Page 1

Temperature differential controller

5 inputs, 2 outputs

742.114 | Z03 | 14.50 | Subject to change due to technical improvements!

EN

Installation and operating instructions

Page 2

2

742.114 | 14.50

EN

1 General safety instructions ....................................................................3

2 Proper usage .........................................................................................4

3 About these instructions .......................................................................4

3.1 Contents ........................................................................................................ 4

3.2 Target audience ............................................................................................. 4

3.3 Danger levels in warning notices

Évaluation du niveau de risque dans les avertissements....................................4

4 Installation .............................................................................................5

4.1 Opening / Closing the casing ......................................................................... 5

4.2 Mounting the casing .....................................................................................6

4.3 Establishing the electrical connections...........................................................7

4.4 Terminal pin assignments ............................................................................. 10

5 Commissioning the device for the first time .......................................13

6 Structure ..............................................................................................17

6.1 Casing ..........................................................................................................17

6.2 Display ......................................................................................................... 17

7 Operation .............................................................................................20

7.1 Operating buttons ....................................................................................... 20

7.2 Display when operating ............................................................................... 20

8 Modes of operation .............................................................................20

8.1 Changing the mode of operation ................................................................20

8.2 "Off" mode ...................................................................................................21

8.3 “Manual” mode ........................................................................................... 21

8.4 "Automatic" mode ........................................................................................22

9 Settings menu ......................................................................................23

9.1 Overview ......................................................................................................23

9.2 Calling up the settings menu and selecting a menu entry ..............................26

9.3 Setting the time ........................................................................................... 26

9.4 Setting the system ....................................................................................... 26

9.5 Setting the functions .................................................................................. 26

9.6 Setting the parameters ............................................................................... 26

9.7 Setting the priority ......................................................................................27

9.8 Resetting to factory defaults ........................................................................27

10 Functions ..............................................................................................28

10.1 Operation ....................................................................................................28

10.2 Characteristics .............................................................................................29

10.3 Functional description .................................................................................31

11 Parameters ...........................................................................................45

12 Dismantling and disposal ....................................................................48

13 Info messages ......................................................................................48

Contents

Page 3

3

742.114 | 14.50

EN

1 General safety instructions

• This document is part of the product.

• Install and use the device only after reading and understanding this document.

• Keep this document in a safe place for the entire service life of the device. Pass the

document on to subsequent owners and operators of the device.

• Adhere to all safety instructions. Consult (further) professional personnel in the

event of any ambiguities.

• The measures described in this document may only be performed by qualified

technical professionals. Exception: End-customers may operate the device when they

have previously been trained by a technical professional.

• The solar energy system can be damaged by improper operation of the device.

• The device must not be connected to the mains power supply when:

– the casing is open or damaged.

– cables are damaged.

• Factory labels and markings must never be altered, removed or rendered unreadable.

• The prescribed conditions of use must be adhered to; more information is provided

in 15, p. 53.

• This device is not intended for:

– children.

– persons with physical, sensory or mental impairment.

– persons without sufficient experience or knowledge, unless they are instructed

in the use of the device, and initially supervised, by a person responsible for their

safety.

This product is CSA certified and complies with the requirements of the applicable UL

and CSA standards in terms of design and operating behaviour. Please contact your

dealer should you require further information on this.

14 Troubleshooting ...................................................................................49

14.1 General faults ..............................................................................................49

14.2 Error messages ............................................................................................50

14.3 Checking the Pt1000 temperature sensor ....................................................52

15 Technical data ......................................................................................53

15.1 Controller ....................................................................................................53

15.2 Cable specifications .....................................................................................54

16 Exclusion of liability .............................................................................54

17 Legal guarantee ...................................................................................54

18 Notes ...................................................................................................55

Page 4

4

742.114 | 14.50

EN

2 Proper usage

The temperature differential controller, subsequently referred to as the controller, is an

independently installed electronic temperature controller for on-surface installation.

Integration into a pump assembly is possible when the technical specifications of the

controller are adhered to.

The maintenance-free controller is exclusively intended for controlling solar energy and

heating systems.

3 About these instructions

3.1 Contents

This manual contains all information required by a technical professional for setting up

and operating the temperature differential controller.

3.2 Target audience

The target audience of this manual are technical professionals who:

• have the knowledge of terminology and the skills necessary for setting up and operating solar energy systems.

• have the necessary training, knowledge and experience, and knowledge of the applicable regulations in order to evaluate and recognise the dangers inherent in the

following work:

– Installation of electrical equipment

– Production and connection of data communication cables

– Production and connection of mains grid power supply cables

3.3 Danger levels in warning notices

Évaluation du niveau de risque dans les avertissements

Danger level

Niveau de risque

Likelihood of occurrence

Éventualité de l’intervention

Consequences resulting from non-compliance

Conséquences en cas de non-respect

Danger

Danger

Imminent threat of danger

Danger imminent

Death, serious bodily injury

Mort, lésions corporelles graves

Warning

Avertissement

Possible threat of danger

Danger éventuel

Death, serious bodily injury

Mort, lésions corporelles graves

Caution

Attention

Possible threat of danger

Danger éventuel

Minor bodily injury

Lésions corporelles simples

Notice

Avis

Possible threat of danger

Danger éventuel

Property damage

Dommages matériels

Page 5

5

742.114 | 14.50

EN

4 Installation

The following section describes only the installation of the

4.1 Opening / Closing the casing

4.1.1 Removing the front panel

by the grooves at the sides

and pull forwards

(Fig.

4.1.2 Mounting the front panel

and then press it onto the casing until it latches

4.1.3 Removing the terminal cover

(Fig. 1).

4.1.4 Mount the terminal cover.

Tighten the screw

to a torque of 0.5

Page 6

6

742.114 | 14.50

EN

4.2 Mounting the casing

√ The mounting location must satisfy the prescribed conditions of use; more informa-

tion on this is provided in section 15, p. 53.

√ The mounting surface is vertical and allows good access for installation.

Danger

Risk of death by electrocution!

• Disconnect the controller from the power supply before opening the casing.

• Make sure that the power supply cannot be unintentionally switched on when the

casing is open.

• Do not use the casing as a drilling template.

1. If necessary, remove the terminal cover.

2. Screw in the screw for the upper mounting hole (Fig. 2) until the screw head has

a clearance of 5 ... 7 mm (0.20 ... 0.28 inch) from the mounting surface.

3. Hang the controller on the screw by the upper mounting hole and align it vertically.

4. Mark the position of the lower mounting hole through the casing.

5. Remove the controller and prepare the mounting hole for the lower screw.

6. Hang the controller by the upper mounting hole and then fasten the screw in the

lower mounting hole .

7. Mount the terminal cover.

ø5 (0.20 inch)

ø5 (0.20 inch)

8.5 (0.33 inch)

140 (5.51 inch)

105 (4.13 inch)

156 (6.14 inch)

Fig. 2: Rear side of the controller with the upper and lower mounting holes.

Page 7

7

742.114 | 14.50

EN

4.3 Establishing the electrical connections

Danger

Risk of death by electrocution! Make sure that the following conditions are satisfied

when performing the work described in this section:

• All cables leading to the controller must be disconnected from the power supply and

it must be ensured that they cannot be unintentionally reconnected during installation.

• Each terminal must only be connected to a single conductor.

• The protective earth conductors (PE) from the mains cable and pump and valve

cables must be connected to the protective earth conductor terminal block.

• All cables must be laid so that persons cannot stand on them or trip over them.

• The cables must satisfy the requirements listed in Section 15, p. 53.

• The local power supply must match the specifications on the type plate of the con-

troller.

• The power supply cable is to be connected to the mains power as follows:

– using a plug connected to a wall mains socket or

– via an isolating mechanism allowing complete isolation in the case of permanent

wiring.

• The power supply cable must be laid in conformance to all applicable legal guide-

lines and regulations of the local electricity supplier.

Notice

Danger of damage and malfunction.

• Connect only components that do not overload the controller inputs and outputs;

more information is provided on the type plate and in Section 15, p. 53.

• For outputs R1 and R2, the following applies:

– Speed control must be deactivated when an external relay is connected.

– The correct pump type must be set (standard/high-efficiency pump).

More information on this is provided in Sections 5, p. 13 and 11, p. 45 (P18, P19).

Notes

• Any connection polarity may be used for the 1 – 5 and RS signal inputs and outputs.

• Only type Pt1000 temperature sensors may be used.

• Lay the sensor cables at least 100 mm (4 inch) away from any power supply cables.

• Use shielded sensor cables when inductive sources are present, e.g. high-voltage

lines, radio transmitters, microwave devices.

Page 8

8

742.114 | 14.50

EN

4.3.1 Position of the terminals

11

2

13

14

6

7

18

L R1

L

const.

X

NN

PE PEPEPE

N

R1 R2

R

S54321

N

R2

L

const.

11

13

R

S

0-10

15

Fig. 3: Terminals in the lower part of the controller (terminal cover removed)

Power connection terminal block:

L

1x phase conductor (mains input)

R1, R2 2x output (TRIAC, for pumps or valves)

X

not used

L

const.

2x phase conductor (outputs, permanent voltage)

N

4x neutral conductor (common neutral conductors for mains power

input and outputs)

Note

Outputs R1 and R2 are protected by an electronic fuse.

Protective conductor terminal block:

PE

4x protective earth (common protective earth for power connection

terminal block)

Signals terminal block:

1 – 4 4x sensor input (Pt1000 temperature sensor)

5

1x sensor input (Pt1000 temperature sensor or pulse water meter input)

R

S

1x signal output (potential-free relay contact for safety extra-low voltage)

0–10 R1

0–10 R2

2x control output (for 0–10 V-controlled high-efficiency pumps)

7x mass connection (common mass for sensor inputs and control outputs)

Pin strip, for internal use only.

Cable openings on the rear side of the casing

Upper strain relief clamps (2 identical plastic links, each with 2 strain relief clamps,

supplied in the scope of delivery)

Lower strain relief clamps

Cable openings at the bottom of the casing

Page 9

9

742.114 | 14.50

EN

4.3.2 Preparing the cable openings

The cables can be fed through openings in the rear wall of the casing or at the bottom

of the casing. The openings are pre-punched and must be prepared as required before

installation.

Prepare the cable openings in the rear wall of the casing as follows:

1. Break out the cable openings (Fig. 3) using a suitable tool.

2. Deburr the edges.

Prepare the cable openings at the bottom of the casing as follows:

1. Cut the required cable openings (Fig. 3) at the left and right using a suitable knife

and break them out.

2. Deburr the edges.

4.3.3 Connecting the cables

√ All cables are voltage-free.

√ The cable openings have been prepared.

X Observe the following points when connecting the cables:

• Connect the cable conductors to the correct terminals as described in Section

4.4, p. 10.

• Mains input and outputs: First connect PE, then N and L.

• Strain relief:

– First clamp the lower strain relief clamps and then the upper strain relief clamps.

– When using the upper strain relief clamps, use the plastic links as described

below.

– If the opening in the strain relief clamp is too large, e.g. in the case of thin ca-

bles, turn over the strain relief clamping bar (with the bend facing down).

– Only use the strain relief clamps for cables entering the bottom of the casing.

Use external strain relief clamps when feeding cables through the rear of the

casing.

4.3.4 Inserting / Removing plastic links

Insert the plastic links as follows:

1. Insert the right plastic link with the latching protrusion first (Fig. 4).

2. Press the other side of the plastic link down , until the spring clamp latches into

place.

3. Insert the left plastic link the other way around (latching protrusion to the left,

spring clamp to the right).

Fig. 4: Inserting the right plastic link

Remove the plastic links as follows:

1. Insert a flat-blade screwdriver under the right plastic link between the casing and

the spring clamp , (Fig. 5).

Page 10

10

742.114 | 14.50

EN

2. Carefully push the flat-blade screwdriver to the left . Lever the spring clamp to

the right until the plastic link is free.

3. Pull out the plastic link upwards by hand .

4. Remove the left plastic link accordingly.

Fig. 5: Removing the right plastic link

4.4 Terminal pin assignments

For each solar energy system that can be selected at the controller, the external components (pumps, valves, temperature sensors) must be connected to particular terminals.

The following table provides information on

• the graphic and number of the solar energy system on the controller display (the

graphic is only intended to provide an overview and is not a technical drawing) and

• the terminal pin assignments of the connected components.

Display Legend Terminal layout

No system

Note

No system is used when only the functions are used. When No

system is selected, then all inputs and outputs are freely available

for use by the functions. More information on this is provided in

Section 10, p. 28.

1 storage tank, 1 collector array

T1

T2

R1

T1: collector array sensor

T2: lower storage tank sensor

R1: solar circuit pump

1,

2,

R1, N, PE (0–10 R1,

1)

)

Page 11

11

742.114 | 14.50

EN

Display Legend Terminal layout

1 storage tank with heating return increase, 1 collector array

R1

R2

T1

T2

T3

T4

T1: collector array sensor

T2: lower storage tank sensor

T3: upper storage tank sensor

T4: heating return increase sensor

R1: solar circuit pump

R2: heating return switching valve

3)

1,

2,

3,

4,

R1, N, PE (0–10 R1,

1)

)

R2, N, PE

1 storage tank with external heat exchanger, 1 collector array

R2 R1

T1

T2

T3

T1: collector array sensor

T2: lower storage tank sensor

T3: external heat exchanger sensor

R1: storage tank loading circuit pump

R2: solar circuit pump

1,

2,

3,

R1, N, PE (0–10 R1,

1)

)

R2, N, PE (0–10 R2,

2)

)

1 storage tank with zone loading, 1 collector array

R1

R2

T1

T2

T3

T1: collector array sensor

T2: lower storage tank sensor

T3: upper storage tank sensor

R1: solar circuit pump

R2: zone loading switching valve

4)

1,

2,

3,

R1, N, PE (0–10 R1,

1)

)

R2, N, PE

1 storage tank, 2 collector arrays

R1

R2

T1

T3

T2

T1: collector array 1 sensor

T2: collector array 2 sensor

T3: lower storage tank sensor

R1: solar circuit pump, collector array 1

R2: solar circuit pump, collector array 2

1,

2,

3,

R1, N, PE (0–10 R1,

1)

)

R2, N, PE (0–10 R2,

2)

)

2 storage tanks, 1 collector array (pump-controlled)

T1

T2

T3

R1

R2

T1: collector array sensor

T2: lower storage tank 1 sensor

T3: lower storage tank 2 sensor

R1: solar circuit pump, storage tank 1

R2: solar circuit pump, storage tank 2

1,

2,

3,

R1, N, PE (0–10 R1,

1)

)

R2, N, PE (0–10 R2,

2)

)

2 storage tanks, 1 collector array (pump-/valve-controlled)

T1

T2

T3

R1

R2

T1: collector array sensor

T2: lower storage tank 1 sensor

T3: lower storage tank 2 sensor

R1: solar circuit pump

R2: storage tank switching valve

5)

1,

2,

3,

R1, N, PE (0–10 R1,

1)

)

R2, N, PE

Page 12

12

742.114 | 14.50

EN

Display Legend Terminal layout

1 swimming pool, 1 collector array

R2

T1

T2

T1: collector array sensor

T2: swimming pool sensor

R2: solar circuit pump

1,

2,

R2, N, PE (0–10 R2,

2)

)

1 swimming pool with external heat exchanger, 1 collector array

R1

R2

T1

T2

T3

T1: collector array sensor

T2: swimming pool sensor

T3: external heat exchanger sensor

R1: solar circuit pump

R2: swimming pool loading circuit

pump

1,

2,

3,

R1, N, PE (0–10 R1,

1)

)

R2, N, PE (0–10 R2,

2)

)

1 storage tank, 1 swimming pool, 1 collector array (pump-controlled)

T1

T2

T3

R1

R2

T1: collector array sensor

T2: lower storage tank sensor

T3: swimming pool sensor

R1: storage tank solar circuit pump

R2: swimming pool solar circuit pump

1,

2,

3,

R1, N, PE (0–10 R1,

1)

)

R2, N, PE (0–10 R2,

2)

)

1 storage tank, 1 swimming pool, 1 collector array (pump-/valve-controlled)

R1

R2

T1

T2

T3

T1: collector array sensor

T2: lower storage tank sensor

T3: swimming pool sensor

R1: solar circuit pump

R2: storage tank switching valve

6)

1,

2,

3,

R1, N, PE (0–10 R1,

1)

)

R2, N, PE

Tab. 1: Terminal pin assignments

1)

Terminal pin assignments for 0–10 V-controlled high-efficiency pumps: The power supply must

be connected to output R1 (N, PE); the control cable for the pump electronics must be connected to 0–10 R1 and

2)

Terminal pin assignments for 0–10 V-controlled high-efficiency pumps: The power supply must

be connected to output R2 (N, PE); the control cable for the pump electronics must be connected to 0–10 R2 and .

3)

Installation regulation: When no power is supplied to the switching valve, then no flow occurs

through the storage tank.

4)

Installation regulation: When no power is supplied to the switching valve, then the lower part

of the storage tank (T2) is loaded.

5)

Installation regulation: When no power is supplied to the switching valve, then the first priority

storage tank (T2) is loaded.

6)

Installation regulation: When no power is supplied to the switching valve, then the storage

tank (T2) is loaded.

Page 13

13

742.114 | 14.50

EN

5 Commissioning the device for the first time

Danger

Risk of death by electrocution! Be sure to perform all the measures listed in Section 4

before starting the first commissioning.

Notes

• After commissioning the controller for the first time, it is configured in such a man-

ner that it can be used in most applications without changes.

• After completing the first commissioning, later recommissioning is not necessary.

• The following steps must also be performed after the device has been reset to the

factory defaults.

Overview

Operation mode Off is

switched on.

ESC /

OK

SET

Time

System

Pump R1 (R2)

Type / minimum speed

Functions

ESC /

ESC /

ESC /

The first time the controller is switched on, the following

main settings are made blockwise via a guided configuration process (Fig. left):

• Time

• System (hydraulic variant)

• Type (Standard/high-efficiency pump) and minimum

speed of the connected pumps (not System 0.1)

• Functions

Values can be subsequently changed during the guided

configuration process. The following applies:

• /ESC/ blockwise navigation forwards and back

(Fig. left: = forwards; ESC/ = back).

• Navigation (with /ESC/) is always possible after

completing a block.

• Subsequent modification of a block is started with

SET.

Commission the controller for the first time as follows:

Setting the time

1. Apply power to the controller.

– The time 12:00 is displayed.

– 12 flashes (Fig. left)

– The backlighting is red.

2. Press to set the hours.

3. Press SET. The minutes flash.

4. Press to set the minutes.

5. Press SET. The time is displayed.

Page 14

14

742.114 | 14.50

EN

Selecting a system

6. Press . System 1.1 is displayed, 1.1 flashes

(Fig. left).

7. Press to select another system.

8. Press SET.

If System 0.1 was selected in step 7, proceed with

step 20.

Setting pump 1 (output R1)

9. Press . AC and (pump 1) flash (example in fig.

left).

10.

Notice

Standard pump: Select AC!

High-efficiency pump: Select HE!

Press to select the type for pump 1.

11. Press SET.

12.

Notice

When selecting HE (high-efficiency pump) pay attention to the pump characteristics.

Only if HE was selected in step 10:

Press to set the characteristic of the high-efficiency pump; see Tab. 2 and Fig. 6, p. 16.

13. Press SET.

– If bA or bb was selected in step 12 then SC is

displayed; off, and (pump 1) flash (example in Fig. left; SC = Speed Control).

– If C was selected in step 12, proceed with

step 18 (for 2 pumps) or step 20 (for 1 pump).

14. If required, press to switch on the speed control (on flashes).

15. Press SET.

If off was selected in step 14, proceed with step 18

(for 2 pumps) or step 20 (for 1 pump).

16. min, Value %,

and (pump 1) flash.

Press to set the minimum speed of pump 1

in %.

17. Press SET.

Page 15

15

742.114 | 14.50

EN

Set pump 2 (output R2; only if a system with 2 pumps was selected in step 7; otherwise

continue with step 20)

18. Press . AC and (pump 2) flash (example in fig.

left).

19. Perform steps 10 to 17 accordingly for pump 2.

20. Press . F: is displayed.

Set the functions (necessary for System 0.1, or as required for other systems; The functions can also be set at a later date.)

21. Press SET to set the functions. F:01 (function num-

ber) flashes (example in Fig. left).

or

Press to skip the setting of the functions; Ok

flashes. Continue with step 30.

22. Press to select a different function. (Function

description in Section 10.3)

23. Press SET. oFF is displayed.

24. Press SET. oFF flashes.

25. Press . on flashes.

26. Press SET. The function is activated.

27. Set the characteristics (see Section 10.1).

28. Press ESC.

29. Press . Ok flashes.

Finishing initial commissioning

30. Press SET to finish initial commissioning. The

controller switches to the operating mode Off

(Example in Fig. left).

or

Press /ESC to display the previous settings and

correct them if necessary.

Set the operating mode (off, manual, automatic)

31. Remove the front panel (Fig. left and Section 4.1.1).

Page 16

16

742.114 | 14.50

EN

32.

Notice

Danger of pump damage if run dry. Only switch the

system to manual or automatic mode when the

system is filled.

Press and hold the mode button (arrow

in Fig. left) for 2 seconds to change the operating

mode; more information on this is provided in Section 8.

33. Mount the front panel. The controller is now ready

for operation.

Characteristics of high-efficiency pumps

Display Pump type Characteristic curve

bA

High-efficiency pump with a 0–10 V

profile for a rising characteristic curve

(Fig. 6)

0 V: Pump off

10 V: Max. pump speed

bb

High-efficiency pump with a 0–10 V

profile for a falling characteristic curve

(Fig. 6)

0 V: Max. pump speed

10 V: Pump off

C

Pressure regulated high-efficiency pump –

(no control cable, switching on/off

via the supply voltage)

Tab. 2: Characteristics of high-efficiency pumps

U/V

RPM

U/V

RPM

Fig. 6: Characteristics of high-efficiency pumps with 0–10 V profiles for a rising characteristic curve

(bA, left) and a falling characteristic curve (bb, right)

Page 17

17

742.114 | 14.50

EN

6 Structure

6.1 Casing

11

13

2

16

15

14

ESC

SET

No. Element

See

Section

Mode button (under

front panel)

7.1

8

Operating buttons , SET,

ESC,

7.1

Display 6.2

Front panel 4.1

Terminal cover 4.3.1

1)

Terminal cover fastening

screw

–

1)

Section 4.3.1 describes the terminals under the

terminal cover.

Fig. 7: Front view of the controller

6.2 Display

6.2.1 Overview

B

l

g

p

Fig. 8: Overview of the display areas (all elements visible)

System graphics

Settings menu

Pictograms for functions

Operational and setting values

The display areas are described below.

Page 18

18

742.114 | 14.50

EN

6.2.2 System graphics symbols

The following tables describe the symbols used in the system graphics ( in Fig. 8).

General

Symbol Description Symbol Description

Pipework Pump, switched on

Collector (array) Pump, switched off

Maximum collector temperature reached

3-way valve with flow direction

Storage tank Domestic water outlet

Swimming pool Cooler for active cooling

External heat exchanger Back-up heating

Temperature sensor Solid fuel boiler

Sufficient solar irradiation

available for loading

Drainback

Symbols Description

1

2

3

4

5

Drainback tank

Booster pump

Symbol Short startup for drainage assistance

Symbol Draining

Symbol Filling

+ Symbol Stabilising

6.2.3 Settings menu

The settings menu ( in Fig. 8) contains the following entries:

Time System

Functions Parameter

Priority Reset to factory defaults

Page 19

19

742.114 | 14.50

EN

6.2.4 Pictograms for functions

The following table describes the pictograms used for functions ( in Fig. 8).

Symbol Description Symbol Description

Manual operation Holiday – recooling

2)

Pump is speed controlled

1)

Alarm output

1)

Interval

2)

Stagnation reduction

2)

Freeze recirculation

2)

1)

Symbol is visible while the function/parameter is being edited in the settings menu.

2)

Symbol flashes: The function is activated and is actively intervening in the control process.

Symbol does not flash: The function is activated and is not actively intervening in the control

process or the function is currently being edited in the setting menu.

6.2.5 Operational and setting values

The display of the operational and setting values ( in Fig. 8) consists of the following

elements:

B

l

g

p

1

2

3

5

6

4

Symbol for time control of functions. This symbol is displayed when:

• a time restriction / control has been set,

• the status of time restriction/control is displayed,

• the time restriction blocks a temperature control (symbol flashes).

Number of the time window that is currently being set/displayed or within which

the current time lies.

The time control of a function consists of 1 to 3 configurable time windows. Example:

Time window 1: 06:00 – 08:00

Time window 2: 11:00 – 12:30

Time window 3: 17:00 – 19:00

Additional information:

on, off: switching state/condition on, off

max, min: maximum value, minimum value

Σ: summed operational value since first commissioning, cannot be reset

Δ: summed operational value since last reset to 0

Symbol is displayed when a temperature sensor is selected when setting a function.

Display of:

• Measurements

• Settings

• Error codes

• Additional information, e.g. software version

Physical unit of the value displayed in : °F, F, psi, gal/min, MBtu, MBtu/h, MMBtu,

%, tn sh CO2

Note

The physical units are only displayed as appropriate.

Page 20

20

742.114 | 14.50

EN

7 Operation

This section contains general information on operating the controller.

7.1 Operating buttons

The device is operated using the , , SET, ESC and buttons as follows:

• Scrolls up through the menu/initial commissioning

• Increases the setting value by 1 step

• Scrolls down through the menu/initial commissioning

• Decreases the setting value by 1 step

SET

• Selects a setting to be changed (setting value flashes)

• Confirms a setting value or jumps one level down in the menu

structure

• Calls up the settings menu (not in manual mode)

ESC

• Discards an entered setting

• Jumps up by one operating level

• Scrolls up through the initial commissioning

Sets the operating mode

Note

We recommend that you write down all settings that you have changed, e.g. in Section 18, p. 55.

7.2 Display when operating

• A flashing component in the system graphic means: the displayed operational or

setting value applies to the flashing component.

Exception: always flashes in manual mode.

• A flashing symbol is indicated in the figures by

.

• Displays that are automatically alternately displayed are shown overlapping in the

figures. Example: Figure in Section 8.2.

8 Modes of operation

8.1 Changing the mode of operation

Notice

Danger of pump damage if run dry. Only switch the system to manual or automatic

mode when the system is filled.

1. Remove the front panel.

2. Press the button for 2 seconds to change the mode of operation.

3. Repeat step 2 if necessary.

4. Mount the front panel.

Off

Manual operation

Automatic

T

2 s 2 s 2 s

Page 21

21

742.114 | 14.50

EN

8.2 "Off" mode

Functionality

• All outputs are switched off (outputs/control outputs without power, relays open).

• OFF and the software version are displayed alternately.

See example in Fig. below: software version St 1.3.

• Backlighting is red.

• Settings menu can be called up.

• The Off mode is preset when the device is delivered.

Operation

X Press and hold the SET button for 2 seconds to call up the settings menu ( ).

8.3 “Manual” mode

Functionality

• Backlighting is red, spanner symbol flashes.

• The controller outputs (pumps, valves) can be manually switched. Possible switching

states:

0: off

1: on

A: automatic operation as per the settings in the settings menu

• Current temperatures and operating hours can be displayed (status display).

• When changing to manual mode all outputs are switched to A; R1 is displayed.

Exception: initial commissioning (all outputs at 0).

• Typical application: functional test (maintenance), fault-finding.

Operation

You switch the outputs on and off as follows:

1. If necessary, press to select a different output.

2. Press SET. The switching state flashes.

3. Press to change the switching state.

4. Press SET to adopt the change.

See

in the following Figure (system 1.1 and output R1 are shown as an example).

You display the current temperatures and operating hours as follows:

1. Press ESC. The temperature/operating hours are displayed and the associated component flashes ( , display is not illustrated).

2. Press to select a different component.

3. Press SET to leave the temperature/operating hours display.

Page 22

22

742.114 | 14.50

EN

SET

SET

SET

SET

SET

ESC

33

2

8.4 "Automatic" mode

Functionality

Automatic is the normal mode of operation and the system is automatically controlled.

The following actions are possible:

• Display status (status display): display the status of external components (temperatures, switching states, run times).

• Display stored min./max. values (temperature sensors) or sum/difference values (operating hours1) of the pumps and valves.

Summed values (symbol ∑): operating hours since initial commissioning. Summed

values cannot be reset.

Difference values (symbol Δ): operating hours since the last reset to 0.

• Reset the stored min./max./difference values.

• Call up the settings menu.

1)

Summed switch-on times of the outputs

Page 23

23

742.114 | 14.50

EN

Operation

√ The controller shows the status display.

You can display the status of external components as follows:

X Press to display the status of other components ( , shown using system 1.1 as

an example).

You can display and reset the stored min./max./difference values as follows:

1. Press as required, in order to display other components (

, component

flashes).

2. Press SET. The min./max./difference values are displayed alternately

.

3. If desired, press and hold the SET button for 2 seconds to reset the currently (!)

displayed value .

4. Press ESC. The status display is shown.

5. Repeat steps 1 to 4 if necessary.

You access the settings menu as follows:

X Press and hold SET for 2 seconds . The settings menu appears.

SET

SET

7

2 s

SET

SET

7

2 s

SET

SET

7

2 s

SET

6

2 s

SET

6

2 s

SET

6

2 s

4

5

9 Settings menu

9.1 Overview

The following graphic provides an overview of the structure of the settings menu.

Page 24

24

742.114 | 14.50

EN

SET SET

SET for 5 seconds

Control of return increase – P22

Loading strategy storage tank 1 – P16

Loading strategy storage tank 2 – P17

Pump characteristic and speed control R1 – P18

Pump characteristic and speed control R2 – P19

Control of storage tank loading valve – P20

Control of zone loading valve – P21

Maximum temperature storage tank 1 – P01

Parameters

1)

Factory settingPriority

Storage tank 1 before

storage tank 2

Maximum temperature storage tank 2 – P02

Storage tank 2 before

storage tank 1

Only storage tank 1

Only storage tank 2

Reset to factory

settings

Switch-off temperature difference solar circuit 2

– P07

Switch-on temperature difference external

heat exchanger – P08

Switch-off temperature difference external

heat exchanger – P09

Maximum temperature loading circuit – P14

Maximum collector temperature – P10

Minimum collector temperature – P11

Switch-on temperature difference

heating return increase – P12

Switch-off temperature difference

heating return increase – P13

Maximum temperature swimming pool – P03

Switch-on temperature difference solar circuit 1

– P04

Switch-off temperature difference solar circuit 1

– P05

Switch-on temperature difference solar circuit 2

– P06

1)

Only specific functions and parameters may be

called up depending on the selected system.

Minimum temperature loading circuit – P15

SET SET SET

Time System

Circulation – F02

Functions

1)

Drainback – F01 No system – 0.1

Quick charge – F05

Heat quantity – F06

Set time

1 storage tank with external heat exchanger,

1 collector array – 1.3

1 storage tank with zone loading,

1 collector array – 1.4

1 storage tank,

2 collector arrays – 1.5

Back-up heating – F03

Solid fuel boiler – F04

2 storage tanks,

1 collector array (pump/valve-controlled) – 2.2

1 swimming pool,

1 collector array – 3.1

1 storage tank,

1 collector array – 1.1

1 storage tank with heating return increase,

1 collector array – 1.2

2 storage tanks,

1 collector array (pump-controlled) – 2.1

Thermostat – F07

Differential thermostat – F08

Interval – F09

Stagnation reduction – F10

Holiday – recooling – F11

1 swimming pool with external heat exchanger,

1 collector array – 3.2

1 storage tank, 1 swimming pool,

1 collector array (pump-controlled) – 4.1

1 storage tank, 1 swimming pool,

1 collector array (pump/valve-controlled) – 4.2

Active cooling – F12

Freeze recirculation – F13

Upper storage tank display – F14

Alarm output – F15

Page 25

25

742.114 | 14.50

EN

SET SET

SET for 5 seconds

Control of return increase – P22

Loading strategy storage tank 1 – P16

Loading strategy storage tank 2 – P17

Pump characteristic and speed control R1 – P18

Pump characteristic and speed control R2 – P19

Control of storage tank loading valve – P20

Control of zone loading valve – P21

Maximum temperature storage tank 1 – P01

Parameters

1)

Factory settingPriority

Storage tank 1 before

storage tank 2

Maximum temperature storage tank 2 – P02

Storage tank 2 before

storage tank 1

Only storage tank 1

Only storage tank 2

Reset to factory

settings

Switch-off temperature difference solar circuit 2

– P07

Switch-on temperature difference external

heat exchanger – P08

Switch-off temperature difference external

heat exchanger – P09

Maximum temperature loading circuit – P14

Maximum collector temperature – P10

Minimum collector temperature – P11

Switch-on temperature difference

heating return increase – P12

Switch-off temperature difference

heating return increase – P13

Maximum temperature swimming pool – P03

Switch-on temperature difference solar circuit 1

– P04

Switch-off temperature difference solar circuit 1

– P05

Switch-on temperature difference solar circuit 2

– P06

1)

Only specific functions and parameters may be

called up depending on the selected system.

Minimum temperature loading circuit – P15

Page 26

26

742.114 | 14.50

EN

9.2 Calling up the settings menu and selecting a menu entry

√ Automatic or Off mode is selected.

1. Press and hold SET for two seconds. The settings menu is displayed, menu entry

flashes.

2. Press to select a different menu entry.

3. Change the settings as described in the following sections.

9.3 Setting the time

Note

The time must be once more set to the correct values if power is removed for a longer

period of time. After this, the same operating mode is displayed as was active previous

to the removal of power.

√ flashes.

1. Press SET. The hours display flashes.

2. Press to change the hour.

3. Press SET. The minutes flash.

4. Press to change the minute.

5. Press SET. The change is adopted.

9.4 Setting the system

Note

A system overview is provided in Section 4.4, p. 10.

√

S

yst

flashes.

1. Press SET. The number of the current system flashes.

2. Press to select another system.

3. Press SET. The change is adopted.

9.5 Setting the functions

√

F

unc

flashes.

X Continue as described in Section 10, p. 28.

9.6 Setting the parameters

Note

Details on the parameters are provided in Section 11, p. 45.

√

P

ara

flashes.

1. Press SET. P:01 (parameter number) flashes.

2. Press to display a different parameter.

3. Press SET. The value of the parameter is displayed, associated components flash in

the system graphics.

4. Press SET. The parameter value flashes.

5. Press to change the value.

6. Press SET to adopt the change.

7. Press ESC. The parameter number is displayed (flashing).

8. If necessary, repeat steps 2 – 7.

Page 27

27

742.114 | 14.50

EN

9.7 Setting the priority

Functionality

The priority determines the sequence in which the storage tanks are loaded (only for

systems with more than 1 storage tank). If the higher priority storage tank (first-priority

storage tank) cannot be loaded because the collector temperature is too low, then the

lower priority storage tank (second-priority storage tank) is loaded

1)

. The following

values can be selected:

-1-: only storage tank 1 is loaded.

-2-: only storage tank 2 is loaded.

1-2: storage tank 1 is the first-priority storage tank.

2-1: storage tank 2 is the first-priority storage tank.

1)

Every 30 minutes, the controller checks to see if the first-priority storage tank can be loaded.

Due to the warming of the collector array, this check can take several minutes. On the basis of

the heating process, the controller predicts whether it is possible to load the first-priority storage

tank in a foreseeable period of time.

Operation

√

P

rio

flashes.

1. Press SET. The current value flashes.

2. Press to change the priority. The system graphics change accordingly.

3. Press SET. The change is adopted.

9.8 Resetting to factory defaults

√ flashes; RESEt is displayed (RE and SEt alternately).

1. Press and hold SET for 5 seconds.

2. A progress display is shown for a few seconds. After this the reset is finished.

3. Continue as described in Section 5, p. 13.

Page 28

28

742.114 | 14.50

EN

10 Functions

10.1 Operation

Displaying the functions

The following information is visible when the functions are

displayed:

• Function number, e.g. F:02 (Fig. left)

• Switching state:

on: function is activated

off: function is deactivated (Fig. left)

Note

If neither on nor off are displayed, then the function cannot be

used. Possible causes:

• The set system does not allow the use of this function.

• All outputs are used.

You display the functions as follows:

√

F

unc

flashes.

1. Press SET. F:01 flashes.

2. Press to display the next function.

Activating the function

A function must be activated (activation = on; Fig. left) and all

the associated characteristics must be correctly set before it can

be used.

If a function is activated and then exited before the characteristics are set, then oFF flashes briefly. After this, the function

is displayed with a switching state of off (function is deactivated).

You activate a function as follows:

√ Function number flashes.

1. Press SET. The function is selected.

2. Press SET. oFF flashes.

3. Press . on flashes.

4. Press SET. The function is activated.

5. Set the characteristics as described below.

Page 29

29

742.114 | 14.50

EN

Setting the characteristics

The functions have different numbers of characteristics. The

characteristic values are always set via the same sequence of

operating steps.

You set the values of characteristics as follows:

√ The function has been activated as described previously.

1. Press to select a characteristic.

2. Press SET. The value of the characteristic and the associated

components in the system graphics flash.

3. Press to change the value.

4. Press SET to adopt the change.

5. Repeat steps 1 to 4 for the other characteristics.

6. Press ESC when all characteristics of the function have been

set. The function number flashes.

10.2 Characteristics

The main characteristics for the functions are described below. The figures show examples.

Output

When a function should control an output, instead of the factory setting R- (= no output; Fig. left), one of the outputs R1,

R2 or RS must be selected. Only free outputs are displayed for

selection.

Temperature control

When a function is to be temperature controlled, the temperature control must be switched on (tc = temperature control). In

the figure, the temperature control is switched off (off).

Input

When a function requires a temperature sensor, a sensor input

must be selected instead of the factory setting. The factory setting is " –" (no input; Fig. left).

All sensor inputs are displayed for selection. A single sensor

input can be simultaneously used by several functions.

Page 30

30

742.114 | 14.50

EN

Switch-on temperature difference

If a function contains a differential thermostat, then the switchon temperature difference can be set. The relevant sensor

symbols flash.

Switch-off temperature difference

If a function contains a differential thermostat, then the switchoff temperature difference can be set. The relevant sensor

symbols flash.

Switch-on temperature

If a function contains a thermostat, then the switch-on temperature can be set. The relevant sensor symbol flashes.

Switch-off temperature

If a function contains a thermostat, then the switch-off temperature can be set. The relevant sensor symbol flashes.

Time control

If a function is to be time controlled, then the time control must

be activated and the time windows must be set (cc = clock

control). In the Fig. at the left, the time control is switched off

(off).

Page 31

31

742.114 | 14.50

EN

Starting time of a time window

When setting the start time of a time window, the following is

displayed to the left of the start time (see Fig. left):

•

• Number of time window 1 ... 3, whose end time is to be set

(in this case: 1)

• on

End time of a time window

When setting the end time of a time window, the following is

displayed to the left of the end time (see Fig. left):

•

• Number of time window 1 ... 3, whose end time is to be set

(in this case: 1)

• off

Note

The start time always lies before the end time! When an attempt is made to set a start time that is later than the end time,

the end time is automatically adjusted.

10.3 Functional description

The tables in this section describe the function characteristics as follows:

• The rows contain the characteristics in the same sequence as they appear on the

display.

• The columns contain the following information, from left to right:

Column Description

Display Sample display when setting the characteristics.

Characteristic Designation of the characteristics and their interdependence.

Dependent characteristics can only be selected and set when

the higher level characteristic has the value on. This is shown as

follows:

• Higher-level characteristic: bold text

• Dependent characteristics: indented to the right below the

higher level characteristic

Example: In the table for the circulation function (p. 33), the

sensor input, switch-on temperature and switch-off temperature characteristics are only displayed when the temperature

control is set to on.

Min., max.,

factory default

setting

Lower (min.) and upper limit (max.) of a characteristic range

and the factory setting. When a value range only contains a few

values, then these are individually listed. Example: on, oFF.

Page 32

32

742.114 | 14.50

EN

10.3.1 Drainback

Notice

Danger of malfunction in drainback systems

• In drainback systems, the drainback function must be activated.

• In drainback systems with speed-controlled solar circuit pumps (sys-

tems 1.1 to 4.2), note the following:

– Activation of the drainback function switches off the speed

control of the solar circuit pump, but this can be subsequently

switched on again if desired (P:18/P:19 in Section 11).

– Adjust the minimum speed high enough so that the heat trans-

fer fluid is reliably pumped into the collector.

The following drainback function characteristics can be set:

Filling time: When switched on, the solar circuit pump runs for the

duration of the filling time in order to pump the heat transfer fluid into

the collector.

Stabilising time: After the filling time has expired, the solar circuit

pump continues to run for the duration of the stabilising time. The following applies:

• The solar circuit pump also continues to run for this time even when the

switch-off conditions are satisfied.

• When the speed control is activated and the solar irradiation is too

low (no sun symbol on the display) the pump runs at minimum

speed.

• After expiry of the stabilising time, the controller checks to see if the

solar irradiation is sufficient to continue loading the storage tanks.

Draining time: The solar circuit pump is switched off during the draining time. This allows the heat transfer fluid to flow back into the drainback tank and the solar circuit is automatically drained.

Short startup time: After the draining time has expired, the solar circuit

pump runs for the duration of the short startup time (a few seconds). In

most cases, this supports the draining process and sucks the remaining

heat transfer fluid out of the solar circuit.

Booster pump: The booster pump supports the solar circuit pump during the filling time and short startup time. The booster pump can only

be connected when a free output is available.

Notes

• The drainback function cannot be active simultaneously with the

following functions:

– Interval

– Reduction of stagnation phases

– Holiday – recooling

– Active cooling

– Freeze recirculation

• The drainback function can only be activated in systems with a

single solar circuit.

Page 33

33

742.114 | 14.50

EN

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Filling time 1 ... 10 minutes 3 minutes

Stabilising time 1 ... 15 minutes 2 minutes

Draining time: 1 ... 30 minutes 5 minutes

Short startup time 0 ... 60 seconds 0 seconds

Booster pump on, oFF

oFF

Output (booster pump) free output R1/R2/R

S

–

Pump type (R1, R2 only) AC, HE

1)

AC

Pump characteristic (HE only) bA, bb, C (see p. 16) –

1)

Notice

Standard pump: Set AC!

High-efficiency pump: Set HE!

External relay: Set AC pump type!

10.3.2 Circulation

Switches a circulation pump on and off on a temperature and/or time

controlled basis.

Temperature control: If the temperature in the circulation return falls

below the Ton value, then the circulation pump is switched on until the

T

off

temperature is reached.

Time control: The circulation pump is switched on when the current

time lies within one of 3 configurable time windows.

Temperature and time control: The circulation pump is switched on when

the switch-on conditions for the temperature and time control are satisfied.

Note

Install the circulation sensor at least 1.5 m (60 inch) away from the storage

tank to avoid false measurements due to heat conduction of the pipes.

Page 34

34

742.114 | 14.50

EN

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Output (circulation pump) free output R1/R2/R

S

–

Pump type (R1, R2 only) AC, HE

1)

AC

Pump characteristic (HE only) bA, bb, C (see p. 16) –

Temperature control on, oFF

oFF

Sensor input for circulation

return temperature sensor

1 ... 5 –

Switch-on temperature T

on

32 °F T

off

– 4 F 85 °F

Switch-off temperature T

off

Ton + 4 F 200 °F 95 °F

Time control on, off

off

Time window 1 start/end 0:00 23:59 6:00/8:00

Time window 2 start/end 0:00 23:59 12:00/13:30

Time window 3 start/end 0:00 23:59 18:00/20:00

1)

Notice

Standard pump: Set AC!

High-efficiency pump: Set HE!

External relay: Set AC pump type!

10.3.3 Back-up heating

Performs temperature-dependent switching of an output for heating a storage tank using an oil or gas burner. The function can be time restricted.

Temperature control: If the temperature in the storage tank falls below

the Ton value, then the external heating is switched on until the T

off

tem-

perature is reached.

Time restriction: The function is executed when the current time lies

within one of 3 configurable time windows.

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Output (external heating) free output R1/R2/R

S

–

Pump type (R1, R2 only) AC, HE

1)

AC

Pump characteristic (HE only) bA, bb, C (see p. 16) –

Sensor input for readiness part of

the storage tank

1 ... 5 –

Switch-on temperature T

on

32 °F T

off

– 4 F 130 °F

Switch-off temperature T

off

Ton + 4 F 200 °F 140 °F

Time restriction on, oFF

oFF

Time window 1 start/end

Time window 2 start/end

Time window 3 start/end

0:00

0:00

0:00

23:59

23:59

23:59

6:00/8:00

12:00/13:30

18:00/20:00

1)

Notice

Standard pump: Set AC!

High-efficiency pump: Set HE!

External consumer (e.g. 115 V relay): Set AC pump type.

Page 35

35

742.114 | 14.50

EN

10.3.4 Solid fuel boiler

Controls a pump in order to heat a storage tank using a solid fuel boiler.

The pump is switched on when all of the following conditions are satisfied at the same time:

• The temperature difference between the solid fuel boiler and the

storage tank exceeds T

diff on

.

• The solid fuel boiler temperature lies above the min. solid fuel boiler

temperature.

• The storage tank temperature lies below the max. storage tank

temperature.

The pump is switched off when one of the following conditions is satisfied:

• The temperature difference between the solid fuel boiler and the

storage tank drops below T

diff off

.

• The solid fuel boiler temperature drops below the min. solid fuel

boiler temperature.

• The storage tank temperature reaches the max. storage tank tem-

perature.

Speed control of the pump can be activated as required. The loading

strategy of the speed control system attempts to regulate the temperature of the solid fuel boiler to match the control target that has been set.

The control target should be at least 20 F above the minimum temperature of the solid fuel boiler.

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Output (pump) free output R1/R2/R

S

–

Pump type (R1, R2 only) AC, HE

1) 2)

AC

Pump characteristic (HE only) bA, bb, C (see p. 16) –

Speed control (R1, R2 only) on, oFF

2)

oFF

Minimum speed (AC only) 30% 100% 50%

Minimum speed (HE + bA only) 0% 100% 25%

Minimum speed (HE + bb only) 0% 100% 75%

Sensor input for storage tank

temperature

1 ... 5 –

Sensor input for solid fuel boiler

temperature

1 ... 5 –

Switch-on temperature difference

T

diff on

T

diff off

+ 4 F 40 F 12 F

Switch-off temperature difference

T

diff off

0 F T

diff on

– 4 F 6 F

Max. storage tank temperature 32 °F 300 °F 140 °F

Page 36

36

742.114 | 14.50

EN

Min. solid fuel boiler temperature 85 °F 200 °F 125 °F

Control target for solid fuel boiler

temperature (Speed control = on)

32 °F 200 °F 140 °F

1)

Notice

Standard pump: Set AC!

High-efficiency pump: Set HE!

2)

Notice

External consumer (e.g. 115 V relay): Set AC pump type and set the speed control to oFF!

10.3.5 Quick charge

Uses a higher loading temperature to load the upper region of the storage

tank more quickly in order to provide early prevention of back-up heating

by the conventional heating system. To do this, the loading strategy of the

first-priority storage tank is changed from differential loading to absolute

temperature loading as soon as the temperature in the upper tank region

drops below T

on

*)

. At the same time, an attempt is made to achieve a

higher temperature in the storage tank by using the speed control.

*)

To retain the proven quick charge functionality, when Ton is changed, the value

of T

off

is changed in parallel.

Note

To use the quick charge function, the speed control must be switched on;

more information on this is provided in Section 11, p. 45 (P18, P19).

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Sensor input for upper storage tank

temperature

1 ... 5 –

Switch-on temperature T

on

32 °F 185 °F 125 °F

Switch-off temperature T

off

Ton + 4 F Ton + 20 F 130 °F

Page 37

37

742.114 | 14.50

EN

10.3.6 Heat quantity

B

Calculates the acquired heat volume based on the following information:

• Supply temperature

• Return temperature

• Flow rate determined using the following methods:

– Calculated via pump speed

– Measured using a pulse water meter (terminal 5)

Notes

– Calculation based on the pump speed cannot be performed

when No system (system 0.1) has been selected.

– In drainback systems, the correct flow rate value can only be

read when the system is filled.

• Glycol proportion and accounting for the temperature dependent

thermophysical properties of the heat transfer fluid

Additional possibility: display of the amount of CO2 saved by using the

system. The amount of CO2 is calculated from the acquired heat volume.

To do this, the controller requires the conversion factor lbs

CO2

/kWh

therm

to be entered.

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Type of flow rate acquisition tyP 1, tyP 2

1)

–

l

g

Type 1: flow rate value at max.

speed F

max.

(pump 1).

When the Fig. at the left is displayed (value flashes), then enter

the value read from the flow rate

display.

F

min.

999.9

gal/min

0.0 gal/min

l

g

Type 1: flow rate value at min.

speed F

min.

(pump 1).

When the Fig. at the left is displayed (value flashes), then enter

the value read from the flow rate

display.

0.0 gal/min F

max.

0.0 gal/min

Type 1: flow rate value at max.

speed F

max.

(pump 2)

2)

F

min.

999.9

gal/min

0.0 gal/min

Type 1: flow rate value at min.

speed F

min.

(pump 2)

2)

0.0 gal/min F

max.

0.0 gal/min

l

g

Type 2: flow rate of the pulse

water meter in litres/pulse; see

the pulse water meter data

sheet.

1.0 gal...10.0 gal,

1 l, 10 l, 25 l

– gal

(no flow

rate value

selected)

Glycol proportion 0% 60% 40%

Supply sensor input (warm) 1 ... 5 –

Return sensor input (cold) 1 ... 5 –

Page 38

38

742.114 | 14.50

EN

CO2 display on, oFF

oFF

T

T

F

unc

SET

lbs

CO2

/kWh

therm

0.100 2.500 1.918

3)

1)

tyP 1: calculation of the flow rate from the pump speed. To do this, the displayed flow rate values are entered

at two measuring points (pump speed min. and max.).

tyP 2: determining the flow rate using a pulse water meter. The flow rate of the pulse water meter is entered in litres/pulse.

2)

Only for systems with 2 pumps. Enter the displayed flow rate values at F

max./Fmin.

in the same manner as with

type 1, pump 1.

3)

Source: Hawaiian Electric Co., Inc. HECO Residential Rebate Program, Solar water heating system information

sheet (2007): 1.918 Ibs

CO2

/kWh

therm

.

Page 39

39

742.114 | 14.50

EN

10.3.7 Thermostat

Switches an output on and off, depending on the temperature range

of any desired sensor. The function can be time restricted and is set for

heating or cooling as follows:

Heating: The Ton value is set lower than T

off

.

When the sensor temperature drops below Ton, the output is switched on

until the temperature exceeds T

off

.

Cooling: The Ton value is set higher than T

off

.

When the sensor temperature exceeds Ton, the output is switched on

until the temperature drops below T

off

.

Time restriction: The function is executed when the current time lies

within one of 3 configurable time windows.

Note

The Ton value can be set to the same value as T

off

. However, this setting

has no practical application.

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Output free output R1/R2/R

S

–

Pump type (R1, R2 only) AC, HE

1)

AC

Pump characteristic (HE only) bA, bb, C (see p. 16) –

Sensor input 1 5 –

Switch-on temperature T

on

32 °F 350 °F 70 °F

Switch-off temperature T

off

32 °F 350 °F 70 °F

Time restriction on, oFF

oFF

Time window 1 start/end

Time window 2 start/end

Time window 3 start/end

0:00

0:00

0:00

23:59

23:59

23:59

00:00/00:00

00:00/00:00

00:00/00:00

1)

Notice

Standard pump: Set AC!

High-efficiency pump: Set HE!

External consumer (e.g. 115 V relay): Set AC pump type!

10.3.8 Differential thermostat

Switches an output on and off as follows – time restricted and depending on the set temperature difference between 2 selectable sensors:

When the temperature difference exceeds T

diff on

, the output is switched

on until the temperature difference drops below T

diff off

. In addition to

this, the discharging of the heating source can be limited to a particular

temperature range (T

src min./Tsrc max.

) and the loading of the heating target

can be limited to a maximum value (T

sink max.

).

Time restriction: The function is executed when the current time lies

within one of 3 configurable time windows.

Speed control of the pump can be activated as required. The loading

strategy of the speed control system attempts to regulate the temperature

difference to match the switch-on temperature difference that has been set.

Page 40

40

742.114 | 14.50

EN

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Output free output R1/R2/R

S

–

Pump type (R1, R2 only) AC, HE

1) 2)

AC

Pump characteristic (HE only) bA, bb, C (see p. 16) –

Speed control (R1, R2 only) on, oFF

2)

oFF

Minimum speed (AC only) 30% 100% 50%

Minimum speed (HE + bA only) 0% 100% 25%

Minimum speed (HE + bb only) 0% 100% 75%

Heat source sensor input 1 ... 5 –

Heat sink sensor input 1 ... 5 –

Switch-on temperature difference

T

diff on

T

diff off

+ 4 F 160 F 12 F

Switch-off temperature difference

T

diff off

0 F T

diff on

– 4 F 6 F

Heat source max. temperature

T

src max.

T

src min.

+ 4 F 350 °F 212 °F

Heat source min. temperature

T

src min.

32 °F T

src max.

– 4 F 32 °F

Heat sink max. temperature T

sink max.

32 °F 200 °F 140 °F

Time restriction on, oFF

oFF

Time window 1 start/end

Time window 2 start/end

Time window 3 start/end

0:00

0:00

0:00

23:59

23:59

23:59

00:00/00:00

00:00/00:00

00:00/00:00

1)

Notice

Standard pump: Set AC!

High-efficiency pump: Set HE!

2)

Notice

External consumer (e.g. 115 V relay): Set AC pump type and set the speed control to oFF!

Page 41

41

742.114 | 14.50

EN

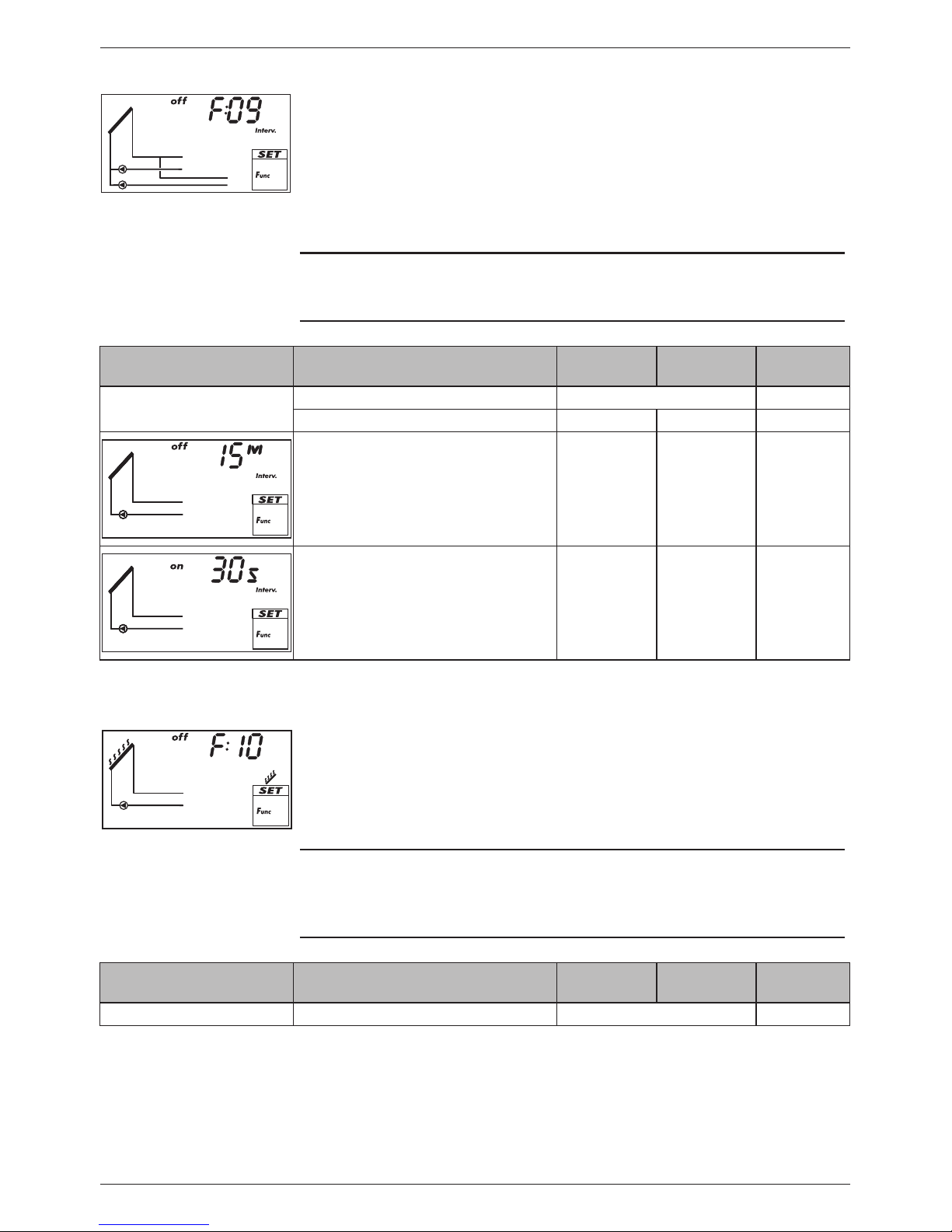

10.3.9 Interval

Periodically switches the solar circuit pump on and off in order to measure the actual collector temperature. The delay between 2 switch-on

operations and the switch-on duration can be set. Applications:

• Collector types where the mechanical construction prevents the

temperature from being measured at a suitable place

• Unsuitable position of the temperature sensor on the collector

The function can be time restricted to prevent unnecessary periodic

operation at night.

Note

This function cannot be active at the same time as the drainback function.

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Time window start/end 0:00 23:59 08:00/19:00

Wait time 1 min 999 min 15 min

Switch-on duration 3 s 999 s 5 s

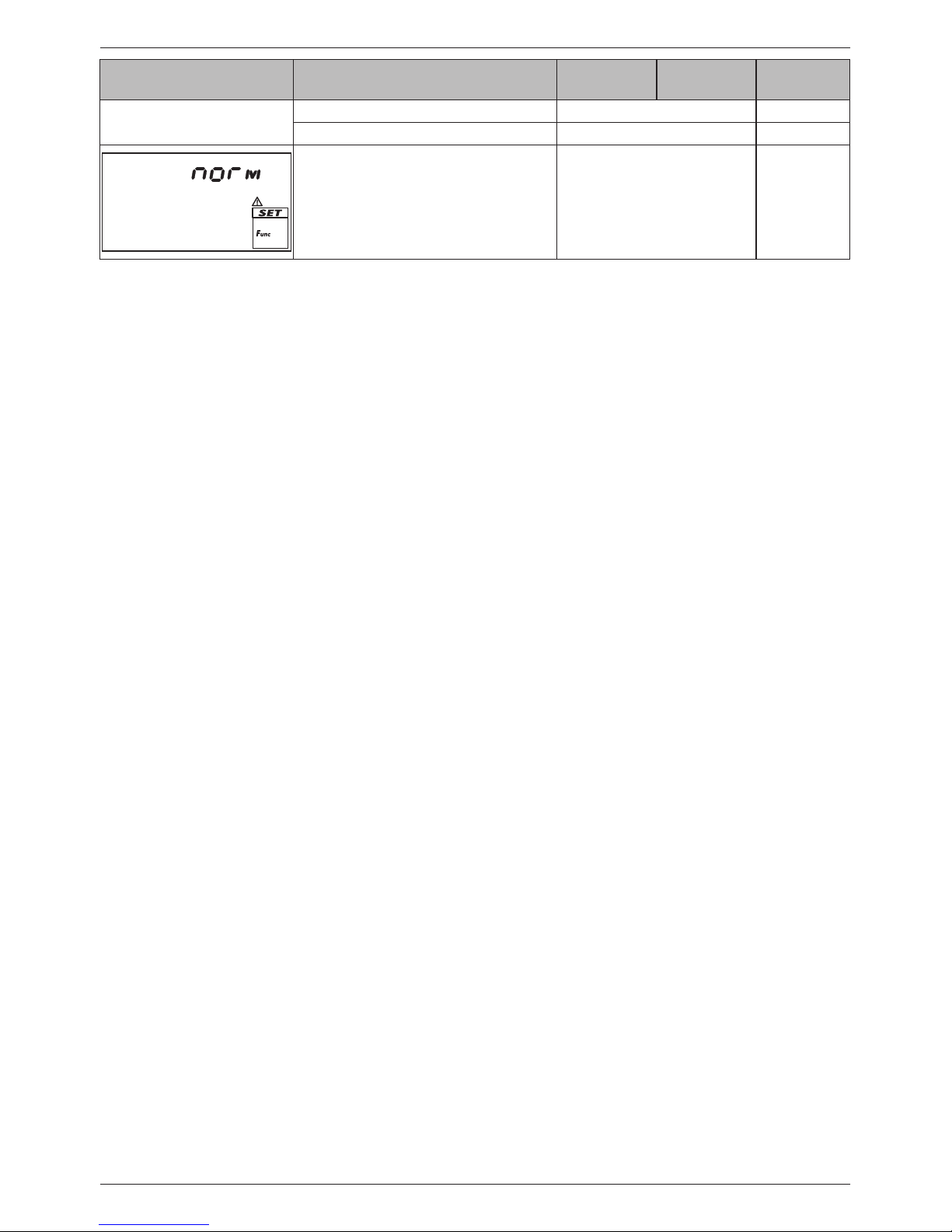

10.3.10 Reduction of stagnation phases

Delays the end of the storage tank's loading phase in order to reduce, or

even to avoid, the system standstill (stagnation) times at high temperatures. To do this, the pump is stopped repeatedly, and only briefly

switched on again at high collector temperatures. Since the efficiency

drops heavily at high collector temperatures, the loading takes longer

and possible stagnation occurs later.

Note

This function cannot be activated

• in systems with swimming pools,

• when the drainback function is activated.

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Page 42

42

742.114 | 14.50

EN

10.3.11 Holiday – recooling

Attempts to reduce, or even to avoid, the system standstill (stagnation)

times at high temperatures. To do this, at night the storage tank – or the

second-priority storage tank if 2 storage tanks are present – is charged

as far as possible to the set minimum temperature, if the storage tank

temperature during the day was 20 F below the set maximum temperature.

Stagnation occurs when not enough hot water is removed from the

system during an absence (holiday).

Notes

The following applies to this function:

• Only activate if you intend to be absent for an extended period.

• Deactivate this after returning from a holiday in order to avoid an

unnecessary waste of energy via the collector circuit.

• This function cannot be activated in systems with swimming pools.

• This function cannot be active at the same time as the drainback

function.

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Minimum storage tank temperature:

32 °F 200 °F 95 °F

10.3.12 Active cooling

Switches an additional cooler into the solar circuit when one of the following conditions is satisfied:

• The temperature of the storage tank – or of the second-priority

storage tank in the case of 2 storage tanks – lies 20 F below the set

maximum temperature.

• Holiday recooling is performed at night.

Application examples: areas with strong solar irradiation, avoidance of

stagnation.

Note

This function cannot be active at the same time as the drainback function.

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Output (switching-in of additional

cooler)

free output R1/R2/R

S

–

Page 43

43

742.114 | 14.50

EN

10.3.13 Freeze recirculation

Attempts to prevent freezing of the collectors by pumping heat from the

first-priority storage tank into the collectors:

• The collector temperature is below 40 °F: solar circuit pump is switched on.

• The collector temperature is above 45 °F: solar circuit pump is switched off.

The freeze recirculation function is only useful when the heat transfer

fluid contains insufficient or no anti-freeze. It is recommended to generally use heat transfer fluid with anti-freeze!

Notice

Despite the freeze recirculation function being activated, the solar energy system can freeze under the following conditions:

• The first-priority storage tank is unloaded and a back-up heating

system is not present.

• Heat transfer fluid contains insufficient or no anti-freeze.

• Power outage.

• Unsuitable position of the temperature sensor on the collector.

• Collector sensor or cable is broken or has a short circuit.

• The collectors are installed in a position exposed to the wind.

• Solar circuit pump is faulty.

Note

This function cannot be active at the same time as the drainback function.

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

10.3.14 Display storage tank top

Shows the temperature in the upper region of 1 or 2 storage tanks. For

this, an appropriate sensor must be connected to each tank. The measured temperatures are not used for control purposes.

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Storage tank 1 upper sensor input 1 ... 5 –

Storage tank 2 upper sensor input

1)

1 ... 5 –

1)

Only for systems with 2 storage tanks

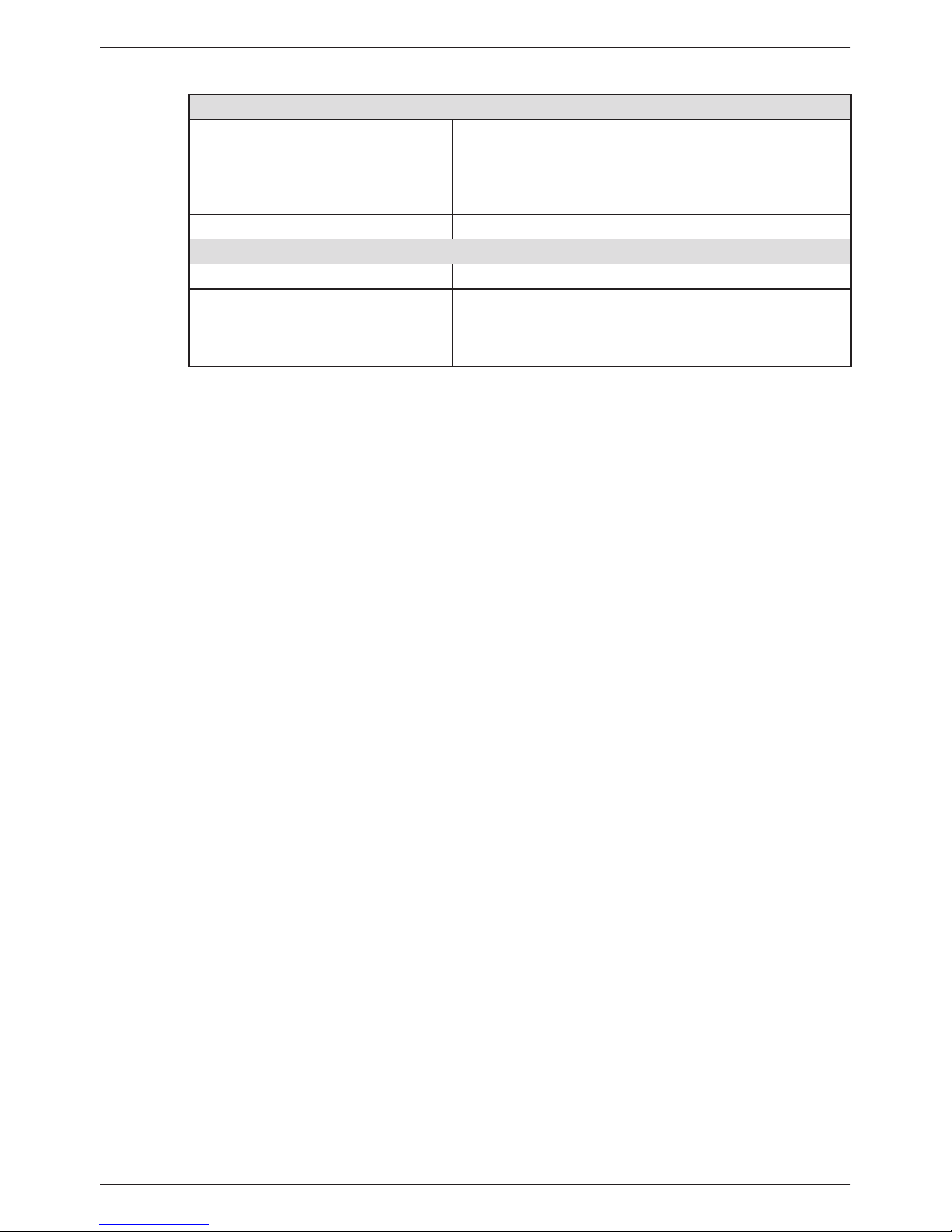

10.3.15 Alarm output

Activates the set output in the case of the following faults:

• Sensor fault due to short-circuit or interruption.

• Clock loses the current time due to an extended power outage.

• Volume flow fault: Er: 1

1)

.

• The electronic overload switch or fuse has triggered: Er: 3 ... Er: 6

1)

.

Page 44

44

742.114 | 14.50

EN

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Output free output R1/R2/Rs –

Control norm, InV

2)

norm

1)

More information is provided in Section 14.2, p. 50.

2)

norm = normal: contact closes when a fault occurs.

InV = inverted: contact opens when a fault occurs.

Page 45

45

742.114 | 14.50

EN

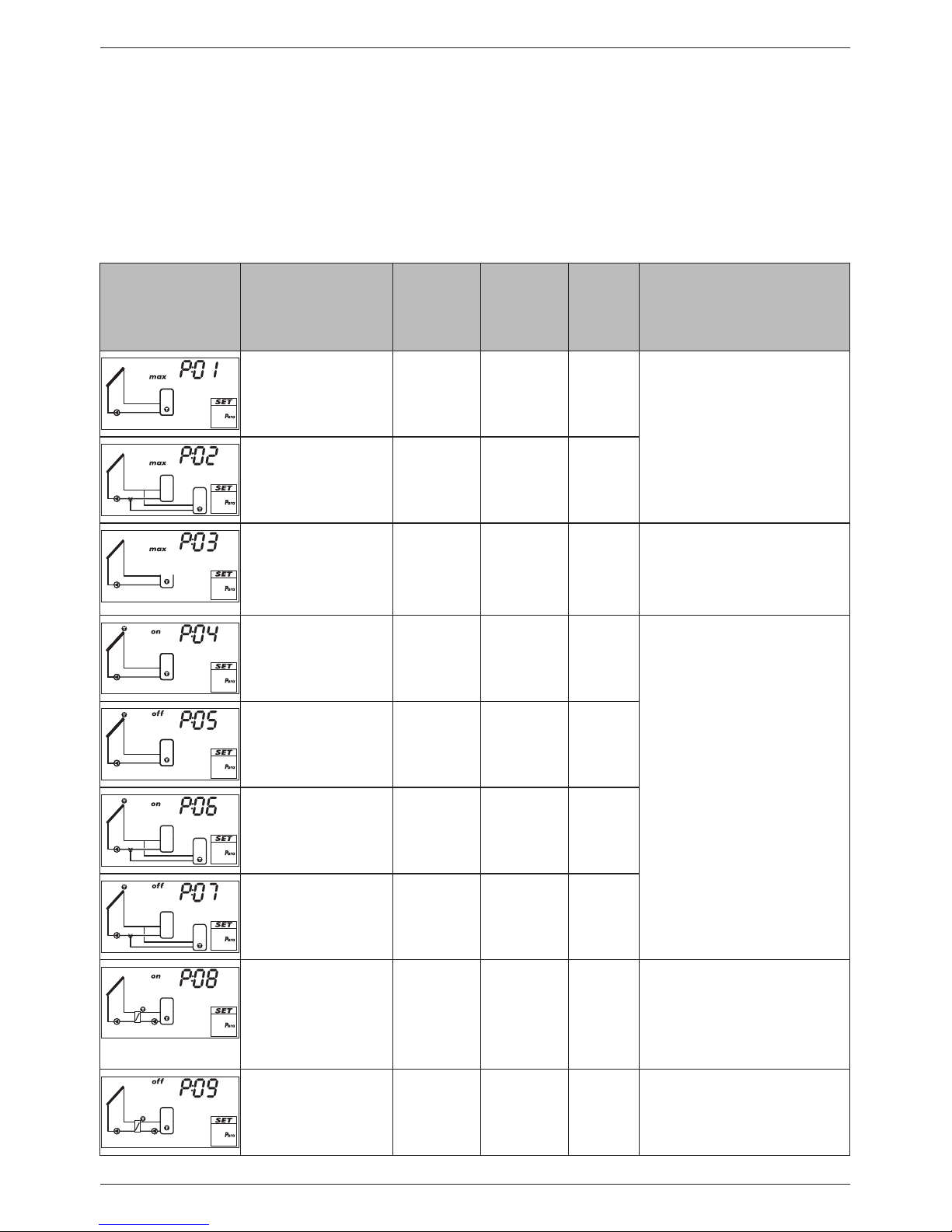

11 Parameters