Page 1

TM

STATESMAN Electric Models

SSE-5 THRU SSE-120 COMMERCIAL WATER HEATERS

• Installation • Operation • Maintenance • Checklist • Limited Warranty

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS INFORMATION

RELATIVE TO YOUR SAFETY.

BEFORE INSTALLING AND USING THIS APPLIANCE.

PRINTED IN U.S.A. 0203

PLEASE READ THOROUGHLY

KEEP THIS MANUAL WITH THE HEATER FOR FUTURE REFERENCE.

WHENEVER MAINTENANCE ADJUSTMENTS OR SERVICE IS REQUIRED.

500 Lindahl Parkway

Ashland City, TN 37015

PART NO. 09063322

1

Page 2

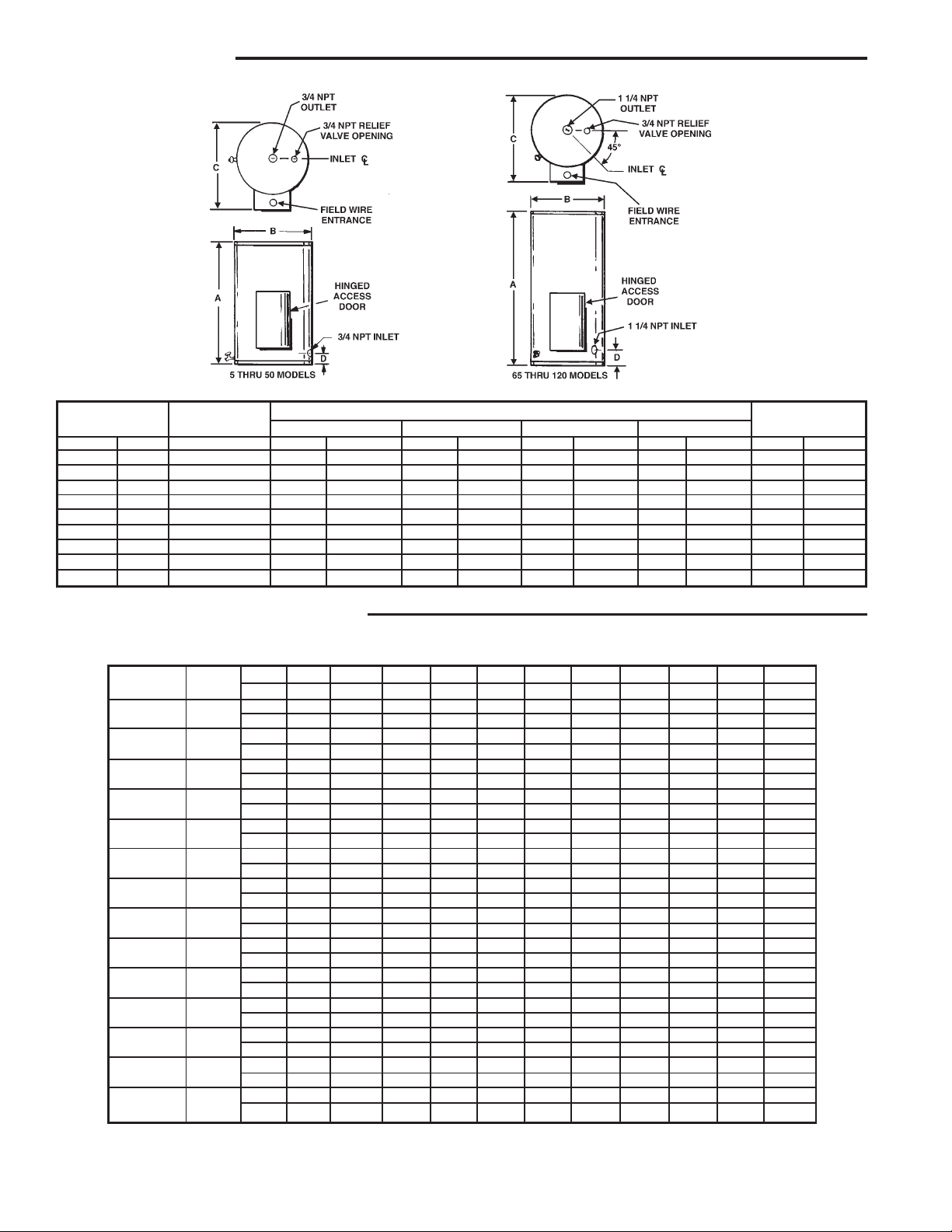

DIMENSIONS

Tank Capacity Maximum All Dimensions in Inches (mm) Approx. Ship

in Gals.(Ltrs) KW Input A B C D Wt.Lbs.(Kgs)

5 19 3 20 1/2 521mm 16 1/4 413 mm 21 1/2 546 mm 5 1/4 133 mm 82 37.2

10 38 6 26 1/4 667 mm 18 3/4 476 mm 24 610 mm 5 1/4 133 mm 106 48.1

20 76 18 27 1/4 692 mm 20 1/2 521 mm 27 686 mm 5 3/4 146 mm 130 59

30 114 24 35 3/4 908 mm 20 1/2 521 mm 27 686 mm 5 3/4 146 mm 150 68

40 151 36 45 3/4 1,162 mm 20 1/2 521 mm 27 686 mm 5 3/4 146 mm 190 86.2

50 189 90 54 3/4 1,391 mm 20 1/2 521 mm 27 686 mm 5 3/4 146 mm 221 100.2

65 246 90 50 1/2 1,283 mm 24 1/2 622 mm 30 1/4 768 mm 7 178 mm 267 121.1

80 303 90 49 1/4 1,251 mm 26 1/2 673 mm 32 1/4 819 mm 7 178 mm 285 129.3

100 379 90 58 1/4 1,480 mm 26 1/2 673 mm 32 1/4 819 mm 7 178 mm 354 160.6

119 450 90 63 1/4 1,607 mm 28 711 mm 33 3/4 845 mm 7 1/2 191 mm 420 190.5

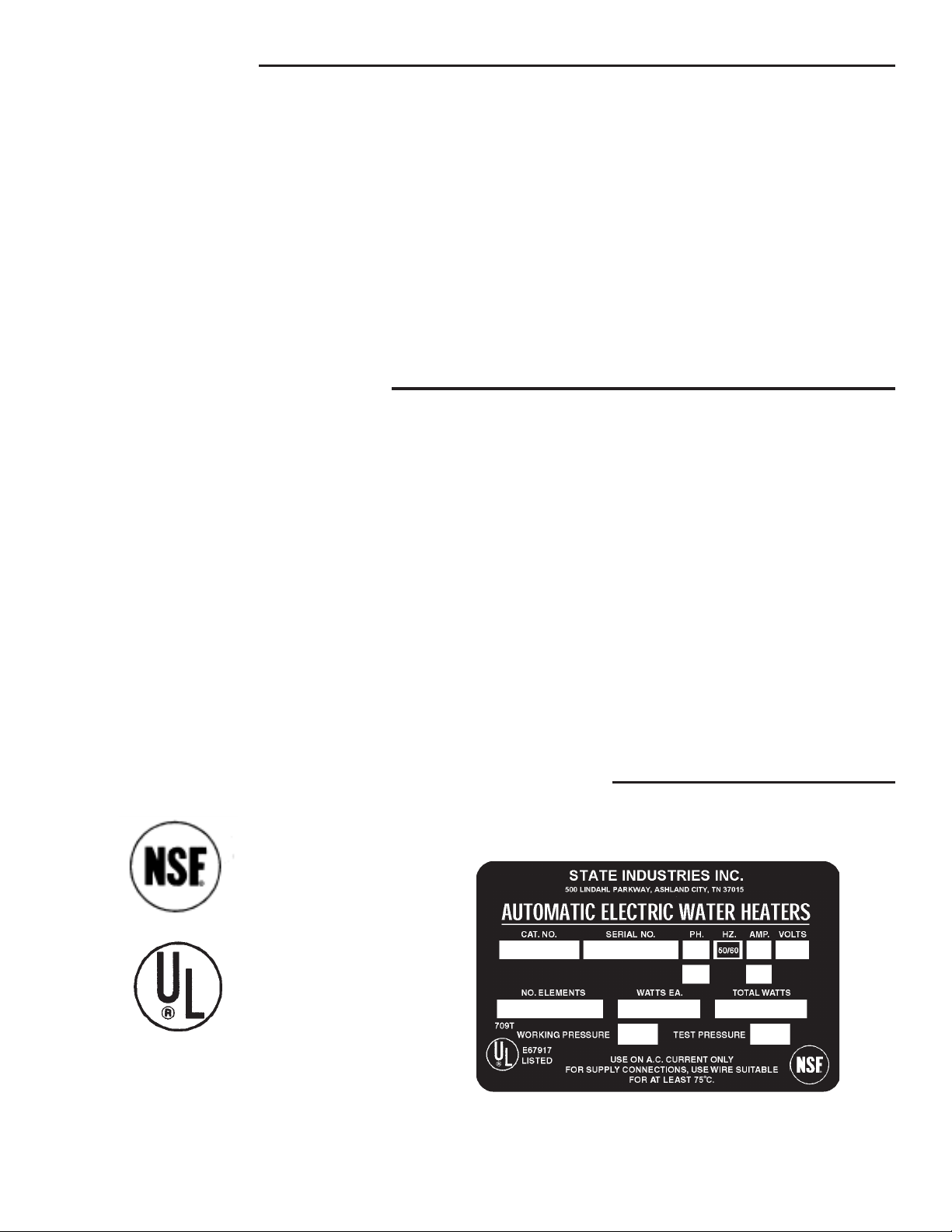

RECOVERY CAPACITY

RECOVERY RATE IN GALLONS PER HOUR *

STANDARD INPUT F° 40F° 50F° 60F° 70F° 80F° 90F° 100F° 110F° 120F° 130F° 140F°

KW INPUT BTUH C° 22C° 28C° 33C° 39C° 44C° 50C° 56C° 61C° 67C° 72C° 78C°

3 10,239

6 20,478

9 30,717

12 40,956

15 51,195

18 61,434

24 81,912

30 102,390

36 122,868

45 153,585

54 184,302

60** 204,780

75** 255,975

90** 307,170

* Figured at 1KW (3413 Btu) = 4.1 Gallons at 100°F (56°C) temperature rise.

To determine recovery rate per minute, divide recovery rate per hour by 60.

NSF ratings may be obtained by multiplying above figures by 0.98.

**Available on 50 gallon models or larger.

GPH 31 25 20 18 15 14 12 11 10 9 9

LPH11693776658524642 393633

GPH 61 49 41 35 31 27 25 22 20 19 18

LPH 232 186 155 133 116 103 93 84 77 71 66

GPH 92 74 61 53 46 41 37 33 31 28 26

LPH 349 279 232 199 174 155 139 127 116 107 100

GPH 123 98 82 70 61 55 49 45 41 38 35

LPH 465 372 310 266 232 207 186 169 155 143 133

GPH 153 123 102 88 77 68 61 56 51 47 44

LPH 581 465 387 332 290 258 232 211 194 179 166

GPH 184 147 123 105 92 82 74 67 61 57 53

LPH 697 558 465 398 349 310 279 253 232 214 199

GPH 246 196 164 140 123 109 98 89 82 76 70

LPH 929 744 620 531 465 413 372 338 310 286 266

GPH 307 246 205 175 153 136 123 112 102 94 88

LPH 1162 929 775 664 581 516 465 422 387 357 332

GPH 368 295 246 210 184 164 147 134 123 113 105

LPH 1394 1115 929 797 697 620 558 507 465 429 398

GPH 460 368 307 263 230 205 184 167 153 142 132

LPH 1743 1394 1162 996 871 775 697 634 581 536 498

GPH 552 442 368 316 276 246 221 201 184 170 158

LPH 2091 1673 1394 1195 1046 929 836 760 697 643 597

GPH 614 491 409 351 307 273 246 223 205 189 175

LPH 2324 1859 1549 1328 1162 1033 929 845 775 715 664

GPH 767 614 512 438 384 341 307 279 256 236 219

LPH 2905 2324 1936 1660 1452 1291 1162 1056 968 894 830

GPH 921 737 614 526 460 409 368 335 307 283 263

LPH 3485 2788 2324 1992 1743 1549 1394 1267 1162 1072 996

Temperature Rise F° (C°)

2

Page 3

FOREWORD

Detailed installation diagrams are in this manual. These

diagrams will serve to provide the installer with a reference for

the materials and method of piping suggested. IT IS NECESSARY

THAT ALL WATER PIPING AND THE ELECTRICAL WIRING BE

INSTALLED AND CONNECTED AS SHOWN IN THE DIAGRAMS.

Particular attention should be given to the installation of

thermometers at the locations indicated in the diagrams as

these are necessary for checking the operation of the heater.

In addition to these instructions, the equipment shall be installed

in accordance with those installation regulations in force in the

local area where installation is to be made. Authorities having

jurisdiction shall be consulted before installations are made.

BE SURE TO TURN OFF POWER WHEN WORKING ON OR

TABLE OF CONTENTS

PAGE

ROUGH-IN-DIMENSIONS ...................................... 2

RECOVERY CAPACITY ....................................... 2

FOREWORD ......................................................... 3

TABLE OF CONTENTS ......................................... 3

APPROVALS & MODEL & RATING PLATE .......... 3

GETTING TO KNOW YOUR WATER HEATER ..... 4

GENERAL SAFETY INFORMATION

Insulation Blankets .............................................. 5

External Damage ................................................. 5

INSTALLATION

Required Ability ................................................... 5

General ................................................................ 5

Location ............................................................... 5

Connections ........................................................ 5

Relief Devices ..................................................... 6

Temperature Limiting Control ............................... 6

Hydrogen Gas (Flammable) ................................ 6

PIPING DIAGRAMS .............................................. 7-12

ELECTRICAL

General ................................................................ 13

Branch Circuit ...................................................... 13

NEAR THE ELECTRICAL SYSTEM OF THE HEATER. NEVER

TOUCH ELECTRICAL COMPONENTS WITH WET HANDS OR

WHEN STANDING IN WATER. WHEN REPLACING FUSES

ALWAYS USE THE CORRECT SIZE FOR THE CIRCUIT. SEE

PAGE 14.

DO NOT TEST ELECTRICAL SYSTEM BEFORE HEATER IS

FILLED WITH WATER, FOLLOW START UP PROCEDURE ON

PAGE 17.

The principal components of the heater are identified on

page 4. The model and rating plate on page 3 interprets certain

markings into useful information. Both of these references

should be used to identify the heater, its components and optional

equipment.

PAGE

Amperage Table/Overcurrent Protection ....... 14

Heater Circuits ................................................ 14

Control Circuit ................................................. 14

Power Circuit .................................................. 14

Wiring Diagram ................................................ 15-17

OPERATION

General ............................................................ 18

Filling ................................................................ 18

Start Up ........................................................... 18

Temperature Regulation .................................. 18-19

Draining ........................................................... 19

MAINTENANCE

General ............................................................ 19

Flushing ........................................................... 19

Sediment Removal ........................................... 19

Lime Scale Removal ........................................ 19-20

Checklist .......................................................... 20-21

Anode Maintenance ........................................ 21

Replacement Parts .......................................... 21

LEAKAGE CHECKPOINTS ............................... 22

LIMITED WARRANTY ...................................... 23

APPROVALS MODEL & RATING PLATE

All models bear the

National Sanitation

Foundation seal of

approval.

All models are

listed by

Underwriters’

Laboratories, Inc.

125 PSI Working Pressure

(65 thru 120 Gallons)

ASME

150 PSI Working Pressure

(5 thru 50 Gallons)

3

Page 4

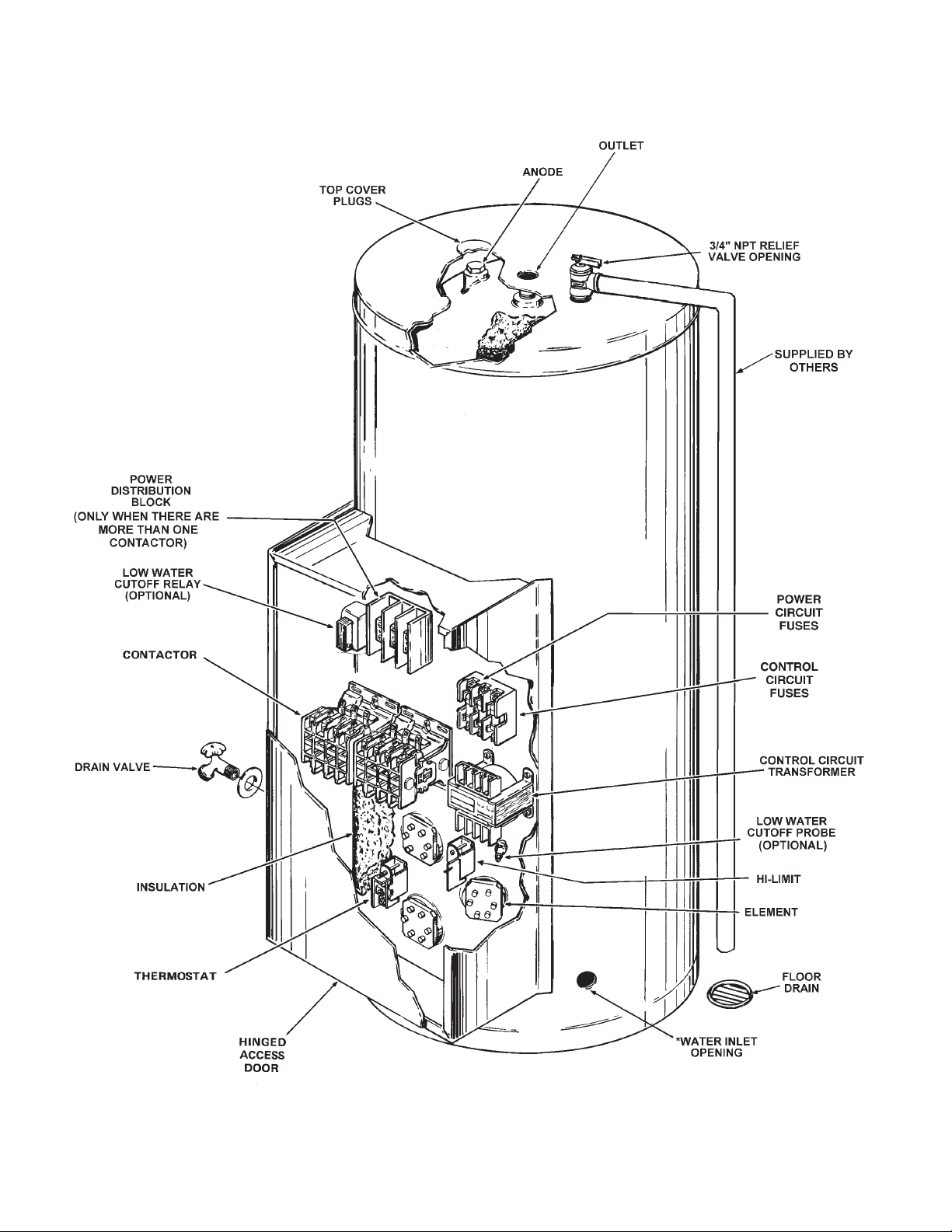

GETTING TO KNOW YOUR WATER HEATER

Below is an illustration of the water heater with its features called

out. The text of this manual will refer to the items shown.

NOTE:

• 3/4” NPT SSE 5 THRU 50 MODELS

• 1 1/4” NPT SSE 65 THRU 120 MODELS

• A LOW WATER CUTOFF SWITCH IS

AVAILABLE AS AN OPTIONAL SAFETY

DEVICE TO PROTECT THE ELEMENTS

FROM DAMAGE DUE TO LACK OF WATER

IN THE HEATER.

FIGURE 1

4

Page 5

GENERAL SAFETY

INFORMATION

INSULATION BLANKETS

Insulation blankets available to the general public for external

use on electric water heaters are not approved for use on your

State water heater. The purpose of an insulation blanket is to

reduce the standby heat loss encountered with storage tank

water heaters. Your State water heater meets or exceeds the

National Appliance Energy Conservation Act standards with

respect to insulation and standby loss requirements, making

an insulation blanket unnecessary.

GENERAL

The installation must conform to these instructions and the

local code authority having jurisdiction. Grounding and electrical

wiring connected to the water heater must also conform to the

latest version of the

NFPA-70. Copies of these codes may be obtained from

American National Standards Institute, 1430 Broadway, New

York, NY 10018.

If your location requires the installation of the water heater to

comply with National Sanitation Foundation requirements, the

heater must be sealed to the floor so as to prevent seepage

underneath the heater. The following are recommended

sealants that may be used on all types of flooring except

concrete: GE Silicone Seal RTV-120, 103, 108 and 109.

NATIONAL ELECTRICAL CODE and

WARNING

Should you choose to apply an insulation blanket to this heater,

you should follow these instructions (See Figure 1 for

identification of components mentioned below). Failure to follow

these instructions can result in fire, asphyxiation, serious

personal injury or death.

DO NOT COVER THE JUNCTION BOX EXTERNAL WIRING,

1.

THERMOSTATS OR HEATING ELEMENTS ON ELECTRIC

WATER HEATER.

2. DO NOT COVER THE TEMPERATURE-PRESSURE RELIEF

VALVE.

3. DO NOT COVER OPERATING INSTRUCTIONS,

INSTALLATION OR SAFETY RELATED LABELS.

4. DO OBTAIN NEW WARNING AND INSTRUCTION LABELS

FROM STATE WATER HEATERS FOR PLACEMENT ON THE

BLANKET DIRECTLY OVER THE EXISTING LABELS.

5. WATER AND/OR CONDENSATE CAN COLLECT IN AN

INSULATION BLANKET. STATE WATER HEATERS WILL NOT

BE LIABLE FOR ANY RUST OR CORROSION DAMAGE

CAUSED BY THE INSTALLATION OF INSULATION

BLANKETS.

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT

IN SERIOUS PERSONAL INJURY OR DEATH.

EXTERNAL DAMAGE

DO NOT TEST ELECTRICAL SYSTEM BEFORE HEATER IS

FILLED WITH WATER, FOLLOW START UP PROCEDURE AS

WRITTEN IN “OPERATION” SECTION OF THIS MANUAL.

The principal components of the heater are identified in

figure 1. The model and rating plate on page 3 interprets certain

markings into useful information. Both of these references should

be used to identify the heater, its components and optional

equipment.

LOCATION

For proper installation, the heater should be installed on a level

surface.

LOCATE IT NEAR A FLOOR DRAIN. THE HEATER SHOULD BE

LOCATED IN AN AREA WHERE LEAKAGE FROM THE HEATER

OR CONNECTIONS WILL NOT RESULT IN DAMAGE TO THE

ADJACENT AREA OR TO LOWER FLOORS OF THE

STRUCTURE.

WHEN SUCH LOCATIONS CANNOT BE AVOIDED, A SUITABLE

DRAIN PAN SHOULD BE INSTALLED UNDER THE HEATER.

Such pans should be fabricated with sides at least

2” (50.8 mm) deep, with length and width at least 2” (50.8 mm)

greater than the diameter of the heater and must be piped to an

adequate drain. Drain pans suitable for these heaters are

available from your distributor or State Water Heaters, 500

Lindahl Parkway, Ashland City, TN 37015.

Locate the heater close to the point of major hot water usage

and the power supply.

Do not operate the water heater until it has been fully checked

out by a qualified service technician, if the water heater:

• Has been exposed to fire or damage.

• Produces steam or unusually hot water.

If the water heater has been subject to flooding, it must be

replaced.

INSTALLATION

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER

REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED

TRADESMAN IN THE FIELD INVOLVED. PLUMBING AND

ELECTRICAL WORK INVOLVED.

• Try to make hot water piping and branch circuit wiring

as short as possible.

• Insulate hot and cold water piping where heat loss

and condensation may be a problem.

THE HEATER SHOULD NOT BE LOCATED IN AN AREA WHERE

IT WILL BE SUBJECT TO FREEZING.

Suggested clearances from adjacent surfaces are 18 inches

(457.2 mm) in front for access to the controls and elements and

12 inches (304.8 mm) from top. The heater may be installed on

or against combustible surfaces.

CONNECTIONS

The heater water inlet is located on the side of the heater near

the bottom. The heater outlet is located at the top of the heater.

Piping and wiring diagrams are included in this manual.

5

Page 6

RELIEF DEVICES

An unplugged 3/4” NPT relief valve opening is provided for

installing temperature and pressure relief valve.

temperature setting of the relief valve should not exceed

210°F (98.9°C).

TEMPERATURE LIMITING CONTROL

CAUTION: TO REDUCE THE RISK OF EXCESSIVE PRESSURES

AND TEMPERATURE IN THIS WATER HEATER INSTALL

TEMPERATURE AND PRESSURE PROTECTIVE EQUIPMENT

REQUIRED BY LOCAL CODES but not less than a combination

temperature and pressure relief valve certified by a nationally

recognized testing laboratory that maintains periodic inspection

of production of listed equipment or materials, as meeting the

requirements for relief valve devices for hot water supply

systems, ANSI Z21.22 (latest version).

This valve must be marked with a maximum set pressure not to

exceed the marked maximum working pressure of the water

heater. INSTALL THE VALVE INTO THE OPENING PROVIDED

AND MARKED FOR THIS PURPOSE IN THE WATER HEATER,

AND ORIENT IT OR PROVIDE TUBING SO THAT ANY

DISCHARGE FROM THE VALVE WILL EXIT ONLY WITHIN

6 INCHES (152.4 mm) ABOVE, OR AT ANY DISTANCE BELOW

THE STRUCTURAL FLOOR AND CANNOT CONTACT ANY LIVE

ELECTRICAL PART. THIS DISCHARGE OPENING MUST NOT

BE BLOCKED OR REDUCED IN SIZE UNDER ANY

CIRCUMSTANCES.

The pressure setting of the relief valve should not exceed the

pressure capacity of any component in the system. The

The heater control circuit contains a high temperature cutoff

switch which operates if excessive water temperatures are

reached. The high temperature cutoff contacts open at 190°F

(87.7°C) and must be manually reset (after a 30°F (16.6°C) drop

in water temperature). Disconnect the power before resetting

button.

HYDROGEN GAS (FLAMMABLE)

CAUTION

HYDROGEN GAS CAN BE PRODUCED IN A HOT WATER

SYSTEM SERVED BY THIS HEATER THAT HAS NOT BEEN USED

FOR A LONG PERIOD OF TIME (GENERALLY TWO WEEKS OR

MORE). HYDROGEN GAS IS EXTREMELY FLAMMABLE. To

reduce the risk of injury under these conditions, it is

recommended that the hot water faucet be opened for several

minutes at the kitchen sink before using any electrical appliance

connected to the hot water system. If hydrogen is present, there

will probably be an unusual sound such as air escaping through

the pipe as the water begins to flow. THERE SHOULD BE NO

SMOKING OR OPEN FLAME NEAR THE FAUCET AT THE TIME

IT IS OPEN.

6

Page 7

PIPING DIAGRAM

ONE OR TWO TEMPERATURE - ONE HEATER

CAUTION: IF BUILDING COLD WATER SUPPLY HAS A BACK-FLOW

PREVENTER, CHECK VALVE OR WATER METER WITH CHECK VALVE,

PROVISIONS FOR THERMAL EXPANSION OF WATER IN THE HOT

WATER SYSTEM MUST BE PROVIDED.

*PIPE TO OPEN DRAIN.

INSTALL IN ACCORDANCE WITH ALL LOCAL CODES.

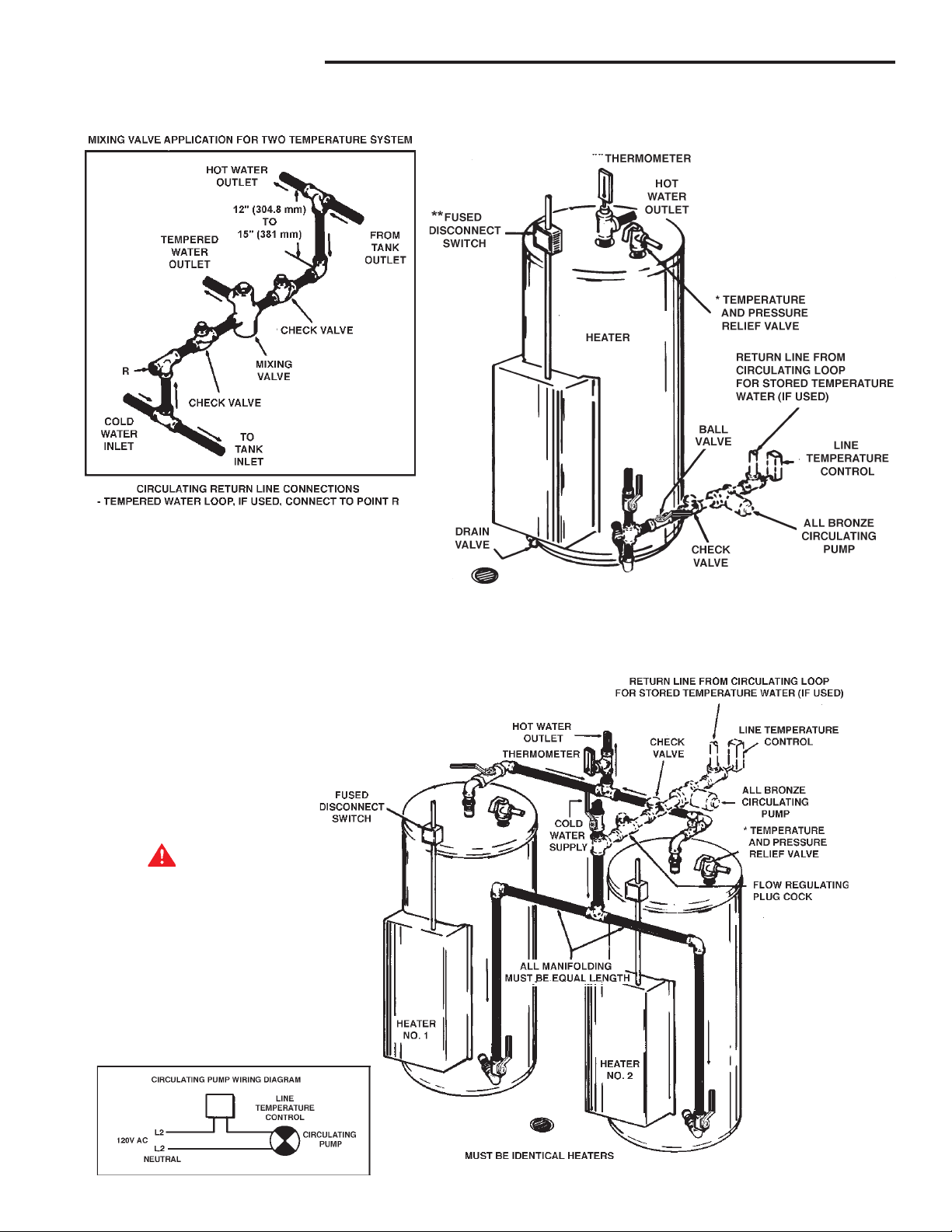

ONE OR TWO TEMPERATURE - TWO HEATER

DANGER:

TEMPERATURE SETTING SHOULD NOT

EXCEED SAFE USE TEMPERATURE AT

FIXTURES. SEE WATER TEMPERATURE

CONTROL WARNING ON PAGES 17 & 18. IF

HIGHER PREHEAT TEMPERATURES ARE

NECESSARY TO OBTAIN ADEQUATE

BOOSTER OUTPUT, ADD AN ANTI-SCALD

VALVE FOR HOT WATER SUPPLIED TO

FIXTURES..

7

Page 8

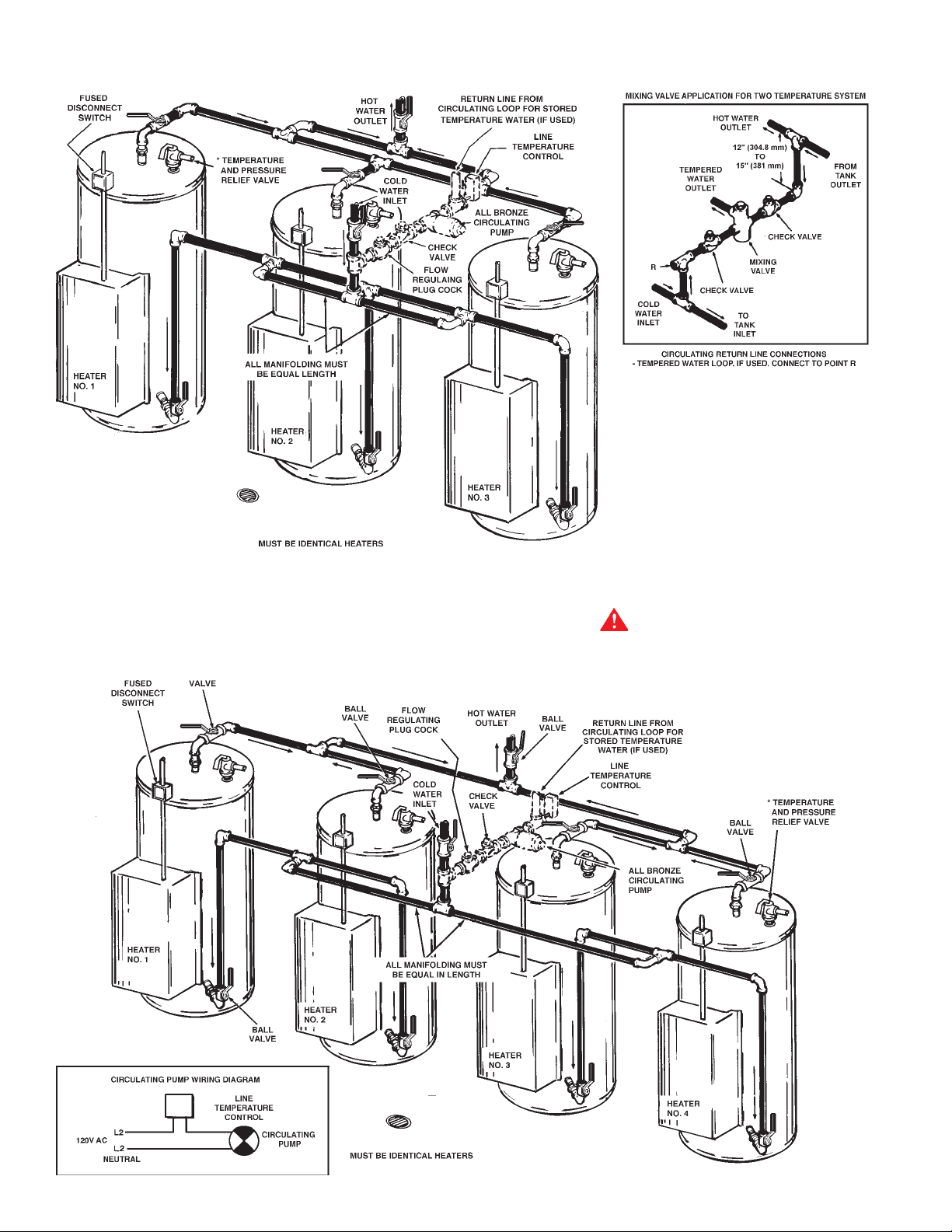

ONE OR TWO TEMPERATURE - THREE HEATERS

CAUTION: IF BUILDING COLD WATER SUPPLY

HAS A BACK-FLOW PREVENTER, CHECK VALVE

OR WATER METER WITH CHECK VALVE,

PROVISIONS FOR THERMAL EXPANSION OF

WATER IN THE HOT WATER SYSTEM MUST BE

PROVIDED.

*PIPE TO OPEN DRAIN.

INSTALL IN ACCORDANCE WITH ALL LOCAL

CODES.

ONE OR TWO TEMPERATURE - FOUR HEATERS

DANGER:

TEMPERATURE SETTING SHOULD NOT EXCEED SAFE USE TEMPERATURE AT FIXTURES.

SEE WATER TEMPERATURE CONTROL WARNING ON PAGES 17 & 18. IF HIGHER

PREHEAT TEMPERATURES ARE NECESSARY TO OBTAIN ADEQUATE BOOSTER OUTPUT,

ADD AN ANTI-SCALD VALVE FOR HOT WATER SUPPLIED TO FIXTURES..

8

Page 9

MEDIUM TEMPERATURE - ONE HEATER VERTICAL STORAGE TANK

DANGER:

TEMPERATURE SETTING SHOULD NOT EXCEED SAFE USE

TEMPERATURE AT FIXTURES. SEE WATER TEMPERATURE

CONTROL WARNING ON PAGES 17 & 18. IF HIGHER PREHEAT

TEMPERATURES ARE NECCESARY TO OBTAIN ADEQUATE

BOOSTER OUTPUT, ADD AN ANTI-SCALD VALVE FOR HOT WATER

SUPPLIED TO FIXTURES..

MEDIUM TEMPERATURE - ONE HEATER HORIZONTAL STORAGE TANK

*PIPE RELIEF VALVE TO OPEN DRAIN.

†TANK TEMPERATURE CONTROL SET AT DESIRED

TEMPERATURE - MAX. 170°F (76.6 mm). HEATER

THERMOSTAT SET AT LEAST 5° HIGHER.

INSTALL IN ACCORDANCE WITH ALL LOCAL

CODES.

CAUTION: IF BUILDING COLD WATER SUPPLY HAS

A BACK-FLOW PREVENTER, CHECK VALVE OR

WATER METER WITH CHECK VALVE, PROVISIONS

FOR THERMAL EXPANSION OF WATER IN THE HOT

WATER SYSTEM MUST BE PROVIDED.

9

Page 10

MEDIUM TEMPERATURE - TWO HEATERS VERTICAL STORAGE TANK

DANGER:

TEMPERATURE SETTING SHOULD NOT

EXCEED SAFE USE TEMPERATURE AT

FIXTURES. SEE WATER TEMPERATURE

CONTROL WARNING ON PAGES 17 & 18.

IF HIGHER PREHEAT TEMPERATURES ARE

NECESSARY TO OBTAIN ADEQUATE

BOOSTER OUTPUT, ADD AN ANTI-SCALD

VALVE FOR HOT WATER SUPPLIED TO

FIXTURES..

MEDIUM TEMPERATURE - TWO HEATERS HORIZONTAL STORAGE TANK

RETURN LINE FROM FIXTURE

CIRCULATING LOOP (IF USED)

SHOULD CONNECT TO ANY OPENING

NEAR BOTTOM OF TANK.

* PIPE RELIEF VALVE TO OPEN DRAIN.

† TANK TEMPERATURE CONTROL SET

AT DESIRED TEMPERATURE - MAX. 170°F

( 76.6°C). HEATER THERMOSTAT SET AT

LEAST 5° HIGHER.

INSTALL IN ACCORDANCE WITH ALL

LOCAL CODES.

CAUTION: IF BUILDING COLD WATER

SUPPLY HAS A BACK-FLOW

PREVENTER, CHECK VALVE OR WATER

METER WITH CHECK VALVE,

PROVISIONS FOR THERMAL

EXPANSION OF WATER IN THE HOT

WATER SYSTEM MUST BE PROVIDED.

NOTE:

BRANCH PIPING TO ALL HEATERS

MUST BE SAME SIZE AND LENGTH FOR

EQUAL FLOW. THESE BRANCHES MAY

BE SIZED UP TO 1 1/4” (31.75 mm) SO

THAT CROSS SECTIONAL AREAS OF ALL

INLETS AND OUTLETS AT LEAST EQUAL

AREA OF THEIR RESPECTIVE MAIN

PIPING.

REVERSE RETURN PIPING SHOWN.

10

Page 11

MEDIUM TEMPERATURE - THREE HEATERS VERTICAL STORAGE TANK

DANGER:

TEMPERATURE SETTING SHOULD NOT EXCEED SAFE USE TEMPERATURE

AT FIXTURES. SEE WATER TEMPERATURE CONTROL WARNING ON PAGES

17 & 18. IF HIGHER PREHEAT TEMPERATURES ARE NECESSARY TO

OBTAIN ADEQUATE BOOSTER OUTPUT, ADD AN ANTI-SCALD VALVE FOR

HOT WATER SUPPLIED TO FIXTURES..

MEDIUM TEMPERATURE - THREE HEATERS HORIZONTAL STORAGE TANK

* PIPE RELIEF VALVE TO OPEN DRAIN

† TANK TEMPERATURE CONTROL SET

AT DESIRED TEMPERATURE (MAX. 170°F

(76.6°C). HEATER THERMOSTAT SET AT

LEAST 5° HIGHER.

CAUTION: IF BUILDING COLD WATER

SUPPLY HAS A BACK-FLOW

PREVENTER, CHECK VALVE OR WATER

METER WITH CHECK VALVE,

PROVISIONS FOR THERMAL

EXPANSION OF WATER IN THE HOT

WATER SYSTEM MUST BE PROVIDED.

INSTALL IN ACCORDANCE WITH ALL

LOCAL CODES.

NOTE:

BRANCH PIPING TO ALL HEATERS

MUST BE SAME SIZE AND LENGTH FOR

EQUAL FLOW. THESE BRANCHES MAY

BE SIZED UP TO 1 1/4” (31.75 mm) SO

THAT CROSS SECTIONAL AREAS OF ALL

INLETS AND OUTLETS AT LEAST EQUAL

AREA OF THEIR RESPECTIVE MAIN

PIPING.

REVERSE RETURN PIPING SHOWN.

11

Page 12

MEDIUM TEMPERATURE - FOUR HEATERS VERTICAL STORAGE TANK

MEDIUM TEMPERATURE - FOUR HEATERS HORIZONTAL STORAGE TANK

CAUTION: IF BUILDING COLD WATER

SUPPLY HAS A BACK-FLOW

PREVENTER, CHECK VALVE OR WATER

METER WITH CHECK VALVE,

PROVISIONS FOR THERMAL

EXPANSION OF WATER IN THE HOT

WATER SYSTEM MUST BE PROVIDED.

* PIPE RELIEF VALVE TO OPEN DRAIN.

† TANK TEMPERATURE CONTROL SET

AT DESIRED TEMPERATURE - MAX. 170°F

(76.6 mm). HEATER THERMOSTAT SET

AT LEAST 5° HIGHER.

INSTALL IN ACCORDANCE WITH ALL

LOCAL CODES.

NOTE:

BRANCH PIPING TO ALL HEATERS

MUST BE SAME SIZE AND LENGTH FOR

EQUAL FLOW. THESE BRANCHES MAY

BE SIZED UP TO 1 1/4” (31.75 mm) SO

THAT CROSS SECTIONAL AREAS OF ALL

INLETS AND OUTLETS AT LEAST EQUAL

AREA OF THEIR RESPECTIVE MAIN

PIPING.

REVERSE RETURN PIPING SHOWN.

DANGER:

TEMPERATURE SETTING SHOULD NOT

EXCEED SAFE USE TEMPERATURE AT

FIXTURES. SEE WATER TEMPERATURE

CONTROL WARNING ON PAGES 17 & 18. IF

HIGHER PREHEAT TEMPERATURES ARE

NECESSARY TO OBTAIN ADEQUATE

BOOSTER OUTPUT, ADD AN ANTI-SCALD

VALVE FOR HOT WATER SUPPLIED TO

FIXTURES..

12

Page 13

ELECTRICAL

GENERAL

The installation must conform to these instructions, the local

code authority having jurisdiction, and the requirements of the

power company. In the absence of code requirements follow

the latest version of NFPA-70,

which may be ordered from: American National Standards

Institute, 1430 Broadway, New York, NY 10018.

AN ELECTRICAL GROUND IS REQUIRED TO REDUCE RISK

OF ELECTRIC SHOCK OR POSSIBLE ELECTROCUTION. The

water heater should be connected to a separate, grounded,

branch circuit with overcurrent protection and disconnect switch.

The water heater should be grounded in accordance with

national and local codes.

Check the heater model and rating plate information against

the characteristics of the branch circuit electrical supply. DO NOT

CONNECT THE HEATER TO AN IMPROPER SOURCE OF

ELECTRICITY.

Not More Than Three Conductors in Raceway or Cable or Earth (Directly Buried), Based on Ambient Temperature of 30°C (86°F)

Size Temperature Rating of Conductor, See table 310-13 Size

60°C 75°C 85°C 90°C 60°C 75°C 85°C 90°C

(140°F) (167°F) (185°F) (194°F) (140°F) (167°F) (185°F) (194°F)

TYPES TYPES TYPES TYPES TYPES TYPES TYPES TYPES

AWG TW, UF RH,RHW SA, AVB TW, UF R UH SA, AVB

MCM THWN, =RHH, XHHW, =THHN, MCM

000 200 210 210 155 165 165 000

0000 230 235 235 180 185 185 0000

250 255 270 270 205 215 215 250

300 285 300 300 230 240 240 300

350 310 325 325 250 260 260 350

400 335 360 360 270 290 290 400

500 380 405 405 310 330 330 500

Ambient For ambient temperatures over 30°C, multiply the amacities shown by the appropriate Ambient

Temp.°C correction factor to determine the maximum allowable load current. Temp.°F

31-40 .8 2 .88 .90 .91 .82 .88 .90 .91 86-104

41-50 .58 .75 .80 .82 .58 . 75 .80 .82 105-122

51-60 …… .58 .67 .71 …… .58 .67 .71 123-141

61-70 …… .35 .52 .58 …… .35 .52 .58 142-158

71-80 …… …… .30 .41 …… …… .30 .41 159-176

= The load current rating and the overcurrent protection for these conductors shall not exceed 15 amperes for 14 AWG,

20 amperes for 12 AWG, and 30 amperes for 10 AWG copper; or 15 amperes for 12 AWG and 25 amperes for 10 AWG

aluminum and copper-clad aluminum.

* For dry locations only. See 75°C column for wet locations.

RUW, T FEPW V, MI TA, TBS RUW, T RH, RHW V, MI TA, TBS,

18 …… …… …… 2 1 …… …… …… …… ……

16 …… …… 22 22 …… …… …… …… ……

14 15 15 25 25 …… …… …… …… ……

12 20 20 30 30 15 15 25 25 12

10 30 30 40 40 25 25 30 30 10

840455050 304040408

655657070 405055556

470859090 556570704

3 80 100 105 105 65 75 80 80 3

2 115 120 120 75 90 95 95 2

1 130 140 140 100 110 110 1

0 150 155 155 120 125 125 0

00 175 185 185 135 145 145 00

The National Electrical Code

WARNING

TABLE 310-16. Allowable Ampacities of Insulated Conductors

RUH, SIS, =FEP, THW, SIS, AWG

THW, =FEPB, THWN =RHH,

XHHW =THHN, USE =XHHW*

USE, ZW =XHHW*

COPPER ALUMINUMOR COPPER-CLAD ALUMINUM

CORRECTION FACTORS

Voltage applied to the heater should not vary more than +5%

to -10% of the model and rating plate marking for satisfactory

operation.

DO NOT ENERGIZE THE BRANCH CIRCUIT FOR ANY REASON

BEFORE THE HEATER TANK IS FILLED WITH WATER. DOING

SO WILL CAUSE THE HEATING ELEMENT TO BURN OUT.

The branch circuit is connected to the heater wiring through an

opening provided on the heater.

BRANCH CIRCUIT

The branch circuit wire and fuse size should be established

through reference to the latest version of the

Code or other locally approved source in conjunction with the

heater amperage rating. Branch circuit wires should be 75°C

temperature rated. For convenience, portions of the wire size

tables from the Code are reproduced here. It is suggested the

electrician size the branch circuit at 125 percent of the heater

ampere rating and further increase wire size as necessary to

compensate for voltage drop in long runs. Branch circuit voltage

drop should not exceed 3% at the heater.

National Electrical

13

Page 14

AMPERAGE TABLE/OVERCURRENT

PROTECTION

This table provides the total connected heating element load in

amperes for branch circuit conductor and over current protection

sizing. Single-phase heaters are two wire circuits. Three-phase

heaters are three wire circuits. In addition to the foregoing a

ground conductor may be required.

The rating of the overcurrent protection should be computed on

the basis of 125 percent of the total connected load amperage.

Where the standard ratings and settings do not correspond with

this computation, the next higher standard rating or setting

should be selected.

CONTROL CIRCUIT

The heater is equipped with 120 volt control circuit where all of

the heating elements are switched on and off together. This is

the standard circuit and may be used with up to five elements.

The control circuit wiring is 14 AWG rated 600 volts, 105°C.

A low water cutoff switch is available as an optional safety device

to protect the elements from damage due to lack of water in the

heater.

POWER CIRCUIT

Power circuit wiring is rated 600 volts, 75°C.

HEATER CIRCUITS

The water heater’s electrical components are pictured and

identified in Figure 1.

The following describes the heater circuits and includes wiring

diagrams. All heater circuits are designed for 60 hertz alternating

current.

STANDARD KW INPUTS

Standard Immersion Number of Full Load Current In Amperes

KW Heaters*** 50A Contractors Single Phase Three Phase

Ratings No. Of Wattage 208V 240V 480V 208V 240V 277V 480V 208V 240V 480V

3 1 3,000 14.4 12.5 10.8 6.3 8.3 7.2 3.6

6 1 6,000 1 28.8 25.0 21.2 12.5 16.7 14.4 7.2

9 1 9,000 1 43.3 37.5 32.5 18.8 25.0 21.7 10.8

12 1 12,000 1 57.7 50.0 43.3 25.0 33.3 28.9 14.4

15 1 15,000 72.1 62.5 54.2 31.3 41.6 36.1 18.0

18* 1 18,000 86.5 75.0 65.0 37.5 50.0 43.3 21.7

24 2 12,000 2 115.4 100.0 86.6 50.0 66.6 57.7 28.9

30 2 15,000 2 144.2 125.0 108.3 62.5 83.3 72.2 36.1

36* 2 18,000 173.1 150.0 130.0 75.0 99.9 86.6 43.3

45 3 15,000 3 3 216.3 187.5 162.5 93.8 124.9 108.3 54.1

54 3 18,000 2 N/A 225.0 194.9 112.5 149.9 129.9 65.0

60** 4 15,000 4 4 N/A 250.0 216.6 125 166.7 145 72

75** 5 18,000 5 5 3 N/A 312.5 270.8 156 208.4 181 90

90** 5 18,000 N/A 375.0 324.9 188 250 217 108

* 208V models use one additional immersion heater.

** Available on 50 gallon models or larger.

***Each immersion heater contains three electric elements.

The following wiring diagrams are included in this manual to

show typical arrangement of electrical components in the control

and power circuits by voltage and phase characteristics. They

are to be used as a reference by the installer or servicer in

performing their work. An actual diagram of the water heater

wiring is furnished with the heater.

WIRING DIAGRAMS

14

Page 15

SMALL COMMERCIAL WIRE DIAGRAM

208-240V / 3PH

SMALL COMMERCIAL WIRE DIAGRAM

208-240V / 3-1PH

15

Page 16

3-1 PHASE CONVERSIONS

In the case where the unit is phase convertible and it has only one contactor, jumper wires (provided) must be added according to

the phase of the supply voltage. See the diagram below. For single-phase connection, jumpers A-C and B-D must be added. For

three-phase connection, jumper B-C must be added.

3-1 PHASE CONTACTOR JUMPER CONFIGURATION

FIGURE 1

1 PHASE CONNECTION

3 PHASE CONNECTION

SMALL COMMERCIAL WIRE DIAGRAM

SINGLE PHASE

FIGURE 2

16

Page 17

SMALL COMMERCIAL WIRE DIAGRAM

300-600V / 3PH

NOTES

17

Page 18

OPERATION

GENERAL

Never operate the heating elements without being certain the

water heater is filled with water, and a temperature and pressure

relief valve is installed in the relief valve opening.

FILLING

1. Turn off the electrical disconnect switch.

2. Close the water heater drain valve by turning knob to right

(clockwise).

3. Open a nearby hot water faucet to permit the air in the system

to escape.

4. Fully open the cold water inlet valve allowing the heater and

piping to be filled.

5. Close the hot water faucet as water starts to flow. The heater

is now ready for START UP and TEMPERATURE

REGULATION.

START UP

The following checks should be made by the installer when the

heater is placed into operation for the first time.

1. Open the hinged access door, check all water and electrical

connections for tightness. Also check connections on top

and side of heater.

• Repair water leaks and tighten electrical connections

as necessary.

2. Depress red button on manual reset high limit switch.

DANGER

THIS WATER HEATER IS EQUIPPED WITH AN ADJUSTABLE

THERMOSTAT TO CONTROL WATER TEMPERATURE. HOT

WATER TEMPERATURES REQUIRED FOR AUTOMATIC

DISHWASHER AND LAUNDRY USE CAN CAUSE SCALD

BURNS RESULTING IN SERIOUS PERSONAL INJURY AND/

OR DEATH. THE TEMPERATURE AT WHICH INJURY OCCURS

VARIES WITH THE PERSON’S AGE AND TIME OF EXPOSURE.

THE SLOWER RESPONSE TIME OF CHILDREN, AGED OR

DISABLED PERSONS INCREASES THE HAZARDS TO THEM.

NEVER ALLOW SMALL CHILDREN TO A HOT WATER TAP, OR

TO DRAW THEIR OWN BATH WATER. NEVER LEAVE A CHILD

DISABLED PERSON UNATTENDED IN A BATHTUB OR

SHOWER.

THE WATER HEATER SHOULD BE LOCATED IN AN AREA

WHERE THE GENERAL PUBLIC DOES NOT HAVE ACCESS TO

SET TEMPERATURES.

SETTING THE WATER HEATER TEMPERATURE AT 120°F WILL

REDUCE THE RISK OF SCALDS. Some states require settings

at specific lower temperatures.

Figure 1 shows the approximate time-to-burn relationship for

normal adult skin.

Temperature Time to Produce 2nd & 3rd

Setting Degree Burns on Adult Skin

180°F (82°C) Nearly instantaneous

170°F (77°C) Nearly instantaneous

160°F (71°C) About 1/2 second

150°F (65°C) About 1-1/2 seconds

140°F (60°C) Less than 5 seconds

130°F (54°C) About 30 seconds

120°F (49°C) More than 5 minutes

3. Turn on the electrical disconnect switch.

4. Observe the operation of the electrical components during

the first heating cycle. Use care as the electrical circuits

are energized.

• Thermostat and contactor operation should be checked

by (a) manually operating thermostat and (b) allowing

the heater to come up to temperature and shutoff

automatically.

• The thermostat operates all contactor coils

simultaneously.

5. Close the access door.

TEMPERATURE REGULATION

FIGURE 1

Valves for reducing point-of-use temperature by mixing cold and

hot water are available. Also available are inexpensive devices

that attach to faucets to limit hot water temperatures

licensed plumber or the local plumbing authority.

The thermostat factory setting is 130°F (54°C). The dial is

adjustable through a range of 95°F (35°C) to 194°F (90°C).

The thermostat is behind the front access door. TURN OFF THE

ELECTRICAL DISCONNECT SWITCH BEFORE OPENING

DOOR.

• It is suggested the thermostat be turned to the lowest

setting which satisfies the hot water requirements of

the system. This helps minimize water scale

formations on the heating elements.

• The thermostat contacts close on about 6F° (3.3C°)

(not adjustable) drop in water temperature.

• Where multiple thermostats are used, they may be all

set at the same temperature or 2F° to 4F° (1C° to 2C°)

apart to achieve “step control”. The bottom thermostat

is set the hottest and top thermostat the coolest.

Contact a

18

Page 19

Always close the front access door after making a temperature

adjustment. Turn on electricity.

3. Attach hose to outlet opening of drain valve and direct end to

drain.

DRAINING

The water heater must be drained if it is to be shut down and

exposed to freezing temperatures. Maintenance and service

procedures may also require draining the heater.

1. Turn off the electrical disconnect switch.

2. Close the supply water inlet valve to heater.

MAINTENANCE

GENERAL

Periodically the drain valve should be opened and the water

allowed to run until it flows clean. This will help to prevent

sediment build-up in the tank bottom.

Periodically check the temperature and pressure relief valve to

ensure that it is in operating condition. Lift the lever at the top of

the valve several times until the valve seats properly and operates

freely.

CAUTION

THE WATER PASSING OUT OF THE VALVE DURING THIS

CHECKING OPERATION MAY BE EXTREMELY HOT.

Water heater maintenance includes periodic tank flushing and

cleaning, and removal of lime scale from the heating elements.

4. Open a nearby hot water faucet and the heater drain valve.

5. If the heater is being drained for extended shutdown, it is

suggested the drain valve be left open during this period.

The hose may be removed.

• Follow FILLING instructions when restoring hot water

service.

SEDIMENT REMOVAL

Water borne impurities consist of fine particles of soil and sand

which settle out and form a layer of sediment on the bottom of

the tank. In time, if not removed, the level of sediment might

reach the heating elements and cause their failure.

For convenience, sediment removal and element lime scale

removal should be performed at the same time as follows.

LIME SCALE REMOVAL

Lime scale accumulations on the heating elements is a normal

condition, common to all immersion type elements. Factors

which affect the amount of this formation are:

Component Operation Interval Required

Flushing Monthly -------------

Tank Sediment

Removal As needed -------------

Elements Lime Scale As needed UN•Lime® delimer

Removal and element gaskets,

Part No.5109.

Tank flushing should be performed in accordance with the above

schedule. Tank sediment removal and element lime scale

removal must be performed when needed as determined by

periodic inspections. Following are the instructions for

performing recommended maintenance.

FLUSHING

The water heater drain valve should be opened once a month to

help prevent sediment buildup on the tank bottom.

1. Turn off the electrical disconnect switch.

2. Attach hose to outlet opening of drain valve and direct end to

drain.

• Open the drain valve by turning the knob to the left

(counterclockwise). Allow water to flow until it runs

clean.

• If water does not flow from opened drain valve, follow

instructions for sediment removal.

3. When finished flushing:

• Close heater drain valve and remove hose.

• Turn on electricity.

1. Amount of hot water used. As the volume of water heated

increases, more scale results.

2. Water temperature. As the temperature of water is increased,

more scale is deposited on the elements.

3. Characteristics of water supply. Regardless of water

treatment, the elements should be examined regularly.

Lime scale accumulations may cause noises to occur during

operation.

It is recommended that a heating element be removed

periodically for examination. If it is scaled, all of the elements

should be removed and cleaned. If the tank bottom has an

accumulation of sediment it should be cleaned.

Lime scale should be removed by dissolving the accumulation

in UN•LIME

available from State Water Heaters, 500 Lindahl Parkway,

Ashland City, TN 37015. Do not use muriatic or hydrochloric acid

base deliming solutions to remove lime scale from the elements.

1. Turn off electrical disconnect switch.

2. Drain the heater following DRAINING instructions.

3. Open front access door.

4. Disconnect the element wiring. Try not to disturb the wiring

unnecessarily and reconnection will be easier.

5. Remove the bolts from each element.

®

delimer. UN•LIME is a non-muriatic delimer,

19

Page 20

6. Remove the elements from the openings.

• Use a twisting, pulling action to remove elements

scaled beyond size of the tank openings.

• Brush loose scale from elements.

7. Lime scale removal.

• The electrical disconnect switch usually contains

fuses.

3. If the water was excessively hot, and is now cold, the

high limit switch may have operated.

• To reset, remove the plug from the top cover of the

heater and push the reset button.

• Place limed ends of heating elements into UN•LIME

delimer and allow scale to dissolve. Do not permit

delimer or water to contact heating element electrical

terminals.

Other scale removal:

• Silicates, sulfates and aluminates must be removed

by scraping or other mechanical means. Lime scale

solvents will not remove these types of scale which are

occasionally encountered.

8. Flush cleaned ends of elements with water when deliming

or cleaning is completed.

9. Remove sediment and scale from the tank bottom through

the access provided by the element opening(s).

• The cold water inlet valve and drain valve may be

opened to aid the cleanout process.

10. Clean remaining gasket material from tank and element

flanges. DO not reuse original element gaskets.

• The element gaskets should be replaced whenever an

element is removed.

• Repeated operation of the high temperature cutoff

should be investigated by your dealer.

4. The capacity of the heater may have been exceeded

by a large demand for hot water.

• Large demands require a recovery period to restore

water temperature.

5. Cooler incoming water temperature will lengthen the

time required to heat water to the desired temperature.

6. Look for hot water wastage and leakage.

7. Sediment or lime scale may be affecting water heater

operation. Refer to page 18 for details.

Water is too hot

1. Refer to TEMPERATURE REGULATION.

Water heater makes sounds

1. Sediment or lime scale accumulations on the elements

causes sizzling and hissing noises when the heater is

operating.

11. Put new gaskets on each element and install into tank

openings.

• Uniformly tighten element bolts.

12. Attach element wires to connection points from which

they were removed.

13. Follow FILLING instruction to restore hot water service.

• Check for water leaks around elements and proper

operation when heater is filled.

• Close front access door.

CHECKLIST

Before calling for service, check the following points to see if

the cause of trouble can be identified and corrected. Reviewing

this checklist may eliminate the need of a service call and quickly

restore hot water service. Figure 1 identifies the location of all

of the heater components.

BE SURE TO TURN OFF THE ELECTRICITY WHEN CHECKING

EQUIPMENT.

Not enough or no hot water.

1. Be certain the electrical disconnect switch serving the

water heater is in the ON position.

2. Check the fuses.

• The sounds are normal. However, the tank bottom

and elements should be cleaned. Refer to page 18

for details.

2. Some of the electrical components of the water heater

make sounds which are normal.

• Contactors will “click” or snap as the heater starts

and stops.

• Contactors often hum.

Water leakage is suspected.

1. Check to see if the heater drain valve is tightly closed.

2. If the outlet of the relief valve is leaking it may represent:

• Excessive water temperature.

• Faulty relief valve.

• Excessive water pressure.

• Excessive water pressure is the most common cause

of relief valve leakage. It is often caused by a “closed

system”. A check valve in the inlet system will not

permit the expanded hot water volume to equalize

pressure with the main. A relief valve must release

this water or the water heater or plumbing system will

be damaged.

20

Page 21

When such a condition is encountered, local codes or inspection

agency should be consulted to determine which system is

acceptable in your area. These may consist of:

• Installation of a second relief valve set to lower

than the primary safety relief valve.

• An expansion tank of suitable pressure and provision

to avoid water logging.

Anode rod deterioration depends on water conductivity, not

necessarily water condition. A corroded or pitted anode rod

indicates high water conductivity and should be checked and/or

replaced more often than an anode rod that appears to be intact.

Replacement of a depleted anode rod can extend the life of your

water heater. Inspection should be conducted by a qualified

technician, and at a minimum should be checked annually after

the warranty period.

• Removal of the check valve.

4. Examine the flange area of the elements for gasket

leakage.

• Tighten the bolts or, if necessary, follow the WATER

AND LIME SCALE REMOVAL procedure to replace the

gaskets.

• Refer to “LEAKAGE CHECKPOINTS” on page 22.

ANODE MAINTENANCE

The anode rod is used to protect the tank from corrosion. Most

hot water tanks are equipped with an anode rod. The submerged

rod sacrifices itself to protect the tank. Instead of corroding the

tank, water ions attack and eat away the anode rod. This does

not affect the water’s taste or color. The rod must be maintained

to keep the tank in operating condition.

IF YOU CANNOT IDENTIFY OR CORRECT THE SOURCE OF

MALFUNCTION

1. Place the water heater electrical switch in the OFF

position

2. Close the supply water inlet valve to the heater.

3. Contact your dealer.

REPLACEMENT PARTS

Replacement parts may be ordered through dealers, authorized

servicers or distributors. Refer to Yellow Pages for where to call

or contact the State Water Heaters, 500 Lindahl Parkway, Ashland

City, TN 37015. When ordering parts, specify complete model

no., serial no., (see rating plate), quantity and name of part

desired. Standard hardware items should be purchased locally.

21

Page 22

LEAKAGE CHECKPOINTS

INSTRUCTIONS: USE THIS ILLUSTRATION AS A GUIDE WHEN CHECKING FOR SOURCES OF WATER LEAKAGE. YOU OR

YOUR DEALER MAY BE ABLE TO CORRECT WHAT APPEARS TO BE A PROBLEM.

Where possible, remove or lift top cover to examine threads of

ANODE

fittings installed into tank for evidence of leakage. Correct fitting

leaks as necessary.

Relief valve operation and leakage may be due to water

expansion during heating cycle or foreign material on seat

of valve. If the valve is not piped to an open drain the

released water could be mistaken for a leaking heater. To

check where threaded portion enters tank, insert Q-tip or

similar absorbent material between jacket opening and

valve to swab spud area. Remove valve* if leak is indicated

and repair with pipe joint compound.

Drain valve leakage could be from the

valve itself. Either correct the problem

or replace the valve.* To check for

leakage where threaded portion enters

tank, insert Q-tip or similar absorbent

material between jacket opening and

valve to swab spud area. Remove valve*

if leak is indicated and repair with pipe

joint compound.

*Contact your dealer as it is necessary

to shut off electricity and drain tank to

perform procedure.

Water on side of the tank may be condensation due to the

panel or insulation not being in place.

Water leaks at the elements may be due to:

1. Defective element which leaks at terminals or through

flange. Replace element*.

2. Loose element/gasket leak:

Flange type: Tighten screws with wrench. If leak

continues remove element* and discard gasket.

Clean gasket seating areas and reinstall element

with new gasket.

NOTE: Part No. 5288 scale cleaning replacement

screws available where threads have become rusted

or damaged, preventing tightening.

Condensation and dripping may appear on pipes when cold

water temperature is low. Pipe fitting may be leaking.

All water which appears at the heater bottom or on the surrounding floor

may be caused by condensation, loose connections or relief valve

operation and leakage. Do not replace the heater until a full inspection of

all potential leak points is made and corrective steps taken to stop the

leak. Leakage from other appliances, water lines or ground seepage

should also be suspected until proven otherwise.

22

Page 23

MODEL SSE LIMITED WARRANTY

State Water Heaters, the warrantor, extends the following LIMITED WARRANTY to the owner of this water heater:

1. THE TANK

If the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable

water therein, during the first THREE years after initial installation, the warrantor will supply a complete new State water heater of equivalent size

and current model. Some government agencies are requiring energy efficient standards for water heaters. In the event regulations prohibit sale

of a model of equivalent size and construction, State Water Heaters will provide a model which complies with the regulations of your area, in

which case the consumer will be charged the difference in price between the like replacement and the energy efficient model required. The

warranty on the replacement water heater will be limited to the unexpired term of the original warranty.

2. ALL OTHER PARTS

If within ONE year after initial installation of this water heater, any part or portion shall prove upon examination by the warrantor to be defective

in material or workmanship, the warrantor will repair or replace such part or portion at its option.

3. CONDITIONS AND EXCEPTIONS

This warranty shall apply only when the water heater is installed in accordance with local plumbing and building codes, ordinances and

regulations, the printed instructions provided with it and good industry practices. In addition, a temperature and pressure relief valve, certified by

A.G.A. and approved by the American Society of Mechanical Engineers, must have been installed.

a. This warranty shall apply only when the heater is used:

b. Any accident to the water heater, any misuse, abuse (including freezing) or alteration of it, any operation of it in a modified

c. This warranty is void if a device acting as a backflow prevention device (check valves etc) is installed in the cold water supply the heater

4. SERVICE AND REPAIR EXPENSES

Under the limited warranty the warrantor will provide only a replacement water heater or part thereof. The owner is responsible for all other

costs. Such costs may include but are not limited to:

a. Labor charges for service removal, repair or reinstallation of the water heater or any component part;

b. Shipping, delivery, handling, and administrative charges for forwarding the new heater or replacement part from the nearest

c. All cost necessary or incidental for any material and/or permits required for installation of the replacement heater or part.

5. LIMITATIONS ON IMPLIED WARRANTIES

Implied warranties, including the warranty of merchantability imposed on the sale of this heater under state law are limited to (1) year duration for

the heater or any of its parts. Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to

you.

6. CLAIM PROCEDURE

Any claim under the warranty should be initiated with the dealer who sold the heater, or with any other dealer handling the warrantor’s products.

If this is not practicable, the owner should contact:

(1) at temperatures not exceeding the maximum setting of its thermostat;

(2) at water pressure not exceeding the working pressure shown on the water heater;

(3) when operated free from the damaging effects of uncontrolled water hammer;

(4) when filled with potable water, free to circulate at all times;

(5) in a non-corrosive and non-contaminated atmosphere;

(6) with factory approved anode(s) installed;

(7) in the United States, its territories or possessions, and Canada.

form, any use of insulation blankets, or any attempt to repair tank leaks will void this warranty.

is connected to, unless an effective method of controlling thermal expansion is also installed at the heater(s) and operational at all times.

The relief valve installed on the heater is not an acceptable method.

distributor and returning the claimed defective heater or part to such distributor.

State Water Heaters

500 Lindahl Parkway

Ashland City, TN 37015

a. The warrantor will only honor replacement with identical or similar water heater or parts thereof which are manufactured or distributed by the

warrantor.

b. Dealer replacements are made subject to in-warranty validation by warrantor.

7. DISCLAIMERS

NO OTHER EXPRESS WARRANTY HAS BEEN OR WILL BE MADE IN BEHALF OF THE WARRANTOR WITH RESPECT TO THE MERCHANTABILITY OF

THE HEATER OR THE INSTALLATION, OPERATION, REPAIR OR REPLACEMENT OF THE HEATER. THE WARRANTOR SHALL NOT BE RESPONSIBLE

FOR WATER DAMAGE, LOSS OF USE OF THE UNIT, INCONVENIENCE, LOSS OF DAMAGE TO PERSONAL PROPERTY OR OTHER CONSEQUENTIAL

DAMAGE. THE WARRANTOR SHALL NOT BE LIABLE BY VIRTUE OF THIS WARRANTY OR OTHERWISE FOR DAMAGE TO ANY PERSONS OR

PROPERTY, WHETHER DIRECT OR INDIRECT, AND WHETHER ARISING IN CONTRACT OR IN TORT.

a. Some states do not allow the exclusion or limitation of incidental or consequential damage, so the above limitations or exclusions may not apply

to you.

b. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Fill in the following for your own reference. Keep it. Registration is not a condition of warranty. The model and serial number are found on the

heater’s rating plate.

Model No. ____________________________________ Serial No. _____________________________________ Date Installed _______________

Dealer’s Name __________________________________________________________________________________________________________

Dealer’s Address _____________________________________________________________________________ Phone No. __________________

City and State _______________________________________________________________________________ Zip Code __________________

KEEP THIS WARRANTY AND MANUAL POSTED ADJACENT TO THE HEATER FOR FUTURE

REFERENCE WHENEVER MAINTENANCE, ADJUSTMENT OR SERVICE IS REQUIRED.

23

Page 24

500 Lindahl Parkway, Ashland City, TN 37015

Phone: 800-821-2017 Fax: 800-644-9306

www.stateind.com

24

Loading...

Loading...