Installation and Operating Instructions

STEAMASTER

®

Electric Steam Cleaner Model: HPJ-2S

General Installation

06/14

- 1 -

IMPORTANT!

Please carefully review the contents of this

Manual prior to set-up and operation of your

steam cleaner. File this Manual in a safe place.

Pub. No. 908-F

Installation and Operating Instructions

Electric Steam Cleaner Model: HPJ-2S

INST ALLATION AND ASSEMBLY INSTRUCTIONS

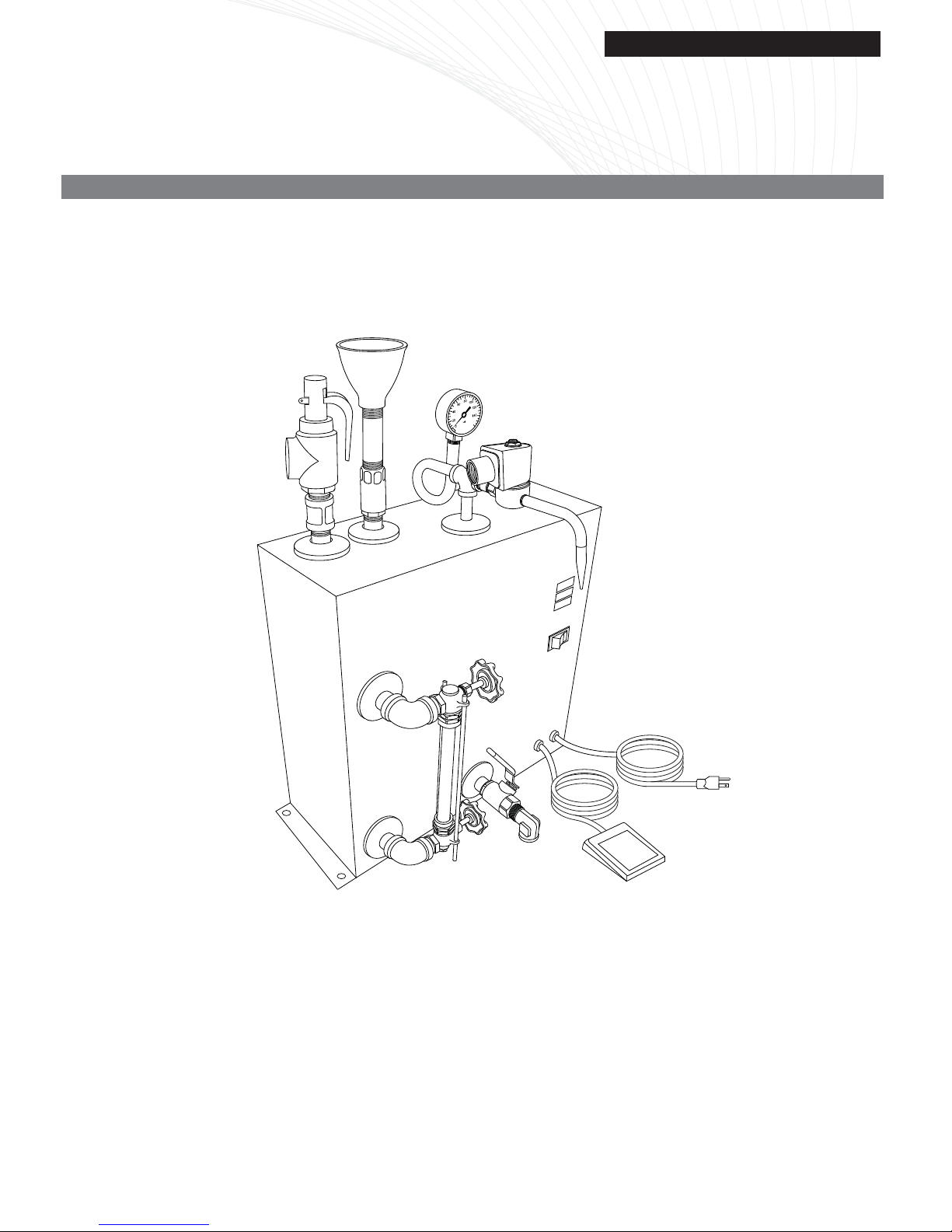

1. The Steamaster HPJ-2S steam cleaner should only be

placed on a sturdy work table, and positioned for accessible use and drainage.

2. Place the Steam Release Foot Pedal on the floor in a

convenient area for ease of foot operation.

3. Make certain the 3-Position Toggle Switch on the side of

the machine is OFF which is in the center position. The

switch turns off all electrical power to the machine.

4. Before plugging in the electrical cord, check you ELECTRIC CURRENT which must correspond to that indicated

on the nameplate located on the side of the machine.

Steamaster HPJ-2S units (except 240-Volt special orders)

are wired for 15 amps, 120 Volt operation in any standard

120 Volt outlet. However, we recommend an isolated

(20-amp line).

WARNING: The Safety Value must be pointed in a direction in

which it can release without causing personal injury or property

damage. If necessary have a plumber pipe the outlet to a safe

location. When piping the discharge outlet, do not pipe it in a

manner which would restrict it's flow.

OPERATING INSTRUCTIONS

Air Venting the System. The following procedure will expedite

the water fill procedure and operation.

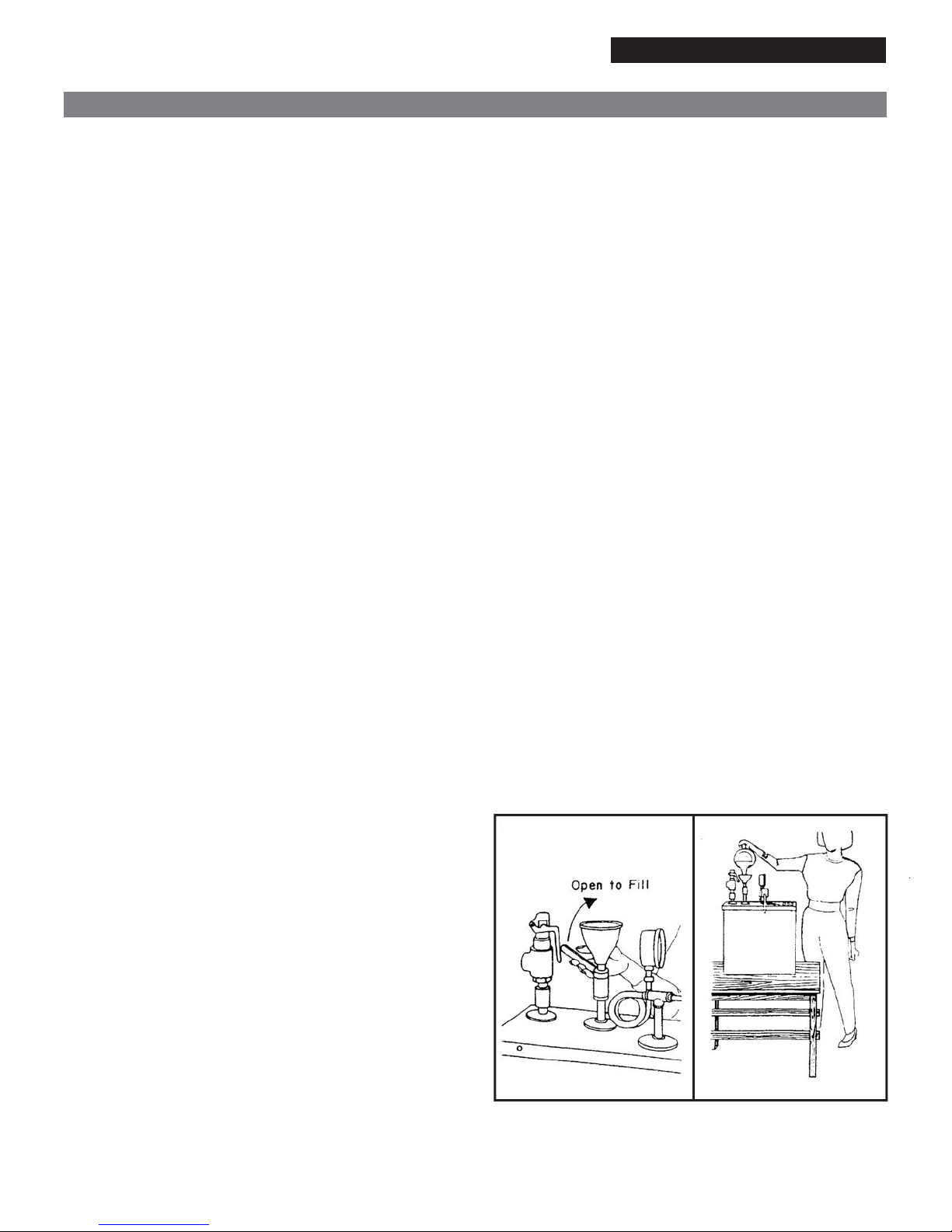

1. Open Funnel Valve (Fig. 1) by raising handle at top of

machine.

IMPORTANT! Water in machine MUST always be kept above

LOW LEVEL MARK on Glass Gauge (½" from bottom of Glass

Gauge). Water must be added at this time.

2. Place the Rocker Switch in the Fill position. This will

energize (open) the steam solenoid valve and allow air to

escape when water is added to the machine.

3. Fill with clean water until water level reaches the HIGH

LEVEL MARK on glass gauge, about 6½ quarts (Fig. 2).

Place Rocker switch in the OFF position. Close the funnel

valve.

4. Place Rocker Switch in the Heat Cycle position. The

HEATING Light will now go on, indicating that machine is

now heating up and building steam pressure.

5. Allow machine to heat up (at least 45 minutes) until

maximum (75-80 PSI) is reached. Check pressure gauge.

HEAT light will go out indicating when the machine has

reached maximum pressure. You will notice that HEAT

Light comes on from time to time, as the pressure drops,

and must be built up again.

6. Use the Foot Pedal to release steam, or place the Rocker

Switch to the STEAM position to get constant steam.

NOTE: At each usage, do not steam directly on jewelry as

there is condensation in the steam release pipe which must be

released before steaming jewelry. Depress the Steam Release

Foot Pedal to discharge condensation into sink or other vessel.

After condensation has been discharged (approximately 5

seconds), the machine will be ready to steam jewelry.

7. To refill the Steam Cleaner during operation: Place the

Rocker Switch in the FILL STEAM position. This will

release steam pressure. Check Steam pressure Gauge.

When there is NO STEAM PRESSURE, open the Funnel

Valve and fill to the HIGH WATER MARK level in the

Water Level Gauge. Close Funnel Valve. Return Rocker

Switch to Heat Cycle position and allow cleaner to build

pressure.

8. When Machine is Finished for the Day - Place Rocker

Switch in the "OFF" position.

For Best Cleaning Results - Always depress Steam Release

Foot Pedal for about five seconds to remove excess condensation. Carefully hold item to be cleaned With tweezers approximately one inch below the Steam Nozzle.

To clean trays of merchandise, hold tray about five Inches

below Steam Nozzle. Move tray In a rapid side to side motion

while steam cleaning.

NOTE: Do not attempt to clean soft, porous stones such

as Opals. Nor, is it advisable to steam clean precious

stones which have cracks. Do not steam clean stones

exposed to extreme cold temperatures until they reach

room temperature.

SPECIAL PRECAUTIONS

Live steam can cause bodily injury. Exercise care not to come

in contact with the Steam Line during operation. Fittings on the

machine are HOT and should not be touched during operation.

Place the Steam Release Foot Pedal in a location where it will

not be accidentally depressed.

NOTE: Every time water is added to the steam cleaner air

enters the boiler and will cause the pressure to build to a level

which is a few pounds higher than normal. This condition will

return to normal when the air is released by releasing some

steam.

06/14

- 2 -

Pub. No. 908-F

Installation and Operating Instructions

Electric Steam Cleaner Model: HPJ-2S

TROUBLESHOOTING YOUR STEAM ASTER

MODEL HPJ-2S

When starting up, machine fails to operate:

1. Check to see if plug is in electrical outlet. Is outlet good?

2. Check fuses in your main power supply.

3. Recheck your start-up operation steps.

Machine cuts off while operating:

A low water condition can activate Manual Reset Low Water

Cut-Off Switch, reset light will come on. If this should

happen, follow this procedure.

1. Bleed out all steam pressure in generator.

2. Fill water up to high level mark on Glass Gauge.

3. Push Reset Button on side of machine.

NOTE: Reset Button is to be used ONLY when machine

cuts-off due to a low water condition!

(When low water cut off is activated) under normal

conditions it is not necessary to use reset button.

4. Pilot Light will go on indicating that machine is now

operational.

IMPORTANT! If Pilot Light fails to go on after following

above instructions, check fuses in your main power supply.

Condensation forms each time machine is used:

This is a normal condition. Always depress lever of Steam

Release Pedal Valve for about five seconds to remove

excess condensation at each usage.

MAINTENANCE INFORMATION

During the first week of operation only, drain boiler at least

every other day. In order to extend the life of the machine,

drain boiler at least once each week under 10 Ibs. of steam

pressure, with electric current turned off.

After draining, flush out boiler with plain water, then refill

machine to high level mark on Glass Gauge. Drain Valve is

located on lower left side of the machine.

The exterior metal cabinet and parts should be wiped off

on a regular basis with a damp cloth to maintain the new

appearance of the machine. Do not allow the parts to

become clogged with dirt and grime.

IMPORTANT! Water in machine MUST always be kept

above LOW level mark on Glass Gauge (½" from bottom of

Glass Gauge) in order to protect and extend the operating

life of the heating element.

WARNING: Steam slowly erodes the sight glass. To

prevent the sudden breakage or explosion of the gauge

glass. It must be inspected on a regular basis for signs of

deterioration.

Sight Glass Inspection: The sight glass should be

inspected for deterioration each time the unit is refilled.

Scratches, corrosion, chips, surface flaws, cracks, or nicks

weaken the glass. To examine for these imperfections shine

a very bright concentrated light at about 45 degree angle.

Anything which glistens and catches the fingernail or any

star-shaped or crescent-shaped mark which glistens is

cause for replacement. Any gauge glass which appears

cloudy or roughened and cannot be cleaned with commercial

glass cleaners, should be replaced.

Model HPJ-2S - General Arrangement

80

60

100

40

120

140

20

psi

0

16 3/4"

16 3/4"

18"

06/14

FILL/STEAM

HEATING

RESET

HEAT

OFF

CYCLE

MANUAL

RESET

6 1/2"

11 1/2"

- 3 -

25 1/2"

Pub. No. 908-F

Installation and Operating Instructions

Electric Steam Cleaner

MODEL HPJ-2S PARTS LISTING

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17A

17B

17C

18

19

19A

20

21

22

23

24

PART NO.

N/A

N/A

006-6348

007-4114

007-4102

007-1212

005-1014

007-1260

006-3207

005-2138

007-4105

006-3216

007-1102

005-2074

005-2122K

005-2023

007-1240-1

007-1240-2

007-1240-3

007-5275

006-3215

005-2017

007-1205

006-4201

007-1122

002-1075

007-1129

Tank

Cabinet

Heating Element 120V, 1.5kW

Pressure Control

Thermodisc High Limit Reset Switch

Water Gauge Fixture Top and Bottom

Elbow, ½”NPT

Water Gauge Friction Washer

Water Gauge Rubber Washer

Gauge Glass Packing Nut

Gauge Glass, ⅝” x 8”L

Aluminum Nozzle

¼" Steam Solenoid Assembly

Pig Tail

¼” Adaptor with Strainer (inside)

"L" Shape Nipple (¼" Male THD x ⅛" FTHD

Indicator light Fill/Steam, Orange

Indicator light Heat, Orange

Indicator light Reset, Red

Rocker Switch

Funnel

½” x 3” nipple

½" Ball Valve, Fill/Drain

Gasket for heating element

Electric Foot Switch – Pedal

Cord with plug

Pressure Gauge

DESCRIPTION

QTY

1

1

1

1

1

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

Model: HPJ-2S

ITEM

To order replacement parts:

When ordering replacement parts for your Steam Cleaner

please provide your authorized Steamaster Sales Agent

with both the part number and description.

wiring Diagram

25

26

27

120 VAC

PART NO.

007-1214

005-1101

005-2109

BK

GN

WT

HEATING LIGHT RESET LIGHT

½" Safety Valve 100psi

¼" x 1½", nipple

Street Elbow ½" x ½"

3

TEMPERATURE

HEATING

ELEMENT

CONTROL

4

18

SWITCH

DESCRIPTION

FILL

HEAT

FILL

HEAT

5

LOW WATER

CUT-OFF

1717

FOOT SWITCH

22

STEAM

SOLENOID

VALVE

FILL/STEAM

LIGHT

17

QTY

1

1

1

13

HPJ-2S Exploded View

24

19

24

14

19A

25

11

20

10

6

8

7

9

2

Details "A"

Details "A"

IMPORTANT:

Please fill out and retain for your records. See label on machine for Serial

Number.

Model No.

Serial No.

Date Purchased

Purchased from

27

26

15

17

18

4

20

STEAMASTER CO., INC.

East Rutherford, NJ 07073

Tel. (201) 933-5800

13

16

12

5

23

3

21

22

25 East Union Ave

Fax (201) 933-0746

1

06/14

- 4 -

Pub. No. 908-F

Loading...

Loading...