Steca XPC 1400-12, XPC 2200-24, XPC 2200-48, XP-COMPACT XPC 1400-12, XP-COMPACT XPC 2200-24 User's And Installer's Manual

...Page 1

User´s and Installer´s Manual

Betriebs- und Montageanleitung

Sine Wave Inverter with Battery Charger and Transfer System

Sinuswechselrichter mit Batterielader und Transfersystem

Steca XPC

XPC 1400-12

XPC 2200-24

XPC 2200-48

714.828 | V5.5

PHOTOVOLTAIK - PHOTOVOLTAIC - PHOTOVOLTAIQUE - FOTOVOLTAICA

EN / DE

Page 2

Steca XP-COMPACT

XP-COMPACT V5.5 2/57

1 General Information.........................................................................................3

1.1 Operating instructions........................................................................................ 3

1.2 Quality and Warranty.........................................................................................3

1.3 Warranty Disclaimer........................................................................................... 3

1.5 Warning................................................................................................................4

2 Introduction........................................................................................................5

2.1 Principle schematic ............................................................................................5

2.2 Description of the main functions..................................................................... 6

2.3 Battery connecting..............................................................................................7

3 Mounting and installing.................................................................................. 8

3.1 Installation place.................................................................................................8

3.2 Fixing....................................................................................................................8

3.3 Connections......................................................................................................... 8

3.5 Cabling............................................................................................................... 11

3.6 Pre-installation settings....................................................................................11

4 Control............................................................................................................... 13

4.1 Display and control parameters......................................................................13

4.2 Display and control parameters on remote control panel (optional)......... 13

4.3 Light Emitting Diodes (LED)............................................................................14

4.4 Push buttons......................................................................................................15

4.5 Turning Knobs................................................................................................... 15

4.6 The Inverter....................................................................................................... 15

4.7 The battery charger.......................................................................................... 16

4.8 The Transfer system........................................................................................18

4.9 The Multifunctional Contact ............................................................................ 20

4.10 The Remote Control RCC-01......................................................................... 21

4.11 The Temperature sensor CT-35..................................................................... 21

5 Programming (possible only with the remote control RCC-01)......... 22

5.1 Standard setting................................................................................................22

5.2 Reset value (default settings).........................................................................22

5.3 Battery voltages and absorption time............................................................ 22

5.4 Auxiliary contact................................................................................................23

6 Installation Maintenance .............................................................................. 26

7 Declaration of CE Compliance .................................................................... 26

8 Technical Data................................................................................................. 27

Page 3

Steca XP-COMPACT

XP-COMPACT V5.5 3/57

1 General Information

1.1 Operating instructions

This manual is part of the delivery package of every XP-COMPACT inverter-charger.

It serves as guidelines for safe and efficient operation of XP-COMPACT. The

instructions are only valid for use with the following devices and options:

XP-COMPACT XPC 1400-12

XP-COMPACT XPC 2200-24

XP-COMPACT XPC 2200-48

Temperature sensor CT-35 AC cable cover CFC-01

Remote Control RCC-01 IP23 cover C-IP23

Solar charge controller XPC xxxx-xx-S

Every person who installs a XP-COMPACT and/or works with it must be fully familiar

with the content of this manual and must follow exactly all the warning and safety

instructions. Installation of or any work on the XP-COMPACT must be carried out by

a skilled and trained personnel. Installation and application must comply with the

respective local installations codes and safety regulations.

1.2 Quality and Warranty

During production and assembling, all XP-COMPACT appliances go through many

controls and tests. Production, controls and tests are carried out in accordance with

firm and established procedures. Every XP-COMPACT has its own serial number,

which helps to refer back to its original data in the event of controls or repairs. That is

why you should never remove the identification plate showing the serial number. The

warranty for these appliances is valid for uses and operating possibilities mentioned

in this manual.

The warranty period for the XP-COMPACT is 2 years.

1.3 Warranty Disclaimer

We do not accept any liability for any damages occurring through use, manipulation,

working situation and handling, which are not explicitly mentioned in these operating

instructions.

Following cases are not covered by the warranty:

− High voltage at INPUT (i.e. 48V at the Battery INPUT of XP-COMPACT 1400-

12)

− Reverse polarity on Battery connections (+/- reversed)

− Running liquid or oxidation through condensation in the appliance

− Defects caused by force, physical or mechanical means

− Changes not explicitly authorized by STECA

− Not or only partly tightened screws and nuts after change of fuses or cables

connecting

− Transport damage, i.e. through bad handling and /or packing

− Damage from atmospheric over voltage (lightning)

Page 4

Steca XP-COMPACT

XP-COMPACT V5.5 4/57

1.4 Liability Disclaimer

Respecting this manual, servicing and method of installation, functioning, application

and maintenance of the appliance can not be controlled or supervised by STECA.

Hence we do not accept any liability and responsibility for damages, losses and costs

which result through the use of this appliance or which result through incorrect

installation, incorrect operation or wrong application and maintenance, or which by

some other means maybe connected to each other.

The use of STECA’s inverters does exclusively involve the user’s liability.

This device is not designed for applications involving health care and medical

treatments where the patient life is concerned and where any mishap may be lethal.

Similarly, we do not accept any liability for any violation of the patents rights or

violation of any third party’s rights resulting from the use of this appliance

STECA reserves the right to modify the technical data or these operating instructions

without any prior notice.

1.5 Warning

This manual must be readily available for the user at any time. The user must be

familiar with the precautions and safety aspects in the country of installation.

During operation of XP-COMPACT, high voltages are generated at the connections

and inside of the appliance which could be lethal. Work on the appliance and on the

installation should only be carried out by skilled and trained people.

The whole installation connected with the XP-COMPACT must comply with the rules

and codes in force.

People without the written authorization from STECA are strictly forbidden to carry

out any change or repair on the appliances. For authorized changes only original

parts are to be used.

The XP-COMPACT may only be used when it has been installed in accordance with

these instructions and all parts have been correctly assembled and installed.

The XP-COMPACT may only be connected to lead-acid or lead-gel batteries.

Caution: Even when a XP-COMPACT has been disconnected from all

connections, at the OUTPUT point there could still be deadly voltages present.

To remove these voltages you must switch on the XP-COMPACT ON with the

ON/OFF switch. After one minute the electronics are discharged and any work

can now be safely carried out.

The XP-COMPACT is only suitable for internal use and under no circumstances

should it be subjected to snow, rain, or any other wet conditions.

By installations in motorized vehicles the XP-COMPACT must be protected from

water-spray and any other wet conditions.

Caution: In normal use lead-acid and lead-gel batteries give out explosive

gases. Never smoke or allow a spark or flame in the vicinity of batteries. The

batteries must always be stored or placed in a well ventilated room, they

should be placed in such a way that there is no danger of short-circuit through

carelessness. Never charge frozen batteries.

Page 5

Steca XP-COMPACT

XP-COMPACT V5.5 5/57

1.6 Special precautions

− While working on batteries there should always be a second person close to you

or within your voice range, in case help is needed.

− Plenty of fresh water and soap must be ready at hand so that in case of acid

coming in contact with skin, eyes and clothes, the areas in question can be

thoroughly washed.

− If acid enters the eyes, you must thoroughly wash them with cold running water

for at least 15 minutes. It is recommended that you immediately consult a

medical doctor.

− Baking powder neutralizes battery acid electrolyte. Always keep some at hand.

− Special care must be taken when working with metal tools near or on the

batteries. With tools such as screwdrivers, spanners etc. short-circuits can

result. Sparks produced by the short circuit can cause an explosion.

− When working on batteries all personal metal items such as rings, necklaces

and bracelets must be removed. Batteries are so powerful that short-circuit with

these items can melt them and thus cause severe burns. Always follow the

battery manufacturer instructions.

− Under certain conditions XP-COMPACT or a connected generator can start

automatically. While working on an electrical installation you must ensure that

these appliances are disconnected beforehand from the installation.

2 Introduction

The XP-COMPACT is a sine wave inverter with integrated battery charger with many

additional functions, it has been developed to be used as stand-alone (no gridfeeding) AC provider, or as continuous / break-free current supply provider (UPS).

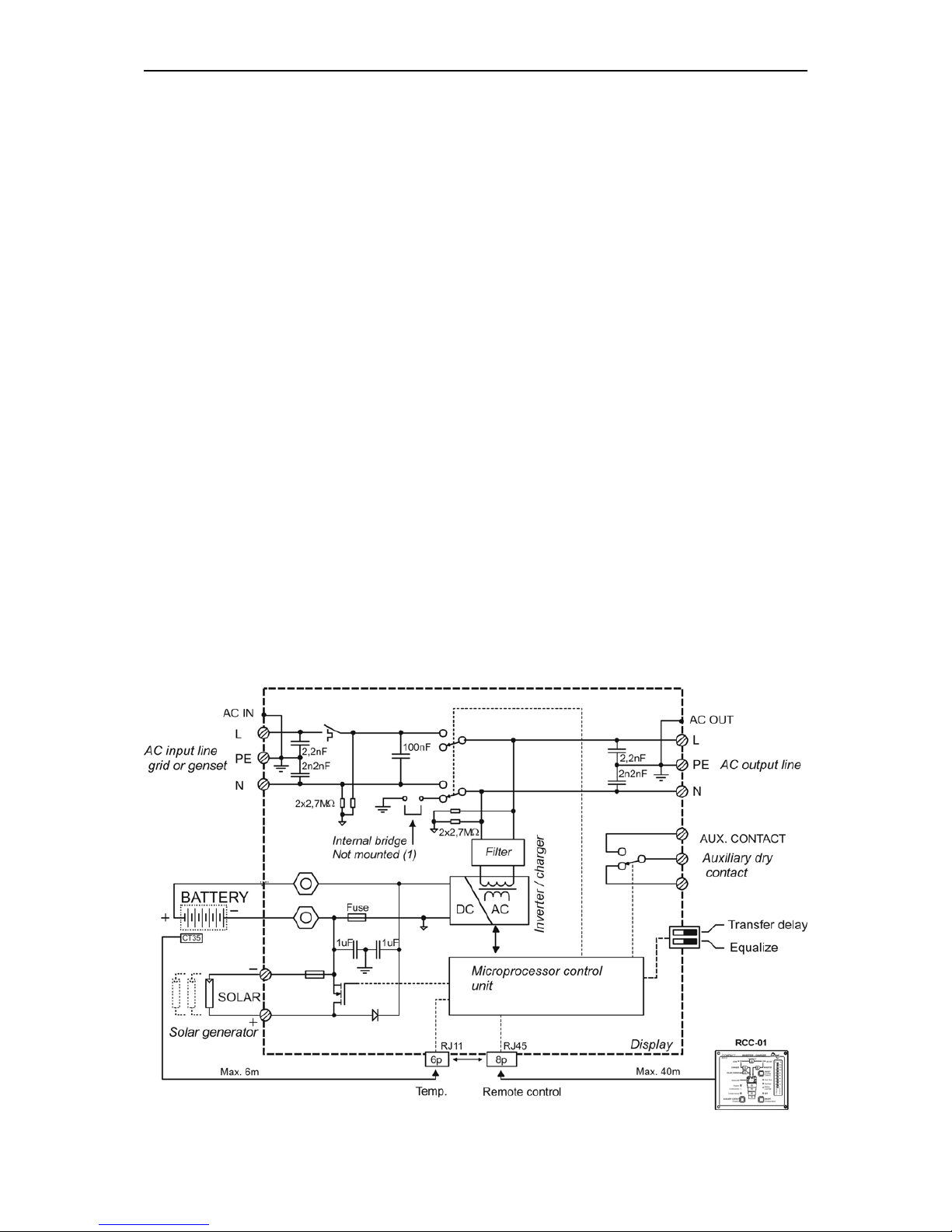

2.1 Principle schematic

Page 6

Steca XP-COMPACT

XP-COMPACT V5.5 6/57

Notes:

(1) The neutral of the appliance is not connected to the earth whatever the

function mode is. If requested and according to the local regulation, an automatic

connection between Neutral and earth in inverter mode only may be done by

installing a bridge internally to the unit. Please contact your installer regarding this

point.

(2) Remote control for remote adjustment of the input limit. (see chap. 4.6.3)

2.2 Description of the main functions

2.2.1 The inverter

The sine wave inverter XP-COMPACT generates a sinusoidal AC voltage with an

exceptionally precise voltage and stabilized frequency. In order to start large electric

motors, the user has the possibility to use a short surge power which is 3 times the

nominal power of the XP-COMPACT.

The inverter is protected against overload and short circuit. A power stage with the

latest MOS-FET power transistors, a toroidal transformer, and a fast regulating

system makes a robust and reliable inverter with the highest efficiency. A 1-20 Watt

adjustable charge detection system allows the smallest energy consumption and

ensures a long life for the battery.

2.2.2 The transfer system

XP-COMPACT can be connected to an AC source. For example a stand-by

emergency generator or the AC network. With the transfer system, on one side you

have an alternating voltage at the output for the use of consumer appliances. On the

other side the battery park is being charged. The distribution of energy between the

consumer appliances and battery charger is automatic.

2.2.3 The battery charger

The built-in battery charger is so designed that it can charge the battery quickly and

fully. A microprocessor controlled, Step charging process, ensures the optimal

charging of the battery. The desired charging current can be set continuously from 0

to 20/37/45 A, as per the model. The setting is made accordingly to the battery

capacity and power available.

The battery charger is designed for lead-acid and lead-gel batteries. Thanks to the

floating charge system the batteries can remain continuously connected.

2.2.4 Remote control

As an option, a remote control RCC-01 can be connected to XP-COMPACT. All

operating features and displays, save the adjustment levels (22/23/24/26), are

available on the remote control. It is supplied with a 20m long cable. This cable can

be up to 40m long. On the remote control, output power and charging current are

also displayed.

Page 7

Steca XP-COMPACT

XP-COMPACT V5.5 7/57

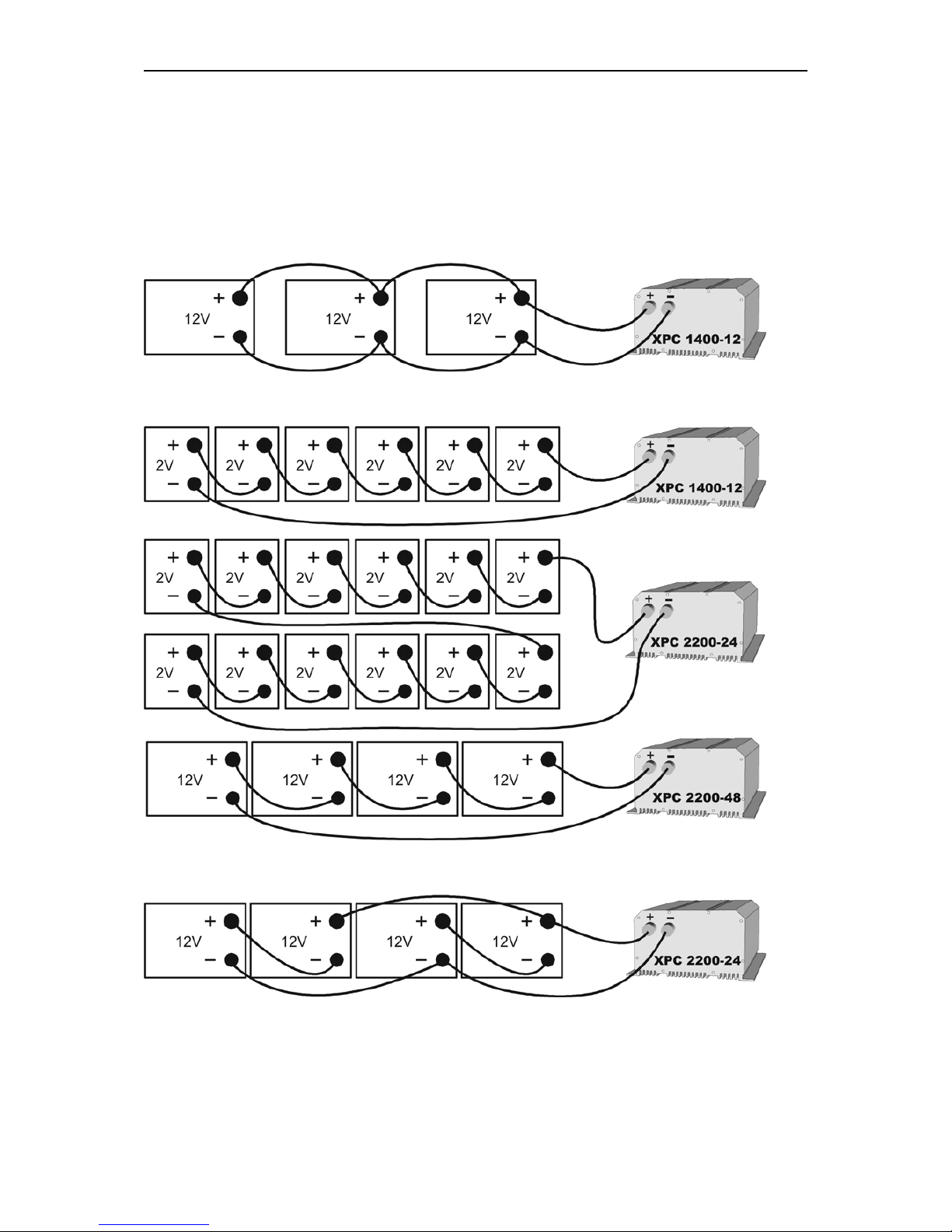

2.3 Battery connecting

Lead-acid batteries are normally available in blocks of 2V, 6V or 12V. In most cases,

to generate the necessary operating voltage and the capacity of the batteries for the

XP-COMPACT many batteries have to be connected together in parallel and or in

series. Here are 3 examples of connection:

2.3.1 Connection in parallel

2.3.2 Serial connection

2.3.3 Serial and parallel connection

Page 8

Steca XP-COMPACT

XP-COMPACT V5.5 8/57

3 Mounting and installing

3.1 Installation place

The location of the XP-COMPACT must be driven by the following criteria:

− Protection from unauthorized handling

− Dry dust free room, no condensation

− Never install directly over the battery and never in a cabinet together with the

batteries

− Keep ventilation holes free

− In mobile installations it is important to keep the vibrations down as low as

possible

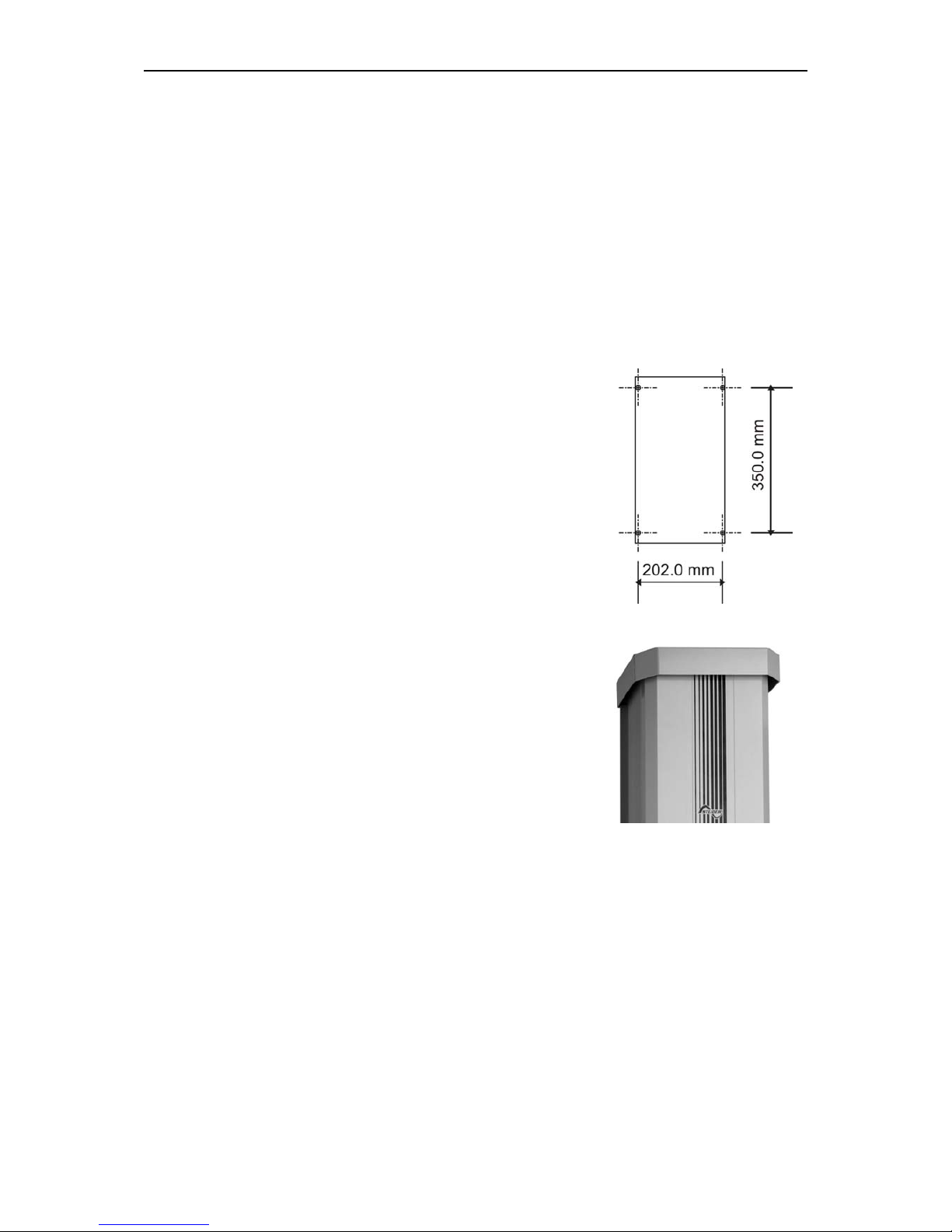

3.2 Fixing

3.2.1 Fixing the XP-COMPACT

Basically the XP-COMPACT can be installed in any

desired location. Preferred is that the appliance be wall

mounted with battery cables downwards. The XPCOMPACT is fixed on the wall with four screws through the

four holes (diameter 5.5mm) which are accessible from the

outside. In motor vehicles XP-COMPACT must be fixed on

vibrations reducing elements. The XP-COMPACT must not

be fixed on a combustible base, as the back of the casing

can get hot and reach up to 80 degree Celsius.

3.2.2 Protection cover IP-23

This cover IP23 (Order ref. CIP-23) can be easily

installed after the fixation of the XP-COMPACT. For that

release a little the too screws down and more the tow up.

Then it’s possible to pass the IP 23 cover between the

XP-COMPACT and the wall. The cover must touch the

screws. Lock on the four screws, it’s ready.

3.3 Connections

3.3.1 General instructions on connecting

− The cable connection on the terminals AC INPUT / AC OUTPUT / 16A 230VAC

are carried out with a screwdriver Nr.1 and the connection on the SOLAR

terminal with a screwdriver Nr.2.

− The conductor cross section on the terminals AC INPUT / AC OUTPUT / 16A

230VAC of the connecting cable must be minimum 2.5mm2.

− All connecting cables and also the mounted battery cables, must be fixed with

strain relief clamps.

− The XP-COMPACT is delivered with battery cables already connected.

− The battery cables must never be extended. If the extension is unavoidable then

the conductor cross section must be elevated accordingly.

− To protect the battery cable, a fuse corresponding to the conductor cross

section must be fixed directly on to the battery.

Page 9

Steca XP-COMPACT

XP-COMPACT V5.5 9/57

− All cables must be tightly screwed in place. For safety, a yearly control is

recommended. In mobile installations control must be carried out more often.

− Connecting must be done by qualified personnel. Material such as cable,

connectors and distribution boxes, fuses etc. used in the installation must

comply with the respective valid low-voltage installation rules and regulations.

3.3.2 Protection cover of the terminals

connections

The protection is available as an option (Order ref.

CFC-01) and avoid to do wrong hazardous

connection on the terminals 230Vac. It mounted

with strain relief clamps for the cable.

Page 10

Steca XP-COMPACT

XP-COMPACT V5.5 10/57

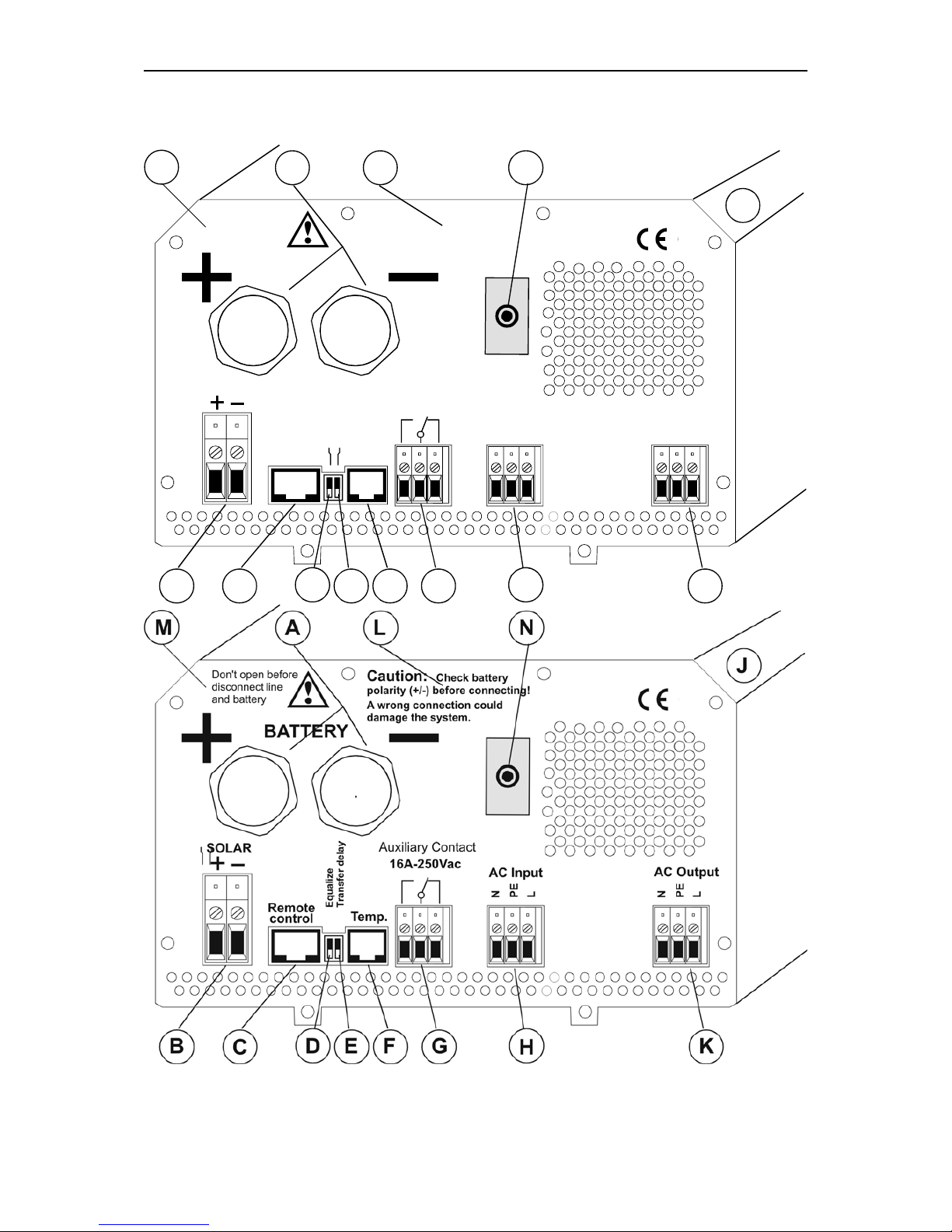

3.4 Connection Plan

.

Caution:

Check battery

polarity (+/-) before connecting!

A wrong connection could

damage the system .

16A-250Vac

BATTERY

SOLAR

Remote

control

Temp.

Don't open before

disconnect line

and battery

N

AC Input

AC Output

L

Equalize

Transfer delay

Auxiliary Contact

PE

N

L

PE

M AL

B

C

D

E

FG

H

J

K

N

Page 11

Steca XP-COMPACT

XP-COMPACT V5.5 11/57

A Battery +/- Battery cable (already installed)

B SOLAR +/- Connection terminal for Solar modules, function not

offered

C Remote contr. Connection terminal for Remote Control RCC-01

D Transfer delay Slide switch for delayed opening of transfer

swichEqualize Slide switch for equalization of the

Battery

E Transfer delay Slide switch for Transfer DelayEqualize Slide switch

for equalization of the Battery

F Temp. Connection terminal for Temperature sensor CT-35

G Aux. Contact Connection terminal for Auxiliary Contact

H AC Input Connection terminal for AC-input. Located directly

above this terminal is the automatic safety cut-out for

this terminal.

J ID Plate Identification plate with Technical data and Serial

number

K AC Output Connection terminal for AC-output

L Caution… Caution: Check Polarity (+/-) before connecting the

battery !

M Don’t… Do not open without disconnecting all terminals

N 16A Protection 16A Protection switch for the Transfer system

3.5 Cabling

Connecting the XP-COMPACT is a very important step of the installation. You must

take care that all connection work is carried out in a clean and correct way and that

under no circumstance a cable is connected to a wrong terminal.

Connecting of the XP-COMPACT must be carried out in the following order. In case

of dismantling this order must be reversed.

3.6 Pre-installation settings

Before you start with the cabling of the XP-COMPACT you must set the type of

battery. In case sealed-gel batteries are used then you must set the small slideswitch „Equalize“ (E) which is on the front with the connection terminals, in OFF

position. In case of „normal“ lead-acid – batteries, these can handle a higher

equalizing charge, the same slide switch (E) can be set in ON position. In case of

doubt leave the setting in OFF position.

This will allow an equalizing cycle (higher end of charge voltage) during the next

charge process. Since then equalizing will occur every 25 usual cycles.

In case of doubt leave the setting in OFF position.

3.6.1 Connection to battery

Get the batteries ready for connection: Matching battery terminals, matching fuse on

a clamp. Prepare battery cables, if necessary press on cable tabs/shoes. Connect

red cable on Plus (+)-Pole and the black cable on the Minus (-) Pole. On connecting

the second cable to the battery pole a spark is produced, because for a short time

high current flows in the XP-COMPACT to charge the capacitors. For this reason

follow strictly the safety measures described in this manual. Check if the red LED

OFF (13) is lit. If it is not lit, press shortly on the switch ON/OFF (19), now OFF

should be lit.

Page 12

Steca XP-COMPACT

XP-COMPACT V5.5 12/57

On connecting the battery the XP-COMPACT needs 1 – 2 Minutes to calculate the

actual capacity of the battery. During this time the battery condition is shown as

100% charged. (LED 14 – 17 lit).

If the LED 12 Battery Low/High is lit, the battery charge is too low. If the LED 12

Battery Low/High is blinking, the battery charge is too high.

Caution: With a wrong battery voltage the XP-COMPACT can be destroyed. (for

example: connecting a XPC 1400-12 to a 48V-Battery).

Nevertheless, if the XP-COMPACT had been connected with reverse polarity, it is

highly probable that the fuse inside the casing is defect. Before opening the casing

cover all terminals must be disconnected including the battery. If the XP-COMPACT

does not function after the changing of the fuse and correcting of the polarity, it

means that it is defect and must be sent for repair.

3.6.2 Connection to the 230Vac-consumer appliances (AC OUTPUT)

The 230V consumer appliances must be connected to the terminals AC OUTPUT

with cables which cross section has to follow the local rules in force (usually

2.5mm2). Connections are marked as follows “N“ Neutral, “PE“ Earth (connected to

the appliance boxenclosure), “L“ Live.

Caution: High voltages can be there. Make sure that the XP-COMPACT is

turned off (LED 13 lighting) before the connection.

3.6.3 Connection to the 230Vac Input (AC INPUT)

The 230V-supply from network or from a generator must be connected to the input

terminals AC INPUT with cables which cross section depends on the power source

(usually 2.5mm2). Connections are marked as follows: “N“ Neutral, “PE“ Earth

(connected to the appliance case), “L“ Live (connected to the appliance case).

3.6.4 Connection to Auxiliary Contact

This contact is a potential free change over contact the currents and voltages allowed

for this contact are max. 16A/250Vac. The LED 5 “Contact active” shows the position

of them: alight mind active and off mind non-active. The schematic view of the

connections on the front, show the relay in the non-active mode.

3.6.5 Connection to Remote control

The Remote Control RCC-01 is connected in the terminal marked „Remote control“

with a 20m long cable and a RJ11/8 connector. The Remote Control can be plugged

IN or plugged OUT during any operation situation. Push in the connector softly until

you hear the „click“ showing that the connector is locked. The same applies to the

plug in the Remote Control.

The length of the cable for Remote Control should not exceed 40m. We deliver it with

20m cable.

3.6.6 Connection to Temperature Sensor (Temp.)

The temperature sensor CT-35 is connected in the terminal marked „Temp“ with a

3m long cable and a RJ11/6 connector. The temperature sensor can be plugged IN

or plugged OUT during any operating situation. Push in the connector softly until you

hear the „click“ showing that the connector is locked. The temperature sensor must

be glued to the wall of the battery or near it. The Temperature Sensor cable must

not be tied together with the battery cables or laid in a rope/bundle.

Page 13

Steca XP-COMPACT

XP-COMPACT V5.5 13/57

4 Control

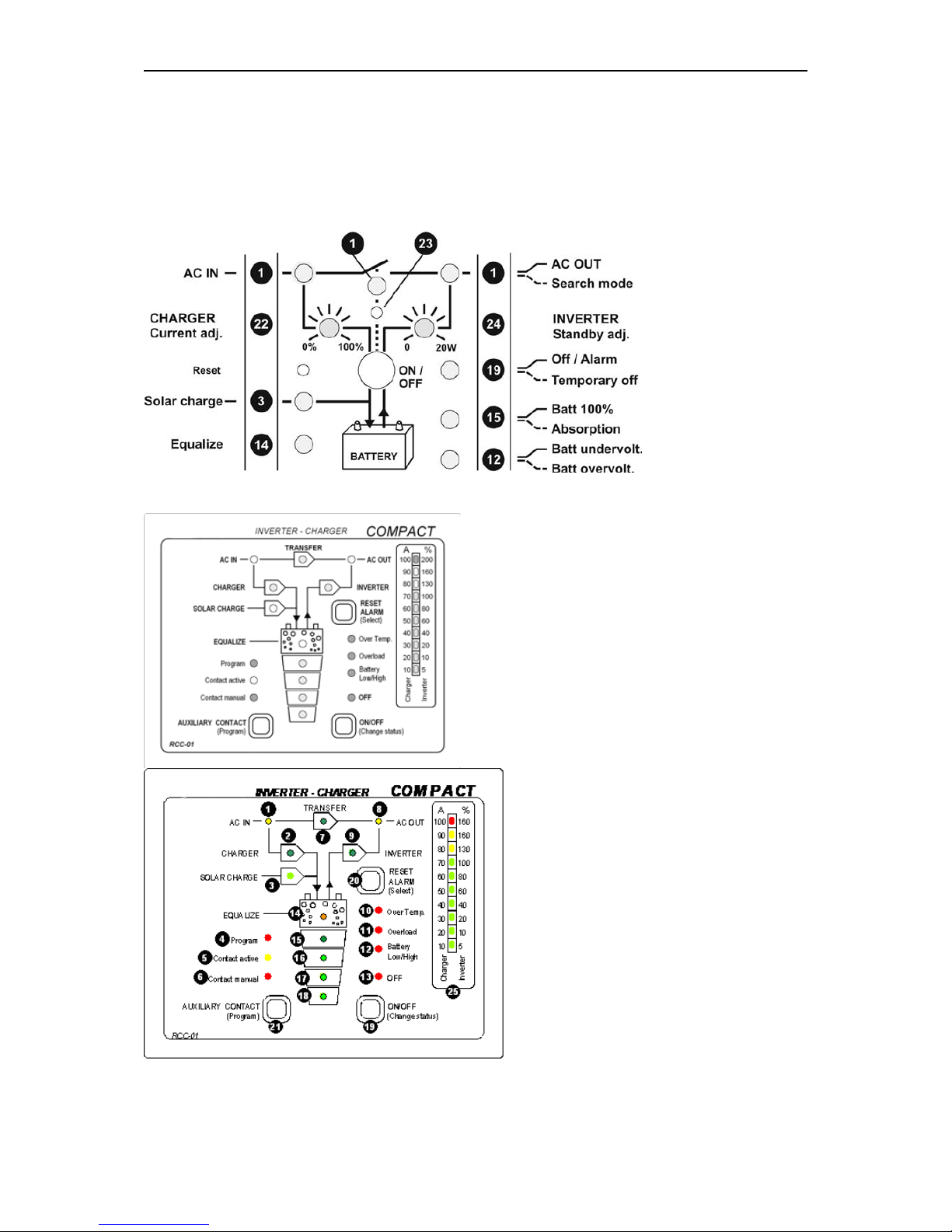

4.1 Display and control parameters

4.2 Display and control parameters on remote control panel (optional)

Page 14

Steca XP-COMPACT

XP-COMPACT V5.5 14/57

4.3 Light Emitting Diodes (LED)

LED Marking LED lit LED blinks

1 AC IN

Voltage

corresponding to

self-adjusted

values is at the AC

IN input.

A voltage outside the self-adjusted

values is at the AC IN input, or the XPCOMPACT is in synchronization

phases

2 CHARGER

Battery charger is

working

The battery charger is locked OFF

(see chap. 4.7) or provisory out of

order. In that last case it will restart

within 10 seconds

3

SOLAR

CHARGE

This function is not offered for the XP-Compact

4 Program

Program mode for

Aux. Contact

5

Contact

active

Auxiliary Contact is

activated

6

Contact

manual

Aux. Cont.

manually activated

7 TRANSFER

Transfer system is

active. In- coming

voltage is being

sent directly to AC

OUT outlet

Transfer (bypass) is disabled (see

chap. 4.8)

8 AC OUT

There is a voltage

at the AC OUT

outlet

The Inverter is in Standby-Mode

9 INVERTER Inverter is working Forced Inverter Mode (see chap. 4.6)

10 Over Temp.

For the time being

the XP-COMPACT

is out of service

because of

overheating.

11 Overload

The XP-COMPACT

is out of service

because of

overload or shortcircuit

12

Batt.

Low/High

Battery voltage is

too low

Battery voltage is or was to high

13 OFF

XP-COMPACT is

turned off. Turning

it back on is only

possible manually.

XP-COMPACT is for the time being

turned off. Turning it back on will

follow automatically !

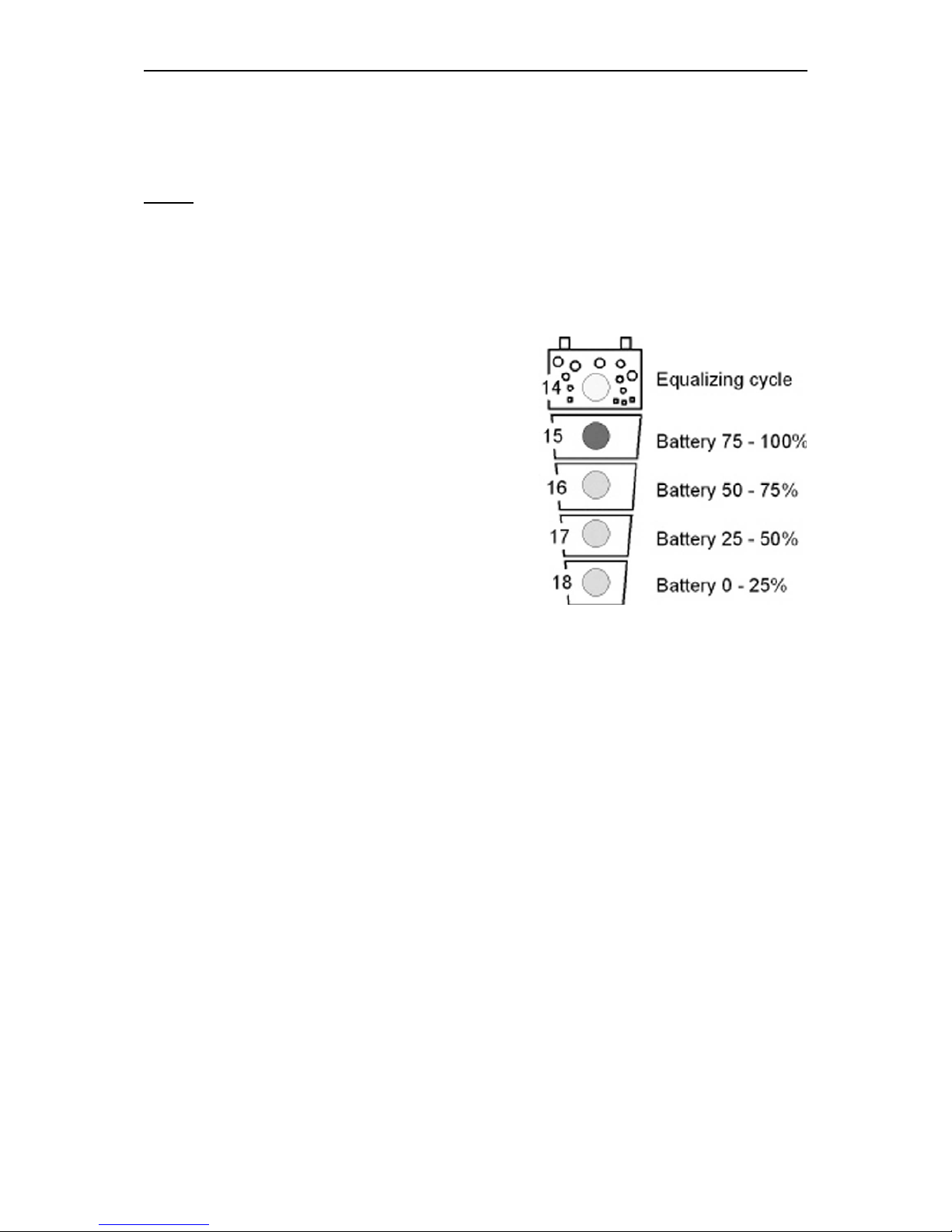

14 EQUALIZE

Battery equalizing

is set

15–18

State of charge of

the battery

LED 15 – Absorption time is running

Page 15

Steca XP-COMPACT

XP-COMPACT V5.5 15/57

25

POWER

MONITOR

Display the value of the output power in % of Pnom (in

Inverter Mode) and the charge current in Amps (in Charger

Mode).

4.4 Push buttons

19 ON/OFF

Turning the XP-COMPACT on and off (Help Button for

Programming)

20 RESET Alarm Signal off (Help Button for Programming)

21 Aux. Contact Control Aux. contact (Help Button for Programming)

4.5 Turning Knobs

22 CHARGER Adjustment for max. Charging Current

23 TRANSFER

Adjustment for Transfer Voltage Threshold (TRANSFER –

INVERTER)

24 STANDBY Adjustment for „Standby“ system

4.6 The Inverter

An Inverter is built in the XP-COMPACT, which generates a sinusoidal alternating

voltage of a very high quality. With this Inverter any 230Vac alternating voltage

appliance up to the nominal power of your XP-COMPACT can be operated. Thanks

to the generous dimensioning of the XP-COMPACT, you can operate appliances

requiring higher power than the nominal power of the XP-COMPACT for a short time.

The XP-COMPACT provides up to 3-times the nominal power to start motors.

The Inverter mode is displayed through LED 9 (Inverter). If the Inverter Mode is

disabled (see chap. 5.5) LED 9 will blink. If the LED 9 is lit, the Inverter is in operation

and you have 230Vac at the output AC OUT. The actual power of the connected

appliance is displayed on the power monitor 25 and on the Remote Control.

4.6.1 Charge detection system „Standby“

In order to avoid unnecessary discharge of the battery, the inverter switches OFF

automatically if no appliance is connected and switches ON automatically again if

appliance is connected. The LED 8 blinks if the inverter is in Standby-Mode. The

switching-on/starting level can be adjusted with the turning knob 24 „STANDBY”.

Adjusting the switching-on level is as follows: Switch off all consuming devices, turn

the Turning Knob 24 to the right until the LED 8 is blinking, switch on the smallest

consuming device (i.e. Mobile phone charger), turn the Turning Knob slowly to the

left until LED 8 is lit.

If the Standby-Mode is not wanted, turn the Turning Knob 24 to the left, to the OFF

position.

4.6.2 Overload

If the Inverter is too long or too heavily overloaded, it switches off. The LED 11

„Overload“ is lit and LED 13 „OFF“ blinks. After ca. 10 seconds the Inverter switches

on automatically. If the Inverter is overloaded four times one after another in a short

time, then it no longer switches on automatically. The LED 13 remains lit. Press the

push button 19 „ON/OFF“ in order to switch on the Inverter.

Page 16

Steca XP-COMPACT

XP-COMPACT V5.5 16/57

4.6.3 Overheating (Over Temp.)

If the Inverter has been overloaded for a long time or it has been working in too high

surrounding temperatures, it will switch off. The LED 10 „Over Temp.“ is lit and the

LED 13 „OFF“ blinks. After cooling down, the inverter switches back on automatically.

One minute before the inverter switches off for too high temperature it gives out an

acoustic alarm signal. If the Auxiliary Contact has been programmed to detect the

high temperature then it synchronizes the relay with the alarm signal. In this way, for

example, an emergency back- up system can be started without any break in the

energy supply.

4.6.4 Battery Condition

Deep discharge of the lead-acid batteries leads to high losses in capacity and early

aging. That is why the battery condition is continuously controlled and supervised.

With low volt-age the inverter switches off. The LED 12 „L/H Batt.“ is lit and the LED

13 „OFF“ blinks. When the battery voltage gets up to 12.1V / 24.2V / 48.4V, the

Inverter switches on automatically. One minute before the Inverter switches off due to

low voltage it gives out an acoustic alarm signal. If the Auxiliary Contact has been

programmed to detect the low voltage then it synchronizes the Aux. Contact with the

alarm signal. In this way, for example, an emergency back up system can be started

without any break in the energy supply.

The low voltage is set to 11.6V / 23.2V / 46.4V. These settings are standard for most

batteries. These voltage levels are maintained by the built-in Battery-ManagementSystem of the XP-COMPACT by matching the load and the battery condition.

This setting is comparable with the levels of 10.8V/ 21.6V / 43.2 which are given

for most batteries at nominal load.

All voltage levels can be programmed. See the instructions under the section on

Programming. Check with your battery supplier which voltage values should be set.

4.7 The battery charger

4.7.1 Cycle of charge

The full automatic XP-COMPACT Battery Charger is adjusted at the factory so that

most lead-acid and lead-gel batteries can be charged to the maximum. As soon as

the minimum alternating voltage for the AC IN set on the Turning Knob 23 is available

at the input (LED 1 AC IN is lit), the Battery Charger is switched on automatically

(LED 2 CHARGER is lit). The battery is fully automatically charged matching to the

charge level, the adjusted volt-age levels and the charge current. Thanks to the builtin Float Charge System, the batteries can be left connected for unlimited time with

the Battery Charger switched on.

During the charging phase the appliances at the outlet AC OUT are continually

supplied with power (LED 8 AC OUT is lit).

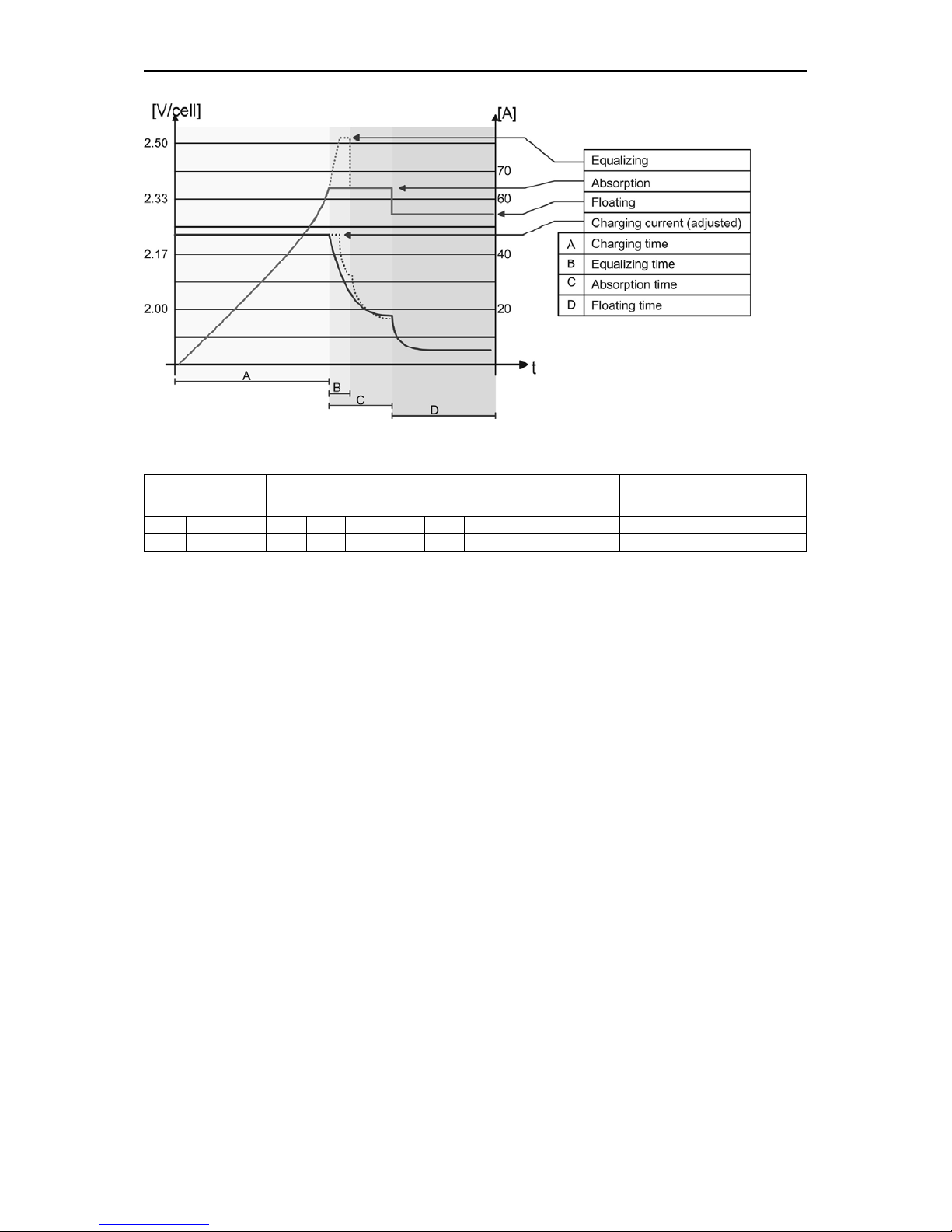

The charger functions are shown in the following diagram:

Page 17

Steca XP-COMPACT

XP-COMPACT V5.5 17/57

4.7.2 Default values for battery voltage thresholds

Low voltage Float charge Absorption Equalization

Absorption

time

Equalization

time

12V 24V 48V 12V 24V 48V 12V 24V 48V 12V 24V 48V 12/24/48V 12/24/48V

11.6 23.2 46.4 13.5 27.0 54.0 14.4 28.8 57.6 15.6 31.2 62.4 2h 20’

These values can be modified by mean of the optional remote control

4.7.3 Equalization charging

Before you program the XP-COMPACT for Equalization-charge you must check with

your supplier that the batteries are suitable for this process.

Equalization is recommended for the lead-acid batteries in order to mix well the

electrolyte fluid and to clean the lead plates.

If the XP-COMPACT is operating with a lead-acid battery, which is suitable for

equalization, the slide switch „Equalize“ which is on the cable connection side, must

be placed in the ON position. In this setting, every 25 charge cycles an equalization is

carried out for 20 minutes (factory setting). During such a charge cycle the LED 14 is

lit and during equalizing it is blinking. Charge cycle with equalization can be started

independently from the actual program. For this purpose the slide switch must be slid

from “OFF” to the “ON” position. The LED 14 will light up. If the periodic equalization

is not required, slide switch must be slid back to the „OFF“ position after the

completion of the manual cycle.

The equalizing voltage can be changed. How to proceed is explained in chap. 5.3.

Batteries not designed for equalize should never been charged this way.

CAUTION: During the equalization process, the batteries produce a lot more

gas. DANGER OF AN EXPLOSION !! The battery room must be well ventilated.

Equalization mode should never be used when using Gel-Batteries.

4.7.4 Charging current

The maximum charging current for the battery can be adjusted with the Turning Knob

22 (CHARGER). The charging current of the battery should be set to approximately

10 – 20% of the battery capacity (at C10). This means that the charging current for a

battery with 200Ah should be set between 20 – 40A.

The charging current is displayed on POWER MONITOR (25) of the front panel

or on the Remote Control.

Page 18

Steca XP-COMPACT

XP-COMPACT V5.5 18/57

4.7.5 Battery Condition

Built-in microprocessor with a specially developed algorithm calculates the actual

state of charge of the battery and displays it on LED 15 – 18. The LED 14 is lit when

the system is carrying out a charge cycle with equalization.

Notice: the exact measure of the battery state of charge with electrical parameters is

al-most impossible. The display of the state of charge is always more or less precise.

The measure system built in the XP-COMPACT takes into account the battery

voltage, the discharge and charge current as well as the undulation of the voltage. If

the battery and the XP-COMPACT are used according to their technical data, the

battery state of charge is displayed accurately. In the following cases of use the

display can diverge:

− Battery charge or discharge with too high

currents

− Battery cable cross section too small

− Battery connections badly tightened or

corroded

− Charge of the battery with external battery

charger

− Discharge of the battery with users not

connected to the XP-COMPACT

− Work with defective or sulphated batteries

This means that the display can, within few

minutes during the charge, commute from 25%

to 75% or during the discharge, to the opposite

direction.

As many of the working cases mentioned above often occur, the measure system of

the XP-COMPACT takes into account, during the charge, only the peaks of the

voltage undulation. As a consequence, the battery voltage at the start of the

absorption stage, measured by a voltmeter will appear deeper. By decrease of the

charge current the voltage will reach the exact values.

For safety reasons, you must get the recommended charge voltage and charge

currents from your battery supplier. The voltage levels and charge characteristics can

be changed through Programming. The instruction for programming of battery

charger is in the section „Programming“ (Chap. 5.3). The correct charging is

mandatory for a safe function and a long-life of the battery.

The battery charger functions are described by the graphic in chap. 4.7.1.

4.8 The Transfer system

When an AC voltage is at the input AC IN of the XP-COMPACT, the LED 1 AC IN is

lit. When this voltage matches the lowest adjusted value set by the Turning Knob 23

TRANSFER, and the frequency is between 44Hz and 65Hz, this voltage is switched

directly to the battery charger and to the output AC OUT. The LED 7 TRANSFER is

lit. The inverter is switched off and the battery charger switched on. This process is

automatic, unless the charger mode or the transfer mode is disabled (see Chap. 5.5).

The maximum current of the Transfer switch is 16A. That means through this system,

consuming devices up to a maximum of al 3700 Watt can be operated. When the

Battery Charger is working, part of this power is used for charging according to the

power sharing system.

Page 19

Steca XP-COMPACT

XP-COMPACT V5.5 19/57

The Transfer system is protected against overload with a circuit breaker on the AC

Input side of the XP-COMPACT. If the system has been overloaded, the button/pin of

the fuse will pop out. To put the automatic safety system back in to operating you

must push this pin back.

Note: in the Inverter operation, The XP-COMPACT generates a true sinusoidal and

quartz stabilized output voltage. However if the XP-COMPACT is supplied from a grid

or a generator and the transfer contact is active, then you have at the output AC OUT

the same voltage as that at the input. This voltage can not be modified by the XPCOMPACT !

4.8.1 Set the transfer voltage threshold

The voltage threshold of the transfer can be adjusted between 150 to 230V with the

turning knobs (23). From factory this value is 200V. Most appliances can work on this

voltage. When the Input voltages reach the selected value on turning knob, the

inverter switches off and the AC INPUT goes directly on the AC OUTPUT. When the

voltage INPUT is less of 20V the value set, the transfer is stopped and the OUTPUT

switches back on the inverter.

Note : Don’t use the turning knobs “TRANSFER” (23) to adjust the AC OUTPUT

voltage ! This is only it’s only a voltage threshold level to enable or disable the

transfer.

4.8.2 FAST (UPS)- MODE for the Transfer Switch

The quick and break free Transfer mode is programmed with a slide switch „Transfer

De-lay“ OFF, which is on the front side (cable connections side).

The aim of the XP-COMPACT is to supply the appliance with a break-free alternating

volt-age. When the incoming voltage AC IN no longer matches values which have

been set with the Turning Knob 23, the inverter switches on at once. The transfer is

carried out in 0.02 seconds. This quick transfer ensures a break-free function for

most appliances. If you have an alternating voltage back at the input AC IN, transfer

system starts up again with-out any break, and the inverter is stopped.

4.8.3 Delayed mode of the Transfer System

The delayed mode of the transfer system „Transfer Delay ON“ is programmed with

the slide switch (D) on front with the cable connections. The XP-COMPACT provides

a break-free alternating voltage for the appliance. A quick transfer switch is not

always sensitive nor is it always desired. For exampleI.E., when the appliances are

operated by a small back-up generator. An overload of a short period on such a

generator, i.e. start of a vacuum cleaner etc., has the effect of decreasing the voltage

for a short time. As in such cases the transfer to the Inverter is not desired, the

transfer system can be programmed with a delay. When the slide switch “(Transfer

delay” (D) is in the „On“ position, the transfer to the inverter takes place with a delay

of 5 seconds. If the voltage falls below 100Vac, the transfer takes place without delay

! The transfer switching to the Inverter takes place without any break.

Page 20

Steca XP-COMPACT

XP-COMPACT V5.5 20/57

4.9 The Multifunctional Contact

In the XP-COMPACT there is a built-in programmable power relay. The potential-free

change-over contact (NO – NC) of this power relay is connected to the screw

terminal AUX CONTACT.

Maximum Contact load: 230Vac / 12Vdc / 24Vdc / 16A !

> 36Vdc / 3A !

With the Push Button 21 „AUXILIARY CONTACT“ the contact can be manually

switched on or off independently from programming and from the operating situation.

The LED 5 “Contact active” shows the status of the contact. The drawing up the

screw terminal “AUX CONTACT” is the inactive position mode, LED 5 “Contact

active” off.

The switching on and off of this contact can be freely programmed for every

operating situation of the XP-COMPACT witch situation is indicated with a LED.

There is no limitation to its application and it is left to your wishes as to where and

how you would like to use it. The example and the setting of this contact are

explained in chapter 5.4.

In factory we program this for a dysfunction alarm. The contact is active when one of

these situations is detected:

− Over temperature (LED 10 lit)

− Overload (LED 11 lit)

− Over or less voltage of batteries (LED 12 lit or blinking)

− XP-COMPACT is turned off manually or with a fault (LED 13 lit)

In case this function is not wished, it must be modified by programming according to

procedure in chap. 5.4.

Page 21

Steca XP-COMPACT

XP-COMPACT V5.5 21/57

4.10 The Remote Control RCC-01

As an option, a Remote Control

can be connected to the XPCOMPACT. All operating controls

and displays except from level

adjustment are available on the

Remote Control. The Remote

Control is supplied with a 20m long

cable. It can as long as 40m. The

Remote Control is suitable for

surface mounting on the wall or on

to a switch board. It is fixed with 4

screws. The XP-COMPACT can

also be programmed with the

Remote Control. The Programming

is descry-bed in the section

„Programming“.

The output power and the charging currents are displayed on the Remote Control.

In the Remote Control there is an additional Alarm Contact and a built-in Control

Input. These two functions are available through Tip-jack RJ11/4 for use. This

Auxiliary Contact is Front / Work

Contact (max. 0.5A!), which is

independent from the Auxiliary

Contact of the XP-COMPACT.

This con-tact is active in case of

an alarm of the XP-COMPACT.

The Control Input is connected in

parallel to the ON/OFF- push

button. The XP-COMPACT can

be switched on or off through this

input with an impulse button or an

impulse contact.

Caution: No external voltage

should be connected to this

Input Control.

Order Number for Remote Control: RCC-01

Dimensions: H x B x T / 111.5 x 136.5 x 25mm

4.11 The Temperature sensor CT-35

Operating voltage of lead-acid batteries change depends

on the temperature. To correct the operating voltages

according to the actual temperatures, a temperature

sensor can be connected to the XP-COMPACT.

The compensation through the sensor is –3mV/°C/Cell.

Order Number: CT-35

Dimensions: H x B x T / 58 x 51.5 x 22mm

Page 22

Steca XP-COMPACT

XP-COMPACT V5.5 22/57

5 Programming (possible only with the remote control RCC-01)

The XP-COMPACT (except for 60Hz versions) is equipped with a Flash

processor fitted out with a Flash EEPROM Memory, which means that even

when it is disconnected from the battery, the parameters that were

programmed for the application remain after a new connection to the battery.

It is possible to reinitialize (RESET) the XP-COMPACT by pressing the small

black button on the left of the On/Off or by pressing simultaneously on the

three push buttons 19/20/21 of the remote control during at least 2 seconds. A

beep will confirm the RESET. The inverter switches off after this operation. It

can be turned on again after the beep. The programmed parameters will

remain.

5.1 Standard setting

The XP-COMPACT is delivered with the following default settings:

Auxiliary contact: active in case of defect or manual turn off with the LED 10/11/12/13

Battery voltage : Low voltage 11.6V / 23.2V / 46.4V

Float Charge 13.5V / 27.0V / 54.0V

End of Charge Voltage 14.4V / 28.8V / 57.6V

Equalization 15.6V / 31.2V / 62.4V

Absorption Time : 2 Hours

Equalizing Time : 20 Minutes

5.2 Reset value (default settings)

To come back to the default settings, press simultaneously on the push buttons

20/21 during at least 2 seconds. A beep will confirm the comeback to the factory

settings. The inverter switches off after this operation. It can be turned on again after

the beep.

5.3 Battery voltages and absorption time

5.3.1 Set the voltage and timing threshold

The programming is done in accordance with

the following steps:

Push and hold down, the Push Button 21

(Program) and the Push Button 19 (Change

status) for minimum 2 seconds

simultaneously.

With the Push Button 20 (select) select which

of the battery level and of the absorption time

have to be changed.

These four red LED’s show the function set:

Low voltage LED 13 (ON/OFF)

Float charge LED 12 (Batt. Low/high)

Absorption (End of charge) LED 11 (Overload)

Equalization LED 10 (Overtemp.)

Absorption Time LED 10/11/12/13 (altogether)

Page 23

Steca XP-COMPACT

XP-COMPACT V5.5 23/57

With the Push Button 19 (Change status) set the desired parameter (voltage or time)

to modify (LED 14/ 15/16/17/18). Push Button 19 (Change status) to set the desired

value according to the table 5.3.2.

If desired, repeat the operation with any other parameter (voltage or time) to be

changed.

If during 30 seconds no buttons are pressed, the selected values are automatically

stored and the XP-COMPACT switches back in to the normal operating status.

The voltage levels and times changed through programming are only first active with

the next charge cycle!

The voltage level which is not suitable can greatly reduce the battery life or

could even destroy it ! Therefore check beforehand with your battery supplier.

5.3.2 Table of voltage and timing threshold

The voltage levels (low voltage, float charge, end of charge and equalization) and the

duration of the absorption charge can be changed.

The display of these voltages and the times in the program mode are in accordance

with the diagram shown below:

Low voltage Float charge Absorption Equalization

Absorption

time

Equali-zation

time

LED

LED 13 LED 12 LED 11 LED 10

LED

10/11/12/13

LED 10/11

12 24 48 12 24 48 12 24 48 12 24 48 12/24/48 12/24/48

14

12.0 24.0 48.0 13.7 27.4 54.8 16.2 32.4 64.8 16.2 32.4 64.8 4h 3h

15

11.8 23.6 47.2 13.6 27.2 54.4 15.6 31.2 62.4 15.9 31.8 63.6 3h 2h

16 11.6 23.2 46.4 13.5 27.0 54.0

15 30 60

15.6 31.2 62.4 2h

1h

17

11.4 22.8 45.6 13.4 26.8 53.6

14.4 28.8 57.6

15.3 30.6 61.2 1h 40’

18

11.2 22.4 44.8 13.3 26.6 53.2 14.2 28.4 56.8 15 30 60 0 – 1’

20’

The heavy printed values show the standard settings.

5.4 Auxiliary contact

5.4.1 Principle

The Auxiliary Contact can be basically programmed for any operating situation of the

XP-COMPACT which is indicated with a LED. The programming is possible for one

or more operating situations. If the contact is programmed for many situations, it is

activated as soon as the XP-COMPACT finds itself in any one of the programmed

situations. That means that the work of the contact meets that of the logic OR–

Function.

5.4.2 The programming of the Auxiliary Contact

The programming of the Auxiliary Contact is carried out in the following Steps:

− The Push Button 21 (Program) presses down for min. 2 seconds. The LED 4

„Program“ is lit as an indication, that the XP-COMPACT is in program mode.

− A blinking LED shows the programmed condition for the auxiliary contact (LED

10/11/ 12/13 factory setting).

− With the Push Button 20 (select), select the desired condition in which the

contact should be activated.

− With the Push Button 19 (Change status) confirm or change the status for this

condition. If desired, with the Push Button 20 (select) select another condition in

which the contact should be activated.

Page 24

Steca XP-COMPACT

XP-COMPACT V5.5 24/57

− With the Push Button 19 (Change status) confirm or change the status for this

condition. If during 30 seconds no buttons are pushed, then the settled values

are automatically stored and the XP-COMPACT switches back to normal

operating condition.

5.4.3 Auxiliary Contact as generator starter

As per the battery capacity

When in the programming of the Auxiliary Contact, the Battery Capacity (LED 15-18)

is used as a condition, you must then take note of the following requirements.

If you have to start an emergency back-up supply with a battery having a certain

residual capacity, then two battery levels must be programmed. The first (i.e. Battery

25% LED 17) for the starting or activating the Auxiliary Contact and the second (i.e.

Battery 100% LED15) for stopping or disabling the Auxiliary Contact. Programmed

like this the Auxiliary Contact works with the lowest set condition and stops when it

has reached the highest programmed condition through charging.

Example: start of a generator with the XP-COMPACT

In order to program the auxiliary contact to start at 25% and to stop at 75% of the

battery state-of-charge, here is the procedure to follow:

− Press the key AUX. CONTACT (Program) 21 during at least 2 seconds. Then

the states will be displayed blinking (factory settings LED’s 10/11/12/13). As

these states are not wished for the start of the generator, they must be disabled.

− With the key (select) 20, select the LED’s to disable (the active LED’s are

blinking) and disable them with the key 19 Change Status. Select the other

LED’s to switch off with the key (select) 20 and switch them off with the key 19

Change Status until all are disabled.

− Then select the LED 17 with the key (select) 20 and activate the contact with the

key 19 Change Status. The generator will start once the LED 17 switches of.

− Then select the LED 16 with the key (select) 20 and activate the contact with the

key 19 Change Status. The generator will stop once the LED 16 switches on.

− If no key is activated during 30 seconds, the normal operation states are

displayed automatically again.

For a control the key Program can be pressed at least 2 seconds. The values set are

displayed blinking.

5.4.4 Power cut of the second priority loads

The auxiliary contact can also be used to cut the power of less priority loads when

the battery state of charge is lower than a given threshold. In that case, only one of

the battery state of charge, or the “transfer” function will be programmed as power cut

criteria.

The second priority loads will be supplied only when the generator is ON or when the

battery has a sufficient threshold.

5.4.5 Manual operating of Auxiliary Contact

The Auxiliary Contact can be operated at any time with the Push Button 21 (AUX.

CONTACT). The LED 6 „Contact manual“ lights up as information that the Contact is

manually operated, and LED 5 „Contact active“ lights up when the Contact is active.

By pushing the Push Button 21 a second time, the Contact is disabled. By pushing it

the third time, automatic functions are restored.

Page 25

Steca XP-COMPACT

XP-COMPACT V5.5 25/57

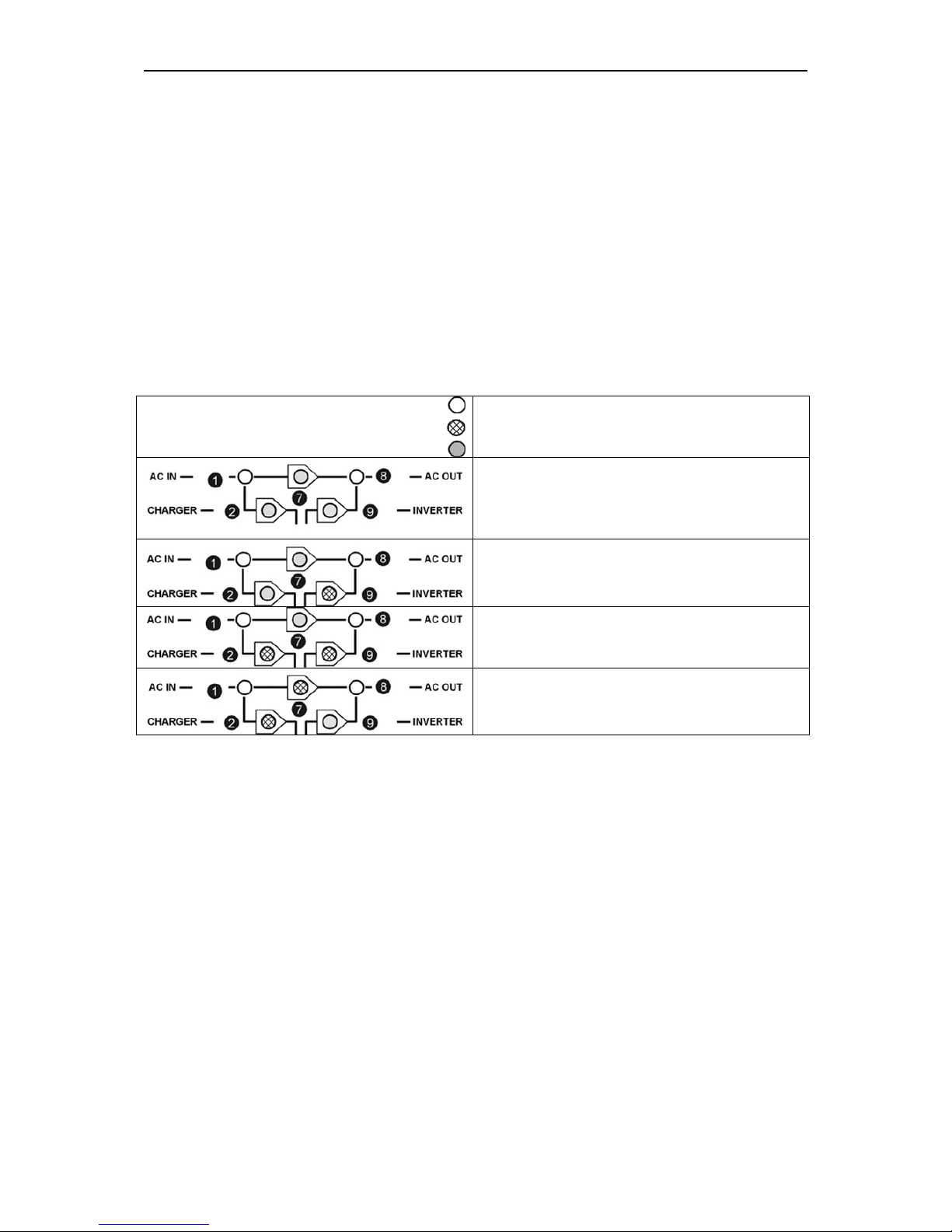

5.5 Disabling some of the XP-COMPACT functions

Each different function charger, inverter and transfer can be disabled. This is useful

for specific applications witch required to disable some of these three functions.

If you press the buttons 19 and 20 more than 2 seconds you can have access to the

different possibilities, shown in the following diagram.

In programming mode the display shows only the different types of program with the

three LED’s 2, 7 and 9 to each function. To change the type of programming, press

shortly the button 20 until you reach the right function used according to the table

below. After 10 seconds the XP-COMPACT exits the programming mode and loads

the new change.

In user mode, the disabled functions are displayed by blinking LED. So you can see

which mode is disabled.

5.5.1 Diagram of the different modes

Shows an off LED

Shows a blinking LED

Shows a lighted LED

All the functions are enabled. This is the

factory setting.

The inverter is disabled. Only the transfer

switch and the charger will work normally.

Inverter and charger are both disabled.

Only the transfer switch function is enabled in input voltage and frequency is OK

Charger and transfer switch are disabled

the inverter will work continuously even if

there is a correct AC voltage at the input.

Page 26

Steca XP-COMPACT

XP-COMPACT V5.5 26/57

6 Installation Maintenance

Apart from the periodic controls mentioned for the connections, the XP-COMPACT

does need any maintenance. Keep the appliance clean and from time to time, wipe it

clean with a damp cloth.

7 Declaration of CE Compliance

Hereby we state that the products described in this user manual comply with the

following standards:

EN 61000-6-1, EN 61000-6-3, EN 55014, EN 55022, EN 61000-3-2, Dir.

89/336/EEC, LVD 73/23/EEC, EN 50091-2, EN 60950-1.

CH - 1950 Sion, the 1st of March 2003 STUDER INNOTEC (R. Studer)

Page 27

Steca XP-COMPACT

XP-COMPACT V5.5 27/57

8 Technical Data

Page 28

Steca XP-COMPACT

XP-COMPACT V5.5 28/57

1 Allgemeine Informationen ______________________________________ 29

1.1 Zu dieser Bedienungsanleitung......................................................................29

1.2 Qualität und Garantie....................................................................................... 29

1.3 Garantieausschluss..........................................................................................29

1.4 Haftungsausschluss.........................................................................................30

1.5 Warnungen........................................................................................................30

1.6 Besondere Schutzmassnahmen....................................................................31

2 Einführung____________________________________________________32

2.1 Prinzip Schema................................................................................................. 32

2.2 Beschreibung der Hauptfunktionen............................................................... 32

2.3 Batterie Verschaltungen..................................................................................33

3 Montage und Installation_______________________________________ 35

3.1 Ort der Montage................................................................................................35

3.2 Befestigung........................................................................................................35

3.3 Anschluss........................................................................................................... 35

3.4 Anschlussplan / Frontseite.............................................................................. 37

3.5 Verdrahtung....................................................................................................... 38

3.6 Voreinstellungen...............................................................................................38

4 Bedienung____________________________________________________40

4.1 Anzeigen und Bedienelemente ...................................................................... 40

4.2 Anzeigen und Bedienelemente für der Fernsteuerung (Remote control) 41

4.4 Tasten................................................................................................................. 43

4.5 Drehknöpfe........................................................................................................43

4.6 Der Wechselrichter........................................................................................... 44

4.7 Der Batterielader............................................................................................... 45

4.8 Der Umschaltautomat (Transferschalter)......................................................47

4.9 Der Multifunktionskontakt................................................................................ 48

4.10 Die Fernsteuerung RCC-01............................................................................49

4.11 Die Temperatursonde CT-35.......................................................................... 50

5 Programmierung (nur mit Fernsteuerung RCC-01 möglich)_______50

5.1 Standardeinstellungen.....................................................................................50

5.2 Zurücksetzen der Programmierung (Standardeinstellung)........................ 50

5.3 Batteriespannungen und Absorptionsdauer................................................. 51

5.4 Hilfskontak

t........................................................................................................52

5.5 Sperren von Funktionen..................................................................................54

6 Wartung ______________________________________________________ 55

7 Konformitätserklärung CE _____________________________________55

8 Technisch

e Daten _____________________________________________ 56

Page 29

Steca XP-COMPACT

XP-COMPACT V5.5 29/57

1 Allgemeine Informationen

1.1 Zu dieser Bedienungsanleitung

Diese Anleitung ist ein fester Lieferbestandteil jedes Kombiwechselrichters XPCOMPACT. Sie dient als Richtlinie für den sicheren und effizienten Betrieb des XPCOMPACT. Die Anleitung ist nur gültig für die folgenden Geräte und Optionen:

XP-COMPACT XPC 1400-12

XP-COMPACT XPC 2200-24

XP-COMPACT XPC 2200-24

Temperatursonde CT-35 AC-Kabeleinführung CFC-01

Fernsteuerung RCC-01 IP-23 Abdeckung C-IP23

Solarladeregler XPC xxxx-xx-S

Jede Person, die einen XP-COMPACT installiert und/oder mit einem XP-COMPACT

arbeitet, muss vollständig mit dem Inhalt dieser Anleitung vertraut sein und strikt alle

Warn- und Sicherheitshinweise befolgen. Die Installation des XP-COMPACT und

Arbeiten daran müssen von qualifiziertem und dafür ausgebildetem Personal

ausgeführt werden. Installation und Anwendung müssen in jedem Fall den jeweiligen

örtlichen Installations- und Sicherheitsvorschriften entsprechen.

1.2 Qualität und Garantie

Während der Produktion und der Montage der XP-COMPACT durchlaufen sämtliche

Geräte mehrere Kontrollen und Tests. Fabrikation, Kontrollen und Tests erfolgen

gemäss genau festgelegten Protokollen. Jeder XP-COMPACT hat seine eigene

Seriennummer, welche dazu dient bei eventuellen Kontrollen oder Reparaturen auf

die genauen Gerätedaten zurückzugreifen. Entfernen Sie darum nie das Typenschild

mit der Seriennummer. Die Garantie für dieses Gerät gilt für die in dieser

Betriebsanleitung aufgeführten Anwendungen und Betriebsfälle.

Die Garantiedauer für die XP-COMPACT beträgt 2 Jahre.

1.3 Garantieausschluss

Für Schäden, welche durch Anwendungen, Manipulationen, Betriebsfälle und

Behandlungen entstehen, welche nicht ausdrücklich in dieser Betriebsanleitung

aufgeführt sind, können keine Garantieleistungen gewährt werden.

Nachfolgend eine Liste von Fällen für welche explizit keine Garantie gewährt wird.

− Überspannungen an den Eingängen (z.B. 48V am Batterieeingang des XPCOMPACT 1400-12)

− Verpolung bei Batterieanschluss(+/- vertauscht)

− In das Gerät eingelaufene Flüssigkeiten oder Oxydation durch Kondensation

− Defekte durch mechanische Einflüsse

− Nicht ausdrücklich von Steca Elektronik GmbH autorisierte Änderungen

− Nicht oder nur teilweis e festgezogene Schrauben und Muttern nach Wechseln

von Sicherungen oder Anschlusskabeln.

− Transportschäden, z.B. durch unsachgemässe Behandlung oder Verpackung

− Schäden durch atmosphärische Überspannungen (Blitzschlag)

Page 30

Steca XP-COMPACT

XP-COMPACT V5.5 30/57

1.4 Haftungsausschluss

Die Einhaltung dieser Betriebsanleitung und der Bedingungen und Methoden der

Installation, dem Betrieb, der Verwendung und der Wartung dieses Gerätes können

von der Firma Steca Elektronik GmbH nicht kontrolliert oder überwacht werden.

Daher übernehmen wir keinerlei Haftung und Verantwortung für Schäden, Verluste

und Kosten, die aus dem Betrieb dieses Gerätes entstehen oder die aus fehlerhafter

Installation, unsachgemässem Betrieb oder falscher Verwendung und Wartung

entstehen oder in irgendwelcher Art und Weise damit zusammenhängen. Ebenso

übernehmen wir keine Verantwortung für patentrechtliche Verletzungen oder

Verletzung anderer Rechte Dritter, die aus der Verwendung dieses Gerätes

entstehen.

Der Einsatz und Betrieb von Geräten von Steca obliegt in jedem Fall der

Verantwortung des Kunden.

Die in dieser Beschreibung erwähnten Geräte sind nicht für den Betrieb von

lebenserhaltenden Systemen einzusetzen.

Die Firma Steca Elektronik GmbH behält sich das Recht vor, Änderungen der

technischen Daten dieses Gerätes oder dieser Betriebsanleitung ohne vorherige

Mitteilung oder Ankündigung vorzunehmen.

1.5 Warnungen

Diese Betriebsanleitung muss so aufbewahrt werden, dass sie den Benutzern

jederzeit zur Verfügung steht. Die Benutzer müssen mit den Warn- und

Sicherheitsangaben vertraut sein.

Beim Betrieb des XP-COMPACT treten an dessen Anschlüssen und im Geräteinnern

lebensgefährliche Spannungen auf. Arbeiten am Gerät und an der Installation dürfen

nur von entsprechend ausgebildeten und dafür geschulten Personen ausgeführt

werden.

Die gesamte mit dem XP-COMPACT zusammenhängende Installation muss in jedem

Fall den jeweiligen gültigen Vorschriften entsprechen.

Nicht von Steca Elektronik GmbH schriftlich autorisierten Personen ist es

ausdrücklich untersagt, Änderungen oder Reparaturen am Gerät auszuführen. Für

autorisierte Änderungen dürfen nur Originalteile verwendet werden.

Der XP-COMPACT darf nur dann betrieben werden, wenn er gemäss dieser

Anweisung installiert ist und wenn sämtliche Teile richtig montiert sind.

An den Ein- und Ausgängen der Geräte dürfen nur die dafür vorgesehenen

Energiequellen oder Verbraucher angeschlossen werden.

Um an einem XP-COMPACT gefahrlos Unterhalt oder Reparaturen auszuführen,

müssen sämtliche Anschlüsse vorher abgetrennt werden.

Vorsicht: Auch wenn ein XP-COMPACT von sämtlichen Anschlüssen getrennt

wurde, können an dessen Ausgang noch lebensgefährliche Spannungen

anliegen. Um dies zu vermeiden, muss der XP-COMPACT mit der ON/OFF-Taste

eingeschaltet werden. Nach einer Minute ist die Elektronik entladen und die

jeweiligen Arbeiten können gefahrlos ausgeführt werden.

Der XP-COMPACT ist nur für Innenmontage geeignet und darf auf keinen Fall

Schnee, Regen oder sonstigen Flüssigkeiten ausgesetzt werden. Bei Montage in

Fahrzeugen muss darauf geachtet werden, dass er vor Spritzwasser geschützt ist.

An einen XP-COMPACT dürfen nur Blei-Säure- oder Blei-Gel- Batterien

angeschlossen werden.

Vorsicht: Blei- Säure- Batterien sowie auch Blei- Gel- Batterien erzeugen im

normalen Betrieb ein hoch explosives Gas. In der Nähe von Batterien dürfen

Page 31

Steca XP-COMPACT

XP-COMPACT V5.5 31/57

weder Feuer entfacht noch Funken erzeugt werden. Die Batterien müssen in

einem gut belüfteten Raum untergebracht sein, und sie müssen so

untergebracht sein, dass aus Unachtsamkeit keine Kurzschlüsse auf deren

Anschlüssen entstehen können.

Versuchen Sie nie gefrorene Batterien zu laden.

Ein XP-COMPACT darf nicht für lebenserhaltende Anlagen oder Applikationen

verkauft oder in solchen Anlagen eingesetzt werden.

1.6 Besondere Schutzmassnahmen

− Bei Arbeiten an Batterien muss für eventuelle Hilfeleistung immer eine 2.

Person in Rufnähe sein.

− Genügend frisches Wasser und Seife muss in der Nähe bereitgestellt werden,

damit bei Kontakt der Säure mit Kleidern Haut oder Augen die entsprechenden

Stellen sofort gut gewaschen werden können.

− Bei Säurekontakt mit den Augen müssen diese mindestens während 15 Minuten

mit kaltem Wasser gründlich gespült werden. Es empfiehlt sich, danach sofort

einen Arzt aufzusuchen.

− Mit Backpulver kann Batteriesäure neutralisiert werden. Halten Sie darum

immer eine Handvoll davon bereit.

− Bei Arbeiten mit metallischen Werkzeugen in der Nähe oder an den Batterien ist

besondere Vorsicht geboten. Mit Werkzeugen wie Schraubenzieher,

Schraubenschlüssel usw. können Kurzschlüsse verursacht werden. Dabei

entstehende Funken können eine Explosion verursachen.

− Bei Arbeiten an Batterien müssen auch alle persönlichen Metallteile wie Ringe,

Hals- und Armbänder, Uhren usw. abgelegt werden. Batterien sind so stark,

dass bei Kurzschlüssen mit solchen Gegenständen diese sofort zum Schmelzen

gebracht werden und somit schwere Brandwunden entstehen können.

− Halten Sie sich an die Vorschriften des Batteriefabrikanten.

− Unter bestimmten Bedingungen kann der XP-COMPACT oder ein

angeschlossener Generator automatisch starten. Bei Arbeiten an der

elektrischen Installation muss darum sichergestellt sein, dass diese Geräte

vorher von der Installation getrennt wurden.

Page 32

Steca XP-COMPACT

XP-COMPACT V5.5 32/57

2 Einführung

Der XP-COMPACT ist ein Sinuswechselrichter mit integriertem Batterielader mit

vielen Zusatzfunktionen der für den Einsatz als netzunabhängiges

Wechselstromversorgungssystem oder als unterbrechungsfreie Stromversorgung

entwickelt wurde.

2.1 Prinzip Schema

Bemerkung :

(1) Der Neutralleiter “N“ des XP-COMPACT ist in keiner Funktionsart mit

dem Erdleiter “PE“ verbunden. Falls nötig und wenn es die jeweiligen gültigen

Vorschriften verlangen kann die automatische Zuschaltung der Erde mit dem

Neutralleiter mit dem Einbringen einer Brücke im Geräteinnern realisiert werden.

Klären Sie eine eventuelle Änderung mit dem Installateur.

(2) Fernbedienung für das Einstellen des maximalen Eingangsstroms (siehe

Abschnitt 4.6.3)

2.2 Beschreibung der Hauptfunktionen

2.2.1 Der Wechselrichter

Der im XP-COMPACT eingebaute Sinuswechselrichter erzeugt eine äusserst präzise

spannungs- und frequenzstabile, sinusförmige Wechselspannung. Um auch grosse

Lasten wie Elektromotoren usw. starten zu können, steht dem Verbraucher eine

kurzzeitige Startleistung grösser als die Nominalleistung des XP-COMPACT zur

Verfügung.

Der Wechselrichter ist gegen Überlast, Übertemperatur und Kurzschluss geschützt.

Ein Leistungsteil mit modernsten Power-MOS-FET Transistoren, ein

Ringkerntransformator und ein schnelles Regelsystem bilden einen robusten und

zuverlässigen Wechselrichter mit höchstem Wirkungsgrad. Eine von 1 – 20 Watt

Page 33

Steca XP-COMPACT

XP-COMPACT V5.5 33/57

einstellbare Standby- oder Lasterkennungsschaltung sorgt für kleinsten

Energieverbrauch und möglichst lange Lebensdauer der Batterie.

2.2.2 Der Transferschalter

Der XP-COMPACT kann an eine Wechselstromquelle angeschlossen werden. Zum

Beispiel an Notstromgeneratoren oder ans öffentliche Netz. Über den

Transferschalter steht einerseits diese Wechselspannung am Ausgang für die

angeschlossenen Verbraucher zur Verfügung. Andererseits werden damit die

Batterien geladen. Die Energieaufteilung zwischen Verbraucher und Batterielader

erfolgt automatisch.

2.2.3 Der Batterielader

Der eingebaute Batterielader ist so ausgelegt, dass er die Batterien möglichst schnell

und voll-ständig laden kann. Ein mikroprozessorgesteuerter, 3- resp. 4- stufiger

Ladeprozess sorgt für eine optimale Ladung der Batterien. Der gewünschte

Ladestrom kann von 0 – 20/37/45A (je nach Model) stufenlos eingestellt werden. Der

Batterielader ist für Blei- Säure- und Blei- Gel- Batterien ausgelegt. Dank einem

geregelten Schwebeladungssystem (Ladeerhaltung) kann die Batterie

ununterbrochen angeschlossen bleiben.

Die Einstellung muss entsprechend den Batteriekapazitäten und der zu ladenden

Energiequelle vorgenommen werden.

2.2.4 Die Fernsteuerung (Remote control)

Als Option kann eine Fernsteuerung am XP-COMPACT angeschlossen werden. Alle

Bedienungselemente und Anzeigen mit Ausnahme der Pegeleinstellungen sind auf

dieser Fernsteuerung vorhanden. Die Fernsteuerung ist mit einem 20m langen Kabel

versehen. Dieses Kabel kann bis auf 40m verlängert werden.

2.3 Batterie Verschaltungen

Blei- Säure- Batterien stehen normalerweise als Blöcke für 2V, 6V oder 12V zur

Verfügung. Um die benötigte Betriebsspannung und Kapazität der Batterien für den

Betrieb des XP-COMPACT zu erzeugen, müssen in den meisten Fällen mehrere

Batterien parallel und oder in Serie geschaltet werden. Nachfolgend sind einige

Beispiele aufgeführt.

Page 34

Steca XP-COMPACT

XP-COMPACT V5.5 34/57

2.3.1 Parallelschaltung

2.3.2 Serieschaltung

2.3.3 Parallel- Serieschaltung

Page 35

Steca XP-COMPACT

XP-COMPACT V5.5 35/57

3 Montage und Installation

3.1 Ort der Montage

Der Standort des XP-COMPACT muss nach folgenden Kriterien ausgewählt werden:

− Geschützt vor unbefugtem Zugriff

− Trockener, staubfreier Raum, keine Kondensation

− Nie direkt über der Batterie montieren und auch nie in einem Schrank

zusammen mit der Batterie

− Belüftungslöcher freihalten. Bei mobilem Einsatz muss darauf geachtet werden,

dass die Vibrationen möglichst klein sind.

3.2 Befestigung

3.2.1 Befestigung des XP-COMPACT’S

Grundsätzlich kann der XP-COMPACT in jeder beliebigen

Lage montiert werden. Vorzugsweise ist das Gerät aber für

Wandmontage mit den Batteriekabeln nach unten zu

montieren. Der XP-COMPACT wird mit vier Schrauben

durch die vier von aussen zugänglichen Löcher (Durchm.

5.5mm) an einer Wand befestigt. In Fahrzeugen sollte der

XP-COMPACT auf vibrationsdämpfenden Elementen

befestigt werden. Der XP-COMPACT darf nicht auf eine

brennbare Unterlage montiert werden, da die

Gehäuserückseite bis 80 Grad Celsius heiss werden kann.

3.2.2 Schutzabdeckung IP23 (Option)

Die Schutzabdeckung IP23 (Best. Nr. C-IP23) wird auf der

Oberseite des XP-COMPACT montiert. Am einfachsten

erfolgt die Montage nachdem der XP-COMPACT an der

Wand befestigt wurde. Die 4 Befestigungsschrauben des

XP-COMPACT leicht lösen. Die oberen beiden Schrauben

soweit lösen, dass die Abdeckung mit der Seite mit den Uförmigen Ausschnitten zwischen Wand und XP-COMPACT

eingeschoben werden kann bis sie auf den Schrauben

ansteht. Danach die 4 Befestigungsschrauben gut

festziehen.

3.3 Anschluss

3.3.1 Allgemeine Hinweise zum Anschluss:

− Der Kabelanschluss auf den Klemmen AC INPUT / AC OUTPUT / 16A 230VAC

erfolgt mit einem Schraubenzieher Nr.1 und der Anschluss auf den Klemmen

SOLAR mit einem Schraubenzieher Nr.2.

− Der Leiterquerschnitt der auf den Klemmen AC INPUT / AC OUTPUT / 16A

230VAC anzuschliessenden Kabel muss mind. 2.5mm2 betragen.

− Sämtliche Anschlusskabel, auch die Batteriekabel, müssen mit einer

Zugentlastung montiert werden.

− Die Batteriekabel dürfen grundsätzlich nicht verlängert werden. Ist eine

Verlängerung unumgänglich, muss der Leiterquerschnitt entsprechend erhöht

werden.

Page 36

Steca XP-COMPACT

XP-COMPACT V5.5 36/57

− Um die Batteriekabel zu schützen, muss direkt auf der Batterie eine dem

Leiterquerschnitt entsprechende Sicherung montiert werden.

− Sämtliche Kabel müssen gut festgeschraubt sein. Zur Sicherheit empfehlen wir

eine jährliche Kontrolle. Bei mobilen Anlagen sollten die Anschlüsse öfter

kontrolliert werden.

− Der Anschluss muss von ausgebildeten Fachleuten ausgeführt werden. Das für

die Installation verwendete Material wie Kabel, Steck- und Verteildosen,

Sicherungen usw. muss den jeweils gültigen Installationsvorschriften für

Niederspannungsanlagen entsprechen.

Der XP-COMPACT wird mit bereits angeschlossenen Batteriekabeln geliefert.

3.3.2 Kabeleinführung mit Stopfbuchsen (Option CFC-01)

Eine Schutzabdeckung mit Zugentlastung für die

Kabel kann als Option CFC-01 angebracht werden.

Diese Abdeckung wird mit 2 Schrauben befestigt

und erlaubt die korrekte Zugentlastung der

Anschlusskabel.

Page 37

Steca XP-COMPACT

XP-COMPACT V5.5 37/57

3.4 Anschlussplan / Frontseite

.

Caution:

Check battery

polarity (+/-) before connecting!

A wrong connection could

damage the system .

16A-250Vac

BATTERY

SOLAR

Remote

control

Temp.

Don't open before

disconnect line

and battery

N

AC Input

AC Output

L

Equalize

Transfer delay

Auxiliary Contact

PE

N

L

PE

M AL

B

C

D

E

FG

H

J

K

N

Page 38

Steca XP-COMPACT

XP-COMPACT V5.5 38/57

A Battery +/- Batteriekabel (bereits montiert)

B SOLAR +/- Anschlussklemmen für Solarmodule, Funktion wird nicht

angeboten

C Remote contr. Steckanschluss für Fernsteuerung RCC-01

D Transfer delay Schiebeschalter für Transferverzögerung Equalize

Schiebeschalter für Egalisierung der Batterie

E Equalize Schiebeschalter für Egalisierung der Batterie Transfer

delay Schiebeschalter für Transferverzögerung

F Temp. Steckanschluss für Temperatursonde CT-35

G Aux. Contact Anschlussklemmen für den Hilfskontakt

H AC Input Anschlussklemmen für Wechselspannungseingang.

Direkt über diesen Klemmen liegt der dazugehörige

Sicherungsautomat.

J Typ… Typenschild mit Leistungsdaten und Seriennummer

K AC Output Anschlussklemmen für Wechselspannungsausgang

L Caution… Vorsicht: Vor dem Anschliessen der Batterie unbedingt

Polarität (+/-) kontrollieren! Faschanschluss kann den

XP-COMPACT beschädigen

M Don’t… Nicht öffnen bevor sämtliche Anschlüsse entfernt

wurden

N 16A Schutzsch. 16A Schutzschalter für das Transfersystem

3.5 Verdrahtung

Der Anschluss des Kombigerätes XP-COMPACT ist eine wichtige Etappe bei der

Installation. Achten Sie darum gut darauf, dass die Anschlussarbeiten sauber und

korrekt ausgeführt werden und dass auf keinen Fall die Anschlussdrähte auf falsche

Klemmen geführt werden.

Der Anschluss des XP-COMPACT muss in folgender Reihenfolge ausgeführt

werden. Bei einer eventuellen Demontage ist die umgekehrte Reihenfolge

einzuhalten.

3.6 Voreinstellungen

Bevor Sie mit der Verdrahtung des XP-COMPACT beginnen, muss der verwendete

Batterietyp eingestellt werden. Falls Gel-Batterien verwendet werden, muss der

kleine Schiebeschalter „E-qualize“(E) in die Position OFF (Schiebeschalter nach