Steca coolcept fleX StecaGrid 1511, coolcept fleX StecaGrid 3611, coolcept fleX StecaGrid 2011, coolcept fleX StecaGrid 2511, coolcept fleX StecaGrid 3011 Technical Information

...Page 1

coolcept fleX

Technical Information

EN

Z02 | 1913 | 763.134

Page 2

EN

Preface

Thank you for choosing inverters of the coolcept fleX product family of Steca Elektronik

GmbH. Through the use of solar energy, you significantly help to protect the environment

by reducing the pollution of the atmosphere by the emissions of carbon dioxide (CO

other harmful gases.

Manufacturer: Steca Elektronik GmbH

Mammostrasse 1

87700 Memmingen, Germany

www.steca.com

Phone: 49 (0) 8331 85 58-0

Fax: 49 (0) 8331 85 58-131

Edition: Z02 | March 2019

) and

2

2 763.134 Z02 1913 coolcept_fleX

Page 3

EN

Table of contents

1 General information ................................................................... 6

1.1 Types .................................................................................................................... 6

1.2 Accessories .......................................................................................................... 6

1.3 Documents ........................................................................................................... 6

1.4 Monitoring portal ................................................................................................... 6

1.5 Scope of delivery .................................................................................................. 7

1.6 Labelling ............................................................................................................... 7

1.7 Type plate ............................................................................................................. 7

1.8 EU Declaration of Conformity ............................................................................... 8

1.9 Abbreviations ........................................................................................................ 8

2 Safety .......................................................................................... 9

2.1 General safety instructions ................................................................................... 9

2.2 Designated use ................................................................................................... 10

2.3 Target group ....................................................................................................... 10

2.4 Labels and symbols ............................................................................................ 11

2.4.1 Safety marks ....................................................................................................... 11

2.4.2 Keywords ............................................................................................................ 11

2.5 Safety symbols on the device ............................................................................. 12

3 Structure and functioning ........................................................ 12

3.1 Structure of the inverter ...................................................................................... 12

3.2 Connections ........................................................................................................ 13

3.3 Operating buttons ............................................................................................... 13

3.3.1 Functions of the operating buttons...................................................................... 13

3.4 Display ................................................................................................................ 14

3.5 Cooling ............................................................................................................... 15

3.6 Grid monitoring ................................................................................................... 15

3.7 Data .................................................................................................................... 15

3.7.1 Data communication ........................................................................................... 15

3.7.2 Data display ........................................................................................................ 16

3.7.3 Data storage ....................................................................................................... 16

3.8 Network (TCP/IP)................................................................................................ 16

3.9 "COM1" and "COM2" connections ...................................................................... 17

3.9.1 Connecting further master devices ..................................................................... 17

3.9.2 Connecting further inverters ............................................................................... 18

3.9.3 Fehler! Textmarke nicht definiert.

3.9.4 Alternative RS485 data connecting cable ........................................................... 19

3.9.5 RS485 termination .............................................................................................. 20

3.9.6 RS485 addressing .............................................................................................. 20

3.9.7 Connecting an energy meter (Modbus RTU) ...................................................... 20

3.9.8 Remote shutdown by the grid operator and rapid shutdown

"Teledistacco" (Italy) ........................................................................................... 21

763.134 Z02 1913 coolcept_fleX 3

Page 4

EN

4 Installing the inverter ............................................................... 22

4.1 Safety instructions for installation ....................................................................... 22

4.2 Mounting the inverter .......................................................................................... 23

4.2.1 Attaching the mounting plate .............................................................................. 23

4.2.2 Fixing the inverter to the mounting plate ............................................................. 24

4.3 Preparing AC connection .................................................................................... 24

4.3.1 Selecting AC cable ............................................................................................. 24

4.3.2 Residual current circuit breaker .......................................................................... 25

4.3.3 Assembling the AC plug ..................................................................................... 25

4.4 Preparing DC connection .................................................................................... 28

4.4.1 Fitting cable to DC plug ...................................................................................... 28

4.4.2 Preparing data connecting cable ........................................................................ 28

4.5 Connecting inverter and switching AC on ........................................................... 29

4.6 Performing initial commissioning ........................................................................ 29

4.7 Setting the feed-in management ......................................................................... 30

4.7.1 Switching the energy meter on or off .................................................................. 30

4.7.2 Limiting the dynamic feed-in value...................................................................... 30

4.7.3 Selecting an energy meter .................................................................................. 30

4.8 Switching DC on ................................................................................................. 31

5 Initial commissioning ............................................................... 31

5.1 Setting the display language ............................................................................... 31

5.2 Setting the date and time .................................................................................... 32

5.3 Setting the country .............................................................................................. 32

5.4 Setting the reactive power .................................................................................. 33

5.4.1 Setting the mode................................................................................................. 33

5.4.2 Changing parameters of the nodes..................................................................... 34

5.4.3 Displaying the reactive power characteristic curve ............................................. 34

5.5 Finishing the initial commissioning...................................................................... 34

6 Dismounting the inverter ......................................................... 35

6.1 Switching AC and DC off .................................................................................... 35

6.2 Disconnecting DC connection from inverter ........................................................ 35

6.3 Disconnecting AC plug from inverter .................................................................. 35

6.4 Opening the AC plug .......................................................................................... 36

6.5 Removing inverter from mounting plate .............................................................. 36

7 Operation .................................................................................. 37

7.1 Menu structure .................................................................................................... 37

7.2 Navigating the menu structure ............................................................................ 38

7.3 Status displays.................................................................................................... 38

7.3.1 Displaying output power ..................................................................................... 38

7.4 Main menu .......................................................................................................... 39

7.4.1 Displaying yields ................................................................................................. 39

7.4.2 Generator characteristic curve ............................................................................ 39

7.4.3 Event log ............................................................................................................. 39

7.4.4 Information .......................................................................................................... 40

7.4.5 Self-test (only Italy) ............................................................................................. 41

7.4.6 Settings ............................................................................................................... 42

7.4.7 Service ................................................................................................................ 45

4 763.134 Z02 1913 coolcept_fleX

Page 5

EN

8 Web portal ................................................................................ 48

9 Fault elimination ....................................................................... 49

9.1 Event message type ........................................................................................... 49

9.2 Alerting behaviour ............................................................................................... 50

9.3 Operation ............................................................................................................ 50

9.4 Event messages ................................................................................................. 50

10 Maintenance and care .............................................................. 56

10.1 Maintenance ....................................................................................................... 56

10.2 Care .................................................................................................................... 56

10.2.1 Removing dust .................................................................................................... 56

10.2.2 Cleaning ............................................................................................................. 56

11 Disposal .................................................................................... 56

12 Technical data .......................................................................... 57

12.1 StecaGrid 1511, 2011, 2511, 3011 and 3611 ..................................................... 57

12.2 StecaGrid 3011_2, 3611_2 and 4611_2 ............................................................. 60

13 Table of countries .................................................................... 62

14 Liability, warranty ..................................................................... 62

15 Contact ...................................................................................... 63

16 Annex ........................................................................................ 63

16.1 Drilling pattern for wall mounting......................................................................... 63

763.134 Z02 1913 coolcept_fleX 5

Page 6

EN

1 General information

These instructions contain information for the safe use of the inverter and all the information that a specialist needs for setting up, and the operator needs for operating the inverter. When installing other components (e.g. PV generator, wiring), follow the instructions

of the respective manufacturer.

The coolcept fleX inverters are available in various models for different power classes.

The StecaGrid #### inverters are suitable for the connection to one PV generator.

The StecaGrid ####_2 inverters are suitable for the connection to two PV generators.

1.1 Types

The coolcept fleX inverters are available in the following models:

• StecaGrid 1511

• StecaGrid 2011

• StecaGrid 2511

• StecaGrid 3011

• StecaGrid 3611

• StecaGrid 3011_2

• StecaGrid 3611_2

• StecaGrid 4611_2

1.2 Accessories

Ask for possible accessories, options, suitable PV generators, and installation material at

the installer's or at Steca.

1.3 Documents

Data sheets, drawings, country tables, and certificates are available in the download area

of the STECA homepage.

1.4 Monitoring portal

Steca's monitoring portal sunCloud offers online monitoring of the PV generator at no

charge: https://steca.powerdoo.com

6 763.134 Z02 1913 coolcept_fleX

Page 7

1.5 Scope of delivery

1 Inverter

4 DC plug (one pair*)

1 Type plate

Only for Australia: cover the "Protection Class II" symbol (2) on the type

2 Mounting plate

3 AC plug

* coolcept fleX ####_2: two pairs

1.6 Labelling

5 Sealing cap (3 units)

6 Quick guide

2 Safety marks

EN

1.7 Type plate

1 Manufacturer address

2 "Protection Class II" symbol

3 Technical data of the AC output

4 Standard for grid monitoring

5 Country-specific characteristic

6 Barcode (for internal purposes)

7 Device topology

8 Degree of protection

9 Technical data of the DC input

10 Item number and product name

763.134 Z02 1913 coolcept_fleX 7

plate.

Page 8

EN

Abbreviation

Description

1.8 EU Declaration of Conformity

The products described in this document comply with the applicable European directives.

The certificate is available in the download area of our homepage.

1.9 Abbreviations

AC Alternating Current

DC Direct Current

DHCP

Dynamic Host Configuration Protocol (automatic connection of the

device to an existing network)

DNS Domain Name System (name of the IP address)

LAN Local Area Network

MAC Media Access Control (device address)

MPP Maximum Power Point

MPP tracker Regulates the power of the connected module strings to the MPP

MSD

Mains monitoring with allocated Switching Devices (internal grid

monitoring of the inverter)

PV

Photovoltaics (technology for the conversion of solar energy into

electrical energy)

RTU Remote Terminal Unit

SELV Safety Extra Low Voltage

TCP/IP Transmission Control Protocol/Internet Protocol

URL Uniform Resource Locator (internet address)

8 763.134 Z02 1913 coolcept_fleX

Page 9

2 Safety

The inverter does not cause any inrush current.

NOTE

Any repair work may only be carried out by the manufacturer's customer

service department.

2.1 General safety instructions

• This document must be kept to hand at the site of use of the inverter.

In case of a change of ownership pass on the document with the inverter.

• This document must have been read and understood in full before installing and using

the inverter.

• Incorrectly connected components may cause damage to the inverter.

• If one of the following components is damaged, immediately take the inverter out of

operation and disconnect it from the grid and the PV generators:

- Inverter (not functioning, visible damage, smoke, penetration of liquid etc.)

- Cables

- PV generators

• Do not switch on the system again until it has been repaired and checked by a suitably

qualified and authorised technical specialist.

• Dangerous voltages may be present for up to 10 minutes after disconnecting the inverter from the voltage sources.

• Disconnect inverter from both voltage sources (power grid and PV generator) prior to

any work on the inverter.

• Always carry out the measures described in this document in the specified sequence.

• Do not change nor remove any factory-applied labels on the inverter.

EN

• Do not open the inverter. Danger to life! Opening the inverter will also void any warranty.

• Do not cover the inverter.

• Keep children away from the inverter.

• Follow the instructions of manufacturers of the connected components.

• Follow the general and national safety and accident prevention regulations.

763.134 Z02 1913 coolcept_fleX 9

Page 10

EN

2.2 Designated use

The coolcept fleX inverters are intended for single-phase feed-in and are suitable for indoor

and outdoor (degree of soiling 3) installation. The inverters are designed for wall mounting.

• Only use the inverter for grid-connected PV generators.

• The inverter is suitable for PV generators whose connections are not grounded.

• All connected solar modules must be classified as Class A according to IEC 61730,

because these inverters do not have galvanic isolation.

• The maximum permissible system voltage of the PV generator must be higher than the

AC grid voltage.

• The installation location for the inverter must not be at an altitude higher than 2000 m

above MSL.

NOTE

Only for Australia: the inverter may only be operated as a single device. It is

not permitted to interconnect several devices.

NOTE

Only for Italy: information about the particularities for the use in Italy have

been added to the Italian version of the installation and operating instructions.

2.3 Target group

Unless otherwise noted, the target group for these instructions are specialists and system

operators. The following persons are considered specialists:

• Persons that have knowledge of the established terms and skills for setting up and

operating PV generators.

• Persons that due to their knowledge and experience are able to evaluate the following

tasks and recognise possible hazards:

- Mounting electrical equipment

- Assembling and connecting data cables

- Assembling and connecting power supply cables

10 763.134 Z02 1913 coolcept_fleX

Page 11

2.4 Labels and symbols

2.4.1 Safety marks

The following safety marks are used on the inverter and in these instructions:

Warning sign Nature of the danger

Warning of hazardous voltage

Warning of hazardous area

Follow the instructions

2.4.2 Keywords

The following keywords are used in these instructions:

Keywo rd Meaning

EN

DANGER

Indicates a hazardous situation which, if not avoided, leads to death or

serious injuries.

WARNING

Indicates a potentially hazardous situation which, if not avoided, may

lead to death or serious injuries.

NOTE

Indicates a potentially hazardous situation which, if not avoided, may

lead to damage to property and/or the environment.

763.134 Z02 1913 coolcept_fleX 11

Page 12

EN

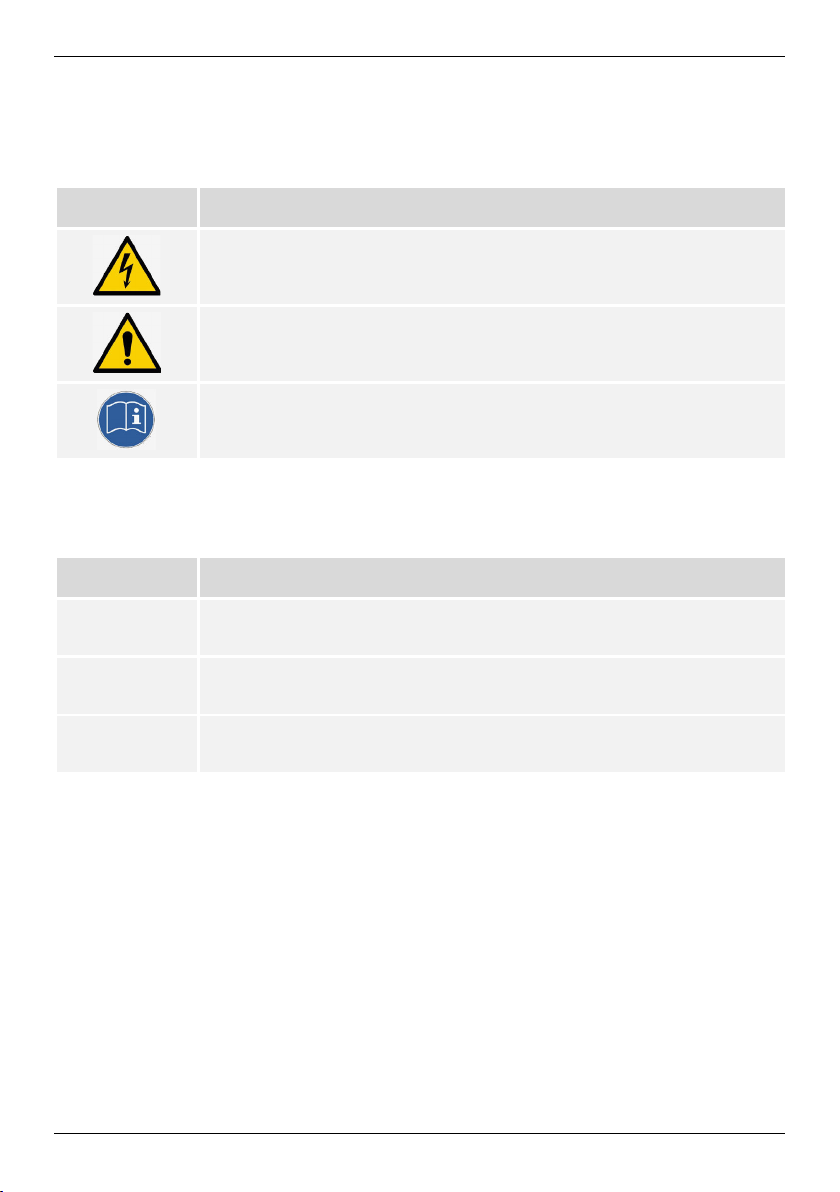

2.5 Safety symbols on the device

1 Disposal information (separate collection of electrical and

electronic equipment)

2 Request to disconnect the power sources prior to any

intervention

3 Information on presence of voltage after switching off the

inverter

4 Serial number (barcode and plain text)

5 Warning of voltage (two voltage sources)

6 Warning of hot surface

7 Follow the instructions

3 Structure and functioning

The coolcept fleX inverter is connected between PV generators and consumers. Via the

DC input and the MPP tracker, PV generators feed in DC, which the inverter converts into

AC. Consumers connected to the AC connection are supplied AC by the inverter.

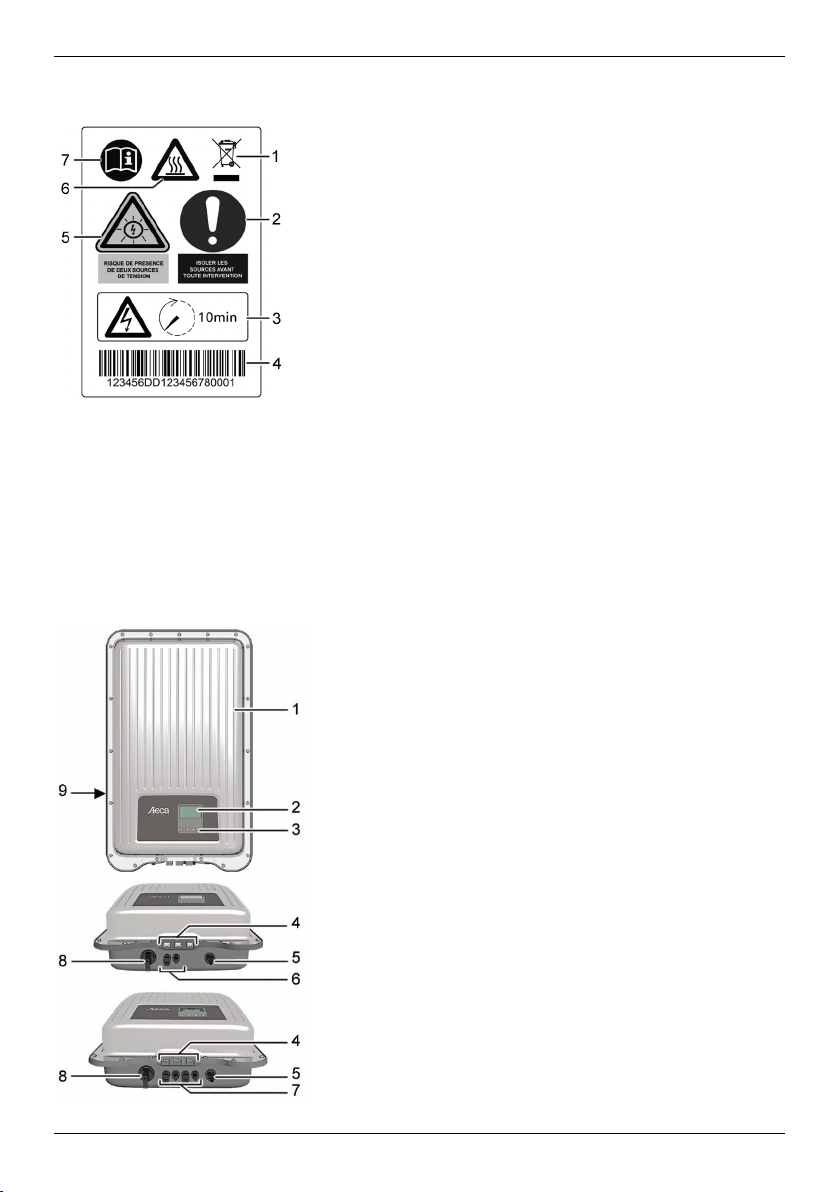

3.1 Structure of the inverter

1 Case

2 Display (monochrome, 128 x 64 pixels)

3 Operating buttons: ESC, , , SET (from left to right)

4 RJ45 sockets (LAN, COM1, COM2)

5 AC connection

6 DC connection (DC input, MPP tracker)

7 DC connection (StecaGrid ####_2: 2 x DC-input,

2 x MPP tracker)

8 DC disconnector (interrupts the plus and minus inputs

simultaneously)

9 Type plate, serial number, warning notices

12 763.134 Z02 1913 coolcept_fleX

Page 13

3.2 Connections

1 TCP/IP connection (LAN)

4 AC connection

5 DC connection

Button

Acti on

Function

EN

2 RS485 connection (COM1)

3 Modbus RTU connection (COM2)

6 DC connection (StecaGrid ####_2)

7 DC disconnector

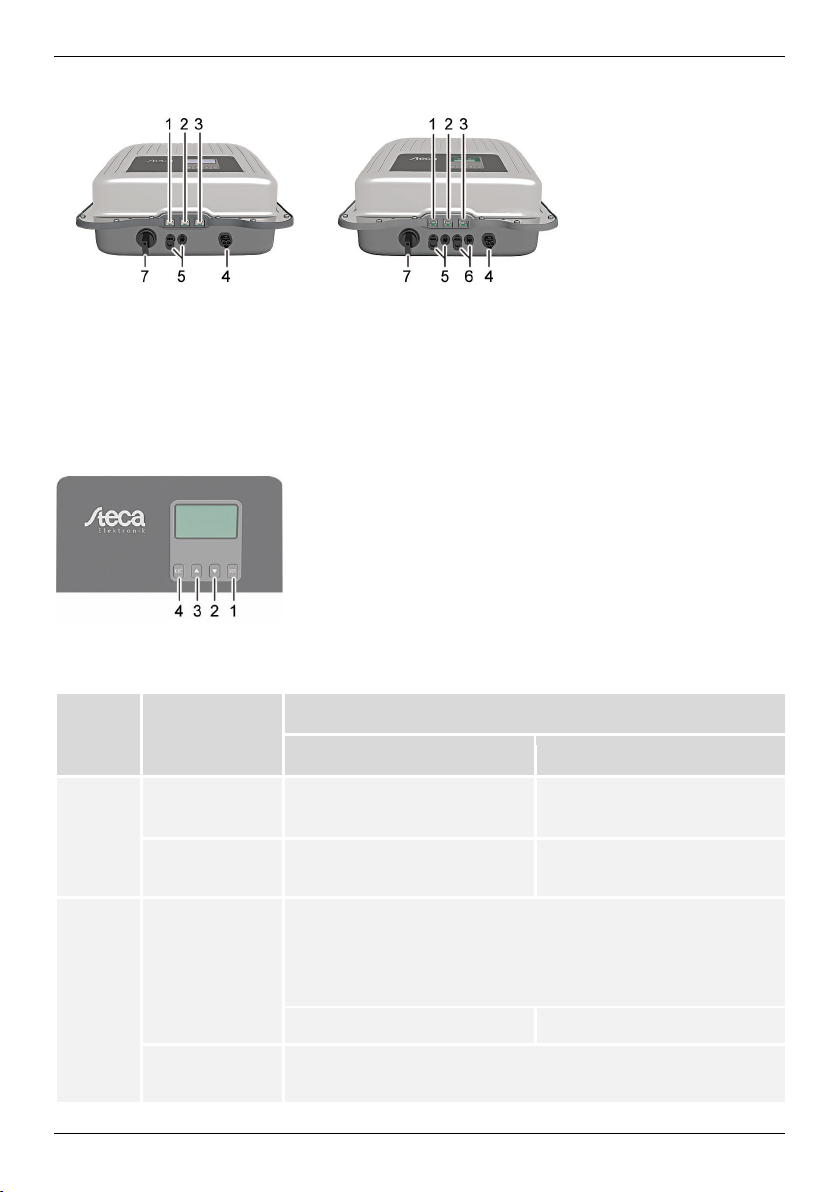

3.3 Operating buttons

1 SET

2

3

4 ESC

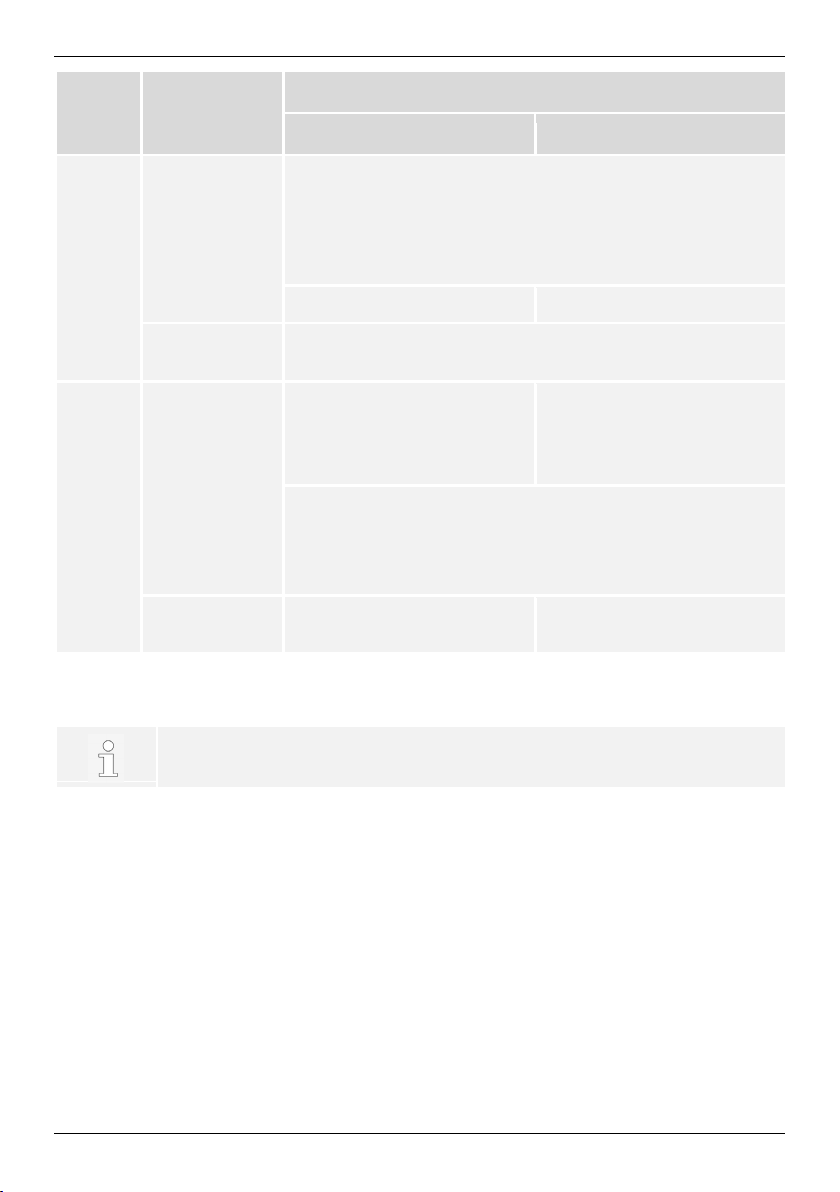

3.3.1 Functions of the operating buttons

Normal operation Commissioning

ESC Press briefly

Press longer

(≥ 1 second)

Press briefly

- Jumps 1 menu level up

- Discards changes

Jumps to the start image

- Moves the selection bar or the display content upwards

- Moves the selection bar 1 position to the left when setting

numeric values

- Increases the setting value by 1 step

Jumps 1 step back

Jumps to the start of the

guided operation

Press longer

(≥ 1 second)

Browses in menu structure -

Triggers a repetition of the command. The repetition rate

increases when pressing for a longer period

763.134 Z02 1913 coolcept_fleX 13

Page 14

EN

Button

Acti on

Function

Normal operation

Commissioning

At very low temperatures, the display may respond more slowly than usual.

Press briefly

- Moves the selection bar or the display content

downwards

- Moves the selection bar 1 position to the right when

setting numeric values

- Decreases the setting values by 1 step

Browses in menu structure -

Press longer

(≥ 1 second)

SET Press briefly

Triggers a repetition of the command. The repetition rate

increases when pressing for a longer period

- Jumps down by 1 menu

-

level

- Jumps to the diagram

view in certain menus

- A selected value starts flashing and can be changed

- Accepts any entered changes

- Changes the state of a control element (check box / radio

button)

Press longer

(≥ 1 second)

Answers a query dialogue

with Yes

Navigates 1 step forward

3.4 Display

The display shows the menus of the inverter (for an overview of the menus refer to section

7.1).

As a general rule, the menu name is located in the top left corner, and the corresponding

values or selection lines underneath.

14 763.134 Z02 1913 coolcept_fleX

Page 15

EN

The backlight of the display is switched on by pressing any button. The operating states of

the inverter are shown as follows:

Display Meaning

Backlight flashing red

with event message

The inverter is processing large data volumes.

It is not possible to enter user data

Fault

3.5 Cooling

The inverter may heat up during operation. This is a normal operating characteristic.

When the internal temperature rises above a certain value, an internal temperature controller regulates the power consumption from the PV generator. The operating temperature

decreases when power consumption is lower.

A fan disperses the waste heat inside the closed case evenly onto the case surface.

Cooling fins allow the heat to dissipate to the surrounding.

3.6 Grid monitoring

The grid monitoring in the device permanently monitors the grid parameters of the public

grid. If the grid monitoring detects a deviation of the grid parameters from the statutory requirements, the device switches off automatically. When the public grid meets the statutory

requirements again, the device switches on again automatically.

3.7 Data

3.7.1 Data communication

The device has the following communication interfaces:

• "LAN" connection (Ethernet for TCP/IP network) for the communication with a central

data server

• "COM2" connection (Modbus RTU) for the communication with e.g. an external energy

meter

• "COM1" connection (RS485 bus) for the communication with external devices, e.g. with

a data logger (in the case of StecaGrid ####_2: two connections)

For data analysis purposes, the inverter can provide a wide range of data via the RS485

and LAN interfaces (e.g. data logger). The RS485 bus also allows the connection to other

inverters.

763.134 Z02 1913 coolcept_fleX 15

Page 16

EN

3.7.2 Data display

The following data are shown on the display:

• voltage and current generated by the PV generator

• power and current fed into the public grid

• current voltage and frequency of the public grid

• generated energy yields on a daily, monthly and annual basis

• current error states and notes

• Information on the version of the device

3.7.3 Data storage

In the internal memory (EEPROM), event messages and energy yields are stored with the

date. The energy yields are stored for the specified period.

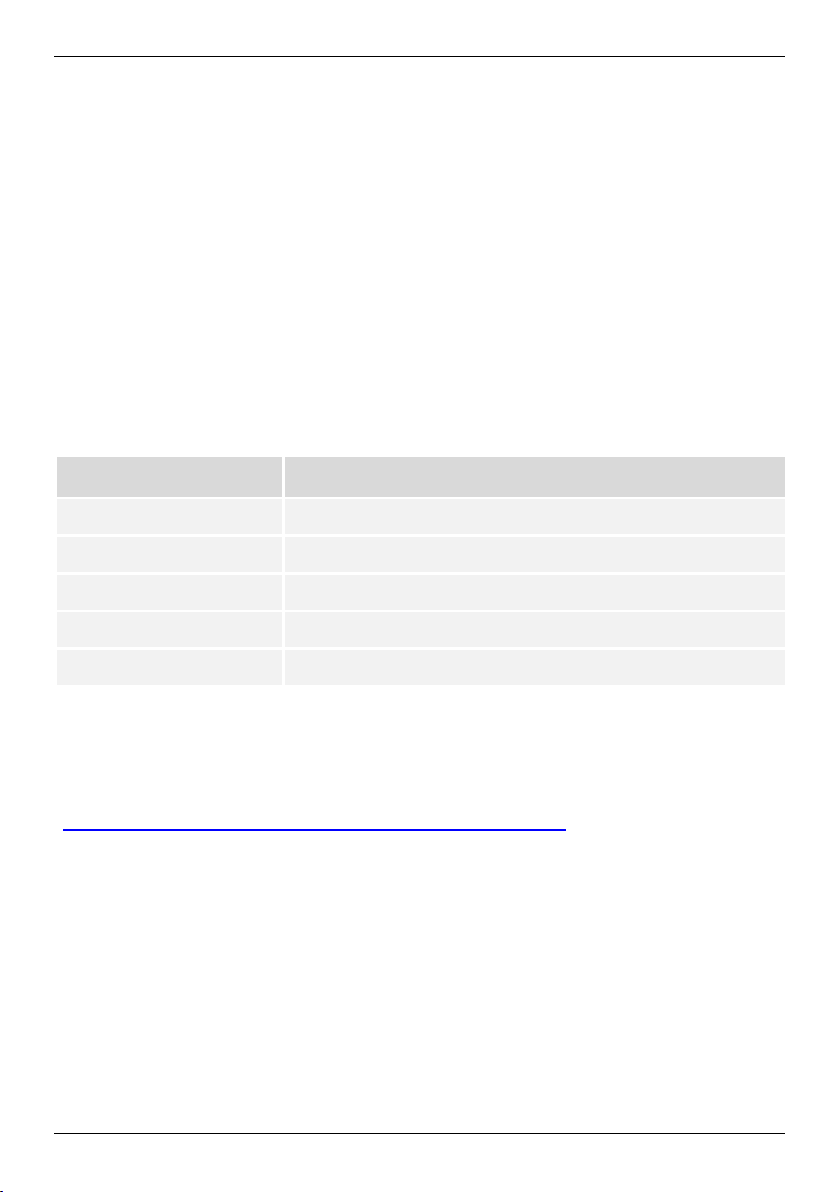

Energy yi eld Storage resolution/period

10-minutes values 31 days

Daily values 13 months

Monthly values 30 years

Annual values 30 years

Total yield Permanent

3.8 Network (TCP/IP)

Via the "LAN" connection, the device can send yield data and event messages to the

server of a web portal. The "Stecagrid Portal" web portal

(https://www.steca.com/index.php?Steca-sunCloud-Registration

resentation of the yield data.

In "Settings" > "Network", the operator can enter the network parameters in further submenu masks (refer to section 7.4.6).

16 763.134 Z02 1913 coolcept_fleX

) allows the graphical rep-

Page 17

EN

Set an external data logger prior to the connection. Follow the instructions of

3.9 "COM1" and "COM2" connections

The inverter can communicate with other device via the "COM1" and "COM2" connections.

Requirements for the communication:

• Both ends of the data connection are terminated.

• RJ45 standard cables or alternative data connecting cables are used as bus cables.

3.9.1 Connecting further master devices

the manufacturers.

Optionally, one of the following master devices can be connected to the "COM1" connection. These devices support the transfer protocol of the inverter.

• StecaGrid SEM, Smart Energy Manager:

- Interface to a ripple control receiver for a feed-in management that is in accordance

with the Renewable Energy Sources Act or EEG (German: Erneuerbare-EnergienGesetz)

• PC or notebook (with related software):

- Read inverter information out with "StecaGrid User Software"

(https://www.steca.com/index.php?StecaGrid-User-en).

- Connection to the inverter possible via optional RS485 adapter => USB; the adapter

is available at Steca, with part number 746.610 (IP21) or 737.707 (IP65).

- Transmission of firmware updates (only specialists).

• External data logger for professional system monitoring (recommended by Steca):

- WEB’log (Meteocontrol)

- Solar-Log (Solare Datensysteme)

- Energy-Manager (Kiwigrid GmbH)

763.134 Z02 1913 coolcept_fleX 17

Page 18

EN

The following inverters have compatible data interfaces and can be con-

1 External data logger

3 Inverter

4 Last inverter, terminated

3.9.2 Connecting further inverters

Inverters connected via the "COM2" connection operate as slave devices. RJ45 standard

cables (patch cables) for outdoor installation are suitable connecting cables.

2 First inverter

nected as slaves to the "COM1" and "COM2" connections:

- StecaGrid 2020

- StecaGrid 1500, 1800, 2000, 2300, 2500, 3010

- StecaGrid 3000, 3600, 4200 and StecaGrid 1500, 1800x

- StecaGrid 2000x, 2300x, 2500x, 3010x, 3000x, 3600x, 4200x

- StecaGrid 1511, 2011, 2511, 3011, 3611, 3011_2, 3611_2, 4611_2

Follow the instructions on addressing, termination, and approved data cables

in the operating instructions of these devices.

5 RJ45 standard cable (patch cable)

18 763.134 Z02 1913 coolcept_fleX

Page 19

EN

Device

Inverter

Solar-Log

WEB’log1)

Kiwigrid

Signal

Connection

COM1/COM2

Terminal block

RJ12

Terminal

3.9.3 Alternative RS485 data connecting cable

NOTE

Voltage may cause property damage.

►

Only have specialists manufacture the alternative data connecting cable.

Use a CAT 5 cable for the alternative data connecting cable in the case of long data connecting distances.

The total length of the data connecting cable shall exceed 1000 m.

If the alternative data connecting cable is connected to the RJ45 socket of the first inverter

and to the connection of the external data logger, the connections in the plug must be assigned in accordance with the following table.

Plug assignment of alternative RS485 data connecting cable

block

1 1 2 A Data A

2 4 4 B Data B

3 - - - -

4 - - - -

Contact

5 - - - -

6 - - - -

7 - - - -

8 3 6 GND Ground

NOTE

1)

Contact 1 of the RJ12 socket supplies 24 V DC!

The RS485 input of the inverter may be damaged.

►

Never connect the alternative data connecting cable to contact 1.

763.134 Z02 1913 coolcept_fleX 19

Page 20

EN

3.9.4 RS485 termination

Terminate the data connection at its beginning and at its end to ensure faultless data transmission:

• Beginning of the data connection: terminate external data logger in accordance with the

manufacturer's instructions.

• End of the data connection: insert termination plug into the vacant RS485 interface of

the last inverter.

3.9.5 RS485 addressing

All inverters are set to address "1" at the factory. For the master-slave communication,

each inverter requires its own address. The address is changed in the menu under "Settings" > "RS485 address".

• If possible, assign the addresses starting with 1 at the first inverter and ascending to the

last, as the number of possible addresses in the inverters is limited.

• The sequence of addresses should mirror the order of the mounted devices, to facilitate

the identification of the devices.

3.9.6 Connecting an energy meter (Modbus RTU)

The inverter is able to communicate with energy meters via the "COM2" connection. To do

this, the energy meter must meet the following requirements:

• The energy meter has been preprogrammed in the inverter.

• The energy meter measures the draw from the grid in positive direction (refer to instruc-

tions of the energy meter).

Modbus RTU data connecting cable

NOTE

Voltage may cause property damage.

►

Only have specialists manufacture the alternative data connecting cable.

Use a RJ45 standard cable or a CAT5 patch cable as data connecting cable.

20 763.134 Z02 1913 coolcept_fleX

Page 21

Plug connection of the Modbus RTU data connecting cable

Connection

COM2

Signal

This configuration meets both the requirements in accordance with VDE-AR-

To allow a rapid shutdown of the generating plant by the grid operator

Device Inverter

RJ45

1 -

2 -

3 -

EN

Contact

4 -

5 -

6 Data A

7 Data B

8 Ground

3.9.7 Remote shutdown by the grid operator and rapid shutdown

"Teledistacco" (Italy)

Assignment of contacts for rapid shutdown

For external fas shutdown, lines 3 and 8 of COM1 or COM2 are connected (e.g. with an

external relay). The following applies:

N-4105 and the requirements for a rapid shutdown ("Teledistacco") for

Italy in accordance with CEI 0-21.

(RAPID SHUTDOWN) via an external device used for control purposes, the

connections "COM1" or "COM2" must be connected as described below.

Assignment of contacts corresponds to the conductor number of the

RJ45 plug.

• Relay closes: Inverters connected to the bus disconnect from the grid.

• Relay opens: Inverters connected to the bus connect to the grid in normal operation.

763.134 Z02 1913 coolcept_fleX 21

Page 22

EN

4 Installing the inverter

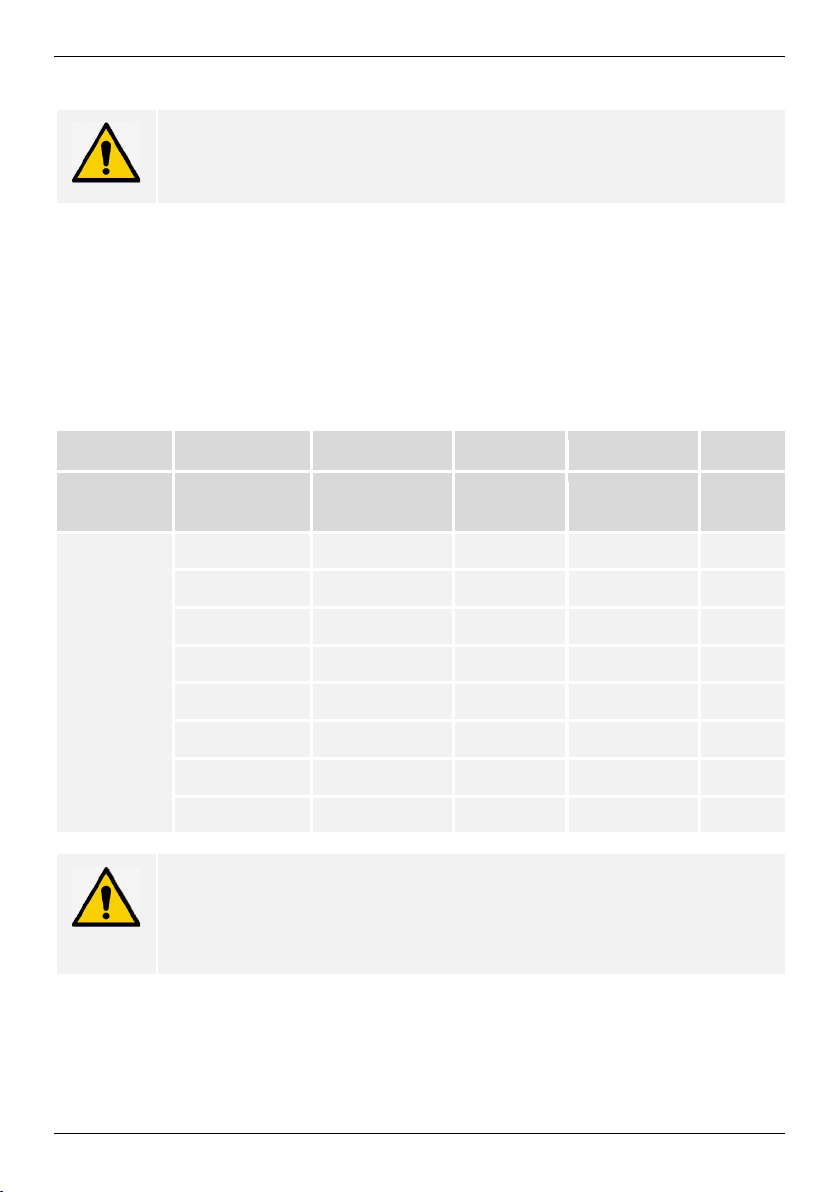

4.1 Safety instructions for installation

DANGER

Voltage

Under solar radiation, the PV generators and cables may be energised.

There is the risk of death due electrocution and electric discharge.

►

Disconnect the DC and AC connections from the power source prior to

any work on the inverter:

– Switch off all AC line circuit breakers and secure them against being

switched on again.

– Set the DC disconnector on the inverter to position '0' and secure it

against being switched on again.

– Disconnect the plugs of the DC cables (follow the instructions of the

manufacturer).

– Disconnect AC plug from the inverter: press locking hook on the

AC plug slightly an remove AC plug.

►

Only have specialists carry out any installation work.

►

Only connect the cables to the inverter when it is requested by the instructions.

►

Only connect SELV circuits to the RJ45 socket.

NOTE

Improper installation my cause performance reduction or damages on the inverter.

►

Ensure that the installation site meets the following requirements:

– The mounting surface and immediate surrounding must be: perma-

nently fixed, vertical, level, of low flammability, and not subject to constant vibration.

– The ambient conditions are within the permissible range (refer to chap-

ter 12).

– Open spaces are provided for around the device (above and under-

neath ≥ 200 mm, to the sides and in front ≥ 60 mm).

►

Do not install the device in stables where animals are kept.

►

Avoid exposure to direct sunlight of the device.

►

Ensure that the display can be easily read on the installed device.

22 763.134 Z02 1913 coolcept_fleX

Page 23

EN

Data transmitted via a public network are not protected from being accessed

by third parties.

Data transmission via a public network may cause additional costs.

►

Obtain information on costs possibly involved prior to the use of a public

network.

►

Use a public network at your own risk.

A type A residual current breaker (RCCB) is sufficient.

• Lay the cables such that the connection cannot come loose accidentally.

• Ensure that the fire safety measures of the building are not impaired when routing

cables for the device.

• Make sure that no inflammable gases are present.

• Observe all applicable installation regulations and standards, national laws and connec-

tion values specified by the regional power supply company.

• Observe the connection ratings specified on the type plate.

• Do not connect the DC cables to ground potential.

The DC inputs and the AC output are nor galvanically isolated from each other.

4.2 Mounting the inverter

4.2.1 Attaching the mounting plate

1. Place mounting plate on the mounting surface. The

locking plate (1) must point upwards. The retaining tabs

point to the front.

2. Fasten the mounting plate to the mounting surface with

4 screws. For the drilling pattern refer to chapter 16.

The mounting materials are not included in the scope of

delivery.

763.134 Z02 1913 coolcept_fleX 23

Page 24

EN

Inverter

Cable cross section

Power loss

Circuit breaker

4.2.2 Fixing the inverter to the mounting

plate

1. Place inverter centrally on the mounting plate. In

doing so, hold the inverter by the edge (1).

2. Slightly press on the inverter and slide it downwards.

The locating pins (4) on the inverter must hook into

the retaining tabs on the mounting plate.

3. Introduce detent (2) into the opening of the locking

plate (3). When the detent audibly click into place, the

device can no longer be lifted.

4.3 Preparing AC connection

DANGER

Voltage

There is a risk of death by electrocution.

►

Follow the safety instructions and warning notices in chapter 5.

4.3.1 Selecting AC cable

Install the circuit breaker prior to any work on the AC connection.

Depending on the power of the inverter, you may have to use different circuit breakers and

connecting cables.

AC cable

(with 10 m cable

length)

StecaGrid 1511 1.5 mm² 10 W

4.0 mm² 4W

StecaGrid 2011 1.5 mm² 18 W

4.0 mm² 6 W

StecaGrid 2511 2.5 mm² 16 W

4.0 mm² 11 W

24 763.134 Z02 1913 coolcept_fleX

B16 2.5 mm² 6 W

B16 2.5 mm² 11 W

B16

Page 25

EN

Inverter

Cable cross section

Power loss

Circuit breaker

1 AC plug housing

3 L connection (outer conductor)

AC cable

(with 10 m cable

length)

StecaGrid 3011

and

StecaGrid 3011_2

StecaGrid 3611

and

StecaGrid 3611_2

2.5 mm² 25 W

B16 or B25

4.0 mm² 15 W

2.5 mm² 35 W

B25

4.0 mm² 23 W

StecaGrid 4611_2 2.5 mm² 56 W

B25

4.0 mm² 35 W

4.3.2 Residual current circuit breaker

If the local installation specifications prescribe the installation of an external residual

current circuit breaker, install a residual current circuit breaker. In accordance with

IEC 62109-1, a type A residual current circuit breaker is adequate.

4.3.3 Assembling the AC plug

NOTE

If the instructions of the plug manufacturer are not followed when connecting

the AC plug, the cable and the device may be damaged.

►

Follow the instructions of the plug manufacturer.

Assemble the AC plug (refer to section "Assembly instruction for AC plug") and connect it.

220 V to 240 V grid voltage

Connect conductors N, L, and PE on the AC plug in 1-phase grid with 220 V to 240 V grid

voltage.

2 PE connection

4 N connection (outer conductor)

763.134 Z02 1913 coolcept_fleX 25

Page 26

EN

1 AC plug housing

3 L1 connection (outer conductor)

100 V to 127 V grid voltage

DANGER

Voltage

There is a risk of death by electrocution when connecting the phases L1, L2,

or L3 to PE or N.

►

Follow the safety instructions and warning notices in chapter 5.

The structure of 100 V to 127 V grid voltages differs from that of 220 V to 240 V grid voltages as it is not a 1-phase but a 2 or 3-phase grid.

2 PE connection

4 L2 connection (outer conductor)

Connecting AC plug to 2-phased grid

Connect the inverter between the L1 and L2 outer conductors.

1. Connect the N and L connection of the AC plug (1) between the L1 (3) and L2 (4)

outer conductors of the grid cable.

2. Connect PE cable to PE connection on the AC plug.

Connecting AC plug to 3-phased grid (not depicted)

In the 3-phase grid, there are 3 outer conductors in the cable:

1. Connect N and L connections of the AC plug between any 2 outer conductors

(between L1 and L2, or L1 and L3, or L2 and L3).

2. Connect PE cable to PE connection on the AC plug.

26 763.134 Z02 1913 coolcept_fleX

Page 27

Voltage distribution in the 2 and 3-phase grid

The voltage in 2 and 3-phase grids is the same in every outer conductor: 100 V to 127 V.

Assembly instruction for AC plug

EN

1. Guide cable through the plug housing. Slide plug housing (1) onto the cable.

2. Introduce wire ends (2) into the plug. Ensure that the bending radius of the cables is

large enough (at least 4 times the cable diameter).

3. Using a screwdriver (Pozidriv PZ1) (3), secure wire ends with clamping screws. Tightening torque: 0.8 to 1 Nm. Ensure that the clamping connection holds.

4. Slide plug housing onto the plug and tighten until a click sound is heard.

763.134 Z02 1913 coolcept_fleX 27

Page 28

EN

4.4 Preparing DC connection

DANGER

Voltage

There is a risk of death by electrocution.

►

Follow the safety instructions and warning notices in chapter 5.

►

Use the SUNCLIX plug connectors (DC plugs) included in the scope of delivery to ensure the specified degree of protection.

NOTE

If the DC plugs are not connected correctly to the DC cable, there is a risk of

short circuit. The inverter and modules may be damaged.

►

Connect counterparts to the DC connections to the DC cable ensuring correct polarity.

4.4.1 Fitting cable to DC plug

NOTE

Soiled, displaced, or damaged seals impair the strain relief and the impermeability.

►

Do not soil, shift, nor damage the seals during DC plug assembly.

1. Strip 15 mm of cable end of cable (1).

2. Release spring (2) upwards.

3. Introduce stripped cable end into the

DC plug until the cable end becomes

visible underneath the spring (2).

4. Press spring (2) against the stripped

cable end until it engages audibly. Ensure that the cable end is securely fastened.

5. Slide union nut (4) onto inset (3) of the DC plug.

6. Hold inset with a size 16 wrench and tighten the union nut (4) with a wrench, applying

a tightening torque of 2 Nm.

4.4.2 Preparing data connecting cable

You can use a standard cable (patch cable, CAT4) suitable for outdoor operation or an

alternative RS485 data connecting cable for the data connection. Observe section 3.9.4

when manufacturing an alternative data connecting cable.

28 763.134 Z02 1913 coolcept_fleX

Page 29

4.5 Connecting inverter and switching AC on

DC and AC cables may interfere with data transmission.

DANGER

Voltage

There is a risk of death by electrocution.

►

Follow the safety instructions and warning notices in chapter 5.

EN

►

Keep a distance of 200 mm between the data connecting cables

(RS485/Ethernet) and the DC/AC cables.

NOTE

If sealing caps are missing, moisture may get into the inverter.

►

Seal vacant RJ45 sockets with sealing caps.

1. If required, establish the data connection:

- Connect inverters (mater device and further connected inverters) with data connect-

ing cable(s).

- Switch on termination on the last inverter (slide switch).

2. Seal vacant RJ45 sockets with sealing caps.

3. Press DC plug firmly into the DC connection in the inverter until it engages audibly.

4. Insert AC plug into the AC connection in the inverter until it engages audibly.

5. Switch on the AC circuit breaker.

The display shows the start page of initial commissioning.

4.6 Performing initial commissioning

Any further actions required for the installation of the inverter cannot be carried out before

the initial commissioning has been performed. The initial commissioning is comprehensibly

described in chapter 5.

763.134 Z02 1913 coolcept_fleX 29

Page 30

EN

4.7 Setting the feed-in management

Depending on the country, PV generators must be able to reduce the fed-in active power.

The following products are suitable for implementing this legal requirement:

• StecaGrid SEM

• WEB’log from Meteocontrol

• Solar-Log from Solare Datensysteme

• Energy-Manager from Kiwigrid

An energy meter can be connected to the inverter via the Modbus RTU interface (refer to

section 3.9.7).

The feed-in management is set in the "Energy management"

submenu (refer to section 7.1).

• "Mode": switching the energy meter on or off

• "Dyn. feed in control": limiting the value of feed-in

• "Configuration": selecting an energy meter

4.7.1 Switching the energy meter on or off

• "Off": switching the energy meter off

• "Energymeter": switching the energy meter on

4.7.2 Limiting the dynamic feed-in value

1. Limit the power fed into the grid. You can enter values

starting from 0 W and incrementing by 10 W.

4.7.3 Selecting an energy meter

The inverter can only communicate with the energy meters that

have been preprogrammed.

1. Call the "Metertype" menu by pressing "SET".

2. Using " ", select a meter type from the list of preprogrammed energy meters.

3. Exit the menu with "ESC".

30 763.134 Z02 1913 coolcept_fleX

Page 31

EN

Not until all the checkboxes in the checklist have been marked and the

4.8 Switching DC on

Switching on the DC disconnector on the inverter finishes the

installation of the inverter. After approx. 2 minutes, the display

can show the fed-in power (provided that there is solar radiation).

1. Turn DC disconnector on the inverter to position 'I'.

5 Initial commissioning

After installing and switching on the inverter, the dialogue for initial commissioning starts

automatically. During initial commissioning, the user will navigate through the menu structure via the display.

If the initial commissioning is not completed, the dialogue for initial commissioning will start

again after switching on the inverter.

During initial commissioning, you will set the display language, the date, the time, the country, and the reactive power characteristic curve (only when prescribed for the selected

country).

A checklist with all the settings required for the initial commissioning is shown on the display.

The settings in the menus of the initial commissioning are performed via the operating buttons (for a comprehensive description of the function of the operating buttons, refer to section 3.3).

"Finish" menu is closed, will the initial commissioning be concluded.

5.1 Setting the display language

The default display language is English.

1. Select and confirm the desired language.

763.134 Z02 1913 coolcept_fleX 31

Page 32

EN

5.2 Setting the date and time

1. Select and confirm the desired date format.

2. Set and confirm date/time. The inverter will automatically

correct any invalid input.

5.3 Setting the country

With this menu item, you will set the country of use. Depending on the selection, the inverter will load the grid parameters specified for the country (refer to "Table of countries" in

the download area https://www.steca.com/index.php?coolcept-fleX-1-MPPT-en

https://www.steca.com/index.php?coolcept-fleX-2-MPPT-en).

The country can only be set once. In case of an incorrect input or change of country:

1. Please, contact Steca (ask for password).

2. In the "Del. country settin" menu, delete the set country (password-protected setting).

3. Perform the initial commissioning again.

If the respective country is not present in the country selection, select a country with stricter

specifications.

The selection of a country has no impact on the display language.

1. Select and confirm the country.

2. If a correction is required, return to the country selection

mask by pressing "ESC".

3. If the input is correct, confirm the set country (press "SET"

longer).

and

32 763.134 Z02 1913 coolcept_fleX

Page 33

5.4 Setting the reactive power

The "Reactive power" menu only appears when in the selected country a

The data for the reactive power control are not indicated in the consumer

EN

reactive power setting is prescribed.

counting arrow system but in the generator counting arrow system.

In the "Reactive power" menu, you can set the reactive power mode and display the

reactive power characteristic curve.

5.4.1 Setting the mode

1. Select and confirm the "Mode" menu.

2. Select and confirm the desired mode. The "Reactive

power" menu is displayed again.

If another mode than "cosPhi = 1" has been selected, the display in the "Reactive power" menu will additionally show the

"Load Defaults" and "Number of nodes" menu items. In this

case, additionally perform the following actions:

3. Select and confirm the "Load Defaults" menu.

4. Select the desired defaults and confirm with "SET". The

"Reactive power" menu is displayed again.

5. Select and confirm "Number of nodes".

6. Enter and confirm the number of nodes. The characteristic

curve is freely programmable through the nodes.

7. With "ESC" continue to the "Nodes" menu (for > 2 nodes)

or go back to the "Reactive power" menu (for ≤ 2 nodes).

763.134 Z02 1913 coolcept_fleX 33

Page 34

EN

"P (%)" cannot be changed for the first and the last node (000 %, 100 %).

5.4.2 Changing parameters of the nodes

The "Nodes" menu mask only appears when at least 3 nodes

have been entered.

1. Enter and confirm the desired value for "P" and "cos ψ".

2. Return to the "Reactive power" menu with "ESC".

5.4.3 Displaying the reactive power characteristic curve

The characteristic curve previously entered is displayed.

1. Return to the checklist with "ESC".

5.5 Finishing the initial commissioning

1. Select "Finish" from the checklist and confirm.

If the checklist has not been processed completely, the message "Settings are incomplete"

is displayed. In this case:

1. Press "SET". The checklist is displayed again.

2. Process the open items and finish the processing.

When all settings have been processed, a dialogue stating "Are all settings correct?" is displayed. In this case:

1. Check the settings.

2. If any settings have to be corrected, select the corresponding menu in the checklist and correct the settings.

3. If all the settings are correct: press "SET" longer. The inverter is restarted and synchronises itself with the grid.

After finishing the initial commissioning, you can set the feed-in management and switch

DC on (refer to section 4.7).

34 763.134 Z02 1913 coolcept_fleX

Page 35

6 Dismounting the inverter

The safety instruction from chapter 5 apply.

6.1 Switching AC and DC off

1. Turn DC disconnector on the inverter to position "0".

2. Switch the AC circuit breaker off.

6.2 Disconnecting DC connection from

inverter

DANGER

Voltage can be present at the DC-connection for up to 10 minutes after

switching off the DC circuit breaker.

There is a risk of death by electrocution.

►

Wait 10 minutes after switching off the DC disconnector.

EN

DANGER

The PV generator carries voltage when there is solar radiation.

There is a risk of death by electrocution.

►

Only have specialists carry out any work on the DC connection.

1. Disconnect plug of the DC cables as described in the instructions of the DC plug

manufacturer (refer to annex).

6.3 Disconnecting AC plug from inverter

1. Using a suitable tool, press locking hook on the AC plug slightly in and remove the

plug.

2. Ensure that none of the AC plug poles carries voltage with the help of a suitable voltage tester (do no use a phase testing probe).

763.134 Z02 1913 coolcept_fleX 35

Page 36

EN

6.4 Opening the AC plug

1. Open the rear cable gland.

2. Simultaneously press in the locking hooks on the left and on the right of the plug housing with a suitable tool.

3. Remove the upper part of the housing form the contacting part.

6.5 Removing inverter from mounting

plate

1. Press locking plate (3) towards the wall and hold it

there.

2. Push inverter upwards until the detent (2) can no

longer snap in.

3. Release the locking plate.

4. Hold inverter by the edge (1) with both hands and lift it

off upwards. The locating pins (4) must separate from

the retaining tabs of the mounting plate.

5. Remove inverter from mounting plate.

6. Unscrew the fastening screws of the mounting plate.

7. Remove mounting plate.

36 763.134 Z02 1913 coolcept_fleX

Page 37

EN

7 Operation

7.1 Menu structure

The menu structure of the inverter is divided into Status display, the Main menu und

Submenus, which themselves may contain further submenus.

When switching on the inverter, the "Output power" status display is always shown as start

image. From this status display you can go to all other menus.

763.134 Z02 1913 coolcept_fleX 37

Page 38

EN

Due to further technical development, changes of the menu structure are

For reasons of clarity, only the "" and "SET" operating buttons are depicted in the

menu structure. The individual functions of the operating buttons are described in section 3.4.

possible after delivery of this document. The current version of the menu

structure is available in the download area of our homepage.

7.2 Navigating the menu structure

• To go from one "Output power" status display to the other status displays: scroll through

the status displays with the "" operating buttons.

• To go from the "Output power" status display to the main menu: press "SET".

• To go to the other menu items within the main menu: scroll through the menu with the

"" operating buttons.

• To go from a menu item to a submenu: press "SET".

• To go to other menu items within a submenu: scroll through the submenu with the ""

operating buttons.

• To return from any menu to the "Output power" status display: press and hold "ESC" for

1 second.

7.3 Status displays

The status displays show various measured values. "Output power" and "Grid voltage"

have been preset in the factory and are always displayed. Further status displays that shall

be shown can be defined in "Settings" > "Meas. values".

7.3.1 Displaying output power

1 Menu name

2 Measurement with units

3 Time

4 IP address

In the event of too little solar radiation, the display does not show any measured value (e.g.

at night).

All other menus of the status display are similar in structure and are therefore not mentioned separately.

38 763.134 Z02 1913 coolcept_fleX

Page 39

EN

7.4 Main menu

In the menu items of the main menu and the submenus, you can call various data and perform various settings. The most important menu items are described in the following section. The respective figures show examples.

7.4.1 Displaying yields

Structure of the "Yield" menus:

• On the left: definition of the period (daily/monthly/an-

nual/total)

• On the right: individual yields per period

Via "SET" in the subsequent menu, the period of time displayed can be changed.

The periods contain the following number of individual yields:

- Daily yield: the last 31 days

- Monthly yield: the last 13 months

- Annual yield: the last 30 years

If the inverter had not been installed in one of the listed periods, the yield value "0" is displayed.

Yield (diagram representation)

By pressing "SET" in the menus with the daily, monthly and

annual yields, you can go to the respective diagram view.

7.4.2 Generator characteristic curve

The "Gener. ch. Curve" menu displays the PV generator characteristic curve graphically.

1 Y axis: power in kW

2 Vertex = MPP

3 X axis: input voltage in V

7.4.3 Event log

In the "Event log" menu, it is possible to call event messages sorted chronologically. By

pressing "SET", the list of event messages can be displayed. The event messages possible are described in the section 9.4.

763.134 Z02 1913 coolcept_fleX 39

Page 40

EN

7.4.4 Information

The "Information" menu item contains the following submenu items:

• "Contact info": data for establishing contact with Steca

• "System info" with:

- Product name

- Serial number of the inverter

- Software and hardware versions of the inverter

- Inverter address

- Version of the inverter's operating instructions

• "Country setting": set country and country-specific grid parameters; set during initial

commissioning

• "React.pwr.char. curve": diagram of the reactive power characteristic curve; only in cer-

tain countries

• "Network": network parameters, in part configurable in "Settings" > "Network"

- Hostname

- DHCP status: on/off

- Link status: condition of the network connection

- IP address of the inverter

- Subnet mask

- Gateway: IP address of the network gateway

- DNS address: IP address of the DNS server

- MAC: hardware address of the inverter

• "Results of last self-test" (only when Italy is set in the country setting)

• "Discovery Service": Yes = inverter is visible in the network for other participants of the

network. Yes = inverter is not visible in the network for other participants of the network.

40 763.134 Z02 1913 coolcept_fleX

Page 41

7.4.5 Self-test (only Italy)

Message

Cause

Remedy

If the self-test could not be run successfully, the inverter does no longer feed

The results of the self-test stored in the inverter can be shown on the display

During the self-test, the inverter tests its shutdown behaviour

with regard to too high / too low grid voltage and frequency

(7 test sections, approx. 40 minutes).

You will start the self-test by pressing "SET" longer. While the

self-test is running, the measured values are shown on the display.

If the self-test has been successful, you can exit the menu by pressing "SET".

If a measured value lies outside of the required tolerance, the self-test aborts.

The "Self-test failed" message displayed has to be confirmed by pressing "SET". The, the

self-test has to be repeated as soon as possible.

If not all the required conditions for performing the self-test have been met, an error message appears on the display:

EN

MSD not ready

An error was detected

Invalid grid conditions

Not enough sunlight

in.

►

Repeat self-test as soon as possible.

in "Information" > "Self-test".

The self-test does not start

because the inverter is not

operational

The self-test does not start

because an internal error is

present

Self-test abort due to

invalid network conditions,

e.g. in the event of an AC

voltage that is too low

Self-test does not start or

aborts due to the fact that

the solar radiation is too

low, e.g. in the evening or

at night

Repeat the self-test later,

when the inverter is feeding

in

If this error occurs

repeatedly, inform the

installer

Repeat the self-test later

Repeat the self-test when

there is sufficient solar

radiation

763.134 Z02 1913 coolcept_fleX 41

Page 42

EN

7.4.6 Settings

From the "Settings" main menu you can go to the submenus with configurable parameters

by pressing "SET".

Self-explanatory menus are not described in the following section.

Input mode

The "Input mode" menu is only visible in StecaGrid ####_2 devices with two PV inputs. It is

possible to select the functioning mode of the connected PV inputs: "Independent" or "Parallel".

"Independent"

Both PV inputs (MPP tracker) operate independently from each other.

This mode is applied when connecting two PV generator fields that are differently oriented

to each other, e.g. east/west roof mounting.

"Parallel"

Both PV inputs (MPP tracker) operate synchronously. In this, the MPP tracking is determined by the first PV input.

This mode is applied when mounting two PV generator fields next to each other, e.g. when

the input current exceeds the maximum permissible value in accordance with the type

plate. The PV cables must be connected via a wye junction.

Energy management

The settings related to the energy management are described in "Feed-in management"

(refer to section 4.7). The energy management includes the following submenus:

• "Mode": energy meter can be switched on or off

• "Dyn. feedin control": parameters for feed-in can be set.

• "Configuration": energy meters can be defined more precisely with the "Meter type" and

"Meter position" submenus

Measured values

In the "Meas. values" submenu, you determine which menus

the status display shall contain.

The following measured values are available:

1)

• "Output power": output power of the inverter

• "Current day yield": day yield since 00:00

• "PV voltage": voltage supplied by the PV generators

• "PV current": current supplied by the PV generators

• "PV performance": power generated by the PV generators

42 763.134 Z02 1913 coolcept_fleX

Page 43

• "Grid voltage": voltage at the inverter connection1)

To set up the TCP/IP network connection, an input of parameters is required.

it is not possible to set up the TCP/IP network

• "Grid frequency": frequency of the public grid

• "Internal temp": internal temperature of the inverter

• "Derating": reason for the power reduction

Possible reasons:

- Internal temperature too high

- User default for power limit

- Frequency too high

- Control by grid operator (feed-in management)

- Delayed power increase after start

• "Max. daily power": maximum power of the current day

2)

• "Abs. max. power": highest power fed in2)

• "Day max. yield": max. achieved day yield

2)

• "Operating hours": operating hours on the grid (including hours at night)

• "Total yield ": yield since commissioning

EN

• "CO

1)

2)

saving": CO2 saving since commissioning

2

Measured value is always displayed (it is not possible to switch it off)

Can be reset to zero via "Settings" > "Reset max. vals.".

RS485 address

The address of the RS485 connection can be entered.

Network

By pressing "SET", you can go to the following submenus: "DHCP", "IP address", "Subnet

mask", "Gateway", "DNS", and "Web portal", which itself has submenus.

Without knowing the parameter

connection.

►

If necessary, seek the advice of another specialist.

DHCP is activated in the inverter ex factory. Therefore, the IP address is automatically assigned to the network.

763.134 Z02 1913 coolcept_fleX 43

Page 44

EN

The parameters that are required for network communication

(e.g. with a web portal) are configurable.

The following parameters can be opened and edited by pressing "SET":

• "DHCP"

• "IP address": IP address of the inverter

• "Subnet mask": information on the network and address space

• "Gateway": IP address of the network gateway

• "DNS address": IP address of the DNS server

• "Web portal": parameters related to the web portal

with the following submenus:

- "Setup": selection of the web portal

- "Retransmission": renewed transmission of existing data

- "Connection test": test of the internet connection

Alarm

Acoustic signals for event messages can be switched on or off (factory setting = switched

off):

• 2 sounds: warnings

• 3 sounds: errors

Backlight

The behaviour of the display lighting can be set:

• "Off": no backlight

• "Automatic": the backlight is switched on for 30 seconds after pressing a button

• "Feed-in mode": backlight depends on feed-in

- "No feed-in": switched on for 30 seconds after pressing a button and, then, switched

off

- "Feed-in": switched on for 30 seconds after pressing a button and, then, dimmed

44 763.134 Z02 1913 coolcept_fleX

Page 45

7.4.7 Service

Legally required parameters can be changed in the service menus. Any

EN

change may have a negative effect on the performance of the inverter and

possibly even break a law.

►

Only specialists that can ensure that the changes do not violate any applicable regulations and standards are allowed to perform any changes on

the parameters of the service menus.

To go to the service submenus, the "" operating buttons

must be pressed simultaneously for 3 seconds.

Some dialogues of the service menus are password-protected.

This password can be obtained from Steca's support department (refer to chapter 15).

Setting the reactive power characteristic curve

Setting the reactive power characteristic curve is only required if this is specified for the

selected country.

Deleting the country setting

The selected country setting can be deleted. This task is password-protected (contact to

Steca is required). The inverter restarts and displays the guided initial commissioning

again.

Voltage limits

The voltage limits (peak values of the voltage) can be set by defining the following values:

• "Lower value"

• "Upper value"

763.134 Z02 1913 coolcept_fleX 45

Page 46

EN

Frequency limits

1)

The frequency limits

can be set by defining the following val-

ues:

• "Lower value"

• "Reactivation value"

• "Start value"

• "Upper value"

1)

Switch-on threshold for power reduction (when frequency is too high)

P(f) activation delay

The function of active power limitation for frequency transient

has an activation delay which can be changed.

Voltage limits ø

Voltage limits ø (mean values of the voltage) can be set by defining the following values:

• "Upper value"

• "Lower value"

Power limiter

The output power of the inverter can be limited up to a minimum

of 500 W.

When the power is manually limited, the status display shows

the "Power reduction" symbol and "Reason: user default".

46 763.134 Z02 1913 coolcept_fleX

Page 47

EN

Fixed voltage

Using the inverter for fixed voltage operation is not considered an intended use. If, nevertheless, the inverter shall be used for fixed voltage operation, consultation with Steca is required.

NOTE

The PV generator must be suitable for feeding in a fixed voltage.

Fixed input voltages in the inverter may damage unsuitable PV generators or

reduce their yield.

►

The parameter for fixed voltage are password-protected. The specialist

can only change these parameters after consultation with Steca.

The device can adjust the input voltage to a manually configurable value. Thereby, the automatic setting of the MPP (MPP

tracking) is switched off.

The entered parameter value may lie between the maximum

and minimum input voltage in 1 V increments.

A possible example for application of fixed voltage operation

are hydropower plants.

PowerPeak Scan

With the PowerPeak scan, the energy yield of the inverter can

be improved in the case of partial shadowing of PV strings (e.g.

by parts of buildings, trees or power lines). The current MPP is

intentionally left for a short time to hereby find the better MPP.

The scan is only performed approx. every 10 minutes to impair

the total energy yield caused by the brief power reduction during the scan process as little as possible.

The PowerPeak scan can be switched off in "Settings" >

"Service" > "PowerPeak Scan".

763.134 Z02 1913 coolcept_fleX 47

Page 48

EN

Automatic start of the transmission of unencrypted data.

Factory setting

Resetting the data to factory settings deletes the following data:

• Yield data

• Event messages

• Date and time

• Country setting

• Display language

• Network settings

The inverter restarts. The initial commissioning must be performed again.

All parameters

This menu item allows the change of further ENS parameters (only service technician).

8 Web portal

After establishing the network connection, the inverter automatically starts

data transmission to the server. If automatic transmission is not wanted:

►

Remove network cable.

Or:

►

Deactivate data transmission in "Settings" > "Network".

With the monitoring portal sunCloud, permanently free of charge, online monitoring of

PV generators is easy and comfortable. Registration of the operator and the system in the

sunCloud portal is possible at: https://steca.powerdoo.com

Operator guidance in the sunCloud portal is easy and allows intuitive navigation. After registering and connecting the TCP/IP interface LAN to a PC, the portal displays data (e.g.

yield data and performance of the connected PV generator).

The local network settings for the connection to the server have been set on the inverter.

Setting the local network can be done automatically or manually:

.

• Automatic: if the DHCP prescribes the IP address in the network automatically, no settings are required on the inverter.

• Manual: if the IP address in the network is not assigned automatically, the IP address

must be set manually on the inverter in "Settings" > "Network" (refer to section 7.4.4).

The URL of the web portal is saved permanently in the inverter and cannot be changed.

48 763.134 Z02 1913 coolcept_fleX

Page 49

EN

9 Fault elimination

Event messages indicate faults: the display will be flashing red and a text will describe the

fault present.

Typical display of an event message

Event messages contain the following information:

1 Event message type

2 Date/time of the event message

3 Note on the status of the event:

Active = fault is still present

Date/time = fault was eliminated at the indicated time

4 Cause of the fault

5 Consecutive number / total number in the list of events

6 Acknowledged / not acknowledged fault

Events are acknowledged by pressing the "ESC" or "" operating buttons.

9.1 Event message type

Information

The inverter has detected an error which does not impair feed-in. There is no need for the

user to intervene.

Warning

The inverter has detected an error which may cause reduced yields. It is recommended to

eliminate the cause of error.

Error

The inverter has detected a serious error. The inverter does not feed in as long as the error

is present.

Inform the installer.

763.134 Z02 1913 coolcept_fleX 49

Page 50

EN

By acknowledging the event message, the staff confirms that they have no-

9.2 Alerting behaviour

ticed the event message. The fault, however, persists. The cause of the fault

is not eliminated thus.

New event messages appear immediately on the display. An event message disappears

after the operator has acknowledged the event message or eliminated the cause of the

fault.

If event messages, whose cause has been eliminated, have not yet been acknowledged,

the status display will show an not opened message: .

9.3 Operation

In the main menu, select the "Event log" submenu.

• "SET": a list of the event messages appears.

• "": scroll through the list.

• "NEW": select new event messages by pressing "SET" and acknowledge by pressing

"ESC" or "".

9.4 Event messages

The following table contains examples for event messages and their elimination.

Event message Description Type

Data transfer failed

Grid islanding detected

FE not connected

50 763.134 Z02 1913 coolcept_fleX

A setting has failed, e.g. during initial

commissioning, because it has not been

transmitted correctly.

- Perform the setting again.

- If this error persists, inform the installer.

The grid does not carry voltage. The inverter

must not feed into the grid for safety reasons.

The inverter is switched off as long as this

error condition is present. The display remains

dark.

- If the error occurs repeatedly, inform the

installer.

Functional ground is not connected. The

inverter must not feed into the grid for safety

reasons.

- Inform the installer.

Page 51

EN

Event message

Description

Type

Residual current too high

Boost converter

malfunction

Device overheated

Boost converter has wrong

HW version

Boost converter not

connected

The residual current flowing from the positive

or negative input through the PV generators to

ground exceeds the legally permissible value.

The inverter is switched off automatically as

long as this error condition is present.

- Inform the installer.

An internal component of the inverter is

defective. The inverter does not feed into the

grid or feeds into the grid with reduced power.

- Inform the installer.

Despite power reduction, the maximum

permissible temperature has been exceeded.

The inverter does not feed into the grid until

the permissible temperature range has been

reached.

- Check mounting conditions.

- If the error occurs repeatedly, inform the

installer.

The inverter cannot detect an internal

component, or the component does not match

the other components. The inverter does not

feed into the grid.

- Inform the installer.

The connection of the internal components is

disrupted. The inverter does not feed into the

grid.

- Inform the installer.

Boost converter defect

The boost converter is defective; the inverter

does not feed into the grid or feeds into the

grid with reduced power.

- Inform the installer.

Boost converter not

- Inform the installer.

recognised

Intern. info.

- If the error occurs repeatedly, inform the

installer.

Intern. warning

- If the error occurs repeatedly, inform the

installer.

Intern. error

- If the error occurs repeatedly, inform the

installer.

763.134 Z02 1913 coolcept_fleX 51

Page 52

EN

Event message

Description

Type

Isolation error

No branding

No connection to the

energy meter

L and N swapped

CountryCode failed

Country parameters invalid

The insulation resistance between positive or

negative input and ground falls below the

permissible value. The inverter does not feed

into the grid.

- Inform the installer.

The inverter has wrong or inaccurate device

data. The inverter does not feed into the grid.

- Inform the installer.