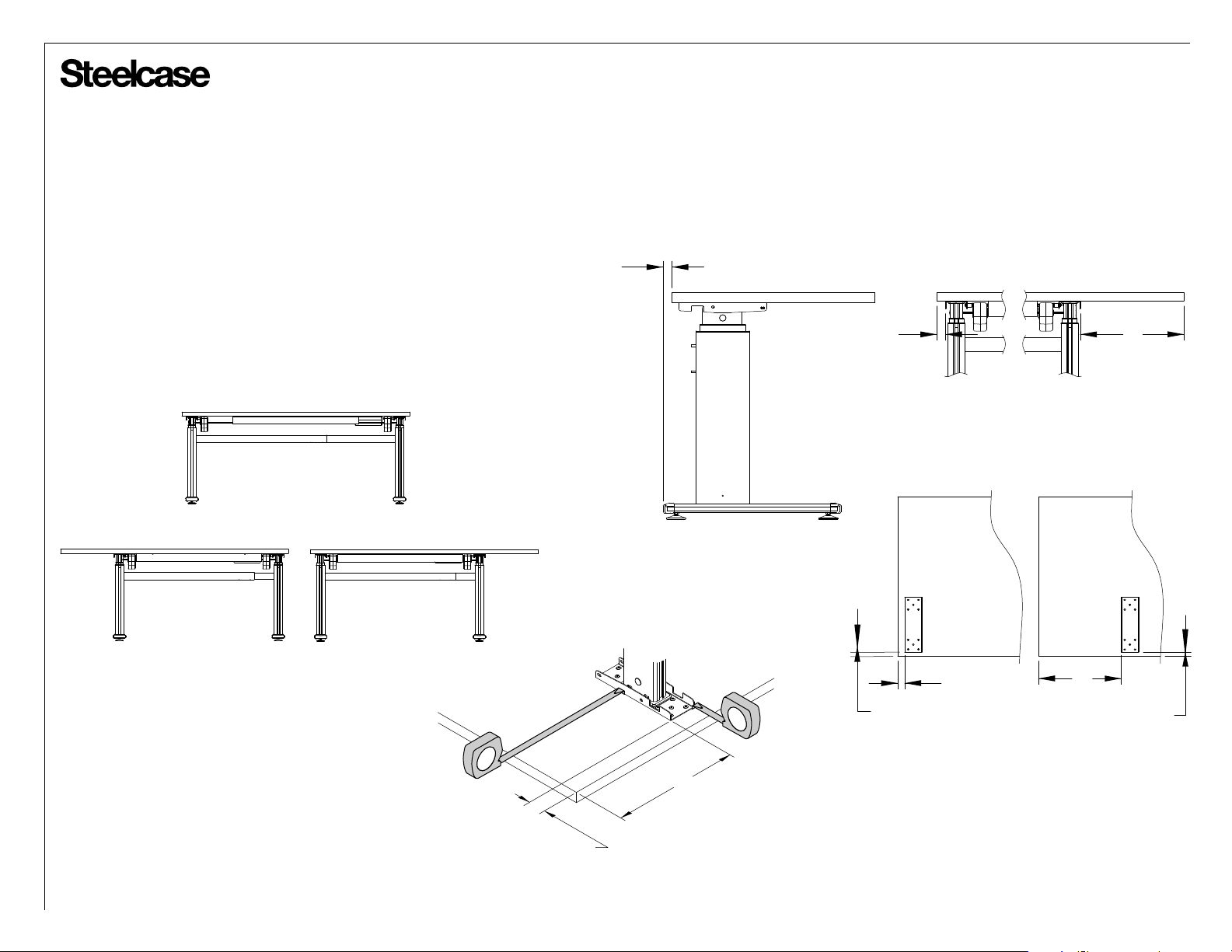

DIMENSIONAL LIMITATIONS:

Work surface depth not to exceed 36.0” (914.4 mm)

Longitudinal work surface position on base must be on centerline ± 2.0” (50.8 mm)

Work surface overhang (distance from side of support cantilever to edge of work surface) must be

greater than .984” (25.0mm) and may not exceed 15.0” (381 mm)

Work surface overhangs larger than .984” (25.0mm) are not allowed on widths < 64.0” (1625.6 mm)

Work surface overhangs between .984” (25.0mm) and 15.0” (381 mm) may exist on one side only for

tops that are ≥ 64.0” (1625.6 mm) and ≤ 71.645” (1820.8 mm)

Work surfaces larger than 71.685” (1820.8 mm) must have overhangs larger than .984” (25.0mm) on

at least one side, but may not exceed 15.0” (381 mm) on any side

Maximum work surface width may not exceed 101.685” (2582.8 mm)

+

C

L

FOLLOW ALL WARNINGS PROVIDED FOR BASE + WORK SURFACE.

NOTE: Desk image

is for reference only.

Table shape and leg

quantity may change

based on the style

and configuration.

WORKSURFACE

OVERHANG

Page 3 of 35

004231D Rev T

®

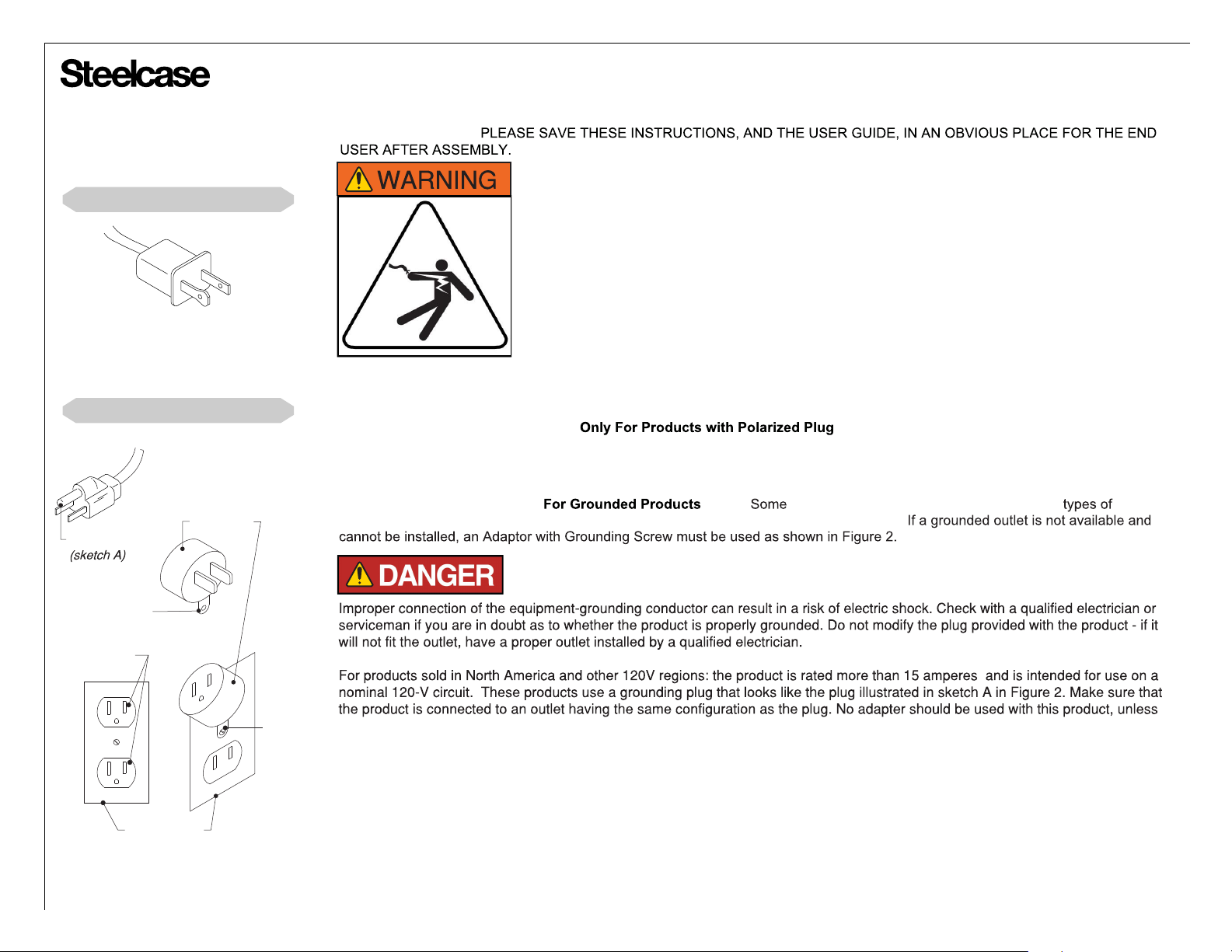

Products with Polarized Plugs

Figure 1

Polarized Plug

Products with Grounded Plugs

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical furnishing, basic precautions should always be followed, including the following: Read all instructions before

using (this furnishing).

1. Always unplug this furnishing from the electrical outlet before cleaning.

2. Use this table only for its intended use as described in these instructions. Do not use attachments not

recommended by the manufacturer.

3. Never operate this table if it has a damaged cord or plug, if it is not working properly, or if it has been

dropped or damaged.

4. Keep the cord away from heated surfaces.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. For loading always put heavier items at the bottom and not near the top in order to help prevent the

possibility of the furnishing tipping over.

The desk or table shall be installed near power socket & the plug shall be easily accessible.

POLARIZED PLUG INSTRUCTIONS ( ) - To reduce the risk of electrical shock, some

furnishings have a polarized plug (one blade is wider than the other) like the plug illustrated in Figure 1. This plug will fit in a polarized

outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to

install the proper outlet. Do not change the plug in any way.

GROUNDING PIN

TAB FOR

GROUNDING SCREW

GROUNDED

OUTLET

(A)

GROUNDED

OUTLET BOX

Figure 2

Grounding methods

ADAPTER

(B)

METAL

SCREW

GROUNDING INSTRUCTIONS (

appliances to a properly grounded outlet in accordance with all local codes and ordinances.

using the Adapter w Grounding Screw shown in illustration.

only) - products must be grounded. Connect these

PLUG ILLUSTRATION DISCLAIMER - The illustrations shown to the left show a plug typically seen in North America and other 120V

regions. Illustrations shown here may not match your product. Depending on your region, the plug pin size and shape may change.

OPERATING INSTRUCTIONS

Please refer to the provided User Guide, which is also available at www.steelcase.com

Page 4 of 35

004231D Rev T

®

DRIVESHAFT PKG: 9506000 09~34DRIVESHAFT PKG: 9506000 09~34

Parts Provided

Page 5 of 35

004231D Rev T

®

TABLE OF CONTENTS:

PAGE(S):

Lets Get Started!.........................................................................................................

Which Legs Go Where?..............................................................................................

Determine Leg Positions on your Table......................................................................

Overhangs and Custom Leg Positions.......................................................................

Mounting Legs to Worksurfaces.................................................................................

Determine Switch Position on your Table...................................................................

o

Corner Tables.......................................................................................................

90

Left-Hand Tables.........................................................................................................

o

For 90

For 120

Tables.............................................................................................................

o

Tables...........................................................................................................

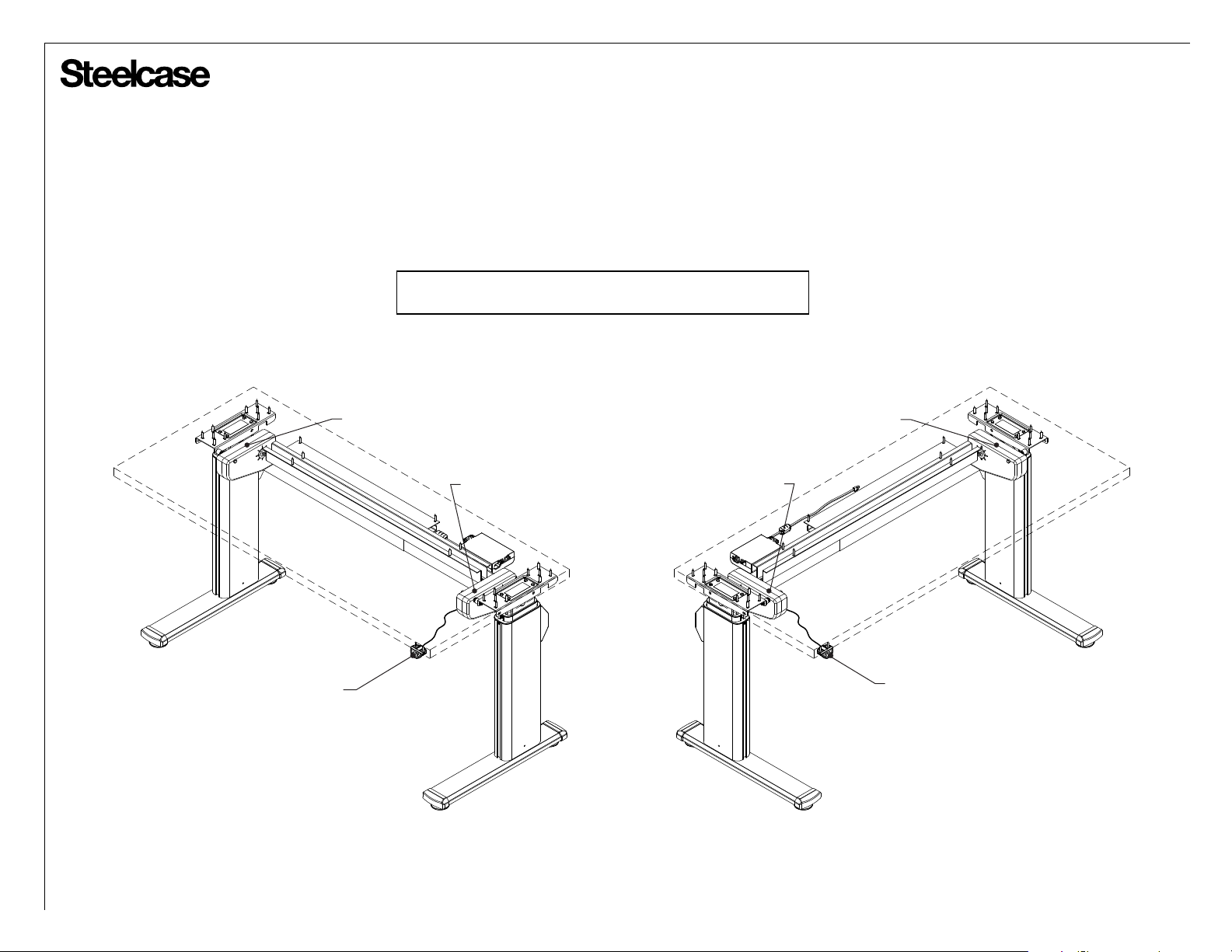

Identify the Primary and Secondary Motors..........................................................................

Installing Motors and Synchronizing Legs...................................................................

Driveshafts and Leg Synchronization..........................................................................

Installing Driveshafts...................................................................................................

Installing Switch & Power Supply................................................................................

Attach Driveshaft Covers and Wire Managers............................................................

Installing Stretchers....................................................................................................

Connect and Route All Cables....................................................................................

Finishing the Table Assembly......................................................................................

Appendix A: 2-Piece Worksurface Assembly..............................................................

Appendix B: Installing a Keyboard Mechanism for Bi-Level Worksurfaces................

6

7

8

8

9

10

11

12

13

13

14

15

15

16 through 19

20

21

22 & 23

24

25

26 & 27

28 through 34

Overview of Assembly Process

1) Decide on the table configuration.

2) Assemble 2-piece worksurface or bi-level mechanism (if applicable).

3) Attach legs to worksurface (with worksurface upside-down).

4) Assemble motors, power supply, and gearbox (if applicable).

5) Synchronize legs and add driveshaft(s).

6) Add stretcher(s) and decorative parts.

7) Add driveshaft cover(s) and wire manager(s).

8) Connect and route all cables, mount switch.

9) Flip table upright and test function.

10) Level and clean it up.

11)

PLEASE LEAVE THESE INSTRUCTIONS, AND THE USER GUIDE,

IN AN OBVIOUS PLACE FOR THE END USER AFTER ASSEMBLY.

Page 6 of 35

004231D Rev T

®

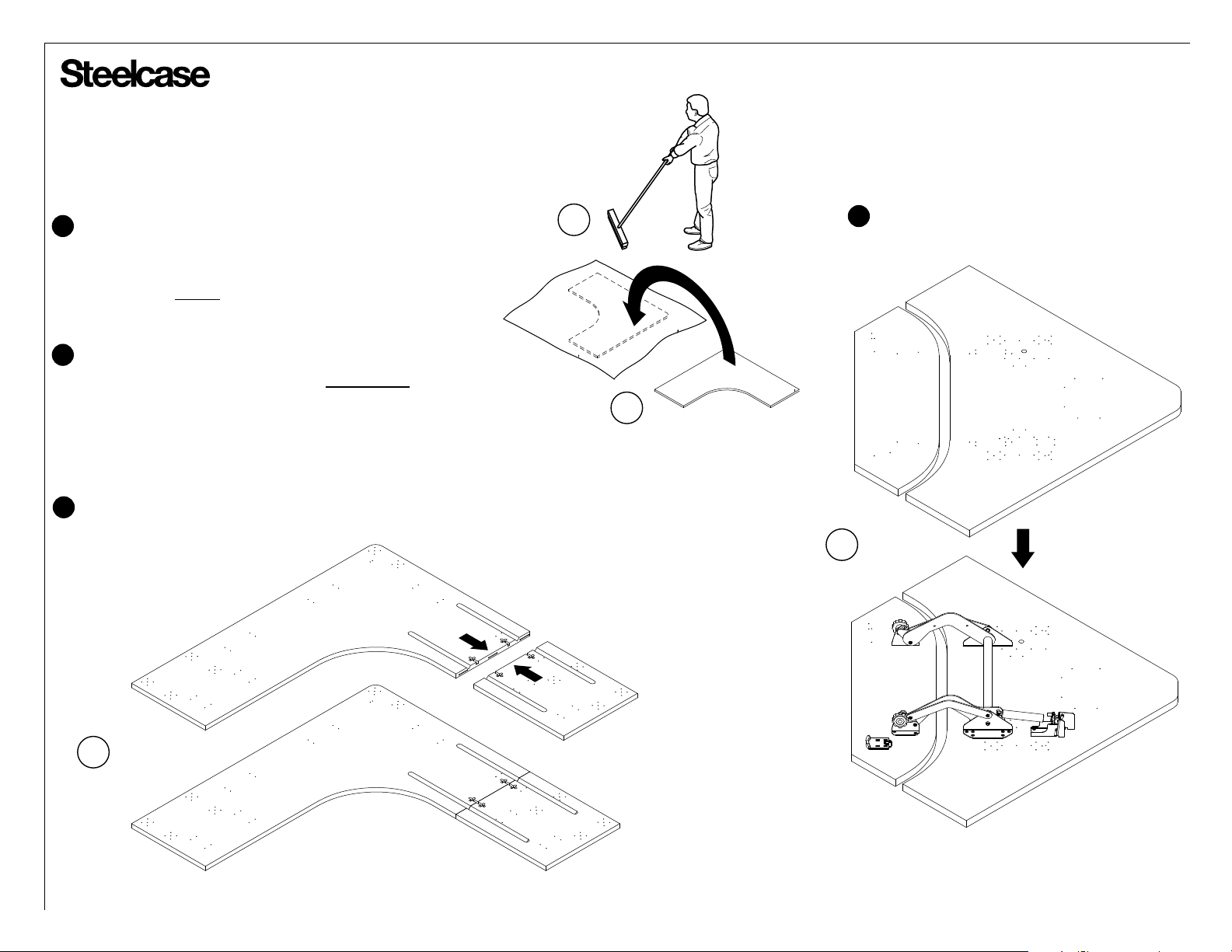

Let’s Get Started

Prepare a large open space to assemble the table.

1

• Sweep the floor! Screws and small parts can damage

the worksurface.

• Put down a CLEAN shipping blanket to protect the worksurface.

Unpack the worksurface and place on the shipping blanket upside -down.

2

• REMEMBER - You're looking at the UNDERSIDE of the worksurface.

Are you sure which side is left or right?

Assembling a monitor-keyboard worksurface with

1

2

4

a bi-level mechanism?

Jump to Appendix 'B' now.

Assembling a 90

3

worksurface?

3

o

corner table with a 2-piece

Jump to Appendix 'A' now.

4

Page 7 of 35

004231D Rev T

®

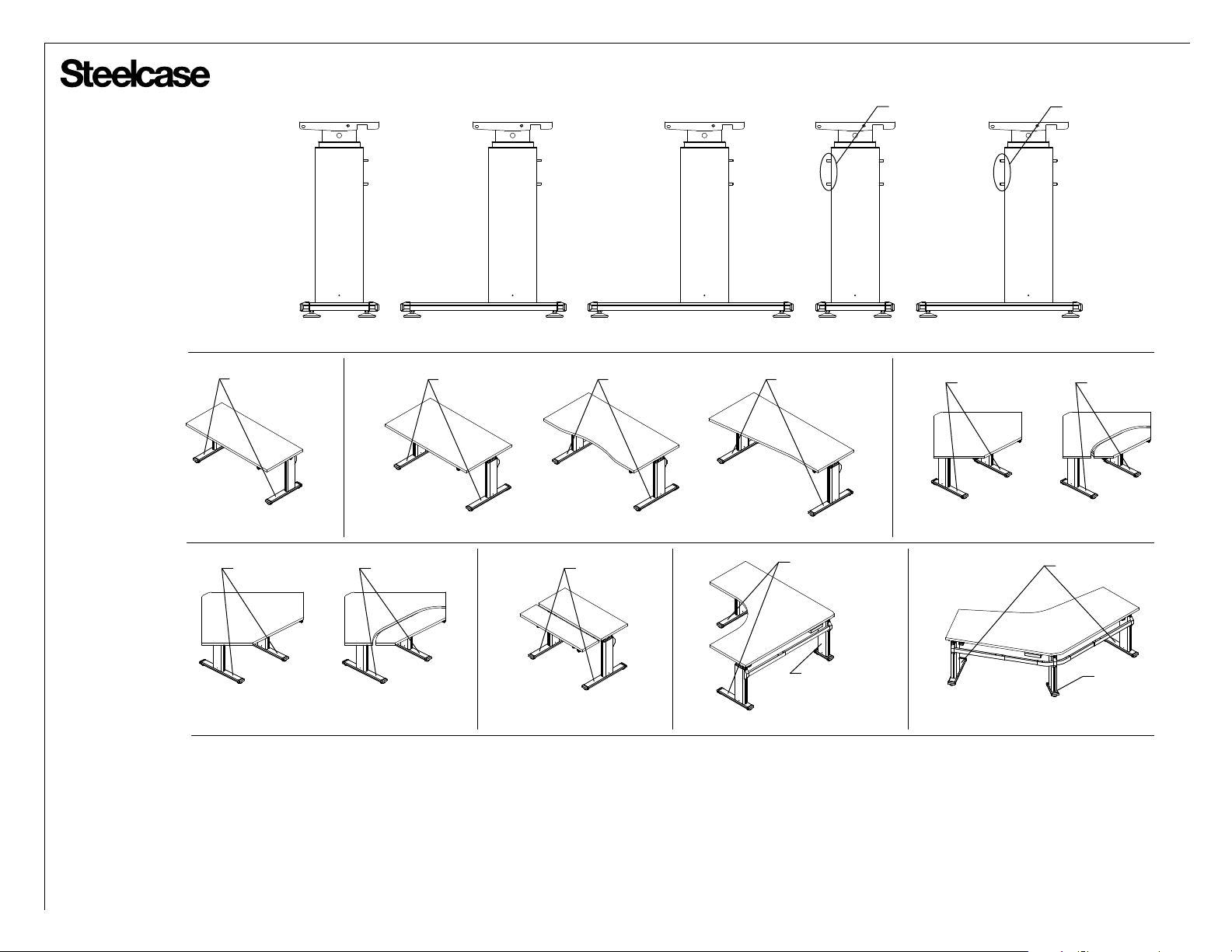

Which Legs Go Where?

Leg Types:

NOTE: Extra studs.

10" Standard 21" Standard 26" Standard 10" Corner 21" Corner

NOTE: Extra studs.

21" Std.

26" Std.

26" Std. 26" Std.

23"D Rectangle 29"D Rectangle Concave Taper-Flat

26" Std.

46" 90

26" Std.

o

46" 90o Bi-Level Rectangle Bi-Level 90o 3-Leg

26" Std.

21" Std.

10" Corner

21" Std. 21" Std.

o

40" 90

40" 90o Bi-Level

21" Std.

10" Std.

o

120

Page 8 of 35

004231D Rev T

®

Determine Leg Positions on your Table:

• Many Series 5 tables allow multiple leg postions, providing flexibility to

maximize leg space, and allow overhangs for CPU slings and mo bile

pedestal placement.

• The smallest tables may not allow for larger worksurface overhangs.

(The standard overhang is 1-1/4".)

• The mid-size tables may allow for a single 15" overhang.

• The largest tables may be capable of allowing dual 15" overhangs.

(One on each side.)

• Refer to the specification guide for the capabilities of your specific table.

NO OVERHANGS

LEFT-HAND OVERHANG

RIGHT-HAND OVERHANG

Overhangs and Custom Leg Positions:

• There are pilot holes in worksurfaces that result in the standard

overhangs (1-1/4" and 15"), as well as a clearance at the back to

avoid pinch-points and provide for cable drop.

1"

CABLE

AND

PINCH-POINT

CLEARANCE

Side View:

1-1/4"

OVERHANG

Standard Mounting Plate Positions:

(Bottom View)

Front of Wksf.

(User Edge)

Front View:

15"

Front of Wksf.

(User Edge)

Legs may be mounted on the worksurface

in locations other than the factory default,

provided that:

• The overhangs DO NOT exceed 15".

• All screws are at least 1" from outside edges.

• All provided components still fit together (stretchers, driveshafts).

• No safety hazards are posed to the end users or installers.

(NO CABLE / PINCH-POINT

1.769"

CLEARANCE, BACK OF

FOOT FLUSH WITH BACK

OF WORKSURACE)

9"

CUSTOM

OVERHANG

0.769"

OFFSET

Back of Wksf.

1-1/4"

OVERHANG

Back of Wksf.

15"

OVERHANG

0.769"

OFFSET

Page 9 of 35

004231D Rev T

®

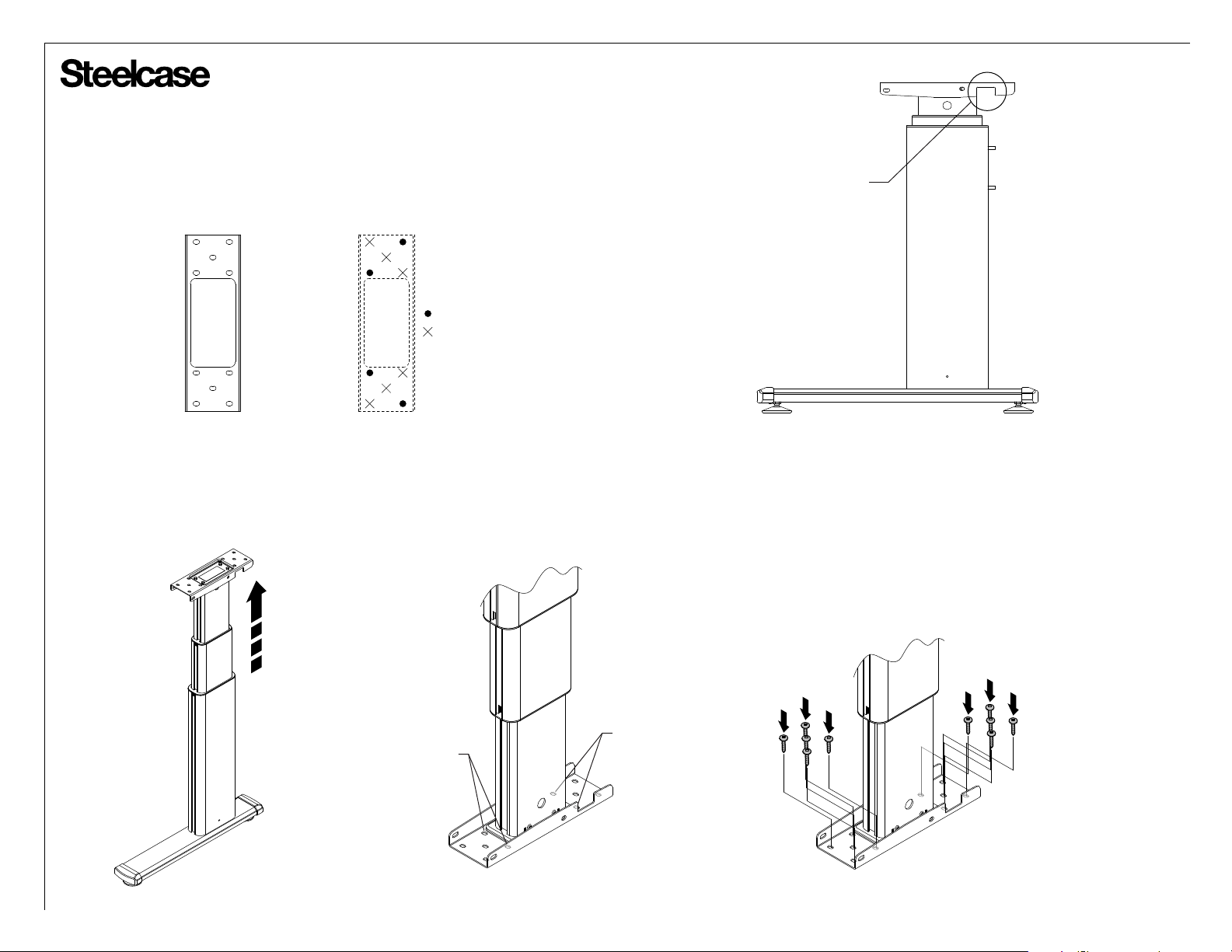

Mounting Legs to Worksurfaces

CAUTION: All holes in the leg mounting plates MUST

be filled with screws. Failure to install all

screws may result in structural instability.

Mounting Plate

Raise leg all the way up.

Worksurface

Pilot Holes

Raising leg allows access to the screws

adjacent to the inner column.

= PILOT HOLE

= NO PILOT HOLE PROVIDED

NOTCH IS ALWAYS

AT BACK OF LEG

(BACK OF TABLE)

Align each leg with the pilot holes in the desired

location, in the correct orientation. Attach each

leg with ten (10) of the provided #10 x 1.075 long

screws. These screws have a special drill-point,

making them easy to drive in without a pilot hole.

See step 10 on Page 18 for additional considerations

before finalizing the mounting of the legs.

FOR EASIER

ACCESS

FOR EASIER

ACCESS

Page 10 of 35

004231D Rev T

®

Determine Switch Position on your Table:

• The switch can be located on either side of your table, but the

switch comes with a short cable to minimize clutter. So, be sure

to always locate the primary motor near the switch location.

NOTE: It does not matter which side of the table the primary or

secondary motor goes on. This applies to all tables.

Switch & Primary Motor on Right:

SECONDARY MOTOR

SWITCH

PRIMARY MOTOR

Switch & Primary Motor on Left:

SECONDARY MOTOR

PRIMARY MOTOR

SWITCH

Page 11 of 35

004231D Rev T

Loading...

Loading...