St. Croix Auburn, Lancaster Operation & Maintenance Manual

Auburn

Operation & Maintenance

Manual

Table of Contents

St. CROIX FEATURES........................................................................................ 1

INSTALLATION ................................................................................................. 2

PREVENTING CHIMNEY PROBLEMS ......................................................... 2

SATISFACTORY PERFORMANCE ................................................................ 2

SHELLED CORN ................................................................................................. 2

OPERATING INSTRUCTIONS ........................................................................ 3

Combustion air damper............................................................................ 3

Pre-Lighting Instructions ......................................................................... 4

Lighting Your Stove ................................................................................ 5

Damper Adjustment ................................................................................ 5

Thermostat Control................................................................................... 6

Diagnostic Features ................................................................................... 6

Shutting the Stove Off .............................................................................. 7

Safety Features .......................................................................................... 7

MAINTAINING THE STOVE ........................................................................... 8

Clinker Removal........................................................................................ 8

Daily Maintenance ................................................................................... 8

Periodic Maintenance ........................................................................... 10

Yearly Maintenance .............................................................................. 11

Electrical Layout ..................................................................................... 11

SAFE OPERATION ........................................................................................... 12

TROUBLESHOOTING .................................................................................... 12

ELECTRICAL LAYOUT ..................................................................................13

WARRANTY...................................................................................................... 14

403

Your Dealer Is:

Dear St. Croix Corn Stove Owner:

Congratulations! Your purchase of a St. Croix corn stove places you among a select group of

individuals who have demonstrated their concern about residential heating efficiency and our

environment.

This owner's manual is designed to help you obtain maximum benefit from your St. Croix corn stove.

Please read this manual in its entirety BEFORE operating your corn stove. During the manufacturing

process every effort has been expended to ensure that each St. Croix corn stove meets the highest

quality standards of material and workmanship.

Here are some important aspects of corn stove installation and operation which you must observe in

order to obtain maximum comfort and safety from your new St. Croix corn stove.

1. Have your new St. Croix corn stove installed by trained, qualified personnel.

2. Use only clean, dry quality corn for optimum performance in your St. Croix corn stove.

3. Faithfully adhere to the maintenance program described in this manual. Thank you for selecting a

St. Croix corn stove as the environmentally preferred answer to your residential heating needs.

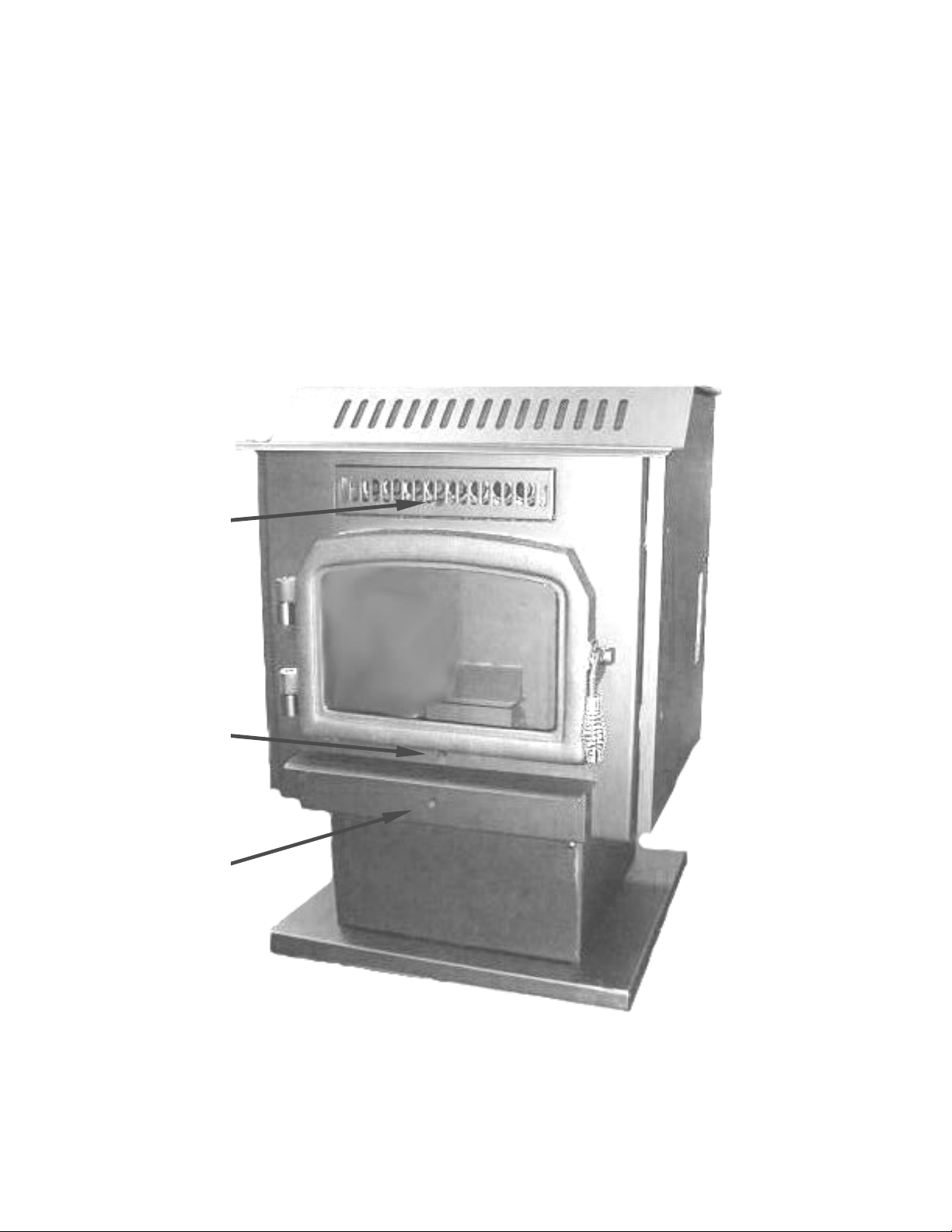

Coal Rake

Tube

Scraper

Rod

Rod

St. Croix

Auburn

Corn stove

Features

User Friendly

Digital

Control Board

With Diagnostic

Features

Thermostatic

Control Option

Available

Patent Pending

Burn System

Slide-out

Bottom Rod

Large Ash Pan Area

With Quick Release Latches

1

Operation and maintenance

Operation and Maintenance

of the

Auburn corn Stove

SAVE THIS OPERATIONS AND

MAINTENANCE MANUAL

CAUTION: Operate this unit only with the fuel hopper lid closed. Failure to do so may result in

emission of products of combustion from the hopper under certain conditions. Maintain hopper

seal in good condition.

INSTALLATION

Proper installation is essential for safety,

effective operation, warranty coverage,

insurance requirements and to meet local

building codes. Installation requirements are

described in the Installation Manual included

with your new stove.

PREVENTING CHIMNEY PROBLEMS

When burning corn care should be taken in

how the venting system is installed. To burn

corn the moisture content should be 15% or

less. This is much higher that the moisture

content of wood pellets and can result in

condensation forming in the venting system

in certain installations. The chimney system

should stay within the warm envelope of the

house as much as possible. Only penetrate

the exterior of the home where the exhaust

system will terminate. Remember

condensation from a corn stove is

detrimental to the venting system. Only

buy venting systems that are warranted

when burning corn.

The chimney and chimney connector should

be inspected at least once every two months

during the heating season to prevent the

system from getting plugged with Fly ash.

Clean the exhaust system if needed. Use of

an appropriately sized chimney brush or the

Services of a Professional chimney sweep are

recommended.

SHELLED CORN

SATISFACTORY PERFORMANCE

Shelled corn must be 15% or less moisture

content. The keys to satisfactory performance

are: proper operation of the stove, diligent

maintenance and burning only dry, clean, quality

corn. Corn dust must be screened prior to using.

NOTE: Corn with excessive grain dust must be

screened, by sifting with 3/16" mesh screening.

Large pieces of cob may plug the auger.

Clinkers and ash are a by-product of burning corn

and are not caused by your stove. Stove performance

can be quickly and severely reduced if poor quality

corn is used. Contact your dealer for more information on where to get high quality corn to burn in

your new corn stove.

Store corn in a tight container use other methods to

ensure they do not become rain soaked or absorb

moisture from damp or wet floors. This will also

prevent rodents from becoming a problem. Do not

store corn within stove installation clearances or

within the space required for clinker removal.

The stove is not warranted against damage caused by

poor quality corn, incorrect operation, poor

maintenance or incorrect installation.

2

Operation and maintenance

OPERATING INSTRUCTIONS

A different type of heater. The corn stove is

neither a cordwood stove nor a furnace. Its

operation and maintenance differ from the traditional wood stove. FOLLOW THESE

OPERATING INSTRUCTIONS EXACTLY AS

STATED TO ENSURE SAFE AND RELIABLE

OPERATION.

1. Carefully read this “Operation and Mainte-

nance” manual in its entirety BEFORE lighting

your stove for the first time.

2. Obtain final inspection and approval of

installation from local building officials.

3. Carefully clean all marks off the gold plated

parts before the first fire is lighted. Use a soft

cloth and a “Windex” type cleaner. Caution:

Never use an abrasive cleaner on any plated or

painted parts of the stove.

4. Have your dealer demonstrate all the opera-

tional and maintenance steps necessary for proper

use of the stove. Sign and return the warranty

card, to the address listed on the back page.

5. Some odors may be given off during the first

few hours of burning during initial break-in.

These odors are normal and not harmful.

However, ventilating the room until the odors

disappear is recommended.

6. The stove will become HOT while in

operation. Keep children, clothing and furniture

away from all stove surfaces.

WARNING: Direct contact with the stove

while operating may cause skin burns.

7. To avoid the possibility of smoke and/or sparks

entering the room always keep firebox and ash

pan doors closed whenever the stove is operating.

8. A certain amount of carbon monoxide may be

produced within the stove as a by-product of

combustion. All exhaust vent connections must

be sealed with RTV silicone to assure a gas tight

seal. Any leaks into a confined area caused by

faulty installation or improper operation of the

stove could produce dizziness, nausea and in

extreme cases, death.

9. An outside source of combustion air is strongly

recommended and is required on all mobile home

installations. If room air is used to supply

combustion air, room air starvation, operation of

exhaust fans and icing of air vents can adversely

affect proper stove operation.

10. Smoke detectors, installed in the same general

area as the stove, may be activated if the stove door

is left open and smoke is allowed to enter the area.

Combustion air damper.

This is one of the most important areas of setting up

your stove to burn corn. (See Figure 1 on page 4)

Your stove is equipped with an air inlet damper. The

purpose of this damper is to adjust combustion

airflow to match the characteristic of each specific

air inlet and chimney configuration. The damper is

preset at the factory with a setscrew. The damper

will most likely only need s small adjustment during

the break in period. To know if the damper needs to

be adjusted you should learn to recognize how the

corn burns in St. Croix corn burning system. The

burn pot should be “BALANCED”. What this

means is the corn that is being augered into the burn

pot rapidly turns into glowing coals. If you see a lot

of unburned corn in the pot an adjustment is needed.

In an unbalanced pot the corn will quickly stick

together and prevent the proper flow of combustion

air. The pot will overload and the fire will go out.

Once the damper is adjusted for your installation, it

should not be necessary to make any further

adjustments to the damper. The combustion air is

automatically increased every time the feed rate is

advanced on the control board. If you notice a

difference in the operation of the stove, check to see

if the stove needs cleaning or if the moisture content

of your corn is too high. Break-in requires the

burning of 15 bags of corn or continuous burn for

two weeks. If you experience problems adjusting

the stove after the break-in period contact your

dealer.

For instructions on adjusting the damper see

“Damper Adjustment on page 5.

3

Operation and maintenance

Pre-Lighting Instructions

When lighting your stove for the first time or any

time you have run out of corn you will need to fill

the hopper with corn. Corn is fed from the hopper

to the burn pot by an auger. A high torque motor

that is capable of doing SERIOUS harm to

fingers drives the auger. Keep fingers and other

objects away from the auger.

WARNING: The auger can start at any time

while the stove is running

CAUTION: The coal rake must be pulled out

and the slide bottom pushed in to operate the

stove. (See stove layout on page 1)

WARNING: The fire door and ash pan doors

must be in the latched position during normal

operation.

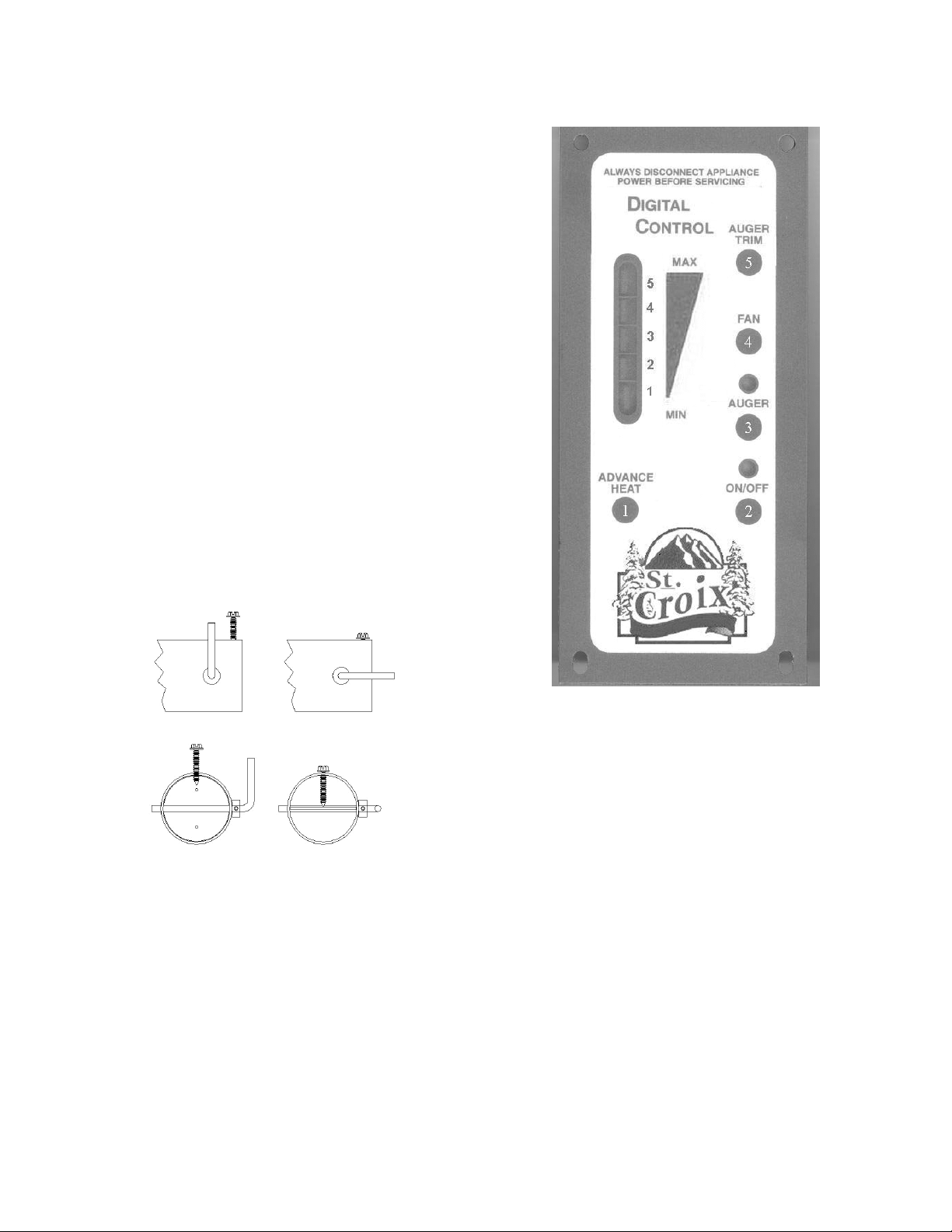

Air Intake Damper Positioning

Fully Closed Fully Open

Figure 1. Air Inlet Damper

The buttons on the board function as follows:

(Refer to Figure 2. The touch pad buttons are

labeled with the white numbers 1 through 5)

1. The heat advance button (1) will advance the

setting between level 1 and 5. Once you reach

level 5, it will drop back to level 1. Each level has

a LED light to indicate where the board is set.

Operation and maintenance

Figure 2. Control Box

2. The On/Off button (2) turns the stove on and

also acts as the toggle switch to reset the board after

the board switches to Diagnostic mode.

3. The auger button (3) will allow the customer to

manually auger corn into the burn pot on start up

when needed.

4. The fan button (4) allows for adjusting the

Exhaust fan voltage on level 1 only. Push the button

and the LEDs flash once to decrease the voltage 5

volts. Push the button a second time and the LEDs

flash twice to decrease the voltage another 5 volts.

Pushing the button a 3

rd

time will reset the voltage to

the normal setting. This adjustment is only to be

used under rare circumstances when there is a

problem with over drafting chimneys and the stove

is going out on the #1 setting because of too much

draft.

4

Loading...

Loading...