St. Croix Afton Bay, Prescott EX, York Insert, Prescott EXL Installation Manual

t.

S

Croix

PELLET STOVES

Save this

Installation Manual

General Information ............................................................................... 1

Installation Check List ......................................................................... 2

Approved Installations ......................................................................... 3

Exhaust Venting ................................................................................... 4

Combustion Air ................................................................................... 17

Afton Bay, Prescott EX, Prescott EXL, York Insert

Table of Contents

Venting: Approved Materials ................................................. 4

Venting: Determining Materials ............................................. 6

Venting: Stove Dimensions..................................................... 7

Venting: Through Combustibles ............................................ 11

Venting: Into an Existing Chimney ........................................ 13

Venting: Termination Requirements ...................................... 15

Electrical Connections ......................................................................... 18

Floor Protection .................................................................................... 19

Clearances to Combustible Materials ..................................................... 20

Mobile Home Installation ....................................................................... 22

Thermostat Installation and Operation .................................................... 24

Notes .................................................................................................... 25

GENERAL INFORMATION

SAFETY PRECAUTIONS

SAFETY NOTICE: The stove must be properly installed in order to prevent the possibility

of a house fire! These installation instructions must be strictly observed! Failure to follow

instructions may result in property damage, bodily injury or even death.

The stove’s exhaust system works with negative combustion chamber pressure and a

slightly positive chimney pressure. Therefore, it is imperative that the air intake and

exhaust system be airtight and installed correctly. Do not install a flue damper in the

exhaust vent of this unit.

Do not connect this unit to a chimney flue serving another appliance or to any air distribution duct or system.

BUILDING PERMIT

Contact the local building officials to obtain a permit and information on any local installation restrictions and inspection requirements.

DEFINITION OF “STOVE”

The word “stove” as used in this manual is interpreted to mean a wood pellet burning

freestanding stove, insert, or zero-clearance fireplace unless otherwise noted.

SAFETY TESTING

The stove has been independently tested and listed by Warnock Hersey Laboratories in

accordance with the proposed ASTM Standards and the applicable portions of UL 1482

and ULC S627/B366.2, and Oregon Administrative Rules 814-23-901 through 814-23909, stating requirements for installation as a stove, heater or hearth insert for masonry,

metal and zero clearance fireplaces and for mobile home installations. The safety listing

label is located inside the right-side access panel.

DISCLAIMER OF WARRANTY

Since Even Temp Company has no control over the installation of a stove, Even Temp

Company grants no warranty, implied or stated, for the installation of a stove and assumes no responsibility for any special, incidental or consequential damages.

1

INSTALLATION CHECK LIST

BEFORE INSTALLATION

1. Thoroughly read and understand this manual. SAVE THIS MANUAL.

2. Check with local authorities and obtain needed permits.

3. It is strongly recommended that the stove receive a Dealer’s “Pre-delivery Check” prior to

installation.

4. We recommend installation by a qualified professional.

BEFORE STARTING THE STOVE FOR THE FIRST TIME

1. Outside combustion air is recommended for all installations. Use only approved parts.

Check that the outside air inlet is connected to draw fresh air from outside the building.

2. All joints of PL vent and single wall stainless steel pipe should be fastened by at least 3

screws and correctly installed. (Follow vent manufacturer’s instructions).

3. Any “plated” areas should be cleaned thoroughly with a glass cleaner such as Windex® and

a soft cloth just before lighting the first fire. This will remove finger prints and oils that may

cause a permanent stain or mark on the gold plating the first time it is heated. Never use an

abrasive cleaner or material on any plated or painted surfaces. Never clean the plated

surfaces when stove is hot.

4. WARNING: The high temperature paint on this stove may take several hours of burning at

a high fuel setting to cure fully. During this time, an odor which is not harmful, may be

evident. When odors are present, the area around the stove should be well ventilated.

5. Caution: The high temperature paint can be easily scratched prior to burning the stove.

2

Approved Installations

The St. Croix are approved for Conventional and Mobile Home installations as:

1. A FREESTANDING stove on an approved floor pad or as a Hearth Mount stove.

2. A FIREPLACE Insert when installed on the Hearth, in a masonary or Zero Clearance type

Fireplace.

3

EXHAUST VENTING

VENTING: APPROVED MATERIALS

The stove requires a venting system, approved for pellet stoves by a certified testing lab. Approved

pellet stove venting materials are: 1) PL vent, a double wall vent with a stainless steel liner; and 2)

Single wall rigid or flexible stainless steel pipe. PL Vent and Single wall vent is available through

manufacturers such as: Energy Vent LTD, James A. Ryder, Simpson DuraVent and Selkirk Metalbestos

and is carried by many local pellet stove dealers. In this manual approved venting will be referred to

a “PL vent” or “Single wall vent”. All single wall vent adaptors must be stainless steel.

NOTE: TYPE “B” GAS VENT MUST NOT BE USED IN ANY PELLET STOVE INSTALLATION.

Examples of venting system components follow:

High temperature ceramic roping reduces potential fly ash escaping through joints.

Stainless steel inner liners resist corrosive flue gas damage to the system..

Flex pipe is 430 stainless steel, 4 ply construction with a total thickness of approx. .07 inches.

4

TYPICAL PL VENT COMPONENTS

RAIN CAP WALL THIMBLE CHIMNEY SUPPORT

VERTICAL OR ADAPTER BRACKET

HORIZONTAL

ADJUSTABLE SINGLE TEE SINGLE REDUCTION TEE DOUBEL TEE

LENGTH W/ TEE CAP W/ TEE CAP W/ TEE CAP

PIPE

PIPE ADAPTER INCREASER 45 DEGREE 90 DEGREE

ELBOW ELBOW

5

VENTING: DETERMINING MATERIALS

TYPE OF MATERIALS:

1. PL Vent must be used for venting all Freestanding stoves and the Zero Clearance Fireplace.

2. PL Vent must be used for all Inserts. Exception: Single wall stainless steel may be used

inside a fireplace or fireplace chimney. (No clearances to combustibles are needed on single

wall stainless steel adaptors, rigid or flex pipe installed within a fireplace or inside a chimney.)

3. A clean out “tee” (PL Vent or “Quick-Connect Exhaust”) must be installed directly to the

stove and at the bottom of each vertical run of the exhaust system. These tee’s are to assist in

periodically cleaning the pipe. Single or double clean-out tee’s may be used. The exhaust

system must be installed so the entire system can be cleaned without disassembly.

NOTE: ADHERE TO THE PL VENT CLEARANCES TO COMBUSTIBLES AS REQUIRED.

STRICTLY OBSERVE THE PL VENT MANUFACTURER’S SAFETY SPECIFICATIONS.

QUANTITY OF MATERIALS:

1. It is recommended that the vent system be installed with a minimum of three feet (3’) of

vertical rise above the stove exhaust port.

FAILURE TO PROVIDE THE NATURAL DRAFT THAT RESULTS FROM A VERTICAL RISE

MAY RESULT IN SMOKE BEING RELEASED INTO THE HOUSE WHEN ELECTRICITY TO

THE UNIT IS INTERRUPTED WHILE BURNING OR SMOLDERING PELLETS REMAIN IN

THE BURN GRATE.

2. Additional vertical exhaust venting should be provided when using:

a. More than one (1) elbow or tee; and/or

b. Horizontal runs of over three (3) feet.

3. For a venting system ending in a horizontal run, the exhaust pipe must be terminated by a

listed end cap or a PL vent elbow (45 or 90 degrees). Note: End caps or elbows must vent

exhaust gases away from the building.

4. For termination above the building roof line a rain cap is required.

5. The exhaust pipe on all stoves is 2.95” O.D. to accommodate a 3” pellet stove pipe adaptor.

Your installation may require the use of 4” vent. (3” to 4” adapters are available for both PL

Vent and Single Wall Vent.) Use the following guidelines:

6

Type of installation: Size: Recommendation

A. Less than 10’ horizontal: 3” Acceptable

B. 10’ to 12’ horizontal: 4” Recommended

C. Over 12’ horizontal: 4” Required

(A horizontal installation over 12’ is

D. Less than 15’ vertical: 3” Acceptable

E. Over 15’ vertical: 4” Required

F. Above 4000’ elevation: 4” Recommended

Note: Four (4) inch vent may be used in all installations. If in doubt, use 4” vent.

NOT RECOMMENDED)

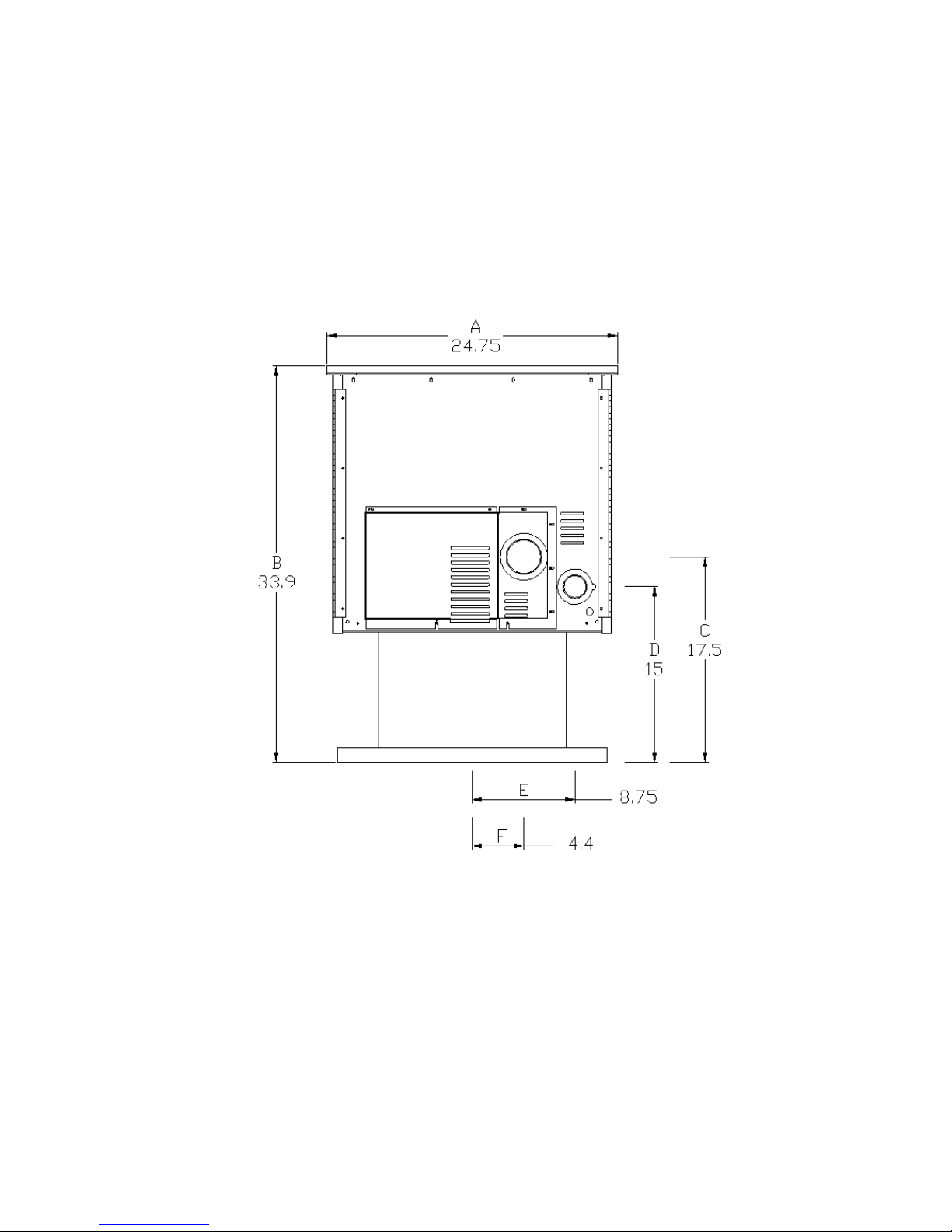

Afton Bay dimensions

A – Width of stove

B – Height of stove

C – Center of exhaust tube from floor

D-Center of intake tube from floor

E-Center of stove to center of intake tube

F-Center of stove to center of exhaust

7

Prescott EX Dimensions

A – Width of stove D-Center of intake tube from floor

B – Height of stove E-Center of stove to center of intake tube

C – Center of exhaust tube from floor F-Center of stove to center exhaust tube

8

Loading...

Loading...