Page 1

SERVICE HANDBOOK

SandBlaster

Self-Cleaning Induced Draft Multi Flue

Commercial Gas Water Heaters

®

MODE L S COVERE D

SBN71 120 Through SBN85 390 (A)

Series 108 Models and

SBD30 150, SBD30 199

Booster Heaters

SBN Meets Low NOx Requirements of SCAQMD

Rules 1121 & 1146.2

Part Number 317927-000

Printed in the U.S.A. - 0810

COMMERCIAL

Page 2

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT1sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

Table of Contents

SBN 71-120 thru 85-390, SBD30-150/199 SERVICE HANDBOOK INTRODUCTION.........2

QUALIFICATIONS..................................................................................................................3

TOOLS REQUIRED...............................................................................................................3

COMMERCIAL TANK TYPE GAS MODEL NUMBER BREAK DOWN..................................3

INSTALLATION CONSIDERATIONS - CLEARANCES.........................................................4

TOP AND FRONT VIEWS OF MINIMUM CLEARANCES TO COMBUSTIBLES..................4

MINIMUM CLEARANCE TO COMBUSTIBLES.....................................................................5

REQUIRED EXTERIOR CLEARANCES................................................................................6

REQUIRED EXTERIOR CLEARANCES................................................................................7

INSUFFICIENT MAKEUP AIR ........ NEGATIVE AIR PRESSURE .....DOWNDRAFTS........7

MAKE-UP AIR – DIRECT COMMUNICATION WITH OUTDOORS.......................................8

CONTAMINATED AIR............................................................................................................9

AIR FOR

COMBUSTION – FLAMMABLE ITEMS..................................................................9

GAS VALVE.........................................................................................................................10

GAS VALVE.........................................................................................................................11

VENTING.............................................................................................................................12

VENTING – MULTIPLE CATEGORY I GAS WATER HEATERS.........................................12

VENT TABLES FOR CATEGORY I - TYPE B GAS VENT..................................................13

VENT TABLES FOR CATEGORY I - TYPE B GAS VENT..................................................14

VENT TABLES FOR CATEGORY I - TYPE B GAS VENT..................................................15

VENT TABLES FOR CATEGORY I - TYPE B GAS VENT..................................................16

VENT TABLES FOR CATEGORY I - TYPE B GAS VENT..................................................17

SBN /SBD30-150/199 SEQUENCE OF OPERATION.........................................................18

COMBINED VENTING.........................................................................................................19

9 RULES FOR GOOD VENTING.........................................................................................

20

9 RULES FOR GOOD VENTING.........................................................................................21

9 RULES FOR GOOD VENTING.........................................................................................22

DRAFT PROVING PRESSURE SWITCH - SETTINGS.......................................................23

THERMOSTAT AND IGNITION CONTROL BOARD VIEW.................................................24

WHITE RODGERS INTEGRATED CONTROL - THERMOSTAT........................................25

WHITE RODGERS IGNITION CONTROL BOARD..............................................................26

GAS CONTROL VALVE / BURNER AREA VIEW................................................................27

WIRING DIAGRAM..............................................................................................................28

ELECTRICAL SEQUENCE – SBN, SBD30-150/199...........................................................29

OPERATING SEQUENCE – FLOW CHART........................................................................30

DIAGNOSTIC SEQUENCE OF OPERATION – FLOW CHART..........................................31

PRE-SERVICE CHECK LIST...............................................................................................32

TEST 1 – 120VAC POWER

CHECK ...................................................................................33

Page 3

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT2sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

This service handbook is a supplement to the SBN and SBD151/201 Installation and

Operation Manual. The handbook provides information on servicing and troubleshooting State

SBN/SBD30-150/199/ water heaters in the field. While this handbook is not intended to be all

inclusive, it contains:

• step-by-step procedures with illustrations to verify proper installation, operation,

and troubleshooting

• quick reference data to assist in servicing the product line

• answers to common questions encountered in the operation of the product line.

The handbook is intended to be used by licensed plumbing professionals. Reference should

be made to the installation manual accompanying the product. If you are experiencing a

problem not covered in this handbook, please contact the State Technical Information

Department at 1-800-365-0024 or your local State Water

Heater representative for further

assistance. No duplication or reproduction of this book may be made without the expressed

written authorization of the State Water Heaters.

SBN 71-120 thru 85-390, SBD30-150/199 SERVICE HANDBOOK INTRODUCTION

WATER HEATER CONTROL BOARD TROUBLESHOOTING AND DIAGNOSTIC LED

INTERPRETATION.............................................................................................................................33

WATER HEATER CONTROL BOARD TROUBLESHOOTING AND DIAGNOSTIC LED

INTERPRETATION.............................................................................................................................34

TEST 2 – POLARITY CHECK.............................................................................................................35

TEST 3 - CONTINUITY CHECK OF HIGH LIMIT (ECO)....................................................................36

TEST 4 - UPPER TEMPERATURE PROBE CONTINUITY CHECK..................................................37

TEST 5 - CALLING FOR HEAT – NO INDUCER OPERATION.........................................................38

TEST 6 - INDUCER ON.............NO IGNITION..................................................................................39

TEST 7 – INDUCER ON, PROVER SWITCH AND LOW GAS PRESSURE SWITCH CLOSED

....................NO IGNITER OPERATION.............................................................................................40

TEST 8 – IGNITER HEATS .............. NO MAIN BURNER.................................................................41

TEST 9 – IG

NITER HEATS .......NO MAIN BURNER.........................................................................42

TEST 10 - MAIN BURNER IGNITION FOR LESS THAN 5 SECONDS.............................................43

TEST 11 - WATER HEATER SHUTTING OFF BELOW SETTING....................................................44

DISPLAY LIGHTS ON INTEGRATED WATER HEATER CONTROL................................................45

PARTS SBN71-120 thru 85-390 series 100.......................................................................................46

PARTS SBN71-120 thru 85-390 series 100.......................................................................................47

PARTS SBN71-120 thru 85-390 series 100.......................................................................................48

PARTS SBN71-120 thru 85-390 series 108.......................................................................................49

PARTS SBN71-120 thru 85-390 series 108.......................................................................................50

PARTS SBN71-120 thru 85-390 series 108.......................................................................................51

PARTS SBD30-150/199NE.................................................................................................................52

PARTS SBD30-150/199NE.................................................................................................................53

Page 4

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT3sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

QUALIFICATIONS

Installation or service of this water heater requires ability equivalent to that of a licensed

tradesman in the field involved. Plumbing, air supply, venting, gas supply and electrical testing

skills are required.

TOOLS REQUIRED

• Phillips head screwdriver

• standard screwdrivers

• 3/8 and 7/16 inch open end wrench

• set of marked drill bits

• electrical multimeter tester capable of measuring continuity, AC voltage and DC

voltage

• gas pressure gauge or manometer

• water pressure gauge

• thermometer (range 0 - 220 degrees F)

• 1/2 inch socket with extension for removal of the clean out cover

• 1-1/16 inch socket with extension for anode removal

Rev. 1 Adds SBD30-150 and 30-199 models with parts lists. Adds SBN series 108 parts list.

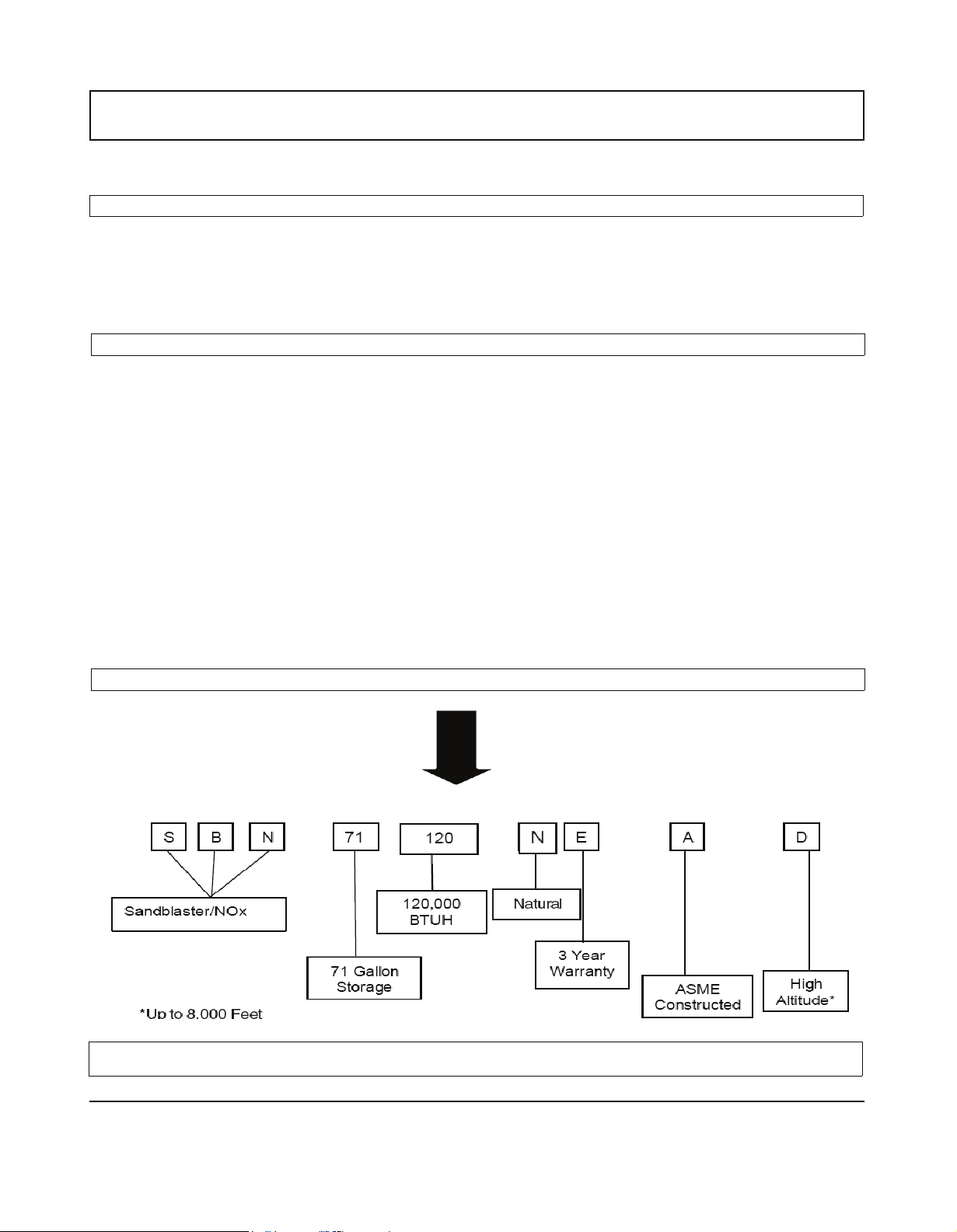

COMMERCIAL TANK TYPE GAS MODEL NUMBER BREAK DOWN

Page 5

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT4sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

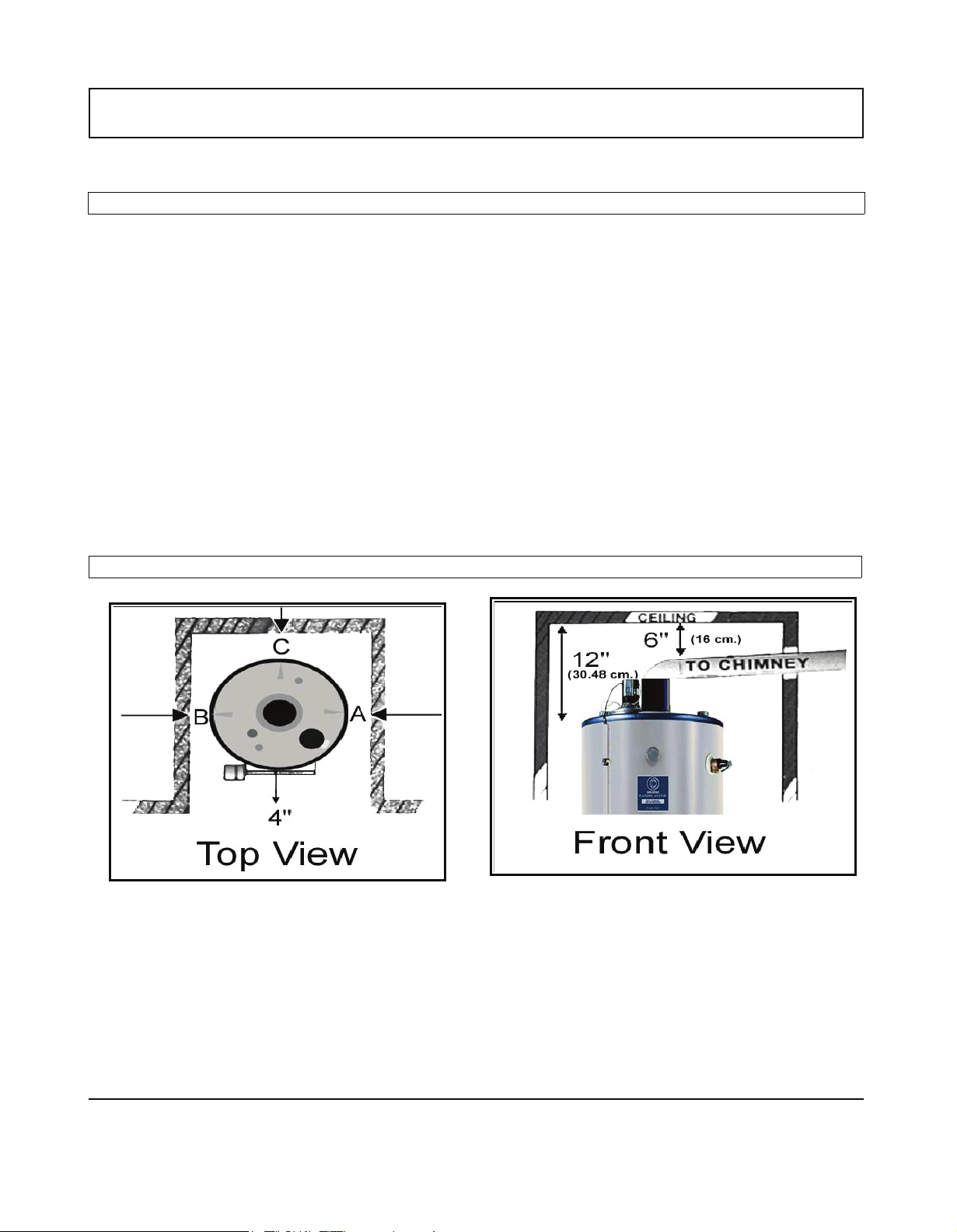

INSTALLATION CONSIDERATIONS - CLEARANCES

This portion of the handbook reviews some often overlooked installation considerations

clearances, air supply, gas pressure requirements, and venting—taking note of necessary

installation requirements for SBN and SBD30-150/199 . The installation manual covers most

of these items in detail.

A 24-inch clearance for all serviceable parts is recommended. Clearances may vary between

models. See instruction manual or the label on the heater for clearances applicable to your

specific model.

TOP AND FRONT VIEWS OF MINIMUM CLEARANCES TO COMBUSTIBLES

Page 6

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT5sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

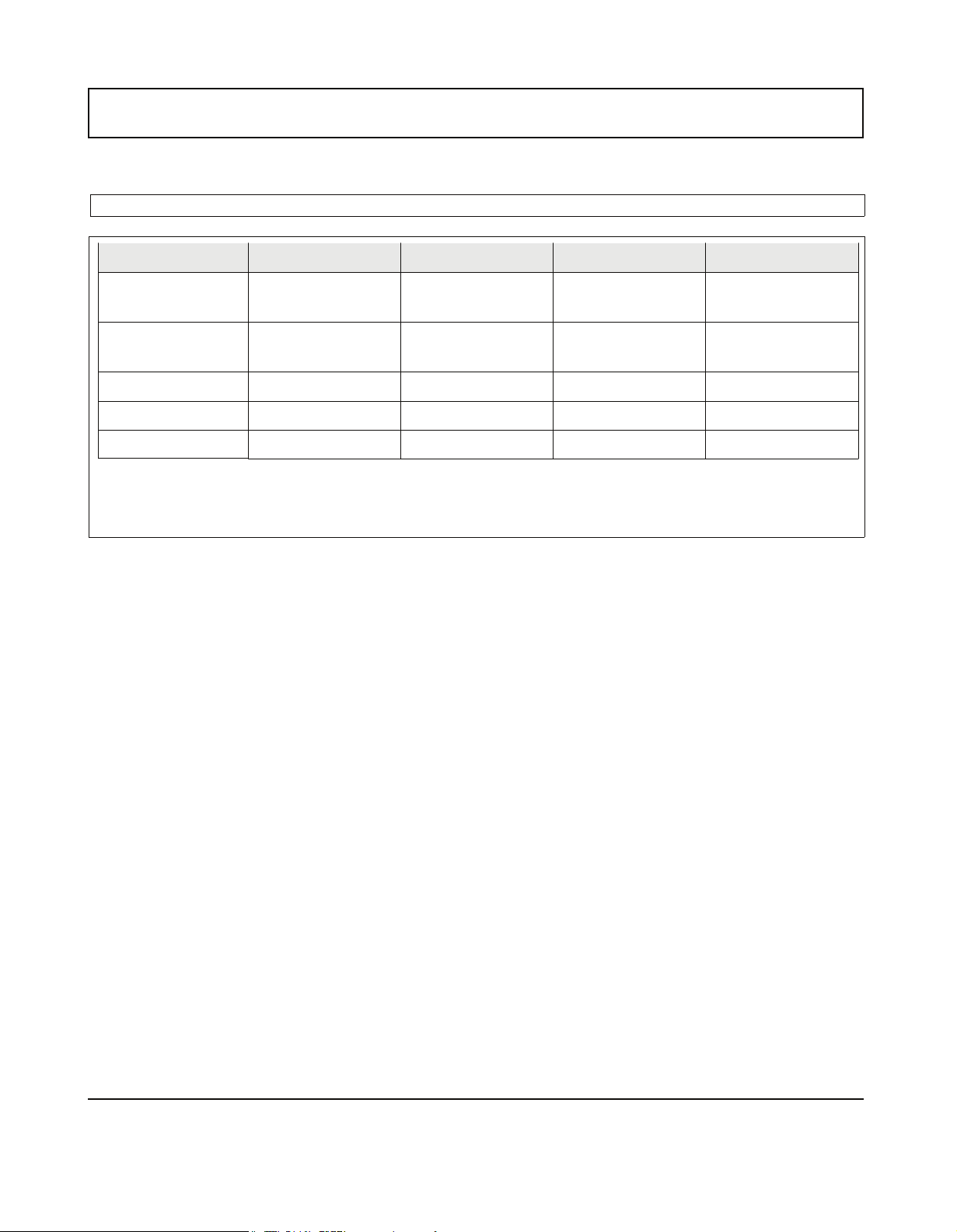

MINIMUM CLEARANCE TO COMBUSTIBLES

Model Number "A" Right Side "B" Left Side "C" Back "D" Ceiling

SBN-120 thru

200A

2" 2" 2" 12"

SBN-250/A thru

310/A

3" 3" 3" 12"

SBN-366 6" 6" 6" 6"

SBN-390 4" 4" 4" 4"

SBD30-150/199 2” 2” 2” 12”

A, B, and C clearances to non-combustibles is “0” inches - a 12 inch clearance to cover remains

unchanged.

Page 7

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT6sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

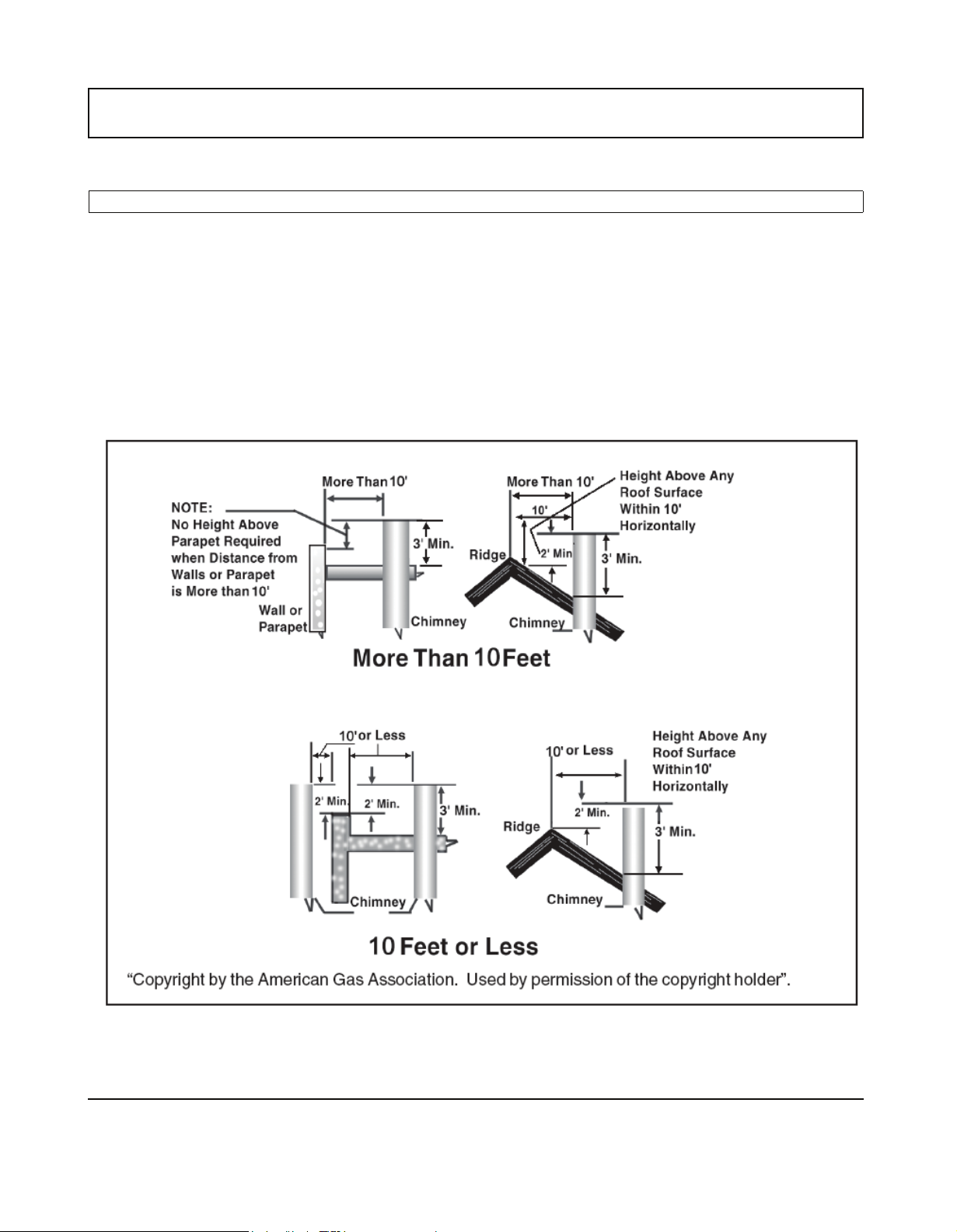

REQUIRED EXTERIOR CLEARANCES

The illustration below shows the required clearances for venting units using natural draft

venting.

The vent must extend at least 3 feet above the highest point where it passes through a roof of

a building and at least 2 feet higher than any portion of a building within a horizontal distance

of 10 feet (for vents of 12 inches in diameter or less).

References: NFPA 54 2006; ANSI Z 223.1 SEC 12.6.2 and Sec12.7.2 may allow reduction to

8 feet with a “listed vent cap.”

“

Copyright by the American Gas Association. Used by permission of the copyright holder”.

Page 8

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

REQUIRED EXTERIOR CLEARANCES

tnemtrapeD gniniarT lacinhceT7sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

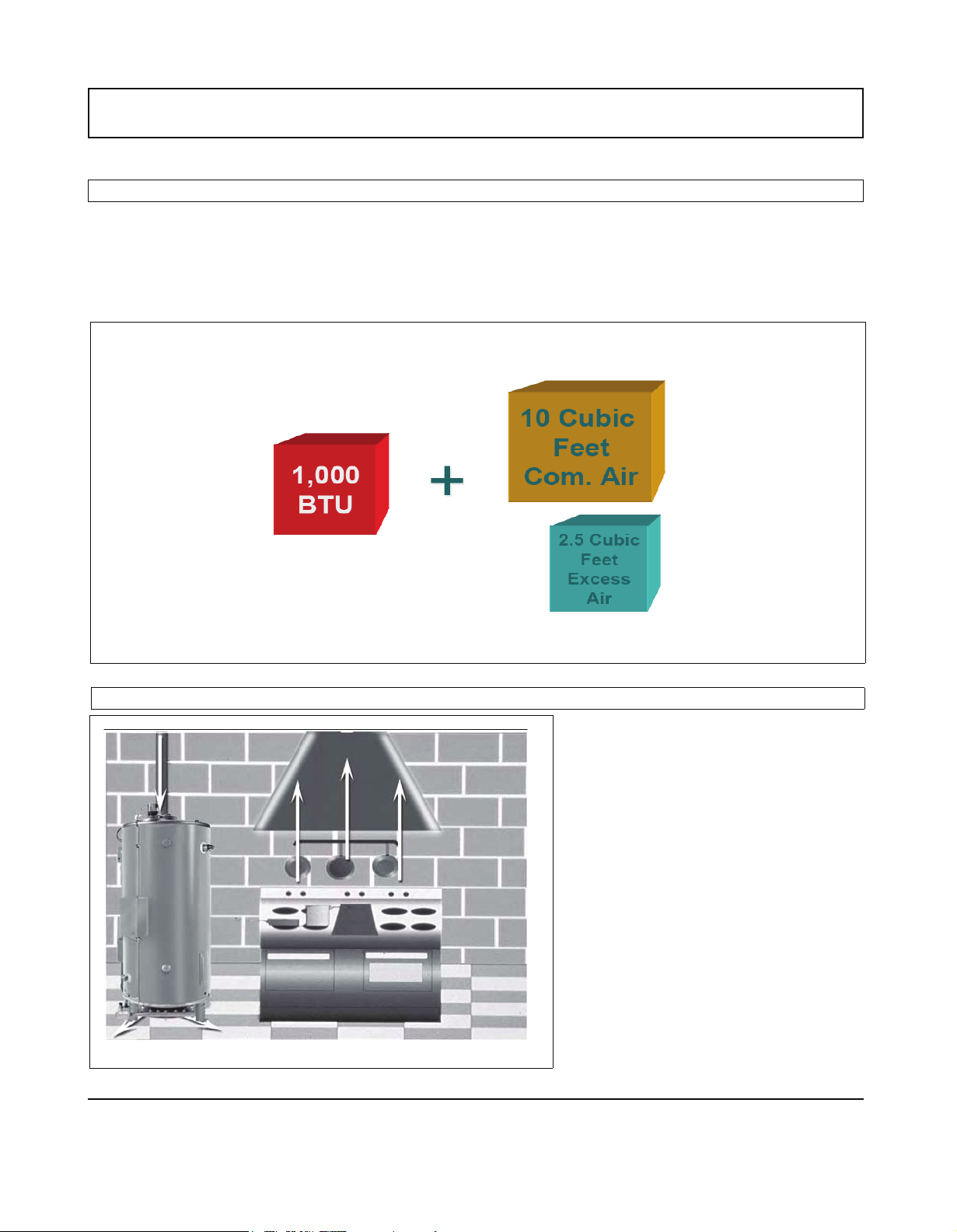

INSUFFICIENT MAKEUP AIR ........ NEGATIVE AIR PRESSURE .....DOWNDRAFTS

One common example is in a

restaurant installation where

exhaust vent equipment was not

considered in sizing make-up

requirements. This condition may

result in air being back drafted by

the restaurant exhaust equipment

through the heater causing the draft

proving switch to open and/or

erratic heater shutdown.

Stoichiometric or theoretical complete combustion requires 10 cubic feet of air per 1,000

BTUH of gas supplied. The National Fuel Gas code also recommends an additional 2.5 cubic

feet of “excess” air. For information on minimum make-up air opening sizes for various

building installations, refer to the National Fuel Gas Code NFPA 54, ANSI Z223.1, Sec. 5.3

Page 9

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT8sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

A fresh supply of make-up air for combustion can be supplied to the heater through

make-up air ducts, which directly communicate with the outdoors.(Not Direct Vent)

1 SQUARE INCH PER

4,000 Btu FOR EACH

OPENING

Two openings are required: one within 12 inches of the top of the enclosure and one within 12

inches of the bottom of the enclosure. Each opening must have a free area of not less than 1 square

inch per 4,000 BTUH of the total input of all appliances within the enclosure. The lower opening

primarily provides combustion air. The upper opening provides vent dilution air and acts as a relief

opening for flue gases should the vent become obstructed or a downdraft condition occur.

Additionally, when the heater is installed in a co

nfined space and communicating with the outdoor air,

one permanent opening, beginning within 12 inches (30 cm) of the top of the enclosure, must be

permitted where the equipment has clearances of at least 1 inch (2.5 cm) from the sides and back,

and 6 inches (16 cm) from the front of the appliance. The opening must directly communicate with the

outdoors and must communicate through a vertical or horizontal duct to the outdoors or spaces (crawl

or attic) that freely communicate with the outdoors, and must have a minimum free area of a) 1

square

inch per 3,000 BTUH (7cm2 per kW) of the total input of all equipment located in the enclosure and b)

not less than the sum of the areas of all vent connectors in the confined space.

MAKE-UP AIR – DIRECT COMMUNICATION WITH OUTDOORS

Page 10

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT9sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

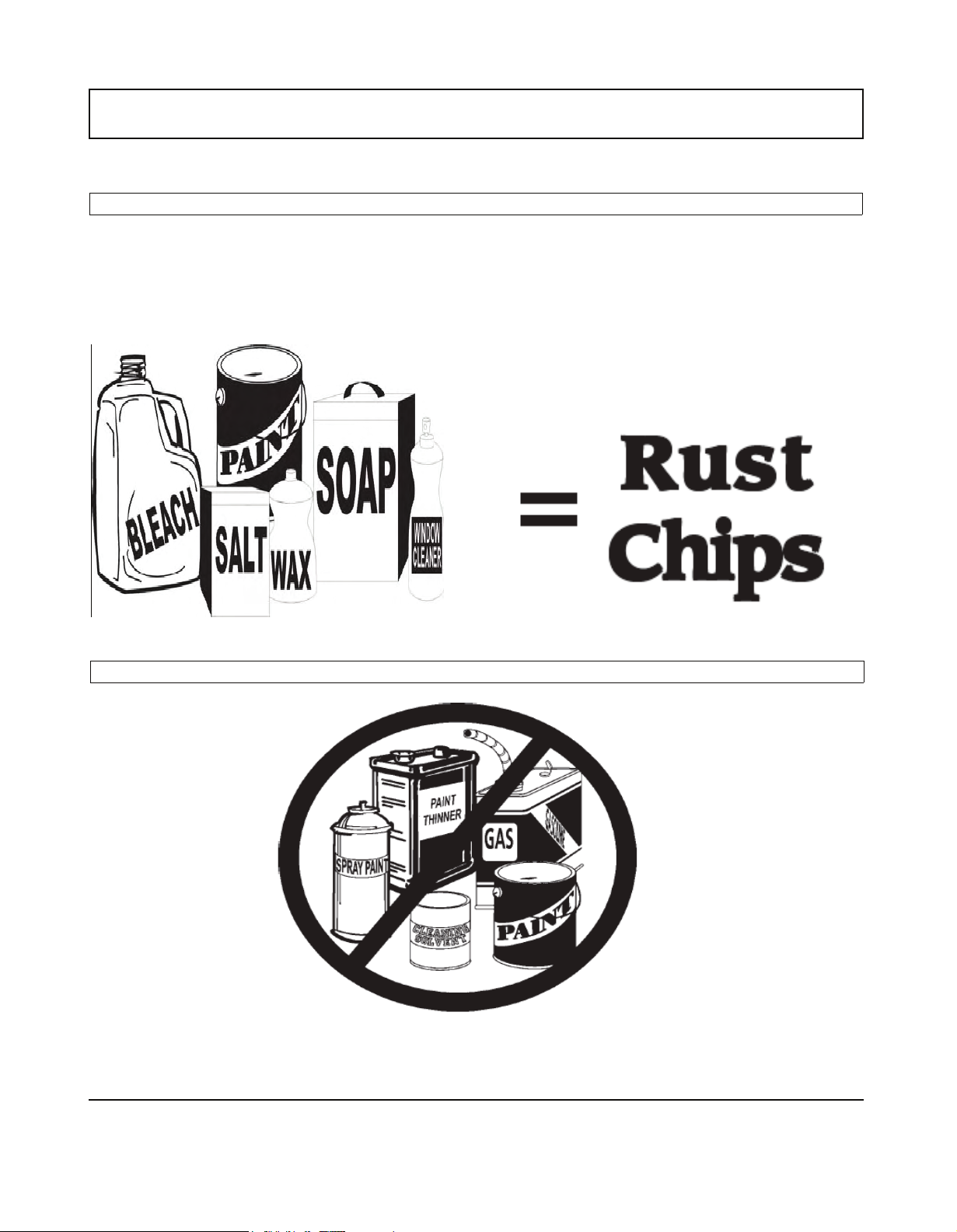

Along with adequate make-up air, the quality of the air is important. Contaminants in

combustion air can lead to premature heater failure. Vapors from bleaches, soaps, waxes,

salts, etc. are drawn into the combustion chamber with the make-up air and, once fired, mix

with water vapor in the gases to form extremely corrosive hydrochloric or hydrofluoric acid

and other corrosive by-products.

CONTAMINATED AIR

AIR FOR COMBUSTION – FLAMMABLE ITEMS

Page 11

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT01sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

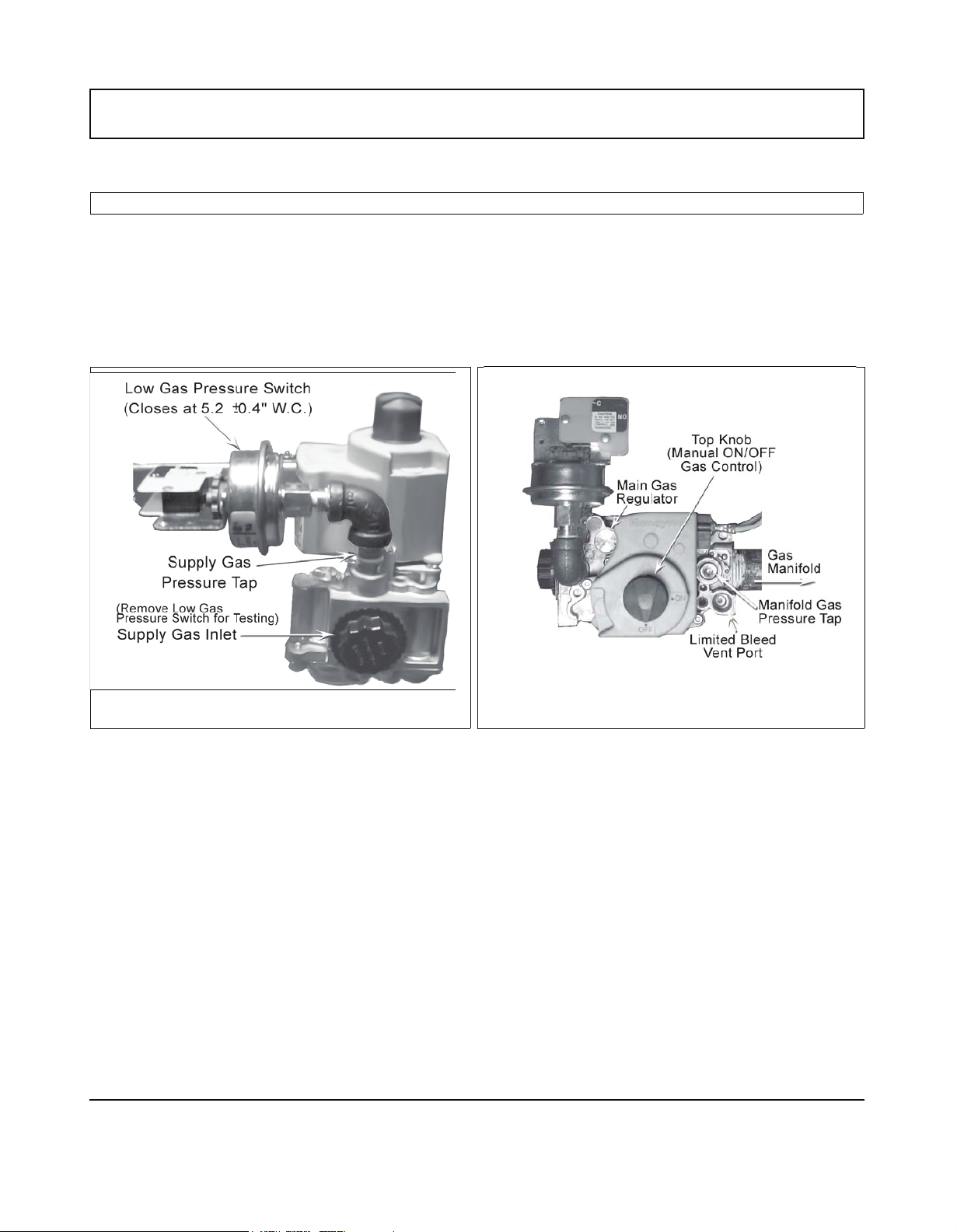

INLET VIEW

The supply gas pressure is normally measured at the gas valve inlet gas pressure tap, if

available, when the gas is flowing. The manifold gas pressure is measured at the manifold

pressure tap of the gas valve when the gas is flowing. Gas valves used are 24 volt AC

combination-step opening gas valves. They incorporate the main valve and gas pressure

regulator into one body. The Low Gas Pressure Switch, the Supply Gas Inlet, and the Supply

Gas Pressure Tap are shown in the Inlet View to the right.

The top view of the gas valve, shown on the right, shows the Main Gas Regulator, Manifold

Pressure Tap, Top Knob, and the Limited Bleed Vent Port. The main gas regulator is found

under the silver cap (silver cap for Natural Gas or black cap for Propane) screw. It is factory

preset to 3.5 inches W.C. and

adjusts gas pressure output from 3.0 to 5 inches water column.

Caution: Always test the

manifold pressure at the outlet when the gas is flowing.

TOP VIEW

GAS VALVE

Page 12

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT11sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

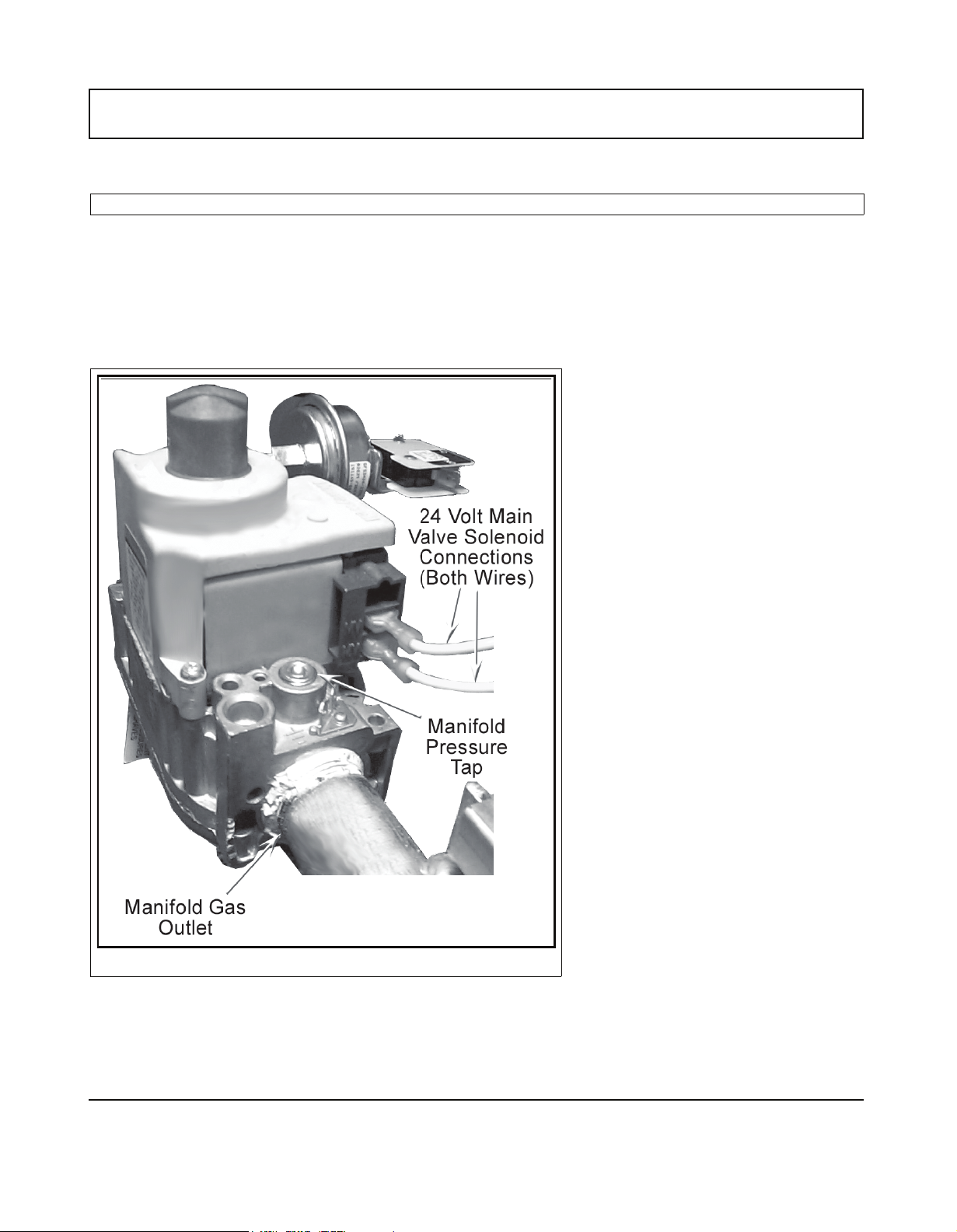

The outlet view of the Gas Valve, shown on the right, shows the Manifold Gas Outlet

Connection, the two 24 volt Main Valve (MV) Solenoid connections, and the Manifold

Pressure Tap. The two yellow wires from the 12-pin plug on the Ignition Board attach to the

MV terminals.

OUTLET VIEW

GAS VALVE

Page 13

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT21sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

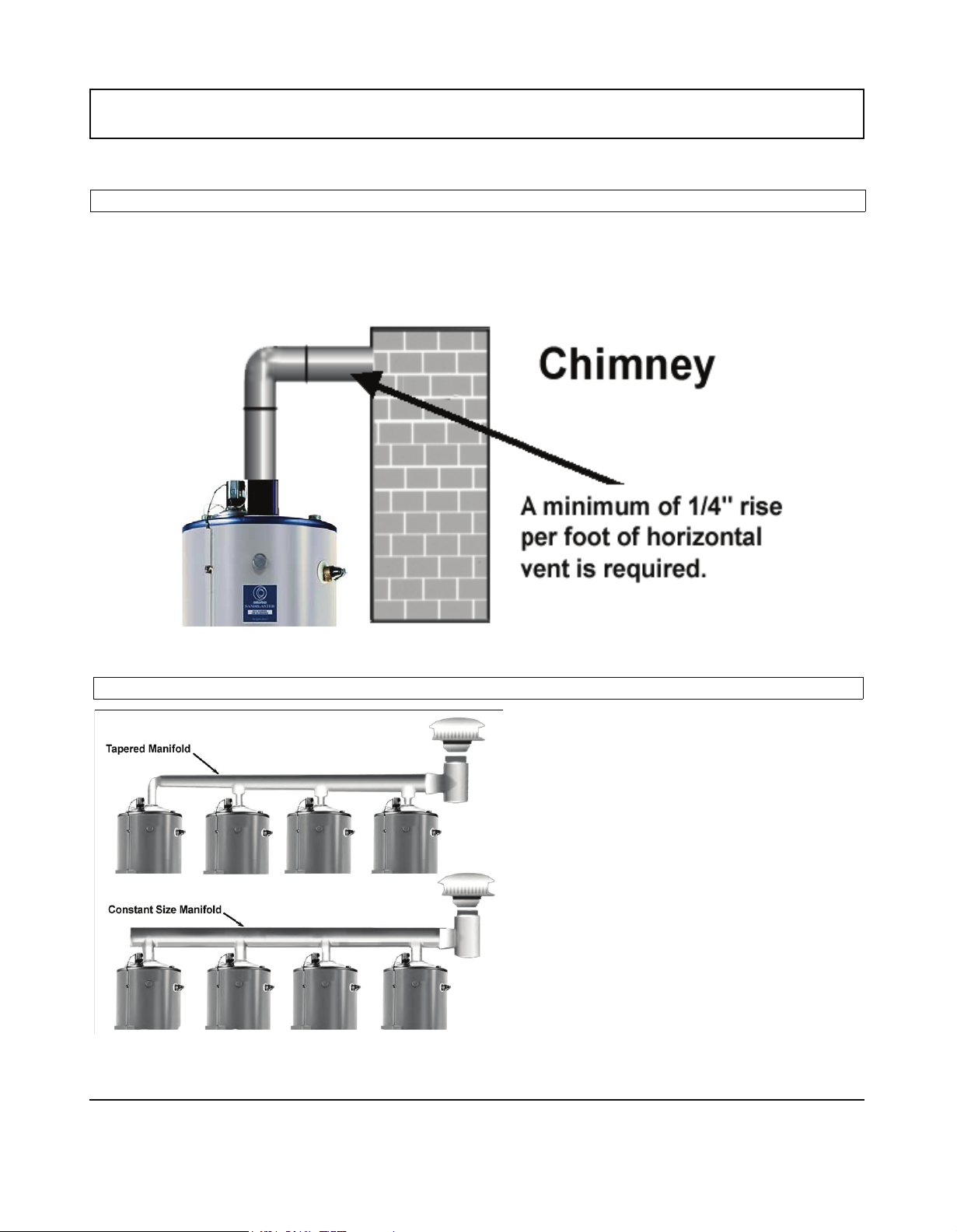

All SBN and SBD water heaters are classified by ANSI as Category I (non-condensing,

negative pressure venting) appliances. They are approved for type B vent. The draft inducer

does not pressurize the exhaust.

VENTING

VENTING – MULTIPLE CATEGORY I GAS WATER HEATERS

Page 14

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT31sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

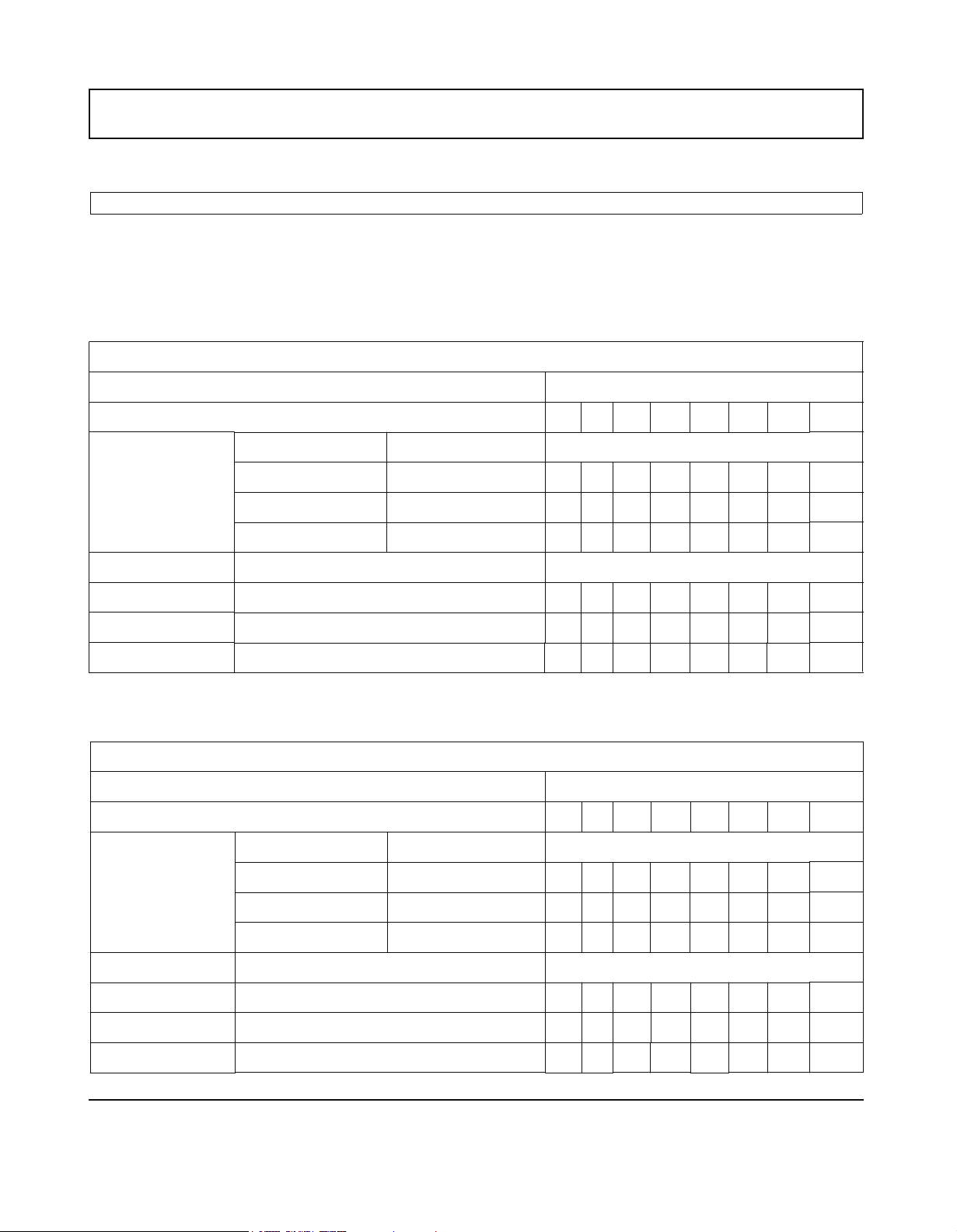

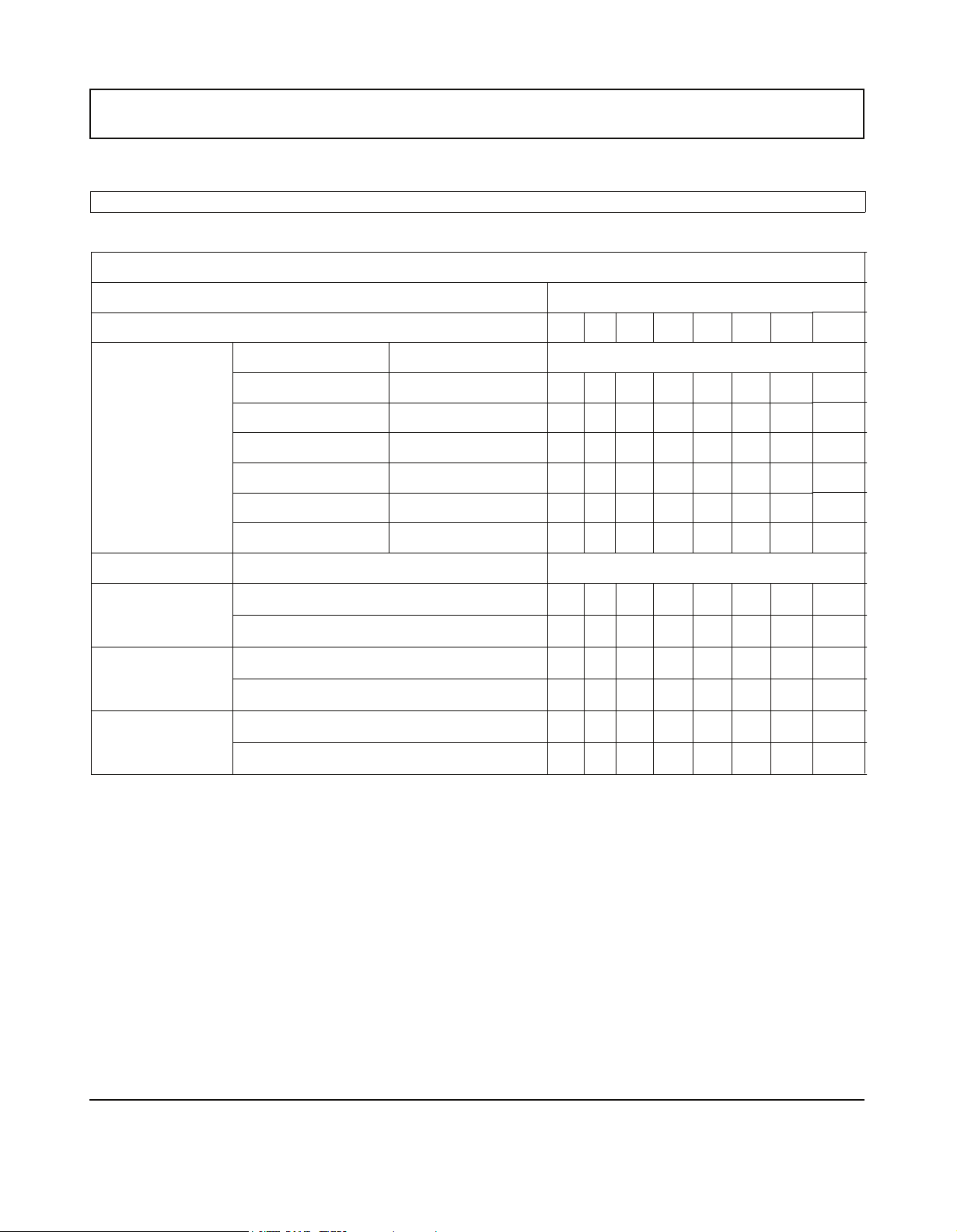

Multiple Gas Fired Tank-Type Heaters

When venting multiple Category I tank type heaters using Type B vent pipe, follow the

installation tables below which give sizing and data based upon NFPA 54/ANSI Z223.1-2006.

Model: SBN 71-120

latoT.rh/utB 000,021:tupnI Vent Height (feet)

001050302510186”5 :eziS rotcennoC tneV

Input Btu/hr Rise Vent Connector Diameter (inches)

120,000 1' 6 6 5 5 5 5 5 5

120,000 2' 5 5 5 5 5 5 5 5

120,000 3' 5 5 5 5 5 5 5 5

No. of Units Combined Input (Btu/hr x 1,000) Combined Vent/Manifold Diameter

66666677000,0422

66677788000,0633

67788999000,0844

Model: SBN 154; SBD30-150

T.rh/utB 000,451/000,051:tupnI otal Vent Height (feet)

001050302510186”6 :eziS rotcennoC tneV

Input Btu/hr Rise Vent Connector Diameter (inches)

150,000/154,000 1' 6 6 6 6 6 6 6 6

150,000/154,000 2' 6 6 6 6 6 6 6 6

150,000/154,000 3' 6 6 6 6 6 6 6 6

No. of Units Combined Input (Btu/hr x 1,000) Combined Vent/Manifold Diameter

2 300,000/ 308,000 7 7 6 6 6 6 6 6

3 450,000/ 462,000 8 8 7 7 7 6 6 6

4 600,000/ 616,000 9 9 9 8 8 7 7 6

VENT TABLES FOR CATEGORY I - TYPE B GAS VENT

Page 15

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT41sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

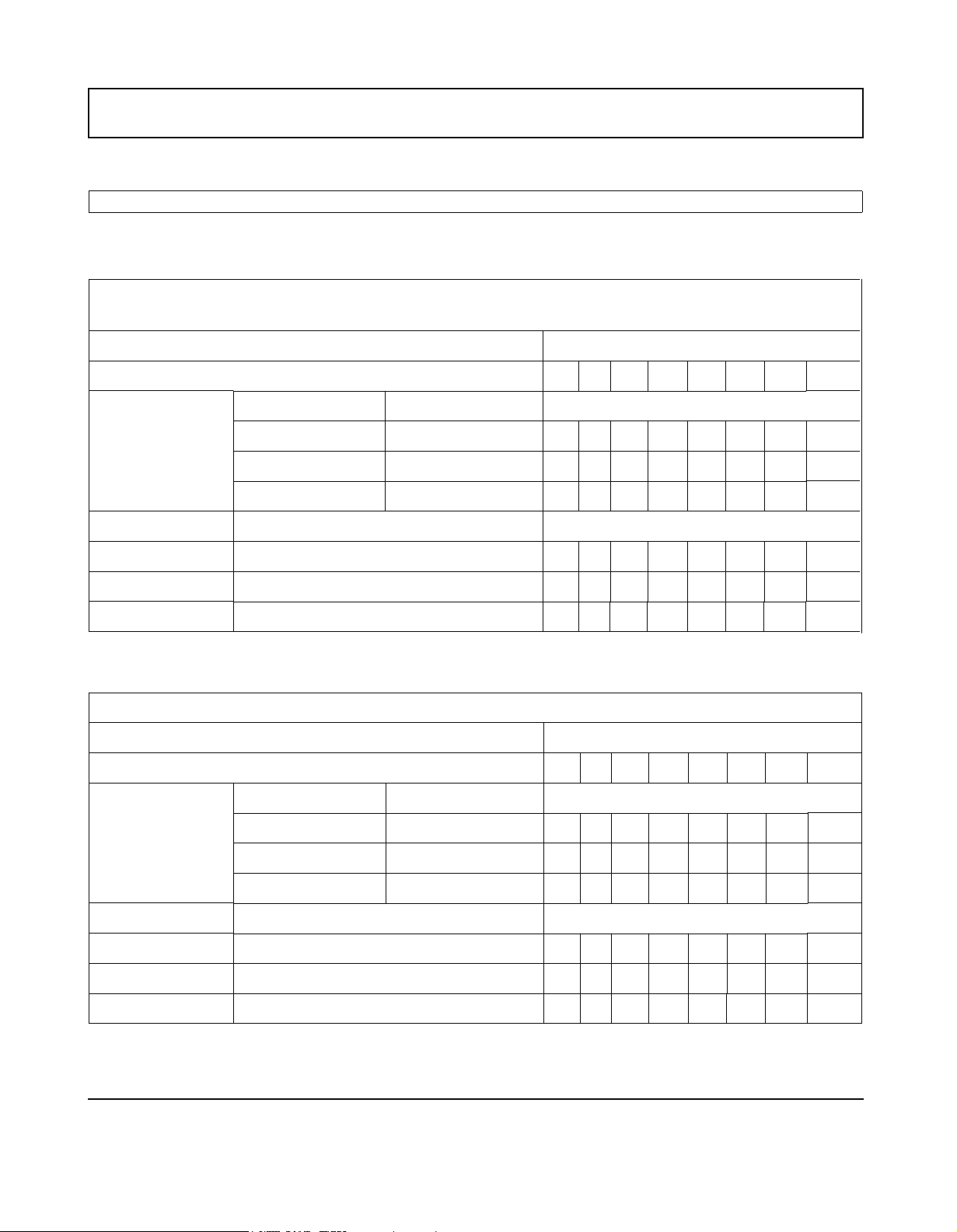

Model: SBN80-180; SBN100-199; SBN100-200; SBD30-199

Input:180,000, 190,000 and 199,000 Btu/hr. Total Vent Height (feet)

001050302510186”6 :eziS rotcennoC tneV

Input Btu/hr Rise Vent Connector Diameter (inches)

180,000 1' 7 7 6 6 6 6 6 6

199,000/200,000 1' 7 7 7 6 6 6 6 6

180,000 2' 6 6 6 6 6 6 6 6

199,000/200,000 2' 7 7 6 6 6 6 6 6

180,000 3' 6 6 6 6 6 6 6 6

199,000/200,000 3' 6 6 6 6 6 6 6 6

No. of Units Combined Input (Btu/hr x 1,000) Combined Vent/Manifold Diameter

2

360,000

7 7 6 6 6 6 6 6

398,000/400,000

7 7 7 6 6 6 6 6

3

540,000

7 6 6 6 6 6 6 6

597,000/600,000

6 6 6 6 6 6 6 6

4

720,000

6 6 6 6 6 6 6 6

796,000/800,000

6 6 6 6 6 6 6 6

VENT TABLES FOR CATEGORY I - TYPE B GAS VENT

Page 16

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT51sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

Model: SBN100-275

latoT.rh/utB 000,572:tupnI Vent Height (feet)

001050302510186”6 :eziS rotcennoC tneV

Input Btu/hr Rise Vent Connector Diameter (inches)

275,000 1' 8 8 7 7 6 6 6 6

275,000 2' 8 8 7 7 6 6 6 6

275,000 3' 7 7 7 7 6 6 6 6

No. of Units Combined Input (Btu/hr x 1,000) Combined Vent/Manifold Diameter

2 550,000 10 9 9 8 8 8 7 7

3 825,000 12 12 12 10 9 9 8 8

4 1,100,000 14 14 14 12 12 10 9 9

VENT TABLES FOR CATEGORY I - TYPE B GAS VENT

Model: SBN100-250

latoT.rh/utB 000,052:tupnI Vent Height (feet)

001050302510186”6 :eziS rotcennoC tneV

Input Btu/hr Rise Vent Connector Diameter (inches)

250,000 1' 8 8 7 7 7 6 6 6

250,000 2' 7 7 7 7 6 6 6 6

250,000 3' 7 7 7 7 6 6 6 6

No. of Units Combined Input (Btu/hr x 1,000) Combined Vent/Manifold Diameter

2 500,000 9 9 9 8 8 7 7 7

3 750,000 12 12 10 10 10 9 8 8

4 1,000,000 14 14 12 12 10 10 9 9

Page 17

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT61sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

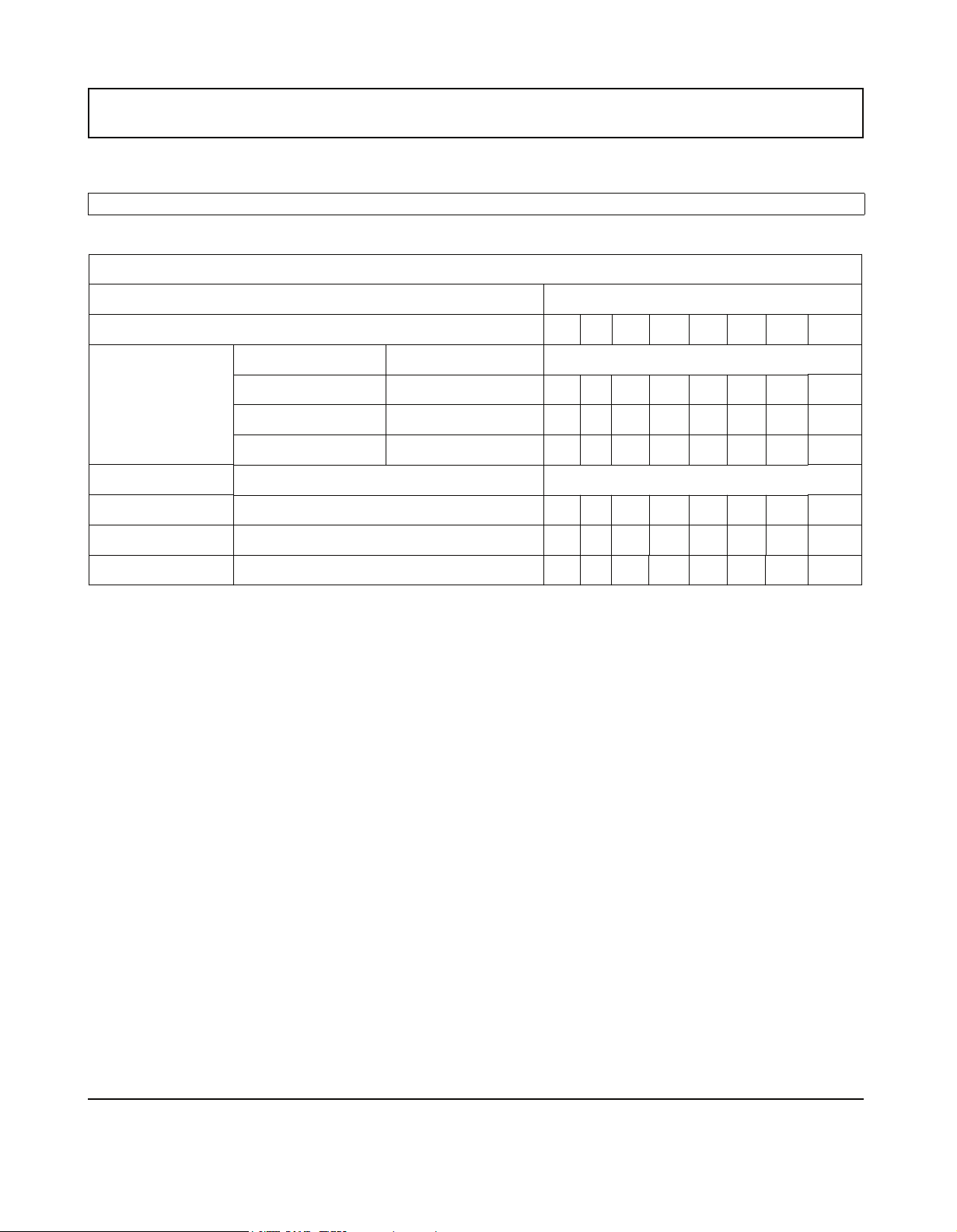

Model: SBN 85-310

latoT.rh/utB 000,013:tupnI Vent Height (feet)

001050302510186”6 :eziS rotcennoC tneV

Input Btu/hr Rise Vent Connector Diameter (inches)

310,000 1' 9 8 8 8 7 7 6 6

310,000 2' 8 8 8 7 7 7 6 6

310,000 3' 8 8 8 7 7 7 6 6

No. of Units Combined Input (Btu/hr x 1,000) Combined Vent/Manifold Diameter

2 620,000 10 10 9 9 8 8 7 7

3 930,000 14 12 12 12 10 9 9 8

4 1,240,000 14 14 14 12 12 12 10 9

VENT TABLES FOR CATEGORY I - TYPE B GAS VENT

Page 18

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT71sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

Model: SBN 85-366NE, SBN 85-390NE

T.rh/utB 000,993/000,663:tupnI otal Vent Height (feet)

001050302510186”6 :eziS rotcennoC tneV

Input Btu/hr Rise Vent Connector Diameter (inches)

366,000

399,000

1'

9 9 9 8 8 8 8 8

10 9 9 9 8 8 8 8

366,000

399,000

2'

9 9 8 8 8 8 8 8

9 9 9 8 8 8 8 8

366,000

399,000

3'

9 8 8 8 8 8 8 8

9 9 8 8 8 8 8 8

No. of Units Combined Input (Btu/hr x 1,000) Combined Vent/Manifold Diameter

2

732,000 12 10 10 9 9 9 8 8

798,000 12 12 10 10 9 9 8 8

3

1,098,000 14 14 14 12 12 10 9 9

1,197,000 14 14 14 12 12 10 10 9

4

1,464,000 16 16 14 14 14 12 12 10

1,596,000 16 16 16 14 14 12 12 10

VENT TABLES FOR CATEGORY I - TYPE B GAS VENT

Page 19

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT81sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

SBN /SBD30-150/199 SEQUENCE OF OPERATION

Sequence

1. Thermistors (probes) call for heat.

2. Inducer fan starts and provides draft.

3. Hot surface igniter = 20 sec. warm-up.

4. Main gas valve opens 4 sec. trial for

ignition. (Maximum 5 trials.)

5. Main burner ignites and proves.

6. Thermostat reaches the temperature

setting.

7. Main burners “OFF” - Auto restart after

60 min. - 20 sec blower

6

1

4

2

1

5 & 7

3

Page 20

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT91sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

COMBINING VENTS (MANIFOLDING

When vents are combined, the area of the

combined vent should be equal to area of

the largest single vent, plus 50% of area of

all others joining.

EXAMPLE: To combine two 6” vents with

an 8” vent, the area of a combined vent

should be one half area of two 6 inch vents

(14 + 14) plus area of 8 inch vent (50)

or 78 sq. inches.

Referring to chart: 78 sq. inches requires

a 10” diameter vent.

Vent Size Area in

Square

Inches

Vent Size Area in

Square

Inches

5" 20 10" 79

6" 28 12" 113

7" 38 14" 154

8" 50 16" 201

9" 64 18" 254

COMBINED VENTING

Maximize height from water heater vent connection to first elbow or tee.

Page 21

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT02sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

1.The vent pipe should ALWAYS be the

same size as the outlet of the draft hood or

factory supplied vent reducer.

Model SBN71-120 is supplied with a

6” to 5” reducer.

2. The diameter of a vent pipe should

NEVER be reduced, no matter what the

circumstances.

3. In some cases it may be necessary to

run a vent larger than the vent connector.

4. Take the maximum vertical rise (x)

possible immediately above the draft hood.

9 RULES FOR GOOD VENTING

VENT

CONNECTOR

VENT PIPE

Page 22

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT12sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

5.Use a 45° elbow in place of a 90° elbow where possible. Avoid the use of a 90° elbow

immediately above the draft hood. Allow the maximum vertical rise before any elbow.

6.Horizontal pipe should be sloped

upward at a minimum of ¼” per foot.

9 RULES FOR GOOD VENTING

HORIZONTAL RUN

VERTICAL RISE

EQUAL TO

1/4” PER FOOT OF

HOROZONTAL

RUN

Page 23

SBN71-120 thru 85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT22sretaeH retaW etatS

7002 © eessenneT ,ytiC dnalhsA

9.Obstructions can cause down drafts. The vent pipe should be extended to meet local

codes.

9 RULES FOR GOOD VENTING

7.Horizontal elements should be limited

to 75% of the vertical rise of the vent above

the connection.

8.Flue gases must be kept hot for proper

venting. Single wall vent exposed to cold air

may not vent properly.

HORIZONTAL

ELEMENTS

LIMITED TO

75% OF

TOTAL

VERTICAL

HEIGHT

VENT RUNS

BEYOND EXTERIOR

WALLS OR INTO

UNHEATED AREAS

SHOULD BE

DOUBLE WALL.

Page 24

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT32sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

DRAFT PROVING PRESSURE SWITCH - SETTINGS

Draft Proving Pressure Switch Table

SBN

Models

SBD

Models

Pressure Setting

To Close Switch

(Inches W.C.)

"01. ± 06.1 )-(663

"01. ± "00.2 )-(572

"01. ± "57,1 )-(013

"01. ± "04.2 )-(002/021

"01. ± "06.2 )-(081/451

30-150/199

NOTE: Pressure Switch Contacts are Normally Open “N.O.” and close on a fall in pressure.

(-) 2.50" ± .10"

Page 25

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT42sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

THERMOSTAT AND IGNITION CONTROL BOARD VIEW

Page 26

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT52sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

WHITE RODGERS INTEGRATED CONTROL - THERMOSTAT

Page 27

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT62sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

WHITE RODGERS IGNITION CONTROL BOARD

Page 28

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT72sretaeH retaW etatS

Ashland City, Tennessee 317927-0007002 ©

GAS CONTROL VALVE / BURNER AREA VIEW

HSI

Part Number 194405

Volts AC Nominal 80 VAC

Ohms Resistance 11.0 - 20.0 @ 77° F (25°

C)

NOTICE FLAME ROD CROSSES PATH OF

FLAME .1 - .25”

SBN's

Page 29

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT82sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

WIRING DIAGRAM

Page 30

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT92sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

ELECTRICAL SEQUENCE – SBN, SBD30-150/199

1. Switch Power on to unit.

2. Thermostat calls for heat.

3. Ignition Control Board performs diagnostic check on system components.

4. On completion of diagnostics check, the Ignition Control Board sends signal to

Exhaust Inducer.

5. Exhaust Inducer begins drawing air through appliance closing the Prover Switch.

6. On completion of Prover Switch engagement, the Ignition Control Board begins

the ignition cycle.

7. The Ignition Control Board provides power to the Silicon Nitride Ignitor.

8. The Silicon Nitride Ignitor heats up for approximately 17 to 20 seconds.

9. At the end of Silicon Nitride Ignitor’s warm-up, the Ignition Control Board opens

the Gas Valve.

10. From the time the Gas Valve opens, the Ignition Control Board waits 3 seconds

and then shuts off power to the Silicon Nitride Ignitor.

11. From the time the Silicon Nitride

Ignitor’s power is shut off, the Ignition Control

Board waits 3 more seconds to monitor the Flame Sensor.

12. If the Flame Sensor does not detect a strong enough flame, the Ignition Control

Board shuts off the Gas Valve and allows the Exhaust Inducer to purge the

unit for 20 seconds. At that time, the Ignition Control Board restarts with step

7. It will try and ignite the main burners 2 more times. If the unit does not light,

the Ignition Control Board will wait one hour and then re-start at step 3. This

cycle will continue until the unit lights or the power is shutoff to the unit.

13. If the Flame Sensor detects a strong flame, the Ignition ControlBoard will allow

the unit to operate until the thermostat is satisfied.

14. Once the unit is satisfied, the Ignition Control Board will shut off the Gas Valve

and the unit will be in standby mode until another call for heat is initiated by

the thermostat.

.

Page 31

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT03sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

OPERATING SEQUENCE – FLOW CHART

Page 32

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT13sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

DIAGNOSTIC SEQUENCE OF OPERATION – FLOW CHART

Page 33

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT23sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

PRE-SERVICE CHECK LIST

Use the following checklist BEFORE you begin servicing the water heater.

1. Have you removed the cover from the controls?

____________________________________________________

Did you take notice of the status lights on the upper water

heater control?

____________________________________________________

Did you take notice of the red LED in the upper left corner of

the lower ignition control?

____________________________________________________

2.Did you note conditions of the room?

____________________________________________________

Where does the supply air come from?

____________________________________________________

Is the room clean?

____________________________________________________

What is stored with the heater?

____________________________________________________

How is the heater vented?

____________________________________________________

Are all water and gas shut-off valves open?

____________________________________________________

Are there room exhaust or air intake fans?

____________________________________________________

3. Did you note the condition of the heater?

____________________________________________________

Is the ON/OFF switch “On”?

____________________________________________________

What is the temperature of the stored water? (Test at T&P valve or nearby faucet.)

____________________________________________________

Is the thermal expansion tank installed?

____________________________________________________

4. Did you write down the complete model and serial number of the water heater? If so,

what are they? ____________________________________________________

5. Does the heater have a good ground wire connection? If not, the inducer will typically

come on for a short time (3-5 seconds), then go off, and the re

d LED will flash 8

times.

Page 34

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT33sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

WATER HEATER CONTROL BOARD TROUBLESHOOTING AND DIAGNOSTIC LED

INTERPRETATION

TEST 1 – 120VAC POWER CHECK

● No Green display “Power” LED on.

● Plugs are in receptacles.

● Supply power breaker is not “open”

● On/Off heater switch is “On”.

White Rodgers

Integrated Control

TEST 1

120 V. AC check to water heater ON/OFF switch

Check for 115-125 V. AC black wire to ground\

115 V. AC check to E13 Terminal and 2B receptacle.

............nehT.........FI

voltage is not present from on/off switch center

black wire to ground

Check conditions above

Check wiring from switch to break box

Power is present from center on/off terminal Check power from on/off switch to ignition board terminal

E13

Voltage is not present at E13 to ground check wiring from on/off. Left-outside terminal to E13.

Replace on/off switch.

Power is present elcatpecer 2E lortnoc retaeh retaw ot 41E morf rewop kcehC31E ta

Voltage is not present from water heater control receptacle

E2 black

to ground

Check wiring from ignition control board E14 to water heater

control receptacle E2.

Replace ignition control board.

.no eb dluohs DEL neerG.2E ta tneserp si rewoP

Page 35

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT43sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

WATER HEATER CONTROL BOARD TROUBLESHOOTING AND DIAGNOSTIC LED

INTERPRETATION

Conditions:

● Power On

● Red, heater control “Call for Heat” LED – on

● Red, ignition control board diagnostic LED – Flashing

● Note LED Flash Code before resetting heater.

noitacidnIsutatS DEL

1 Flash System is in lock out.

2 Flashes Draft proving (pressure) switch failed to open within 5 seconds at the end of the last

cycle.

3 Flashes Draft proving (pressure) switch failed to close ( -2.1 inches of water column pressure)

within 5 seconds after the inducer was started. The low gas pressure switch )closes

at 5.2" ± .04" w. c.) may have remained open (Nat Gas only.)

4 Flashes Open on high temperature limit switch (ECO).

5 Flashes Not Used

6 Flashes 115-volt supply power connection is indicating reversed polarity.

7 Flashes Flam

e sensor reads a low flame signal for more than 4.25 sec.

8 Flashes No ignition sensed.

Continuous Flash Continuous flame sensed for more than 5 seconds without gas valve being energized.

Continuous ON Internal control board failure.

*Control system self adjusts to use a minimum voltage for ignition. Lower voltage results in lower IGNITOR

temperature which results in longer IGNITOR life. IGNITOR voltage may vary from Nominal 80 VAC.

Page 36

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT53sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

TEST 2 – POLARITY CHECK

Conditions:

● No hot water

● Green “Power” LED is on.

● Tank is more than 5° F below

temperature dial setting.

● Red ignition control board diagnostic

LED is flashing 6 times between

pauses.

● Red, diagnostic “Call for Heat” LED-

OFF.

TEST 2

Polarity Check

Check from on/off switch center and white wire terminals to ground

115-125 VAC is not present see Test 1.

Voltage is present white (right terminal) to ground but not

black (center terminal) to ground

reverse supply wire connections - polarity is

reversed.

Page 37

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT63sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

TEST 3 - CONTINUITY CHECK OF HIGH LIMIT (ECO)

Conditions:

● Power On – No Hot Water

● Red, heater control “Call for Heat”

LED – on

● Red ignition control board

diagnostic LED – 4 Flashing

● Note LED Flash Code before

resetting water heater control.

● See Description of diagnostic LED

Flashes.

● Turn Power “Off”

0.0

Ohms

TEST 3

Continuity check of ECO (energy cut-off, high limit)

Black to Black wires of upper probe. Power is off.

.....neht …fI

continuity is indicated (ZERO “0.0” Resistance) opens at 203° F; closes at 193° F. If water is

below 193° F, continuity is correct.

continuity is not present (meter reads “0.L”) replace ECO sensor, if water temperature is

below 193° F.

.no eb dluohs DEL sutats teser•F °021 naht ssel si retaw

•replace heater control if control will not manually

reset.

Page 38

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT73sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

TEST 4 - UPPER TEMPERATURE PROBE CONTINUITY CHECK

Conditions:

● Power On - Water below temperature

set point.

● Red, water heater control “Reset

Status” LED-OFF

● Call For Heat” LED off.

Ohms Resistance Table

° F Ohms

70° 11,884

120° 3,759

140° 2,488

180° 1,169

TEST 4

Upper Temperature probe continuity check

Red wire to red wire - Turn supply power "Off" for this test

.....neht…fI

Test indicates no continuity Replace probe.

Continuity smhO yfirev osla( yako eb dluohs eborPdetacidni si

resistance for water temperature). (Reading will

be approximate.)

Page 39

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT83sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

TEST 5 - CALLING FOR HEAT – NO INDUCER OPERATION

Conditions:

● Power on

● Plugs in Receptacles

● Red “ Call for Heat” LED-ON

● Inducer “Off”

Note flash code on ignition control board

diagnostic LED

Water Heater Control - Thermostat

“call for heat”

LED Indicator

“diagnostic LED

indicator”

120

........neht…fI

Pin 1 to ground check has no voltage •reset control by interrupting power - note

possible reasons for this from flashing LED code

•replace ignition board

Pin 1 to ground egatlov sah Proceed

Pin 3 to ground egatlov on sah •check wiring harness and plugs •replace inducer

Page 40

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT93sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

TEST 6 - INDUCER ON.............NO IGNITION

Conditions:

● Power on

● Plugs in receptacles

● Inducer operating

● No power to Hot Surface IGNITOR

(HSI) Note LED flash code

TEST 6

24 VAC Check of Blower Prover/Low Gas Pressure Circuit

........neht…fI

ignition board receptacles E1, Pin 7 to ground shows no voltage replace Ignition board

E1, Pin 7 has 24 Volt recudni morf dna ot noitcennoc eriw kcehcdnuorg ot

voltage check of each blower switch terminal to ground shows

voltage to only 1 terminal

Switch is open - check for proper draft (should also see LED 3 flash

code)...Check for blocked exhaust.... Check that blower outlet exhaust

damper is open....Replace blower (draft) proving switch

Natural Gas ONLY!

24V is present from each switch terminal to ground Check wiring from blower switch to low gas pressure switch

Voltage c

heck to each terminal of low gas pressure switch and

ground shows only voltage on 1terminal

Switch is open - test for a minimum of 5.2 ± " W.C. Natural Gas or

10.5" Propane, flowing supply gas pressure (should also see 3 Flash

LED code)..............Replace low gas pressure switch

Voltage is present to each pressure switch terminal and ground Check wiring from low gas pressure switch to ignition board

receptacles E1, Pin 10

INDUCER EXHAUST/

VENT CONNECTION

DRAFT PROVING

PRESSURE

SWITCH

LOW GAS

PRESSURE

SWITCH

INDUCER

MOTOR

Page 41

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT04sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

TEST 7 – INDUCER ON, PROVER SWITCH AND LOW GAS PRESSURE SWITCH

CLOSED ....................NO IGNITOR OPERATION

Conditions:

● Power on

● Plugs in receptacles

● Inducer on

● 24V at ignition board E1, Pin

10

● No Power to IGNITOR

Note:LED Flash code

TEST 7

Voltage check and continuity check of hot surface IGNITOR

circuit

Continuity check - Power off- Plug removed from E4 receptacles.

Nominal 80 VAC check - Plug in E4- Power "On".

If.......

then.......

Continuity is not indicated between E4plug pin 2 to 4. Check wiring and connection from E4 plug to HSI receiving

plug...................Replace HSI Assembly

Continuity is present Resistance should be between 11 and 20 Ohms at a

temperature of 77°F

Voltage is not present between E4, Pin 2 to ground Replace ignition board

Voltage Ctneserp si ontinue

Voltage is not present between E4, Pin 4 to ground Check wiring and plug connections to HSI.........Replace HSI

Voltage is present Note ignition board, Flash code LED...

..........HSI should work

CHECK E1PIN 10 TO

GROUND – 24 V.

CONTINUITY TEST E4

PLUG

CHECK E4 PIN 4 TO GROUND

Page 42

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT14sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

TEST 8 – IGNITOR HEATS .............. NO MAIN BURNER

TEST 8 IGNITOR HEATS......NO MAIN BURNER

........neht.......fI

short heat up time of IGNITOR

Check control box grounding.

Normal (Approximate 20 seconds) warm up - no ignition Check for 24V from E1, Pin 12 to ground during 4 second trial.

........Yes - Continue................No - Replace Ignition Board

No voltage present E4, Pin 12 to ground Replace ignition board

24 Volt was present from E1, Pin 12 to ground, but no

main burner

Check that air has been purged from gas circuit........check that

wiring and connections to gas valve and E1, Pin 9 are correct

.........check fo

r 24 VAC at E1, Pin 9 to ground during 4 second

trial for ignition.

24 V.

E1 PLUG TO

PIN 9

E1 PLUG TO

PIN 12

Page 43

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT24sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

TEST 9 – IGNITOR HEATS .......NO MAIN BURNER

Conditions:

● Test 8 completed then:

● Turn off power

● Disconnect wires from gas valve

TEST 9 IGNITOR HEATS – NO MAIN BURNER

.....neht…fI

Meter reads 0 or 1

Check meter scale setting to read between 550 and 650 Ohms

R

eplace Gas Valve

Meter indicates pilot and main coil have

continuity

Valve should be okay....still no gas to main burner, then coil

may be stuck .........Replace Gas Valve

Page 44

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT34sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

TEST 10 - MAIN BURNER IGNITION FOR LESS THAN 5 SECONDS

Conditions:

● Power On – plug connected

● Main Burner ignites for approximately 5

seconds then goes out.

● Tests 8 and 9 completed

● Note flash code on ignition board LED.

TEST 10

MAIN BURNER IGNITION FOR LESS THAN 5 SECONDS

.........neht.......fI

No extended gulp ylbmessa ISH fo snoitcennoc gulp dna gniriw kcehCnoitingi renrub niam

and ignition board receptacles E1, Pin 2.......Check that HSI

assembly is not cracked or dirty......Check that flame prover

will be in main flame ......................Replace HSI assembly

Still no extended draob lortnoc noitingi ecalpeRnoitingi renrub niam

E1, Pin 2 - From Flame Proving Rod

Hot Surface IGNITOR

(Illustration of low NOx burner)

Page 45

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT44sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

TEST 11 - WATER HEATER SHUTTING OFF BELOW SETTING

Conditions:

● Main burner ignited

● Stored water is below temperature setting more than 5° F (Tank

Average).

● Power off

● Plug disconnected from heater control board receptacle E3 and E4

TEST 11

WATER TEMPERATURE CIRCUIT CHECK - CONTINUITY

.....neht …fI

continuity check pin to pin of lower

temperature probe shows 1 or 0 (E4)

See Test 4

Check wiring and plug connections to heater

control board receptacle E4

Replace lower temperature probe

continuity check red wire pin to red wire pin

on upper temperature sensor shows 1 or 0 (E3)

see Test 4

Check wiring and plug connections to heater

control board receptacle

Replace upper temperature probe

.lortnoc retaeh retaw eht ecalpeR yako era skcehc evoba llA

Page 46

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT54sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

DISPLAY LIGHTS ON INTEGRATED WATER HEATER CONTROL

Page 47

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT64sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

PARTS SBN71-120 thru 85-390 series 100

Page 48

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT74sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

PARTS SBN71-120 thru 85-390 series 100

Page 49

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT84sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

PARTS SBN71-120 thru 85-390 series 100

Page 50

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT94sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

PARTS SBN71-120 thru 85-390 series 108

Page 51

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT05sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

PARTS SBN71-120 thru 85-390 series 108

Page 52

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT15sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

PARTS SBN71-120 thru 85-390 series 108

Page 53

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT25sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

PARTS SBD30-150/199NE

Page 54

SBN71-120 thru SBN85-390, SBD30-150/199 TANK TYPE COMMERCIAL

GAS WATER HEATER SERVICE HANDBOOK

tnemtrapeD gniniarT lacinhceT35sretaeH retaW etatS

Ashland City, Tennessee 7002 ©

PARTS SBD30-150/199NE

Page 55

COMMERCIAL

Prepared by the State Water Heaters Training Department.

For additional technical information call 800-365-0577.

©Copyright 2007 State Industries, Inc.

State Water Heaters

500 Tennessee Waltz Parkway

Ashland City, TN 37015

800-365-8170

www.statewaterheaters.com

Loading...

Loading...