Page 1

Direct Vent Tankless Water Heater

Operation and Installation Manual

Models:

305

505

705

FOR INDOOR APPLICATIONS ONLY

Models 305 and 505 are Energy Star Qualified

Table of Contents .................... 2

Consumer Safety Information .. 4

Operating Instructions .............. 5

Maintenance ............................ 8

ANS Z21.10.3

●

CSA 4.3

Error Codes ............................. 9

Installation Instructions ............ 13

Warranty .................................. 38

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

WARNING: If the information in these instructions is not

followed exactly, a fire or explosion may result causing

property damage, personal injury or death.

— Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

Page 2

Table of Contents

Specifications ..................................................... 3

Consumer Safety Information

Safety Definitions ............................................. 4

Safety Behaviors and Practices ....................... 4

Safety Features ............................................... 4

Description of Operation ................................... 5

Operating Instructions

Features Available on Temperature

Controllers ....................................................... 5

Setting the Temperature .................................. 6

Temperature Options Without

a Temperature Controller ................................ 6

Temperature Ranges ....................................... 7

Setting Controller to Mute ................................ 7

Maintenance

Cleaning ...................................................... 8

Vent System ................................................ 8

Motors ......................................................... 8

Temperature Controller ............................... 8

Lime / Scale Build-up .................................. 8

Snow Accumulation..................................... 8

Visual Inspection of Flame .......................... 8

Error Codes

Error Code Table ....................................... 9, 10

Trouble Shooting for Common Issues ........... 11

Accessing Operating Information .................. 11

Water Quality ................................................. 11

Flushing the Heat Exchanger ........................ 12

(Error Code: LC or 00)

Installation Instructions ................................... 13

General Instructions ...................................... 13

Clearances from Appliance ........................... 14

Attachment of the Water Heater .................... 14

Electrical Connection ..................................... 15

Gas Piping

General Instructions ................................ 15

Pipe Sizing Procedure - Example ........... 16

Water Piping

General Instructions ................................ 17

Pressure Relief Valve .............................. 17

Freeze Protection .................................... 17

Freeze Protection Piping ............................... 18

Recommended Piping for Basic Installation .. 19

Recommended Piping for

Circulation Systems ....................................... 20

Optional Piping for Circulation Systems ........ 21

Venting Instructions

Intake / Exhaust Guidelines .................... 22

Condensate ............................................. 22

Maximum Vent Length ............................ 23

Venting Products ........................................... 24

Flue Terminal Clearances

(ANS Z21.10.3 ● CSA 4.3

Additional Clearances - Vent Terminal .......... 26

Flue Installation for 305 and 505 Models ...... 27

Flue Installation for 705 Model ................ 28, 29

High Altitude Installation ................................ 30

Connecting Multiple Water Heaters ............... 30

Temperature Controller Installation

Location ................................................... 31

Configurations ......................................... 31

Cable Lengths and Size .......................... 31

Mounting the Controller ........................... 32

Operating Instructions ................................... 33

Technical Data

Pressure Drop Curve ..................................... 34

Outlet Flow Data ............................................ 34

Space Heating ............................................... 35

Dimensions .................................................... 36

Ladder Diagram ............................................. 37

Warranty ...................................................... 38, 39

) ............................ 25

2 305, 505, 705 Indoor Manual

Page 3

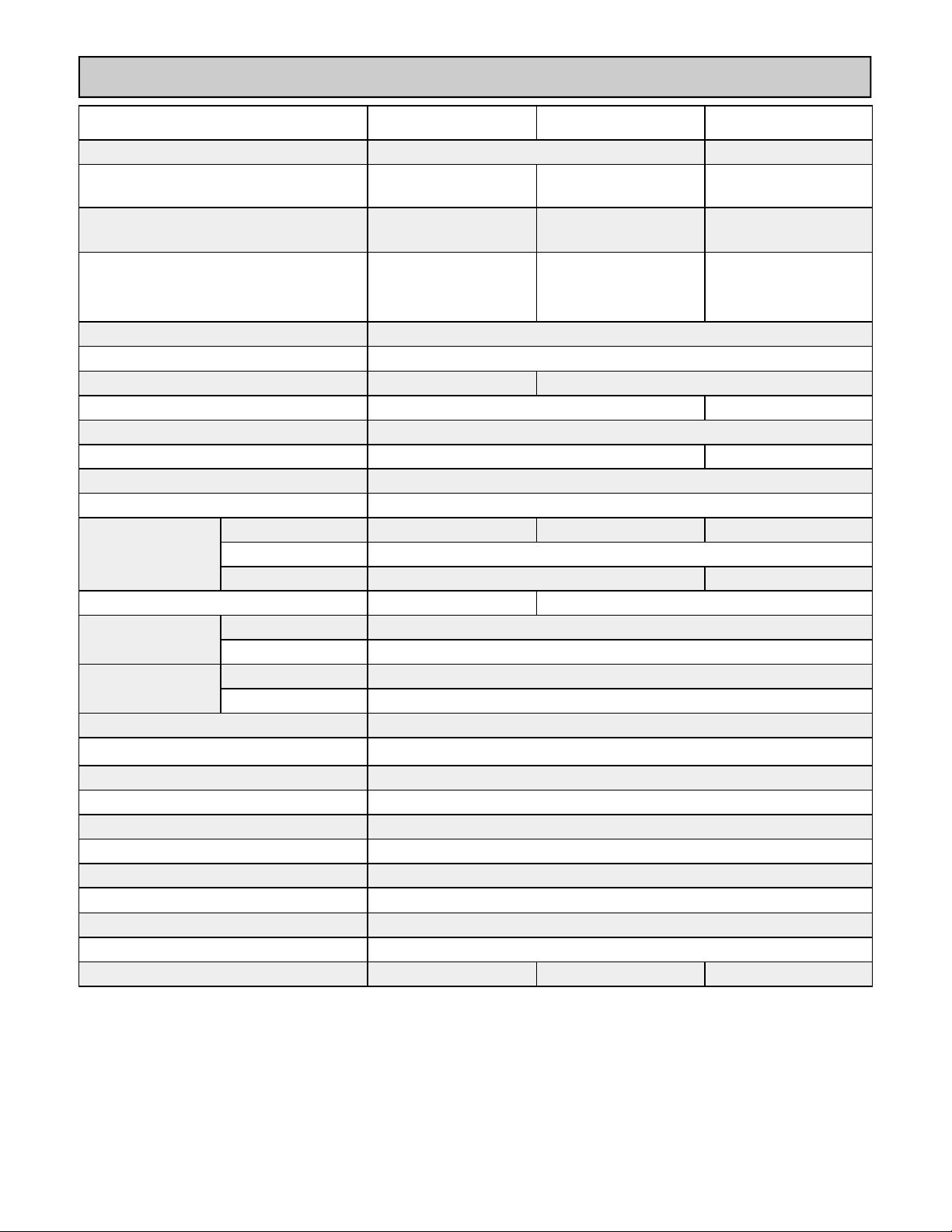

Specifications

Model

Minimum Gas Consumption Btu/h 15,000 19,000

Maximum Gas Consumption Btu/h 180,000

Hot water capacity (Min - Max) *

Hot water capacity (45°F rise) 6.6 GPM (25.0 L/min)

Default Temperature Setting (no controller) 120º F (49º C)

Temperature Controller Default Setting 104º F (40º C)

Maximum Temp Setting (Commercial) ** 160º F (71º C) 185º F (85º C)

Maximum Temp Setting (Residential) Selectable at 120º F (49º C) or at 140º F (60º C) 140º F (60º C)

Minimum Temperature Setting 98º F (37º C)

Weight 50 lb (23 kg) 55 lb (25 kg)

Efficiency Rating 84%

Noise level 49 dB

Normal 65 W 79 W 99 W

Electrical Consumption

By-Pass Control Fixed Electronic

Minimum Gas Supply

Pressure

Maximum Gas Supply

Pressure

Type of Appliance Direct Vent, Temperature controlled continuous flow gas hot water system.

Operation With or without temperature controls, mounted in kitchen, bathroom, etc.

Approved Gas Type Natural Gas or Propane - Ensure unit matches gas type it's being installed on.

Connections Gas Supply: 3/4" MNPT, Cold Water Inlet: 3/4" MNPT, Hot Water Outlet: 3/4" MNPT

Ignition System Direct Electronic Ignition

Electric Connections Appliance: AC 120 Volts, 60Hz. Temperature Control: DC 12 Volts (Digital)

Water Temperature Control Simulation Feedforward and Feedback.

Water Supply Pressure Minimum Water Pressure: 20 PSI (Recommended 30-80 PSI for maximum performance)

Maximum Water Supply Pressure 150 PSI

Temperature Control Cable Non-Polarized Two Core Cable (Minimum 22 AWG)

Energy Star Qualified Yes Yes No

Standby

Anti-frost Protection 100 W 116 W

Natural Gas 5.0 inch W.C.

Propane 8.0 inch W.C.

Natural Gas 10.5 inch W.C.

Propane 13.5 inch W.C.

305

0.6 - 7.5 GPM

(2.3 - 28.4 L/min)

505 705

199,000 Natural Gas

190,000 Propane Gas

0.6 - 9.4 GPM

(2.3 - 35.5 L/min)

7.4 GPM (28.0 L/min)

Natural Gas

7.1 GPM (26.9 L/min)

Propane Gas

2 W

237,000

0.6 - 9.8 GPM

(2.3 - 37 L/min)

8.8 GPM (33.5 L/min)

* Minimum flow may vary slightly depending on the temperature setting and the inlet water temperature.

** for commercial and hydronic applications requiring higher temperatures

Specifications are subject to change without prior notice.

The maximum inlet gas pressure must not exceed the value specified by the manufacturer. The minimum value

listed is for the purpose of input adjustment.

305, 505, 705 Indoor Manual 3

Page 4

Consumer Safety Information

Safety Definitions

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill or hurt you and

others.

DANGER

WARNING

CAUTION

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in minor or

moderate injury. It may also be used to alert against unsafe practices.

Safety Behavior and Practices

WARNING

• Keep the area around the appliance clear and free

from combustible materials, gasoline, and other

flammable vapors and liquids.

• Do not use this appliance if any part has been under

water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been under water.

• This appliance is equipped with a three-prong plug

for your protection against shock hazard and should

be plugged directly into a properly grounded threeprong receptacle. Do not cut or remove the ground

prong from this plug.

• Any alteration to the appliance or its controls can be

dangerous and will void the warranty.

• Always check the water temperature before entering

a shower or bath.

Safety Features

• Overheat: The appliance will automatically shut

down when the appliance exceeds a predetermined

temperature.

• Flame Failure: The appliance will automatically

shut down if the burner flame is extinguished.

• Power Failure: The appliance will cut off the gas if

it loses electrical power.

• Power Surge Fuse: A glass fuse protects against

overcurrent. If the fuse blows then all indicator

lamps will be off.

• Fusible Link: In case the overheat feature does

not prevent the temperature from rising then the

fusible link will break shutting off the appliance.

4 305, 505, 705 Indoor Manual

Page 5

Description of Operation

This appliance is one of the most advanced water

heaters available. It provides a continuous supply of

hot water at a preset temperature. This appliance is

direct vent where air is brought in from the outside and

combustion gases are exhausted to the outside.

While electricity, water, and gas supplies are

connected, this appliance produces hot water

whenever a hot water tap is open.

Ignition is electronic. There is no pilot light consuming

gas while the water heater is not being used. The gas

burner lights automatically when the hot water tap is

opened and goes out when the tap is closed.

Installation of the temperature controller is highly

recommended. The temperature controller can set the

temperature within a specific range and can provide

error codes to diagnose any problems.

The temperature of the outgoing hot water is constantly

monitored. This appliance may adjust the water flow in

order to maintain the temperature setting. The water

flow may vary from summer to winter due to the

difference in ground water temperature.

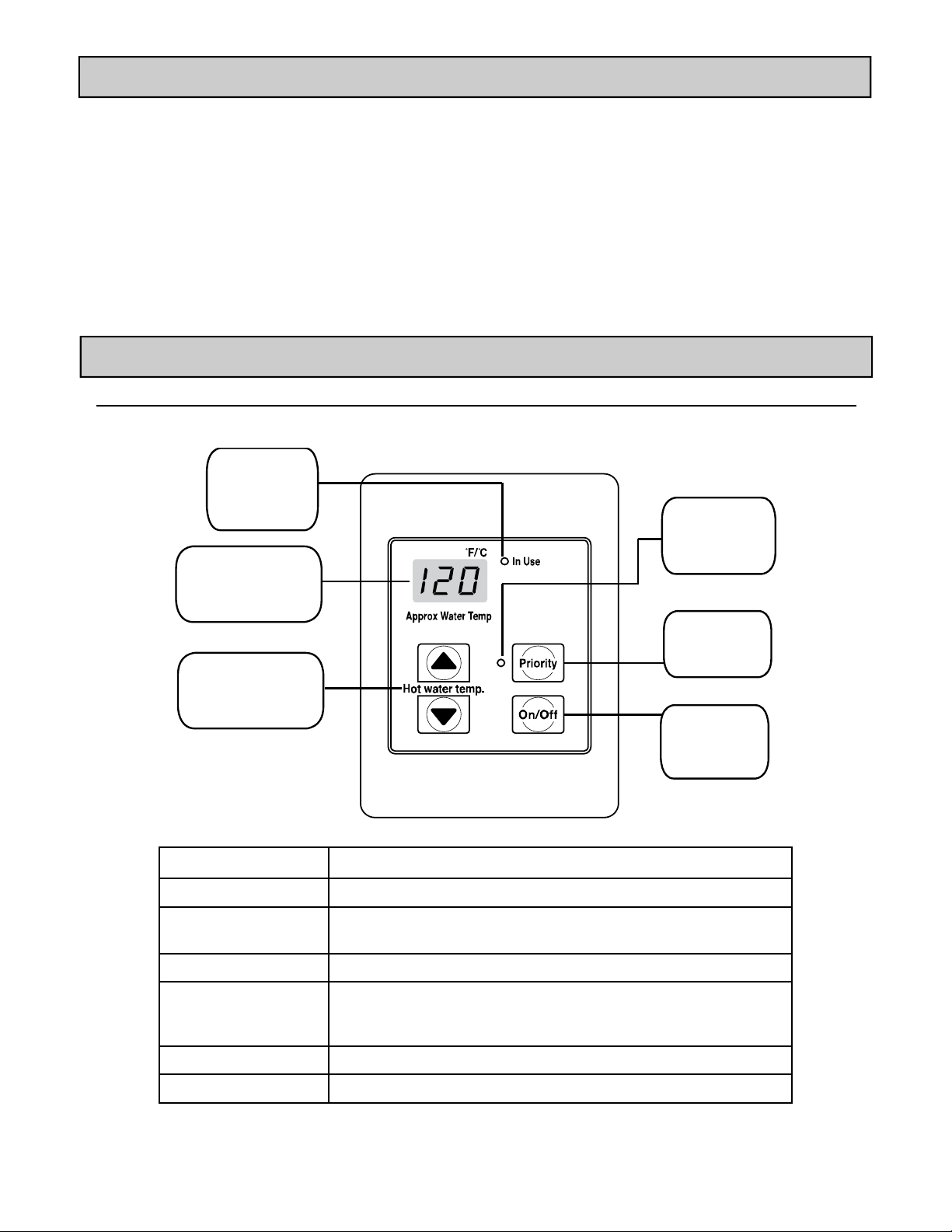

Operating Instructions

Features Available on Temperature Controllers

The temperature controller is supplied with the appliance. Dimensions (inches): 3.5 W x 4.75 H x 0.75 D

In Use

Indicator

Priority

Indicator

Temperature

Display

Priority

Button

Temperature

Selection

On/Off

Button

Features

Error Codes When a fault is detected an error code flashes at the temperature

In Use Indicator Indicates that hot water is being supplied (i.e. a hot water tap is

open).

On/Off Button Used to turn the water heater On or Off.

Priority Button /

Indicator

Temperature Display Shows the temperature setting.

Indicates that this controller is setting the temperature . Priority

can be switched to another controller by pressing its Priority

Button when no hot water is running.

Description

Thermostat Increases or decreases the temperature setting.

305, 505, 705 Indoor Manual 5

Page 6

Setting the Temperature

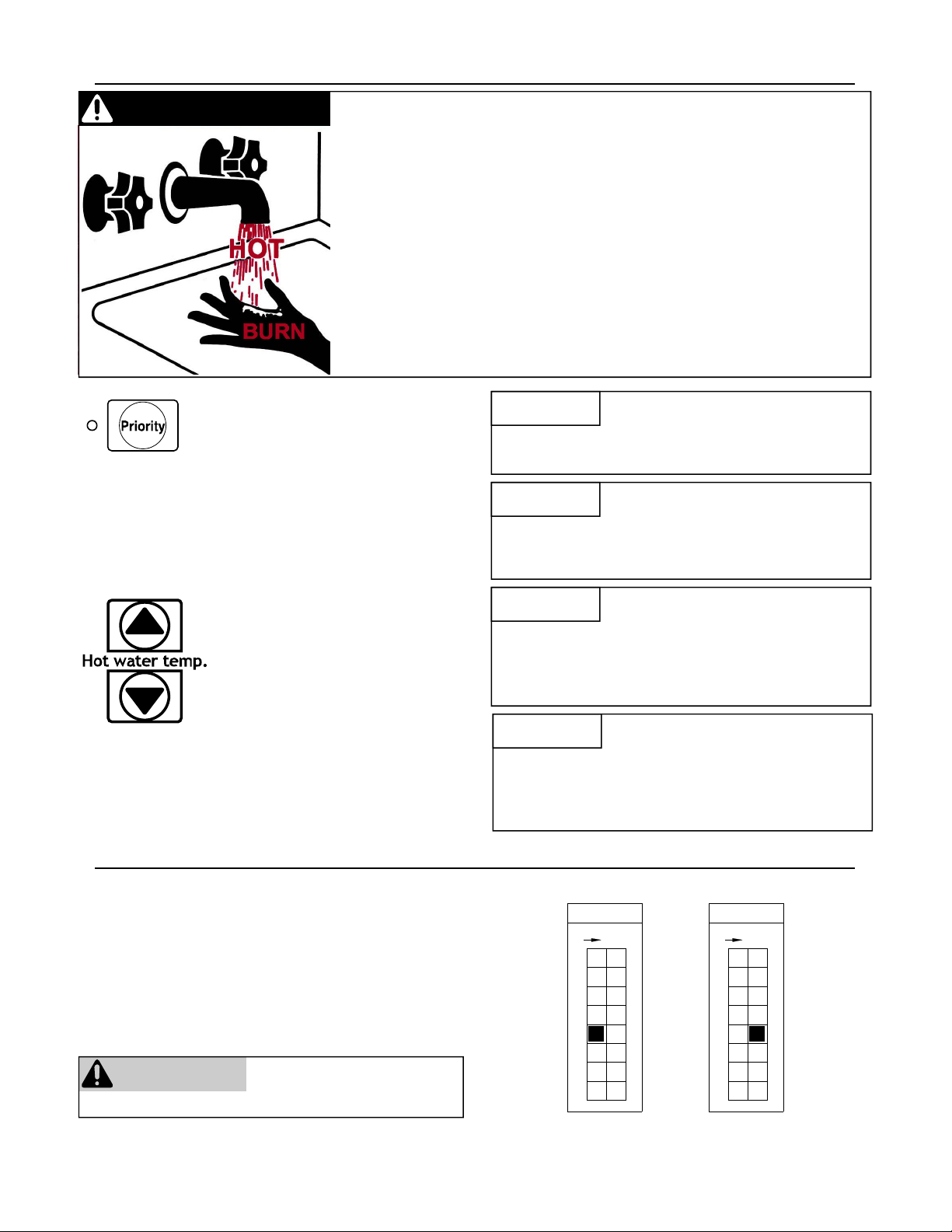

DANGER

1. Press the “Priority button” on the

temperature controller. The

green Priority light will glow

indicating that this controller is

controlling the temperature and

that the water heater is ready to

supply hot water.

The priority can only be changed

while no hot water is running.

Hot water can be dangerous, especially for infants or children, the elderly,

or infirm. There is hot water scald potential if the thermostat is set too high.

Water temperatures over 125º F (51º C) can cause severe burns or

scalding resulting in death.

Hot water can cause first degree burns with exposure for as little as:

3 seconds at 140º F (60º C)

20 seconds at 130º F (54º C)

8 minutes at 120º F (48º C)

Test the temperature of the water before placing a child in the bath or

shower.

Do not leave a child or an infirm person in the bath unsupervised.

NOTICE

While any hot water is being

provided, the temperature setting can

only be adjusted between 98º F and

110º F.

NOTICE

Check local codes for the maximum

water temperature setting allowed

when used in nursing homes,

schools, day care centers, and all

other public applications.

2. Press the ▲ or ▼ buttons to

obtain the desired temperature

setting.

All hot water sources are able to

provide water at this temperature

NOTICE

If a newly installed unit with a

temperature controller has not been

powered for at least 6 hours then the

temperature will return to the default

setting of 104º F (40º C) if power is

interrupted.

setting until it is changed again at

this or another temperature

controller.

NOTICE

There may be a variation between

the temperature displayed on the

temperature controller and the

temperature at the tap due to

weather conditions or the length of

pipe to the water heater.

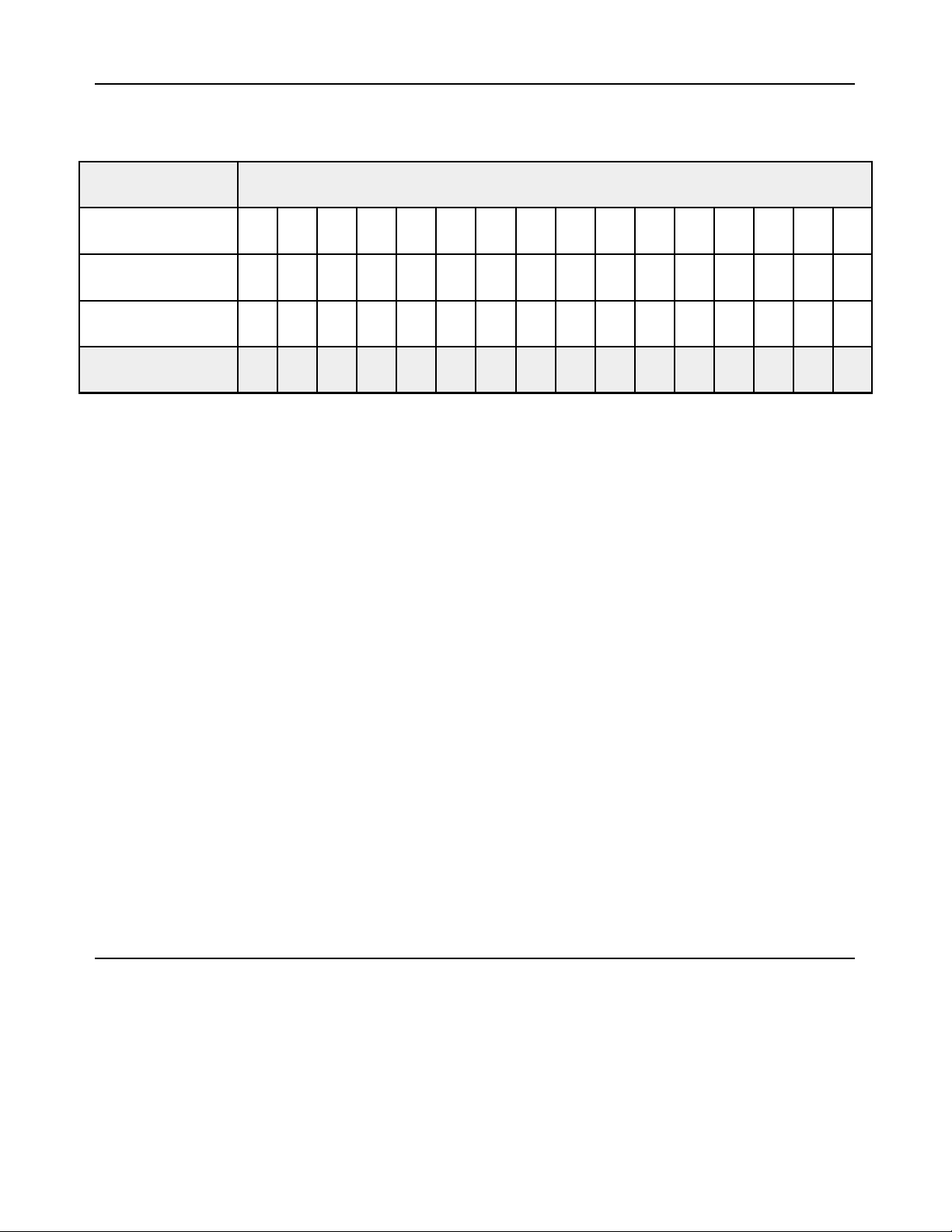

Temperature Options Without a Temperature Controller

The default temperature setting for this appliance

installed without a temperature controller is 120º F

(49º C). If desired the temperature setting can be

changed to 140º F (60º C) by adjustment of a dip

switch.

Set dip switch 5 to ON to obtain 140º F water

temperature setting.

Set dip switch 5 to OFF (default) to obtain 120º F

WARNING

DO NOT adjust the other dip

switches unless specifically

instructed to do so.

120º F (49º C) 140º F (60º C)

Switch No.

ON

O

F

F

1

2

3

4

5

6

7

8

Switch No.

ON

O

F

F

1

2

3

4

5

6

7

8

6 305, 505, 705 Indoor Manual

Page 7

Temperature Ranges

This water heater will attempt to provide hot water at the temperature setting even when the water flow is varied

or when more than 1 tap is in use. The water heater can deliver water at only one temperature setting at a time.

The available temperatures for a given model are provided below.

Model

305

505

705

Temp in Celsius ºC 37 38 39 40 41 42 43 46 49 52 54 57 60 66 71 85

* Re-setting the Maximum Temperature

Models 305 and 505 have a default maximum temperature of 120º F (49º C) and an option to increase the

maximum temperature to 140 ºF (60 ºC). Temperature settings from 125-140 ºF (52-60 ºC) are available by

setting dip switch 6 to ON in the SW1 bank of 8 dip switches.

Model 705 has a default maximum temperature of 140 ºF (60 ºC).

** Commercial Controller

These settings require the commercial controller which is for commercial and hydronic applications requiring

higher temperatures. When the commercial controller is connected, these higher temperatures are available

on all controller models in the system.

98 100 102 104 106 108 110 115 120

98 100 102 104 106 108 110 115 120

98 100 102 104 106 108 110 115 120 125 130 135 140

Temperature Settings Available (ºF)

125 * 130* 135* 140* 150

125* 130* 135* 140* 150

**

**

150

**

160

**

160

**

160

**

185

**

185

**

The commercial controller is intended for commercial and hydronic applications only. If commercial controller

is used in a residential dwelling for a hydronics application, a mixing valve must also be installed to limit the

potable hot water temperature to a safe temperature. Water temperatures over 125º F (51º C) can cause

severe burns or scalding. Refer to the Danger Alert on water temperatures. The manufacturer shall not, in

any event, be liable for damages resulting from such misuse or misapplication.

Suggested temperatures are

• Kitchen 120 ºF (49º C)

• Shower 98º - 110º F (37º - 43º C)

To change the temperature scale from Celsius to Fahrenheit or vice versa, press and hold the “On/Off” button for

5 seconds while the water heater is OFF.

These temperatures are suggestions only.

A temperature lower than 98º F (37º C) can be

obtained at the tap by mixing with cold water.

Setting Controller to Mute

To eliminate the beeps when keys are pressed or to turn the beeps back on, press and hold both the ▲and ▼

buttons until a beep is heard (approximately 5 seconds).

305, 505, 705 Indoor Manual 7

Page 8

Maintenance

WARNING

Turn off the electrical power supply, the manual gas

valve and the manual water control valve whenever

servicing the unit.

Repairs and maintenance should be performed by a

qualified service technician. The appliance should be

inspected annually by a qualified service technician.

Verify proper operation after servicing.

Cleaning

It is imperative that control compartments, burners,

and circulating air passageways of the appliance be

kept clean.

Clean as follows:

1. Turn off and disconnect electrical power. Allow to

cool.

2. Remove and clean the water inlet filter.

3. Remove the front panel by removing 4 screws.

4. Use pressurized air to remove dust from the main

burner, heat exchanger, and fan blades. Do not

use a wet cloth or spray cleaners on the burner.

Do not use volatile substances such as benzene

and thinners. They may ignite or fade the paint.

Snow Accumulation

Keep the area around flue terminal free of snow and

ice. The appliance will not function properly if the

intake air or exhaust is impeded (blocked or partially

blocked) by obstructions.

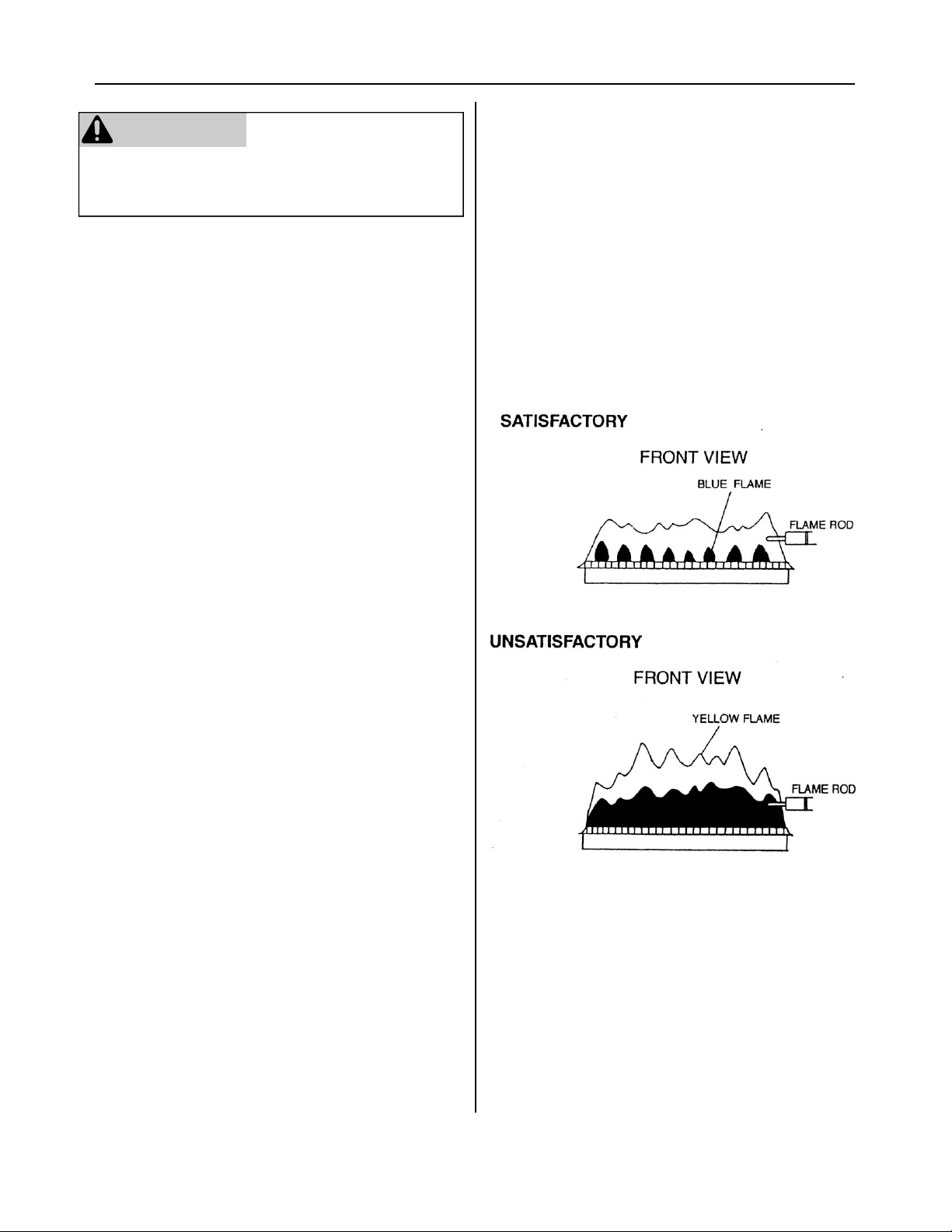

Visual Inspection of Flame

The burner must flame evenly over the entire surface

when operating correctly. The flame must burn with a

clear, blue, stable flame. See the parts breakdown of

the burner for the location of the view ports.

The flame pattern should be as shown in the figures

below.

5. Use soft dry cloth to wipe cabinet.

Vent System

The vent system should be inspected at least annually

for blockages or damage.

Motors

Motors are permanently lubricated and do not need

periodic lubrication. Keep fan and motor free of dust

and dirt by cleaning annually.

Temperature Controller

Use a soft damp cloth to clean the temperature

controller. Do not use solvents.

Lime / Scale Build-up

If you receive Error Code “LC”, refer to the procedure,

Flushing the Heat Exchanger. Refer to the section on

Water Quality to see if your water needs to be treated

or conditioned. (When checking maintenance code

history, “00” is substituted for “LC”.)

8 305, 505, 705 Indoor Manual

Page 9

Error Codes

This appliance has the ability to check its own operation continuously. If a fault occurs, an error code will flash on

the Display of the temperature controller. This assists with diagnosing the fault and may enable you to overcome

a problem without a service call. Please identify the code displayed when inquiring about service.

WARNING

Some of the checks below may need to be done by a qualified service technician. Call a

service technician for any remedy that involves gas or electricity. Call a service

technician if you have any doubt or reservation about performing the remedy yourself.

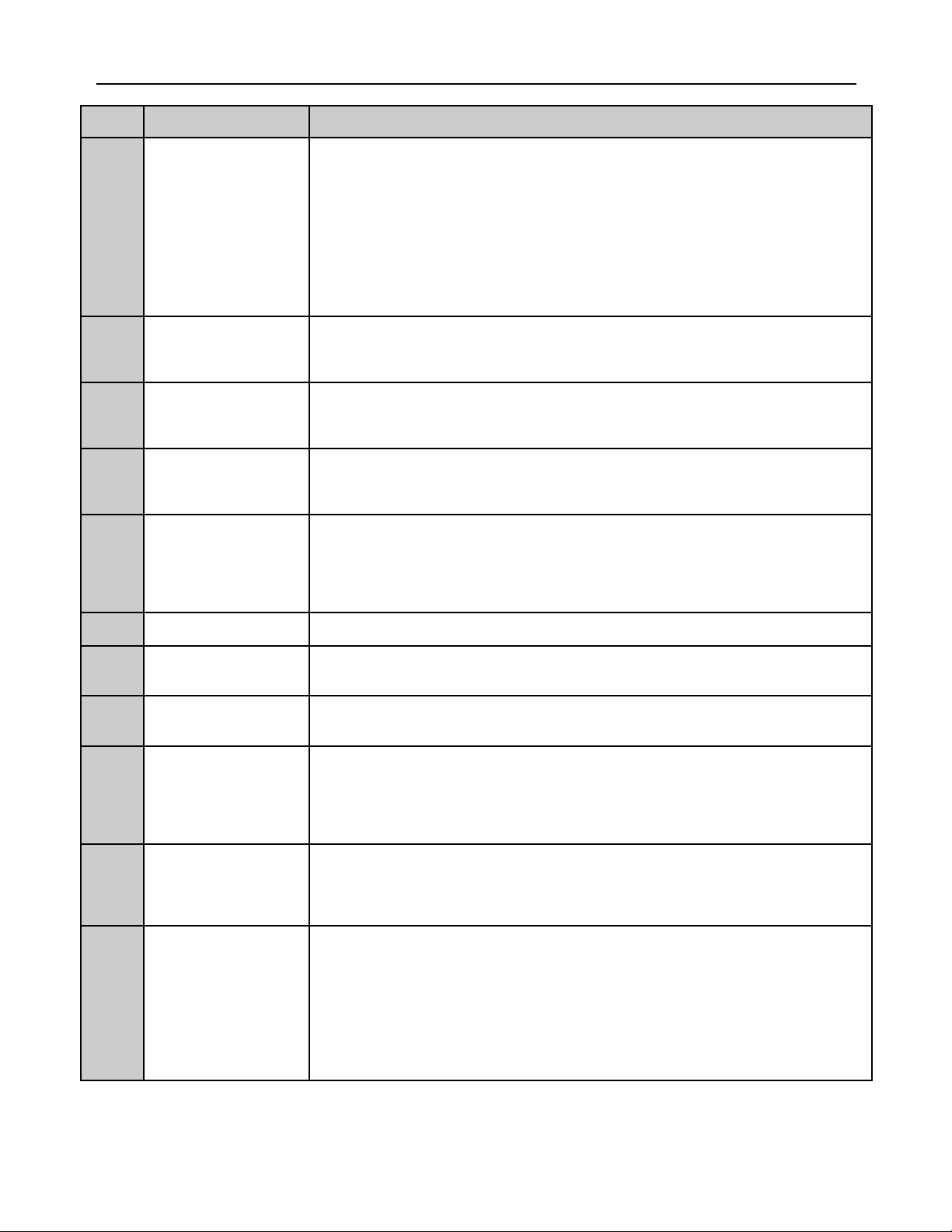

Error Code Table

Code Fault Remedy

02

10

11

12

No burner operation during

freeze protection mode

Air Supply or Exhaust

Blockage

No Ignition Check that the gas is turned on at the water heater, gas meter, or cylinder.

Flame Failure Check that the gas is turned on at the water heater and gas meter. Check for

Service Call

Ensure approved venting materials are being used.

Check that nothing is blocking the flue inlet or exhaust.

Check all vent components for proper connections.

Ensure vent length is within limits.

Ensure condensation collar was installed correctly.

Verify dip switches are set properly.

Check fan for blockage.

Ensure gas type and pressure is correct.

Ensure gas line, meter, and/or regulator is sized properly.

Bleed all air from gas lines.

Verify dip switches are set properly.

Ensure appliance is properly grounded.

Disconnect all 2-Unit or Multi-Unit connections to isolate the problem.

Ensure igniter is operational.

Check igniter wiring harness for damage.

Check gas solenoid valves for open or short circuits.

Remove burner cover and ensure all burners are properly seated.

Remove burner plate and inspect burner surface for condensation or debris.

obstructions in the flue outlet.

Ensure gas line, meter, and/or regulator is sized properly.

Ensure gas type and pressure is correct.

Bleed all air from gas lines.

Ensure proper venting material was installed.

Ensure condensation collar was installed properly.

Ensure vent length is within limits.

Verify dip switches are set properly.

Ensure appliance is properly grounded.

Disconnect keypad.

Disconnect all 2-Unit or Multi-Unit connections to isolate the problem.

Check power supply for loose connections.

Check power supply for proper voltage and voltage drops.

Ensure flame rod wire is connected.

Check flame rod for carbon build-up.

Disconnect and reconnect all wiring harnesses on unit and PC board.

Check all components for electrical short.

Check gas solenoid valves for open or short circuits.

Remove burner plate and inspect burner surface for condensation or debris.

305, 505, 705 Indoor Manual 9

Page 10

Error Code Table

Code Fault Remedy

14

16

32

33

34

52

61

71

72

LC

No

code

Thermal Fuse Check gas type of unit and ensure it matches gas type being used.

Check for restrictions in air flow around unit and vent terminal.

Check for low water flow in a circulating system causing short-cycling.

Ensure dip switches are set to the proper position.

Check for foreign materials in combustion chamber and/or exhaust piping.

Check heat exchanger for cracks and/or separations.

Check heat exchanger surface for hot spots which indicate blockage due to scale build-

up. Refer to instructions in manual for flushing heat exchanger.

Measure resistance of safety circuit.

Ensure high fire and low fire manifold pressure is correct.

Check for improper conversion of product.

Over Temperature

Warning

Outgoing Water

Temperature Sensor

Fault

Heat Exchanger

Outgoing Temperature

Sensor Fault

Combustion Air

Temperature Sensor

Fault

Modulating Solenoid

Valve Signal Abnormal

Combustion Fan

Failure

SV0, SV1, SV2, and

SV3 Solenoid Valve

Circuit Fault

Flame Sensing Device

Fault

Scale Build-up in Heat

Exchanger (when

checking maintenance

code history, “00” is

substituted for “LC”)

Nothing happens when

water flow is activated.

Check for restrictions in air flow around unit and vent terminal.

Check for low water flow in a circulating system causing short-cycling.

Check for foreign materials in combustion chamber and/or exhaust piping.

Check for clogged heat exchanger.

Check sensor wiring for damage.

Measure resistance of sensor.

Clean sensor of scale build-up.

Replace sensor.

Check sensor wiring for damage.

Measure resistance of sensor.

Clean sensor of scale build-up.

Replace sensor.

Check for restrictions in air flow around unit and vent terminal.

Check sensor wiring for damage.

Measure resistance of sensor.

Clean sensor of scale build-up.

Ensure fan blade is tight on motor shaft and is in good condition.

Replace sensor.

Check modulating gas solenoid valve wiring harness for loose or damaged terminals.

Measure resistance of valve coil.

Ensure fan will turn freely.

Check wiring harness to motor for damaged and/or loose connections.

Measure resistance of motor winding.

Check wiring harness to all solenoids for damage and/or loose connections.

Measure resistance of each solenoid valve coil.

Ensure flame rod is touching flame when unit fires.

Check all wiring to flame rod for damage.

Remove flame rod and check for carbon build-up; clean with sand paper.

Check inside burner chamber for any foreign material blocking flame at flame rod.

Measure micro amp output of sensor circuit with flame present.

Replace flame rod.

Flush heat exchanger. Refer to instructions in manual.

Replace heat exchanger.

Clean inlet water supply filter.

On new installations ensure hot and cold water lines are not reversed.

Check for bleed over. Isolate unit from building by turning off hot water line to building.

Isolate the circulating system if present. Open your pressure relief valve; if water is

flowing, there is bleed over in your plumbing.

Ensure you have at least the minimum flow rate required to fire unit.

Ensure turbine spins freely.

Measure the resistance of the water flow control sensor.

Check for DC shorts at components.

10 305, 505, 705 Indoor Manual

Page 11

Trouble Shooting for Common Issues

I don’t have any hot water when I open the tap.

Make sure there is gas, water, and electricity to the

water heater (power is turned on and the gas is turned

on).

When I was using the hot water, the water got cold.

If you adjusted the flow from the tap to lessen it, you

may have gone below the minimum flow required. This

water heater requires a minimum flow rate to operate.

(See the specification page for the flow rate of your

model.) Decrease the temperature setting at the

temperature controller or increase the water flow.

White smoke comes out of the exhaust.

During colder weather when the exhaust temperature

is much hotter than the outside air, the exhaust fumes

condense producing water vapor.

When I open a hot tap, I do not immediately get hot

water.

Hot water must travel through your plumbing from the

water heater to the faucet. The time period for hot

water to reach your fixture is determined by the amount

of water in the plumbing system between the water

heater and the fixture, water pressure, and the flow

rate of the fixture.

After I turn off the hot water tap, the fan on the

water heater continues to run.

The fan is designed to continue running for a short time

after the flow of water stops. This is to ensure constant

water temperatures during rapid starting and stopping,

as well as exhausting any residual gas flue products

from the unit.

Accessing Operating Information

To display the most recent error codes press and hold the “On/Off” button for 2 seconds. While holding the “On/

Off” button press the ▲ button. The last 9 error codes will flash one after the other. To exit this mode press the

“On/Off” and ▲ button as before.

To display the water flow through the water heater press and hold the ▲ button for 2 seconds and without

releasing the ▲ button press the “On/Off” button.

To display the outlet water temperature press and hold the ▼ button for 2 seconds and without releasing the ▼

button press the “On/Off” button.

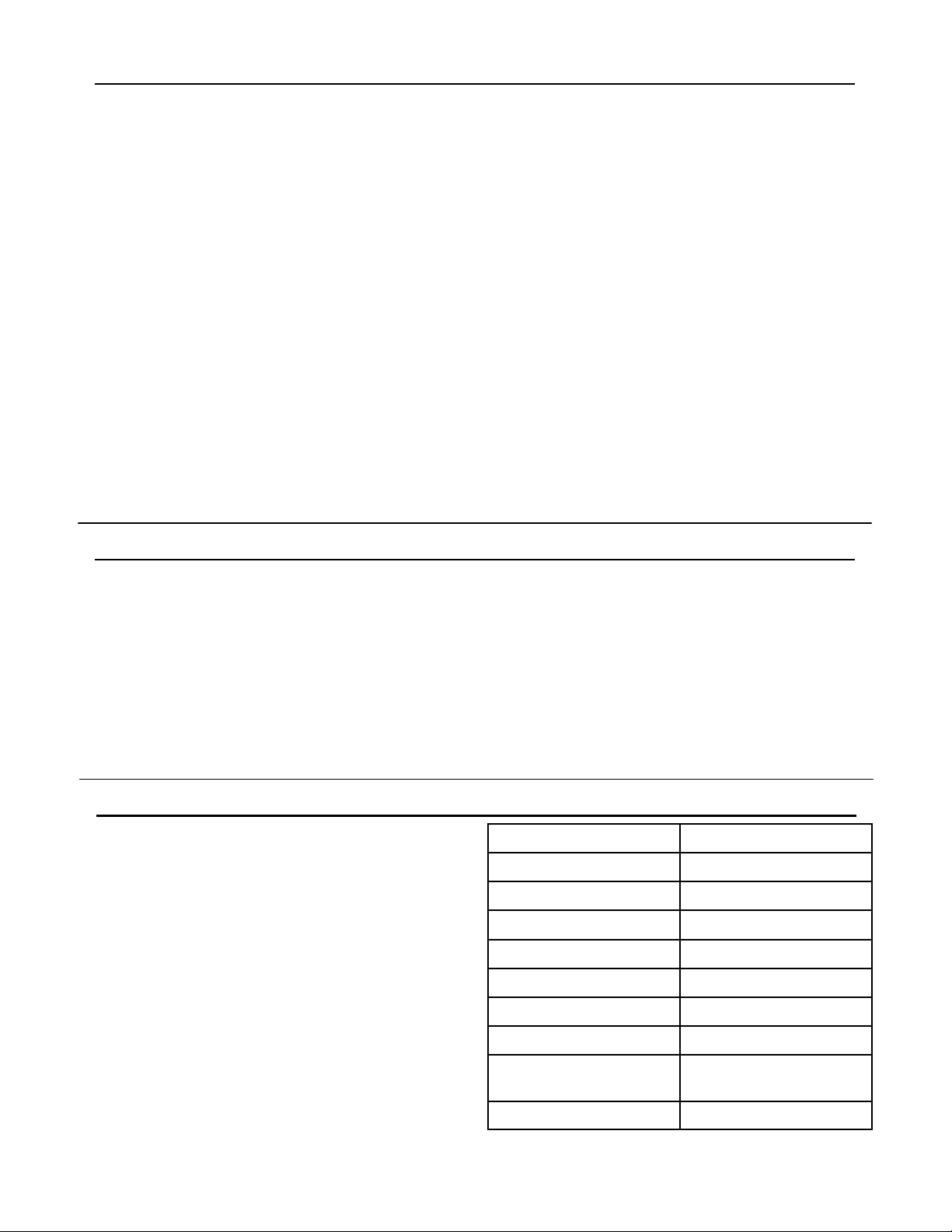

Water Quality

Consideration of care for your water heater should

include evaluation of water quality. If the water quality

exceeds the target levels provided in the table, you

may want to treat or condition the water.

* Source: Part 143 National Secondary Drinking Water

Regulations

Total Hardness Up to 200 mg / L

Aluminum * Up to 0.2 mg / L

Chlorides * Up to 250 mg / L

Copper * Up to 1.0 mg / L

Iron * Up to 0.3 mg / L

Manganese * Up to 0.05 mg / L

Maximum Level

pH * 6.5 to 8.5

TDS (Total Dissolved

Solids) *

Zinc * Up to 5 mg / L

305, 505, 705 Indoor Manual 11

Up to 500 mg / L

Page 12

y

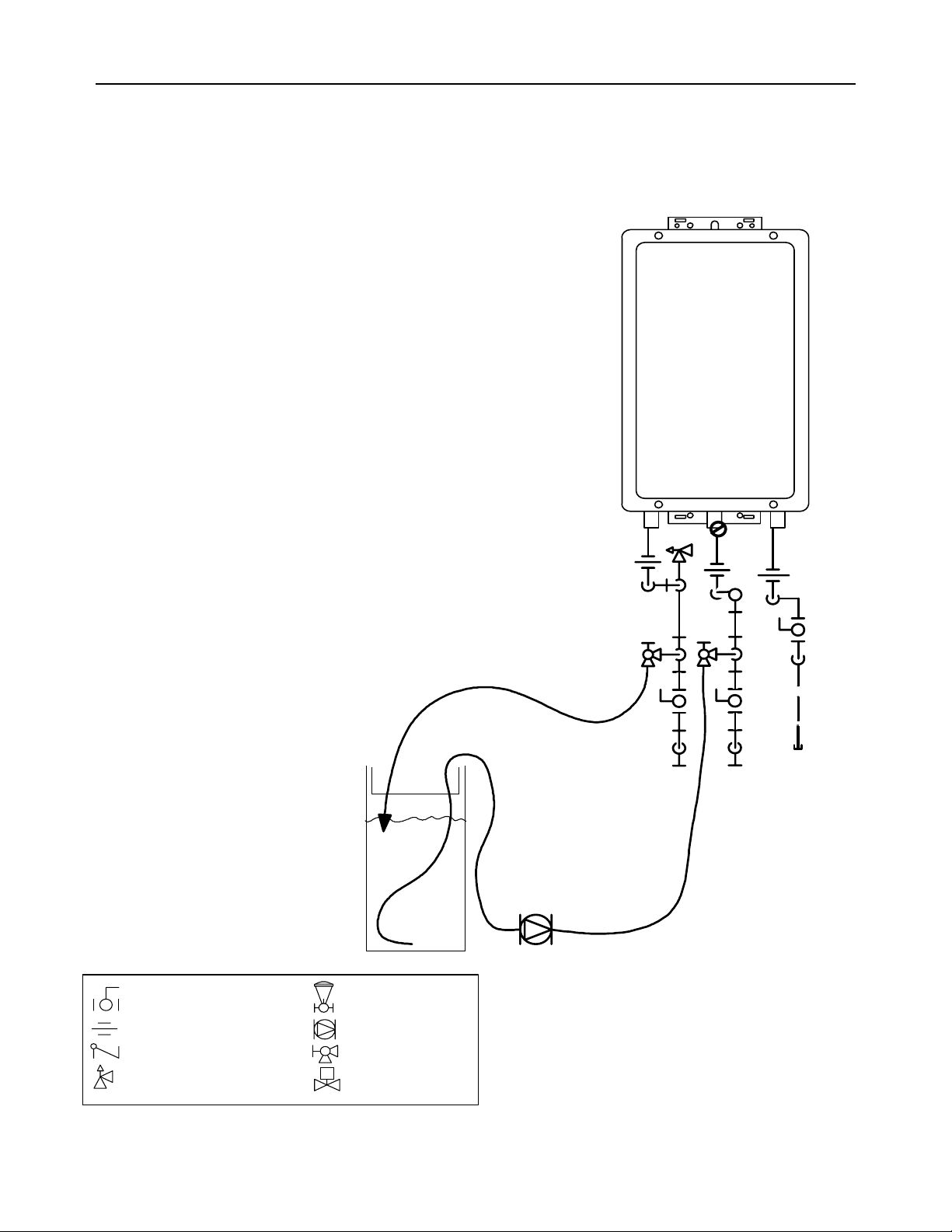

Flushing the Heat Exchanger (Error Code: LC or 00)

An “LC” or “00” error code indicates the unit is beginning to lime up and must be flushed. Failure to flush the

appliance will cause damage to the heat exchanger. Damage caused by lime build-up is not covered by the unit’s

warranty. After flushing, reset the LC fault code by turning off the power to the unit and turning the power back

on.

1. Disconnect electrical power to the water heater.

2. Close the shutoff valves on both the hot water and cold

water lines (V3 and V4).

3. Connect pump outlet hose (H1) to the cold water line at

service valve V2.

4. Connect drain hose (H3) to service valve V1.

5. Pour approximately 4 gallons of virgin, food grade, white

vinegar or citric acid into pail.

Water Heater

6. Place the drain hose (H3) and the hose (H2) to the pump

inlet into the cleaning solution.

7. Open both service valves (V1 and V2) on the hot water and

cold water lines.

8. Operate the pump and allow the cleaning solution to

circulate through the water heater for at least 45 minutes.

9. Turn off the pump.

10. Rinse the cleaning solution from the water heater as follows:

a. Remove the free end of the drain hose (H3) from the pail.

n

b. Close service valve, (V2), and open shutoff valve, (V4).

Do not open shutoff valve, (V3).

I

n

i

e

l

e

t

r

l

F

i

G

a

s

S

c. Allow water to flow through the water heater for 5 minutes

d. Close service valve, (V1), and open shutoff valve, (V3).

11. Disconnect all hoses.

V1

V2

12. Remove the in-line filter at the cold water inlet and clean out

any residue. Place filter back into unit.

13. Restore electrical power to the water heater.

H3

V4

V3

u

p

p

l

C

o

W

d

H

o

t

W

n

a

e

i

t

r

L

e

l

r

L

n

e

a

i

e

t

H2

5 gallon pail of virgin, food

grade, white vinegar (or virgin,

food grade, citric acid).

Circulating Pump

KEY

3/4" Ball Valve

3/4" Union

Check Valve

Pressure Relief Valve

Pressure Regulator

Circulating Pump

Boiler Drain Valve

S

Solenoid Valve

12 305, 505, 705 Indoor Manual

H1

Page 13

Installation Instructions

Only properly trained and qualified installers should

install this appliance. The warranty may be voided due

to improper installation or installation by a non-qualified

installer.

It is highly recommended that all installers attend a

product knowledge class.

General Instructions

WARNING

Do not use substitute materials.

Use only parts certified with the appliance.

• This appliance must be installed by a state qualified

or licensed contractor. It is the responsibility of the

person having the water heater installed to ensure

the installing contractor has proper licenses and

permits for installing water heaters in your location.

It is highly recommended that installers attend a

product knowledge class to ensure customer

satisfaction and warranty coverage. Failure to

comply with state and local codes pertaining to

water heater installations may void the warranty.

• This appliance is not to be installed outdoors.

• A qualified installer or service technician should

install the appliance, inspect it, and leak test it

before use.

• The installation must conform with local codes or, in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, or the Natural

Gas and Propane Installation Code, CSA B149.1.

• The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.1.

• The appliance and its appliance main gas valve

must be disconnected from the gas supply piping

system during any pressure testing of that system at

test pressures in excess of 1/2 psi (3.5 kPa) (13.84

in W.C.).

• Follow the installation instructions and those in Care

and Maintenance for adequate combustion and

ventilation air.

• The appliance should be located in an area where

water leakage of the unit or connections will not

result in damage to the area adjacent to the

appliance or to lower floors of the structure. When

such locations cannot be avoided, it is

recommended that a suitable drain pan, adequately

drained, be installed under the appliance. The pan

must not restrict combustion air flow.

• The flow of combustion and ventilation air shall not

be obstructed.

• This appliance is not suitable for use in an

application such as a pool or spa heater that uses

chemically treated water . (This appliance is

suitable for filling large or whirlpool bath tubs with

potable water.)

• If a water heater is installed in a closed water supply

system, such as one having a backflow preventer in

the cold water supply line, means shall be provided

to control thermal expansion. Contact the water

supplier or local plumbing inspector on how to

control thermal expansion.

• Should overheating occur or the gas supply fail to

shut off, turn off the manual gas control valve to the

appliance.

• Keep the air intake location free of chemicals such

as chlorine or bleach that produce fumes. These

fumes can damage components and reduce the life

of your appliance.

• The appliance must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the gas

supply piping system at test pressures equal to or

less than 1/2 psi (3.5 kPa) (13.84 in W.C.).

305, 505, 705 Indoor Manual 13

Page 14

Clearances from Appliance

to top

to Combustibles

to Non-

Combustibles

Top of

Heater

Back of

Heater

Front of

Heater

Sides of

Heater

Floor/

Ground

Vent

* 4 inches (102 mm) for enclosed area; 1 inch (26 mm) for unenclosed area.

The clearance for servicing is 24 inches in front of the water heater.

For closet installation: 305, 505: clearance is 6 inches (152 mm) from the front.

705: clearance is 24 inches (610 mm) from the front.

305

505

6 inches

(152 mm)

0 (zero) 0 (zero) 0 (zero) 0 (zero)

6 inches

(152 mm)

2 inches

(51 mm)

12 inches

(305 mm)

0 (zero) 4 inches * 0 (zero) 0 (zero)

705

12 inches

(305 mm)

24 inches

(610 mm)

2 inches

(51 mm)

12 inches

(305 mm)

305

505

2 inches

(51 mm)

6 inches

(152 mm)

1/2 inch

(13 mm)

12 inches

(305 mm)

705

2 inches

(51 mm)

to side

24 inches

(610 mm)

1/2 inch

(13 mm)

2 inches

(51 mm)

to floor/ground

to front

Attachment of the Water Heater

1. Identify the installation location and confirm that

the installation will meet all required clearances.

2. Securely attach the water heater to the wall using

any of the holes in the wall installation brackets

which are at the top and bottom of the water

heater. Ensure that the attachment strength is

sufficient to support the weight. Refer to the

weight of the water heater in the Specifications

section.

14 305, 505, 705 Indoor Manual

wall installation

brackets

Page 15

Electrical Connection

The water heater requires a standard 3 prong 120 VAC, 60 Hz properly grounded wall outlet. Plug the 6ft long

power cord into the wall outlet.

Gas Piping

General Instructions

• A manual gas control valve must be placed in the

gas supply line to the water heater. A union can be

used on the connection above the shut off valve for

the future servicing or disconnection of the unit.

• Check the type of gas and the gas inlet pressure

before connecting the water heater. If the water

heater is not of the gas type that the building is

supplied with, DO NOT connect the water heater.

Contact the dealer for the proper unit to match the

gas type.

• Check the gas supply pressure immediately

upstream at a location provided by the gas

company. Supplied gas pressure must be within the

limits shown in the Specifications section.

• Before placing the appliance in operation all joints

including the heater must be checked for gas

tightness by means of leak detector solution, soap

and water, or an equivalent nonflammable solution,

as applicable. (Since some leak test solutions,

including soap and water, may cause corrosion or

stress cracking, the piping shall be rinsed with water

after testing, unless it has been determined that the

leak test solution is non-corrosive.)

• Always use approved connectors to connect the unit

to the gas line. Always purge the gas line of any

debris before connection to the water heater.

• The gas supply line shall be gas tight, sized, and so

installed as to provide a supply of gas sufficient to

meet the maximum demand of the heater and all

other gas consuming appliances at the location

without loss of pressure.

• Any compound used on the threaded joint of the gas

piping shall be a type which resists the action of

liquefied petroleum gas (propane / LPG).

• Refer to an approved pipe sizing chart if in doubt

about the size of the gas line.

305, 505, 705 Indoor Manual 15

Page 16

Gas Piping

Pipe Sizing Procedure - Example

The gas supply must be capable of handling the entire gas load at the location. Gas line sizing is based on gas

type, the pressure drop in the system, the gas pressure supplied, and gas line type. Refer to the National Fuel

Gas Code, NFPA 54, for proper gas line sizing. The below information is provided as an example.

1. Determine the cubic feet per hour of gas required by dividing the gas input (on the rating plate) by the heating

value of the gas (available from the local gas company). The gas input needs to include all gas products at

the location and the maximum BTU usage at full load when all gas products are in use.

Gas Input of the water heater (BTU / HR)

Cubic Feet per Hour (CFH) =

Heating Value of Gas (BTU / FT 3 )

2. Use the table for your gas type to find the pipe size required for your cubic feet per hour of gas and your pipe

length.

Example: The heating value of propane gas for your location is 2516 BTU / FT

The gas input is 190,000 BTU/HR. Additional appliances at the location require 75,000 BTU/HR.

Therefore the cubic feet per hour = (190,000+75,000) / 2516 = 105.3 FT

If the pipe length is 100 ft then the 3/4 inch pipe size capable of supplying 197 FT

will be adequate.

3

.

3

/ HR.

3

/ HR of propane gas

Pipe Sizing Table - Natural Gas

cubic feet per hour Schedule 40 Metallic Pipe

Inlet Pressure: less than 2 psi (55 inches W.C.)

Pressure Drop: 0.3 inches W.C.

Specific Gravity: 0.60

Length

10

20

30

40

50

60

70

80

90

100

3/4 1 1 1/4 1 1/2

273 514 1060 1580

188 353 726 1090

151 284 583 873

129 243 499 747

114 215 442 662

104 195 400 600

95 179 368 552

89 167 343 514

83 157 322 482

79 148 304 455

Schedule 40 Metallic Pipe

Pipe Size (inches)

Pipe Sizing Table - Propane Gas

cubic feet per hour

Inlet Pressure: 11.0 inches W.C.

Pressure Drop: 0.5 inches W.C.

Specific Gravity: 1.50

Length

10

20

30

40

50

60

80

100

125

150

1/2 3/4 1 1 1/4

291 608 1150 2350

200 418 787 1620

160 336 632 1300

137 287 541 1110

122 255 480 985

110 231 434 892

101 212 400 821

94 197 372 763

89 185 349 716

84 175 330 677

Pipe Size (inches)

125

150

175

200

16 305, 505, 705 Indoor Manual

70 131 269 403

63 119 244 366

58 109 224 336

54 102 209 313

175

200

74 155 292 600

67 140 265 543

Page 17

Water Piping

General Instructions

• A manual water control valve must be placed in the

water inlet connection to the water heater before it is

connected to the water line. Unions may be used

on both the hot and cold water lines for future

servicing and disconnection of the unit.

• The piping (including soldering materials) and

components connected to this appliance must be

approved for use in potable water systems.

• Purge the water line to remove all debris and air.

Debris will damage the water heater.

• Toxic chemicals such as those used for boiler water

treatment are not to be introduced to the potable

water used for space heating.

• If the appliance will be used as a potable water

source, it must not be connected to a system that

was previously used with a nonpotable water

heating appliance.

• Ensure that the water filter on the water heater is

clean and installed.

Pressure Relief Valve

• An approved pressure relief valve is required by the

American National Standard (ANSI Z21.10.3) /

Canadian Standard (CSA 4.3) for all water heating

systems.

• The relief valve must comply with the standard for

Relief Valves and Automatic Gas Shutoff Devices

for Hot Water Supply Systems ANSI Z21.22 and /or

the standard Temperature, Pressure, Temperature

and Pressure Relief Valves and Vacuum Relief

Valves, CAN1-4.4.

• The relief valve must be rated up to 150 psi and to

at least the maximum BTU/hr of the appliance.

• The discharge from the pressure relief valve should

be piped to the ground or into a drain system to

prevent exposure or possible burn hazards to

humans or other plant or animal life. Follow local

codes. Water discharged from the relief valve could

cause severe burns instantly, scalds, or death.

• The pressure relief valve must be manually

operated once a year to check for correct operation.

Freeze Protection

• The relief valve should be added to the hot water

outlet line according to the manufacturer’s

instructions. DO NOT place any other type valve or

shut off device between the relief valve and the

water heater.

• Do not plug the relief valve and do not install any

reducing fittings or other restrictions in the relief line.

The relief line should allow for complete drainage of

the valve and the line.

• If a relief valve discharges periodically, this may be

due to thermal expansion in a closed water supply

system. Contact the water supplier or local

plumbing inspector on how to correct this situation.

Do not plug the relief valve.

• Neither this water heater nor the American National

Standard (ANSI Z21.10.3) / Canadian Standard

(CSA 4.3) requires a combination temperature and

pressure relief valve for this appliance. However,

local codes may require a combination temperature

and pressure relief valve.

The freeze protection features include electrical

heating elements and intermittent firing of the burner.

Freeze protection may be disabled if electricity or gas

is not supplied, or if there is an error preventing the

water heater from functioning. Loss of freeze

protection may result in water damage from a burst

heat exchanger or water lines.

The installation of auto drain down solenoid valves is

optional. However, it is strongly recommended that

these valves be installed to prevent damage from

freezing in case the normal freeze protection should

become disabled. Any product damage due to

freezing will not be covered by the warranty.

305, 505, 705 Indoor Manual 17

In addition, the solenoid valves should be connected

electrically to a surge protector with terminals that

attaches to the PC board in the unit. This allows the

solenoid valves to operate if the water heater is

disabled due to an error code.

The solenoid valves and the surge protector with

terminals are available for purchase separately.

Page 18

Freeze Protection Piping

Vacuum

Breaker

NOTICE

Warranty does not cover damage due to freezing.

When electrical power and gas are supplied to the

water heater, it will not freeze in environments as cold

as -30º F when protected from direct wind exposure.

In the event of a power failure at temperatures below

freezing the water heater should be drained of all

water to prevent freezing damage.

The unit may be drained manually. However, it is

highly recommended that drain down solenoid valves

be installed that will automatically drain the unit if

power is lost. It is also recommended that a surge

protector with terminals be installed that attaches to

the PC board in the unit and allows the solenoid

valves to operate if the unit is disabled due to an error

code.

Water Heater

When the electrical power to the water heater fails, the

3/4” solenoid valve closes (stopping the flow of water

into the heater) and the 1/2” solenoid valve opens

(allowing the water heater and associated piping to

drain. Ensure that you run the drain for the solenoids

to the outside environment to prevent discharging

water inside the building causing water damage).

NOTE:

Heat trace ALL water pipe and fittings located

outside home (attic, crawl space) or building

structure. (ALL water pipe and fittings shown

above the dashed line in the drawing.)

NOTE:

ALL pipe and fittings shown below dashed line

should be located inside home or building

structure.

The vacuum breaker line should be located

inside the building structure.

Minimum 3/4" Hot Water

Supply Line

KEY

3/4" Ball Valve

3/4" Union

Check Valve

Pressure Relief Valve

Pressure Regulator

Circulating Pump

Boiler Drain Valve

S

Solenoid Valve

4

/

s

G

"

3

a

e

t

n

c

n

C

o

o

i

n

G

u

s

p

S

a

p

y

l

S

3/4" Minimum

Normally Closed

1/2" Minimum

Normally Open

Solenoid Valve

This is not an engineered drawing. It is intended only as a guide and not

as a replacement for professionally engineered project drawings. This

drawing is not intended to describe a complete system. It is up to the

contractor/engineer to determine the necessary components and

configuration of the particular system being installed. This drawing does

not imply compliance with local building code requirements. It is the

responsibility of the contractor/engineer to ensure installation is in

accordance with all local building codes. Confer with local building

officials before installation.

Solenoid Valve

S

Route to Floor Drain

i

M

n

i

C

o

u

S

4

/

3

m

m

u

d

l

p

"

W

a

e

t

r

p

n

i

y

l

e

L

18 305, 505, 705 Indoor Manual

Page 19

Recommended Piping for Basic Installation

Water Heater

3/4" Hot Water Supply Line

For Building Fixtures

Equipment List

Water Heaters

Plumbing Installation

Kit (Optional)

(3/4" Fittings Include:

2 Unions, 2 Ball Valves,

2Drain Valves and

1 Pressure Relief Valve.)

3

4

G

/

"

a

s

C

3

4

/

"

o

c

n

o

i

n

t

e

n

G

a

s

S

u

p

p

y

l

C

o

d

a

W

l

e

t

r

S

u

p

p

y

l

QTY

1

1

L

n

i

e

3/4" Ball Valve

3/4" Union

Check Valve

Pressure Relief Valve

KEY

Pressure Regulator

Circulating Pump

Boiler Drain Valve

S

Solenoid Valve

This is not an engineered drawing. It is intended only as a guide and not

as a replacement for professionally engineered project drawings. This

drawing is not intended to describe a complete system. It is up to the

contractor/engineer to determine the necessary components and

configuration of the particular system being installed. This drawing does

not imply compliance with local building code requirements. It is the

responsibility of the contractor/engineer to ensure installation is in

accordance with all local building codes. Confer with local building

officials before installation.

305, 505, 705 Indoor Manual 19

Page 20

t

Recommended Piping for Circulation Systems

NOTE:

For residential and commercial

applications, this piping arrangement maintains full warranty.

For this application:

Pump should be controlled by an Aquastat, Timer or Combination Aquastat and

Timer.

Pump to be sized to maintain circulation

loop temperature.

The pump should be sized to overcome

he pressure loss through the tank water

heater, and supply and return plumbing.

Pump to be of bronze or stainless

construction.

Water Heater

Tank Water Heater to be Sized for

Heat Loss of Circulation Loop.

Equipment List

Water Heaters

Plumbing Installation

Kit (Optional)

(3/4" Fittings Include:

2 Unions, 2 Ball Valves,

2Drain Valves and

1 Pressure Relief Valve.)

3

4

/

"

s

G

C

a

o

n

o

i

n

t

n

c

e

G

s

S

a

u

p

p

y

l

Minimum 3/4" Cold Water Supply Line

Building Supply

QTY

1

1

IMPORTANT: Connect the building

return line to the hot water supply line

as close as possible to the water

heater.

KEY

3/4" Ball Valve

3/4" Union

Check Valve

Pressure Relief Valve

Pressure Regulator

Circulating Pump

Boiler Drain Valve

S

Solenoid Valve

This is not an engineered drawing. It is intended only as a guide and not

as a replacement for professionally engineered project drawings. This

drawing is not intended to describe a complete system. It is up to the

contractor/engineer to determine the necessary components and

configuration of the particular system being installed. This drawing does

not imply compliance with local building code requirements. It is the

responsibility of the contractor/engineer to ensure installation is in

accordance with all local building codes. Confer with local building

officials before installation.

Electric Water

20 305, 505, 705 Indoor Manual

Heater

Building

Fixtures

k

n

a

T

n

o

i

s

n

a

p

x

E

Page 21

Optional Piping for Circulation Systems

NOTE:

For residential and commercial

applications, this piping arrangement

reduces the warranty to the following:

3 years on heat exchanger

3 year on parts

Full warranty will be maintained if an

on-demand recirculation system in

incorporated. Refer to the Limited

Warranty.

For this application:

Pump should be controlled by an Aquastat,

Timer or Combination Aquastat and Timer.

Pump to be sized to maintain circulation

loop temperature.

A minimum of 3 GPM flow is recommended

for the circulation system.

The pump should be sized to overcome the

pressure loss through the water heate r,

supply and return plumbing.

Pump to be of bronze or stainless construc tion.

Water Heater

Equipment List

Water Heaters

Plumbing Installation

Kit (Optional)

(3/4" Fittings Include:

2 Unions, 2 Ball Valves,

2Drain Valves and

1 Pressure Relief Valve.)

s

G

"

a

4

/

3

G

s

a

e

n

n

C

o

y

l

p

p

u

S

QTY

1

1

t

c

n

o

i

Note:

Water heater outlet temperature

cannot be adjusted when

circulationpumpisrunning.

Minimum 3/4" Hot Water

Supply Line

g

n

i

d

l

i

u

B

e

r

u

t

x

i

F

s

t

e

l

t

u

O

KEY

3/4" Ball Valve

3/4" Union

Check Valve

Pressure Relief Valve

(Optional)

2-6 Gallon

Storage Tank

(To elim inate cold water

sandwich effect caused by

frequent On/Off operation)

Pressure Regulator

Circulating Pump

Boiler Drain Valve

S

Solenoid Valve

Minimum 3/4 “ Cold Water Supply Line

k

n

a

T

n

i

o

s

n

a

p

x

E

This is not an engineered drawing. It is intended only as a guide and not

as a replacement for professionally engineered project drawings. This

drawing is not intended to describe a complete system. It is up to the

contractor/engineer to determine the necessary components and

configuration of the particular system being installed. This drawing does

not imply compliance with local building code requirements. It is the

responsibility of the contractor/engineer to ensure installation is in

accordance with all local building codes. Confer with local building

officials before installation.

305, 505, 705 Indoor Manual 21

Page 22

Venting Instructions

Intake / Exhaust Guidelines

Refer to the specific instructions on your vent product for additional installation requirements.

• This water heater is a direct vent water heater and

therefore is certified and listed with the vent

system. You must use vent components that are

certified and listed with the water heater model.

• Do not combine vent components from different

manufacturers.

• The vent system must vent directly to the outside

of the building and use outside air for combustion.

• Venting should be as direct as possible with a

minimum number of pipe fittings.

• Avoid dips or sags in horizontal vent runs by

installing supports per the vent manufacturer’s

instructions.

• Support horizontal vent runs every four feet and all

vertical vent runs every six feet or in accordance

with local codes.

• Vent diameter must not be reduced.

• Do not connect the venting system with an existing

vent or chimney.

• Do not common vent with the vent pipe of any

other water heater or appliance.

• Vent connections must be firmly pressed together

so that the gaskets form an air tight seal.

• On the 305 and 505 models, the vent piece

connected to the water heater must be secured

with one self-tapping screw.

• Refer to the instructions of the vent system

manufacturer for component assembly instructions.

• If the vent system is to be enclosed, it is suggested

that the design of the enclosure shall permit

inspection of the vent system. The design of such

enclosure shall be deemed acceptable by the

installer or the local inspector.

NOTICE

If it becomes necessary to access an enclosed vent

system for service or repairs, the manufacturer is not

responsible for any costs or difficulties in accessing

the vent system. Warranty does not cover obtaining

access to an enclosed vent system.

Condensate

Condensate formation can occur in high efficiency

direct vent appliances. To prevent condensate

damage follow these instructions.

• Vertical terminations must incorporate a condensate

drain and trap as close as possible to the appliance.

• Slope any horizontal venting 1/4 inch per foot (19

mm / m), towards the heater if the condensate

collector is used, or towards the exhaust terminal if

the condensate collector is not used.

• Dispose of condensate per local codes.

• The condensate trap must contain a minimum of 3

inches (75 mm) of water.

WARNING

If the condensate collector is not used, the drain pipe

must be capped to prevent exhaust gases and

condensate from entering the building. The cap is

supplied on the appliance.

NOTICE

Provisions must be made to prevent the condensate

from entering the water heater. Without proper

drainage or disposal, condensate will damage the heat

exchanger.

• This water heater has an integrated condensate

collector.

• Regions of cold climate will create more condensate

in the vent system. The condensate collector

should be used in cold climates.

22 305, 505, 705 Indoor Manual

Page 23

Venting Instructions

Maximum Vent Length

1. Determine the number of 90 degree elbows in the vent system. (Two 45 degree elbows count as one 90

degree elbow.)

2. Refer to the table to find the maximum vent length based on the number of elbows.

3. Follow the applicable note.

Example: If you have one elbow then your maximum vent length is 35 feet (10.7 m). If your actual length is

greater than 15 ft (4.6 m) then move dip switch no. 1 (SW1) to OFF.

Number of 90° Elbows

0 1 2 3 4 5 6

41 ft 1

(12.5 m)

1 If the length is greater than 21 ft (6.4 m) then move

dip switch no. 1 (SW1) to OFF.

2 If the length is greater than 15 ft (4.6 m) then move

dip switch no. 1 (SW1) to OFF.

3 If the length is greater than 9 ft (2.7 m) then move

dip switch no. 1 (SW1) to OFF.

4 Move dip switch no. 1 (SW1) to OFF.

35 ft 2

(10.7 m)

29 ft 3

(8.8 m)

23 ft 4

(7.0 m)

17 ft 4

(5.2 m)

Notes 1234

11 ft 4

(3.4 m)

5 ft 4

(1.5 m)

Switch No.

ON

O

F

F

1

2

3

4

5

6

7

8

NOTICE

If you have a longer vent length, dip switch no. 1 is required to be in the OFF position. This ensures the water

heater will run properly. Blocked flue error codes and shutdowns may result if dip switch no. 1 is not in the

correct position. On the 505 model, the maximum water flow capacity will be reduced by about 10% when dip

switch no. 1 is OFF.

305, 505, 705 Indoor Manual 23

Page 24

Venting Products

Listed and Tested Vent Products for the 305 and 505 Models

Manufacturer Product Parts

Ubbink Rolux Vent System

Heat-Fab Saf-T Vent SC system

Metal-Fab Corr/Guard Vent/Air

Intake System

Refer to the manufacturer’s technical literature for

specific part numbers and instructions.

Listed and Tested Vent Products for the 705 Model

Manufacturer Product

Heat-Fab Saf-T Vent 9401AMTK 5400CI 9492 NA

Z-Flex Z-Vent 2SVSNA04.5 2SVSRCF4 2SVSTPX4 NA

ProTech

Systems

Metal-Fab Corr/Guard 4CGOA 4CGSWC 4CGSWMCM

FasNSeal FSAAU4 * FSRC4 * FSBS4 *

Appliance

Adapter

Vertical

Termination

Horizontal

Termination

Horizontal

Concentric

Termination

FSDVPTB04LH *

FSDVWT4

4CG7HT90

4CG7HT

FSDVWMTP4LH,

FSEDVWMTP4LH

Vent Manufacturer Contact Information for Installation Instructions and Parts Lists:

Adjustable

Horizontal

Concentric

Termination

NA

NA

NA

Ubbink

Telephone: 866-677-4960

500 Tennessee Waltz Parkway

Ashland City, TN 37015

Heat-Fab

Telephone: 800-772-0739

Fax: 413-863-4803

E-mail: custsvc@heat-fab.com

Web Site: www.heatfab.com

ProTech Systems, Inc.

Telephone: 800-766-3473

518-463-7284

Fax: 518-463-5271

E-mail: support@protechinfo.com

Web Site: www.protechinfo.com

Z-Flex

Telephone: 800-654-5600

Fax: 888-889-3539

E-mail: sales@z-flex.com

Web Site: www.novaflex.com

Metal-Fab Inc.

Telephone: 800-835-2830

316-943-2351

Fax: 316-943-2717

E-mail: info@mtlfab.com

Web Site: www.metal-fabinc.com

24 305, 505, 705 Indoor Manual

Page 25

X

Flue Terminal Clearances (ANS Z21.10.3 ● CSA 4.3)

INSIDE

CORNER DE TAI L

G

H

A

I

B

D

E

B

OPERABLE

FIXED

CLOSED

M

K

C

FIXED

B

L

F

Ref

CLOSED

OPERABLE

B

Description US Installations

B

B

J

A

V

A Clearance above grade, veranda, porch, deck, or balcony 12 inches (30 cm)

B Clearance to window or door that may be opened 12 inches (30 cm)

C Clearance to permanently closed window *

Vertical clearance to ventilated soffit, located above the terminal

D

within a horizontal distance of 2 feet (61 cm) from the center line

of the terminal

E Clearance to unventilated soffit *

F Clearance to outside corner *

G Clearance to inside corner *

Clearance to each side of center line extended above meter/

H

regulator assembly

AIR SUPPLY INLET

VENT TERMINAL

AREA WHERE

TERMINAL IS NOT

PERMITTTED

*

*

I Clearance to service regulator vent outlet *

Clearance to nonmechanical air supply inlet to building or the

J

combustion air inlet to any other appliance

K Clearance to a mechanical air supply inlet

Clearance above paved sidewalk or paved driveway located on

L

public property

12 inches (30 cm)

3 feet (91 cm) above if within

10 feet (3 m) horizontally

*

M Clearance under veranda, porch, deck, or balcony *

1 A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single family dwellings and serves

both dwellings.

2 Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor.

∗ For clearances not specified in ANSI Z223.1/NFPA 54 or CSA B149.1, clearances are in accordance with local installation codes and the

requirements of the gas supplier.

305, 505, 705 Indoor Manual 25

Page 26

Additional Clearances - Vent Terminal

Local codes supersede these clearances.

• Avoid termination locations near a dryer vent.

• Avoid termination locations near commercial cooking exhaust.

Vent terminal (represents concentric vent terminal for the water heater)

V

(1.52 m) vertically

60"

between water heater

terminals

(0.91 m) to ventilated

or unventilated soffit

or eve vent; or to a

36"

deck or porch

V

(0.30 m ) to an

inside corner

(1.52 m) between

water heater

terminals at

different levels

V

12"

VV

12"

(0.30 m) between

water heater terminals

at same level

INSIDE

CORNER

60"

V

(0.61 m) to wall or parapet

24"

12"

V V

V

(0.30 m) between water

heater terminals at same

level

26 305, 505, 705 Indoor Manual

Page 27

Flue Installation for the 305 and 505 Models

Horizontal Termination without using the Condensate Collector

WARNING

If the condensate collector is not used, the drain pipe

must be capped to prevent exhaust gases and

condensate from entering the building. The cap is

supplied on the appliance.

Maximum Height *

5 feet (1.52 m)

Horizontal Termination using

the Condensate Collector

(condensate collector must be used in all installations)

* The condensate collector must be used

in horizontal terminations if a vertical rise

in the vent system exceeds 5ft.

Regions of cold climate will create

more condensate in the vent system.

The condensate collector should be

used in cold climates.

If more than one elbow is used in the

vertical section the condensate

collector must be used.

Vertical Termination

Condensate

Trap

3 in (75 mm)

minimum

Condensate Collector

Bracket

Securing Screw

Condensate

Trap

3 in (75 mm)

minimum

3 in (75 mm)

minimum

3 in (75 mm)

minimum

To adjust the condensate collector position or to

replace the female vent top with a male vent top:

1. Loosen the 4 screws at the rear bracket

2. Slide the bracket away from the female vent top.

3. Remove the 4 screws attaching the female vent

top to the water heater.

4. Lift up the female vent top and reposition as

desired (or replace with a male vent top).

5. Install the 4 screws at the vent top and tighten the

4 screws at the bracket.

Secure the first vent component to the water heater

with one self-tapping screw at the hole located above

the condensate collector.

305, 505, 705 Indoor Manual 27

Page 28

Flue Installation for the 705 Model

Air Intake Assembly

The air intake system consists of a field supplied 4

inch diameter stainless steel, Schedule 40 PVC, ABS

or CPVC pipe. A maximum 6 feet of semi-rigid

flexible aluminum ducting can also be used. Foil

wrapped dryer vent and cell core products are not

authorized.

The air intake has a zero clearance to combustibles.

Air Intake Connection

1.Drill 2 small holes at the end of the air intake pipe.

2.Slide the pipe over the air intake terminal.

3.Using a level, ensure the pipe is straight up and

down.

4.With self tapping screws, attach the pipe to the air

intake terminal.

5.Apply a bead of silicone around the pipe and air

intake terminal, ensuring an air tight connection.

Exhaust Pipe Assembly

Refer to the manufacturer’s installation instructions for

the specific exhaust vent system.

1

3

2

4

Venting Clearances to Combustibles

Enclosed Unenclosed

Vent Size

Horizontal &

Vertical

Horizontal &

Vertical

4" (102 mm) 4" (102 mm) 1" (26 mm)

Horizontal Terminations

The air intake must be located in relation to the exhaust as shown below. The air intake must angle 1/4 inch per

foot to the termination to prevent entry of rain.

6”

Vent

12”

4”

8”

Optional

Intake

Intake

The vent termination and air

intake must be in the same

pressure zone and face the

same direction.

EXHAUST

COMBUSTION AIR /

INTAKE

12” MIN. ABOVE

GRADE OR

SNOW LEVEL

SLOPE INTAKE AND EXHAUST

TOWARD OUTSIDE TERMINATION

MINIMUM 1/4" PER FOOT

28 305, 505, 705 Indoor Manual

Page 29

Flue Installation for the 705 Model

Horizontal with Concentric Termination

SLOPE INTAKE AND EXHAUST

TOWARD OUTSIDE TERMINATION

MINIMUM 1/4" PER FOOT

12” MIN. ABOVE

GRADE OR

SNOW LEVEL

Vertical Terminations

The air intake requires a return bend or two 90º elbows to prevent entry of rain.

The vent termination and air intake must be in the same pressure zone.

3”

MAX

12” MIN

12”

12” MIN

MIN

ANTICIPATED

SNOW LEVEL

COMBUSTION

AIR PIPE

EXHAUST PIPE

3”

MAX

12” MIN

3”

MAX

12” MIN

3”

305, 505, 705 Indoor Manual 29

12” MIN

Page 30

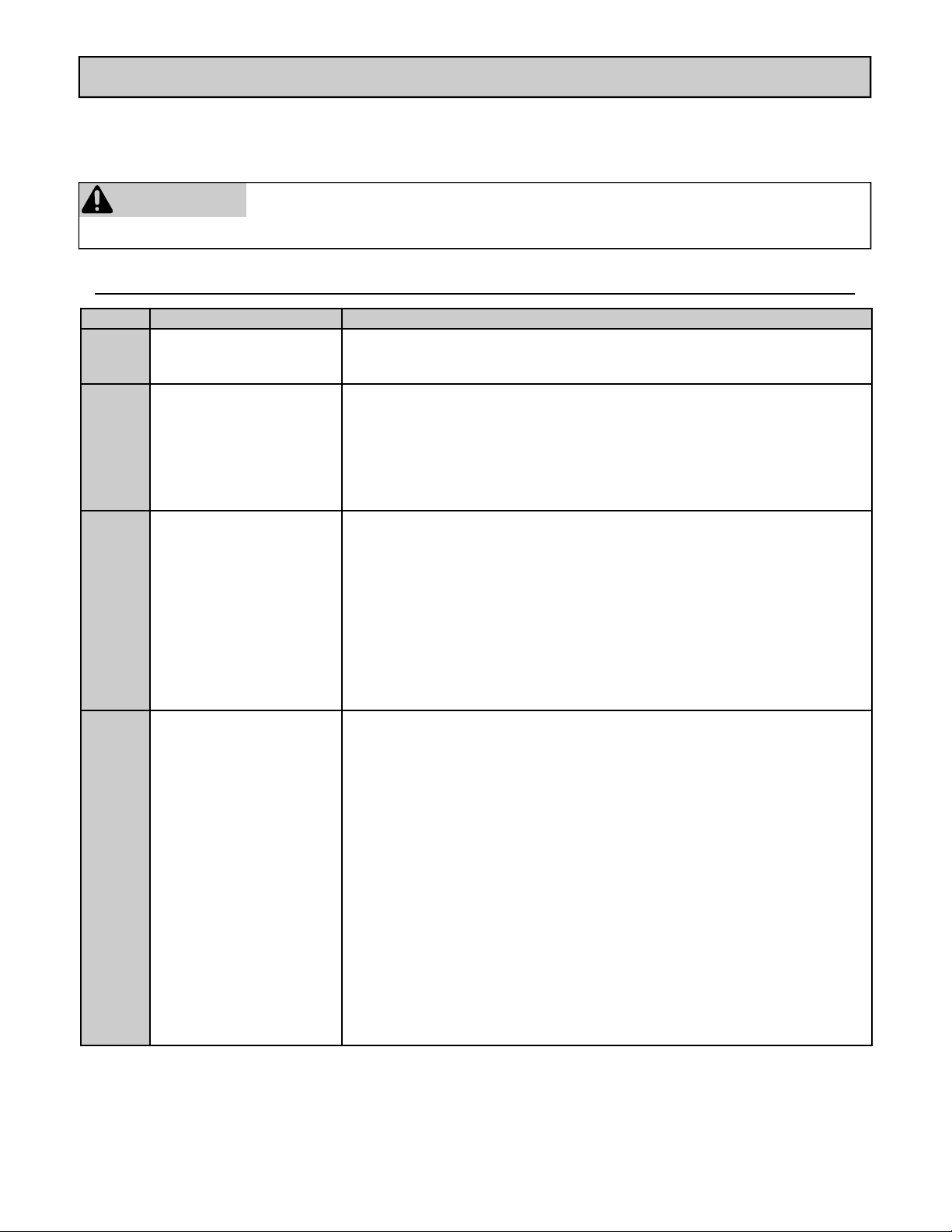

High Altitude Installations

Set dip switches 2 and 3 to the values shown in table

below for your altitude. The default setting for the

appliance is 0-2000 ft (0-610 m) with switches No. 2

and No. 3 in the OFF position.

0-2000 ft

(0-610 m)

2001-5200 ft

(610-1585 m)

WARNING

5201-7700 ft

(1585-2347 m)

DO NOT adjust the other dip

switches unless specifically

instructed to do so.

Switch No. 2 OFF OFF ON ON

Switch No. 3 OFF ON OFF ON

Switch No.

ON

O

F

F

Switch No.

ON

1

2

3

4

5

6

7

8

O

F

F

1

2

3

4

5

6

7

8

Switch No.

ON

O

F

F

1

2

3

4

5

6

7

8

7701-10200 ft

(2347-3109 m)

Switch No.

ON

O

F

F

1

2

3

4

5

6

7

8

Connecting Multiple Water Heaters

The 2-Unit connection cable is an optional accessory

that connects 2 water heaters and allows them to

function as one hot water source.

The Multi-Unit connection kit and Multi-Unit connection

cables are optional accessories that connect 2 to 5

water heaters and allow them to function as one hot

water source.

The Multi-Unit connection kit includes a PC board and

one Multi-Unit connection cable.

Refer to the instructions that come with the accessory

for complete installation information.

Number of Connected Water Heaters: Accessories Necessary:

2

3

4

5

(1) 2-Unit connection cable

(1) Multi-Unit connection kit

(1) Multi-Unit connection kit

(1) Multi-Unit connection kit

Guidelines

• Do not install both the 2-Unit connection cable and

the Multi-Unit connection kit because they are not

designed to operate together.

• Water heaters should be installed less than 18

inches apart so that the cables will reach between

units and to prevent temperature fluctuations (cold

water sandwich effect) when the water is shut off

and turned back on.

• Temperature settings can only be changed on the

controller for the primary unit.

or (1) Multi-Unit connection kit

and (1) Multi-Unit connection cable

and (2) Multi-Unit connection cables

and (3) Multi-Unit connection cables

30 305, 505, 705 Indoor Manual

Page 31

Temperature Controller Installation

Location

Indoor models have their controller built into the front panel. Additional controllers can also be installed.

• The controller should be out of reach of small

children.

• Avoid locations where the controller may become

hot (near the oven or radiant heater).

• Avoid locations in direct sunlight. The digital

display may be difficult to read in direct sunlight.

Configurations

A maximum of 4 temperature controllers can be

installed for a water heater or bank of water heaters.

Controllers can only be wired in parallel. Controllers

cannot be wired in series.

If 4 temperature controllers are installed,

simultaneously press the Priority and On/Off buttons

on the fourth controller until a beep sounds.

• Avoid locations where the temperature controller

could be splashed with liquids.

• Do not install in locations where it can be adjusted

by the public.

Water

Heater

Co n t r o l l e r s

Cable Lengths and Size

The cable for the temperature controller should be a

non-polarized two-core cable with a minimum gauge

of 22 AWG. The maximum cable length from each

controller to the water heater depends on the total

number of wired controllers connected to the water

heater.

Wire controllers in parallel

Number of Wired

Controllers

1 328 ft (100 m)

2 164 ft (50 m)

3 or 4 65 ft (20 m)

Maximum Cable Length for each

Controller to Water Heater

305, 505, 705 Indoor Manual 31

Page 32

"

Temperature Controller Installation

Mounting the Controller

Follow the procedure below to install additional

controllers.

1. Determine a suitable location for the

controller.

2. Make three holes in the wall as shown.

3. Run the cable between the controller and the

water heater or the controller and the other

controller.

4. Remove the face plate from the temperature

controller using a screwdriver.

5. Connect the cable to the temperature

controller.

6. Mount the controller to the wall using the

holes drilled in step 2.

7. Disconnect the power from the water heater.

WARNING

Do not attempt to connect the temperature controllers

with the power on. There is 120 volt potential, next to

the temperature controller connections inside the unit.

Do not connect the temperature controller to the

120VAC terminals provided for the optional

solenoid drain valves.

All service and wiring should be performed by a

registered installer.

Outline of Controller

Outline of Remote

8. Remove the cover of the water heater.

9. Remove the plastic cover from the PCB and

electrical connections.

10. Thread the cable through the access hole at

the base of the unit and connect the wires to

the controller terminals on the right hand side

bottom of the PCB.

11. Secure the controller cable using the clamp

provided.

12. Replace plastic cover over PCB and then

replace the cover of the water heater.

securing screw

wiring hole