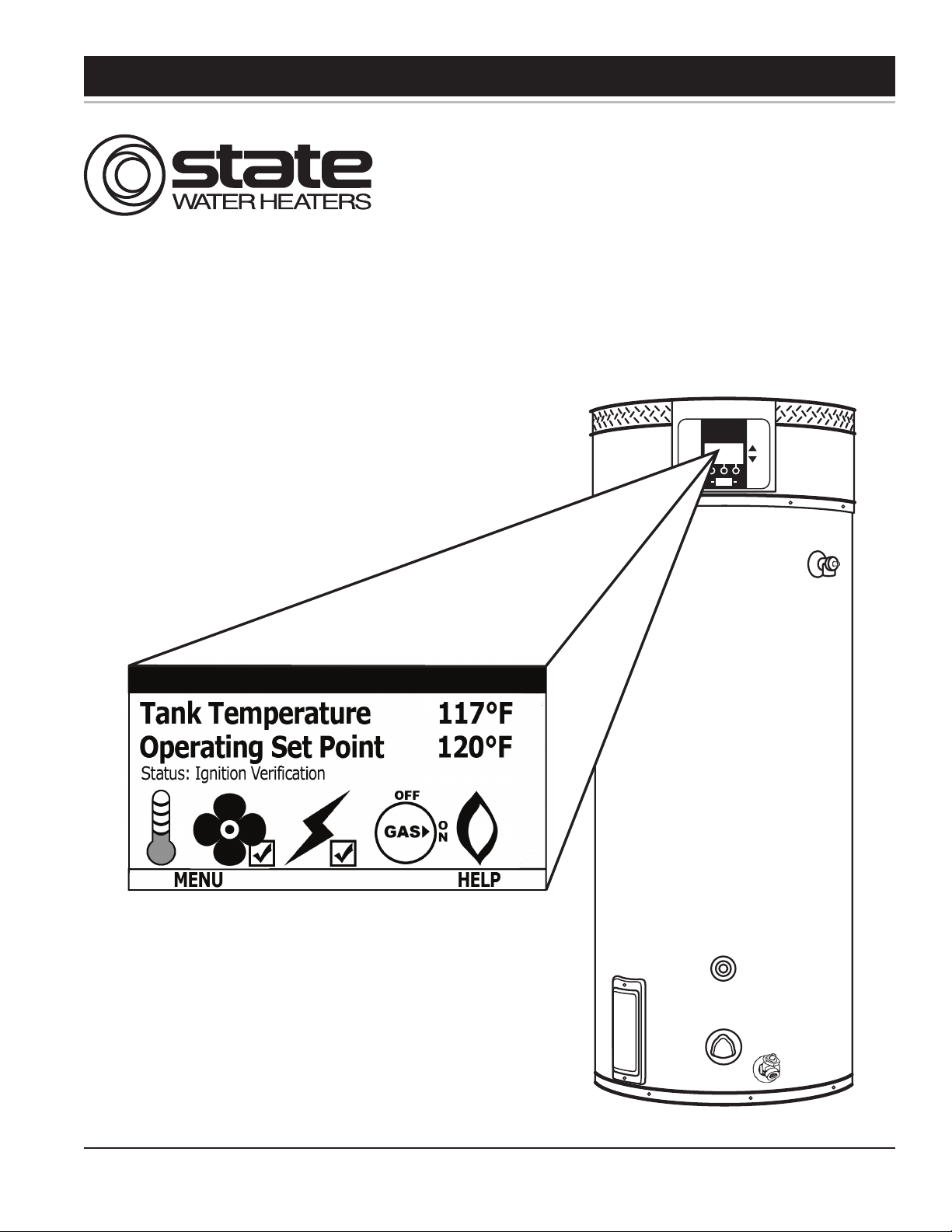

Page 1

COMMERCIAL GAS WATER HEATERS

SERVICE HANDBOOK

HIGH EFFICIENCY

FOR MODELS:

• SUF60120

• SUF100150

• SUF100199

• SUF100250

• SUF130300

• SUF130400

COMMERCIAL GAS SERIES

PRINTED 0509 198152-002

1

Page 2

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

TABLE OF CONTENTS

INTRODUCTION...............................................................2

QUALIFICATIONS............................................................2

TOOLS REQUIRED.........................................................3

GENERAL INFORMATION................................................4

GAS PRESSURE SPECIFICATIONS ................................4

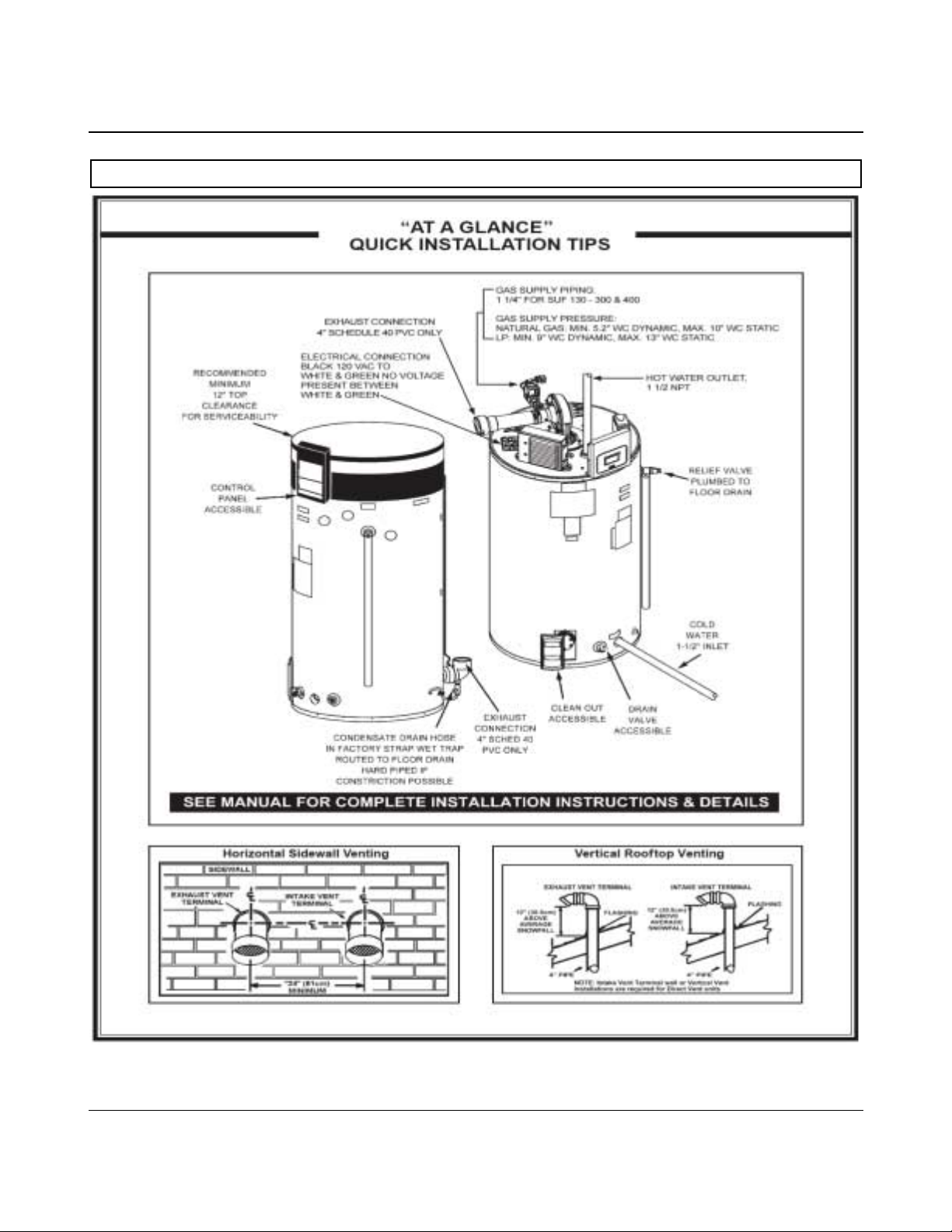

INSTALLATION QUICK TIPS – SUF 120 and 150 GAS

PRESSURE .....................................................................5

ADJUSTMENT PROCEDURE: .........................................5

GAS PRESSURE .............................................................5

SUF120 AND 150 MODELS..............................................5

HIGH ALTITUDE INSTALLATIONS ...................................5

SUF 120 - 150 .................................................................5

INSTALLATION QUICK TIPS - SUF 199 AND 250 GAS

PRESSURE .....................................................................6

ADJUSTMENT PROCEDURE:..........................................6

GAS PRESSURE .............................................................6

SUF 199 AND 250 MODELS ............................................6

HIGH ALTITUDE INSTALLATION......................................6

INSTALLATION QUICK TIPS - SUF 300, 400 GAS

PRESSURE......................................................................7

ADJUSTMENT PROCEDURE:..........................................7

GAS PRESSURE..............................................................7

SUF 300,400,....................................................................7

HIGH ALTITUDE ADJUSTMENT ......................................7

SUF 300,400,....................................................................7

INSTALLATION TIPS - SUF 300, 400 ...............................8

VENTING TABLES SUF 120 – 250....................................9

VENTING TABLES SUF 300,400,.....................................9

VENTING - ALL MODELS – SINGLE PIPE POWER VENT –

USING ROOM AIR..........................................................10

VENTING – ALL MODELS – TWO PIPE DIRECT VENT –

USING OUTSIDE AIR.....................................................11

VENT TERMINATION – DIRECT VENT – ALL MODELS. .12

DIRECT VENTING – ALL MODELS.................................13

CONTROL OVERVIEW ..................................................14

CONTROL OVERVIEW – ALL MODELS..........................14

ADJUSTING TANK TEMPERATURE – OPERATING SET

POINT - DIFFERENTIAL.................................................15

CHANGING THE DISPLAY UNITS..................................16

FAULT AND WARNING CONDITIONS – ADVANCED

DIAGNOSTIC INFORMATION.........................................17

ACCESS TO THE CURRENT FAULT OR WARNING.......18

VIEWING THE FAULT HISTORY - VIEWING

INFORMATION ABOUT THE HEATER............................19

CONTROL SEQUENCE (TYPICAL ALL MODELS).........20

CONTROL SEQUENCE FLOW CHART...........................21

CONTROLS – CENTRAL CONTROL BOARD – CCB ......22

CONTROLS – GAS VALVE SUF 120...............................23

CONTROLS – GAS VALVE SUF 150...............................23

CONTROLS – GAS VALVE SUF 199 and 250..................24

ADJUSTMENT PROCEDURE:........................................24

GAS PRESSURE ...........................................................24

SUF 199 AND 250 MODELS ..........................................24

CONTROLS – GAS VALVE SUF 199 and 250..................25

CONTROLS – GAS VALVE , ORIFICE CHART–

SUF300,400,...................................................................26

CONTROLS – PRESSURE SWITCHES – ALL MODELS..27

CONTROLS – PRESSURE SWITCHES – SUF 120 through

250.................................................................................28

CONTROLS – PRESSURE SWITCHES – SUF 300,400,. .29

CONTROLS – CONNECTIONS, IGNITER, FLAME

SENSOR, SIGHT GLASS, POWERED ANODES.............30

HOT SURFACE IGNITER / FLAME SENSOR / CONTROL

TIMING...........................................................................31

BLOWER SPEED CONTROL SUF 199 AND 250.............32

VARIABLE FREQUENCY DRIVE – SUF 400...................33

VARIABLE FREQUENCY DRIVE - BLOWER SPEED AND

PRESSURE READINGS..................................................34

WIRING DIAGRAM – SUF 120 – 300 ..............................35

WIRING DIAGRAM – SUF 400,.......................................36

State Water Heaters – Technical Training Department 1 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 3

INTRODUCTION

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

The service handbook is designed to aid in

servicing and trou bleshooting S tate W ater

Heaters Ultra Force SUF commercial water

heaters i n t he f ield. No duplication or

reproduction of t his bo ok m ay be m ade

without the ex press w ritten authorization o f

State Water Heaters .

The fol lowing tex t and i llustrations w ill

provide you with a step by step procedure to

verify pr oper i nstallation, opera tion, and

troubleshooting procedures. Additional quick

reference da ta i s i ncluded to ass ist you in

servicing these products.

The information contai ned i n this handbook

is designed to answer co mmonly face d

situations enc ountered in the ope ration of

this product l ine and is not meant to be all

QUALIFICATIONS

inclusive. If you are experiencing a problem

not covered in this handbook, please contact

State Water Heaters Technical Information at

1-800-365-0024, by e mail at

help@statewaterheaters.com

or your local

State Water Heater representative for further

assistance.

Our website:www.statewaterheaters.com

is also a resource for installation and service

information. Thi s handbook i s i ntended for

use by licensed plumbing professionals and

reference should be made to the installation

manual accom panying the prod uct. This

handbook contains supplemental information

to the produ ct’s i nstallation and ope ration

manual.

ANSI Z223.1 Sec 3.3.83

"Qualified Agency"

"Any individual, firm, corporation or company

that ei ther i n person o r through a

representative i s e ngaged i n an d i s

responsible for (a) the installation, testing or

replacement of g as p iping or (b) the

connection, i nstallation, testing, re pair or

servicing of appliances and equipment; that

is experienced i n such work; that is familiar

with all precautions required; and that has

complied w ith al l the re quirements o f the

authority having jurisdiction."

Service of this water heater requires ability

equivalent to th at of a Qual ified S ervice

Agent (l icensed t radesman) i n the fi eld

involved. Installation skills such as plumbing,

air supp ly, vent ing, gas s upply, e lectrical

supply are r equired i n addition to electrical

testing ski lls. S ome pro ducts m ay requ ire

combustion testi ng equipment and

certification. If you do not possess these

skills or do not h ave the pr oper t ools y ou

should not attem pt to serv ice thi s w ater

heater.

State Water Heaters – Technical Training Department 2 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 4

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

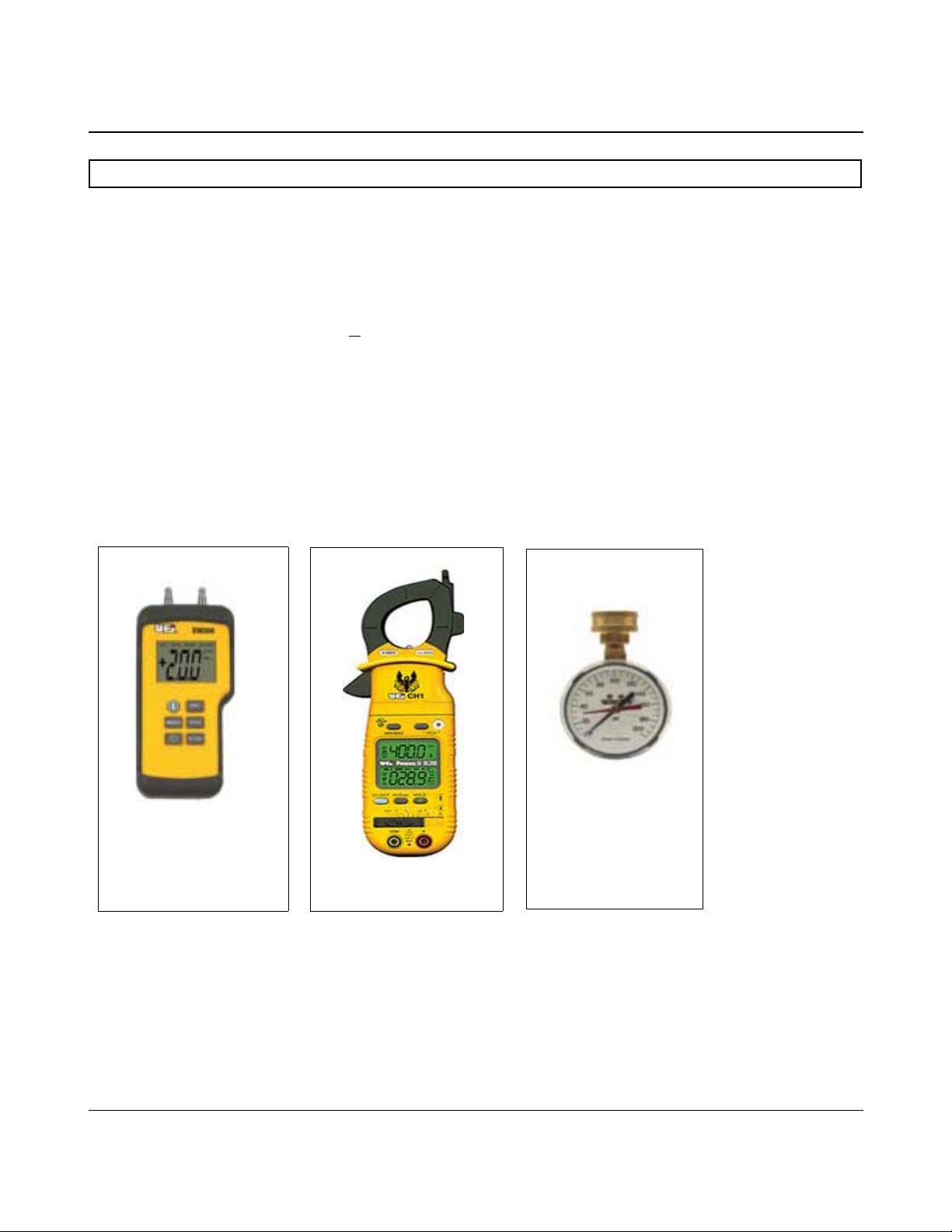

TOOLS REQUIRED

● ELECTRICAL MULTIMETER CAPABLE OF MEASURING CONTINUITY/ OHMS, AC

& DC VOLTS, AMPERES, MICROAMPERES, MILLIVOLTS, and FREQUENCY(Hz)

○ UEi Model DL289 or equivalent

● DIGITAL MANOMETER + 60” W. C. in .01” increments

Note: A digital manometer is required for testing pressure switches and can replace

a gas pressure gauge, draft gauge or slack tube manometer for checking gas

pressure.

○ UEi model EM200 or equivalent

● WATER PRESSURE GAUGE w/ LAZY HAND AND HOSE BIBB CONNECTION

● THERMOMETER

● 1-1/16 INCH SOCKET WITH EXTENSION FOR ANODE REPLACEMENT

● SET OF NUMBERED DRILL BITS

WATER PRESSURE

TEST GAUGE W/ LAZY

HAND AND HOSE BIBB

CONNECTION

DIGITAL MANOMETER

DIGITAL MULTIMETER

State Water Heaters – Technical Training Department 3 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 5

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

GENERAL INFORMATION

INSTALLATION REQUIREMENTS FOR THE

COMMO NWEALTH OF MASSACHUSETTS

For al l side w all terminated, hor izontally vented

power v ent, direct vent, and power direct v ent gas

fueled w ater heat ers installed i n ev ery dwelling,

building or structure used in w hole or i n p art for

residential pur poses, including t hose ow ned or

operated by the Commonwealth and where the side

wall exhaust vent termination is less than seven (7)

feet above finished grade in the area of the venting,

including but not limited to decks and porches, the

following requirements shall be satisfied:

INSTA LLATION OF CARBON MONOXIDE

DETECTORS

At the time of installation of the side wall horizontal

vented gas fueled equipment, the installing plumber

or gas fitter s hall observe that a hard wired carbon

monoxide detector with an alarm and battery backup is in stalled on t he f loor le vel wh ere t he g as

equipment is t o b e i nstalled. In add ition, t he

installing plumber or gas fitter shall obs erve t hat a

battery operated or har d w ired carbon monoxide

detector w ith an al arm i s i nstalled on eac h

additional level of the dwelling, building or structure

served by the sidewall horizontal vented gas fueled

equipment. It s hall b e the re sponsibility o f the

property owner to secure t he services of q ualified

licensed pr ofessionals for the i nstallation of har d

wired carbon monoxide detectors. In the event that

the s ide wall hor izontally v ented gas fueled

equipment is installed i n a c rawl space or an attic,

the hard wired carbon monoxide detector with alarm

and battery back-up may be installed on the nex t

adjacent f loor l evel. I n t he e vent t hat the

requirements of this subdivision can not be met at

the t ime of c ompletion o f i nstallation, t he ow ner

shall have a period of thirty (30) days to comply with

the a bove requirements p rovided t hat dur ing said

thirty ( 30) day p eriod, a bat tery op erated carbon

monoxide detector with an alarm shall be installed

APPROVED CARBON MONOXIDE DETECTORS

Each carbon monoxide de tector as r equired in

accordance with the above provisions shall comply

with N FPA 720 and be AN SI/UL 20 34 listed and

CSA certified.

SIGNAGE

A m etal or p lastic i dentification plate s hall b e

permanently mounted to the exterior of the b uilding

at a minimum height of eight ( 8) feet ab ove grade

directly in line with the exhaust vent terminal for the

horizontally vented gas fueled heating appliance or

equipment. The sign shall read, in print size no less

than one-half (1/2”) inch in size,

“GAS VENT DIRECTLY BELOW. KEEP CLEAR

OF ALL OBSTRUCTIONS.”

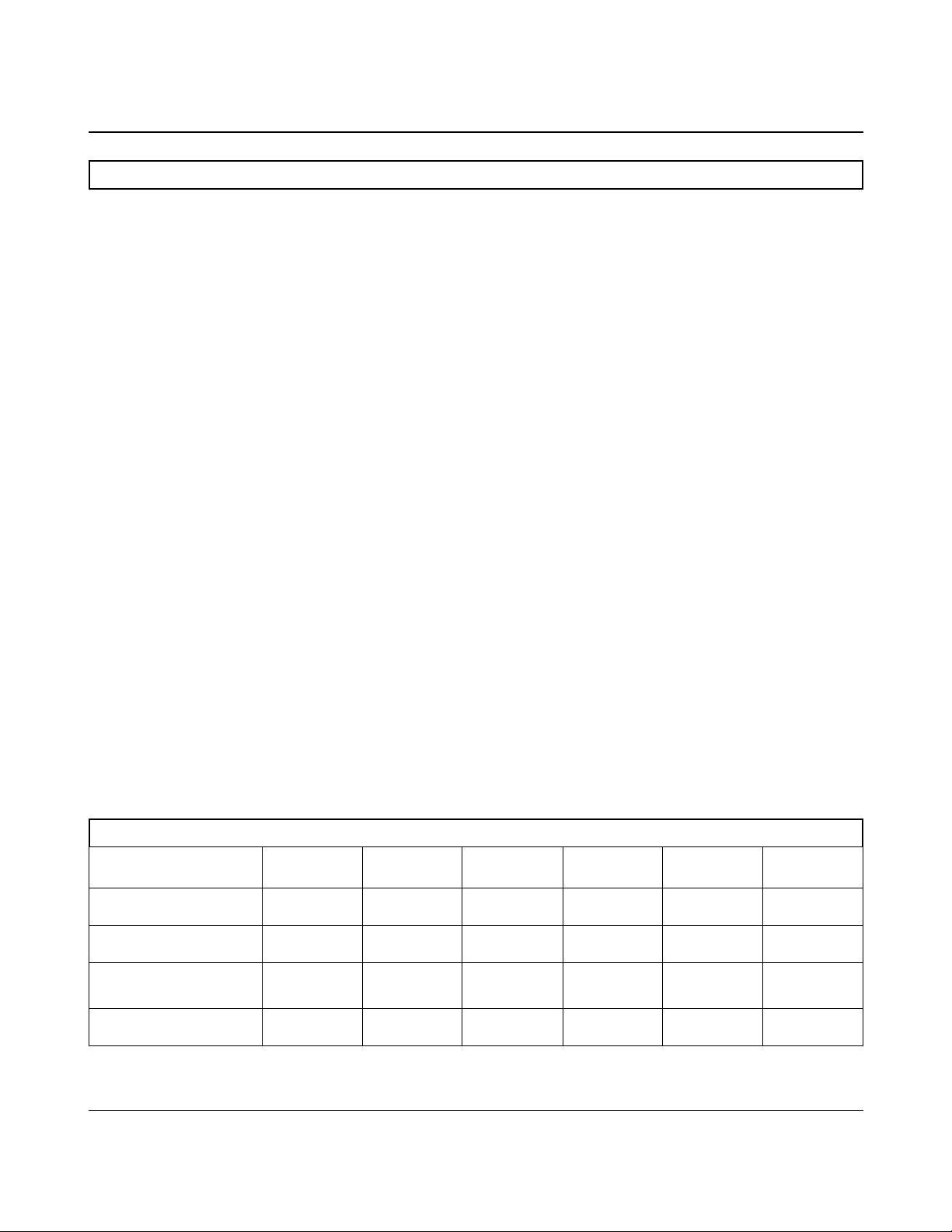

GAS PRESSURE SPECIFICATIONS

MODELS

Maximum Gas Supply Pressure

Nominal Gas Suppl y Pressure

Minimum Gas Supply Pressure

(Low Gas Press. Switch

Setting)

Manifold Pressure

Natural

120-150

10.5” W C

(2.59kPa)

7.0”WC

(1.74kPa)

4.8”WC

(1.20kPa)

4.0”WC

(0.98kPa)

State Water Heaters – Technical Training Department 4 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Propane

120-150

14.0“WC

( 3.45kPa)

11.0“WC

( 2.74kPa)

8.5“WC

( 2.12kPa)

10.0“WC

(2.49 kPa)

Natural

199-250

10.5“WC

(2.59kPa)

7.0“WC

(1.74kPa)

4.8”WC

(1.20kPa)

0“WC

( 0 kPa)

Propane

199-250

14.0“WC

( 3.45kPa)

11.0“WC

( 2.74kPa)

8.5“WC

( 2.12kPa)

0“WC

( 0 kPa)

Natural

300/400/500

11.0”WC

(2.74kPa)

7.0”WC

(1.74kPa)

5.2”WC

(1.54kPa)

4.00“WC

( 1.25kPa)

Propane

300/400/500

14.00”W C

(3.49kPa)

11.0”WC

(2.74kPa)

11.0“WC

( 2.74kPa)

10.0“WC

( 2.49kPa)

Page 6

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

INSTALLATION QUICK TIPS – SUF 120 and 150 GAS PRESSURE

ADJUSTMENT PROCEDURE:

GAS PRESSURE

SUF120 AND 150 MODELS

a. Attach a pressure gauge (manometer) to the

manifold pressure tap and refer to page 4 for correct

pressure.

Main line gas pressure to the water heater for natural

gas should be between a maximum of 10.5"W.C.

(2.59kPa) for natural gas, 14.0"W.C.(3.45kPa) for

propane and a minimum of 4.8W.C.(1.18kPa) for

Natural Gas, and 8.5"W.C. (2.08kPa) for Propane

Gas.

A supply gas pressure regulator

(service regulator) must be installed on

the gas supply line within 10' (305 cm)

of the unit.

Also see gas pressure specification table on page 4.

1.Check gas line pressure with a manometer.

2.Check manifold pressure gauge (manometer)

connected to the manifold pressure tap on the gas

control valve,

If full rate adjustment is required, remove cover screw

from top of the gas control valve. Using a small

screwdriver, turn adjusting screw clockwise to

increase or counterclockwise to decrease gas

pressure to obtain 4.0" W.C.(1 K pa) for natural gas

and 10.0" W.C. (2.5 kPa) for L.P. Gas.

3. Cycle the burner on and off several times to check

its operation.

4. Check the operation of the limit and operating

controls.

5. Check the vent system seams and joints and

ensure that there is no discharge of flue products into

the room.

6. Check the input rate.

HIGH ALTITUDE INSTALLATIONS

SUF 120 - 150

For appliance installation locations with elevations

above 6,500 feet (1982 meters) consult the “High

Altitude Installation” section of the owners manual.

b. Use this formula to “clock” the meter. Be sure

other gas consuming appliances are not operating

during this interval.

Btuh = 3600 X H/ T

T = Time in seconds to burn 1 cubic foot of gas.

(With a stopwatch read the gas meter and measure

the amount of time required for the heater to consume

1 cubic foot of gas.)

H = Heating value of gas (in Btu’s per cubic foot of

gas).

Btuh = Actual heater input rate, in Btuh.

EXAMPLE: (Using SUF-150 heater)

T = 25.25 seconds

H = 1050 Btu/ft.3

BTUH = ?

Compare result to the de-rated input required for

the elevation at the installat ion location.

Should it be necessary to adjust the gas pressure to

the burner, to obtain the full input rate, the steps below

should be followed:

c. Remove the pressure regulator cover screw and

adjust the pressure by turning the adjusting screw with

a small screwdriver. Do not exceed 4.0" (1 kPa)

natural gas models and 10.0" w.c. (2.5kPa) on the

propane models. Clockwise to increase gas pressure

and input rate. Counterclockwise to decrease gas

pressure and input rate.

d. “Clock” the meter as in step (b) above.

e. Repeat steps (c) and (d) until the specified input

rate is achieved.

f. Turn the manual gas valve to “OFF”. Replace the

pressure regulator cover screw. Remove the pressure

gauge or manometer from the manifold pressure tap.

Replace the set screw in the manifold pressure tap. If

the gas pressure regulator cannot be adjusted to give

the full input rating with sufficient gas pressure at the

valve, check to ensure the unit is equipped with the

correct orifice.

State Water Heaters – Technical Training Department 5 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 7

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

INSTALLATION QUICK T IPS - SUF 199 AND 250 GAS PRESSURE

ADJUSTMENT PROCEDURE:

GAS PRESSURE

SUF 199 AND 250 MODELS

IMPORTANT NOTE

THE SUF 199 AND 250 MODELS

INCORPORATE A NEW GAS CONTROL,

WHICH OPERATES AT A MANIFOLD

PRESSURE OF 0" W.C. (0 kPa) FOR BOTH

NATURAL AND PROPANE GAS. SEE T HE

GAS PRESSURE CHART ON PAGE 4.

THESE MODELS ARE CONFIGURED

PRIOR TO BEING SHIPPED FROM THE

FACTORY AND NO ADJUSTMENTS ARE

NECESSARY PRIOR TO STARTUP. THE

CONTROLLER MONITORS T HE AIR FLOW

AND MAKES ADJUSTMENTS TO THE FAN

SPEED WHICH IN EFFECT CONTROLS

THE AMOUNT OF GAS FLOW.

THEREFORE, THE UNIT WILL SELF

ADJUST TO ACQUIRE THE CORRECT

AMOUNT OF INPUT.

"Supply gas pressure to the water heater

must not exceed a maximum of 10.5" w.c.

(295kPa) for natural gas, or 14" w.c. (3.45

kPa) for propane. The minimum supply gas

pressure is 4.8" w.c. (1.20 kPa) for natural

gas and 8.5" w.c. (2.12 kPa) for propane

gas."

HIGH ALTITUDE INSTALLATION

The SUF 199 and 250 models are suitable

for installation up to 10,100 feet above sea

level with no adjustments.

GAS ORIFICE

The SUF 199 and 250 models do not have a

natural gas orifice. A .230” orifice is used on

LP gas models.

Venturi

Gasket

w/o orifice

Gas Control Without Orifice

Natural Gas

Venturi

Gasket w/

LP Gas

Orifice

(.230”

Brass)

Gas Control with .230” LP Orifice

Once the unit is installed and filled with water

and the inlet pressures confirmed, simply

turn the switch "on" and observe operation.

Cycle the unit "off" and "on" several times to

ensure proper operation.

A supply gas pressure regulator

(service regulator) must be installed on

the gas supply line within 10' (305 cm)

of the unit.

State Water Heaters – Technical Training Department 6 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 8

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

INSTALLATION Q UICK TIPS - SUF 300, 400 GAS PRESSURE

ADJUSTMENT PROCEDURE:

GAS PRESSURE

SUF 300,400,

A minimum dynamic gas suppl y pressure of

5.2" w.c. (1.29 kPa) for Natural Gas and 11"

w.c. (2.74 kP a) for LP Gas is requir ed befo re

making any adjustment to th e gas control

pressure regulator. Attempts to adjust the

regulator during periods of low gas supply

pressure could result in over firing of the water

heater when the gas supply pressure returns to

normal.

1. Check gas line pressure with a manometer,

adjust the gas supply line pressure Gas Pressure

table on page 4.

2. Check manifold pressure using a pressure

gauge (manometer) connected to the manifold

pressure tap on the gas control valve, If full rate

adjustment is required, remove cover screw from

top of the gas control valve. Using a small

screwdriver, turn adjusting screw clockwise to

increase or counter clockwise to decrease gas

pressure to obtain 4.0" w.c. (0.996 kPa) for

Natural Gas and 10" w.c. (2.49kPa) for LP gas.

3. Cycle the burner on and off several times to

check its operation.

4. Check the operation of the limit and operating

controls.

5. Check the vent system seams and joints and

ensure that there is no discharge of flue products

into the room.

6. Check the input rate as shown on page 5.

HIGH ALTITUDE ADJUSTMENT

SUF 300,400,

For high altitude adjustments, contact the

help line on the front of the water heater or

contact help@statewaterheaters.com .

State Water Heaters – Technical Training Department 7 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 9

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

INSTALLATION TIPS - SUF 300, 400

State Water Heaters – Technical Training Department 8 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 10

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

VENTING TABLES SUF 120 – 250

Maximum equivalent feet of intake and vent pipe using 3” PVC is 50 feet (15.2m). Equivalent feet

must include any 90° elbows (two 45° elbows equal one 90° elbow). Three inch diameter 90° elbows

are equivalent to 5' (1.5m) of pipe.

Maximum equivalent feet of intake and vent pipe using 4” PVC is 120 feet (36.6m).

Equivalent feet must include any 90° elbows (two 45° elbows equal one 90° elbow). Four inch

diameter 90° elbows are equivalent to 5' (1.5m) of pipe.

Vent Length Table Equi valent Feet (Meters) 120 thro ugh 25 0

Number of 90°

Elbows

ONE (1) 7/2.1 45/13.7 115/35

TWO (2) 7/2.1 40/12.2 110/33.5

THREE (3) 7/2.1 35/10.7 105/ 32

FOUR (4) 7/2.1 30/9.1 100/30.5

FIVE (5) 7/2.1 --- 95/29

SIX (6) 7/2.1 --- 90/27.4

3" Minimum

Pipe (Ft./M.)

3" Maximum

Pipe (Ft./M.)

VENTING TABLES SUF 300,400,

Vent Length Table Equivalent Feet (Meters) 300,400,

Number of

90°Elbows

ONE (1) 65' / 19.7 m

TWO (2) 60' / 18.2 m

Maximum Feet / meters of Pipe

4" PVC

4"Maximum

Pipe (Ft./M.)

THREE (3) 55' / 16.7 m

FOUR (4) 50' / 15.2 m

FIVE (5) 45' / 13.6 m

SIX (6) 40' / 12.1 m

State Water Heaters – Technical Training Department 9 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 11

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

VENTING - ALL MODELS – SINGLE PIPE POWER VENT – USING ROOM AIR

State Water Heaters – Technical Training Department 10 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 12

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

VENTING – ALL MODELS – TWO PIPE DIRECT VENT – USING OUTSIDE AIR

State Water Heaters – Technical Training Department 11 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 13

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

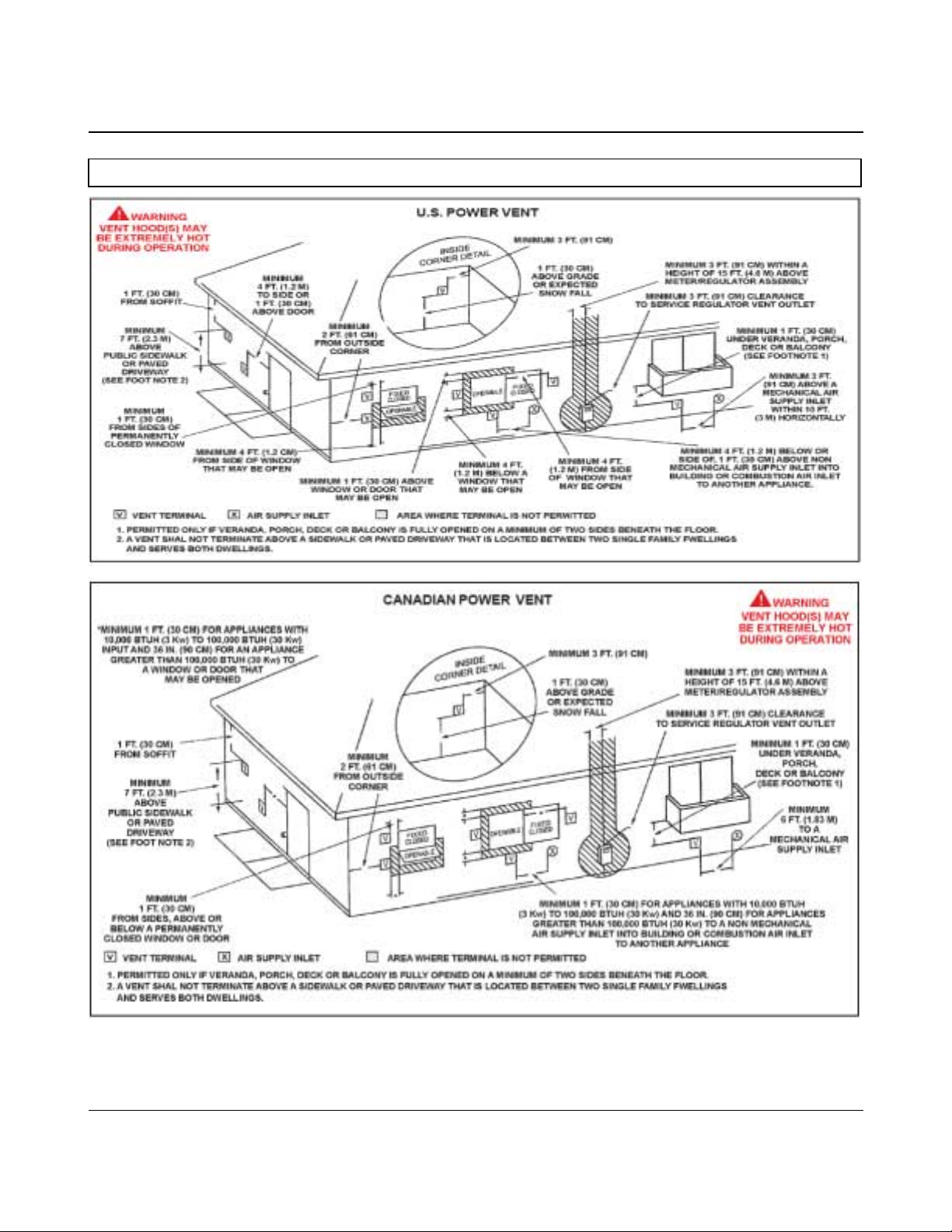

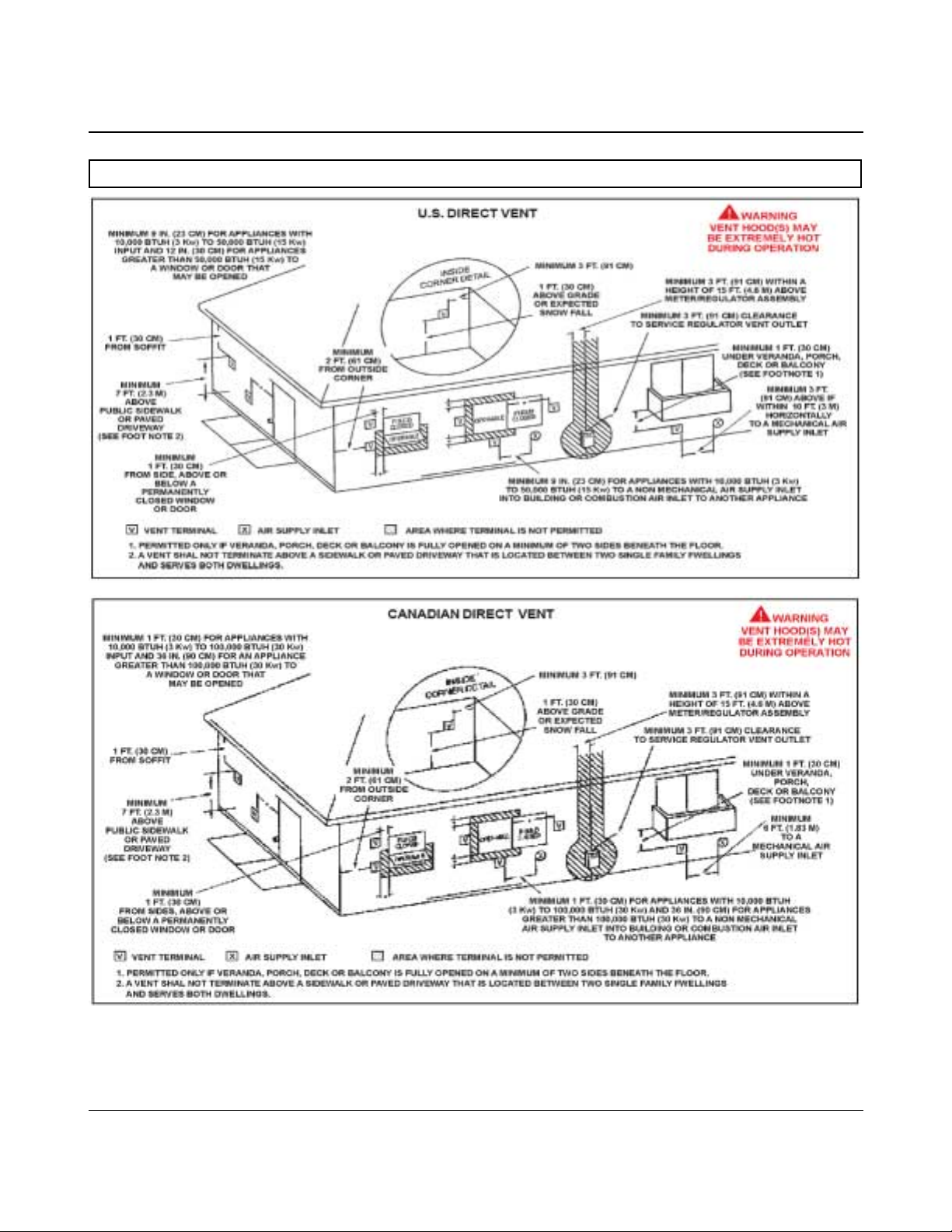

VENT TERMINAT ION – DIRECT VENT – ALL MODELS

WHEN LOCATING THE TERMINALS ON A SIDEWALL, THE FOLLOWING SPECIFICATIONS

PERTAINING TO TERMINAL LOCATION MUST BE FOLLOWED.

1. The intake vent terminal and the exhaust vent terminal must terminate on

the same exterior wall and must be located at a minimum of 24" (61cm)

from the vertical centerline of the exhaust vent terminal (see Figure 9).

In colder climates increasing the 24" (61cm) minimum will reduce

possibility of frost over from side winds blowing exhaust vapors to the

air intake of the direct vent.

2. The horizontal centerline of the intake vent terminal may not be located

lower than the horizontal centerline of the exhaust vent terminal

State Water Heaters – Technical Training Department 12 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 14

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

DIRECT VENTING – ALL MODELS

The air intake provided on the unit contains a mesh screen to prevent large particles from entering the

unit. WHEN THE UNIT IS TO BE SET UP AS A DIRECT VENT, THE BALANCE PLATE AND MESH

SCREEN MUST BE REMOVED BEFORE GLUING PIPE TO THE CONNECTOR. THE INLET VENT

PIPE MAY THEN BE GLUED TO THE AIR INTAKE PROVIDED ON THE UNIT.

45° PVC Elb ow

Remove the balance plate and mesh

screen before gluing intake air pipe

to the fitting.

3” 120-25 0

4” 300- 400

Two 3” or 4” 45° PVC elbows with mesh screens are provided with each unit. Both elbows are

to be used in direct vent applications. The screens are provided to keep vermin and large

debris from entering the intake air and exhaust vent runs.

State Water Heaters – Technical Training Department 13 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 15

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

CONTROL OVERVIEW

CONTROL OVERVIEW – ALL MODELS

Interaction with the water heater controller is done

through an LCD display called the Universal

Interf a c e Mod ule (UIM).This screen is also referred to

as the “desktop” or “desktop menu”. Up and down

buttons and three operation buttons allow navigation

through the control menus and to make adjustments to

the water heater. Operation of the three lower buttons

is defined immediately above them on the screen.

While the water heater is operating, the user interface

will display the desktop screen (if there are no active

faults or warnings).

● An example of this screen is shown below.

● The first temperature on this screen is the

temperature of the water inside the tank.

● The second temperature on this screen is the

Operating Set Point.

● The Operating Set Point is the temperature at

which the water heater will maintain the water

inside the tank.

● The third line on the screen is a text

description of the Operational State of the

water heater. The operating state of the water

heater is also indicated graphically by status

icons.

The table of status icons describes graphically

operational details of the water heater. Below is a

legend of all the status icons:

Status

Description

Icon

The t emperature o f the water in the tank has

fallen and the water heater will now initialize a

new heating cycle.

The t emperature o f the water in the tank has

reached the Operating Set Point.

The cont rol i s un able t o i nitiate any f urther

heating cycles. This is usually caused by a fault

condition detected by the control, but can also

occur when an external system (like an energy

management sys tem) has as ked t he w ater

heater to discontinue any further heat cycles.

The blower is being energized.

The blower pressure switch has been made.

The igniter has been energized.

The igniter has been energized and sufficient

curr ent for ignition has been detected.

^

The cont rol has requested that the gas valve

be turned on.

The control has sensed flame in the burner.

The control has detected a fault condition. A

fault condition will cause the water heater to

discontinue operation.

OPERATION

BUTTONS

UP AND

DOWN

BUTTONS

State Water Heaters – Technical Training Department 14 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

The control has detected a warning condition.

These conditions w ill not cause t he water

heater to discontinue further heating cycles, but

does merit attention.

Page 16

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

ADJUSTING T ANK TEMPERATURE – OPERATING SET POINT - DIFFERENTIAL

The Operating Set Point of this water heater

determines the regulated temperature for the water in

the tank. This parameter is adjusted in the desktop

Temperature menu. Items in this menu allow you to

monitor different temperature readings in the tank

along with adjusting the Operating Set Point and

Differential.

ACTION:

From the desktop screen, press Menu.

DISPLAY:

ACTION:

Press Change then use the UP and DOWN buttons to

change the temperature Set Point.

DISPLAY:

Note: This procedure can also be used to change the

Differential. The tank Upper and Lower Temperatures

are not user changeable. They are determined by the

temperature probes on the heater.

ACTION:

From the Main Menu, press Select to enter the

"Temperatures" screen.

DISPLAY:

ACTION:

Press Update to accept the change or Cancel to reset

it.

DISPLAY:

State Water Heaters – Technical Training Department 15 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 17

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

CHANGING THE DISPLAY UNITS

The desktop menu has the option of selecting

between degrees Fahrenheit and degrees Celsius for

temperature displays. This can be found in the

“Display Settings” menu. Also in this menu, you may

adjust how the back-light operates and the contrast of

the LCD screen.

ACTION:

From the Main Menu, press the DOWN button to

highlight "Display Settings" then press Select.

DISPLAY:

ACTION:

Press Update to accept the change or Cancel to

reject it.

DISPLAY:

ACTION:

Use the UP and DOWN buttons to highlight the

desired setting. Then press Change. Again, use the

UP and DOWN buttons to scroll through the options

for that setting.

DISPLAY:

State Water Heaters – Technical Training Department 16 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 18

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

FAULT AND WARNING CONDITIONS – ADVANCED DIAGNOSTIC INFORMATION

This w ater heat er c ontrol has t he abil ity t o m onitor

almost all aspects of the w ater heater's oper ation. In

the c ase t hat there i s an undes irable or uns afe

condition t hat o ccurs, t he water heat er control will

detect t his c ondition and de termine the appropriate

action. T he w ater heat er c ontrol will di splay t he

information on the desktop in plain text that accurately

describes the condition and diagn ostics i nformation

that can be used to correct the issue.

There are t wo t ypes o f c onditions t hat c an oc cur

during operation. These are Warnings and Faults:

Warnings: This is a non-safety related condition that

the c ontrol has det ected t hat m ay c ause the w ater

heater to operate in a less than optimal condition, but

does not pose a safety concern.

NOTE: When t hese conditions oc cur, continued

heating cycles will continue and the heater will attempt

to regulate the water in the tank to the Operati ng Set

Point.

Example of a Warning:

Faults: This is a safety related condition that has been

detected by the heater.

NOTE: W hen these conditions occur, the water heater

WILL NOT CONTINUE any further heating cycles and

the water will no longer be heated until the condition is

corrected and, in most cases, power has been cycled.

Example of a Fault:

Advanced Diagnostic Information

When a fault or warning has been declared, advanced

information can be found in t he c ontrol. By pressing

the A dvanced but ton, det ailed i nformation can be

found regarding diagnosing and resolving the problem.

WARNING: Usage of the Advanced information

requires ability equivalent to that of a licensed

tradesmen in the field involved.

State Water Heaters – Technical Training Department 17 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 19

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

ACCESS TO THE CURRENT FAULT OR WARNING

When a fault or warning has been detected by the

control it will automatically be displayed on the screen

and the back light will blink. If you choose to leave the

current fault or warning by pressing the Back key, you

can always return to the fault through the display

menu through the menu.

ACTION:

Press the DOWN button for more information.

DISPLAY:

ACTION:

To get to the current fault information screen, press

Menu.

DISPLAY:

State Water Heaters – Technical Training Department 18 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 20

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

VIEWING THE FAULT HISTORY - VIEWING INFORMATION ABOUT TH E HEATER

The controller for this water heater will store a history

of ten of the last Fault and Warning conditions that

occurred. This is stored in the Fault History. The

information about the fault or warning will include

diagnostic information as well as an estimate of how

long ago the fault occurred.

ACTION:

Press the SELECT button for more information.

DISPLAY:

Viewi ng Inf ormation A bout t he W ater Heater

The control for this water heater monitors many

different aspects of the water to ensure safe and

optimal operation. Much of the information monitored

is available to view in two areas of the control. The

first is the "Heater Status" and; the second is

"Heater Informatio n. "

These items can be selected through the desktop

menu. In these menus, detailed information about the

water heater and the current status of specific

conditions can be found.

ACTION:

Press the DOWN key to scroll through the fault

history. If you select a specific fault or warning, you

may press the VIEW button to view details regarding

this fault.

DISPLAY:

State Water Heaters – Technical Training Department 19 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 21

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

CONTROL SEQUENCE (TYPICAL ALL MODELS)

TYPICAL SEQUENCE

1. When the control is powered it should display

“waiting for connection” and “UIM v2.06”*. The

manufacturer and unit model will be next. The next

display will include water temperature, temperature

setting and heater status.

* This number may change as software revisions are

made.

2. The control performed selected system diagnostic

checks immediately upon power up. This includes

confirming the proper state of the air/gas switches and

ECO limit device and powered anodes.

3. If the control determines that the actual water

temperature inside the tank is below the programmed

temperature set-point less the differential, a call for

heat is activated.

4. If all checks are successfully passed, the

combustion blower is energized for the pre-purge

cycle.

5. When the pre-purge cycle is complete, power is

applied to the igniter element for the igniter warm-up

period.

10. The combustion blower will run for the duration of

the post purge cycle to purge the system of all

combustion gases. When the post purge cycle is

complete, the blower is de-energized and will coast to

a stop.

11. The control will now enter the idle state while

continuing to monitor the internal tank water

temperature and the state of other system devices. If

the temperature drops below the set-point value less

differential, the control will automatically return to

step 2 and repeat the entire operating cycle.

6. At the conclusion of the igniter warm-up period, the

gas valve will open, allowing gas to enter the burner

chamber.

7. The igniter will remain on for a short predetermined

time period, then will be turned off.

8. The control will monitor the flame sense probe to

confirm a flame is present. If a flame is not verified

within predetermined time period, the gas valve will

immediately be closed, and the blower will continue to

run for approximately 30 seconds inter-purge. The

control will try for ignition two more times before

Blow er icon

indicates

pow er to the

blow er

Check mark in the box

indicates the blow er

proving sw itch contacts

are made

Flame icon indicates

burner is ignited and

that flame has been

sensed.

lockout.

9. If a flame is confirmed, the control will enter the

heating mode where it will continue heating the tank

water until the set point temperature plus differential is

reached. At this point, the gas valve is closed and the

control enters the post-purge cycle.

State Water Heaters – Technical Training Department 20 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 22

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

CONTROL SEQUENCE FLOW CHART

Power on

Control displays

model ,

temperat ure

setting and

st atus

If checks are not

passed the

control will

display an error

or warning .

The cont rol will

st ore an error

history to show

what fault occurred

and the time

elapsed since t he

fault.

The control

performs internal

system checks

and determines

tank temperat ure

is below s et point

If all checks are

passed and there is

a call for heat the

blower is ener gized

for a pre purge

cycle

When the pre

purge is complete

power is appl ied to

the i gnit er for

Warm-up.

At t he conclusion

of the igniter

warm up the gas

valve w il l open for

4 seconds .

If the control

senses f lame the

water heater will

fire unti l the set

point is reached .

If the c ontrol fai ls

to see flame the

blower will continue to

run for a 30 s econd

Inter purge . There will

be 3 trials f or ignit ion

before a fault is

declared .

At the c onclusion

of t he inter purge

the i gnit er will

warm and the gas

valve will open.

At t he conclusion

of t he heating

cycle the blower

will enter a post

purge cycle and

the control will

enter an idle state .

State Water Heaters – Technical Training Department 21 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 23

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

CONTROLS – CENTRAL CONTROL BOARD – CCB

The Central Control Board or CCB is contained

in the housing shown below. Access to the

board and the wiring harness plugs can be

accomplished by removing two Phillips screws

holding the cover.

This view shows the cover removed from the

CCB.

Remove these

screws to release

cover

The CCB is controlled by the settings given

through the desk top menu (UIM). The CCB also

monitors all pressure switches, the hot surface

igniter, tank temperatures, the gas valve, the

anodes, and the flame sensor.

The CCB directly controls blower speed on the

SUF199 and 250 models and indirectly controls

blower speed on the SUF 400 by means of a

Variable Frequency Drive (see page 33).

Note: Improper operation may be the result of a

loose connection. Please check all wiring

connections and the power supply to the water

heater.

This is the back of the UIM.

State Water Heaters – Technical Training Department 22 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 24

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

CONTROLS – GAS VALVE SUF 120

The gas control valve on the SUF 120 has a

built i n adj ustable pre ssure regulator. T he

adjustment screw is accessed by removing

the cap screw m arket regulator i n t he

illustration.

Inlet gas pressure may be read a t the inlet

pressure tap only if the manual shut off valve

(gas cock) i s in the “ON” position. Leaving

the knob in the “OFF” position will not allow

the bu rner to fi re an d w ill genera te a fault

code on th e UIM ( Universal I nterface

Module).

CONTROLS – GAS VALVE SUF 150

The gas control valve on the SUF 150 is has

a built in pressure regulator. The regulator

may be adjusted by removing the cap screw

marked “regulator” in the illustration.

Inlet gas pressure may be read at the i nlet

pressure tap only if the manual switch is set

the “ON” position.

State Water Heaters – Technical Training Department 23 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 25

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

CONTROLS – GAS VALVE SUF 199 and 250

ADJUSTMENT PROCEDURE:

GAS PRESSURE

SUF 199 AND 250 MODELS

IMPORTANT NOTE

THE SUF 199 AND 250 MODELS

INCORPORATE A NEW GAS CONTROL,

WHICH OPERATES AT A MANIFOLD

PRESSURE OF 0"W.C. (0 kPa) FOR BOTH

NATURAL AND PROPANE GAS. SEE THE

GAS PRESSURE CHART ON PAGE 4.

THESE MODELS ARE CONFIGURED

PRIOR TO BEING SHIPPED FROM THE

FACTORY AND NO ADJUSTMENTS ARE

NECESSARY PRIOR TO STARTUP. THE

CONTROLLER MONITORS THE AIR FLOW

AND MAKES ADJUSTMENTS TO THE FAN

SPEED WHICH IN EFFECT CONTROLS

THE AMOUNT OF GAS FLOW.

THEREF ORE, THE UNIT WILL SELF

ADJUST TO ACQUIRE T HE CORRECT

AMOUNT OF INPUT.

Supply gas pressure to the water heater for

natural gas should be between a maximum

of 10.5" (2.59kPa for natural gas) W.C.

(14.0"/3.45kPa for propane) and a minimum

as shown on page 4: that is, for Natural Gas

4" (.98kPa) W.C. And 9.0" (1.97kPa) for

Propane Gas. The inlet gas pressure must

not exceed the maximum value.

Once the unit is installed and filled with water

and the in let p ressures c onfirmed, s imply

turn the switch "on" and observe operation.

Cycle the unit "off" and "on" several times to

ensure proper operation.

HIGH ALTITUDE INSTALLATION

The SUF 199 and 250 models are suitable

for installation up to 10,100 feet above sea

level with no adjustments.

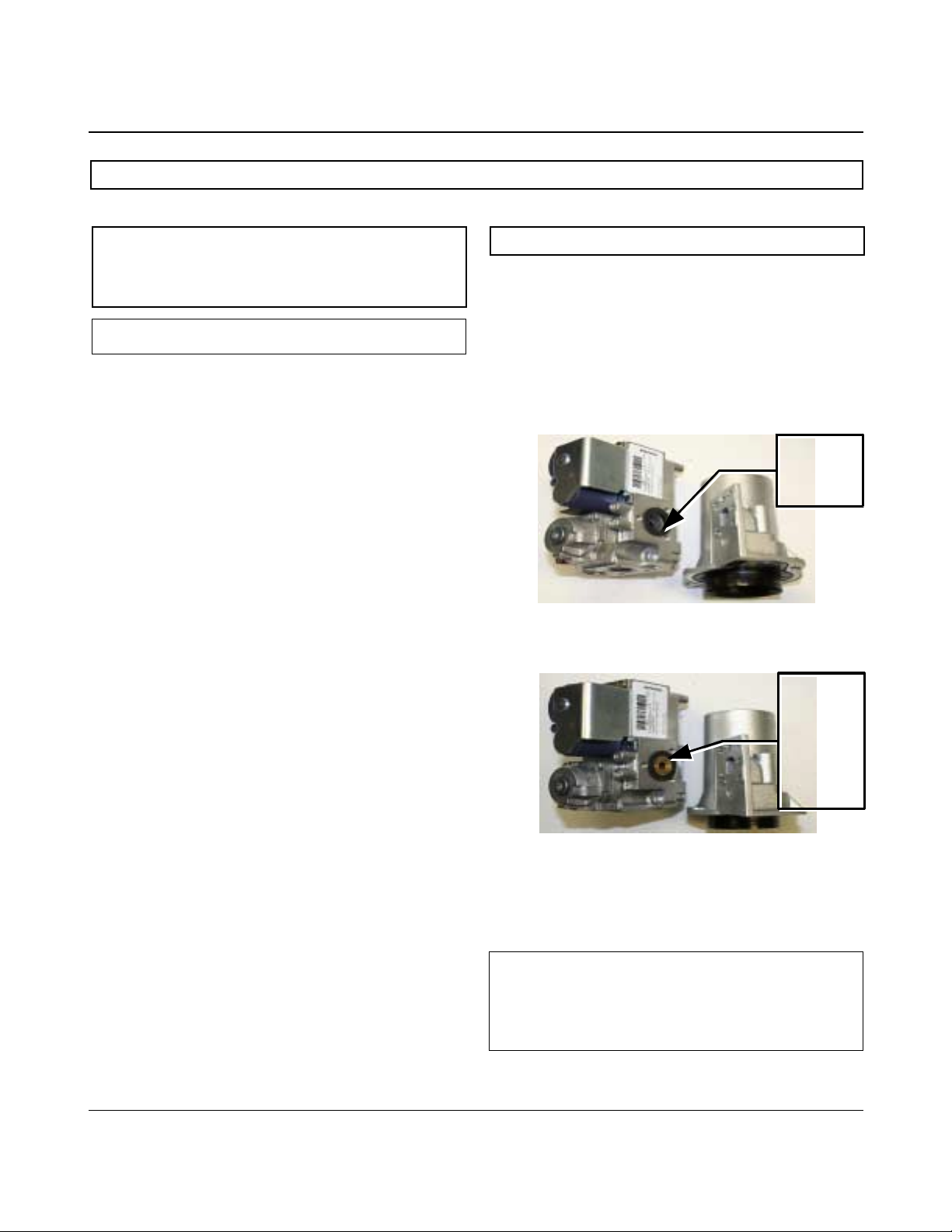

GAS ORIFICE

The SUF 199 and 250 models do not have a

natural gas orifice. A .230” orifice is used on

LP gas models.

Venturi

Gasket

w/o orifice

Gas Control Without Orifice

Natural Gas

Venturi

Gasket w/

LP Gas

Orifice

(.230”

Brass)

A supply gas pressure regulator

Gas Control with .230” LP Orifice

(service regulator) must be installed on

the gas supply line within 10' (305 cm)

of the unit.

State Water Heaters – Technical Training Department 24 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 26

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

CONTROLS – GAS VALVE SUF 199 and 250

Pressure readings may be taken on the gas

valve by connecting to the pressure ports on

the valve. The manifold pressure on this

valve is 0”w.c. (0kPa) when the water heater

is running. Refer to the gas pressure chart on

page 4.

Note: Tubing shown on pressure connections

is installed for manometer connections. It is

not supplied with the water heater.

WARNING: Do not attempt adjustments on

this gas valve unless you have a

combustion analyzer. Contact the “help

line” listed on the water heater for

assistance.

Manifold

gas

Pressure

Supply

gas

pressure

0” WC

(0kPa)

State Water Heaters – Technical Training Department 25 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 27

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

CONTROLS – GAS VALVE , ORIFICE CHART– SUF300,400,

The gas cont rol va lve h as a bu ilt in field

adjustable pressure regulator. The regulator

may be adjusted by removing the cap screw

marked “regulator”. The adjustment screw is

underneath. The g as val ve for the SUF

Natural gas model is shown above. This is

a 24V. solenoid operated gas valve.

Manual Gas

Control Knob

ORIFICE CHART – SUF 300,400,

Model 300 400

Natural .27 4” .314”

LP .189” .219”

Low Gas

Pressure

Switch

24V

Solenoid

connection

Refer to the replacement parts information at

the back of this manual for part numbers for

Natural and LP gas valves for all SUF 300,

400, and models.

State Water Heaters – Technical Training Department 26 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 28

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

CONTROLS – PRESSURE SWITCHES – ALL MODELS

All SUF models are provided with four pressure

switches. T hese s witches ar e es sential to the

safe an d pr oper op eration o f the uni t. T he

switches are wired to the c entral control b oard

(CCB) individually an d ea ch i s monitored

individually. The (CCB) is set up to shut the unit

down whenever there is a failure o f any of the

switches and declare a fault for each individual

switch. It is important to understand the purpose

of each switch.

Low Gas Press ure

Sw itch

Pressure

Sw itches

BLOCKED OUTLET PROVING SWITCH

The blocked outlet proving switch electrical contacts

are normal ly clo sed. The blocked outlet proving

switch el ectrical c ontacts w ill open on a rise in

pressure. Check t o see i f t he c ondensate i s

allowed to f low f reely from the exhaust elbow and

for obstructions in the exhaust venting and exhaust

vent t erminal. Also c heck the t hat t he equivalent

feet of vent pipe for the specific model has not been

exceeded. Check the vent length tables on page 9

BLOCKED INLET PROVING SWITCH

The Blocked Inlet Proving switch electrical contacts

are normally closed. The bl ocked i nlet pr oving

switch el ectrical c ontacts w ill op en when an

increase in neg ative pressur e (vacuum ) occurs

in the intake vent pipe. The switch is connected to

the pressure tap on t he PV C flange connected to

the i nlet of the b lower. W hen this switch pr events

the u nit f rom ig niting, most li kely the in take is

blocked by s ome means. Verify that the air intake

pipe and ai r i ntake v ent t erminal ar e f ree of

obstructions that may prevent air from entering the

unit. Also check the that the equivalent feet of vent

pipe for the specific model has not been exceeded.

Check the vent length tables on page 9

LOW GAS PRESSURE SWITCH

BLOWER PROVING SWITCH

The Blower Proving S witch i s pr ovided on t he

heater t o v erify that t he f an i s op erating. It i s a

positive pr essure s witch w hose electrical c ontacts

are normally open. Th e blower p roving switch

electrical contacts will close on a rise in pre ssure

as the blower increases the pressure in the burner.

This s witch i s c onnected t o t he b urner t ap b y a

piece of Tygon (s oft pl astic) t ubing. This t ubing

must b e connected in order f or the switch to close

the el ectrical contacts. T he c ontroller requires that

the el ectrical contacts on t his p ressure switch b e

open before it will allow the blower to come on. The

control w ill declare a f ault on the U IM if ei ther

condition occurs.

State Water Heaters – Technical Training Department 27 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

The Low Gas Pr essure Switch electrical contacts

are normal ly open. The low gas pressure switch

electrical c ontacts w ill close on a rise pressure.

The c ontacts w ill open w hen t he p ressure falls

below the fixed set point. If this happens during a

heating cycle a the burner will b e shut down and a

fault will be declared on the UIM.

Page 29

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

CONTROLS – PRESSURE SWITCHES – SUF 120 through 250

BLOCKED INLET

PRESSURE SWITCH

MODEL PRESSURE

All 0.85”WC

Normally Closed /

Open on a Rise in

Pressure

Tolera nce +/- . 05” WC

LOW GAS PRESSURE

SWITCH

MODEL PRESSURE

Natural 4.0”WC

LP 8.0”WC

Normally Open / Close

on a Rise in Pressure

Tolerance +/-.05”WC

BLOCKED OUTLET

PRESSURE SWITCH

MODEL SWITCH

120N +1.2”WC

150N +0.98”WC

199N +1.06”WC

250N +4.0”WC

120LP +1.3”WC

150LP +1.3”WC

199LP +4.0”WC

250LP +2.0”WC

Normally Close d /

Open on a Rise in

Pressure

Tolera nce +/- . 05” WC

BLOWER PROVER

PRESSURE SWITCH

MODEL PRESSURE

All +.075”WC

Norm ally Open / Close

on a Rise in Pressure

Tolerance +/-.05”WC

Top View of Pressure Switches

Note: Check the website www.statewaterheaters.com

for Technical Bulletin S023-06 “Air

Pressure Switches” under “Literature/Service Handbooks”

State Water Heaters – Technical Training Department 28 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 30

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

CONTROLS – PRESSURE SWITCHES – SUF 300,400,

BLOCKED INLET

PRESSURE SWITCH

MODEL PRESSURE

300 -.085”WC

400 -1.25”WC

500 -1.35”WC

Norm ally Closed/

Open on a Rise in

Pressure

Tolera nce +/- . 05” WC

LOW GAS PRESSURE

SWITCH

MODEL PRESSURE

Na tural +4.6”WC

LP +9.0”WC

Norm ally Open/

Close on a Rise in

Pressure

Tolerance +/-.05”WC

BLOWER PROVER

PRESSURE SWITCH

MODEL PRESSURE

300 +1.0”WC

400 +2.5”WC

500 +4.5 'WC

Nor mally Open / Close on

a rise in Pressur e

Tolerance +/-.05”WC

BLOCKED EXHAUST

PRESSURE SWITCH

MODEL PRESSURE

300 +1.15”WC

400 +1.39”WC

500 +1.77”WC

Normally Close d /

Open on a Rise in

Pressure

Tolera nce +/- . 05” WC

Top View of Pressure Switches

SUF 300,400,

Note: Check the website www.statewaterheaters.com

for Technical Bulletin S023-06 “Air

Pressure Switches” under “Literature/Service Handbooks”

State Water Heaters – Technical Training Department 29 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 31

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

CONTROLS – CONNECTIONS, IGNITER, FLAME SENSOR, SIGHT GLASS, POWERED

ANODES

The connections for the hot surface i gniter

and the fl ame sense rod are shown below.

Also shown is the burner sight glass. These

features are typical for all models.

Flame

Sensor

Hot Surface Igniter

The new U ltra Force com mercial w ater

heater i s eq uipped w ith pow ered an odes.

These anodes never need replacement. The

CCB monitors the cur rent th rough t he

anodes and will declare a fault if there i s a

disconnected wire or i f there is no water in

the tank.

Powered anode connection

Burner Mounting

Bolts

Burner Sight Glass

State Water Heaters – Technical Training Department 30 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 32

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

HOT SURFACE IGNITER / FLAME SENSOR / CONTROL TIMING

HOT SURFACE IGNITER

This water i s eq uipped with an electric hot

surface i gniter. The i gniter m aterial i s

silicone carbide and sho uld not be handled

with bare hands because of possible damage

to the igniter.

The norm al ohm read ing at 77°F is listed

between 40 and 70 ohm s. T he minimum

igniter current monitored by the CCB is 2.7

amps. Once this threshold is met a check

mark w ill a ppear by th e i gniter i con i n the

UIM (display).

FLAME SENS O R

This water hea ter is eq uipped w ith an

electronic f lame sensor. The flame sensor

senses fl ame by passi ng a s mall electric

current through the burner flame. This type

of f lame s ensing is al so k nown a s fl ame

rectification. T he CCB is l ooking fo r a

minimum current of .7 micro amperes for the

water heater to operate. Once this current is

established the UIM will display a flame icon.

CONTROL TIMING

Pre-purge 25 seconds

Igniter Warm-up 17 seconds

Trial for ignition

Gas Control Open

5 seconds

Inter/Post Purge 30 seconds

State Water Heaters – Technical Training Department 31 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 33

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

BLOWER SPEED CONTROL SUF 199 AN D 250

The i nput of the S UF 199 an d S UF 250 is

determined by the blower. The input of the

water heater may be determined by clocking

the meter as shown on page 5 or by making

sure t he b lower i s rece iving the proper Hz

signal. The blower rpm is controlled by the

Central Control Board (CCB). The signal to

the blower may be measured by attaching a

MULTIMETER that has a Hertz (Hz) setting

as shown in the illustration to the right. If the

Hz signal is within +/

Model Hz Hz

199 N 133

250 N 133

199 LP 200

250 LP 266

87

87

156

96

Note: R emoving the plug show n in the

illustration will cause the blower to accelerate

and the input of the water heater to increase

to a much higher rate.

Meter black lead is connected to ground (not

shown) and the red lead is connected to an

open te rminal o n bl ower spee d con trol

connection.

Meter red probe

connected to

open terminal on

plug

State Water Heaters – Technical Training Department 32 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 34

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

VARIABLE FREQUENCY DRIVE – SUF 400

The Ultra Force SUF 400 model has a variable frequency drive (VFD) that controls the

rpm of the blower motor. The VFD receives a signal from the central control board that

instructs the VFD to transmit the proper frequency to the blower to produce the proper blower

speed and proper input.

Three conditions must be met for the frequency drive to start the blower:

1. 120VAC must be supplied to the VFD 120VAC input.

2. The ignition control board closes an enable circuit – terminals LI1 and +15V

3. The ignition control board sends a 1-10VDC instruction – terminals 0V and AI1. See table

on the next page for voltage and frequency information.

GROUND HOT NEUTRAL

G

R/L1 N

BLOWER MOTOR WIRES

BLACK WHITE RED

U/T1 V/T2 W/T3

NOTE: BE SURE TO MATCH WIRE

COLORS WHEN CONNECTING BLOWER

WIRES OR BLOWER MAY RUN

BACKWARD AND CAUSE A FAULT.

VARIABLE FREQUENCY DRIVE

155

RC RA 0V AI1 +5V DO LI1 LI2 LI3 LI4 +15V

1-10 VDC Speed Instruction Enable Disable Circuit

State Water Heaters – Technical Training Department 33 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 35

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

VARIABLE FREQUENCY DRIVE - BLOWER SPEED AND PRE SSURE READINGS

The instructions for the VFD are sent from the CCB to in the form of a DC current. The chart

below lists the current readings, the frequency signal displayed by the VFD, and the pressure

switch settings needed for the CCB to let the burner operate. The frequency numbers

displayed may vary slightly with slight variations in the DC voltage generated by the CCB. If

the water heater exhibits poor run characteristics check the frequency display. If the

frequency is more than 5% out of range, check the DC volt signal at the terminals shown on

page 33.

Voltage – Frequency – Speed Instructions - VFD

Model SUF

400

Instruction Volts DC

Terminals 0V and AI1

Ignition (low speed) 7.53 150 Hz+/- 2 5.3”

Purge (high speed) 7.77 155 Hz+/- 2 5.85”

VFD Part Number 197500-000

0 – 10

VDC

Volts Frequency Pressure

W.C.”

155

Frequency is displayed

in the red LED. 155Hz

State Water Heaters – Technical Training Department 34 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 36

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

WIRING DIAGRAM – SUF 120 – 300

State Water Heaters – Technical Training Department 35 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 37

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

WIRING DIAGRAM – SUF 400,

State Water Heaters – Technical Training Department 36 Ashland City, Tennessee © 2009

Servicing should only be performed by a Qualified Service Agent 198152-002

Page 38

500 Tennessee Waltz Parkway

Ashland City, TN 37015

www.statewaterheaters.com

2

Loading...

Loading...