Page 1

Rooftop Water Heater Model SRT80 1 20NE

COMMERCIAL GAS W A TER HEA TER

GAS-FIRED POWER BURNER

FOR DOMESTIC HOT W A TER

• INST ALLA TION • OPERA TION • SERVICE • MAINTENANCE • LIMITED W ARRANTY

Thank you for buying this energy efficient water heater from

State Industries. We appreciate your confidence in our

products.

W ARNING: If the information in these

instructions is not followed exactly , a fire

or explosion may result causing property

damage, personal injury or death.

– Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions.

• If you cannot reach your gas supplier,

call the fire department.

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY. PLEASE

READ THOROUGHL Y BEFORE INST ALLING AND USING

THIS APPLIANCE.

– Installation and service must be

performed by a qualified installer,

service agency or the gas supplier .

PLACE THESE INSTRUCTIONS ADJACENT TO HEA TER AND

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PRINTED IN U.S.A. 1005 PART NO. 1 97242-000

1

500 Tennessee Waltz Parkway

Ashland City, TN 37015

www.statewaterheaters.com

SUPERSEDES PART NO. 196758-000

Page 2

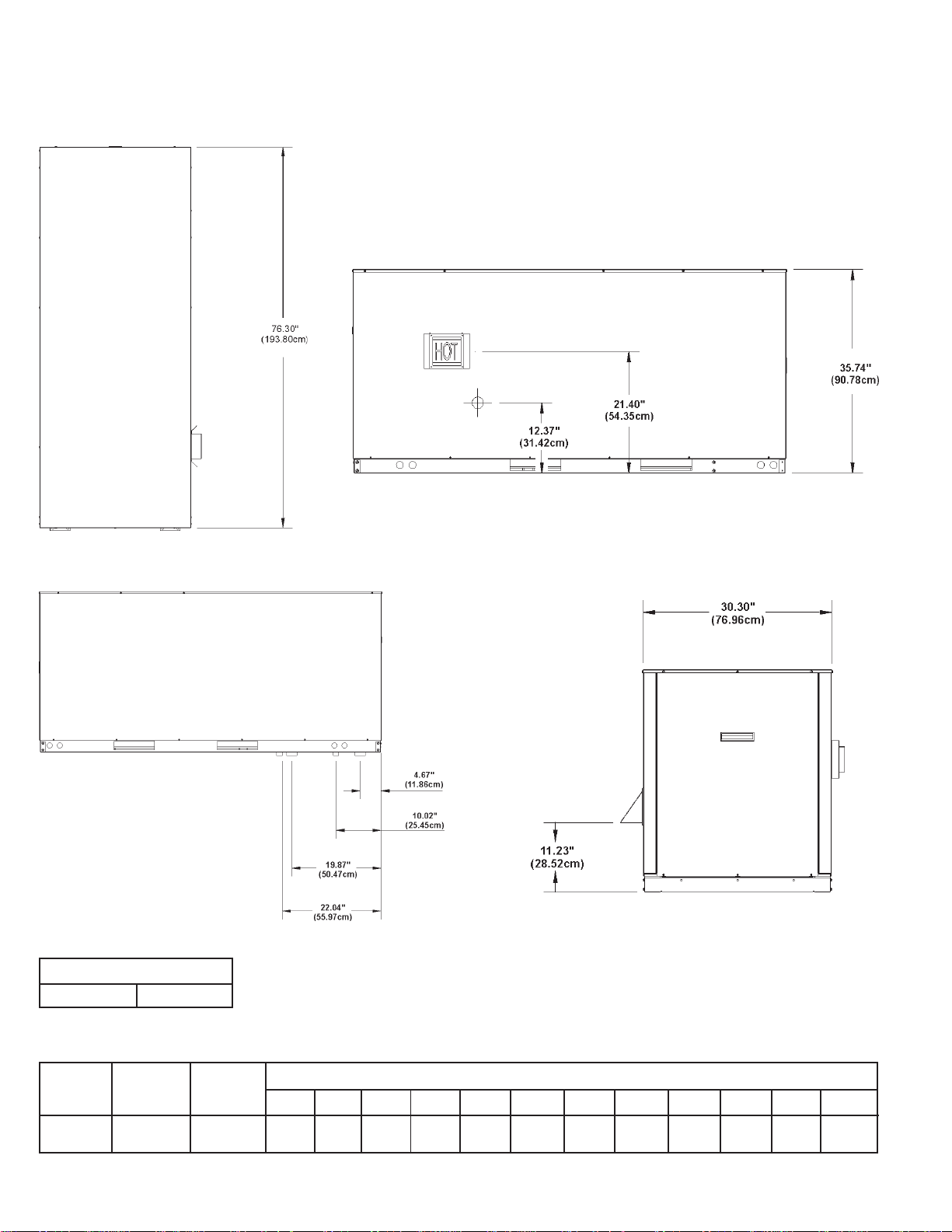

TOP VIEW

ROOFTOP SRT80-120NE

ROUGH-IN-DIMENSIONS

RIGHT SIDE VIEW

LEFT SIDE VIEW

GAS VAL VE PIPING

SRT80-120 1/2" NPT

FRONT VIEW

T able 1. RECOVERY CAP ACITIES - NA TURAL GAS / L.P.

BTU Gallon

Model Input Capacity 30 40 50 60 70 80 90 100 110 120 130 140

SRT80-120

Recovery capacities are based on heater performance at 80% thermal efficiency .

120,000 80 388 291 233 194 166 145 129 116 106 97 90 83

35.17 kwh 303L (1469) (1102) (882) (734) (628) (549) (488) (439) (401) (367) (341) (314)

Approx.

TEMPERATURE RISE - DEGREES °F - GALLONS PER HOUR (LPH)

2

Page 3

INST ALLA TION INFORMA TION

OUTBACK

Installation Information

Model: SRT 80-1 20NE series Input: 120,000 btuh

Electrical: 120/24V AC/60 Hz/5 A Side Clearances: 0"

Maximum Inlet Pressure: 14"WC T op Clearances: 1.50"

Manifold Pressure: 4.50"WC Unit is Polarity Sensitive

Minimum Inlet Pressure: 6.2"WC No external venting required

Warnings

Dummy hot return required if hot return from appliance is not used*

Avoid flex gas line usage

Avoid use of forklift truck to mount unit on outdoor stand

Provide enough clearance to service unit

Available Kits

Anti-freeze kit

Remote Interface kit

3

Page 4

FOREWORD

This design complies with the current edition of ANSI Z21.10.3 as

an automatic circulating tank type water heater and automatic

storage water heater.

Detailed installation diagrams are found in this manual. These

diagrams will serve to provide the installer with a reference for the

materials and methods of piping necessary. It is highly essential

that all water, gas piping and wiring be installed as shown on the

diagrams.

Particular attention should be given to the installation of

thermometers at the locations indicated on the diagrams as these

are necessary for checking the proper functioning of the heater.

TABLE OF CONTENTS

PAGE PAGE

ROUGH-IN DIMENSIONS .................................................................... 2

INST ALLATION INFORMA TION........................................................... 3

FOREWORD ....................................................................................... 4

FEATURES ......................................................................................... 5

Water Temperature Control........................................................... 5

High Limit Switch (E.C.O.) ............................................................. 6

Dishwashing Machine Requirement ............................................. 5

Circulating Pump............................................................................ 6

PLUMBING MANIFOLD ASSEMBL Y ................................................... 6

Flow Diagram ................................................................................ 5

Automatic Air Bleed Valve ............................................................ 5

Hot Return Recirculation Pump ..................................................... 7

Drain Valve.................................................................................... 7

AIR SYSTEM ASSEMBL Y .................................................................. 7

Blower Assembly.......................................................................... 7

Blower Plenum .............................................................................. 7

Air Hose ........................................................................................ 8

Flue Adapter.................................................................................. 8

Exhaust Vent ................................................................................. 8

CONTROL SYSTEM ........................................................................... 8

Blocked Outlet Switch .................................................................. 8

Blocked Inlet/Prover Switch .......................................................... 8

Low Gas Pressure Switch ........................................................... 9

On/Off Switch ............................................................................... 9

Hot Surface Igniter ........................................................................ 9

OIM - Outdoor Interface Module ................................................... 9

WR Ignition Control Board ............................................................. 9

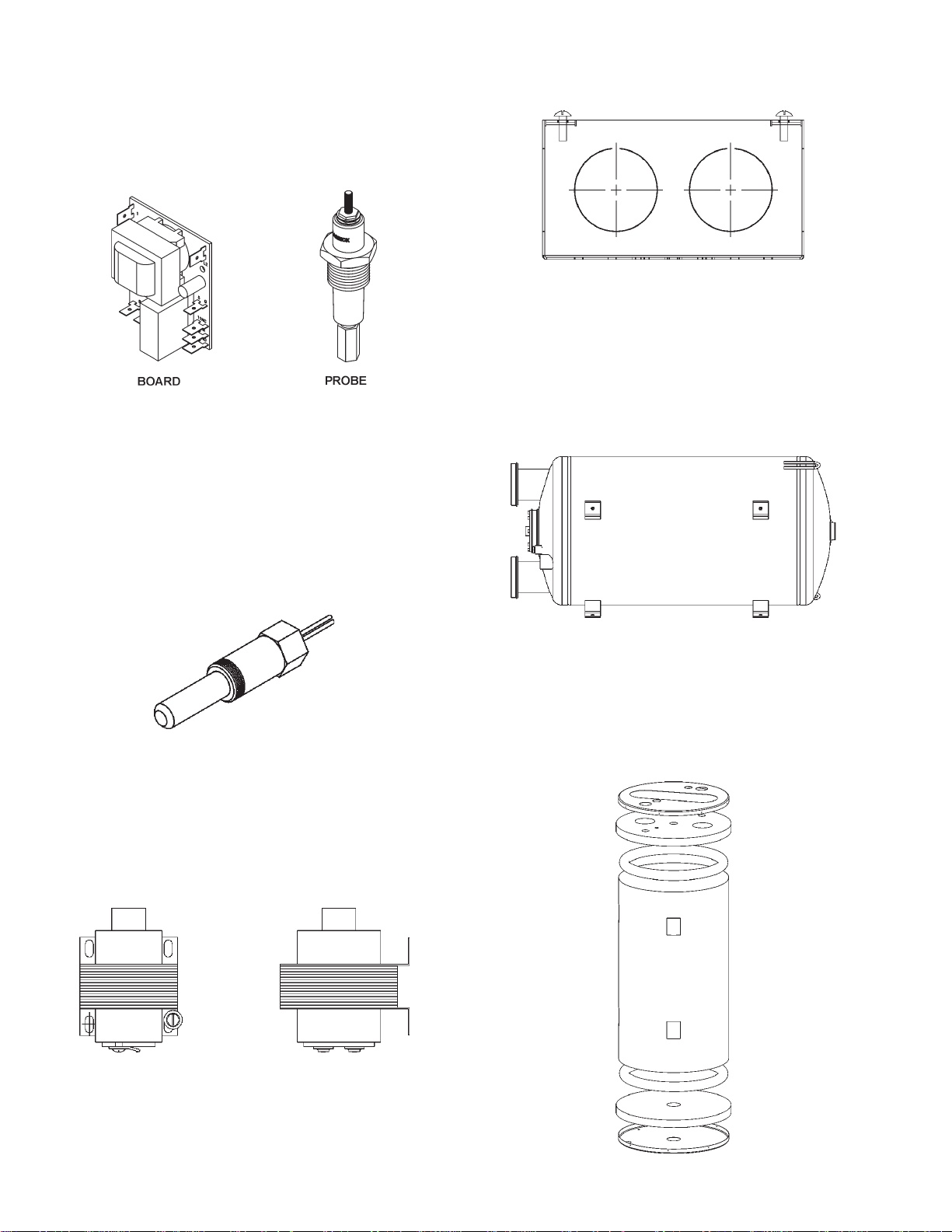

Low Water Cutoff Board and Probe ............................................ 10

Thermostat/E.C.O. Probes ............................................................ 10

Transformer .................................................................................. 10

Junction Box ................................................................................. 10

TANK ASSEMBLY SYSTEM .............................................................. 10

T ank Insulation............................................................................... 10

CABINET ASSEMBLY......................................................................... 11

Cabinet Panels .............................................................................. 11

ADDITIONAL CONTROLS .................................................................. 11

Gas Valve ...................................................................................... 11

Flame Sensor ................................................................................ 11

INSTALLA TION INSTRUCTIONS ......................................................... 11

Required Ability ............................................................................. 11

Insulation Blankets ........................................................................ 11

Locating The Heater...................................................................... 11-12

Provide Unit Support ..................................................................... 12

Roof Curb ...................................................................................... 12-13

Rig and Place Unit ......................................................................... 13

Outdoor Stand ............................................................................... 14

Clearances .................................................................................... 14

Hard Water .................................................................................... 14

Air Requirements .......................................................................... 14

In addition to these instructions, the equipment shall be

installed in accordance with all local codes. The authority

having jurisdiction should be consulted before installing.

In the absence of local codes, the installation must comply

with the current editions of the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 and the National Electric Code, NFPA 70.

The former is available from the Canadian Standards

Association, 8501 East Pleasant Valley Road, Cleveland, OH

44131, and both documents are available from the National

Fire Protection Association, 1 Batterymarch Park, Quincy, MA

02269.

Chemical Vapor Corrosion ............................................................ 14

VENTING ............................................................................................ 15

Vent Terminals ............................................................................... 15

Pressure Switches ....................................................................... 15

Gas Piping ..................................................................................... 15-16

Connection of Gas Pipe ................................................................ 16

Purging .......................................................................................... 16

Gas Meter Size - City Gases Only ............................................... 16

Gas Pressure Regulation.............................................................. 16

Gas Valves .................................................................................... 17

SYSTEM CONNECTIONS ................................................................... 17

Thermometers ............................................................................... 17

Relief Valve ................................................................................... 17

Water Line Connections ............................................................... 17

Closed System .............................................................................. 17

Water (Potable) Heating and Space Heating ................................ 17

Water Heater Wiring...................................................................... 17-18

OPERATION........................................................................................ 19-20

Sequence of Operation ................................................................ 21

Error Codes ................................................................................... 21

Fault Conditions............................................................................. 21-22

PRIOR TO ST ART-UP ......................................................................... 22

Required Ability ............................................................................. 22

OPERATING INSTRUCTIONS.............................................................. 23

Adjustment Procedure (Initial Start-Up) ........................................ 23-24

Cathodic Protection....................................................................... 24

Precautions ................................................................................... 24

Lighting & Operating Label............................................................ 25

GENERAL INFORMA TION .................................................................. 26

Power Burner ............................................................................... 26

High Limit ....................................................................................... 26

High Altitude Installations .............................................................. 26

MAINTENANCE .................................................................................. 26

General.......................................................................................... 26

Maintenance Schedule ................................................................. 26

Flushing ......................................................................................... 26

Draining ......................................................................................... 26

Sediment Removal......................................................................... 26

Lime Scale Removal ...................................................................... 26-27

Anode Inspection and Replacement............................................. 27

Drain Valve and Access Panels ................................................... 27

Relief Valve ................................................................................... 27

Circulating Pump............................................................................ 27

Vent System .................................................................................. 27

INSTALLA TION DIAGRAMS ............................................................... 28-32

CHECKLIST AND SERVICE INFORMATION ........................................ 33

TROUBLE-SHOOTING........................................................................ 33-34

REPLACEMENT PARTS ...................................................................... 34

LIMITED WARRANTY......................................................................... 35

4

Page 5

FEATURES

IMPORT ANT

IT IS REQUIRED THAT A QUALIFIED SERVICE TECHNICIAN

PERFORM THE INITIAL FIRING OF THE HEATER.

A CHECKLIST AND SER VICE INFORMATION section are included

at the rear of this manual. By using this checklist the user may be

able to make minor operational adjustments and save himself

unnecessary service calls. However, the user should not attempt

repairs which are not listed in this section.

WA TER TEMPERA TURE CONTROL

DANGER

THIS WATER HEATER IS EQUIPPED WITH AN ADJUSTABLE

THERMOSTAT TO CONTROL WATER TEMPERATURE. HOT

WATER TEMPERATURES REQUIRED FOR AUTOMATIC

DISHWASHER AND LAUNDRY USE CAN CAUSE SCALD BURNS

RESULTING IN SERIOUS PERSONAL INJURY AND/OR DEATH.

THE TEMPERATURE A T WHICH INJURY OCCURS V ARIES WITH

THE PERSON’S AGE AND TIME OF EXPOSURE. THE SLOWER

RESPONSE TIME OF CHILDREN, THE ELDERLY OR DISABLED

PERSONS INCREASES THE HAZARDS TO THEM. NEVER ALLOW

SMALL CHILDREN TO USE A HOT WATER TAP, OR TO DRAW

THEIR OWN BATH W A TER. NEVER LEAV E A CHILD OR DISABLED

PERSON UNATTENDED IN A BA THTUB OR SHOWER.

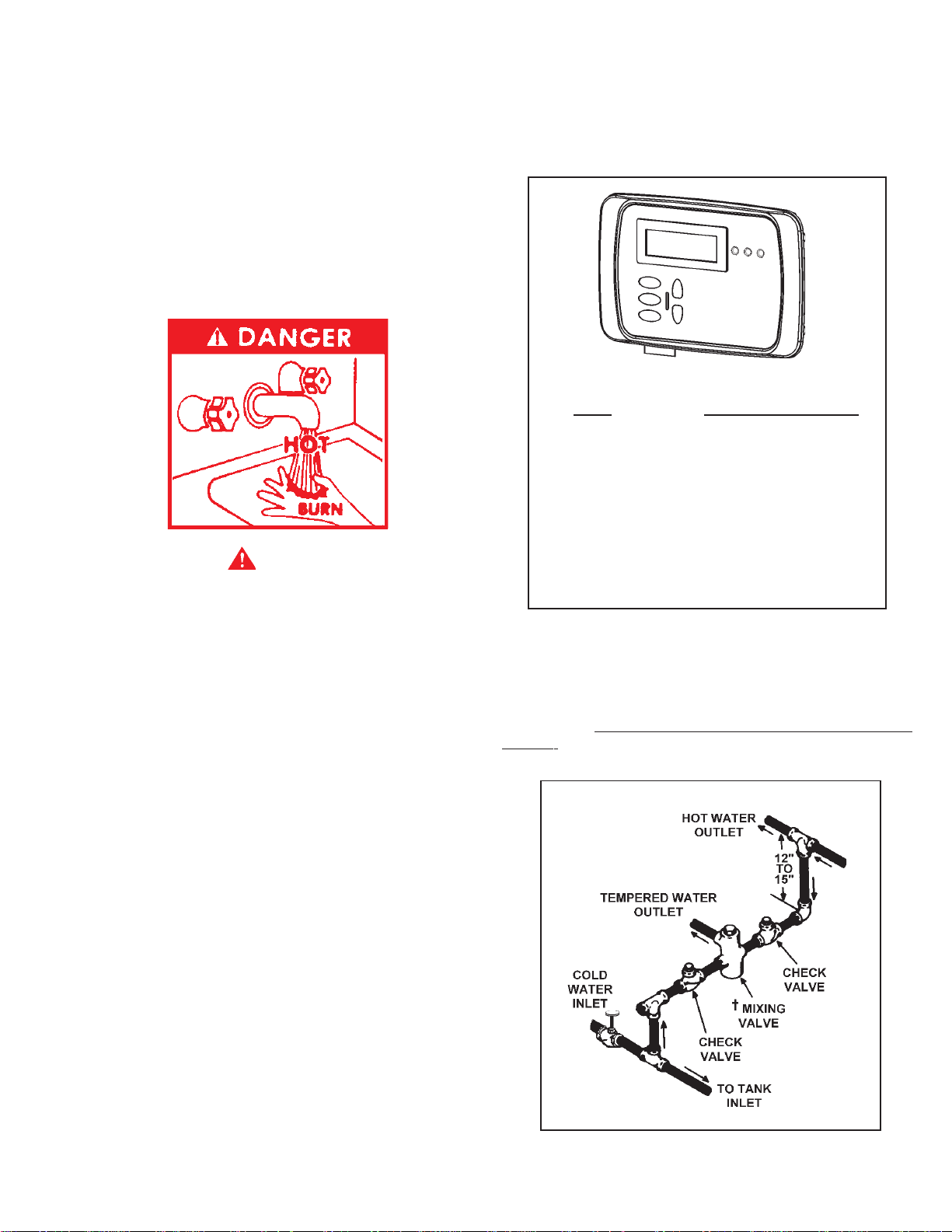

Figure 1 shows the approximate time-to-burn relationship for

normal adult skin. Short repeated heating cycles caused by small

hot water uses can cause temperatures at the point of use to

exceed the thermostat setting by up to 20°F/-1 1°C. If you experience

this type of use, you should consider using lower temperature

settings to reduce scald hazards.

Temperature Time to Produce 2nd & 3rd

Setting Degree Burns on Adult Skin

180°F / 82°C Nearly instantaneous

170°F / 77°C Nearly instantaneous

160°F / 71°C About 1/2 second

150°F / 66°C About 1-1/2 seconds

140°F / 60°C Less than 5 seconds

130°F / 54°C About 30 seconds

120°F / 49°C More than 5 minutes

FIGURE 1

Valves for reducing point-of-use temperature by mixing cold and

hot water are available (see Figure 2). Also available are

inexpensive devices that attach to faucets to limit hot water

temperatures. Contact a licensed plumber or the local plumbing

authority.

THE WA TER HEA TER SHOULD BE LOCA TED IN AN AREA WHERE

THE GENERAL PUBLIC DOES NOT HAVE ACCESS TO SET

TEMPERATURES.

The water temperature is controlled using the Touch Pad Buttons

on the Display at the front of the unit (See Figure 1). This control

utilizes two temperature probes to determine the tank temperature.

The upper temperature probe is located on top of the unit in the

back and the lower probe is located on the front center axis of the

tank.

The temperature may be adjusted from 70°F/21°C to 180°F/82°C.

The thermostat was adjusted to 70°F/21°C before the heater was

shipped from the factory. It is recommended that lower water

temperatures be used to avoid the risk of scalding. It is further

recommended, in all cases, that the water temperature be set for

the lowest temperature which satisfies your hot water needs. This

will also provide the most energy efficient operation of the water

heater and minimize scale formation.

SETTING THE WATER HEATER TEMPERATURE AT 120°F/49°C

WILL REDUCE THE RISK OF SCALDS. Some states require

settings at specific lower temperatures.

FIGURE 2

5

Page 6

HIGH LIMIT SWITCH (E.C.O.)

The top immersion well of the upper probe also contains the high

limit (energy cutoff) sensor. The high limit switch interrupts the

main burner gas flow should the water temperature reach

approximately 199°F/93°C.

Should the high limit switch activate, it must be reset by cycling

power to the unit. The water temperature must drop below 180°F/

82°C before the controller can be reset.

Continued manual resetting of the high limit control, preceded

by higher than usual water temperature is evidence of high

limit switch operation. For example, a malfunction of the control

system allowing the gas valve to stay open could cause water

temperature to rise until the high limit switch opens. Contact

your dealer or servicer if continued high limit switch operation

occurs.

DISHWASHING MACHINE REQUIREMENT

All dishwashing machines meeting the National Sanitation

Foundation requirements are designed to operate with water

flow pressures between 15 and 25 pounds per square inch

(103 kPa and 173 kPa). Flow pressures above 25 pounds per

square inch (173 kPa), or below 15 pounds per square inch

(103 kPa), will result in improperly sanitized dishes. Where

pressures are high, a water pressure reducing or flow

regulating control valve should be used in the 180°F (82°C)

line to the dishwashing machine, and should be adjusted to

deliver water between these limits.

The National Sanitation Foundation also recommends circulation

of 180°F (82°C) water. Where this is done, the circulation should

be very gentle so that it does not cause any unnecessary

turbulence inside the water heater. The circulation should be

just enough to provide 180°F (82°C) water at the point of takeoff to the dishwashing machine. Adjust flow by means of the

plug cock in the circulating line. (See INSTALLATION DIAGRAMS

section.)

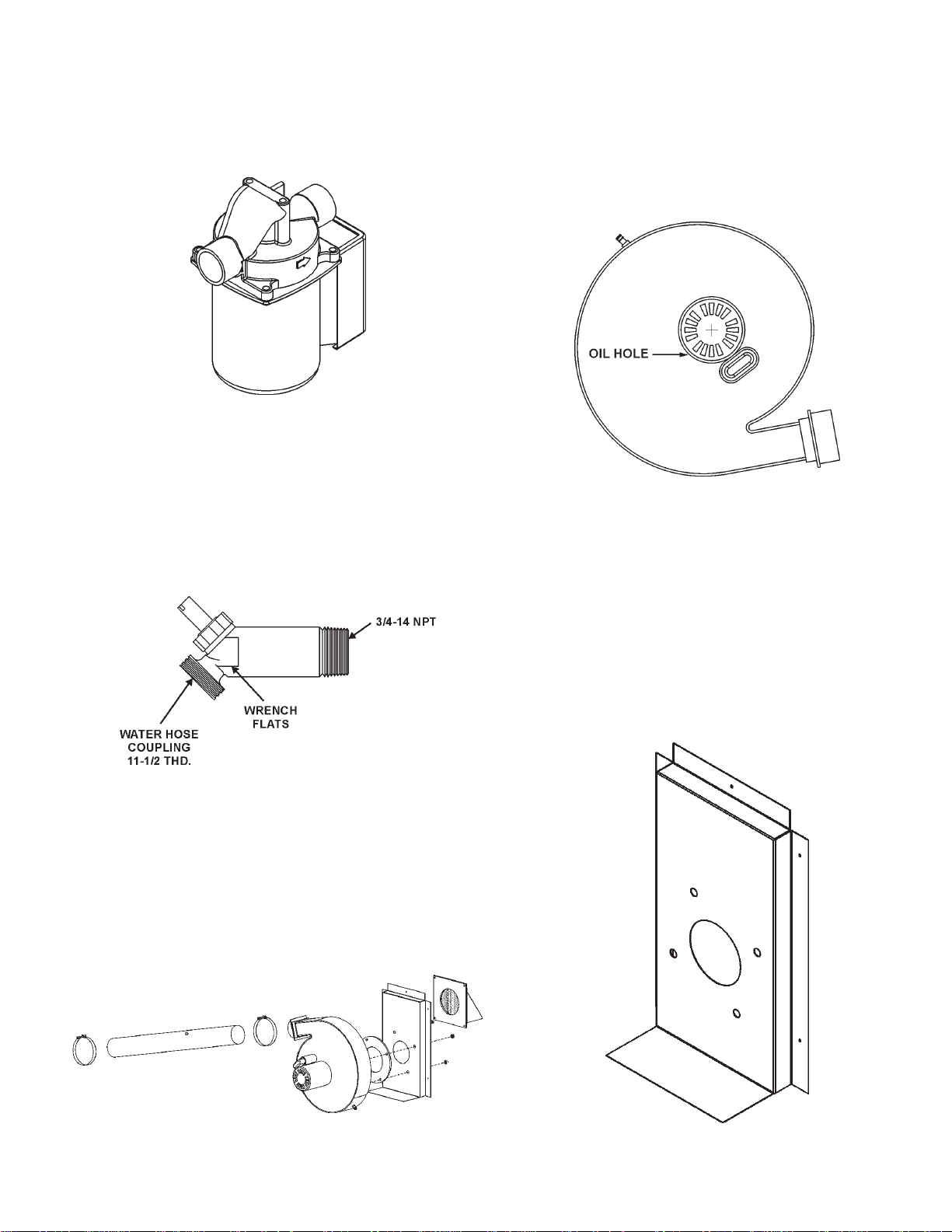

CIRCULATING PUMP

A circulating pump is used when a system requires a circulating

loop or there is a storage tank used in conjunction with the heater.

Refer to the piping diagrams at rear of manual for electrical hookup

information and install in accordance with the current version of

the National Electric Code NFPA No. 70.

All bronze circulators are recommended for use with commercial

water heaters.

Although circulators are oiled and operated by the manufacturer

some circulators must be oiled again before being operated.

Please refer to manufacturer's instructions.

PLUMBING MANIFOLD ASSEMBLY

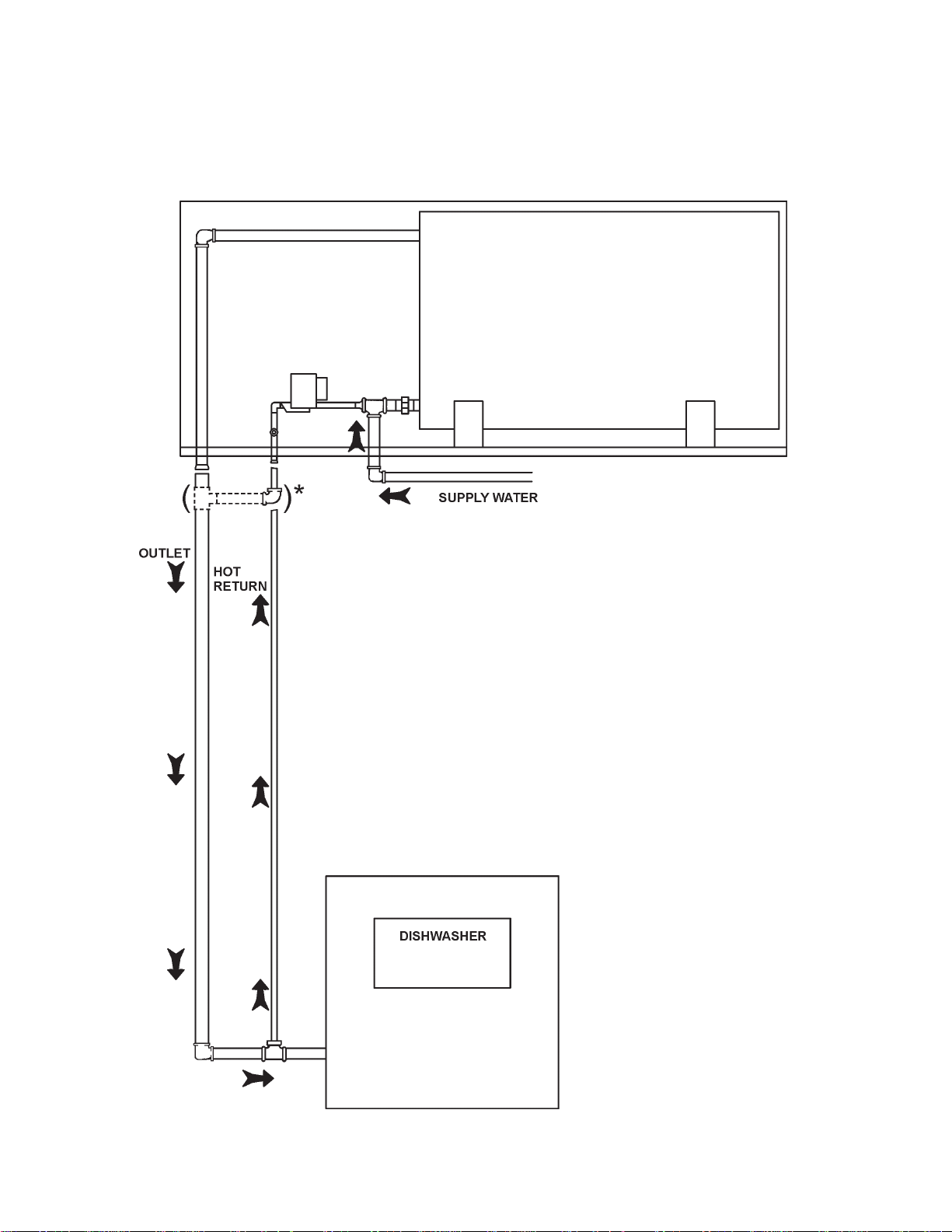

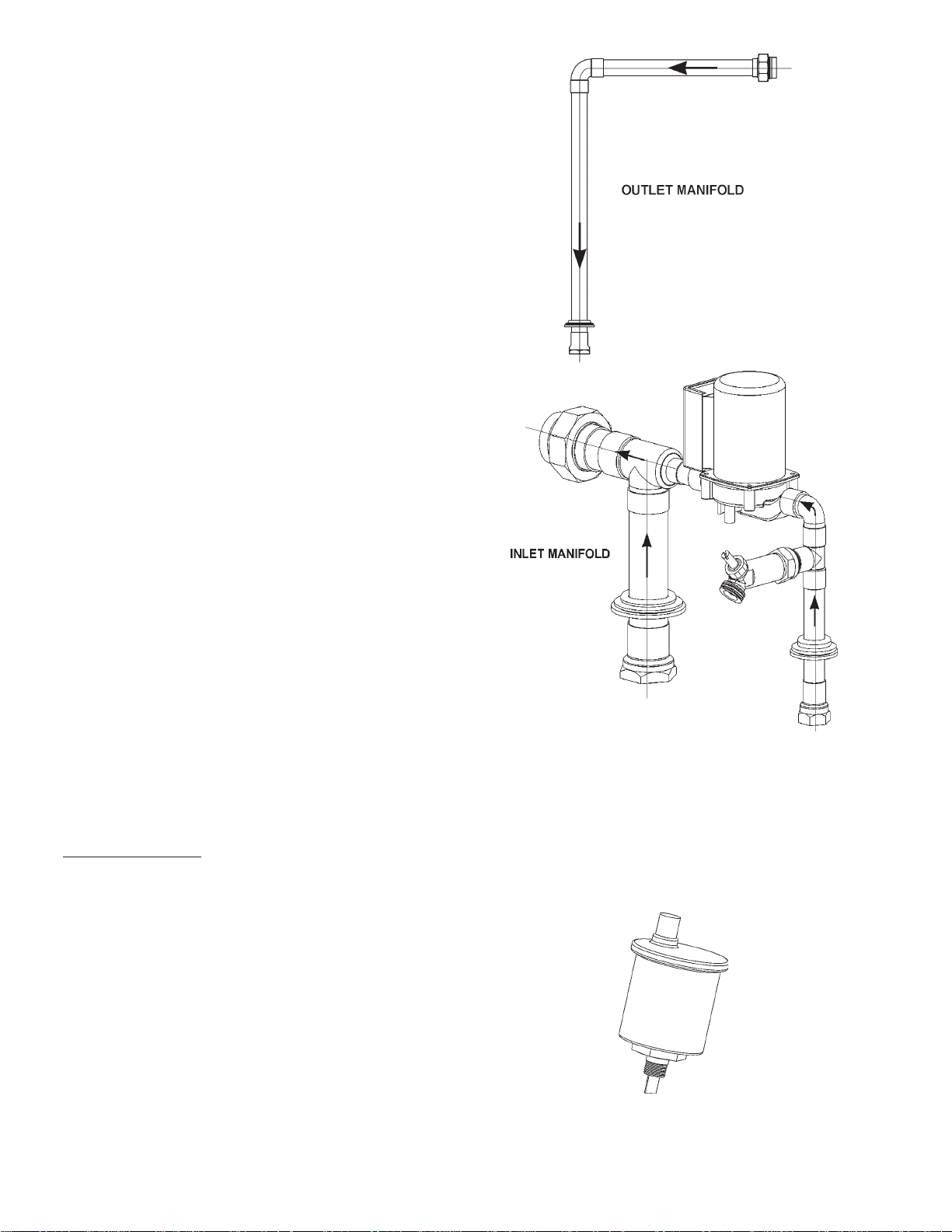

FLOW DIAGRAM

FIGURE 3

AUTOMA TIC AIR BLEED V AL VE

The tank assembly utilizes an automatic air bleed valve. The

purpose for this automatic air bleed valve is to allow air to escape

the tank when the unit is filled with water. When the unit is drained,

the opposite occurs with the valve allowing air to replace the drained

water. It removes the pressure vacuum that occurs in the system

causing incomplete drainage. This valve is automatic which allows

it to sense when the tank assembly is filled with water, see

Figure 4.

The plumbing manifold assembly is composed of several

components with each having a unique function. Please see

Figures 3, 5, and 6 to observe the water flow to the plumbing

manifold assembly and the components that make it up.

FIGURE 4

6

Page 7

HOT RETURN RECIRCULA TION PUMP

BLOWER ASSEMBLY

The hot return recirculation pump circulates the hot water through

the hot water line to eliminate delays at plumbing fixtures, see

Figure 5.

FIGURE 5

DRAIN V ALVE

The drain valve is used to drain the water from the tank assembly

and plumbing manifold assembly, see Figure 6.

The blower assembly functions by pulling in air from outside the

unit to supply to the burner assembly for proper combustion. The

blower pushes the air through the burner assembly and heat

exchanger where the flue gases then exit the exhaust system

assembly, see Figure 8.

FIGURE 8

BLOWER PLENUM

FIGURE 6

AIR SYSTEM ASSEMBLY

The air system assembly is comprised of the blower assembly,

blower plenum, air hose, and inlet vent terminal. This is where

combustion air is acquired for combustion, see Figure 7.

The blower plenum is used to draw air into the blower inlet. The

inlet of the air system must maintain enough height from the ground

to take into account yearly snow levels to prevent possible inlet

vent blockage. The air plenum allows the blower to pull air into the

unit from a higher inlet location to provide protection required, see

Figure 9.

FIGURE 7

FIGURE 9

7

Page 8

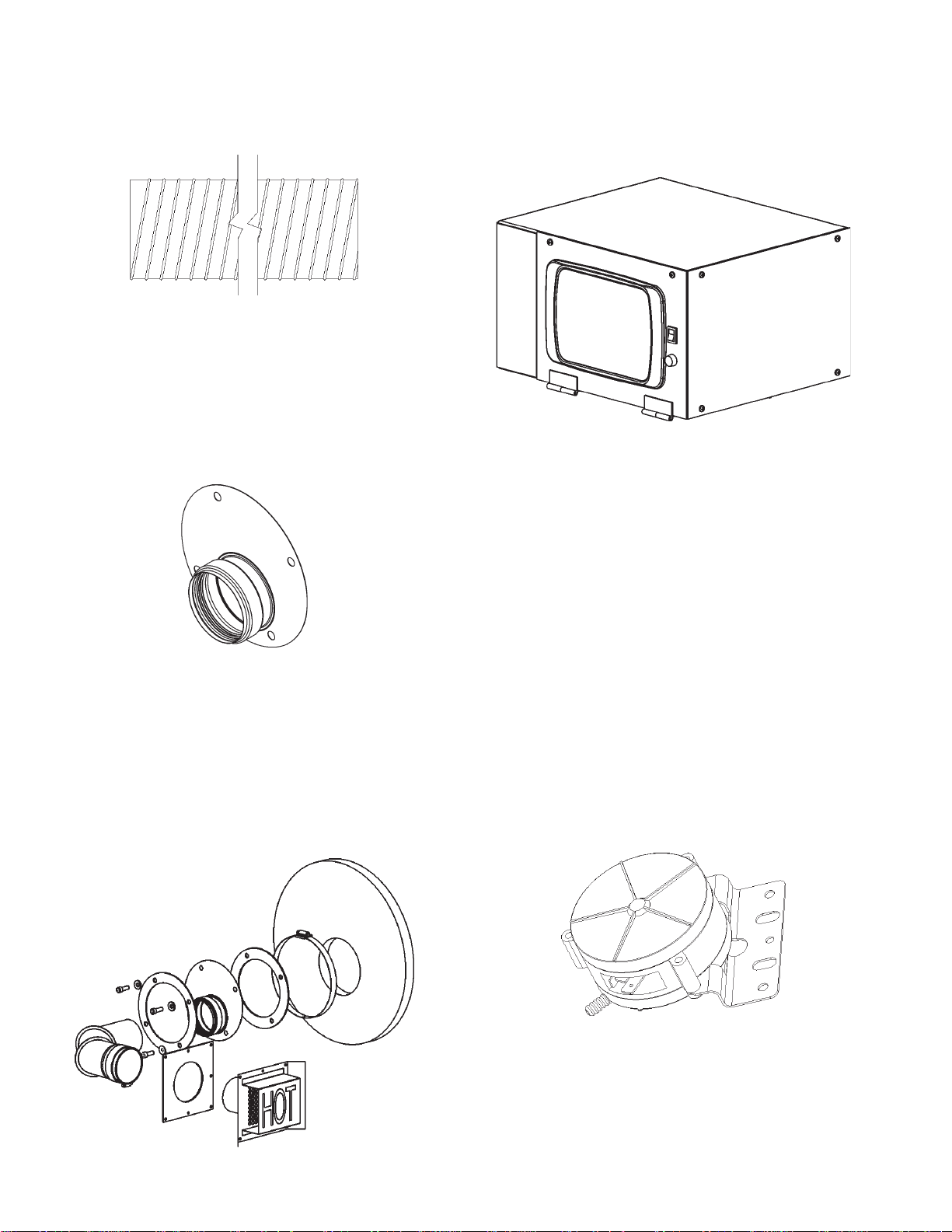

AIR HOSE

CONTROL SYSTEM

The air hose is used to provide a flexible air path from the blower

to the burner assembly. It is held in place with two standard hose

clamps, see Figure 10.

FIGURE 10

FLUE ADAPTER

The flue adapter is made of a flat metal plate with an exhaust

adapter to mate with the exhaust elbow. This is where the flue

gases exit the heat exchanger. This is a very hot region and is

covered with a layer of high temperature fiberglass insulation, see

Figure 11.

The control system is comprised of an Outdoor Interface Module

that monitors the functions of the WR ignition system, pressure

switches, low water cutoff and temperatures in the tank.

FIGURE 13

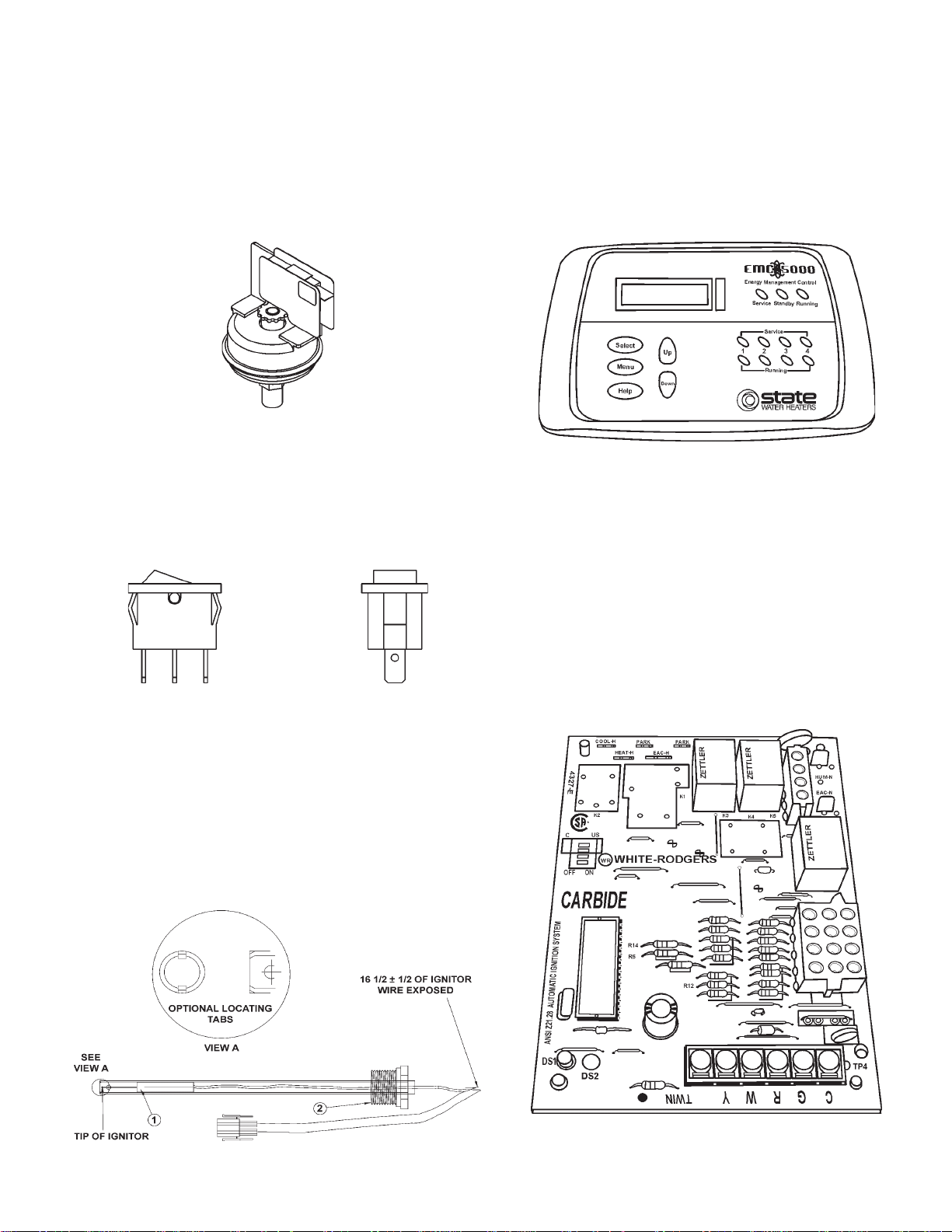

BLOCKED OUTLET SWITCH

The Blocked Outlet Switch is set up to shut the unit off when a

pressure buildup in the exhaust vent pipe occurs. This switch is a

positive pressure switch that requires an increase in pressure to

change the electrical contacts from normally closed to open. When

this switch prevents the unit from igniting, most likely the exhaust

is blocked. Check for obstructions in the exhaust venting and

exhaust vent terminal, see Figure 14.

FIGURE 11

EXHAUST VENT

The exhaust vent elbow mates with the flue adapter. The elbow

mates with the exhaust terminal to dispose the flue gases to the

outdoors. This venting section is covered with a fiberglass

insulated wrap to protect from heat and condensation. These

pipes are sealed with a high temperature gasket integral to the

vent pipe fittings, see Figure 12.

FIGURE 12

BLOCKED INLET/PROVER SWITCH

The Blocked Inlet/Prover Switch is set up to shut the unit off when

a reduction in pressure in the intake vent occurs. This switch is a

negative pressure switch that requires an increase in negative

pressure to change the electrical contacts from normally open to

closed. The switch is connected to the pressure tap connected to

the housing of the blower. When this switch prevents the unit from

ignition, most likely the intake is blocked. Check for obstructions in

the inlet vent terminal, see Figure 14.

FIGURE 14

The blocked Inlet/Prover Switch has a second function. It is provided

on the heater to verify that the fan is operating. When the fan

increases in negative pressure, the electrical contacts close

signaling that the blower is operational and is at peak performance.

The controller requires that the electrical contacts on the switch

close before it will allow the blower to come on.

8

Page 9

LOW GAS PRESSURE SWITCH

OIM - OUTDOOR INTERFACE MODULE

The Low Gas Pressure Switch is a single pole, normally open

pressure switch that will close its contacts when a rising pressure

of 6.2 inches (1.53 kPa) w.c. is encountered. The contacts will

open when the pressure falls below the fixed set point of 6.2 inches

of w.c. The Low Gas Pressure Switch monitors the gas supply

pressure to the heater. If the gas supply falls below the 6.2 inches

of w.c., the main burner is extinguished (if heater is running) or the

heater will not start up, see Figure 15.

FIGURE 15

ON/OFF SWITCH

The ON/OFF Switch is a single pole, single throw rocker switch.

This switch provides 120V from the electrical source to the heater,

see Figure 16.

The OIM is a device that monitors the control system. It monitors

the ignition control assembly, the tank and outlet temperatures,

the low water cutoff device, and the pressure switches. The display

board provides operating information. It records and logs error

messages for diagnostics. The module is equipped with a touch

pad for easy access to observe menus and current status of

control, see Figure 18.

FIGURE 18

WR IGNITION CONTROL BOARD

The WR Ignition Control Board performs the ignition sequence for

the water heater. It controls the diagnostics of the system and

monitors all the pressure switches, the flame sensing device, the

thermostats, the E.C.O., and components that make up the control

system. The difference between the WR Ignition Control Board is

that the OIM board monitors all the controls and provides that

information through the LCD display where the WR Ignition Control

Board provides the means to control the complete sequence of

operation and switches, see Figure 19.

FIGURE 16

HOT SURFACE IGNITER

The Hot Surface Igniter is a device that ignites the main burner by

high temperature (1800°F). When the 120 VAC is applied to the

igniter, sufficient heat is generated to ignite the main burner.

Although improvements have been made to strengthen the igniter,

it is still fragile and care must be taken when handling the igniter to

prevent breakage, see Figure 17.

FIGURE 17

FIGURE 19

9

Page 10

LOW WA TER CUT OFF BOARD AND PROBE

The Low Water Cutoff Board and Probe monitors the water level to

confirm the tank is completely full. This function is very important

when the unit is first filled with water and when complete loss of

power is encountered during freezing temperatures (in case the

unit drains while using the anti-freeze kit), see Figure 20.

FIGURE 20

THERMOST A T/E.C.O. PROBES

The Outback utilizes a two probe system. The upper probe located

on top of the unit toward the back of the cabinet consists of a

thermostat and E.C.O. The thermostat monitors the top temperature

in the tank. The E.C.O. high limit switch interrupts the main burner

gas flow should the water temperature reach approximately 205°F.

The lower probe measures the water temperature in the lower half

of the tank assembly.

grounding screw to tie into the metal panel to assure the unit is

grounded, see Figure 23.

FIGURE 23

TANK ASSEMBLY SYSTEM

The Tank Assembly is an 80 gallon unit with a U-shaped heat

exchanger. It incorporates two inlet tubes to control flow inside the

tank. The heat exchanger is equipped with a stainless steel baffle

which is non-removable. The working pressure is 150 psi, see

Figure 24.

FIGURE 21

TRANSFORMER

The control system utilizes a 120/24 VAC step down transformer.

Most of the control system utilizes 24 VAC for operation. See wiring

diagram for those components utilizing 24 VAC and 120 VAC, see

Figure 22.

FIGURE 22

FIGURE 24

TANK INSULA TION

The tank assembly is wrapped in foam insulation sealed inside a

round jacket. The ends of the tank consist of high temperature

fiberglass insulation and foam dams to prevent foam leakage,

see Figure 25.

JUNCTION BOX

The junction box is where the 120 VAC is supplied to the unit and

tied into the rest of the controls. The junction box provides a

FIGURE 25

10

Page 11

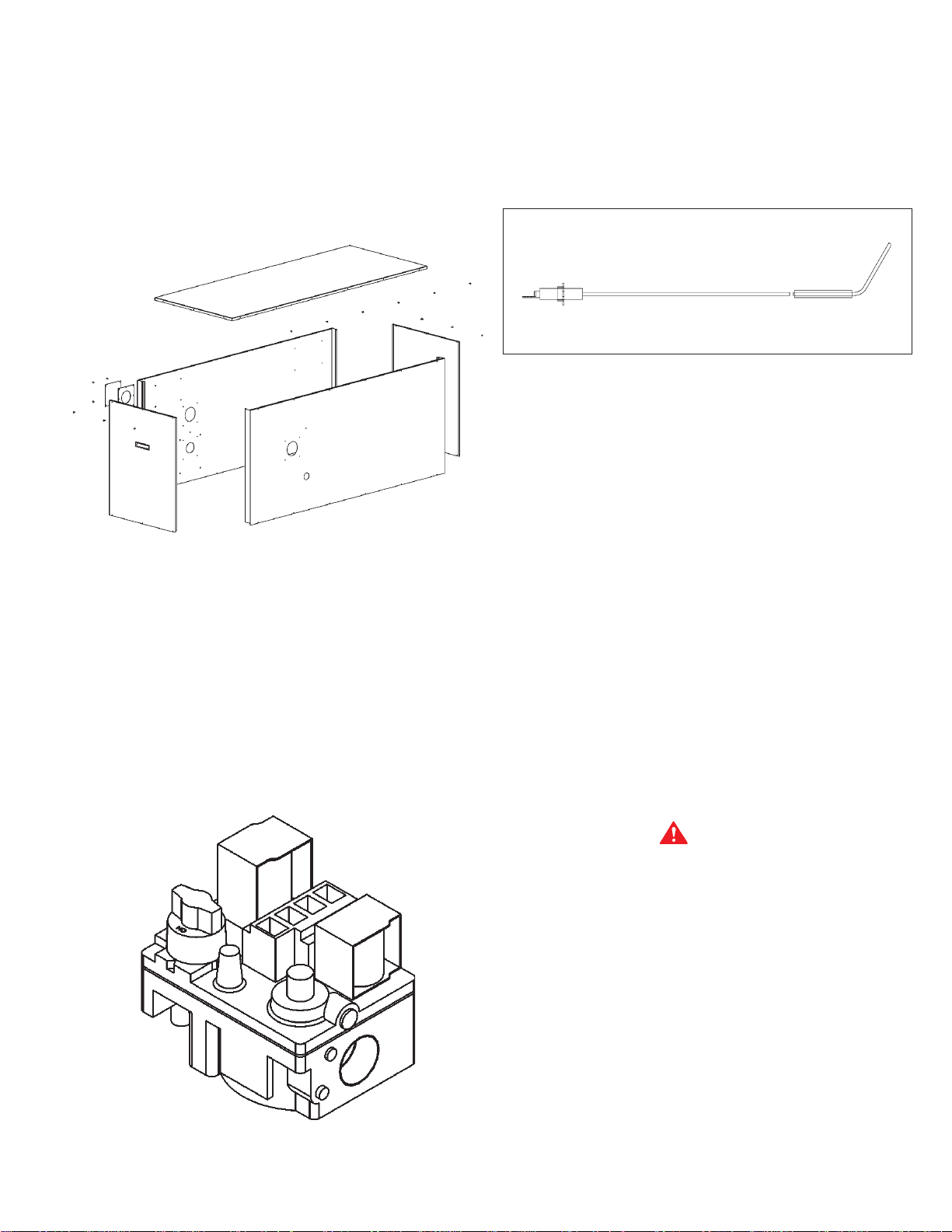

CABINET ASSEMBLY

FLAME SENSOR

CABINET P ANELS

There are five panels that comprise the cabinet assembly. The

ends of the cabinet allow access to all controls and plumbing.

Please confirm all joints are attached correctly and sealed to

prevent water leakage inside the cabinet, see Figure 26.

FIGURE 26

The flame sensor is used to sense the burner flame. When there

is sufficient flame, and the burner is properly grounded, the flame

sensor signals back to the ignition board that the burner is operating

properly and to maintain the operation of the gas valve until the

thermostat is satisfied.

FIGURE 28

INSTALLATION INSTRUCTIONS

REQUIRED ABILITY

INSTALLA TION OR SERVICE OF THIS WA TER HEATER REQUIRES

ABILITY EQUIV ALENT TO THAT OF A LICENSED TRADESMAN IN

THE FIELD INVOL VED. PLUMBING , AIR SUPPL Y , VENTING, GAS

SUPPL Y AND ELECTRICAL WORK ARE REQUIRED.

INSULA TION BLANKETS

ADDITIONAL CONTROLS

GAS V AL VE

The gas valve is used to supply the gas to the unit during heat up

periods. The ignition control board monitors the thermostat's call

for heat and sends a signal to the gas valve when to open to allow

gas flow, see Figure 27.

Insulation blankets available to the general public for external use

on gas water heaters are not approved for use on your State

water heater. The purpose of an insulation blanket is to reduce the

standby heat loss encountered with storage tank water heaters.

Yo ur State water heater meets or exceeds the ASHRAE/IES 90.1 b

1999 standards with respect to insulation and standby loss

requirements, making an insulation blanket unnecessary.

LOCA TING THE HEATER

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES SUCH

AS GAS WATER HEATERS IN ROOMS, GARAGES OR OTHER

AREAS WHERE GASOLINE, OTHER FLAMMABLE LIQUIDS OR

ENGINE DRIVEN EQUIPMENT OR VEHICLES ARE STORED,

OPERATED OR REP AIRED. FLAMMABLE V APORS ARE HEA VY AND

TRAVEL ALONG THE FLOOR AND MAY BE IGNITED BY THE

HEA TER’S IGNITER OR MAIN BURNER FLAMES CAUSING FIRE

OR EXPLOSION. SOME LOCAL CODES PERMIT OPERA TION OF

GAS APPLIANCES IF INSTALLED 18 INCHES (46 cm) OR MORE

ABOVE THE FLOOR. THIS MAY REDUCE THE RISK IF LOCATION

IN SUCH AN AREA CANNOT BE AVOIDED.

THE HEATER SHALL BE LOCATED OR PROTECTED SO IT IS

NOT SUBJECT TO PHYSICAL DAMAGE BY A MOVING VEHICLE.

FIGURE 27

DO NOT LOCATE THE HEATER WHERE NOISE FROM THE

EXHAUST OR INTAKE WILL BE OBJECTIONABLE. THIS

INCLUDES LOCATIONS CLOSE T O OR ACROSS FROM WINDOWS

AND DOORS.

11

Page 12

FIGURE 29

WARNING

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY

OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST NEVER

BE PLACED ON OR ADJACENT TO THE HEATER. OPEN

CONTAINERS OF FLAMMABLE MATERIAL SHOULD NOT BE

STORED OR USED IN THE SAME ROOM WITH THE HEA TER.

Water heater life depends upon water quality, water pressure and

the environment in which the water heater is installed. Water

heaters are sometimes installed in locations where leakage may

result in property damage, even with the use of a drain pan piped

to a drain. However, unanticipated damage can be reduced or

prevented by a leak detector or water shutoff device used in

conjunction with a piped drain pan. These devices are available

from some plumbing supply wholesalers and retailers, and detect

and react to leakage in various ways:

• Sensors mounted in the drain pan that trigger an alarm or turn

off the incoming water to the water heater when leakage is

detected.

• Sensors mounted in the drain pan that turn off the water supply

to the entire home when water is detected in the drain pan.

• Water supply shutoff devices that activate based on the water

pressure differential between the cold water and hot water

pipes connected to the water heater.

• Devices that will turn off the gas supply to a gas water heater

while at the same time shutting off its water supply.

PROVIDE UNIT SUPPORT

the unit full of water. (Full weight of approximately 1300 lbs. Add

extra load and safety factors.) This is very important and the user's

responsibility, see Figure 29. If you are uncertain as to the load

bearing capability of the roof, consult a licensed structural

engineering expert.

The unit should be placed on a solid level roof curb of adequate

strength. A properly designed roof curb is provided through

State Order Entry.

IMPORTANT: THE W ATER HEA TER SHOULD BE EMPTY OF WA TER

DURING LIFTING . MAKE SURE ALL F ASTENERS ON THE BASE OF

THE UNIT ARE IN PLACE DURING LIFTING .

The location of the unit on the roof should be such that exhaust

gas is not located near any air intakes or ventilation ducts.

Provide a minimum of 36" on each side of the unit for servicing.

Plumbing connections for water are made from inside the building.

Gas and electric connections are made from the rooftop. Remote

control wiring passes through the leak-tight fitting in the base of

the unit.

ROOF CURB

Assemble and install accessory roof curb in accordance with

instructions shipped with curb.

IMPORT ANT : THE GASKETING OF THE UNIT TO THE ROOF CURB

IS CRITICAL FOR A WATER TIGHT SEAL. INSTALL GASKET

SUPPLIED WITH THE ROOF CURB AS SHOWN IN FIGURE 30.

Before locating the unit on the roof, make sure the strength of the

roof and beams are adequate at that point to support the weight of

Curb should be level. Refer to Accessory Roof Curb Installation

Instructions for additional information as required.

12

Page 13

FIGURE 30

RIG AND PLACE UNIT

Inspect unit for transportation damage. File any claim with

transportation agency . Keep unit upright and do not drop. Spreader

bars are not required if top crating is left on unit. Rollers may be

used to move unit across the roof. Level the unit by using unit

frame.

Lifting holes are provided in base rails as shown in Figure 31. All

panels must be in place when rigging.

The unit cannot be placed on the curb with a fork lift or other lifting

device through the fork lift openings. Doing so would interfere with

placement on the roof curb.

Maintain clearance around and above the unit to provide minimum

distance from combustible materials, proper air flow, and service

access.

Do not install unit in an indoor location. Do not locate unit air inlets

near exhaust vents or other sources of contaminated air.

Be sure that unit is installed such that snow will not block the

combustion intake or flue outlet.

Unit may be installed directly on wood flooring or on Class A, B, or

C roof covering material when roof curb is used.

Although unit is weatherproof, guard against water from higher

level runoff and overhangs.

Exhaust vent terminal must have a minimum horizontal clearance

of 4 ft. from electric and gas meters, gas regulators, and gas relief

equipment. Minimum distance between unit and other electrically

live parts is 48 inches.

Flue gases can deteriorate building materials. Orient unit such

that flue gas will not affect building materials.

Adequate combustion and ventilation air space must be provided

for proper operation of this equipment.

After unit is in position, remove rigging skids and shipping

materials.

FIGURE 31

13

Page 14

OUTDOOR ST AND

This rooftop water heater is approved for an outdoor installation

with an optional stand. Contact State Order Entry to acquire

optional stand kit.

WARNING

DO NOT USE THIS APPLIANCE IF ANY P ART HAS BEEN UNDER

WA TER. IMMEDIA TEL Y CONT ACT A QUALIFIED INST ALLER OR

SERVICE AGENCY TO REPLACE A FL OODED WATER HEATER.

DO NOT A TTEMPT T O REPAIR THE UNIT! IT MUST BE REPLACED!

The rooftop stand is constructed of a tubular steel frame along

with tubular steel legs. See Figure 32. The legs are three feet in

length and slide into the corners of the tubular steel frame. The

legs may be cut to length to reduce the overall height of the stand

if necessary.

The rooftop unit is located on the stand the same way as located

on the roof curb. Please locate panels at one end of the stand.

This area is used to run the water lines into the rooftop unit. It

provides added protection to the water lines. For additional

information see Optional Stand Kit Instructions.

CLEARANCES

These heaters are approved for outdoor installations on

combustible flooring (roof) with the minimum clearances of 0" for

sides and 1.50" for top.

Always disconnect electrical power before servicing the unit.

HARD W A TER

Where hard water conditions exist, water softening or the

threshold type of water treatment is recommended. This will

protect the dishwashers, coffee urns, water heaters, water

piping and other equipment.

See MAINTENANCE section for details of tank cleanout procedure.

AIR REQUIREMENTS

KEEP APPLIANCE AREA CLEAR AND FREE OF COMBUSTIBLE

MATERIALS, GASOLINE AND OTHER FLAMMABLE V APORS AND

LIQUIDS.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND

VENTILATING AIR.

FIGURE 32

When installing the heater, consideration must be given to proper

location. Location selected should be as close to the intake and

exhaust termination points as practicable, with adequate air supply

and as centralized with the piping system as possible.

LOCA TE IT NEAR A DRAIN. THE HEA TER SHOULD BE LOCA TED

IN AN AREA WHERE LEAKAGE FROM THE HEATER OR

CONNECTIONS WILL NOT RESULT IN DAMAGE TO THE

ADJACENT AREA OR TO LOWER FLOORS OF THE STRUCTURE.

When such locations cannot be avoided, it is recommended that a

suitable drain pan, adequately drained, be installed under the

appliance.

State Water Heater provides an after market anti-freeze kit for use

when there is a loss of power. This kit provides drainage to the

tank and plumbing manifold to prevent freeze-up. When power is

restored, the system is equipped with automatic air bleed and a

low-water cut-off device to prove the tank is full of water prior to

startup. See kit instructions for complete details.

WARNING

FOR SAFE OPERATION PROVIDE ADEQUATE AIR FOR

COMBUSTION AND VENTILATION. AN INSUFFICIENT SUPPLY OF

AIR WILL CAUSE RECIRCULATION OF COMBUSTION

PRODUCTS RESULTING IN CONTAMINATION THAT MAY BE

HAZARDOUS TO LIFE. SUCH A CONDITION OFTEN WILL RESUL T

IN A YELLOW, LUMINOUS BURNER FLAME, CAUSING

CARBONING OR SOOTING OF THE COMBUSTION CHAMBER,

BURNERS AND FLUE TUBES AND CREATES A RISK OF

ASPHYXIATION.

CHEMICAL V APOR CORROSION

WARNING

CORROSION OF THE FLUE WAYS AND VENT SYSTEM MAY

OCCUR IF AIR FOR COMBUSTION CONTAINS CERTAIN

CHEMICAL VAPORS. SUCH CORROSION MAY RESULT IN

FAILURE AND RISK OF ASPHYXIATION.

Spray can propellants, cleaning solvents, refrigerator and air

conditioning refrigerants, swimming pool chemicals, calcium and

sodium chloride, waxes, and process chemicals are typical

compounds which are potentially corrosive.

PRODUCTS OF THIS SORT SHOULD NOT BE STORED NEAR

THE HEATER. ALSO, AIR WHICH IS BROUGHT IN CONT ACT WITH

THE HEATER SHOULD NOT CONTAIN ANY OF THESE

CHEMICALS. IF NECESSARY , UNCONT AMINA TED AIR SHOULD

BE OBTAINED FROM REMOTE OR OUTSIDE SOURCES.

14

Page 15

VENTING

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING MUST

BE FOLLOWED TO AVOID CHOKED COMBUSTION OR

RECIRCULATION OF FLUE GASES. SUCH CONDITIONS CAUSE

SOOTING OR RISKS OF FIRE AND ASPHYXIATION.

WARNING

NEVER OPERATE THE HEATER UNLESS IT IS VENTED TO

THE OUTDOORS AND HAS ADEQUATE AIR SUPPLY TO AVOID

RISKS OF IMPROPER OPERATION, FIRE, EXPLOSION OR

ASPHYXIATION.

CAUTION

DO NOT TERMINA TE THE VENTING WHERE NOISE FROM THE

EXHAUST OR INTAKE WILL BE OBJECTIONABLE. THIS

INCLUDES LOCATIONS CLOSE T O OR ACROSS FROM WINDOWS

AND DOORS.

The vent shall terminate a minimum of 12" (30.5 cm) above expected

snowfall level to prevent blockage of vent termination.

WARNING

USE ONLY THE VENT TERMINALS SUPPLIED WITH THIS UNIT .

TERMINATION OF A VENT SYSTEM WITH A DEVICE OTHER

THAN THE SUPPLIED VENT TERMINATIONS WILL AFFECT

SYSTEM PERFORMANCE AND RESULT IN A SAFETY HAZARD.

PRESSURE SWITCHES

The SRT80-120NE is provided with three pressure switches.

These switches are essential to the safe and proper operation of

the unit. All switches are wired in series. The controller is set up to

shut the unit down whenever there is a failure of any of the switches.

CAUTION

THE WATER HEATER IS POLARITY SENSITIVE. BEFORE

APPLYING ELECTRICITY TO THIS HEATER BE CERTAIN THAT

SUPPLY NEUTRAL WIRE TO GROUND CHECK INDICA TES ZERO

VOLTAGE.

GAS PIPING

Contact your local gas service company to ensure that adequate

gas service is available and to review applicable installation codes

for your area.

FIGURE 33

VENT TERMINALS

The vent system must terminate so that proper clearances are

maintained as cited in local codes or the current edition of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54.

The SRT80-120NE series is designed with an internal vent

construction. The exhaust vent terminal and the inlet air terminal

are located on the sides of the appliance. Do not add vent pipe to

the appliance, see Figure 33.

Assure the exhaust vent terminal is not in a public area where the

hoods are exposed. The exhaust vent terminal gets very HOT

during operation and can cause burns. Please use caution when

working around the exhaust vent terminal.

It is imperative that the area around the vent terminal hoods are

kept clear from obstructions so plenty of fresh air is available for

combustion.

MAXIMUM CAP ACITY OF PIPE IN CUBIC FEET OF GAS PER HOUR

(Based upon a Pressure Drop of 0.5 inch Water Column

LENGTH NORMAL IRON PIPE SIZES (INCHES)

IN INPUT IN THOUSANDS BTU/HR

FEET 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2" 3" 4"

10 175 360 680 1400 2100 3960 6300 11000 23000

20 120 250 485 950 1460 2750 4360 7700 15800

30 — 200 375 770 1180 2200 3520 6250 12800

40 — 170 320 660 990 1900 3000 5300 10900

50 — 151 285 580 900 1680 2650 4750 9700

60 — 138 260 530 810 1520 2400 4300 8800

70 — 125 240 490 750 1400 2250 3900 8100

80 — — 220 460 690 1300 2050 3700 7500

90 — — 205 430 650 1220 1950 3450 7200

100 — — 195 400 620 1150 1850 3250 6700

125 — — 175 360 550 1020 1650 2950 6000

150 — — 160 325 500 950 1500 2650 5500

175 — — 145 300 460 850 1370 2450 5000

200 — — 135 280 430 800 1280 2280 4600

LENGTH NORMAL IRON PIPE SIZES (INCHES)

IN INPUT IN KW

METERS 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2" 3" 4"

3.0 51 105 199 410 615 1160 1845 3221 6735

6.1 35 73 142 278 428 805 1277 2255 4626

9.1 — 59 11 0 225 346 644 1031 1830 3748

12.2 — 50 94 193 290 556 878 1552 3192

15.2 — 44 83 170 264 492 776 1391 2840

18.3 — 40 76 155 237 445 703 1259 2577

21.3 — 37 70 143 220 410 659 1142 2372

24.4 — — 64 135 202 381 600 1083 2196

27.4 — — 60 126 190 357 571 1010 2108

30.5 — — 57 1 1 7 182 337 542 952 1962

38.1 — — 51 105 161 299 483 864 1757

45.7 — — 47 95 146 278 439 776 1610

53.3 — — 42 88 135 249 401 717 1464

61.0 — — 40 82 126 234 375 688 1347

and 0.6 Specific Gravity Gas

TABLE 3

Size the main gas line in accordance with Table 3. The figures

shown are for straight lengths of pipe at 0.5 in. (125 kPa) W.C.

pressure drop, which is considered normal for low pressure

systems. Note that fittings such as elbows and tees will add to the

pipe pressure drop.

CAUTION

DO NOT USE FLEXIBLE GAS PIPING .

15

Page 16

WARNING

THE HEATER IS NOT INTENDED FOR OPERATION AT HIGHER

THAN 14.0" WATER COLUMN (1/2 POUND OR 3.45 kPa PER

SQUARE INCH) SUPPLY GAS PRESSURE. HIGHER GAS SUPPLY

PRESSURES REQUIRE SUPPLEMENTAL REDUCING SERVICE

REGULA TION. EXPOSURE TO HIGHER GAS SUPPL Y PRESSURE

MA Y CAUSE DAMAGE TO THE GAS CONTROLS WHICH COULD

RESULT IN FIRE OR EXPLOSION. IF OVERPRESSURE HAS

OCCURRED SUCH AS THROUGH IMPROPER TESTING OF GAS

LINES OR EMERGENCY MALFUNCTION OF THE SUPPL Y SYSTEM

THE GAS VALVE MUST BE CHECKED FOR SAFE OPERATION.

MAKE SURE THAT THE OUTSIDE VENTS ON THE SUPPLY

REGULATORS AND THE SAFETY VENT VALVES ARE PROTECTED

AGAINST BLOCKAGE. THESE ARE P ARTS OF THE GAS SUPPLY

SYSTEM, NOT THE HEATER. VENT BLOCKAGE MAY OCCUR

DURING ICE STORMS.

IT IS IMPORT ANT TO GUARD AGAINST GAS V ALVE FOULING FROM

CONT AMINANTS IN THE GAS WA YS. SUCH FOULING MA Y CAUSE

IMPROPER OPERATION, FIRE OR EXPLOSION.

IF COPPER SUPPLY LINES ARE USED THEY MUST BE

INTERNALL Y TINNED AND CERTIFIED FOR GAS SERVICE.

BEFORE AT TACHING THE GAS LINE BE SURE THAT ALL GAS

PIPE IS CLEAN ON THE INSIDE.

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS SUPPL Y

LINE, A DIR T LEG (SOMETIMES CALLED A SEDIMENT TRAP OR

DRIP LEG) MUST BE INCORPORA TED IN THE PIPING . THE DIRT

LEG MUST BE READILY ACCESSIBLE AND NOT SUBJECT TO

FREEZING CONDITIONS. INSTALL IN ACCORDANCE WITH

RECOMMENDATIONS OF SERVING GAS SUPPLIERS. REFER TO

NATIONAL FUEL GAS CODE.

THE

Apply joint compounds (pipe dope) sparingly and only to the male

threads of pipe joints. Do not apply compound to the first two

threads. Use compounds resistant to the action of liquefied

petroleum gases.

DISCONNECT THE APPLIANCE AND ITS MANUAL GAS SHUTOFF

VALVE FROM THE GAS SUPPLY PIPING SYSTEM DURING ANY

SUPPL Y PRESSURE TESTING EXCEEDING 1/2 PSIG (3.45 kPa).

GAS SUPPL Y LINE MUST BE CAPPED WHEN DISCONNECTED

FROM THE HEA TER. FOR TEST PRESSURES OF 1/2 PSIG (3.45

kPa). OR LESS, THE APPLIANCE NEED NOT BE DISCONNECTED,

BUT MUST BE ISOLA TED FROM THE SUPPL Y PRESSURE TEST

BY CLOSING THE MANUAL GAS SHUTOFF V AL VE.

BEFORE PLACING THE HEATER IN OPERATION, CHECK FOR

GAS LEAKAGE. USE SOAP AND W A TER SOLUTION OR OTHER

MATERIAL ACCEPT ABLE FOR THE PURPOSE OF LOCA TING GAS

LEAKS. DO NOT USE MA TCHES, CANDLES, FLAME OR OTHER

SOURCES OF IGNITION FOR THIS PURPOSE.

PURGING

Gas line purging is required with new piping or systems in

which air has entered.

CAUTION

PURGING SHOULD BE PERFORMED BY PERSONS

EXPERIENCED IN THIS TYPE OF GAS SERVICE. TO A VOID RISK

OF FIRE OR EXPLOSION, PURGE DISCHARGE MUST NOT ENTER

CONFINED AREAS OR SP ACES WHERE IGNITION CAN OCCUR.

THE AREA MUST BE WELL VENTILA TED AND ALL SOURCES OF

IGNITION MUST BE INACTIV ATED OR REMOVED.

GAS METER SIZE - CITY GASES ONL Y

FIGURE 34

CONNECTION OF GAS PIPE

W ARNING

PERFORM THE GAS LEAK TEST ANY TIME WORK IS DONE ON A

GAS SYSTEM TO AVOID THE POSSIBILITY OF FIRE OR

EXPLOSION WITH PROPERTY DAMAGE, PERSONAL INJURY OR

LOSS OF LIFE.

The gas leak test is performed as follows: Paint pipe connections

upstream of gas control with a rich soap and water solution to test

for leaks before operating main burner. Bubbles indicate gas leak.

To stop leak, tighten pipe connections. After piping connections

are checked, turn on main burner. With main burner in operation,

paint pipe joints (including flanges), pilot gas tubing connections

and control inlet and outlet with rich soap and water solution.

Bubbles indicate gas leak. To stop leak, tighten flange screws,

joints and pipe connections. Replace part if leak can’t be stopped.

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply pipe to gas valve inlet.

Be sure that the gas meter has sufficient capacity to supply the full

rated gas input of the water heater as well as the requirements of

all other gas fired equipment supplied by the meter. If the gas

meter is too small, ask the gas company to install a larger meter

having adequate capacity.

GAS PRESSURE REGULA TION

Main line gas pressure to the water heater should be between a

maximum 14.0" (3.45 kPa). W.C. and a minimum of 6.2 W.C. (1.53

kPa).

The inlet gas pressure must not exceed the maximum value. A

service regulator must be installed within 10' (305 cm) of unit.

GAS VAL VES

WARNING

SHOULD OVERHEATING OCCUR OR THE GAS SUPPL Y F AIL T O

SHUT OFF , TURN OFF THE MANUAL GAS CONTROL VAL VE TO

THE APPLIANCE.

SYSTEM CONNECTIONS

The system installation must conform to these instructions and to

the local code authority having jurisdiction. Good practice requires

that all heavy piping be supported.

THERMOMETERS (Not Supplied)

Thermometers should be obtained and field installed as shown

in the installation diagrams.

16

Page 17

Thermometers are installed in the system as a means of detecting

the temperature of the outlet water supply.

bypass) is installed in the cold water line between the water heater

and street main (or well).

RELIEF VAL VE

This heater is equipped with an approved temperature and

pressure relief valve. ASME ratings cover pressure relief. CSA

ratings cover release rate with temperature actuation.

FOR SAFE OPERATION OF THE WATER HEATER, THE RELIEF

VAL VE(S) MUST NOT BE REMOVED OR PLUGGED.

In addition to the appliance relief valve, each remote storage tank

which may be used in conjunction with this appliance shall also

be installed with a properly sized, rated and approved temperature

(ANSI) and pressure (ASME) relief valve(s). This relief valve shall

comply with the standard for relief valves and automatic gas shutoff

devices for hot water supply systems, ANSI Z21.22.

Your local code authority may have other specific relief valve

requirements.

WARNING

THE PURPOSE OF A RELIEF VALVE IS TO AVOID EXCESSIVE

PRESSURE OR TEMPERATURE INTO THE STEAM RANGE,

WHICH MA Y CAUSE SCALDING A T FIXTURES, TANK EXPLOSION,

SYSTEM OR HEATER DAMAGE. NO VALVE IS TO BE PLACED

BETWEEN THE RELIEF VALVE AND THE T ANK.

A DRAIN LINE MUST BE CONNECTED TO THE RELIEF V AL VE TO

DIRECT DISCHARGE TO A SAFE LOCA TION TO A VOID SCALDING

OR WA TER DAMAGE. THIS LINE MUST NOT BE REDUCED FROM

THE SIZE OF THE VALVE OUTLET AND MUST NOT CONTAIN

V ALVES OR RESTRICTIONS, NOR SHOULD IT BE LOCATED IN

FREEZING AREAS. DO NOT THREAD OR CAP THE END OF THIS

LINE. RESTRICTED OR BLOCKED DISCHARGE WILL DEFEAT

THE PURPOSE OF THE VAL VE AND IS UNSAFE. THE DISCHARGE

LINE SHALL BE INSTALLED TO ALLOW COMPLETE DRAINAGE

OF BOTH THE V AL VE AND LINE.

Excessive pressure may develop causing premature tank failure

or intermittent relief valve operation. This type of failure is not

covered by the limited warranty. An expansion tank or a similar

device may be required in the inlet supply line between the

appliance and the meter or valve to compensate for the thermal

expansion of water under supply pressure.

Water heater damage due to installation in a closed system is not

covered by the limited warranty. The solution is to install a thermal

expansion tank between the check valve and the water heater.

WATER (POTABLE) HEA TING AND SP ACE HEA TING

1. All piping components connected to this unit for space heating

applications shall be suitable for use with potable water.

2. Toxic chemicals, such as those used for boiler treatment,

shall

NEVER be introduced into this system.

3. This unit may never be connected to any existing heating

system or component(s) previously used with non-potable

water heating appliance.

4. When the system requires water for space heating at

temperatures higher than required for domestic water

purposes, a tempering valve must be installed. Please refer

to installation diagrams on pages 29 through 33 in back of

manual for suggested piping arrangements.

WA TER HEATER WIRING

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE APPLIANCE

MUST BE REPLACED, IT MUST BE REPLACED WITH 105C WIRE OR

ITS EQUIV ALENT, EXCEPT IN THE BURNER HOUSING . IN THIS CASE

USE 200°C WIRE.

THE COMPUTER CONTROL REQUIRES A SOURCE OF ST ABLE

CLEAN ELECTRICITY FOR PROPER OPERA TION. INSTALLING

THE HEATER ON A BRANCH CIRCUIT THAT HAS ELECTRONIC

NOISE, IS SUBJECT TO FLUCTUA TIONS IN VOL T AGE LEVEL OR

HAS AN APPLIANCE WHICH GENERATES EMF OF RFI

INTERFERENCE CAN CAUSE THE CONTROLLER TO

MALFUNCTION. A HIGH QUALITY POWER CONDITIONER MUST

BE INSTALLED IF THE ABOVE CONDITIONS EXIST.

MALFUNCTIONS CAUSED BY A POOR ELECTRICAL SUPPL Y ARE

NOT COVERED UNDER YOUR WARRANTY.

FIGURE 35

WA TER LINE CONNECTIONS

This manual provides detailed installation diagrams (see back

section of this manual) for typical methods of application for the

water heaters.

The water heater may be installed by itself, or with a separate

storage tank. When used with a separate storage tank, the

circulation may be either by gravity or by means of circulating pump.

When a circulating pump is used, it is important to note that the

flow rate should be slow so that there will be a minimum of

turbulence inside the heater.

CLOSED SYSTEM

CAUTION

A closed system will exist if a check valve (without bypass),

pressure reducing valve (without bypass), or a water meter (without

CAUTION

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN

SERVICING CONTROLS. WIRING ERRORS CAN CAUSE

IMPROPER AND DANGEROUS OPERA TION.

CAUTION

VERIFY PROPER OPERATION AFTER SER VICING UNIT .

The controller is wired to the heater. The model and rating

plate provides the electrical information needed to size the

complete heater branch supply.

All electrical work must be installed in accordance with the

National Electrical Code and local requirements.

When installed, the appliance must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the

NOTE: This controller is polarity sensitive. If the hot and

neutral supply voltage is reversed, the controller will not

sense flame. Verify polarity before connecting the unit.

17

National Electrical Code, NFPA 70.

Page 18

FIGURE 36

18

Page 19

OPERATION

MENU NAVIGA TION

The EMC-5000 Interface has 5 buttons on the touch panel of the interface.

The EMC-5000's menus are navigated through the touch panel, as shown to

the right, which can be found on the outdoor and remote interface box. Basic

navigation through the menus begins with the Main Menu. With the exception

of changing a user set point, touching {menu} will bring you to the Main Menu,

as is illustrated here:

> Temperatures

System Status

From the Main Menu, you can use the [up] and [down] arrow keys to navigate through the Main Menu. The arrow > on the left

displays the current item that you have selected. Touching [select] will select the item from the menu and navigate to its

appropriate sub menu. Navigation through the sub menus is the same as navigation through the Main Menu.

Note: Some sub menus do not have the > visible, navigation through the screen operates through touching [up] and [down].

The up and down arrows, and , found on the right of the screen are an indication that there are more items available on the

current screen. As described above, touching [up] and [down] will allow you to display these items.

The User Settings sub menu contains items that are adjustable by the user. These items can be adjusted by following these

steps:

1. Move the > to the items you wish to adjust by touching [up] and [down].

2. Touch [select] to adjust the parameter.

3. Touch [up] and [down] to adjust the value.

4. Touch [select] to accept the new value, or touch [menu] to cancel any changes made.

Changes will not be made until the [select} key is pressed again to accept the changed value.

The following example steps through the process of adjusting the operating set point:

1. Touch [menu] to display the Main Menu:

> Temperatures

System Status

2. Touch [down] until User Settings is selected:

System Status

> User Settings

3. Touch [select] to enter the User Settings sub menu:

> Setpoint 120°F

Diff 20°F

4. To adjust the operating set point, touch [select] once. The > should now be blinking indicating that you are adjusting this

parameter.

5. Touch [up] and [down] to adjust the parameter.

6. Touch [select] again to accept the new parameter (or touch [menu] to return to cancel any changes and return to the previous

setting).

19

Page 20

Menu Tree

Main Menu Description

Temperatures

Outlet Displays the temperature of the outlet tank probe.

Tank Displays the temperature of the probe located in the tank.

System Status

L WCO Low Water Cut-Off status. The status can be either Closed or Open. A Closed status indicates that there is not

a low water condition in the tank. An Open status indicates that there is a low water condition in the tank.

ECO Emergency Cut-Off status. The st atus can be either Closed or Open. A Closed status indicates safe operation.

An Open status indicates that the system is locked out due to the water temperature reaching an unsafe

temperature value.

BlwPrv Blower prover status. The status can be either Closed or Open. A Closed status indicates that combustion air

is adequate. An Open status indicates that combustion air is inadequate.

Blk Out Blocked outlet status. The status can be either Closed or Open. A Closed status indicates normal operation.

An Open status indicates that the exhaust outlet is blocked.

Low Gas Low gas status. The status can be either Closed or Open. A Closed status indicates normal operation. An

Open status indicates low supply gas pressure.

Freeze State (Anti-Freeze kit only)

This indicates the status of the freeze condition aquastat. The status can either be OK or Freeze. An OK

status indicates normal operation. A Freeze condition indicates that freezing conditions exist and the system

is responding.

T ank Drain (Anti-Freeze kit only)

Tank drain status. This status can either be Closed or Open. A Closed status indicates that the system is in

normal operation and the tank drain valve is closed. An Open status indicates that the system is draining the

tank to deter freezing.

Tank Pump Status of the tank pump. This indicates if the tank pump is enabled by the control. The status is either On or

Off. An On status indicates the control is asking for the tank pump to be turned on. An Off status indicates that

the control is asking for the tank pump to be turned off.

Loop Pumps Status of the loop pumps. This indicates if the loop pumps are enabled by the control. The status is either

Enabled or Disabled. An Enabled status indicates the control is asking for the loop pumps to be turned on.

A Disabled status indicates that the control is asking for the loop pumps to be turned off.

User Settings

Setpoint The setpoint is the temperature to which water will be heated and stored. Allowable range is 100°F to 180°F.

Diff Temperature difference below the operating set point before the system will call for heat. Allowable range of

0°F to 50°F.

Temp Units Temperature unit of the system for display. This can either be °F or °C.

Netwrt Addr (PC Networking only)

Network address of the heater on State Industries Networking network. This number must be unique to all

devices on the network. Allowable range of 1 to 32 on the network, or 0 to place the device off the network.

Log Info

Run Min The total number of minutes of heating.

Cycles The total number of cycles the heater achieved. A cycle is defined as a transition from an idle state to a heat

state.

kBTU (for reference only)

This is a factory setting for reference only.

Prop Rev This will display the current software revision.

Current Error The current error screen displays the current error, if the system is in an error state.

Error History The error history screen will display the previous nine recorded errors by the system along with the running

minutes of when the error occurred.

Reload Defaults Allows for re-setting the system to its factory defaults.

20

Page 21

SEQUENCE OF OPERATION

1. When the control is powered up the outdoor interface and the

remote interface should display a blank line and copyright on

the 2-line display.

the control will automatically return to step 5 and repeat the

entire operating cycle. During this entire process, if the control

detects an improper operating state for external devices such

as the ECO switch, blower prover switch, etc., the appropriate

indication will be given on the interface modules.

2. After one second, the display should switch to indicate that the

touch switches are calibrating. During this process, the

Running LED will flash once per second until all of the switches

have been calibrated. This is an automatic process and can

take several seconds. Placing hands or fingers near the

switches can delay this process.

3. The control is now initialized and the display will change to

display the temperatures screen if no error is detected.

4. The system is checked for faults and, if detected, the Service

light will flash. If the fault is a temperature probe fault, the Service

LED will remain on without flashing. Whenever a fault is

detected, the display will switch to display the Current Error

screen.

5. If the control determines that the actual water temperature

inside the tank is below the programmed temperature setpoint

less the differential, a call for heat is activated. This call for heat

is generated even if the ignition module has detected an error,

however, if the ignition module has detected a fault, the ignition

sequence will not advance. Provided that no fault has been

detected, the Running LED will turn on.

6. If the Low-Water Cut-Off is satisfied, the ignition module will

then perform selected system diagnostic checks. This includes

confirming the proper state of the air switches and the ECO

limit device.

ERROR CODES

These error codes will be displayed if there is a problem with

ignition or operation of the heater. They will be displayed on the

LCD screen on the outdoor interface module and the remote

interface module.

The following error codes are codes related to the temperature

probes:

Outlet Probe

Tank Probe

The following error codes are related directly to the Ignition Module:

I.M. Lock Out

I.M. PS Closed

I.M. PS Open

I.M. ECO

I.M. 1 15V Reversed

I.M. Low Flame

I.M. Igniter

I.M. Flame Fault

Note: The ignition module faults are only reset after a one hour

delay period after the fault, or by cycling the power.

7. If all checks are successfully passed, the combustion blower

is energized for the pre-purge cycle.

8. When the pre-purge cycle is complete, power is applied to the

igniter element for the igniter warm-up period.

9. At the conclusion of the igniter warm-up period, the gas valve

will open, allowing gas to enter the burner chamber.

10. The igniter will remain on for a short predetermined time period,

then it will be turned off.

11. The control will monitor the flame sense probe to confirm a

flame is present. If a flame is not verified within the

predetermined flame prove time, the gas valve will immediately

be closed and the blower will continue to run for approximately

10 seconds. The control will then return to step 6.

12. If a flame is confirmed, the control will enter the heating mode

where it will continue heating the tank until the setpoint

temperature is reached. At this point, the gas valve is closed

and the control enters the post-purge cycle.

13. The combustion blower will run for the duration of the postpurge

cycle to purge the system of all combustion gasses. When the

post purge cycle is complete, the blower is deenergized and

will coast to a stop.

14. The control will now enter the standby state as indicated by the

Standby LED. The control will continue to monitor the tank

water temperature and the state of the other system devices. If

the temperature drops below the setpoint value less differential,

FAUL T CONDITIONS

Fault: OUTLET PROBE

There is a problem with the outlet temperature probe

Possible Cause Remedy

1. Outlet temperature probe 1. Check that the temperature

is not connected (Wiring probe is connected properly

disconnect)

2. Outlet temperature probe 2. Repair wiring

wiring is open or closed

3. Defective outlet 3. Replace probe

temperature probe

Fault: TANK PROBE

There is a problem with the tank temperature probe

Possible Cause Remedy

1. Tank temperature probe is 1. Check that the temperature

not connected (Wiring probe is connected properly

disconnect)

2. Tank temperature probe 2. Repair wiring

wiring is open or closed

3. Defective tank temperature 3. Replace probe

probe

21

Page 22

The following are fault conditions related to the ignition module:

Fault: I.M. LOCK OUT

I.M Failed an internal hardware or software check

Possible Cause Remedy

1. Ignition Module Failure 1. Replace Ignition Module

Fault: I.M. PS CLOSED

The pressure switch is stuck closed

Fault: I.M. IGNITER

There is a problem with the ignition module

Possible Cause Remedy

1. Igniter is not wired in or 1. Check that the igniter is

the wiring is damaged wired in properly or that

the wiring is not damaged

2. Igniter is damaged 2. Replace igniter

Possible Cause Remedy

1. Pressure switch is shorted 1. Check and replace wiring

or not wired properly

2. Defective pressure switch 2. Replace pressure switch

Fault: I.M. PS OPEN

The pressure switch is stuck open

Possible Cause Remedy

1. Pressure switch is not 1. Check that the pressure

connected switched is wired properly

2. Pressure switch is open or 2. Check and repair wiring

not wired properly

3. Defective pressure switch 3. Replace pressure switch

4. Insufficient pressure 4. Verify blower operation

developed by combustion to the ignition module

blower

Fault: I.M. ECO

Emergency cut-off, water temperature has reached an unsafe

temperature

Possible Cause Remedy

3. The ignition module is 3. Replace ignition module

damaged

Fault: I.M. FLAME FAUL T

A flame was detected when there is not supposed to be a flame

(no call for heat).

Possible Cause Remedy

1. Flame sense wiring is 1. Check and repair wiring

damaged

2. Ignition module is 2. Replace ignition module

damaged

PRIOR TO START UP

REQUIRED ABILITY

INSTALLA TION OR SERVICE OF THIS W A TER HEATER REQUIRES

ABILITY EQUIVALENT TO THAT OF A LICENSED TRADESMAN IN

THE FIELD INVOL VED. PLUMBING , AIR SUPPL Y, VENTING, GAS

SUPPL Y AND ELECTRICAL WORK ARE REQUIRED.

1. Temperature probe is 1. Check that the temperature

damaged probe is not damaged and

replace probe if necessary

2. Temperature probe wiring 2. Check and repair wiring

is damaged

3. Water in tank too hot 3. Normal condition when

water temperature exceeds

safety limit. Allow water

to cool or admit water into

tank and manually reset the

control. Determine cause

for over temp condition

Fault: I.M. 115V REVERSED

The line hot and the neutral line are reversed wired

Possible Cause Remedy

1. Line hot and neutral 1. Check wiring and reverse

reversed line hot and neutral

Fault: I.M. LOW FLAME

Low flame has been sensed

Possible Cause Remedy

1. Weak or insufficient flame 1. Check flame rod

detected

Before attempting start-up, thoroughly study and familiarize yourself

with the exact sequence of operation and all other details on the

specific heater being used.

The power burner is equipped with an ignition system which

automatically sequences prepurge and ignition, senses and

ignites main burner flame and sequences burner operation. Heater

is equipped with an ignition control which locks out after three

unsuccessful ignition attempts. Familiarize yourself with the

sequence of operation of this unit prior to start-up.

Be certain that the water heater is full of water, that air is purged

from all lines, there are no leaks (gas and water), and all inlet

water lines are open.

The following test equipment should be on hand (all test equipment

must be acclimated to ambient temperature before calibration and

use.)

– Two U-tube manometers or calibration 0-10" (0-2.5 kPa) and

0-35" (0-2.5 kPa) W.C. pressure gauges.

• Attach a gas pressure gauge or manometer to the upstream

side of main gas cock and a gas pressure gauge or manometer

to the manifold pressure tap.

• You are now ready to begin the burner start-up procedure.

22

Page 23

OPERATING INSTRUCTIONS

IMPORTANT

IT IS RECOMMENDED THA T A QUALIFIED SER VICE TECHNICIAN

PERFORM THE INITIAL FIRING OF THE HEATER. A T THIS TIME

THE USER SHOULD ASK THE TECHNICIAN ANY QUESTIONS IN

REGARD TO THE OPERA TION AND MAINTENANCE OF THE UNIT .

CAUTION

BEFORE PROCEEDING WITH THE OPERATION OF THE UNIT,

MAKE SURE HEATER AND SYSTEM ARE FILLED WITH WA TER

AND ALL AIR IS EXPELLED FROM HEA TER AND PIPING.

2. Check manifold pressure (see Table 4) using a pressure gauge

(manometer) connected to the manifold pressure tap on the

gas control valve.

If full rate adjustment is required, remove cover screw from top of

the gas control valve.

Using a small screwdriver, turn adjusting screw clockwise

increase or counterclockwise

obtain 4.5" (1 kPa) for natural gas Water Column.

3. Cycle the burner on and off several times to check its operation.

to decrease gas pressure to

to

NEVER OPERA TE THE HEA TER WITHOUT FIRST BEING CERT AIN

IT IS FILLED WITH WATER AND A TEMPERATURE AND A

PRESSURE RELIEF V ALVE IS INSTALLED IN THE RELIEF V AL VE

OPENING OF THE HEATER. DO NOT ATTEMPT TO OPERATE

HEA TER WITH COLD WA TER INLET V AL VE CLOSED.

FILLING:

1. Close the heater drain valve.

2. Open a nearby hot water faucet to permit the air in the system

to escape.

3. Fully open the cold water inlet pipe valve allowing the heater

and piping to be filled.

4. Close the hot water faucet as water starts to flow.

5. The heater is ready to be operated.

THE MAIN MANUAL GAS SHUTOFF VALVE MUST HAVE BEEN

CLOSED FOR A T LEAST FIVE (5) MINUTES. THIS WAITING PERIOD

IS AN IMPOR TANT SAFETY STEP . ITS PURPOSE IS TO PERMIT

GAS THA T MIGHT HAVE ACCUMULA TED IN THE COMBUSTION

CHAMBER TO CLEAR. IF YOU DETECT GAS AT THE END OF

THIS PERIOD, DO NOT PROCEED WITH LIGHTING . RECOGNIZE

THAT GAS ODOR, EVEN IF IT SEEMS WEAK, MA Y INDICA TE THE

PRESENCE OF ACCUMULA TED GAS SOMEPLACE IN THE AREA

WITH A RISK OF FIRE OR EXPLOSION. SEE THE FRONT PAGE

FOR STEPS TO BE T AKEN.

4. Check the operation of the limit and operating controls.

5. Check the input rate:

For appliance installation locations with elevations above 2000

feet (610 m) refer to HIGH ALTITUDE INSTALLATIONS section of

this manual.

a. Attach a pressure gauge (manometer) to the manifold

pressure tap and refer to Table 4, page 26 for correct

pressure.

b. Use this formula to “clock” the meter. Be sure other gas

consuming appliances are not operating during this interval.

3600 X H = Btuh

T

Should it be necessary to adjust the gas pressure to the

burner, to obtain the full input rate, the steps below should

be followed:

T = Time in seconds to burn 1 cubic foot of gas. (With a stopwatch

read the gas meter and measure the amount of time required

for the heater to consume 1 cubic foot of gas.)

H = Heating value of gas (in Btu’s per cubic foot of gas).

Btuh = Actual heater input rate, in Btuh.

DO NOT USE THIS HEATER IF ANY PART HAS BEEN UNDER

WA TER. IMMEDIA TELY CALL A QUALIFIED SER VICE TECHNICIAN

TO INSPECT THE HEATER AND TO REPLACE ANY PAR T OF THE

CONTROL SYSTEM AND ANY GAS CONTROL WHICH HAS

BEEN UNDER WATER.

LIGHT THE UNIT IN ACCORDANCE WITH THE OPERATING

INSTRUCTIONS LABEL A TT ACHED TO THE HEA TER.

THESE INSTRUCTIONS ARE REPEATED IN THE LIGHTING AND

OPERATING LABEL ILLUSTRATION IN THIS MANUAL.

INITIAL ST ART -UP

A minimum gas supply pressure of 6.2" W.C. for natural gas is

required before making any adjustment to the gas control pressure

regulator. Attempts to adjust the regulator during periods of low

gas supply pressure could result in overfiring of the heater when

the gas supply pressure returns to normal.

1. Check gas line pressure with a manometer.

EXAMPLE: (Using RTF-120 heater)

T = 18.9 seconds

H = 1050 Btu/ft.

For high altitude installations, compare result to the derated input

required for the elevation at the installation location.

c. Remove the pressure regulator cover screw and adjust the

pressure by turning the adjusting screw with a small

screwdriver. Do not exceed 4.5" (1 kPa) Water Column.

Clockwise to increase gas pressure and input rate.

Counterclockwise to decrease gas pressure and input

rate.

d. “Clock” the meter as in step (b) above.

23

3600 X 1050 = 199,900 Btuh (59 kW)

18.9

3

Page 24

e. Repeat steps (c) and (d) until the specified input rate is

achieved.

f. Turn the manual gas valve to “OFF”. Replace the pressure

regulator cover screw. Remove the pressure gauge or

manometer from the manifold pressure tap. Replace the set

screw in the manifold pressure tap. If the gas pressure

regulator cannot be adjusted to give the full input rating with

sufficient gas pressure at the valve, check to ensure the unit

is equipped with the correct orifice.

WARNING

UNDER NO CIRCUMSTANCES SHOULD THE INPUT EXCEED

THE RATE SHOWN ON THE HEATER RATING PLATE.

OVERFIRING COULD RESUL T IN DAMAGE OR SOOTING OF THE

HEATER.

CA THODIC PROTECTION

is present, there will probably be an unusual sound such as air

escaping through the pipe as the water begins to flow. There should

be no smoking or open flame near the faucet at the time it is open.

PRECAUTIONS

IF THE UNIT IS EXPOSED TO THE FOLLOWING, DO NOT

OPERATE HEATER UNTIL ALL CORRECTIVE STEPS HA VE BEEN

MADE BY A QUALIFIED SERVICEMAN.

1. FLOODING TO OR ABOVE THE LEVEL OF THE BURNER OR

CONTROLS

2. EXTERNAL FIRING

3. DAMAGE

4. FIRING WITHOUT W A TER

5. SOOTING

CAUTION