Page 1

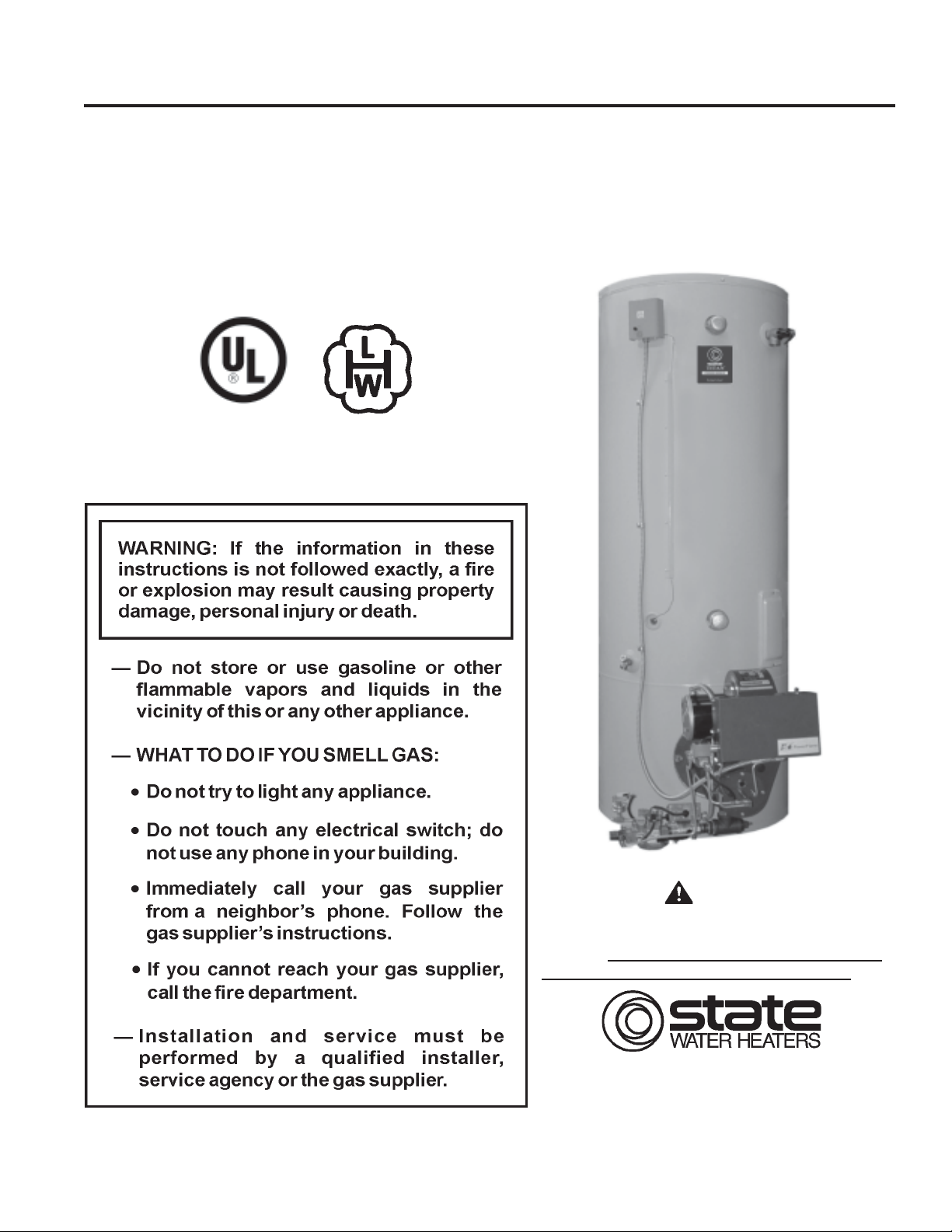

MODELS GPG/GPV-540A, 650A AND 740A

COMMERCIAL GAS, GLASS-LINED, TANK-TYPE LOW NOx

WATER HEATER

• INSTALLATION • OPERATION • MAINTENANCE • LIMITED WARRANTY

PRINTED IN U.S.A. 1004

CAUTION

TEXT IN BLACK BOLD TYPE OR UNDERLINED

CONT AINS INFORMATION RELA TIVE T O YOUR

SAFETY . PLEASE READ THOROUGHL Y BEFORE

INSTALLING AND USING THIS APPLIANCE.

ASHLAND CITY , TN

www.statewaterheaters.com

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PART NO. 195047-000

1

Page 2

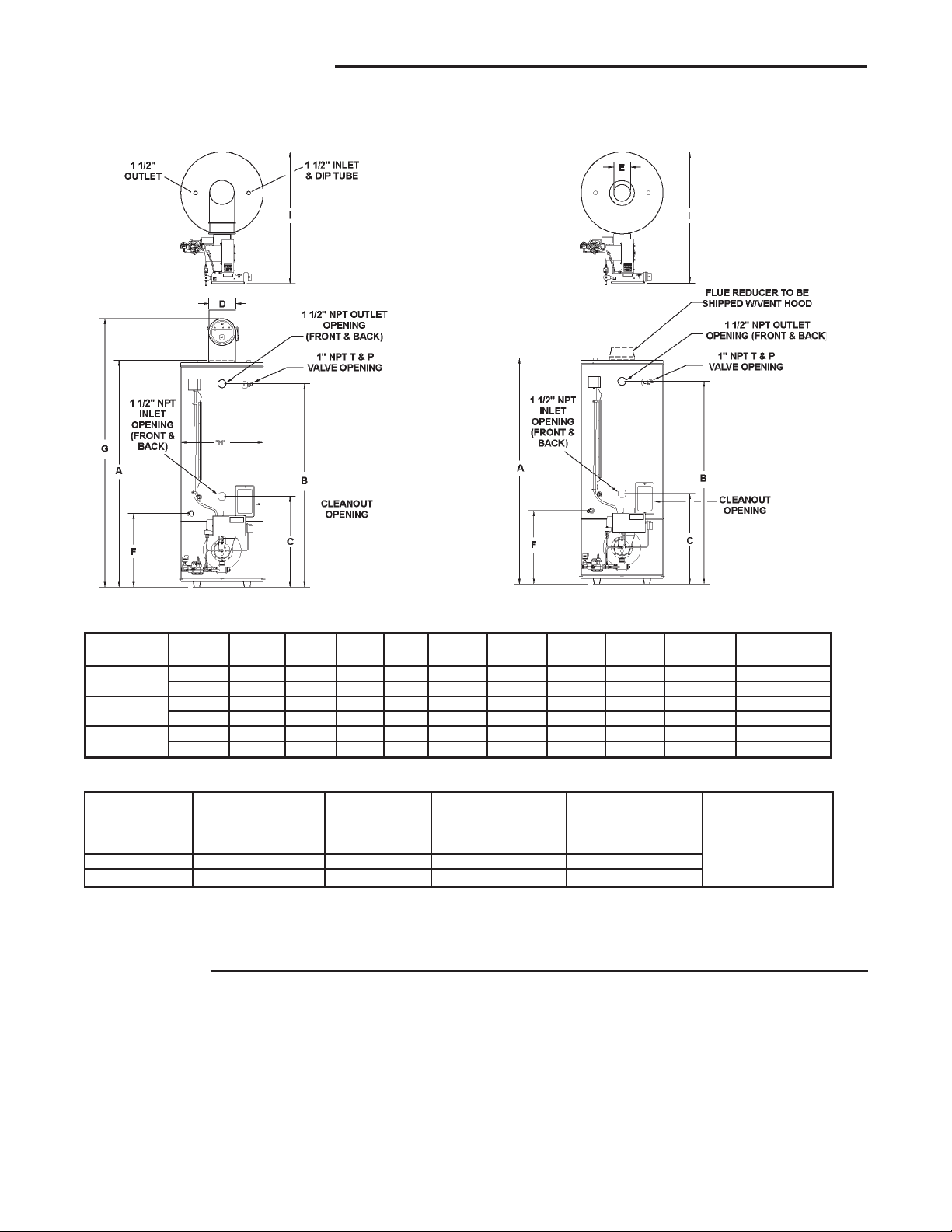

ROUGH-IN DIMENSIONS

STANDARD BAROMETRIC DRAFT CONTROL

GPG MODELS

HORIZONT AL & DIRECT VENTING

GPV MODELS

MAXIMUM TOTAL 75 EQUIVA LE N T

FEET INTAKE AND EXHAUST

ALLOWED.

ALL DIMENSIONS IN INCHES (MILLIMETERS)

Models A B C D E F G H I Conn. Ship. Wt.

GPG/GPV 80 3 / 4 73 32 1 / 4 9 6 26 1/2 93 29 1/ 2 48 1 / 2 1 * 950

540A 2,051 1,854 819 229 152 673 2,362 749 1,232 25.4 431 kg

GPG/GPV 80 3 / 4 7 3 32 1/ 4 9 8 2 6 1 /2 93 29 1/ 2 48 1 / 2 1 * 950

650A 2,051 1,854 819 229 203 673 2,362 749 1,232 25.4 431 kg

GPG/GPV 80 3 / 4 7 3 32 1/ 4 9 8 2 6 1 /2 93 29 1/ 2 48 1 / 2 1 * 950

740A 2,051 1,854 819 229 203 673 2,362 749 1,232 25.4 431 kg

*Minimum gas supply pipe is 1 1/4”, reference Table 7 for gas supply pipe size.

Storage Input Rating Recovery Rating Recovery Rating Current Draw

Capacity BTU/HR. GPH GPH 120V

Models U.S. Gals. (Litres) Nat. 100°F Rise 140°F Rise 60Hz 1 Phase

GPG/GPV-540A 85 (261) 540,000 523.6 374

GPG/GPV-650A 85 (261) 650,000 630 450

GPG/GPV-740A 85 (261) 740,000 718 512

Based on 80% thermal efficiency obtained in State engineering laboratories.

NOTE: To compensate for the effects of high altitude areas above 2000 feet, recovery ratings should be reduced approximately

4% for every 1000 feet above sea level.

Gas Approx.

FOREWORD

The design of the GPG 540A through 740A models complies

with ANSI Z21.10.3/CSA 4.3 as an automatic circulating tank

and an automatic instantaneous type heater. The GPV 540A

through 740A models are designed for sidewall venting and

direct venting applications and are certified under UL 795.

Particular attention should be given to the installation of

thermometers at the locations indicated on the diagrams, as

these are necessary for checking the proper functioning of the

heater.

6.0 Amps

Detailed installation diagrams are found in this manual. These

diagrams will serve to provide the installer with a reference for

the materials and methods of piping necessary. It is highly

essential that all water, gas piping and wiring be installed as

shown on the diagrams.

THE HEA TER IS DESIGNED TO OPERA TE ONL Y ON NA TURAL

GAS.

THESE HEATERS MUST NOT BE INSTALLED ON

COMBUSTIBLE FLOORS.

2

Page 3

In addition to these instructions, the equipment shall be installed

in accordance with those installation regulations in accordance

with those installation regulations in force in the local area where

the installation is to be made. These shall be carefully followed

in all cases. Authorities having jurisdiction should be consulted

before installations are made.

TABLE OF CONTENTS

ROUGH-IN-DIMENSIONS ........................................................................2

FORE WORD ....................................................................................... 2,3

TABLE OF CONTENTS........................................................................... 3

GENERAL SAFETY INFORMA TION .......................................................3

Precautions ...................................................................................3

Liquid Petroleum Models................................................................3

Chemical Vapor Corrosion ........................................................ 3,4

Improper Combustion ....................................................................4

EXTENDED NON-USE PERIODS ............................................................. 4

Cathodic Protection .......................................................................4

Insulation Blankets.........................................................................4

High Altitude Installations ..............................................................4

FEATURES ............................................................................................. 4

Low Emmission Control.................................................................4

High Limit Switch (E.C.O.) ......................................................... 4,5

Dishwashing Machine Requirement .............................................5

INSTALLA TION INSTRUCTIONS .............................................................5

Required Ability .............................................................................5

Uncrating ....................................................................................... 5

Locating the Heater ................................................................... 5,6

Hard Water ....................................................................................6

Clearances ....................................................................................6

Air Requirements...........................................................................6

Venting....................................................................................... 6,7

Vertical Venting - For GPG Models ...............................................7

Horizontal (Side-wall) Venting - For GPV Models .................... 7,8

Direct Venting - For GPV Models ............................................ 9-11

Gas Piping ............................................................................. 11-12

Gas Meter Size............................................................................12

Gas Pressure Regulation ............................................................12

Gas Valves ............................................................................ 12,13

Water Line Connections..............................................................13

Thermometers .............................................................................13

Relief Valve .................................................................................13

INSTALLA TION DIAGRAMS........................................................... 14-17

Manifold Kits ................................................................................18

In the absence of local codes, the installation must conform with

the instructions as outlined in the latest publication of National

Fuel Gas Code (NFPA-54/ANSI Z223.1) and National Electric

Code (NFPA-70). These manuals can be purchased from the

Canadian Standards Association Laboratories, 8501 East

Pleasant Valley Road, Cleveland, OH 44131, National Fire

Protection Association, 1 Batterymarch Park, Quincy MA 02269.

P AGEP AGE

Heater Wiring...............................................................................19

ST ART UP ............................................................................................ 19

Important ......................................................................................19

Filling ............................................................................................ 19

Purging.........................................................................................19

Wiring Diagram ...................................................................... 20,21

Lighting and Operating Label ......................................................22

Sequence of Operation ............................................................... 23

Water Temperature Control .........................................................23

Adjustment Procedure (Initial Start-Up) ................................ 23,24

Adjustment Procedure for Fire-Rate, Low Nox and

High Elevation (Fine-Tune) .................................................... 24-26

GENERAL INFORMATION ....................................................................27

Power Burner ..............................................................................27

Thermostat ..................................................................................27

High Limit......................................................................................27

MAINTENANCE ....................................................................................27

General ........................................................................................27

Maintenance Schedule................................................................27

Electrical Servicing ......................................................................27

Flushing .......................................................................................27

Draining........................................................................................28

Sediment Removal .......................................................................28

Lime Scale ...................................................................................28

Relief Valve ........................................................................... 28,29

Circulating Pump ..........................................................................29

Low Emission Power Burner ......................................................29

Cleaning Flues .............................................................................29

Barometric Draft Control .............................................................29

Vent System ................................................................................ 29

CHECKLIST AND SERVICE INFORMA TION ....................................29-30

TROUBLESHOOTING ..................................................................... 30-32

Replacement Parts ......................................................................32

WARRANTY ........................................................................................33

PARTS LIST.................................................................................... 34-39

GENERAL SAFETY INFORMATION

PRECAUTIONS

DO NOT USE THIS APPLIANCE IF ANY PA RT HAS BEEN UNDER

WA TER. Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system and

any gas control which has been under water.

IF THE UNIT IS EXPOSED TO THE FOLLOWING, DO NOT

OPERATE HEATER UNTIL ALL CORRECTIVE STEPS HAVE

BEEN MADE BY A QUALIFIED SERVICEMAN.

1. EXTERNAL FIRE.

2. DAMAGE.

3. FIRING WITHOUT WA TER.

4. SOOTING.

LIQUID PETROLEUM MODELS

WARNING

Water heaters for propane or liquefied petroleum gas (LPG)

are different from natural gas models. A natural gas heater

will not function safely on LP gas and no attempt should be

made to convert a heater from natural gas to LP gas.

GPG/GPV-540A, 650A & 740A models are not available for use

with Liquefied Petroleum or LP gas. If you have obtained a

GPG/GPV-540A, 650A or 740A model with the intent to use it

with Liquefied Petroleum, LP gas - STOP! Immediately contact

your dealer to obtain a correct model.

CHEMICAL VAPOR CORROSION

WARNING

CORROSION OF THE FLUEWAYS AND VENT SYSTEM MAY

OCCUR IF AIR FOR COMBUSTION CONTAINS CERTAIN

CHEMICAL VAPORS. SUCH CORROSION MAY RESULT IN

FAILURE AND RISK OF ASPHYXIA TION.

Spray can propellants, cleaning solvents, refrigerator and air

conditioning refrigerants, swimming pool chemicals, calcium

3

Page 4

and sodium chloride (water softener salt), waxes, and process

chemicals are typical compounds which are potentially corrosive.

Do not store products of this sort near the heater . Also, air which

is brought in contact with the heater should no contain any of

these chemicals. If necessary, uncontaminated air should be

obtained from remote or outside sources. The limited warranty

is voided when failure of water heater is due to a corrosive

atmosphere. (Refer to the limited warranty for complete terms

and conditions).

2. INSULATION BLANKETS CAN RESTRICT THE AIR FLOW

NEEDED FOR PROPER OPERA TION OF THE COMBUSTION

SYSTEM AND COULD RESULT IN FIRE, ASPHYXIATION,

SERIOUS PERSONAL INJURY OR DEATH.

WARNING

FAILURE T O FOLLOW THESE INSTRUCTIONS CAN RESULT IN

SERIOUS PERSONAL INJURY OR DEATH.

IMPROPER COMBUSTION

WARNING

ATTIC AND OR EXHAUST F ANS OPERATING ON THE PREMISES

WITH A WA TER HEATER CAN RESUL T IN CARBON MONOXIDE

POISONING AND DEATH.

OPERATION OF THESE FANS CAN PRODUCE A NEGATIVE

DRAFT IN THE AREA OF THE WATER HEA TER PREVENTING

THE PRODUCTS OF COMBUSTION FROM EXHAUSTING

THROUGH THE CHIMNEY OR VENT PIPE.

The venting of the water heater should be inspected by a qualified

service technician at the time of installation and periodically

thereafter to ensure a down-draft condition does not exist.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND

VENTILATION AIR, ADEQUATE AIR FOR COMBUSTION AND

VENTILATION MUST BE PROVIDED FOR SAFE OPERA TION.

EXTENDED NON-USE PERIODS

CATHODIC PROTECTION

CAUTION

HYDROGEN GAS CAN BE PRODUCED IN A HOT W A TER SYSTEM

SERVED BY THIS HEA TER THA T HAS NOT BEEN USED FOR A

LONG PERIOD OF TIME (GENERALL Y TWO WEEKS OR MORE).

HYDROGEN GAS IS EXTREMEL Y FLAMMABLE. T o reduce the

risk of injury under these conditions, it is recommended that a

hot water faucet be opened for several minutes before using any

electrical appliance connected to the hot water system. If

hydrogen is present, there will probably be an unusual sound

such as air escaping through the pipe as the water begins to

flow. There should be not smoking or open flame near the

faucet at the time it is open.

INSULA TION BLANKETS

HIGH ALTITUDE INSTALLATIONS

Y our S tate water heater has been designed to operate at altitudes

below 2000 Ft. (609.6 m), for appliance installation locations

with elevations above 2000 Ft. (609.6 m), special considerations

need to be taken. Adjustments for high altitude can only be made

by a State authorized GPG/GPV Start-up Agent. To ensure your

water heater operates properly at high elevation, a State

authorized GPG/GPV Start-up Agent will readjust the air-intake

damper setting and the gas manifold pressure (if required).

NOTE: Some gas utility companies derate the heating value of

the supplied gas at high elevation. Y our authorized st art-up agent

must adjust for actual heating value of the gas at the time of start

up.

FEATURES

LOW EMISSION CONTROL

Your State water heater has been designed to comply with

standards established by California South Coast Air Quality

Management District (SCAQMD), the most stringent emissions

control agency in the nation. To ensure compliance with SCAQMD

Rule 1 146.2, your heater is equipped with an internal recirculation

premix power burner, and must be started/adjusted by a

State Authorized GPG/GPV Start-Up Agent.

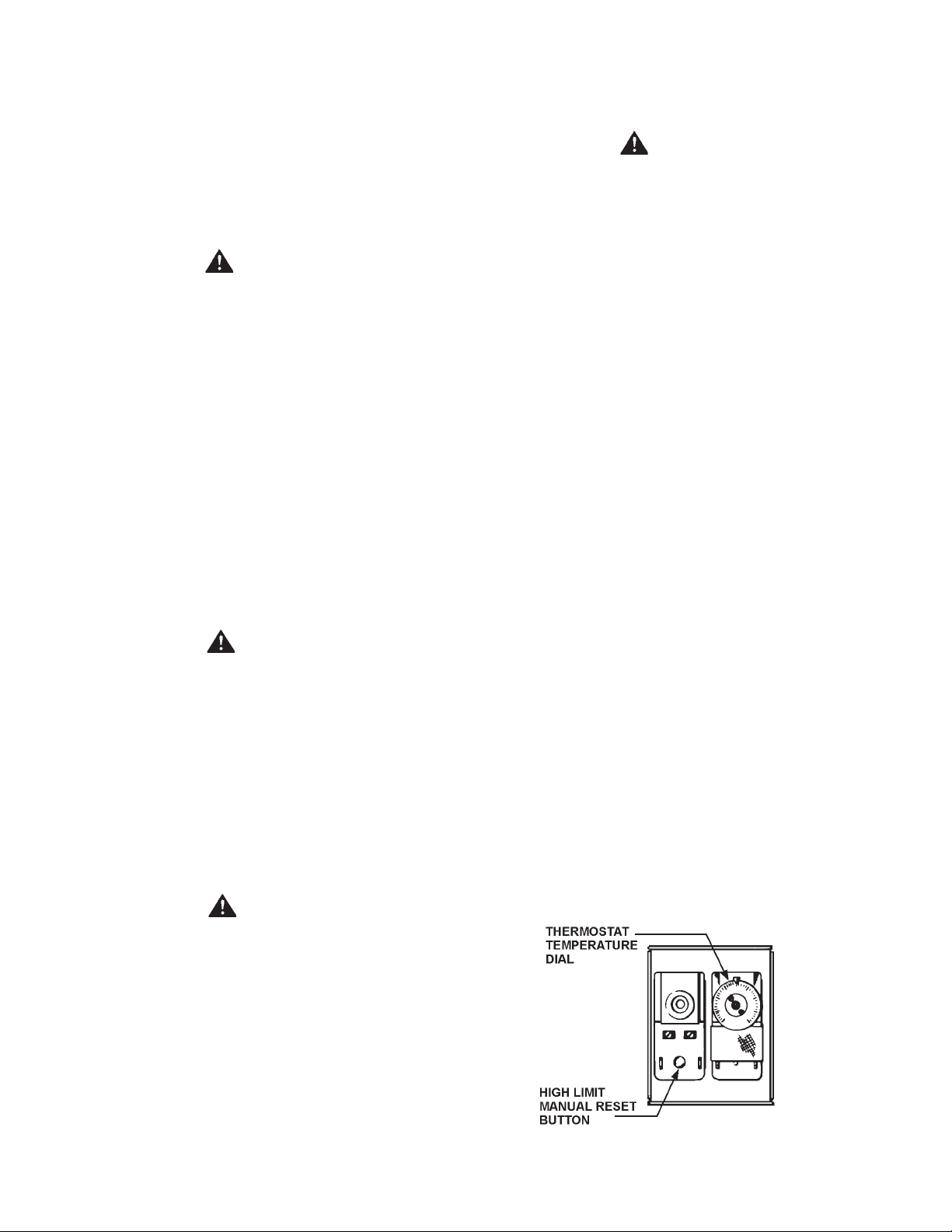

HIGH LIMIT SWITCH (E.C.O.)

The dual bulb controller also contains the high limit (energy

cutoff) sensor. The high limit switch interrupts main burner gas

flow should the water temperature reach 205°F (96°C).

In the event of high limit switch operation, the appliance cannot

be restarted unless the water temperature is reduced by 20°F

(11°C) approx. and the high limit reset button on front of limit

control is depressed, see Figure 1.

WARNING

INSULA TION BLANKET A VAILABLE T O THE GENERAL PUBLIC

FOR EXTERNAL USE ON GAS WATER HEATERS ARE NOT

APPROVED FOR USE ON YOUR ST A TE W ATER HEA TER. THE

PURPOSE OF AN INSULA TION BLANKET IS TO REDUCE THE

STANDBY HEA T LOSS ENCOUNTERED WITH STORAGE T ANK

WATER HEATER. YOUR STA TE W ATER HEATER MEETS OR

EXCEEDS THE ASHRAE/IES 90.1B 2001 STANDARDS WITH

RESPECT TO INSULATION AND STANDBY LOSS

REQUIREMENTS, MAKING AN INSULATION BLANKET

UNNECESSARY. THE USE OF INSULATION BLANKETS IN

CONJUNCTION WITH A STA TE WA TER HEATER WILL ALSO VOID

THE ST ATE W ARRANTY FOR THE FOLLOWING REASONS:

1. INSULATION BLANKETS COVER IMPORT ANT OPERA TING

INSTRUCTIONS AND SAFETY LABELS.

FIGURE 1.

4

Page 5

Continued manual resetting of high limit control, preceded by

higher than usual water temperature is evidence of high limit

switch operation. The following are possible reasons for high

limit switch operation.

• A malfunction in the thermostatic controls would allow the

gas valve to remain open causing water temperature to exceed

the thermostat setting. The water temperature would continue

to rise until high limit switch operation.

• An improper thermostat setting for a short repetitive usage

pattern may lead to a stacking effect. This causes a

temperature gradient increasing from the bottom to the top of

the tank. It is possible that the water at the high limit switch

sensor could reach its maximum temperature before the water

temperature at the thermostat reaches the dial setting,

causing the high limit switch to activate.

• A warming of ambient conditions associated with seasonal

change could magnify the stacking process described above

to the point where high limit switch operation would occur.

Contact your dealer or servicer if continued high limit switch

operation occurs.

DISHWASHING MACHINE REQUIREMENT

All dishwashing machines meeting the National Sanitation

Foundation requirements are designed to operate with water

flow pressures between 15 and 25 pounds per square inch.

Flow pressures above 25 pounds per square inch, or below

15 pounds per square inch, will result in improperly sanitized

dishes. Where pressures are high, a water pressure reducing

or flow regulating control valve should be used in 180°F (82°C)

line to the dishwashing machine, and should be adjusted to

deliver water between these limits.

The National Sanitation Foundation also recommends

circulation of 180°F (82°C) water. Where this is done, the

circulation should be very gentle so that it does not cause any

unnecessary turbulence inside the water heater. The circulation

should be just enough to provide 180°F (82°C) water at the point

of take-off to the dishwashing machine. Adjust flow by means of

the plug cock in the circulating line.

INSTALLATION INSTRUCTIONS

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER

REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED

TRADESMAN IN THE FIELD INVOLVED. PLUMBING, AIR

SUPPL Y , VENTING , GAS SUPPL Y AND ELECTRICAL WORK ARE

REQUIRED. NOTE: AUTHORIZED ST ART-UP IS REQUIRED.

UNCRATING

The heater is shipped in standard form for vertical venting with a

barometric draft control assembly in a separate carton.

Optional horizontal vent models are shipped with one (1) exhaust

vent hood and one (1) flue reducer in a separate carton. Optional

direct vent models are shipped with two (2) vent hoods in separate

cartons. The exhaust vent hood carton contains one (1) exhaust

vent hood and one (1) flue reducer. The intake vent hood carton

contains one (1) intake vent hood and one (1) inlet adapter. All

parts should be installed as received without alteration.

LOCATING THE HEATER

When installing the heater, consideration must be given to proper

location. Location selected should be as close to the stack

chimney as practicable, with adequate air supply and as

centralized with the piping system as possible.

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES SUCH

AS GAS WA TER HEA TERS IN ROOMS, GARAGES OR OTHER

AREAS WHERE GASOLINE, OTHER FLAMMABLE LIQUIDS OR

ENGINE DRIVEN EQUIPMENT OR VEHICLES ARE STORED,

OPERATED OR REP AIRED. FLAMMABLE V APORS ARE HEA VY

AND TRAVEL ALONG THE FLOOR AND MA Y BE IGNITED BY THE

HEATER’S IGNITER OR MAIN BURNER FLAMES CAUSING FIRE

OR EXPLOSION. SOME LOCAL CODES PERMIT OPERA TION OF

GAS APPLIANCES IF INST ALLED 18 INCHES OR MORE ABOVE

THE FLOOR. THIS MA Y REDUCE THE RISK IF LOCATION IN SUCH

AN AREA CANNOT BE AVOIDED.

THE HEA TER SHALL BE LOCATED OR PROTECTED SO IT IS

NOT SUBJECT TO PHYSICAL DAMAGE BY A MOVING VEHICLE.

WARNING

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY

OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST NEVER

BE PLACED ON OR ADJACENT TO THE HEATER. OPEN

CONTAINERS OF FLAMMABLE MA TERIAL SHOULD NOT BE

STORED OR USED IN THE SAME ROOM WITH THE HEA TER.

THE HEATER MUST NOT BE LOCA TED IN AN AREA WHERE IT

WILL BE SUBJECT TO FREEZING.

LOCA TE IT NEAR A FLOOR DRAIN. THE HEA TER SHOULD BE

LOCATED IN AN AREA WHERE LEAKAGE FROM THE HEA TER

OR CONNECTIONS WILL NOT RESULT IN DAMAGE TO THE

ADJACENT AREA OR TO LOWER FLOORS OF THE

STRUCTURE.

WHEN SUCH LOCATIONS CANNOT BE A VOIDED, A SUIT ABLE

DRAIN PAN SHOULD BE INST ALLED UNDER THE HEA TER. Such

pans should be fabricated with sides at least 2” (50.8 mm) deep,

with length and width at least 2” (50,8 mm) greater than the

diameter of the heater and must be piped to an adequate drain.

THE P AN MUST NOT RESTRICT COMBUSTION AIRFLOW.

Water heater life depends upon water quality, water pressure

and the environment in which the water heater is installed. Water

heaters are sometimes installed in locations where leakage

may result in property damage, even with the use of a drain pan

piped to a drain. However, unanticip ated damage can be reduced

or prevented by a leak detector or water shut-off device used in

conjunction with a piped drain pan. These devices are available

from some plumbing supply wholesalers and retailers, and

detect and react to leakage in various ways:

• Sensors mounted in the drain pan that trigger an alarm or turn

off the incoming water to the water heater when leakage is

detected.

• Sensors mounted in the drain pan that turn off the water supply

to the entire home when water is detected in the drain pan.

• Water supply shut-off devices that activate based on the water

pressure differential between the cold water and hot water

pipes connected to the water heater.

• Devices that will turn off the gas supply to a gas water heater

while at the same time shutting off its water supply.

5

Page 6

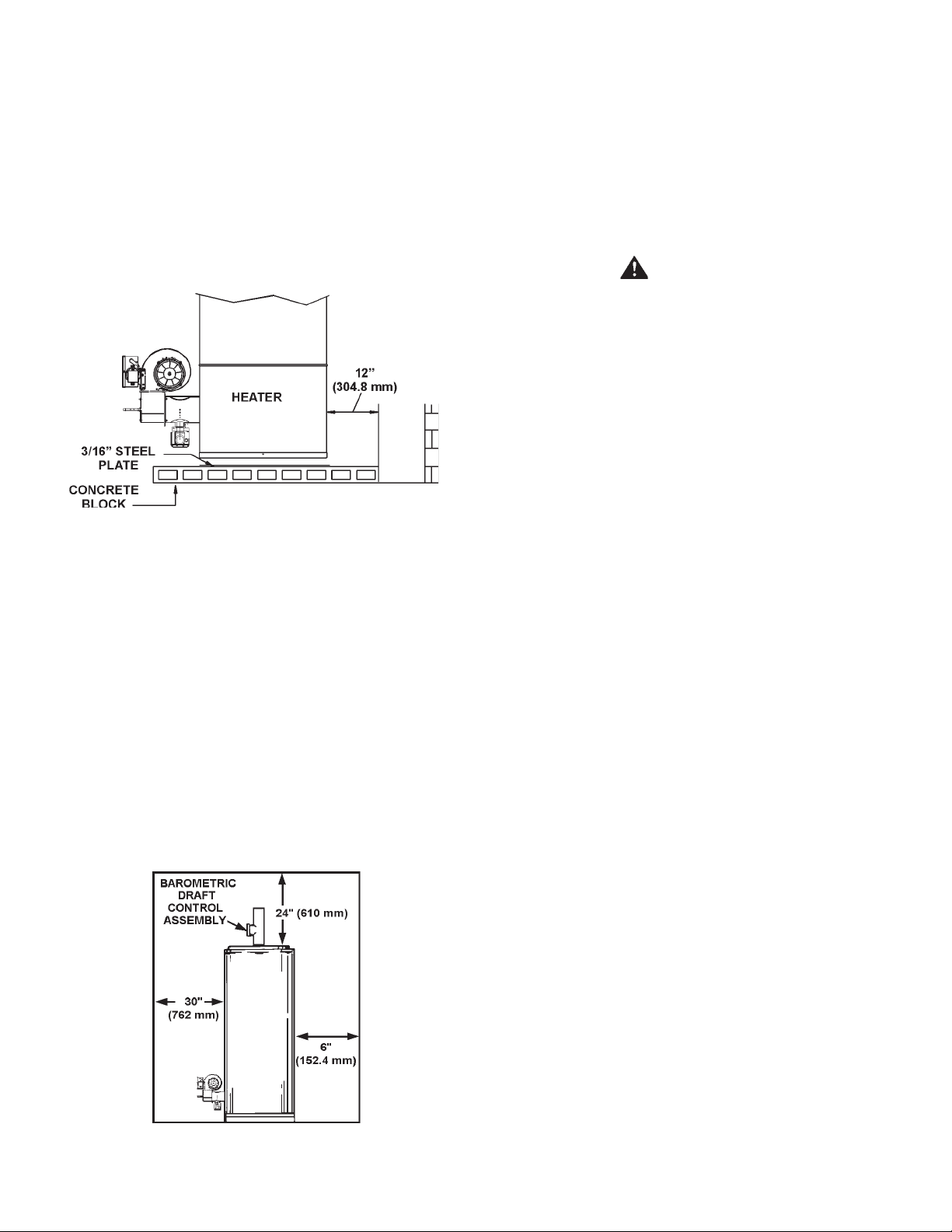

Units, which are to be installed on combustible flooring, must

be supported by a full layer of hollow concrete blocks, from

8” (203.2 mm) to 12” (304.8 mm) thick and extending

12” (304.8 mm) minimum beyond the heater in all directions.

The concrete blocks must provide an unbroken concrete surface

under the heater with the hollows running continuously and

horizontally. A 3/16-inch steel plate must cover the concrete

blocks, see Figure 2.

NOTE: If electrical conduits run under the floor of the proposed

heater location, insulate the floor as recommended above.

For appliances installation locations with elevations above 2000

feet (609.6 m), refer to HIGH AL TITUDE INST ALLA TIONS section.

PROPER INSTALLA TION ON COMBUSTIBLE FLOORING

FIGURE 2.

HARD W A TER

Where hard water conditions exist, water softening or the

threshold type of water treatment is recommended. This will

protect the dishwasher, Coffee urns, water heaters, water piping

and other equipment.

See MAINTENANCE section for details of tank cleanout

procedure.

CLEARANCES

These heaters are designed for installation on non-combustible

flooring in an alcove with clearances to combustible construction

of 6” (152.4 mm) from the sides and rear, 24” (610 mm) from the

top with a 6” (152.4 mm) minimum between vent pipe and ceiling.

Minimum clearance from flue pipe to combustible material is

6” (152.4 mm), see Figure 3.

A clearance of 30” (762 mm) shall be maintained from

serviceable parts, such as power burners, relief valves flue

baffles, thermostats or drain valves.

AIR REQUIREMENTS

KEEP APPLIANCE AREA CLEAR AND FREE OF COMBUSTIBLE

MA TERIALS, GASOLINE AND OTHER FLAMMABLE VAPORS AND

LIQUIDS.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION OR

VENTILATING AIR.

WARNING

FOR SAFE OPERATION PROVIDE ADEQUATE AIR FOR

COMBUSTION AND VENTILA TION. AN INSUFFICIENT SUPPL Y

OF AIR WILL CAUSE RECIRCULATION OF COMBUSTION

PRODUCTS RESULTING IN AIR CONTAMINA TION THA T MA Y BE

HAZARDOUS TO LIFE. SUCH A CONDITION OFTEN WILL RESUL T

IN A YELLOW, LUMINOUS BURNER FLAME, CAUSING

CARBONING OR SOOTING OF THE COMBUSTION CHAMBER,

BURNERS AND FLUE TUBES AND CREATES A RISK OF

ASPHYXIA TION.

Where an exhaust fan is installed in the same room with a heater ,

sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRA WN INTO

THE ROOM THROUGH THE CHIMNEY, CAUSING POOR

COMBUSTION. SOOTING MA Y RESUL T IN SERIOUS DAMAGE

TO THE HEA TER AND RISK OF FIRE OR EXPLOSION.

UNCONFINED SP ACE

In buildings of conventional frame, brick or stone construction,

unconfined spaces may provide adequate air for combustion

and ventilation.

If the unconfined space is within a building of tight construction,

(building using the following construction: weather stripping,

heavy insulation, caulking, vapor barrier , etc.), air for combustion

and ventilation must be obtained from outdoors or spaces freely

communicating with the outdoors. The installation instructions

for confined spaces in tightly constructed buildings must be

followed to ensure adequate air supply.

CONFINED SP ACE

When drawing combustion and dilution air from inside a

conventionally constructed building to a confined space, such a

space shall be provided with two permanent openings, ONE IN

OR WITHIN 12 INCHES (304.8 mm) OF THE ENCLOSURE TOP

AND ONE IN OR WITHIN 12 INCHES (304.8 mm) OF THE

ENCLOSURE BOTTOM. Each opening shall have a free area of

at least one square inch per 1000 Btuh of the total input of all

appliances in the enclosure, but not less than 100 square inches.

PROPER INSTALLA TION CLEARANCES

FIGURE 3.

If the confined space is within a building of tight construction, air

for combustion and ventilation must be obtained from outdoors.

When directly communication with the outdoors through vertical

ducts, two permanent openings, located in the above manner,

shall be provided. Each opening shall have a free area of not

less than one square inch per 4000 Btuh of the total input of all

appliances in the enclosure.

VENTING

THE INSTRUCTIONS IN THIS SECTION ON VENTING MUST BE

FOLLOWED TO AVOID CHOKED COMBUSTION OR

RECIRCULATION OF FLUE GASES. SUCH CONDITIONS CAUSE

SOOTING OR RISKS OF FIRE AND ASPHYXIA TION.

6

Page 7

Heater must be protected from freezing downdrafts during

shutdown periods.

The GPG 540A, 650A and 750A water heater are classified as a

category I appliance (non-positive vent pressure, noncondensing) when installed with the supplied barometric draft

control assembly in a vertical vent installation.

The GPV 540A through 740A heater is classified as a category

III appliance (positive vent pressure, non-condensing) when

installed with supplied sidewall vent kits or direct vent kit.

All regulations pertaining to the venting of these heaters must

be followed.

The following vent installation instructions cover vertical,

horizontal, and direct vent applications.

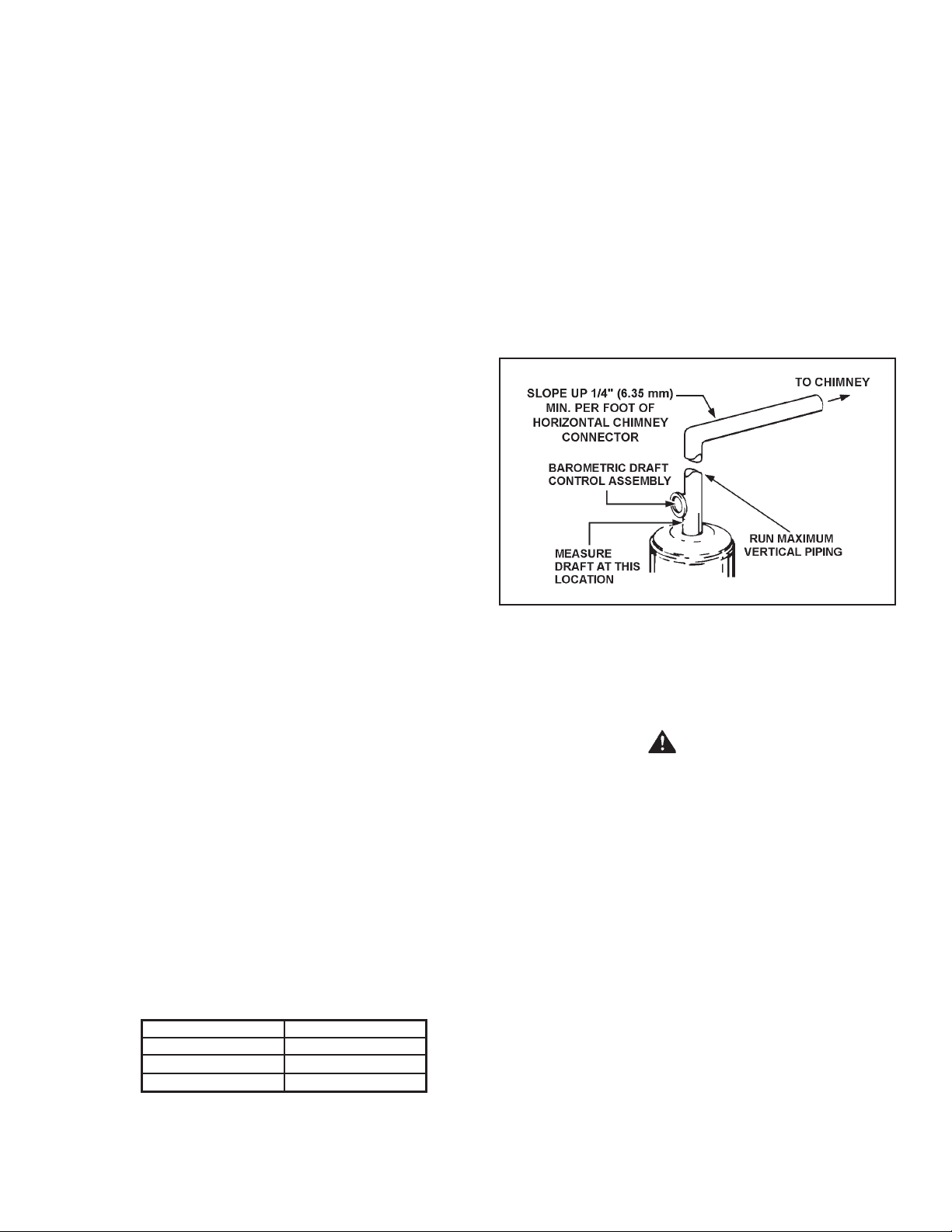

VERTICAL VENTING - FOR GPG MODELS

BAROMETRIC DRAFT CONTROL ASSEMBL Y

A double-acting barometric draft control assembly is provided

with any unit intended for chimney venting. The purpose of this

draft control is twofold. During downdrafts it acts as a pressure

relief control to prevent the downdraft from blowing into the heater.

It also allows for makeup air to enter the chimney without being

drawn through the heater. In both cases the control prevent s the

heater performance from being adversely affected by conditions

within the chimney.

NOTE: A NEGA TIVE DRAFT MUST BE MAINT AINED IN VENTING .

A negative draft of 0.02” to 0.04” w.c. Must be maintained in

venting system. Measure draft at the location illustrated in

Figure 4. Adjust the control counter-weights if necessary as

shown in the MAINTENANCE portion of this manual.

Where an existing chimney or vent is to be used, be sure that the

chimney or vent has adequate capacity for the number and sizes

of gas appliances being vented through it. Inspect the chimney

or vent and remove all soot or other obstructions, which will

retard free draft.

Vent connectors making horizontal runs must have a minimum

upward slope toward the chimney or vent of ¼ inch per foot. Vent

connector length should be kept as short as possible. Be sure

that the vent pipe does not extend beyond the inside wall of a

chimney, see Figure 4.

The draft control assembly must be installed without alteration.

This assembly is factory adjusted for horizontal application only

and must be attached to the heater as shown in Figure 4. The

direction in which the outlet to the draft controls assembly faces

is arbitrary . The assembly must be fitted to the jacket cover such

that it is plumb and level to the ground. Fasten the draft control

assembly to the top cover using sheet metal screws at three

locations, or more, as required.

Damper or other obstructions must not be installed between the

heater and the barometric draft control assembly.

Do not adjust settings on gate.

When installed, the damper gate must pivot freely in the ring

guides. This gate will automatically adjust to regulate the

chimney draft imposed on the heater.

VENT CONNECTIONS

Vent connections must be made to an adequate st ack or chimney .

Refer to the National Fuel Gas Code or to the vent pipe

manufacturer’s gas vent and chimney sizing table to properly

design and size the venting system. Refer to Table 1 for the vent

pipe size required for installation to the barometric draft control

assembly outlet.

TABLE 1.

Model Flue Outlet

GPG-540A 9” (228.6 mm)

GPG-650A 9” (228.6 mm)

GPG-740A 9” (228.6 mm)

Single-wall or type B venting may be used with these heaters in

vertical vent installations. All local and utility regulations on

venting must be followed.

FIGURE 4.

In venting systems where a continuous or intermittent back

(positive) draft is found to exist, the cause must be determined

and corrected. In some cases, a special vent cap may be

required.

WARNING

Failure to correct back drafts may cause air contamination

and unsafe conditions.

Do not connect the heater to a common vent or chimney with

solid fuel burning equipment. This practice is prohibited by

many local building codes as is the practice of venting gas fired

equipment to the ductwork of ventilation systems.

Connectors shall not be connected to a chimney, vent or venting

system served by a power exhauster, unless the connection is

made on the negative pressure side of the exhauster.

Do not connect any heater vented by natural draft to any vent

serving mechanical draft equipment operating under positive

vent pressure such as category III or category IV appliances.

HORIZONTAL (SIDE-WALL) VENTING -

FOR GPV MODELS

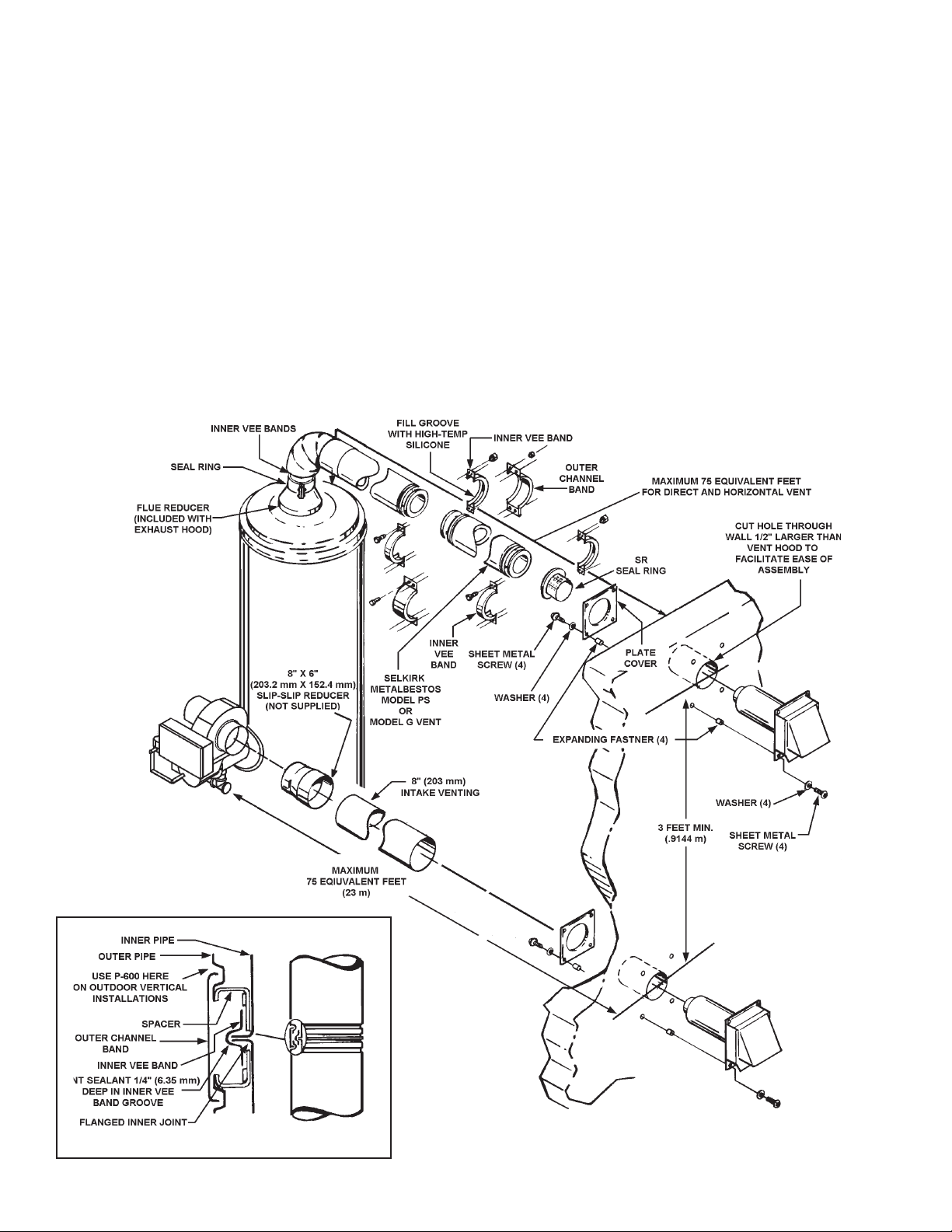

An exhaust vent hood, vent hood and a flue reducer are supplied

with any unit intended for through-the-wall horizontal venting.

These parts must be installed without alteration. The vent hood

adapter is designed for use with Selkirk Metalbestos Model PS

or Model G venting, see Figure 7 on page 10.

7

Page 8

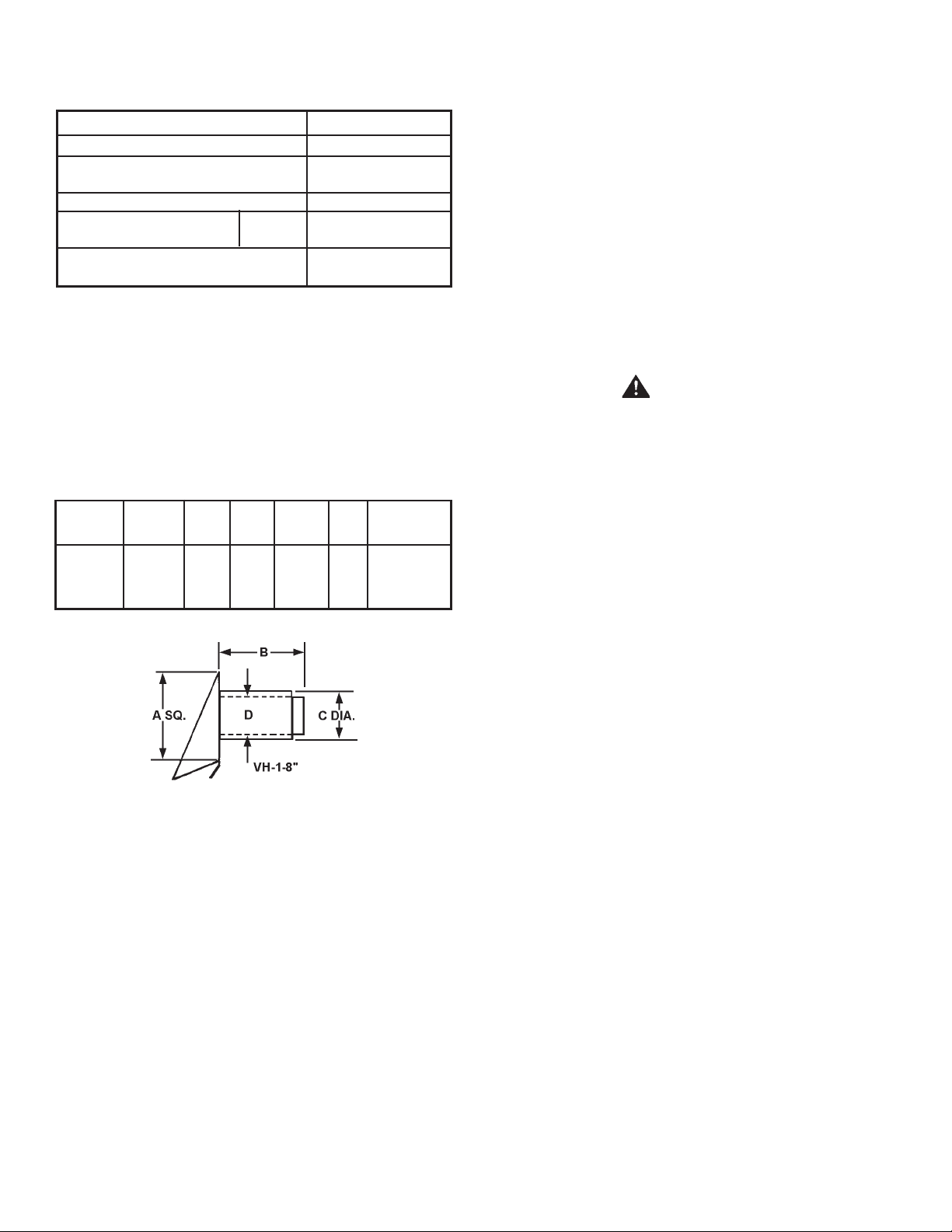

Refer to Table 2 for limitations of venting system design for

horizontal venting.

TABLE 2

GPV-540A-740A

Flue Outlet Dia. (Inches/mm) 9” (228.6)

Flue Reducer 9” x 8”

Dimensions -Supplied (Inches/mm) 228.6 x 203.2

Minimum Outlet Vent Dia. (Inches/mm) 8” (203.2)

Maximum Number 90° 4

Of Elbows 45° 8

Maximum T ot al Vent System 75

Length, Equiv. Feet/Meters (23 m)

5. Shall not be closer than 3 feet (0.9 m) from the inside corner

of an L- shaped structure.

6. Shall be located above the snow line in geographical areas

where snow accumulates.

VENT SYSTEM INST ALLATION

This heater is a category III appliance when horizontally vented

through a wall using the supplied sidewall vent terminal. All

national and local codes pertaining to the installation of such

venting systems must be followed.

Horizontal portions of the vent system must be installed with a

minimum upward slope of 1/4” per foot of length.

When calculating the equivalent length of a venting system each

90° elbow is equivalent to 10 feet (3 m) of straight pipe. In no

case 45° elbow is equivalent to 5 feet (1.5 m) of straight pipe. In

no case may the sum of the straight pipe lengths and the

equivalent length of the elbows exceeds 80 feet (24.3 m).

Note the minimum vent diameter in Table 2.

Refer to Table 3 for the correct vent terminal size for each heater.

The dimensions noted in Table 3 refer to Figure 5.

TABLE 3

Heater Terminal Rough-In

Model Model A B C D Dimensions

GPV

540A- VH-1-8” 19-7/8” 13” 10-9/16” 8-5/8” 11-1/16”

740A

All joints and seams in the venting system must be sealed gas

tight. If a silicone sealer is used, it must have a continuous

temperature rating of at least 500°F (260°C); Dow Corning

736 or equivalent must be used.

CAUTION

Use only the vent hood supplied with this kit. Only supplied

hood provides required clearances from combustibles, both

through the wall and the exterior siding. Termination of a

sidewall vent system with a device other than the supplied

vent hood could affect system performance and result in a

safety hazard.

IMPORT ANT

Plan the layout of the vent system backward from the vent

termination to the water heater.

1. Use the layout of the vent system backward from the vent

termination to the water heater.

BEWARE OF CONCEALED WIRING AND PIPING INSIDE OF

WALL. REFER TO TABLE 5 FOR THE MAXIMUM WALL

THICKNESS “B” FOR EACH MODEL.

2. Slide hood through opening from outside. Fasten hood to

exterior wall with anchors and screws supplied.

FIGURE 5

Use only the sidewall vent terminal supplied with the heater.

These terminals are specifically listed for use on these

State heaters.

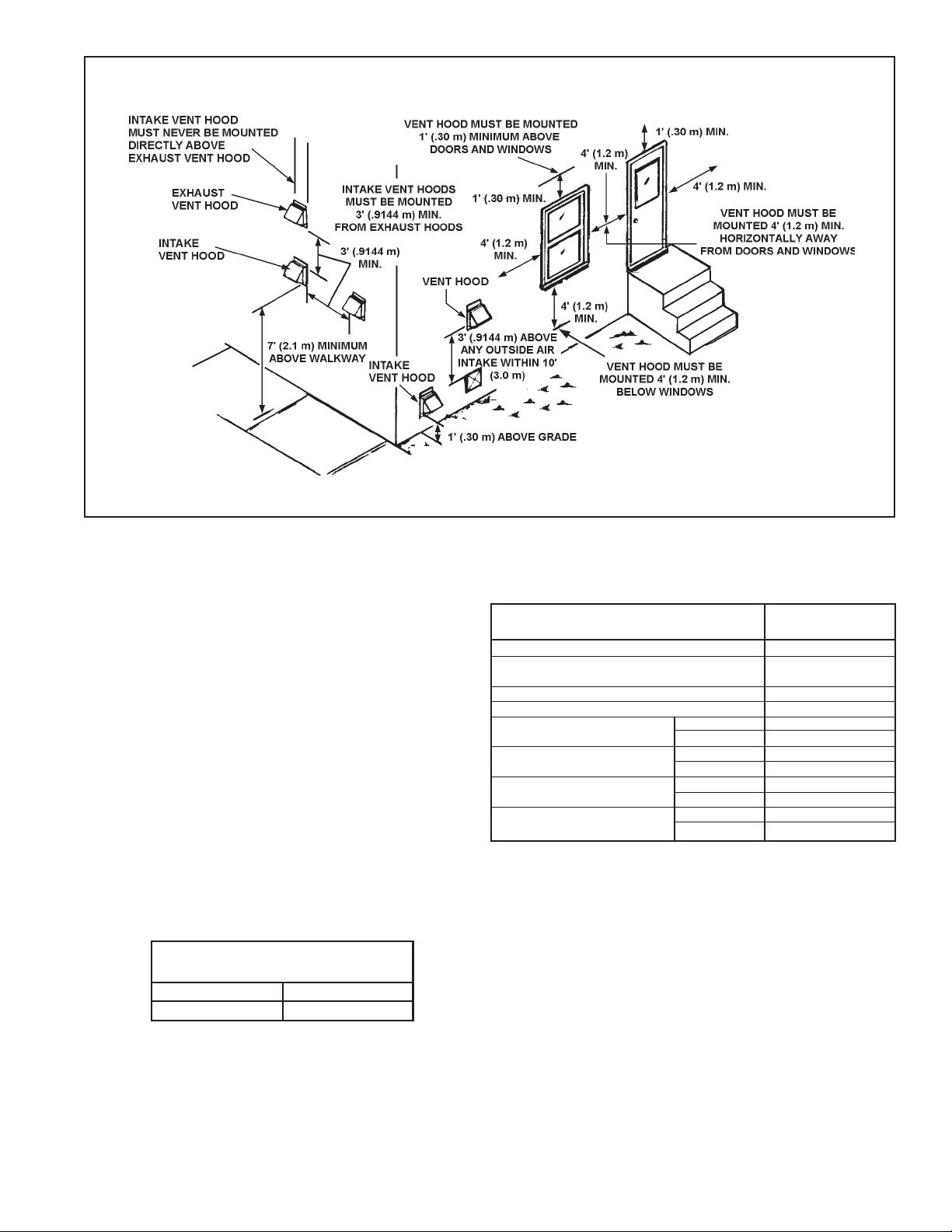

VENT TERMINAL LOCATIONS-EXHAUST

When considering location for sidewall vent terminals refer to

the latest edition of the National Fuel Gas Code which

recommends that vent terminals:

1. Shall be located not less than 12” (304.8 mm) above grade.

2. Shall be located not less than 7 feet (2.1 m) above grade

when adjacent to a public walkway.

3. Shall terminate at least 3 feet (0.9 m) above any forced air

inlet within 10 feet (3 m).

4. Shall terminate at least 4 feet (1.2 m) below, 4 feet (1.2 m)

horizontally from or 1 foot above any door, window or gravity

air inlet into any building.

3. Install covers plate and fasten to inside wall with 4 screws.

4. Attach a seal ring (Meltalbestos SR or equivalent) to the vent

hood collar, see Figure 7. Attach Selkirk Metalbestos model

PS or model G venting to the seal ring following the venting

manufacturer’s instructions. For total safety, it is

recommended that only venting listed for use with category III

appliances (positive vent pressure, non-condensing) should

be used between the heater and the vent hood, even through

national or local codes may allow the use of type B or singlewall vent.

5. Install the remaining vent sections back to the heater , following

the venting manufacturer’s instructions on assembling and

sealing joints. Follow good venting practice regarding

properly supporting vent system and keeping the number of

offsets to a minimum. See Table 2 for the maximum allowable

number of elbows in venting system.

6. Install the flue reducer included with the exhaust hood between

the vent system and the heater.

7. Seal all vent connections and venting with sealants supplied

by vent pipe manufacturer or with a high-temperature silicone

sealant suitable for continuous temperatures of 500°F

(260°C). Acceptable sealant include Dow Corning 736

or equivalent.

8

Page 9

FIGURE 6.

DIRECT VENTING - FOR GPV MODELS

All exhaust vent terminal, flue reducer, and int ake vent terminal

are supplied with any unit intended for direct venting. These

parts must be installed without alteration.

This heater is category III appliance when used in a direct vent

application. All national and local codes pertaining to the

installation of such an appliance must be followed.

Horizontal portions of the exhaust vent system must be installed

with a minimum upward slope of 1/4” (6.35 mm) per foot of

length.

Selkirk metalbestos model PS or G vent is approved for use as

exhaust venting on these models. Model PS is a double-wall

vent with a 1” (25.4 mm) air space between pipes. Model G is a

single-wall variation of model PS for use where combustible

clearance is not a concern, see Table 4.

TABLE 4.

Selkirk Metalbestos Model PS

Clearance to Combustibles

Interior 6” (152.4 mm)

Exterior 6” (152.4 mm)

8” diameter PVC or galvanized pipe is approved for use as

intake venting on these models. Class 63, 100, 125, 200, and

schedule 40 pipe may be used for PVC pipe. Intake venting

must be adequately supported to avoid unnecessary stress on

vent hood, venting, or burner.

TABLE 5.

Dimension in GPV

Inches (mm) 540A -740A

Flue Outlet Dia. 9 (229)

Flue Reducer Dimension 9 x 8

(Supplied) (229 x 203)

Min. Exhaust Vent Dia. Inch (mm) 8 (203)

Min. Intake Vent Dia. Inch (mm) 8 (203)

Maximum Number Of 90° 4

Elbows, Intake 45° 8

Maximum Number Of 90° 4

Elbows, Exhaust 45° 8

Total Intake Vent Max. 75 (23 m)

Length, Equiv. Ft. Min. 3 (1 m)

Total Exhaust Vent Max. 75 (23 m)

Length, Equiv. Ft. Min. 6 (1.8)

Note: Barometric draft control is not used in direct vent installations

as the venting system must be sealed.

When calculating the equivalent length of a venting system each

90 elbow is equivalent to 10 feet of straight pipe. Each 45 elbow

is equivalent to 5 feet (1.5 m) of straight pipe. Do not exceed the

maximum number of elbows as shown in Table 5. In no case may

the sum of the straight pipe lengths and the equivalent lengths of

the elbows exceed the valves in Table 5.

VENT TERMINAL LOCATIONS-EXHAUST

See “Horizontal Venting” in this manual for acceptable locations

for exhaust hoods.

VENT TERMINAL LOCA TIONS-INTAKE

See Table 5 limitations on venting system design for direct vent

installations.

When considering locations for the intake terminal, bear in mind

that the terminal:

9

Page 10

1. Shall be located not less than 12” (304.8 mm) above grade.

DIRECT VENT SYSTEM INST ALLATION

2. Shall be located not less than 3 (.9144 m) feet horizontally

from and not less than 3 feet (.9144 m) below an exhaust vent

terminal.

3. Shall not be located directly above an exhaust terminal.

4. Shall be located 12” (304.8 mm) above the snow line in

geographical areas where snow accumulates.

5. Shall be located not less than 7 feet 2.1 m) above grade

when adjacent to a public walkway.

6. Shall not be closer than 3 feet (.9144 m) from the inside

corner of an L - shaped structure.

7. Shall be located not less than 3 feet (.9144 m) horizontally or

3 feet (.9144 m) vertically from gas line, meter, or other gas

supply entering a structure, see Figure 6.

Plan the vent system backwards from the vent hood to the heater .

1. Use the inside wall cover plate as a template to mark two

holes in the appropriate places on the wall. Cut holes

1/2” (12.7 mm) larger to facilitate easy installation of vent

hoods, see Figures 6 and 7.

BEWARE OF CONCEALED WIRING AND PIPING INSIDE WALL.

REFER TO T ABLE 3 FOR THE MAXIMUM WAL L THICKNESS

“B” FOR EACH MODEL.

2. Slide hoods through openings from outside. Fasten hoods

to exterior wall with anchors and screws supplied.

3. Install cover plate and fasten to inside wall with 4 screws

4. Attach a seal ring (Selkirk Metalbestos Model SR or equivalent)

to the vent hood collar, see Figure 7.

FIGURE 7B.

FIGURE 7.

10

Page 11

5. Attach a properly sized length of Selkirk Metalbestos model

PS or model G venting to the exhaust vent adapter using the

inner vee bands, see Figures 7 and 7B on page 10.

6. Fill the grooves in both inner vee bands with high-temp

silicone sealant, Dow Corning 736 or equivalent.

7. Position the inner vee bands around the inner pipe flanges

and tighten the screws securing the bands.

8. Align the outer channel band with the outer pipe grooves

and tighten the screws securing the bands.

9. Repeat steps 6-8 for each successive pipe length until the

venting reaches the heater.

10. Follow the manufacturer’s instructions for proper support

and guide spacing for horizontal runs of pipe, see Table 6.

TABLE 6.

WARNING

PRIMERS AND CEMENTS ARE EXTREMELY FLAMMABLE, AND

MUST NOT BE STORED OR USED NEAR HEA T OR OPEN FLAME.

ALLOW ADEQUA TE CURING TIME BEFORE OPERATING HEA TER.

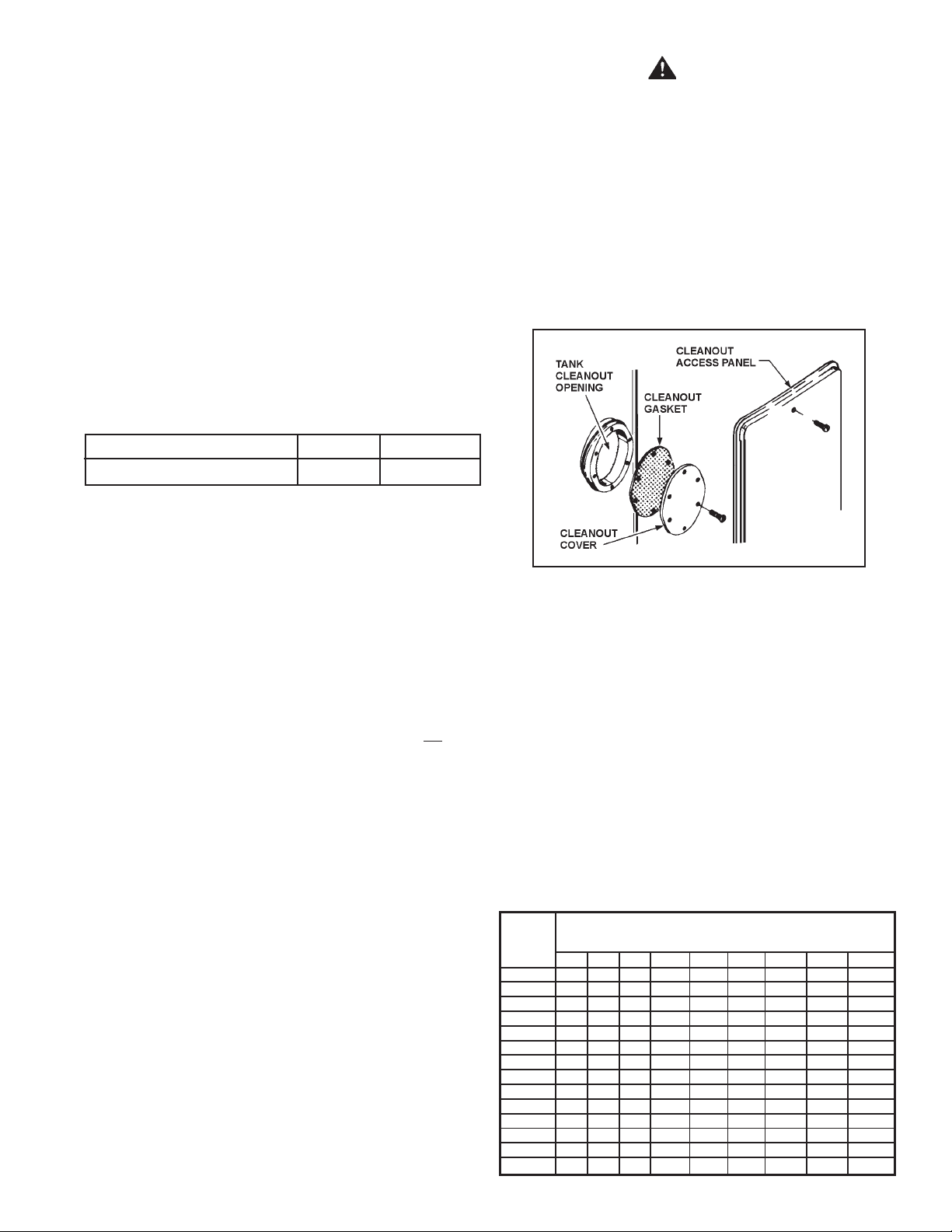

DRAIN V ALVE AND ACCESS PANELS

The heaters are equipped with a 3/4” NPT drain valves mounted

above and to the left of the burner.

An access panel is located above and to the right of the burner,

see Figure 8. This panel covers the cleanout opening in the tank

which is sealed by a gasket and cover. Another cleanout access

panel is located towards the back of the heater.

Vent Diameter S F

8” - GPV -540A, 650A & 740A 15’ 3” 7’ 6”

S = Maximum spacing between two guides or a support

and a guide in either a vertical or horizontal direction.

F = Maximum height above a guide or support for free

standing system above a roof or parapet wall.

11. Use an expansion joint between any two fixed points in the

exhaust venting system wherever the expansion may exceed

1/4”. Selkirk Metalbestos model PS and model G venting

will expand by one inch per 100°F in gas temperature per

100 feet of vent length. The expansion can be calculated by

the following formula:

Expansion, Vent length between

= x

5

Inches two fixed points, feet 100

If the expansion calculated is greater than 1/4”, an expansion

joint must be used between the two fixed points.

12. Attach the flue reducer included in the exhaust vent hood

package to the flue collar on the heater.

13. Attach the flue reducer to the vent system using a seal ring.

Attach this ring to the venting using the inner vee bands as

outlined in Steps 5-7.

14. Attach 8” air-intake connector to intake vent hood collar. It

may be necessary to use a slip-slip coupling to fit the pipe

to the intake vent hood.

15. Attach 8” air-intake connector back to the 6” burner air inlet

with 8” x 6” reducer. Prime and cement each joint to assure

gas-tight construction.

16. Seal all joints at the vent hoods with silicone sealant. Also

seal the joints at the flue collar and air inlet adapter . Joint on

the exhaust side must be sealed with high-temp silicone

sealant, Dow Corning 736 or equivalent.

FIGURE 8.

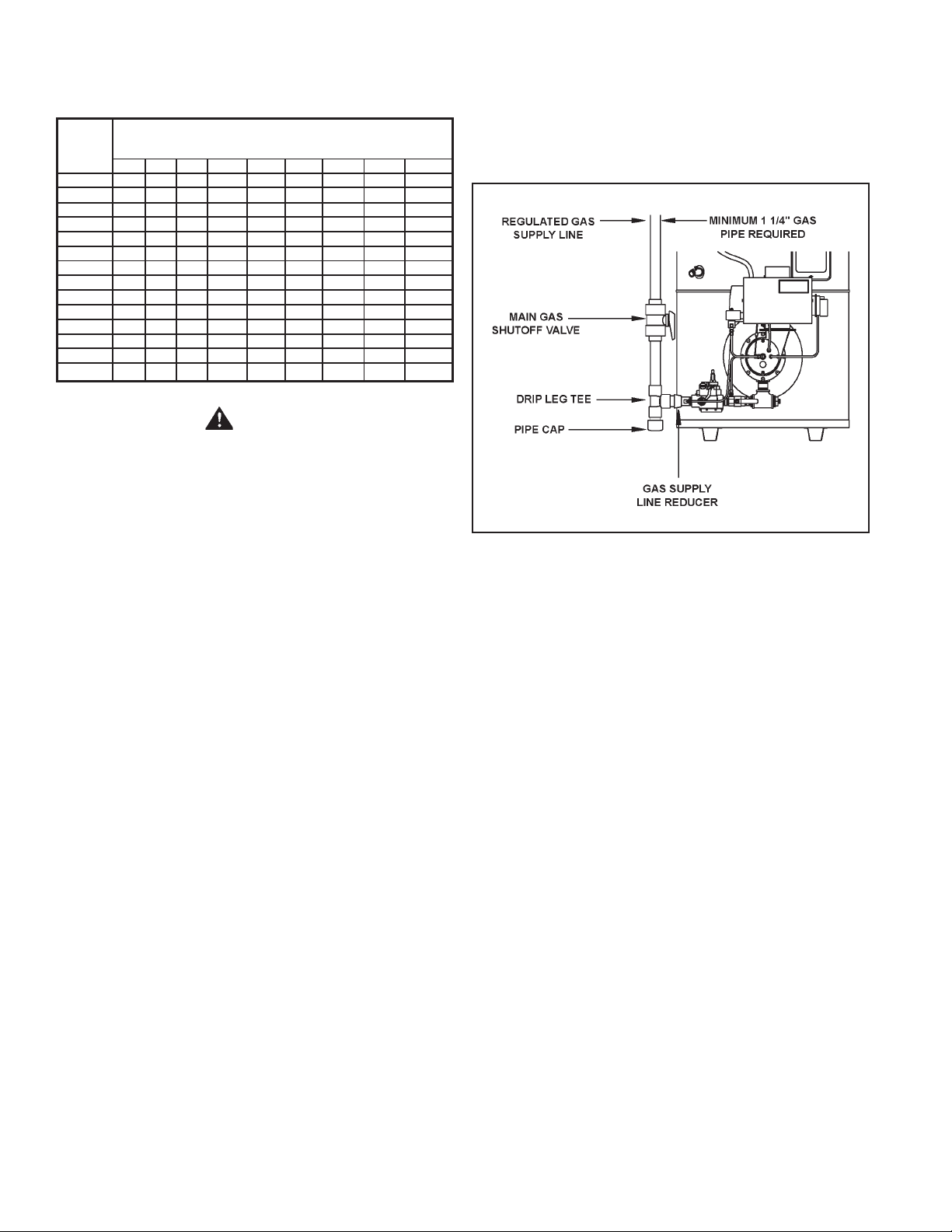

GAS PIPING

Contact your local gas service company to ensure that adequate

gas service is available and to review applicable installation

codes for your area.

Size the main gas line in accordance with Table 9 and 9A.

Minimum required gas supply pipe size is 1 1/4”. The figures

shown are for straight lengths of pipe at 0.5 in. w.c. pressure

drop, which is considered normal for low pressure systems.

Note that fittings such as elbows and tees will add to the pipe

pressure drop.

T ABLE 9

MAXIMUM CAP ACITY OF PIPE IN CUBIC FEET OF GAS PER HOUR

(Based upon a Pressure Drop of 0.5 inch Water Column

and 0.5 Specific Gravity Gas and max. gas press. of .5 psig)

LENGTH

IN Nominal Iron Pipe Sizes, Inches

FEET 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2" 3" 4 "

10 175 360 680 1400 2100 3960 6300 11000 23000

20 120 250 485 950 1460 2750 4360 7700 15800

30 97 200 375 770 1180 2200 3520 6250 12800

40 82 170 320 660 990 1900 3000 5300 10900

50 73 151 285 580 900 1680 2650 4750 9700

60 66 138 260 530 810 1520 2400 4300 8800

70 61 125 240 490 750 1400 2250 3900 8100

80 57 118 220 460 690 1300 2050 3700 7500

90 53 110 205 430 650 1220 1950 3450 7200

100 50 103 195 400 620 1150 1850 3250 6700

125 44 93 175 360 550 1020 1650 2950 6000

150 40 84 160 325 500 950 1500 2650 5500

175 37 77 145 300 460 850 1370 2450 5000

200 35 72 135 280 430 800 1280 2280 4600

11

Page 12

T ABLE 9A

MAXIMUM CAP ACITY OF PIPE IN CUBIC FEET OF GAS PER HOUR

(Based upon a Pressure Drop of 0.5 inch Water Column

and 0.5 Specific Gravity Gas and max. gas press. of .5 psig)

LENGTH

IN Nominal Iron Pipe Sizes, Millimeters

METERS 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2" 3" 4"

3.0 51 105 199 410 615 1160 1845 3221 6735

6.1 35 73 142 278 428 805 1277 2255 4626

9.1 28 59 110 225 346 644 1031 1830 3748

12.2 24 50 94 193 290 556 878 1552 3192

15.2 21 44 83 170 264 492 776 1391 2840

18.3 19 40 76 155 237 445 703 1259 2577

21.3 18 37 70 143 220 410 659 1142 2372

24.4 17 35 64 135 202 381 600 1083 2196

27.4 16 32 60 126 190 357 571 1010 2108

30.5 15 30 57 117 182 337 542 952 1962

38.1 13 27 51 105 161 299 483 864 1757

45.7 12 25 47 95 146 278 439 776 1610

53.3 1 1 23 42 88 135 249 401 717 1464

61.0 10 21 40 82 126 234 375 688 1347

WARNING

THE HEATER IS NOT INTENDED FOR OPERA TION A T HIGHER

THAN 14” (3.5 kPa) WA TER COLUMN (1/2 POUND PER SQUARE

INCH) SUPPL Y GAS PRESSURE. HIGHER GAS PRESSURES

REQUIRE SUPPLEMENTAL REDUCING SERVICE REGULATION.

EXPOSURE TO HIGHER GAS SUPPL Y PRESSURE MA Y CAUSE

DAMAGE TO THE GAS CONTROLS WHICH COULD RESUL T IN

FIRE OR EXPLOSION. IF OVERPRESSURE HAS OCCURRED

SUCH AS THROUGH IMPROPER TESTING OF GAS LINES OR

EMERGENCY MALFUNCTION OF THE SUPPL Y SYSTEM, THE GAS

V ALVE MUST BE CHECKED FOR SAFE OPERA TION. MAKE SURE

THAT THE OUTSIDE VENTS ON THE SUPPL Y REGULATORS AND

THE SAFETY VENT VALVES ARE PROTECTED AGAINST

BLOCKAGE. THESE ARE P ARTS OF THE GAS SUPPL Y SYSTEM,

NOT THE HEATER. VENT BLOCKAGE MA Y OCCUR DURING ICE

STORMS.

IT IS IMPORTANT T O GUARD AGAINST GAS V AL VE FOULING

FROM CONTAMINANTS IN THE GAS W A YS. SUCH FOULING MA Y

CAUSE IMPROPER OPERATION, FIRE OR EXPLOSION.

IF COPPER SUPPLY LINES ARE USED THEY MUST BE

INTERNALL Y TINNED AND CERTIFIED FOR GAS SERVICE.

BEFORE A TT ACHING THE GAS LINE, BE SURE THA T ALL GAS

PIPE IS CLEAN ON THE INSIDE.

TO TRAP ANY DIRT OR FOREIGN MA TERIAL IN THE GAS SUPPL Y

LINE, A DIRT LEG (SOMETIMES CALLED A SEDIMENT TRAP OR

DRIP LEG) MUST BE INCORPORA TED IN THE PIPING (SEE FIG .

10) THE DIRT LEG MUST BE READIL Y ACCESSIBLE AND NOT

SUBJECT TO FREEZING CONDITIONS. INSTALL IN

ACCORDANCE WITH RECOMMENDATIONS OF SER VING GAS

SUPPLIERS. REFER TO THE NATIONAL FUEL GAS CODE.

ANY SUPPLY PRESSURE TESTING EXCEEDING

1/2 PSIG. GAS SUPPLY LINE MUST BE CAPPED WHEN

DISCONNECTED FROM THE HEATER. FOR TEST

PRESSURES OF ½ PSIG OR LESS, THE APPLIANCE NEED

NOT BE DISCONNECTED, BUT MUST BE ISOLATED FROM

THE SUPPLY PRESSURE TEST BY CLOSING THE MANUAL

GAS SHUT -OFF VAL VE.

GAS PIPING AND DIRT LEG INST ALLA TION

FIGURE 9.

BEFORE PLACING THE HEA TER IN OPERATION, CHECK FOR GAS

LEAKAGE. USE SOAP AND WATER SOLUTION OR OTHER

MATERIAL ACCEPTABLE FOR THE PURPOSE IN LOCATING

GAS LEAKS. DO NOT USE MA TCHES, CANDLES, FLAME OR

OTHER SOURCES OF IGNITION FOR THIS PURPOSE.

GAS METER SIZE – CITY GASES ONLY

Be sure that the gas meter has sufficient capacity to supply the

full rated gas input of the water heater as well as the requirements

of all other gas fired equipment supplied by the meter. If the gas

meter is too small, request the gas company to install a larger

meter having adequate capacity.

GAS PRESSURE REGULATION

Main line gas pressure to the water heater should be between

8” w.c. (2 kPa) minimum (dynamic pressure or net pressure)

and 14” (3.5 kPa) maximum w .c. (st atic pressure). The inlet gas

pressure must not exceed the maximum value. A service

regulator is necessary if higher gas pressures are encountered,

see Table 10.

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply to gas valve inlet.

Apply joint compounds (pipe dope) sparingly and only to the

male threads of pipe joints. Do not apply compound to the first

two threads. Use compounds resistant to the action of liquefied

petroleum gases.

DISCONNECT THE APPLIANCE AND ITS MANUAL GAS SHUTOFF V ALVE FROM THE GAS SUPPL Y PIPING SYSTEM DURING

Due to pressure drop along gas supply line, to maintain

8” w.c. (2 kPa) minimum dynamic pressure, initial gas inlet

pressure must be set at higher than 8” w.c. (2 kPa). The gas

regulator must be properly sized to prevent unstable control or

excessive pressure drop.

GAS V ALVES

Figure 10 shows the gas control valve that is supplied on these

heaters.

12

Page 13

ROBERTSHA W® 7000 DERHC GAS CONTROL V AL VE

FIGURE 10.

to the local code authority having jurisdiction. Good practice

requires that all heavy piping be supported.

THERMOMETERS (Not supplied)

Thermometers should be obtained and field installed as shown

in the installation diagrams.

Thermometers are installed in the system as a means of

detecting the temperature of the outlet water supply.

RELIEF V ALVE

This heater is equipped with an approved temperature and

pressure relief valve. ASME ratings cover pressure relief.

A.G.A ratings cover release rate with temperature actuation.

WATER LINE CONNECTIONS

Following are detailed installation diagrams for typical methods

of application for the water heaters.

The water heater may be installed by itself, or with a separate

storage tank, on both single and two-temperature systems.

When used with a separate storage tank, the circulation may be

either by gravity or by means of a circulating pump. When a

circulating pump is used it is important to note that the flow rate

should be slow so that there will be a minimum of turbulence

inside the heater.

If a water heater is installed in a closed water system, contact

the water supplier or local plumbing inspector on how to control

this situation.

CAUTION

A closed system will exist if a check valve (without bypass)

pressure reducing valve (without bypass), or a water meter

(without bypass) is installed in the cold water line between

the water heater and street main (or well).

Excessive pressure may develop causing premature tank failure

or intermittent relief valve operation.

An expansion tank or a similar device may be required in the

inlet supply line between the appliance and the meter or valve to

compensate for the thermal expansion of water under supply

pressure.

SYSTEM CONNECTIONS

The system installation must conform to these instructions and

This is not a warranty failure.

FOR SAFE OPERATION OF THE W A TER HEA TER, THE RELIEF

VAL VE(S) MUST NOT BE REMOVED OR PLUGGED.

In addition to the appliance relief valve, each remote storage

tank that may be used in conjunction with this appliance shall

also be installed with a properly sized, rated and approved

temperature (ANSI) and pressure (ASME) relief valve(s). This

relief valve shall comply with the standard for relief valves and

automatic gas shut-off devices for hot water supply systems,

ANSI Z21.22/CSA 4.4.

Your local code authority may have other specific relief valve

requirements.

WARNING

THE PURPOSE OF A RELIEF V AL VE IS TO A VOID EXCESSIVE

PRESSURE OR TEMPERATURE INTO THE STEAM RANGE, WHICH

MA Y CAUSE SCALDING A T FIXTURES, T ANK EXPLOSION, AND

SYSTEM OR HEATER DAMAGE. NO V AL VE IS TO BE PLACED

BETWEEN THE RELIEF VAL VE AND THE T ANK.

A DRAIN LINE MUST BE CONNECTED TO THE RELIEF V AL VE TO

DIRECT DISCHARGE TO A SAFE LOCATION TO A VOID SCALDING

OR WA TER DAMAGE. THIS LINE MUST NOT BE REDUCED FROM

THE SIZE OF THE VAL VE OUTLET AND MUST NOT CONT AIN

VALVES, RESTRICTIONS NOR SHOULD IT BE LOCATED IN

FREEZING AREAS. DO NOT THREAD OR CAP THE END OF THIS

LINE. RESTRICTED OR BLOCKED DISCHARGE WILL DEFECT

THE PURPOSE OF THE VAL VE AND IS UNSAFE. DISCHARGE

LINE SHALL BE INST ALLED TO ALLOW COMPLETE DRAINAGE

OF BOTH THE V ALVE AND LINE.

® Robertshaw is a registered trademark of the Robertshaw Controls

Company Corporation.

13

Page 14

INSTALLATION DIAGRAMS

ONE TEMPERA TURE - ONE HEA TER VERTICAL STORAGE T ANK

FORCED CIRCULA TION WITH OR WITHOUT BUILDING RECIRCULATION

NOTE:

WHEN USING A State T-140, 200, 350 OR 400

STORAGE TANK, USE LOWER 3/4” OPENING FOR TANK TEMP. CONTROL

ONE TEMPERA TURE - ONE HEATER HORIZONT AL STORAGE T ANK

FORCED CIRCULA TION WITH OR WITHOUT BUILDING RECIRCULATION

IF BUILDING COLD WATER SUPPLY HAS A

DANGER

BACKFLOW PREVENTER, CHECK VALVE OR

WATER METER WITH CHECK VALVE,

PROVISIONS FOR THERMAL EXPANSION OF

WATER IN THE HOT WATER SYSTEM MUST BE

PROVIDED.

NOTE: CONNECT RETURN LINE FROM HOT

WATER RECIRCULATING LOOP (IF USED) TO

COLD WATER INLET LINE.

DANGER

TEMPERATURE SETTING SHOULD NOT EXCEED SAFE

TEMPERATURE AT FIXTURES. SEE WATER TEMPERATURE

CONTROL WARNING ON PAGE 23. IF HIGHER PREHEAT

TEMPERATURES ARE NECESSARY TO OBTAIN ADEQUATE

BOOSTER OUTPUT, ADD AN ANTI-SCALD VALVE FOR HOT

WA TER SUPPLIED T O FIXTURES.

*PIPE TO OPEN DRAIN INSTALL IN ACCORDANCE WITH LOCAL CODES

14

CIRCULA TING PUMP WIRING DIAGRAM

Page 15

TWO TEMPERA TURE - ONE HEATER HIGH TEMPERA TURE

WITH OR WITHOUT BUILDING RECIRCULATION

*PIPE RELIEF VALVE TO OPEN DRAIN

NOTE: IF TEMPERED WATER IS

INSTALL IN ACCORDANCE WITH LOCAL

CODES

TEMPERATURE SETTING SHOULD NOT

EXCEED SAFE TEMPERATURE AT

FIXTURES. SEE WATER TEMPERATURE

CONTROL WARNING ON PAGE 23. IF

HIGHER PREHEAT TEMPERATURES ARE

NECESSARY TO OBTAIN ADEQUATE

BOOSTER OUTPUT, ADD AN ANTI-SCALD

VALVE FOR HOT WATER SUPPLIED TO

FIXTURES.

CAUTION: IF BUILDING COLD WATER

SUPPLY HAS A BACKFLOW PREVENTER,

CHECK VALVE OR WATER METER WITH

CHECK VALVE, PROVISIONS FOR

THERMAL EXPANSION OF WATER IN THE

HOT WATER SYSTEM MUST BE

PROVIDED.

WIRING DIAGRAM FOR TEMPERED WATER LOOP (IF USED)

CIRCULATING PUMP WIRING DIAGRAM

RECIRCULATED, RETURN LINE

SHOULD BE CONNECTED AT

POINT “A”.

DANGER

TWO TEMPERATURE - TWO HEA TERS HIGH TEMPERA TURE

WITH OR WITHOUT BUILDING RECIRCULATION

15

Page 16

TWO TEMPERA TURE - THREE HEATERS (TWO PRE-HEA TERS/ONE BOOSTER)

WITH OR WITHOUT BUILDING RECIRCULATION

CAUTION: IF BUILDING COLD WATER SUPPLY HAS A

BACKFLOW PREVENTER, CHECK VALVE OR WATER

METER WITH CHECK VALVE, PROVISIONS FOR

THERMAL EXPANSION OF WATER IN THE HOT WATER

SYSTEM MUST BE PROVIDED.

FOR MULTIPLE HEATER INSTALLATION SEE

MANIFOLD KIT SPECIFICATIONS, PAGE 18.

TWO TEMPERA TURE - TWO HEATERS (ONE PRE-HEA TER/ONE BOOSTER HEA TER)

WITH OR WITHOUT BUILDING RECIRCULA TION

TEMPERATURE SETTING SHOULD NOT EXCEED SAFE TEMPERATURE AT

DANGER

FIXTURES. SEE WATER TEMPERATURE CONTROL WARNING ON PAGE 23. IF

HIGHER PREHEAT TEMPERATURES ARE NECESSARY TO OBTAIN ADEQUATE

BOOSTER OUTPUT , ADD AN ANTI-SCALD VAL VE FOR HOT WATER SUPPLIED TO

FIXTURES.

* PIPE RELIEF V ALVE TO OPEN DRAIN.

** 140°F TO 150°F SHOULD BE MAXIMUM

WA TER TEMPERA TURE MAINTAINED IN THE

PRE-HEATERS.

120°F SHOULD BE THE MINIMUM

TEMPERA TURE OF WA TER IN THE PREHEA TERS.

CIRCULATING PUMP WIRING DIAGRAM

CONNECT CIRCULA TING LINE FROM FIXTURES, IF

USED, TO COLD WATER SUPPLY LINE OF PREHEATER.

CONNECT CIRCULATING LINE OF 180°F OR BOOSTED

WA TER, IF USED, TO INLET WA TER LINE TO BOOSTER.

INSTALL IN ACCORDANCE WITH LOCAL CODES.

16

Page 17

TWO TEMPERA TURE - ONE HEATER HIGH TEMPERA TURE

WITH RECIRCULATION OF SANITIZING LOOP

TEMPERATURE SETTING SHOULD NOT EXCEED SAFE TEMPERATURE

AT FIXTURES. SEE WATER TEMPERATURE CONTROL WARNING ON

PAGE 23. IF HIGHER PREHEAT TEMPERATURES ARE NECESSARY TO

OBTAIN ADEQUATE BOOSTER OUTPUT, ADD AN ANTI-SCALD VALVE

FOR HOT WATER SUPPLIED TO FIXTURES.

CAUTION: IF BUILDING COLD WATER SUPPLY HAS A BACKFLOW

PREVENTER, CHECK VALVE OR WATER METER WITH CHECK VALVE,

PROVISIONS FOR THERMAL EXPANSION OF WATER IN THE HOT

WATER SYSTEM MUST BE PROVIDED.

*PIPE TO OPEN DRAIN

INSTALL IN ACCORDANCE WITH LOCAL CODES

DANGER

NOTE 1: TOGGLE SWITCH CONTROLS 180° WA TER CIRCULA TION.

INSTALL ON OR CLOSE TO DISHWASHING MACHINE.

TOGGLE SWITCH MUST BE CLOSED (ON) DURING THE RINSE

OPERATION AND OPEN (OFF) WHEN DISHWASHER IS NOT

OPERATING OR WHEN ON LONG ST ANDBY.

NOTE 2: INSTALL LINE TEMPERATURE CONTROL IN AN UNINSULA TED

TEE BEYOND THE DISHWASHING MACHINE TAKEOFF IN THE

SANITIZING LOOP . CONTROL SHOULD BE SET A T 185°F .

NOTE 3: ADJUST PLUG COCK SO THE SANITIZING LOOP FLOW RA TE

DOES NOT CAUSE UNNECESSARY TURBULENCE IN THE

TANK.

NOTE 4: IF TEMPERED WATER IS RECIRCULATED, RETURN LINE

SHOULD BE CONNECTED A T POINT “’A”.

17

Page 18

MANIFOLD KITS

Precision cut type “L” all copper State manifold kits assure water

flow balance of all units. Without this balance, the full water

heating and storage potential of the system cannot be achieved.

Plus, the units with the higher water flow may have a shortened

life. Unions shown in piping diagrams are not included in the

manifold kits.

Dimensions shown are for minimum space occupied by the

water heaters assemblies.

Space for the barometric draft control assemblies, combustion

clearances and servicing must be added.

WARNING

FAILURE TO PROPERLY MANIFOLD MULTIPLE WATER

HEATERS AND PROVIDE ADEQUA TE STORAGE CAPACITY IN

ACCORDANCE WITH PROPER SIZING TECHNIQUES CAN RESULT

IN IMPROPER OPERA TION AND POSSIBLE FIRE RESUL TING IN

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

HEATERS SHOULD BE MANIFOLDED IN PARALLEL FOR

UNIFORM HYDRONIC LOADING PER THE DIAGRAMS SHOWN

IN THIS MANUAL.

THREE UNIT MANIFOLD KIT

PART NO. 195703

TWO UNIT MANIFOLD KIT

PART NO. 195702

FOUR UNIT MANIFOLD KIT

PART NO. 195704

18

Page 19

HEATER WIRING

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE

APPLIANCE MUST BE REPLACED, IT MUST BE REPLACED

WITH 105°C WIRE OR ITS EQUIVALENT, EXCEPT IN THE

BURNER HOUSING USE 200°C WIRE.

2. Open a nearby hot water faucet to permit the air in the system

to escape.

3. Fully open the cold water inlet pipe valve allowing the heater

and piping to be filled.

4. Close the hot water faucet as water starts to flow.

The power burner is wired to the heater as shown in Figure 11

for GPG models and Figure 12 for GPV models. The model

and rating plate provided the electrical information needed

to size the complete heater branch supply.

All electrical work must be installed in accordance with the

National Electrical Code and local requirements.

When installed, the appliance must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSI/NFPA 70-1987.

DO NOT ENERGIZE THE BRANCH CIRCUIT BEFORE THE HEA TER

T ANK IS FILLED WITH WA TER.

START UP

IMPORTANT

AUTHORIZED START-UP REQUIRED. Start-up by a State

Authorized GPG/GPV Start-Up Agent is required on the model

covered by this manual. Start-up and Operation of this unit by

other than an Authorized GPG/GPV Start-Up Agent will void the

warranty.

If you have not already done so, contact your local State Sales

Representative or Authorized GPG/GPV Start-Up Agent and

set-up a date for the start-up service.

The time to ask any questions you may have about your unit is

when the State Authorized GPG/GPV Start-Up Agent is there.

Please do not hesitate to ask the agent any questions which you

may have regarding the units start-up, operation or maintenance.

CAUTION

BEFORE PROCEEDING WITH THE OPERATION OF THE UNIT,

MAKE SURE HEA TER AND SYSTEM ARE FILLED WITH W A TER

AND ALL AIR IS EXPELLED FROM HEATER AND PIPING .

5. The heater is ready to be operated.

PURGING

Gas line purging is required with new piping or systems in which

air has entered.

CAUTION

PURGING SHOULD BE PERFORMED BY PERSONS EXPERIENCED

IN THIS TYPE GAS SERVICE. TO AVOID RISK OR FIRE OR

EXPLOSION, PURGE DISCHARGE MUST NOT ENTER CONFINED

AREA OR SP ACES WHERE IGNITION CAN OCCUR. THE AREA

MUST BE WELL VENTILA TED AND ALL SOURCES OF IGNITION

MUST BE INACTIVA TED OR REMOVED.

The following test equipment should be on hand: (all test

equipment must be acclimated to ambient temperature before

calibration and use.)

–CO2 indicator (Fyrite or similar) or O2 analyzer

– CO indicator (Monoxor or similar)

– Stack thermometer

– Draft Gauge or inlined manometer

– Two U-Tube manometers or calibrated 0-10” and 0-35” w.c.

pressure gauges

– Combination volt/ammeter

• Attach a gas pressure gauge or manometer to upstream

side of main gas cock and a gas pressure gauge or

manometer to the manifold pressure tapping.

• Check voltage at disconnect switch to make certain that it

matches that shown on the burner label.

NEVER OPERATE THE HEATER WITHOUT FIRST BEING

CERTAIN IT IS FILLED WITH WATER AND A TEMPERATURE

AND PRESSURE RELIEF VAL VE IS INST ALLED IN THE RELIEF

VALVE OPENING OF THE HEA TER.

FILLING

1. Close the heater drain valve by turning handle clockwise.

• Apply a few drops of No. 20 SAE non-detergent oil to motor

bearings.

• Drill max. 5/16” hole in breeching as close as possible to flue

connection on heater to install stack thermometer and

combustion analyzing equipment, see Figure 4.

• You are now ready to begin the burner start-up procedure.

19

Page 20

FIGURE 11.

20

Page 21

FIGURE 12.

21

Page 22

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or

explosion may result causing property damage, personal injury

or loss of life.

BEFORE OPERATING: ENTIRE SYSTEM MUST BE FILLED WITH W A TER AND AIR PURGED FROM ALL LINES.

A. This appliance is equipped with an ignition device which

automatically lights the burner.

Do NOT try to light burner by hand.

B. BEFORE LIGHTING: Smell all around the appliance area for

gas. Be sure to smell next to the floor because some gas is

heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch;

do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

C . Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by hand,

don’t try to repair it, call a qualified service technician. Force

or attempted repair may result in a fire or explosion.

D . Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

E . Do not operate appliance unless unit is filled with water and

inlet lines are fully open.

FIGURE “A”

“OFF POSITION”

OPERA TING INSTRUCTIONS

1. STOP! Read the safety information above on this

label.

2. Remove appliance thermostat cover. Rotate thermostat dial

counterclockwise

3. Turn off all electric power to the appliance.

4. This appliance is equipped an ignition device which

automatically lights the burner. Do

by hand.

5. Refer to diagrams above. Turn top knob of gas control

clockwise to “OFF” position (Figure A).

6. Wait five (5) minutes to clear out any gas. If you then smell

gas,

STOP! Follow “B” in the safety information above

on this label. If you don’t smell gas, go to next

step.

7. Turn top knob of gas control counterclockwise

“ON” (Figure B).

to lowest setting.

NOT try to light the burner

to

FIGURE “B”

“ON POSITION”

8. Turn on all electric power to the appliance.

9. Set thermostat to desired setting.

10. Turn switch to “ON” position.

11. Heater will automatically begin operation. Blower motor will

run approximately 40 seconds, then pilot gas valve will

open. Upon confirming the pilot flame the main gas valve

will open and the heater will operate in heating mode.

Reference “Sequence of Operation” section of manual for

details.

12. Heater is equipped with an ignition module which locks out

after one (1) unsuccessful ignition attempt. Blower motor

will continue to run. If lockout occurs, turn burner switch to

“OFF” position for at least one minute, then turn the switch

back to “ON”. Heater will automatically begin operation.

13. Replace thermostat control cover.

14. If the appliance will not operate, follow the instructions “TO

TURN OFF GAS APPLIANCE” and call your service

technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Remove thermostat control cover.

2. Set thermostat to lowest setting.

3. Turn burner switch to “OFF”.

4. Turn off all electric power to the appliance if service is to

be performed.

5. Turn top knob of gas control to the “OFF” position. Refer to

Step 5 of ‘OPERA TING INSTRUCTION” above.

6. Replace thermostat control cover.

22

Page 23

SEQUENCE OF OPERA TION

– Power on.

– Heater in standby mode.

– Thermostat calls for heat.

– Blower motor starts.

– Blower operation closes the normally open blower prover/

blocked outlet safety pressure switch.

– On proof of airflow, Honeywell S8680J flame control module

energized.

– 45 seconds prepurge cycle begins.

– Following prepurge cycle, the pilot gas valve is energized.

– At the same time, the electronic spark generator in the module

produces a high voltage spark pulse output.

– The voltage generates a spark at the ignitor that lights the

pilot.

– If the pilot does not light (or flame signal is less than 1 micro

A) within 15 seconds system locks out and must be reset by

turning burner switch “OFF” for a minimum of 1 minute. During

system lockout, blower still runs.

– When the pilot flame is established (flame is sensed by flame

rod), the main gas valve is energized.

– Main gas flows to main burner where it’s ignited by the pilot

flame. Now heater is in Heating Mode.

– During the Heating Mode:

If gas line pressure drops below the setting point, the flame

module is de-energized, gas valves closed, blower still runs.

If gas line pressure drops below the setting point then gas

line pressure increases to above the setpoint, heater starts

again from purging cycle.

If gas line pressure fluctuates around the setpoint too quick

(less than a second) burner may still run with excessive gas

valve ON/OFF cycle you must turn off the unit immediately,

re-adjust the gas line regulator and/or install a larger gas

supply line!

If the blower inlet and/or intake hood, or flue outlet/hood is/

are blocked for any reason, the safety switches will open,

which will de-energize the flame control module.

– The spark generator is off.

– The flame module monitors pilot flame current. Should the

flame failure occur during the Heating Mode, the unit will start

again from purging cycle.

– Thermostat is satisfied, switch opens.

– Power is interrupted to the flame control module and blower

motor. Gas valves are closed.

– Heater is in Standby Mode.

– Thermostat is satisfied, switch opens.

– Power is interrupted to burner, turning off blower and ignition

control module. Solenoid and main gas valves are closed.

– Insufficient blower pressure causes safety pressure switches

to open.

WA TER TEMPERA TURE CONTROL

DANGER

THIS WATER HEATER IS EQUIPPED WITH AN ADJUST ABLE

THERMOSTAT TO CONTROL WATER TEMPERATURE. HOT

WATER TEMPERATURES REQUIRED FOR AUTOMATIC

DISHWASHER AND LAUNDRY USE CAN CAUSE SCALD BURNS

RESULTING IN SERIOUS PERSONAL INJURY AND/OR DEATH.

THE TEMPERATURE A T WHICH INJURY OCCURS V ARIES WITH

THE PERSON'S AGE AND TIME OF EXPOSURE. THE SLOWER

RESPONSE TIME OF CHILDREN, AGED OR DISABLED PERSONS

INCREASES THE HAZARDS TO THEM. NEVER ALLOW SMALL

CHILDREN TO USE A HOT WATER TAP, OR T O DRA W THEIR

OWN BA TH WATER. NEVER LEAVE A CHILD OR DISABLED

PERSON UNATTENDED IN A BA THTUB OR SHOWER.

THE WA TER HEATER SHOULD BE LOCA TED IN AN AREA WHERE

THE GENERAL PUBLIC DOES NOT HAVE ACCESS TO SET

TEMPERATURES.

SETTING THE WA TER HEA TER TEMPERA TURE A T 120°F (49°C)

WILL REDUCE THE RISK OF SCALDS. Some states or provinces

require settings at specific lower temperatures.

Below you will find listed the approximate time-to-burn

relationship for normal adult skin. Short repeated heating cycles

caused by small hot water uses can cause temperatures at the

point of use to exceed the thermostat setting by up to 20F°. If you

experience this type of use, you should consider using lower

temperature settings to reduce scald hazards.

Temperature Time to Produce 2nd & 3rd

Setting Degree Burns on Adult Skin

180°F (82°C) Nearly instantaneous

170°F (77°C) Nearly instantaneous

160°F (71°C) About 1/2 second

150°F (66°C) About 1-1/2 seconds

140°F (60°C) Less than 5 seconds

130°F (54°C) About 30 seconds

120°F (49°C) More than 5 minutes

Valves for reducing point-of-use temperature by mixing cold and

hot water are available. Also available are inexpensive devices

that attach to faucets to limit hot water temperatures. Contact a

licensed plumber or the local plumbing authority.

The water temperature is controlled by a thermostat, fig. 2, which

has two sensing elements. One sensor is located near the top

of the tank and the other is near the center . The thermostat is set

in the lowest position before the heater leaves the factory.

0

The dial is adjustable and may be set for 120

(49°C) to 1800F

(82°C) water temperature, but 1200F (49°C) is the recommended

starting point. It is suggested the dial be placed on the lowest

setting which produces an acceptable hot water supply. This

will always give the most energy efficient operation. The

temperature control has a 4F° fixed differential.

ADJUSTMENT PROCEDURE (Initial Start-Up)

A minimum dynamic gas supply pressure of 8” w.c. for natural

gas is required before making any adjustment to the gas control

pressure regulator. Attempts to adjust the regulator during

periods of low gas supply pressure could result in overfiring of

the heater when the gas supply pressure returns to normal.

23

Page 24

1. Check gas line pressure with a manometer.

Set initial gas line pressure at 9-10” w.c. before turning the

heater “ON”.

it’s a high elevation application and/or a direct vent (long air

intake vent) application.

1. Fire Rate Adjustment (including direct vent installation).

Read gas line pressure and gas manifold pressure when

the heater main gas is “ON”.

Adjust gas line regulator setting if the gas line pressure drops

below 8” w.c. when heater main gas is “ON”.

Check heater gas manifold pressure (see Table 10) using a

manometer connected to the manifold pressure tap on the

Robertshaw gas control valve, see Figure 10.

Important Note: Use gas manifold pressure as initial setup

only. The final air and gas settings should be based on fire rate

and flue gas 02/C02 reading, see Table 10 for normal 02/C0

reading.

WARNING

Excessive gas line pressure drop and/or burner manifold

pressure too low may cause burner start/operate with

excessive noise!

2. Cycle the burner “ON” and “OFF” several times to check its

operation. Make sure the gas line pressure is below

14” w.c. when burner is “OFF”. If gas line pressure exceeds

14” w.c. when the burner is off, the gas supply line size must

be increased to correct this problem (see Table 9 for gas

pipe size).

3. Check the operation of the limiting and operating controls.

a. Make sure the gas supply line pressure reads

8” w.c. (2 kPa) or higher when the heater is running.

b. Remove the pressure regulator cover screw

(Figure 10) and adjust the pressure by tuning the

adjustment screw w/a small screwdriver clockwise to

increase gas pressure into the burner and fire rate.

Counterclockwise to decrease gas pressure and input

rate.

c. Clock gas meter, repeat above Step (b) to achieve the

specific input rate.

2

d. Measure flue gas O

acceptable O

If the O

then proceed to Step (f).

/CO2 range.

2

or CO2 reading is within the acceptable range,

2

and/or CO2 (see Table 10) for

2

If the O2 or CO2 reading is out of range, adjust air

damper is required.

e. Repeat Steps (b), (c), (d) if air damper is adjusted.

f. Cycle heater ON/OFF.

g. Replace the gas regulator cover, pressure tap and

tighten the damper center bolt.

4. Check the vent system seams and joints and ensure that

there is no discharge of flue products into the room. For

standard vertical vent systems, check the barometric damper

control to make sure it operates freely and there is no

discharge of flue products into the room.

5. Check the input rate by clocking the gas meter.

ADJUSTMENT PROCEDURE FOR FIRE-RATE,

LOW NOX AND HIGH ELEVATION (Fine-Tune)