Page 1

ULTRA FORCE SUF-130-300 AND 400

COMMERCIAL GAS WATER HEATER

GAS-FIRED POWER BURNER

FOR DOMESTIC HOT WATER

• INSTALLATION • OPERATION • SERVICE • MAINTENANCE • LIMITED WARRANTY

WARNING: If the information in these

instructions is not followed exactly, a re

or explosion may result causing property

damage, personal injury or death.

– Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not us e any ph one in your

building.

• Immediately call your gas supplier

from a neighbor's phone. Follow

the gas supplier's instructions.

• If you cannot reach your gas supplier,

call the re department.

– Instal la ti on a nd s er vi ce m us t be

performed by a qualified installer,

service agency or the gas supplier.

Thank you for buying this energy efcient water heater

from State Industries. We appreciate your condence in

our products.

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY. PLEASE

READ THOROUGHLY BEFORE INSTALLING AND USING

THIS APPLIANCE.

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PRINTED 0307 197483-002

1

500 TENNESSEE WALTZ PARKWAY

ASHLAND CITY, TN 37015

Page 2

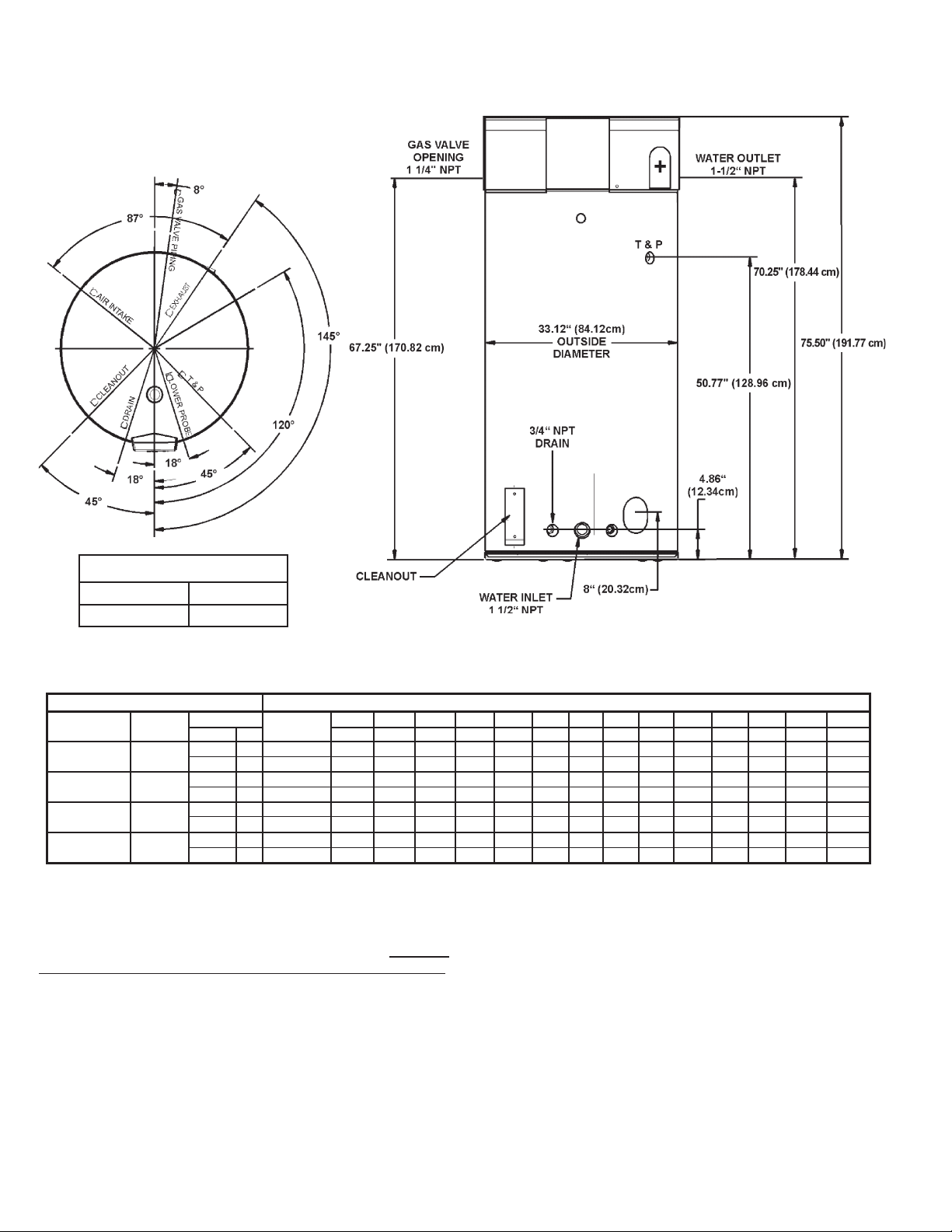

ROUGH-IN-DIMENSIONS

GAS VALVE PIPING

SUF 130-300 1 1/4" NPT

SUF 130-400 1 1/4" NPT

TABLE 1 RECOVERY CAPACITIES.

TYPE OF INPUT Approx. F° 20F° 30F° 40F° 50F° 60F° 70F° 80F° 90F° 100F° 110° 120F° 130F° 140F°

MODEL GAS BTUH KW Capacity C° 11C° 17C° 22C° 28C° 33C° 39C° 44C° 50C° 56C° 61C° 67C° 72C° 78C°

300,000 130 US Gals. GPH 1746 1164 873 699 582 499 436 388 349 318 291 269 250

SUF 130-300

88 492 Litres LPH 6610 4406 3304 2644 2203 1888 1652 1469 1322 1201 1102 1017 945

300,000 130 US Gals. GPH 1746 1164 873 699 582 499 436 388 349 318 291 269 250

SUF 130-300

88 492 Litres LPH 6610 4406 3304 2644 2203 1888 1652 1469 1322 1201 1102 1017 945

399,900 130 US Gals. GPH 2328 1552 1164 931 776 665 582 517 466 423 388 359 332

SUF 130-400

117 492 Litres LPH 8813 5875 4406 3525 2938 2518 2203 1958 1763 1602 1469 1356 1259

399,900 130 US Gals. GPH 2328 1552 1164 931 776 665 582 517 466 423 388 359 332

SUF 130-400

117 492 Litres LPH 8813 5875 4406 3525 2938 2518 2203 1958 1763 1602 1469 1356 1259

Recovery capacities are based on heater performance at 96% thermal efciency for SUF 300 and 400.

NATURAL

PROPANE

NATURAL

PROPANE

U.S. Gallons/Hr and Litres/Hr at TEMPERATURE RISE INDICATED

FOREWORD

These designs comply with the current edition of the American

Natio n a l S t an d ar d fo r G a s Wate r H e a t er s , Volum e I I I ,

ANSI Z21.10.3 / CSA 4.3 as an automatic circulating tank water

heater, and automatic storage water heaters.

Detailed installation diagrams are found in this manual. These

diagrams will serve to provide the installer with a reference for the

materials and methods of piping necessary. It is highly essential

that all water, gas piping and wiring be installed as shown on the

diagrams.

Particular attention should be given to the installation of thermometers

at the locations indicated on the diagrams as these are necessary

for checking the proper functioning of the heater.

In addition to these instructions, the equipment shall be installed in

accordance with those installation regulations in force in the local

area where the installation is to be made. These shall be carefully

followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

In the absence of local codes, the installation must comply

wi th the curre n t edit ions of the Na tion a l Fuel Gas Cod e,

AN S I Z223.1 / N FPA 54 and the Na tional El ectric a l Code,

NFPA 70 or CAN/CSA-B149.1, the Natural Gas and Propane

Installation Code and CSA C22.1, the Canadian Electrical Code. All

documents are available from the Canadian Standards Association,

8501 East Pleasant Valley Road, Cleveland, OH 44131. NFPA

documents are also available from the National Fire Protection

Association, 1 Batterymarch Park, Quincy, MA 02269.

2

Page 3

TABLE OF CONTENTS

ROUGH-IN DIMENSIONS ......................................................................... 2

FOREWORD .............................................................................................2

FEATURES ................................................................................................ 3

Water Temperature Control ................................................................3-5

Water Temperature Setpoint Adjustment Procedure ............................. 5

High Limit Switch (E.C.O.) ....................................................................5

Dishwashing Machine Requirement ...................................................... 5

Circulating Pump ................................................................................... 6

INSTALLATION INSTRUCTIONS ............................................................. 6

Required Ability .....................................................................................6

Insulation Blankets ................................................................................6

Locating The Heater .............................................................................. 6

Clearances ............................................................................................7

Hard Water ............................................................................................ 7

Air Requirements ..................................................................................7

Mechanical Exhausting of Room Air .....................................................7

Unconned Space ................................................................................. 7

Conned Space ..................................................................................... 7

Chemical Vapor Corrosion ....................................................................7

Installation Requirements for the

Commonwealth of Massachusetts ........................................................ 8

VENTING .............................................................................................. 8-11

Vent Pipe Termination ......................................................................... 11

Direct Venting ...................................................................................... 11

Direct Vent Terminal Installation ..................................................... 11-12

Installation Sequence .......................................................................... 12

Vertical Vent Terminal Installation .......................................................12

Installation Sequence .....................................................................12-13

Installation of Vent System .................................................................. 13

Vent Pipe Preparation .........................................................................14

CONTROLS AND SWITCHES ................................................................ 14

Blower Prover Switch ..........................................................................14

Blocked Outlet Prover Switch .............................................................. 14

Blocked Inlet Prover Switch ................................................................14

Low Gas Pressure Switch ...................................................................14

On/Off Switch .................................................................................14-15

Hot Surface Igniter .............................................................................. 15

GAS PIPING ............................................................................................ 15

Connection of Gas Pipe .................................................................15-16

Purging ................................................................................................ 16

Gas Meter Size - City Gases Only ...................................................... 16

Gas Valves ..........................................................................................16

SYSTEM CONNECTIONS ......................................................................16

Thermometers ..................................................................................... 16

Relief Valve .........................................................................................16

Water Line Connections ...................................................................... 16

Closed System ...............................................................................16-17

Water (Potable) Heating & Space Heating ..........................................17

Heater Wiring .................................................................................17-19

OPERATION ............................................................................................ 20

Sequence of Operation ....................................................................... 20

ELECTRONIC CONTROL .......................................................................20

Overview .............................................................................................

Operating States ............................................................................20-21

Adjusting the Operating Set Point .......................................................21

Changing the Display Units .................................................................22

Fault and Warning Conditions ........................................................

Access to the Current Fault or Warning ..............................................23

Viewing the Fault History ....................................................................24

Viewing Information About the Heater ................................................. 24

PRIOR TO START-UP REQUIRED ABILITY ...........................................25

OPERATING INSTRUCTIONS ................................................................ 25

Adjustment Procedure (Initial Start-Up) .........................................25-26

Lighting Instructions ............................................................................ 26

Cathodic Protection .............................................................................

Precautions ......................................................................................... 27

GENERAL INFORMATION ...................................................................... 27

Power Burner ...................................................................................... 27

High Limit ............................................................................................

High Altitude Installations .................................................................... 27

MAINTENANCE ......................................................................................27

General ...............................................................................................27

Maintenance Schedule ........................................................................ 27

Flushing ............................................................................................... 28

Draining ............................................................................................... 28

Sediment Removal .............................................................................. 28

Lime Scale Removal ......................................................................28-29

Powered Anode System ...................................................................... 29

Drain Valve and Access Panels ..........................................................29

Relief Valve .........................................................................................29

Vent System ........................................................................................ 29

INSTALLATION DIAGRAMS ..............................................................30-34

Multiple Unit Installations ....................................................................35

CHECKLIST AND SERVICE INFORMATION .........................................36

Burner Operational Problems .............................................................. 36

Not Enough or No Hot Water ..............................................................36

Water Is Too Hot .................................................................................. 36

Water Heater Makes Sounds ..............................................................36

Water Leakage is Suspected ................................................................... 36

TROUBLESHOOTING .......................................................................36-38

REPLACEMENT PARTS ......................................................................... 38

LIMITED WARRANTY .............................................................................39

20

22-23

27

27

FEATURES

IMPORTANT

IT IS REQUIRED THAT A QUALIFIED SERVICE TECHNICIAN

PERFORM THE INITIAL FIRING OF THE HEATER. AT THIS TIME

THE USER SHOULD NOT HESITATE TO ASK THE TECHNICIAN

ANY QUESTIONS WHICH HE MAY HAVE IN REGARD TO THE

OPERATION AND MAINTENANCE OF THE UNIT.

A CHECKLIST AND SERVICE INFORMATION section are included

at the rear of this manual. By using this checklist the user may

be able to make minor operational adjustments and save himself

unnecessary service calls. However, the user should not attempt

repairs which are not listed in this section.

WATER TEMPERATURE CONTROL

DANGER

THIS WATER HEATER IS EQUIPPED WITH AN AD JUSTAB LE

THERMOSTAT TO CON TRO L WATER TEMPERATURE. HOT

WAT E R TEM PER ATURES REQUIRED FOR AUTO M AT I C

DISHWA S H E R AND LAUNDRY U S E CAN C A U S E SCALD

BURN S RES ULT I NG IN SE R I O US PERSON A L INJ U R Y

A N D /O R D E AT H. T H E T E M PE R A T U R E AT W H IC H

INJU RY OC CU R S VA R IE S WITH TH E PERSON’ S AG E

AND TIM E OF EXPOSURE . TH E SL OW ER RES P O N S E

TIME OF CHI L D R E N , AG E D OR DI S A BL ED PE R S O NS

INCREASES T H E HA Z ARDS TO THEM. N E VE R ALLO W

SMALL C H I L D R EN TO U S E A H OT W AT E R TAP, OR TO

DR AW THEIR OWN BAT H WATER. NEVER LE AV E A CH ILD

OR DISABLED PER S O N UN ATTEN DE D IN A BATHTU B

OR S H O W E R .

THE WATER HEATER SHOULD BE LOCATED IN AN AREA

WHERE THE GENERAL PUBLIC DOES NOT HAVE ACCESS TO

SET TEMPERATURES.

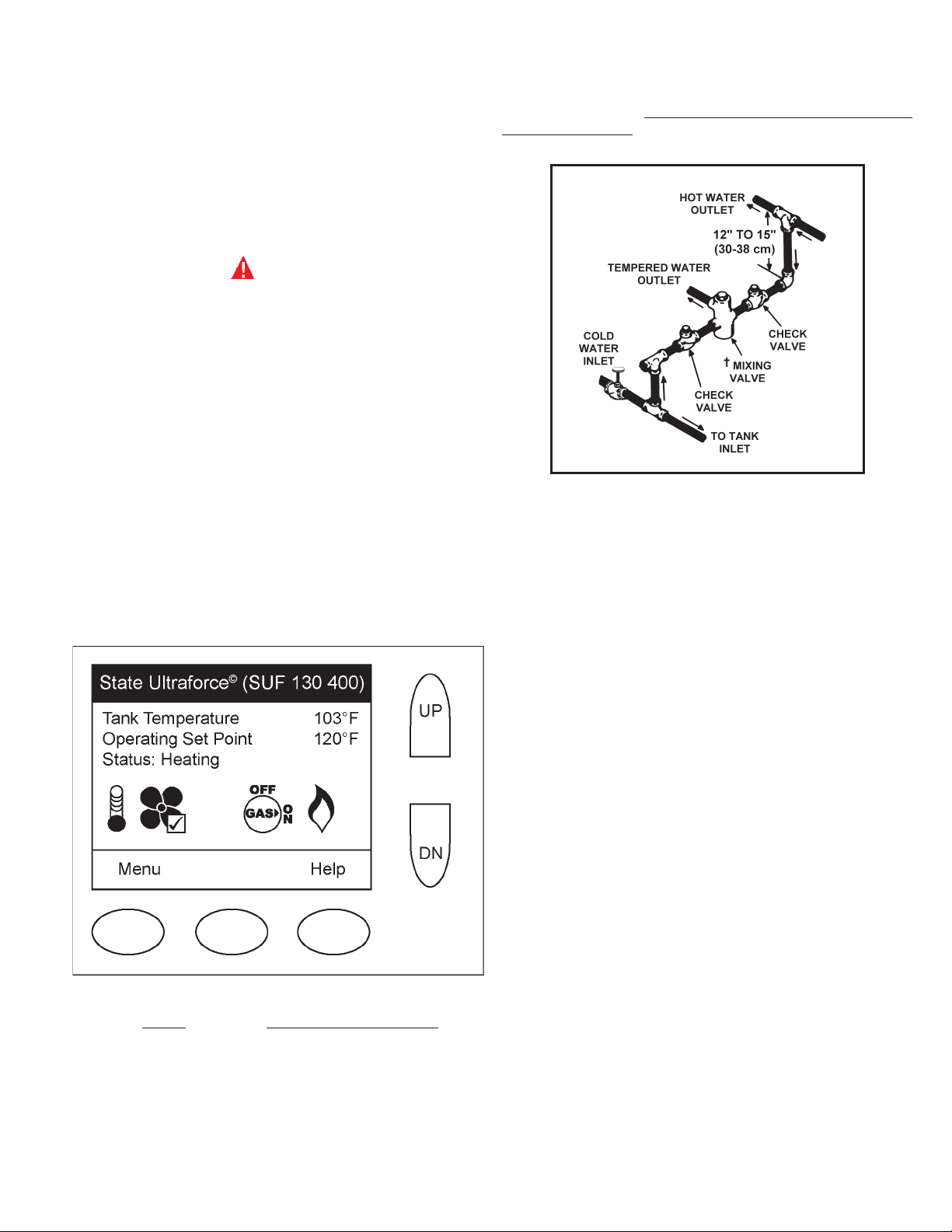

The water temperature is controlled using the Temperature Control

UP/DN Button on the Display at the front of the unit (See Figure 1).

This control utilizes two temperature probes to determine the tank

temperature. The primary temperature probe is located at the top

of the tank and the other is near the water inlet.

3

Page 4

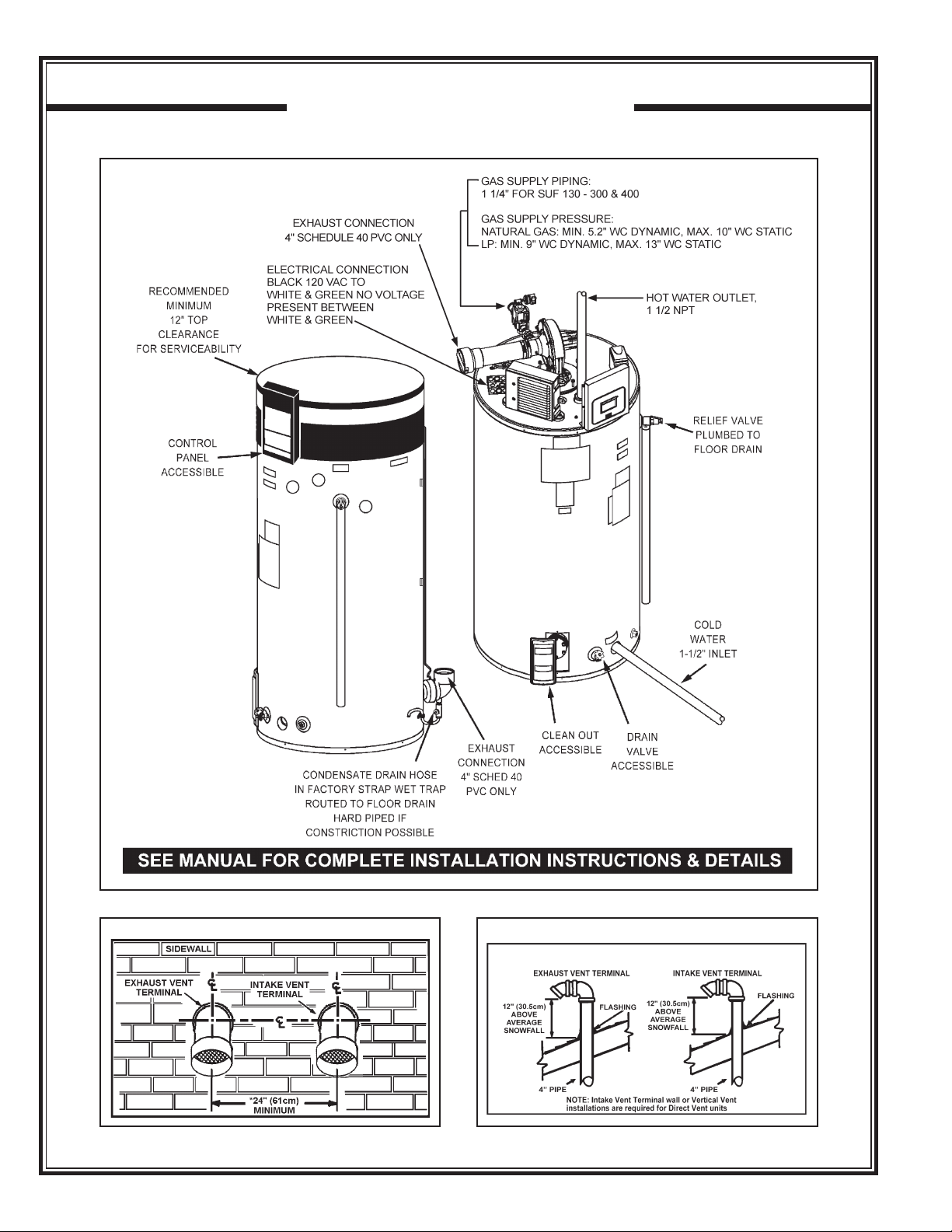

“AT A GLANCE”

QUICK INSTALLATION TIPS

Horizontal Sidewall Venting Vertical Rooftop Venting

4

Page 5

The temperature may be adjusted from 80°F/27°C to 180°F/82°C.

The thermostat was adjusted to 120°F/49°C before the heater

was shipped from the factory. It is recommended that lower water

temperatures be used to avoid the risk of scalding. It is further

recommended, in all cases, that the water temperature be set for the

lowest temperature which satises your hot water needs. This will

also provide the most energy efcient operation of the water heater

and minimize scale formation.

WATER TEMPERATURE SETPOINT ADJUSTMENT

PROCEDURE

CAUTION

THE TEMPERATURE OF THE WATER AT THE TANK OUTLET

MAY NOT CORRESPOND TO THE TEMPERATURE SETPOINT

PROGRAMMED IN THE CONTROLLER. THE USER CAN EASILY

CHANGE THE TEMPERATURE SETPOINT AT ANY TIME BY USING

THE FOLLOWING PROCEDURE. IN ALL CASES, INPUT POWER

MUST BE APPLIED TO THE CONTROLLER TO PERFORM ANY

PROGRAMMING OPERATIONS.

The Operating Set Point of this water heater determines the regulated

temperature for the water in the tank. This parameter is adjusted in the

Temperature menu. Items in this menu allow you to monitor different

temperature readings in the tank along with adjusting the Operating

Set Point and Differential. To change the current programmed

temperature setpoint value, see OPERATION section for details.

Figure 1 shows the approximate time-to-burn relationship for normal

adult skin. Short repeated heating cycles caused by small hot water

uses can cause temperatures at the point of use to exceed the

thermostat setting by up to 20°F (11C°). If you experience this type

of use, you should consider using lower temperature settings to

reduce scald hazards.

Valv es for reducing poi nt-of-us e temper ature by mi xing col d

and hot water are available (see Figure 2). Also avai lable

are inexpen siv e de vices that attach to faucets to limit hot

wate r temperatures. Conta ct a licensed plumber or t he local

plum bing aut hority.

FIGURE 2.

HIGH LIMIT SWITCH (E.C.O.)

The top immersion well of the dual bulb controller also contains

the high limit (energy cutoff) sensor. The high limit switch interrupts

the main burner gas ow should the water temperature reach

approximately 202°F/94°C. Should the high limit switch activate,

the water temperature must drop below 140°F/60°C before the

controller can be reset. The following is a possible reason for high

limit switch operation.

Temperature Time to Produce 2nd & 3rd

Setting Degree Burns on Adult Skin

180°F / 82°C Nearly instantaneous

170°F / 77°C Nearly instantaneous

160°F / 71°C About 1/2 second

150°F / 66°C About 1-1/2 seconds

140°F / 60°C Less than 5 seconds

130°F / 54°C About 30 seconds

120°F / 49°C More than 5 minutes

FIGURE 1.

• A malfunction in the thermostatic controls would allow the gas

valve to remain open causing water temperature to exceed the

thermostat setting. The water temperature would continue to

rise until high limit switch operation.

Contact your dealer or servicer if continued high limit switch

operation occurs.

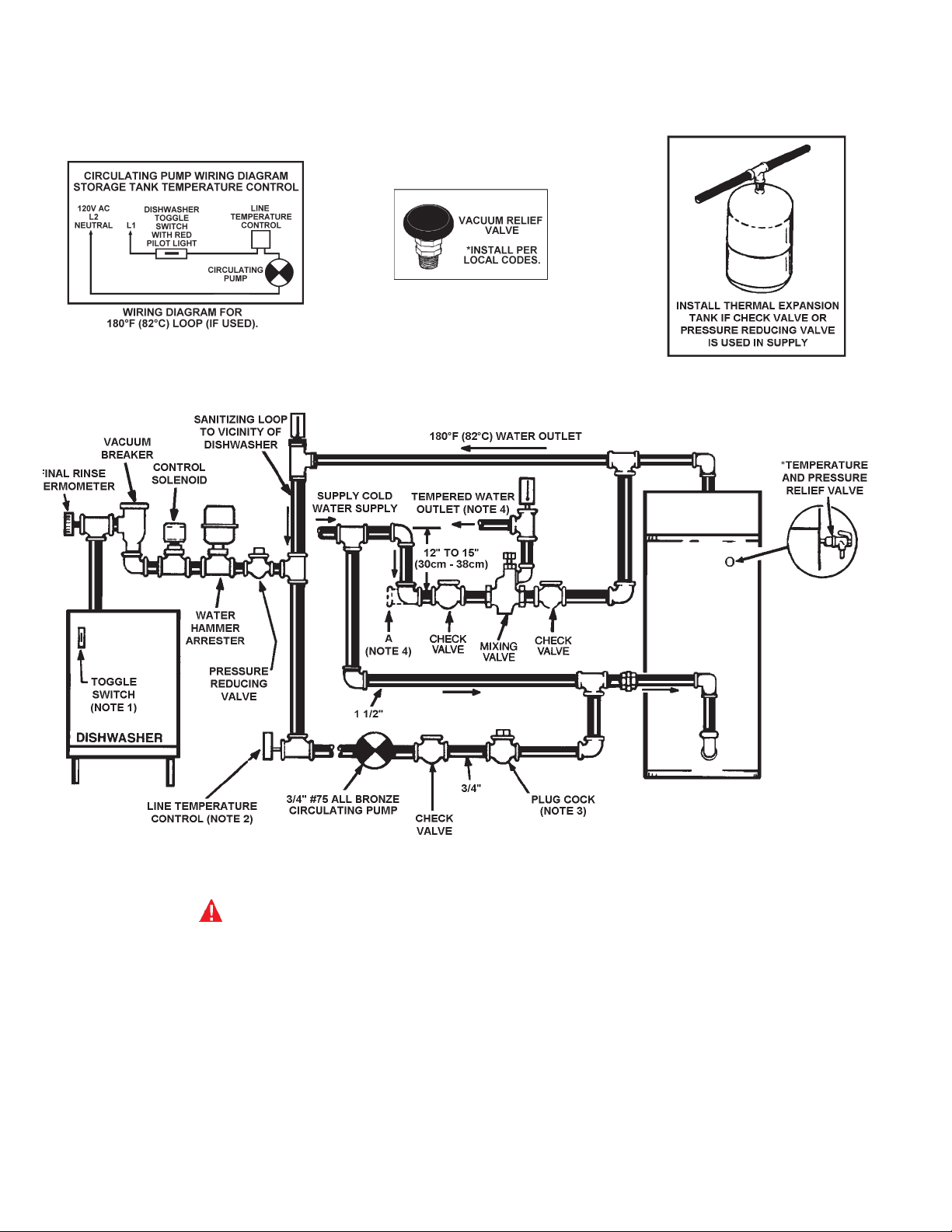

DISHWASHING MACHINE REQUIREMENT

All dishwas hin g ma chines meeti ng the Nation al Sanitation

Foundation requirements are designed to operate with water

flow pressures between 15 and 25 pounds per square inch

(103 Kpa and 173 Kpa). Flow pressures above 25 pounds per

square inch (173 Kpa), or below 15 pounds per square inch

(103 Kpa), will result in improperly sanitized dishes. Where

pressures are high, a water pressure reducing or flow regulating

control valve should be used in the 180°F (82°C) line to the

dishwashing machine, and should be adjusted to deliver water

between these limits.

The Na t i on al Sani t a tion Fo u n da tion al s o re c o mmen d s

circ ulation of 180°F (82°C) water. Where this is done, the

circ ulation should be very gentle s o that it d oes not cause

an y unnece ssar y tur bulence insi de the wat er he ater . The

circ ulation should be just enough to provide 180°F (82° C)

wate r at the point of take-of f to the dishwashi ng mac hine.

Adju st fl ow by means of the plug cock in t he ci rculatin g lin e.

(See install ation di agrams.)

5

Page 6

CIRCULATING PUMP

A circulating pump is used when a system requires a circulating

loop or there is a storage tank used in conjunction with the heater.

Refer to the piping diagrams at rear of manual for electrical hookup

information and install in accordance with the current edition of the

National Electrical Code, NFPA 70 or the Canadian Electrical Code,

CSA C22.1.

All bronze circulators are recommended for used with commercial

water heaters.

Although circulators are oiled and operated by the manufacturer

some circulators must be oiled again before operated. Please refer

to manufacturer's instructions.

INSTALLATION INSTRUCTIONS

REQUIRED ABILITY

IN S TALLAT ION OR SE RVIC E OF THI S WATER HEATE R

REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED

TRADESMAN IN THE FIELD INVOLVED. PLUMBING, AIR

SUPPLY, VENTING, GAS SUPPLY AND ELECTRICAL WORK

ARE REQUIRED.

INSULATION BLANKETS

Insulation blankets available to the general public for external use

on gas water heaters are not approved for use on your water heater.

The purpose of an insulation blanket is to reduce the standby heat

loss encountered with storage tank water heaters. Your water

heater meets or exceeds the ASHRAE/IES 90.1-1999 standards

with respect to insulation and standby loss requirements, making

an insulation blanket unnecessary.

WARNING

Should you choose to apply an insulation blanket to this heater, you

should follow these instructions. Failure to follow these instructions

can result in re, asphyxiation, serious personal injury or death.

• Do not apply insulation to the top, or the upper 15" (38 cm) of the

water heater, as this will interfere with safe operation.

• Do not cover the temperature & pressure relief valve.

• Do not cover the instruction manual. Keep it on the side of the

water heater or nearby for future reference.

THE HEATER SHALL BE LOCATED OR PROTECTED SO IT IS NOT

SUBJECT TO PHYSICAL DAMAGE BY A MOVING VEHICLE.

DO NOT LOCATE THE HEATER WHERE NOISE FROM THE

EX HAUS T OR INTAK E WIL L BE OBJ ECTI ONAB LE. THIS

IN C LUDES LOCATI O NS CLO S E TO OR AC ROSS FR O M

WINDOWS AND DOORS. AVOID ANCHORING THE VENT AND

INTAKE PIPES DIRECTLY TO FRAMED WALLS, FLOORS OF

CEILINGS UNLESS RUBBER ISOLATION PIPE HANGERS

ARE USED. THIS PREVENTS ANY VIBRATIONS FROM BEING

TRANSMITTED INTO THE LIVING SPACES.

WARNING

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY

OTHER POTENTIAL FIRE HAZARD OUS A RTICLES MUST

NEVER BE PLACED ON OR ADJACENT TO THE HEATER. OPEN

CONTAINERS OF FLAMMABLE MATERIAL SHOULD NOT BE

STORED OR USED IN THE SAME ROOM WITH THE HEATER.

When installing the heater, consideration must be given to

proper location. Location selected should be as close to the

intake and exhaust termination poin ts as practicable, with

adequate air supply and as centralized with the piping system

as possible.

THE HEATER MUST NOT BE LOCATED IN AN AREA WHERE IT

WILL BE SUBJECT TO FREEZING.

LOCATE IT NEAR A FLOOR DRAIN. THE HEATER SHOULD

BE LOCATED IN AN AREA WHERE LEAKAGE FROM THE

HEATER OR CONNECTIONS WILL NOT RESULT IN DAMAGE

TO THE ADJACENT AREA OR TO LOWER FLOORS OF THE

STRUCTURE.

When such locations cannot be avoided, it is recommended that

a suitable drain pan, adequately drained, be installed under the

appliance.

WARNING

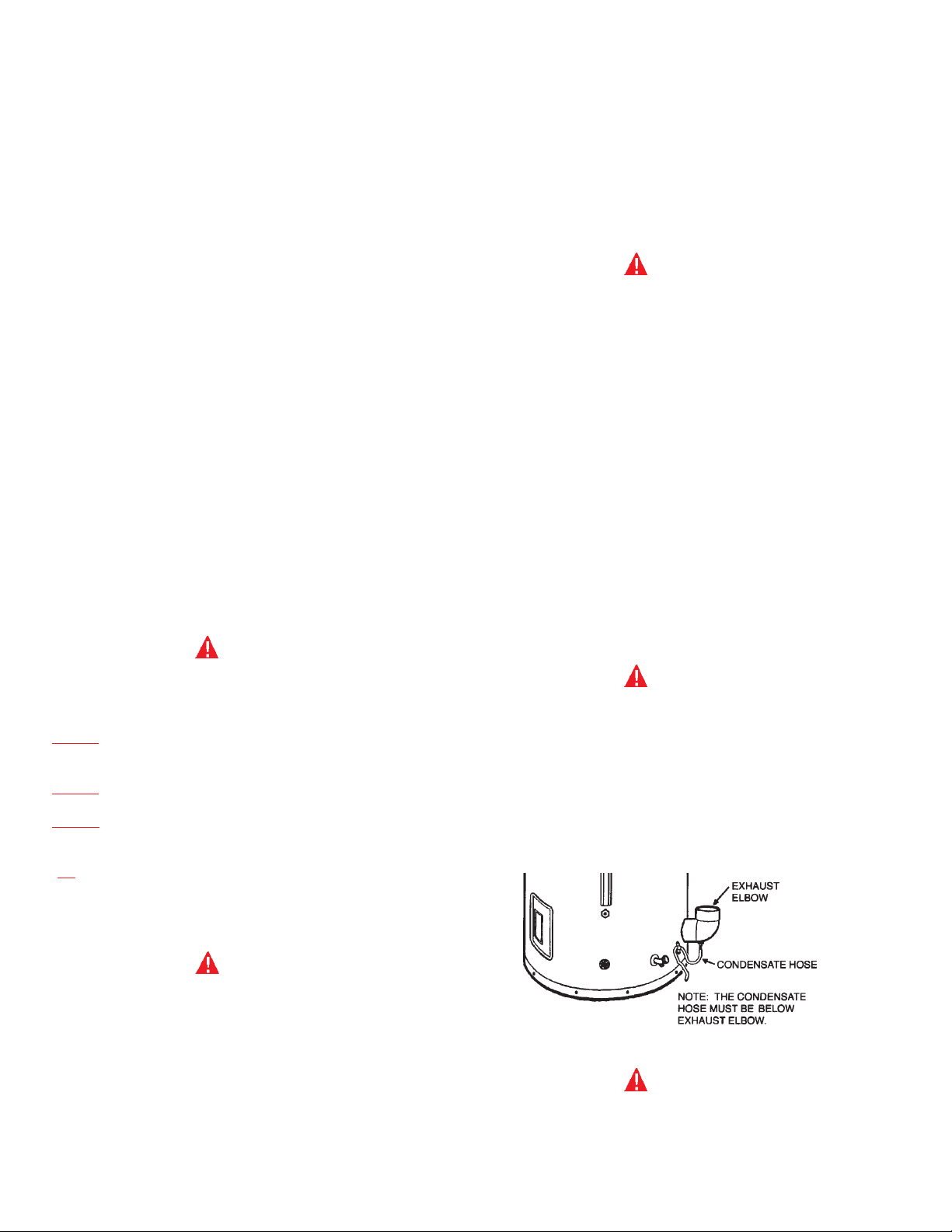

THIS WATER HEATER IS A CONDENSING UNIT AND REQUIRES

A DRAIN TO BE LOCATED IN CLOSE PROXIMITY TO ALLOW

THE CONDENSATE TO DRAIN SAFELY. THE CONDENSATE

DRAINS FROM THE UNIT AT THE EXHAUST ELBOW LOCATED

AT THE BOTTOM OF THE UNIT. NOTE: IT IS IMPORTANT THAT

THE CONDENSATE HOSE NOT BE ELEVATED ABOVE THE

EXHAUST ELBOW (SEE FIGURE 3). THE CONDENSATE BUILDUP WILL BLOCK THE EXHAUST OUTLET, WHICH WILL CAUSE

IMPROPER OPERATION.

•

Do obtain new labels for placement on the blanket directly over

the existing labels.

LOCATING THE HEATER

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES

SUCH AS GAS WATER HEATERS IN ROOMS, GARAGES OR

OTHER AREAS WHERE GASOLINE, OTHER FLAMMABLE

LIQUIDS OR ENGINE DRIVEN EQUIPMENT OR VEHICLES ARE

STORED, OPERATED OR REPAIRED. FLAMMABLE VAPORS

ARE HEAVY AND TRAVEL ALONG THE FLOOR AND MAY BE

IGNITED BY THE HEATER’S IGNITER OR MAIN BURNER

FLAMES CAUSING FIRE OR EXPLOSION. SOME LOCAL CODES

PERMIT OPERATION OF GAS APPLIANCES IF INSTALLED

18 INCHES (46 cm) OR MORE ABOVE THE FLOOR. THIS

MAY REDUCE THE RISK IF LOCATION IN SUCH AN AREA

CANNOT BE AVOIDED.

FIGURE 3.

WARNING

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN

UNDER WATER. IMMEDIATELY CALL A QUALIFIED SERVICE

TECHNICIAN TO INSPECT THE APPLIANCE AND TO REPLACE

ANY PART OF THE CONTROL SYSTEM AND ANY GAS CONTROL

WHICH HAS BEEN UNDER WATER.

6

Page 7

CLEARANCES

MECHANICAL EXHAUSTING OF ROOM AIR

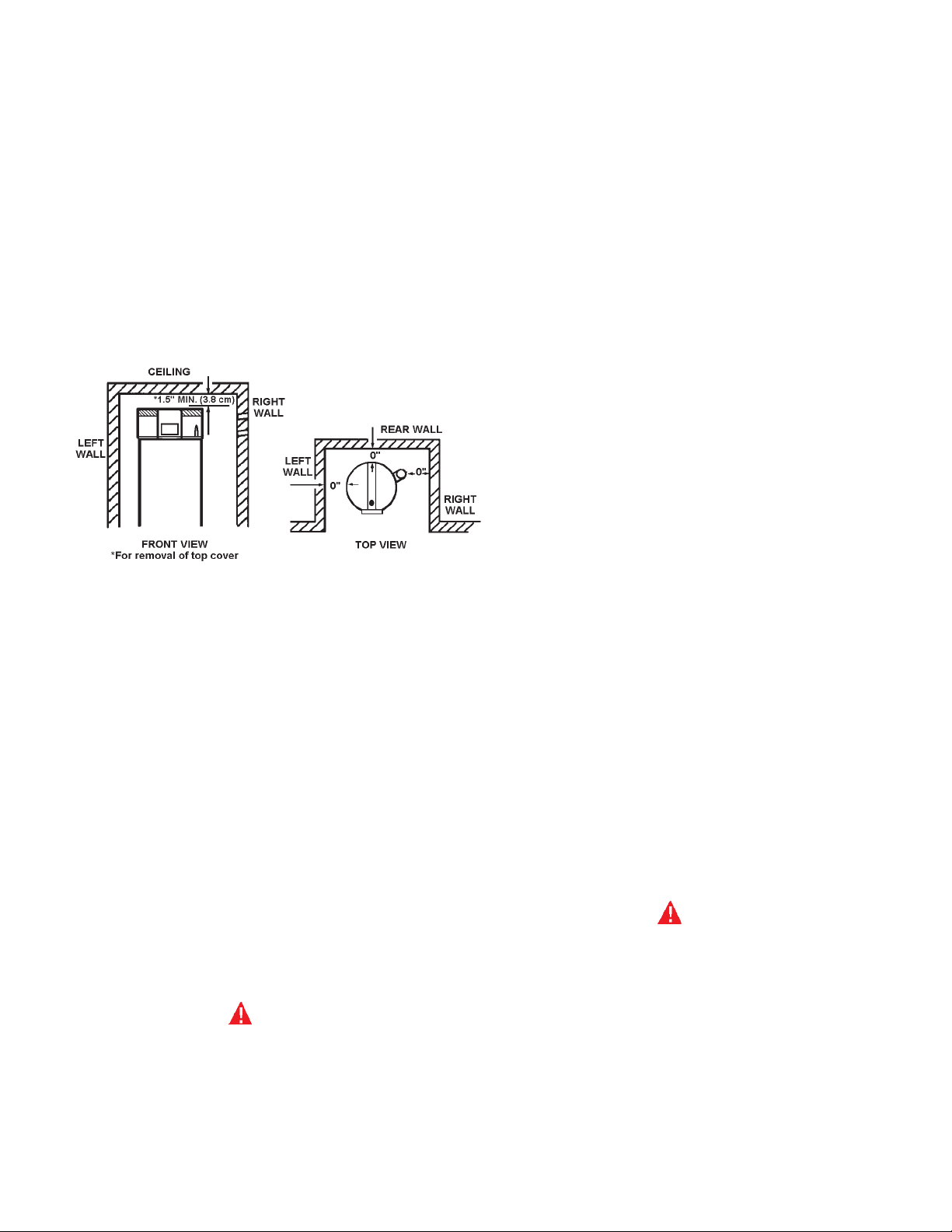

These heaters are approved for installation on combustible ooring

in an alcove when the minimum clearances from any combustion

construction are followed as indicated in Figure 4.

In all installations the minimum combustible clearances from any

vent piping shall be 0". Vent piping passing through a combustible

wall or ceiling must be a continuous run (no joints).

A service clearance of 24" (61 cm) should be maintained from

serviceable parts such as relief valves, thermostats, cleanout

openings, drain valves and venting connections.

Always disconnect electrical power before servicing the unit.

*ILLUSTRATION OF MINIMUM COMBUSTIBLE CLEARANCES

IN AN ALCOVE.

Where an exhaust fan is installed in the same room with a heater,

sufcient openings for air must be provided in the walls. UNDERSIZED

OPENINGS WILL CAUSE AIR TO BE DRAWN INTO THE ROOM

THROUGH THE HEATER’S VENTING SYSTEM, CAUSING POOR

COMBUSTION. SOOTING MAY RESULT IN SERIOUS DAMAGE

TO THE HEATER AND RISK OF FIRE OR EXPLOSION. IT CAN

ALSO CREATE A RISK OF ASPHYXIATION.

UNCONFINED SPACE

In buildings of conventional frame, brick or stone construction,

unconned spaces may provide adequate air for combustion and

ventilation.

If the unconned space is within a building of tight construction

(buildings using the following construction: weather stripping,

heavy insulation, caulking, vapor barrier, etc.), air for combustion

and ventilation must be obtained from outdoors. The installation

instructions for conned spaces in tightly constructed buildings must

be followed to ensure adequate air supply.

CONFINED SPACE

When drawing comb ustion air from ins ide a conventionally

constructed building to a conned space, such a space shall be

provided with two permanent openings, ONE IN OR WITHIN

12 INCHES (31 cm) OF THE ENCLOSURE TOP AND ONE IN OR

WITHIN 12 INCHES (31 cm) OF THE ENCLOSURE BOTTOM. Each

opening shall have a free area of at least one square inch per 1000

Btuh (2,203mm2/kW) appliances in the enclosure, but not less than

100 square inches (645 cm²).

FIGURE 4.

HARD WATER

Where hard water conditions exist, water softening or the threshold

type of water treatment is recommended. This will protect the

dishwashers, coffee urns, water heaters, water piping and other

equipment.

See MAINTENANCE section for details of tank cleanout procedure.

AIR REQUIREMENTS

KEEP APPLIANCE AREA CLEAR AND FREE OF COMBUSTIBLE

MATERIALS, GASOLINE AND OTHER FLAMMABLE VAPORS

AND LIQUIDS.

DO NOT OB STRUCT THE FLOW OF COMBU STI ON AND

VENTILATING AIR.

WARNING

FO R SAFE OPERAT ION PRO VIDE ADE QUATE AIR FOR

COMBUSTION AND VENTILATION. AN INSUFFICIENT SUPPLY

OF AIR WILL CAUSE RECIRCULATION OF COMBUSTION

PRODUCTS RESULTING IN CONTAMINATION THAT MAY BE

HAZARDOUS TO LIFE. SUCH A CONDITION OFTEN WILL

RESULT IN A YELLOW, LUMINOUS BURNER FLAME, CAUSING

CARBONING OR SOOTING OF THE COMBUSTION CHAMBER,

BURN ERS AND FLU E TUBE S A ND CREATE S A RISK OF

ASPHYXIATION.

If the conned space is within a building of tight construction, air

for combustion and ventilation must be obtained from outdoors.

When directly communicating with the outdoors through vertical

ducts, two permanent openings, located in the above manner, shall

be provided. Each opening shall have a free area of not less than

one square inch per 4000 Btuh (551mm2/kW) of the total input of

all appliances in the enclosure. If horizontal ducts are used, each

opening shall have a free area of not less than one square inch per

2000 Btuh (1,102mm2/kW) of the total input of all appliances in

the enclosure.

CHEMICAL VAPOR CORROSION

WARNING

CORROSION OF THE FLUE WAYS AND VENT SYSTEM MAY

OCCUR IF AI R FOR COMBUSTION CONTAINS CERTAIN

CHEMICAL VAPORS. SUCH CORROSION MAY RESULT IN

FAILURE AND RISK OF ASPHYXIATION.

Spray can propellants, cleaning solvents, refrigerator and air

conditioning refrigerants, swimming pool chemicals, calcium

and sodium chloride, waxes, and process chemicals are typical

compounds which are potentially corrosive.

PRODUCTS OF THIS SORT SHOULD NOT BE STORED NEAR

THE HEATER. ALSO, AIR WHICH IS BROUGHT IN CONTACT

WITH THE HEATER SHOULD NOT CONTAIN ANY OF THESE

CHEMICALS. IF NECESSARY, UNCONTAMINATED AIR SHOULD

BE OBTAINED FROM REMOTE OR OUTSIDE SOURCES.

7

Page 8

INSTALLATION REQUIREMENTS FOR THE

COMMONWEALTH OF MASSACHUSETTS

For all side wall terminated, horizontally vented power vent, direct

vent, and power direct vent gas fueled water heaters installed in every

dwelling, building or structure used in whole or in part for residential

purposes, including those owned or operated by the Commonwealth

and where the side wall exhaust vent termination is less than seven

(7) feet above nished grade in the area of the venting, including

but not limited to decks and porches, the following requirements

shall be satised:

INSTALLATION OF CARBON MONOXIDE DETECTORS

EXEMPTIONS

The following equipment is exempt from 248 CMR 5.08(2)(a)1

through 4:

1. The equipment listed in Chapter 10 entitled “Equipment Not

Required To Be Vented” in the most current edition of NFPA 54

as adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled

equipment installed in a room or structure separate from the

dwelling, building, or structure used in whole or in part for

residential purposes.

At the time of installation of the side wall horizontal vented gas

fueled equipment, the installing plumber or gastter shall observe

that a hard wired carbon monoxide detector with an alarm and

battery back-up is installed on the floor level where the gas

equipment is to be installed. In addition, the installing plumber or

gastter shall observe that a battery operated or hard wired carbon

monoxide detector with an alarm is installed on each additional

level of the dwelling, building or structure served by the sidewall

horizontal vented gas fueled equipment. It shall be the responsibility

of the property owner to secure the services of qualied licensed

professionals for the installation of hard wired carbon monoxide

detectors.

In the event that the side wall horizontally vented gas fueled

equipment is installed in a crawl space or an attic, the hard wired

carbon monoxide detector with alarm and battery back-up may be

installed on the next adjacent oor level.

In the event that the requirements of this subdivision can not be

met at the time of completion of installation, the owner shall have

a period of thirty (30) days to comply with the above requirements

provided that during said thirty (30) day period, a battery operated

carbon monoxide detector with an alarm shall be installed.

APPROVED CARBON MONOXIDE DETECTORS

Each carbon monoxide detector as required in accordance with the

above provisions shall comply with NFPA 720 and be ANSI/UL 2034

listed and CSA certied.

SIGNAGE

A metal or plastic identication plate shall be permanently mounted

to the exterior of the building at a minimum height of eight (8) feet

above grade directly in line with the exhaust vent terminal for the

horizontally vented gas fueled heating appliance or equipment.

The sign shall read, in print size no less than one-half (1/2) inch

in size, “GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL

OBSTRUCTIONS.”

MA N UFACTURE R REQUIR E MENTS - GA S EQUIPM E NT

VENTING SYSTEM PROVIDED

When the manufacturer of Product Approved side wall horizontally

vented gas equipment provides a venting system design or venting

system components with the equipment, the instructions provided

by the manufacturer for installation of the equipment and the venting

system shall include:

1. Detailed instructions for the installation of the venting system

design or the venting system components; and

2. A complete parts list for the venting system design or venting

system.

MA N UFACTURE R REQUIR E MENTS - GA S EQUIPM E NT

VENTING SYSTEM NOT PROVIDED

When the manufacturer of a Product Approved side wall horizontally

vented gas fueled equipment does not provide the parts for venting

the ue gases, but identies “special venting systems,” the following

requirements shall be satised by the manufacturer:

1. The referenced “special venting system” instructions shall

be included with the appliance or equipment installation

instructions; and

2. The “special venting systems” shall be Product Approved by the

Board, and the instructions for that system shall include a parts

list and detailed installation instructions.

A copy of all installation instructions for all Product Approved

side wall horizontally vented gas fueled equipment, all venting

instructions, all parts lists for venting instructions, and/or all

venting design instructions shall remain with the appliance or

equipment at the completion of the installation.

VENTING

INSPECTION

The state or local gas inspector of the side wall horizontally vented

gas fueled equipment shall not approve the installation unless, upon

inspection, the inspector observes carbon monoxide detectors and

signage installed in accordance with the provisions of 248 CMR

5.08(2)(a) 1 through 4.

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING MUST

BE FOLL O W E D TO AVO I D CH O K ED COMBUSTION OR

RECIRCULATION OF FLUE GASES. SUCH CONDITIONS CAUSE

SOOTING OR RISKS OF FIRE AND ASPHYXIATION.

Heat er mus t be protected from freezing downdra fts during

shutdown periods.

8

Page 9

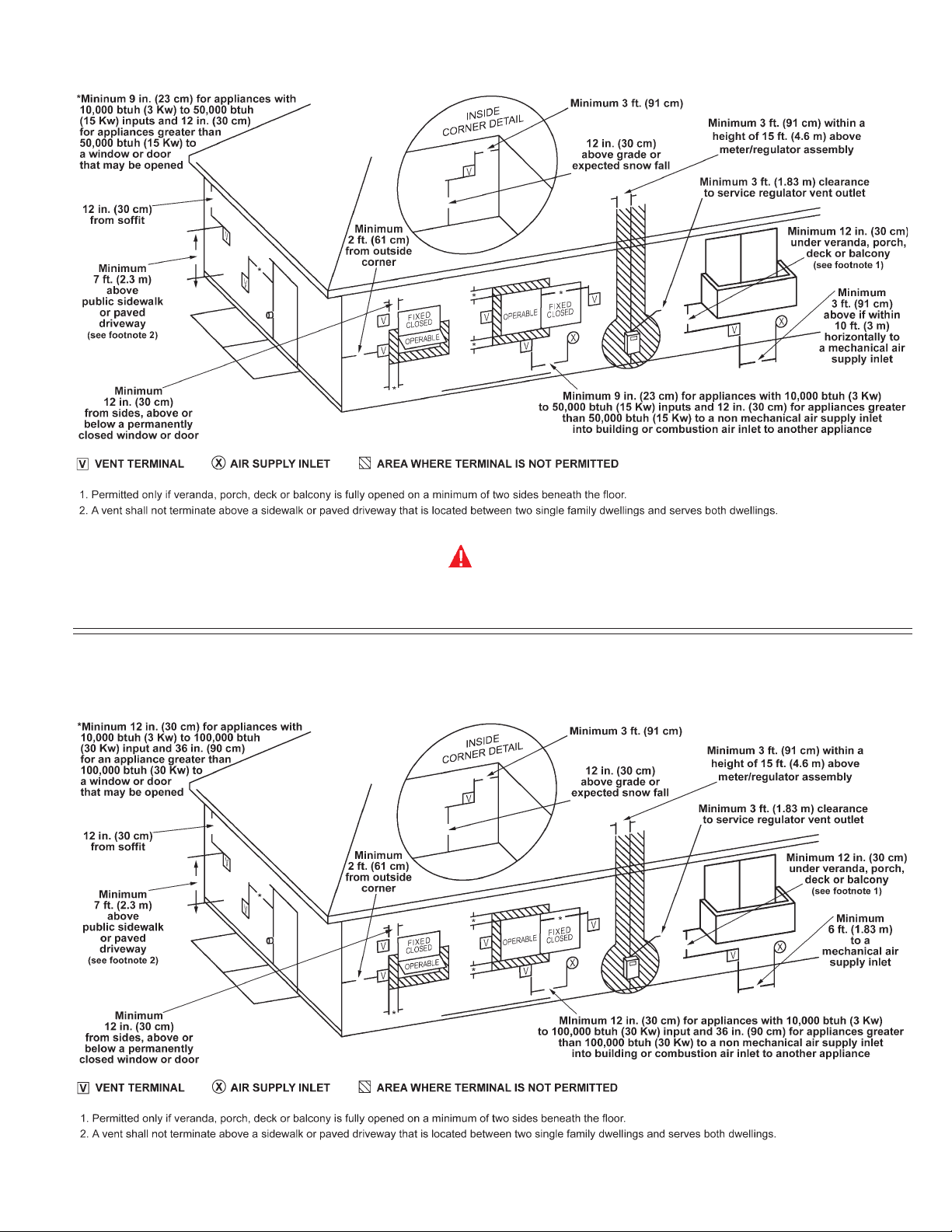

US DIRECT VENT

TO PREVENT EXHAUSTING PRODUCTS FROM CIRCULATING TO THE

AIR INTAKE IN WINDY/COLD AREAS, THE MAXIMUM PRACTICAL

DISTANCE BETWEEN THESE TWO TERMINALS IS RECOMMENDED.

CANADIAN DIRECT VENT

CAUTION

FIGURE 5.

9

Page 10

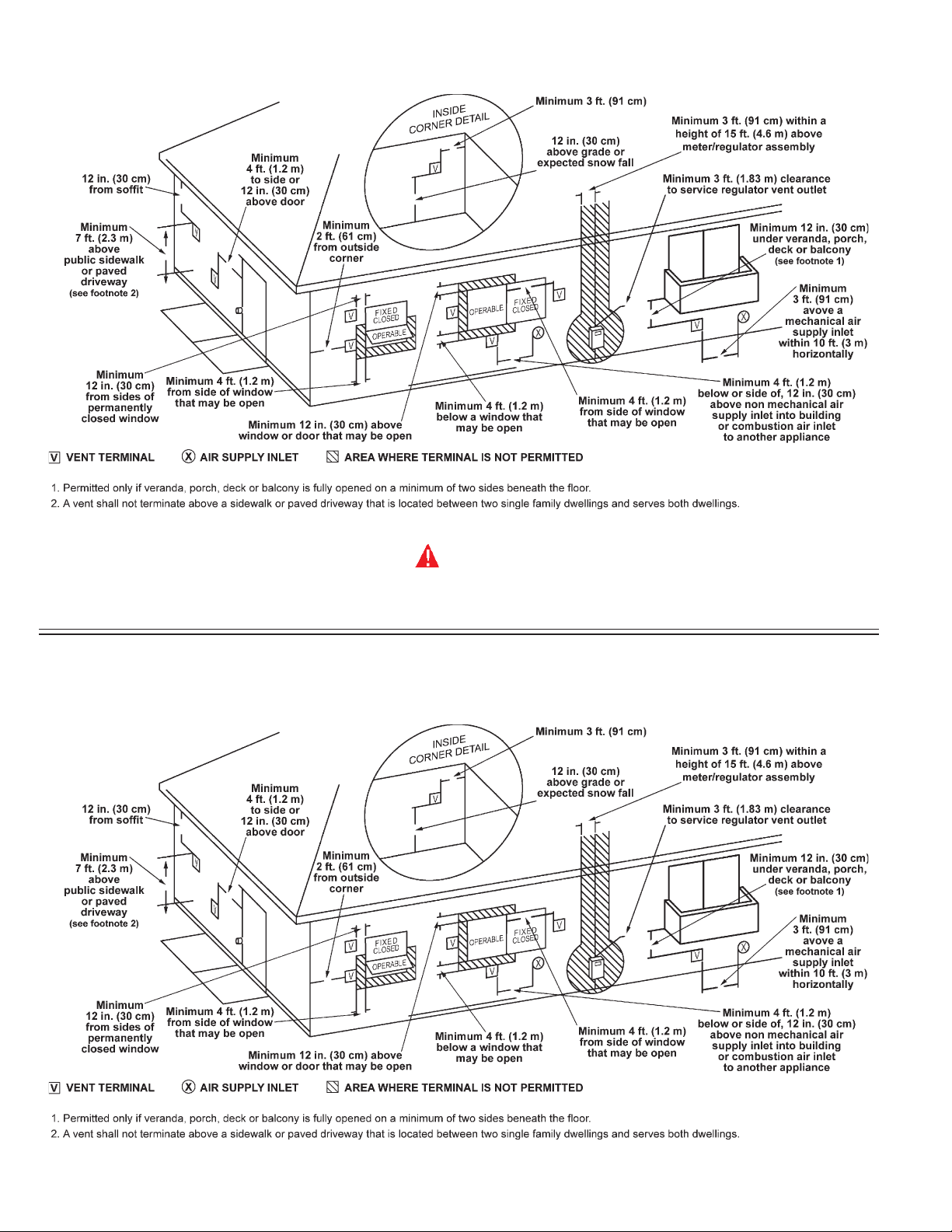

US HORIZONTAL VENT

TO PREVENT EXHAUSTING PRODUCTS FROM CIRCULATING TO THE

AIR INTAKE IN WINDY/COLD AREAS, THE MAXIMUM PRACTICAL

DISTANCE BETWEEN THESE TWO TERMINALS IS RECOMMENDED.

CANADIAN HORIZONTAL VENT

CAUTION

FIGURE 6.

10

Page 11

WARNING

NEVER OPERATE THE HEATER UNLESS IT IS VENTED TO THE

OUTDOORS AND HAS ADEQUATE AIR SUPPLY TO AVOID RISKS OF

IMPROPER OPERATION, FIRE, EXPLOSION OR ASPHYXIATION.

VENT PIPE TERMINATION

NOTE: Before installing venting, determine place of vent pipe

termination. See Figure 5 and 6 before proceeding.

CAUTION

DO NOT TERMINATE THE VENTING WHERE NOISE FROM THE

EXHAUST OR INTAKE WILL BE OBJECTIONABLE. THIS INCLUDES

LOCATIONS CLOSE TO OR ACROSS FROM WINDOWS AND DOORS.

AVOID ANCHORING THE VENT AND INTAKE PIPES DIRECTLY TO

FRAMED WALLS, FLOORS OR CEILINGS UNLESS RUBBER ISOLATION

PIPE HANGERS ARE USED. THIS PREVENTS ANY VIBRATIONS FROM

BEING TRANSMITTED INTO THE LIVING SPACES.

IMPORTANT

The vent system must terminate so that proper clearances are

maintained as cited in local codes or the current editions of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 or the Natural Gas

and Propane Installation Code, CAN/CSA-B149.1.

WARNING

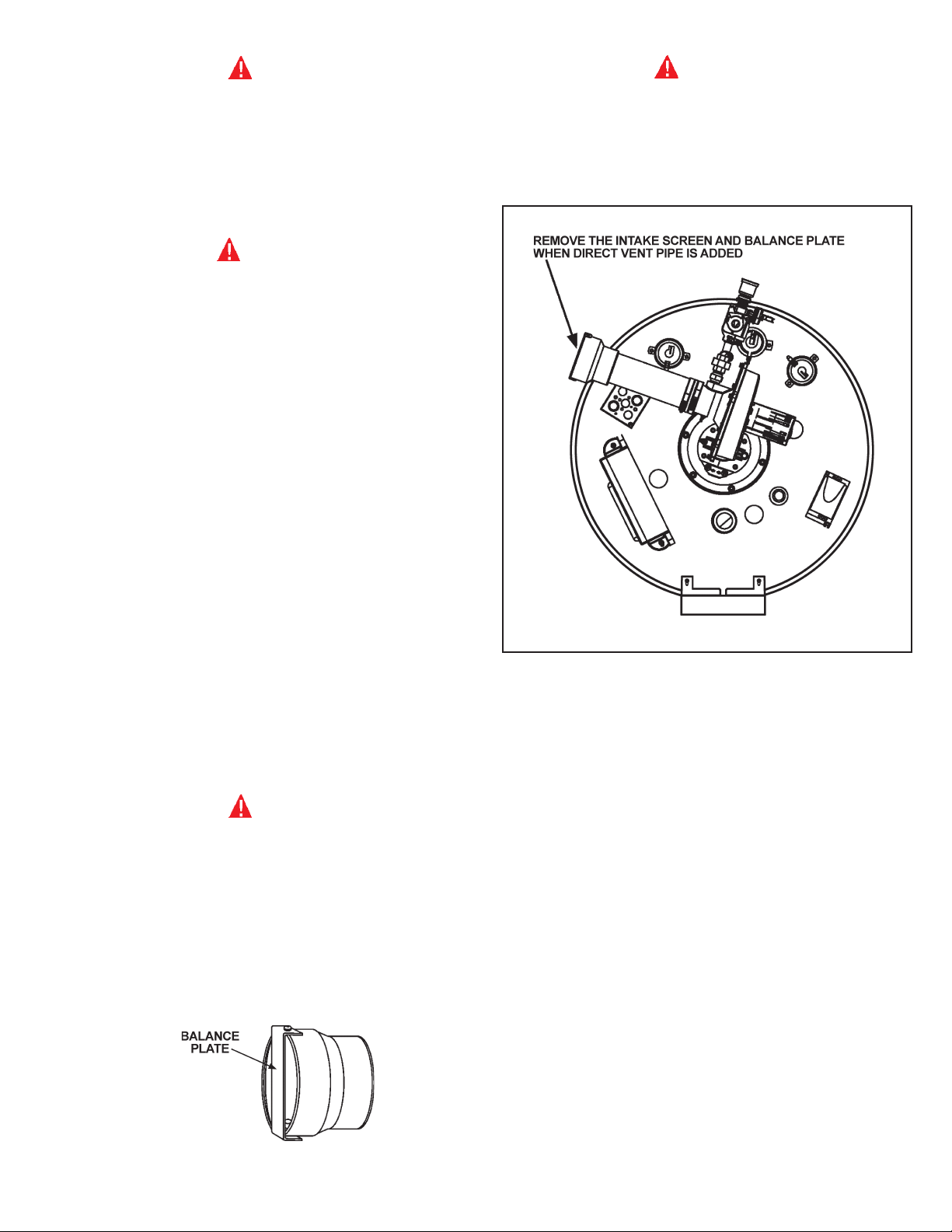

WH EN THE U NIT IS TO BE SETUP AS A DI RECT VENT,

TH E INTAKE GUAR D AND THE BALA NCE PLATE MUST

BE REMOVED. TH E INLE T VE N T PI P E MAY THEN BE

GL UED TO THE AI R INTAK E (see Figure 8) PRO VIDED

ON TH E UN IT.

Do not terminate the exhaust vent terminal over public area where

condensate or vapor can cause nuisance or hazard.

Plan the vent system layout so that proper clearances are maintained

from plumbing and wiring.

Vent pipes serving power vented appliances are classied by building

codes as "vent connectors". Required clearances from combustible

materials must be provided in accordance with information in this

manual under LOCATION OF HEATER and CLEARANCES, and

with National Fuel Gas Code and local Codes.

IMPORTANT

Plan the layout of the vent system backwards from the vent

termination to the appliance.

WARNING

USE ONLY THE VENT TERMINALS SUPPLIED WITH THIS UNIT.

TERMINATION OF A VENT SYSTEM WITH A DEVICE OTHER THAN

THE SUPPLIED VENT TERMINATIONS WILL AFFECT SYSTEM

PERFORMANCE AND RESULT IN A SAFETY HAZARD.

DIRECT VENTING

The air intake provided on the unit contains an intake guard, see

Figure 7.

3"x 4" PVC REDUCER WITH INTAKE SCREEN

FIGURE 8.

DIRECT VENT TERMINAL INSTALLATION

IMPORTANT

4" V ENT AND I NTAK E TERMINALS A RE PRO VIDE D FOR

N E W IN S TA LL AT I ON S . TO P R E V EN T E XH A US T I N G

PR O DUCTS FR OM CIRCU L ATING TO THE AIR IN TAKE

IN WI N D Y/ C OL D AR E A S, THE MA X IM U M PRA C T I C A L

D I STA N CE BE T W E EN T HE S E T W O T E R M I N AL S I S

RE COMM ENDE D.

IMPORTANT

WHEN LOCATING THE TERMINALS ON A SIDEWALL, THE

FOLLOWING SPECIFICATIONS PERTAINING TO TERMINAL

LOCATION MUST BE FOLLOWED.

FIGURE 7.

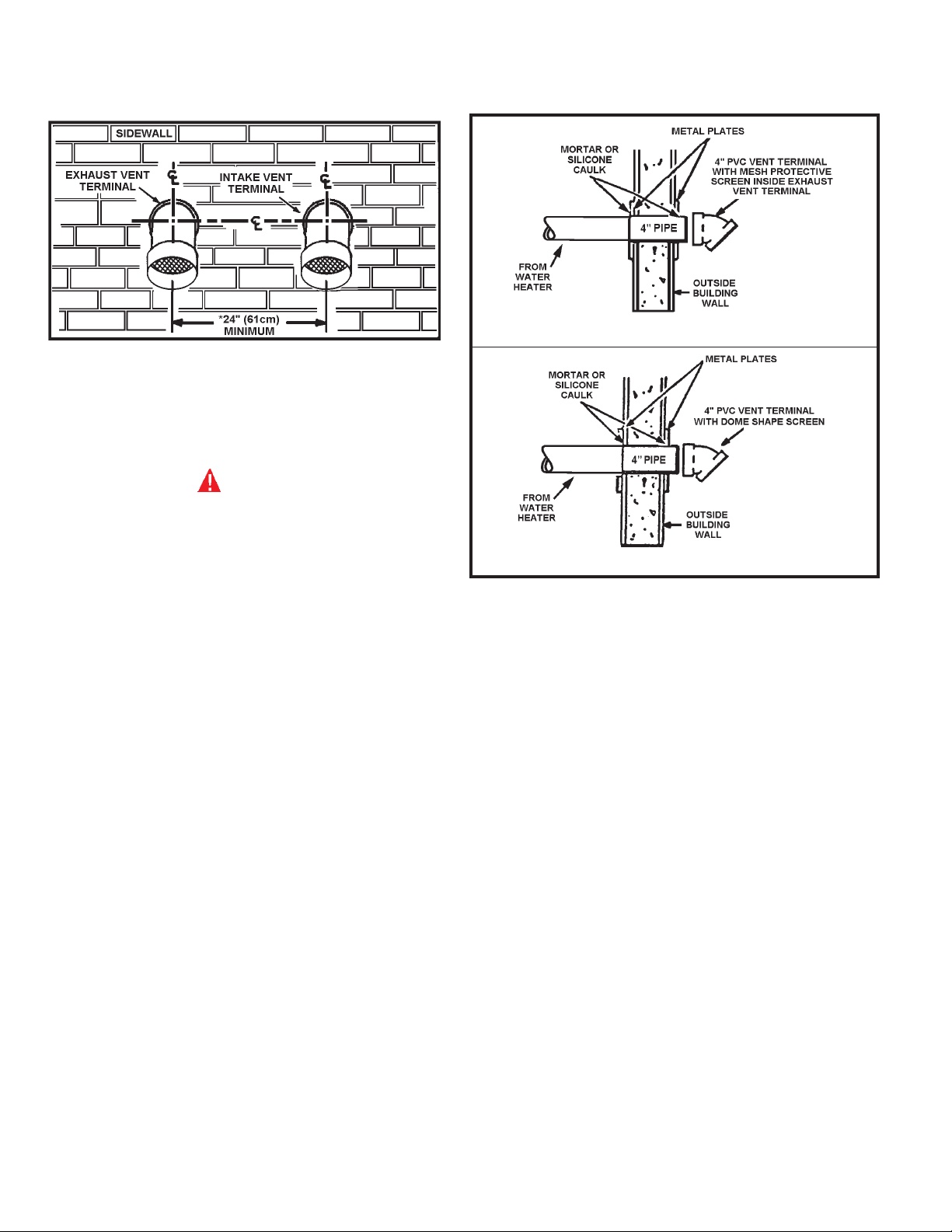

1. The intake vent terminal and the exhaust vent terminal must

terminate on the same exterior wall and must be located at

a minimum of 24" (61cm) from the vertical centerline of the

exhaust vent terminal (see Figure 9). In colder climates

increasing the 24" (61cm) minimum to 48" (122cm) will

reduce possibility of frost over from side winds blowing

exhaust vapors to the air intake of the direct the vent and is

recommended for Canada.

11

Page 12

2. The horizontal centerline of the intake vent terminal may not be

located lower than the horizontal centerline of the exhaust vent

terminal (see Figure 9).

FIGURE 9.

INSTALLATION SEQUENCE

For installations in the City of Los Angeles, California Category IV

PVC Pipe such as that manufactured by Brownline Pipe Company,

must be used as vent pipe material.

CAUTION

Vent terminals supplied with the heater must be used.

Slide the pipe through the wall and insert into coupling on the

other side of the wall, making sure that the vent terminal ends

up pointed in the correct position. See Figure 10.

EXHAUST VENT TERMINAL

NOTE: BEFORE BEGINNING INSTALLATION OF ANY VENT

PIPE READ THE VENT PIPE MANUFACTURER'S INSTALLATION

INSTRUCTIONS.

1. After the points of termination have been determined, use the

cover plates as templates to mark the holes for the vent pipes

to be inserted through the wall. BEWARE OF CONCEALED

WIRING AND PIPING INSIDE OF WALL.

2. If the vent terminals are being installed on the outside of a nished

wall, it may be easier to mark both the inside and outside wall.

Align the holes by drilling a hole through the center of the template

from the inside through to the outside. The template can now be

positioned on the outside wall using the drilled holes as a centering

point for the template.

3. A) MASONRY SIDE WALLS

Chisel an opening approximately 1/2" (1.3 cm) larger than the

marked circle.

B) WOODEN SIDE WALLS

Drill a pilot hole approximately one quarter inch outside of the

marked circle. This pilot hole is used as a starting point for a

saws-all or sabre saw blade. Cut around the marked circle staying

approximately one quarter inch outside of the line. (This will allow

the vent pipe to easily slide through the opening. The resulting

gap will be covered by the vent terminal cover plates.) Repeat

this step on the inside wall if necessary.

4. Cut a length of PVC pipe about 3.5" (8.9 cm) longer than the wall

thickness at the opening.

5. Glue the intake vent terminal to the section of the pipe.

6. Slide the wall plate over the pipe to stop against intake vent terminal.

7. Place a bead of caulking (not supplied) around the gap between

the pipe and the wall. Place some of the caulking on the back of

the plate to hold it against the wall after installation.

8. If the vent pipe is installed up to the wall, with a coupling on the

end against the wall opening, the pipe with the vent terminal

can be prepared for gluing before inserting through the wall.

INTAKE VENT TERMINAL

FIGURE 10.

VERTICAL VENT TERMINAL INSTALLATION

IMPORTANT

WHEN TERMINATING THROUGH A ROOF, THE FOLLOWING

SPECIFICATIONS PERTAINING TO TERMINAL LOCATION MUST

BE FOLLOWED.

1. Proper support must be provided for all pipe protruding through

the roof.

2. The vertical roof terminations should be sealed with a plumbing

roof boot or equivalent ashing.

3. The intake vent termination and the exhaust vent termination

must penetrate the same side of roof.

4. The center line of the intake vent termination and the center

line of the exhaust vent termination must be no closer than

24" (61cm).

5. The intake vent terminal and the exhaust vent terminal must be

oriented facing downward and the same direction.

The specications are displayed in Figure 11.

NOTE: Exhaust vent terminal is installed using the same procedure.

INSTALLATION SEQUENCE

NOTE: BEFORE BEGINNING INSTALLATION OF ANY VENT PIPE,

READ “VENT PIPE PREPARATION” SECTION ON PAGE 12.

1. After the points of termination have been determined, use the

cover plates as templates to mark the holes for the vent pipes to

be inserted through the roof.

12

Page 13

2. Drill a pilot hole approximately 1/4" (6 mm) outside of the marked

circle. This pilot hole is used as a starting point for a sawsall or sabre saw blade. Cut around the marked circle staying

approximately one quarter inch outside the line. (This will allow

the vent pipe to easily slide through the opening). The resulting

gap will be covered by the roof boot/ashing.

3. Suspend the pipe through center of hole using proper support.

4. Slide roof boot or equivalent ashing over pipe and secure roof

boot equivalent ashing to roof.

5. Seal around ashing.

6. Terminate intake terminal and exhaust vent terminal facing down.

See Figure 11.

FIGURE 11.

INSTALLATION OF VENT SYSTEM

WARNING

THE OPTIONAL INTAKE VENTING ARRANGEMENT AND THE

EXHAUST VENTING ARRANGEMENT MUST BE INSTALLED TO

RUN DIRECTLY TO THE OUTDOORS AND NOT IN ANY WAY BE

CONNECTED TO ANOTHER VENTING SYSTEM (I.E. FURNACE,

DRYERS OR SPACE HEATERS). IT IS CRUCIAL THAT THE

VENTING ARRANGEMENT BE KEPT SEPARATE FROM OTHER

VENTING SYSTEMS. IF THIS WARNING IS IGNORED, AND THE

SYSTEM IS VENTED INCORRECTLY, IT MAY CAUSE IMPROPER

OPERATION, FIRE, EXPLOSION, OR ASPHYXIATION.

1. Plan the route of the vent system from the vent termination to the

planned location of the appliance. Layout the total vent system

to use the minimum of vent pipe and elbows possible.

3. The unit is certied to a minimum amount of 4-inch pipe for

the exhaust venting arrangement of 15-equivalent feet. This is

the minimum amount of pipe required for the exhaust venting

arrangement. The intake venting arrangement is certied to use

a minimum of 0-equivalent feet of 4-inch PVC pipe.

IMPORTANT

When multiple units are direct vented through a wall (4-inch venting),

all intake vent terminals should be no lower than the highest exhaust

vent terminal.

NOTE: This unit can be vented using only PVC (Class 160, ASTM

D-2241 Schedule 40, ASTM D-1785 ; or Cellular Core Schedule

40 DWV, ASTM F-891) , Schedule 40 CPVC (ASTM F-411), or ABS

(ASTM D-2661) pipe. The ttings, other than the TERMINATIONS

should be equivalent to PVC-DWV ttings meeting ASTM D-2665

(Use CPVC ttings, ASTM F-438 for CPVC pipe and ABS ttings,

ASTM D-2661/3311 for ABS pipe. If CPVC or ABS pipe and ttings

are used, then the proper cement must be used for all joints, including

joining the pipe to the Termination (PVC Material). PVC Materials

should use ASTM D-2564 Grade Cement; CPVC Materials should

use ASTM F-493 Grade Cement and ; ABS Materials should use

ASTM D-2235 Grade Cement.

NO TE: for Water Heat ers in loca tion s wit h hig h ambi ent

temperatures (above 100°F or 38°C) and/or insufcient dilution air,

it is recommended that CPVC or ABS pipe and ttings (MUST USE

SUPPLIED VENT TERMINAL) be used.

5. It is important that condensate not be allowed to buildup in the

exhaust vent pipe. To prevent this from happening the pipe should

be installed with a slight, 1/8 inch (3mm) per 5 feet (152 cm) of

pipe maximum downward slope.

6. The vent system should be supported every 5 feet (152 cm) of

vertical run and every 3 feet (91cm) of horizontal run of vent pipe

length.

NOTE: Stress levels in the pipe and ttings can be signicantly

increased by improper installation. If rigid pipe clamps are used to

hold the pipe in place, or if the pipe cannot move freely through a

wall penetration, the pipe may be directly stressed, or high thermal

stresses may be formed when the pipe heats up and expands. Install

accordingly to minimize such stresses.

2. This unit is certied for the use of 4-inch PVC pipe for venting.

The maximum length of 70-equivalent feet of 4-inch PVC pipe

may be used for the intake venting arrangement and a maximum

length of 70-equivalent feet of 4-inch PVC pipe may be used on

the exhaust venting arrangement. If the gas pressure (dynamic)

is set between 7” wc - 9” wc, the maximum allowed length is

80 equivalent feet for both air intake and exhaust venting. The

maximum number of 90 degree elbows for the 4-inch venting is

six (6) in the intake and six (6) on the exhaust. A 90 degree elbow

is equal to ve (5) equivalent feet of 4-inch pipe. One 90 degree

elbow is equaled to two 45 degree elbows.

Table 2. VENT LENGTH TABLE

Number 4" PVC

of 90° Maximum Maximum

Elbows Feet. of Pipe Meters of Pipe

ONE (1) 65' 19.7 m

TWO (2) 60' 18.2 m

THREE (3) 55' 16.7 m

FOUR (4) 50' 15.2 m

FIVE (5) 45' 13.6 m

SIX (6) 40' 12.1 m

INLET VIEW

OUTLET VIEW

FIGURE 12.

13

Page 14

VENT PIPE PREPARATION

1. INITIAL PREPARATION

A. Make sure the solvent cement you are planning to use is

designed for the specic application you are attempting.

B. Know the physical and chemical characteristics and limitations

of the PVC, PVC cellular core, ABS or CPVC piping materials

that you are about to use.

C. Know the reputation of your pipe and cement manufacturer

and their products.

D. Know your own qualications or those of your contractor. The

solvent welding technique of joining PVC, PVC cellular core,

ABS or CPVC pipe is a specialized skill just as any other pipe

tting technique.

E. Closely supervise the installation and inspect the nished

job before start-up.

contacts are normally open. When the fan increases the pressure

in the burner, the pressure switch will allow the electrical contacts

to close. The pressure switch is connected to the burner tap by a

piece of tygon tubing. This tubing must be connected in order for

the switch to change the electrical contacts. The controller requires

that the electrical contacts on this air ow switch be open before

it will allow the blower to come on. See Figure 13.

BLOCKED OUTLET PROVER SWITCH

The Blocked Outlet Prover Switch is set up to shut the unit off when

a build-up of positive pressure in the exhaust vent pipe occurs.

This switch is a positive pressure switch that requires an increase

in pressure to change the electrical contacts from normally closed

to open. When this switch prevents the unit from igniting, most

likely the exhaust is blocked by some means. Check to see if the

condensate is allowed to ow freely from the exhaust elbow and

for obstructions in the exhaust venting and exhaust vent terminal.

See Figure 13.

BLOCKED INLET PROVER SWITCH

F. Contact the manufacturer, supplier, or competent consulting

agency if you have any questions about the application or

installation of PVC, PVC cellular core, ABS or CPVC pipe.

G. Take the time and effort to do a professional job. Shortcuts will

only cause you problems and delays in start-up. The majority

of failures in these systems are the result of shortcuts and/or

improper joining techniques.

2. SELECTION OF MATERIALS

PRIMER

It is recommended that Tetrahydrofuran (THF) be used to prepare

the surfaces of pipe and ttings for solvent welding. Do not use

water, rags, gasoline or any other substitutes for cleaning PVC

cellular core, ABS or CPVC surfaces. A chemical cleaner such as

MEK may be used.

CEMENT

The cement should be a bodied cement of approximately 500 to

1600 centipoise viscosity containing 10-20% (by weight) virgin PVC

material solvated with tetrahydrofuran (THF). Small quantities of

dimethyl formamide (DMF) may be included to act as a retarding

agent to extend curing time. Select the proper cement; Schedule

40 cement should be used for Schedule 40 pipe. Never use

al l-pu rpose ceme nts, comme rcia l glue s and adhes ives or

ABS cement to join PVC or CPVC pipe and ttings.

The Blocked Inlet Prover Switch is set up to shut the unit off when

a build-up of negative pressure in the intake vent pipe occurs. This

switch is a negative pressure switch that requires an increase in

negative pressure to change the electrical contacts from normally

closed to open. The switch is connected to the pressure tap on

the ange connected to the inlet of the blower. When this switch

prevents the unit from igniting, most likely the intake is blocked by

some means. Check to see if there is no more than seventy (70)

equivalent feet (24.8m) of four inch PVC vent pipe on the intake. Also

verify that the intake and intake vent terminal is free of obstructions

that may prevent air from entering the unit. See Figure 13.

LOW GAS PRESSURE SWITCH

The Low Gas Switch (LGS) is a single-pole, normally open pressure

switch that will close its contacts when a rising pressure of 4.6 in.

W.C. (1.25 Kpa) is encountered. The contacts will open when the

pressure falls below the xed set point of 4.6 in. W.C. (1.25 Kpa)

The LGS monitors the gas supply pressure to the heater. If the

gas supply falls below 4.6 in. W.C. (1.25 Kpa), the main burner is

extinguished (if heater is running) or the heater will not start up.

NOTE: LOW GAS SWITCH IS LOCATED ON INLET SIDE OF GAS

VALVE. See Figure 13.

SA F E T Y PRECAUTI O N : PR I MERS AN D CE M E N TS ARE

EXTREMELY FLAMMABLE AND MUST NOT BE STORED OR

USED NEAR HEAT OR OPEN FLAME. ALSO, USE ONLY IN A

WELL-VENTILATED AREA.

CONTROLS AND SWITCHES

The SUF-130-300 and 400 are equipped with four pressure switches.

These switches are essential to the safe and proper operation of the

unit. All switches are wired in series. The controller is set up to shut

the unit down whenever there is a failure of any of the switches. It is

important to understand the purpose of each switch.

BLOWER PROVER SWITCH

The Blower Prover Switch is provided on the heater to verify that

the fan is operating. It is a positive pressure switch whose electrical

FIGURE 13.

ON/OFF SWITCH

The ON/OFF Switch is a single-pole, single-throw rocker switch. This

switch provides 120VAC from the line source to the heater.

14

Page 15

CAUTION

THE WATER HEATER IS POLARITY SENSITIVE. BEFORE

APPLYING ELECTRICITY TO THIS HEATER BE CERTAIN THAT

SUPPLY NEUTRAL WIRE TO GROUND CHECK INDICATES ZERO

VOLTAGE.

HOT SURFACE IGNITER

The Hot Surface Igniter is a device that ignites the main burner by

high temperature (>1800°F or >982°C). When 120VAC is applied

to the igniter, sufcient heat is generated to ignite the main burner.

Although improvements have been made to strengthen the igniter,

it is fragile and care must be taken when handling the igniter to

prevent breakage.

GAS PIPING

Contact your local gas service company to ensure that adequate

gas service is available and to review applicable installation codes

for your area.

WARNING

THE HEATER IS NOT INTENDED FOR OPERATION AT HIGHER

THAN 11.0" WATER COLUMN (2.74 Kpa) FOR NATURAL GAS AND

14.0" W.C. (3.49kPa) FOR PROPANE GAS SUPPLY PRESSURE.

HIGHER GAS SUPPLY PRESSURES REQUIRE SUPPLEMENTAL

REDUCING SERVICE REGULATION. EXPOSURE TO HIGHER

GAS SUPPLY PRESSURE MAY CAUSE DAMAGE TO THE GAS

CONTROLS WHICH COULD RESULT IN FIRE OR EXPLOSION.

IF OVERPRESSURE HAS OCCURRED SUCH AS THROUGH

IM P R OPER TE S T ING OF GAS LI N ES OR EMER G E NCY

MALFUNCTION OF THE SUPPLY SYSTEM THE GAS VALVE

MUST BE CHECKED FOR SAFE OPERATION. MAKE SURE THAT

THE OUTSIDE VENTS ON THE SUPPLY REGULATORS AND THE

SAFETY VENT VALVES ARE PROTECTED AGAINST BLOCKAGE.

THESE ARE PARTS OF THE GAS SUPPLY SYSTEM, NOT THE

HEATER. VENT BLOCKAGE MAY OCCUR DURING ICE STORMS.

IT IS IMPORTANT TO GUARD AGAINST GAS VALVE FOULING

FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING

MAY CAUSE IMPROPER OPERATION, FIRE OR EXPLOSION.

IF COPP ER SU PPLY LINE S ARE US ED TH EY MUST BE

INTERNALLY TINNED AND CERTIFIED FOR GAS SERVICE.

Size the main gas line in accordance with Table 3. The gures

shown are for straight lengths of pipe at 0.5 in. W.C. (125Pa)

pressure drop, which is considered normal for low pressure

systems Note that ttings such as elbows and tees will add to the

pipe pressure drop.

CAUTION

DO NOT USE FLEXIBLE GAS PIPING.

TABLE 3. MAXIMUM CAPACITY OF PIPE IN CUBIC FEET OF GAS

PER HOUR (Based upon a Pressure Drop of 0.5 inch Water Column

and 0.6 Specic Gravity Gas and max. gas pressure of 0.5 psig).

LENGTH NORMAL IRON PIPE SIZES (INCHES)

IN INPUT IN THOUSANDS BTU/HR

FEET 1 1/4" 1 1/2" 2" 2 1/2" 3" 4"

10 1400 2100 3960 6300 11000 23000

20 950 1460 2750 4360 7700 15800

30 770 1180 2200 3520 6250 12800

40 660 990 1900 3000 5300 10900

50 580 900 1680 2650 4750 9700

60 530 810 1520 2400 4300 8800

70 490 750 1400 2250 3900 8100

80 460 690 1300 2050 3700 7500

90 430 650 1220 1950 3450 7200

100 400 620 1150 1850 3250 6700

125 360 550 1020 1650 2950 6000

150 325 500 950 1500 2650 5500

175 300 460 850 1370 2450 5000

200 430 800 1280 2280 4600

LENGTH NORMAL IRON PIPE SIZES (INCHES)

IN INPUT IN KW

METERS 1 1/4" 1 1/2" 2" 2 1/2" 3" 4"

3.0 410 615 1160 1845 3221 6735

6.1 278 428 805 1277 2255 4626

9.1 225 346 644 1031 1830 3748

12.2 193 290 556 878 1552 3192

15.2 170 264 492 776 1391 2840

18.3 155 237 445 703 1259 2577

21.3 143 220 410 659 1142 2372

24.4 135 202 381 600 1083 2196

27.4 126 190 357 571 1010 2108

30.5 117 182 337 542 952 1962

38.1 105 161 299 483 864 1757

45.7 95 146 278 439 776 1610

53.3 88 135 249 401 717 1464

61.0 126 234 375 688 1347

BEFORE ATTACHING THE GAS LINE BE SURE THAT ALL GAS

PIPE IS CLEAN ON THE INSIDE.

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS

SUPPLY LINE, A DIRT LEG (SOMETIMES CALLED A SEDIMENT

TRAP OR DRIP LEG) MUST BE INCORPORATED IN THE PIPING

(SEE FIG. 14). THE DIRT LEG MUST BE READILY ACCESSIBLE

AND NOT SUBJECT TO FREEZING CONDITIONS. INSTALL IN

ACCORDANCE WITH RECOMMENDATIONS OF SERVING GAS

SUPPLIERS. REFER TO THE NATIONAL FUEL GAS CODE NFPA

54 OR THE NATURAL GAS AND PROPANE INSTALLATION

CODE CAN/CSA-B149.1.

FIGURE 14.

CONNECTION OF GAS PIPE

1. When connecting gas pipe to unit, apply wrench to ange only.

Note: Do not use wrench on gas valve or gas bracket.

2. PERFORM THE GAS LEAK TEST ANY TIME WORK IS DONE

ON A GAS SYSTEM TO AVOID THE POSSIBILITY OF FIRE OR

EXPLOSION WITH PROPERTY DAMAGE, PERSONAL INJURY

OR LOSS OF LIFE.

The Gas Leak Test is performed as follows: Paint pipe connections

upstream of gas control with a rich soap and water solution to test

for leaks before operating main burner. Bubbles indicate gas leak.

To stop leak, tighten pipe connections. After piping connections are

checked, turn on main burner. With main burner in operation, paint

pipe joints (including anges), pilot gas tubing connections and

control inlet and outlet with rich soap and water solution. Bubbles

indicate gas leak. To stop leak, tighten ange screws, joints and pipe

connections. Replace part if leak can’t be stopped.

15

Page 16

To prevent damage, care must be taken not to apply too much torque

when attaching gas supply pipe to gas valve inlet.

Apply joint compounds (pipe dope) sparingly and only to the male

threads of pipe joints. Do not apply compound to the rst two threads.

Use compounds resistant to the action of liquefied petroleum

gases.

DISCONNECT THE APPLIANCE AND ITS MANUAL GAS SHUTOFF

VALVE FROM THE GAS SUPPLY PIPING SYSTEM DURING ANY

SUPPLY PRESSURE TESTING EXCEEDING 1/2 PSIG (3.45Kpa). GAS

SUPPLY LINE MUST BE CAPPED WHEN DISCONNECTED FROM

THE HEATER. FOR TEST PRESSURES OF 1/2 PSIG (3.45Kpa) OR

LESS, THE APPLIANCE NEED NOT BE DISCONNECTED, BUT MUST

BE ISOLATED FROM THE SUPPLY PRESSURE TEST BY CLOSING

THE MANUAL GAS SHUTOFF VALVE.

BEFORE PLACING THE HEATER IN OPERATION, CHECK FOR

GAS LEAKAGE. USE SOAP AND WATER SOLUTION OR OTHER

MATERIAL ACCEPTABLE FOR THE PURPOSE OF LOCATING

GAS LEAKS. DO NOT USE MATCHES, CANDLES, FLAME OR

OTHER SOURCES OF IGNITION FOR THIS PURPOSE.

PURGING

Gas line purging is required with new piping or systems in which

air has entered.

CAUTION

PU R GI N G S HOU L D B E P ER F OR M E D B Y P E RS O N S

EXPERIENCED IN THIS TYPE OF GAS SERVICE. TO AVOID

RISK OF FIRE OR EXPLOSION, PURGE DISCHARGE MUST

NOT ENTER CONFINED AREAS OR SPACES WHERE IGNITION

CAN OCCUR. THE AREA MUST BE WELL VENTILATED AND

ALL SOURCES OF IGNITION MUST BE INACTIVATED OR

REMOVED.

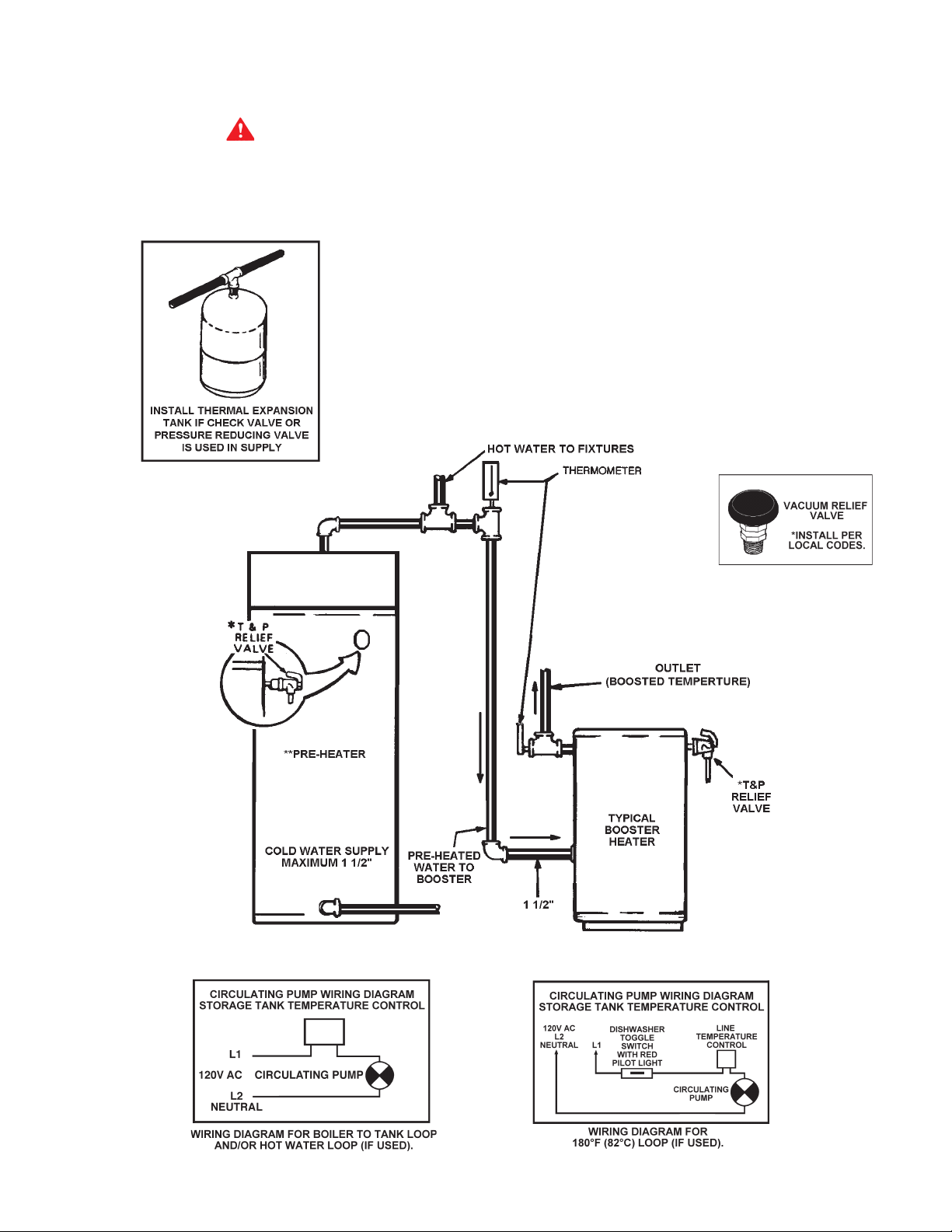

RELIEF VALVE

This heater is equipped with an approved temperature and pressure

relief valve. ASME ratings cover pressure relief. CSA ratings cover

release rate with temperature actuation.

FOR SAFE OPERATION OF THE WATER HEATER, THE RELIEF

VALVE(S) MUST NOT BE REMOVED OR PLUGGED.

In addition to the appliance relief valve, each remote storage tank

which may be used in conjunction with this appliance shall also be

installed with a properly sized, rated and approved temperature

(ANSI) and pressure (ASME) relief valve(s). This relief valve shall

comply with the standard for relief valves and automatic gas shutoff

devices for hot water supply systems. ANSI Z21.22-CSA 4.4.

Your local code authority may have other specic relief valve

requirements.

WARNING

THE PURPOSE OF A RELIEF VALVE IS TO AVOID EXCESSIVE

PRESSURE OR TEMPERATURE INTO THE STEAM RANGE,

WHICH MAY CAUSE SCALDING AT FIXTURES, TANK EXPLOSION,

SYSTEM OR HEATER DAMAGE. NO VALVE IS TO BE PLACED

BETWEEN THE RELIEF VALVE AND THE TANK.

A DRAIN LINE MUST BE CONNECTED TO THE RELIEF VALVE

TO DIRECT DISCHARGE TO A SAFE LOCATION TO AVOID

SCALDING OR WATER DAMAGE. THIS LINE MUST NOT BE

REDUCED FROM THE SIZE OF THE VALVE OUTLET AND MUST

NOT CONTAIN VALVES OR RESTRICTIONS, NOR SHOULD IT BE

LOCATED IN FREEZING AREAS. DO NOT THREAD OR CAP THE

END OF THIS LINE. RESTRICTED OR BLOCKED DISCHARGE

WILL DEFEAT THE PURPOSE OF THE VALVE AND IS UNSAFE.

THE DISCHARGE LINE SHALL BE INSTALLED TO ALLOW

COMPLETE DRAINAGE OF BOTH THE VALVE AND LINE.

GAS METER SIZE - CITY GASES ONLY

Be sure that the gas meter has sufcient capacity to supply the full

rated gas input of the water heater as well as the requirements of

all other gas red equipment supplied by the meter. If the gas meter

is too small, ask the gas company to install a larger meter having

adequate capacity.

GAS VALVES

WARNING

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL

TO SHUT OFF, TURN OFF THE MANUAL GAS CONTROL VALVE

TO THE APPLIANCE.

SYSTEM CONNECTIONS

The system installation must conform to these instructions and to

the local code authority having jurisdiction. Good practice requires

that all heavy piping be supported.

THERMOMETERS (Not Supplied)

Thermometers should be obtained and eld installed as shown in

the installation diagrams.

Thermometers are installed in the system as a means of detecting

the temperature of the outlet water supply.

WATER LINE CONNECTIONS

This manual provides detailed installation diagrams (see back

section of this manual) for typical methods of application for the

water heaters.

The water heater may be installed by itself, or with a separate storage

tank. When used with a separate storage tank, the circulation may be

either by gravity or by means of circulating pump. When a circulating

pump is used, it is important to note that the ow rate should be slow

so that there will be a minimum of turbulence inside the heater.

CLOSED SYSTEM

CAUTION

A closed system will exist if a check valve (without bypass), pressure

reducing valve (without bypass), or a water meter (without bypass) is

installed in the cold water line between the water heater and street

main (or well).

Excessive pressure may develop causing premature tank failure or

intermittent relief valve operation. This type of failure is not covered

by the limited warranty. An expansion tank or a similar device may

be required in the inlet supply line between the appliance and the

meter or valve to compensate for the thermal expansion of water

under supply pressure.

If a water heater is installed in a closed water system, check local

16

Page 17

codes or contact the water supplier or local plumbing inspector on

how to control this situation.

WATER (POTABLE) HEATING AND SPACE HEATING

1. All piping components connected to this unit for space heating

applications shall be suitable for use with potable water.

2. Toxic chemicals, such as those used for boiler treatment, shall

NEVER be introduced into this system.

3. This unit may never be connected to any existing heating system

or component(s) previously used with non-potable water heating

appliance.

4. When the system requires water for space heating at temperatures

higher than required for domestic water purposes, a tempering

valve must be installed. Please refer to installation diagrams

on pages 23 through 28 in back of manual for suggested piping

arrangements.

HEATER WIRING

STABLE CLEAN ELECTRICITY FOR PROPER OPERATION.

INSTALLING THE HEATER ON A BRANCH CIRCUIT THAT HAS

ELECTRONIC NOISE, IS SUBJECT TO FLUCTUATIONS IN

VOLTAGE LEVEL OR HAS AN APPLIANCE WHICH GENERATES

EMF OF RFI INTERFERENCE CAN CAUSE THE CONTROLLER

TO MALFUNCTION. A HIGH QUALITY POWER CONDITIONER

MUST BE INSTALLED IF THE ABOVE CONDITIONS EXIST.

MALFUNCTIONS CAUSED BY A POOR ELECTRICAL SUPPLY

ARE NOT COVERED UNDER YOUR WARRANTY.

The controller is wired to the heater as shown in gures 15 & 16. The

model and rating plate provides the electrical information needed to

size the complete heater branch supply.

All electrical work must be installed in accordance with the National

Electrical Code, NFPA 70 or the Canadian Electrical Code, CSA

C22.1 and local requirements.

When installed, the appliance must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSI/NFPA 70 or the Canadian

Electrical Code, CSA C22.1.

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE

APPLIANCE MUST BE REPLACED, IT MUST BE REPLACED

WITH 105°C OR ITS EQUIVALENT, EXCEPT IN THE BURNER

HOUSING. IN THIS CASE USE 200°C WIRE.

TH E COMPU T ER CONT ROL REQ U IRES A SO URCE OF

DO NOT ENERGIZE THE BRANCH CIRCUIT BEFORE THE

HEATER TANK IS FILLED WITH WATER.

NOTE: This controller is Polarity Sensitive. If the Hot and Neutral

Supply Voltage is reversed, the controller will not sense ame. Verify

polarity before connecting the unit.

17

Page 18

SUF 130-300 WIRING DIAGRAM

FIGURE 15.

18

Page 19

SUF 130-400 WIRING DIAGRAM

FIGURE 16.

19

Page 20

OPERATION

SEQUENCE OF OPERATION

Typical Control/Appliance Operating Sequence

1. When the control is powered, it should display the unit model,

water temperature, setting temperature and heater status.

2. If the control determines that the actual water temperature inside

the tank is below the programmed temperature setpoint less the

differential, a call for heat is activated.

3. The control then performs selected system diagnostic checks.

This includes conrming the proper state of the air/gas switches

and ECO limit device.

4. If all checks are successfully passed, the combustion blower is

energized for the pre-purge cycle.

5. When the pre-purge cycle is complete, power is applied to the

ignitor element for the ignitor warm-up period.

6. At the conclusion of the igniter warm-up period, the gas valve

will open, allowing gas to enter the burner chamber.

7. The igniter will remain on for a short predetermined time period,

then will be turned off.

8. The control will monitor the ame sense probe to conrm a

ame is present. If a ame is not veried within predetermined

time period, the gas valve will immediately be closed, and

the blower will continue to run for approximately 30 seconds

interpurge. The control will try for ignition two more times

before lockout.

inside the tank. The second temperature on this screen is the

Operating Set Point. The Operating Set Point is the temperature

at which the water heater will maintain the water inside the tank.

The third line on the screen is a text description of the Operational

State of the water heater (please see Operating States for more

details).

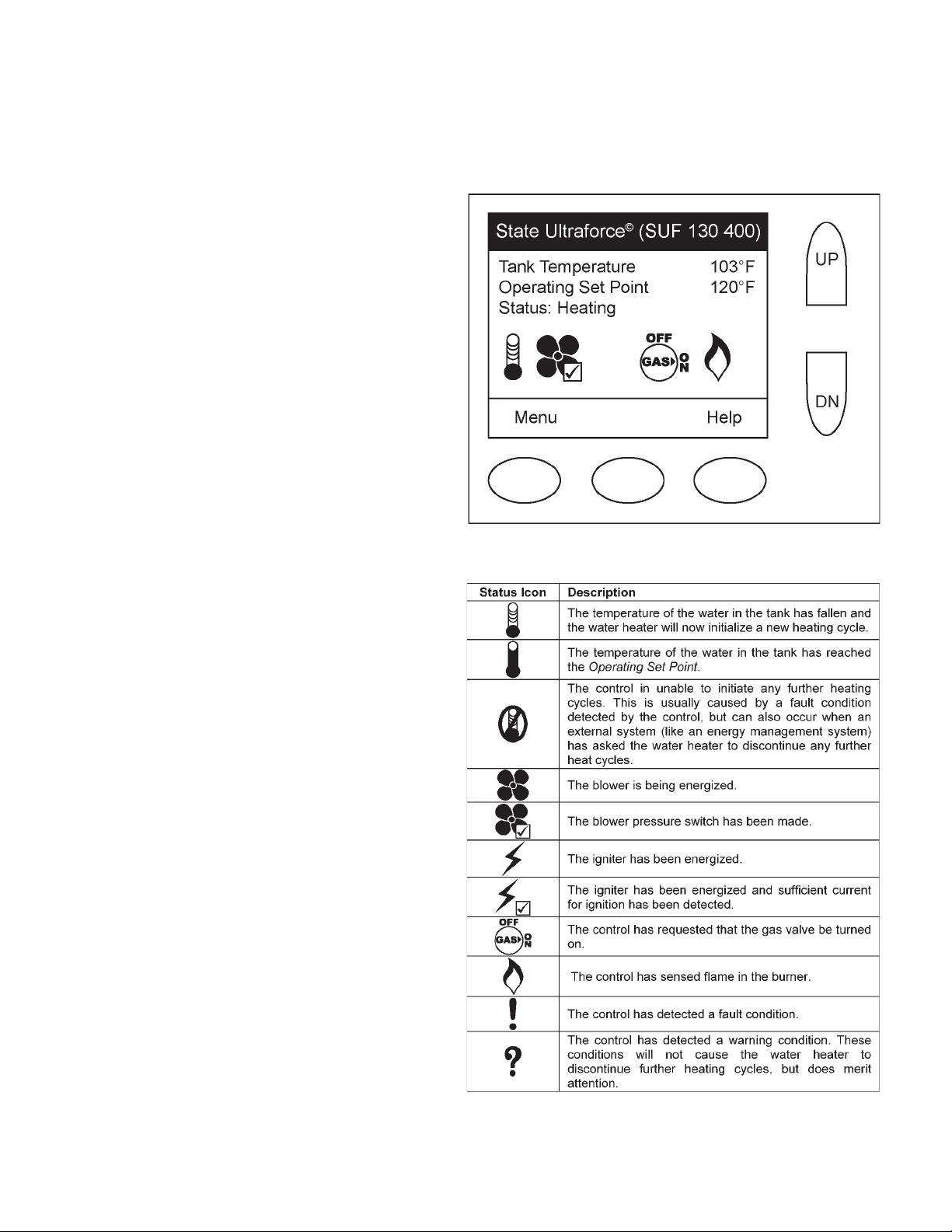

The row of status icons describe graphically operational details

of the heater. Following is a legend of all the status icons:

9. If a ame is conrmed, the control will enter the heating mode

where it will continue heating the tank water until the setpoint

temperature plus differential is reached. At this point, the gas

valve is closed and the control enters the post-purge cycle.

10. The combustion blower will run for the duration of the post purge

cycle to purge the system of all combustion gases. When the

post purge cycle is complete, the blower is de-energized and

will coast to a stop.

11. The control will now enter the idle state while continuing to

monitor the internal tank water temperature and the state of other

system devices. If the temperature drops below the setpoint

value less differential, the control will automatically return to

step 2 and repeat the entire operating cycle.

ELECTRONIC CONTROL

1. Overview

Interaction with the water heater controller is done through an up,

a down and three operation buttons. These buttons are shown

in the following illustration. Operation of the three lower buttons

is dened immediately above them on the screen. The UP and

DN buttons are used to navigate through the menus and make

adjustments to the water heater.

While the water heater is operating, the user interface will display

the desktop screen (if there are no active faults or warnings). An

example of this screen is shown in the following illustration. The

rst temperature on this screen is the temperature of the water

2. Operating States

In the main desktop screen, there are some specic Operating

States that are indicated on the status line. These are summerized

in the following table:

20

Page 21

3. Adjusting the Operating Set Point

The Operating Set Point of this water heater determines the regulated temperature for the water in the tank. This parameter is adjusted

in the Temperature menu. Items in this menu allow you to monitor different temperature readings in the tank along with adjusting the

Operating Set Point and Differential.

21

Page 22

4. Changing the Display Units

The display interface to the heater has the option of selecting between degrees and Fahrenheit and degrees Celsius for temperature

displays. This can be found in the "Display Settings" menu. Also in this menu, you may adjust how the backlight operates and the

contrast of the LCD screen.

5. Fault and Warning Conditions

This water heater is equipped with electronic controls that have the ability to monitor almost all aspects of the water heater operation. In

the case that there is an undesirable or unsafe condition that occurs, the water heater controls will detect this condition and determine

the appropriate action. Part of this is displaying the information on the LCD in plain text that accurately describes the condition and

diagnostics information that can be used to correct the issue.

There are two types of conditions that can occur during operation. These are: Warnings and Faults:

• Warnings: This is a non-safety related condition that the control has detected that may cause the water heater to operate in a less

than optimal condition, but does not pose a safety concern.

NOTE: When these conditions occur, continued heating cycles will continue and the heater will attempt to regulate the water in the

tank to the Operating Set Point.

Example of a Warning:

22

Page 23

• Faults: This is a safety related condition that has been detected by the heater.

NOTE: When these conditions occur, the water heater will not continue any further heating cycles and the water will no longer be

heated until the condition is corrected and, in most cases, power has been cycled.

Example of a Fault:

Advanced Diagnostics Information

When a fault or warning has been declared, advanced information can be found in the control. By pressing the Advanced button,

detailed information can be found regarding diagnosing and resolving the problem.

WAR NING: U sage of t he Advanc ed information r equires ability equivale nt to th at of a li cense t radesmen in the

eld involve d.

6. Access to the Current Fault or Warning

When a fault or warning has been detected by the control, it will automatically be displayed on the screen and the back light will

blink. If you choose to leave the current fault or warning by pressing the Back key, you can always return to the fault screen through

the menu.

23

Page 24

7. Viewing the Fault History

The controller for this water heater will store a history of ten of the last Fault and Warning conditions that occurred. This is stored in the

Fault History. Along with all the information about the fault, including a estimate time of when the fault occurred, information regarding

the advanced diagnostics for that fault can be accessed at any time.

8. Viewing Information About the Heater

The electronic control for this water heater monitors many different aspects of the water to ensure safe and optimal operation. Much

of the information monitored is available to view in two areas of the control. The rst is the "Heater Status" and; the second is "Heater

Information". These items can be selected through the main menu in the same fashion as described above. In these menus, detailed

information about the water heater and the current status of specic conditions can be found.

24

Page 25

PRIOR TO START UP - REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER REQUIRES

ABILITY EQUIVALENT TO THAT OF A LICENSED TRADESMAN IN

THE FIELD INVOLVED. PLUMBING, AIR SUPPLY, VENTING, GAS

SUPPLY AND ELECTRICAL WORK ARE REQUIRED.

Before attempting start-up, thoroughly study and familiarize yourself

with the exact sequence of operation and all other details on the

specic heater being used.

The power burner is equipped with an ignition system which

automatically sequences prepurge and ignition, senses and

ignites main burner flame and sequences burner operation.

Heater is equipped with an ignition control which locks out after

three unsuccessful ignition attempts. Familiarize yourself with the

sequence of operation of this unit prior to start-up.

Be certain that the water heater is full of water, that air is purged

from all lines, there are no leaks (gas and water), and all inlet water

lines are open.

Th e fol lowi ng test equ ipme nt should be on hand (all test

equipment must be acclimated to ambient temperature before

calibration and use.)

– Two U-tube manometers or calibration 0-10" W.C. (0-2.5Kpa) and

0-35" W.C. (0-8.7Kpa) pressure gauges.

• Attach a gas pressure gauge or manometer to the upstream side

of main gas cock and a gas pressure gauge or manometer to the

manifold pressure tap.

• You are now ready to begin the burner start-up procedure.

OPERATING INSTRUCTIONS

IMPORTANT

IT IS RECOMMENDED THAT A QUALIFIED SERVICE TECHNICIAN

PERFORM THE INITIAL FIRING OF THE HEATER. AT THIS TIME

THE USER SHOULD ASK THE TECHNICIAN ANY QUESTIONS IN

REGARD TO THE OPERATION AND MAINTENANCE OF THE UNIT.

CAUTION

BEFORE PROCEEDING WITH THE OPERATION OF THE UNIT,

MAKE SURE HEATER AND SYSTEM ARE FILLED WITH WATER

AND ALL AIR IS EXPELLED FROM HEATER AND PIPING.

NEVER OPERATE THE HEATER WITHOUT FIRST BEING

CERTAIN IT IS FILLED WITH WATER AND A TEMPERATURE AND

A PRESSURE RELIEF VALVE IS INSTALLED IN THE RELIEF VALVE

OPENING OF THE HEATER. DO NOT ATTEMPT TO OPERATE

HEATER WITH COLD WATER INLET VALVE CLOSED.

FILLING:

1. Close the heater drain valve.

2. Open a nearby hot water faucet to permit the air in the system

to escape.

3. Fully open the cold water inlet pipe valve allowing the heater

and piping to be lled.

4. Close the hot water faucet as water starts to ow.

5. The heater is ready to be operated.

THE MAIN MANUAL GAS SHUTOFF VALVE MUST HAVE BEEN CLOSED

FOR AT LEAST FIVE (5) MINUTES. THIS WAITING PERIOD IS AN

IMPORTANT SAFETY STEP. ITS PURPOSE IS TO PERMIT GAS THAT

MIGHT HAVE ACCUMULATED IN THE COMBUSTION CHAMBER TO

CLEAR. IF YOU DETECT GAS AT THE END OF THIS PERIOD, DO NOT

PROCEED WITH LIGHTING. RECOGNIZE THAT GAS ODOR, EVEN IF

IT SEEMS WEAK, MAY INDICATE THE PRESENCE OF ACCUMULATED

GAS SOMEPLACE IN THE AREA WITH A RISK OF FIRE OR EXPLOSION.

SEE THE FRONT PAGE FOR STEPS TO BE TAKEN.

DO NOT USE THIS HEATER IF ANY PART HAS BEEN UNDER

WATER. IMMEDIATELY CALL A QUALIFIED SERVICE TECHNICIAN

TO INSPECT THE HEATER AND TO REPLACE ANY PART OF THE