State Water Heaters TPD-140-140, TPG-600-2500, TPG-140-140, TPD-600-2500, TPO-140-140 Instruction Manual

...Page 1

MODELS TPG-140-140 thru 600-2500

INCLUDING TPX/TPO & TPD

COMMERCIAL GAS, OIL AND GAS/OIL TANK-TYPE WATER HEATERS

• INSTALLATION • OPERATION • SERVICE • MAINTENANCE • LIMITED WARRANTY

ASME

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY.

PLEASE READ THOUROUGHLY BEFORE USING

APPLIANCE.

WARNING – PROPANE MODEL

Water heaters for propane gas are different from natural gas models. A natural gas heater will not function

safely on propane gas and no attempt should be made to convert a heater from natural gas to propane gas.

Propane gas must be used with great caution. It is highly explosive and heavier than air. It collects first in the

low areas making its odor difficult to detect. If propane gas is present or even suspected, do not attempt to

find the cause yourself. Ventilate the room, then call your gas supplier or service agent. Keep area clear until

a service agent has been called.

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE

PRINTED IN U.S.A. 1202 PART NO. 09063370T

1

Page 2

FOREWORD

This manual is intended to be used in conjunction with other

literature provided with the heater. This includes power burner

and related gas control information. It is important that this manual

and the additional publications be reviewed in their entirety before

beginning any work.

The installation should be made in accordance with the regulations

of the local code authorities and utility companies, which pertain

to this type of water heating equipment.

MAKE SURE the fuel on which the heater will operate is the same

as that specified on the heater model and rating plate.

THESE HEATERS MUST NOT BE INSTALLED ON

COMBUSTIBLE FLOORS.

Instructions for periodic testing of various water heater safety

devices are included in section titled COMBUSTION

TABLE OF CONTENTS

PAGE

FOREWORD ................................................................................ 2

IDENTIFICATION ......................................................................... 2

GENERAL SAFETY INFORMATION ........................................... 3

Precautions ............................................................................. 3

Grounding Instructions ............................................................ 3

Improper Combustion .............................................................. 3

Liquid Petroleum Models ......................................................... 3

Extended Non-Use Periods (TPG Models Only) ..................... 3

Insulation Blankets .................................................................. 3

High Altitude Installations ........................................................ 3-4

FEATURES .................................................................................. 4

Water Temperature Control ..................................................... 4

INSTALLATION INSTRUCTIONS ................................................ 4

Required Ability ....................................................................... 4

Uncrating ................................................................................. 4-5

Locating the Heater ................................................................. 5

Leveling ................................................................................... 5

Clearances .............................................................................. 5

Air Requirements ..................................................................... 5-6

Thermal Expansion (Closed System) ...................................... 6

Venting .................................................................................... 6

Vent Connector........................................................................ 6

Barometric Draft Control Assembly ......................................... 6-7

Water Line Connections .......................................................... 7

Thermometers (Not Supplied) ................................................. 7

Relief Valve ............................................................................. 7

ARRANGEMENT REQUIREMENTS AND SERVICE

RECOMMENDATIONS.

In the absence of local codes, the installation must comply with

the instruction as outlined in the latest publication of ANSI booklet

NFPA-54/ANSI Z223.1

“NATIONAL ELECTRICAL CODE”, or Canadian Gas

70

“NATIONAL FUEL GAS CODE”, NFPA No.

Association booklet CAN 1-B149.1 or CAN 1-B149.2 for Canadian

Installations also be followed.

These manuals can be purchased from the American Gas

Association Laboratories, 8501 East Pleasant Valley Road,

Cleveland, OH 44131 or the National Fire Protection Association,

1 Batterymarch Park, Quincy, MA 02269-9101, or Canadian Gas

Association Laboratories, 55 Scarsdale Road, Don Mills, Ontario,

Canada M3B 2R3.

PAGE

Gas Piping ............................................................................... 7-8

Purging .................................................................................... 8

Gas Meter Size (City Gases Only) .......................................... 8

Gas Pressure Regulator .......................................................... 8

Wiring ...................................................................................... 8-11

TWO UNIT MANIFOLD INSTALLATION ..................................... 11

OPERATION ................................................................................ 11

Important ................................................................................. 11

General .................................................................................... 11

Filling ....................................................................................... 11

Combustion Air Requirements

And Service Recommendations .............................................. 11-12

MAINTENANCE ........................................................................... 12

General .................................................................................... 12

Flushing ................................................................................... 12

Draining ................................................................................... 12

Sediment Removal .................................................................. 12

Lime Scale Removal ............................................................... 12-13

Relief Valve ............................................................................. 13

Power Burner ........................................................................... 13-14

Cleaning Flues - TPO & TPD Only .......................................... 14

Vent Systems .......................................................................... 14

Barometric Draft Control ......................................................... 14

TROUBLESHOOTING ................................................................. 14-15

Replacement Parts .................................................................. 15

LIMITED WARRANTY ................................................................. 16

This manual is supplemented by the power burner manual. All information, including start-up and

maintenance relating to the burner, can be found in that manual.

IDENTIFICATION

The heater and burner mounted identification plates provide

valuable information. When ordering parts or inquiring about a

unit, be sure to include serial number, model number and type of

fuel.

2

Page 3

GENERAL SAFETY

INFORMATION

PRECAUTIONS

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN

UNDERWATER. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the control

system and any gas control which has been under water.

IF THE UNIT IS EXPOSED TO THE FOLLOWING, DO NOT

OPERATE HEATER UNTIL ALL CORRECTIVE STEPS HAVE

BEEN MADE BY A QUALIFIED SERVICEMAN.

The venting of the water heater should be inspected by a qualified

service technician at the time of installation and periodically

thereafter to ensure a down-draft condition does not exist.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND

VENTILATING AIR. ADEQUATE AIR FOR COMBUSTION AND

VENTILATION MUST BE PROVIDED FOR SAFE OPERATION.

LIQUID PETROLEUM MODELS

Water heaters for propane or liquefied petroleum gas (LPG) are

different from natural gas models. A natural gas heater will not

function safely on LP gas and no attempt should be made to

convert a heater from natural gas to LP gas.

1. EXTERNAL FIRE.

2. DAMAGE.

3. FIRING WITHOUT WATER.

4 SOOTING.

Heater must be protected from freezing downdrafts during

shutdown periods.

GROUNDING INSTRUCTIONS

This water heater must be grounded in accordance with the

National Electric Code and/or local codes. These must be followed

in all cases.

This water heater must be connected to a grounded metal,

permanent wiring system; or an equipment grounding conductor

must be run with the circuit conductors and connected to the

equipment grounding terminal or lead on the water heater.

CHEMICAL VAPOR CORROSION

WARNING

CORROSION OF THE FLUEWAYS AND VENT SYSTEM MAY

OCCUR IF AIR FOR COMBUSTION CONTAINS CERTAIN

CHEMICAL VAPORS WHICH BREAK DOWN INTO ACIDS AT

HIGH TEMPERATURE. SUCH CORROSION MAY RESULT IN

FAILURE AND RISK OF ASPHYXIATION.

LP gas must be used with great caution. It is highly explosive

and heavier than air. It collects first in the low areas making its

odor difficult to detect at nose level. If LP gas is present or even

suspected, do not attempt to find the cause yourself. Ventilate

the area, then call your gas supplier or service agent. Keep area

clear until a service call has been made.

The presence of LP gas may be difficult to detect. The use of a

propane gas detector is recommended.

Only trained LP professionals should conduct the required safety

checks in accordance with industry standards.

EXTENDED NON-USE PERIODS

WARNING

HYDROGEN GAS CAN BE PRODUCED IN A HOT WATER

SYSTEM SERVED BY THIS HEATER THAT HAS NOT BEEN

USED FOR A LONG PERIOD OF TIME (GENERALLY TWO

WEEKS OR MORE). HYDROGEN GAS IS EXTREMELY

FLAMMABLE. To reduce the risk of injury under these conditions,

it is recommended that a hot water faucet be opened for several

minutes before using any electrical appliance connected to the

hot water system. If hydrogen is present, there will probably be

an unusual sound such as air escaping through the pipe as the

water begins to flow. THERE SHOULD BE NO SMOKING OR

OPEN FLAME NEAR THE FAUCET AT THE TIME IT IS OPEN.

Spray can propellants, cleaning solvents, refrigerator and air

conditioning refrigerants, swimming pool chemicals, calcium and

sodium chloride (water softener salt), waxes, and process

chemicals and typical compounds which are potentially corrosive.

Do not store products of this sort near the heater. Also, air which

is brought in contact with the heater should not contain any of

these chemicals. If necessary, uncontaminated air should be

obtained from remote or outside sources. The limited warranty is

voided when failure of water heater is due to a corrosive

atmosphere. (Refer to the limited warranty for complete terms

and conditions).

IMPROPER COMBUSTION

WARNING

ATTIC AND/OR EXHAUST FANS OPERATING ON THE

PREMISES WITH A WATER HEATER CAN RESULT IN CARBON

MONOXIDE POISONING AND DEATH.

OPERATING OF THESE FANS CAN PRODUCE A DOWN

DRAFT IN THE AREA OF THE WATER HEATER PREVENTING

THE PRODUCTS OF COMBUSTION FROM EXHAUSTING

THROUGH THE CHIMNEY OR VENT PIPE.

INSULATION BLANKETS

Insulation blankets available to the general public for external

use on gas water heaters are not approved for use on your

State water heater. The purpose of an insulation blanket is to

reduce the standby heat loss encountered with storage tank water

heaters. Your State water heater meets or exceeds the ASHRAE/

IES 90.1b-1992 standards with respect to insulation and standby

loss requirements making an insulation blanket unnecessary.

WARNING

The application of an insulation blanket will void the warranty for

this water heater. Furthermore, the application of an insulation

blanket may interfere with the operation of this water heater,

possibly resulting in property damage, injury, or death.

HIGH ALTITUDE INSTALLATIONS

Your State water heater has been designed to operate at altitudes

above 2000 feet, provided that requirement was specified at the

time of order. The firing rate will be specified on the water heater

rating plate.

3

Page 4

Note: Some gas utility companies derate the heating value of the

supplied gas at high elevations. Your authorized State Start-Up

Agent must adjust for actual heating valve of the gas at the time

of start-up.

FEATURES

WATER TEMPERATURE CONTROL

The water temperature is controlled by two thermostats. One

thermostat is located near the top of the tank and the other is in

the lower part of the tank. The upper thermostat must be set at

least 5°F higher than the lower thermostat. In the case where the

water heater has electronic thermostats, this differential has been

factory set and cannot be changed.

The thermostat temperature dials are accessible by opening the

control compartment cover.

WARNING

THIS WATER HEATER IS EQUIPPED WITH AN ADJUSTABLE

THERMOSTAT TO CONTROL WATER TEMPERATURE. HOT

WATER TEMPERATURES REQUIRED FOR AUTOMATIC

DISHWASHER AND LAUNDRY USE CAN CAUSE SCALD

BURNS RESULTING IN SERIOUS PERSONAL INJURY AND/

OR DEATH. THE TEMPERATURE AT WHICH INJURY OCCURS

VARIES WITH THE PERSON’S AGE AND TIME OF EXPOSURE.

THE SLOWER RESPONSE TIME OF CHILDREN, AGED OR

DISABLED PERSONS INCREASES THE HAZARDS TO THEM.

NEVER ALLOW SMALL CHILDREN TO USE HOT WATER TAP,

OR TO DRAW THEIR OWN BATH WATER. NEVER LEAVE A

CHILD OR DISABLED PERSON UNATTENDED IN A BATHTUB

OR SHOWER.

THE WATER HEATER SHOULD BE LOCATED IN AN AREA

WHERE THE GENERAL PUBLIC DOES NOT HAVE ACCESS

TO SET TEMPERATURES.

SETTING THE WATER HEATER TEMPERATURE AT 120°F WILL

REDUCE THE RISK OF SCALDS. Some states or provinces

require settings at specific lower temperatures.

Below you will find listed the appropriate time-to-burn relationship

for normal adult skin. Short repeated heating cycles caused by

small hot water uses can cause temperatures at the point of use

to exceed the thermostat setting by up to 20°F (11°C). If you

experience this type of use, you should consider using lower

temperature settings to reduce scald hazards.

Temperature Time to Produce 2nd & 3rd

Setting Degree Burns on Adult Skin

180°F (82°C) Nearly Instantaneous

170°F (77°C) Nearly Instantaneous

160°F (71°C) About 1/2 Second

150°F (65°C) About 1-1/2 Seconds

140°F (60°C) Less than 5 Seconds

130°F (54°C) About 30 Seconds

120°F (49°C) More than 5 Minutes

Valves for reducing point-of-use temperature by mixing cold and

hot water are available. Also available are inexpensive devices

that attach to faucets to limit hot water temperatures.

licensed plumber or the local plumbing authority.

Contact a

FIGURE 1

A high limit switch interrupts the power burner operation should

the water temperature reach 200°F.

The high limit switch must be manually reset by depressing the

red button on the front of the control when water temperature

drops to about 180°F. The manual reset high limit can be found

inside the control compartment.

INSTALLATION INSTRUCTIONS

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER IS

REQUIRED TO BE PERFORMED BY AN AUTHORIZED STATE

STARTUP AGENT. PLUMBING, AIR SUPPLY, VENTING, GAS

SUPPLY AND ELECTRICAL WORK ARE REQUIRED.

UNCRATING

The heater should be moved in the crate as close as possible to

the installation site. Depending upon size, shipping weights range

from about 1,300 to 4,500 pounds.

The installer should be guided by the instructions furnished with

the heater, local codes and utility company requirements.

Preference should be given to codes and requirements where

they differ from the heater furnished instructions.

Additional publications, which should guide the installer, include:

The latest version of the

from American Gas Association Laboratories, 8501 East

Pleasant Valley Road, Cleveland, OH 44131.

In Canada – CGA No. B149 (latest version), from Canadian

Gas Association Laboratories, 55 Scarsdale Road, Don Mills,

Ontario, Canada M3B 2R3.

Code for the installation of Heat Producing Appliances (latest

version), from American Insurance Association, 85 John Street,

New York, NY 11038.

National Fuel Gas Code, ANSI Z223.1,

4

Page 5

The latest version of the National Electrical Code, NFPA No.

70. In Canada refer to Canadian Electrical Code C 22.1, from

National Fire Protection Association, 1 Batterymarch Park,

Quincy, MA 02269-9101.

A clearance of 24” should be maintained from serviceable parts,

such as relief valve, power burner, thermostat and drain valve.

MINIMUM INST ALLATION CLEARANCES

LOCA TING THE HEATER

When installing the heater, consideration must be given to proper

location. Location selected should be as close to the stack or

chimney as practicable, with adequate air supply and as

centralized with the piping system as possible.

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES

SUCH AS GAS WATER HEATERS IN ROOMS, GARAGES OR

OTHER AREAS WHERE GASOLINE, OTHER FLAMMABLE

LIQUIDS OR ENGINE DRIVEN EQUIPMENT OR VEHICLES ARE

STORED, OPERA TED OR REPAIRED. FLAMMABLE V APORS

ARE HEAVY AND TRAVEL ALONG THE FLOOR AND MAY BE

IGNITED BY THE HEATER’S IGNITION SYSTEM OR MAIN

BURNER FLAMES CAUSING FIRE OR EXPLOSION.

SOME LOCAL CODES PERMIT OPERATION OF GAS

APPLIANCES IF INST ALLED 18 INCHES OR MORE ABOVE THE

FLOOR. THIS MA Y REDUCE THE RISK IF LOCA TION IN SUCH

AN AREA CANNOT BE AVOIDED.

THE HEATER SHALL BE LOCATED OR PROTECTED SO IT IS

NOT SUBJECT TO PHYSICAL DAMAGE BY A MOVING

VEHICLE.

TPG/TPX TPO/TPD

FRONT - 18 Inches FRONT - 18 Inches

BACK - 0 Inches Back - 6 Inches

TOP - 5 Inches Top - 12 Inches

LEFT SIDE - 0 Inches LEFT SIDE - 6 Inches

RIGHT SIDE - 0 Inches RIGHT SIDE - 6 Inches

NOTE: If a chimney connector is used, the minimum clearance

from the top of the unit to the connector is 18 inches.

AIR REQUIREMENTS

WARNING

FOR SAFE OPERATION, AN AMPLE SUPPLY OF AIR MUST

BE PROVIDED FOR PROPER COMBUSTION AND

VENTILATION AIR IN ACCORDANCE WITH SECTION 5.3, AIR

FOR COMBUSTION AND VENTILATION, OF THE

FUEL GAS CODE, NFPA-54/ANSI Z223.1 OR APPLICABLE

PROVISIONS OF THE LOCAL BUILDING CODES. AN

INSUFFICIENT SUPPLY OF AIR WILL RESULT IN A YELLOW,

LUMINOUS BURNER FLAME, CAUSING CARBONING OR

SOOTING OF THE HEAT EXCHANGER AND CREA TING A RISK

OF ASPHYXIATION. DO NOT OBSTRUCT THE FLOW OF

COMBUSTION AND VENTILA TION AIR.

UNCONFINED SP ACE

NATIONAL

WARNING

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY

OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST

NEVER BE PLACED ON OR ADJACENT TO THE HEATER.

OPEN CONTAINERS OF FLAMMABLE MATERIAL SHOULD

NOT BE STORED OR USED IN THE SAME ROOM WITH THE

HEATER.

THE HEATER MUST NOT BE LOCATED IN AN AREA WHERE

IT WILL BE SUBJECT TO FREEZING.

LOCATE HEATER NEAR A FLOOR DRAIN. THE HEATER

SHOULD BE LOCA TED IN AN AREA WHERE LEAKAGE FROM

THE TANK OR CONNECTIONS WILL NOT RESULT IN DAMAGE

TO THE ADJACENT AREA OR TO LOWER FLOORS OF THE

STRUCTURE.

WHEN SUCH LOCATIONS CANNOT BE A VOIDED, A SUIT ABLE

METAL DRAIN PAN, ADEQUATELY DRAINED, SHOULD BE

INSTALLED UNDER THE HEATER. Such pans should be

fabricated with sides at least 2” deep, with length and width at

least 2” greater than the diameter of the heater and must be piped

to an adequate drain. The pan must not restrict combustion air

flow.

This unit must be installed on a non-combustible surface.

LEVELING

The heater shall be installed level. If it is necessary to adjust the

heater, use metal shims under the channel-type skid base.

In buildings of conventional frame, brick or stone construction,

unconfined spaces may provide adequate air for combustion.

If the unconfined space is within a building of tight construction

(buildings using the following construction: weather stripping,

heavy insulation, caulking, vapor barrier, etc.), air for combustion,

ventilation and draft hood dilution must be obtained from outdoors

or spaces freely communicating with the outdoors. The installation

instructions for confined spaces in tightly constructed buildings

must be followed to ensure adequate air supply.

CONFINED SPACE

When drawing combustion and dilution air from inside a

conventionally constructed building to a confined space, such a

space shall be provided with two permanent openings, ONE IN

OR WITHIN 12 INCHES OF THE ENCLOSURE TOP AND ONE

IN OR WITHIN 12 INCHES OF THE ENCLOSURE BOTTOM.

Each opening shall have a free area of at least one square inch

per 1000 Btu/hr of the total input of all appliances in the enclosure,

but not less than 100 square inches.

If the confined space is within a building of tight construction, air

for combustion, ventilation and draft dilution must be obtained

from outdoors. When directly venting with the outdoors or venting

with the outdoors through vertical ducts, two permanent openings,

located in the aforementioned manner, shall be provided. Each

opening shall have a free area of not less than one square inch

per 4000 Btu/hr of the total input of all appliances in the enclosure.

If horizontal ducts are used, each opening shall have a free area

of not less than one square inch per 2000 Btu/hr of the total input

of all appliances in the enclosure.

CLEARANCES

Provide ample clearance on all sides for installation, adjustment

and replacement of burner, control components and other parts.

Where an exhaust fan is installed in the same room with the boiler,

sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN

INTO THE ROOM THROUGH THE CHIMNEY OR OTHER

5

Page 6

UNDESIRABLE OPENINGS, CAUSING POOR COMBUSTION.

SOOTING MAY RESULT WITH AN INCREASED RISK OF

ASPHYXIATION.

THERMAL EXPANSION (CLOSED SYSTEM)

Thermal expansion occurs in any hot water system when system

water is heated or “recovered” during periods of non-use.

If the system is operated in an “open” condition such as being

connected directly to the city main, the volume of expanded water

generated during the recovery periods can be dissipated back

through the “open” connection to the city main so pressure cannot

increase.

However, once a back flow preventer is installed to isolate system

water from the public supply; or a pressure reducing valve is

installed to protect a water meter; or any device preventing flow

back into the cold water supply, the “open” condition becomes

“closed”. During periods of temperature recovery and no usage,

water expands and the pressure increases until a relief valve

opens spilling hot water.

A relief valve opening on pressure will flow small amounts of water,

whereas relieving on temperature releases large amounts of water.

Consult the section under “High Water Temperature” to determine

the cause of the relief valve to open due to temperature.

Since the water is not compressible, some provision must be made

for THERMAL EXPANSION to protect the system from excessive

pressures. Two options are:

VENT CONNECTOR

The chimney vent connector diameter should be the same size

as the heater flue outlet, see table 1. A minimum rise of 1/4” per

foot of horizontal connector length must be maintained between

the heater and chimney opening, fig. 2. The connector length

should be kept as short as possible.

TABLE 1

TPG/TPX/TPO/TPD FLUE OUTLET

INPUT (KBTUh) (INCHES)

140, 199 5

255, 270, 300 6

400 7

540, 600 8

720, 800, 1000 10

1250, 1500 12

1750, 2000 14

2250, 2500 16

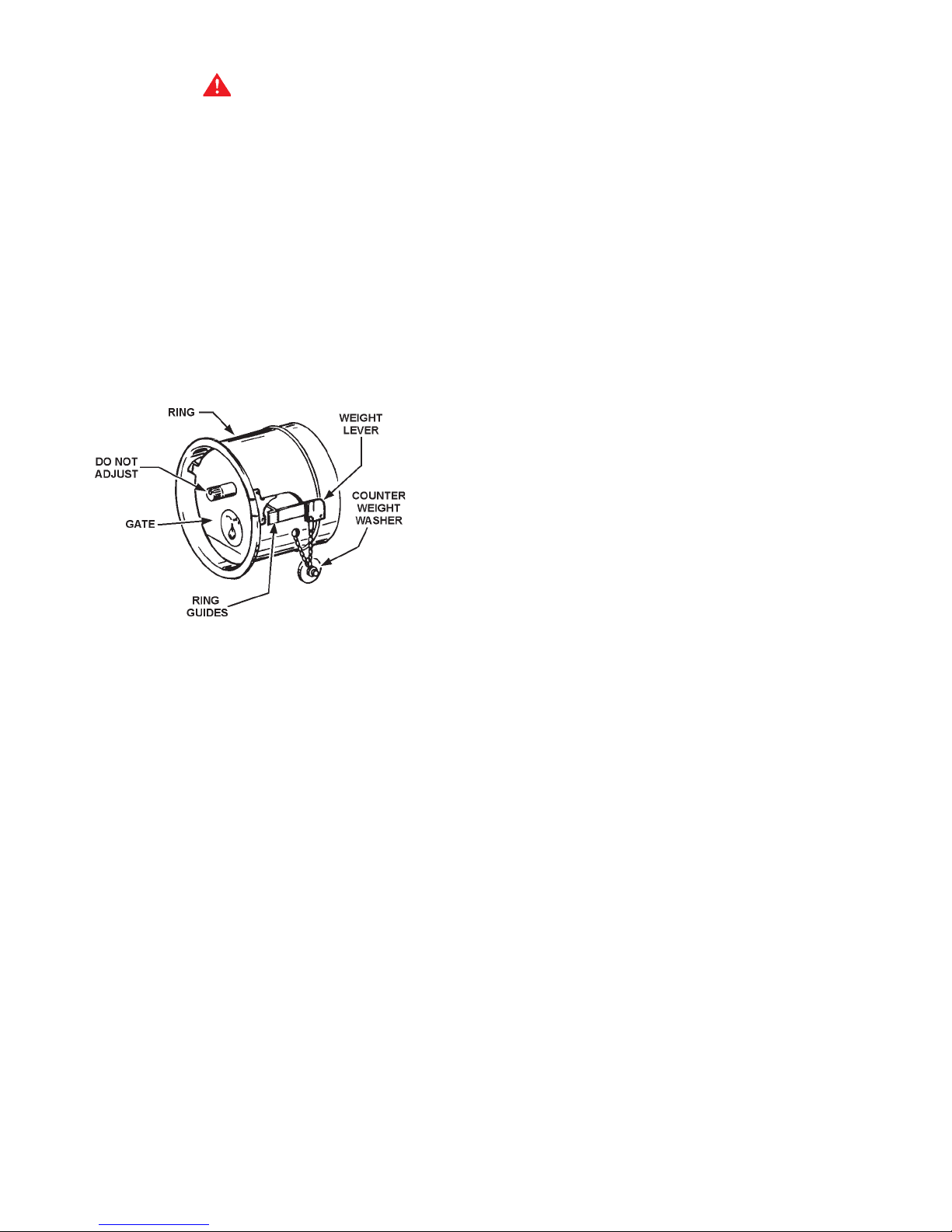

BAROMETRIC DRAFT CONTROL ASSEMBLY

A double-acting barometric draft control assembly is provided with

each unit. This assembly must be attached to the heater as shown

in figure 2. The direction in which the outlet to the draft control

assembly faces is arbitrary. This assembly must be fitted to the

jacket cover such that it is plumb and level to the ground. Fasten

the draft control assembly to the top cover using sheet metal

screws at three locations, or more, as required.

1. Install an expansion tank properly and adequately sized for

the expanding volume of water.

2. Install a pressure relief valve in the cold water supply line having

a setting of at least 10lbs.

located at or near a suitable drain. This valve will open at

each heat cycle when there is no hot water demand on the

system.

Service problems or parts failure due to excessive pressure are

NOT covered under warranty.

The pressure and temperature relief valve supplied with the water

IS NOT considered to be protection against thermal

heater

expansion.

below the system working pressure,

VENTING

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING MUST

BE FOLLOWED TO AVOID CHOKED COMBUSTION OR

RECIRCULATION OF FLUE GASES. SUCH CONDITIONS

CAUSE SOOTING OR RISKS OF FIRE AND ASPHYXIATION.

Heater must be protected from freezing downdrafts during

shutdown periods.

Remove all soot or other obstructions from chimney, which will

retard free draft.

Refer to the instructions provided with the barometric damper for

complete installation requirements.

Dampers or other obstructions must not be installed between the

heater and the barometric draft control assembly.

Barometric draft control counterweights can be adjusted for

installation conditions by an authorized State Start-Up Agent. Any

readjustment must be by authorized State Start-Up agent.

PROPER DRAFT CONTROLLER AND

VENT PIPE INSTALLATION - FIGURE 2

VENT CONNECTION

Venting materials used for this category 1 appliance must be in

accordance with the National Fuel Gas Code and all state and

local requirements.

NOTE: A NEGATIVE DRAFT MUST BE MAINTAINED IN VENT

PIPING (-0.02 to -0.06).

Vent connections must be made to an adequate stack or chimney.

Refer to the National Fuel Gas Code or to the vent pipe

manufacturer’s gas vent and chimney sizing table to properly

design and size the venting system. Refer to Table 2 for the vent

pipe size required for installation to the barometric draft control

assembly outlet.

6

Page 7

TABLE 2

CAPACITY OF PIPE - NATURAL GAS IN CUBIC FEET PER HOUR

Maximum Based Upon Pressure Drop of 0.3” w.c. and Specific Gravity

of 0.60 and Maximum Gas Pressure of .5 psig.

Pipe Length Pipe Size - Inches (IPS)

In Feet 1 1 1/4 1 1/2 2 2 1/2 3 4

10 520 1050 1600 3050 4800 8500 17500

20 350 730 1100 2100 3300 5900 12000

30 285 590 890 1650 2700 4700 9700

40 245 500 760 1450 2300 4100 8300

50 215 440 670 1270 2000 3600 7400

60 195 400 610 1150 1850 3250 6800

70 180 370 560 1050 1700 3000 6200

80 170 350 530 990 1600 2800 5800

90 160 320 490 930 1500 2600 5400

100 150 305 460 870 1400 2500 5100

125 130 275 410 780 1250 2200 4500

150 120 250 380 710 1130 2000 4100

175 110 225 350 650 1050 1850 3800

200 100 210 320 610 980 1700 3500

NOTE: Use Multiplier at right for other specific gravities and pressure drops.

CORRECTION FACTORS

Specific Gravity Pressure Drop

Other than 0.60 Other than 0.3

Specific Multplier Pressure Multiplier

Gravity Drop

0.50 1.10 0.1 0.577

0.60 1.00 0.2 0.815

0.70 0.926 0.3 1.00

0.80 0.867 0.4 1.16

0.90 0.817 0.6 1.42

1.00 0.775 0.8 1.64

Propane - Air 1.0 1.83

1.10 0.740 2.0 2.58

Propane 3.0 3.16

1.55 0.622 4.0 3.65

6.0 4.47

8.0 5.15

Where an existing chimney or vent is to be used, be sure that the

chimney or vent has adequate capacity for the number and sizes

of gas appliances being vented through it. Inspect the chimney

or vent and remove all soot or other obstructions, which will retard

free draft.

Vent piping making horizontal runs must have a minimum upward

slope toward the chimney or vent of 1/4” per foot. Vent pipe

length should be kept as short as possible. Be sure that the vent

pipe does not extend beyond the inside wall of a chimney.

In venting systems, where a continuous or intermittent back

(positive) draft is found to exist, the cause must be determined

and corrected. In some cases, a special vent cap may be required.

WATER LINE CONNECTIONS

The water heater may be installed by itself, or with a separate

storage tank, on both single and two-temperature systems. When

used with a separate storage tank, the circulation may be either

by gravity or by means of a circulating pump.

SYSTEM CONNECTIONS

The system installation must conform to these instructions and to

the local code authority having jurisdiction. Good practice requires

that all heavy piping be supported.

THERMOMETERS (Not supplied)

WARNING

THE PURPOSE OF A RELIEF VALVE IS TO AVOID EXCESSIVE

PRESSURE OR TEMPERATURE INTO THE STEAM RANGE,

WHICH MAY CAUSE SCALDING AT FIXTURES, TANK

EXPLOSIONS, SYSTEM OR HEATER DAMAGE. NO VALVE IS

TO BE PLACED BETWEEN THE RELIEF VALVE AND THE

TANK.

A DRAIN LINE MUST BE CONNECTED TO THE RELIEF VALVE

TO DIRECT DISCHARGE TO A SAFE LOCATION TO AVOID

SCALDING OR WATER DAMAGE. THIS LINE MUST NOT BE

REDUCED FROM THE SIZE OF THE VALVE OUTLET AND

MUST NOT CONTAIN VALVES, RESTRICTIONS NOR SHOULD

IT BE LOCATED IN FREEZING AREAS. DO NOT THREAD OR

CAP THE END OF THIS LINE. RESTRICTED OR BLOCKED

DISCHARGE WILL DEFEAT THE PURPOSE OF THE VALVE

AND IS UNSAFE. DISCHARGE LINE SHALL BE INSTALLED

TO ALLOW COMPLETE DRAINAGE OF BOTH THE VALVE AND

LINE.

Your local code authority may have other specific relief valve

requirements.

GAS PIPING

Contact your local gas service company to ensure that adequate

gas service is available and to review applicable installation codes

for your area.

Thermometers should be obtained and field installed as shown

in the installation diagrams.

Thermometers are installed in the system as a means of detecting

the temperature of the outlet water.

RELIEF VALVE

This water heater has been provided with an ASME rated pressure

and temperature relief valve.

In addition to the appliance relief valve, each remote storage tank,

which may be used in conjunction with this appliance, shall also

be installed with a properly sized, rated and approved temperature

(ANSI) and pressure (ASME) relief valve(s).

Size the main gas line in accordance with Table 3. The figures

shown are for straight lengths of pipe at 0.3 in. w.c. pressure

drop, which is considered normal for low-pressure systems. Note

that fittings such as elbows and tees will add to the pipe pressure

drop.

Equivalent lengths of standard pipe in feet for listed fittings (add

below values to Table 3).

Install vent lines from main gas regulator and (if applicable) a

diaphragm gas valve. Vent line should be run to the outside of

the building, terminating clear of windows or fresh air intakes.

Outside terminal of vent should have a screen to prevent insects

from building nests in vent pipe. The vent should terminate in a

manner, which will preclude the possibility of water, snow, dirt or

other matter from entering the line.

7

Page 8

TABLE 3

EQUIVALENT LENGTH OF FITTINGS IN FEET

Pipe Size (IPS) 1 1.25 1.5 2 2.5 3 4

Std. Tee through side 5.5 7.5 9.0 12.0 14.0 17.0 22.0

Std. E11 2.7 3.7 4.3 5.5 6.5 8.0 12.0

45°F E11 1.2 1.6 2.0 2.5 3.0 3.7 5.0

Plug Cock 3.0 4.0 5.5 7.5 9.0 12.0 16.0

WARNING

THE HEATER IS NOT INTENDED FOR OPERATION AT HIGHER

THAN 13.8” WATER COLUMN (1/2 POUND PER SQUARE INCH)

SUPPLY GAS PRESSURE. HIGHER GAS PRESSURE

REQUIRES SUPPLEMENTAL REDUCING SERVICE

REGULATION. EXPOSURE TO HIGHER GAS SUPPLY

PRESSURE MAY CAUSE DAMAGE TO THE GAS CONTROLS

WHICH COULD RESULT IN FIRE OR EXPLOSION. IF

OVERPRESSURE HAS OCCURRED SUCH AS THROUGH

IMPROPER TESTING OF GAS LINES OR EMERGENCY

MALFUNCTION OF THE SUPPLY SYSTEM, THE GAS VALVE

MUST BE CHECKED FOR SAFE OPERATION. MAKE SURE

THAT THE OUTSIDE VENTS ON THE SUPPLY REGULATORS

AND THE SAFETY VENT VALVES ARE PROTECTED AGAINST

BLOCKAGE. THESE ARE PARTS OF THE GAS SUPPLY

SYSTEM, NOT THE HEATER. VENT BLOCKAGE MAY OCCUR

DURING ICE STORMS.

IT IS IMPORTANT TO GUARD AGAINST GAS VALVE FOULING

FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING

MAY CAUSE IMPROPER OPERATION, FIRE OR EXPLOSION.

IF COPPER SUPPLY LINES ARE USED THEY MUST BE

INTERNALLY TINNED AND CERTIFIED FOR GAS SERVICE.

BEFORE ATTACHING THE GAS LINE, BE SURE THAT ALL GAS

PIPE IS CLEANED ON THE INSIDE.

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS

SUPPLY LINE, A DIRT LEG (SOMETIMES CALLED A SEDIMENT

TRAP OR DRIP LEG) MUST BE INCORPORATED IN THE

PIPING. THE DIRT LEG MUST BE READILY ACCESSIBLE AND

NOT SUBJECT TO FREEZING CONDITIONS. INSTALL IN

ACCORDANCE WITH RECOMMENDATIONS OF SERVING GAS

SUPPLIERS. REFER TO THE

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply pipes to gas valve inlet.

Apply joint compounds (pipe dope) sparingly and only to the male

threads of pipe joints. Do not apply compound to the first two

threads. Use compounds resistant to the action of liquefied

petroleum gases.

DISCONNECT THE APPLIANCE AND ITS MANUAL GAS

SHUTOFF VALVE FROM THE GAS SUPPLY PIPING SYSTEM

DURING ANY SUPPLY PRESSURE TESTING EXCEEDING

1/2 PSIG. GAS SUPPLY LINE MUST BE CAPPED WHEN

DISCONNECTED FROM THE HEATER. FOR TEST

PRESSURES OF 1/2 PSIG OR LESS, THE APPLIANCE NEED

NOT BE DISCONNECTED, BUT MUST BE ISOLATED FROM

THE SUPPLY PRESSURE TEST BY CLOSING THE MANUAL

GAS SHUTOFF VALVE.

BEFORE PLACING THE HEATER IN OPERATION, CHECK FOR

GAS LEAKAGE. USE SOAP AND WATER SOLUTION OR

OTHER MATERIAL ACCEPTABLE FOR THE PURPOSE OF

LOCATING GAS LEAKS. DO NOT USE MATCHES, CANDLES,

FLAME OR OTHER SOURCES OF IGNITION FOR THIS

PURPOSE.

NATIONAL FUEL GAS CODE.

PURGING

Gas line purging is required with new piping or systems in which

air has entered.

CAUTION

PURGING SHOULD BE PERFORMED BY PERSONS

EXPERIENCED IN THIS TYPE GAS SERVICE. TO AVOID RISK

OF FIRE OR EXPLOSION, PURGE DISCHARGE MUST NOT

ENTER CONFINED AREAS OR SPACES WHERE IGNITION

CAN OCCUR. THE AREA MUST BE WELL VENTILATED AND

ALL SOURCES OF IGNITION MUST BE INACTIVATED OR

REMOVED.

GAS METER SIZE – CITY GASES ONLY

Be sure that the gas meter has sufficient capacity to supply the

full rated gas input of the water heater as well as the requirements

of all other gas fired equipment supplied by the meter. If gas

meter is too small, request the gas company to install a meter

having adequate capacity.

GAS PRESSURE REGULATOR

DO NOT SUBJECT COMBINATION GAS VALVE TO INLET GAS

PRESSURE OF MORE THAN 14 I.W.C. A SERVICE

REGULATOR IS NECESSARY IF HIGH GAS PRESSURES ARE

ENCOUNTERED.

The gas pressure regulator vent line must be vented to the

outside of the building.

POWER BURNER

For information relating to the power burner supplied with this

water heater, refer to the power burner manual provided.

LIFTING LUGS

This water heater is supplied with lifting lugs. Prior to lifting, insure

that the lugs are threaded into their receptacles as tight as

possible.

These lugs may be removed after installation. Sheet metal covers

are provided to cover the receptacle openings.

WIRING

The rating plate provides the electrical information needed to size

the water heater branch supply circuit.

Typical water heater electrical diagrams are provided in this

manual (pages 9 and 10). The actual diagram, corresponding to

each water heater, is provided with each water heater, and may

differ from the diagrams shown in this manual.

The TPG unit burner is wired to the water heater control

compartment as shown in the following diagram. The electrical

service should be connected to the N & L Terminals located in

the control compartment. Ground from control compartment to

suitable ground.

All electrical work must be installed in accordance with the

Electrical Code (latest version) and local requirements. AN

ELECTRICAL GROUND IS REQUIRED TO REDUCE THE RISK

OF ELECTRICAL SHOCK. DO NOT ENERGIZE THE BRANCH

CIRCUIT BEFORE THE HEATER TANK IS FILLED WITH

WATER.

National

8

Page 9

TYPICAL WIRE DIAGRAM

TPG, 270 - 2,500 KBTUH

TPO, 800 - 2,500 KBTUH

TPD, 400 - 2,500 KBTUH

TYPICAL WIRE DIAGRAM

TPG, 140 - 255 KBTUH

9

Page 10

TYPICAL WIRE DIAGRAM

TPD, 140 - 300 KBTUH

TYPICAL WIRE DIAGRAM

TPO, 140 - 720 KBTUH

10

Page 11

TWO UNIT MANIFOLD

INSTALLATION

The time to ask any questions you may have about your unit is

when the State Authorized TPG/TPO/TPD Start-Up Agent is there.

Please do not hesitate to ask the agent any questions which you

may have regarding the units start-up, operation or maintenance.

Assure water flow balance of all units. Without this balance, the

full water heating and storage potential of the system cannot be

achieved. Otherwise, the units with the higher water flow may

have a shortened life.

Dimensions shown are for minimum space occupied by complete

assemblies. Service space in front of units must be included.

MODEL MANIFOLD SIZE

TPX/TPG/TPO/TPD - 140 2”

TPX/TPG/TPO/TPD - 200 2 1/2”

TPX/TPG/TPO/TPD - 300 2 1/2”

TPX/TPG/TPO/TPD - 400 3”

TPX/TPG/TPO/TPD - 600 3”

A MAINTENANCE section is included at the rear of this manual.

Any service required should be performed by an Authorized State

Service Agent.

GENERAL

NEVER OPERATE THE HEATER WITHOUT FIRST BEING

CERTAIN IT IS FILLED WITH WATER AND A TEMPERATURE

AND PRESSURE RELIEF VALVE IS INSTALLED IN THE RELIEF

VALVE OPENING OF THE HEATER.

CAUTION

Before proceeding with the operation of the unit make sure the

water heater and system are filled with water and all air is expelled.

FILLING

1. Close the heater drain valve by turning handle clockwise.

2. Open a nearby hot water faucet to permit the air in the system

to escape.

3. Fully open the cold water inlet pipe valve allowing the heater

and piping to be filled.

4. Close the hot water faucet as water starts to flow.

5. The heater is ready to be operated.

OPERATION

IMPORTANT

AUTHORIZED START-UP REQUIRED. Start-up by a

State Authorized TPG/TPX/TPO/TPD Start-Up Agent is

required on the models covered in this manual. Start-up and

Operation of the units covered by this manual by other than

a State Authorized TPG/TPX/TPO/TPD Start-Up Agent will void

the warranty.

If you have not already done so, contact your local State Sales

Representative or Authorized TPG/TPX/TPO/TPD Start-Up Agent

and set-up a date for the start-up service.

The Authorized Start-Up Agent will when they come out to

start-up the unit(s) complete one of the following forms for each

unit you have and submit it to State Industries to activate your

warranty:

Start-Up Covering Models

Form No.

09063511 TPG Models, 140 - 255 kBTUH

09063510 TPG Models, 270 - 2500 kBTUH

09063512 TPD Models, 140 - 2500 kBTUH

09063514 TPO Models, 140 - 2500 kBTUH

09063515 TPX Models, 400 - 2000 kBTUH

COMBUSTION AIR REQUIREMENTS AND

SERVICE RECOMMENDATIONS

1. In order to fire correctly, the burner requires an adequate supply

of combustion air. Ventilation to the boiler room should be

provided on the basis of one square inch of free air opening

for each 1000 BTU/HR input. This excludes the requirements

for any other fired equipment in the room. The boiler room

should not become excessively hot and under no

circumstances should be under negative pressure.

2. The burner must be set up initially and serviced at regular

intervals (suggested semi-annually) by a trained serviceman

using the proper instruments. During this semi-annual service,

primary safety devices should be tested under operating

conditions. Failure to routinely test primary safety devices may

cause hazards. Suggested test procedures are listed in the

following paragraphs. Failure to maintain the correct burner

settings may result in inefficient gas consumption, premature

wear of burner components, or explosion hazard.

3. The correct test instruments are:

•CO

• CO indicator

• Stack thermometer

• Draft gauge or inclined manometer

• U-tube manometer or calibrated 0-10” and 0-35” w.c.

• Combination volt/ammeter.

indicator or 02 analyzer

2

pressure gauge

11

Page 12

Suggested safety device test procedures are:

DRAINING

A. While heater is operating, turn valve, main burner and pilot

gas line manual gas cocks to the OFF position. Burner should

shutdown within 3-4 seconds and lockout on flame failure,

requiring reset of the flame safeguard device.

B. While heater is operating, lower the setting of each of (2)

operating thermostats (one at a time). During this setting

change, the burner should shutdown when the called for

temperature is less than the temperature indicated on the

thermometer. Restore the settings to original values and burner

should restart.

Should any of the above operating test fail, replace the involved

component.

MAINTENANCE

GENERAL

Water heater maintenance includes periodic tank flushing and

cleaning, and removal of lime scale. The power burner should

be inspected and adjusted to maintain proper combustion. Refer

to the following table. A periodic inspection of the venting system

should be made. Where used, the water heating system

circulating pump should be oiled.

KEEP APPLIANCE AREA CLEAR AND FREE FROM

COMBUSTIBLE MATERIALS, GASOLINE AND OTHER

FLAMMABLE VAPORS AND LIQUIDS.

FLUSHING

1. Turn off the heater electrical disconnect switch.

• For convenience, the switch on the outside of the control

compartment can be used.

2. Open the drain valve and allow water to flow until it runs clean.

The heater must be drained if it is to be shut down or exposed to

freezing temperatures. Maintenance and service procedures may

also require draining the heater.

1. Tun off the heater electrical disconnect switch.

2. Close the cold water inlet valve to heater.

3. Open a nearby hot water faucet to vent the system.

4. Open the heater drain valve.

5. If the heater is being drained for an extended shutdown, it is

suggested the drain valve be left open during this period.

• Follow FILLING instructions when restoring hot water service

SEDIMENT REMOVAL

Waterborne impurities consist of fine particles of soil and sand

which settle out and form a layer of sediment on the bottom of the

tank.

For convenience, sediment removal and lime scale removal

should be performed at the same time.

LIME SCALE REMOVAL

The amount of calcium (lime) released from water is indirect

proportion to water temperature and usage. The higher the water

temperature or water usage, the more lime deposits are dropped

out of the water. This is the lime scale which forms in pipes, heaters

and on cooking utensils.

Lime accumulation not only reduces the life of the equipment but

also reduces efficiency of the heater and increases fuel

consumption.

3. Close the drain valve when finished flushing.

4. Turn on the heater electrical disconnect switch.

MAINTENANCE SCHEDULE

Component Operation Interval Required

Flushing Monthly

Sediment

Tank Removal Semi-Annually

Lime Scale UN•LIME

Removal As Required Delimer

Relief Valve Inspect Semi-Annually

Power Burner SAE No. 20

Motor(1) Inspect Quarterly non-detergent

motor oil

Power Burner Combustion

and Ignition Inspection Semi-Annually test kit &

Device(2) test

specifications

Main Burner Check Flame Annually

Flue Baffle

Pipe(3) Cleaning As Required Wire Brush

Vent System

and Barometric Inspect Semi-Annually Draft Gauge

Damper

(1) If furnished with oiling provisions

(2) If flange gasket is damaged, it must be repaired.

(3) TPO and TPD Only.

®

The usage of water softening equipment greatly reduces the

hardness of the water. However, this equipment does not always

remove all of the hardness (lime). For this reason it is

recommended that a regular schedule for deliming be maintained.

12

Page 13

The depth of lime build-up should be measured periodically.

Heaters will have about 3” of lime build-up when the level of lime

has reached the bottom of the cleanout opening or about 1” of

lime build-up if it has reached the drain valve opening. A schedule

for deliming should be set-up; based on the amount of time it

would take for a 1” build-up of lime.

Example 1 = Initial inspection, after 1 year, shows 1/2” of lime

accumulation. Therefore, the heater can be

delimed once a year.

check the relief valve, lift the lever at the end of the valve several

times. The valve should seat properly and operate freely.

CAUTION

BEFORE MANUALLY OPERATING THE VALVE, MAKE SURE

THAT A DRAIN LINE HAS BEEN ATTACHED TO THE VALVE

TO DIRECT THE DISCHARGE TO AN OPEN DRAIN. FAILURE

TO TAKE THIS PRECAUTION COULD MEAN CONTACT WITH

EXTREMELY HOT WATER PASSING OUT OF THE VALVE

DURING THIS CHECKING OPERATION.

Example 2 = Initial inspection, after 1 year, shows 2” of lime

accumulation. Therefore, the heater should be

delimed every 3 months.

Following are the instructions for performing some of the

recommended maintenance. Power burner inspection and

adjustment should be performed by a competent technician.

Heater failure due to excessive lime build-up voids the warranty.

Sediment and lime scale removal may be accomplished through

the cleanout opening furnished on the heater. The heater must

be drained, see DRAINING, before removing cleanout cover on

tank.

To dissolve and remove the more stubborn mineral deposits,

UN•LIME Professional Delimer should be used.

UN-LIME Delimer is an easy to handle patented food grade acid

formulated specifically for lime scale removal from all types of

water using equipment. Available in 1 gallon (part no. 4763) and

5 gallon (part no. 4813) sizes. Hydrochloric acids are not

recommended for use on glass-lined tanks.

Form no. 4800, entitled, “Why, When and How”, describes tank

cleaning methods and materials. UN•LIME and the booklet may

be obtained through your State dealer or distributor.

To clean heater through cleanout opening, proceed as follows:

1. Turn off water inlet valve, the heater electrical disconnect switch

and open drain valve.

2. Remove outer cover plate from lower side of heater jacket.

3. Remove plug from cleanout opening.

• Place a short pipe nipple into the tank to extend beyond

the heater jacket.

If the temperature and pressure relief valve on the heater

discharges periodically or continuously, it may be due to the

thermal expansion of water in a closed water supply system, or it

may be due to a faulty relief valve.

Thermal expansion is the normal response of water when it is

heated. In a closed system, thermal expansion will cause the

system pressure to increase until the relief valve actuation

pressure is equaled. Then, the relief valve will open, allowing

some water to escape slightly lowering the pressure. (See

THERMAL EXPANSION Section of pages 5 and 6).

Contact your water supplier or local plumbing inspector on how

to control this situation.

ABOVE ALL, DO NOT PLUG THE TEMPERATURE AND

PRESSURE RELIEF VALVE. THIS IS NOT A SOLUTION AND

CAN CREATE A HAZARDOUS SITUATION.

POWER BURNER

KEEP THE AREA AROUND THE BURNER CLEAR AND FREE

OF COMBUSTIBLE MATERIALS, GASOLINE OR OTHER

FLAMMABLE LIQUIDS OR VAPORS. DO NOT OBSTRUCT

BURNER AIR OPENINGS OR VENTILATION GRILLES FOR

COMBUSTION AIR. REMOVE LINT ACCUMULATION FROM

AIR INTAKE GRILL.

At least annually, contact a qualified service agency for burner

cleaning and other routine maintenance.

CLEANING FLUES-TPO & TPD ONLY

The following describes how to gain access to the tank flues for

cleaning if necessary.

1. Turn off the heater electrical disconnect switch.

4. Remove lime, scale and sediment using care not to damage

the glass coatings inside the tank.

5. Remove the nipple.

6. Replace cleanout plug.

7. Follow filling instructions when restoring hot water service..

8. Check for water leakage and correct as necessary.

9. Replace outer jacket cover plate.

RELIEF VALVE

At least twice a year, the temperature and pressure relief valve

should be checked to ensure that it is in operating condition. To

• The switch on the outside of the control compartment

may be used.

2. Remove the vent connector from on top the heater.

3. Remove the jacket top from the heater by taking out the screws

and lifting it off.

• The insulating pad should then be lifted out.

4. Take out the screws holding the flue gas collector top to the

tank and lift off.

5. The flue baffles may now be removed by lifting out.

• The flue baffles are flexible enough to bend for removal

within headroom.

13

Page 14

6. Using a wire brush, remove soot from flue passages in heater

tank.

• If the heater was installed when incoming water temperature

was warm, colder water creates the effect of less hot water.

CAUTION

While cleaning tank flue passages, care must be taken that brush

does not come in contact with the combustion chamber lining as

damage could occur.

• If burner flue collector flange gaskets are damaged, replace.

VENT SYSTEMS

Examine the vent system every six months for obstruction and/or

deterioration of vent piping. Remove any soot or obstructions and

replace damaged vent piping.

BAROMETRIC DRAFT CONTROL

The heater is equipped with a double acting barometric draft

control. The damper gate must pivot freely in the ring guides.

5. Look for hot water wastage and leaking or open hot water

faucets.

6. Sediment or lime scale may be affecting water heater operation.

Refer to MAINTENANCE for details.

7. Heater or burner may be dirty.

• Clean all heater flue pipes and flue connector, see

MAINTENANCE.

• Have burner properly cleaned and readjusted.

8. Burner may not be firing at proper rate.

• Check gas pressure, see burner manufacturer’s instruction

manual.

9. Burner fan wheel may be dirty.

10.Draft regulator may be stuck.

• Check to see if vane swings freely. Clean, if vane is stuck.

11.Reset button or burner flame safeguard primary control has

operated.

FIGURE 3

To test gate for operation, gently tap gate and observe. DO NOT

OIL.

The red solid fuel tabs supplied with the draft regulator must be

removed (See instructions supplied with Draft Regulator).

TROUBLESHOOTING

NOT ENOUGH OR NO HOT WATER

1. Be certain the electrical disconnect switch serving the water

heater is in the ON position.

• The outside of the control compartment and the power burner

housing also have switches.

2. Check the fuses

• The electrical disconnect switch usually contains fuses.

3. The capacity of the heater may have been exceeded by a large

demand for hot water.

WATER IS TOO HOT

1. Water temperature control may be set too high.

2. If lowering the control setting does not reduce the water

temperature, contact your dealer.

WATER HEATER MAKES NOISE

1. Sediment or lime scale accumulations cause noises when the

heater is operating.

• The sounds are normal, however, the tank bottom should

be cleaned. Refer to MAINTENANCE for details.

2. Some of the electrical components of the water heater make

sounds, which are normal.

• Contacts click or snap as the heater starts and stops.

• Transformers often hum.

WATER LEAKAGE IS SUSPECTED

1. Check to see if the water heater drain valve is tightly closed.

Also check the cleanout-opening plug for leakage.

2. The apparent leakage may be condensation, which forms on

cool surfaces of the heater and piping.

3. If the outlet of the relief valve is leaking it may represent:

• Large demands require a recovery period to restore water

temperature.

4. Colder incoming water temperature will lengthen the time

required to heat water to the desired temperature.

• Excessive water pressure.

• Excessive water temperature.

• Faulty relief valve.

14

Page 15

Excessive water pressure is the most common cause of relief

valve leakage. It is often caused by a “closed system”. If a

check valve is in the inlet system it will not permit the expanded

hot water volume to equalize pressure with the main. The

relief valve must release this water or the water heater or

plumbing system will be damaged.

When such a condition is encountered, local codes or

inspection agency should be consulted to determine which

system is acceptable in your area. These may consist of:

• Installation of a second relief valve with lower setting than

the primary relief valve.

• An expansion tank of suitable size and pressure rating and

provision to avoid water logging.

REPLACEMENT PARTS

Replacement parts may be ordered through authorized servicers

or distributors, refer to your local Yellow Pages for where to call

or contact State Water Heaters, 500 Lindahl Parkway,

Ashland City, TN 37015. When ordering parts, be sure to state

the quantity, part number and description of the item including

the complete model and serial number as it appears on the

product. Refer to the parts list for more information.

For additional troubleshooting information, refer to the power

burner manual.

15

Page 16

Model TPG/TPX/TPO/TPD Limited Warranty

CERTIFIED FACTORY START - UP REQUIRED

To activate your warranty, contact your local sales representative or Authorized Start-up Agent to arrange for a FREE Certified Start-up.

State Water Heaters, the warrantor, extends the following LIMITED WARRANTY to the owner of this water heater.

1. THE TANK

If the glass lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable water

therein, during the first THREE years after initial installation, the warrantor will at its option, provide a replacement State water heater of equivalent

size and current model, less burner and controls. Some government agencies are requiring energy efficient standards for water heaters. In the

event regulations prohibit sale of a model of equivalent size and construction, State Water Heaters will provide a model which complies with the

regulations of your area, in which case the consumer will be charged the difference in price between the like replacement and the energy efficient

model required. The warranty on the replacement water heater will be limited to the unexpired term of the original warranty.

2. ALL OTHER PARTS

If within ONE year after initial installation of this water heater, any part or portion shall prove upon examination by the warrantor to be defective in

material or workmanship, the warrantor will repair such part or portion at its option.

3. CONDITIONS AND EXCEPTIONS

This warranty shall apply only if a certified factory start-up was performed and if the water heater is installed in accordance with local plumbing and

building codes, ordinances and regulations, the printed instructions provided with it and good industry practices. In addition, a temperature and

pressure relief valve, approved by the American Society of Mechanical Engineers, must have been installed.

a) This warranty shall apply only when the heater is:

(1) owned by the original purchaser.

(2) sized in accordance with proper sizing techniques for commercial water heaters.

(3) bearing a rating plate which has not been altered, defaced or removed except as required by the warrantor.

(4) used in an open system, or in a closed system with a properly sized and installed thermal expansion tank.

(5) fired with the fuel for which it was factory built.

(6) fired at the factory rated input.

(7) used at temperatures not exceeding the maximum setting of its thermostat;

(8) used at water pressure not exceeding the working pressure shown on the water heater;

(9) used when operated free from the damaging effects of uncontrolled water hammer;

(10) used when filled with potable water, free to circulate at all times and the tank free of damaging water sediment or scaled deposits;

(11) in a non-corrosive and not-contaminated atmosphere;

(12) in its original installation location;

(13) used with factory approved anode(s) installed;

(14) in the United States, its territories or possessions, and Canada.

b) Any accident to the water heater, any misuse, abuse (including freezing) or alteration of it, any operation of it in a modified

form, or any attempt to repair tank leaks will void this warranty.

c) This warranty is void if a device acting as a backflow prevention device (check valves etc.) is installed in the cold water supply the heater is

connected to, unless an effective method of controlling thermal expansion is also installed at the heater(s) and operational at all times. The

relief valve installed on the heater is not an acceptable method.

4. SERVICE AND REPAIR EXPENSES

Under the limited warranty the warrantor will provide only a replacement water heater or part thereof. The owner is responsible for all other costs.

Such costs may include but are not limited to:

a) Labor charges for service removal, repair or reinstallation of the water heater or any component part;

b) Shipping, delivery, handling, and administrative charges for forwarding the new heater or replacement part from the nearest distributor and

returning the claimed defective heater or part to such distributor.

c) All cost necessary or incidental for any material and/or permits required for installation of the replacement heater or part.

5. LIMITATIONS ON IMPLIED WARRANTIES

Implied warranties, including the warranty of merchantability imposed on the sale of this heater under state law are limited to one (1) year duration

for the heater or any of its parts. Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply

to you.

6. CLAIM PROCEDURE

Any claim under the warranty should be initiated with the dealer who sold the heater, or with any other dealer handling the warrantor’s products.

If this is not practicable, the owner should contact:

State Water Heaters

500 Lindahl Parkway

Ashland City, TN 37015

a) The warrantor will only honor replacement with identical or similar water heater or parts thereof, which are manufactured or distributed by the

warrantor.

b) Dealer replacements are made subject to in-warranty validation by warrantor.

7. DISCLAIMERS

NO OTHER EXPRESS WARRANTY HAS BEEN OR WILL BE MADE IN BEHALF OF THE WARRANTOR WITH RESPECT TO THE HEATER

OR THE INSTALLATION, OPERATION, REPAIR OR REPLACEMENT OF THE HEATER. THE WARRANTOR SHALL NOT BE RESPONSIBLE

FOR WATER DAMAGE, LOSS OF USE OF THE UNIT, INCONVENIENCE, LOSS OR DAMAGE TO PERSONAL PROPERTY OR OTHER

CONSEQUENTIAL DAMAGE. THE WARRANTOR SHALL NOT BE LIABLE BY VIRTUE OF THIS WARRANTY OR OTHERWISE FOR DAMAGE

TO ANY PERSONS OR PROPERTY, WHETHER DIRECT OR INDIRECT, AND WHETHER ARISING IN CONTRACT OR IN TORT.

a) Some states do not allow the exclusion or limitation of the incidental or consequential damage, so the above limitations or exclusions may

not apply to you

b) This warranty gives you specific legal rights, and you may also have other rights, which may vary, from state to state.

Fill in the following for your own reference. KEEP IT. Registration is not a condition of warranty. The model and serial number are found on the

heater’s rating plate.

Model No. _____________________ Serial No. ______________________________________ Date Installed ___________________

Dealer’s Name __________________________________________________________________________________________________________

Dealer’s Address __________________________________________________________________Phone Number _________________________

City and State _____________________________________________________________________ Zip _________________________________

KEEP THIS WARRANTY POSTED ADJACENT TO THE HEATER FOR FUTURE REFERENCE.

16

Loading...

Loading...