Page 1

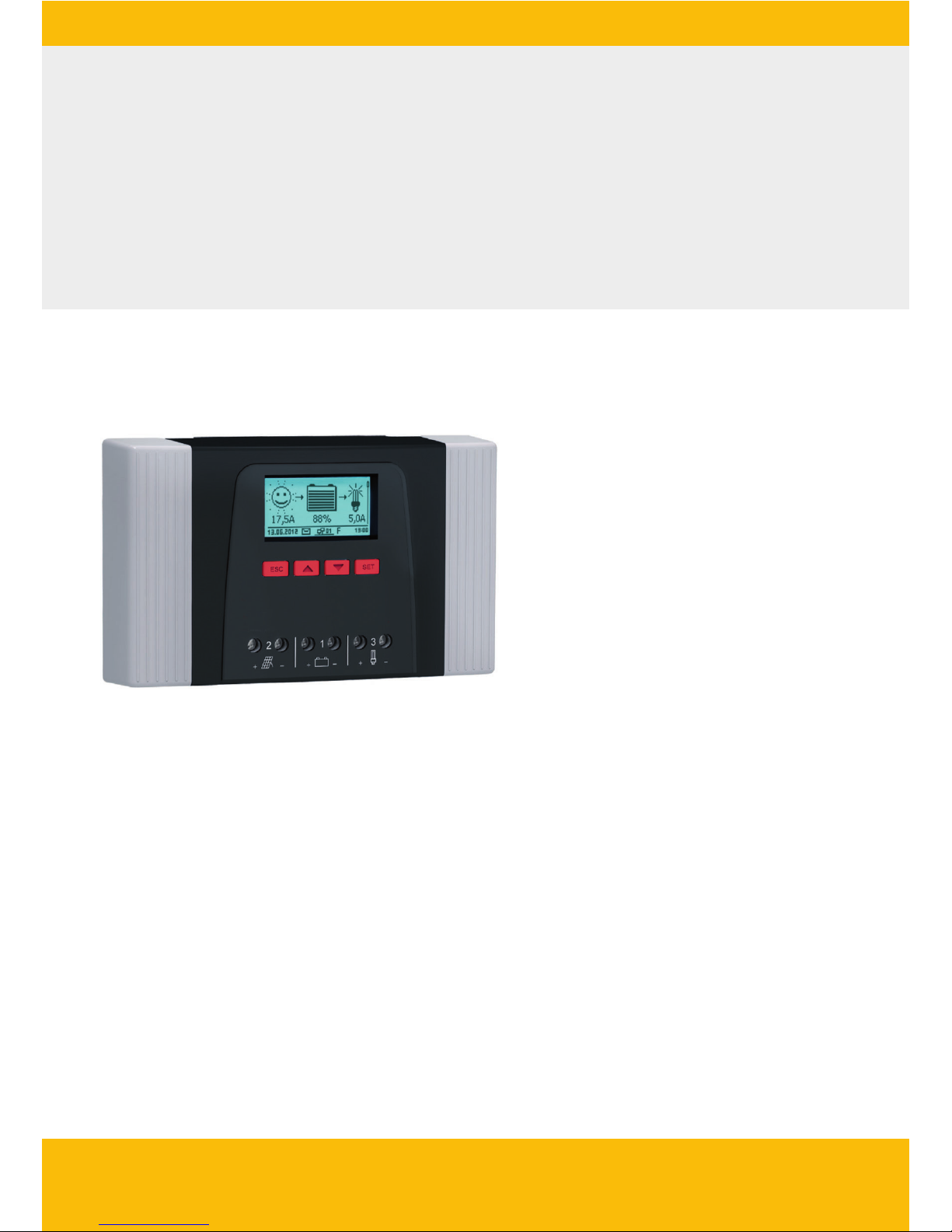

Solar Charge Controller

Adjustable, for hybrid and telecommunication systems

Tarom 4545 (12 V/24 V accumulator)

Tarom 4545-48 (12 V/24 V/48 V accumulator)

Installation and operating instructions

GB

Z03 | 17.05

Page 2

2

DE

1 General safety instructions ................................................................................................. 5

2 Identification ...................................................................................................................... 6

3 Scope of delivery ................................................................................................................ 7

4 Proper usage....................................................................................................................... 8

5 Markings ............................................................................................................................ 9

5.1 Symbols for warnings and notices ........................................................................... 9

5.2 Keywords ................................................................................................................. 9

6 Quick guide ...................................................................................................................... 10

7 Overview of the controller ................................................................................................ 11

8 Menu structure ................................................................................................................. 12

9 Installation ........................................................................................................................ 13

9.1 Safety instructions ................................................................................................. 14

9.2 Connections and operating buttons ...................................................................... 16

9.2.1 StecaLink slave connection ..................................................................... 16

9.2.2 StecaLink master connection .................................................................. 19

9.2.3 Slot for microSD card ( in Fig. 1) .......................................................... 20

9.2.4 Relay outputs AUX 1, AUX 2 (, in Fig. 1) ........................................... 20

9.2.5 Temperature sensor connection TEMP ( in Fig. 1) ................................. 21

9.2.6 Open UART interface, 3.3 V ( in Fig. 1) ................................................. 21

9.2.7 Function ground ( in Fig. 1) ................................................................ 22

9.2.8 Operating buttons .................................................................................. 23

9.3 Removing/installing the cover ................................................................................ 23

9.3.1 Removing the cover ................................................................................ 23

9.3.2 Installing the cover ................................................................................. 24

9.4 Installing the device ............................................................................................... 24

9.5 Establishing the electrical connections .................................................................. 25

9.5.1 Preparing the cables ............................................................................... 26

9.5.2 Connecting the battery ........................................................................... 26

9.5.3 Connecting the solar module .................................................................. 27

9.5.4 Connecting loads .................................................................................... 28

9.5.5 Connecting optional components ........................................................... 29

Table of contents

Page 3

3

DE

10 Performing initial commissioning ..................................................................................... 31

11 Dismounting the controller .............................................................................................. 34

12 System functions .............................................................................................................. 35

12.1 Protection functions .............................................................................................. 35

12.1.1 Controller overload ................................................................................. 35

12.1.2 Overheating of the controller ................................................................. 35

12.1.3 Deep discharging of the battery ............................................................. 35

12.2 Control mode ........................................................................................................ 36

12.3 Battery charging functions .................................................................................... 37

12.3.1 Float charging ......................................................................................... 37

12.3.2 Boost charging ....................................................................................... 37

12.3.3 Equalise charging ................................................................................... 38

12.4 Data logger ........................................................................................................... 38

13 Display (layout, function, operation) ................................................................................ 39

13.1 Overview (menu structure) .................................................................................... 39

13.2 Status display ........................................................................................................ 39

13.3 Display of special states ......................................................................................... 41

13.4 General operation .................................................................................................. 42

13.5 Advanced operation .............................................................................................. 42

14 Control functions .............................................................................................................. 44

14.1 Overview ............................................................................................................... 44

14.2 Operation .............................................................................................................. 45

14.3 Functionality .......................................................................................................... 47

14.3.1 Deep discharge protection ...................................................................... 48

14.3.2 Morning light function ........................................................................... 48

14.3.3 Evening light function ............................................................................ 49

14.3.4 Night light function ................................................................................ 49

14.3.5 Excess energy control ............................................................................. 50

14.3.6 Generator manager ................................................................................ 50

14.3.7 Alarm ...................................................................................................... 51

14.3.8 Timer 1 ... 4 ............................................................................................ 51

Page 4

4

DE

14.3.9 StecaLink bus .......................................................................................... 52

14.3.9.1 StecaLink slave address setting .............................................. 52

14.3.9.2 StecaLink master setting ........................................................ 53

14.3.9.3 Changing the slave settings .................................................. 54

14.3.10 SD card ................................................................................................... 56

15 Troubleshooting................................................................................................................ 58

15.1 Event messages ..................................................................................................... 58

15.2 Errors without event messages .............................................................................. 64

15.3 Self test ................................................................................................................. 65

16 Maintenance ..................................................................................................................... 66

16.1 Controller .............................................................................................................. 66

16.1.1 Removing dust ........................................................................................ 66

16.1.2 Removing heavy soiling .......................................................................... 66

16.1.3 Checking the charging functionality ....................................................... 67

16.1.4 System .................................................................................................... 67

17 Disposal ............................................................................................................................ 68

18 Technical data ................................................................................................................... 69

18.1 Controller .............................................................................................................. 69

18.2 Connection cables ................................................................................................. 71

18.3 Protocol of the open UART interface ..................................................................... 72

18.3.1 Settings .................................................................................................. 72

18.3.2 UART Data .............................................................................................. 73

18.4 Recording data on an SD card ............................................................................... 75

18.4.1 Master data file ...................................................................................... 76

18.4.2 TIMECHG data file ................................................................................... 77

18.4.3 PA HS400 data file .................................................................................. 78

19 Guarantee conditions ....................................................................................................... 79

19.1 Exclusion of liability ............................................................................................... 79

20 Contact ............................................................................................................................. 80

21 Notes ................................................................................................................................ 81

Page 5

5

DE

1 General safety instructions

Q This document is part of the product.

Q Only technical professionals may perform the work described in this manual.

Q Install and use the device only after reading and understanding this document.

Q Always perform the measures described in this document in the sequence specified.

Q Keep this document in a safe place for the entire service life of the device. Pass the document

on to subsequent owners and operators of the device.

Q Incorrect operation can reduce solar system yields or damage system components.

Q The device must not be connected to the DC cables if it has a damaged casing.

Q If one of the following components is damaged immediately take the device out of operation

and disconnect it from the battery and modules

– Device (not functioning, visible damage, smoke, penetration of liquid etc.),

– Connected cables,

– Solar module.

Do not switch the system on again before

– the device has been repaired by a dealer or the manufacturer,

– damaged cables or solar modules have been repaired by a technical specialist.

Q Battery acid splashes on skin or clothing should be immediately treated with soap suds and

rinsed with plenty of water. Immediately seek medical advice in the case of injuries.

Q If battery acid splashes into the eyes, immediately rinse with plenty of water and seek medical

advice.

Q Never cover the device.

Q Do not open the casing: Risk of death. Invalidation of the guarantee.

Q Factory labels and markings must never be altered, removed or rendered unreadable.

Q Observe the manufacturer's manual when connecting an external device that is not described in

this document. Incorrectly connected devices can damage the controller.

Q This device is not intended for

– children,

– persons with physical, sensory or mental impairment,

– persons without sufficient experience or knowledge unless they are instructed in the use of

the device, and initially supervised, by a person responsible for their safety.

Page 6

6

DE

2 Identification

General information

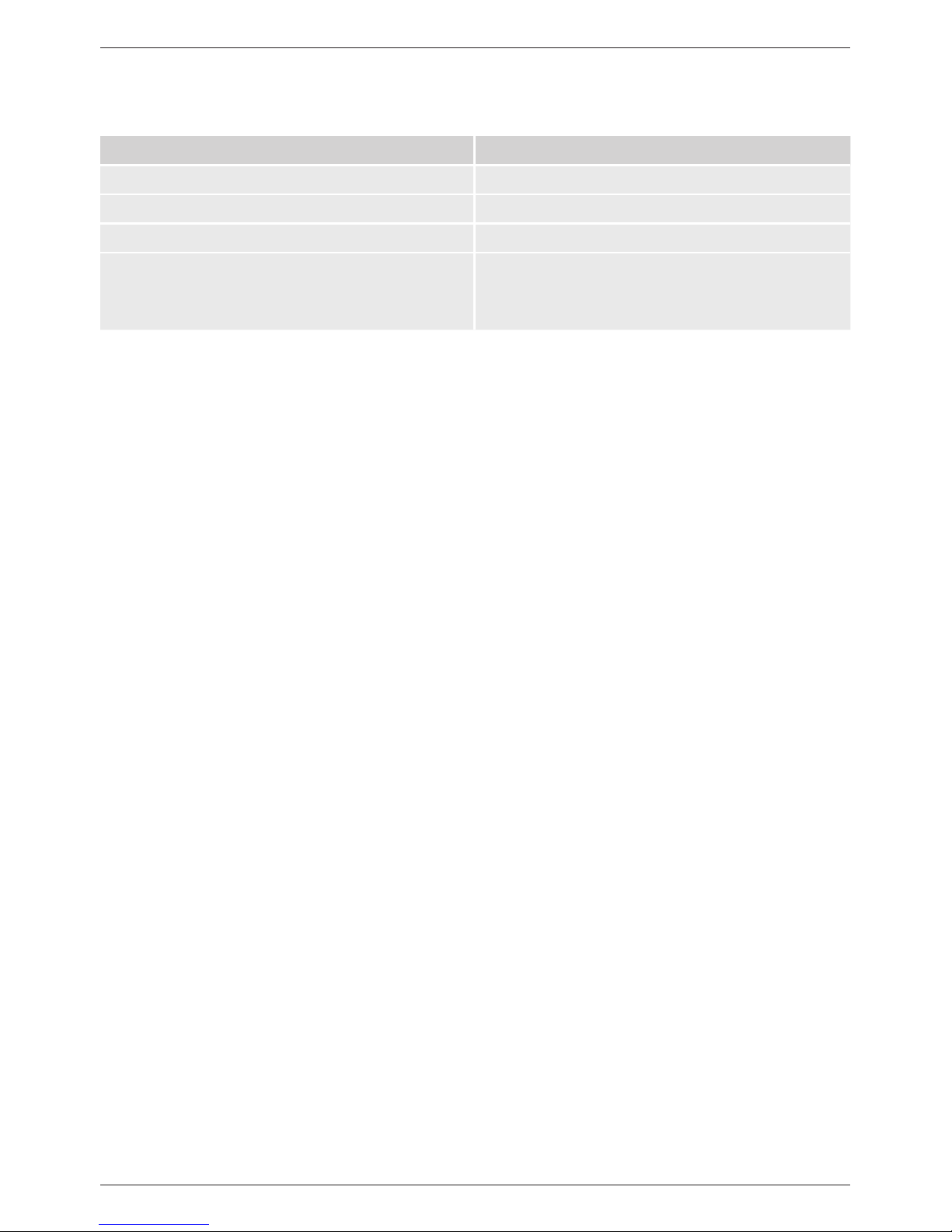

Feature Description

Type Tarom 4545, Tarom 4545–48

Issue version of the manual Z03

Manufacturer's address See nameplate on the charge controller

Optional accessories Q External temperature sensor Steca PA TS-S

Q Current sensor PA HS400

Q StecaLink termination plug

Display

The controller indicates the version of the manual matching the software under ‘Main menu’

‘Information’ ‘System info’

Page 7

7

DE

3 Scope of delivery

Q Tarom 4545 or Tarom 4545–48

Q Operating instructions

Page 8

8

DE

4 Proper usage

The solar charge controller, hereinafter named as the controller or device, may only be used in standalone photovoltaic systems for charging and controlling a lead-acid battery containing liquid or gel

electrolyte. The following applies in addition:

Q The controller must not be connected to the public power grid.

Q Only solar modules may be connected to the solar module connection.

Q Depending on the battery used, the connected loads must be suitable for use with one of the

following voltages:

Tarom 4545: 12 VDC, 24 VDC

Tarom 4545–48: 12 VDC, 24 VDC, 48 VDC

Q The controller performs the following tasks:

– Monitoring of the battery charging process

– Controlling of the charging process, protection of the battery from overcharging

– Switching loads on and off, protection of the battery from deep discharge

Page 9

9

DE

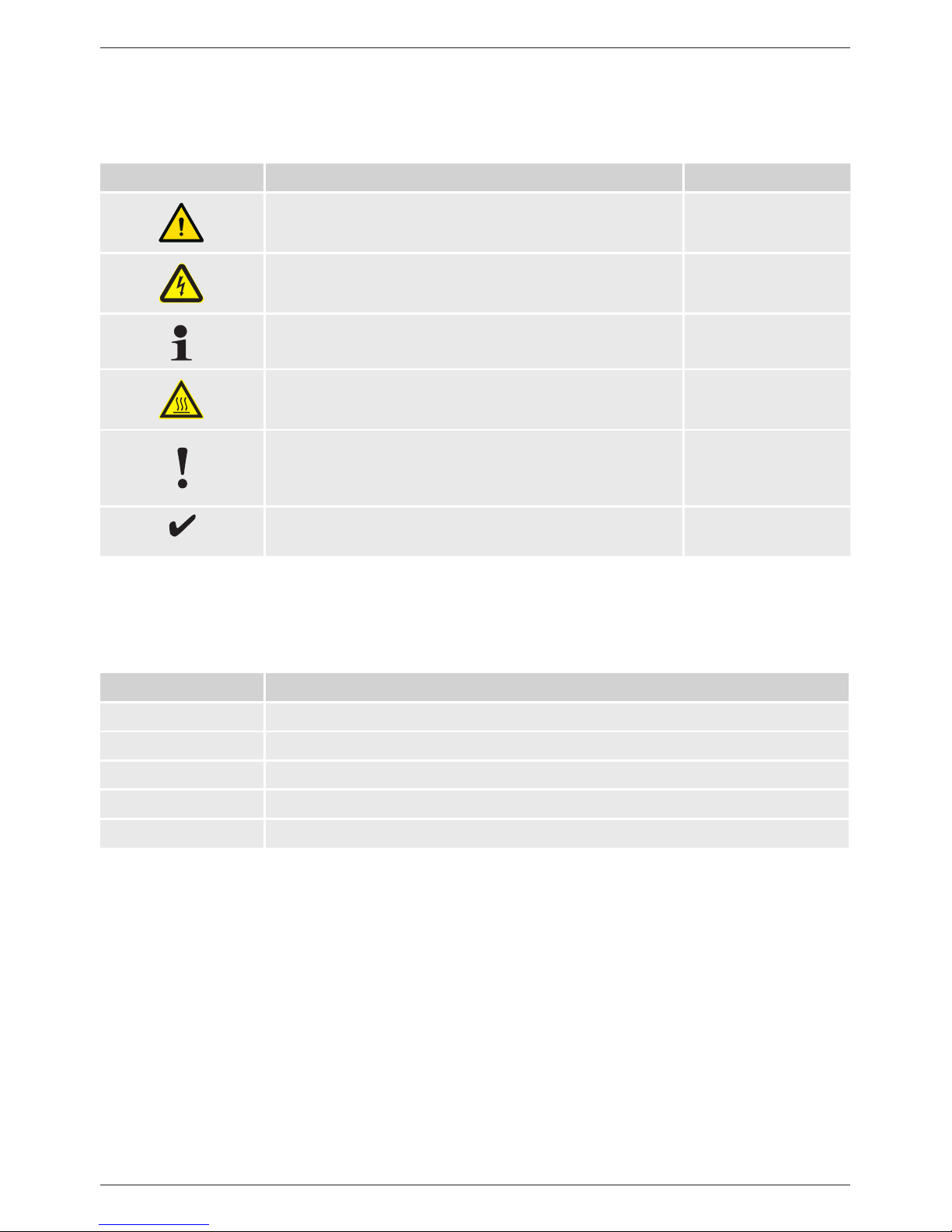

5 Markings

5.1

Symbols for warnings and notices

Symbol Description Location

General danger warning Manual

Danger from electricity Manual

Read the manual before using the product. Device

Danger from hot surfaces Manual, Device

General information. Manual

The following information describes prerequisites for

further operation

Manual

5.2 Keywords

The following symbols are used in conjunction with the symbols from chapter 5.1.

Keyword Description

Danger immediate danger of death or serious bodily injury

Warning possible danger of death or serious bodily injury

Caution possible danger of light or medium bodily injury

Notice possible damage to property

Note note on operation of the device or use of the manual

Page 10

10

DE

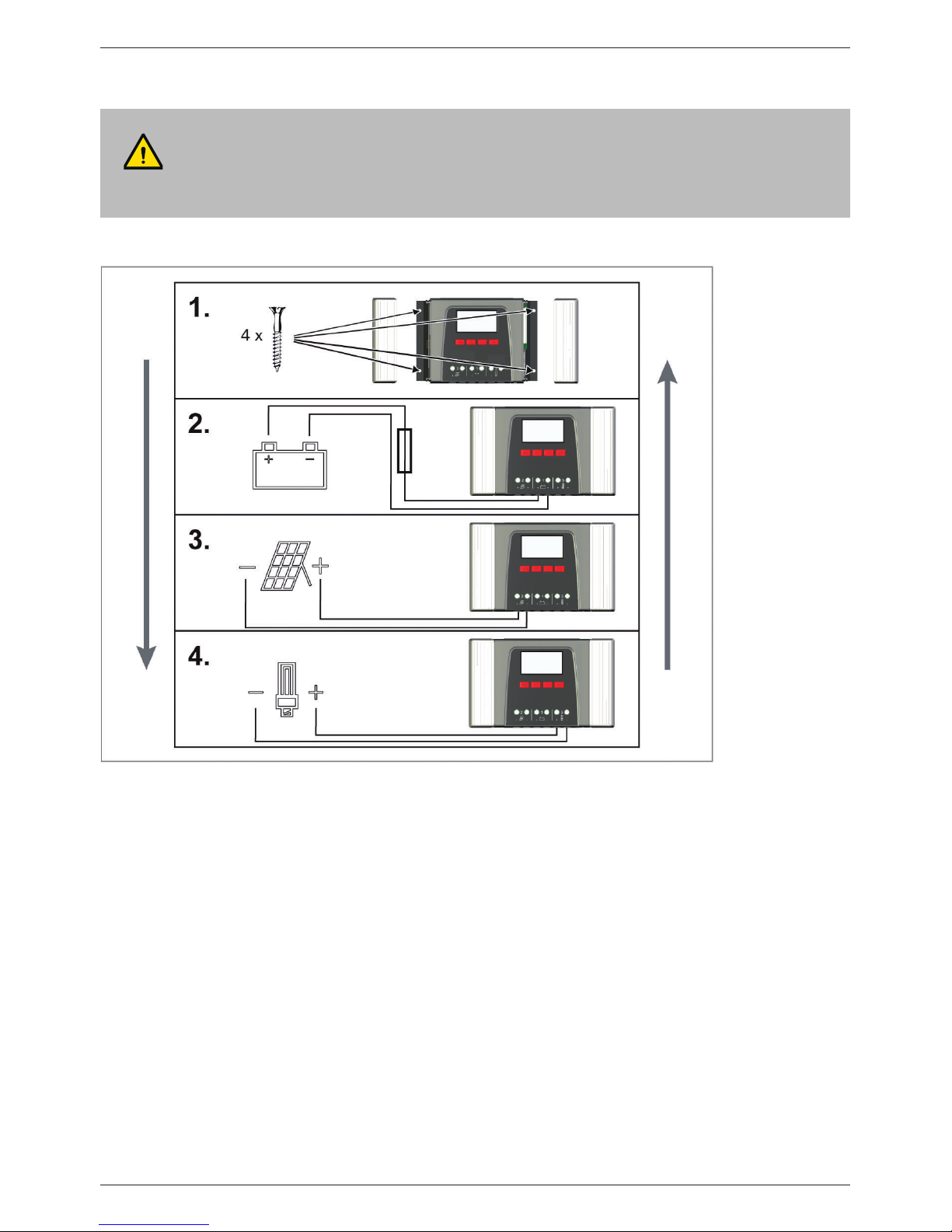

6 Quick guide

DANGER!

Risk of death by electrocution. Observe the safety instructions in chapter 9.1.

Installation

Uninstallation

Page 11

11

DE

7 Overview of the controller

Fig. 1 Overview of casing and connections

1)

Technical data at section 18.1.

2)

Optional

3)

Not included in scope of delivery

Connections

Batteryconnection:terminals1+and1−

Solar module connection: terminals 2+ and

2−

Load output for connecting the loads:

terminals3+and3−

Micro SD slot for microSD card

SLAVE IN and SLAVE OUT RJ45 sockets

for StecaLink Bus

MASTER RJ45 socket for StecaLink Bus

Open UART interface, 3.3 V

Temperature sensor connection TEMP for

Steca PA TS-S

AUX 2 relay output

AUX 1 relay output

Other components

External battery fuse (safety fuse or DC line

circuit breaker

1) 3)

DC load circuit breake

1) 2) 3)

Left cover

Display

Right cover

ESC,

r, s, SET operating buttons

Type plate

Positive ground, optional

Page 12

12

DE

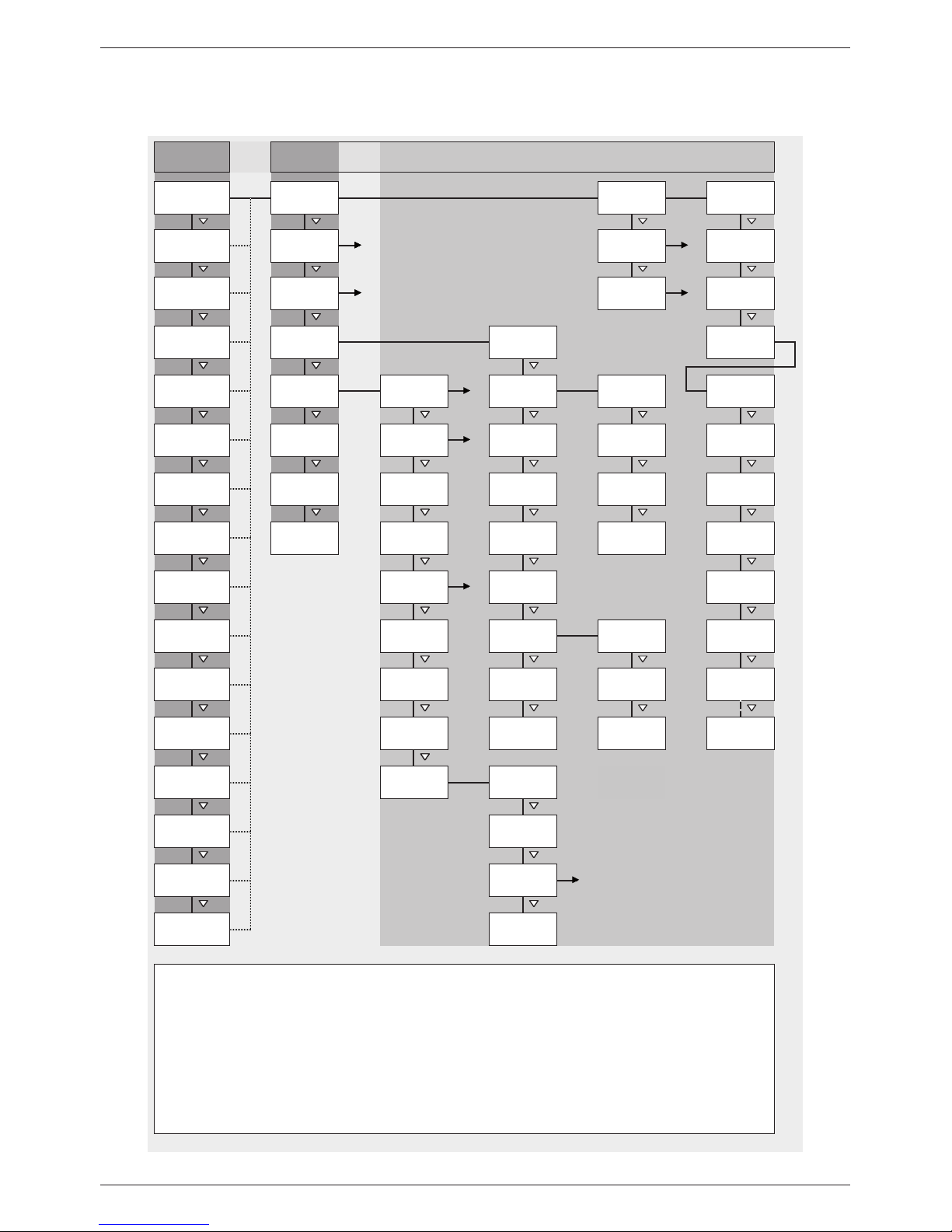

8 Menu structure

For the sake of clarity, only the s and ‘SET’ operating buttons are illustrated.

SET SET SET

SET SET SET

SET SET SET

SET SET SET

SET SET SET SET

SET SET

SET

SET

SET SET

Daily input

Daily load

Information

Load current Clear event log

Event log

Battery type

5)

Time format

Date format

Status display Main menu

Basic setting

Battery voltage

Output settings

Internal data

logger

Charge /

discharge

current

Battery

settings

Battery

capacity

Charge voltage 6)

Contrast

2)

SD card

Date

Time / date

Clear log data

4)

Battery control

mode

Equalisation

cycle

Time

Language

Self test

3)SOC

Input current

System

settings

PV current

Operation

mode

Load

AUX 1

AUX 2

Deep discharge

protection

Select function

Function

settings

8)

8)

Evening light

Night light

Morning light

Submenus

Generator

control

Excess energy

control

StecaLink slave

address

SET

SET

SET

SET SET

SET

SET SET

SET

1)

2)

3)

4)

5)

6)

7)

8)

System voltage

Open UART

Temperature

sensor

Device

temperature

Cable

compensation

Available if battery type = lead acid battery. Submenus: On/Off, cycle

Equalisation

charge

duration

Boost charge

duration

Expert menu

Start boost

charge

Battery

temperature

Remaining

capacity

Operating hours

StecaLink

master menu

Add slave

device

Submenus: SOC control mode, sensor member list

7)

Temperature

compensation

Total charge /

discharge current

of battery

Total discharge

current of battery

Total charge

current of battery

Factory reset

Change slave

Delete slave

Timer 1

Timer 4

Submenus for displaying the stored energy, current and voltage, configuration of sensors

Submenus: Datalogger On/Off, load parameter, store parameter

1)

Measurements of registered StecaLink slaves (if available)

Submenus: Float charging, boost charging, equalisation charging (available if battery type = Lead acid battery)

Submenus: On/Off, temperature coefficient

Same menus as Load, additionally with Alarm

Alarm 9)

)

9)

Only for AUX 1 and AUX 2

Page 13

13

DE

9 Installation

The following section describes only the installation of the controller. Observe the respective

manufacturer's manual when connecting external components (solar module, battery, load,

sensors).

Page 14

14

DE

9.1 Safety instructions

DANGER!

Risk of death by electrocution! Observe the following safety instructions when performing the

measures described in the installation section.

General information

– Only technical professionals may perform the work described in the 'installation' section.

– Do not open the controller case.

– All covers must be installed during operation.

– Always take the following measures before working on the controller:

1. Switch off all loads.

2. If present, switch off the DC load circuit breaker (solar module) and secure it against

being switched on again or safely cover the solar module (wind).

3. Switch off the external battery fuse: Remove the fuse insert from the fuse holder (safety

fuse) or switch off the DC line circuit breaker and secure it against being switched on

again.

4. Disconnect the battery cable from both battery terminals.

Cable connections

– The module cables carry voltage when the solar module is illuminated.

– Insulate exposed cable ends with insulation tape or wire connector blocks.

– Connect the cables for the battery, solar module and loads to the controller in the

described sequence.

– Secure the connected cables with a strain relief clamp, see Quick Guide section 6. Clearance

of strain-relief to controller: 200 mm.

– Connect only 1 cable to each connection terminal.

– Cables used: Observe the specifications in the Technical data section.

– Lay the cables so that

– connections cannot accidentally come loose,

– persons cannot tread on or trip over these,

– fire protection devices must not be impaired.

– The entire installation must be designed with Protection Class II if the open-circuit module

voltage exceeds 60 V DC at least once anywhere over the entire temperature range.

– Observe all applicable installation regulations and standards, national laws and connection

values specified by the regional power supply company.

Fuses and switching devices

Installation of an external battery fuse (line fuse or DC line circuit breaker) is mandatory.

Observe the following:

– Mount the external battery fuse directly next to the battery.

– The external battery fuse must conform to the specifications in the technical data section.

– The external battery fuse is not included in the scope of delivery.

Page 15

15

DE

WARNING!

Danger of acid injuries.

– Do not subject the battery to open flames or sparks.

– Provide adequate ventilation in the installation location of the battery. Inflammable gases

can escape from the battery.

– Follow the charging instructions of the battery manufacturer.

ATTENTION!

Danger of destroying the device through overloading.

– Conform to the technical specifications, especially the connection values. See the type plate

and section 18.

– When selecting the solar module, note that the open-circuit module voltage is higher than

the value specified on the type plate at temperatures below 25 °C.

– Connect only 1 controller to each solar module.

– Tighten the connection terminals as shown: Battery, solar module and loads with

2.5 ... 4.5 Nm

Page 16

16

DE

9.2 Connections and operating buttons

The following section describes the connections and operating buttons. For information on the display and operation see section 13.

9.2.1 StecaLink slave connection

1. Set a unique slave address at the device with the StecaLink slave connection; see section

14.3.9.1 ‘StecaLink slave address setting’.

2. Connect the StecaLink slave connection to the ‘StecaLink master’ connection of the superordinate master device.

3. Use a free ‘StecaLink slave’ connection for looping the connection through further slaves.

NOTICE!

– The StecaLink slave connection is an RS-485 communication interface using a proprietary

bus protocol.

– The StecaLink slave connection allows connection of superordinate communication levels

and control devices. The superordinate communication partner functions as the master and

controls the device via the StecaLink slave interface.

– A standard RJ45 network cable (CAT-5 Patch cable, 1:1) is used for connecting StecaLink

communication bus members.

– The last unused StecaLink slave connection of a communication chain must be terminated.

A termination plug can be acquired separately at your Steca dealer.

– A StecaLink slave device may only be connected to one StecaLink master. Multiple Steca-

Link slave devices are connected to form a communication chain. Only one StecaLink slave

device is connected to the StecaLink master device.

– Up to 5 PA HS 400 current sensor units can be connected via the StecaLink master socket

to a Tarom 4545 / Tarom 4545-48.

– The StecaLink slave bus is not galvanically isolated from the power supply unit of the

Tarom 4545 / Tarom 4545-48.

– At the device, at the StecaLink master connection, a supply voltage is available for slave

devices that do not have an own voltage supply. By connecting a slave to the StecaLink

master, the supply voltage is looped through the slave members.

– Each slave must have its own unique address within a range of 1 to 99. No duplicate ad-

dresses may be present. Set the address of the slave according to the slave manual.

– The maximum length of the entire bus cabling should not exceed 25 m.

– The Tarom 4545 / Tarom 4545-48:

– has 2 StecaLink slave bus connections,

– is a slave for Tarom MPPT 6000-M devices at the StecaLink slave connection,

– has a StecaLink master connection,

– is always the master at the StecaLink master connection.

Page 17

17

DE

4. Terminate the free ‘StecaLink slave’ connection of the last slave member using the termination plug.

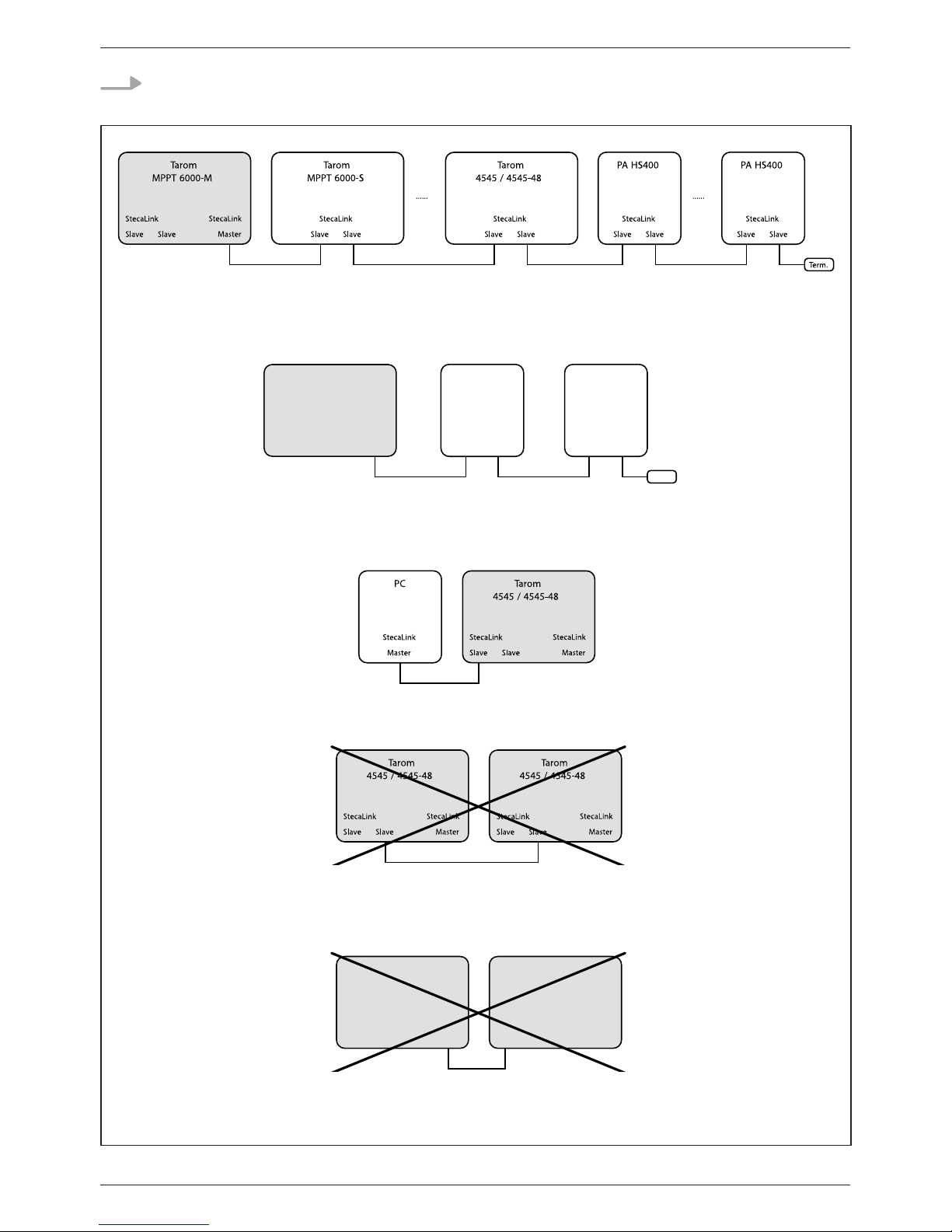

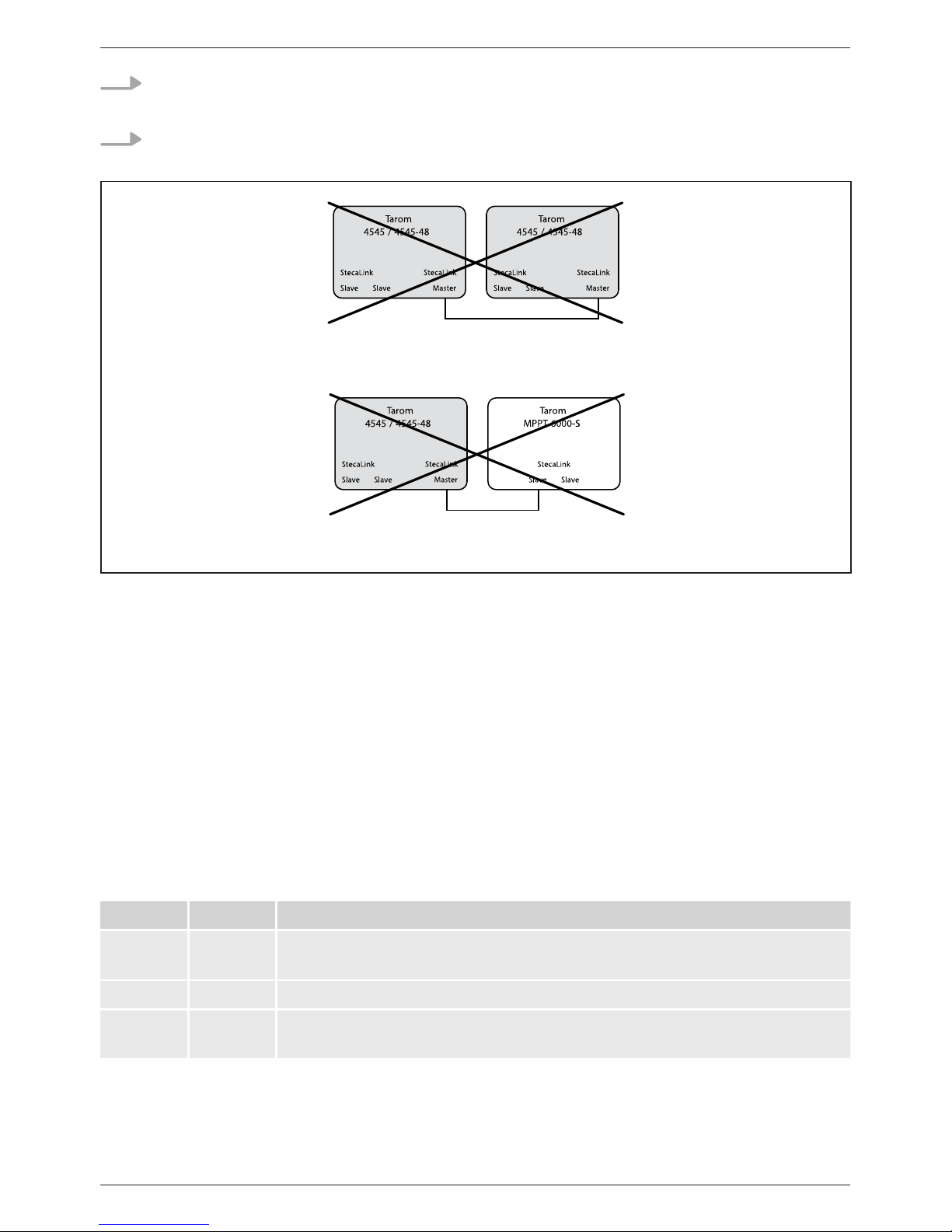

Fig. 2 Bus cabling example using an MPPT 6000-M, MPPT 6000-S, one Tarom 4545/4545-48

and PA HS400 current sensors

Fig. 3 Bus cabling example using one Tarom 4545/4545-48 and one or more PA HS400

current sensors

Fig. 4 Example of connecting a PC to the Tarom 4545/4545-48, e.g. for the update function

Fig. 5 The connection of Tarom 4545/4545-48 slave connection to other Tarom 4545/4545-48

slave connections, other charge controllers or PA HS400 without master is not permitted

Fig. 6 The connection of Tarom 4545/4545-48 master connection to other Tarom 4545/4545-48

slave connections is not permitted

Tarom

4545 / 4545-48

StecaLink

Slave Slave

StecaLink

Master

PA HS400

StecaLink

Slave Slave

......

PA HS400

StecaLink

Slave Slave

Term.

Tarom

4545 / 4545-48

StecaLink

Slave Slave

StecaLink

Master

Tarom

4545 / 4545-48

StecaLink

Slave Slave

StecaLink

Master

Page 18

18

DE

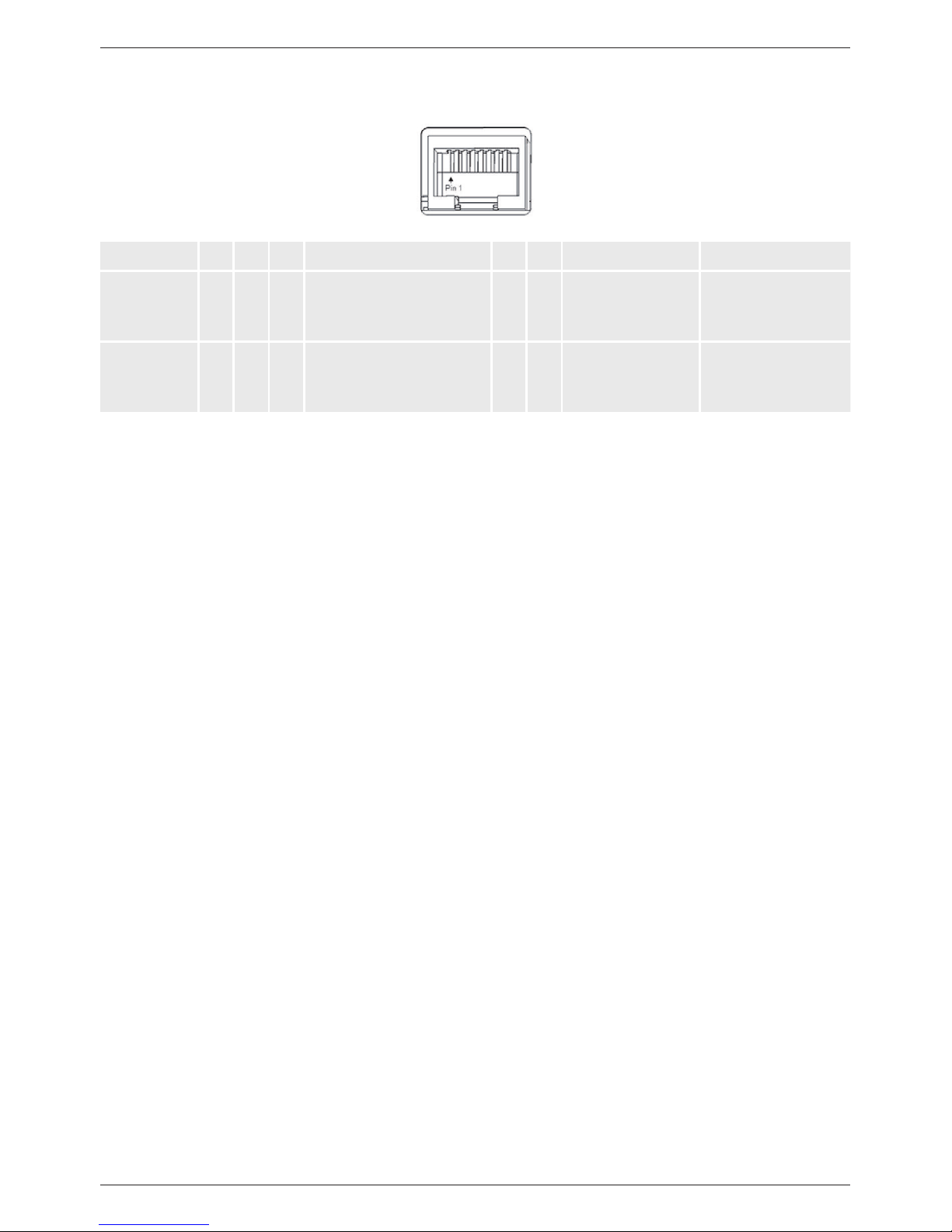

The bus cable pin assignments are specified in the following table.

Pin 1 2 3 4 5 6 7 8

Signal

(master

socket)

A B - + Battery voltage

1)

- - GND

2)

GND

2)

Signal

(slave

socket)

A B - - - - GND

2)

GND

2)

1)

The battery voltage is looped through from the master as supply voltage for slaves.

2)

GND or rather battery minus

Page 19

19

DE

9.2.2 StecaLink master connection

1. Set a unique slave address on the device with the StecaLink slave connection, see section

14.3.9.1 'StecaLink slave address setting'.

2. Plug the slave device into the StecaLink master connection. Connect the 'MASTER for Steca-

Link Bus' connection to the 'SLAVE IN for StecaLink Bus' connection.

3. If further slaves shall be connected, connect them via the slave device, at its free 'SLAVE OUT

für StecaLink Bus' connection.

NOTICE!

– The StecaLink master connection is an RS-485 communication interface using a proprietary

bus protocol.

– The StecaLink master connection allows the connection of subordinate communication

partners.

– The StecaLink slave devices connected to the StecaLink master connection are controlled by

the Tarom 4545 / Tarom 4545-48 as communication master.

– E.g. external current sensors PA HS400 can be connected to the StecaLink master connecti-

on.

– A standard RJ45 network cable (CAT-5 Patch cable, 1:1) is used for connecting StecaLink

communication bus members.

– Termination plugs for the StecaLink communication bus are available as accessories.

The communication network connected to the StecaLink master must be terminated at the

last free StecaLink slave connection.

– No further StecaLink master may be used in the communication network that is connected

to the StecaLink master connection.

– The Tarom 4545 / Tarom 4545-48 can manage a maximum of 5 PA HS400 units.

– Each slave must have its own unique address within a range of 1 to 99. No duplicate ad-

dresses may be present. Set the address of the slave according to the slave manual.

– The maximum length of the entire bus cabling should not exceed 25 m.

– The controller:

– has 1 StecaLink master connection,

– has 2 StecaLink slave bus connections,

– is always the master at the StecaLink master connection.

ATTENTION!

Tarom 4545 / Tarom 4545-48 devices can only communicate via the StecaLink bus if they have

a serial number from 757324 / 757325 or higher, as well as a APP software version 1.7.0 or

higher.

It is never permitted to integrate more than one Tarom 4545 / Tarom 4545-48 in a StecaLink bus

because otherwise dangerous compensation currents may occur!

Page 20

20

DE

4. On the last slave member, terminate the free 'StecaLink Slave' connection with the termination plug.

5. Register and configure the added StecaLink slave devices on the master device, see section

14.3.9.2 ' StecaLink master setting'.

Fig. 7 Master/slave connection of two Tarom 4545/4545-48 via the master connection

is not possible

Fig. 8 Tarom 4545/4545-48 / Tarom MPPT 6000-S connection is not possible without Tarom

MPPT 6000-M

StecaLink bus cable pin assignment: see page 23.

9.2.3 Slot for microSD card ( in Fig. 1)

Data can be logged and parameters can be saved on an inserted microSD card (not included in

scope of delivery). See 'Commissioning of the microSD card' in section 9.5.5.

9.2.4 Relay outputs AUX 1, AUX 2 (, in Fig. 1)

The relay outputs can be used for switching devices or loads (loads via an external power relay).

Devices connected to the relay outputs are controlled via the control functions provided by the controller. Relay output pin assignments:

AUX 1 AUX 2 Description

1 (NC) 4 (NC) Normally closed relay contact; the contact is closed when the relay is

switched off.

2 (COM) 5 (COM) Common relay contact

3 (NO) 6 (NO) Normally open relay contact; the contact is open when the relay is

switched off.

Page 21

21

DE

9.2.5 Temperature sensor connection TEMP ( in Fig. 1)

If the controller and battery are not located in the same room then an external temperature sensor

for measuring the battery temperature must be installed. We recommend using the optionally available Steca PA TS-S. Pin assignments:

Pin 7 (EXT.) 8 (GND)

Signal Sensor connection

1)

Sensor connection

1)

1)

Any polarity can be used.

9.2.6 Open UART interface, 3.3 V ( in Fig. 1)

The open UART interface outputs the values measured by the controller.

The interface can be switched on and off.

Interface protocol: see section 18.3.

Pin assignments:

Pin 9 (GND) 10 (TX) 11 (RX)

Signal Battery minus TX RX

Heavy loads directly connected to the battery can be switched using an additional power relay

connected to the AUX 1 or AUX 2 outputs, e.g. via the Steca PA EV 200.

Page 22

22

DE

9.2.7 Function ground ( in Fig. 1)

DANGER!

Risk of death by electrocution. Grounding causes the system to leave the safety extra-low

voltage range. Protection against directly touching live components must be restored via appropriate isolation measures.

The controller does not need to be grounded in stand-alone systems. We recommend not

grounding the controller. Also observe the local regulations.

If required, the controller can be grounded via the positive battery terminal '1+' Bat+ Fig. 1 of the

controller.

Observe the following:

Q The connection point must lie between the external battery fuse and the controller.

Q The connection point can be used as a common ground for all system components.

Q Take the grounding of the entire system into account.

ATTENTION!

– The system voltage of thin-film modules must be positive to avoid corrosion. This require-

ment is satisfied in stand-alone systems that are not grounded.

– Danger of damaging the devices (e.g. computer) connected to the Master/Slave bus or the

UART interface. All bus connections must be galvanically isolated when the system is

grounded.

Page 23

23

DE

9.2.8 Operating buttons

The operating buttons have the following functions:

Button Function

SET Q jumps down by one menu level

Q changes the state of a control element (check box/radio button)

Q causes the selected numeral to blink so that it can be modified

Q answers a query dialog with Yes

Q adopts a change

ESC Q jumps up by one menu level

Q jumps to the status display (press for 1 s)

Q answers a query dialog with No

Q discards any changes

r/s Q moves the selection bar or the display content upwards/downwards

Q moves the selection 1 position to the left/right on a settings page

Q increases/reduces the setting value by 1 step

Q repeated button presses: press button for a longer time

9.3 Removing/installing the cover

9.3.1 Removing the cover

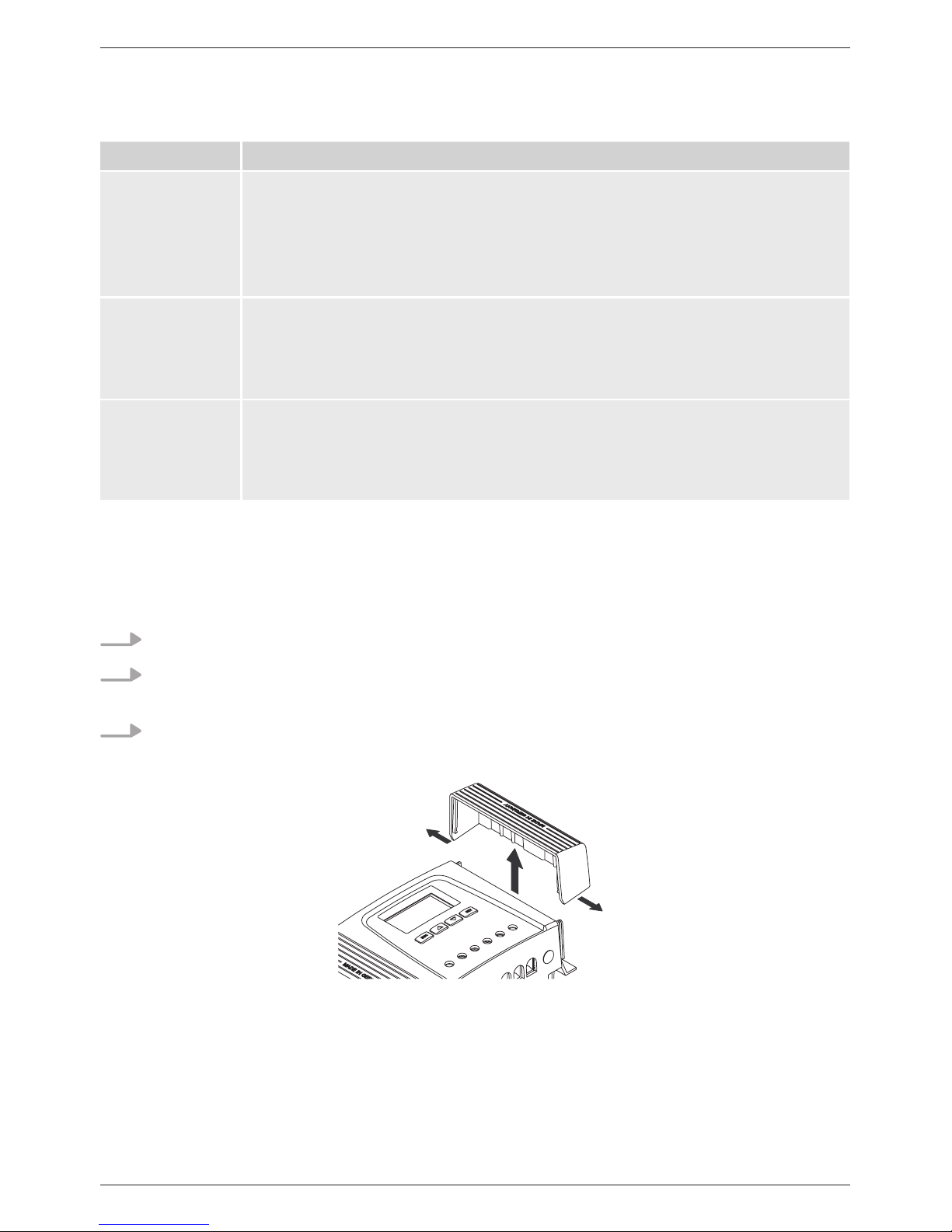

1. Grip the cover with both hands as shown in Fig. 9.

2. Use your index fingers to pull the edges slightly outwards and then pull upwards so that the

cover is released from the end position.

3. Pull off the cover entirely by lifting it upwards.

Fig. 9 Release the cover from the end position (here the right cover)

1.

2.

1.

Page 24

24

DE

9.3.2 Installing the cover

1. Position the cover on the casing so that the two guide lugs on the cover fit into the guide

slots in the casing.

2. Slide the cover onto the casing until it audibly latches into place.

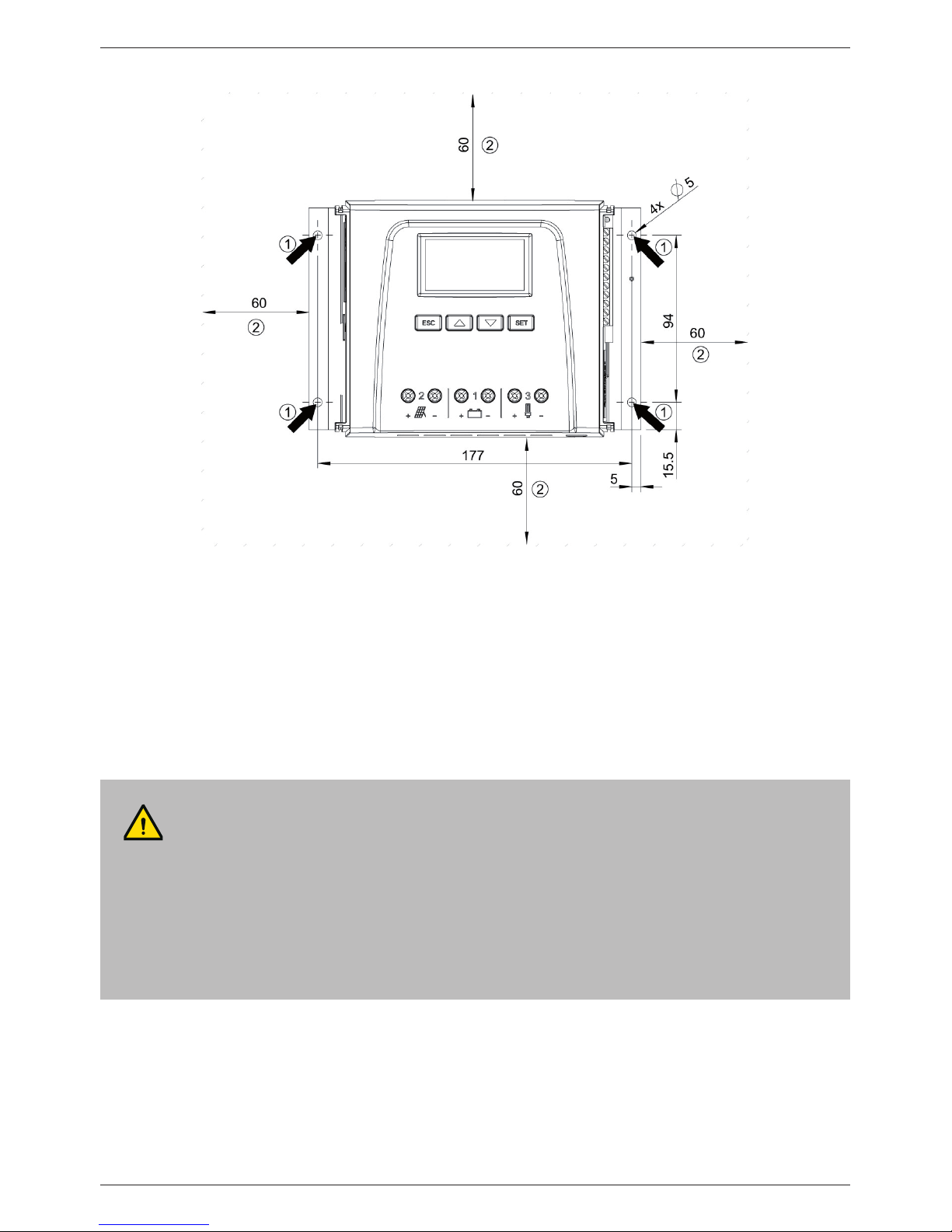

9.4 Installing the device

1. Select the mounting location under consideration of the previously mentioned safety requirements.

2. Remove both controller covers.

3. Position the controller level on the mounting surface and mark the mounting holes through

the fastening openings .

4. Remove the controller and drill the mounting holes.

5. Use 4 suitable screws (max. M5) to fasten the controller to the mounting surface.

6. Install the covers.

ATTENTION!

Danger of damage to the controller and reduction of power. Observe the following safety

requirements during installation:

– The mounting location and immediate environment are permanently fixed, vertical, flat,

non-inflammable and not subject to constant vibration.

– A free space of at least 60 mm must be present on all sides of the controller. The required

free space relates to the controller without covers; see in Fig. 10.

– The controller must be easily accessible and the display easily readable.

– The controller is mounted as close as possible to the battery; the prescribed minimum

safety clearance of 0.5 m between the controller and battery is adhered to.

– The controller must not be located

– outdoors or in a location subject to rain or splashing water,

– in dusty environments,

– in areas with active animal husbandry,

– in direct sunlight.

– The battery cable is no longer than 2 m (recommended), to keep cable losses and compen-

sating voltage as low as possible.

– Do not drill through the fastening openings (Fig. 10).

Page 25

25

DE

Fig. 10 Fastening openings and free space

9.5 Establishing the electrical connections

Always make connections in the following sequence:

CAUTION!

Always make connections in the following sequence:

1. First connect the load and then the source.

Example: First connect the cable to the controller and then to the battery.

2. Connect the positive pole first then the negative pole.

Example: First connect B+ then B–.

Page 26

26

DE

9.5.1 Preparing the cables

1. Label the cable ends as per Fig. 1 (M+, M–, B+, ...).

2. Lay the battery, module and load cables directly next to each other. Do not yet connect the

cables!

3. Connect the external battery fuse, close to the battery and easily accessible, to the battery

cable B+ ( in Fig. 1).

4. Switch off the external battery fuse: Remove the fuse insert from the fuse holder (safety fuse)

or switch off the DC line circuit breaker and secure it against being switched on again.

5. Connect the optional DC load circuit breaker, close to the controller and easily accessible, to

the module cable M+ ( in Fig. 1).

6. Switch off the DC load circuit breaker and secure it against being switched on again.

9.5.2 Connecting the battery

No devices are connected to the battery.

1.

Connect the battery cable and external battery fuse to the battery connection of the control-

ler and to the battery.

2. Switch on the external battery fuse: Insert the fuse insert into the fuse holder (safety fuse) or

switch on the DC line circuit breaker . The controller automatically starts operation and, after

a few seconds, displays the detected system voltage (= battery voltage) in an event message

(Fig. 11).

3. Note the system voltage displayed in Fig. 11.

4. Press ‘ESC’ to confirm the event message. The basic setting display appears (Fig. 12).

5. Confirm other event messages with ‘ESC’ , e.g. ‘RTC not set’ .

6. If Fig. 11 and Fig. 12 are not displayed then check the installation and if necessary correct the

error using section 15.

7. Check that the noted system voltage corresponds to the actual battery voltage. If not, set

the system voltage in the expert menu (‘Main menu’

‘Battery settings’ ‘Expert menu’

‘System voltage’; more information on this is provided in section 13.5).

CAUTION!

Danger of damage to the controller. Observe the maximum battery voltage as per

section 18.1.

Page 27

27

DE

Fig. 11 Event message with the detected system voltage (in the example: 12 V)

Fig. 12 Basic setting of the status display

9.5.3 Connecting the solar module

1. Safely cover the module (wind)

2. Connect the module cable and optional DC load circuit breaker to the solar module connection of the controller and to the solar module.

3. Remove covers from the solar module and, if present, switch on the DC load circuit breaker.

The display shows Fig. 13 or Fig. 14.

4. If Fig. 13/Fig. 14 is not displayed, check the installation and if necessary correct the error on

the basis of section 15.

Fig. 13 Display with sunshine after connecting the solar module (possibly delayed)

The battery can be charged from multiple sources. The following applies:

– The battery can be charged by multiple controllers connected to the battery in parallel.

– Apart from the controller, other suitable charging sources can also be connected to the bat-

tery. These charging sources can be switched on and off by the controller via the

‘AUX 1’ and ‘AUX 2’ relay outputs.

Page 28

28

DE

Fig. 14 Display without sunshine after connecting the solar module

9.5.4 Connecting loads

1. Switch off the load output (section 13.5 'Switching loads on/off (load output)').

2. Connect the load cable to the loads and to the load output of the controller.

3. Switch on the load output. The lamp (Fig. 15) appears on the display.

4. Switch on the load. Load currents greater than 0.1 A are shown on the display.

5. If Fig. 15 is not displayed then check the installation and if necessary correct the error using

section 15.

Fig. 15 Display content after connecting the load output

CAUTION!

– Danger of destroying the controller through overloading.

– Loads that consume more current than can be supplied by the controller must be

directly connected to the battery!

– Always directly connect inverters to the battery!

– Danger of battery destruction due to deep discharging. Consumers that are not allowed

to be switched off by the deep discharge protection of the controller (emergency lighting,

radio link) must be directly connected to the battery and must not deeply discharge the

battery.

– Danger of battery and cable destruction due to overloading. Directly connected loads must

be separately fused.

Page 29

29

DE

9.5.5 Connecting optional components

Installing cable strain relief

Secure the cables with a strain relief clamp. Clearance to controller: 200 mm.

Connecting function ground

Connect ground to positive battery terminal '1+' Bat+ Fig. 1 (observe section 9.2.7).

Installing lightning protection

Install suitable lightning protection.

Connecting relay outputs 1 and 2

1. Connect external components to the relay outputs ‘AUX 1‘ und ‘AUX 2‘.

2. Configure the relay outputs as per section 14.

Connecting the external temperature sensor Steca PA TS-S

1. Install the temperature sensor Steca PA TS-S near to the battery.

2. Connect the sensor cable to contacts 7 (‘EXT.’) and 8 (‘GND’) (any polarity).

3. Set the temperature sensor under ‘Main menu’

‘Battery settings’ ‘Temperature sensor’

to ‘external’.

StecaLink bus: connecting master and slave devices

1. Set the addresses of suitable slave devices (observe section 9.2.1).

2. Connect the slave devices to the StecaLink bus.

3. Connect the StecaLink bus to the ‘MASTER’ RJ45 socket.

4. Connect the slave bus to the ‘SLAVE IN’ and ‘SLAVE OUT’ RJ45 sockets.

5. Terminate the last slave device according to the manufacturer's instructions.

Controller: plug optionally available termination plug into the open socket 'SLAVE IN' / 'SLAVE

OUT' on the last controller.

Connecting the open UART interface

Connect external devices to the open UART interface (observe in section 9.2.6).

CAUTION!

Danger of destruction of the relays. Observe the technical data of the relays (section 18)!

Maximum length of the Master bus cable: see section 18.2.

Page 30

30

DE

Commissioning the microSD card

1. Insert a formatted microSD card.

2. Configure the data logging function and save/load the parameters as described in section

14.3.10 'SD card'.

CAUTION!

Never forcibly insert or remove the microSD card. This can damage the card holder and/or the

microSD card.

NOTICE

– A microSD card is not included in the scope of delivery for the device.

– microSD and microSDHC cards with a capacity of up to 8 GB can be used.

– The microSD card must be formatted with a FAT16 or FAT32 file system.

– Using the microSD card, the data of the device as well as of connected StecaLink slave

devices can be recorded.

– Using the microSD card, setting parameters of the device can be saved and read in.

– Take care to observe the correct insertion direction, as shown on the microSD card and the

device.

– Carefully and gently push the microSD card into the opening in the device casing until it

latches into place.

– Remove the microSD card by pushing it towards the device until it unlatches, then let go of

the card and, finally, pull the card out (Push-Pull connector).

– Data recording onto the SD card is deactivated at the factory.

Page 31

31

DE

10 Performing initial commissioning

All the measures described in section 9.4 and section 9.5 have

been completed.

Showing the basic setting of the status display

If necessary, press ‘ESC’ for 1 s to show the basic setting of

the status display.

Setting the language

1. Press ‘SET’. The main menu appears and the ‘Output

settings’ entry is selected (Fig. left).

Note

English is set as the default menu language at the factory

2. Press

s 3 times to select 'System settings'.

3. Press ‘SET’. The ‘System settings’ menu appears and

‘Language’ is selected (Fig. left).

4. Press ‘SET’ . The ‘Language’ menu appears (Fig. left).

5. Press

r s to select a different language.

6. Press ‘SET’.

ATTENTION!

Danger of damage to the device and reduction of power. Only technical professionals may

perform the work described in this section.

Page 32

32

DE

Setting the time

1. Press ‘ESC’. The ‘System settings’ menu appears (Fig. left).

2. Press

s to select ‘Time/date’.

3. Press ‘SET’. The ‘Time/date’ menu appears and ‘Time’ is selected.

4. Press ‘SET’. The ‘Time setting’ dialog appears (Fig. left).

5. Press ‘SET’. The hour flashes.

6. Press

rs to change the hour.

7. Press ‘SET’. The hour stops flashing.

8. Press

s. The minutes are selected.

9. Repeat steps 5 to 7 for setting the minutes.

Setting the date

1. Press ‘ESC’. The ‘Time/date’ menu appears.

2. Press

s to select ‘Date’.

3. Press ‘SET’. The ‘Date setting’ dialog appears (Fig. left).

4. Press ‘SET’. The day flashes.

5. Press

sr to change the day.

6. Press ‘SET’ . The day stops flashing.

7. Press

s to select the month.

8. Repeat steps 4 to 6 for setting the month.

9. Press

s to select the year.

10. Repeat steps 4 to 6 for setting the year.

Setting the battery type

1. Press ‘ESC’ for 1 s. The basic setting display appears

2. Press ‘SET’. The main menu appears.

3. Press

s to select ‘Battery settings’.

4. Press ‘SET’. The ‘Battery settings’ menu appears.

5. Press

s to select ‘Battery type’.

6. Press ‘SET’ . The ‘Battery type’ dialog appears (Fig. left).

7. Press

sr to select a different battery type.

8. Press ‘SET’. The selected battery type is set.

Page 33

33

DE

Setting the battery capacity

1. Press ‘ESC’. The ‘Battery settings’ menu appears.

2. Press

s to select ‘Battery capacity’.

3. Press ‘SET’. The ‘Battery capacity’ dialog appears (Fig. left).

4. Press ‘SET’.

5. Press

sr to change the value.

6. Press ‘SET’. The value stops flashing.

Setting the control mode

Note

The control mode ‘State of charge (SOC)’ is preset at the factory

and only needs to be changed if required. More information on

this is provided in section 12.2.

1. Press ‘ESC’. The ‘Battery settings’ menu appears.

2. Press

s to select ‘Battery control mode‘.

3. Press ‘SET‘, the ‘SOC Control mode‘ dialogue appears.

4. Press

sr to select ‘Voltage control’.

5. Press ‘SET’. The voltage control is set.

Switching off cable compensation

Note

Cable compensation is switched on at the factory and only needs

to be switched off if required. More information on this is provided

in section 12.2.

1. Press ‘ESC’. The ‘Battery settings’ menu appears.

2. Press

sr to select ‘Cable compensation‘’

3. Press SET. The ‘Cable compensation’ dialog appears.

4. Press

sr to select ‘Off’.

5. Press ‘SET’. Cable compensation is switched off (Fig. left).

Finishing initial commissioning

Press ‘ESC’ for 1 s. The basic setting of the status display

appears and initial commissioning is finished.

Note

You can usually now use the controller without making any further

settings. For information on important additional functions see

section 14.

Page 34

34

DE

11 Dismounting the controller

Disconnecting the loads from the controller

1. Switch off all loads.

2. Disconnect the load cables L− and L+ from the controller.

Disconnecting the solar module from the controller

3. If present, Switch off the DC load circuit breaker (solar module) and secure it against being

switched on again or Safely cover the module (wind).

4. Disconnect the module cables M− and M+ from the controller and insulate the cable ends

Disconnecting the battery from the controller

5. Switch off the external battery fuse: Remove the fuse insert from the fuse holder (safety fuse)

or switch off the DC line circuit breaker and secure it against being switched on again.

6. Disconnect the battery cables B− and B+ from the controller and insulate the cable ends.

Finishing dismounting

7. If present, disconnect any remaining components from the controller (buses, sensors etc.).

8. Remove the controller from the mounting surface.

DANGER!

Risk of death by electrocution. Only technical professionals may perform the work described in

this section. Observe the warning notes in section 9.1.

WARNING!

Danger from hot surfaces. Allow the heatsink on the rear of the device to cool down before

touching.

Page 35

35

DE

12 System functions

12.1

Protection functions

12.1.1 Controller overload

The controller is protected from the following faults and is not damaged when these faults occur

individually.

Q Solar module or battery or load connected with the wrong polarity

Q Solar module or battery or load incorrectly connected

Q Solar module or load short-circuited

Q Battery not connected

Once the individual fault has been corrected the controller will operate correctly without taking any

further measures.

If the battery voltage drops below 9.5 VDC, safe operation of the controller can no longer be

guaranteed. The controller stops all functions, especially charging of the battery.

12.1.2 Overheating of the controller

The cooling fins on the rear side and the internal temperature controller prevent the controller from

overheating. If the controller becomes too hot then the battery is no longer charged and the load

output is also switched off if necessary.

12.1.3 Deep discharging of the battery

To protect the battery from deep discharge the controller switches off the load output and the

‘AUX 1’ and ‘AUX 2’ relay outputs if necessary. More information on this is provided in section 14.

ATTENTION!

The following faults damage the controller:

– At least 2 of the above mentioned faults occur simultaneously.

– The load outputs of multiple controllers are connected in parallel.

– A solar module is connected to multiple controllers in parallel.

Page 36

36

DE

12.2 Control mode

The controller has 2 control modes:

Q Based on the actual state of charge of the battery (SOC control)

Q Based on the battery voltage (voltage control)

The use of the SOC control is strongly recommended because a longer battery life can be

expected by using it.

When SOC control is switched on the charge state of the battery is displayed in percent, with

Voltage control the charge state is displayed in volts. The following applies in addition:

Q If components are connected directly to the battery, the controller can only determine the SOC

correctly if it measures the battery currents with device-specific Steca current sensor PA HS400.

If it is not possible to measure the battery currents, the controller must be changed to Voltage

control.

Q The controller takes the battery temperature into account for accurate determination of the

charge completion voltage. To do this, the controller measures the room temperature using its

own internal temperature sensor and assumes that the battery is also at room temperature. If

the battery is located in a different room then the external temperature sensor Steca PA TS-S

(optional) should be used.

Q The voltage drop in the battery cables distorts the battery voltage measurement of the battery

and, thus, the actual charging voltage present at the battery. The cable compensation of the

controller compensates for this voltage drop. Additional sensors are not required. Cable compensation is switched on in the factory settings.

Operation

Q Control mode: ‘Main menu’

‘Battery settings’ ‘Battery control mode’

Q Temperature sensor: ‘Main menu’

‘Battery settings’ ‘Temperature sensor Bat.’

Q Cable compensation: ‘Main menu’

‘Battery settings’ ‘Cable compensation’

Page 37

37

DE

12.3 Battery charging functions

12.3.1 Float charging

When the battery is fully charged, the controller automatically switches to float charging (charging

with the float charge voltage). This prevents the battery from being discharged.

ATTENTION!

The float charging voltage must be set according to the specifications of the battery manufacturer to ensure optimum charging of the battery.

Operation

Float charging voltage: ‘Main menu’

‘Battery settings’ ‘Charge voltages’ ‘Float charging’

12.3.2 Boost charging

Boost charging provides more intensive care of the battery than float charging. The following

applies in addition:

Q Boost charging starts when the switch-on threshold1) is reached. Boost charging can also be

started manually.

Q Boost charging stops after the charge duration has expired.

Q With boost charging the charging voltage is higher than with float charging.

Q After boost charging the controller automatically switches to float charging.

Observe the manufacturer's specifications when setting the charge duration and charge completion voltage.

Operation

Q Switch-on threshold: ‘Main menu’

‘Battery settings’ ‘Charge voltages’ ‘Boost

charging’ ‘Starting threshold’

Q Charge duration: ‘Main menu’

‘Battery settings’ ‘Expert menu’

2)

‘Boost charge dur.’

Q Charge completion voltage: ‘Main menu'

‘Battery settings’ ‘Charge voltages’

‘Boost charging’ ‘Boost charge voltage’

Q Starting boost charging manually: ‘Main menu’

‘Battery settings’ ‘Start boost charge’

1)

Value in percent with SOC control, in volts with voltage control

2)

More information on this is provided in section 13.5 'Calling up the expert menu for battery set-

tings'.

Page 38

38

DE

12.3.3 Equalise charging

Equalise charging prevents acid layering via controlled gassing and thus extends the service life of

the battery. The following applies in addition:

Q Equalise charging starts when the cycle has expired or the switch-on threshold

1)

is crossed.

Q Equalise charging stops after the charge duration has expired.

Q Equalise charging is switched on in the factory settings. Prerequisite: battery type = ’Lead acid

battery’.

Q After equalise charging, the controller automatically changes to float charging.

Operation

Q Generally switching equalise charging on/off: ’Main menu’

’Battery settings’ ’Equal.

charging cycle’ ’On/off'’

Q Cycle: ’Main menu’

’Battery settings’ ’Equal. charging cycle’ ’Cycle duration’

Q Switch-on threshold: ‘Main menu’

‘Battery settings’ ‘Charge voltages’ ‘Equal.

charging’ ‘Starting threshold’

Q Charge completion voltage: ’Main menu’

’Battery settings’ ’Charge voltages’ ’Equal.

charging’ ’Equal. charging voltage’

Q Battery type: ‘Main menu’

‘Battery settings’ ‘Battery type’

Q Charge duration: ‘Main menu’

‘Battery settings’ ‘Expert menu’

2)

‘Equal. charge dur.’

1)

Value in percent with SOC control, in volts with voltage control

2)

More information on this is provided in section 13.5 'Calling up the expert menu for battery set-

tings'.

12.4 Data logger

The data logger stores the following data in internal memory:

Q Energy input

Q Energy output

Q Min. battery voltage

Q Max. battery voltage

Q Max. input current

Q Max. load current

Internally stored data is shown on the display and can be deleted.

– Observe the manufacturer's specifications when setting the cycle and charge duration.

– Equalise charging is only possible if the battery type 'Lead acid battery' is set.

Page 39

39

DE

13 Display (layout, function, operation)

13.1

Overview (menu structure)

An overview of the operating structure of the display is provided on section 8.

13.2 Status display

The status display consists of the Basic setting, the pages with the Measurements and the Information bar.

Basic setting

The Solar module/system symbol shows the status of the

solar module and the system as follows:

The solar module is illuminated and the controller has

detected the Day condition. No event message or a

message of type Information1) is present.

The solar module is illuminated and the controller has

detected the Day condition. An event message of

type Warning

1)

or Error1) is present.

The solar module is not illuminated and the controller

has detected the Night condition. No event message

or a message of type Information

1)

is present

The solar module is not illuminated and the controller

has detected the Night condition. An event message

of type Warning

1)

or Error1) is present.

Input current in amperes

The Battery symbol indicates charging of the battery as

follows:

Battery almost full

Battery almost empty

Charge state of the battery in % or volts.

With SOC control: Charge state in %

With voltage control: Battery voltage in volts

The Load symbol is shown when the load output is

switched on.

Load current in amperes

1)

More information on this is provided in section 15.1.

Page 40

40

DE

Measured values

Name of the measured value

Measurement with units

The following measurements are displayed:

Q Battery voltage

Q SOC: battery state of charge in % (only shown in SOC control)

Q PV current: presently available max. module current

Q Input current: amount of PV current that is actually being

used.

Q Charge/discharge current:

Positive = current flowing from controller to battery

Negative = current flowing from battery to controller

Q Load current: current from the controller to the loads

Q Daily input

1)

: the daily energy supplied by the modules

Q Daily load

1)

: the daily energy supplied to loads (connected to

the controller)

Q Device temperature

Q Battery temperature

Q Remaining battery capacity (usable)

Note

As the battery capacity changes over time, the displayed remaining capacity may deviate from the actual remaining capacity.

Q Operating hours

Q

Q

Total charge/discharge current of the battery: total of all currents of the components that have been activated in the menu

’Battery settings’

’Battery control mode’ ’Sensor member

list’. Display of the current median in A.

1)

Generators/loads that are not connected directly to the device must be covered by the device

specific Steca current sensor PA HS400 to allow for correct values to be displayed (depending on the

sensors selected in the data logger).

The following display of information on currents of additional StecaLink slave devices (only on

the master): extent and designation of the representation depends on the respective slave and

its settings.

Page 41

41

DE

Q Total discharge current of the battery: total of all battery

discharge currents of the components that have been activated

in the menu ’Battery settings’

’Battery control mode’ ’Sen-

sor member list’. Display of the current median in A.

Q Total charge current of the battery: total of all battery charge

currents of the components that have been activated in the

menu ’Battery settings’

’Battery control mode’ ’Sensor

member list’. Display of the current median in A.

Attention

The controller is not approved as a calibrated measuring

device.

Information bar

Date

Symbol for unacknowledged event messages; more informa-

tion on this is provided in section 15.1.

Connect symbol with 2-digit StecaLink slave address; indicates

data traffic on the StecaLink bus.

Symbol for the charging function being executed at the

moment:

‘E’ (equalise charge)

‘F’ (float charge)

‘B’ (boost charge)

‘S‘ (StecaLink slave mode active)

Time

13.3 Display of special states

Q When the inverter is processing large amounts of data it is not able to process any user input.

This is indicated by an animated sun symbol:

Q The backlight flashes red when faults occur. An event message is also displayed.

Q The display can also temporarily malfunction when the controller is operated outside the per-

missible temperature range.

Page 42

42

DE

13.4 General operation

1. If necessary, press ‘ESC’ for 1 s to show the basic setting of

the status display.

2. Press

sr to display the measurements.

3. Press ‘SET’. The main menu is displayed with the top item

selected.

4. Press

sr to select a different entry (Fig. left).

5. Press ‘SET’. The submenu appears.

6. Repeat steps 4 and 5 if necessary.

7. Press ‘ESC’ briefly to jump one menu level higher or press ‘ESC’

for a longer time (1 s) to show the basic setting display.

13.5 Advanced operation

Switching loads on/off (load output)

‘Main menu’

‘Output settings’ ‘Load’ ‘Operation

mode’

1. Press

sr to select ‘On’ or ‘Off’.

2. Press ‘SET’. The load output is switched on/off.

Displaying advanced information

‘Main menu’

‘Information’

1. Press

sr to select an entry (Fig. left).

2. Press ‘SET’ to open the entry.

The entries contain the following information:

Q ‘Contact details’: manufacturer address as text and QR code.

Q ‘System info’ (Fig. left):

– Product designation

– Serial number

– Version of the software modules

– Address of the controller on the Slave bus

– Version of the manual for the inverter

Page 43

43

DE

Calling up the expert menu for battery settings

ATTENTION!

Risk of damaging the system. The expert menu allows modification of settings that require specialist technical knowledge. The expert menu must therefore only be used by professional personnel who know the applicable regulations and standards.

‘Main menu’ ‘Battery settings’ ‘Expert menu’

1. Press ‘SET’. The password entry dialog is displayed and the

1st character from the left is selected (Fig. left).

Note

The password is 17038.

2. Press ‘SET’.

3. Set ‘1’ with

sr and confirm with ‘SET’.

4. Press

s to select the 2nd digit from the left.

5. Press ‘SET’.

6. Set ‘7’ with

sr and confirm with ‘SET’.

7. Repeat steps 4 to 6 for the other digits.

8. Press ‘SET’ for 1 s. The expert menu is displayed (Fig. left).

9. Press

sr to select an entry.

10. Press ‘SET’ to open the entry.

Page 44

44

DE

14 Control functions

14.1

Overview

The load output and relay outputs can be automatically switched by the following control functions:

Q Morning light function

Q Evening light function

Q Night light function

Q Excess energy control

Q Generator manager

Q Alarm (AUX 1 and AUX 2 only)

Q Timer 1 ... 4

The following applies to the control functions:

Q The operating mode can be set for each output ( ‘On’ /‘Off’ /‘Function controlled’ ).

Q An individual switch-off threshold for deep discharge protection of the battery can be set for

each output.

Q When a control function is switched off its setting is retained.

Q The switching times and thresholds of the control functions can be individually set for each

output.

Q The control functions for an output are logically ORed. This means:

– Each control function can switch on the output independently of the other control func-

tions.

– The output is switched off when all control functions have switched it off, or the deep

discharge protection is active for this output.

Page 45

45

DE

14.2 Operation

The control functions are set for each output using the following steps:

Setting the operating mode

‘Main menu’

‘Output settings’

1. Select an output in the ‘Output settings’ window (Fig. left).

2. Press ‘SET’. The menu for setting the output appears,

‘Operation mode’ is selected (Fig. left).

3. Press ‘SET’. The option fields for setting the operating mode

are displayed.

Note

The load output is switched on in the factory settings (operating mode = ‘On’ ).

4. Press

sr to select an option field:

‘On’: the output is switched on.

‘Off’: the output is switched off.

‘Function’: the control functions automatically switch the

output.

5. Press ‘SET’. The selected operating mode is switched on

(Fig. left).

6. Press ‘ESC’ to leave the page.

Setting the deep discharge protection

‘Main menu’

‘Output settings’ <Output> ‘Low volt.

discon. - LVD’

1. Press ‘SET’. The switch-off threshold is displayed (Fig. left).

2. Use

sr to set the switch-off threshold and confirm with

‘SET’.

Note

Avalue≥30%isrecommended

3. Press

s. The switch-on difference is shown.

4. Press ‘SET’, use

sr to set the switch-on difference and confirm

with ‘SET’ .

5. Press ‘ESC’ to leave the page.

Page 46

46

DE

Switching control functions individually on and off

‘Main menu’

‘Output settings’ <Output> ‘Select

function’

1. Press

sr and ‘SET’ to switch the control functions on and

off (Fig. left).

Note

The switched-on control functions only take effect in the

‘Function’ operating mode.

2. Press ‘ESC’ to leave the page.

Setting control functions

Setting of the control functions is described below using Evening light and ‘Timer 1’ as examples.

Setting the evening light

‘Main menu’

‘Output settings’ <Output> ‘Function

settings’

1. Press

sr as required to select ‘Evening light’ (Fig. left).

2. Press ‘SET’. The ‘Switch-on delay’ dialog appears (Fig. left).

3. Press ‘SET’, use

sr to set the switch-on delay hours and

confirm with ‘SET’.

4. Press

s. The minutes are selected.

5. Press ‘SET’, use

sr to set the minutes and confirm with ‘SET’.

6. Press

s. The ‘Switch-on duration’ dialog appears.

7. Press ‘SET’, repeat steps 3 to 5 for the switch-on duration.

8. Press ‘SET’. The ‘Function settings’ menu appears.

Page 47

47

DE

Setting Timer 1

1. Select ‘Timer 1’.

2. Press ‘SET’. The ‘Switch-on time’ dialog appears and the

selected day is underlined (Fig. left: Monday is selected and

switched off).

3. Press

sr to select a different day.

4. Press ‘SET’. The state of the selected day changes (Fig. left:

Monday is switched on).

5. Press

sr to select a different day.

6. Repeat steps 4 to 5 until all days are switched on for which the

switch-on time is to apply.

7. Press

s (several times if necessary) until the hour of the

switch-on time is selected (Fig. left).

8. Press ‘SET’, use

sr to set the hours and confirm with

‘SET’.

9. Press

s. The minutes are selected.

10. Press ‘SET’, use

sr to set the minutes and confirm with

‘SET’.

11. Press

s. The ‘Switch-off time’ dialog appears (Fig. left).

12. Set the day and time of the switch-off time in the same

manner as described in steps 3 to 10.

13. The Evening light and Timer 1 control functions have now

been set. Press ‘ESC’ to leave the page.

14.3 Functionality

With all brightness-based control functions, the required brightness information is obtained

from the solar module.

Page 48

48

DE

14.3.1 Deep discharge protection

Switching behaviour

The deep discharge protection switches the output off below the switch-off threshold and enables it

again when the battery charge exceeds the switch-off threshold by the switch-on difference (similar

functionality to section 14.3.5 '"StecaLink master connection"').

Operation

‘Main menu’

‘Output settings’ <Output> ‘Low volt. discon. - LVD’

14.3.2 Morning light function

The morning light function switches the output on and off based on the brightness and time. The

reference point is the time of dawn. The morning light function is suitable for loads that are operated a certain time before dawn, e.g. heating, feeding system, bus-stop lighting.

Switching behaviour

Q The output remains switched on during the switch-on duration (Fig. below) and is switched

off by the switch-off duration before dawn.

Q When dawn is detected the output is switched off, even if the switch-on duration has not

expired.

The morning light function relates to the time of dawn, but the resulting switching time lies

before dawn, i.e. in the past. For this reason, the controller must have performed at least one

night-day changeover before the morning light function can be executed. After this, the controller continuously adjusts the time of dawn to suit any changes (weather, annual changes to

the length of the day, disconnection/covering of the solar module).

Operation

‘Main menu’

‘Output settings’ <Output> ‘Select function’

‘Main menu’

‘Output settings’ <Output> ‘Function settings’ ‘Morning light’

Dusk

Switch-on time

Switch-off time

Dawn

‘Switch-on duration’

‘Switch-off delay’

Page 49

49

DE

14.3.3 Evening light function

The evening light function switches the output on and off based on the brightness and time. The

reference point is the time of dusk. The evening light function is suitable for loads that are operated

a certain time after nightfall, e.g. lighting, heating.

Switching behaviour

Q The output remains switched on during the switch-on duration (Fig. below) but the switch-

on is delayed by the switch-on delay .

Q When dawn is detected the output is switched off, even if the switch-on duration has not

expired.

Operation

‘Main menu’

‘Output settings’ <Output> ‘Select function’

‘Main menu’

‘Output settings’ <Output> ‘Function settings’ ‘Evening light’

Dusk

Switch-on time

Switch-off time

Dawn

‘Switch-on delay’

‘Switch-on duration’

14.3.4 Night light function

The night light function switches the output on and off based on the brightness and time. The reference points are the times of dusk and dawn. The night light function is suitable for loads that are

only operated at night, e.g. emergency lighting.

Switching behaviour

The output is switched on at the switch-on delay (Fig. below) after dusk and switched off at the

switch-off delay before dawn. For the Dawn time see note in section 14.3.2.

Operation

‘Main menu’

‘Output settings’ <Output> ‘Select function’

‘Main menu’

‘Output settings’ <Output> ‘Function settings’ ‘Night light’

Dusk

Switch-on time

Switch-off time

Dawn

‘Switch-on delay’

Switch-on duration

‘Switch-off delay’

Page 50

50

DE

14.3.5 Excess energy control

Excess energy control switches the output on as long as the battery has a high state of charge1).

Excess energy control is suitable for non time-critical loads that can be specifically switched on when

a surplus of energy is available, e.g. electric water heating, pumping station for filling an elevated

water tank.

1)

Value in volts with voltage control and in percent with SOC control

Switching behaviour

The output is switched on when the switch-on threshold is reached (Fig. below) and is switched

off when the charge state drops the switch-off difference (hysteresis) below the switch-on

threshold.

Operation

‘Main menu’

‘Output settings’ <Output> ‘Select function’

‘Main menu’

‘Output settings’ <Output> ‘Function settings’ ‘Excess energy contr.’

‘Starting threshold’ ‘Hysteresis’

14.3.6 Generator manager

The generator manager switches the output on as long as the battery has a low state of charge1).

The generator manager is suitable for a generator that is switched on when the battery is at a low

state of charge.

1)

Value in volts with voltage control and in percent with SOC control.

Switching behaviour

The output is switched on when the switch-on threshold is reached (Fig. below) and is switched

off when the charge state reaches the switch-off difference (hysteresis) above the switch-on

threshold.

Page 51

51

DE

Operation

‘Main menu’

‘Output settings’ <Output> ‘Select function’

‘Main menu’

‘Output settings’ <Output> ‘Function settings’ ‘Generator manager’

‘Starting threshold’ ‘Hysteresis’

14.3.7 Alarm

The alarm switches the ‘AUX 1’ and ‘AUX 2’ on as long as one of the selected event messages is

present.

Operation

‘Main menu’

‘Output settings’ <Output> ‘Select function’

‘Main menu’

‘Output settings’ <Output> ‘Function settings’ ‘Alarm’

14.3.8 Timer 1 ... 4

The timers can be used to switch the outputs on and off at specific times in a weekly cycle. The

switch-on and switch-off times for each weekday can be separately defined for each timer.

Switching behaviour

The weekdays for the on and off switching times are set independently; which means that the duration of an on or off time can stretch over several days.

Operation

‘Main menu’

‘Output settings’ <Output> ‘Select function’

‘Main menu’

‘Output settings’ <Output> ‘Function settings’ ‘Timer 1 – 4’

Page 52

52

DE

14.3.9 StecaLink bus

14.3.9.1 StecaLink slave address setting

StecaLink slave address

Notices

Q Setting of the device address used for identifying the device as

a StecaLink slave node.

Q Within a StecaLink communication network each slave device-

must have a unique device address.

Q Problems/error messages will occur during device registration if

multiple devices have the same address.

‘Main menu

System settings StecaLink slave addr.’

1. Press ‘SET‘. The ‘RS485 address‘ dialogue appears (Fig. left).

2. Press ‘SET‘. The value flashes.

3. Press

r, s to change the value.

4. Press ‘SET‘. The value stops blinking.

NOTICE!

– The StecaLink bus is an RS-485 communication interface that uses a special Steca

transmission protocol.

– Various different StecaLink-compatible devices can be networked together via the

StecaLink bus.

– Data exchange and/or remote function execution are possible via the StecaLink bus,

depending on the respective StecaLink member device.

– For information on connecting StecaLink member devices to the controller, see section 9.2.1

‘StecaLink slave connection’.

– Please visit www.steca.com for continuously updated documentation on the compatible

StecaLink devices and the software versions required.

Page 53

53

DE

14.3.9.2 StecaLink master setting

Adding a slave device

‘Main menu‘

‘System settings‘ ‘StecaLink master menu‘