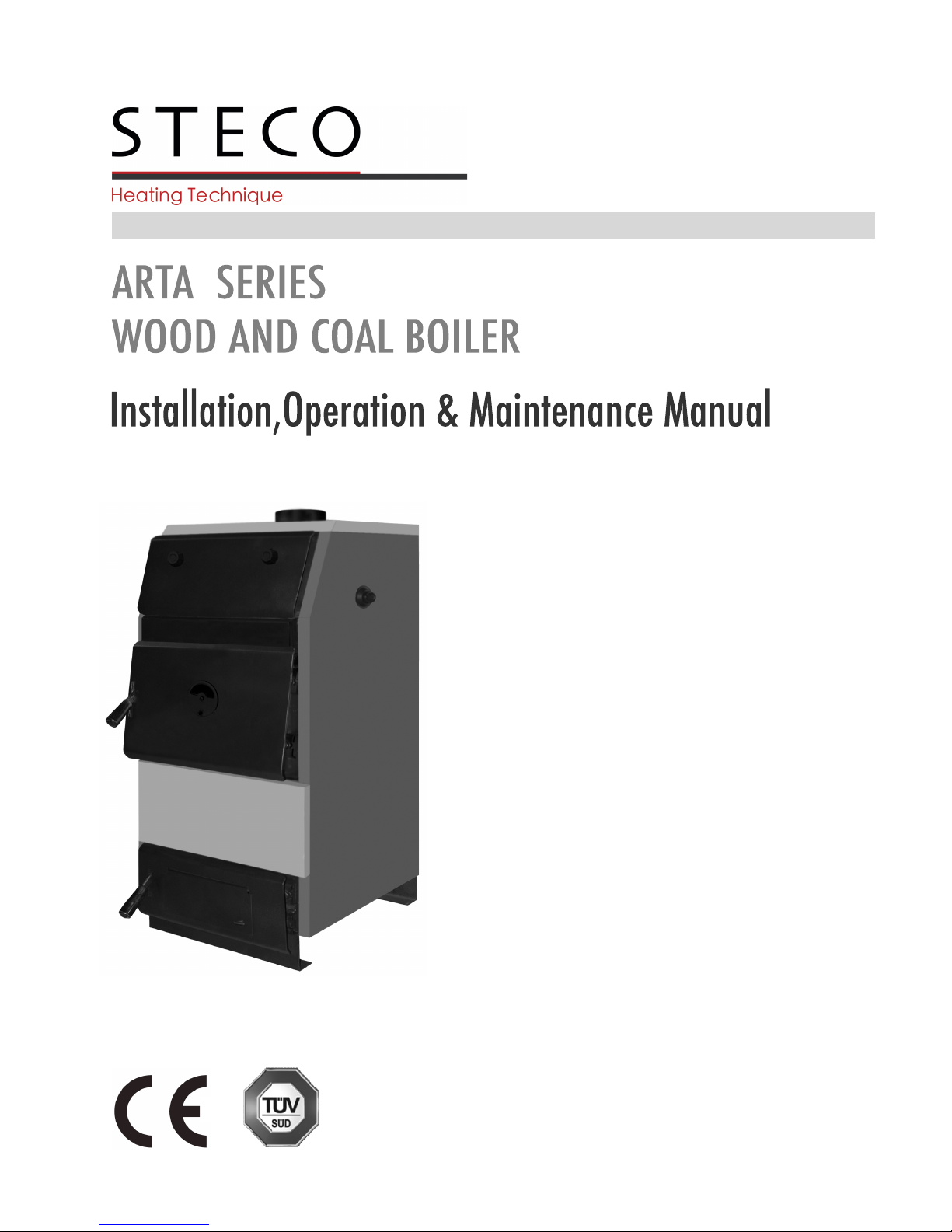

Steco ARTA series, Nova Series Installation, Operation & Maintenance Manual

REV.01 / 2012 122088

2

CAUTION!

Observe the safety instructions of this

installation and maintenance manual

before placing the boiler in operation.

If an unqualified person carries out

installation, adjustment, modification,

operation or maintenance of the heating

system, this may result in danger to life

and limb or property damage. The

directions of this installation and

maintenance manual must be followed

precisely. If you require assistance or

further information, contact a qualified

installer or an appropriate service

provider.

The installation and service instructions

are a component of the technical

documentation and must be handed over

to the operator of the heating system.

Discuss the instruction in this manual

with the owner or operator of the heating

system to ensure that they are familiar

with all information required for operation

of the heating system.

3

Contents

Information on the boilerplate 4

Boiler dimensions 5

Boiler packaging 6

Technical parameters 7

Introduction 8

Ensuring safety of equipment and people 9

Operating instructions 9

ARTA series boiler general features 9

Recommended fuel 9

Control and safety devices 10

Thermo-mechanical regulator 10

Regulating hatch 11

Air rosette 11

Thermometer 11

Putting the boiler into service 11

Checking the boiler before turning it on 11

Filling and draining the heating system 11

Operation and controls 12

Starting a fire 12

Setting outlet water temperature 12

Stoking 12

Overnight heating mode 13

Removing solid combustion residuals 13

Dewing and tarring 13

Boiler shutdown 13

Short-term shutdown 13

Long-term shutdown 14

Important information 14

Boiler repairs 14

Warranty and warranty conditions 14

Boiler delivery 14

Installation instructions 14

Boiler installation – General information 14

Heating water requirements 15

Boiler Location 15

Minimum distance 16

Boiler room disposition layout 16

Chimneys and chimney connection

Warnings, Flue pipe installation 17

Accumulator tank capacity 19

Transportation and storage 19

Boiler cleaning 20

Flue gas cleaning 20

Ash pan cleaning 21

Hydraulic connection diagrams 22

Boiler combustion system 23

Air inlets 23

ARTA boiler parts 24

ARTA boiler spare parts lists 25

Troubleshooting 27

Notes 28

4

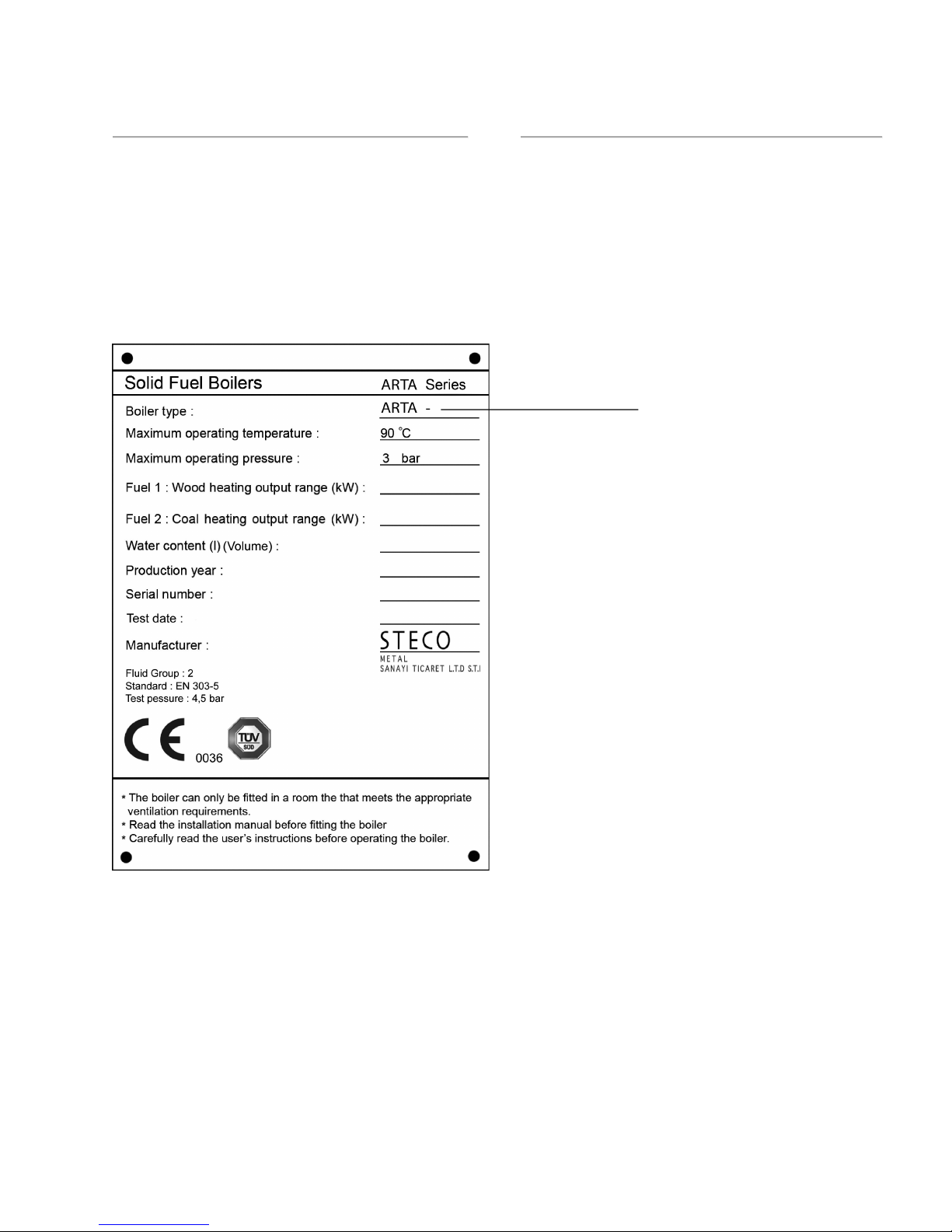

Information on the boilerplate

The boiler serial no is shown on the plate

which is attached to the backside cover panel

of the boiler body.

20, 26, 35, 43

5

Boiler dimensions

6

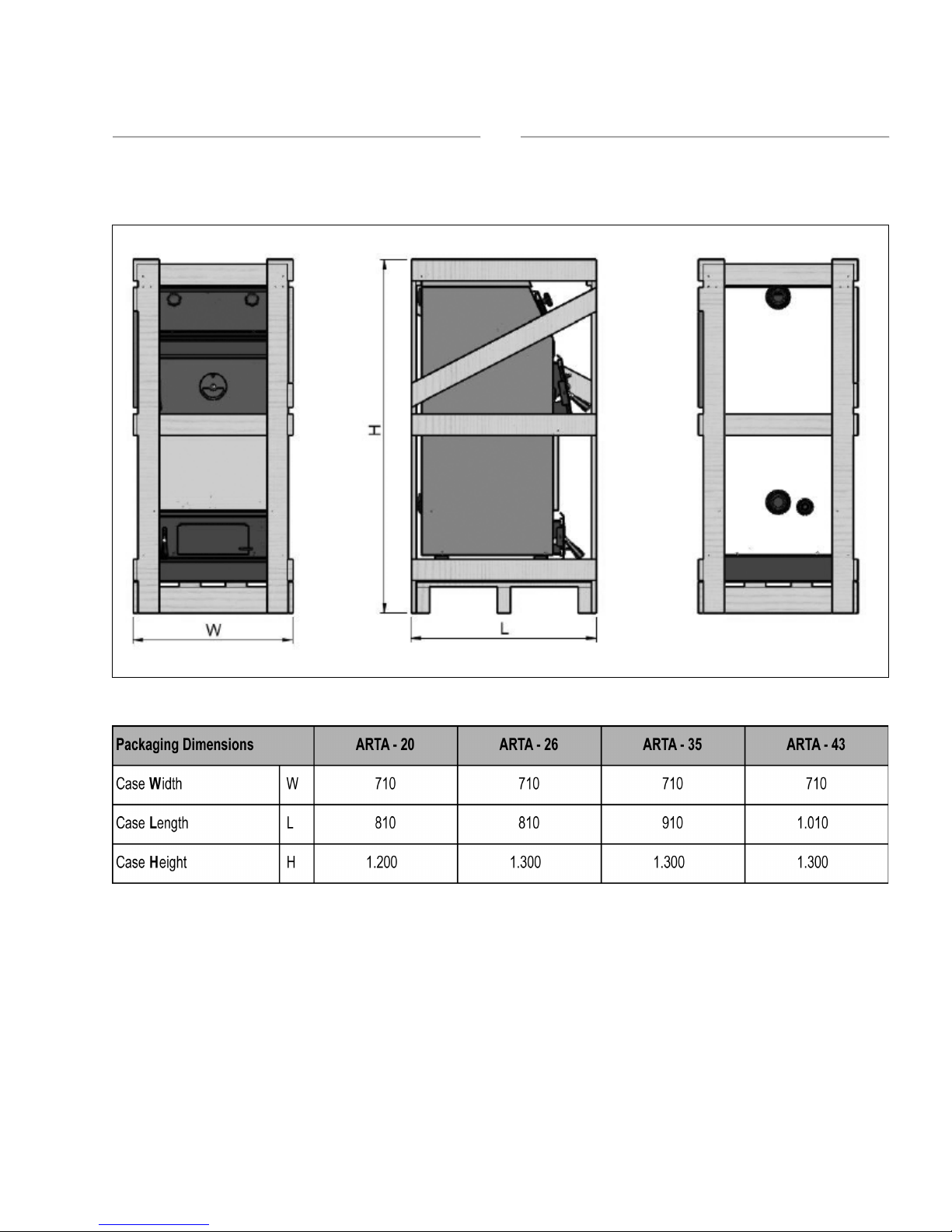

Boiler packaging

7

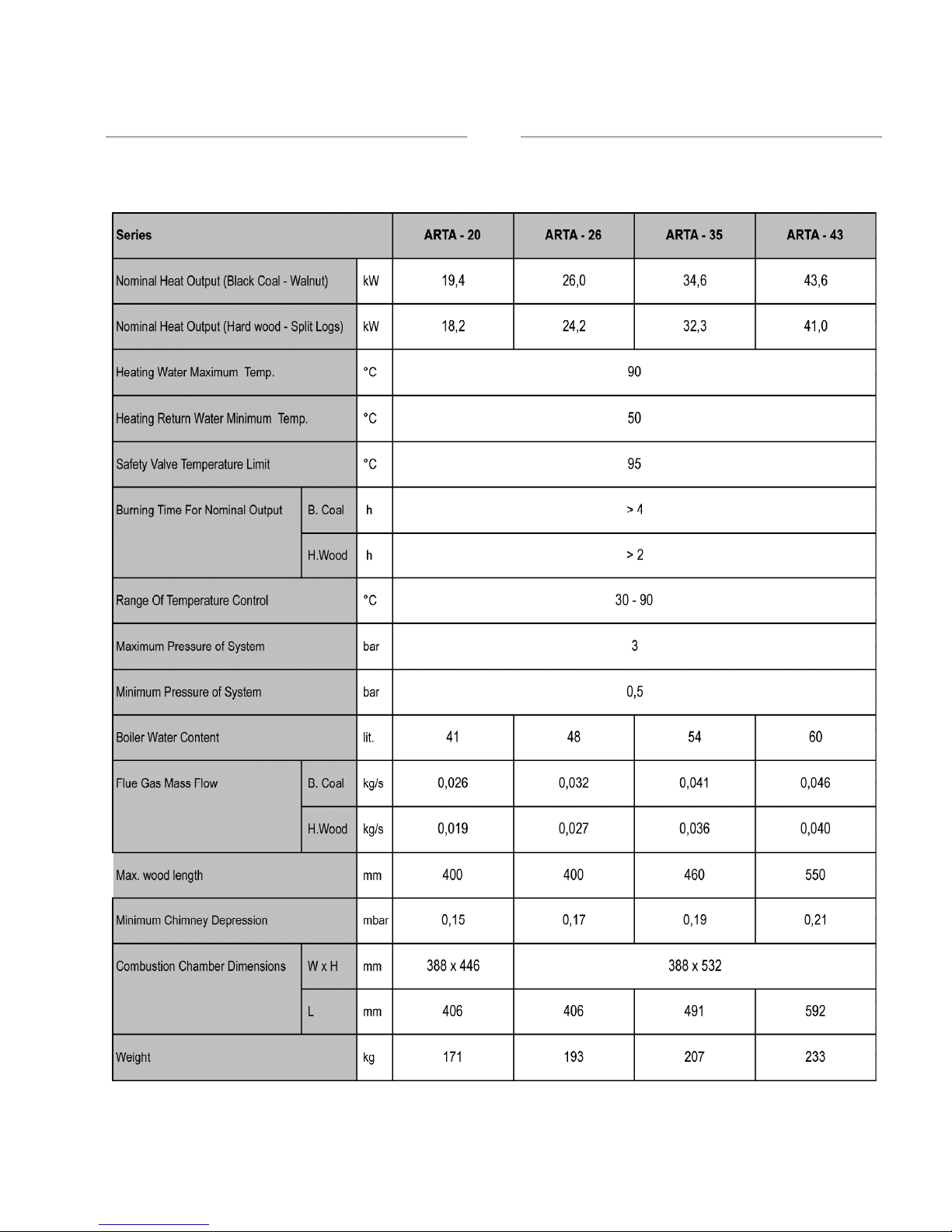

Technical parameters

8

Introduction

1. The boiler and all associated equipment

must be installed and used in accordance

with the installation design, all applicable

legal regulations and technical standards and

with the manufacturer’s instructions. The

boiler may be used only for the purpose for

which it is intended.

2. The boiler may be installed only in an

environment, which it is designed for. If the

same person who installs it delivers the boiler

to the client, he must give the user also all

accompanying boiler documentation (in

particular User Guide, Service Book, etc.).

Until the boiler is put into service, the original

packaging must be kept in case the boiler

has to be transported again.

3. After installation, the boiler must be

put into operation by a service organization

authorized by the manufacturer.

4. The boiler complies with regulations

applicable in the European Union. When

used in the conditions of countries outside at

EU, any deviations from local regulations

must be identified and rectified.

5. In the event of a defect call an

authorized manufacturer’s service

organization – any unauthorized interference

may damage the boiler (and possibly also

associated equipment!).

6. The service technician putting the

boiler into operation for the first time must

show the user the various parts of the boiler

and how to control the boiler, with the boiler

safety elements, their signals and appropriate

user reaction to them, with fundamental parts

of the boiler and their controls. If the same

person who installs it delivers the boiler to the

client, he must make sure that the original

packaging is available in case the boiler has

to be transported again.

7. Check the delivery for completeness.

8. Check whether the model and type supplied

is suitable for the required use.

9. Whenever you are not certain how to

control the boiler, study appropriate

instructions in this Operation and installation

Guide carefully and proceed accordingly.

10. Never remove or damage any markings

and signs on the boiler. Keep the original

packaging until the boiler has been put into

service, in case the boiler has to be

transported again.

11. When making any repairs, only original

parts must always be used. It is forbidden to

make any changes to the boiler’s internal

installation, or to interfere with it in any way.

12. At the end of its life cycle, the boiler its

package and its parts must be disposed of in a

way avoiding harm to the environment.

13. The manufacturer disclaims any

responsibility for damages caused by the

failure to abide by:

• The conditions stipulated in this Operation

and Installation Guide

• Applicable regulations and standards.

• Sound installation and operation

procedures.

• Conditions stated in the Warranty

Certificate and the Service Book.

• The conditions stipulated in this Operation

and Installation guide

Situations might occur in practice, when the

following essential precautions must be taken:

Shut the boiler down every time when here

are any (even temporary)

9

Flammable or explosive fumes present on the

premises from combustion air are supplied to

the boiler (e.g. from paint when painting,

laying and spraying molten substances, from

gas leakage, etc.).

If it is necessary to drain water from the

boiler or from the whole system, the water

must not be dangerously hot;

If there is any leakage from the boiler’s heat

exchanger, or when the exchanger is clogged

up with ice, do not attempt to start up the

boiler until normal operating conditions have

been restored;

Ensuring safety of equipment and people

The boiler (and all accessories) complies with

the requirements of EN 303 – 5 its updates

and all relevant European standards.

In order to run and operate the boiler in

accordance with the purpose for which it is

designed in actual conditions of use

(hereafter referred to only as use), it is

necessary to abide also by additional

requirements the most essential ones of

which (i.e. those which must not be omitted)

are found in the related regulatory

documents.

In addition to the above-mentioned

documents, it is necessary when using the

boiler to proceed in accordance with this

Operation and Installation guide and the

accompanying boiler manufacturer's

documentation.

Any interference by children, persons under

the influence of narcotic drugs, certified

persons, etc., when using the boiler, must be

prevented.

Operating Instructions

ARTA Series Boiler – General features

• ARTA series solid fuel fired boiler is

designed for heating both residential and

industrial buildings.

• Besides professional installation,

precondition for correct functioning of the

boiler is the required chimney thrust and

correct operation.

• ARTA series solid fuel fired boiler is

designed for heating systems, which are

suitable for forced circulation systems only.

• ARTA series boilers are available in four

output series: 20 kW up to 43 kW.

• Attached to the boiler body are sheet

metals covers are fitted on the inside with

thermal insulation.

• To ensure that the boiler functions correctly

and runs economically, it is important that

its nominal output is equal to the thermal

losses of the heated premises.

• Choosing a boiler of insufficient output will

result in inadequate heating of the

premises, and thus failure to provide a

heating comfort.

• Choosing a boiler of unnecessarily high

output will result in the boiler not running in

full output, and as a consequence in tarring

and dewing.

Recommended fuel

Recommended fuels for ARTA boilers are

coal, coke and firewood.

Optimal coal and coke granularity is 24 – 60

mm.

Optimal firewood size is logs of diameter 40 –

100 mm. Their length will depend on how

many kW size.

Loading...

Loading...